Teledyne Laars Hi-E EPH 300 User Manual

Page 1

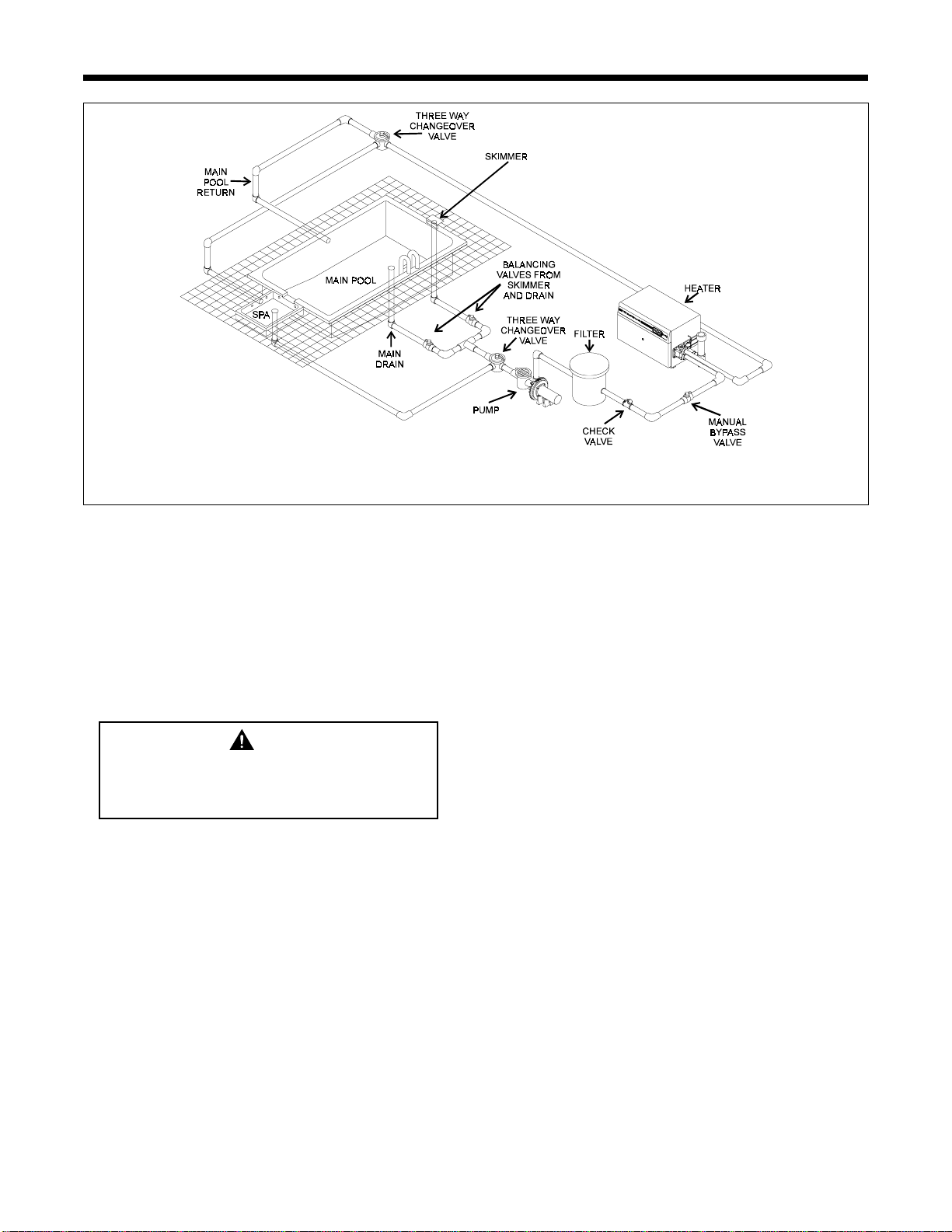

Hi-E Model EPH Pool and Spa Heater

SECTION 1.

General Information

This manual provides maintenance instructions for the

T eledyne Laars Hi-E Model EPH 300 pool and spa heater .

SECTION 2.

Overall Operation and Service

2A. Heater Control Components

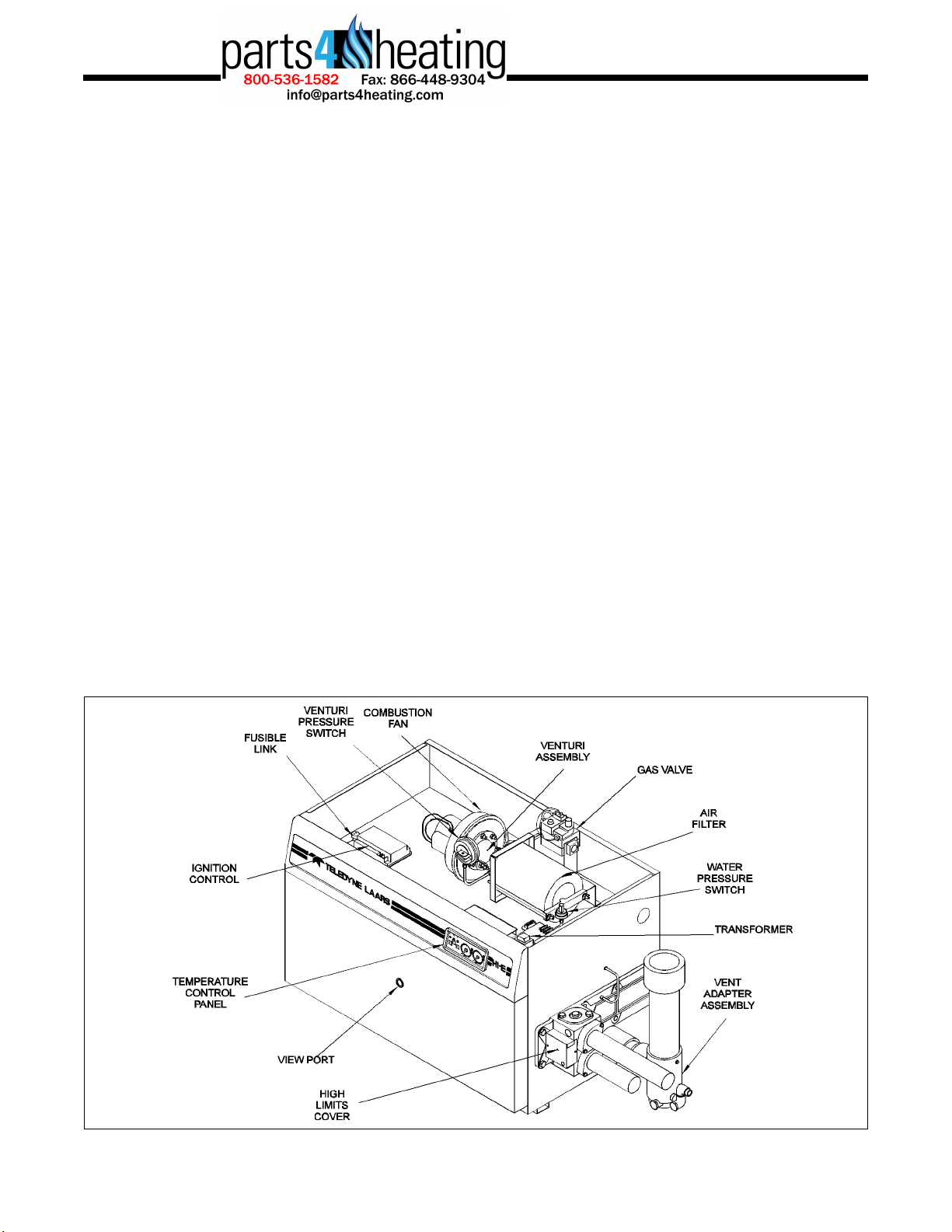

Some of the heater control components are the same

as those used in conventional heaters, but others are

designed specifically for the Hi-E EPH 300 heater (see

Fig. 1).

The following paragraphs describe the special

controls and their operation.

2A-1. Pressure Switch

The pressure switch is a safety device that senses

water pressure or back pressure between the heater and

the pool or spa when the filter pump is operating. The

switch is factory set at 2 pounds per square inch (psi)

(14 kilopascals [kPa]).

When the switch senses adequate water pressure, it

closes, allowing the heater to fire. The switch opens any

time water pressure is below 2 psi (14 kPa) and remains

opens, preventing the heater from firing, regardless of

the temperature control setting. If the water pressure is

too high, the switch remains closed, allowing the

heater to fire even if the filter pump is off. Therefore,

the height difference between the heater and the pool or

spa water surface level must fall within the correct

range.

2A-2. High Limit Switches

The Hi-E heater has two disk-type high limit

switches to meet ANSI safety requirements. The high

limit switches open if the temperature of the water

exceeds the respective limits, shutting down the heater.

The high limit switches close and automatically reset

when exposed to cool water flow for a short time.

The 150 degrees Fahrenheit (°F) (66 degrees

Celsius [°C]) high limit switch senses the temperature

of the hottest water as it leaves the heat exchanger .

The 135°F (57°C) high limit switch senses the temperature of the mixed water after it leaves the heater

and mixes with water that bypasses the heater inlet to

the outlet.

Water can overheat if the water flow rate drops,

usually due to a flow restriction in the heat exchanger,

pool piping system, or a dirty filter. A broken disc or

spring in the automatic flow control valve can cause

the 150°F (66°C) high limit switch to open, allowing

too much water to bypass the heat exchanger, correspondingly lowering the water flow rate through the

heat exchanger.

Figure 1. Component Location

Page 2

2A-3. Fusible Link

This is a one-time, thermally fusible element which

shuts down the heater if it detects temperatures higher

than 305°F (152°C) inside the heater control compartment.

2A-4. Temperature Control Panel

The temperature control panel includes two

temperature controls (regulates pool/spa water temperatures) and a touch pad (OFF, SPA, and POOL)

that turns the heater on and off and selects which

temperature control will be active. An indicator light

above the controls tells you which is active. The

control panel also has lights labeled, WATER BELOW

TEMP, HEAT ON, and FAN ON. These lights indicate the operating status of the heater.

2A-5. Venturi Pressure Switch

The venturi pressure switch senses pressure

through the venturi. Blockage in venting or the heat

exchanger will cause the venturi pressure switch not to

close. The venturi pressure switch is pre-set at the

factory for normal installations. Do not adjust the

venturi pressure switch.

2A-6. Ignition Control

The ignition control provides power to the igniter

and fan, opens the gas valve when there is a call for

heat, and senses when a flame is established. The

ignition control is programmed to make three attempts

at ignition. Each attempt consists of the following

cycle:

1. A 15-second purge period during which the

combustion fan purges the combustion chamber .

2. A 20 to 35-second igniter heat-up period. The

glow of the igniter can be seen through the heater

view port near the end of this period.

3. A 7-second trial for ignition. The gas valve opens

and gas ignites. The gas valve stays open as long

as the igniter senses flame.

If ignition is not successful, the control shuts down

and locks out. It remains in the lockout condition until

the heater is turned off then back on by the touch panel

pads or when the 120 volt alternating current (VAC)

power to the heater is interrupted.

2A-7. Gas Valve

The Hi-E heater has a negative pressure gas valve

that regulates the gas to the heater based on the

amount of air flow through the venturi. The gas valve

is the ON/OFF device that permits gas to flow from

the supply line into the heater. It is ener gized by the

ignition control.

2A-8. Transformer

The transformer converts 120VAC into 24VAC

used by the heater circuit.

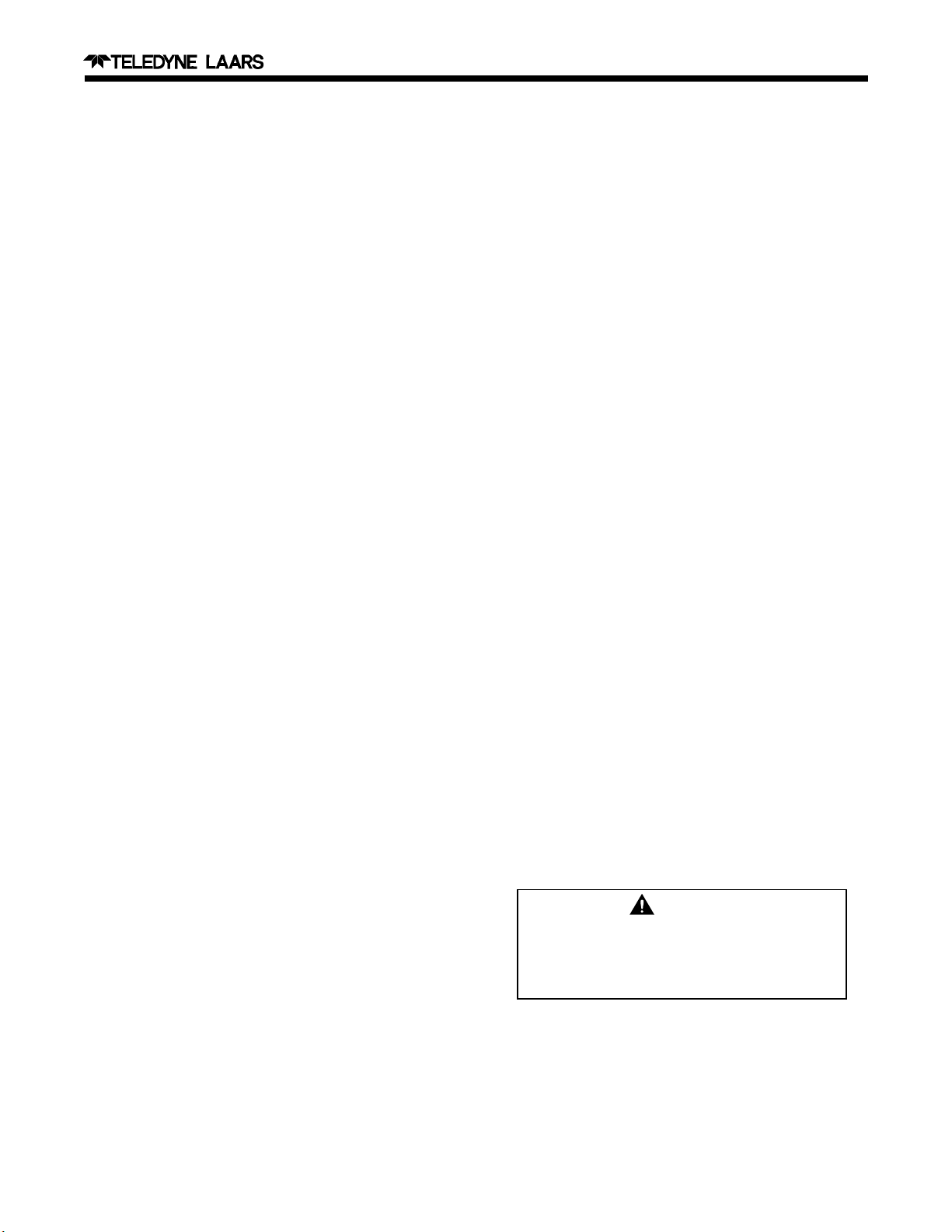

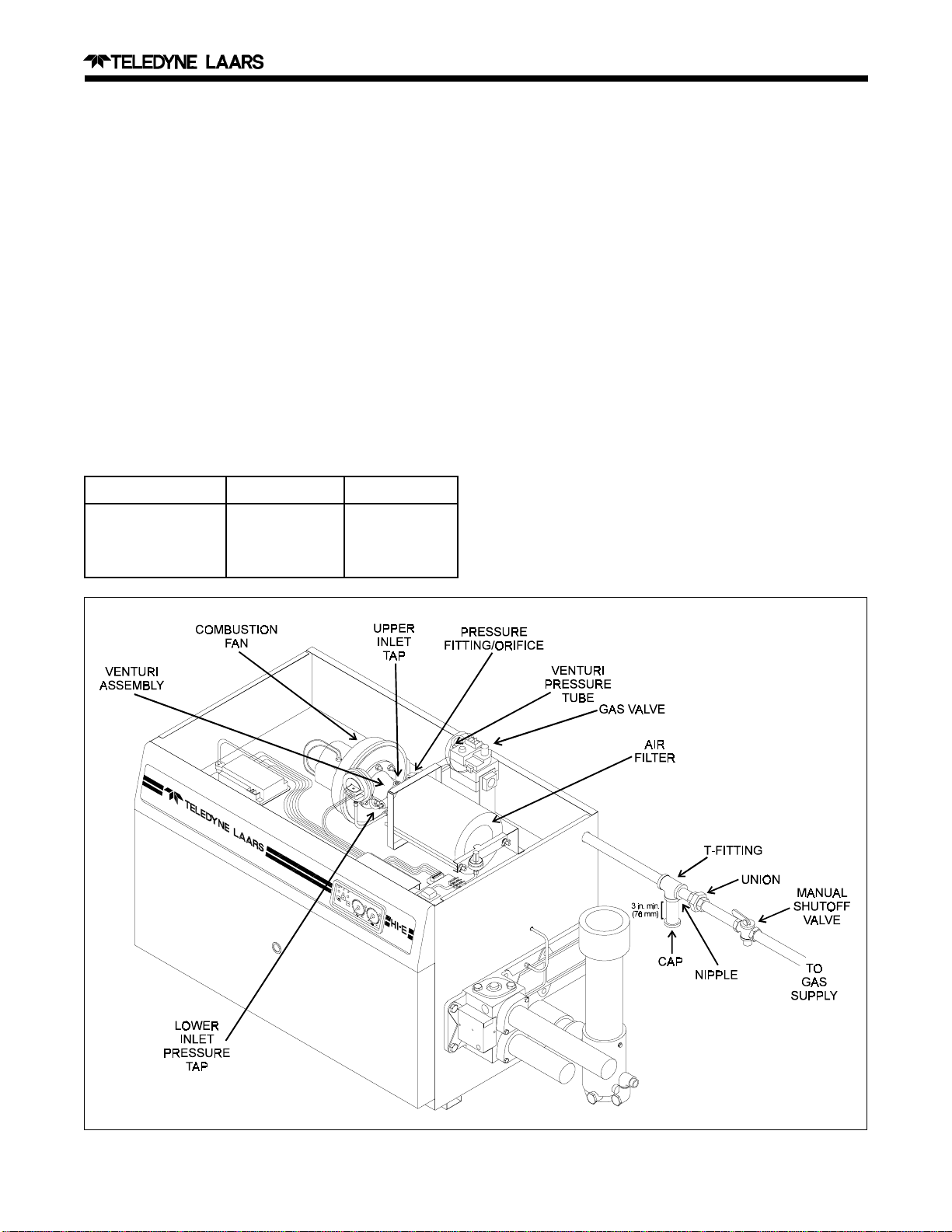

2B. Venturi/Negative Pressure Regulator

System

The fuel/air mixing system in the Hi-E EPH 300

heater makes sure the fuel/air ratio remains the same

under a wide range of flow conditions (see Fig. 2).

An important feature of the pressure system is that

blockage of the combustion air supply or the vent will

only reduce the firing rate; it will not cause poor

quality combustion.

2C. Pressurized Combustion System

The Hi-E EPH 300 heater has a positive pressure

combustion system; the pressure in parts of the system

is slightly higher than atmospheric pressure. This has

an important effect on service procedures. There can

be NO gas leaks in the system from whatever cause. If

a leak exists in the section between the combustion fan

and the burner, a flammable mixture of fuel gas and

air can escape. A leak in the combustion chamber will

release very hot gases. These gases may enlarge the

leak due to their high temperature. Leakage from the

system at points after the heat exchanger will release

combustion products or condensate water. The service

technician must be alert to these possibilities when

servicing the heater.

WARNING

Improper installation or maintenance can

cause nausea or asphyxiation from carbon

monoxide in flue gases which could result in

severe injury, property damage, or death.

2D. Periodic Inspection

Before starting troubleshooting procedures,

inspect the pool or spa system for obvious problems.

All of the pool system components, including pump,

Page 3

Figure 2. Venturi/Negative Pressure Regulator System

Hi-E Model EPH Pool and Spa Heater

filters, and strainers, water valves, gas supply , electrical power and time clocks, have an effect on heater

operation. The following basic checks should be

performed:

1. Is electrical power to the heater turned on?

2. Is there a time clock or other control in the system,

and is that control on?

3. Is the heater turned on at the touch panel? If it is,

the light over the active temperature control will

be lit.

4. Is the temperature control knob set high enough to

call for heat?

5. Is the gas supply turned on at all locations?

6. Is the heater’s combustion air filter clean?

7. Are all wiring connections solid?

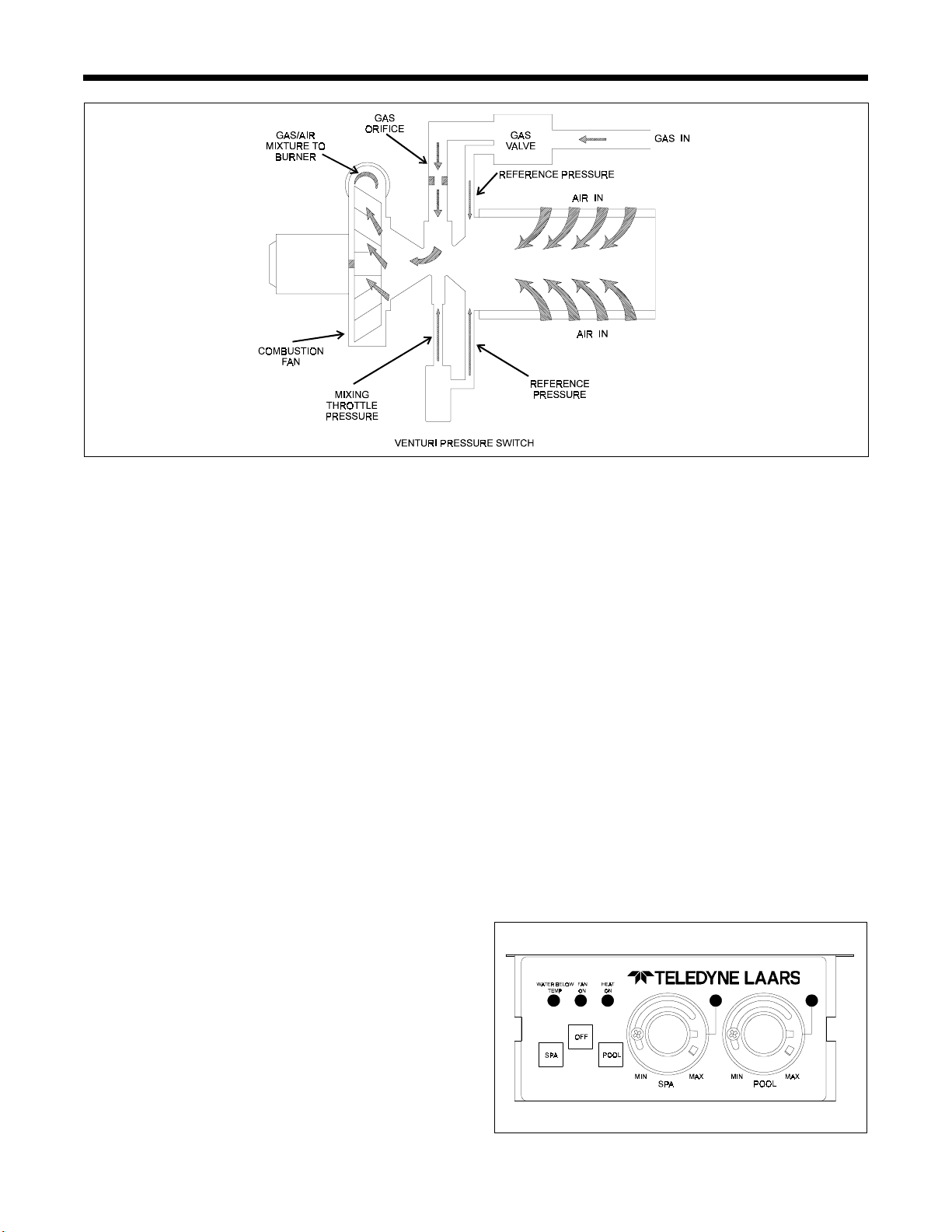

2E. Temperature Rise Test Procedure

A temperature rise test confirms proper water flow

through the heater. Perform a temperature rise test as

follows:

1. Verify the heater is OFF. If it is necessary to turn

the heater off, push the OFF button at the touch

pad (see Fig. 3) and wait at least 3 minutes.

2. Turn the filter pump OFF.

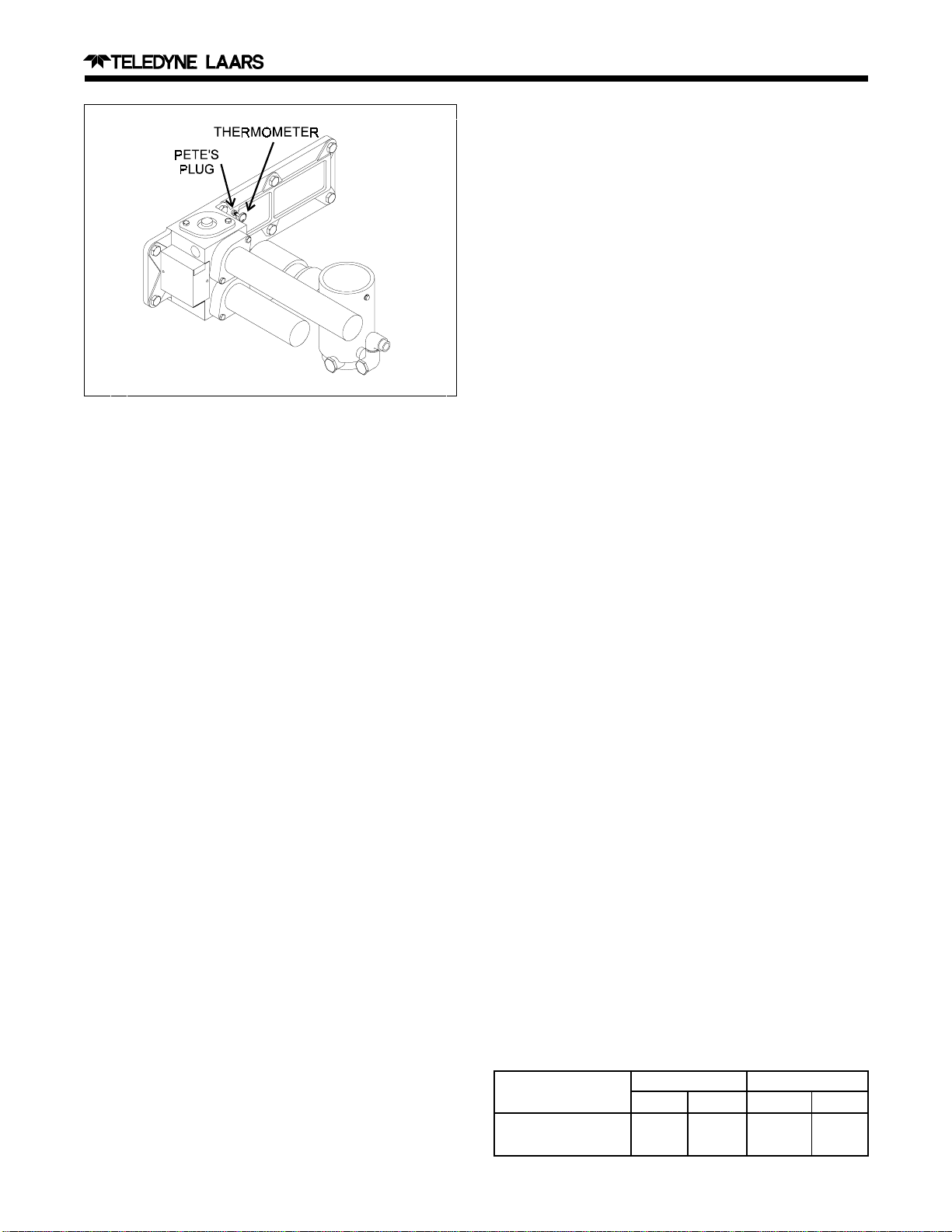

3. Remove the 1/4 inch (6.35 millimeters [mm])

National T aper Pipe (NPT) plug located on the

inlet/outlet header (see Fig. 4) and replace it with a

Pete's plug.

4. Insert a pocket thermometer through the Pete's

plug into the header to a depth of about 5 inches

(127 mm).

8. Is the ignition control in lockout mode? Turn the

heater off and then back on at the touch panel to

restart the ignition sequence.

If all of these items have been checked, look for

less obvious problems (see Section 3, Troubleshooting).

Figure 3. Temperature Control

Figure 4. Thermometer Location

5. Make sure the pool filter is clean.

6. Close manual bypass valve, if installed.

7. Turn the filter pump ON and wait 5 minutes.

8. Record the temperature indicated by the thermometer (cold water).

9. Turn the heater on following the lighting instructions found under the top panel of the heater.

10. Allow the heater to run for 5 minutes. Record the

new temperature reading (hot water).

11. Subtract the first temperature reading (cold water)

from the second temperature reading (hot water).

The difference between the two readings is called

the temperature rise. Proper water flow rate is

obtained when the temperature rise falls between

18 and 22°F (10 and 12.2°C).

12. If the temperature rise is within the correct range

(see step 11), complete the procedure as follows:

Page 4

If the temperature rise is outside the range indi-

cated, two possibilities arise:

1. Case 1: The temperature rise value is less than

18°F (10°C).

2. Case 2: The temperature rise value is greater than

22°F (12.2°C).

2E-1. Temperature Rise Test Case 1

There are two conditions that can produce a

temperature rise value less than 18°F (10°C): The

supply gas pressure is too low or the system's water

flow is too high.

Use table 1 to verify the heater's gas supply while

the unit is firing and as close as possible to the unit

under test.

Low supply gas pressures can be the result of

using the wrong pipe size, meter, valves, or regulators.

Correct the problem, then repeat the temperature rise

test.

If the temperature rise is still below 18°F (10°C)

after a retest, then the system's water flow may be too

high.

If the system filter-flow rate is higher than ap-

proximately 125 gallons per minute (GPM) (474 liters

per minute [LPM]), install a manual bypass valve with

an adjustable valve (see Fig. 5). Then repeat the

temperature rise test, gradually adjusting the flow with

the bypass valve (see Section 2D-3) until the proper

temperature rise is obtained. Once the adjustment is

complete, wire the handle of the manual by-pass to the

pipe to prevent any accidental change in the water

flow .

2E-2. Temperature Rise Test Case 2

The main reason for a temperature rise value

greater than 22°F (12.2°C) is a low water flow

through the heater. Check the installation for the

following:

1. Incorrect water pipe size or a combination of

different pipe sizes.

a. Turn the heater off.

b. W ait 5 minutes, then turn the filter pump of f.

c. Remove the thermometer and the Pete's plug.

d. Replace the 1/4 inch (6.35 mm) NPT plug at

the header.

2. Excessive pipe length for the size pump installed.

3. Pump too small for application.

Table 1. Gas Supply Pressure Requirements

Supply Pressure Natural Gas Propane Gas

Water Column in. mm in. m m

Minimum 5 127 11 279

Maximum 10 254 14 356

Page 5

Notes:

1. When using metal pipe as heat sink, join metal and PVC/CPVC, using metal male and PVC/CPVC female connection.

2. A manual bypass valve is used only when filtration rate normally exceeds 125 GPM (474 LPM).

Hi-E Model EPH Pool and Spa Heater

Figure 5. Typical Manual Bypass Valve Installation

4. T oo many restrictions in the water path which may

include small pumps or 2 speed pumps (low), dirty

filters, clogged pipes, or partially closed water

valves to the heater.

Verify and correct the condition and then repeat

the temperature rise test.

Caution

Operation with the temperature rise above

maximum or below the minimum can

damage the heater and will void the warranty.

2E-3. Adjusting the Manual Bypass Valve

After the manual bypass valve is installed, use the

following procedures to set the bypass valve:

1. Close the manual bypass valve completely .

2. Repeat steps 7 through 12 of the temperature rise

test (see Section 2E), slowly opening the manual

bypass until the temperature falls between 18 and

22°F (10 and 12.2°C).

3. Once the temperature is within the correct range,

wire the handle of the manual bypass valve to the

pipe to prevent change in the water flow .

SECTION 3.

Troubleshooting

3A. Supply Gas and Metering System

If the heater does not supply its rated output

(heating too slow), or if a blue lazy flame (too little

gas), or a bright flame (too much gas) is noticed,

check the supply gas pressure. Proper operation of the

fuel/air balancing system depends on the following:

1. Proper supply gas pressure to heater.

2. Correct gas pressure difference across the meter-

ing orifice.

3. Correct orifice for the fuel being used. Figure 3

shows how the system works.

4. V ent pipe length.

3A-1. Checking the Manifold Regulated Gas

Pressure

The Hi-E heater's negative pressure gas valve

regulates the gas to the heater based on the amount of

air flow through the venturi. Proper operation of the

heater depends on the proper settings of the gas flow .

Symptoms of improper operation are either a blue lazy

flame (too little gas) or a bright yellow flame (too

much gas).

Page 6

NOTE: Gas supply test, stack test, and air flow filter

test should be completed before attempting this test or

making any adjustments.

1. Check supply gas pressure (see Section 3B-2).

2. Check that all ports and tubes are clear that

connect the gas valve and venturi.

3. Check for proper orifice (see T able 2).

4. Attach a manometer or a 1/2 inch (13 mm)

negative pressure gauge between the outlet pressure tap on the gas valve and the venturi (lower)

inlet pressure tap (see Fig. 6).

Table 2. Gas Metering Orifice Size

Natural Gas LP Gas

Orifice Diameter 0.354 in. 0.295 in.

(8.99 mm) (7.49 mm)

Color Code Brass Silver

5. The pressure at the gas valve outlet will be 0.2

inch (5.08 mm) water column (W .C.) less than the

pressure at the venturi (lower) inlet.

6. T ake a reading. The ideal range should be between

-0.1 and -0.3 inches (-2.5 and -7.6 mm) W.C.

when the gas valve is energized.

IMPORT ANT: Before the gas valve is energized, the

pressure reading will be approximately 2.8 inches (71

mm) W .C. on outdoor units fitted with the standard

vent stack. On indoor installations with vent piping as

long as 60 feet (18 meters [m]), the pressure can be as

low as 2.0 inches (51 mm) W.C.

3A-2. Checking the Supply Gas Pressure

T o check the gas supply pressure:

1. Attach one end of a manometer hose to the fitting

on the gas valve (see Fig. 6).

2. Remove threaded cap from T-fitting and replace

with fitting from manometer.

Figure 6. Checking the Gas Pressure

Loading...

Loading...