Teledyne Isco Wash Glands User Manual

Wash Glands for D-Series

Syringe Pumps

Overview

Wash glands are used for additional corrosion

protection and to improve seal life. The syringe

pump can be equipped with a wash gland for

flushing the cylinder of any residue from pumped

liquid. The wash gland is a standard feature in the

model 1000D pump, and is available as an option

with the 500D and 100DM/DX pumps.

Operation

The wash gland requires the following

user-supplied items:

• Inlet and Waste containers (see Figure 4)

• Purified water or appropriate solvent

• Small pump with:

-low pressure (less than 100 psi, 7 Bar)

-low flow (approx. 100 to 500 µL/min.)

A syringe pump equipped for cylinder washing

1

has two

drain the wash gland. Either tube can be used for

the inlet or outlet.

The small pump delivers the wash fluid through

one of the two tubes to rinse the cylinder and seals.

The second tube drains the wash fluid to waste or

recirculates it. If the system is configured to

recirculate the wash fluid, ensure that you change

the wash fluid at regular intervals.

/8” or 1/16” tubes on the back to feed and

Syringe Pump Technical Bulletin

Oct 2020, TB37

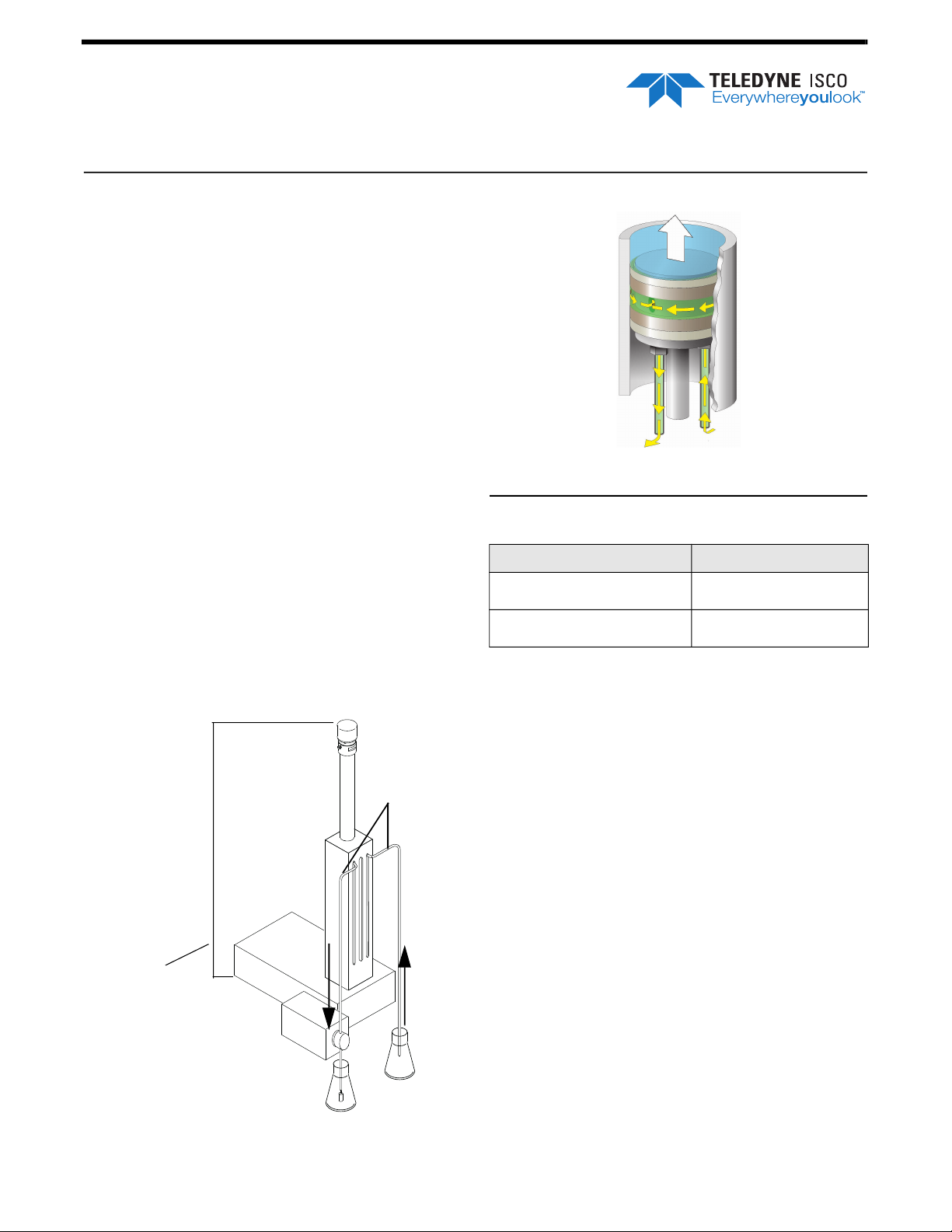

Figure 2: Direction of flow

Table 1: Parts required for 500D wash gland option*

Model Part Number

Wash Glands - Hastelloy- Not PED

Compliant for EU

Wash Glands - Nitronic- Not PED

Compliant for EU

60-5364-171

60-5364-094

*Please note 500D can only be upgraded when

ordered, it is not a retrofittable option.

Height of 100D:

with wash gland 42.86”

w/o wash gland 40.38”

NOTE:

No height difference

or 500D and 1000D.

Figure 1: Washing diagram

Waste

Wash tubes:

1

/16" for 500D

1

/8" for 1000D

Wash fluid*

Syringe Pump Technical Bulletin Oct 2020, TB37

4

1

5

7

# Description

1 Seal

2 Panhead screw

3 Washer

4 Seal Retainer

5 Wear Ring

6 Wiper

7 Piston base

1

6

3

2

Figure 3: Illustration of 500D assembly

5

2

6

7

1

4

# Description

1 Seal

2 Seal

3 Flathead Screw

4 Piston Bottom

5 Seal Retainer

6 Wear Ring

7 Piston Body

8 Lower Wear Ring

3

8

CAUTION

The pressure in the 500D wash glands and lines must

never exceed 175 psi (12 Bar). A wash gland pressure

greater than the system pressure may force wash liquid

past the pump’s main seals and contaminate the

delivery fluid and could potentially cause the wash

gland to deform.

Figure 4: Illustration of 1000D assembly

October 2020

Teledyne Isco

P.O. Box 82531, Lincoln, Nebraska, 68501 USA

Toll-free: (800) 775-2965 • Phone: (402) 464-0231 • Fax: (402) 465-3001

E-mail: IscoService@teledyne.com

Teledyne Isco is continually improving its products and reserves the right to change product

specifications, replacement parts, schematics, and instructions without notice.

Loading...

Loading...