Teledyne ISCO EZ Prep User Manual

EZ Prep System Verification

Using Universal Verification Kit (60-5234-317)

Overview

This document describes the use of the Universal

Verification Kit to verify the operation of the EZ Prep

systems. The kit verifies operation of system fitted with

UV/UV-vis, ELSD, or MS detectors.

Universal Verification Kit Description

Each vial contains 50 mg of Phenacetin and 200 mg

N-Benzylbenzamide. The system may be verified with

either normal or reverse phase solvent systems.

Normal Phase Operational Verification

-

Liquid Load

Follow the system priming directions as described in the

EZ Prep Installation and Operation Guide (available as a

PDF download from www.teledyneisco.com). After priming

the system, follow the steps below to verify operation:

Instruction Sheet #69-5233-949

Revision , Sept 2020

7. If a PurIon is installed, use the TYPICAL ion settings.

Set PurIon loading to LOW on the RUN REQUIREMENT

screen. Use masses of 180 and 212 Da, positive

ionization. Carrier solvent should be either methanol or

acetonitrile with 0.1% acid (formic or TFA). Conditions

are valid whether running ESI or APCI interface.

8. Set the UV detector to 254, 280 nm. Perform a LIQUID

LOAD and inject 1.0 mL of the sample mixture prepared

in steps 2 and 3 directly onto the column.

Expected Results for EZ Prep:

1. Install one of the 12 gram RediSep Rf Gold

columns provided in the kit and select GOLD

RESOLUTION when prompted. Use the pre-defined

method.

2. Add 4 mL of ethyl acetate to one of the vials and dissolve

the sample by capping and shaking the vial (this may

take a couple of minutes).

3. Add 1 mL of hexanes (hexane, cyclohexane, heptane, or

petroleum ether).

4. Use the default gradient and flow rate for the installed

column.

5. If an ELSD is installed, use the factory default spray

chamber and drift tube temperature settings.

•Verify that the ELSD is set to the default conditions

(Sensitivity = NORMAL, Gain = 2).

®

silica

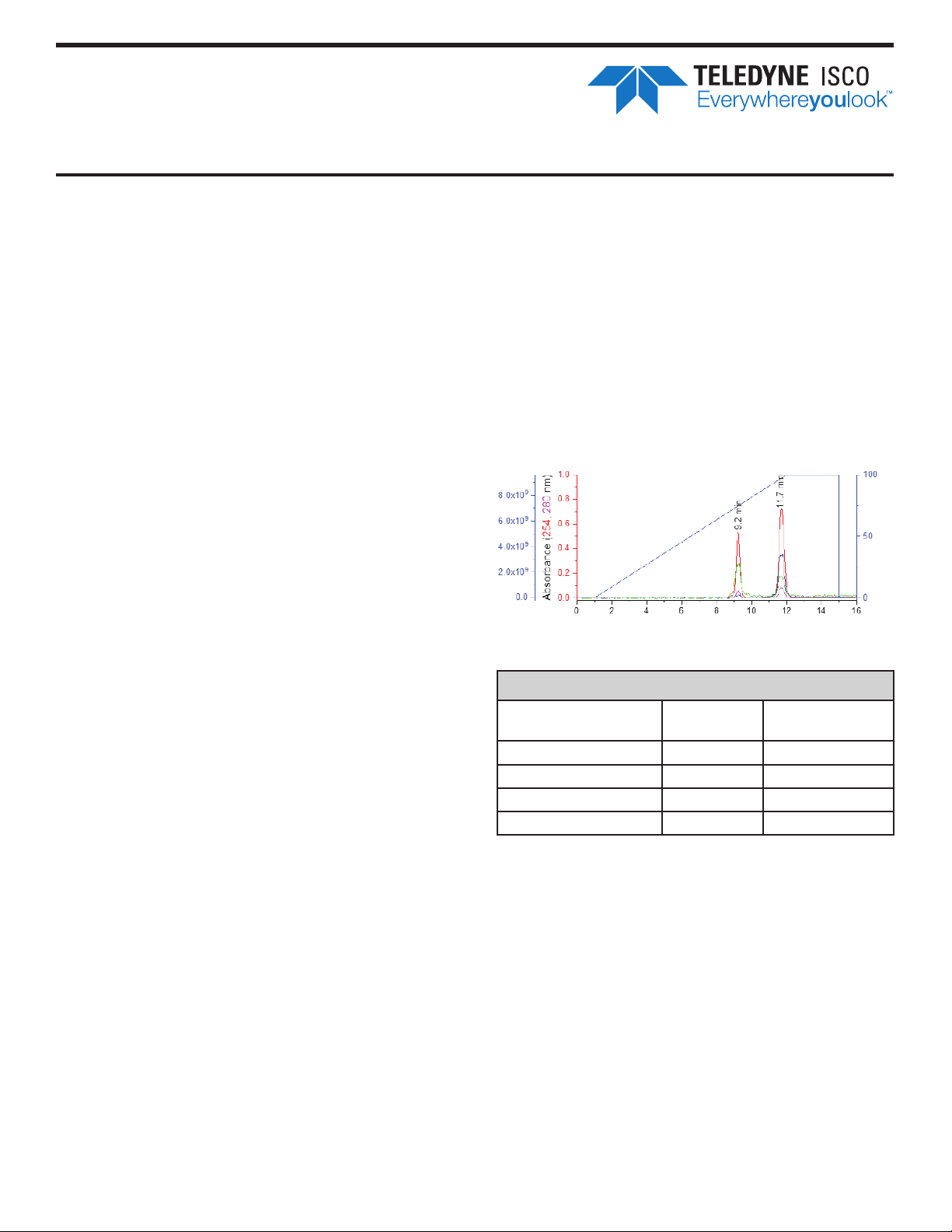

Figure 1: Normal Phase Detector Response

Expected RetentionTime- Liquid Load

EZ Prep Peak 1 (± 1.0)

Minutes

UV/ UV-vis only 7.2 9.8

With PurIon 9.2 11.7

With ELSD 9.0 11.5

With ELSD and PurIon 9.2 11.7

Peak 2 (± 1.0)

Minutes

Information included herein is controlled by the Export Administration Regulations (EAR) and requires an export license, license exception or

other approval from the appropriate U.S. Government agency before being exported from the United States or provided to any foreign person.

Diversion contrary to U.S. law is prohibited.

Instruction Sheet #69-5233-949, Rev , Aug 2020

Normal Phase Operational Verification

-

Solid Load

As an alternative loading technique, the verification

sample can be injected using a sample load cartridge and

associated solid load cartridge cap.

After priming the system, follow the steps below to verify

operation:

1. Choose between a 5 grams solid load cartridge packed

with 2.5 grams of silica (P/N 69-3873-238) or a 25 gram

cartridge packed with 12 grams of silica (P/N 68-3873-243).

2. Add 4 mL of ethyl acetate to one of the vials and

dissolve the sample by capping and shaking the vial

(this may take a couple of minutes).

3. Add 1 mL of hexanes (hexane, cyclohexane, heptane, or

petroleum ether).

4. Inject 1 mL of the resulting sample onto the surface of

the selected cartridge.

5. Place the cartridge onto the corresponding Solid Load

Cartridge Cap (SLCC) and install into the system.

®

6. Install one of the 12 grams RediSep Rf Gold

columns provided in the kit and select GOLD

RESOLUTION when prompted. Use the pre-defined

method.

7. Use the default gradient and flow rate for the installed

column.

8. If an ELSD is installed, use the factory default spray

chamber and drift tube temperature settings.

•Verify that the ELSD is set to the default conditions

(Sensitivity = NORMAL, Gain = 2).

9. If a PurIon is installed, use the TYPICAL ion settings.

Set PurIon loading to LOW on the RUN REQUIREMENT

screen. Use masses of 180 and 212 Da, positive

ionization. Carrier solvent should be either methanol or

acetonitrile with 0.1% acid (formic or TFA). Conditions

are valid whether running ESI or APCI interface.

10. Set the UV detector to 254, 280 nm.

11. Select PLAY and then select SOLID LOAD as the

injection option.

silica

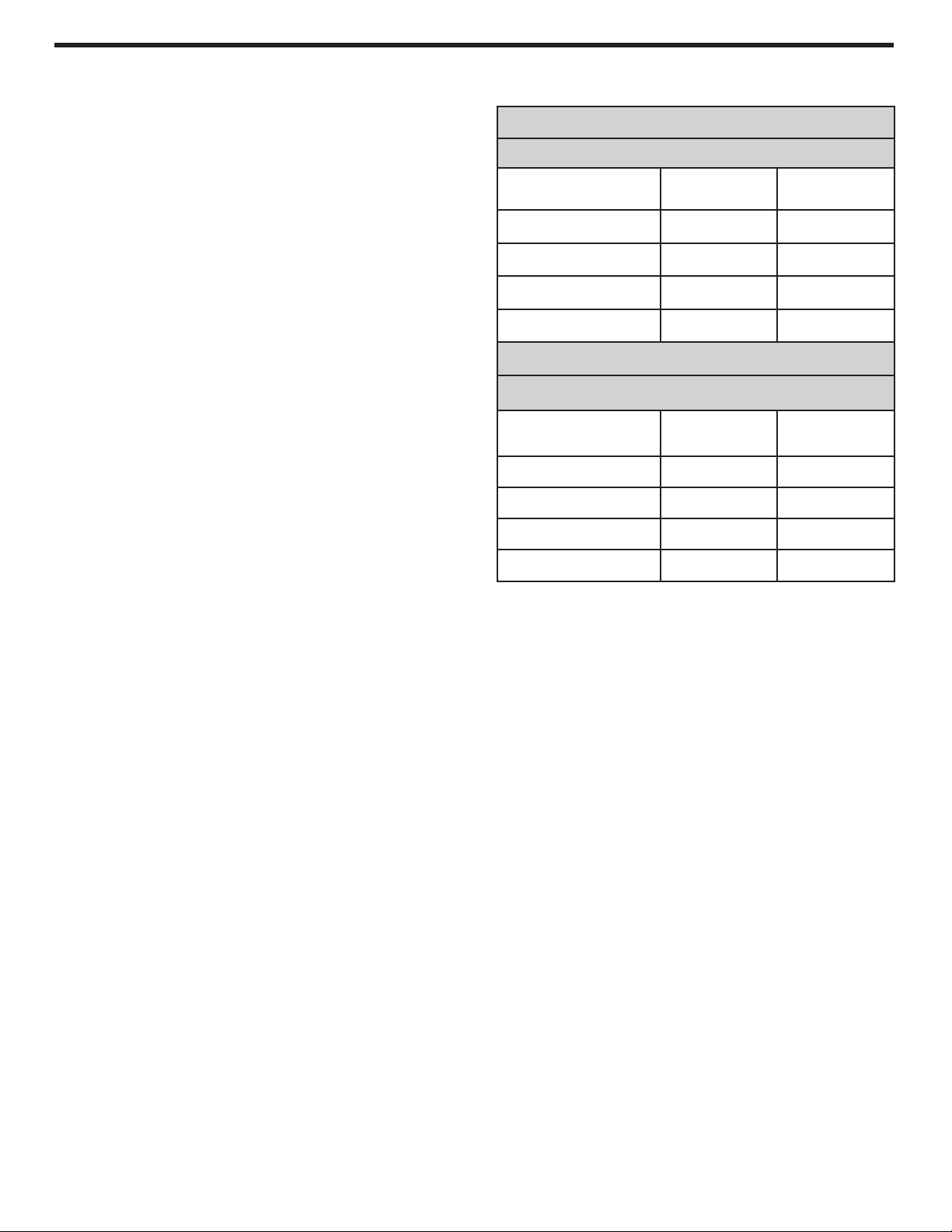

Expected RetentionTime-Solid Load

Using 5 gram solid load cartridge

EZ Prep Peak 1 (± 1)

Minutes

UV/ UV-vis only 7.3 9.9

With PurIon 9.3 11.8

With ELSD 9.1 11.6

With ELSD and PurIon 9.3 11.8

Peak 2 (± 1)

Minutes

Expected RetentionTime-Solid Load

Using 25 gram Solid Load cartridge

EZ Prep Peak 1 (± 1)

Minutes

UV/UV-vis only 8.6 11.6

With PurIon 10.5 13.7

With ELSD 10.3 13.5

With ELSD and PurIon 10.5 13.7

Peak 2 (± 1)

Minutes

Loading...

Loading...