Teledyne ISCO CombiFlash Torrent User Manual

CombiFlash Torrent®

User Manual

For Indoor Use Only

Part #60-5243-135

Revision H, February 16, 2021

COPYRIGHT © 2021 by Teledyne ISCO

1-2

Teledyne Isco One Year Limited Factory Service Warranty*

This warranty exclusively covers Teledyne Isco

instruments, providing a one-year limited warranty

covering parts and labor.

Any instrument that fails during the warranty period due to

faulty parts or workmanship will be repaired at the factory

at no charge to the customer. Teledyne Isco’s exclusive

liability is limited to repair or replacement of defective

instruments. Teledyne Isco is not liable for consequential

damages.

Teledyne Isco will pay surface transportation charges both

ways within the 48 contiguous United States if the

instrument proves to be defective within 30 days of

shipment. Throughout the remainder of the warranty period,

the customer will pay to return the instrument to Teledyne

Isco and Teledyne Isco will pay surface transportation to

return the repaired instrument to the customer. Teledyne

Isco will not pay air freight or customer’s packing and

crating charges. This warranty does not cover loss, damage,

or defects resulting from transportation between the

customer’s facility and the repair facility.

The warranty for any instrument is the one in effect on date

of shipment. The warranty period begins on the shipping

date, unless Teledyne Isco agrees in writing to a different

date.

Excluded from this warranty are normal wear; expendable

items such as desiccant, pH sensors, charts, ribbon, lamps,

tubing, and glassware; fittings and wetted parts of valves;

check valves, pistons, piston seals, wash seals, cylinders,

pulse damper diaphragms, inlet lines and filter elements;

and damage

due to corrosion, misuse, accident, or lack of

proper

installation or

maintenance. This warranty does not

cover products not sold under the Teledyne Isco

trademark or for which any other warranty is specifically

stated.

No item may be returned for warranty service without a

return authorization number (RMA) issued by Teledyne

Isco.

This warranty is expressly in lieu of all other warranties

and obligations and Teledyne Isco specifically disclaims

any warranty of merchantability or fitness for a

particular purpose.

The warrantor is Teledyne Isco, 4700 Superior, Lincoln, NE

68504, U.S.A.

*This warranty applies to the USA and countries where Teledyne Isco does not have an authorized dealer.

Customers in countries outside the USA, where Teledyne Isco has an authorized dealer, should contact

their Teledyne Isco dealer for warranty service.

Problems can of t e n be diagnosed and corrected without returning the instrument to the

factory. Before returning any instrument for repair, please contact the Teledyne Isco Service

Department for instructions and to obtain a return material authorization number (RMA).

Instruments needing factory repair should be packed carefully and shipped to the attention of

the service department. Small, non-fragile items can be sent by insured parcel post. PLEASE

WRITE THE RMA NUMBER ON THE OUTSIDE OF THE SHIPPING CONTAINER and

enclose a note explaining the problem.

Shipping Address: Teledyne Isco - Attention Repair Service

4700 Superior Street

Lincoln, NE 68504 USA

Mailing Address: Teledyne Isco

PO Box 82531

Lincoln, NE 68501 USA

Phone: Repair service: (800) 775-2965 (lab instruments)

(866) 298-6174 (samplers & flow meters)

Sales & General Information: (800) 228-4373 (USA &Canada)

Fax: (402) 465-3001

Email: IscoService@teledyne.com

March 2, 2016 P/N 60-1002-040 Rev J

1-3

1-4

1.1 Documentation Overview

This Installation Guide provides:

• Safety Information

• Unpacking instructions

• Installation instructions, including placing the CombiFlash Torrent module on a

network and direct connections with a computer or hand-held device

• Certification and warranty information.

CombiFlash Torrent

User Manual

Section 1 Introduction

®

Once you are operating the Torrent, you may refer to the Help menu for operati

instructions and further assistance.

Avoid hazardous practices! If you use this instrument in any way not specified in this

manual, the protection provided by the instrument may be impaired; this may increase your

risk of injury.

1.2 Product Overview

The Teledyne ISCO CombiFlash Torrent and Torrent AQ flash chromatography systems give

you high-productivity automation, programmable gradients, UV or UV-Vis detection and

peak separation,

an unattended run under computer control at user selected flow rates between 50 and 1000

mL/min. The Torrent operates up to 100 psi (6.9 bar) and can use low- or medium-pressure

Flash columns for either normal or reversed phase separations. Braided stainless steel 2.75

meter (9 foot) supply lines are supplied with the Torren

solvent level detection features that prevent chromatography runs from running out of

solvent. Samples can be introduced to the Torrent by injecting a liquid sample into the

injection port. Liquid samples can also be pumped into the injection port using the optional

Sample Load Pump. Alternately, liquid samples can automatically be loaded on the Torrent

AQ using t

low-solubility and liquid samples using solid load sample cartridges.

and automatic detection of columns. The Torrent can separate a sample in

he integrated sample load line on the solvent select valve. The Torrent can load

ng

WARNING

t. These supply lines support the

Column eluate passes through the UV or UV-Vis detector which can trigger collection of peak

fluids. The system also accepts an input signal to cut peaks using an external detector such

as an ELSD instrument. The Torrent can control a Foxy R2 High Flo

Fractionation Valve to isolate the fluid in vessels.

Applications include development-scale purification of organic compounds for drug discovery

and chemical research, as well as scale-up production for agrochemicals, petrochemicals,

natural products, polymers, and catalysts.

w fraction collector or a

1-1

CombiFlash Torrent® User Manual

1.3 Operating Overview

The Torrent is equipped with a touch screen display for local control.

The system supports TCP/IP communication. This allows direct control of the Torrent by a

Windows computer via a cross-over cable between Ethernet ports of the Torrent and the

computer. The Windows computer must have Microsoft Internet Explorer 7 or newer.

TCP/IP communication also allows remote control via

controlling devices on the network can be a Windows PC or an Apple mobile digital device (iPod

Touch, iPhone, and iPad).

N ot Note

Teledyne ISCO recommends that you obtain assistance from your Information Technology

department before attempting direct or network connections to a Windows computer.

1.3.1 Multiple Control Possibilities

The system can be accessed from the built-in touch panel and up to ten network computers. The

touch panel shares control with all connected computers. The system performs the most recent

command fr

om any control input.

1.3.2 File Storage

To support operation from a variety of direct and network connections, the CombiFlash Torrent

stores the software and all files on an internal hard drive. This ensures that your compound

purification methods and run history files can be viewed from any connection. Optionally,

individual run history files may be saved to a USB flash drive and the hard drive o

networked computer, and all run history files can be saved to a network drive.

1.4 Specifications

an established network. Remote

r a

1-2

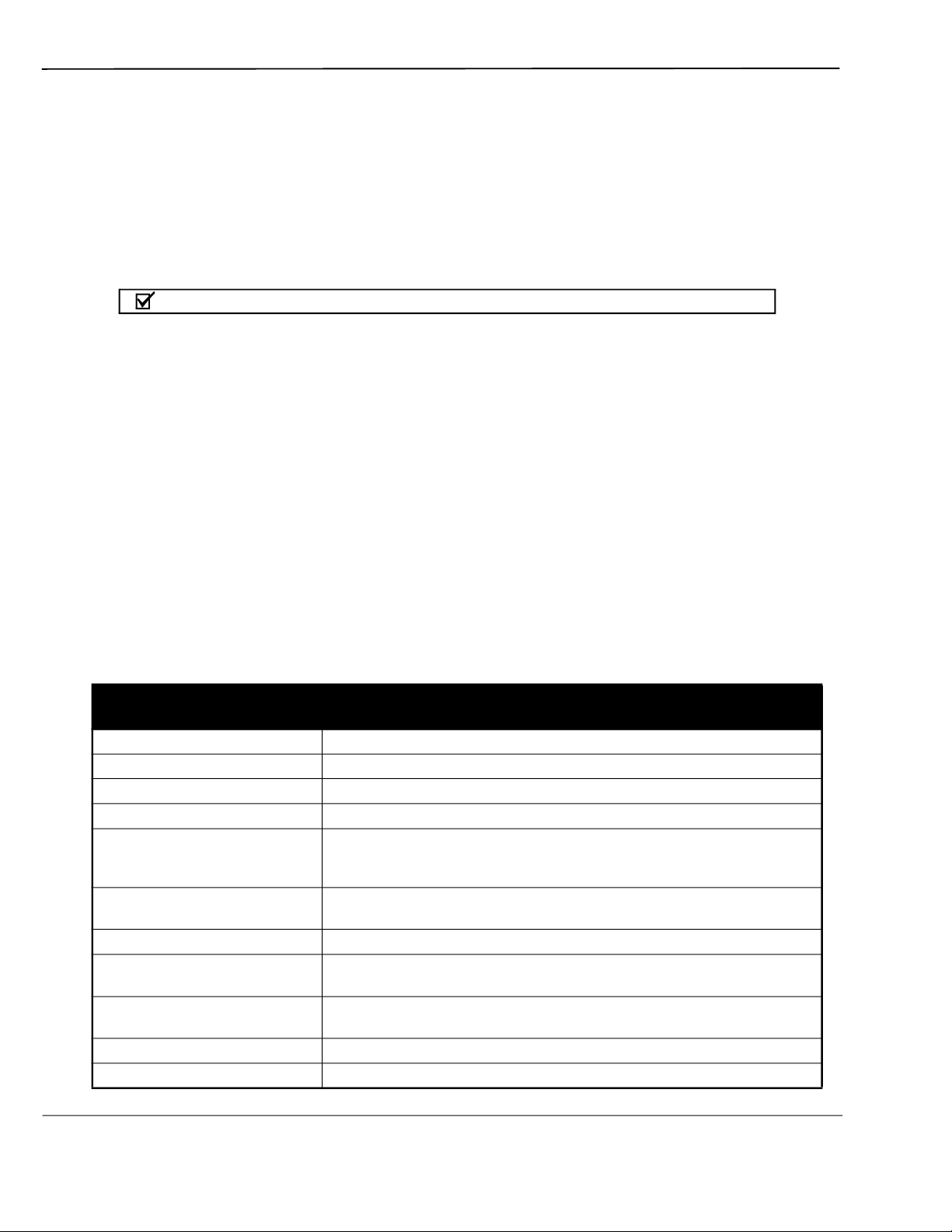

Table 1-1 CombiFlash Torrent Module Specifications

Sample size: 0.5 to 300 grams

RediSep Rf column sizes: 80 gram to 3 kilogram

Flow rate: 50 – 1000 mL/min

2

Maximum pressure

Detection: 200 – 360 nm (200 – 780 nm optional) with single, dual, or

Gradient: Binary, high pressure solvent mixing with linear, step, or isocratic

Gradient accuracy: <2% full scale from 0.2 to 1.0 li

Sample injection: Automated injection with options of solid load cartridges, liquid load, or

Controller: 26.7 cm (10.4 inch) touch screen

Software: On-screen method development and control with PeakTrak software

Fraction collection: Up to four fraction collectors, fractionation valve, or manual collection

: 6.89 bar (100 psi)

All-wavelength Collection.

Accepts external detector input.

capability. Two solvent inlets.

ter/min.

direct injection.

Supports remote control via Windows® PC.

1

Section 1 Introduction

Table 1-1 CombiFlash Torrent Module Specifications

1

(Continued)

Solvent management: Patented, active level sensing for inlet and waste containers

Module dimensions:

(W x D x H)

47 x 43.5 x 71.4 cm

18.5 x 17.9 x 28.1 inches

Module weight: 65 lbs (29.5 kg)

Operating voltage: 100 VAC 50 Hz, 2 amperes

117 VAC 60 Hz, 2 amperes

234 VAC 50 Hz, 1 ampere

(±10% of the region’s nominal line voltage)

Safety and sample securit

y: Static-dissipative tubing throughout,

Vapor sensor for internal leak detection,

Overpressure sensor,

Active solvent and waste level sensing,

Audible alarm when user intervention is required.

Ambient Temperature 20 to 40°C (maximum temperature must be at least 15°C below the

boiling point of the solvent)

Humidity (when connected to

95% relative humidity maximum at 20 to 40°C

power)

Certification: CE

Installation Category II

Maximum Altitude 2000 meters

Pollution Degree 2

Note 1. All specifications are subject to change.

Note 2. For columns undetected by RFID, the max pressure is limited to 50 psi.

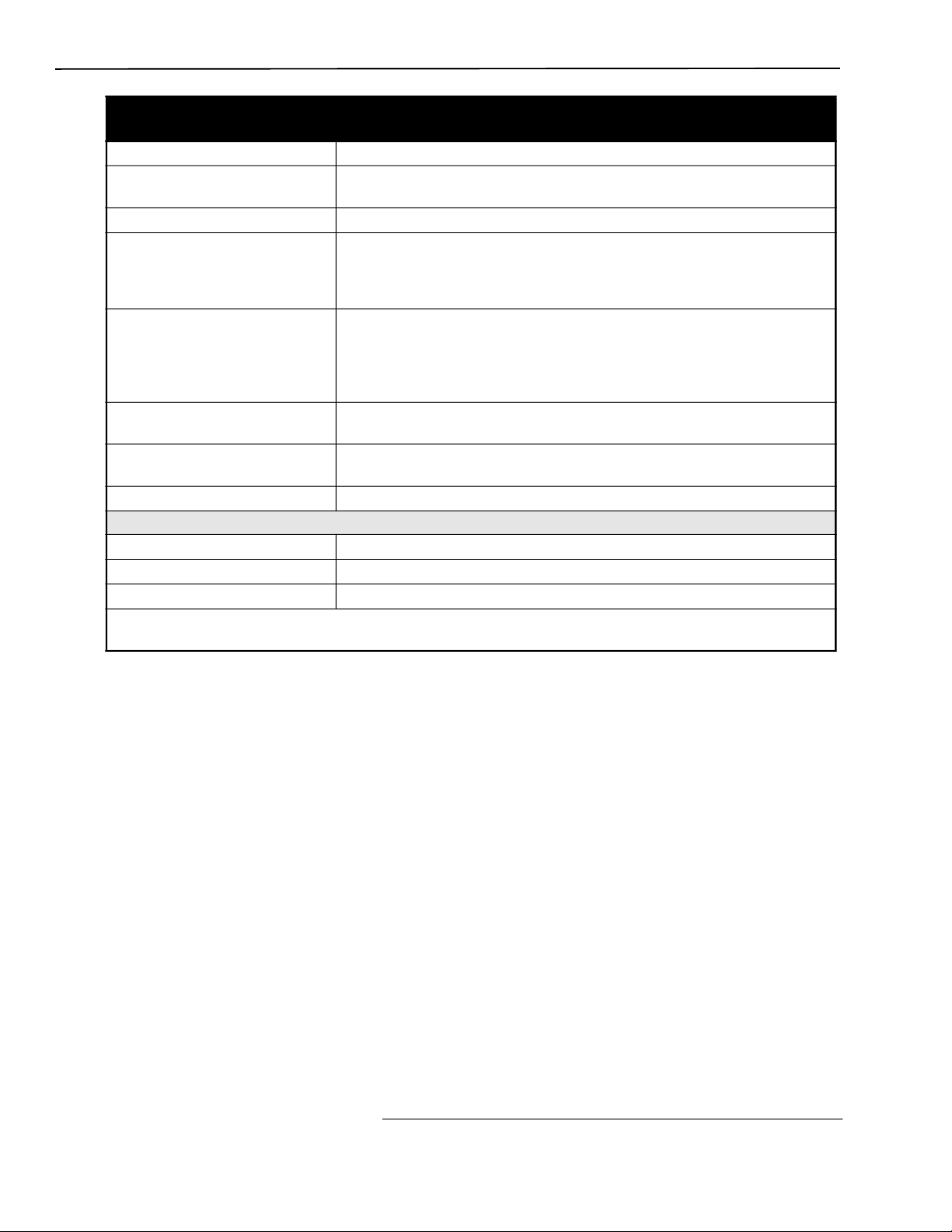

1.5 Controls, Indicators, and Features

Figures 1-1 through 1-3 illustrate key features on the Torrent.

1-3

CombiFlash Torrent® User Manual

Figure 1-1 CombiFlash Torrent Features (Front)

1. Touch Panel LCD display – Large 10.4 inch display for system monitoring and control.

2. On/Standby Switch – 1 = On, = standby.

3. Upper Column Mount Release – The upper column mount will latch at the top of its

travel to ease column replacements. The latch holds the mount in place until the release is

pushed to the left.

4. To Collector – On right side of instrument, not visible in the image. Eluate that is not

diverted to waste is delivered to this outlet port for collection. Collection may be performed

manually, or automated by a Foxy R2 High Flow

fraction collector or a Fractionation Valve.

5. Upper Column Mount – The column mount holds the column in place and plumbs the

mobile phase to the column inlet through interchangeable fittings that support a variety of

column sizes.

6. Column – The Torrent is designed for use with RediSep® Flash chromatography columns

which include RFID technology for automatic detection.

7. Lower Column Mount – The column mount holds the column in place and plumbs the

column outlet to the internal UV or UV-vis detector.

8. Drip Tray and Drain – Should any leaks occur at the front panel fittings, the drip tray and

drain will carry away the fluids.

9. Sample Injection Port – This fitting accepts the sample though either a solid load sample

cartridge

(shown) or a liquid injection using a sample load pump, syringe, or similar device.

10.Injection Valve – The Torrent automatically positions this valve according to its current

mode of operation. Modes include column equilibration, sample injection, elution, column

flushing, valve cleaning, and air purging.

1-4

11.Solid Load Cartridge – Solid load cartridges are a useful way to load low-solubility

samples onto the column. Cartridges are available filled with silica gel, Celite, and C18

media, or as empty cartridges to be filled with yo

ur media of choice. The cartridge outlet

connects to the sample injection port (9).

Section 1 Introduction

12.Solid Load Cartridge Cap – Adds the cartridge to the fluid path. An internal plunger

minimizes any volume above the bed.

13.Solid Load Cartridge Cap Mount – This spring-loaded mount secures the solid load

cartridge and cap in place.

14.USB Port – Convenient, front panel port that accepts USB Flash memory drive. A Flash

memory drive may be inserted into this port for transferring files, importing and exporting

methods, and Torrent software updates.

15.Solid Load Cartridge Tubing – This tubing connects to the Solid Load Cartridge Cap.

In some configurations, such as a system purge, it can be connected to the Sample Injection

Port. In c

onfigurations without solid load cartridges, the tubing is not used.

Figure 1-2 CombiFlash Torrent Features (Side, close up)

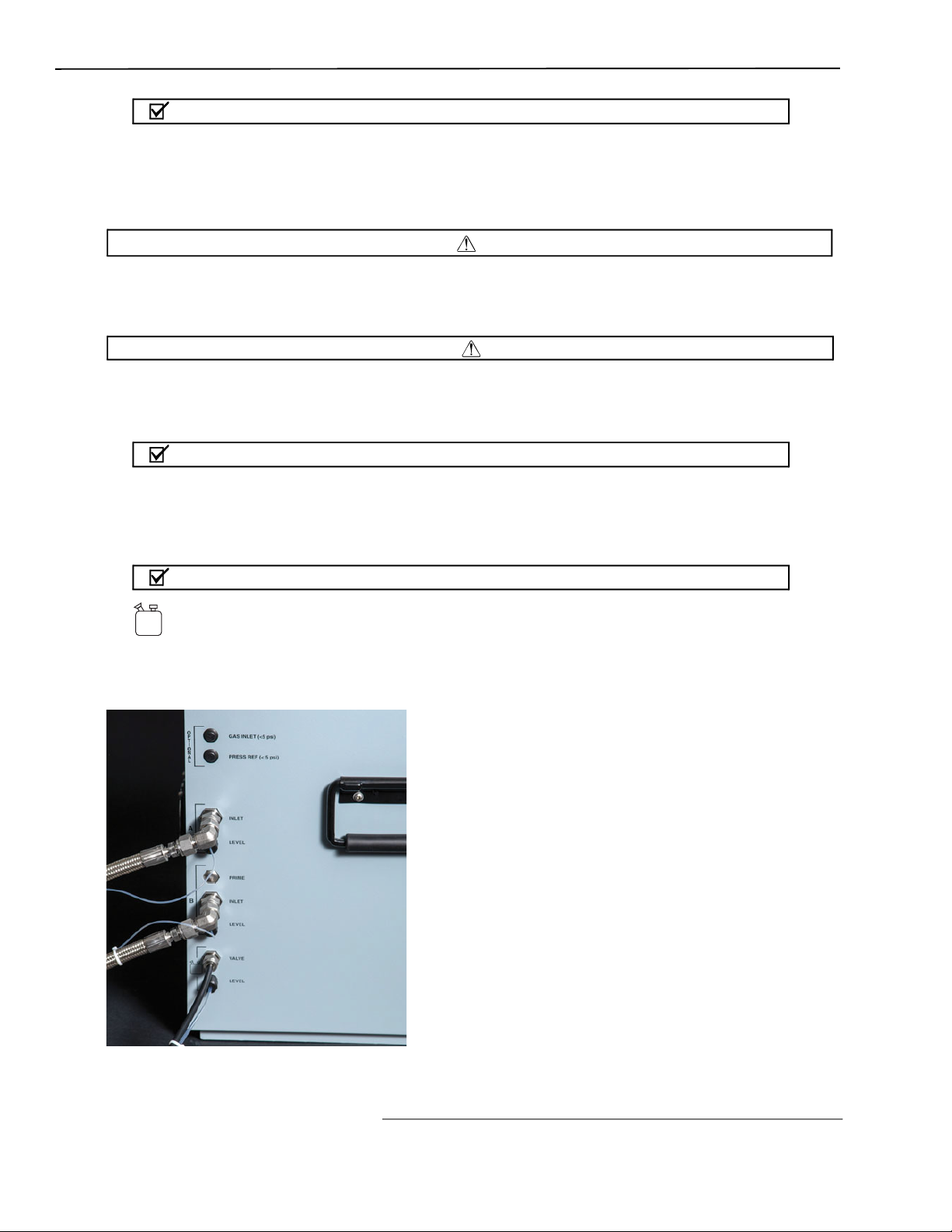

16.Gas Inlet – The Torrent has an internal air pump that delivers air through the column for

a post-run purge. The air is also used to detect solvent and waste levels. If you desire to use

a specific gas such as nitrogen, connect the gas source to this port.

17.Pressure Reference – When detecting solvent or waste levels in containers or conduits

not exposed to atmospheric pressure, a headspace reference pressure is re

quired so that

the Torrent can read the differential pressure to determine levels.

18.A Inlet – This port receives the A solvent.

19.A Level – This port measures the solvent A level by means of pressurized air or gas

source.

20.B Prime – This port primes the B solvent pump (Torrent only).

21.B Inlet – This port receives the B solvent.

22.B Level – This port measures the solvent B level by means of pressurized air or gas

source.

23.Waste Valve – This port delivers waste fluids to a user-supplied waste container.

1-5

CombiFlash Torrent® User Manual

24.Waste Level – The Torrent uses air or user-supplied gas to measure the hydrostatic

pressure of the waste above the level sense line end. The system will suspend operation

when this user-set level is too high.

25.Fraction Valve – The Torrent controls the optional Fractionation Valve through this port.

26.Sample Load Pump – The Torrent controls the optional Sample Load Pump through this

port.

27.Mains Power – Connects the Torrent to AC line voltage.

28.Power Outlet – Provides AC line voltage to an external device that meets the 115 VAC and

2.0 ampere or 230 VAC and 1.0 ampere rating.

The back panel power connector is intended only for use with the Foxy R2 fraction collector.

Do not connect other devices to this outlet.

CAUTION

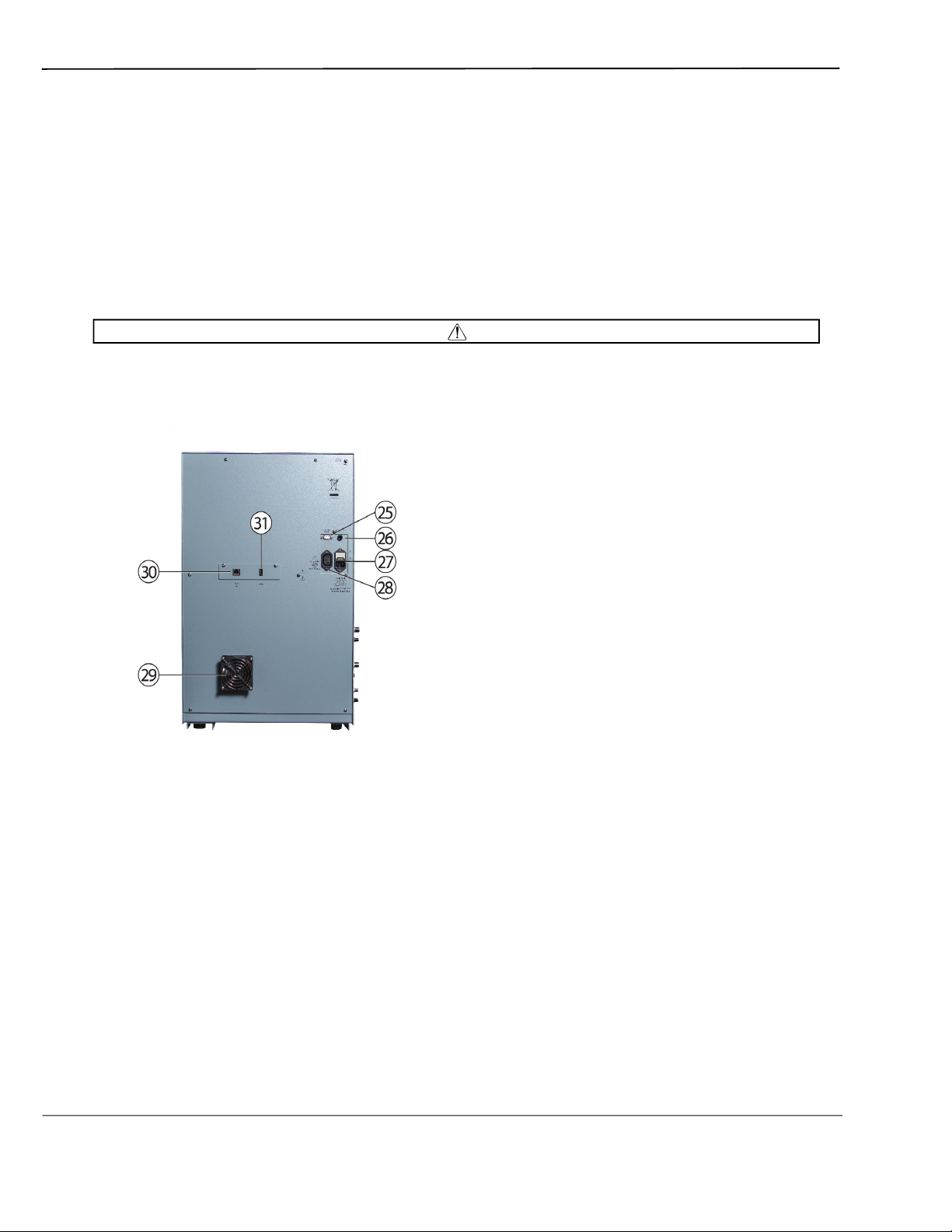

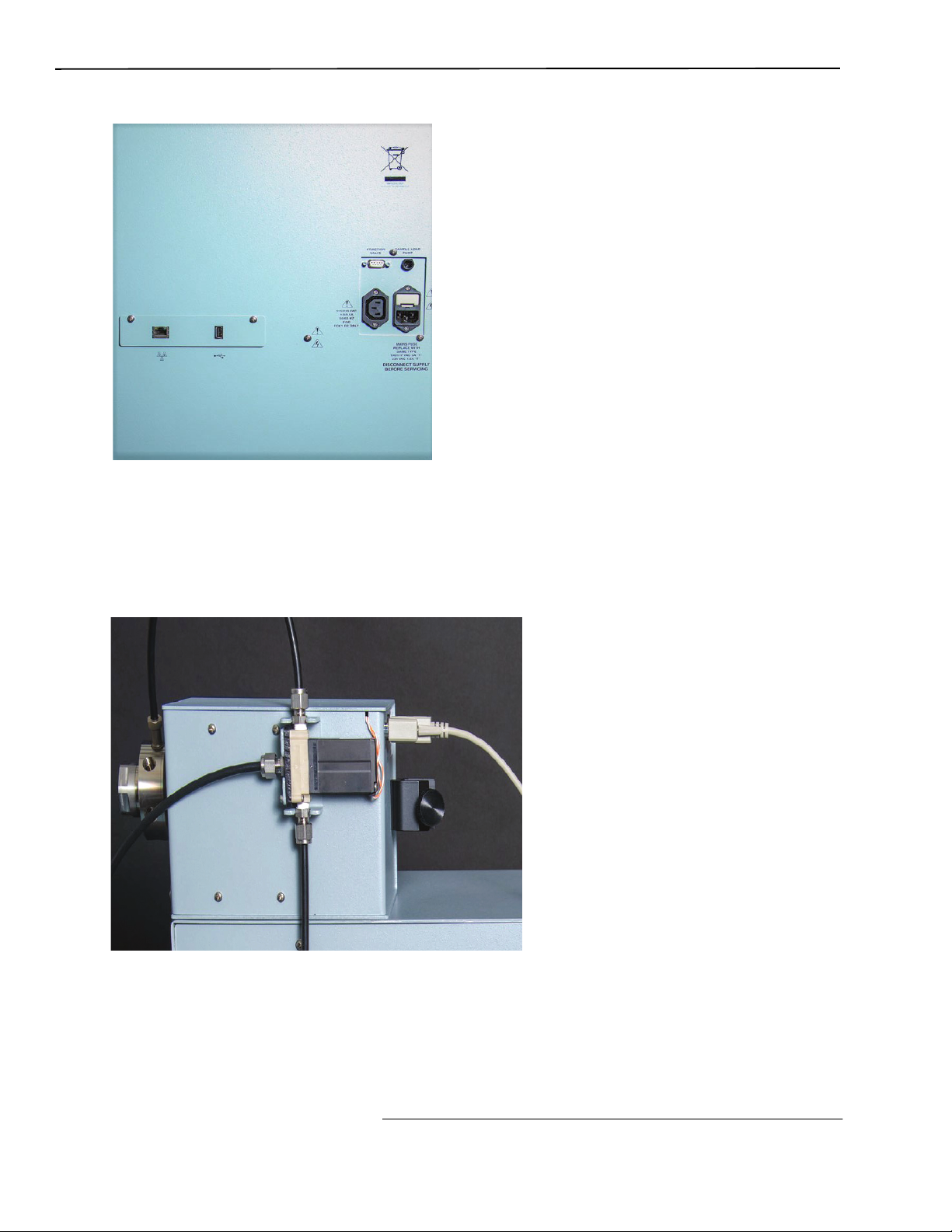

– Figure 1-3 CombiFlash Torrent Features (Back)

29.Cooling Fan – Cools the internal components.

30.Ethernet Port – An 8P8C jack for a network connection using a standard CAT5/6 cable, or

for a direct connection to a computer using a cross-over cable.

31.USB Port – To interface with peripheral devices. This rear panel port is primarily for

service-related functions.

1.6 Safety

Before installing, operating, or maintaining this equipment, it is imperative that all hazards

and preventive measures are fully understood. While specific hazards may vary according to

location and application, take heed in the following general warnings:

1-6

Section 1 Introduction

WARNING

Avoid hazardous practices! If you use this instrument in any way not specified in this

manual, the protection provided by the instrument may be impaired.

WARNING

Liquids associated with this instrument may be classified as carcinogenic, biohazard,

flammable, or radioactive. Should these liquids be used, it is highly recommended that this

application be accomplished in an isolated environment designed for these types of

materials in accordance with federal, state, and local regulatory laws, and in compliance

with your company’s chemical/hygiene plan in the event of a spill.

WARNING

If you are using flammable solvents or chemicals with this system, vapor concentration

levels may exceed the maximum exposure levels as recommended by OSHA Guide

1910.1000. To reduce those levels to a safe exposure, Teledyne ISCO recommends that you

place the system in a laboratory hood designed for the purpose of ventilation. This hood

should be constructed and operated in accordance with federal

In the event of a solvent or chemical spill, your organization should have a plan to deal with

these mishaps. In all cases, use good laboratory practices and standard safety procedures.

state and local regulations.

The CombiFlash Torrent has redundant safety devices to limit pressure to less than 100 psi

(689 kPa). RediSep columns smaller than 100 g are CE certified using standard IEC61010-1

for use on the CombiFlash Torrent. RediSep columns larger than 100 g meet Pressure Vessel

Directive 97/23/EC. Teledyne ISCO strongly recommends against the use of columns rated

less than 100 psi (689 kPa).

1.6.1 Hazard Severity Levels

This manual applies Hazard Severity Levels to the safety alerts. These three levels are

described in the sample alerts below.

Cautions identify a potential hazard, which if not avoided, may result in minor or moderate

injury. This category can also warn you of unsafe practices, or conditions that may cause

property damage.

Warnings identify a potentially hazardous condition, which if not avoided, could result in

death or serious injury.

WARNING

CAUTION

WARNING

1-7

CombiFlash Torrent® User Manual

Limited to the most extreme situations to identify an imminent hazard, which if not avoided,

will result in death or serious injury.

1.6.2 Hazard Symbols

The equipment and this manual use symbols used to warn of hazards. The symbols are

explained in Table 1-2.

Warnings and Cautions

DANGER

Table 1-2 Hazard Symbols

The exclamation point within the triangle is a warning sign alerting you of

important instructions in the instrument’s technical reference manual.

The lightning flash and arrowhead within the triangle is a warning sign alerting you

of “dangerous voltage” inside the product.

The pinch point symbol warns you that your fingers or hands will be seriously

injured if you place them between the moving parts of the mechanism near these

symbols.

Symboles de sécurité

Ce symbole signale l’existence d’instructions importantes relatives au produit

dans ce manuel.

Ce symbole signale la présence d’un danger d’électrocution.

Risque de pincement. Ces symboles vous avertit que les mains ou les doigts

seront blessés sérieusement si vous les mettez entre les éléments en mouvement

du mécanisme près de ces symboles

Warnungen und Vorsichtshinweise

Das Ausrufezeichen in Dreieck ist ein Warnzeichen, das Sie darauf aufmerksam

macht, daß wichtige Anleitungen zu diesem Handbuch gehören.

Der gepfeilte Blitz im Dreieck ist ein Warnzeichen, das Sei vor “gefährlichen

Spannungen” im Inneren des Produkts warnt.

Vorsicht Quetschgefahr! Dieses Symbol warnt vor einer unmittelbar drohenden

Verletzungsgefahr für Finger und Hände, wenn diese zwischen die beweglichen

Teile des gekennzeichneten Gerätes geraten.

1-8

Table 1-2 Hazard Symbols (Continued)

Advertencias y Precauciones

Esta señal le advierte sobre la importancia de las instrucciones del manual que

acompañan a este producto.

Esta señal alerta sobre la presencia de alto voltaje en el interior del producto.

Punto del machacamiento. Sus dedos o manos seriusly serán dañados si usted

los coloca entre las piezas móviles cerca de estos símbolos.

1.7 For Additional Information

Technical assistance for the Torrent can be obtained from:

Teledyne ISCO

4700 Superior St.

Lincoln NE 68504

Phone: (800) 228-4373 or (402) 464-0231

Fax: (402) 465-3001

Email: IscoService@teledyne.com

Section 1 Introduction

1-9

CombiFlash Torrent® User Manual

1-10

Section 2 Preparation

This section provides instructions for unpacking and installing the CombiFlash Torrent

system. To prepare the system for operation, sequentially follow all instructions in sections

2.1 through 2.19. Some of these sections provide instructions for installing optional

equipment which should only be completed as required.

N ot Note

Section 2.21 contains an Installation Qualification checklist. If required, sign off the checklist

entries as you successfully complete the following sections.

2.1 Optional Equipment Modules

The Torrent/Torrent AQ offer several different optional modules. Each module will require

additional set-up steps as noted below. The optional modules are:

• Solvent Selection Valve (see Section 2.4.1; 2.6.2 and

CombiFlash Torrent

User Manual Guide

Section 2 Preparation

2.8).

®

• Sample Load Pump (see Section 2.6.1 and 2.12.1).

• Fractionation Valve (see Section 2.4.2; 2.6.3 and 2.12.3).

• Foxy R2 High Flow Fraction Collector (see Section 2.6.4; 2.12.2 and/or 2.17).

2.2 Unpacking the Unit

The Torrent is shipped in a single carton. The optional equipment will be shipped in

additional cartons. Carefully unpack the shipment and inspect the contents.

The Torrent is heavy. Use a two-person lift to prevent injury.

Lift the Torrent from the container using the lifting handles mounted on the side panels.

If there is damage to the shipping carton or any components, contact the shipping agent and

Teledyne ISCO (or its authorized representative) immediately.

If there is any evidence that the Torrent has been damaged in shipping, do not plug it into

AC power. Contact Teledyne ISCO or its authorized representative for advice.

Compare the contents of the boxes with the enclosed packing slips. If there are any shortages,

contact Teledyne ISCO immediately.

WARNING

WARNING

2-1

CombiFlash Torrent® User Manual Guide

2.3 Instrument Location

The Torrent has a relatively small footprint for a development-scale instrument, requiring

about 2200 square centimeters (350 in

least 3 cm (1.25") of air space behind it for ventilation. Additional space may be required for

solvent and waste containers, and fraction collection.

2

) of level bench space. Ensure that the Torrent has at

Refer to Table 1-1 for environmental condi

The system is heavy. Use a two-person lift to prevent injury.

Before making any connections to the Torrent, place it on the bench or in the fume hood where

it will be operated. Temporarily position the Torrent so you can access the back panel to

complete the connections.

2.4 Mounting Optional Modules

If a Solvent Select Valve or Fractionation valve are not being installed you can skip this section

nd continue to Section 2.5.

a

2.4.1 Solvent Select Valve (if purchased)

Place the Solvent Select Valve on the left-hand side of the Torrent with the valve facing the side

of the Torrent.

Use the supplied metal mounting plate and four (4) screws to secure the Solvent Select Valve to

the Torrent.

tions and power requirements.

WARNING

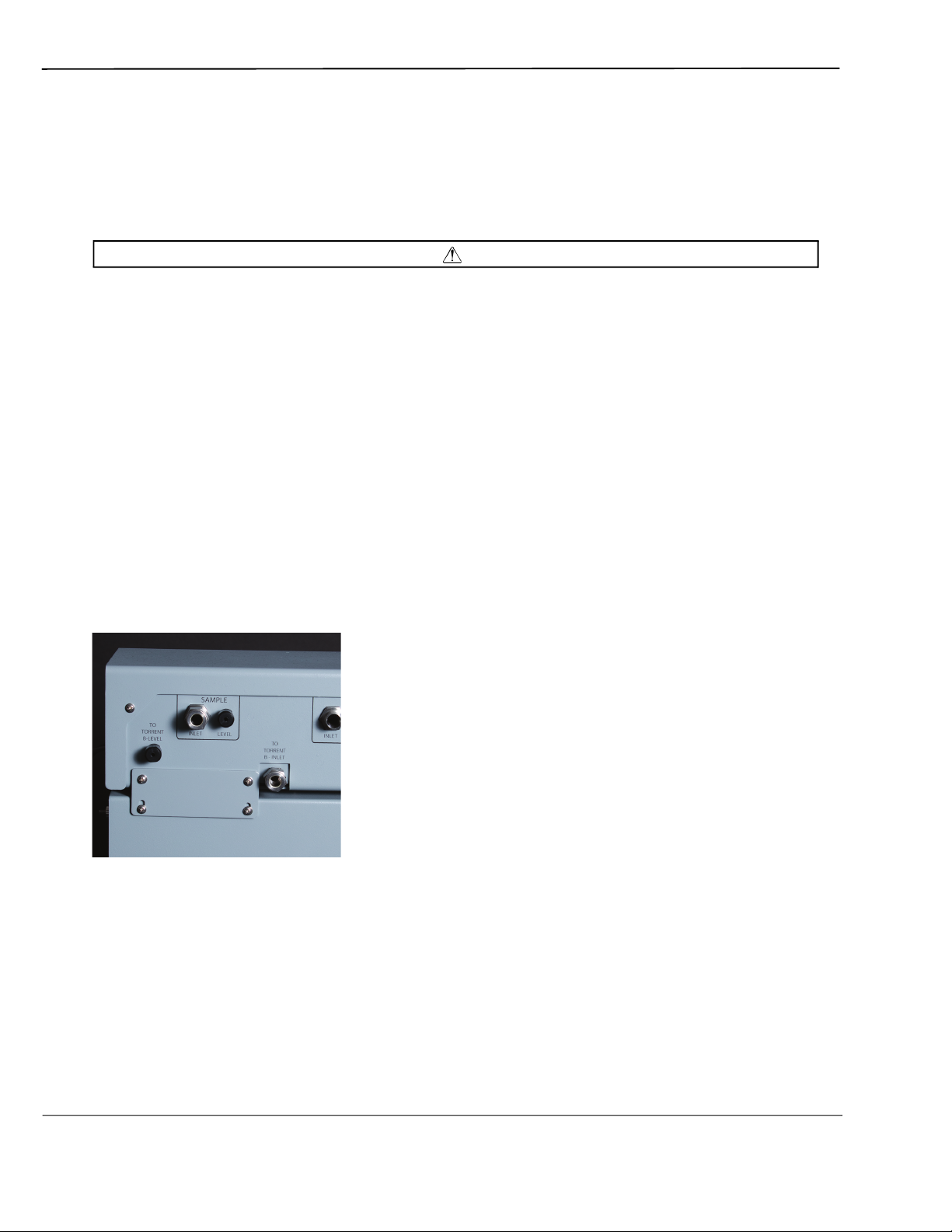

Figure 2-1 Solvent Select Valve mounted on Torrent

2.4.2 Fractionation Valve (if purchased)

Place the Fractionation Valve on the right-hand side of the Torrent with the Valve facing the

side of the Torrent.

2-2

Section 2 Preparation

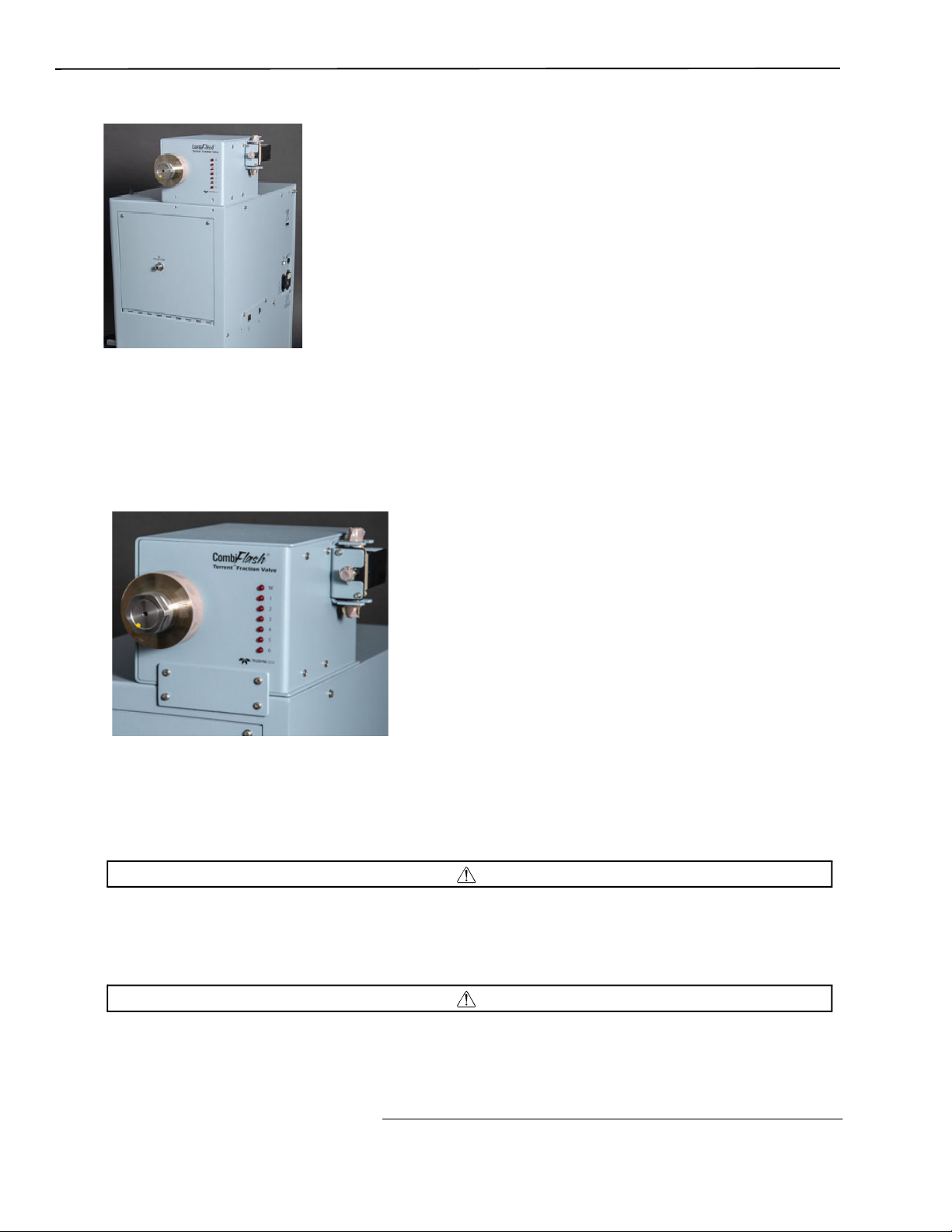

Figure 2-2 Fractionation valve position before mounting.

Use the supplied metal mounting plate and four (4) screws to secure the Fractionation Valve

to the Torrent.

Alternatively, the valve can be connected to a user supplied mast.

Figure 2-3 Fractionation valve after mounting

2.5 Connect Power

Ensure that the On/Standby switch above the touch screen panel is in the Standby position.

Then, use the

Mains power must meet the voltage, frequency, and amperage requirements listed on the

serial number label. Input voltage must be within ±10% of the region’s nominal line voltage.

In the USA, this is 117 volts ±11.7 volts.

As long as the AC mains power cord is connected to a live outlet, power is inside the unit.

The mains power cord is the disconnect device. Position the Torrent so that the power cord

supplied IEC power cord to connect the Torrent to mains power.

WARNING

WARNING

2-3

CombiFlash Torrent® User Manual Guide

can be unplugged, or use a power strip where the plug can quickly be removed from the outlet

in the event of an emergency.

Unless power must be removed due to an emergency, always wait at least one minute after

placing the system in Standby before removing the AC mains power cord.

2.6 Connect Interface Cables

Rear panel connections support a variety of devices. Electrical connections to networks or

optional equipment should be completed at this time.

CAUTION

Review the options below and complete as necessary. If any optional mo

installed you can continue to Section 2.7.

N ot Note

Detailed information about each of these optional devices is provided in Section 2.12 Plumbing

Optional Modules To Torrent.

2.6.1 Cabling: Sample Load Pump

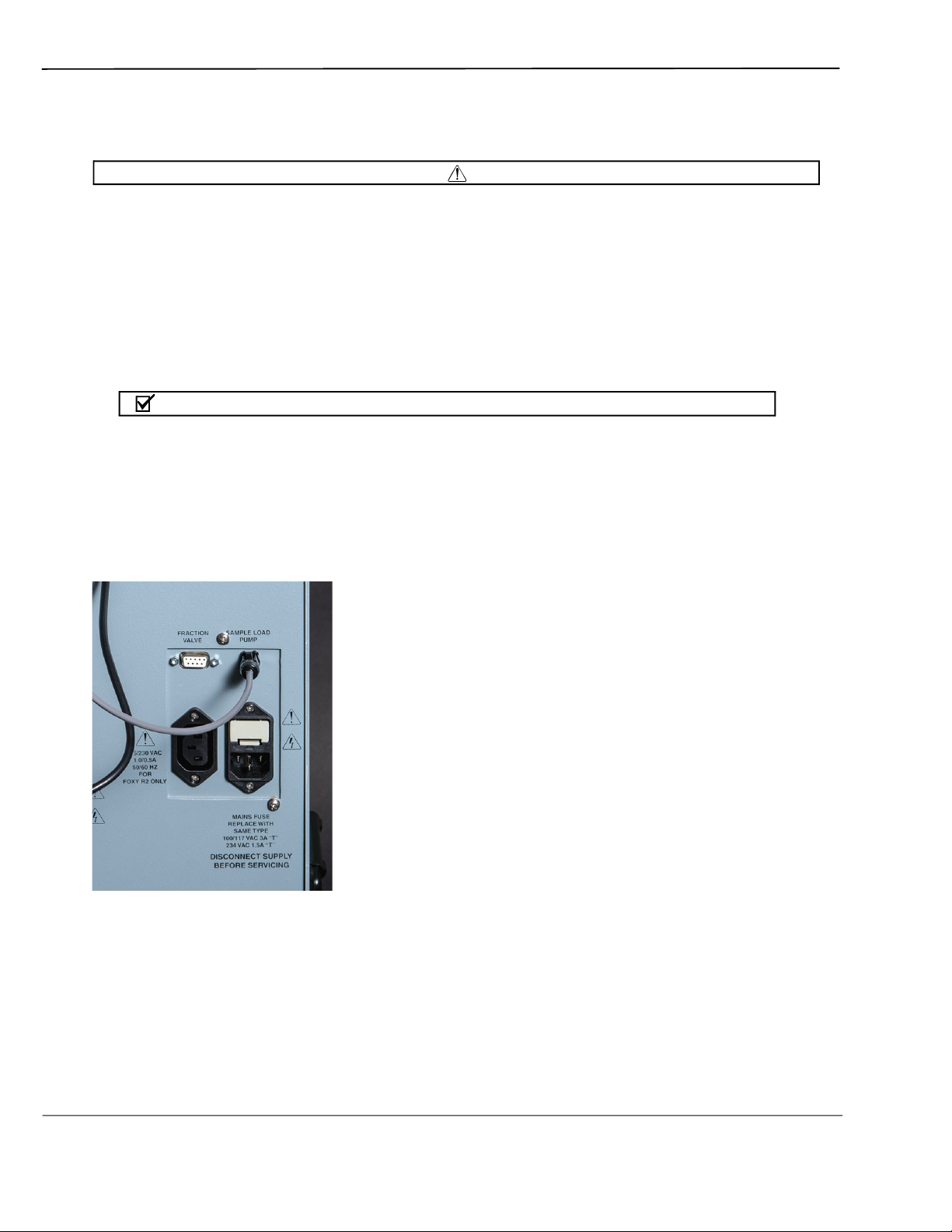

To connect a Sample Load Pump to the Torrent, attach the pump’s power cable to the Torrent’s

back panel connector labeled “SAMPLE LOAD PUMP.”

dules are not being

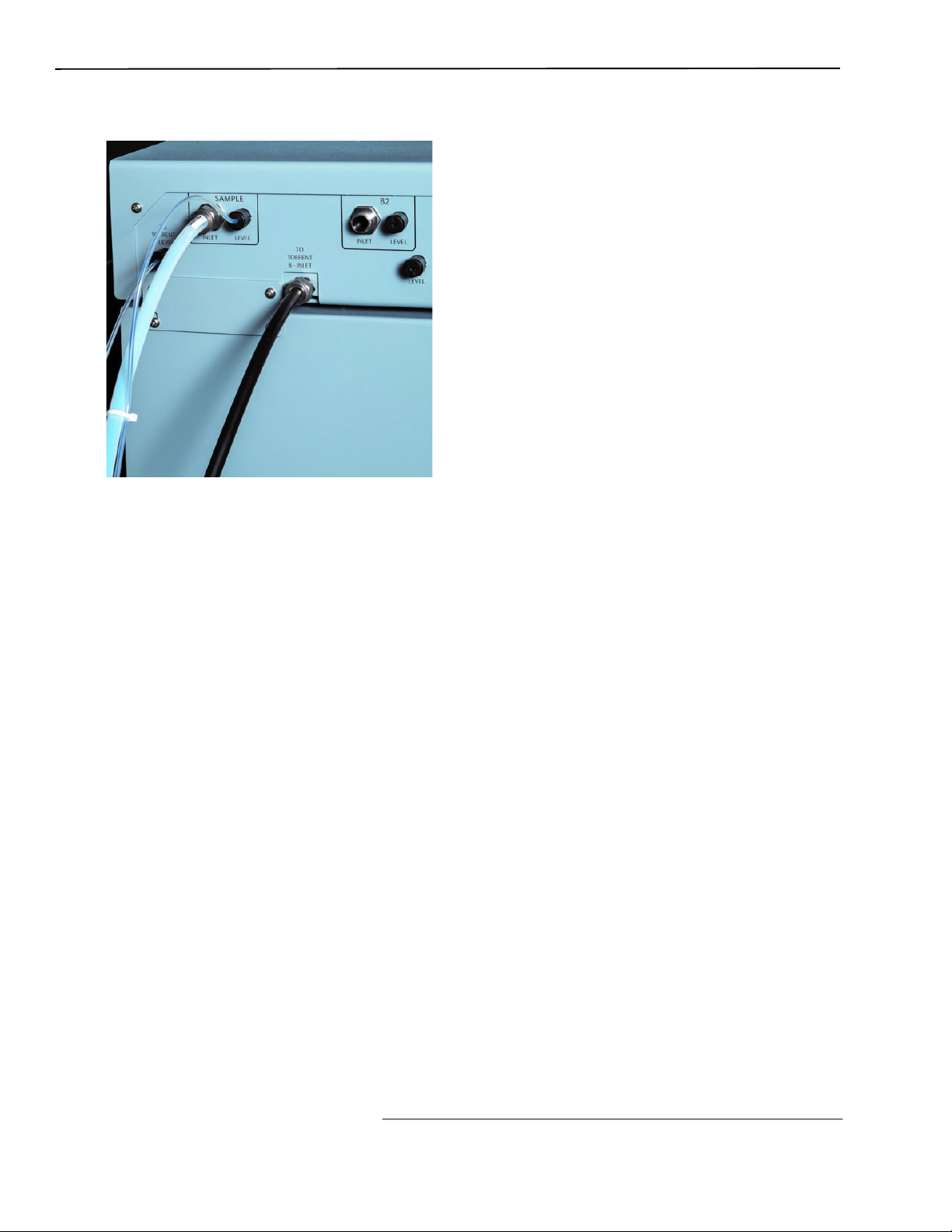

Figure 2-4 Sample Load Pump power supply connection on back of Torrent.

2.6.2 Cabling: Solvent Select Valve

To connect a Solvent Select Valve to the Torrent, attach the valves power cable to the back

panel connector labeled “SAMPLE LOAD PUMP” and connect the USB cable to the USB port

on the back panel.

2-4

Figure 2-5 Back of Torrent for electrical connections

Section 2 Preparation

2.6.3 Cabling: Fractionation Valve

To connect a Fractionation Valve to the Torrent, attach the valve’s 9-pin power/control cable

between the port on the back of the Fractionation Valve to the Torrent’s back panel connector

labeled “FRACTION VALVE.”

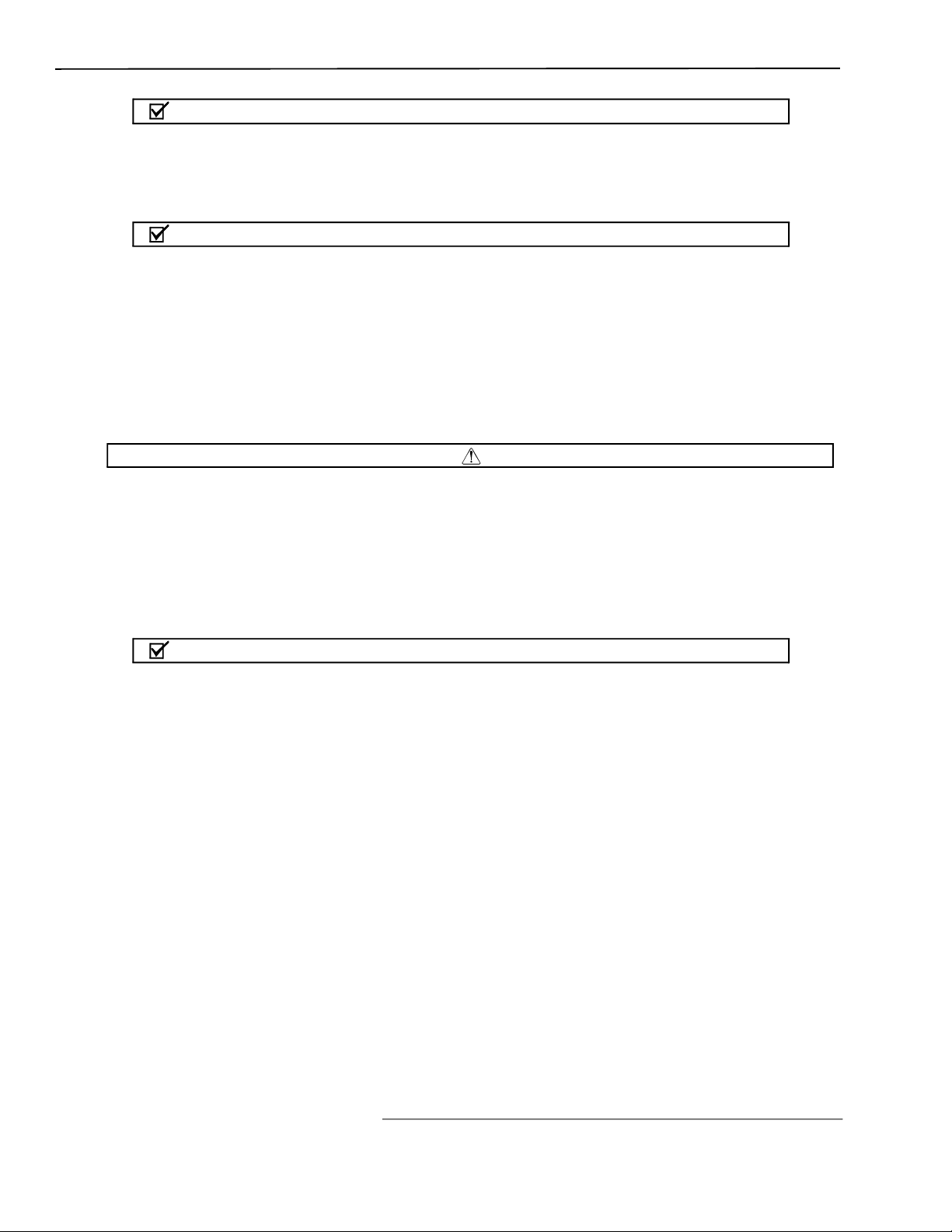

Figure 2-6 Electrical Connection between Fractionation Valve and Torrent

2-5

CombiFlash Torrent® User Manual Guide

2.6.4 Cabling: Foxy R2 High Flow Fraction Collector

The Torrent can control up to four Foxy R2 High Flow fraction collectors via an Ethernet

network.

To connect one, or the first of multiple Foxys, connect a standard straight-through network

cable between the Ethernet ports on the Torrent and a Foxy. The second Ethernet port on the

Foxy can be used to add the next Foxy. See section 2.12.2 for more

The Torrent can supply AC power to one Foxy. Connect one end of the cable to the female IEC

connector on the Torrent. Connect the other end to the Foxy power connector.

details.

Figure 2-7 Connection on back of Foxy R2 Fraction Collector to the Torrent

2.6.5 Cabling: Network Connection

The Torrent can be added to a network or directly connected to a computer for remote control.

To add the Torrent

the Torrent’s Ethernet port and your network.

To connect the Torrent directly to a computer, connect a “crossover” cable between the Ethernet

ports on the Torrent and a stand-alone computer.

To connect to a network, you will need access to IP addresses and network information from

your IT department. For more information on network guidelines, see TN28 Networking

Guidelines for CombiFlash Products, available at www.isco.com.

N ot Note

When using the Foxy R2 High Flow fraction collector, the Torrent’s rear panel Ethernet connector

will be in use. Instead, connect the cable to the available Ethernet port on the last Foxy in the chain.

to a network, connect a standard straight-through network cable between

2-6

N ot Note

The Foxy R2 fraction collector does not support DHCP. If you are adding the Torrent with Foxy R2

fraction collectors to your organization’s network, a static IP address must be assigned to each

unit. Contact your IT department for assistance.

N ot Note

Detailed information about networking the Torrent with one or more Foxys is provided in

Section 2.12.2.

2.7 Position the Torrent

After completing the various back panel connections, the Torrent can be moved to its

operating position. Turn the Torrent so that the operator can access all of the front view

features and controls. Use care not to damage the connections, cables and equipment while

moving

Ensure that the CombiFlash Torrent has at least 3 cm (1.25") of air space behind it for

ventilation.

the Torrent.

Section 2 Preparation

CAUTION

Determine where the solvent and waste containers will be located. Keep in mind that the

valve wash waste is located on the Torrent’s left side panel; diverter valve waste will come

from the fraction collector or fractionation valve, usually positioned on the right side of the

Torrent. If these will use a common waste container, determine the preferred location.

N ot Note

A common waste container is recommended for waste level monitoring to prevent overfilling.

2.8 Connect Solvent Select Valve Plumbing

If a Solvent Select Valve is not being installed you can skip this section and continue to

Section 2.9. If a Solvent Select Valve is to be installed with the Torrent or Torrent AQ it

should already be mounted.

2-7

CombiFlash Torrent® User Manual Guide

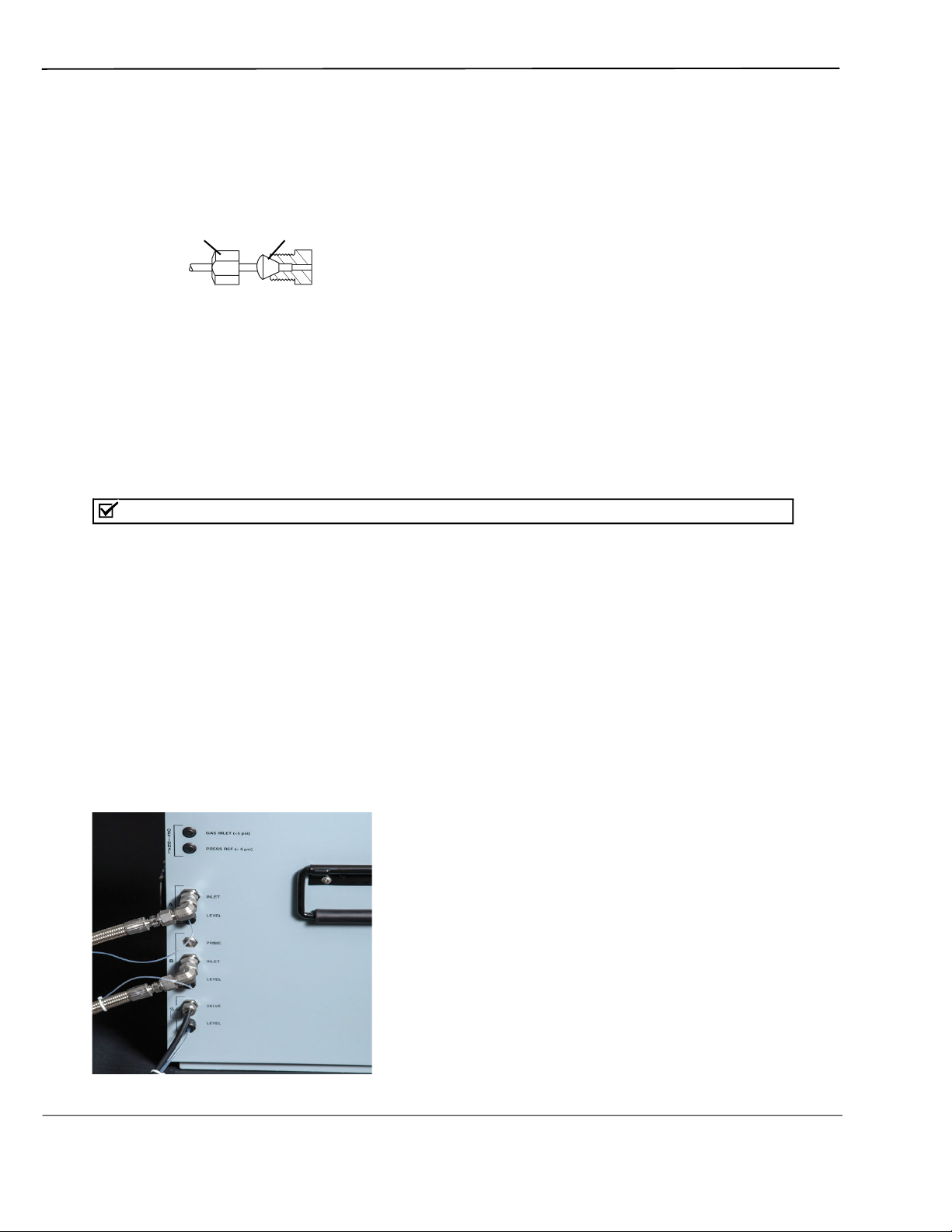

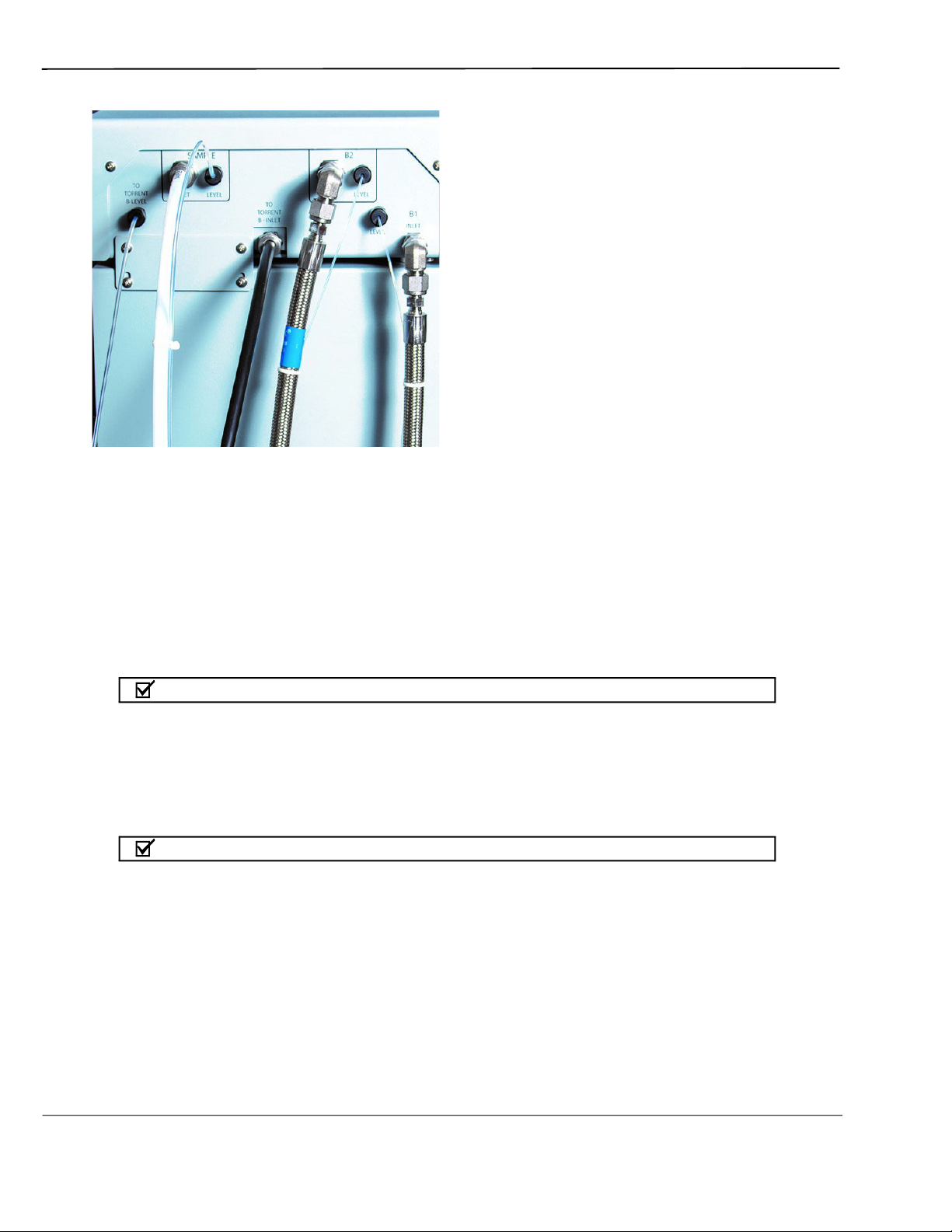

Figure 2-8 Solvent B Line connected to Solvent Selection Valve

1. Connect the preswaged end of black tubing (023050308) to Torrent “B INLET”.

2. Loosen (but don’t remove) the nut and 2-piece ferrule connected to the Solvent Select Valve

port “TO TORRENT B INLET”.

3. Place the free end of the black tubing into the port as far as it will go and finger tighten the

nut. Then use a wrench to tighten for a n additional 1 and 1/4 turn.

4. Locate a nut (60-0923-015) and ferrule (60-0083-163) in the accessory package

(60-5249-002).

5. Insert the ferrule, narrow end first, into the Torrent “B LEVEL”.

2-8

Figure 2-9 Solvent B Line on Torrent Connected to Solvent Selection Valve

6. Loosely thread the nut onto the “B LEVEL” port.

7. Insert the clear air supply line (supplied with Solvent Select Valve) into the “B LEVEL”

port until it is fully seated.

8. Finger tighten the nut. If desired, tighten the nut an additional 1/2 turn using a wrench.

9. Loosen the nut (but do not remove) to the Solvent Select Valve Port “TO TORRENT B

LEVEL”.

10.Following step 4 above, connect the air supply from the B LEVEL on the Torrent to the

Solvent Select Valve “TO TORRENT B LEVEL”.

2.9 Connect Solvent Lines

To prevent damage or premature wear to the pump and internal valves, clean solvent

should be used. The solvent should not contain any dissolved solids. In addition, the B

solvent pump on the Torrent and both Solvent A and Solvent B pumps on the Torrent AQ

are not compatible with alkanes such as hexane due to lack of lubricity. If using water as a

solvent, use Ultra Pure, DI or RO water.

Section 2 Preparation

CAUTION

CAUTION

If solvent containers are reused, particulate matter can accumulate in the container.

Containers should be thoroughly cleaned before each refill. Failure to clean the containers

may result in damage to the solvent selection valve and internal components.

N ot Note

The Torrent is shipped with protective caps on the solvent fittings. Remove these caps as you

connect the solvent lines. The internal solvent lines contain isopropyl alcohol, some of which may

drain when the caps are removed.

The Torrent may receive solvent from:

• User-supplied solvent containers at atmospheric pressure

• Pressurized or gravity-fed solvent delivery lines in the laboratory.

Refer to th

e appropriate installation section (2.9.1 through 2.9.2) according to your solvent

source.

2.9.1 Solvent Containers at Atmospheric Pressure

The Torrent can form a binary gradient from two solvents, A and B. These solvents connect to

the left side panel of the Torrent or Torrent AQ with optional Solvent Select Valve allows for a

binary gradient between one A solvent and either of two different B sol

1. Locate the Solvent A inlet line. This assembly consists of two tubes fastened together— a

solvent line and a smaller diameter air line to measure the solvent level.

vents or liquid sample.

2. Connect the large fitting to the Torrent’s A INLET port:

3. Position the end with the threaded fitting near the port.

2-9

CombiFlash Torrent® User Manual Guide

4. Rotate the fitting until the inlet line is routed the desired direction.

5. Finger-tighten the pre-swaged fitting to the port.

6. Use a wrench to tighten the fitting an additional

7. Connect the air line to the A LEVEL port (refer to Figure 2-10):

1

8 turn.

Nut

60-0923-015

Tubing

Figure 2-10 Level tubing connection with nut and ferrule

Ferrule

60-0083-163

Level Port

8. Locate a nut (60-0923-015) and ferrule (60-0083-163) in the accessory package

(60-5249-0

02).

9. Insert the ferrule, narrow end first, into the A LEVEL port.

10.Loosely thread the nut onto the A LEVEL port.

11.Insert the Solvent A air line into the A LEVEL port until it is fully seated.

12.Finger-tighten the nut. If desired, tighten the nut an additional

Important

1

2 turn using a wrench.

For systems without Solvent Select Valve follow steps 13-18. For systems with Solvent Select

Valve skip to steps 19-27.

13.Locate the Solvent B inlet line. This assembly consists of three tubes fastened together—a

solvent line, a smaller diameter air line, and a solvent line.

14.Connect the large fitting on the Solvent B inlet line to the Torrent’s B INLET port as

described in step 2.

2-10

15.Connect the smallest tube of the Solvent B inlet line to the B LEVEL port as described in

step 7.

16.Connect the remaining tube of the Solvent B inlet line to the B PRIME port:

17.Finger-tighten the pre-swaged fitting to the port labeled B PRIME.

18.Use a wrench to tighten the fitting an additional

Figure 2-11 Solvent A line connected to the Torrent

1

8 turn.

19.The Solvent Select Valve should be plumbed to the B Inlet of the Torrent.

Figure 2-12 Sample Inlet Line connected to Solvent Selection Valve

Section 2 Preparation

20.Locate the Sample Inlet line. This assembly consists of two tubes fastened together--a

white solvent line and a smaller diameter air line.

21.Connect the large tubing on the sample line to the Solvent Select Valve’s SAMPLE INLET

port with the pre-swaged nut and ferrule The connection should be finger-tight. Then, use

a wrench to tighten the fitting an additional 1/8 turn.

22.Connect the smaller tube of the sample inlet line to the Solvent Select Valve’s SAMPLE

Level port as

described in step 7.

23.Locate the Solvent B1 inlet line. This assembly consists of two tubes fastened together--a

solvent line and a smaller diameter air line.

24.Connect the large fitting on the Solvent B1 inlet line to the Solvent Select Valve’s B1

INLET port as described in step 2 above.

25.Connect the smalled tube of the Solvent B1 inlet line to the Solvent Select Valve’s B1 inlet

line to the Solvent Select Valve’s B Level port as described in step 7.

26.Locate the Solvent B2 inlet line and repeat Steps 24 and 25 for the B2 inlet line.

2-11

CombiFlash Torrent® User Manual Guide

Figure 2-13 Solvent B1 and B2 supply lines connected to Solvent Selection Valve

The other ends of the Solvent A and B lines should be placed in the respective solvent

containers.

27.If installing onto a Torrent (not AQ), locate the 1/8-inch plug, part number 209-0165-21, in

accessory kit 60-5249-002. Install this plug on the B Prime port.

2.9.2 Pressurized Solvent Lines in the Laboratory

When receiving solvent from pressurized lines on-site, the Torrent’s solvent level sensing

feature is unsupported (and unnecessary).

N ot Note

The solvent pressure should be regulated to not exceed 5 psi.

To complete the solvent connections:

1. Ensure that the solvent supply lines have shut-off valves. These valves must be accessible to

the user.

N ot Note

The solvent supply should be shut-off when the system is not in use. Otherwise, pressurized

solvent may be forced through the CombiFlash Torrent pump seals and leak from the waste port or

other fluid path from the automated injection valve.

2. Locate the

plug on the B Prime port.

3. Connect user-supplied tubing with

ports on the side panel.

1

8-inch plug, part number 209-0165-21, in accessory kit 60-5249-002. Install this

3

8-inch fittings from the source to the A Inlet and B Inlet

2-12

N ot Note

Solvent Level Sensing and B Solvent Prime options should be disabled when completing the

system configuration settings.

2.10 Connect Waste Lines

Risk of fire or equipment damage. Failure to connect Waste Port tubing may allow organic

solvents to pool in unsafe areas, possibly creating dangerous levels of flammable vapors.

Elevated flammable vapor levels are possible. Ensure that the waste container is

adequately ventilated, preferably by placing it in a fume hood.

N ot Note

The Torrent is shipped with protective caps on the waste fittings. Remove these caps as you

connect the waste lines. The internal solvent lines contain isopropyl alcohol, some of which may

drain when the caps are removed.

Section 2 Preparation

WARNING

CAUTION

N ot Note

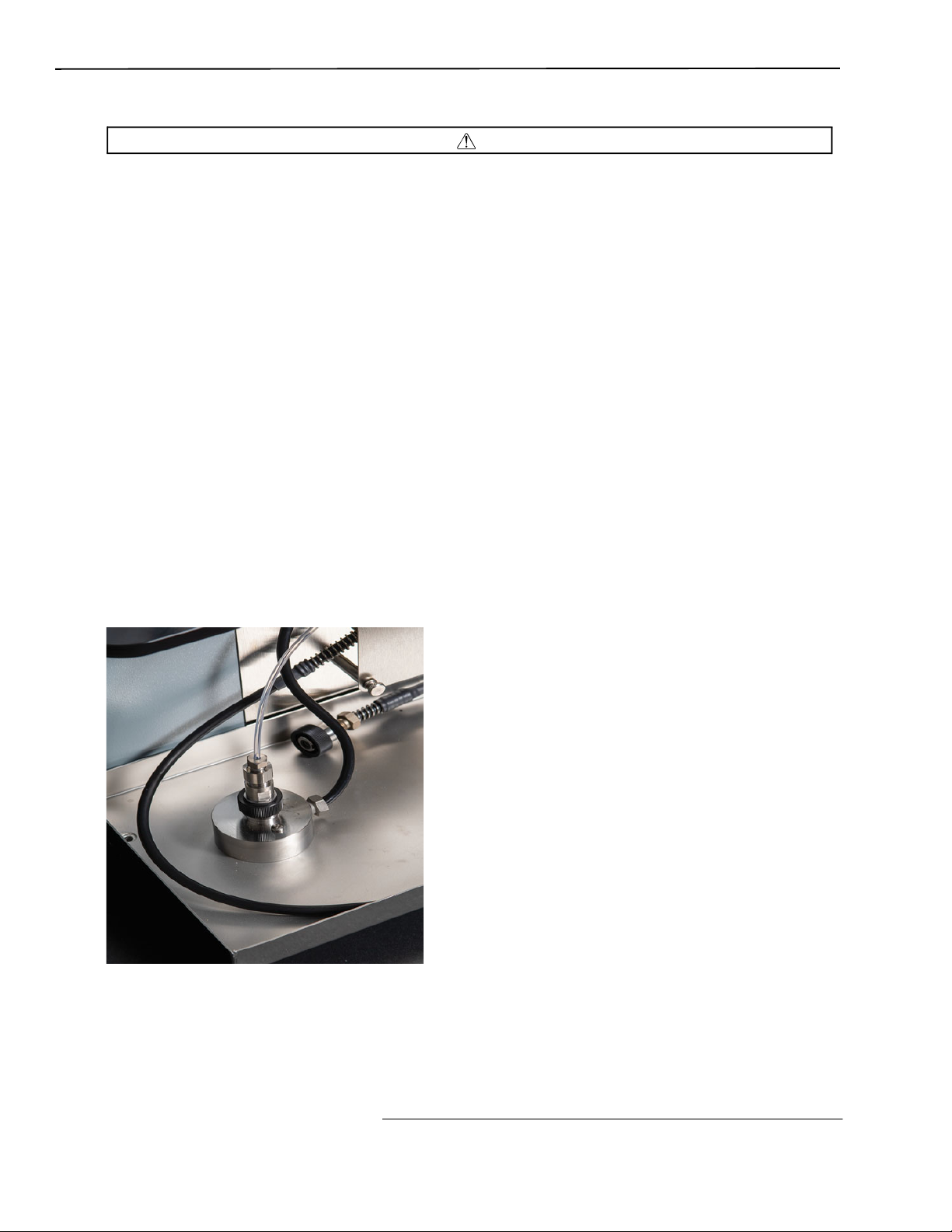

Waste connections on the left side panel are labeled with a Waste icon.

The waste tube assembly is a bundle of two tubes that routes post-run valve wash fluid to a

waste container. Instructions for diverter valve waste tubing is covered in section 2.12.

Figure 2-14 Waste Line connected to the Torrent

2-13

CombiFlash Torrent® User Manual Guide

To connect the waste tube assembly to the Torrent:

1. Select the tube with the pre-swaged nut and ferrule and connect this end to the port labeled

VALVE. The connection should be finger-tight. Then, use a wrench to tighten the fitting an

1

additional

8 turn.

2. Connect the other line to the LEVEL port.

3. Locate a nut (60-0923-015) and ferrule (60-0083-163) in the accessory package

(60-5249-002).

4. Inser

t the ferrule, narrow end first, into the LEVEL port.

5. Loosely thread the nut onto the LEVEL port.

6. Insert the waste air line into the LEVEL port until it is fully seated.

7. Finger-tighten the nut. If desired, tighten the nut an additional

1

2 turn using a wrench.

The other ends of the Waste line should be placed in the waste container.

If using the optional Waste Outlet Cap (60-5394-512 for 83B clo

sures, 60-5394-513 for 100 mm

closures), proceed with the following steps:

8. Place the metal plate inside the plastic cap (Figure 2-15). The plate should be oriented so

that the small tube will extend into the carboy. The small tube should extend 5 ±0.5 cm long

from nut. If the tube is missing, insert it now and finger-tighten the nut.

Nut

Metal Plate

Spring-type

Retainer

Place a retainer above and

5 cm tube extending

into carboy

Figure 2-15 Optional Waste Cap (83B cap shown)

below the metal plate.

2-14

9. The tubing is secured using metal, spring-type retainers. A pair of conventional pliers will

allow you to op

en the retainer enough to slide it onto the tubing. On the larger diameter

waste tube, slide one retainer about 2 inches (5 cm) onto the tubing end.

10.Feed this tube into the top of the metal plate until the retainer is against the top of the

plate.

11.Slide a retainer onto the tubing end until it is seated against the bottom of the metal plate.

12.Thread the cap onto the carboy.

13.The smaller diame

ter tube is the level sense tube. Push this tube about 2 cm into the top

fitting and finger-tighten the nut.

If an optional waste cap is not used, ensure the waste lines are secured so they drain into the

waste container. Secure the Waste Level Sense air tubing so its outlet is at least two inches (5

cm) below the container’s maximum level. Seal the container opening to avoid solvent vapors.

2.11 Connect and Route Drain Line

WARNING

Risk of fire or equipment damage. Failure to connect drain lines may allow organic solvents

to pool in unsafe areas, creating a potential for dangerous levels of flammable vapors.

Improper draining may damage the instrument’s internal components.

The Torrent has a front-mounted drip tray. There is a drain connection under the left side of

the tray. Connect user-supplied tubing to this drain and route it to a suitable waste fluid

collection container.

2.12 Plumbing Optional Modules to Torrent

The installation of optional equipment that was electrically connected to the Torrent in

section 2.6 should be completed now. Review the options below and complete as necessary. If

any optional modules are not being installed you can skip this section and continue to section

2.13.

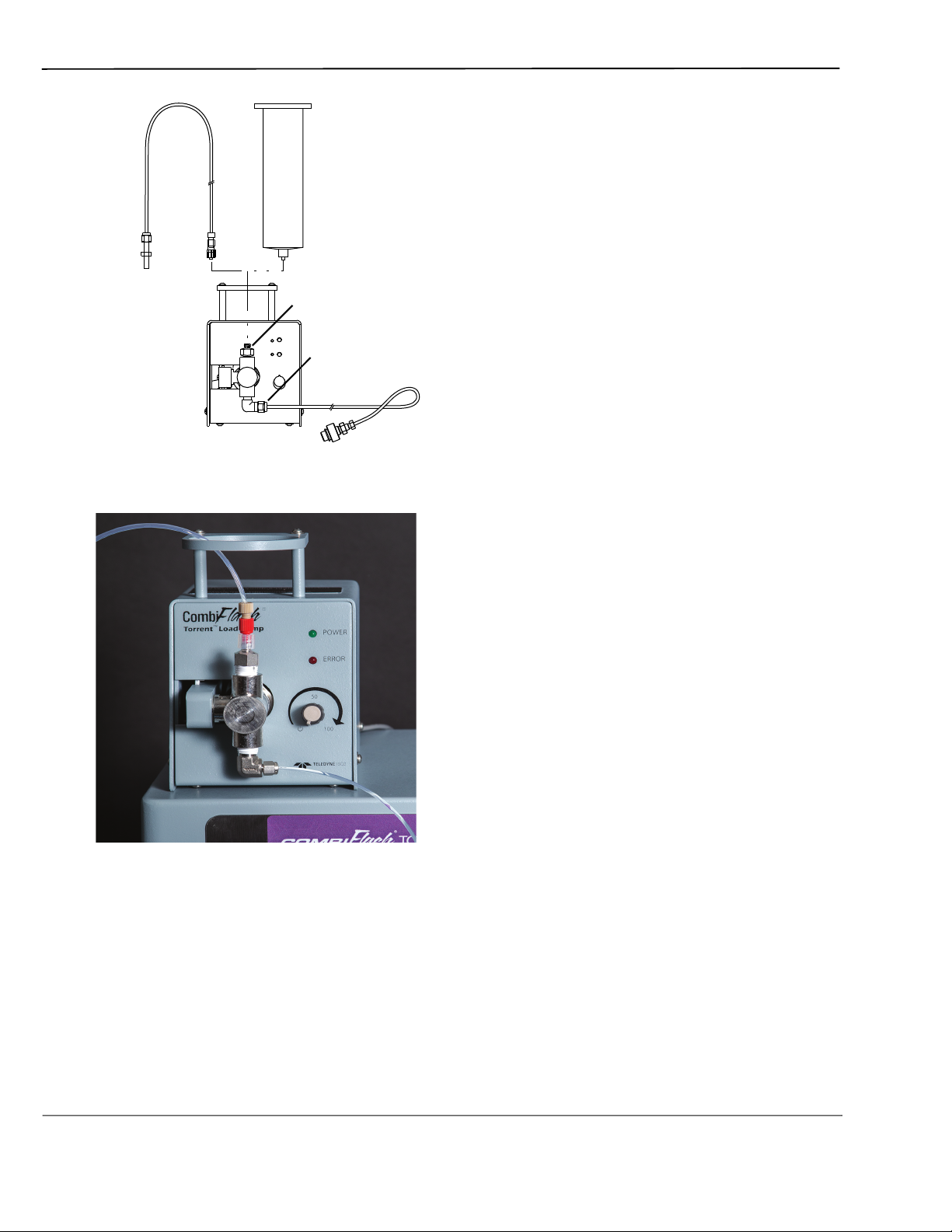

2.12.1 Optional Sample Load Pump

1. Position the Sample Load Pump on top or near the Torrent.

Section 2 Preparation

2. Connect the tubing between the pump outlet (from the bottom of the pump head) and the

Torrent’s sample injection port (Figure 1-1, item 9).

3. Configure the Sample Load Pump by placing either the plastic cartridge reservoir or the

tubing with the weighted end on the pump inlet (Figure 2-17).

Figure 2-16 Sample Load Pump connected to the Torrent Sample Injection Port.

2-15

CombiFlash Torrent® User Manual Guide

Tubing with

Weighted End

Figure 2-17 Sample load pump

Cartridge Reservoir

Pump Inlet

Pump Outlet

To Sample Injection Port

Figure 2-18 Plumbing Sample Inlet to Sample Loading Pump

2.12.2 Optional Foxy R2 High Flow Fraction Collector

The fraction collector(s) should be positioned to the right of the Torrent. Complete information

about the Foxy R2 fraction collector is provided in its user manual, part #69-2133-667.

Plumbing Setup:

1. Connect the 107 cm (42 inch) piece of supplied tubing between the Torrent’s TO

COLLECTOR port and the fraction collector’s diverter valve IN port (Common). Use caution

when tightening the hardware to prevent damage to the dive

2-16

rter valve.

Loading...

Loading...