CO2 Applications &

PTFE

washer

Nipple

Nut

Inline filter

frit assembly

Reducing

connector

To CO

2

Supply

To V a l v e

Inlet

Technical Notes

For Teledyne ISCO Syringe Pumps

Overview

Supercritical CO2 and its associated technologies are

being used in many applications to replace hazardous

solvents, lower costs, and improve efficiencies. Some of

the applications requiring a supercritical fluid pump

include:

● Carbon Sequestration Studies

● Supercritical Fluid Extraction (SFE)

● Supercritical Fluid Chromatography (SFC)

● Catalysis/Reaction Feed

● Injection molding and Extrusion

● Particle Formation

● Cleaning

● Electronic Chip Manufacturing

● Plastics Production

Teledyne ISCO Syringe Pumps are used in R&D and

production in many of these applications. Syringe

pumps are well-suited

at high pressures with great accuracy and reliability.

for use with CO2 and can operate

Syringe Pump Technical Bulletin

Sept 2020, TB08

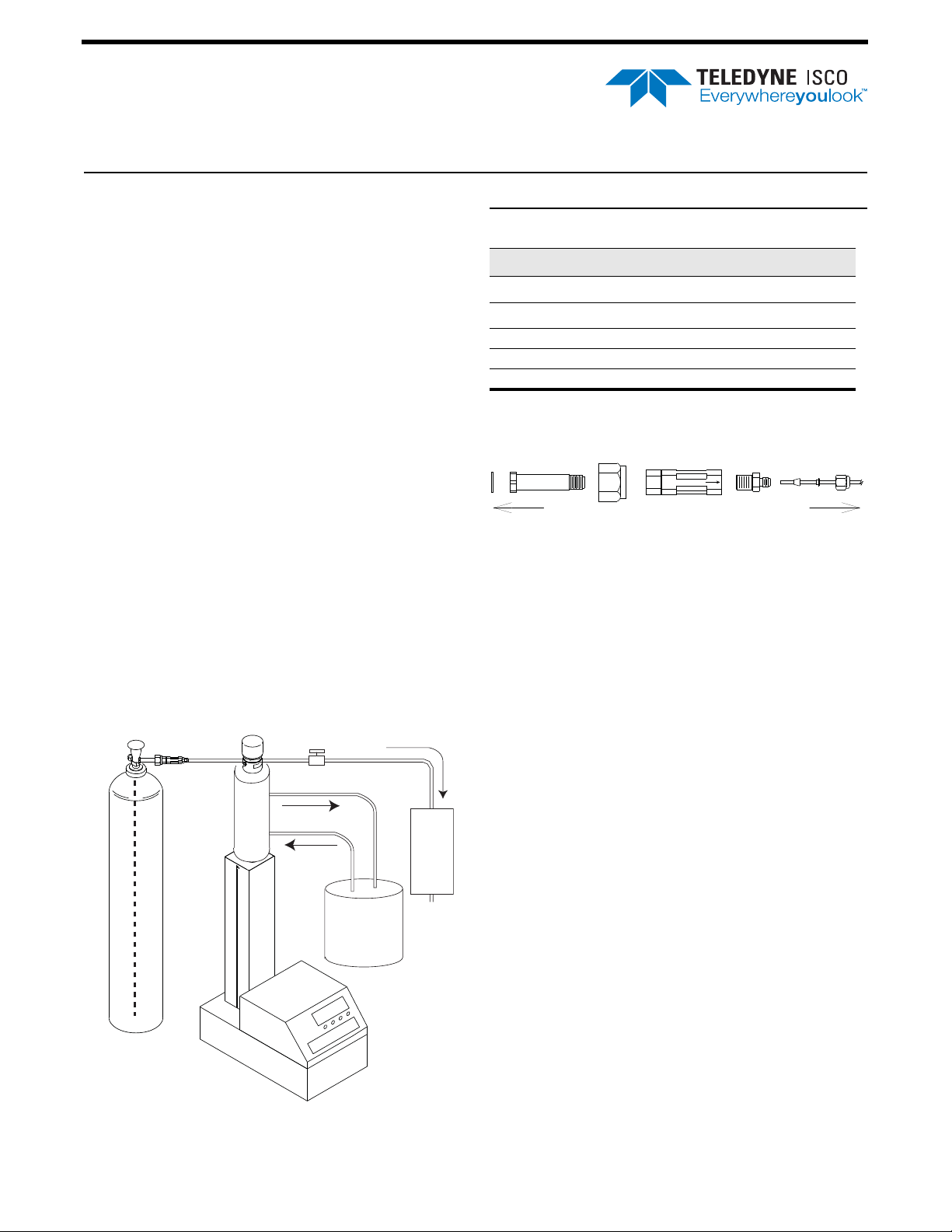

Table 1: CO2 Cylinder Connection Package

Part Number Description

1

209-0161-63

209-0161-16

Reducing connector

1

1

4

" 2

2

" nipple

209-0161-15 0.830-14 nut

209-0161-17 PTFE washer

209-0161-64 In-line filter assembly

Figure 2: CO2 cylinder connection package

8

" to

1

4

"

CO2 Cylinder Connection

For North American gas tank connections, the

optional CO

available from Teledyne Isco.

CO

2

Figure 1: ISCO Pump and CO2 dip tube tank

with Isco temperature control jacket and circulating bath

connection package (part #68-1247-043) is

2

CO2 connection kit

T.C. Jacket

Dip tube

Circulating

bath

Syringe Pump

User-supplied

device

(Extruder

Reactor

Rock Core

Etc.)

Tips and Additional Equipment:

1. Dip Tube

An upright CO2 cylinder must be equipped with a dip

tube in order to pump a steady supply of liquid and not

gas. The dip tube is a piece of copper tubing plumbed

from the valve at the top of the tank to the bottom.

2. Temperature Control

To ensure a good fill, maintain the temperature in the

cylinder with the Isco temperature control jacket. The

temperature control jacket is useful in SFC applications

where cylinder cooling facilitates pump filling with

supercritical liquid CO

lating temperature-controlled bath (user supplied) to

keep the fluid inside the pump at a constant temperature. This can be critical when operating at very low

flow rates (below 100 µl/min), where temperature fluctuation can cause flow variations.

Pump systems are available from Teledyne Isco with

the temperature control jacket already installed. For

existing systems, order the appropriate package for

your pump model. Refer to Technical Bulletin TB07 Tem-

perature Control Jacket for additional information about

installation and operation.

. The jacket is used with a circu-

2

Syringe Pump Technical Bulletin TB08

Note

Note

3. Valve Packages for Dual Pump Systems

A continuous flow system consists of two syringe

pumps and a valve package regulated by one controller.

This allows you to continuously deliver liquefied gas in

constant flow or constant pressure mode.

Teledyne ISCO has

three different types of

valve packages:

● Electric valves

● Air valves

● Manual valves

Electric valves, which provide the best positive valve

closure, are the most commonly used valves in

liquefied gas applications.

Electric valves require the

pump controller to be

equipped with the valve

driver board.

Air valves generally open and close faster and are

less prone to error and component wear, making them

suitable for industrial use and other applications where

the system will be constantly running; however they

require a user-supplied pressurized air source and special upgrade kit in order to operate with CO

wetted materials are CO

compatible.

2

Manual valves are used in lower-cost CO

tions where automation is not required.

For detailed installation and operation instructions,

refer to Technical Bulletin #1 Dual Pump Systems.

. All other

2

applica-

2

Table 2: Valve Packages for Dual Systems

Valv e Pa ckage Part #

Electric

1000D

500D

260D/100DM/DX

Controller for electric valves

Air

1000D

500D

260D/100DM/DX

Air valves require a special upgrade kit in order to

operate with CO

Air Valve Upgrade Kits:

1

/

8

”

1

/

4

”

Manual

1000D Refill

1000D Outlet

500D Refill

500D Outlet

260D/100DM/DX Refill

260D/100DM/DX Outlet

.

2

68-1247-109

68-1247-091

68-1247-090

68-1240-062

60-1247-104

60-1247-061

60-1247-058

60-5364-234

60-5364-259

68-1247-117

68-1247-118

68-1247-083

68-1247-082

68-1247-077

68-1247-078

1

/

8

”

1

/

8

”

4. Low Tank Level Alarm

In constant pressure mode, the Poor Fill feature

allows you to set a fill point as a percentage of pump

volume. If this volume percentage is not reached after a

refill and re-pressurization, the system sounds an alarm

and stops the pump.

To activate the alarm, press

() >

MORE ( ), and select POOR FILL ().

MENU () > MORE

CO2 with Modifier

See the Modifier Addition section of your user manual

for detailed information about two-pump (CO

modifier) systems.

A dual pump system in constant pressure mode

pumping supercritical CO

combined with a third pump

2

delivering a modifier (usually a solvent) can dispense a

mixture with a programmable v/v ratio, with the Modifier Addition Kit (part #68-1247-079) installed. Both

fluids pass through one-way check valves before they

meet and are blended in a mixing tee (see Figure 3 on

the following page).

Note that the CO

input tubing runs behind the valve

2

package mounting bracket before emerging at the valve

inlet.

&

2

Syringe Pump Technical Bulletin TB08

Note

Solvent

modifier

Mixing tee

CO

2

Valve pkg

Figure 3: Modi fier addition se tup

Shown with electric

valve package

Before operation in modifier mode, zero and fill the

pumps under independent control/constant pressure

mode (see Modifier Addition in Section 6 of your D

Series user manual).

Modifier Mode

Once the pumps are ready, place them in modifier

mode:

Press

MENU () > MORE () > MULTI-PUMP

( ), and select

( ) three times to return to the main menu. The

screen will display the words

Teledyne ISCO

P.O. Box 82531, Lincoln, Nebraska, 68501 USA

Toll-free: (800) 775-2965 • Phone: (402) 464-0231 • Fax: (402) 465-3001

MODIFIER (). Press PREVIOUS

MODIFIER ON.

Modifier Concentration

To set the modifier concentration, press % PUMP

( ). Use the numeric keys to enter the desired per-

centage of modifier and press

For additional important information about setup and

operation of the modifier addition system, consult

Section 9 of your D Series user manual.

ENTER to save the value.

Last modified Sept 2020

Teledyne ISCO is continually improving its products and reserves the right to change

product specifications, replacement parts, schematics, and instructions without notice.

Loading...

Loading...