Teledyne ISCO C18Aq User Manual

Desalting Samples with

RediSep Rf Gold

®

C18Aq

Columns

Abstract

Compounds are often purified with solvents that

contain salts or buffers that need to be removed

prior to subsequent studies with the compound. The

RediSep Rf Gold® C18Aq columns have the ability to

adsorb compounds under highly aqueous conditions

and are ideal for removing the salt from a sample.

The method described also removes a large portion

of water from samples dissolved in aqueous solvents

facilitating evaporation. The procedure is similar to

solid phase extraction, but on a larger prep scale.

Background

Compounds run on ion exchange media are often

eluted with buffers that are difficult to remove

from the sample after purification. Buffers, such as

phosphate salts, are often used to improve resolution

during purification on C18 by maintaining the pH of

the solvent at a value such that the eluted compounds

remain in a consistent ionization state.

The RediSep Rf Gold C18Aq columns are well suited

to desalting applications because they resist phase

collapse. Samples requiring desalting are generally

dilute and the large volume of water eventually causes

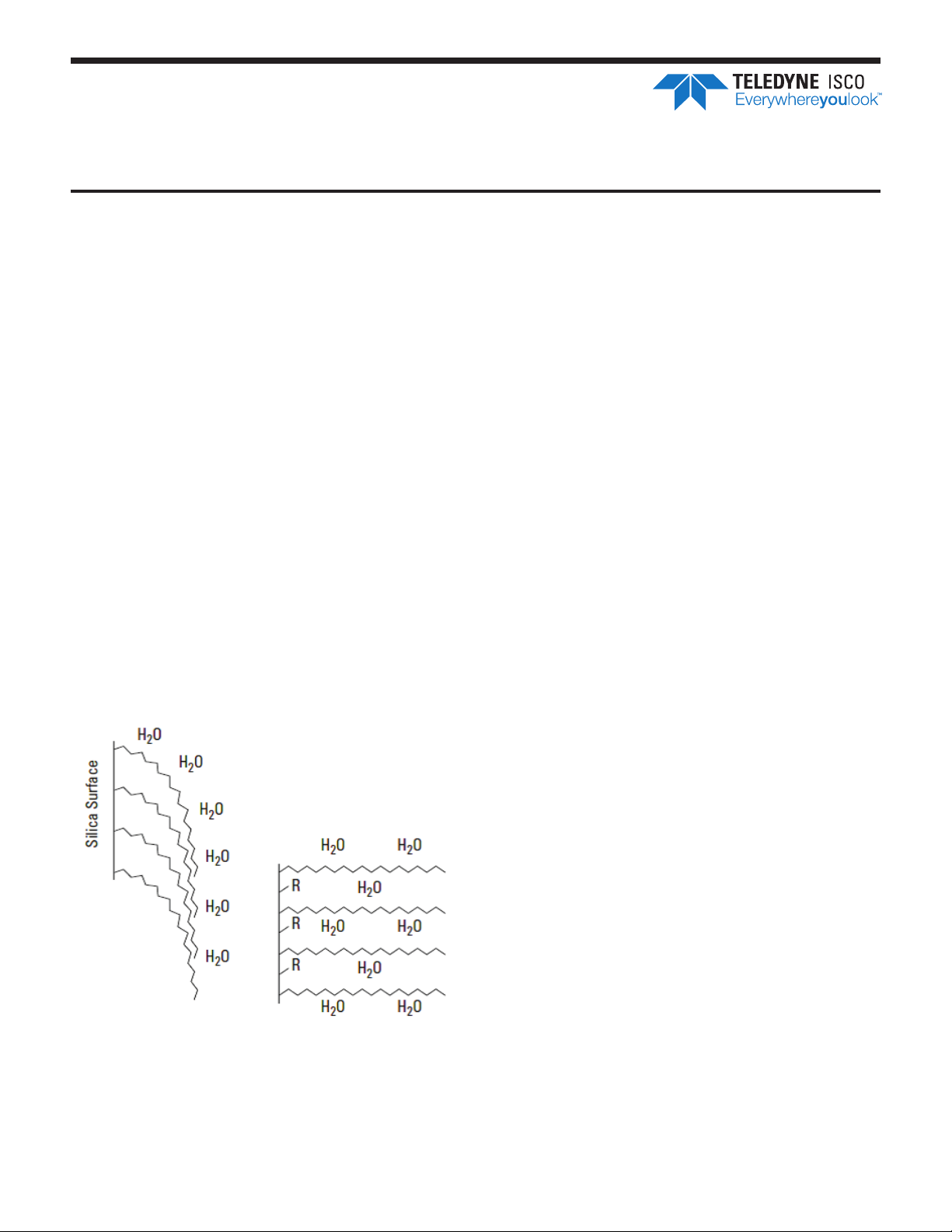

phase collapse with other types of C18 (Figure 1).

Figure 1: C18 chains are fully extended when organic solvent

is present but undergo “phase collapse” (left) under highly

aqueous conditions. Hydrophilic groups (right) reduce phase

collapse (right).

Chromatography Application Note

AN95, August 2020

The general procedure for desalting samples is as follows:

1. Remove any organic solvents by rotary evaporation.

Organic solvents tend to reduce the binding of

compounds to C18. Stop evaporation if the sample

appears to be precipitating.

2. Condition the RediSep Rf Gold C18Aq column by

washing with an organic solvent such as methanol

or acetonitrile for 5 column volumes (CV) followed

by water for 5 CV.

3. Load the sample. For desalting purposes, load up

to 5% by weight on the column because the desired

compound is captured from the salt solution and

released. For example, a 5.5 g RediSep Rf Gold

C18Aq column (PN 69-2203-558) can be used

to capture up to ~250 mg compound. If further

purification is performed after washing off the salt,

use a 1% load. Larger volumes can be loaded with a

CombiFlash® sample load pump

(PN 60-5247-007). Since the sample is being loaded

in a weak, polar solvent the total volume injected

may exceed the column volume without sample loss.

a. Place the CombiFlash in manual control, and

select Liquid Injection (Pumps Disabled) from

the Valve Position control. Place the column on

the instrument and load the sample.

b. For an Rf-150 or NextGen 100, place the

column on the system and load the sample.

c. Verify the column has been conditioned

according to the manufacturer’s instructions.

4. Wash the salt from the column using manual

control. On the CombiFlash, select Through column

and flow cell from the Valve Position control. On an

Rf-150 or NextGen 100, connect the solvent line to

the column shuttle. Set the flow rate to the value

listed on the column label and press the Prime

A button. Wash the column for at least one, and

preferably five, column volumes.

5. Elute the compound. Change the method to a step

gradient after 1 CV. The step should go to 100% B.

If the compound requires further purification, use

a gradient suitable for the purification. From the

Run Requirement screen, select None-On Column

from the Sample Loading Technique control

because the column was equilibrated and the

sample is on the column.

Chromatography Technical Note TN95

2.0

Absorbance (214 nm)

100

Methanol (%)

–

O

H

Always run a small sample to verify the compound will

adsorb on the column before running the entire sample

mixture.

Experiment and Results

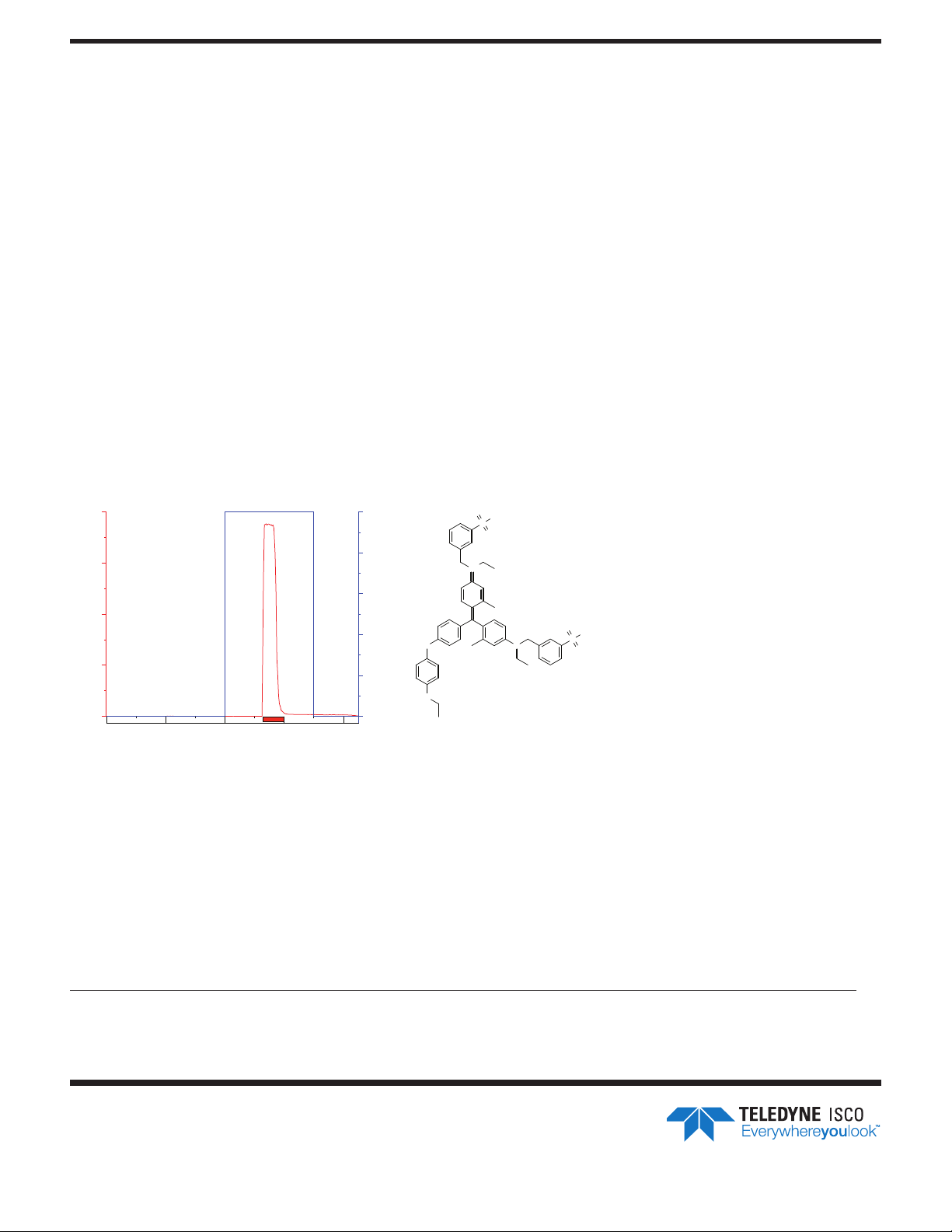

The example in Figure 2 is brilliant blue purified from

a weak anion exchange (WAX) column eluted with 1M

NaH2PO4 in water. As there was no organic solvent

involved, the mixture was not evaporated prior to

loading on the column.

The procedure listed above was altered slightly for

this run; the column was not washed prior to the run

as described in step 4, but was washed with water

for 10 CV during the run to demonstrate that the

compound remained on the column during the wash.

This compound elutes with 30% methanol in water

on a RediSep Rf Gold C18Aq column1 under gradient

conditions and demonstrates that compounds that

normally elute with high water concentrations can be

desalted with this method. The solvent used to elute

1.5

1.0

0.5

0.0

0510 15 20

80

60

40

20

0

NH

O

the sample from the C18Aq column is methanol.

The step gradient provides the following features:

•Run time and solvent usage is reduced.

•The compound elutes in a sharper band reducing

the volume of solvent to evaporate, saving time.

•There is relatively little water in the sample, so

drying time is reduced because methanol is easier

to evaporate.

Conclusion

RediSep Rf Gold C18Aq columns provide a convenient

way to desalt samples. Other benefits include removing

most of the water and reducing the volume of the

fractions to facilitate evaporation. If desired, a regular

gradient can also be run if the compound requires

further purification instead of the step gradient.

O

S

O

+

N

O

O

N

S

O

Figure 2: Desalting of brilliant blue with a RediSep Rf Gold C18Aq column.

1. http://www.isco.com/WebProductFiles/Applications/101/Application_Notes/AN76_RediSep_Rf_Gold_C18A_for_Highly_Aqueous_Mobile_Phases.pdf

retrieved 15 Aug 2012

Teledyne ISCO

P.O. Box 82531, Lincoln, Nebraska, 68501 USA

Toll-free: (800) 228-4373 • Phone: (402) 464-0231 • Fax: (402) 465-3091

Teledyne ISCO is continually improving its products and reserves the right to change product

specifications, replacement parts, schematics, and instructions without notice.

Loading...

Loading...