Teledyne Continental Motors Sandcast Series, IO-550-D, IO-550-E, IO-550-F, IO-550-L Maintenance And Operator's Manual

Page 1

MODEL IO-550-D, E, F & L

SANDCAST SERIES

©

CONTINENTAL

AIRCRAFT ENGINE

MAINTENANCE AND

OPERATOR’S

MANUAL

TM

Teledyne Continental Motors, Inc.

FORM X30605 FAA APPROVED

©1990 TELEDYNE INDUSTRIES, INC. APRIL 1990

Page 2

MAINTENANCE

MANUAL

-

Teledyne Continental Motors (TCM) engine operating instructions are generated prior to and independently of

the aircraft operating instructions established by the

airframe manufacturer.

developed using factory controlled parameters that are

not necessarily the same as those specifications required to satisfy a specific aircraft

Because of this difference the aircraft operator should

use the airframe manufacturer's operating instructions

in

found

operating the aircraft unless otherwise specified by the

original airframe manufacturer.

the Pilots Operating Handbook

AND

NOTICE

TCM's operating instructions are

OPERATOR'S

-

/

engine installation.

(POH)

while

FORM

NO.

X30605

Page 3

MAINTENANCE

AND

FOR

OPERATOR'S MANUAL

10-550t),E,F,L

The operator must comply with all the instructions contained in this manual in order to assure

safe and reliable engine performance. Failure to comply will be deemed misuse, thereby relieving the engine manufacturer

This manual contains

dures contained herein provide the operator with technical information and instructions applicable to safe operation.

no

of

warranties, either expressed or implied. The information and proce-

AIRCRAFT ENGINE

responsibility under its warranty.

Page 4

CHAPTER

Chapter Page

INDEX

1 Introduction 1-1

2 Tools and Equipment 2-1

3

4

5

6

7

8

9

10 Troubleshooting 10-1

1 1 Engine Preservation and Storage 11-1

12 Airworthiness Limitations 12-1

13 Engine Performance and Cruise Control 13-1

Detailed Engine Description 3-1

Engine Specifications and Operating Limits 4-1

Unpacking. Installation. Testing & Removal 5-1

Normal Operating Procedures 6-1

Emergency Operating Procedures 7-1

Abnormal Environmental Conditions 8-1

Service and Maintenance 9-1

...............................................

..........................................

......................................

..............................

..............................

.....................................

...................................

..................................

.......................................

...........................................

..................................

.......................................

...............................

Page 5

CHAPTER

1

INTRODUCTION

Section

Section

1-1

1-2 Related Publications 1-3

1-3 Abbreviations and Glossary

1-4 Manual Revisions 1-9

scope

............................

....................

......................

Index

Page

of

Terms 1-4

...........

..

1.2

Page 6

INTRODUCTION

1-1

SCOPE

Recommendations, cautions and warnings regarding operation of this engine are not intended to impose

undue restrictions, but are inserted to enable the pilot to obtain maximum performance from the engine

commensurate with safety and efficiency. Abuse, misuse, or neglect

cause eventual failure. In the case of an

trous

consequences. Failure to observe the instructions contained in this manual constitutes unautho-

rized

operation in areas unexplored during development of the engine, or in areas which experience has

proved to be undesirable or detrimental.

Notes, Cautions and Warnings are induded throughout this manual. Application is as

NOTE. . .Special interest information which may facilitate the operation of equipment.

.

CAUTION.

gine or accessories.

WARNING.

the engine

.Information issued to emphasize certain instructions or to prevent possible damage to en-

.

.Information which, if disregarded, may result in severe damage to or destructi~n of

or

endangerment to personnel.

aircmft engine

it

should

of

any piece of equipment can

be

obvious that a failure may have disas-

follows:

Page 7

1-2

RELATED

PUBLICATIONS

1. Overhaul Manual for 10-550D,E,F,L Series Aircraft

Engine. Form

2.

Illustrated Parts Catalog for 10-550 Series Aircraft

Engine. Form

X30607A.

X30606A.

3. Teledyne Continental Motors Aircraft Engine Service Bulletins.

4.

Fuel Injection Manual. Form X30593A.

The above publications can be ordered through your

Teledyne Continental Motors Distributor or ordered

if

directly,

prepaid, from:

Teledyne Continental Motors

Aircraft Products Division

P.

0.

Box 90

Mobile, AL 36601

Attn: Accounts Receivable

II. Accessory Manuals:

A. Ignition System

Master Service Manual

TCM lgnition Systems and Components

Form

X40000

Teledyne Continental Motors

Aircraft Products Division

P.

0.

Box 90

Mobile, Alabama 36601

Attn: Publications Dept.

B. Starter Motor

Service Manual

Teledyne Continental Motors

Aircraft Products Division

0.

Box 90

P.

Mobile, Alabama 36601

Attn: Publications Dept.

C. Alternator

Alternator Service Instructions

Form X30531-3

Teledyne Continental Motors

Aircraft Products Division

P.

0.

Box 90

Mobile, Alabama 36601

Attn: Publications Dept.

Page 8

1-3

ABBREVIATIONS AND GLOSSARY OF TERMS

Abbreviation

A.B.C.

ADMP

Approx.

A.T.C.

Bar

B.B.C.

B.H.P.

BSFC

BSOC

B.T.C.

C.A.R.

C.G.

c.f.m.

C.H.T.

CW

CCW

Dia.

EGT

FAA

Fig.

Front

Ft.

F.T.

FT-LBS

G.P.M.

gms

Hex

H20

Hg.

hr.

I.D.

IN-LBS

(")

in.

Left Side

Lbs.

Lockwire

Man.

After Bottom Center

Absolute Dry Manifold Pressure

Approximately

After Top Center

Barometric

Before Bottom Center

Brake Horsepower

Brake Specific Fuel Consumption

Brake Specific Oil Consumption

Before Top Center

Civil Air Regulations

Center of Gravity

Cubic Feet Per Minute

Cylinder Head Temperature

Clockwise Rotation

Counterclockwise Rotation

Degrees Celsius

Degrees Fahrenheit

Degrees of Angle

Diameter

Exhaust Gas Temperature

Federal Aviation Administration

Figure (Illustration)

Propeller End of Engine

Foot or Feet

Full Throttle

Foot Pounds Torque

Gallons Per Minute

Grams

Hexagon

Water

Mercury

Hour

Inside Diameter

Inch Pounds Torque

Inches

Side on which No's

2,4

and 6 cylinders are located.

Pounds

Soft stainless steel wire used to safety connections, etc.

Manifold or Manometer

Page 9

Abbreviation

MAP

Max.

Min.

N.P.T.

N.R.P.

N.C.

N.F.

O.A.T.

O.D.

02.

PPH

Press.

p.s.i.

PSlA

PSlG

Rear

Right Side

R.P.M.

Std.

TBO

T.C.D.P.

T.D.C.

Temp.

T.I.T.

Torque

1

OOLL

1-3-5

2-4-6

30'

Manifold Absolute Pressure

Maximum

Minimum

National Pipe Thread (Tapered)

Normal Rated Power

National Course (Thread)

National Fine (Thread)

Outside Air Temperature

Outside Diameter

Ounce

Pounds Per Hour

Pressure

Pounds Per Square lnch

Power Per Square lnch Absolute

Power Per Square lnch Gauge

Accessory End of Engine

Side on which No's 1, 3 and 5 cylinders are located.

Revolutions Per Minute

Standard

Time Between Overhaul

Turbocharger Deck Pressure

Top Dead Center

Temperature

Turbine Inlet Temperature

Force

x

lever arm (1 25 ft.-lbs. torque = 125 lbs. Force applied

one ft. from bolt center or 62-1/2

100 Octane Low Lead Fuel

Cylinder numbering right side of engine (rear to front)

Cylinder numbering left side of engine (rear to front)

Thirty minutes of angle (60' equal one degree)

lbs 2 ft. from center)

Glossarv

ADMP

Ambient

BHP

Absolute dry manifold pressure, is used in establishing a baseline standard of

engine performance. Manifold pressure is the absolute pressure in the intake

manifold; measured in inches of mercury.

A term used to denote a condition of surrounding atmosphere at a particulartime.

For example; Ambient Temperature or Ambient Pressure.

Brake Horsepower. The power actually delivered to the engine propeller shaft.

It is so called because it was formerly measured by applying a brake to the power

shaft of an engine. The required effort to brake the engine could be converted

to horsepower

-

hence: "brake horsepower".

Page 10

BSFC

Brake Specific Fuel Consumption. Fuel consumption stated in pounds per hour

per brake horsepower. For example, an engine developing

150

while burning

Fuel

Qmsmwtion in PPH

pounds of fuel per hour, has a BSFC of

-

-.

5

Brake Horsepower

.5.

300

horsepower

Cavitation

Cold Soaking

Corrosion

Critical Altitude

Density Altitude

Dynamic Condition

E.G.T.

Exhaust Back Pressure

Four Cycle

Formation of partial vacuums in a flowing liquid as a result of the separation of

its part.

Prolonged exposure of an object to cold temperatures so that its temperature

throughout approaches that of ambient.

Deterioration of a metal surface usually caused by oxidation of the metal.

"Critical Altitude" means the maximum altitude at which, in standard atmosphere,

it is possible to maintain, at a specified rotational speed, a specified power or a

specified manifold pressure. Unless otherwise stated.

Altitude as determined by pressure altitude and existing ambient temperature. In

Standard Atmosphere (IAS) density and pressure altitudes are equal. For a given

pressure altitude, the higher the temperature, the higher the density altitude.

A term referring to properties of a body in motion.

Exhaust Gas Temperature. Measurement of this gas temperature is sometimes

used as an aid to fuel management.

Opposition to the flow of exhaust gas, primarily caused by the size and shape of

the exhaust system. Atmospheric pressure also affects back pressure.

Short for "Four Stroke Cycle." It refers to the four strokes of the piston in

completing a cycle of engine operation (Intake, Compression, Power and Exhaust).

Fuel Injection

Gallery

Galling or Scuffing

Hg"

Heat Soaked

Humidity

Impulse Coupling

Lean Limit Mixture

A process of metering fuel into an engine by means other than a carburetor.

A passageway in the engine or subcomponent. Generally one through which oil

is flowed.

Excessive friction between two metal surfaces resulting in particles of the softer

metal being torn away and literally welded to the harder metal.

A

Inches of Mercury.

pressure or

Prolonged exposure of an object to hot temperature so that its temperature

throughout approaches that of ambient.

Moisture in the atmosphere. Relative humidity, expressed in percent, is the

amount of moisture (water vapor) in the air compared with the maximum amount

of moisture the air could contain at a given temperature.

A mechanical device used in some magnetos to retard the ignition timing and

provide higher voltage at cranking speeds for starting.

The leanest mixture approved for any given power condition. It is not necessarily

the leanest mixture at which the engine will continue to operate.

manifokl pressure.

standard for measuring pressure, especially atmospheric

Page 11

Manifold Pressure

Pressure as measured in the intake

Usually measured in inches of mercury.

manifoM down-stream of the air throttle.

Mixture

Naturally Aspirated (Engine)

NRP

O.A.T.

Octane Number

Oil Temperature Control Valve

Overboost Valves

Overhead Valves

Overspeed

Performance Rating

Mixture ratio. The proportion of fuel to air used for combustion.

A term used to describe an engine which obtains induction air by drawing it

directly from the

Normal Rated Power.

Outside Air Temperature.

A

rating which describes relative anti-knock (detonation) characteristics of fuel.

Fuels with greater detonation resistance than 100 octane are given performance

ratings.

A thermostatic unit to divert oil through or around the oil cooler, as necessary, to

maintain oil temperature within desired limits.

A pressure relief valve, set slightly in excess of maximum deck pressure, is

provided to prevent damaging overboost in the event of

An engine configuration in which the valves are located in the cylinder head itself.

When an engine has exceeded its rated revolutions per minute.

A rating system used to described the ability of fuel to withstand heat and pressure

cornbustion as compared with 100 octane fuel. For example, an engine with

of

high compression and high temperature needs a higher Performance Rated fuel

than a

characteristics of lean (1 00) and rich (130) mixtures respectively.

low

atmosphere into the cylinder. A nonsupercharged engine.

a

system malfunction.

compression engine. A rating of 1001130 denotes performance

Pressure Altitude

Propeller Load Curve

Propeller Pitch

Ram

Rated Power

Retard Breaker

Rich Limit

Rocker Arm

Run Out

Altitude, usually expressed in feet, (using absolute static pressure as a reference)

equivalent to altitude above the standard sea level reference plane (29.92 Hg).

A plot of horsepower, fuel flow, or manifold pressure versus RPM through the full

a

power range of one engine using a fixed pitch propeller or

propeller running on the low pitch stops. This curve is established or determined

during

design and development of the engine.

The angle between the mean chord of the propeller and the plane or rotation.

Increased air pressure due to forward speed.

The maximum horsepower at which an engine is approved for operation. Rated

power may be expressed in horsepower or percent.

A device used in magnetos to delay ignition during cranking. It is used to facilitate

starting.

The richest

necessarily the richest condition at which the engine will run.

A mechanical device used to transfer motion from the

Eccentricity of wobble of a rotating part.

fuellaif ratio permitted for any given power condition. It

pushrod to the valve.

constant speed

is

not

Scavenge Pump

A pump (especially an oil pump) to prevent accumulation of liquid in some

particular area.

Page 12

Sonic Venturi

A restriction, especially in cabin pressurization systems, to limit the flow of air

through a duct.

Standard Day

Static Condition

Sump

TBO

TDC

Thermal Efficiency

Torque

Turbocharger

By general acceptance, temperature

-59°~/150~, pressure

-29.92

In. Hg.

A term referring to properties of a body at rest.

The lowest part of a system. The main oil sump on a wet sump engine contains

the oil supply.

Time Between Overhauls. Usually expressed in operating hours.

Top Dead Center. The position in which the piston

travel.

A

line drawn between crankshaft rotation axis, through the connection rod

has reached the top of its

and axis and the piston pin center would be straight line. Ignition and valve timing

are stated in terms of degrees before or after TDC.

Regarding engines, the percent of total heat generated which is converted into

useful power.

Turbine

Inlet Temperature. The measurement of E.G.T. at the turbocharger

turbine inlet.

Twisting moment or leverage, stated in pounds-foot (or pounds-inch).

A device used to supply increased amounts of air to engine induction system. In

by

operation, a turbine is driven

engine exhaust gas. In turn, the turbine directly

drives a compressor which pumps air into the engine intake.

Vapor Lock

Variable Absolute Controller

Vernatherm Valve

Viscosity

Volatility

Volumetric Efficiency

A condition in which the proper flow of a liquid through a system is disturbed by

the formation of vapor. Any liquid will turn to vapor

if

heated sufficiently. The

amount of heat required for vaporization will depend on the pressure exerted on

the liquid.

A device used to control the speed, and thus the output pressure of the

tuwcharger. It does so by operating the wastegate which diverts, more or less,

exhaust gas over the turbine.

A thermostatic valve used to divert oil through or around the oil cooler, as

necessary, to maintain oil temperature within desired limits.

The characteristic of a liquid to resist flowing. Regarding oil, high viscosity refers

to thicker or "heavier" oil while low viscosity oil is thinner. Relative viscosity is

indicated by the specific "weight" of the oil such as 30 "weight" or 50 "weight".

Some oils are specified as multiple-viscosity such' as

10W30. In such cases, this

oil is more stable and resists the tendency to thin when heated or thicken when

it

becomes cold.

The tendency of a liquid to vaporize.

The ability of an engine to fill its cylinders with air compared to their capacity for

A

air under static conditions.

volumetric efficiency of slightly less than

"normally aspirated engine will always have a

loo%, whereas superchargers permit

volumetric efficiencies in excess of 100%.

Page 13

Wastegate Valve

f

Hydraulic)

A

unit, used on turbocharged engines, to divert exhaust gas through or around

the turbine, as necessary to maintain turbine speed. As more air is demanded

by the engine, due to throttle operation, the compressor must work harder. In

order to maintain compressor and turbine speeds, more exhaust must be flowed

through the turbine. The wastegate valve closes and causes gas, which would

go

directly overboard, to pass through the turbine. The wastegate is usually

operated by an actuator which gets signals from the turbocharger controller.

Wastegate Valve

(Manual)

Critical Altitude

Dynamic Condition

E.G.T.

Exhaust Back Pressure

1-4

MANUAL REVISIONS

This manual and Teledyne Continental Motors

related manuals are current and correct to the

best of Teledyne Continental Motors' knowledge

at the time of publication. Any errors, recommended changes, or questions should

mitted in writing to:

A ground adjustable bypass located in the turbine exhaust (Fixed Orifice) bypass

duct. The position of the fixed orifice wastegate valve remains constant throughout all modes of engine operation.

maximum altitude at which a component can operate at 100% capacity. For

The

example, an engine with a critical altitude of 16,000 feet cannot produce 100%

of its rated

manifold pressure above 16,000 feet.

A term referring to properties of a body in motion.

Exhaust Gas Temperature. Measurement of this gas temperature is sometimes

used as an aid to fuel management.

Opposition to the flow of exhaust gas, primarily caused by the size and shape of

the exhaust system. Atmospheric pressure also affects back pressure.

be

sub-

Technical Publications Department

Teledyne Continental Motors

Box

P.O.

90

Mobile, Alabama 36601

Manuals will be revised and updated as neces-

sary.

Consult Teledyne Continental Motors' Service

Bulletin publications for latest technical information available.

Page 14

INTENTIONALLY

LEFT

BLANK

Page 15

CHAPTER

2

TOOLS

Section Page

2-1

2-2

TOOIS

Special

.

.

. .

Tools

. . . .

. .

AND

Section Index

. .

EQUIPMENT

. . . . . .

. . . . . . . .

.

. . . .

. .

. . .

. .

. . .

. . . .

.

. .

2-2

. . . . 2-2

Page 16

2-1

The mechanic should be equipped with

of common tools to include the minimum of:

1.

TOOLS

Wrenches - 114" thru

1

a

complete set

"

9.

Torque Wrenches (Calibrated) - 0-500 In. Lbs. - 0-

100

Ft.

Lbs.

10.

Micrometers

2-2

SPECIAL TOOLS

2. Common and Phillips Head Screwdrivers

-

3. PliersDuck Bill, Vise Grip, Snap Ring.

4. Ratchets

5.

Sockets - 114" Drive 5/32" thru 112" - 318" Drive 318"

thru 1"

6.

Sockets (Deepwell) - 112" Drive 7/16" thru 1"

7.

Feeler Gages

8. Leather Mallet

Common, Diagonal Cutter, Needle Nose,

1/4", 318", 1/22'' Drive

-

112" Drive 7/16" thru 1-114"

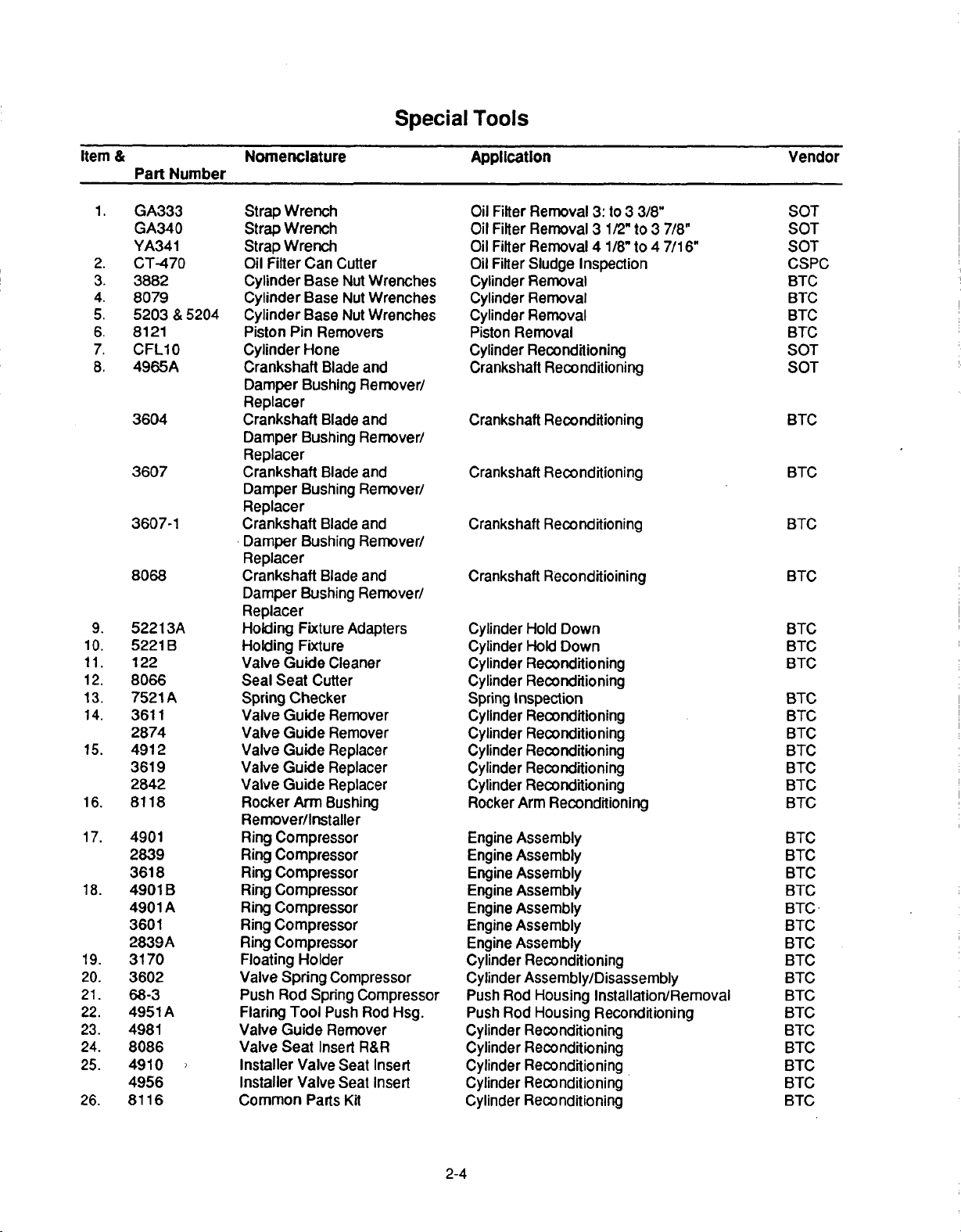

All tools reference Sub-section

promoting or suggesting tools to be purchased from the indicated sources.

Specific tools illustrated or similar tools marketed by

other manufacturers are necessary for service and

maintenance of the aircraft engine. Tool illustrations

shown on the following pages are used with the permis-

sion of the respective manufacturers.

lllustrations in this section show only the general ap-

pearance of tools and do not correspond to the actual

size of shape. Details of special tools, fixtures, equipment and consumable materials appropriate to overhaul procedures are listed in

subsystems of the overhaul manual; the following information is primarily for procurement purposes.

the various chapters and

NOTICE

2-2

Special Tools, are for reference only, not for the purpose of

IDENTIFICATION

CODE SUPPLIER

(ALR)

(BTC)

(CSPC)

(FTSC)

(OTC)

(MCSC)

(SOT)

CODE

FOR TOOLS

ALCOR, INC.

BORROUGHTS TOOL AND EQUIPMENT CORP.

CHAMPION SPARK PLUG, CO.

EASTERN ELECTRONICS, INC.

FEDERAL TOOL SUPPLY CO., INC.

OTC TOOLS

McMASTER-CARR SUPPLY CO.

SNAP ON TOOLS

&

EQUIPMENT CO.

Page 17

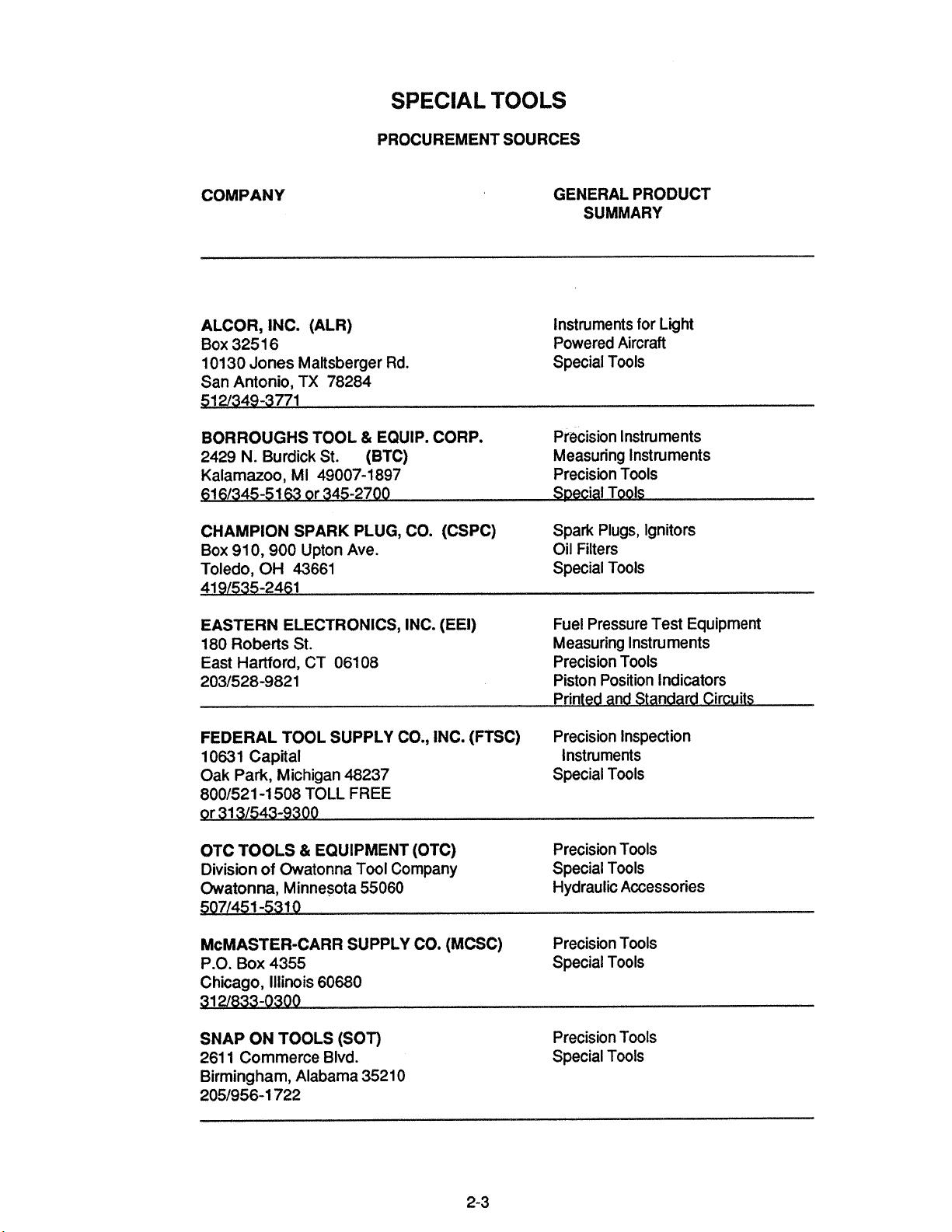

SPECIAL

PROCUREMENT SOURCES

TOOLS

COMPANY

ALCOR, INC. (ALR)

Box 325 1 6

10130 Jones

San Antonio, TX 78284

BORROUGHS TOOL & EQUIP. CORP.

N.

2429

Kalamazoo, MI 49007-1 897

51 61345-51

CHAMPION SPARK PLUG, CO. (CSPC)

Box 91 0,900

Toledo, OH 43661 Special Tools

41 91535-2461

EASTERN ELECTRONICS, INC. (EEI)

180 Roberts St. Measuring Instruments

East Hartford, CT 06108

2031528-9821 Piston Position Indicators

Maltsberger Rd.

Burdick St.

63

or 345-2700

Upton Ave.

(BTC)

GENERAL PRODUCT

SUMMARY

Instruments for

Powered Aircraft

Special Tools

Precision Instruments

Measuring Instruments

Precision Tools

S~ecial Tools

Spark Plugs, Ignitors

Oil Filters

Fuel Pressure Test Equipment

Precision Tools

Printed and Standard Circuits

Light

FEDERAL TOOL SUPPLY CO., INC. (FTSC)

10631 Capital Instruments

Oak Park, Michigan 48237

8001521 -1 508 TOLL

9r 31 31543-9300

OTC TOOLS & EQUIPMENT (OTC)

Division of Owatonna Tool Company

Owatonna, Minnesota 55060 Hydraulic Accessories

5071451 -531 0

McMASTER-CARR SUPPLY CO. (MCSC)

P.O. Box 4355 Special Tools

Chicago, Illinois 60680

SNAP ON TOOLS (SOT)

261 1 Commerce Blvd.

Birmingham, Alabama 3521 0

2051956-1 722

FREE

Precision Inspection

Special Tools

Precision Tools

Special Tools

Precision Tools

Precision Tools

Special Tools

Page 18

Item

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

&

Part

GA333

GA340

YA341

CT-470

3882

8079

5203

8121

CFLIO0

4965A

3604

3607

3607-1

8068

52213A

5221

122

80866

7521

3611

2874

4912

3619

2842

8118

4901

2839

3618

4901

4901

3601

2839A

3170

3602

68-3

4951

4981

8086

4910

4956

8116

Number

&

5204

B

A

B

A

A

Nomenclature

Strap

Wrench

Strap

Wrench

Strap

Wrench

Oil

Filter

Can

Cutter

Cylinder

Cylinder

Cylinder

Piston

Cylinder

Crankshaft

Damper

Base

Base

Base

Pin

Removers

Hone

Blade

Bushing

Nut

Nut

Nut

Replacer

Crankshaft

Damper

Blade and

Bushing Remover/

Replacer

Crankshaft

Damper

Blade

Bushing

Replacer

Crankshaft

Damper

Blade

Bushing

Replacer

Crankshaft

Damper

Blade

Bushing

Replacer

Holding

Holding

Valve

Seal

Spring

Valve

Valve

Valve

Valve

Valve

Rocker

Fixture

Fixture

Guide

Seat

Cutter

Checker

Guide

Guide

Guide

Guide

Guide

Arm

Adapters

Cleaner

Remover

Remover

Replacer

Replacer

Replacer

Bushing

Remover/Installer

Ring

Compressor

Ring

Compressor

Ring

Compressor

Ring

Compressor

Ring

Compressor

Ring

Compressor

Ring

Compressor

Floating

Valve

Push

Flaring

Valve

Valve Seat

Installer

Installer

Common

Holder

Spring

Rod

Spring

Tool

Guide

Insert

Valve

Valve

Parts

Compressor

Compressor

Push Rod

Remover

Seat

Seat

Kit

Special

Wrenches

Wrenches

Wrenches

and

Remover/

and

Remover/

and

Remover/

and

Remover/

Hsg.

R&R

Insert

Insert

Tools

Application

Oil

Filter

Removal

Oil

Filter

Removal

Oil

Filter

Removal 4 1/8"

Oil

Filter

Sludge

Cylinder

Cylinder

Cylinder

Piston

Cylinder

Crankshaft

Crankshaft

Crankshaft

Crankshaft

Crankshaft

Cylinder

Cylinder

Cylinder

Cylinder

Spring

Cylinder

Cylinder

Cylinder

Cylinder

Cylinder

Rocker

Engine

Engine

Engine

Engine

Engine

Engine

Engine

Cylinder

Removal

Removal

Removal

Removal

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Reconditioining

Hold

Hold

Reconditioning

Reconditioning

Inspection

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Arm

Assembly

Assembly

Assembly

Assembly

Assembly

Assembly

Assembly

Reconditioning

Cylinder Assembly/Disassembly

Push

Rod

Housing

Push

Rod

Housing

Cylinder

Cylinder

Cylinder

Cylinder

Cylinder

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Reconditioning

3:

to 3 3/8"

3

1/2"

to 3 7/8"

to 4 7/16"

Inspection

Down

Down

Reconditioning

Installation/Removal

Reconditioning

Vendor

SOT

SOT

SOT

CSPC

BTC

BTC

BTC

BTC

SOT

SOT

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC,

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTCBTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

2-4

Page 19

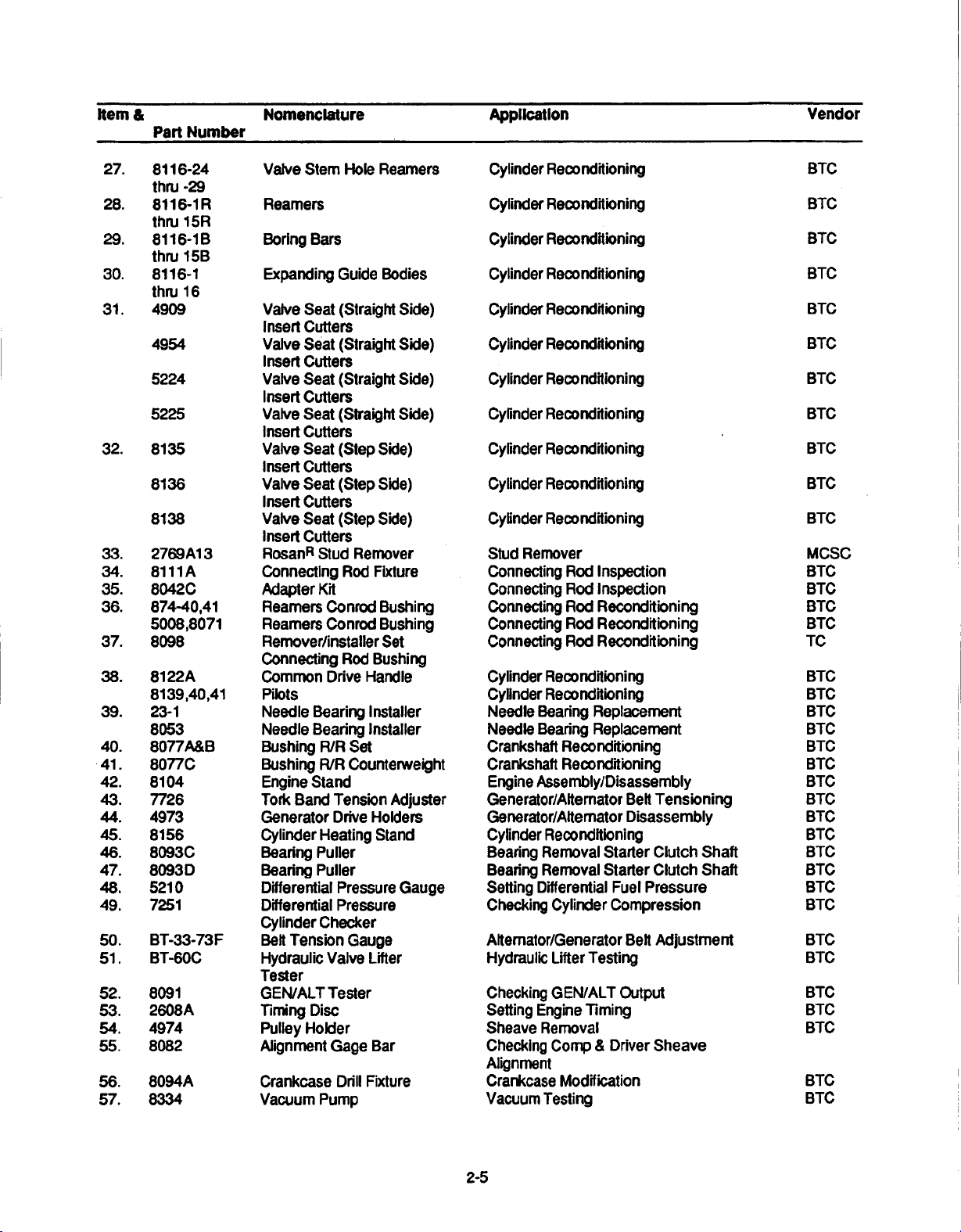

item

&

Part

Number

Nomenclature Application

Vendor

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

.41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

8116-24

thru

-29

8116-1iR

thru

15R

8116-l

B

thru

15B

8116-1

thru 1 6

4909 Valve

4954 Valve

5224

5225

8135

8136

8138

2769A1

8111

8042C Adapter

874-40,41

5008,8071

8098 Remover/installer

8122A

8139,40,41

23-1

8053 Needle

8077A&B

8077C

8104

7726

4973 Generator

8156

8093C

8093D

5210

7251

BT-33-73F

BT-60C

8091

2608A

4974

8082

8094A

8334

3

A

Valve

Stem

Hole

Reamiers

Reamers

Boring

Expanding

insert Cutters

Insert

Valve

Insert

Valve

Insert

Valve Seat (Step

Insert

Valve

Insert

Valve Seat

Insert

RosanR

Connecting

Reamers

Reamers

Connecting

Common

Pilots

Needle Bearing

Bushing

Bushing

Engine

Tork Band

Cylinder Heating

Bearing

Bearing

Differential

Differential Pressure

Cylinder Checker

Belt

Hydraulic

Tester

GEN/ALT Tester

Timing Disc

Pulley Holder

Alignment

Crankcase

Vacuum

Bars

Guide

Bodies

Seat

(Straight Side)

Seat (Straight Side)

Cutters

Seat

(Straight

Cutters

Seat

(Straight

Cutters

Side)

Cutters

Seat

(Step

Side)

Cutters

(Step

Side)

Cutters

Stud

Remover

Rod

Fixture

Kit

Conrod

Conrod

Drive

Bearing

R/R

R/R Counterweight

Stand

Tension

Drive

Puller

Puller

Tension

Valve

Gage

Pump

Bushing

Bushing

Set

Rod

Bushing

Handle

Installer

Installer

Set

Adjuster

Holders

Stand

Pressure

Gauge

Lifter

Bar

Drill

Fixture

Side)

Side)

Gauge

Cylinder

Cylinder

Cylinder

Cylinder

Cylinder

Cylinder Reconditioning

Cyiinder Reconditioning

Cylinder Reconditioning

Cylinder Reconditioning

Cylinder Reconditioning

Cylinder

Stud

Connecting

Connecting

Connecting

Connecting

Connecting

Cylinder

Cylinder

Needle

Needle

Crankshaft

Crankshaft

Engine

Generator/Altemator

Genierator/Alternator

Cylinder Reconditioning

Bearing Removal

Bearing Removal

Setting

Checking

Alternator/Generator

Hydraulic

Checking

Setting

Sheave

Checking

Alignment

Crankcase

Vacuum

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Remover

Rod

Inspection

Rod

Inspection

Rod

Reconditioning

Rod

Reconditioning

Rod

Reconditioning

Reconditioning

Reconditioning

Beaning

Bearing

Assembly/Disassembly

Differential

Engine

Removal

Testing

Replacement

Replacement

Reconditioning

Reconditioning

Belt

Disassembly

Starter

Starter

Cylinder

Lifter

Testing

GEN/ALT

Timing

Camp & Driver

Modification

Clutch

Clutch

Fuel

Pressure

Compression

Belt

Output

Sheave

Tensioning

Adjustment

Shaft

Shaft

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

MCSC,

BTC

BTC

BTC

BTC

TC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

2-5

Page 20

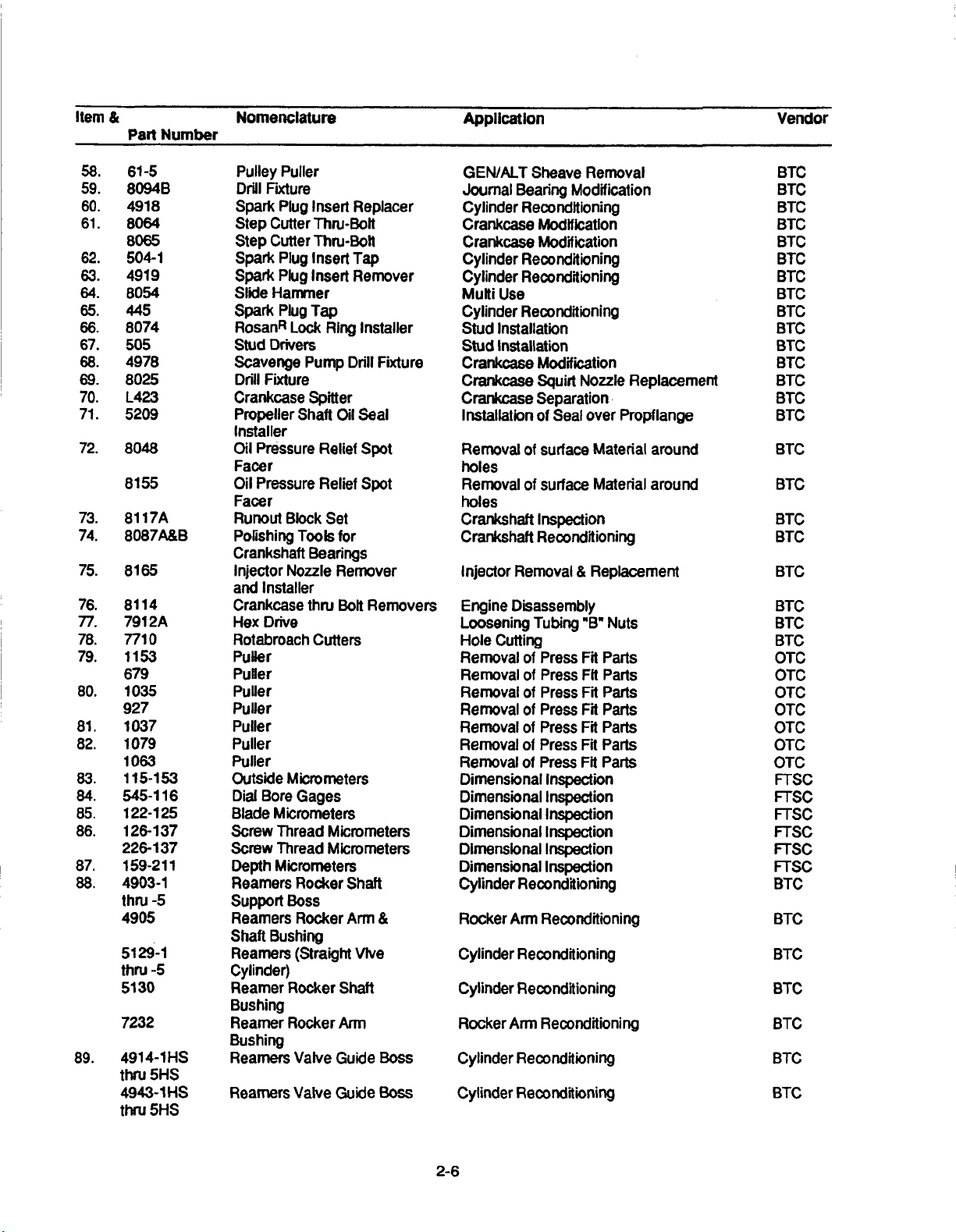

Item

&

Part

Number

Nomenclature

Application

Vendor

58.

59.

60.

61.

62.

63.

64.

65.

66.

67.

68.

69.

70.

71.

72.

73.

74.

75.

76.

77.

78.

79.

80.

81.

82.

83.

84.

85.

86.

87.

88.

89.

61-5

8094B

4918

8084

8065

504-1

4919

8054

445

8074

505

4978

8025

L423

5209

8048

8155

8117A

8087A&B

8165

8114

7912A

7710

1153

679

1035

927

1037

1079

1063

115-153

545-116

122-125

126-137

226-137

159-211

4903-1

thru

-5

4905

5129-1

thru

-5

5130

7232

4914-1H-S

thru 5HS

4943-1HS

thru 5HS

Pulley

Puller

Drill

Fixture

Spark

Plug

Insert

Replacer

Step

Cutter

Thru-Bolt

Step

Cutter

Thru-Bolt

Spark

Plug

Insert Tap

Spark

Plug

Insert

Remover

Slide

Hammer

Spark

Plug

Tap

RosanR

Stud

Scavenge

Drill

Crankcase Spitter

Propeller

Installer

Oil

Facer

Oil

Facer

Runout

Poilshing Tools

Crankshaft

Injector

and

Crankcase

Hex

Rotabroach

Puller

Puler

Puiler

Puller

Puller

Puller

Puller

Outside Micrometers

Dial

Blade

Screw

Screw

Depth

Reamers

Support

Reamers

Shaft

Reamers

Cylinder)

Reamer

Bushing

Reamer

Bushing

Reamers

Reamers

Lock Ring

Drivers

Pump

Fixture

Shaft

Oil

Pressure

Pressure

Installer

Drive

Bore

Bushing

Relief

Relief

Block

Set

Bearings

Nozzle Remover

thru

Cutters

Gages

Micrometers

Thread

Thread

Micrometers

Micrometers

Micrometers

Rocker

Boss

Rocker

(Straight

Rocker

Rocker

Valve

Guide

Valve

Guide

Installer

Drill

Seal

Spot

Spot

for

Bolt

Removers

Shaft

Arm

VIve

Shaft

Arm

Fixture

&

Boss

Boss

GEN/ALT

Journal

Cylinder

Crankcase

Crankcase

Cylinder

Cylinder

Multi

Cylinder

Stud

Stud

Crankcase

Crankcase

Crankcase

Installation

Removal

holes

Removal

holes

Crankshaft

Crankshaft

Injector

Engine

Loosening

Hole

Removal

Removal

Removal

Removal

Removal

Removal

Removal

Dimensional Inspection

Dimensional Inspection

Dimensional

Dimensional

Dimensional

Dimensional Inspection

Cylinder

Rocker

Cylinder

Cylinder

Rocker

Cylinder

Cylinder

Sheave Removal

Bearing

Reconditioning

Reconditioning

Reconditioning

Use

Reconditioning

Installation

Installation

of

of

Removal & Replacement

Disassembly

Cutting

of

of

of

of

of

of

of Press

Reconditioning

Arm

Reconditioning

Reconditioning

Arm

Reconditioning

Reconditioning

Modification

Modification

Modification

Modification

Squirt

Nozzle

Separation

of Seal

Inspection

Reconditioning

Tubing

over Propf

surface

surface

Press

Press

Press

Press

Press

Press

Inspection

Inspection

Inspection

Reconditioning

Reconditioni

Material

Material

"B*

Nuts

Fit

Parts

Fit

Parts

Fit

Parts

Fit

Parts

Fit

Parts

Fit

Parts

Fit

Parts

Replacement

lange

around

around

ng

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

OTC

OTC

OTC

OTC

OTC

OTC

OTC

FTSC

FTSC

FTSC

FTSC,

FTSC

FTSC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

2-6

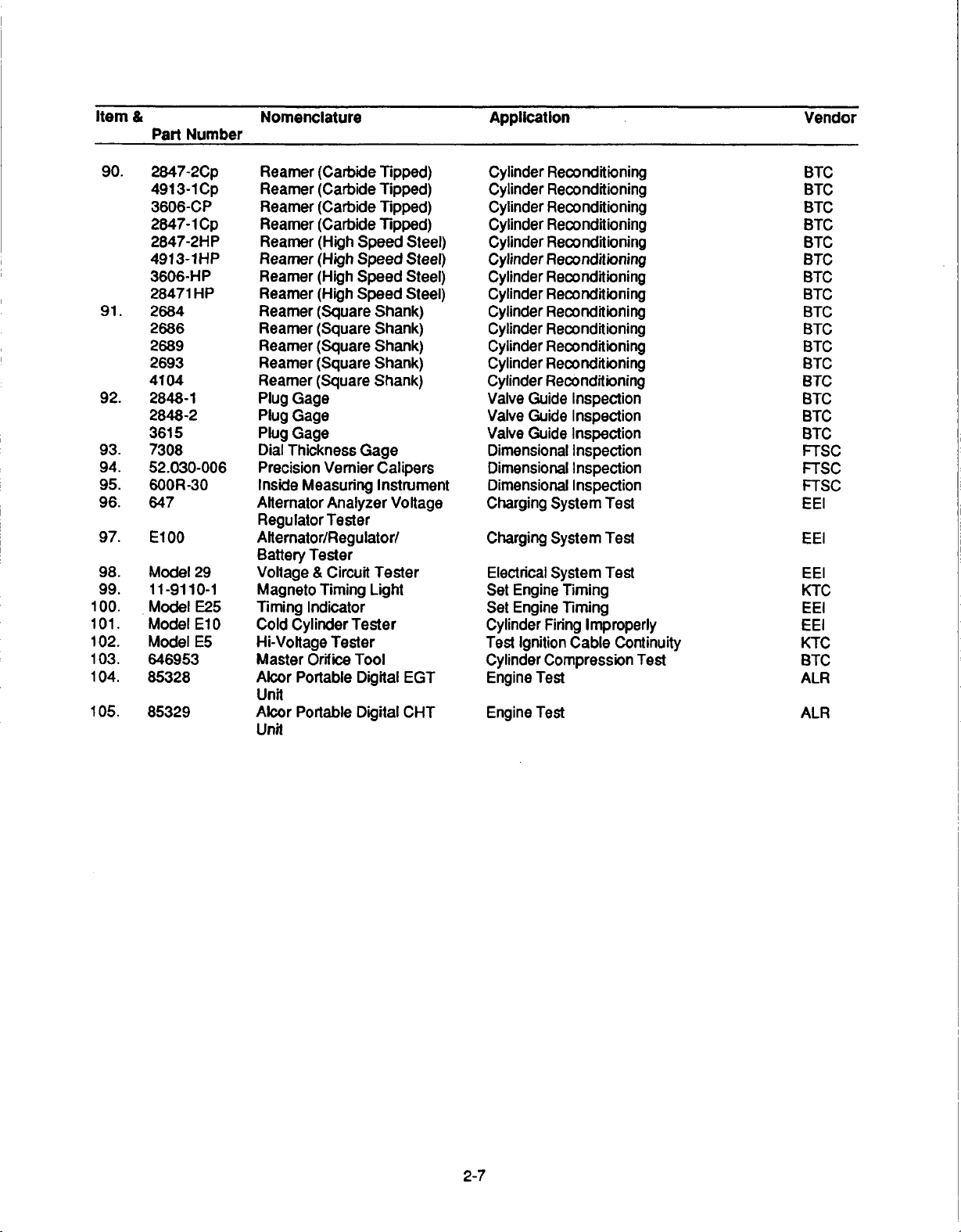

Page 21

Item

&

Part

Number

Nomenclature

Application

Vendor

90. 2847-2Cp

4913-1

3606-CP

2847-1

2847-2HP

4913-1HP

3606-HP

28471

HP

91.

92.

93.

94.

95.

96.

97.

98.

99.

100.

101.

102.

103.

104.

105.

2684

2686

2689

2693

4104

2848-1

2848-2

3615

7308

52.030-006

600R-30

647

E100

Model

29

11-9110-1

Model

E25

Model

El

Model

E5

646953

85328

85329

Cp

Cp

0

Reamer

Reamer (Carbide

Reamer (Carbide

Reamer

Reamer

Reamer

Reamer

Reamer

Reamer

Reamer

Reamer (Square

Reamer

Reamer

Plug

Plug

Plug Gage

Dial

Precision

Inside Measuring

Alternator Analyzer

Regulator

Aftemnator/Regulator/

Battery

Voltage

Magneto

Timing

Cold

Hi-Voltage

Master

Alcor

Unit

Alcor

Unit

(Carbide

(Carbide

(High

(High

(High

(High

(Square

(Square

(Square

(Square

Gage

Gage

Thickness

Vernier

Tester

Tester

&

Circuit

Timing

Indicator

Cylinder Tester

Tester

Orifice Tool

Portable

Portable

Tipped)

Tipped)

Tipped)

Tipped)

Speed

Speed

Speed

Speed

Shank)

Shank)

Shank)

Shank)

Shank)

Gage

Calipers

Instrument

Tester

Light

Digital

Digital

Steel)

Steel)

Steel)

Steel)

Voltage

EGT

CHT

Cylinder

Cylinder Reconditioning

Cylinder

Cylinder

Cylinder

Cylinder

Cylinder

Cylinder

Cylinder

Cylinder

Cylinder

Cylinder

Cylinder Reconditioning

Valve

Valve

Valve

Dimensional

Dimensional

Dimensional

Charging

Charging

Electrical

Set

Set

Cylinder

Test

Cylinder

Engine

Engine Test

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Reconditioning

Guide

Inspection

Guide

Inspection

Guide

Inspection

Inspection

Inspection

Inspection

System

System

System Test

Engine

Engine

Timing

Timing

Firing

Improperly

Ignition

Cable

Compression

Test

Test

Test

Continuity

Test

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

FTSC

FTSC

FTSC

EEl

EEl

EEl

KTC

EEl

EEI

KTC

BTC

ALR

ALR

2-7

Page 22

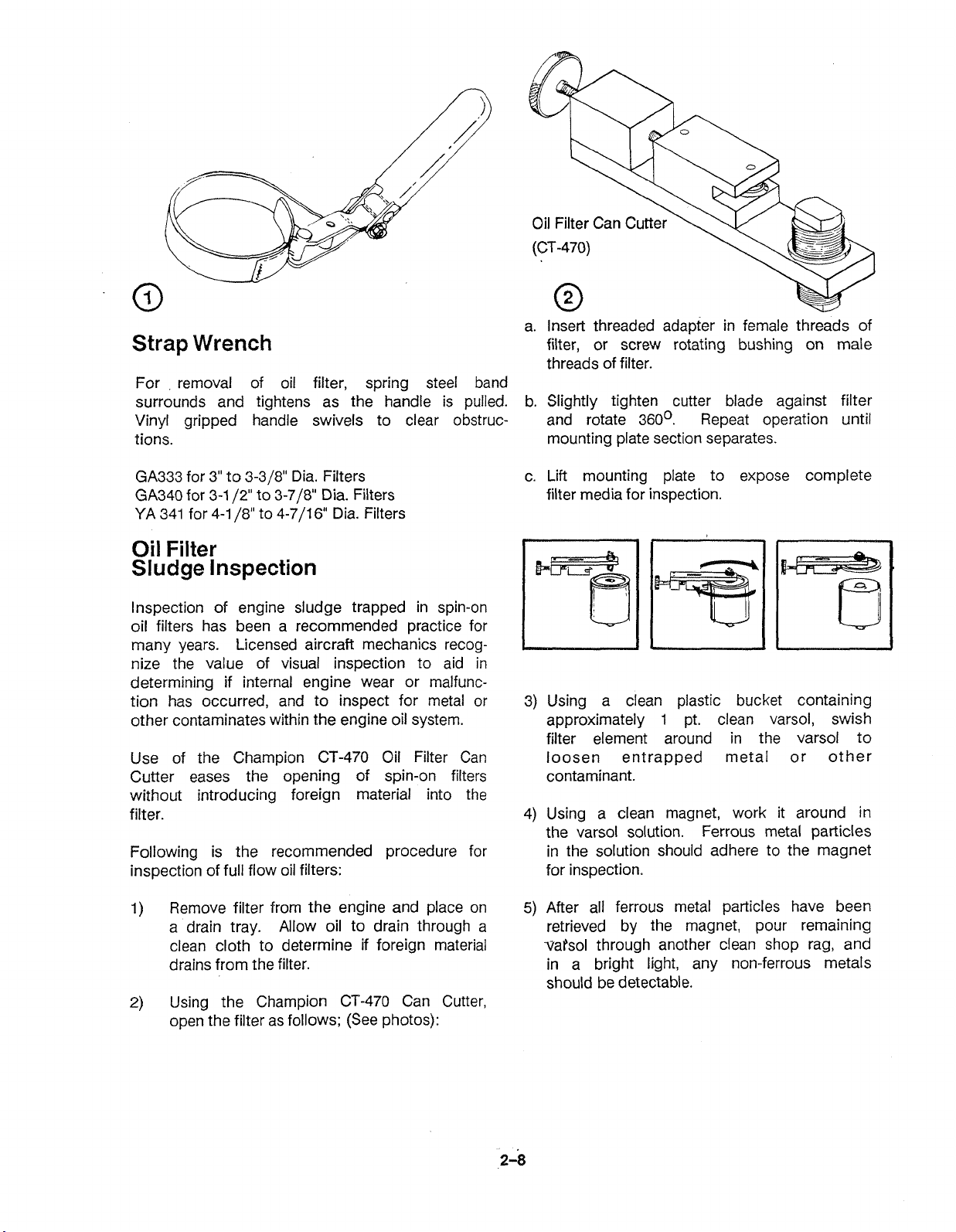

a. Insert threaded adapter in female threads of

Strap

For removal of oil filter, spring steel band

surrounds and tightens as the handle is pulled. b. Slightly tighten cutter blade against filter

Vinyl gripped handle swivels to clear obstruc- and rotate

tions. mounting plate section separates.

GA333 for 3" to 3-3/8" Dia. Filters c. Lift mounting plate to expose complete

GA340 for 3-1

YA 341 for 4-1

Oil

Sludge

lnspection of engine sludge trapped in spin-on

oil filters has been a recommended practice for

many years. Licensed aircraft mechanics recog-

nize the value of visual inspection to aid in

determining if internal engine wear or malfunction has occurred, and to inspect for metal or

other contaminates within the engine oil system.

Use of the Champion CT-470 Oil Filter Can

Cutter eases the opening of spin-on filters

without introducing foreign material into the

filter.

Following is the recommended procedure for

inspection of full flow oil filters:

Wrench

Filter

Inspection

/2"

to 3-7/8" Dia. Filters

/8"

to 4-7/16" Dia. Filters

filter, or screw rotating bushing on male

threads of filter.

360'. Repeat operation until

filter media for inspection.

3) Using a clean plastic bucket containing

1

approximately

filter element around in the varsol to

loosen entrapped metal or other

contaminant.

4)

Using a clean magnet, work it around in

the varsol solution.

in the solution should adhere to the magnet

for inspection.

pt. clean varsol, swish

Ferrous metal particles

Remove filter from the engine and place on

1)

a drain tray. Allow oil to drain through a

clean cloth to determine if foreign material

drains from the filter.

2)

Using the Champion CP-470 Can Cutter,

open the filter as follows; (See photos):

5)

After all ferrous metal particles have been

retrieved by the magnet, pour remaining

vatsol through another clean shop rag, and

in a bright light, any non-ferrous metals

should be detectable.

Page 23

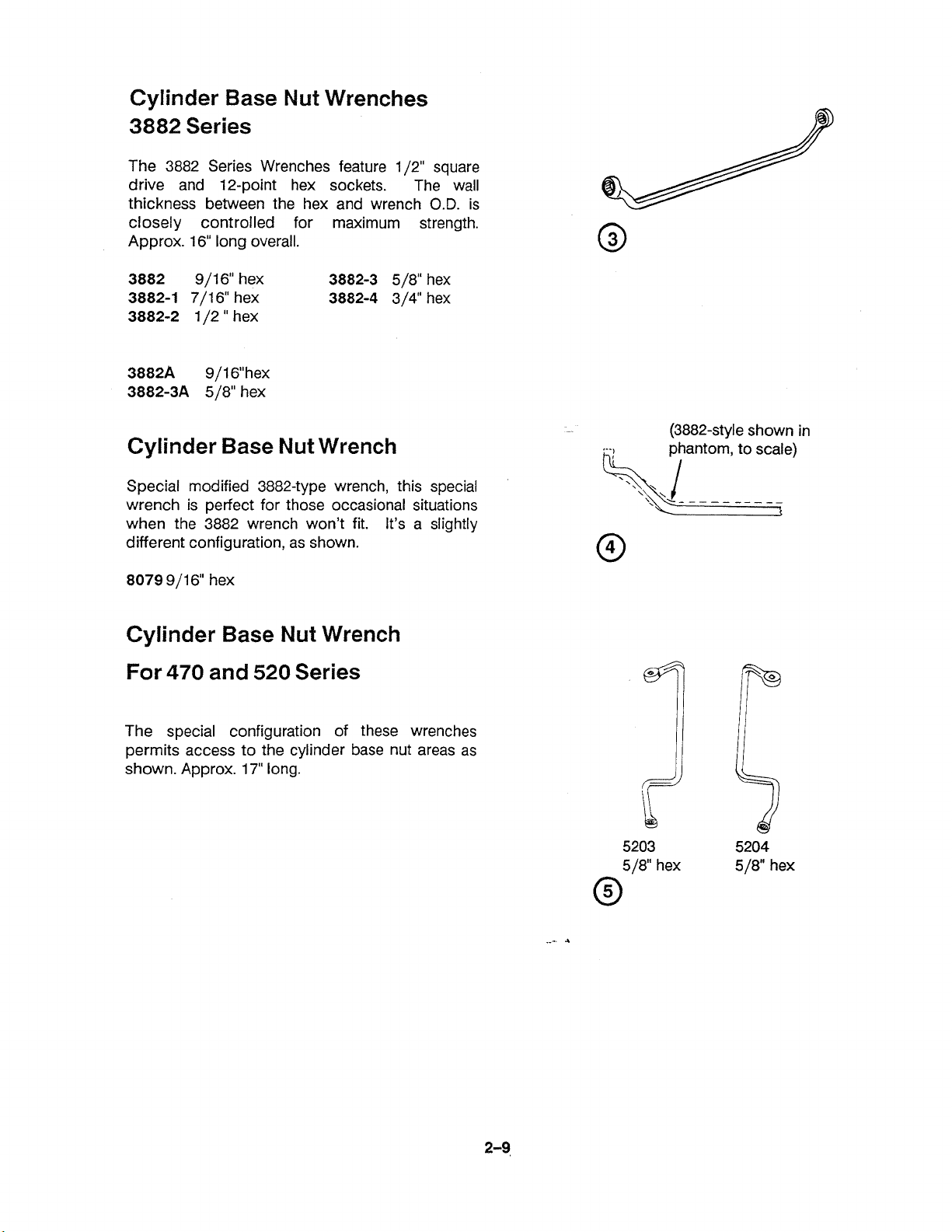

Cylinder Base

Nut

Wrenches

3882 Series

The 3882 Series Wrenches feature 1/2" square

drive and 12-point hex sockets. The wall

thickness between the hex and wrench

closely controlled for maximum strength.

Approx. 16" long overall.

O.D.

is

3882

3882-1

3882-2

3882A

3882-3A

Cylinder Base

Special modified 3882-type wrench, this special

wrench is perfect for those occasional situations

when

different configuration, as shown.

8079

Cylinder Base

9/16" hex

7/16" hex

1 /2 " hex

9/16"hex

5/8" hex

Nut

the 3882 wrench won't fit. It's a slightly

9/16" hex

Nut

3882-3

3882-4

Wrench

Wrench

5/8" hex

3/4" hex

For 470 and 520 Series

(3882-style shown in

The special configuration of these wrenches

permits access to the cylinder base nut areas as

shown. Approx. 17" long.

5203 5204

5

18" hex

5

18" hex

Page 24

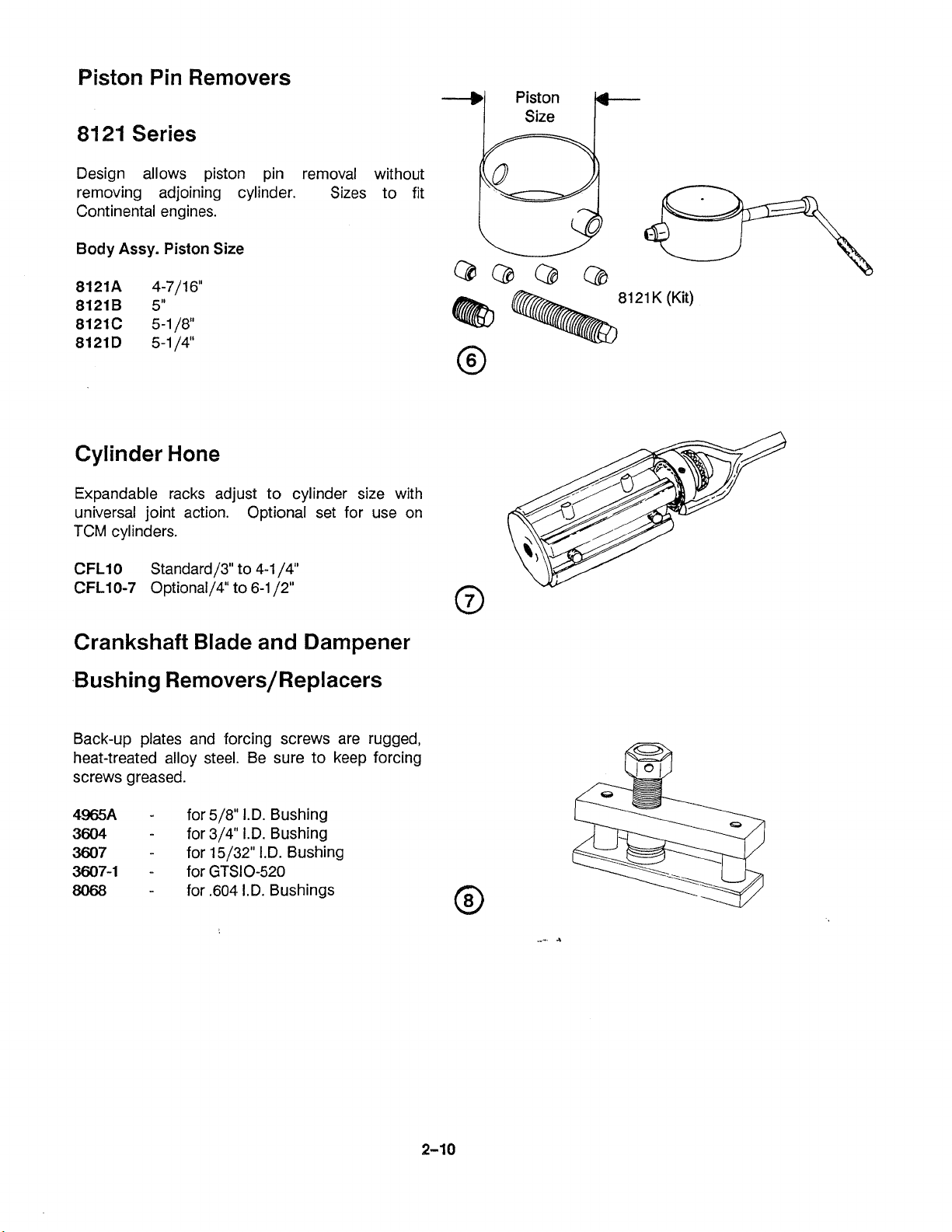

Piston Pin Removers

8121

Design allows piston pin removal without

removing adjoining cylinder. Sizes to fit

Continental engines.

Body Assy.

Series

Piston

Size!

Cylinder Hone

Expandable racks adjust to cylinder size with

universal joint action. Optional set for use on

TCM cylinders.

81

21

K (Kit)

Crankshaft Blade and Dampener

Back-up plates and forcing screws are rugged,

heat-treated alloy steel. Be sure to keep forcing

screws greased.

4965A

3604

3607

3607-1

8068

-

for 518" I.D. Bushing

-

for 314" I.D. Bushing

-

for 15/32" I.D. Bushing

-

for GTSIO-520

-

for

,604

I.D. Bushings

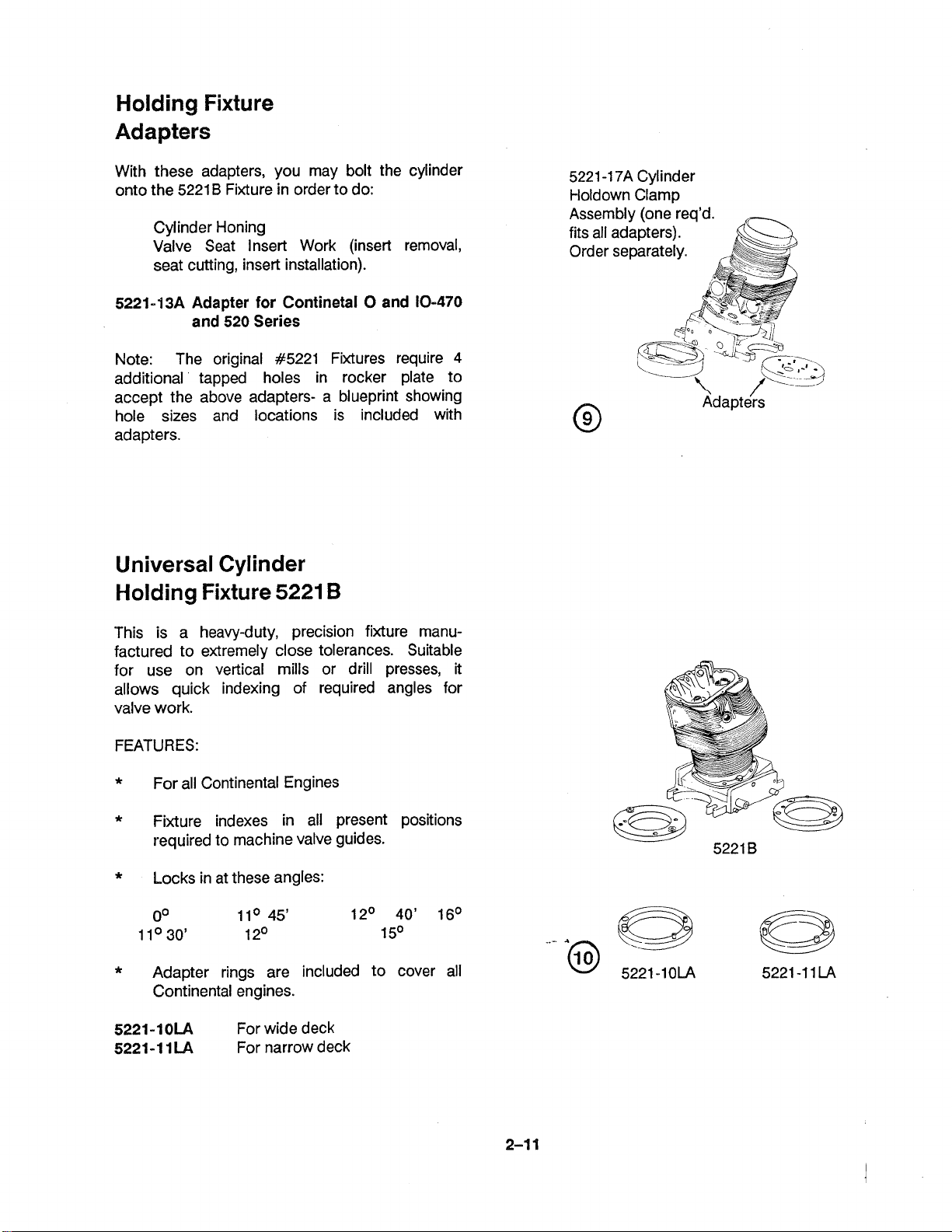

Page 25

Holding Fixture

Adapters

With these adapters, you may bolt the cylinder

onto the 5221

Cylinder Honing

Valve Seat Insert Work (insert removal,

seat cutting, insert installation).

5221-13A Adapter for Continetal 0 and 10-470

Note: The original #5221 Fixtures require

additional tapped holes in rocker plate to

accept the above adapters- a blueprint showing

hole sizes and locations is included with

adapters.

B

Fixture in order to do:

and 520 Series

4

Universal Cylinder

Holding Fixture

5221

B

-1

7A

5221

t-loldown Clamp

Assembly (one req'd.

fits all adapters).

Order separately.

Cylinder

This is a heavy-duty, precision fixture manufactured to extremely close tolerances. Suitable

for use on vertical mills or drill presses, it

allows quick indexing of required angles for

valve work.

FEATURES:

*

For all Continental Engines

*

Fixture indexes in all present positions

required to machine valve guides.

*

Locks in at these angles:

*

Adapter rings are included to cover all

Continental engines.

5221-10LA

5221-1 1LA

For wide deck

For narrow deck

Page 26

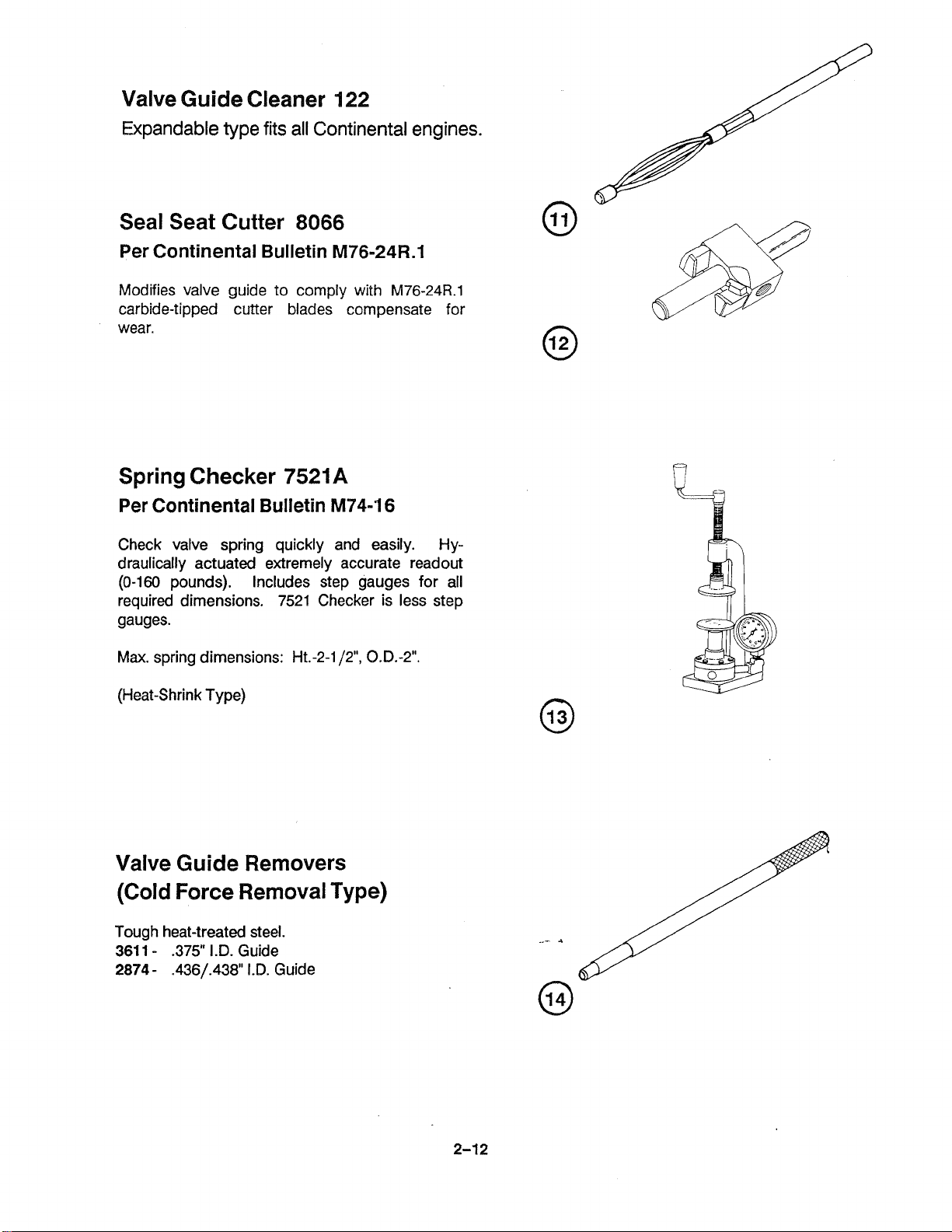

Valve Guide Cleaner 122

Expandable type fits all Continental engines.

Seal Seat Cutter

Per Continental Bulletin

Modifies valve guide to comply with

carbide-tipped cutter blades compensate for

wear.

Spring Checker 7521

Per Continental Bulletin

Check valve spring quickly and easily. Hy-

draulically actuated extremely accurate readout

(0-160

required dimensions. 7521 Checker is less step

gauges.

Max.

pounds). Includes step gauges for all

spring dimensions: Ht.-2-1/2", 0.D.-2".

8066

M76-24R.1

M76-24R.1

A

M74-16

(Heat-Shrink Type)

Valve Guide Removers

(Cold Force Removal 'Type)

Tough heat-treated steel.

361

1

-

.375"

I.D. Guide

2874 - .436/.438"

1.D.

Guide

Page 27

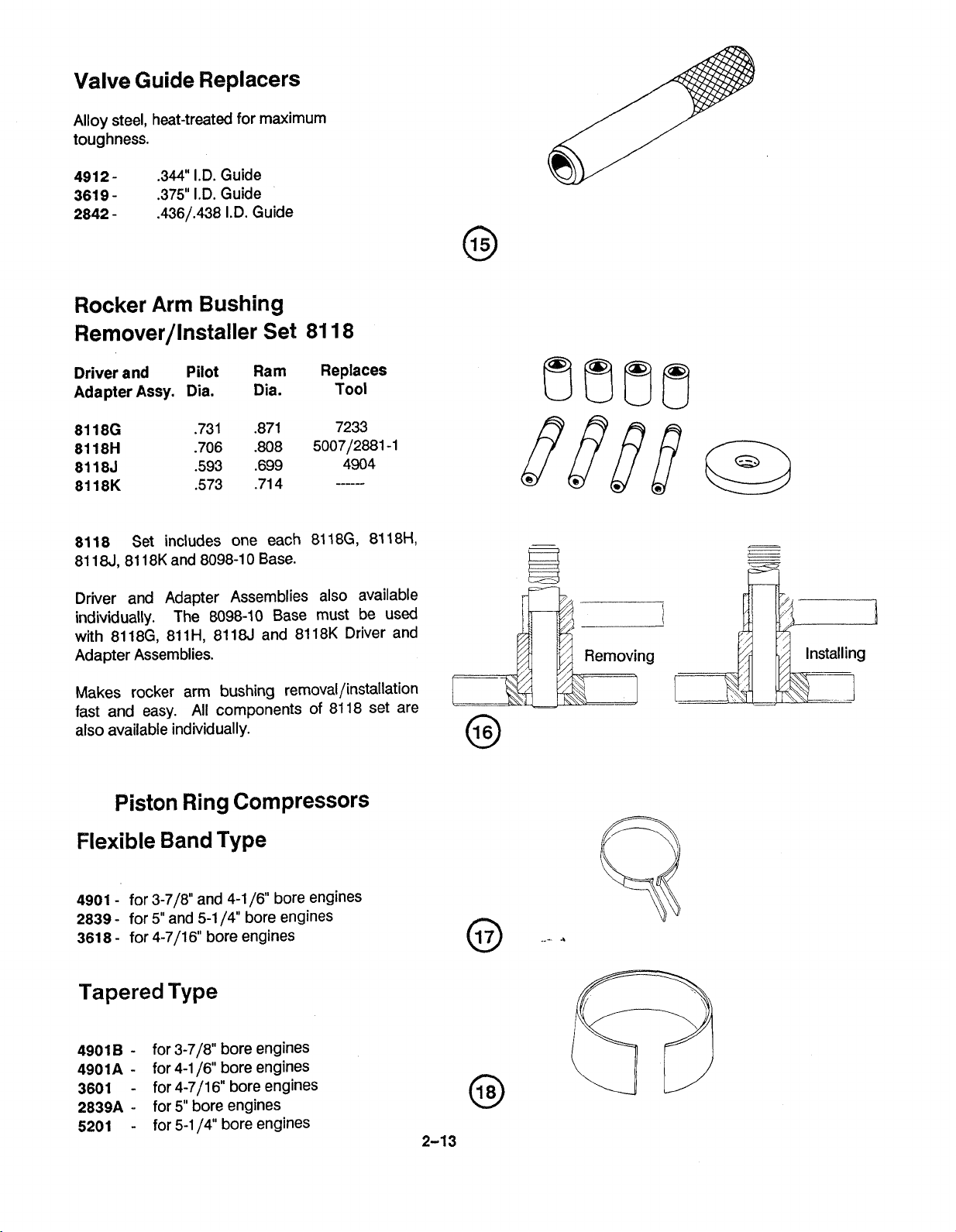

Valve Guide Replacers

Alloy steel, heat-treated for maximum

toughness.

4912361 9

2842

.344" I.D. Guide

-

.375" 1.D. Guide

-

.436/.438 I.D. Guide

Rocker Arm Bushing

Remover/lnstaller Set 81 18

Driver and

Adapter

8118

81 184 81 18K and 8098-1 0 Base.

Driver and Adapter Assemblies also available

individually. The 8098-10 Base must be used

with

Adapter Assemblies.

Assy.

Set includes one each 81 18G, 81 18H,

81 18G, 81 1H, 8118J and 81 18K Driver and

Pilot

Dia.

Ram Replaces

Dia. Tool

Makes rocker arm bushing

fast and easy. All components of 81 18 set are

also available individually.

removal/installation

Piston Ring Compressors

Flexible Band

4901

-

for 3-718" and 4-1 16" bore engines

2839

-

for

5"

and 5-1 14" bore engines

361 8

-

for 4-7/16 bore engines

Type

Tapered Type

4901

B

-

for 3-718" bore engines

4901A

3601

2839A

5201

-

for 4-1 16" bore engines

-

for 4-711 6" bore engines

-

for 5" bore engines

-

for 5-1 14" bore engines

Page 28

31 70 - Floating holder

No. 3 Morse male, compensates for misalignment

between reamer and work. Provides

unrestricted float.

Valve Spring

Compressor 3602

Adjustable type works on all Continental

engines.

Hook installs on rocker shaft (or on special

rocker nut furnished) and c-shaped collar

compresses spring to allow keeper removal.

stressed parts are heated-treated steel. Handle

18"

is approx.

long for good leverage.

All

Push Rod Spring

Compressor 68-3

For compressing and holding push rod springs

on all engines with spring loaded tubes. The

68-3

compresses the spring, which can then be

removed with furnished clips.

Eliminates wiring springs together- to install,

simply insert spring then pull off clip!

instructions.

Includes

Flaring Tool for Push

Rod Housing 4951

For A

Balls rotate inside housing, expanding it into

aluminum boss.

81

C Series - expanding ball type tool.

A

Valve Guide Remover 4981

Removes guides by heat-shrink method.

Cylinder is heated to

water to guide bore.

hammer removes guide.

included) supplies the low water pressure

required to cool the guides for easy removal.

Replacement guide is usually same size as the

one removed.

475O~, then tool injects

A

light tap with the

A

water reservoir (not

slide

Page 29

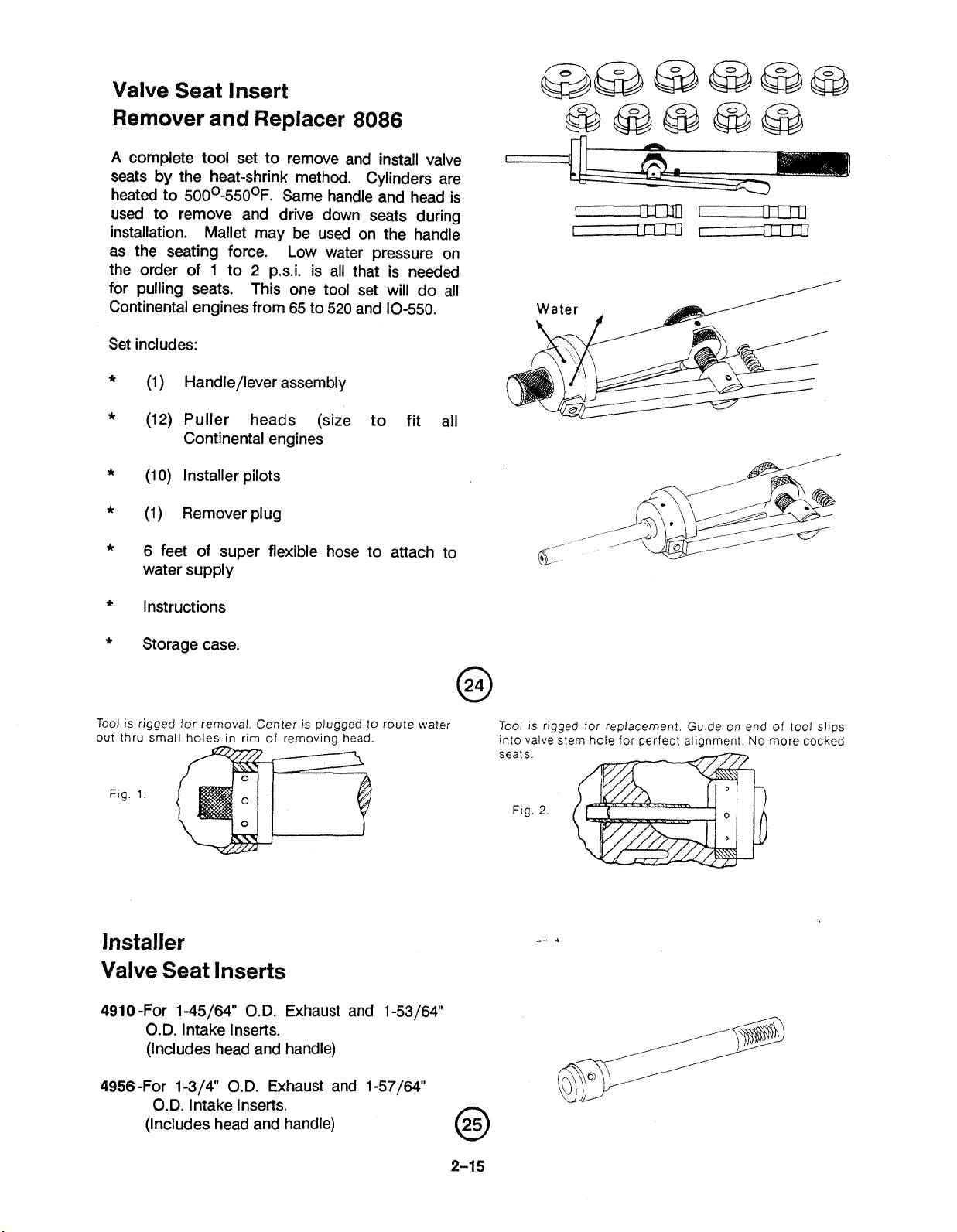

Valve Seat Insert

Remover and Replacer

A

complete tool set to remove and install valve

8086

seats by the heat-shrink method. Cylinders are

heated to

500~-550°F. Same handle and head is

used to remove and drive down seats during

installation. Mallet may be used on the handle

as the seating force. Low water pressure on

the order of

1

to 2 p.s.i. is all that is needed

for pulling seats. This one tool set will do all

Continental engines from 65 to 520 and 10-550.

Set includes:

*

(1) Handle/lever assembly

*

(12) Puller heads (size to fit all

Continental engines

*

(1

0)

Installer pilots

*

(1)

Remover plug

*

6 feet of super flexible hose to attach to

water supply

*

Instructions

*

Storage case.

Tool is rigged for removal. Center

out thru small holes in rim of

Fig.

1.

is

plugged to

removina head.

"

route water

Installer

Valve Seat lnserts

491 0 -For 1-45/64" O.D. Exhaust and 1-53/64"

O.D. Intake lnserts.

(Includes head and handle)

Tool

is

rigged for replacement. Guide on end of tool slips

into valve stem hole for

seats

Flg

2

perfect alianment.

No

more cocked

4956-For

1-3/4" O.D. Exhaust and 1-57/64

O.D. lntake Inserts.

(Includes head and handle)

Page 30

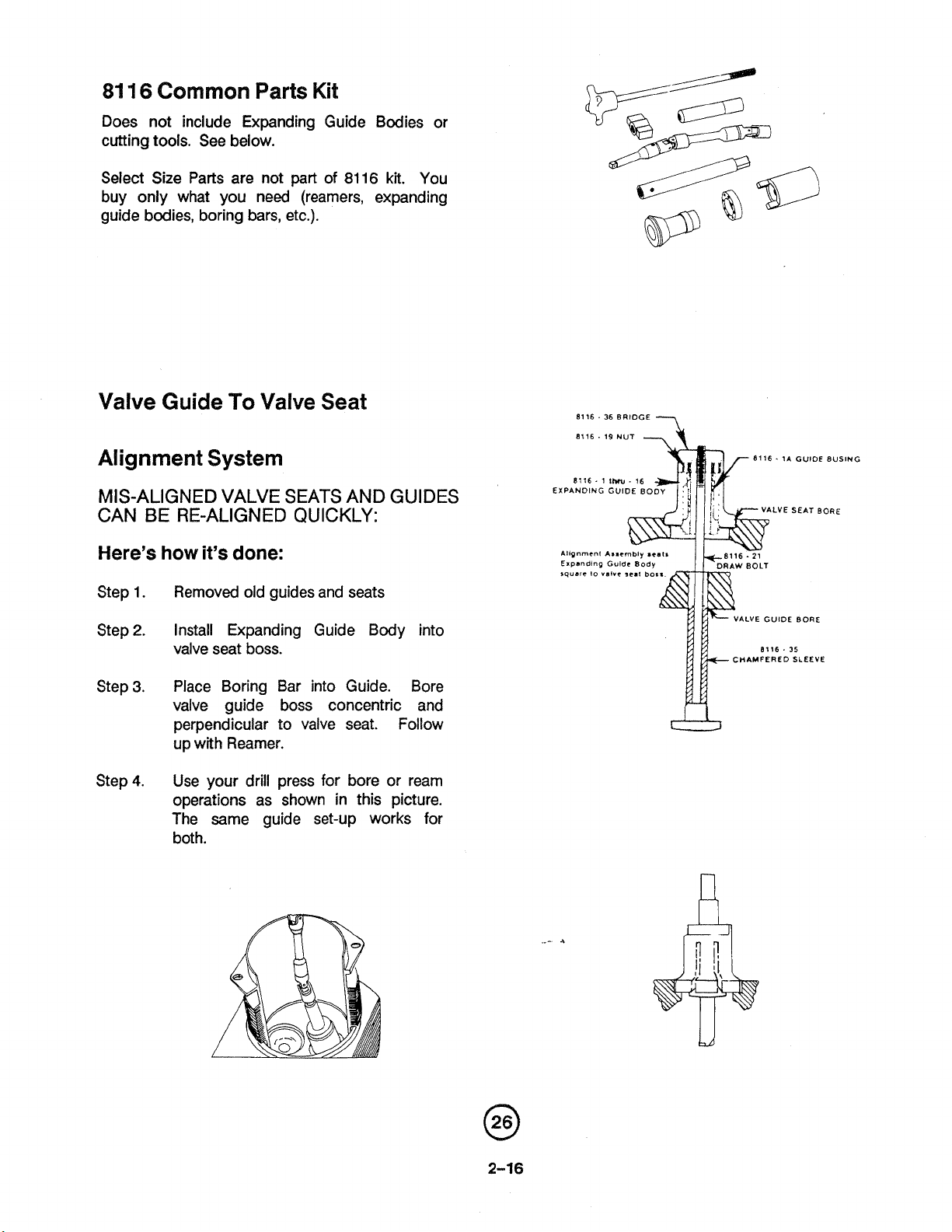

81

16

Common

Parts Kit

Does not include Expanding Guide Bodies or

cutting tools. See below.

part

of

81

16

kit.

Select Size Parts are not

You

buy only what you need (reamers, expanding

guide bodies, boring bars, etc.).

Valve Guide

To

Valve Seat

Alignment System

MIS-ALIGNED VALVE SEATS AND GUIDES

BE

CAN

Here's how it's done:

Step

Step

Step

Step

RE-ALIGNED QUICKLY:

Removed old guides and seats

1.

2.

Install Expanding Guide Body into

valve seat boss.

3.

Place Boring Bar into Guide. Bore

valve guide boss concentric and

perpendicular to valve seat. Follow

up with Reamer.

Use your drill press for bore or ream

4.

operations as shown in this picture.

The same guide set-up works for

both.

8116.

36

BRIDGE

8116 . 19 NUT

11116 - 1

EXPANDING GUIDE

1b.

16

80

---,

8116. 1A GUIDE BUSING

LVE SEAT BORE

GUIDE BORE

ALVE

CHAMFERED SLEEVE

Page 31

Valve Stem Hole Reamers

(T3kes the place

of

2847,3606

81

491

3

Series reamers).

Tool No. Hole Dia.

81 16.24 .344

Boring Bars Reamers

Made

of

ground.

high speed

M2

tool steel, precision

Reamers

Tool No. Hole Dia.

Valve Guide Boss. (Takes place of

491

4

and 4943 Series reamel s).

Boring Bars

Tool No.

Hole Dia.

(*Example: Use

Reamer

6R

Expanding

Guide

Bodies

81

16-6B Boring Bar to bore hole to

to

561

dia.)

Expanding Minimum Maximum

Bodv No. Retracted Dia. Expanded Dia.

8116-1

8116-2

81 16-3

81 16-4

8116-5

81

16-6

81 16-7

81 16-8

81 16-9

8116-10

8116-11

8116-i2

81 16-13

81 16-14

8116-15

8116-16

.555,

then finish with 8116-

Page 32

Valve

Seat

Insert

Straight Side - Non Step

Cutters

Part

No.

Use

4909-8 lnt

4909-9 Int

4909-12

4-13 Exh

4954-5 Int

4954-8 Int

4954-9 Int

4954-10

4954-1 1 Int

4954-12

4954-13 Exh

4954-14 Exh

4954-15 Exh

49851 Int

49852 Int

4985-3 Int

4985-4 Int

Exh

Int

Exh

Finish

Dim.

O.S.

WARNING!

Measure New Insert

select proper cutter.

Straight Side

Cutters

Finish

Part

No.

Use

Dim.

Q&.

4985-5 Int 2.140 .030"

4985-6

4985-7 Exh 1.664 .010

4985-8 Exh 1.669 .015"

4985-9 Exh 1.674

4985-10 Exh 1.684 ,030"

5224-5

5224-10 Int 2.527 .010

5224-15

5224-20 Int 2.537 .020"

5224-30

5225-5 Exh 1.793 .005"

5225-10 Exh 1.798 .O10"

5225-15 Exh 1.808 .015"

5225-20 Exh 1.808 SO20

5225-30 Exh 1.818

Exh 1.669 ,005"

.OW

Int 2.522 .005

Int 2.523 .015

Int 2.547

-030"

.03*

Part

O.D.

and then

Small

No.

Diameter Diameter Part

--

Large

STD

.005

.010"

.015"

.OW'

.w

STD

,005

.O1on

Step Side

Cutters

Small

No.

Diameter Diameter 8.S.

2.070

2.070

2.070

2.632 STD

2.632

2.632 .010

2.632

2.632

2.632 .ON"

Large

,015

.O2OM

.OW

.05"

.015"

.ow

Rosan@

Stud

Remover

This stud remover is for use in extracting studs

from cylinder assemblies using

~osan~type

Studs.

Using the hammer, drive the stud driver

over stud

contact with the cylinder head

(2)

as far as possible without making

(3).

Using the

(1)

ratchet or pull handle, apply a firm, constant

pressure in the clockwise (tightening) direction,

the serration

(4)

on the stud will strip.

When

the stud gives, reverse the ratchet and back

the stud out until there are three threads still

engaged in the lock ring

with the

driver still attached, up, down and

(5).

Move the stud

sideways. The lock ring will pop out of the

cylinder without damaging

is Part No.

2769A13.

it.

The stud driver

2

A

3

Page 33

Connecting Rod Reaming and

Alignment Checking Fixture

With these precision tools, it's easy to check

connecting rods (without bushings) for

alignment and

The 81 11A

well as one (or more) of the Adapter Kits

described below. The 811

high-carbon steel base (hardened and ground for

long life); retaining collar, cap (for connecting

rod) and wing nut.

The

81

11A Base/Retainer

Adapter Kits as described below.

warpage.

Base/Retainer Kit is required as

1A Kt includes the

Kit

fits the following

Adapter Kits

These kits contain the indicator gauge assembly,

which as a dial indicator reading in ten-thou-

sandths of an inch (.0001"). The gauge body is

lapped into the mating bushing for accurate

readings. Instructions are included.

Adapter Kits

8042C

8072C

for 520-470-E Series 1.125"

1

.OOM

&

for 0-200, 0300,360

.922"

@

Q

@

BasejRetainer Kit 81 1 1 A

Complete tool combining

81

11A Base with one of the 3

listed adapter

checking rod for alignment.

Q

a

kits shown

Reamers, Connecting Rod Bushing

High-speed steel reamers with 3/4" diameter

pilot. Use with

proper Adapter

874-40

874-41

5008

8071

.920" Roughing

.923 Finishing

1.1 26" Finishing

1

.OOOM

8111A Base/Retainer Kit and

Kit

as shown above.

use together

Finishing

@

Complete tool

using same adapters

shown above with piston

pin reamer. See at left

for proper reamer to use

Page 34

Universal Connecting

Rod

Bushing

Remover and Installer Set

Complete set for removing and installing con-

necting rod bushings for Continental Support

bushing reverses for either installing or

removing.

8098 Complete Set

8098-10

Driver and

Adapter Assy.

(Above Driver and Adapter Assemblies also

available individually).

Base

Pilot

Dia.

Includes:

Ram Replaces

Dia.

8098

Tool

-+-

8098-10

(Included)

Bare

Common Drive Handle

This Drive Handle fits all pilots and cutters,

and

it

features positive pin drive as shown.

(Combination of Morse taper and pin drive

eliminates any slippage between handle and

cutter.)

By using the

below, you may choose to pilot into valve stem

hole or valve guide boss.

8122A with the proper pilot from

81

22A

Pilots

All pilots are hardened and precision ground for

accuracy. Two choices- pilot into valve stem

hole or valve guide boss.

No.

1-

Pilot Choice

(On

new installations only)

Part No. Pilot Dia.

CAUTION:

Pilot lnto Valve Stem Hole

DO NOT USE ON

WORN

GUIDES!

i

81

22A Common

Drive Handle

This handle fits all

pilots and cutters (also

fiis

your old cutters).

Cutter

Pilots

..-

4

,

Pilot

Choice

Part No. Pilot Dia. Application Part No. Pilot Dia. Application

.-

-

8123

8124

8125

8126

8127

8128 ,560

,530 Standard 8129

,535

,540 Oversize ,010 8131

,545

,550 Oversize ,020 8133

"-2

No.

2

-

Pilot

lnto

Valve

--

Oversize ,005 8130

Oversiz~O15 8132 ,639

Oversize ,030

8134

Guide

,624

529

,634 Oversize ,010

,644 Oversize .020

,654 Oversize .030

Standard

Oversize .005

Oversize .015

Boss

Page 35

Needle Bearing Installers

Precisely machined to make bearing installation

fast.

23-

1

8053

562" pilot

.75OU pilot

Hydraulic Crankshaft Dampener

Bushing

Remover/Replacer Sets

8077A and 80776

Remove and

fraction of the time hydraulically!

strokes of the pump handle removes or installs

bushing with very little effort. Small actuating

head

fits in and around the crankshaft. Once

the bushing is removed (or installed), a turn of

the valve returns actuator for another cycle.

8077A

10,000

cylinder; 3-ft. long Rex hydraulic hose; all

adapters to fit 0-300 and 360, 470 and 520

Series.

80778

Items shown above in 8077A except no

hydraulics are furnished. The actuator head has

114"

hydraulic hose.

includes:

p.s.i. pump and cylinder; 5-ton output

(less hydraulics) includes:

NPT female port for connecting to your

replace crankshaft bushings in a

A

few

Counterweight Bushing

~emover/lnstaller

8077C

Positive guide of all components assures perfect

alignment. Includes adapters for

470 and 520 Series engines.

0-300, 360,

6%~~

,

,,

J-,

......

ii

Page 36

All

Position Engine Stand

Assem

Transportation

Designed to save time on the overhaul floor.

Minimum attaching hardware allows complete

engine accessibility.

Positive frame rotation

number of positions simply by releasing handle.

Engine mounting plate also rotates

locks in place with heat-treated lock pin.

Flange holder is predrilled to accept

tinental

mount non-flanged crankshafts. Shipping

weight

bl

y-Disassem

erigines. Threaded adapters included to

400

Ibs.

bly

81

04

(360~) locks in infinite

360O and

all Con-

Tork Band Tension Adjuster

7726

Adjust belt tension without damage to

nents. Use on alternators, compressors, etc.

Allows grabbing difficult round components.

compo-

Generator Drive Holder

Hold drive gear for torquing or removing

retaining nut.

4973

4973A

2.600" dia.

2.51

0" dia.

..-

4

Page 37

Cylinder Heating Stand

In just 8-10 minutes, you can heat 2 cylinders

simultaneously to

a

time (each tip is separately controlled).

at

Included with the 8156 Cylinder Heat Stand:

(2) Tips

(2)

36"

Propane Hoses wlfittings

(1)

Propane Regulator

(2) Controls

(1)

Y-Connector

(1) Stand

(2) Cylinder Risers

All screws, nuts and washers needed; and

instructions.

600°F. Or, you can heat one

81

56

20

Tip:

/

Ib.

\

Propane

Y-Connector

Tank

Blind Needle Bearing

8093C

Puller

Use to remove 5f8"

and 520 Series engines. Use with 8054 Slide

Hammer.

I.D.

needle bearings in 470

Starter Clutch Shaft

Bearing Pullers

80930

for removing

314"

I.D. bearings.

Use

with

8054

Slide

Harnmer

Page 38

Differential Pressure Gauge

For turbo superchargers. A rugged, high

precision gauge needed to set differential fuel

measures. 50-0-50 psi,

pipe connection.

4-1/2" dia. face,

521

0

1/4"

Differential Pressure 7251

Cylinder Checker

Use standard shop air pressure to check

condition of rings, cylinder walls and valves.

Belt Tension Gauge BT-33-73F

(TSIO-520-BE uses BT-33-89P)

Set belt tension quickly and accurately to

ensure maximum belt and bearing life. The

proper belt-tension eliminates slippage and

increases efficiency of belt-driven opponents.

Compact- only 3

areas. Easy to use- just apply gauge to belt,

release ball handle and read tension on rotating

dial.

Calibrated for A-section V-belts

top width) and K-section

belts. Range 30 to 180 Ibs. and

newtons (dual scale).

1/4" wide to fit in crowded

(3/8

to

1

/2"

(4,5,

and 6 rib) poly-V

130

to 800

Hydraulic Valve BT-6OC

Lifter Tester

For checking bleed down rate on hydraulic

lifters. Hand input turns lifter as

use. Includes one gallon of

(also available separately).

BT-59

in

actual

Test Oil

Page 39

In-Aircraft Alternator/

Generator Tester 8091

Replace test bench. Uses aircraft's own engine

to check systems and tests without component

removal. Long leads permit tester to remain in

cockput during testing.

*

*

Voltage output

*

Stator

*

Windings

Rotor

*

Field Input

*

*

Brushes

Diodes

n

Features 030v

ammeter; circuit breaker protected. Two point

hook-up- field term, and cigarette lighter.

DC

voltmeter; 10-0-10 amp DC

Engine Timing Disc 3608A

For all engines- universal application from

DC3.

Fastens to prop tip and accurate to

degree. lncludes piston stop 3608A-15.

Pulley Holder

For holding 2-1/2" to 3-112" dia. pulleys grip in

pulley groove.

4974

2

J3

to

114

Pulley Alignment Gage Bar

8082

The 8082 gage bar allows a quick and easy

alignment check between driver sheave and

compressor sheave.

Used when installing air conditioning on models

10-520 and TSIO-520. lncludes adapter sleeve

for

112" v-belts.

Page 40

Crankcase Drill Fixture 8094A

For Starter Clutch Adapter

Per Continental Bulletin 79-1

Modifies crankcase by drilling extra oil passage

from rear main to starter bushing area.

0

Vacuum Pump 8334

This new heavy-duty vacuum pump is designed

for one-hand operation. Heavy steel wall; 0-30

in Hg; nozzle fits several sizes of tubing.

Generator Pulley Puller 61

Quick removes pulleys from

diameter. Applies even pressure on outside of

pulley in pulley groove. All components are

tough, heat-treated alloy steel.

2-1

-5

12"

to

5"

Bearing and Bushing 8094B

Drill Fixture

Per Continental Bulletin 79-1

Use to reqork your present stock of main

journal bearings and starter shaft bushings.

Use Bearing Puller 80935 (see at right).

0

M

1

..

-

A

Page 41

Spark

Features 1 /2" square drive. Use on all engines,

Plug

Insert Replacer 491

Thru-Bolt Bore Step Cutters

8

Per Continental Bulletin

Use to chamfer step in thru-bolt dowel boss

prior to inserting improved thru-bolt with

ring seal.

M77-9

O-

Spark Plug Insert Tap 504-1

Use on all engines.

Spark Plug Insert Remover 491

9

Use on all engines.

Slide Hammer 8054

Heavy duty slide hammer features

5/8"-18

and

81

14

Series removers.

Spark Plug Tap

18

millimeter threads. High-speed steel.

thread.

24"

long overall. Use with

445

2-1

12-lb. slide

Page 42

~osan@ Lock Ring Installer

8074

Heat-treated, tough alloy steel. Knurled for

sure grip. Approximately 4" long.

Stud Drivers

Six (6) different thread sizes:

505-1

505-2

505-3

114"-28

5-1 6"-24

318"-24

505-5

505-6

505-4

114"-20

5/16"-18

7/16"-20

Drill Fixture

4978

For Scavenge Pump. Includes fixture and drills

with pre-set stops

To modify 470 Scavenge Pump per Continental

Bulletin M72-8.

Drill Fixture

8025

For drilling and installing piston oil squirt

nozzles in 0-470V engines, converting to

470VO per Continental Bulletin M75-13, 10-470

to 10-4700s.

O-

includes all drills, drill bushings and stops

required to a fast and efficient job.

Crankcase Splitter Set

Makes splitting Continental crankcases easier

and faster. Prevents crankcase damage. Puller

assemblies bolt onto crankcase studs.

L423

Page 43

Propeller Shaft Oil Seal Installer

5209

For all flanged shafts. For installing one piece

stretch seals without damaging sealing surfaces.

Be sure to oil the seal before installing.

Oil

Pressure Relief Spot Facers

Positive stop to prevent excess material

removal. Cutter blades are heat-treated

highspeed steel.

8048

Spot Facer for

470

and 520.

Runout Block Set

Use this set to check runout on crankshafts,

etc. up to

alloy with Teflon bearing surfaces. Approx.

4"

size:

w

x

4"

8"

diameter.

1 x

5"

h each.

81

77A

Blocks are aluminum

Polishing Tools for Crankshafts

Bearings

Special aluminum frame and felt polishing

surfaces.

1

8087A

8087B

-718" to 2-1 14" dia.

2-1 14" to 2-518" dia.

(Dial indicator

not included)

Page 44

Injector Nozzle

Remover and

This tool allows you to remove, install and

tighten injector nozzles located close to intake

parts on Piper Aircraft. Torque Wrench extension allows use of

wrench to tighten nozzles to proper

specifications.

Torque wrench extension is made of

treated steel for durability. Torque input and

output is marked on extension.

Installer

socket.

.

is special, thin-walled 6-pt. 112" hex

Installer 81

318"

square drive torque

65

heat-

Crankcase Thru-Bolt Removers

Use with 8054 Slide Hammer to remove stubborn

bolts.

81 14-8

81 14-7

81 14-6

Remover, 112"-20 threads

Remover, 711 6"-20 threads

Remover, 318"-24 threads

Hex Drive for

791

Hex Tube Nut

Tubing nut wrench set for fuel systems,

hydraulic systems and brakes.

Rotabroach Cutters 771

2A

0

These cutters cut faster

drills with only a fraction of the power and

effort.

and

cleaner than twist

Page 45

Pullers

These pullers provide a more controlled method to remove

press-fit parts.

Page 46

Reamers, Rocker Shaft

Boss

Support

NOTE:

5129

SERIES ARE FOR

STRAIGHT VALVE

ENGINES

ONLY.

4903-14903-24903-3-

4903-4-

4903-5-

.645"

Roughing

.680n Roughing

.703 Finishing (Use with 4903-1

&

4903-2) (.678" Pilot)

.708" Finishing (Use with 4903-1

4903-2

.723' Finishing (Use with 4903-1,

4903-2,4903-3

(.706"

&

Pilot)

(.609"

(.643"

4903-3) (.70lS Pilot)

&

4903-4)

Reamer, Rocker Arm

Shaft Bushing

4905-

.609"

Std. (594" Pilot)

Pilot)

Pilot)

&

51281- .753" Roughing (.718" Pilot)

29-2-

51

5129-3- .813" Finishing (Use with

5129-4- .818" Finishing (Use with

5129-5-

.788"

Roughing (.751" Pilot)

&

5129-1

51 29-1

.833"

5129-1,5129-2,5129-3

5129-4) (.815" Pilot)

5129-2)

&

51 29-3) (.815" Pilot)

Finishing (Use with

(.786"

Pilot)

&

Reamer, Rocker Shaft Bushing

5130- .751" Std (.707" Pilot)

Reamer, Rocker

7232- .751" Std. (.732" Pilot)

Arm

Bushing

4914-1HS

4914-2HS

4914-3HS

4914-4HS

4914-5HS

4943-1 HS

4943-2HS

4943-3HS

4943-4HS

4943-5HS

-

-

-

-

-

-

-

-

-

-

.537"

-542"

.552"

-547"

-561"

.631"

.636"

.646"

-641"

-656"

Reamers, Valve Guide BQSS

Use at 275 RPM maximum

-.

.005" O.S. (.531"

.010" O.S. (.534"

.020" O.S. (.539"

-

.015" O.S.

.030" O.S. (.549"

-005" O.S. (.624"

-010" O.S. (.628"

-020" O.S. (.633"

.015" O.S. (.631"

-030"

(.539'Vilot)

O.S. (.645"

Pilot)

Pilot)

Pilot)

Pilot)

Pilot)

Pilot)

Pilot)

Pilot)

Pilot)

USE

MORSE

ADAPTER

2689

2689

2689

.

2689

2689

2693

2693

2693

2693

2693

Page 47

0

Engine Application Chart For Valve Guide Stem Hole Reamers

Adapt square Shank Reamers to

No.

2

or 3 Morse Taper

Part

No. Morse

2684 2

2686

2689

2693

4104

Reducer Sleeve, No. 2 Morse I.D. to

No.

3

Morse O.D. sleeve only-

will not

NOTE..

ni-resist auides.

.

.

.DO

O.D.

3

3

3

fit

reamer shank.

NOT

use hiah-s~eed reamers on

Shank Flats

.323" .242"

.367" .275"

.48OU

.590"

.360"

.442"

Plug Gauges,

Suggestions For Reaming

Valve Guide Stem Holes

1. Use high quality cutting oil.

2.

Reamers are made to cut right

hand onlydo not turn backwards

even a partial turn!

3. If using power, run high-speed

reamers at

carbide-tipped at

imum. High-speed steel reamers

for hand cutting.

4. The

#5221 B universal cylinder

holding fixture is recommended

for stem hole reaming, using

a drill press or vertical mill.

400

RPM maximum, and

700

RPM max-

Valve Guide Stem Hole

Go and No-go Gauges are used to check

for new limits (and service limits

where applicable). Gauges are

treated alloy steel, precision ground.

2848-1-

2848-2-

3615-

.436"

I.D. Guide

.438"

I.D. Guide

375" I.D. Guide