Teledyne Continental Motors GTSIO-520 Series, GTSIO-520-H, GTSIO-520-L, GTSIO-520-M, GTSIO-520-K Overhaul Manual

...

OVERHAUL

MANUAL

FOR

GTSIO-520

AIRCRAFT

SERIES

ENGINES

FORM

X-30045A

FAA

MARCH

APPROVED

1981

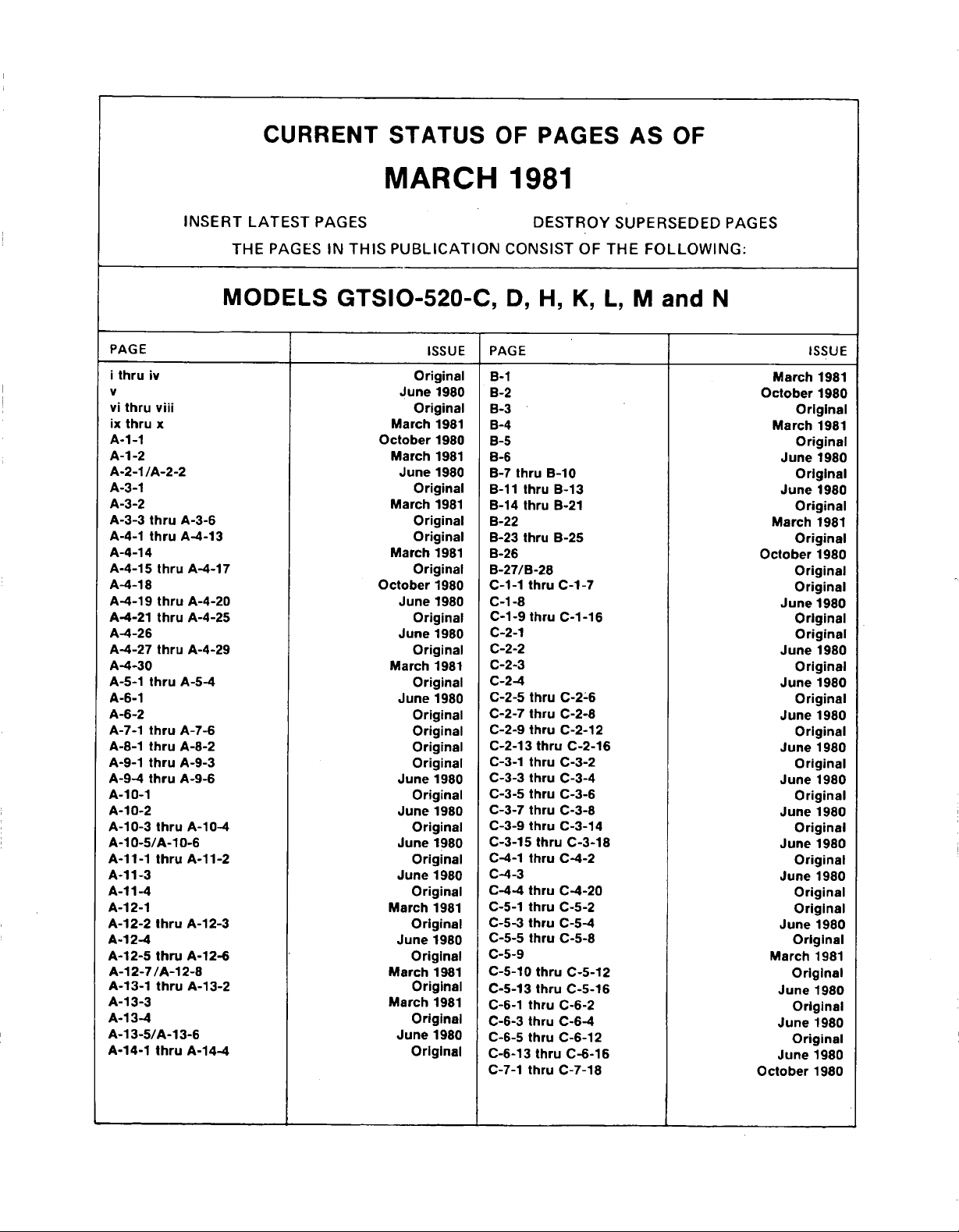

CURRENT

STATUS

OF

PAGES

AS

OF

PAGE

ithru

iv

V

vi

thru

viii

ix

thru

x

A-1-1

A-1

-2

A-2-1/A-2-2

A-3-1

A-3-2

A-3-3

thru

A-3-6

A-4-1

thru

A-4-13

A-4-14

A-4-15

A-4-18

A-4-19

A-4-21

A-4-26

A-4-27

A-4--30

A-5-1

A-6-1

A-6-2

A-7-1

A-8-1

A-9-1

A-9-4

A-10-1

A-10-2

A-10-3

A-10-5/A-10-6

A-11-1

A-1 1 -3

A-1 1 -4

A-1

A-12-2

A-12-4

A-12-5

A-1

A-13-1

A-13-3

A-1

A-13-5/A-13-6

A-14-1

2-1

2-7

3-4

thru

thru

thru

thru

thru

thru

thru

thru

thru

thru

thru

thru

thru

/A-1

thru

thru

A-5-4

A-7-6

A-8-2

A-9-3

A-9-6

2-8

INSERT

THE

MODELS

A-4-17

A-4-20

A-4-25

A-4-29

A-10-4

A-11-2

A-12-3

A-12-6

A-13-2

A-14-4

LATEST

PAGES

MARCH

PAGES

IN

THIS

PUBLICATION

GTSIO-520-C,

ISSUE

Original

June

1980

Original

March

1981

October

October

1980

March

1981

June

1980

Original

March 1981

Original

Original

March

1981

Original

1980

June

1980

Original

June

1980

Original

March

1981

Original

June

1980

Original

Original

Original

Original

June

1980

Original

June

1980

Original

June

1980

Original

June

1980

Original

March

1981

Original

June

1980

Original

March

1981

Original

March

1981

Original

June

1980

Original

1981

DESTROY

CONSIST

D,

PAGE

B-1

B-2

B-3

B-4

B-5

B-6

B-7

thru

B-1l

thru

B-14

thru

B-22

B-23

thru

B-26

B-27/B-28

C-1-1

thru

C-1

-8

C-1-9

thru

C-2-1

C-2-2

C-2-3

C-2-4

C-2-5

thru

C-2-7

thru

C-2-9

thru

C-2-13

C-3-1

thru

C-3-3

thru

C-3-5

thru

C-3-7

thru

C-3-9

thru

C-3-15

C-4-1

thru

C-4-3

C-4-4

thru

C-5-1

thru

C-5-3

thru

C-5-5

thru

C-5-9

C-5-10

C-5-13

C-6-1

thru

C-6-3

thru

C-6-5

thru

C-6-13

C-7-1

thru

H,

B-10

thru

thru

thru

thru

thru

OF

K,

B-13

B-21

B-25

C-1-7

C-1-16

C-2-6

C-2-8

C-2-12

C-2-16

C-3-2

C-3-4

C-3-6

C-3-8

C-3-14

C-3-18

C-4-2

C-4-20

C-5-2

C-5-4

C-5-8

C-5-12

C-5-16

C-6-2

C-6-4

C-6-1

C-6-16

C-7-18

SUPERSEDED

THE

FOLLOWING:

L,

M

and

2

PAGES

N

March

October

Original

March

Original

June

Original

June

Original

March

Original

October

Original

Original

June

Original

Original

June

Original

June

Original

June

Original

June

Original

June

Original

June

Original

June

Original

June

Original

Original

June

Original

March

Original

June

Original

June

Original

June

October

ISSUE

1981

1980

1981

1980

1980

1981

1980

1980

1980

1980

1980

1980

1980

1980

1980

1980

1980

1981

1980

1980

1980

1980

i-1.

COMPOSITION.

i-2.

This

adequate

operations

these

three

The

basic

a

hypothetical

the

most

involved.

basic)

and

covered

Chapter

Table

manual.

covered

cerned

indexed

model,

of

manual

Page

1

3

i-3.

i-4.

instructions

chapter

through

duction,

Illustrations,

Unpacking

Shipment,

Repair

assemblies.

Accessories

model

Chapter

GTSIO-520.

i-5.

i-6.

for

The

Chart

referred

of

only

Chapter

Limits.

A-

13

of

Chapter

Chapter

This

and

engine.

Chapter

This

all

engines

index

are

to

C.

by

are

Specification

publication

information

for

(3)

Chapters

engine

GTSIO-520

common

Any

differences

the

letter

by

the

Chapter

Limits

Personnel

this

with

by

the

A

All

pages,

numbered

-7

refers

A.

A.

chapter

for

the

consists

XIV.

These

Special

and

Preparation

Disassembly,

Replacement,

Final

and

Testing

Hereafter,

A

will

B.

chapter

covered

numbers

listed

as

reference

is

for

the

models

A,

overhaul

use

for

consolidated

letter

(the

of

Assembly,

be

consists

on

in

(Chapter

basic

between

model

of

Difference

B

is

the

all

engines

overhauling

the

Difference

of

basic),

figures

by

to

the

contains

basic

GTSIO

(14)

sections

Limits,

Tools

after

known

of

in

this

the

the

Table

numbers.

constructed

complete

covered

B,

and

C.

engine

the

seventh

for

Cleaning,

Limits

model,

items

engines

combined

covered

any

manual

his

particular

and

Chapter

and

following

complete

520

sections

cover

General

and

Service,

Assembly

Repair

Overhaul,

through

as

the

the

Table

consolidated

and

of

Limits

throughout

A)

is

written

of

all

Chapter

is

adequately

Data

listing

engine

will

Data

tables

page

of

overhaul

engine.

numbered

the

Description,

Equipment,

Storage

Inspection,

of

and

Testing

of

the

this

basic

of

manual.

Lubrication

and

FOREWORD

i-7.

Chapter

to

give

overhaul

covering

engines

A

(the

Section,

of

the

in

this

model

be

con-

Section,

engine

B

Table

in

this

system:

Section

This

Intro-

or

Sub-

of

basic

manual

model

Limits

are

to

I

i-8.

This

instructions

Table

ual

sections,

model.

for

the

coverage

Difference

those

i-9.

AVAILABILITY.

i-10.

Further

Contintal

be

purchased

Approved

craft

engine

such

publications

i-11.

SERVICE

i-12.

Important

changeability

datory

mation

and

duration

which

of

aircraft

study

to

aircraft

personnel

annual

service

i-13.

SERVICE

i-14.

It

Motors

and

requests

Distributors.

touch

them

maintenance

experience

maintenance

aircraft

at

most

C.

chapter

for

of

Contents.

each

Each

section,

basic

model

for

Data

for

the

same

copies

Motors

Distributors

parts.

of

replacements

are

among

covered

are

distributed

engines

at

their

offices.

owners,

may

subscription

covers

is

the

to

handle

for

These

with

operation

more

and

engines.

major

than

problems

work

airports.

contains

all

engine

This

chapter

relating

along

in

Chapter

overhaul.

Section

assemblies

of

aircraft

through

and

It

is

requested

be

placed

BULLETINS.

changes

parts,

and

the

subjects

by

to

and

parts

Service

operators

be

obtained

basis.

only

postage

REPORTS

policy

facilities

There

of

all

reports

information

facilities

and

willing

and

to

on

is

the

models

consists

to

a

with

A,

The

instructions

are

to

in

this

and

service

Teledyne

Parts

with

these

in

part

urgent

modernization

of

factory

all

Approved

and

Bulletins

and

by

direct

The

and

AND

Teledyne

of

through

are

repair.

to

help

well

perform

Teledyne

an

Approved

Difference

as

listed

of

particular

the

instructions

provide

be

the

publications

that

numbers,

inspection,

Service

are

charge

INQUIRIES.

service

complete

used

in

basic

other

Teledyne

Continental

Dealers

all

orders

facilities.

limited

Bulletins,

Distributors

available

of

maintenance

mail

for

handling.

Continental

difficulty

Approved

constantly

You

will

solve

equipped

any

necessary

Continental

Distributor

Data

in

the

individ-

engine

in

the

lieu

model

may

for

air-

for

inter-

man-

infor-

interest

for

interest

on

this

find

your

with

of

an

in

i

. . . . .A-6-1

. .. . .A-6-1

. .. .

. .. . .A-7-1

. .. . .A-7-1

. .. . .A-7-1

. .. .

. .. .

. .. .

. .. .

. .. .

. .. .

. .. .

......

......

......

......

......

......

......

......

.A-6-1

.A-7-1

.A-7-1

.A-7-1

.A-7-1

.A-7-2

.A-7-2

.A-7-2

A-7-2

A-7-2

A-7-2

A-7-3

A-7-3

A-74

A-7-5

A-7-5

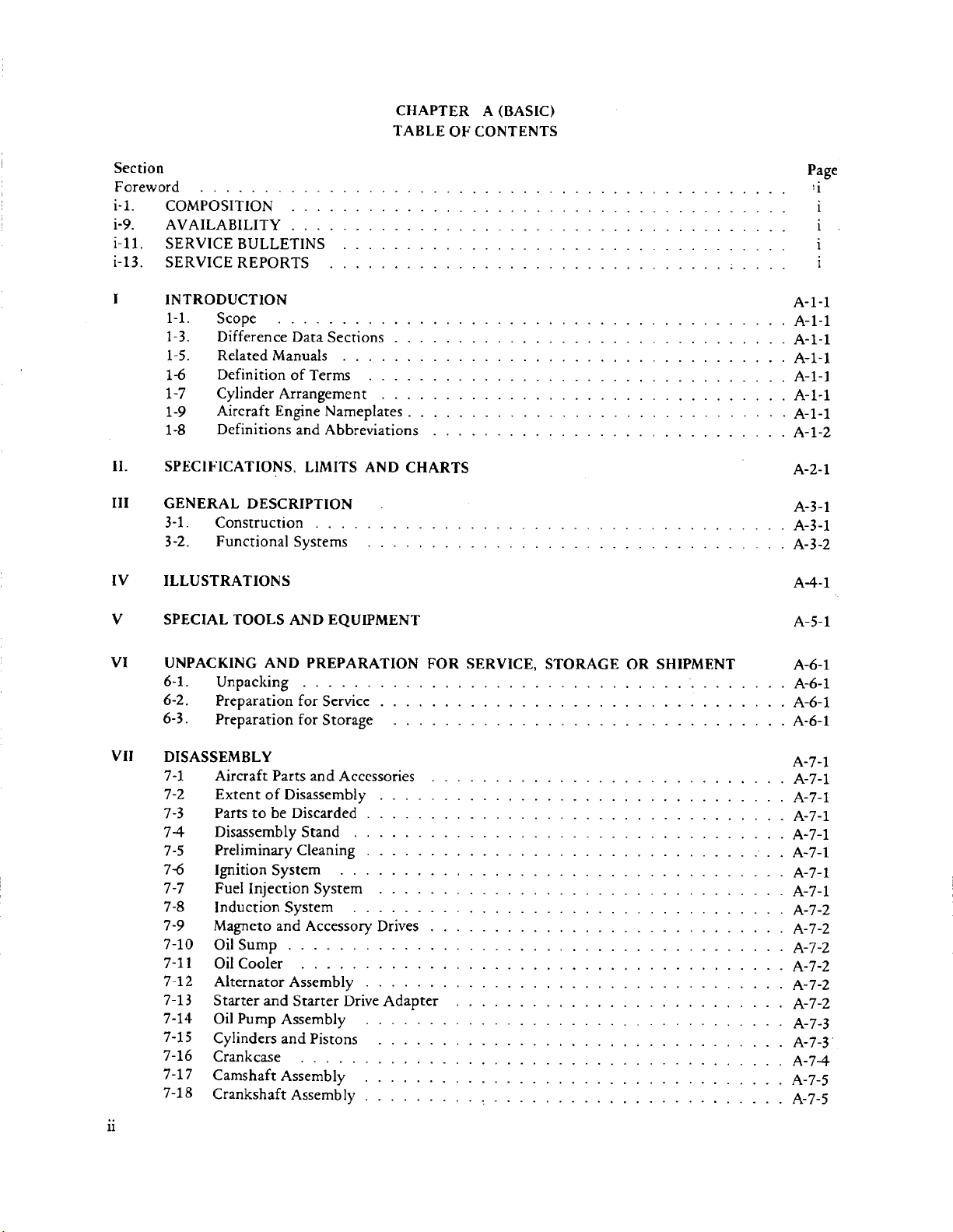

Section

Forew

i-1.

i-9.

i11.

i-13.

I

II.

III

ord

. . . .

. . . . . .

COMPOSITION

AVAILABILITY

SERVICE

SERVICE

BULLETINS.......

REPORTS

INTRODUCTION

1-1.

1-3.

1-5.

1-6

1-7

1-9

1-8

Scope

Difference

Related

Definition

Cylinder

Aircraft

Definitions

SPECIFICATIONS,

GENERAL

3-1.

3-2.

DESCRIPTION

Construction

Functional

. . . . . .

...........

...........

........

. . . . .

Data

Sections...

Manuals

of

Terms.....

.......

Arrangement

Engine

Nameplates

and

Abbreviations

LIMITS

..

Systems

. . . . .

....

AND

.

.........

CHAPTER

TABLE

OF

. .

. .

CHARTS

. . . .

A

(BASIC)

CONTENTS

Page

A-1-1

A-1-1

A-1-1

A-1-1

A-1-1

A-1-1

A-1-1

A-1-2

A-2-

A-3-1

A-3-1

A-3-2

i.

1

IV

V

VI

VII

ILLUSTRATION

SPECIAL

UNPACKING

6-1.

6-2.

6-3.

TOOLS

AND

Unpacking

Preparation

Preparation

DISASSEMBLY

7-1

7-2

7-3

74

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7

7-13

7-14

7-15

7-16

7-17

7-18

Aircraft

Extent

Parts

Disassembly

Preliminary

Ignition

Fuel

Induction

Magneto

Oil

Oil

12

Alternator

Starter

Oil

Cylinders and

Crankcase

Camshaft

Crankshaft

Parts

of

to

be

System

Injection

Sump

Cooler

and

Pump

S

AND

EQUIPMENT

PREPARATION

...................

for

Service

for

Storage

and

Accessories

Disassembly

Discarded

Stand

...........

Cleaning

............

System

System

and

Accessory

................

.

. . . . .

Assembly

Starter

Drive

Assembly

Pistons.........

.. . .

Assembly

Assembly

.............

............

.........

..........

..........

.........

...........

Drives.

. .. . . .

..........

Adapter..

..........

. .. . ..

..........

..........

FOR

.. .

. .. ..

SERVICE,

.

.

.

STORAGE

.

OR

SHIPMENT

A-4-1

A-5-1

A-6-1

...

...

...

A-7-1

...

...

...

...

...

...

...

...

...

...

.

.

.

.

.

.

.

.

ii

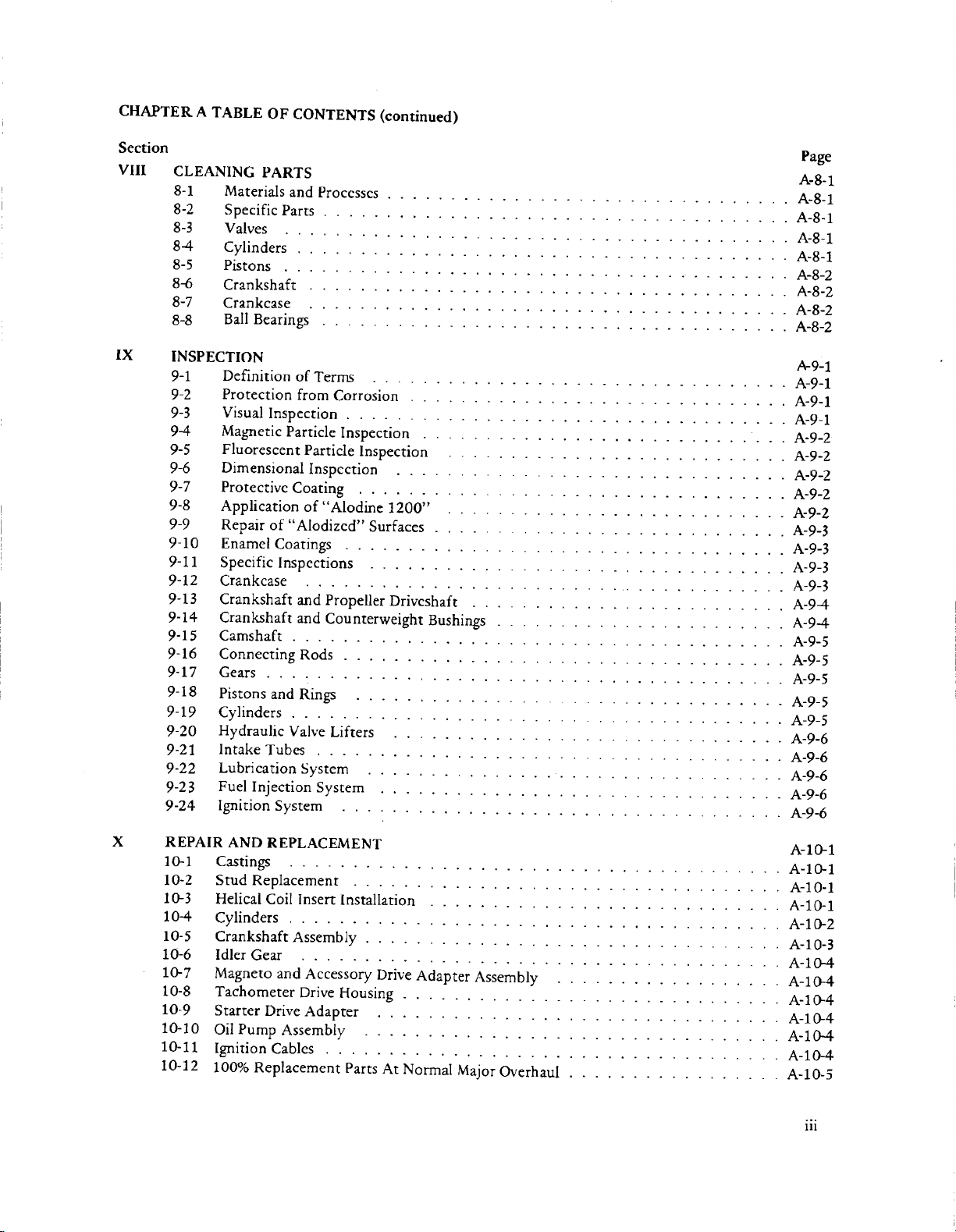

CHAPTER A TABLE OF

CONTENTS

(continued)

Section

VIII

IX

CLEANING

8

1

8-2

8-3

8-4

8-5

8-6

8-7

8-8

PARTS

Materials

Specific

Valves.

Cylinders.

and

Parts.

Processes.

....................................

...............................

.......................................

......................................

Pistons. .......................................

Crankshaft.

Crankcase.

Ball

Bearings.

.....................................

.....................................

...................................

INSPECTION

9-1

9-2

9-3

9-4

9-5

9-6

9-7

9-8

9-9

9-10

9-11

9-12

9-13

9-14

9-15

9-16

9-17

9-18

Definition of

Protection

Visual

Magnetic

Fluorescent

Terms

from

Corrosion. .............................

Inspection. ..................................

Particle

Inspection.

Particle

Inspection.

Dimensional Inspcction.

Protective Coating.

Application

Repair

Enamel

Specific

Crankcase.

Crankshaft

Crankshaft

Camshaft.

Connecting

Gears.

Pistons

of "Alodine

of

"Alodized"

Coatings.

..................................

Inspections.

.....................................

and

Propeller

and

Counterweight

......................................

Rods.

..................................

........................................

and

Rings.

.. .. ... ..... .. .. .. .. .... . ... . .. ..

...........................

.................................

1200".............................A-9-2

Surfaces

. . . .

................................

Driveshaft.

Bushings.

..............

9-19 Cylinders. ......................................

9-20

9-21

9-22

9-2 3 Fuel

9-24

Hydraulic

Intake

Tubes.

Lubrication

Injection

Ignition

System.

Valve

Lifters.

....................................

System.

System.

.................................

..............................

................................

...............................

............................

..........................

........................

........................

......................

.................

Page

A-8-1

A-8-1

A-8-1

A-8-1

A-8-1

A-8-2

A-8-2

A-8-2

A-8-2

A-9-1

A 9-

A-9-1

A-9-1

A-9-2

A-9-2

A-9-2

A-9-2

A-9-3

A-9-3

A-9-3

A-9-3

A-94

A-94

A-9-5

A-9-5

A-9-5

A-9-5

A-9-5

A-9-6

A-9-6

A-9-6

A-9-6

A-9-6

X

REPAIR

10-1

10-2

10-3

104

10-5

10-6

10-7

10-8

10-9

10-10

10-11

10-12

AND REPLACEMENT

Castings.

Stud Replacement.

Helical

......................................

Coil

Insert

Installation.

.................................

Cylinders. ......................................

Crankshaft

Idler

Magneto

Tachometer

Starter

Oil

Pump Assembly.

Ignition

100%

Assembly.

Gear.

.....................................

and

Accessory

Drive

Drive

Adapter.

Cables.

Replacement

................................

Drive

Adapter

Housing.

.............................

...............................

................................

...................................

Parts

At

Normal

...........................

Assembly.

Major

Overhaul.

.................

................

A-10-1

A-1b-1

A-10-1

A-10-1

A-10-2

A-10-3

A-104

A-

10-4

A-

10-4

A-1

0-4

A-1O0-4

A-10-4

A-10-5

iii

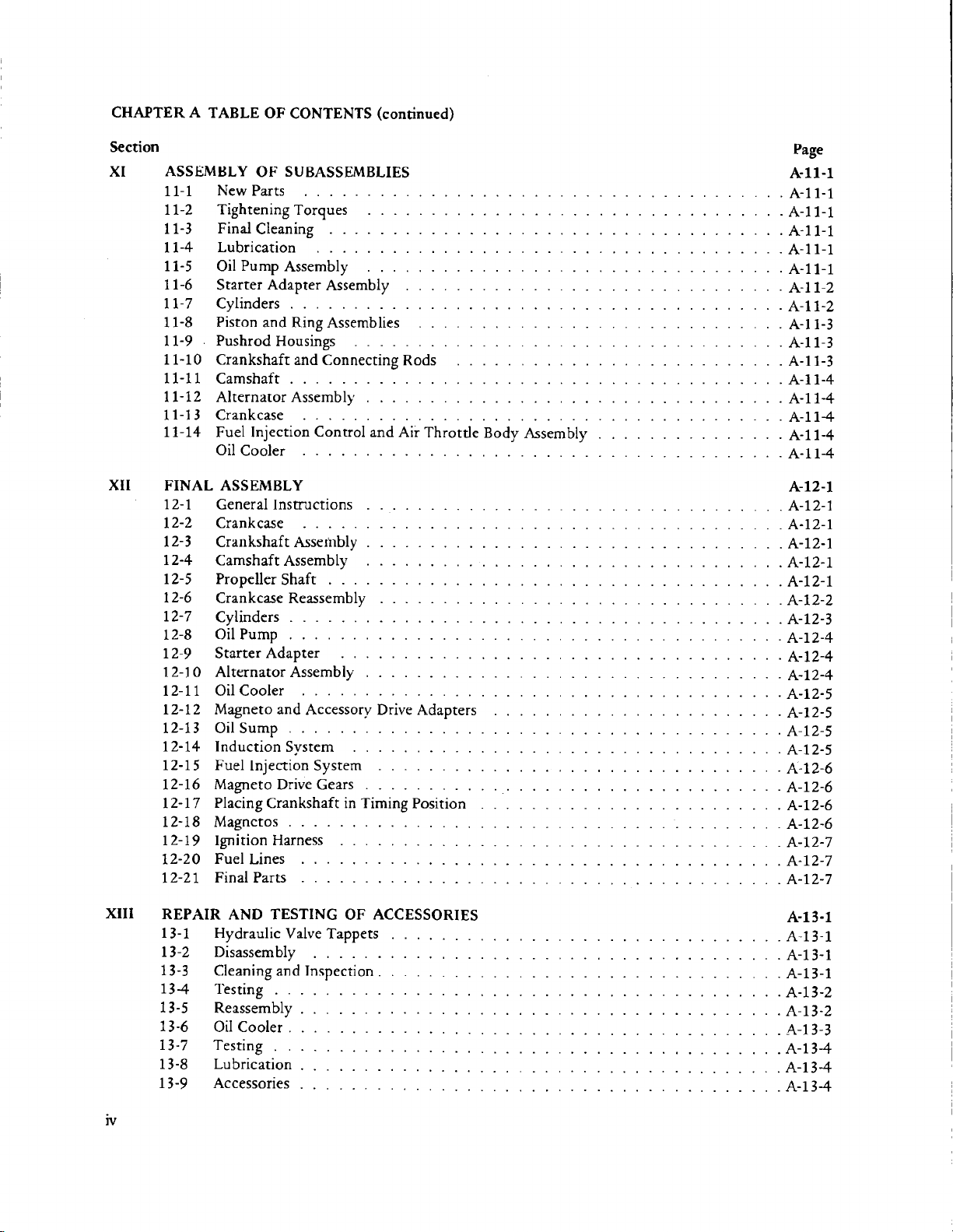

CHAPTER A TABLE

OF

CONTENTS

(continued)

Section

XI

XII

ASSEMBLY

11-1

11-2

11-3

11-4

11-5

11-6

11-7

11-8

11-9

11-10

11-11

11-12

11-13

11-14

FINAL

12-1

12-2

12-3

12-4

12-5

12-6

12-7

12-8 Oil

12

1

12-11

12-12

12-13

12-14

12-15

12-16

12-17

12-18

12-19

12-20

12-21

New

Tightening

Final

Lubrication

Oil

Pump Assembly

Starter

Cylinders

Piston

Pushrod

Crankshaft

Camshaft

Alternator

Crankcase . . . . . . . . . . . . . . . . . . . . . . .

Fuel

O

il

Cooler

ASSEMBLY

General

Crankcase

Crankshaft

Camshaft

Propeller

Crankcase

Cylinders

Pump

9

Starter

2-1 0 Alternator

Oil

Cooler.........

Magneto

Oil

Sump

Induction

Fuel

Injection

Magneto

Placing

Magnetos ..........

Ignition

Fuel

Lines

Final

OF

SUBASSEMBLIES

Parts

..

Torques

Cleaning

.....................

. . ... . . . . . . . . . . . . . . .. .

Adapter

Assembly

........................

and

Ring

Assemblies

Housings

and

Connecting

........................

Assembly

Injection

Control

. . . . . . . . . . . . . . . . . . . . . . .

Instructions....

.........

Assembly....

Assembly

Shaft

.......

Reassembly...

..........

..........

Adapter

Assembly....

and

Accessory

.

System .....

System

Drive

Gears....

Crankshaft

Harness

......

.........

Parts .........

. . . .

..................

..................

..............

...................

Rods...........

..................

and

Air

....

......

Drive

...

in

Timing

..............

Throttle

Adapters

Position

. . . .

Body

Assembly

. .

Page

A-11-1

A-1

1-1

A-11-1

A-1

A-1

1-1

A-11-1

A-1

12

A-1

1-2

A-1

1-3

A1

13

A-11-3

A-1

1-4

A-1

1

A-1

1-4

A-

1 1-4

A-

114

A-

12-1

A-12-1

A-12-1

A-12-1

A-12-1

A-12-1

A-12-2

A-12-3

A-12-4

A-12-4

A-12-4

A-12-5

A-12-5

A

12-5

A-12-5

A-12-6

A-12-6

A-12-6

A-12-6

A-12-7

A-12-7

A-12-7

-

XIII

iv

REPAIR AND

13-1

13-2

13-3

13-4

13-5

13-6

13-7

13-8

13-9

Hydraulic

Disassembly

Cleaning

Testing

Reassembly ..............

Oil

Cooler

Testing

Lubrication

Accessories

TESTING

Valve

..

and

Inspection........

................

...............

................

..............

..............

OF

ACCESSORIES

Tappets

. . . . .

.. ..

A-13-1

.

A13-1

A-13-1

A-13-1

A-13-2

A

A-13-3

A-13-4

A-134

A-134

13-2

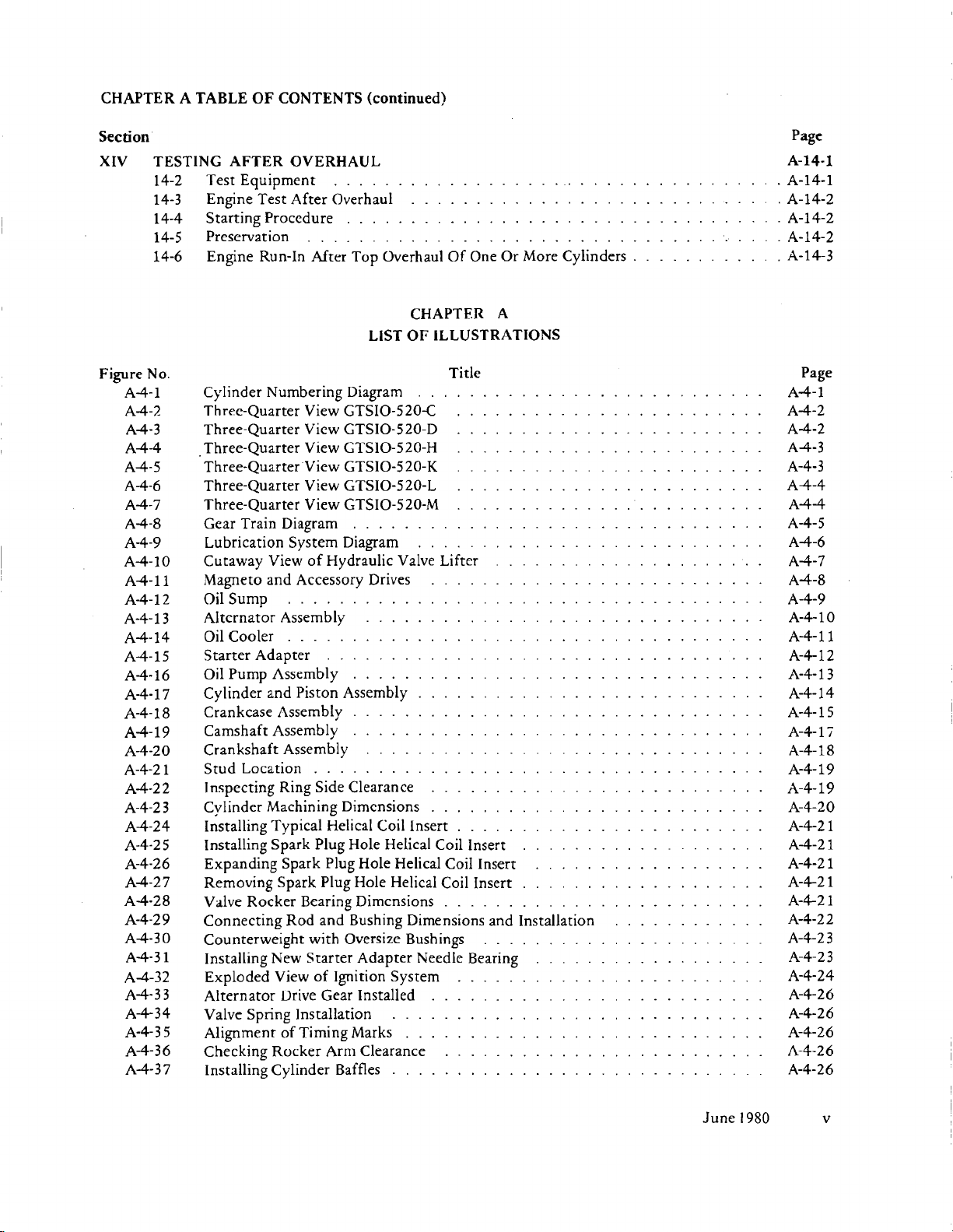

CHAPTER

A

TABLE

CONTENTS

OF

(continued)

Section

XIV

Figure

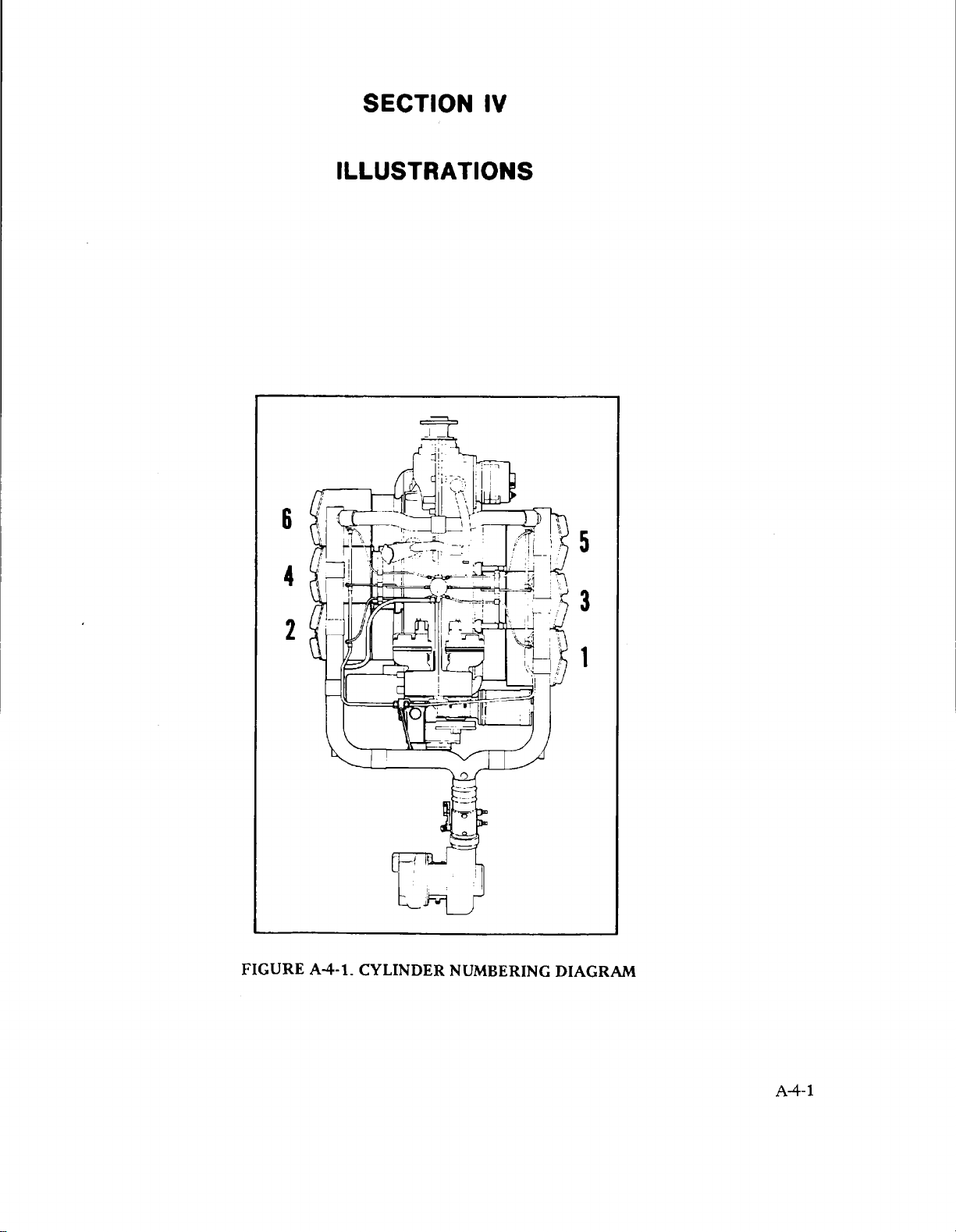

A-4-1

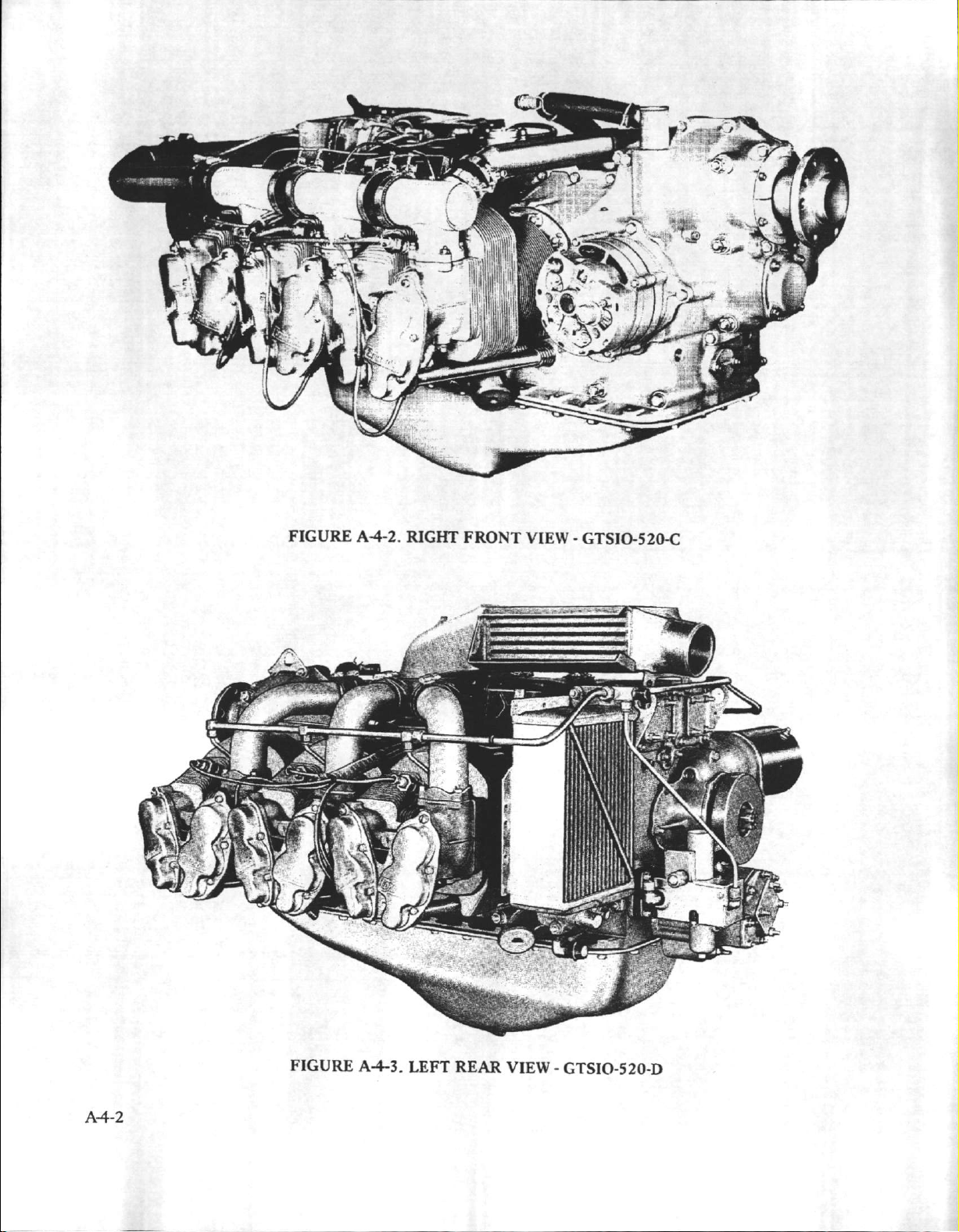

A-4-2

A4-3

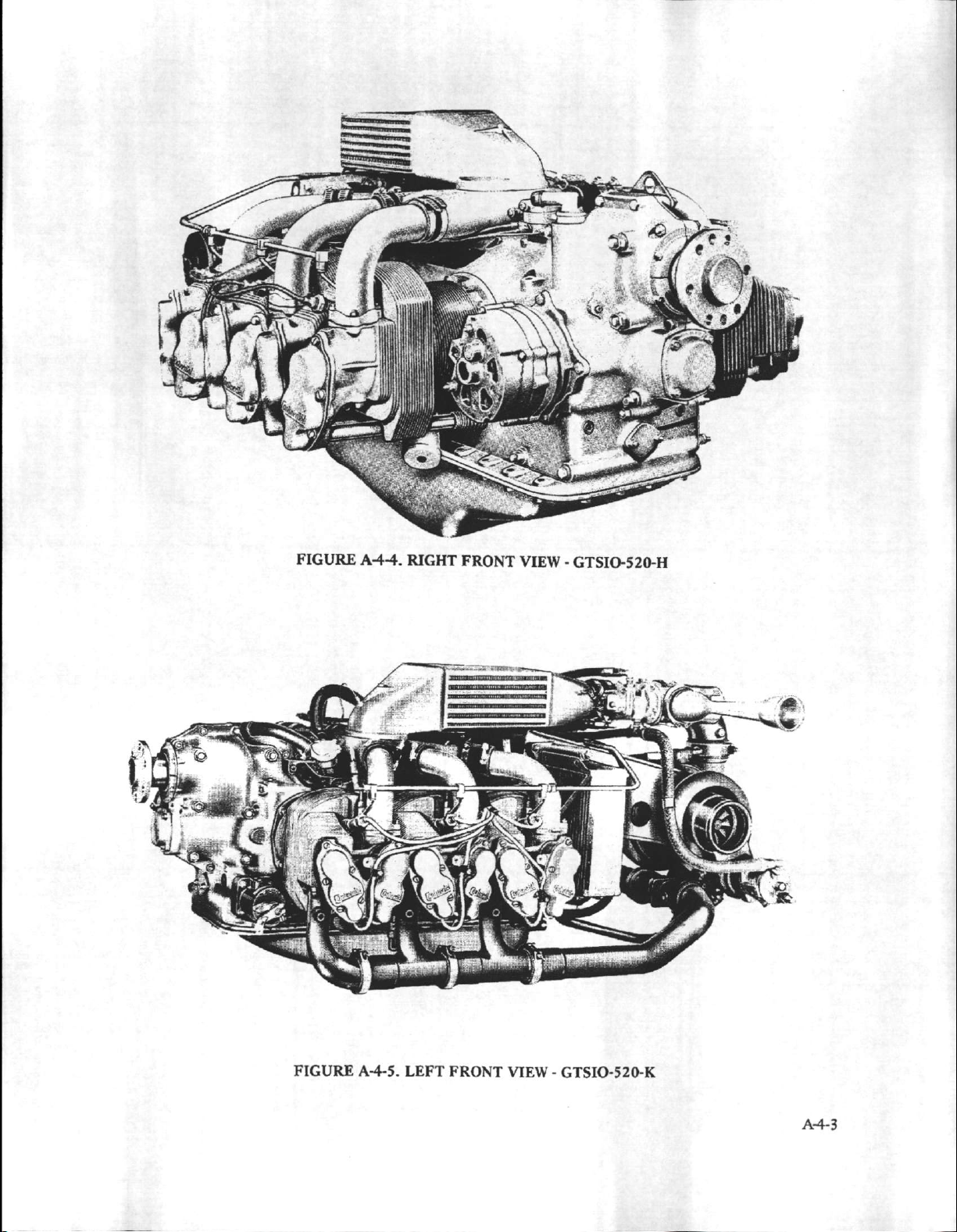

A4-4

A-4-5

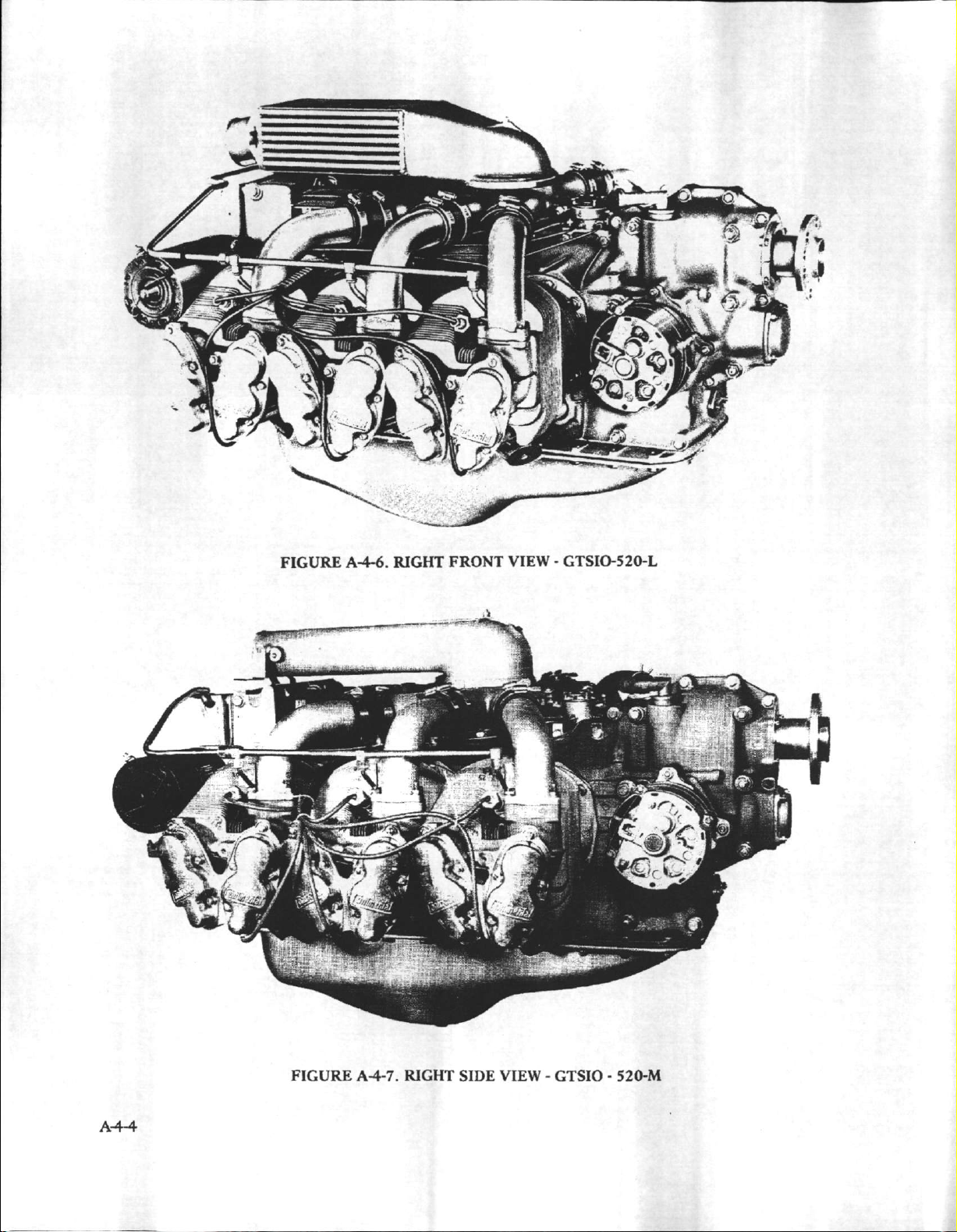

A4-6

A4-7

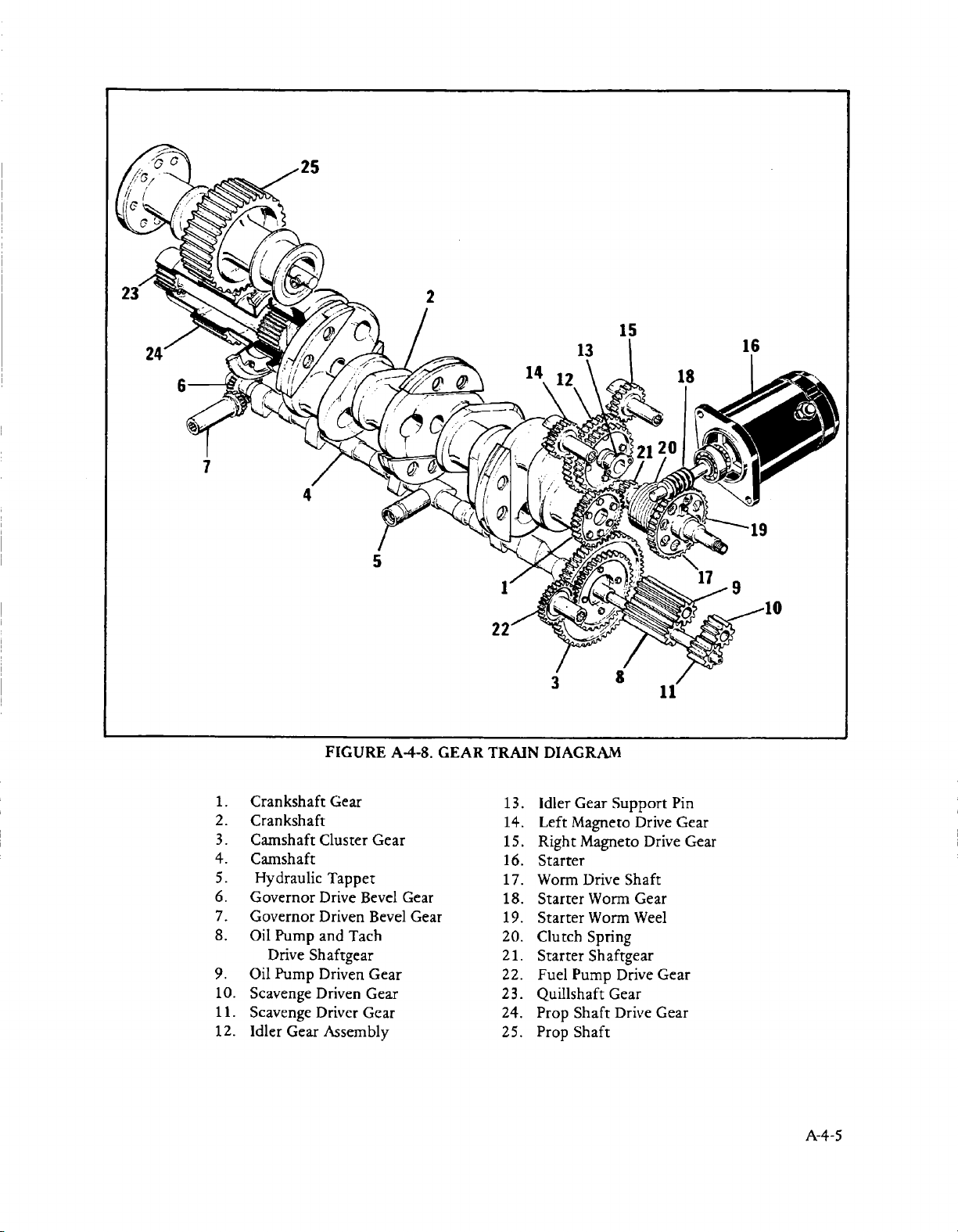

A-4-8

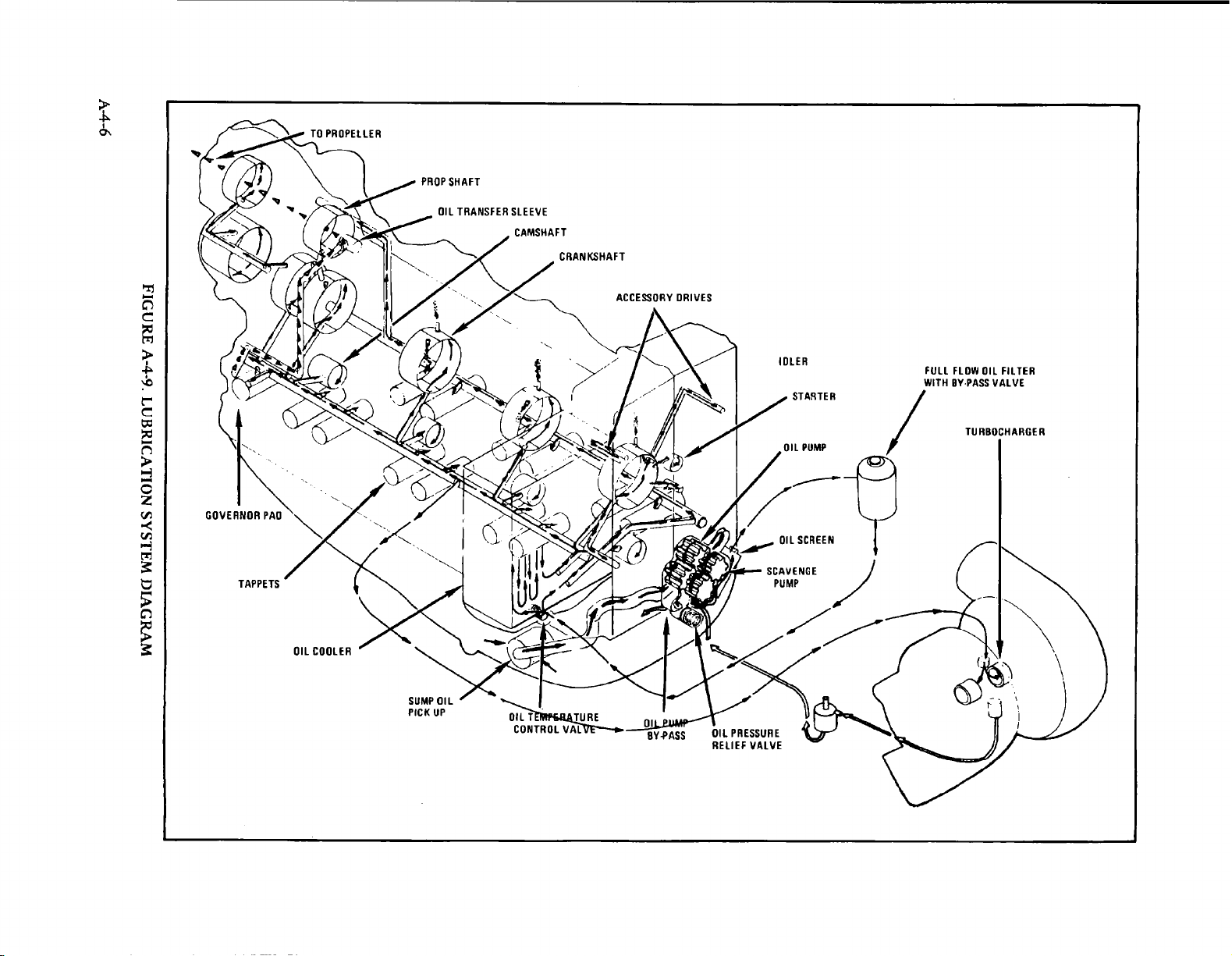

A-4-9

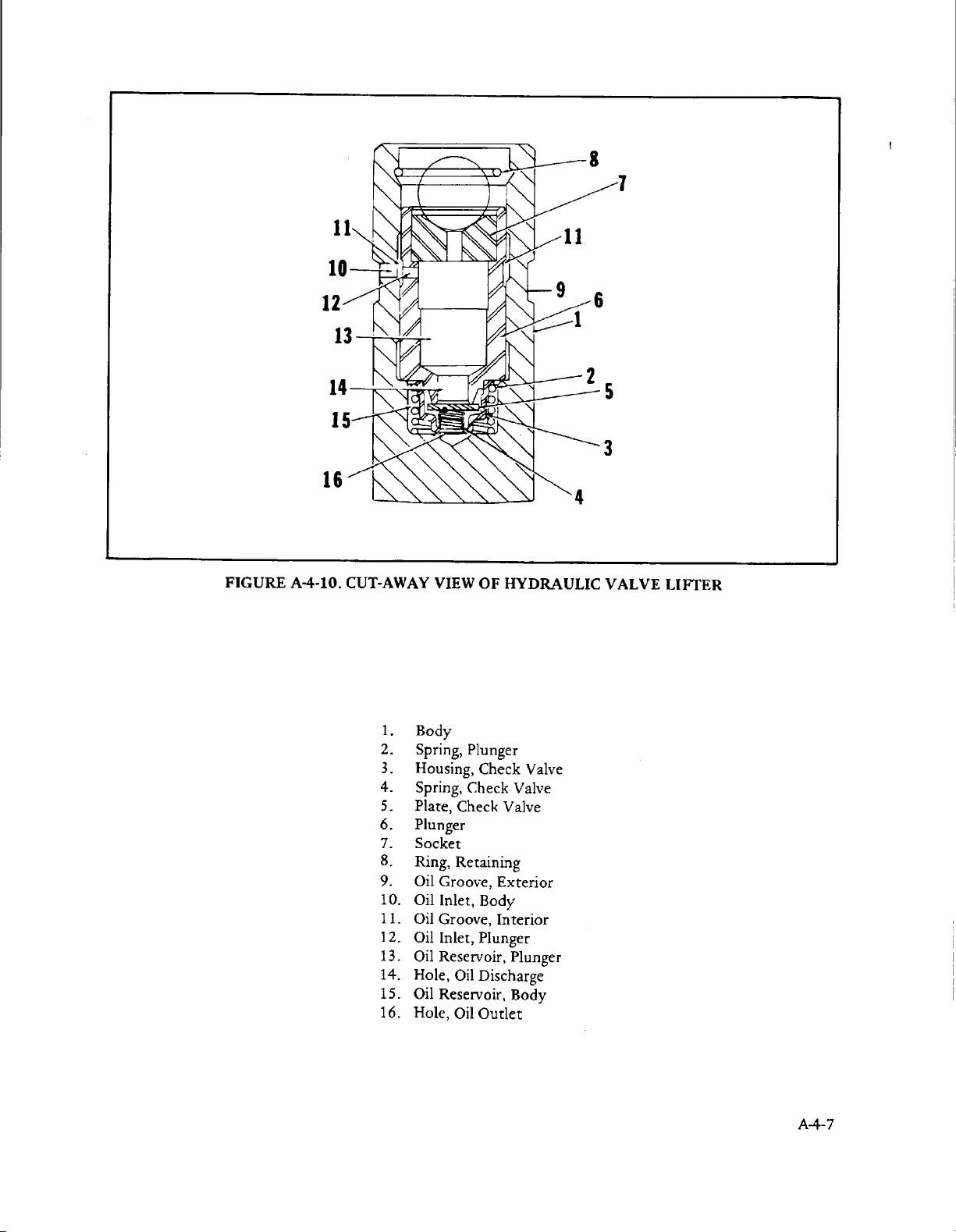

A4-10

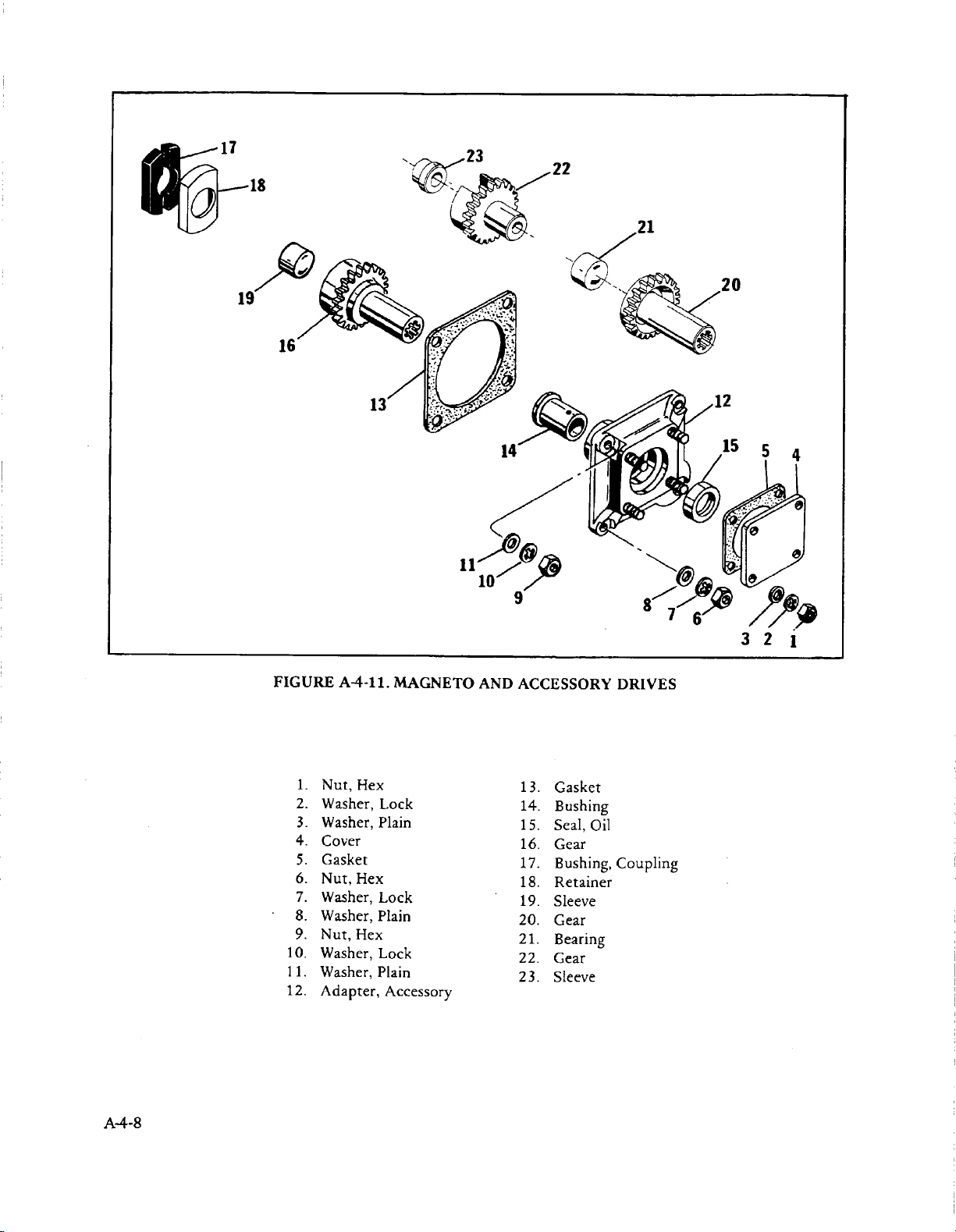

A4-1

A-4-12

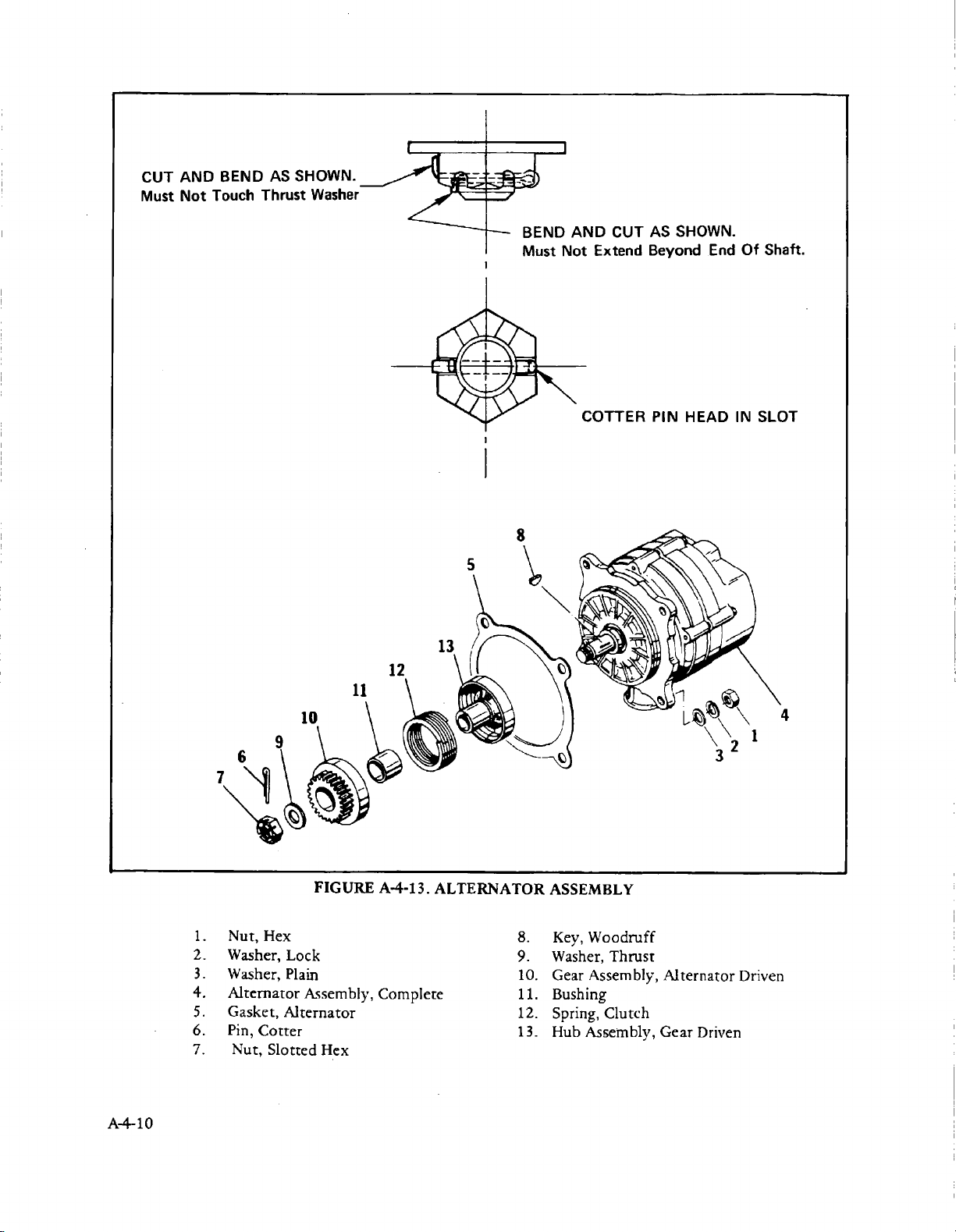

A-4-13

A4-14

A.4-15

A4-16

A4-17

A4-18

A4-19

A-4-20

A-4-2

A-4-22

A-4-2

A-4-24

A-4-2

A-4-26

A-4-27

A4-28

A-4-29

A4-30

A4-31

A-4-32

A4-33

A-4-34

A-4-

A-4-36

A-4-

TESTING

14-2

14-3

14-4

14-5

14-6

No.

1

1

3

5

35

37

AFTER

Equipment

Test

Engine

Starting

Test

Procedure

Preservation.

Engine

Cylinder

Run-In

Numbering

Three-Quarter

Three-Quarter

Three-Quarter

Three-Quarter

Three-Quarter

Three-Quarter

Diagram

Train

Gear

Lubrication

Sump.

Cooler.

Adapter

Pump

Location.

Rocker

View

and

Assembly.

Assembly.

and

Assembly.

Assembly.

Assembly.

Ring

Machining

Typical

Spark

Spark

Spark

Rod

Cutaway

Magneto

Oil

Alternator

Oil

Starter

Oil

Cylinder

Crankcase

Camshaft

Crankshaft

Stud

Inspecting

Cylinder

Installing

Installing

Expanding

Removing

Valve

Connecting

Counterweight

Installing

Exploded

Alternator

Valve

Alignment

Checking

Installing

New

View

Drive

Spring

of

Rocker

Cylinder

OVERHAUL

....................

Overhaul.

After

......

.....................................

Overhaul

Top

After

LIST

Diagram

GTSIO-5

View

CTSIO-520D

View

CTSIO-5

View

GTSIO-5

View

GTSIO-520-L........................

View

GTSIO-520-M.

View

................................

System

Diagram.

of

Hydraulic

Accessory

Valve

Drives

....................................

..............................

....................................

..................................

...............................

Assembly.

Piston

...............................

...............................

..............................

..................................

Clearance.

Side

Dimensions.

Helical

Plug

Plug

Plug

Bearing

and

with

Starter

of Ignition

Gear

Coil

Helical

Hole

Helical

Hole

Helical

Hole

Dimensions.

Bushing

Oversize

Adapter

System.

Installed.

Installation.

Arm

Marks.

Clearance.

Timing

Baffles.

...........................

One

Of

Or

CHAPTER A

ILLUSTRATIONS

OF

Title

...........................

20-C.

.......................

.......................

20-H

20-K.

........................

.......................

.......................

..........................

Lifter.

..........................

..........................

........................

.........................

Insert.

.......................

Insert.

Coil

Coil

Insert.

Coil

Insert.

........................

Dimensions

Bushings.

Needle

and

.....................

Bearing.

.......................

.........................

............................

...........................

........................

............................

............

More

....................

..................

.................

..................

Installation.

.................

Cylinders.

...........

...........

..

Page

A-

14-1

A-14-1

A-14-2

A-14-2

A-14-2

A-14

Page

A4-1

A4-2

A-4-2

A4-3

A-4-3

A4-4

A44

A-4-5

A4-6

A4-7

A4-8

A-4-9

A-4-1

A-4-1

A4-12

A-4-13

A-4-14

A-4-15

A-4-17

A-4-18

A-4-19

A-4-19

A-4-20

A-4-2

A-4-21

A-4-2

A-4-2

A-4-2

A-4-2

A-4-2

A-4-23

A-4-24

A-4-26

A-4-26

A-4-26

A-4-26

A-4-26

3

0

1

1

1

1

1

2

3

June

1980

v

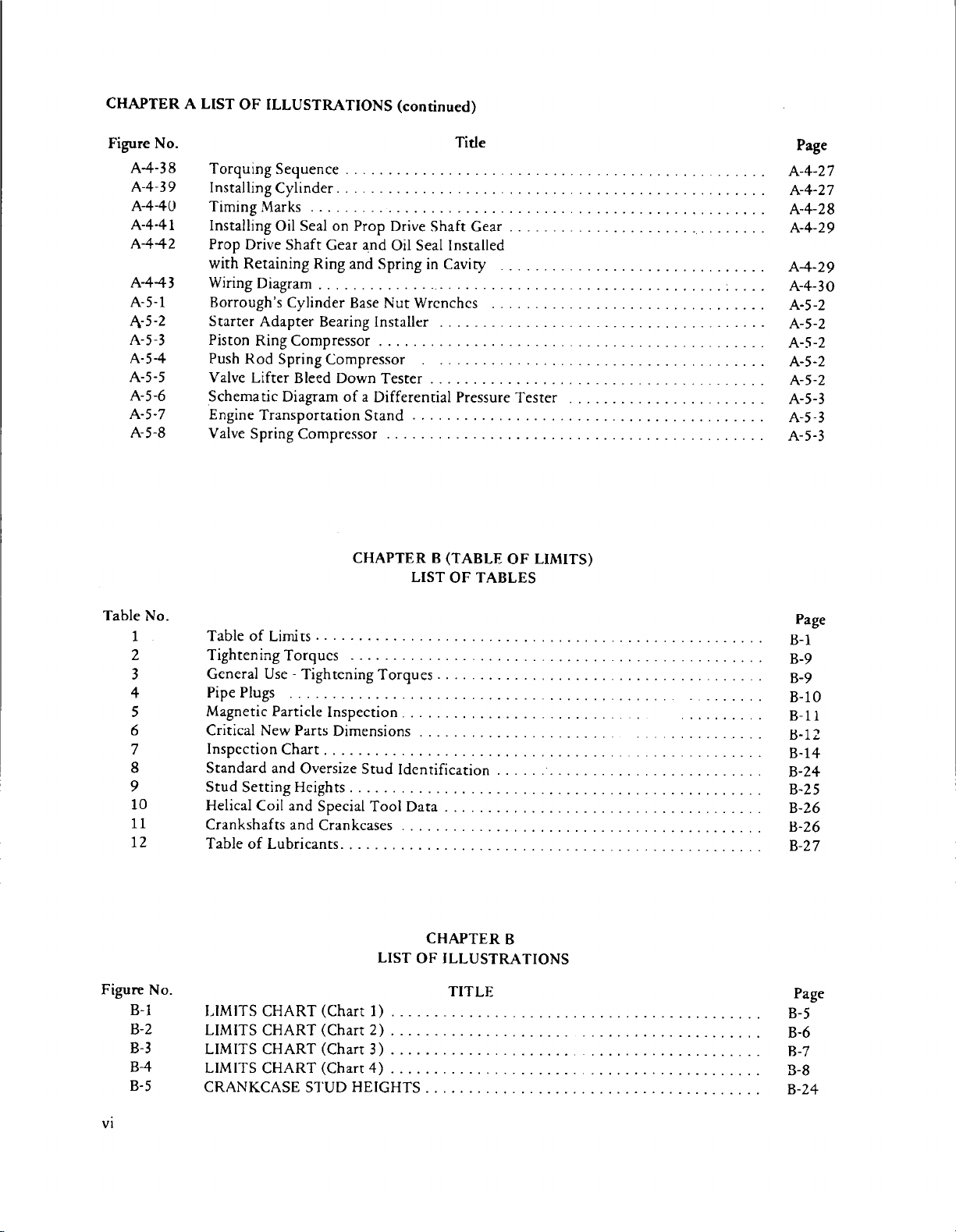

CHAPTER

Figure

No.

A-4-38

A-4-39

A-4-40

A-4-41

A442

A-4-43

A-5-1

A-5-2

A-5-3

A-5-4

A-5-5

A-5-6

A-5-7

A-5-8

A

LIST

Torquing

Installing

Timing

Installing

Prop

with

Wiring

Borrough's

Starter

Piston

Push

Valve

Schematic

Engine

Valve

OF

ILLUSTRATIONS

(continued)

Title

Sequence

.........................

Cylinder..........................

Marks

...........................

Oil

Seal

on

Prop

Drive

Shaft

Gear

................

Drive

Shaft

Retaining

Gear and

Ring

and

Oil

Spring

Seal

in

Installed

Cavity

.

. .. .

Diagram....................................................

Cylinder

Adapter

Ring

Compressor

Rod

Spring

Lifter

Bleed

Diagram

Transportation

Spring

Compressor.......................

Base

Nut

Bearing

Installer....................

.......................

Compressor.

Down

Tester

of

a

Differential

Stand

Wrenches.................

...................

....................

Pressure

Tester

.....................

. . .

............

. . .

... .

.

Page

A-4-2

A-4-27

A-4-28

A-4-

29

A-4-29

A-4-3

A-5-2

A-5

-2

A-5-2

A-5-2

A-

5-2

A-5-3

A-5-3

A-5-3

7

0

Table

1

2

3

4

5

6

7

8

9

10

11

12

Figure

B-1

B-2

B-3

B-4

B-

No.

No.

5

Table

of

Limits......................

Tightening

General

Pipe

Magnetic

Critical

Inspection

Standard

Stud

Helical

Crankshafts

Table

LIMITS

LIMITS

LIMITS

LIMITS

Torques....................

Use

Plugs

.......................

Particle

New

Chart

and

Setting

Coil

and

and

of

Lubricants

CHART

CHART

CHART

CHART

CRANKCASE

CHAPTER

-Tightening

Torques...............

Inspection...............

Parts Dimensions

.....................

Oversize

Stud

Identification

Heights....................

Special

Tool

Data

Crankcases.................

....................

LIST

(Chart

(Chart

(Chart

(Chart

STUD

1) ............

2)

............

3)

............

4)

............

HEIGHTS

B

(TABLE

LIST

OF

TABLES

...............

...........

..............

CHAPTER

OF

ILLUSTRATIONS

TITLE

..........

OF

B

LIMITS)

....................

....................

....................

....................

....................

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

Page

B-1

B-9

B-9

B- 10

B-11

B-

B-14

B-24

B-2

B-26

B-26

B-2

Page

B-5

B-6

B-7

B-8

B-24

12

5

7

vi

CHAPTER

TABLE

C

(DIFFERENCE

OF

CONTENTS

DATA)

Section

II.

1.

DIFFERENCE

General

Detail

Operating

Major

Start

Oil

Fuel

Injection

Cleaning,

Reassembly................................C-1-6

Induction

Cleaning,Inspection

Reassembly...............................

Crankcase

Magneto

Cleaning,Inspection

Reassembly

Turbocharger

Improved

DIFFERENCE

General

Detail

Operating

Major Overhaul

Start

Oil

Fuel

Injection

Disassembly...............................C-2-6

Cleaning,

Reassembly...............................C-2-6

Induction

Disassembly...............................C-2-7

Cleaning,Inspection

Reassembly...............................C-2-7

Turbocharger

Improved

DATA

Information

Engine

Test

Overhaul

SECTION

Specifications

Limits

Test

Run..........................C-i-5

Consumption

System

Inspection

System.............................C-1-6

................................

and

Accessory

...............................

Valve Stem

DATA

Information

Engine

Test

Consumption

Inspection

System

Oil

Valve

and

and

and

Oil

Inlet

SECTION

..............................

Specifications

Limits...........................C-2-4

Test

Run

System...........................C-2-6

and

............................

and

Inlet

Stem

FOR

THE

MODEL

...............-.............

........................

...........................

Determination

...........................

Repair

Repair

Drives........................C-i-7

Repair........................C-1-7

Adapter

and Guide

.........................

Determination.....................C-2-6

Repair

Repair........................C-2-7

Adapter .......................

and

.......................

........................

.......................

Q

FOR

THE

MODEL

........................

.......................

Guide

Lubrication..................C-2-7

GTSIO-520-C

GTSIO-520-D

Page

C-1-1

C-1-2

C-1-2

C-1-4

C-1-5

C-1-6

C-1-6

C-1-7

C-1-7

C-1-7

Cx1-7

C-1C-1-

C-2-1

C-2-2

C-2-2

C-2-5

C-2-6

C-2-7

C-2-7

III.

DIFFERENCE

General

Detail

Operating

Major

Start

Oil

Fuel

Injection

Disassembly...............................C-3-6

Cleaning,

Reassembly...............................C-3-7

Induction

Disassembly...............................C-3-7

Cleaning,Inspection

DATA

Information

Engine

Overhaul

Specifications

Test

Consumption

System...........................C-3-6

Inspection

System

SECTION

...........................

Limits...........................C-3-4

Test

Run..........................C-3-5

Determination.....................C-3-5

and

Repair

............................

and

Repair

FOR

THE

........................

.......................

.......................

MODEL

GTSIO-5

20-H

C-3-1

C-3-2

C-3-2

C-3

C-3-7

C-3-7

-6

vii

CHAPTER C TABLE

OF

CONTENTS

(continued)

Section

III

IV.

CONTINUED

Reassem

Improved

bly...............................C

Valve

Turbocharger

DIFFERENCE

General

Detail

Operating

Major

Start

Oil

Exhaust

Removal

Assembly

Hot

Prime

Removal

Assembly

Induction

Removal

Assembly

Oil

Sump...............................

Removal

Assembly

Oil

Cooler

Removal

Assembly

Oil

Pump

Removal

Assembly

DATA

Information...........................CA4-2

Engine

Test

Overhaul

Consumption

Assembly............................

and

and

Equipment...........................C-4-6

and

and

System

and

and

and

and

................................-

and

and

Assembly

and

and

Stem

and

Guide.......................C-3-7

Oil

Inlet

Adapter

SECTION

Specifications

.......................

FOR

THE MODEL

........................

Limits...........................C-4-4

Test

Run

.........................

Determination.....................C-4-5

Disassembly.........................

Installation

.........................

Disassembly.........................

Installation

.........................

.............................-

Disassembly

Installation

Disassembly

Installation

..........................

.........................

..........................-

.........................

Disassembly.........................CA4-7

Installation

.........................

............................

Disassembly

Installation

..........................-

.........................

GTSIO-5

20-K

Page

3-7

C-3-8

C-4-1

C-4-2

C-4-5

C4-6

C4-6

C-4-6

C4-6

C4-6

4-6

4-6

C-4-7

C4-47

4-7

C4-7

4-7

C-4-7

-4-7

4-7

C-4-7

Viii

V.

VI.

DIFFERENCE

General

Detail

Operating

Major

Start

Oil

Induction

Cleaning,

DATA

Information

Engine

Specifications

Test

Overhaul

Consumption

System

Repair

SECTION

............................-

Limits

...........................

Test

Run

.........................

Determination.....................C-5-5

............................

and

Replacement

FOR

.........................-

Reassembly...............................C-5-6

Fuel

Injection

Cleaning,

Reassembly

DIFFERENCE

System...........................C-5-6

Inspection

and

Repair

...............................

DATA

SECTION

FOR

......................

General Information............................C-6-2

Detail

Engine

Operating

Top

or Minor

Start

Oil

Induction

Specifications

Test Limits

and

Major

Consumption

System

............................

........................

...........................

Overhaul

Determination

THE MODEL

......................

THE

MODEL

Test

Run

...................-

.....................

GTSIO

520-L

GTSIO-520-M

C-5-1

5-2

5-2

2-5-4

C-5-5

C-5-6

-5-6

C-6

-5-6

C-6-1

C-6-2

-6-4

6-5

C-6-5

C-6-6

CHAPTER

C

TABLE

OF

CONTENTS

(continued)

Section

VI

VII.

CONTINUED

Cleaning,

Repair

and

Replacement......................C-6-6

Reassembly...............................C-6-6

Fuel

Injection

Cleaning,

System...........................C-6-6

Inspection

and

Repair.......................C-6-6

Reassembly...............................C-6-6

DIFFERENCE

General

Detail

Engine

Operating

Special

Major

Start

Overhaul

Oil

Inducation

Cleaning,

DATA

Information

SECTION

.............................

Specifications..........................C-7-2

Test

Test

Limits

Items

............................

Required

Test Run...........................C-7-6

Consumption

Determination

System..............................C-7-7

Repair

and

Replacement.......................C-7-7

Reassembly.................................C-7-7

Fuel

Injection

Cleaning,

Reassembly

Fuel

Injection

System ............................

Inspection

and

Repair........................C-7-7

.................................

Adjustment

LIST

FOR

THE

MODEL

or

Equivalent

...................

.....................

Procedures....................C-7-18

CHAPTER

OF

ILLUSTRATIONS

C

GTSIO-520N

Page

C-7-1

C-7-2

C-7-4

C-7-5

C-7-6

C-7-7

C-7-7

Figure

C

CCC-1-4

C-1-5

C-1-6

C-1-7

C-1-8

C-2-1

C-2-2

C-2-3

C-2-4

C-2-5

C-3-1

C-3-2

C-3-3

C-3-4

C-3-5

C4-1

C4-2

C4-3

C-4-4

C-4-5

No.

11

12

1-3

Fuel

Injections

Induction

Crankcase

Magneto

Fuel

Control

Fuel

Cran

Fuel

and

Manifold

Valve

Pump

kcase

Injections

Induction

Fuel

Manifold

Control

Fuel

Fuel

Valve

Pump

Injection

Induction

Control

Manifold

Fuel

Exhaust

[lot

Fuel

Valve

Valve

Pump

Assembly

Prime

Injection

Induction

Oil

Sump(GTSIO-5

System

System

(GTSIO-520-C)

Assembly

Accessory

Valve

Fitting

Fitting

Stud

Setting

System

System

(GISIO-520-D)

Valve

Fitting

Fitting

System

System

(GTSIO-520-H)

Fitting

Fitting

Fitting

Equipment

System

System

(GTSIO-520-K)

Title

(GTSIO-520

C)

....................

......................

(GTSIO-5

Fitting

Locations

Locations

Heights

(GTSIO-520

20-C)

.....................

Drives

(GTSIO-520-C)

Location

(GTSIO-520-C)

(GTSIO-520-C).................C-1-14

(GTSIO-520-C)..................C-1-15

.......................

D)

....................

......................

Fitting

Locations

Locations

Locations

(GTSIO-520-D)..................C-2-13

(GTSIO-5

(GTSIO-520-D)

(GTSIO-5

20-H)

....................

......................

Locations

Locations

Locations

(GTSIO-520-K).

(GTSIO-5

(GTSIO-520

(GTSIO-520-H)

(GTSIO-5

20-H)..................C-3-14

.~....................C4-8

20-K)....................

(GTSIO-520-K)....................

......................

20-K).........................

.................

..............

..............

20-D).................C-2-12

H).................C-3-12

................

Page

C-1-9

C-1-10

C-1-11

C-1-12

C-1-13

C-1-16

C-2-9

C-2

-10

C-2-11

C-3-9

C-3-11

C-3-13

C4-9

C4-10

C4-11

C4-13

MARCH

1981

ix

CHAPTER

C

LIST

OF

ILLUSTRATIONS

(continued)

Figure

C-4-6

C-4-7

C-4-8

C-4-9

C-4-10

C-4-11

C-5-1

C-5-2

C-5-3

C-5-4

C-5-5

C-5

C-6-1

C-6-2

C-6-3

C-6-4

C-6-5

C-6-6

C-7-1

C-7-2

C-7-3

C-7-4

C-7-5

C-7-6

No.

-6

Oil

Cooler

Oil

Pump

Crankcase

Fuel

Pump

Fuel

Manifold

Air

Throttle

Induction

Fuel

Injection

Manifold

Control

Fuel

Pump

Crankcase

Induction

Fuel

Injection

Manifold

Control

Fuel

Pump

Crankcasc

Induction

Fuel

Injection

Manifold

Fuel

Control

Fuel

Pump

Crankcase

(G'TSIO-5

20-K)...........

Assembly(GTSIO-520-K)

Stud

Fitting

System

Valve

Valve

Fitting

Stud

System

Setting

Fitting

&

Controller

System

Fitting

Fitting

Setting

Heights

Locations(GTSIO-5

Locations

Fitting

(GTSIO-520

(GTSIO-520L)

Locations

Locations

Locations

Heights

(GTSIO-520-M)........

System (GTSIO-520-M)

Valve

Valve

Fitting

Stud

System

Valve

Fitting

Stud

Fitting

Fitting

Setting

System

Fitting

Locations

Locations

Locations

Hcights(GTSIO-520-M)

(GTSIO-520-N)......................C-7-9

(GTSIO-520-N)

Fitting

Locations

Locations

Locations

Setting

Heights

Tide

.......

(G'TSIO-520-K)

..

20-K)....

(GTSIO-5

Locations

L)

........

20-K)..

(K)

...

......

(GTSIO-5

20-L)

..

(GTSIO-520-L)...

(GTSIO-520-L)....

(GTSIO-5

20

M).

......

(GTSIO-520-M)

(GTSIO-520-M)

(GTSIO-5

20-M)....

...

...................

(GTSIO-520-N)...............C-7-11

(GTSIO-520-N)

(GTSIO

520-N)

................

(GTSIO-520-N)...............C-7-14

..

..

..

.. .

..

..

..

.. . .

.. .

..............

.. . .

.............

.. . .

.. . .

.. .

.. .

..

...............

. . .

. . .

. .

. . . .

. . .

. . .

. .

. . .

. . .

. . ..

.

. .

. . .

. . .

. .

. .

. . .

. . .

. .

. .

. . .

. . .

. . .

. . .

. . .

. ..

. .

. .. . . .. .. .. .

. .

. . .

. . .

. .

. .

. . .

. . .

. . . .

. .

. .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . . .

. . .

. ... . . . .

.. .

. .

. .

. .

.

.

. ...

.

.C-6-1

.

.C-6-11

.C -6-12

.

.C-6-13

C-7-10

C-7-12

C-7-13

Page

.C

-4-14

.C

-4-15

.C-4-16

.C-4-17

.C-4-18

C4

-19

.C-5-8

.C-5-9

.C-5

C-5-1

.C-5-12

C-513

.C-6-8

.C-6-9

10

1

0

Graph

C-7-1

C-7-2

C-7-3

No.

Fuel

Flow

100%

Meterer

Limits

Power

Fuel

(GTSIO-520-N)......................C-7-15

Fuel

Pump

Pressure

Pressure

vs.

Fuel

Limits

Flow

(GTSIO-520-N).............C-7-17

(GTSIO-520-N)...........C-7-16

x

MARCH

1981

SECTION

I

INTRODUCTION

1-1.

1-2.

structions

hereafter

is a 6

charged,

manufacturered

Aircraft

1-3.

1-4.

overhaul

and

vided

Data

1-5.

numbers

contained

instructions

as

X-30079,

30129,

30533,

a.

Starter

Prestolite

51

b.

Magnetos

Components

C.

Starter

Delco-Remy

Anderson,

SCOPE.

This

cylinder

fuel

Products

DIFFERENCE

Sections

instructions

test

instructions

in

the

Sections.

RELATED

and

follows:

GTSIO-520-F,

GTSIO

and

Service

and

Company,

1

Hamilton

Service

may

Service

and

for

referred

in

GTSIO-520-C,

GTSIO-520-N,

Indiana.

Chapter

a

hypothetical

to

horizontally

injected,

by

I

thru

latter

sections

PUBLICATIONS.

service

Parts

Catalog

are

contained

520-L,

instructions

Alternator

Street,

instructions

be

obtained

Division,

instructions

Alternator

Division,

comprises

as

the

opposed,

air

cooled,

Teledyne

Division,

DATA

XIV

for

the

for

specific

by

assemblies

in

X-30047;

X-30128,

X

30532,

X-30551.

may

Division

Toledo,

from

Sidney,

may

General

the

GTSIO-520

"basic"

geared,

4

Continental

Mobile,

SECTIONS.

of

this

manual

basic

engine.

models

the

use

for

this

X-30046A.

Operator's

GTSIO-520-D,

GTSIO-520-H,

GTSIO-520-M,

for

the

be

obtained

of

Eltra

Ohio

43601.

for

Bendix

New

York

for

the

be

obtained

Motors

overhaul

engine,

engine.

cycle

of

Detail

Handbooks

Corporation,

the

Delco-Remy

Corporation,

This

turbo-

engine

Motors,

Alabama.

contain

Overhaul

are

pro-

Difference

part

engine

Operating

Prestolite

from

Bcndix

Electrical

13838.

from

in-

are

X-

X-

the

1-6.

and

engine

position,

1-7.

are

numbers

1-8.

BEFORE

anyone

first

approval

45,

In

will

to that

serial

approval.

The

submitted

approval,

current

handling,

permanently-stamped

Because

in

wll

the

All

should

shipment:

DEFINITION

right,

as

facing

CYLINDER

numbered

on

AIRCRAFT

a

contact

from

Section

addition,

be

necessary

effect,

number

old

and

price

we

the

past,

not

be

remittance

request,

be

as

used

viewed

the

starting

the

right

Teledyne

new

nameplate,

his

them

45.13

if

the

giving

along

nameplate

to

TCM

a

remittance

list

stamping

did

not,

we

wish

supplied

is

received

along

sent

to

Teledyne

Attn:

P.

0.

Mobile,

(b).

the

Box

OF

TERMS.

in

this

manual,

by

the

mechanic

accessory

ARRANGEMENT.

and

Continental

local

in

old

to

supply

with

along

to

cover

and

nameplate.

in

to

at

the request

with

following

Continental

Service

90

Alabama

end.

from

the

even

ENGINE

the

person

FAA

accordance

nameplate

a

the

engine

the

(when

with

in

the

costs

mailing

all

cases,

emphasize

with

the

Department

36601

numbers

office

notarized

evidence

available)

evidence

make

the request.

correct

address

Front,

rear,

refer

to

in

a

normal

Cylinders

rear,

with

on

the

NAMEPLATES.

Motors

has

amount

involved

that

of anyone

Motors

involved

and

with

been

model

of

it

mandatory

a

remittance,

to

can

issue

must

obtain

FAR

Part

lost,

statement

and

of

FAA

must

of

FAA

listed

in

a

new,

nameplate

unless

expedite

left

the

odd

left.

it

full

be

in

the

OCTOBER

1980

A-1-1

If,

for

any

the

status

and

ask

inquiry

specifying

1-

9.

DEFINITIONS

Term

A.B.C.:

Approx.:

A.T.C.:

Bar.:

B.B.C.:

B.T.C.:

F.A.A..:

c.f.m.:

Dia.:

0

F:

Fig.:

Front:

ft.:

G.P.M.:

1120:

Hg.:

reason,

of

for

to

"Attn:

your

"Service

the

it

becomes

nameplate,

Department,"

Mobile

Service

Department."

AND

Explanation

After

Bottom

Approximately

After

Top

Center

Barometric

Before

Brake

Before

Federal

Cubic

Center

Bottom

Horsepower

Top

Aviation

feet

per

of Gravity

Diameter

Degrees

Degrees

Figure

Propeller

Foot

Gallons

of

Angle

Fahrenheit

(Illustration)

End

or feet

per

Water

Mercury

Inside

Diameter

necessary

to

call (205)

or

address

address

given

ABBREVIATIONS

Center

Center

Center

Administration

minute

minute

check

438-34

your

above

on

11

Term

in.(");

Hex.;

hr.:

Left

Side:

Lbs.:

Lock

Man.:

Max.:

Min.:

3

0':

N.P.T.:

N.C.:

N.

F.:

O.D.:

Press.:

pS.i.:

Rear:

Right

R.

P.M.:

Std.:

T.

D.

C.:

Temp.:

Torque:

Wire:

Side:

Explanation

Inches

Hexagon

Hour

Side

on

cylinders

Pounds

Soft

steel

nections,

Manifold

Maximum

Minimum

Thirty

one

National

National

National

outside

minutes

degree)

pipe

Coarse

Fine

Diameter

Pressure

Pounds

per

Accessory

Side

on

which

cylinders

are

Revolutions

Standard

Top

dead

Temperature

Force

torque

ft.

applied

from

x

=

125

bolt

2

which

are

located

wire

etc.

or

manometer

thread

(thread)

square

end

of

No.'s

located

per

center

lever

lbs.

center

ft.

from

No's

used

of

angle

(thread)

inch

engine

minute

arm

force

center)

2,

to

safety

(60'

(tapered)

1,3

and

(125

applied

or

62-1/2

4

ft.

5

and

con-

equal

-

6

lbs.

one

lbs.

A-1-2

MARCH

1981

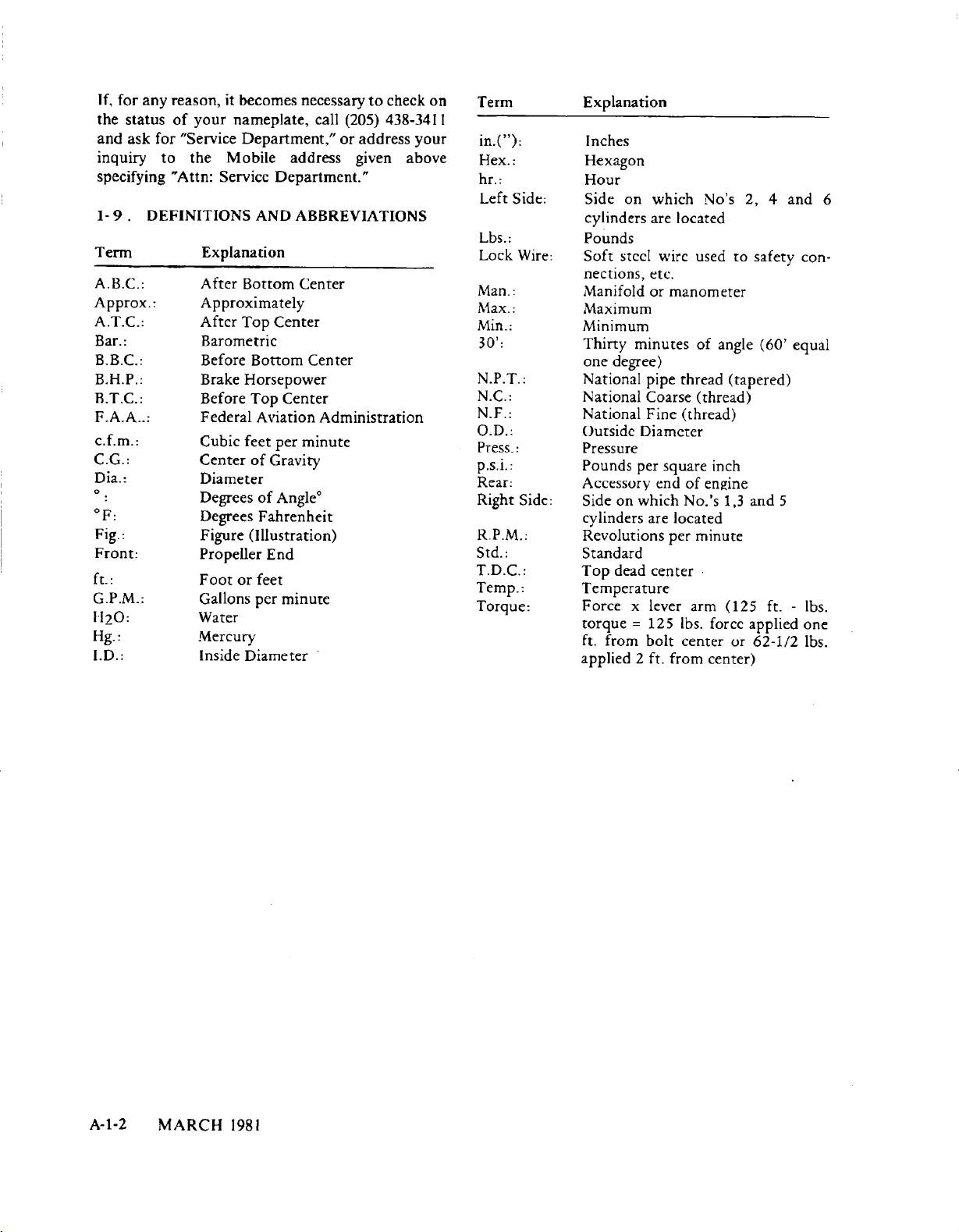

PURCHASED

ACCESSORIES

TEMPERATURE

TMEAUELMT

LIMITS

Accessory

Controller...................

Regulator

Magneto.

Assembly,

...................

Starter.....................

Alternator...................

Turbocharger.................

Oil

Cooler

...................

Intercooler..................

Fuel

Pump

.1..........

Spark

Plugs.

.................

IGNITION

Feature

Left

upper

Right

and

Firing

magneto

No.

magneto

lower

2,

No.

order

fires

4,

6

plugs.

fires

2,

4,

(cylinder

lower

6

5-2-3-6

Fuel

Pressure......

SYSTEM

No.

upper

plugs

numbers)

DETAILS

1,

3,

No.

1,

5

and

3, 5

1-4-

.

Qty.

12

Value

1

1

2

1

1

1

1

1

Indicated

Oil

temperature

Oil

temperature

Cylinder

(bayonet

Magneto

(at

coil

*

Installed

with

downdraft

Indication

Oil

pressure

Oil

pressure

Oil

pressure

Airport

Condition

at

head

temperature

thermocouple)*

temperature

hold-down

in

tapped

holc

cooling

PRESSURE

(idling)

(in

flight)

(

with

OIL

VISCOSITY

Ambient

Air

take-off

screw)

in

bottom

system.

of

LIMITS

cold

oil)

Temperature

Minimum

75F

-

-

-

cylinder

hcad.

Minimum

10

psi

30

psi

-

GRADES

S.A.E.

Maximum

-

0

240

F

0

460

F

170F

Applicable

Maximum

-

60

psi

100

psi

Grade

only

CHARACTERISTICS

Dimension

Piston

Number

Cylinder

Piston

strokes

stroke

of

cylinders

bore

per

(in.)..........

(in.)

cycle........

.........

.

.

.

AND

DIMENSIONS

.

.

All

Va

due

4

6

Temperatures

Or

if

Temperatuers

Below

400

Above

400

Are:

F.

F.

15W

20W

30

50

or

-

50,

-

50

10W

-

30

5.25

.

.

.

.

4

Ambient

Air

Temperature

June

(Sea

1980

Level)

A-2-1/A-2-2

SECTION

III

3-1.

a.

appearance

illustrated

information

Lubrication

b.

ings

form

ings

the

throughout

1.

line

bearings

cision,

main

the

propeller

through

governor

into

main

starter

2.

case

pads

necting

pad

attaching

mount

crankcase

pad

CONSTRUCTION.

GENERAL.

CRANKCASE.

are

joined

the

(with

"left

Bosses

bored

steel-backed,

bearing

crankcase

lateral

the

bearing,

shaftgear.

Cylinder

are

on

rod

has

pad

is

located

of

engine

in

Section

will

Charts.

along

complete

studs

crankcase"

this

publication.

molded

in

the

for

the

inserts.

halves

driveshaft.

bosses

drive

shaft.

right

crankcase,

to

mounting

further

the

right

to

work

six

studs

cylinder

is

located

at

the

lower

on

The

parts

IV,

be

found

Two

the

crankcase.

and

inserts)

and

in

assembled

camshaft

lead-alloy

Provision

at

the

Precision

for

A

support

forward

crankcase

on

and

base

front

the

right

and

Chapter

aluminum

vertical

will

the

the

crankcase

and

top

the

needle

to

the

the

pads

than

a

separate

two

flanges.

on

the

corner.

crankcase

GENERAL

arrangement

components

A.

Additional

in

the

Limits

alloy

The

be

"right

castings

seats

lined

has

front

guides

tappets

bearing

right

front

on

the

to

permit

through

side

center

crankpin.

plane

individual

referred

crankcase"

castings

to

for

the

crankshaft

been

made

to

support

are

and

for

is

pressed

of

the

end

the

left

corresponding

each

bolts

The

governor

of

the

The

alternator

at

the

DESCRIPTION

and

to

and

are

and

cast-

cast-

to

are

form

pre-

the

bored

the

rear

of

the

crank-

con-

Each

for

left

front.

to

as

in

specific

thread

spark

special

solid

spring

semi-circular

grooves.

steel

machined,

are

bosses.

pressed-in

sockets

of

steel

ball

The

bead

ring.

spring,

d.

draulic

crankcase

overhead

reservoirs

the

pushrod

the

bushings.

oil,

valve

cates

the

crankcase

are

rubber

the

returning

barrel

inserts

plug

heat

valve

retainers

Valve

cadmium

held

in

Valve

and

tubes

ends

pushrod

at

the

The

washer,

VALVE

valve

system,

drilled

Each

through

stem.

the

valve

sealed

seals.

assembly.

diameters.

are

holes.

and

stem

tips

are

keys

rocker

plated.

chrome

place

rockers

bronze

rocker

and

which

bead

inside

housings

cylinder

at

seal

lifters,

main

ends

rockers

valve

a

The

stems

through

to

cylinder

Drain

oil

are

galleries,

the

oil

to the

Valve

guides

Special

installed

Exhaust

corrosion-resistant

are

hardened.

locked

which

covers

plated

by

screws

are

bushings,

faces.

pressed

center

are

end

the

crankcase

ring

and

MECHANISM.

under

the

lifter

lifters.

is

forced

and

the

rocker

nozzle,

spray

and

the

heads

holes

in

sump.

in

valves

to

the

engage

are

Rocker

steel.

in

the

steel

hardened

Pushrods

in,

hardened,

drilled

beaded

retains

end

a

second

pressure

is

divided

guide

The

through

groove

directs

towards

from

springs.

pushrod

and

valve

18mm

upper

stems

The

a

oil

the

lifter

are

then

helical

are

faced

material.

The

by

in

stamped

shafts

rocker

cylinder

forgings

are

forged

for

oil

steel

washer

retains

washer.

Oil

fed

between

surfaces

which

the

pushrods

between

a

portion

the

rockers

Oil

is

returned

housings

crankcase

guides

reamed

coil

and

lower

with

The

outer

valve

tapered,

the

stem

sheet

are

fully

shafts

rocker

with

pushrod

composed

steel

passages.

tubes.

The

and

seal

a

heavy

to

from

and

reaches

their

of

respective

lubri-

which

direct

a

hythe

the

the

to

its

to

by

3.

breather

with

breather

crankcase.

C.

are

prior

the

The

a

CYLINDERS.

heated

to

steel

crankcase

consisting

side

extension

assembly

and

the

head

alloy

barrel

of

is

valve

being

interior

a

tube

for

pressed

The

seats

screwed

to

make

is

ventilated

and

baffle

hose

attachment.

into

aluminum

and

guides

and

the

permanent

the

alloy

are

shrunk

by

assembly

upper

heads

installed

onto

head

The

left

a

e.

forging

faces

journals

The

spline

reduction

the

on

crankshaft

CRANKSHAFT.

is

of

front

which

propeller

the

front

machined

the

and

crankpins

end

mates

gear.

driveshaft

for

has

The

all

over

crankcheeks.

are

of

the

crankshaft

with

a

The

reduction

which

attachment

side

blades

six-throw

except

The

nitrided

quill

shaft

gear

has

of

the

projecting

steel

for

some

main

after

grinding.

has

an

to

drive

in

turn

a

flange

propeller.

from

alloy

sur-

bearing

internal

the

drives

formed

The

the

A-3-1

crankcheeks

of

third

order

counterweights

torsional

onto

A

snythetic

the

castings

crankshaft

f.

connecting

bushings

same

end.

limited

g.

ings

lindrical

shaft

built

and

ring

manufactured

cast

machined.

piston

Piston

permanently

variation

h.

machined

gear

journals

the

crankcase

passage.

unequally

relation

with

gear.

vibration.

the

crankshaft

crankshaft

in

the

by

CONNECTING

and

type

Weight

to

1/2

PISTONS.

or

forgings.

relief

counterweights.

since

ring

assembly

model.

steel

insert

Because

configurations

pins

is

CAMSHAFT.

on

mount

are

front

journal

cross

The

spaced

to

the

camshaft

and

are

counterweights.

on

rubber

is

seated

front

a

helical

rods

have

two

identical

as

the

main

variation

ounce.

Pistons

The

cuts

1975

incorporate

Some

engines

with

into

are

full

floating

forged-in

limited

flange

hardened

the

four

journals,

at

passes

passage

camshaft

bolts

camlobes.

gear

to

machined

their

pins

The

crankshaft

and

is

located

oil

seal

shaft

exit,

spring

RODS.

split

bearings)

of

two

are

skirts

at

the

All

GTSIO-520

replacing

in

a

piston

which

of

the

weight

are

aluminum

1/2

ounce

A

steel

the

rear

and

ground.

engine

gear

to

locate

A

and

for

Oscillation

dampen

which

between

and

inside

The

bronze

precision

rods

in

aluminum

are

solid

bottom

a

four

the

current

which

the

top

difference,

not

to

ground

in

alloy

nine

camlobes

end.

A

oil

to

the

is

attached

its

cluster

drives

the

installation

crankshaft

gear

is

by

a

dowel.

is

stretched

the

crankcase

is

sealed

the

seal

"I"

beam-type

piston

inserts

at

the

crankpin

any

one

alloy

and

have

to

clear

series

(4)

ring

original

production

incorporates

ring

groove

be

intermixed.

steel

tubes

plugs.

opposite

forging

The

lobes

groove

from

the

left

crankcase

by

timing

gear

is

the

fuel

of

shrunk

over

to

cavity.

(of

bay

cast-

crank-

engines

piston

five

are

these

with

Weight

bays.

and

the

and

around

right

four

mark

bolted

pump

the

the

pin

the

cy-

(5)

in

a

is

is

is

tappets

from

newer

shoulders

the

1/16"

3-2.

a.

the

(16),

the

turned,

wormwheel

shaftgear

(20)

disengaging

used

(1)

1.

mitted

idler

2.

drive

on

splines

3.

the

the

with

transmits

tachometer

bevel

drives

4.

crankshaft

shaft

quill

propeller

is

the

design,

O.D.

for

FUNCTIONAL

GEAR

engine

through

crankshaft

the

is

to

transmit

to

the generator

Torque

by

gear

The

gears

the

crankcase

of

The

camshaft

oil

pump

internal

gear

the

The

drive

shaft

that

center

which

roughly

The

socket

the

old

TRAIN.

torque

adapter

gear

clutch

hub

(21).

returned

the

the

(12)

and

idler

(14,

magneto

fuel

cluster

and

splines

torque

drive

(6)

governor

internal

(2)

gear

(23).

shaft

gear

the

ball

nearly

must

half

way

hole

and

1/8"

SYSTEMS.

Figure

is

transmitted

components

(1).

spring

and

grips

After

the

to

its

starter.

torque

drive

from

the

crankshaft

camshaft

gear

15).

Optional

upper

drive

pump

drive

gear

tachometer

of

to

the

oil

gear

on

the

front

driven

splined

transmits

(24)

through

The

drive

(25).

socket

to

use

between

diameter

for

As

the

(20)

the

engine

normal

The

shaftgear

from

pulley.

crankshaft

gear

gear

(12)

rear

are

gears.

gear

(3).

the

camshaft

pump

(1

1).

bevel

torque

an

gear

of

the

the

O.D.,

the

new

the

differences

the

new.

A-4-8.

When

from

(17

wormwheel

is

tightened

knurled

the

(1)

drives

accessories

The

drive

The

of

gear

front

(24)

drum

is

started,

position,

(21)

crankshaft

(2)

directly

(3)

the

driven

(22)

is

splined

gear

gear

drive

gear

governor

the

camshaft

(7).

end

to

the

externally

then

old

tapered

while

snap

center

starting

the

thru

onto

is trans-

magneto

mounted

by

internal

driven

(8)

(3)

(9)

of

propeller

splined

drives

ring,

starter

21)

(19)

of

spring

thus

is

now

gear

to

the

end

mates

and

and

drive

the

the

the

and

are

to

is

the

the

by

of

(4)

i.

TAPPETS.

tappets