Teledyne Cetac Technologies SPM-700 Installation Manual

SPM-700 Syringe Pump Module

Manual Part Number 610108 Rev 0

Installation Guide

COPYRIGHT

© 2018 Teledyne CETAC Technologies

610108 Rev 0 , December, 2018

Teledyne CETAC Technologies authorizes its

customers to reproduce, transmit, or store

this document in its entirety, including this

page, for the express purpose of installing,

operating, or maintaining the product

described herein.

Teledyne CETAC Technologies

Customer Service & Support

14306 Industrial Road

Omaha, Nebraska 68144, USA

Phone (800) 369-2822 (USA only)

Phone (402) 733-2829

E-mail cetacservice@teledyne.com

REVISIONS

Teledyne CETAC Technologies strives to

provide the scientific community with an

unparalleled combination of effective

technology and continuing value. Modular

upgrades for existing instruments will

continue to be a prime consideration as

designs progress.

Teledyne CETAC Technologies reserves the

right to revise this document and/or improve

products described herein at any time without

notice or obligation.

TRADEMARK ACKNOWLEDGEMENTS

Windows is a registered trademark of

Microsoft Corporation in the United States and

other countries.

PharMed and Tygon are registered

trademarks of Saint-Gobain Performance

Plastics.

DuPont™ and Viton® are trademarks or

registered trademarks of E.I. du Pont de

Nemours and Company.

Superthane is a registered trademark of

NewAge Industries, Inc.

KIMWIPES is a registered trademark and

KIMTECH SCIENCE is a trademark of

Kimberly-Clark Worldwide, Inc

All other marks are the property of their

respective owners.

3

Contents

1 Introduction .............................................................................................................. 4

Overview.................................................................................................................................... 4

Chemical Compatibility ....................................................................................................... 4

Operator Qualifications ....................................................................................................... 5

Choosing a Location for Installation ............................................................................. 5

Proximity to the Instrumentation ........................................................................... 5

Space Requirements ...................................................................................................... 6

Power Requirements..................................................................................................... 6

Unpacking the Syringe Pump Module .......................................................................... 6

2 Installing the Syringe Module ............................................................................. 7

Installing the Accessory Module Mounting Blocks ................................................. 7

Mounting the Syringe Pump Modules .......................................................................... 9

Connecting the Tubing ...................................................................................................... 10

Connecting the Power Supply ........................................................................................ 11

Connecting the Syringe Module to the Autosampler ........................................... 11

Connecting the Syringe Module Directly to the Host PC .................................... 12

Connecting a USB Cable ............................................................................................ 12

Connecting a Serial Cable ......................................................................................... 13

Installing a Syringe .............................................................................................................. 13

Starting the Pump ................................................................................................................ 14

Shutting Down the Pump ................................................................................................. 15

3 Maintaining and Troubleshooting the Product......................................... 16

Cleaning the Syringe Module .......................................................................................... 16

Cleaning the Syringe ........................................................................................................... 16

Returning the Product to CETAC for Service ........................................................... 18

Shipping the Product .................................................................................................. 18

Product Warranty Statement ................................................................................. 18

4 Safety and Regulatory Information ............................................................... 19

Safety Characteristics ........................................................................................................ 19

Environmental Characteristics ............................................................................... 19

Electrical Characteristics .......................................................................................... 20

Safety Notices ........................................................................................................................ 20

Power Cord Set Requirements and Maintenance ............................................ 20

Mains Disconnect ......................................................................................................... 21

Mechanical Hazards ................................................................................................... 21

Operating Environment............................................................................................. 21

Explanation of Caution and Warning Notices .................................................. 22

Electromagnetic Interference ........................................................................................ 22

Explanation of Regulatory Marks ................................................................................. 23

4

1 Introduction

Overview

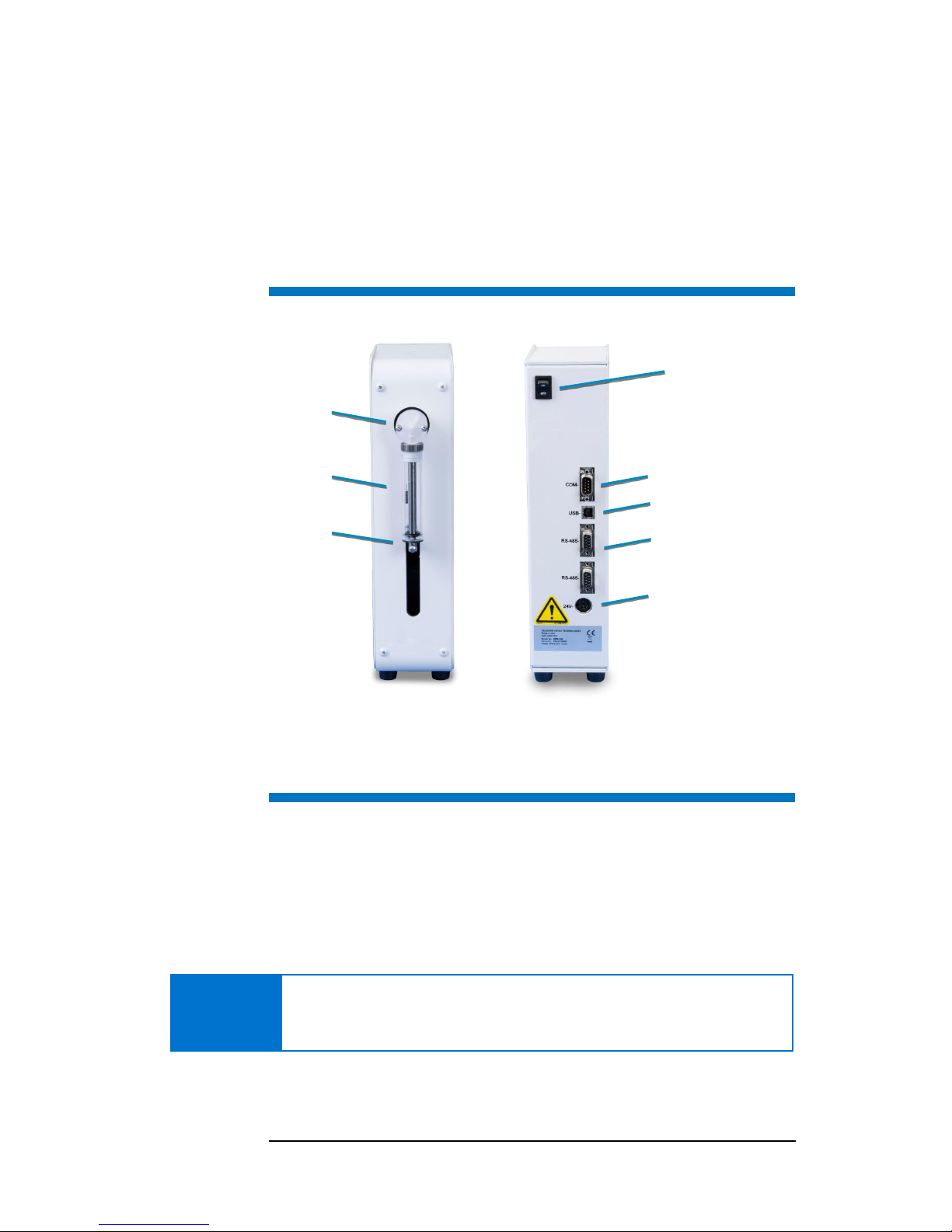

FIGURE 1-1 Front and Back Views.

The color and branding of the module may vary from what is shown here.

Chemical Compatibility

The syringe module is intended for use with sample matrices with the

following characteristics:

low-acid aqueous solutions (up to 1% HNO

3

or HCl)

low-viscosity oils

low to high dissolved solids

The system is not suitable for high viscosity samples.

NOTICE

Avoid use with chemicals which are likely to precipitate or form deposits on

the internal surfaces, such as silver chloride. Samples which contain AgCl may

contaminate the internal surfaces and require the replacement of the tubing.

Wetted components are made of Polyetherimide (PEI) and

Polytetrafluoroethylene (PTFE). When these inert, non-metallic materials are

Power Switch

Serial Port

USB Port

RS-485 Ports

Power Connector

Valve with Input

and Output Ports

Syringe

Plunger

Thumbscrew

5

used at temperatures less than 135°C, they can withstand repeated exposure

to the following substances:

Predominantly aqueous solutions of acids (less than 10%), including HNO

3

and HCl.

Predominantly aqueous solutions of strong bases (less than 10%)

Common organic solvents such as acetone, alcohols, ethyl acetate,

Methylethylketone (MEK), petroleum oils and derived fuels,

tetrachloroethylene, toluene, kerosene and xylene.

NOTICE

DAMAGE FROM CHEMICAL EXPOSURE

Prolonged or repeated exposure to temperatures greater than 135°C and to

the following substances can cause failure of the wetted components:

Acids greater than 10%.

Hydrofluoric acid (HF).

Solutions of concentrated bases (greater than 10% potassium,

ammonium, or sodium hydroxides).

Partially halogenated hydrocarbons or extremely aggressive organic

solvents (chloroform, methylene dichloride, 1,1,2-trichloroethane).

Operator Qualifications

To use this product, you should have a working knowledge of the equipment

with which the syringe module will be used.

WARNING

CHEMICAL INJURY HAZARD

Make sure you know the hazards associated with all of the chemicals you

are using, and take the appropriate precautions. Exposure to laboratory

chemicals may result in serious injury.

Choosing a Location for Installation

Proximity to the Instrumentation

Tubing length affects the time it takes for fluid to reach its destination and the

volume of fluid required. When introducing very small sample volumes (flow

rates less than 50 µL min-1), minimize the length of the connecting sample

tubing. For the introduction of sample volumes to analytical instrumentation

such as ICP-MS, where flow rates of greater than 50 µL min-1 will be employed,

the length of connecting sample tubing between the syringe pump and a

nebulizer is less critical. The syringe module can be mounted on either side of

the autosampler or it may be placed on the workbench.

6

Space Requirements

You will need easy access to the back of the syringe module to reach the power

switch. As a minimum, allow at least 5 cm behind the syringe module for cable

egress, ventilation, and access to the power switch. Always position the

equipment so that it is easy to disconnect the power cord.

Power Requirements

The syringe module receives power through the connection to the external

desktop “brick” power supply. Place the module within 1.2 meters of a power

outlet.

WARNING

SHOCK AND FIRE HAZARD

Use only the provided power supply. The power supply must be plugged into

an outlet which has a protective ground connection.

The power supply must be connected to an AC power source that will not

apply more than 240VAC between the supply conductors and ground. A

protective ground connection is required for safe operation.

Ensure that you position the syringe module so that the plug is easily

accessible (is not blocked) and can be quickly disconnected if needed. In case

of hazard, the power cord should be disconnected from the wall socket. Do not

plug in the power supply until ready to operate the pump.

Unpacking the Syringe Pump Module

Inspect external packaging upon receipt for signs of shipping damage. Inspect

all items during unpacking and notify the carrier immediately of any concealed

damage.

If the system is shipped or removed from storage during cold weather, allow

the equipment to equilibrate to room temperature before opening and

exposing to warm, humid air.

CAUTION

EQUIPMENT DAMAGE FROM CONDENSATION

If condensation forms on or inside the pump module, allow it to dry

thoroughly before connecting it to a power source and operating it. Failure to

do so may cause equipment damage.

NOTE

Keep the factory packaging for use in case the product ever needs to be

returned or shipped to another location.

7

2 Installing the Syringe

Module

The syringe pump module may be placed on the workbench, or it can be

attached to the autosampler using an optional mounting block.

Installing the Accessory Module Mounting Blocks

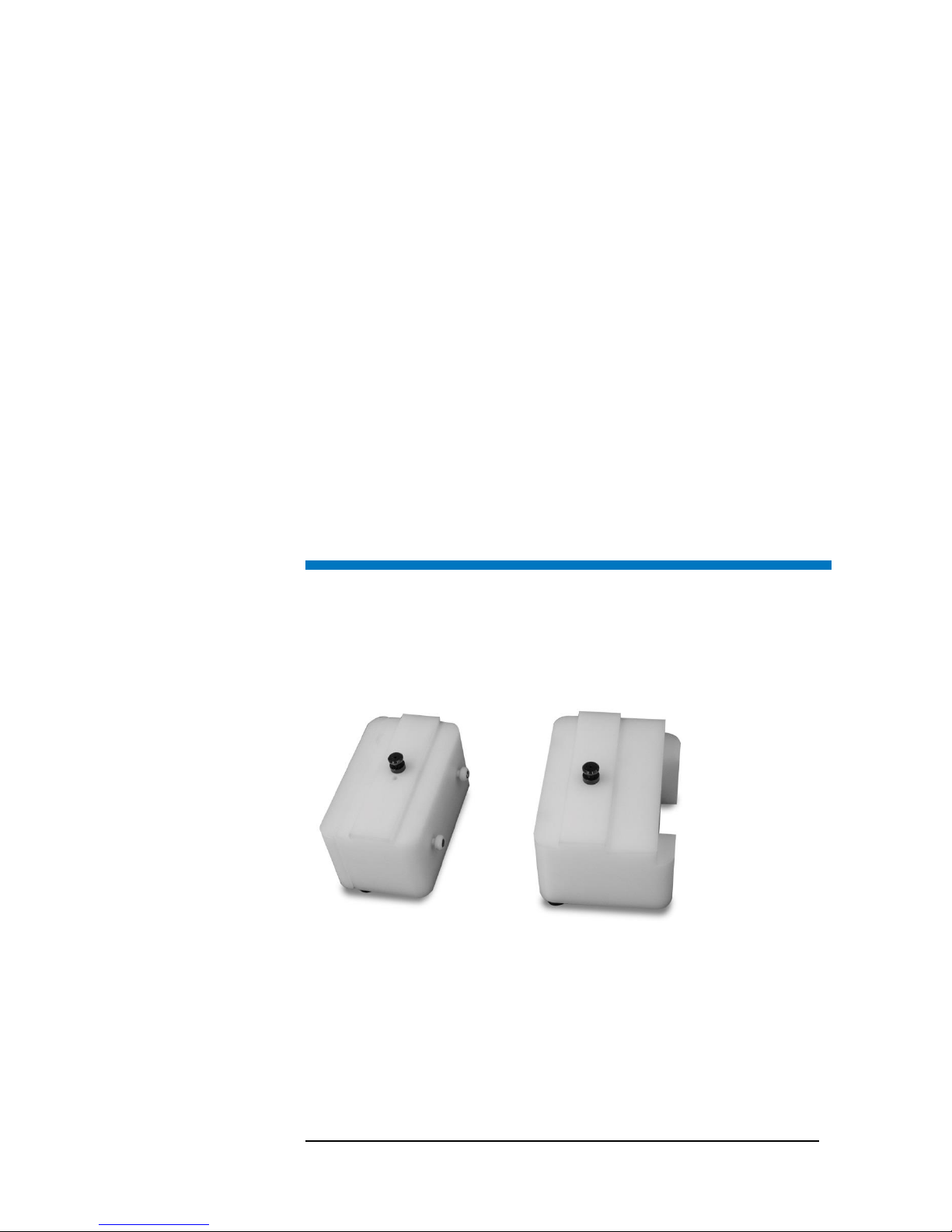

The syringe pump module can be mounted on an accessory mounting block,

and the mounting block can be installed on either side of the autosampler.

There are two types of mounting blocks. An inside mounting block is designed

to attach directly to the autosampler. An outside mounting block is designed to

attach to an inside mounting block.

FIGURE 2-1 Mounting Blocks.

You will need a Philips head screwdriver and a set of Allen (hex) wrenches.

1 Turn the power switches on the power supply, autosampler, and syringe pump

module OFF.

2 Place an inside mounting block next to the autosampler on the side where you

want it.

Inside Block

Outside Block

Loading...

Loading...