Page 1

Copyright 2011-2016

07406B DCN7347

Teledyne API

29 September 2016

Manual Addendum

Models T320 and T320U

N2O Analyzers

(Addendum to T300/T300M Manual, PN 06864)

© TELEDYNE API (TAPI)

9970 CARROLL CANYON ROAD

SAN DIEGO, CA 92131-1106

USA

Toll-free Phone: 800-324-5190

Phone: +1 858-657-9800

Fax: +1 858-657-9816

Email: api-sales@teledyne.com

Website: http://www.teledyne-api.com/

Page 2

Page 3

should only be used for the purpose and in the manner described in

in a manner other than that for which it was

intended, unpredictable behavior could ensue with possible hazardous

SAFETY MESSAGES

Important safety messages are provided throughout this manual. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each safety message is

associated with a safety alert symbol. These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

WARNING: Electrical Shock Hazard

HAZARD: Strong oxidizer

GENERAL WARNING/CAUTION: Read the accompanying

message for s pecifi c i nformation.

CAUTION : Hot Surface Warning

Technician Symbol: All operations marked with this symbol are to

be performed by qualified maintenance personnel only.

DO NOT TOUCH: Touching some parts of the instrument without

protection or proper tools could result in damage to t he part(s)

and/or the instrument.

Electrical Ground: This symbol inside the instrument marks the

central safety grounding point for the instrument.

CAUTION - General Safety Hazard

This instrument

this manual. If you use this instrument

consequences.

NEVER use any gas analyzer to sample combustible gas(es).

Note

Technical Assistance r egarding the use and maintenan ce of the T320/T320U or any other Teledyne API

product can be obtained by contacting Teledyne API’s Technical Support Department:

Phone: 800-324-5190

Email: sda_techsupport@teledyne.com

or by accessing various service options on o ur website at http://www.teledyne-api.com/.

07406B DCN7347 i

Page 4

AVERTISSEMENT : Risque de choc électrique

DANGER : Oxydant puissant

AVERTISSEMENT GÉNÉRAL / MISE EN GARDE : Lire la consigne

MISE EN GARDE : Surface chaude

Ne pas toucher : Toucher à certaines parties de l’instrument sans protection ou

Pictogramme « technicien » : Toutes les opérations portant ce symbole doivent

Mise à la terre : Ce symbole à l’intérieur de l’instrument détermine le point central

MISE EN GARDE

CONSIGNES DE SÉCURITÉ

Des consignes de sécurité importantes sont fournies tout au long du présent manuel dans le but d’éviter des

blessures corporelles ou d’endommager les instruments. Veuillez lire attentivement ces consignes. Chaque

consigne de sécurité est représentée par un pictogramme d’alerte de sécurité; ces pictogrammes se retrouvent

dans ce manuel et à l’intérieur des instruments. Les symboles correspondent aux consignes suivantes:

complémentaire pour des renseignements spécifiques

sans les outils appropriés pourrait entraîner des dommages aux pièces ou à

l’instrument.

être effectuées uniquement par du personnel de maintenance qualifié.

de la mise à la terre sécuritaire de l’instrument.

Cet instrument doit être utilisé aux fins décrites et de la manière décrite dans ce

manuel. Si vous utilisez cet instrument d’une autre manière que celle pour laquelle il

a été prévu, l’instrument pourrait se comporter de façon imprévisible et entraîner des

conséquences dangereuses.

NE JAMAIS utiliser un analyseur de gaz pour échantillonner des gaz combustibles!

ii 07406B DCN7347

Page 5

TABLE OF CONTENTS

1. INTRODUCTION ..................................................................................................................................................................... 5

2. SPECIFICATIONS, APPROVALS AND WARRANTY ........................................................................................................... 7

2.1. Specifications ................................................................................................................................................................... 7

2.2. EPA Equivalency Designation .......................................................................................................................................... 8

2.3. CE Mark Compliance ....................................................................................................................................................... 8

2.4. Warranty ........................................................................................................................................................................... 8

3. GETTING STARTED .............................................................................................................................................................. 9

3.1. Unpacking the T320/T320U .............................................................................................................................................. 9

3.2. Initial Operation of the T320/T320U ................................................................................................................................. 9

3.3. Functional Check .............................................................................................................................................................. 9

3.4. Initial Calibration ............................................................................................................................................................. 10

3.4.1. Calibration Gases ................................................................................................................................................... 10

3.4.2. Internal Pneumatic Flow ......................................................................................................................................... 11

3.4.3. Pneumatic Connections to T320/T320U Basic Configuration: ................................................................................ 12

3.4.4. Pneumatic Connections to T320/T320U with Internal Valve Options Installed ....................................................... 13

3.4.5. Pneumatic Connections to T320/T320U in Multipoint Calibration Applications ....................................................... 14

4. FREQUENTLY ASKED QUESTIONS & GLOSSARY .......................................................................................................... 15

5. OPTIO NAL HARDWARE AND SOFTWARE ....................................................................................................................... 17

5.1. Calibration Valve Options for the T320/T320U ............................................................................................................... 17

5.1.1. Zero/Span with common Shutoff valves (Option 50G) ............................................................................................ 18

6. BASIC OPERATION ............................................................................................................................................................. 19

6.1. Test Functions ................................................................................................................................................................ 19

6.1.1. Selecting a Test Channel Function for Output A4 ................................................................................................... 20

7. ADVANCED FEATURES ...................................................................................................................................................... 21

8. REMOTE OPERATION ......................................................................................................................................................... 23

8.1.1. Hessen Protocol ..................................................................................................................................................... 23

9. CALIBRATION PROCEDURES ........................................................................................................................................... 25

10. EPA PROTOCOL CALIBRATION ..................................................................................................................................... 27

11. PRINCIPLES OF OPERATION .......................................................................................................................................... 29

12. MAINTENANCE SCHEDULE ............................................................................................................................................. 31

13. TROUBLESHOOTING & SERVICE ................................................................................................................................... 33

LIST OF FIGURES

Figure 3-1. T320 Pneumatic Flow ............................................................................................................................11

Figure 3-2. T320U Pneumatic Flow ..........................................................................................................................11

Figure 3-2. Pneumatic Connections, Basic Configuration Using Gas Dilution Calibrator ........................................12

Figure 3-3. Pneumatic Connections, Basic Configuration Using Bottled Span Gas ................................................12

Figure 3-4. Pneumatics: Option Z/S Valve w ith Shutoff Valve for Pressurized Span and Atmospheric Zero..........13

Figure 3-5. Pneumatics: Option Z/S without Shutoff Valve ......................................................................................13

Figure 3-6. Pneumatics: Option Z/S Valve with Common Shutoff Valve for Pressurized Zero and Span ...............14

Figure 5-1. Internal Pneumatic Flow, Option Zero/Span with Common Shutoff Valves ..........................................18

LIST OF TABLES

Table 2-1. T320/T320U Basic Unit Specifications ...................................................................................................... 7

Table 5-1. T320/T320U Available Valve Options .....................................................................................................17

Table 5-2. Zero/Span/Shutoff Valve Operating States for Option 50G ....................................................................18

Table 6-1. Test Functions Defined ...........................................................................................................................19

Table 6-2. Test Channels Functions Available on the T320/T320U’s Analog Output ..............................................20

07406B DCN7347 iii

Page 6

TABLE OF CONTENTS Teledyne API T320/T320U Addendum to T300/T300M Manual

LIST OF APPENDICES

APPENDIX A – MENU TREES and SOFTWARE DOCUMENTATION

APPENDIX B –SPARE PARTS LIST

APPENDIX C - REPAIR QUESTIONNAIRE

APPENDIX D - SCHEMATICS

iv 07406B DCN7347

Page 7

1. INTRODUCTION

The T320 and T320U are Gas Filter Correlation (GFC) analyzers that are designed to measure low level and

trace level nitrous oxide (N

operating range; 1000 ppm for the T320 and 200 ppm for the T320U. The T320 and T320U are designed to be

used for monitoring background levels of N

contamination of bottled gases.

This addendum is a supplement to the T300/T300M manual (P/N 06864) to facilitate setup, operation,

calibration, troubleshooting and repair of T320 and T320U nitrous oxide (N

up information, operating ins tr uctions as well as maintenance, troubleshooting and repair methods are the same

for the T320/T320U and can be found in the T300/T300M manual (P/N 06864). The T320 is very similar to the

T300M, and the T320U is very similar to the T300:

When using the T300/T300M manual, it is necessary to substitute the words nitrous oxide for carbon monoxide

and the chemical abbreviation N

O), respectively. The primary difference between the models is their maximum

2

O in the atmosphere, byproducts of combustion products and

2

O) analyzers. Most of the basic set

2

T320 = T300M T320U = T300

O for CO:

2

Carbon Monoxide

→ Nitrous Oxide CO → N

O

2

There are six major differences between the T320/T320U and their counterpart models, T300M/T300:

• Operating wavelength: A different photo detector is used that closely matches the peak absorption

wavelength of N

• Gas Filter Correlation Filter (GFC) wheel: The GFC wheel is filled with N

correlate properly with N

2

O.

2

O.

O rather than CO to

2

• Software: Display text strings, variable names and variable values reflect the difference in gas name

and physical characteristic. Wherever “CO” is displayed on the T300/T300M “N2O” will be displayed on

the T320/T320U.

• Calibration Methods: There are no specialized USEPA calibration methods since these methods

currently do not exist.

• Calibration Gases: Since there are no readily available low cost N

generators like the TAPI model 701, whic h do not remove N

O, zero gas must be either N2 or synthetic

2

O scrubbers and traditional zero air

2

air - especially for the T320U.

• Calibration Valve Options: Due to there being no N

O scrubbers or traditional zero air generators for

2

either the T320 or the T320U, Options 51B and 51C for the T300M and T300 are not available for the

T320 or T320U.

NOTE

The information contained in this addendum is relevant to T320/T320U analyzers, some of which may

not be applicable to the current version of software.

07406B DCN7347 5

Page 8

Introduction Teledyne API T320/T320U Addendum to T300/T300M Manual

This page intentionally left blank.

6 07406B DCN7347

Page 9

1,2

1, 2, 3

1,2

1 Ethernet: 10/100Base-T

4 analog outputs

1 USB com port

3 4-20mA current outputs

2. SPECIFICATIONS, APPROVALS AND WARRANTY

This section provides the specifications for the T320 and the T320U analyzers, and references approvals and

warranty.

2.1. SPECIFICATIONS

Specifications differ between the T320 and the T320U analyzers for Ranges, Noise, Lower Detectable Limit and

Drift.

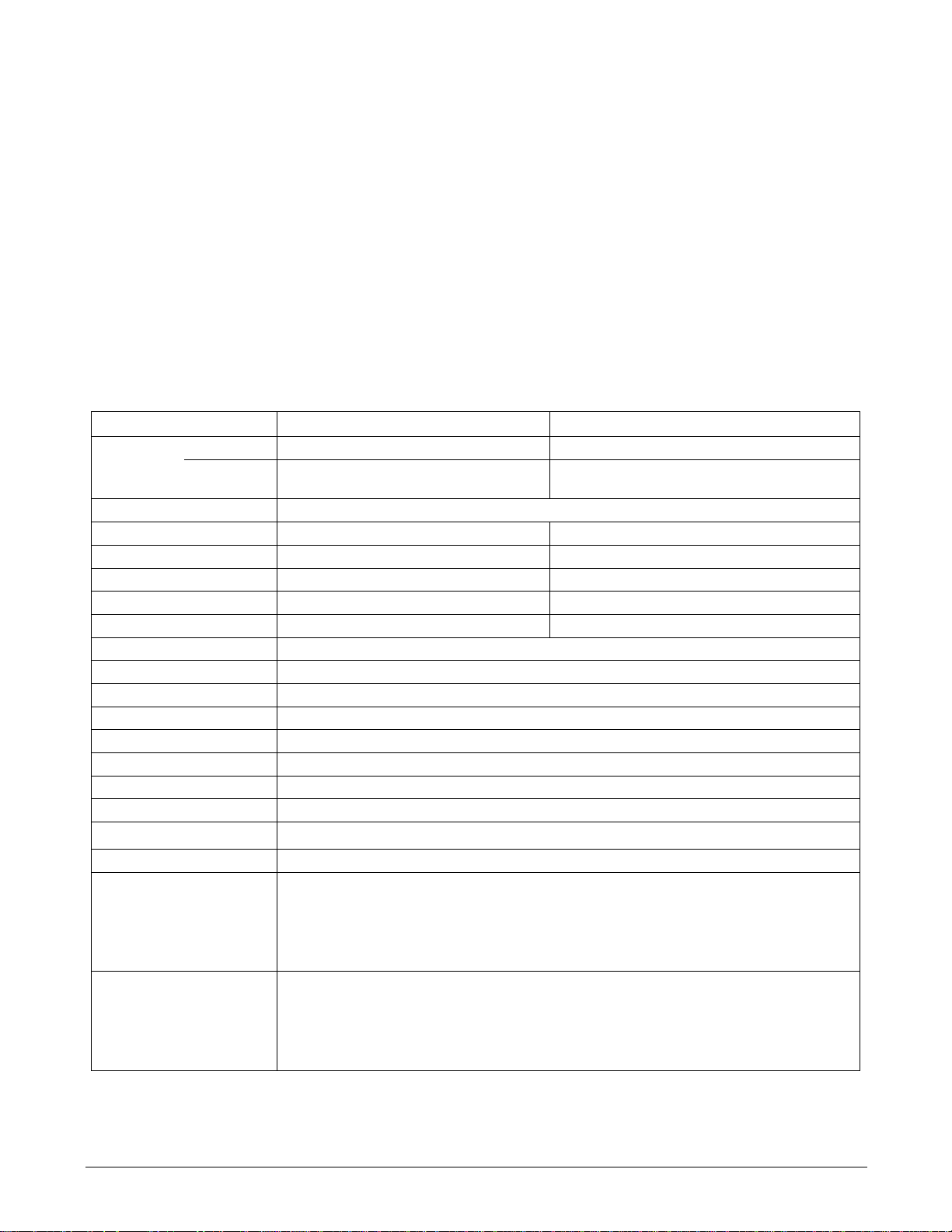

Table 2-1. T320/T320U Basic Unit Specifications

Parameter Model T320 Model T320U

Min: 0-1 ppm Full scale 0-200 ppb Full scale

Ranges

Measurement Units ppb, ppm, µg/m3, mg/m3 (selectable)

Zero Noise

Span Noise

Lower Detectable Limit

Zero Drift (24 hours) 2 < 0.1 ppm < 25 ppb

Span Drift (24 hours) 2, 4 < 0.5% of reading < 0.5% of reading

Lag Time 1 <10 sec

Rise/Fall Time 1 <60 sec to 95%

Linearity 6 1% of full scale

Precision 1, 5 0.5% reading

Sample Flow Rate 800 cm3/min. ± 10%

Voltage Coefficient < 0.05 % of reading per V

Power Requirements 100V-120V, 220V-240V, 50/60 Hz

Analog Output Ranges 10V, 5V, 1V, 0.1V (selectable)

Recorder Offset

Analog Output Resolution 1 part in 4096 of selected full-scale voltage

< 0.02 ppm (RMS) < 5 ppb (RMS)

< 0.5% of reading RMS over 8 ppm < 0.5% of reading RMS over 2 ppm

0-1000 ppm Full scale (selectable, dual

Max:

ranges and auto ranging supported)

< 0.04 ppm < 10 ppb

0-200 ppm Full scale (selectable, dual ranges

and auto ranging supported)

± 10%

Included I/O

Optional I/O

07406B DCN7347 7

2 RS-232 (300 – 115,200 baud)

2 USB device ports

8 opto-isolated digital status outputs

6 opto-isolated digital control inputs

1 RS485

8 analog inputs (0-10V, 12-bit)

4 digital alarm outputs

Multidrop RS232

Page 10

Specifications, Approvals and Warranty Teledyne API T320/T320U Addendum to T300/T300M Manual

Parameter

Model T320

Model T320U

1

Or 20 ppb, whichever is greater

4

For values greater than twice the LDL

Temperature Range

Humidity Range 0-95% RH, Non-Condensing

Dimensions (HxWxD) 7" x 17" x 23.5" (178 mm x 432 mm x 597 mm)

Weight 50 lb (22.7 kg)

Environmental Conditions Installation Category (Over voltage Category) II Pollution Degree 2

Certifications

As defined by the USEPA

2

At constant temperature and sample pressure

3

5 - 40°C operating

CE: IEC 61010-1:2001

North American: cNEMKO (Canada): CAN/CSA-C22.2 No. 61010-1-04

NEMKO-CCL (US): UL No. 61010-1 (2

Or 10 ppb, whichever is greater

5

Or LDL whichever is greater

6

nd

Edition)

2.2. EPA EQUIVALENCY DESIGNATION

There is no US EPA reference method for the measurement of nitrous oxide; therefore, neither the T320 nor the

T320U are designated as reference or equivalent methods. Hence, the EPA Protocol Calibration section of the

Model T300/T300M Operation Manual does not appl y.

2.3. CE MARK COMPLIANCE

See the CE Mark Compliance section of the T300/T300M manual (P/N 06864).

2.4. WARRANTY

See the Warranty page of the T300/T300M manual (P/N 06864).

8 07406B DCN7347

Page 11

1

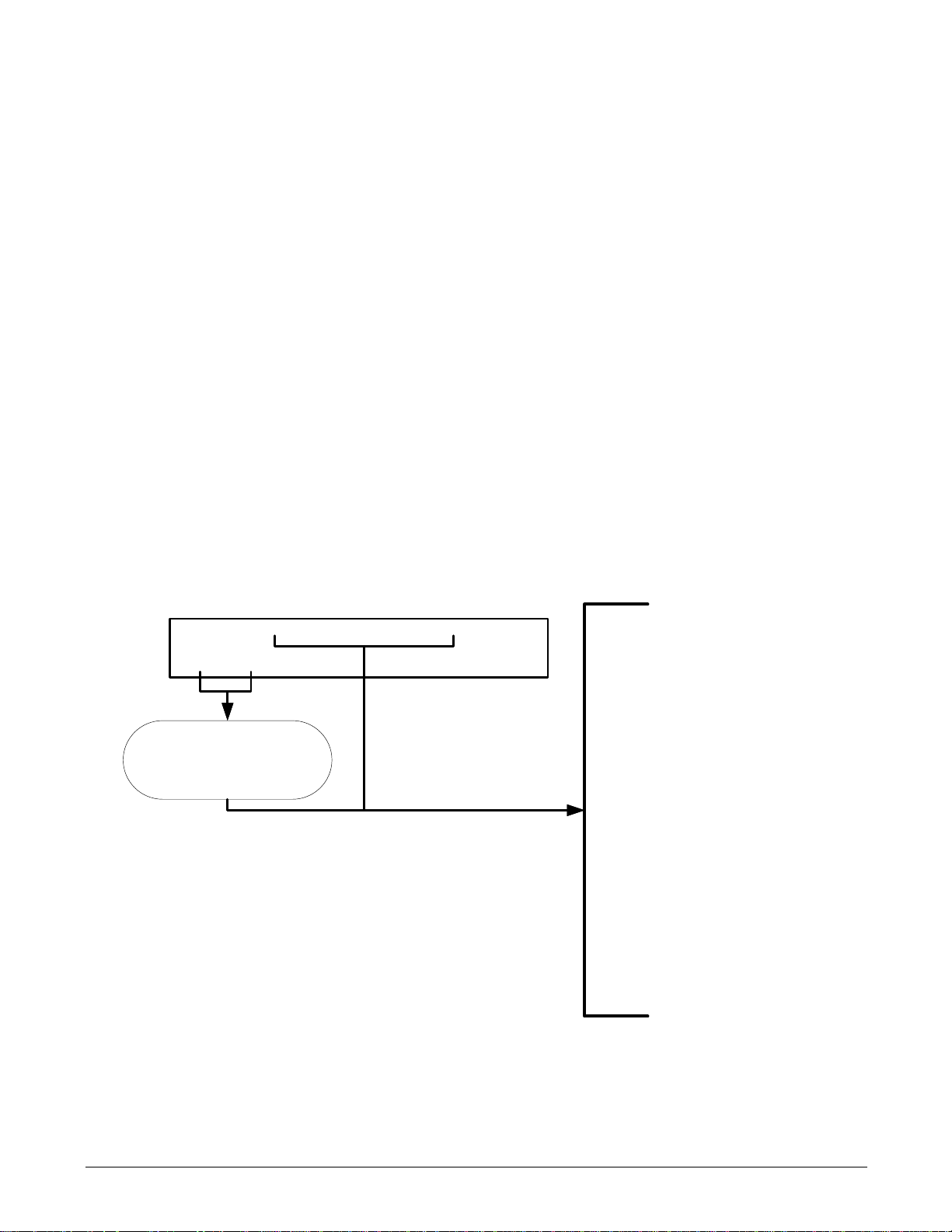

These range displays appear if the

instrument’s reporting ranges are set for

either the DUAL to AUTO modes.

2

Not in “U” models.

3

Only in “U” models.

4

Only appears if analog output A4

is

actively reporting a TEST FUNCTION.

SAMPLE RANGE=50.

000 PPM N2O= XXXX

<TST TST> CAL SETUP

Toggle <TST TST> buttons

to scroll through list of

functions

·

RANGE=[Value] PPB

·

RANGE

1=[

Value] PPB

1

·

RANGE2=[Value

]

PPB

1

·

STABIL=[

Value]

PPM or PPB

·

N2O MEAS=[Value]

MV

·

N2O REF=[Value] MV

·

MR RATIO=[Value]

·

PRES

=[Value] IN-HG-A

·

SAMP FL=[Value] CC/M

·

SAMPLE TEMP=[Value]ºC

2

·

BENCH TEMP=[Value]ºC

·

WHEEL TEMP=[Value]ºC

·

OVEN TEMP=[Value

]ºC

3

·

BOX TEMP=[Value]ºC

2

·

PHT DRIVE=[Value] MV

·

SLOPE=[Value]

·

OFFSET=[Value]

·

TEST

=[Value] MV

4

·

TIME=[HH:MM:SS

]

3. GETTING STARTED

3.1. UNPACKING THE T320/T320U

Follow the unpacking directions in the Getting Started section of the T300/T300M manual (P/N 06864); note that

the Final Test and Validation Data Sheet for the T320 or the T320U are unique .

3.2. INITIAL OPERATION OF THE T320/T320U

The analyzer should be started and allowed to warm up; a functional check followed by calibration should be

performed. The process for starting and warming up the T320/T320U is identical to that described in the Initial

Operation section of the T300/T300M Operators Manual (P/N 06864).

3.3. FUNCTIONAL CHECK

The functional check information also in the Initial Operation section of the T300/T300M Operators Manual (P/N

06864) is applicable to the T320/T320U with the following exc epti on(s ) .

The Test functions available from the front panel of the T320 or T320U are:

07406B DCN7347 9

Page 12

Getting Started Teledyne API T320/T320U Addendum to T300/T300M Manual

3.4. INITIAL CALIBRATION

3.4.1. CALIBRATION GASES

The information found in the Calibration Gases section of the T300/T300M Operators Manual (P/N 06864) is

applicable to the T320/T320U with the following exceptions:

ZERO GAS

Zero gas is similar in chemical composition to the atmosphere that is to be measured but scrubbed of all

components that might affect the analyzers readings, in this case N

T320/T320U this gas MUST be synthetic air, ultra zero air or nitrogen (N

NOTE

Zero air created by a Zero Air Generator like the T-API Model T701 should not be used since the T701

does not scrub N2O. Likewise since there are no effective and convenient catalytic, absor ptive or

reactive scrubbers for N2O, T-API does not offer a zero scrubber cartridge.

O and water vapor. For the

2

).

2

SPAN GAS

Span gas is specifically mixed to match the chemical composition of the type of gas being measured at

near full scale of the desired measurement range. In this case, N

T320/T320U analyzer, it is recommended that you use a span gas with a N

80% of the measurement range for your application.

EXAMPLE: If the application is to measure between 0 ppm and 500 ppm, an appropriate span gas

concentration would be 400 ppm N

Some applications require a multipoint calibration procedure where span gases of different

concentrations are applied to the analyzer under test. We recommend using a bottle of calibrated N

gas of higher concentration in conjunction with a gas dilution calibrator such as a Teledyne Instruments

Model T700. This type of calibrator precisely mixes a high concentration gas from with zero gas (both

supplied externally as either synthetic air or N

concentration. Linearity profiles can be automated with this model and run unattended over night.

Currently there are no Standard Reference Material (SRM) N

(National Institute of Standards and Technology) therefore it is essential that span gas be purchased

from a reputable supplier and that the gas be traceable to a reputable national standards laboratory.

O in N2.

2

O measurements made with the

2

) to accurately produce span gas of the correct

2

O gases available o ff -the-shelf from NIST

2

O concentration equal to

2

O

2

10 07406B DCN7347

Page 13

Teledyne API T320/T320U Addendum to T300/T300M Manual Getting Started

INSTRUMENT CHASSIS

Flow

/ Pressure

Sensor PCA

SAMPLE

PRESSURE

SENSOR

FLOW

SENSOR

Sample Gas

Flow Control

SAMPLE GAS

INLET

EXHAUST

GAS OUTLET

Particulate Filt er

PUMP

GFC Wheel

Housing

GFC Motor Heat Sync

SAMPLE CHAMBER

INST RUM ENT CHASSIS

CO

Scrubber

Flow / Pressure

Sensor PCA

SAMPLE

PRESSURE

SENSOR

FLO W

SENSOR

Sample G as

Flow Control

SAMPLE G AS

INLET

EXHAUST

GAS OUTLET

/

PUMP

GFC Wheel

Housing

GF C Motor Heat Sync

SAMPLE CH AMBE R

Multi-Tube Nafion Dryer

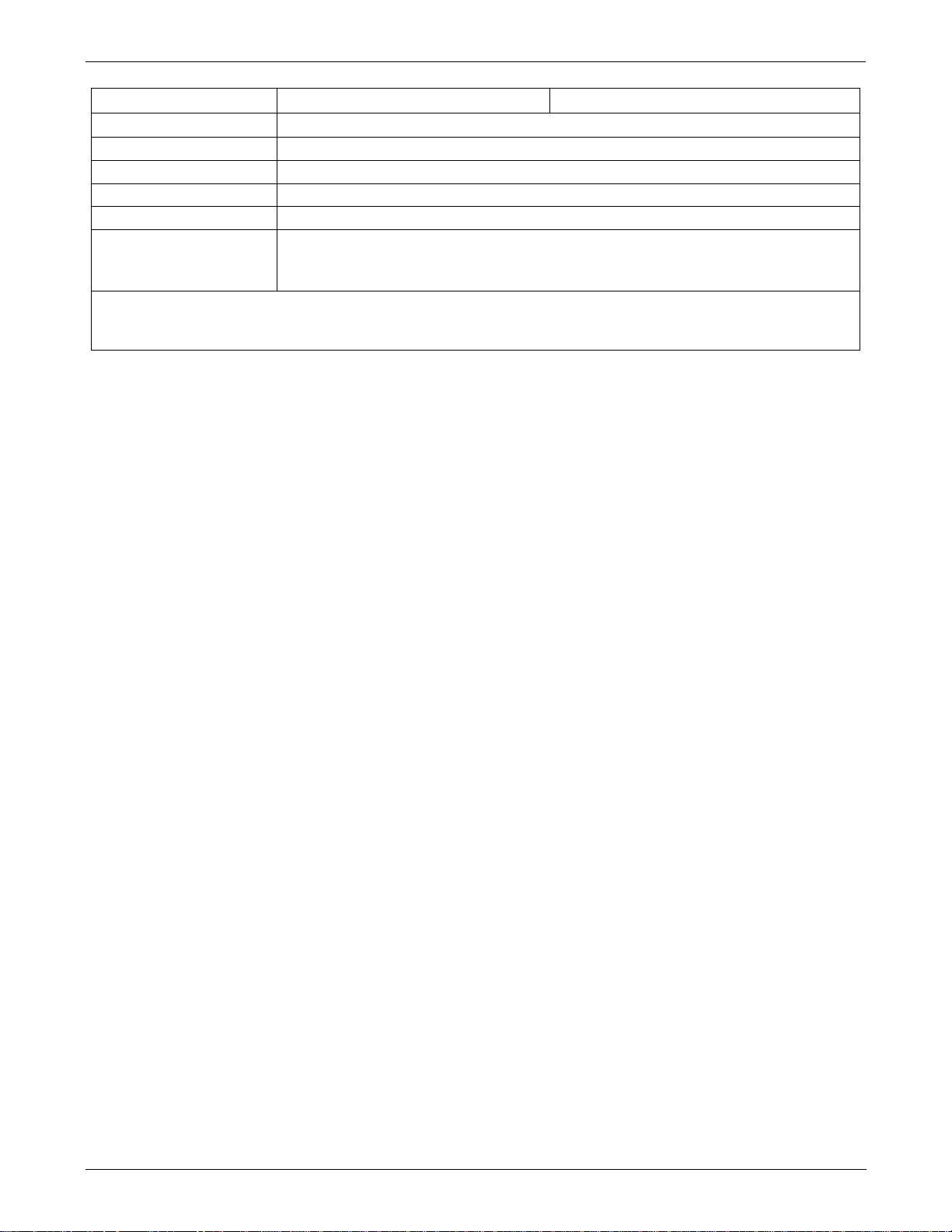

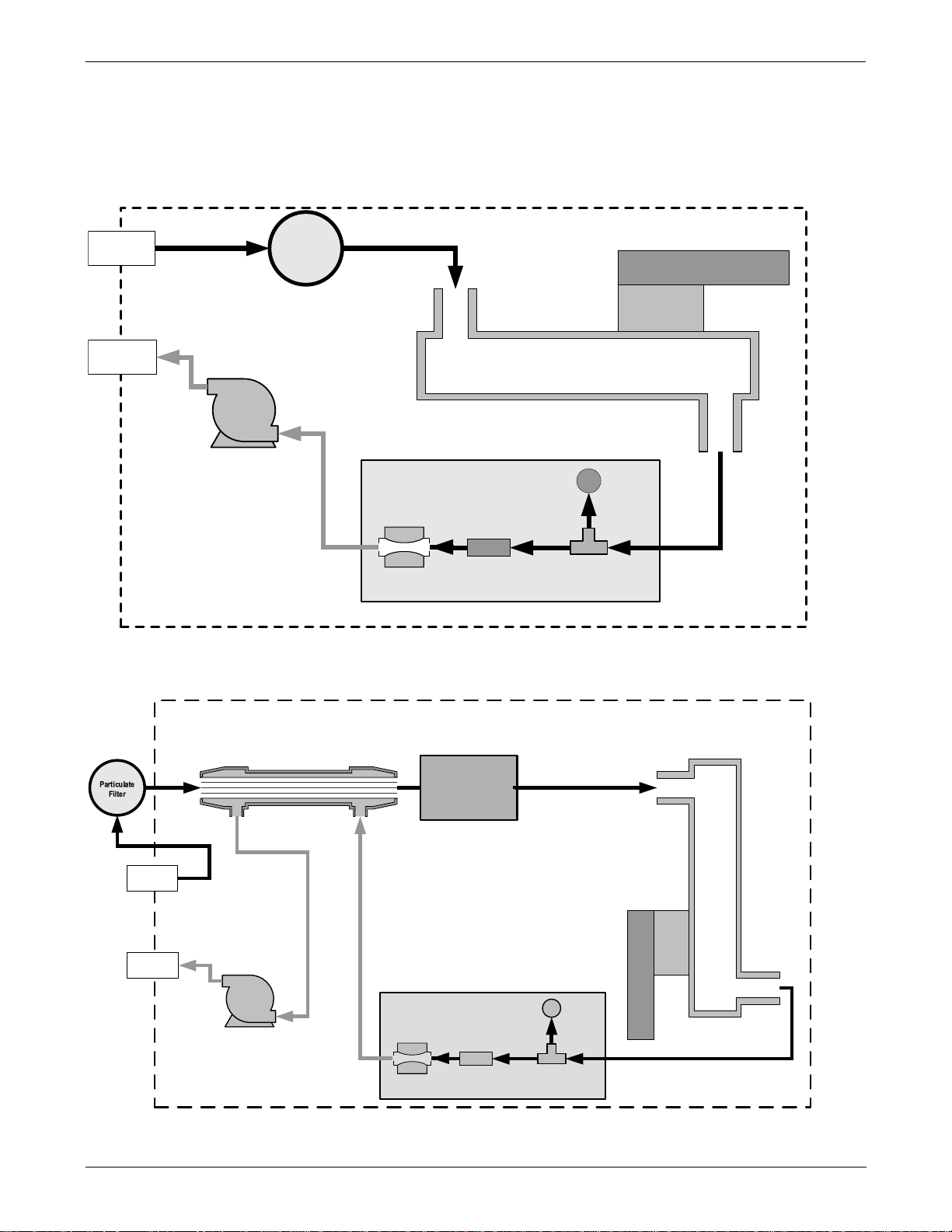

3.4.2. INTERNAL PNEUMATIC FLOW

The T320 internal pneumatic flow is illustrated in Figure 3-1.

The T320U internal pneumatic flow is illustrated in Figure 3-2.

Figure 3-1. T320 Pneumatic Flow

07406B DCN7347 11

Figure 3-2. T320U Pneumatic Flow

Page 14

Getting Started Teledyne API T320/T320U Addendum to T300/T300M Manual

Source of

SAMPLE GAS

Removed during

calibration

VENT

Calibrated N2O

Gas

at 100x span gas

concentration

VENT

here if input

is pressurized

Chassis

PRESSURE SPAN

IZS

SAMPLE

EXHAUST

VENT SPAN

Model T700 Gas

Dilution

Calibrator

Zero Gas

Synthetic Air,

Ultra-Zero Air,

N

2

Source of

SAMPLE GAS

Removed during

calibration

VENT

Calibrated

N

2

O Gas

at span gas

concentration

VENT

here if input

is pressurized

Chassis

PRESSURE SPAN

IZS

SAMPLE

EXHAUST

VENT SPAN

Zero Gas

Synthetic Air,

Ultra-Zero Air,

N

2

3.4.3. PNEUMATIC CONNECTIONS TO T320/T320U BASIC CONFIGURATION:

The information found in the Pneumatic Connections section of the T300/T300M Operators Manual (P/N 06864)

is applicable to the T320/T320U with the following changes:

• Synthetic air, ultra-zero air or N

the TAPI Model 701. The following figures document this difference.

Figure 3-3. Pneumatic Connections, Basic Configuration Using Gas Dil ution Calibrator

should be used as the zero gas rather than a Zero Gas Generator like

2

Figure 3-4. Pneumatic Connections, Basic Configuration Using Bottled Span Gas

12 07406B DCN7347

Page 15

Teledyne API T320/T320U Addendum to T300/T300M Manual Getting Started

Source of

SAMPLE GAS

VENT

Calibrated

N

2

O Gas

at span gas

concentration

VENT

here if input

is pressurized

Chassis

PRESSURE SPAN

IZS

SAMPLE

EXHAUST

VENT SPAN

VENT

Zero Gas

Synthetic Air,

Ultra-Zero Air,

N

2

Source of

SAMPLE GAS

Removed during

calibration

Calibrated

N

2

O

Gas

at span gas

concentration

VENT

here if input

is pressurized

Chassis

PRESSURE SPAN

IZS

SAMPLE

EXHAUST

VENT SPAN

VENT

Zero Gas

Synthetic Air,

Ultra-Zero Air,

N

2

VENT

3.4.4. PNEUMATIC CONNECTIONS TO T320/T320U WITH INTERNAL VALVE

OPTIONS INSTALLED

• The following figures show the pneumatic set up for T320/T320U analyzers with one of the three

available internal valve options installed. For more information on these options see Section 5 of this

addendum.

Figure 3-5. Pneumatics: Option Z/S Valve with Shutoff Valve for Pressurized Span and Atmospheric Zero

Figure 3-6. Pneumatics: Option Z/S without Shutoff Va lve

07406B DCN7347 13

Page 16

Getting Started Teledyne API T320/T320U Addendum to T300/T300M Manual

Source of

SAMPLE GAS

VENT

Calibrated

N2O Gas

at span gas

concentration

VENT

here if input

is pressurized

Chassis

PRESSURE SPAN

IZS

SAMPLE

EXHAUST

VENT SPAN

Zero Gas

Synthetic Air,

Ultra-Zero Air,

N

2

Figure 3-7. Pneumatics: Option Z/S Valve with Common Shutoff Valve for Pressurized Zero and Span

3.4.5. PNEUMATIC CONNECTIONS TO T320/T320U IN MULTIPOINT CALIBRATION

Some applications re quir e multipoint calibration checks where Span gas of several different concentrations is

needed. We recommend using high-concentration, certified, calibration gas supplied to the analyzer through a

gas dilution calibrator such as a Teledyne API T700. This type of calibrator precisely mixes span gas and zero

air to produce max concentration levels between 0 ppm and the concentration of the certified gas. This means

that both the source of zero air and span gas must be connected to the calibrator whose output is then

connected to the span inlet on the rear panel of the instrument.

APPLICATIONS

14 07406B DCN7347

Page 17

4. FREQUENTLY ASKED QUESTIONS & GLOSSARY

The information found in the Frequently Asked Questions section of the T300/T300M Operators Manual (P/N

06864) is applicable to the T320/T320U.

07406B DCN7347 15

Page 18

Frequently Asked Questions & Glossary Teledyne API T320/T320U Addendum to T300/T300M Manual

This page intentionally left blank.

16 07406B DCN7347

Page 19

OPTION

NO.

VALVES AND IZS

50G

Zero / Span Valves with Shut-off Valve (Pressurized Zero/Pressurized Span)

TOLL-FREE:

800-324-5190

FAX:

+1 858-657-9816

TEL:

+1 858-657-9800

E-MAIL:

api-sales@teledyne.com

WEB SITE:

www.teledyne-api.com

5. OPTIONAL HAR DWARE AND S O F TWARE

Not all options are available for the T320 and T320U as are available for the T300 and T300M.

5.1. CALIBRATION VALVE OPTIONS FOR THE

T320/T320U

There three valve options available for the T320 and T320U analyzers

Table 5-1. T320/T320U Available Valve Options

DESCRIPTION

50A Ambient Zero/Ambient Span Valves

50B Zero / Span Valve with shut-off valve (Ambient Zero/ Pressurized Span)

For descriptions of op tio ns 50A and 50B and their use please see the Calibration Valves Options section of the

T300/T300M Operators Manual (P/N 06864) but not ing that wherever a zero air generator like the TAPI 701 is

shown, synthetic air, ultra-zero air, or N

Section 5.1.1 of this addendum.

For assistance with ordering these options, please contact the Sales department of Teledyne API at:

should be substituted. For a description of option 50G please see

2

07406B DCN7347 17

Page 20

Optional Hardware and Software Teledyne API T320/T320U Addendum to T300/T300M Manual

MODE

VALVE

CONDITION

INSTRUMENT CHASSIS

Flow / Pressure

Sensor PCA

SAMPLE

PRESSURE

SENSOR

FLOW

SENSOR

Sample Gas

Flow Control

SAMPLE GAS

INLET

EXHAUST

GAS OUTLET

Particulate Fi lter

PUMP

IZS INLET

PRESSURE

SPAN INLET

VENT SPAN

OUTLET

Sample / Cal

Valve

Zero / Span

Valve

GFC Wheel

Housing

GFC Motor Heat

Sync

SAMPLE CHAMBER

Zero

Gas

In

Sample

Gas

In

Span

Gas

In

Shutoff

Valve

5.1.1. ZERO/SPAN WITH COMMON SHUTOFF VALVES (OPTION 50G)

Option 50G is operationally and pneumatically similar to Option 50B (see T300/T300M manual), except that both

the zero and span gases are applied to the analyzer under pressure. This option is designed to be used with

bottled zero and span gases. A shutoff valve is used to stop flow from the bottles during sample mode and a

common vent is used to bring the pressure of the calibration gas down to local ambient pressure.

Table 5-2. Zero/Span/Shutoff Valve Operating States for Option 50G

Sample/Cal Open to SAMPLE inlet

SAMPLE

(Normal State)

ZERO CAL

SPAN CAL

Zero/Span Open to internal ZERO AIR inlet

Shutoff Valve Closed

Sample/Cal Open to ZERO/SPAN valve

Zero/Span Open to ZERO AIR inlet

Shutoff Valve Open to ZERO/SPAN valve

Sample/Cal Open to ZERO/SPAN valve

Zero/Span Open to SPAN inlet

Shutoff Valve Open to ZERO/SPAN valve

Figure 5-1. Internal Pneumatic Flow, Option Zero/Span with Common Shutoff Valves

18 07406B DCN7347

Page 21

Units

The full-scale limit at which the output range of the analyzer’s Analog

PPB, PPM

Standard deviation of N2O concentration readings. Data points are recorded

The demodulated, peak IR detector output during the reference portion of

The result of N2O MEAS divided by N2O REF based on readings taken

The absolute pressure of the Sample gas as measured by a pressure

Wheel

Photo-detector

The sensitivity of the instrument as calculated during the last calibration

The overall offset of the instrument as calculated during the last calibration

Test Channel

The raw voltage being output on the analyzer’s A4 analog output. Only

The current time. This is used to create a time stamp on DAS readings, and

6. BASIC OPERATION

6.1. TEST FUNCTIONS

The information found in the Test Functions section of the T300/T300M Operators Manual (P/N 06864) is

applicable to the T320/T320U with the following exception(s):

• The following table supersedes Test Functions Defined table of the T300/T300M Operators Manual (P/N

06864).

Table 6-1. Test Functions Defined

Parameter Display Title

RANGE

- RANGE1

RANGE2

Stability

N2O Measure

N2O Reference

Measurement /

Reference Ratio

Sample Pressure

Sample Flow

Bench

Temperature

Temperature

Box Temperature

RANGE

STABIL

MEAS

REF

MR Rat io

PRES

SAMPLE FL

BENCH TEMP

WHEEL TEMP

BOX TEMP

PPB, PPM

UGM, MGM

UGM, MGM

MV

MV

–

In-Hg-A

cm3/min

°C

°C

°C

Meaning

Outputs is currently set.

• THIS IS NOT the Physical Range of the instrument. See Section 6.6.1 of

the T300/T300M Operators Manual (P/N 06864) for more information.

If DUAL or AUTO Range modes have been selected, two RANGE functions

will appear, one for each range.

every ten seconds using the last 25 data points.

The demodulated, peak IR detector output during the measure portion of the

GFC Wheel cycle.

the GFC wheel cycle.

during the normal sample measurement portion of the A-REF cycle.

This ratio is the primary value used to compute N

value displayed is not linearized.

sensor located inside the sample chamber.

Sample mass flow rate as measured by the flow rate sensor in the sample

gas stream,

Optical bench temperature.

GFC wheel temperature.

The temperature inside the analyzer chassis.

O concentration. The

2

Temp. Control

Voltage

Slope

Offset

Output

Current Time

PHT DRIVE

SLOPE

OFFSET

TEST

TIME

mV

–

–

mV

–

07406B DCN7347 19

The drive voltage being supplied to the thermoelectric coolers of the IR

photo-detector by the sync/demod Board.

activity. The SLOPE parameter is used to set the span calibration point of

the analyzer.

activity. The OFFSET parameter is used to set the zero point of the

analyzer response.

appears when the test channel is assigned a function.

by the AUTOCAL feature to trigger calibration events.

Page 22

Basic Operation Teledyne API T320/T320U Addendum to T300/T300M Manual

FULL SCALE

The drive voltage being supplied to the thermoelectric

NOTE

Upper span limit setting for the individual range modes are shared. Resetting the span limit in one mode

also resets the span limit for the corresponding range in the other modes as follows:

NOTE

Concentrations displayed in mg/m3 and ug/m3 use 0°C , 760 mmHg for Standard Temperature and

Pressure (STP). Consult your local regulations for the STP used by your agency.

NOTE

Once the units of measurement have been changed, the unit MUST be recalibrated, as the “expected

span values” previously in effect will no longer be valid. Simply entering new expected span values

without running the entire calibration routine is not sufficient.

The following equations give approximate conversions between volume/volume units and

weight/volume units:

N2O ppb x 2.052 = N2O ug/m

3

N2O ppm x 2.052 = N2O mg/m3

6.1.1. SELECTING A TEST CHANNEL FUNCTION FOR OUTPUT A4

This section supplements the corresponding section of the T300/T300M Operators Manual (P/N 06864)

The Test Functions available to be reported on analog output A4 are:

Table 6-2. Test Channels Functions Available on the T320/T320U’s Analog Output

TEST CHANNEL DESCRIPTION ZERO

NONE TEST CHANNEL IS TURNED OFF

N2O MEAS

N2O REF

SAMPLE

PRESSURE

SAMPLE FLOW

BENCH TEMP

WHEEL TEMP

BOX TEMP

PHT DRIVE

The raw output of the optical bench’s IR detector during

the measure phase of the m/r cycle

The raw output of the optical bench’s IR detector during

the reference phase of the m/r cycle

The pressure of gas in the optical bench’s sample chamber

The gas flow rate through the optical bench’s sample

chamber

The temperature of optical bench’s itself

The temperature of GFC wheel

The temperature of the circulating air inside the convection

oven section of the T320/T320U’s interior.

coolers of the IR photo-detector by the sync/demod Board.

0 mV 5000 mV

0 mV 5000 mV

0” Hg 40” Hg-In-A

0 cm3/min

0 C° 70 C°

0 C° 70 C°

0 C° 70 C°

0 mV 5000 mV

1000

cm

3

/min

Once a function is selected, the instrument not only begins to output a signal on the analog output, but also adds

TEST to the list of Test Functions viewable via the Front Panel Display.

20 07406B DCN7347

Page 23

7. ADVANCED FEATU RES

The information found in the Advanced Features section of the T300/T300M Operators Manual (P/N 06864) is

applicable to the T320 and T320U we recommend that you read that section before continuing.

07406B DCN7347 21

Page 24

Advanced features Teledyne API T320/T320U Addendum to T300/T300M Manual

This page intentionally left blank.

22 07406B DCN7347

Page 25

8. REMOTE OPERATION

The information found in the Remote Operation section of the T300/T300M Operators Manual (P/N 06864) is

applicable to the T320 and T320U we recommend that you read that section before continuing.

8.1.1. HESSEN PROTOCOL

The information found in the Hessen Protocol Gas ID section of the T300/T300M Operators Manual (P/N 06864)

is applicable to the T320/T320U with the following exception(s):

• There is only one default gas type programmed into the T320/T320U: the Hessen Gas ID for N

O is 320.

2

07406B DCN7347 23

Page 26

Remote Operation Teledyne API T320/T320U Addendum to T300/T300M Manual

This page intentionally left blank.

24 07406B DCN7347

Page 27

9. CALIBRATION P ROCEDURES

Calibration of the T320/T320U should be perf ormed according to the procedures des c ribed in the Calibration

esction of the T300/T300M Manual - P/N 06864 with the following notes and exceptions:

• Delivering span and zero gases for the higher resolution the T320/T320U can be difficult. Attention must

be paid to the quality of the gases, the level of contaminants in the gases as well as the history and

conditioning of the gas delivery components.

• The analyzer must be continually operating with and adequate flow of sample gas, for 2 hours prior to

performing a calibration (12 hours is recommended for the initial calibration).

• DO NOT calibrate the analyzer if it has been turned off or if no sample gas has been flow though it

within the last 2 hours.

• After this stabilization period is complete and just prior to performing the initial calibration, force the

instrument to perform an auto-reference measurement.

REQUIRED EQUIPMENT, SUPPLIES AND EXPEND ABL ES

• Gas lines to and from the analyzer should be PTFE or FEP Teflon, glass, or stainless steel only.

• Zero-air source which must be synthetic air, ultra-zero air or nitrogen (N

). A zero air generator like a T-

2

API M701 should not be used.

• Span gas source (defined in the Calibration section’s Span Gas subsection of the T300/T300M

Operators Manual; but use N

O instead of CO).

2

• A recording device such as a strip-chart recorder and/or data logger (optional). Data recording device

should be capable of bi-polar operation so that negative readings can be recorded.

• For electronic documentation, the internal data acquisition system can be used.

NOTE

If any problems occur while performing the fo llowing calibration procedures, refer to Troubleshooting

and Service sectionthe T300/T300M manual for troubleshooting tips.

MANUAL CAL IBRATION

The information found in the Manual Calibration section of the T300/T300M Operators Manual (P/N 06864) is

applicable to the T320/T320U with the following exception:

• Set the display to show the N2OSTB test rather than the CO STB test function mentioned in the

T300/T300M operator’s manual.

07406B DCN7347 25

Page 28

Calibration Procedures Teledyne API T320/T320U Addendum to T300/T300M Manual

This page intentionally left blank.

26 07406B DCN7347

Page 29

10. EPA PROTOCOL CALIBRATION

The information found in the EPA Prot ocil Ca libra ti on section of the T300/T300M Operators Manual (P/N 06864)

does not apply to the T320/T320U as there are no USEPA reference methods for the measurement of N

2

O.

07406B DCN7347 27

Page 30

EPA Protocol Calibration Teledyne API T320/T320U Addendum to T300/T300M Manual

This page intentionally left blank.

28 07406B DCN7347

Page 31

11. PRINCIPLES OF OPERATION

The information found in the Principles of Operation section of the T300/T300M Operators Manual (P/N 06864)

is applicable to the T320 and T320U (we recommend that you read this section before continuing) with the

following exception:

The wavelength of operation is 4.58µm versus 4.7µm for the T300/T300M.

07406B DCN7347 29

Page 32

Principles OF OPERATION Teledyne API T320/T320U Addendum to T300/T300M Manual

This page intentionally left blank.

30 07406B DCN7347

Page 33

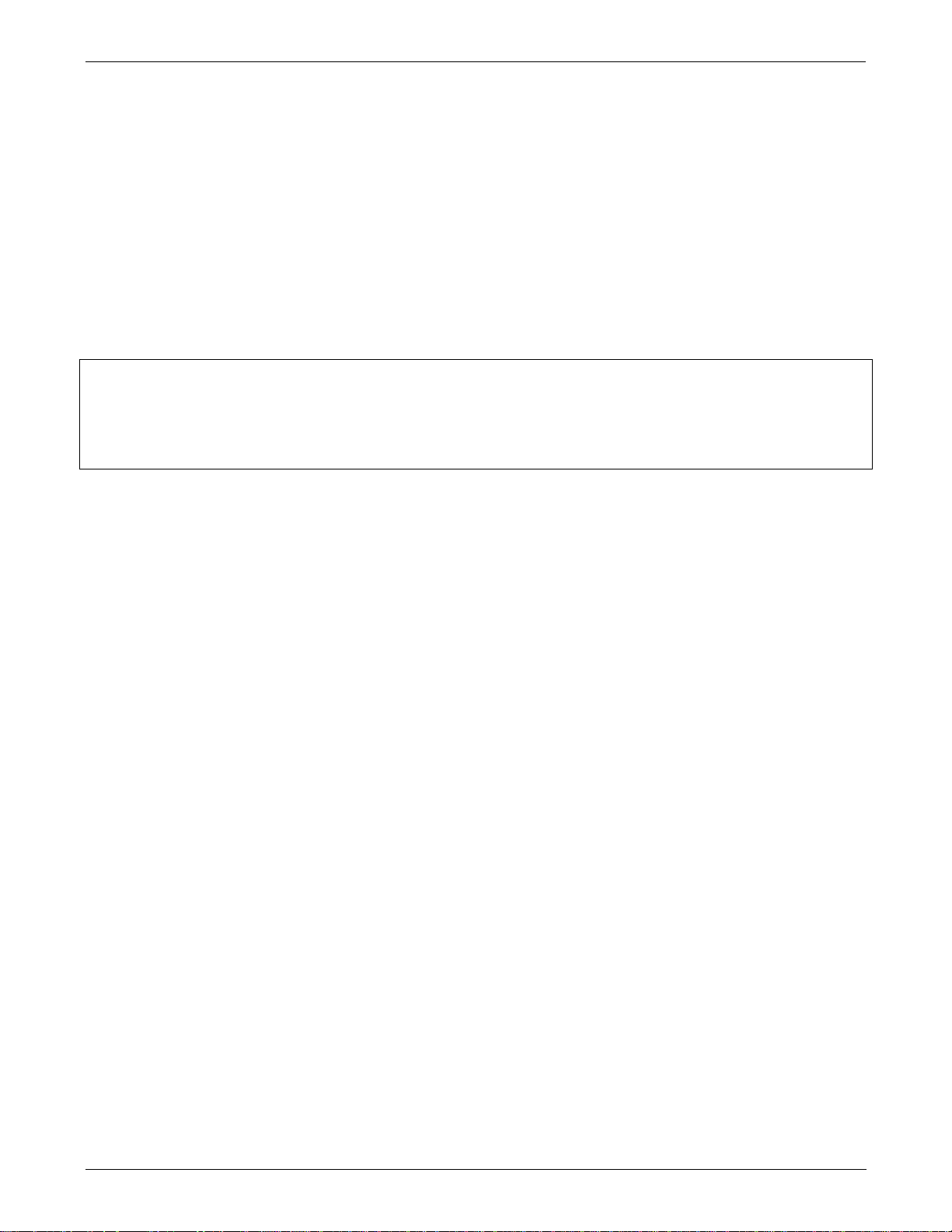

12. MAINTENANCE SCHEDULE

The information found in the Maintenance section of the T300/T300M Operators Manual (P/N 06864) is

applicable to the T320/T320U with the following exception(s):

• Since a catalytic zero scrubber is not available for the T320 or T320U there is no replacement schedule

for the scrubber material.

• The Test record below should be used in place of the one included with the T300/T300M manual.

Table 12-1. T320/T320U Test Function Record

FUNCTION

STABILITY

N2O MEAS

N2O REF

MR RATIO

PRES

PHT DRIVE

SLOPE

OFFSET

BOX TEMP

OPERATING

MODE

ZERO CAL

ZERO CAL

ZERO CAL

ZERO CAL

SPAN CAL

SAMPLE

SAMPLE AFTER

WARM-UP

SPAN CAL

ZERO CAL

SAMPLE

DATE RECORDED

07406B DCN7347 31

Page 34

Maintenance Schedule Teledyne API T320/T320U Addendum to T300/T300M Manual

This page intentionally left blank.

32 07406B DCN7347

Page 35

13. TROUBLESHOOTING & SERVICE

The information found in the Troubleshooting and Service section of the T300/T300M Operators Manual (P/N

06864) is applicable to the T320 and T320U. It is recommended that you read that section before continuing.

07406B DCN7347 33

Page 36

Troubleshooting & Service Teledyne API T320/T320U Addendum to T300/T300M Manual P/N 06864

This page intentionally left blank.

34 07406B DCN7347

Loading...

Loading...