Page 1

MANUAL ADDENDUM

MODEL T300U

CO Analyzer with Auto-Reference

(Addendum to T300/T300M Operation Manual, P/N 06864)

© TELEDYNE API (TAPI)

9970 CARROLL CANYON ROAD

SAN DIEGO, CA 92131-1106

Toll-free Phone:

800-324-5190

Phone:

+1 858-657-9800

Fax:

+1 858-657-9816

Email:

api-sales@teledyne.com

Website:

http://www.teledyne-api.com/

Copyright 2 01 0-2018 06867D DCN7970

Teledyne AP I 21 August 2018

Page 2

Page 3

06867D DCN7970 i

WARRANTY

See Warranty page in the T300/T300M Manual - P/N 06864.

ABOUT THIS MAN UAL

This manual is intended for use in conjunction with the Model T300/T300M

Operation Manual, part number 06864. Where operation of the Model T300U

diverges from that of the Model T300/T300M, this addendum takes precedence.

Page 4

Teledyne API - T300U Addendum to T300/T300M Manual

ii 06867D DCN7970

This page intentionally left blank.

Page 5

06867D DCN7970 iii

SAFETY MESSAGES

Important safety messages are provided throughout this manual for the purpose of avoiding personal injury

or instrument dam age. Ple ase rea d thes e m es sages c aref ully. Eac h saf et y mess age is as socia ted with a

safety alert symbol, and ar e placed throughout this manual an d inside the instrument. The s ymbols with

messages are defined as follows:

WARNING: Electrical Shock Hazard

HAZARD: Strong oxidizer

GENERAL WARNING/CAUTION: Read the accompanying message for

specific information.

CAUTION: Hot Surface Warning

Do Not Touch: Touching some parts of the instrument without

protection or proper tools could result in damage to the part(s) and/or the

instrument.

Technician Symbol: All operations marked with this symbol are to be

performed by qualified maintenance personnel only.

Electrical Ground: This symbol inside the instrument marks the central

safety grounding point for the instrument.

CAUTION

This instrument should only be used for the purpose and in the manner described

in this manual. If you use this instrument in a manner other than that for which it

was intended, unpredictable behavior could ensue with

possible hazardous

consequences.

NEVER use any gas analyzer to sample combustible g as(es)!

Note

Technical Assistance regarding the use and maintenance of the

T300/T300M or any other Teledyne API product can be obtained by

contacting Teledyne API’s Technical Support Department:

Phone: 800-324-5190

Email: api-techsupport@teledyne.com

or by accessing various service options on our website at

http://www.teledyne-api.com/

.

Page 6

Teledyne API - T300U Addendum to T300/T300M Manual

iv 06867D DCN7970

CONSIGNES DE SÉCURITÉ

Des consignes de sécurité importantes sont fournies tout au long du présent manuel dans le but d’éviter des

blessures corporelles ou d’endommager les instruments. Veuillez lire attentivement ces consignes. Chaque

consigne de sécur ité est re présentée par un pictogr amme d’aler te de sécur ité; ces pict ogramm es se retrouven t

dans ce manuel et à l’intérieur des instruments. Les symboles correspondent aux consignes suivantes :

AVERTISSEMENT : Risque de choc électrique

DANGER : Oxydant puissant

AVERTISSEMENT GÉNÉRAL / MISE EN GARDE : Lire la consigne

complémentaire pour des renseignements spécifiques

MISE EN GARDE : Surface chaude

Ne pas toucher : Toucher à certaines parties de l’instrument sans protection ou

sans les outils appropriés pourrait entraîner des dommages aux pièces ou à

l’instrument.

Pictogramme « technicien » : Toutes les opérations portant ce symbole doivent

être effectuées uniquement par du personnel de maintenance qualifié.

Mise à la terre : Ce symbole à l’intérieur de l’instrument détermine le point central

de la mise à la terre sécuritaire de l’instrument.

MISE EN GARDE

Cet instrument doit êt re utilisé aux fins décrites e t de la manière décrite d ans

ce manuel. Si vous utilisez cet instrument d’une autre manière que celle pour

laquelle il a été prévu, l’instrument pourrait se comporter de façon imprévisible

et entraîner des conséquences dangereuses.

NE JAMAIS utiliser un analyseur de gaz pour échantillonner des gaz

combustibles!

Page 7

06867D DCN7970 v

TABLE OF CONTENTS

1. INTRODUCTION ..................................................................................................................................................................... 9

1.1. Reference Numbering Convention ................................................................................................................................... 9

1.2. T300U Overview ............................................................................................................................................................... 9

1.3. Calibration Valve Options for the T300U ........................................................................................................................ 10

2. SPECIFICATIONS, APPROVALS, AND WARRANTY ........................................................................................................ 11

2.1. Specifications ................................................................................................................................................................. 11

2.2. EPA Equivalency Designation ........................................................................................................................................ 12

2.3. Approvals and Certifications ........................................................................................................................................... 12

2.3.1. Safety ..................................................................................................................................................................... 12

2.3.2. EMC ........................................................................................................................................................................ 12

2.3.3. Other Type Certifications ........................................................................................................................................ 12

3. GETTING STARTED ............................................................................................................................................................ 13

3.1. Unpacking the T300U ..................................................................................................................................................... 13

3.2. Instrument Layout ........................................................................................................................................................... 13

3.3. Connections and Setup .................................................................................................................................................. 15

3.3.1. Electrical Connections ............................................................................................................................................ 15

3.3.1.1. Connecting Analog Outputs ............................................................................................................................ 15

3.3.2. Connecting Status Outputs ..................................................................................................................................... 17

3.3.3. Pneumatics ............................................................................................................................................................. 18

3.4. Startup, Functional Checks, and Initial Calibration ......................................................................................................... 20

3.4.1. Startup .................................................................................................................................................................... 20

3.4.2. Warning Messages ................................................................................................................................................. 20

3.4.3. Functional Checks .................................................................................................................................................. 21

3.5. Initial Calibration ............................................................................................................................................................. 22

3.5.1. Pre-Calibration Stabilization ................................................................................................................................... 22

3.5.2. Basic CO Calibration SETUP ................................................................................................................................. 22

3.5.2.1. Calibration Gases ........................................................................................................................................... 22

3.5.3. Basic CO Calibration Procedure ............................................................................................................................. 23

4. T300U OPERATING INSTRUCTIONS ................................................................................................................................. 25

4.1. Summary of Setup and operation Differences between T300U and T300/T300M Analyzers. ........................................ 25

4.2. Operating Modes ............................................................................................................................................................ 26

4.2.1. Auto-Reference Mode (A-REF) .............................................................................................................................. 27

4.2.2. Test Functions ........................................................................................................................................................ 28

4.3. SETUP RNGE: Analog Output Reporting Range Configuration ................................................................................ 29

4.3.1. Physical Range versus Analog Output Reporting Ranges ...................................................................................... 29

4.3.2. Analog Output Ranges for CO Concentration ......................................................................................................... 29

4.3.3. RNGE MODE SNGL: Configuring the T300U Analyzer for Single Range Mode ........................................... 31

4.3.4. RNGE MODE DUAL: Configuring the T300U Analyzer for Dual Range Mode ............................................. 32

4.3.5. RNGE MODE AUTO: Configuring the T300U Analyzer for Auto Range Mode .............................................. 33

4.3.6. SETUP RNGE UNIT: Setting the Reporting Range Unit Type ....................................................................... 35

4.4. SETUP MORE AREF: Configuring and Performing Auto-Reference Measurements ............................................ 36

4.4.1. Adjusting the A-REF Mode Cycle Time .................................................................................................................. 36

4.4.2. Forcing an Auto-Reference Measurement .............................................................................................................. 38

4.5. SETUP MORE VARS: Variables Setup and Definition .......................................................................................... 39

4.6. SETUP MORE DIAG: Diagnostics Functions ....................................................................................................... 40

4.7. Analog Output Configuration .......................................................................................................................................... 41

4.7.1. Analog I/O Configuration ........................................................................................................................................ 41

4.7.2. Analog Output Calibration ....................................................................................................................................... 44

4.7.3. Selecting a Test Channel Function for Output A4 ................................................................................................... 45

4.7.4. Hessen Protocol ..................................................................................................................................................... 47

5. CALIBRATION PROCEDURES ........................................................................................................................................... 49

5.1. Required Equipment, Supplies and Expendables .......................................................................................................... 49

5.2. Manual Calibration ......................................................................................................................................................... 49

5.2.1. Manual Calibration Checks ..................................................................................................................................... 50

5.2.2. Manual Calibration with Zero/Span Valves ............................................................................................................. 50

5.2.3. Manual Calibration Checks with Zero/Span Valves ................................................................................................ 50

5.2.4. Calibration With Remote Contact Closures ............................................................................................................ 50

5.2.5. Automatic Zero/Span Cal/Check (AutoCal) ............................................................................................................ 50

5.2.6. CO Calibration Quality ............................................................................................................................................ 51

5.2.7. Calibration of Optional Sensors .............................................................................................................................. 51

6. EPA PROTOCOL CALIBRATION ........................................................................................................................................ 53

7. INSTRUMENT MAINTENANCE ........................................................................................................................................... 55

Page 8

Teledyne API - T300U Addendum to T300/T300M Manual Table of Contents

vi 06867D DCN7970

7.1. Perfoming an Auto-Reference Measurement after Maintenance .................................................................................... 55

8. PRINCIPLES OF OPERATION............................................................................................................................................. 59

8.1. Measurement Method .................................................................................................................................................... 59

8.1.1. Auto-Reference (A-REF) Ratio ............................................................................................................................... 59

8.2. Pneumatic Operation ...................................................................................................................................................... 60

8.2.1. The A-REF Carbon Monoxide Scrubber ................................................................................................................. 61

8.2.2. The A-REF Valve Assembly ................................................................................................................................... 61

8.2.3. The Nafion Dryer. ................................................................................................................................................. 61

8.3. Electronic Operation ....................................................................................................................................................... 64

8.3.1. Overview ................................................................................................................................................................. 64

8.3.2. The Relay PCA ....................................................................................................................................................... 65

8.3.2.1. Temperature Control of the Convection Oven ................................................................................................ 66

8.3.2.2. Oven Heater AC Power Configuration ............................................................................................................ 67

8.3.2.3. Status LEDs .................................................................................................................................................... 68

8.3.3. Motherboard ........................................................................................................................................................... 68

8.3.3.1. A to D Conversion ........................................................................................................................................... 68

8.3.3.2. Sensor Inputs .................................................................................................................................................. 68

8.3.4. Power Distribution................................................................................................................................................... 69

9. TROUBLESHOOTING & SERVICE ...................................................................................................................................... 71

9.1. General Notes ................................................................................................................................................................ 71

9.2. Fault Diagnosis with Warning Messages ........................................................................................................................ 72

9.2.1. Fault Diagnosis with Test Functions ....................................................................................................................... 74

9.2.2. Relay Board Status LEDs ....................................................................................................................................... 76

9.3. Gas Flow Problems ........................................................................................................................................................ 77

9.4. Other Performance Problems ......................................................................................................................................... 77

9.4.1. Unexplained Drift .................................................................................................................................................... 77

9.5. Subsystem Checkout ..................................................................................................................................................... 78

9.5.1. Relay Board ............................................................................................................................................................ 78

9.5.2. Motherboard ........................................................................................................................................................... 78

9.5.2.1. A/D Functions ................................................................................................................................................. 78

9.6. Technical Assistance ...................................................................................................................................................... 79

LIST OF FIGURES

Figure 3-1: T300U Internal Layout .................................................................................................................14

Figure 3-2: T300U Analog Output Connector ................................................................................................16

Figure 3-4: T300U Internal Pneumatic Flow – Ambient Zero/Span Valves (OPT 50A) .................................19

Figure 4-1: Display during A-REF Mode ........................................................................................................27

Figure 4-2: Analog Output Connector Pin Out ...............................................................................................29

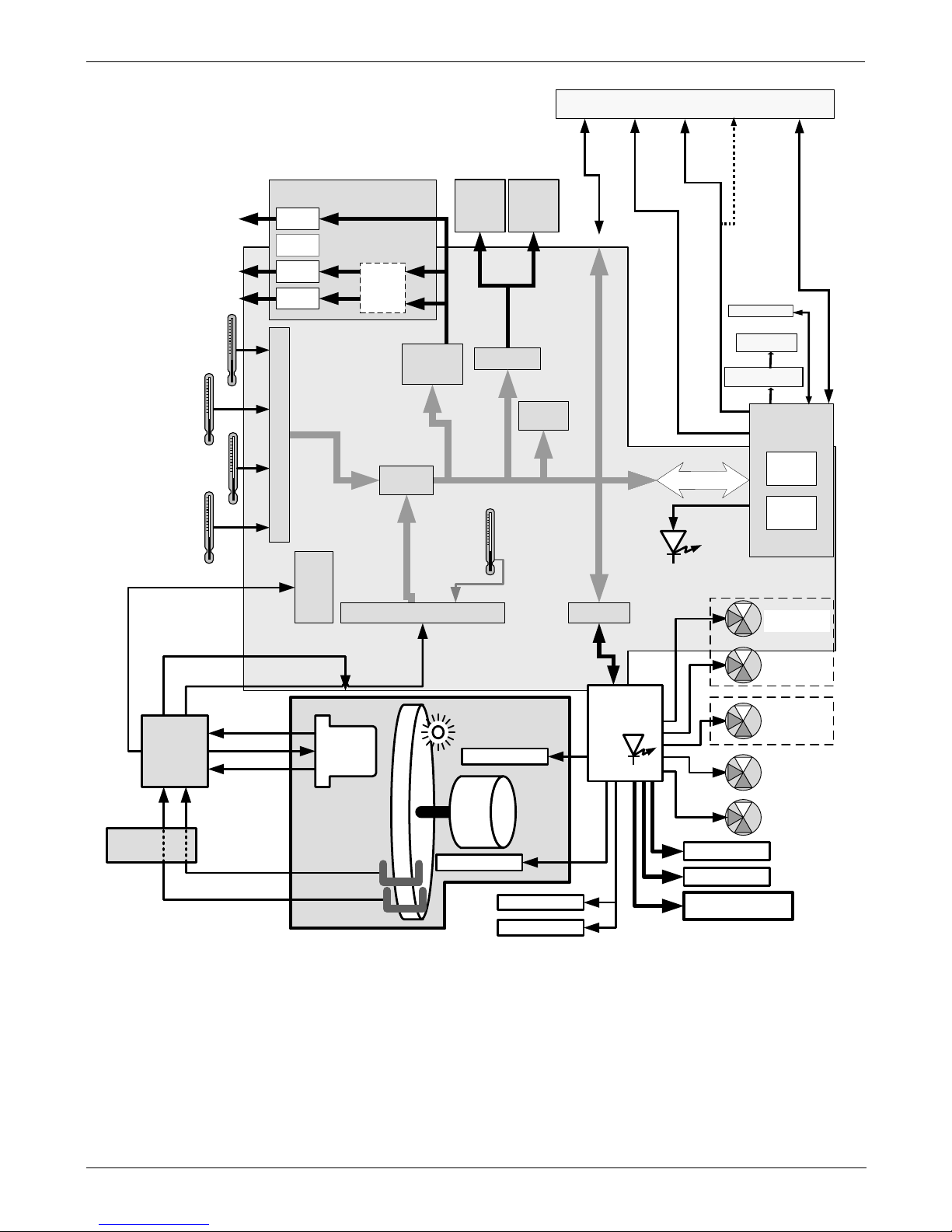

Figure 8-1: T300U Gas Flow during Auto-Reference Measurements............................................................59

Figure 8-2: Auto-Reference Measurement Cycle...........................................................................................60

Figure 8-3: Semi-Permeable Membrane Drying Process ..............................................................................62

Figure 8-4: T300U Electronic Overview Block Diagram .................................................................................65

Figure 8-5: T300U Heating Control Block Diagram........................................................................................66

Figure 8-6: T300U Oven Heater Configuration Jumpers ...............................................................................67

Figure 8-7: T300U Oven Heater Configuration Circuit ...................................................................................67

Figure 8-8: T300U Distribution Block Diagram ...............................................................................................69

LIST OF TABLES

Table 2-1: T300U Basic Unit Specifications ..................................................................................................11

Table 3-1: Analog Output Data Type Default Settings ..................................................................................16

Table 3-2: Analog Output Pin Outs ...............................................................................................................16

Table 3-3: Status Output Pin Assignments ...................................................................................................17

Table 3-4: Possible Warning Messages at Start-Up .....................................................................................20

Table 4-1: T300U Operating Modes .............................................................................................................26

Table 4-2: Test Functions Defined ................................................................................................................28

Page 9

Table of Contents Teledyne API - T300U Addendum to T300/T300M Manual

06867D DCN7970 vii

Table 4-3: T300U VARS Menu .....................................................................................................................39

Table 4-4: T300U Diagnostic (DIAG) Submenus ..........................................................................................40

Table 4-5: DIAG - Analog I/O Functions .......................................................................................................41

Table 4-6: Test Channels Functions Available on the T300U’s Analog Output ............................................45

Table 4-7: T300U Hessen GAS ID List .........................................................................................................47

Table 4-8: Default Hessen Status Bit Assignments ......................................................................................47

Table 5-1: AUTOCAL Modes ........................................................................................................................50

Table 7-1: T300U Test Function Record .......................................................................................................57

Table 8-1: Auto-Reference Valve Operating States .....................................................................................61

Table 8-2: Relay Board Status LED’s ...........................................................................................................68

Table 9-1: Warning Messages - Indicated Failures ......................................................................................72

Table 9-2: Test Functions - Indic at ed Fail ur es ..............................................................................................74

Table 9-3: Relay Board Status LED Failure Indications ...............................................................................76

Table 9-4: Relay Board Control Devices .......................................................................................................78

LIST OF APPENDICES

APPENDIX A: Software Menu Trees, Revision L.8

APPENDIX B: Interconnect List and Diagram

Page 10

Teledyne API - T300U Addendum to T300/T300M Manual Table of Contents

viii 06867D DCN7970

This page intentionally left blank.

Page 11

06867D DCN7970 9

1. INTRODUCTION

This addendum for the Teledyne API Model T300U is a supplement to the T300/T300M

manual (P/N 06864) and provides an overview of the instrument operation and specific

details regarding those areas where the T300U is different in design or operating method

from the T300.

In most ways the T300U is identical to the T300/T300M in design and operation;

therefore, most of the basic set up information, operating instructions and calibration,

maintenance, troubleshooting and repair methods are the same and can be f ound in the

T300/T300M manual (P/N 06864).

1.1. REFERENCE NUMBERING CONVENTION

Unless otherwise specified, section, figure and table reference numbers referred to

within this text are relative to this document. EXAMPLE: “Table 2-1” refers to the table

within this document.

Additionally, in the electronic version(s) of this manual references internal to this

document will be active links to that section, figure or table.

References to sections, figures and tables in other manuals will be labeled as such and

will not be an active link. EXAMPLE: “Figure 6.1 of the T300/T300M Operators

Manual (P/N 06864)”.

1.2. T300U OVERVIEW

The Model T300U is a close derivative of the T300/T300M CO Ana lyzer; however its

higher sensitivity requires some changes to its design and operation, which are

documented in this addendum.

The primary differences between the T300U and the T300/T300M analyzers are:

• INTERFERENT REJECTION: Periodically the sample gas stream is routed through

an internal CO scrubber allowing the instrument to make a measurement of the

sample gas completely free of CO; the measurement made during this autoreference period (A-REF) is subtracted from the sample concentration

measurement. This corrects for instrument drift, ambient temperature changes and

changing CO

2

levels in the sample gas.

• OPERATING METHOD: An additional operating mode is added allowing the user to

manipulate several parameters associated with the A-REF measurement cycle.

• SAMPLE GAS CONDITIONING: A Nafion

drier is used to dry the sample and

alleviate any effects from humidity changes in the sample gas.

• IR OPTICS: The objective and field mirrors on the optical bench are gold plated.

This maximizes their reflectivity and increasing the amount of IR light reaching the

detector and improving the optical bench’s signal-to-noise performance.

• PNEUMATIC OPERATION: The flow rate is higher. It has a 1.8 LPM nominal flow

rate. The flow sensor is rated to 6 LPM.

• MECHANICAL DESIGN: The optical bench is placed in a temperature-controlled,

convection-heated oven. This dramatically reduces instrument noise and

temperature related drift.

Page 12

Introduction Teledyne API - T300U Addendum to T300/T300M Manual

10 06867D DCN7970

1.3. CALIBRATION VALVE OPTIONS FOR THE T300U

The hardware options for the T300x family of analyzers are available in the T300U. For

a list and descriptions of these options please see Section 1 of the T300/T300M

Operators Manual (P/N 06864).

However, the T300U offers one calibration valve option: Ambient Zero and Ambient

Span, except that due to the auto-reference gas path and multi-tube Nafion

dryer, this

option has a different gas flow in the T300U versus the T300/T300M.

Page 13

06867D DCN7970 11

2. SPECIFICATIONS, APPROVALS, AND WARRANTY

2.1. SPECIFICATIONS

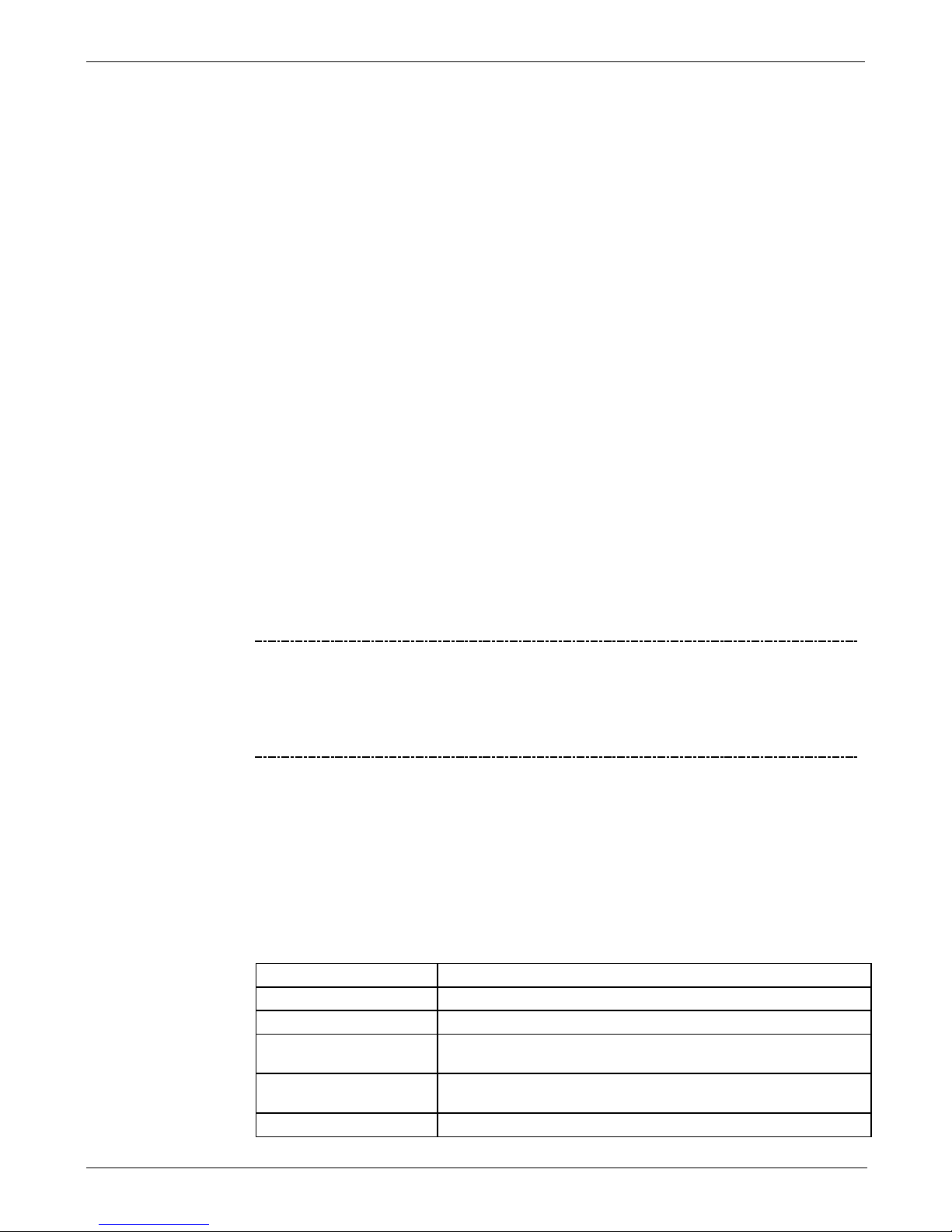

Table 2-1: T300U Basic Unit Specifications

PARAMETER SPECIFICATION

Ranges

Min: 0-100 ppb Fu ll sca le

Max: 0-100 ppm Full scale (selecta ble dual ran ges and aut o rangin g supp or ted)

Measurement Units ppb, ppm, µg/m3, mg/m3 (selectable)

Zero Noise 1 ≤ 10 ppb RMS

Span Noise 1 < 0.5% of reading RMS above 2.5 ppm 3

Lower Detectable Limit < 20 ppb

Zero Drift (24 hours) 2 < 20 ppb

Span Drift (24 hours) 4

< 0.5% of reading above 5ppm

Lag Time 1 10 sec

Rise/Fall Time 1 < 60 sec to 95%

Linearity 5 1% of full scale

Precision 1, 5 0.5% reading

Sample Flow Rate 1800 cm3/min. ± 20%

AC Power Requirements

Rating

100V-120V~, 60Hz, 3.0 A

220V-240V~, 50/60 Hz, 3.0 A

Typical Power Consumption

165 W

225 W

Analog Output Ranges 10V, 5V, 1V, 0.1V (selectable)

Analog Output Resolution 1 part in 4096 of selected full-scale voltage

Recorder Offset ± 10%

Voltage Coefficient < 0.05 % of reading per V

Standard I/O

1 Ethernet: 10/100Base-T

2 RS-232 (300 – 115,200 baud)

2 USB front panel device ports

8 opto-isolated digital status o utput s

6 opto-isolated digital control i nputs (2 defined, 4 spare)

4 analog outputs

Optional I/O

1 USB com port

1 RS485

8 analog inputs (0-10V, 12-bit)

4 digital alarm outputs

Multidrop RS232

3 4-20mA current outputs

Environmental Conditions

Installation Category (Over voltage Category) II Pollution Degree 2

Intended for indoor use only at altitudes ≤ 2000 m

Temperature Range

5 - 40°C operating

Humidity Range 0-95% RH, Non-Condensing

Dimensions (HxWxD) 7" x 17" x 23.5" (178 mm x 432 mm x 597 mm)

Weight 50 lb (22.7 kg)

Certifications CE: EN61010-1:90 + A1:92 + A2:95, EN61326 - Class A

1

As defined by the USEPA

2

At constant temperature and voltage

3

Or 10 ppb, whichever is greater

4

Or 20 ppb, whichever is greater 5 Above 1 ppm range, o therwise 20 ppb for lower ranges

Page 14

Specifications, Approvals, and Warranty Teledyne API - T300U Addendum to T300/T300M Manual

12 06867D DCN7970

2.2. EPA METHOD DESIGNATION

Teledyne API’s T300U carbon monoxide analyzer is designated as a reference method

(RFCA-1093-093) for CO measurement, as defined in 40 CFR Part 53. The official List

of Designated Reference and Equivalent Methods is published in the U.S. Federal

Register

– http://www3.epa.gov/ttn/amtic/criteria.html.

2.3. APPROVALS AND CERTIFICATIONS

The Teledyne API Model T300/T300M analyzer was tested and certified for Safety and

Electromagnetic Compatibility (EMC). This section presents the compliance statements

for those requirements and directives.

2.3.1. SAFETY

IEC 61010-1:2001 (3r d Edit ion) , Safety requirements for electrical equipment for

measurement, control, and laboratory use.

CE: 2006/95/EC, Low-Voltage Directive

2.3.2. EMC

EN 61326-1 (IEC 61326-1), Class A Emissions/Industrial Immunity

EN 55011 (CISPR 11), Group 1, Class A Emissions

FCC 47 CFR Part 15B, Class A Emissions

CE: 2004/108/EC, Electromagnetic Compatibility Directive

2.3.3. OTHER TYPE CERTIFICATIONS

MCERTS: Sira MC 050068/05

For additional certification s , please cont ac t Technical Support.

Page 15

06867D DCN7970 13

3. GETTING STARTED

CAUTION

GENERAL SAFETY HAZARD

To avoid personal injury, always use two persons to lift and carry the

T300/T300M.

ATTENTION

COULD DAMAGE INSTRUMENT AND VOID WARRANTY

Printed Circuit Assemblies (PCAs) are sensitive to electro-static discharges

too small to be felt by the human nervous system. Failure to use ESD

protection when working with electronic assemblies will void the instrument

warranty. See A Primer on Electro-Static Discharge of the T300/300M

manual for more information on preventing ESD damage.

CAUTION!

Do not operate this instrument until you’ve removed dust plugs from SAMPLE

and EXHAUST ports on the rear panel!

Note

Teledyne API recommends that you store shipping containers/materials for

future use if/when the instrument should be returned to the factory for repair

and/or calibration service. See Warranty section in this manual and shipping

procedures on our Website at

http://www.teledyne-api.com under Customer

Support > Return Authorization.

3.1. UNPACKING THE T300U

Unpack and install the T300U per the directions in Sections 3.1 and 3.1.1. of the

T300/T300M manual (P/N 06864).

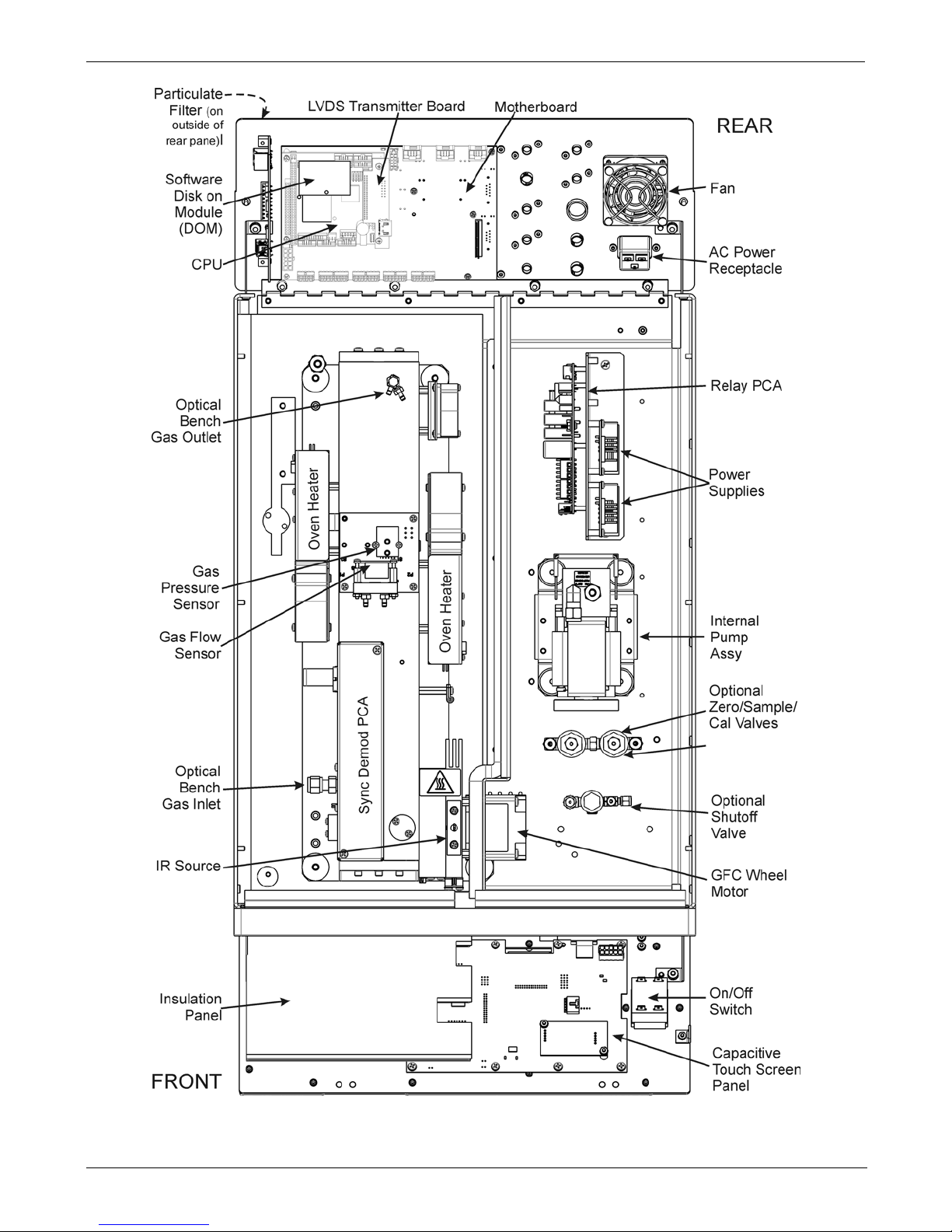

3.2. INSTRUMENT LAYOUT

The front pa nel of the T300U is identical to tha t of the T300/T300M (see Figure 3-1 of

the T300/T300M Operators Manual, P/N 06864). The Rear Panel is also very similar to

that of the T300/T300M (see Figure 3-4 of the T300/T300M Operators Manual, P/N

06864), the only difference being that the instrument’s particulate filter is mounted

externally on the upper left side of the rear panel rather than internally as on the

T300/T300M.

The internal layout of t he T300U (Figure 3-1) differs from the T300/T300M due to the

need to create a thermally insulated, convection-heated oven in which the optical bench

temperature is raised and maintained at a high and very stable temperature. Additionally,

there is a multi-tube, high flow Nafion

dryer t hat removes moisture from the sample

gas.

Page 16

Getting Started Teledyne API - T300U Addendum to T300/T300M Manual

14 06867D DCN7970

Figure 3-1: T300U Internal Layout

Page 17

Teledyne API - T300U Addendum to T300/T300M Manual Getting Started

06867D DCN7970 15

3.3. CONNECTIONS AND SETUP

The information found in Section 3.3 of the T300/T300M Operators Manual (P/N

06864) is applicable to the T300U with the exceptions of the Analog and Status Output

connections, as described here.

Note

To maintain compliance with EMC standards, it is required that the cable

length be no greater than 3 meters for all I/O connections, which include

Analog In, Analog Out, Status Out, Control In, Ethernet/LAN, USB, RS-232,

and RS-485.

3.3.1. ELECTRICAL CONNECTIONS

The electrical connection instructions in the T300/T300M Operators Manual apply

except as differentiated herein.

3.3.1.1. Connecting Analog Outputs

The analog outputs for the T300U are different from those of the T300/T300M. Unlike

the T300/T300M which can include options for measuring both O

2

and CO, the T300U

is a single gas analyzer (CO) and therefore does not require the fully configurable

version of the analog outputs. The following information replaces the Analog Outputs

Section of the T300/T300M Operators Manual.

The T300U is equipped with several analog output channels accessible through a

connector on the rear panel of the instrument:

• Channels A1 and A2 output a signal that is proportional to the CO concentration of

the sample gas.

• The default analog output voltage setting of these channels is 0 to 5 VDC with

a reporting range of 0 to 500 ppb.

• An optional Current Loop output is available for each.

• The output labeled A4 is special. It can be set by the user to output any one a

variety of diagnostic test functions.

• The default analog output voltage setting of these channels is also 0 to 5 VDC.

• See Section 4.2.2 for a list of available functions.

• There is NO optional Current Loop output is available for Channel A4.

Table 3-1 lists the default settings for each of these channels.

Page 18

Getting Started Teledyne API - T300U Addendum to T300/T300M Manual

16 06867D DCN7970

Table 3-1: Analog Output Data Type Default Settings

PARAMETER CHANNEL DEFAULT SETTING

A1

A2

A3

A4

1

DATA TY PE

1

CONC1 CONC2

Not

Available

TEST

CHANNEL

RANGE

0 – 5 VDC2

OVERRANGE

ON

REC OFS

0 mVDC

AUTO CAL.

ON

CALIBRATED

NO

OUTPUT

ON

1

See Table A-6 of T300/T300M Appendix A for definitions of these DAS data types

2

Optional current loop outputs are available for analog output channels A1& A2.

To access these signals attach a strip chart recorder and/or data-logger to the appropriate

analog output connections on the rear panel of the analyzer. Pin-outs for the analog

output connector are:

ANALOG OUT

A1 A2 A3 A4

+ - + - + - + -

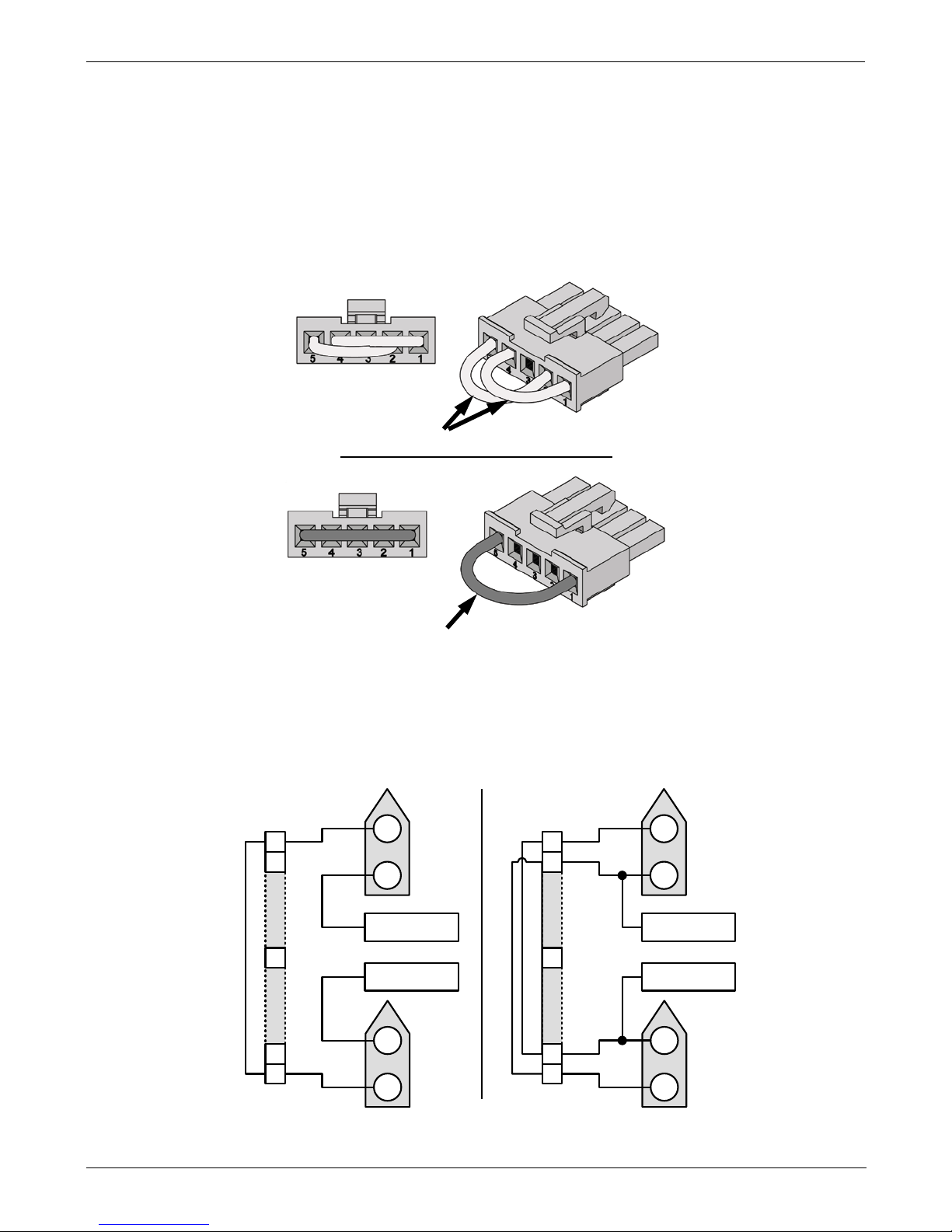

Figure 3-2: T300U Analog Output Connector

Table 3-2: Analog Output Pin Outs

Pin Analog Output

Standard Voltage

Output

Current

Loop Option

1

A1

V Out

I Out +

2

Ground

I Out -

3

A2

V Out

I Out +

4

Ground

I Out -

5

A3

NOT USED

6

7

A4

V Out

Not Available

8

Ground

Not Available

Page 19

Teledyne API - T300U Addendum to T300/T300M Manual Getting Started

06867D DCN7970 17

3.3.2. CONNECTING STATUS OUTPUTS

The information found in Section 3.3.1.5. of the T300/T300M Operators Manual is

correct with the following exception:

Table 3-3: Status Output Pin Assignments

Output #

Status

Definition

Condition

1 SYSTEM OK On if no faults are present.

2

CONC VALID

On if CO concentration measurement is valid.

If the CO concentration measurement is invalid, this bit is OFF.

3 HIGH RANGE

On if unit is in high range of

DUAL

or

AUTO

Range Modes.

4 ZERO CAL On whenever the instruments ZERO point is being calibrated.

5 SPAN CAL On whenever the instruments SPAN point is being calibrated.

6 DIAG MODE On whenever the instrument is in DIAGNOSTIC mode.

7

A-REF On whenever the instrument in is A-REF mode.

8 SPARE

D

EMITTER BUSS The emitters of the transistors on pins 1-8 are bussed together.

+

DC POWER + 5 VDC

Digital Ground The ground level from the analyzer’s internal DC Power Supplies.

Page 20

Getting Started Teledyne API - T300U Addendum to T300/T300M Manual

18 06867D DCN7970

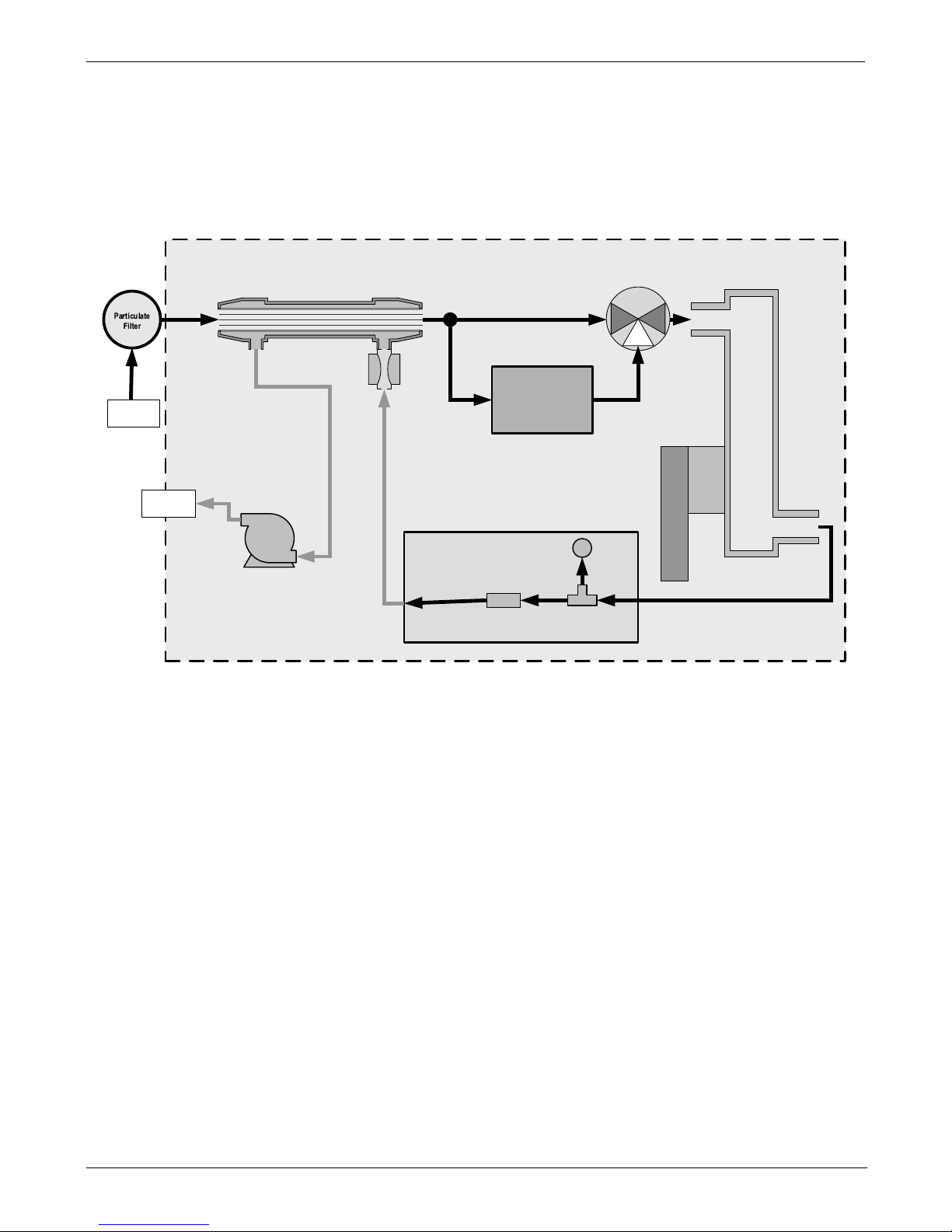

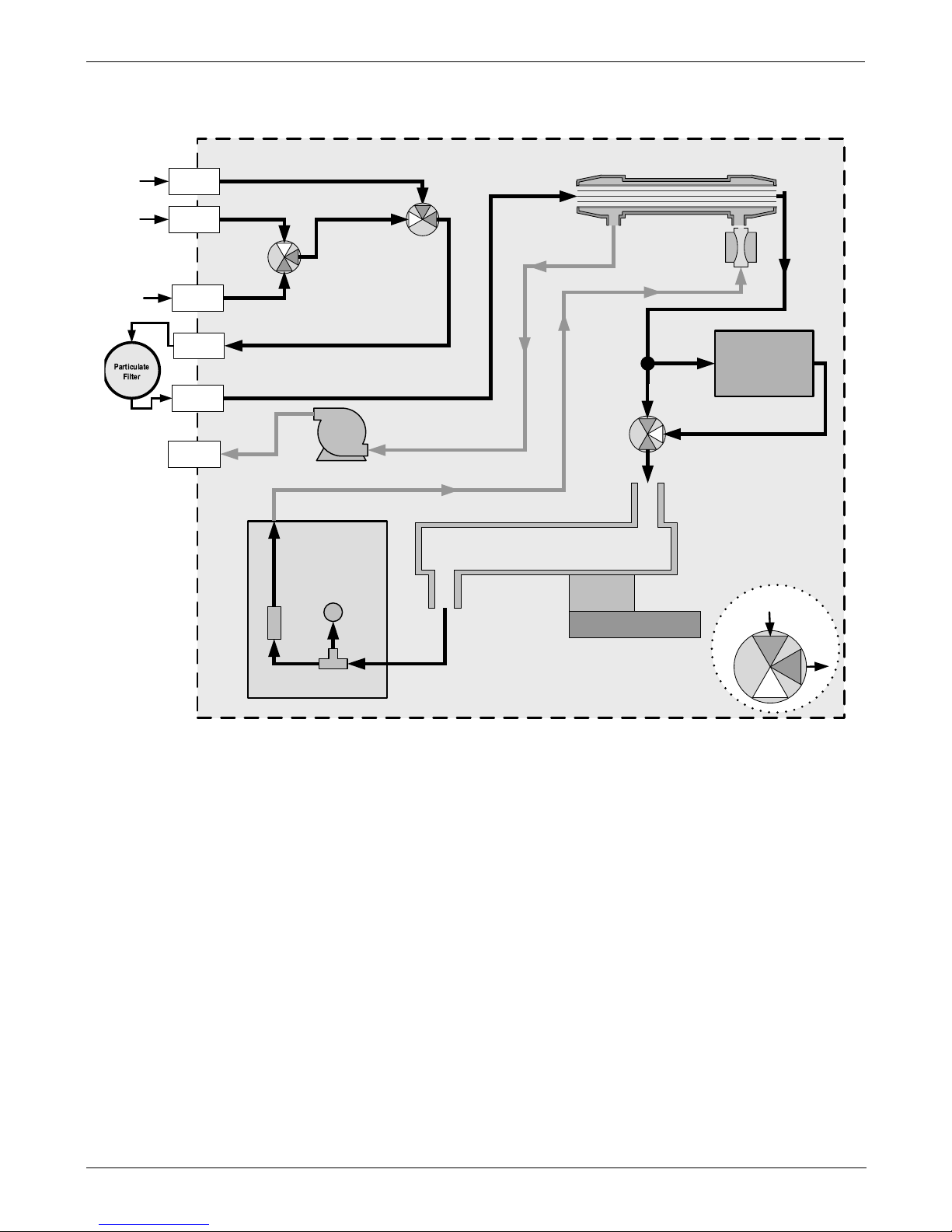

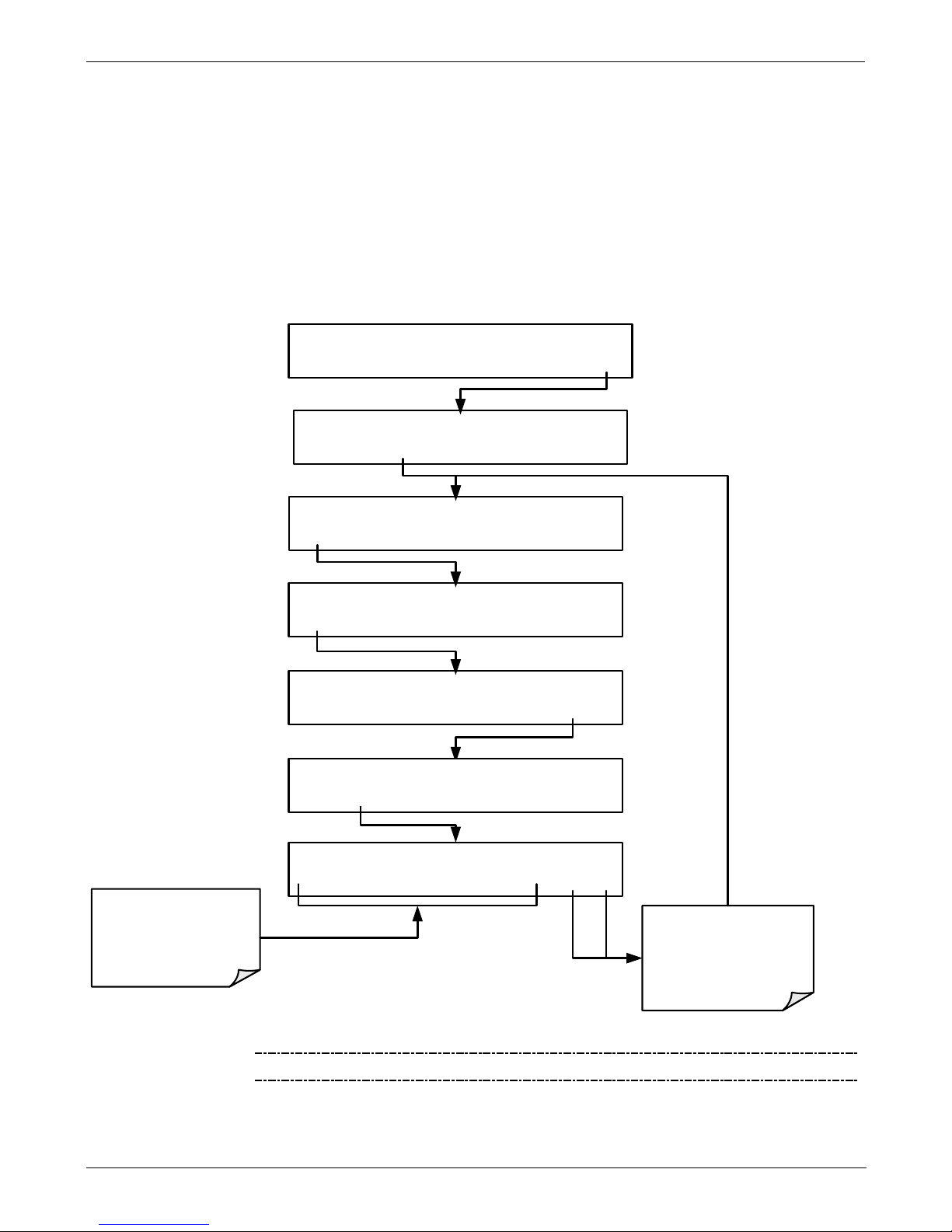

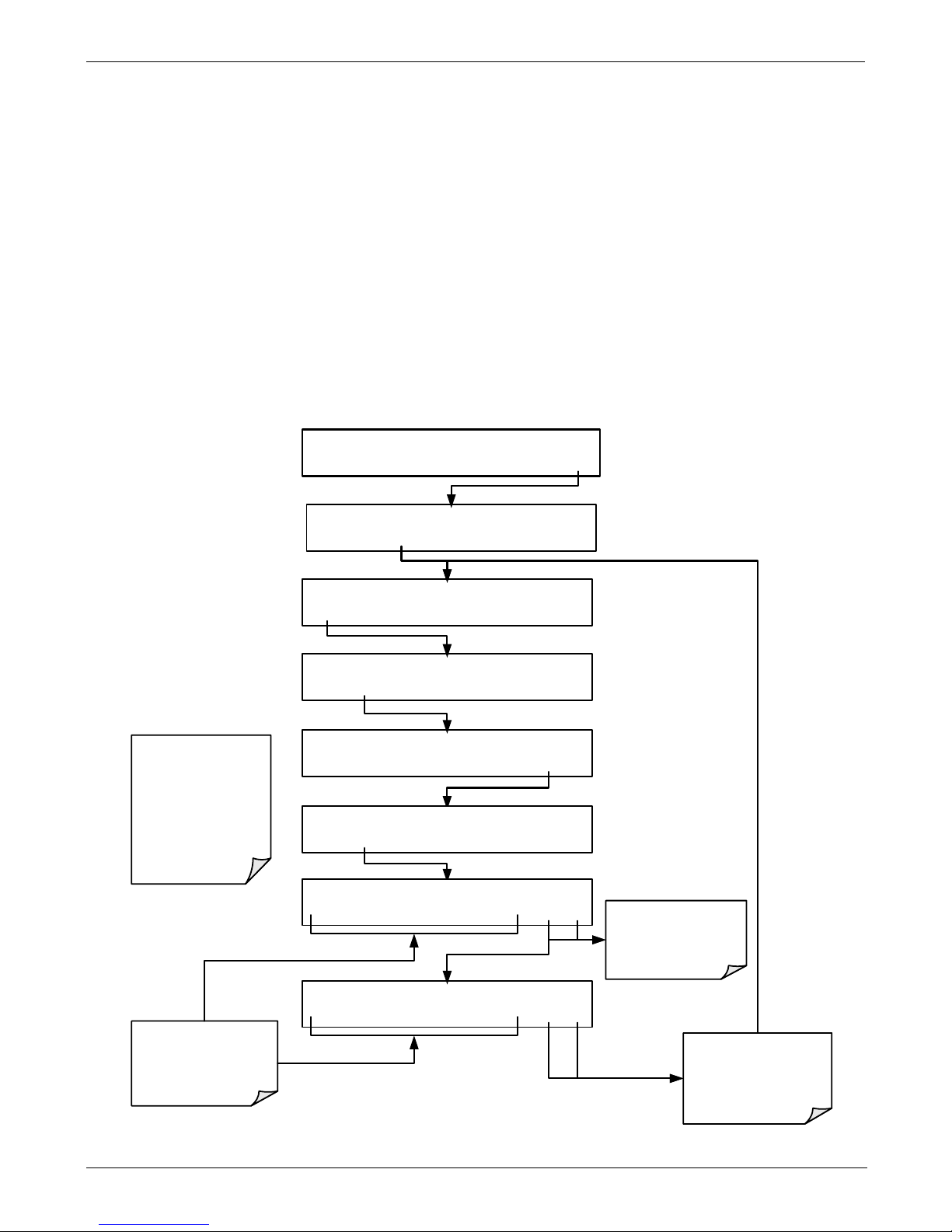

3.3.3. PNEUMATICS

The pneumatic flow of the T300U is different from the T300/T300M in two ways:

• The addition of a high-flow multi-tube Nafion

dryer.

• An additional gas path that passes the sample gas though a CO

scrubber used

during the auto-reference cycle.

INST RUM ENT CHASSIS

CO

Scrubber

Flow / Pressure

Sensor PCA

SAMPLE

PRESSURE

SENSOR

FLO W

SENSOR

Samp l e Gas

Flow Control

SAMPLE GAS

INLET

EXHAUST

GAS OUT LET

/

PUMP

GFC Wheel

Housing

GF C Motor Heat Sync

SAMPLE CH AMBER

Auto-

Reference

Valve

Multi-Tube Nafion

Dryer

3 2

1

NO COM

NC

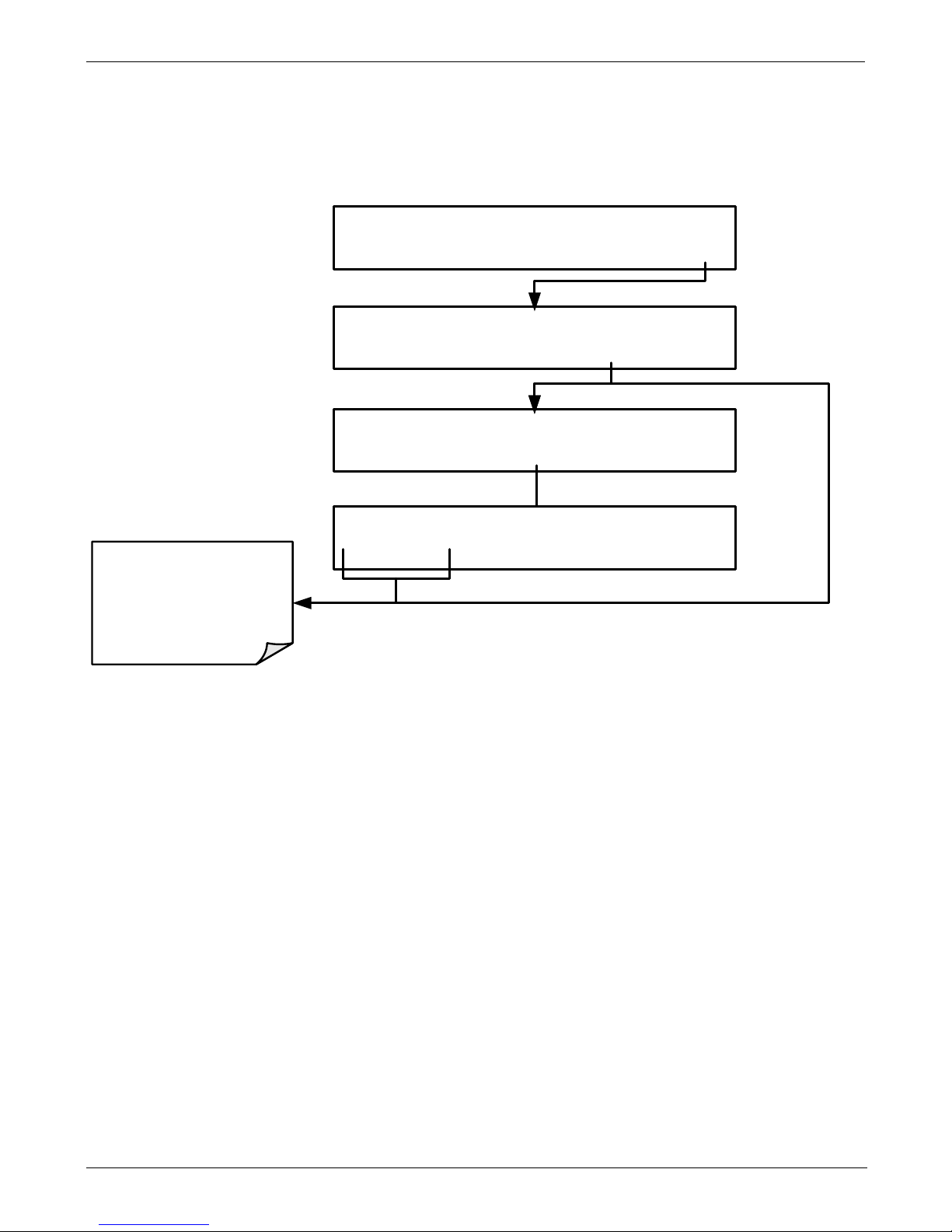

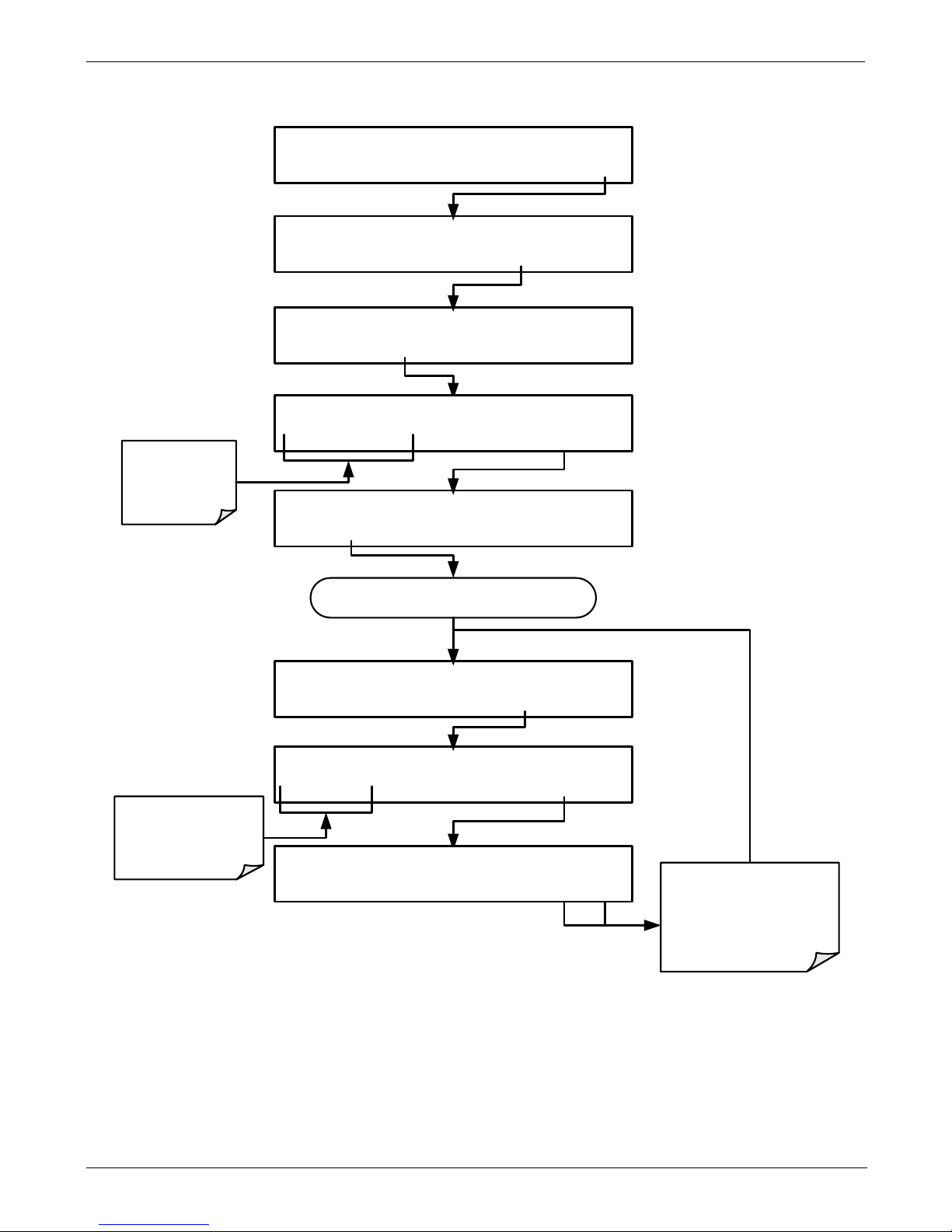

Figure 3-3: T300U Internal Pneumatic Flow – Basic Configuration

Page 21

Teledyne API - T300U Addendum to T300/T300M Manual Getting Started

06867D DCN7970 19

INSTRUMENT CH ASSIS

SAMPLE

PRESSURE

SENSOR

FLO W

SENSOR

Samp l e Gas

Flow Control

Flow / Pressure

Sensor PCA

EXHAUST

GAS OUTLET

PUMP

SAMPLE

GAS I N L ET

ZERO INLET

SPA N

INLET

Sample / Cal

Valve

Zero / Span

Valve

Zero

Gas

In

Sam ple

Gas

In

Span

Gas

In

CO

Scrubber

Auto-

Reference

Valve

Multi-Tube Nafion

Dryer

SAMPLE CHAMBER

GFC Wheel

Housing

GF C Motor Heat Sync

SAMPLE

FILTE R OUT

SAMPLE

FILTER IN

VALVE KEY:

NO

COM

NC

Figure 3-4: T300U Internal Pneumatic Flow – Ambient Zero/Span Valves (OPT 50A)

Page 22

Getting Started Teledyne API - T300U Addendum to T300/T300M Manual

20 06867D DCN7970

3.4. STARTUP, FUNCTIONAL CHECKS, AND INITIAL

CALIBRATION

IMPORTANT IMPACT ON READINGS OR DATA

The analyzer’s cover must be installed and securely fastened to ensure that the

convection oven portion of the internal layout is capable of properly creating

and controlling temperatures of the analyzer’s optical bench.

3.4.1. STARTUP

The process for starting and warming up the T300U is identical to that described in

Section 3.4.1 of the T300/T300M Operators Manual (P/N 06864) except:

• It is best to allow the T300U to operate uninterrupted for at least 2 hours to allow the

temperature of all areas of the convection oven area to equalize.

3.4.2. WARNING MESSAGES

The information found in Section 3.4.2 of the T300/T300M Operators Manual (P/N

06864) is applicable to the T300U with the following exceptions (marked by bold print

and heavy outline):

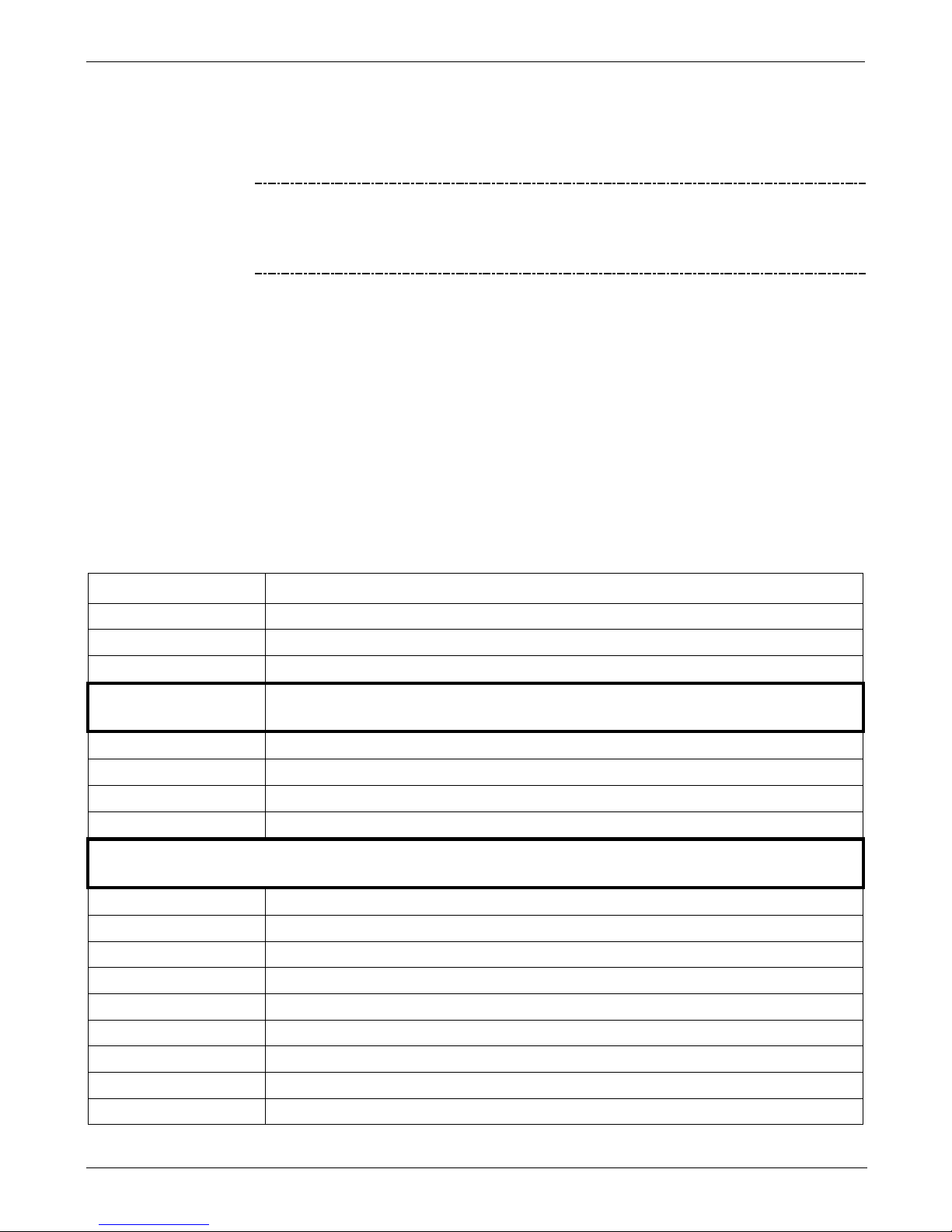

Table 3-4: Possible Warning Messages at Start-Up

MESSAGE MEANING

ANALOG CAL WARNING

The instrument's A/D circuitry or one of its analog outpu ts is not cali brated.

AZERO WARN 1.001

Auto-reference ratio below the specified limits.

BENCH TEMP WARNING

Optical bench temperature is outside the specified limits.

BOX TEMP2 WARNING

The temperature inside the T300U chassis is outside the specified limits

(Replaces BOX TEMP WARNING)

CANNOT DYN SPAN

Remote span calibration failed while the dynamic span feature was set to turned on

CANNOT DYN ZERO

Remote zero calibration failed while the dynamic zero feature was set to turned on

CONFIG INITIALIZED

Configuration was reset to factory defaults or was erased.

DATA INITIALIZED

DAS data storage was erased.

OVEN TEMP WARNING

The temperature of the insulated convection oven area of the analyzer is

outside the specified limits.

PHOTO TEMP WARNING

Photometer temperature outside of warning limits.

REAR BOARD NOT DET

The CPU is unable to communicate with the motherboard.

RELAY BOARD WARN

The firmware is unable to communi cat e w ith the relay boar d.

SAMPLE FLOW WARN

The flow rate of the sample gas is outside the specified limits.

SAMPLE PRESS WARN

Sample pressure outside of operational parameters.

SAMPLE TEMP WARN

The temperature of the sample gas is outside the specified limits.

SOURCE WARNING

The IR source may be faulty.

SYSTEM RESET

The computer was rebooted.

WHEEL TEMP WARNING

The Gas Filter Correlation wheel temperature is outside the specified limits.

Page 23

Teledyne API - T300U Addendum to T300/T300M Manual Getting Started

06867D DCN7970 21

3.4.3. FUNCTIONAL CHECKS

The information found in Section 3.4.3 of the T300/T300M Operators Manual (P/N

06864) regarding performing an initial functional check of the analyzer is applicable to

the T300U with the following exception(s).

The Test functions available from the front panel of the T300U are:

1

These range displays appear if the

instrument’s reporting ranges are set for either

the DUAL or AUTO modes

.

2

Only appears if analog output A4 is actively

reporting a TEST FUNCTION

SAMPLE RANGE=50.000 PPM CO= XXXX

<TST TST> CAL SETUP

Toggle <TST TST> buttons

to scroll through list of

functions

•

RANGE=[Value] PPB

•

RANGE1=[Value] PPB

1

•

RANGE2=[Value] PPB

1

•

STABIL=[Value] PPB

1

•

CO MEAS=[Value] MV

•

CO REF=[Value] MV

•

MR RATIO=[Value]

•

AZERO RATIO=[Value]

•

PRES=[Value] IN-HG-A

•

SAMP FL=[Value] CC/M

•

BENCH TEMP=[Value]ºC

•

WHEEL TEMP=[Value]ºC

•

OVEN TEMP=[Value]ºC

•

SAMPLE TEMP=[Value]ºC

•

PHT DRIVE=[Value] MV

•

SLOPE=[Value]

•

OFFSET=[Value] PPB

•

TEST=[Value] MV

2

•

TIME=[HH:MM:SS]

Page 24

Getting Started Teledyne API - T300U Addendum to T300/T300M Manual

22 06867D DCN7970

3.5. INITIAL CALIBRATION

3.5.1. PRE-CALIBRATION STABILIZ ATION

Before initially calibrating the T300U it must be allowed to operate for a minimum of 12

hours.

After this stabilization period is complete and just prior to performing the initial

calibration, manually initiate an auto-reference measurement by following the

instructions in Section 4.4.

3.5.2. BASIC CO CALIBRATION SETUP

Note

The following procedure assumes that the instrument does not have any o f the

available Zero/Span Valve Options installed.

To perform the following calibration you must have sources for zero air and span gas

available for input into the sample port on the back of the analyzer. See Section 3.3.2.1

of the T300/T300M Operators Manual (P/N 06864) for instructions for connecting these

gas sources.

Note

All Gas lines should be PTFE (Teflon), FEP, glass, stainless steel or brass.

3.5.2.1. Calibration Gases

The information found in Section 3.3.2.11 of the T300/T300M Operators Manual (P/N

06864) is applicable to the T300U with the following exception:

ZER O AI R

Zero air is a gas that is similar in chemical composition to the earth’s atmosphere but

scrubbed of all components that might affect the analyzer’s readings, in this case CO

and water vapor.

For the T300U this gas MUST include at least 5% O

2

(required for the proper operation

of the analyzer’s CO scrubber).

For analyzers without an IZS or external zero air scrubber option, a zero air generator

such as the Teledyne Instruments Model 701 can be used.

Note

The zero air generator MUST be equipped with a hydrocarbon (HC) & CO

scrubber option. For the Teledyne Instruments M701, this is Option 2B.

Page 25

Teledyne API - T300U Addendum to T300/T300M Manual Getting Started

06867D DCN7970 23

3.5.3. BASIC CO CALIBRATION PROCEDURE

The initial calibration should be carried out using the same reporting range set up as

used during the analyzer’s factory calibration. This will allow you to compare your

calibration results to the factory calibration as listed on the Final Test and Validation

Data Sheet.

Because the T300U’s analog output setup differs from that of the T300/T300M and

because the T300U could not be modified to include the optional CO

2

or O2 sensor

packages, there are some minor differences in the initial Calibration procedure as

described in Section 3.4 of the T300/T300M Operators Manual (P/N 06864).

These differences are:

• STEP 1 - Set Lim it s :

• Reporting Range Limit should be set to 50.000 ppm .

• STEP 2 – Dilution Ratio:

• Ignore this step

• STEP 3 – Set CO Span Gas Concentration

• The CO span gas concentration should be 40.000 ppm

• STEP 4 – Zero/Span CalibratiOn

• Set the display to show the STABILITY test function.

• There is no GAS TO CAL step because there are no gas options to choose in

the T300U.

Ignore Sections 3.4.4.3 and 3.4.4.4 of the T300/T300M Operators Manual (P/N 06864)

since they relate to sensor options not available on the T300U.

Page 26

Getting Started Teledyne API - T300U Addendum to T300/T300M Manual

24 06867D DCN7970

This page intentionally left blank.

Page 27

06867D DCN7970 25

4. T300U OPERATING INSTRUCTIONS

4.1. SUMMARY OF SETUP AND OPERATION DIFFERENCES

BETWEEN T300U AND T300/T300M ANALYZERS.

For the most part the setup and operation instruction for the T300U are the same as those

described in Sections 4, 5, and 6 of the T300/T300M manual (P/N 06864) with the

following exceptions:

• There are several additional Test functions related to the optical bench’s convection

oven and the A-REF cycle (see Section 4.2.2).

• There is and additional warning message related to the optical bench’s convection

oven (see Section 3.4.2)

• There is an additional operating mode, AREF, which can be used to force the

instrument to make an auto-reference measurement and calculation.

• There are several additional DAS trigger events and parameters (see Appendix A of

this addendum).

• The reporting range setup and configuration of the A1 and A2 analog outputs is

different (see Section 4.3).

• The optional O

2

and CO2 sensor packages available for the T300/T300M are not

available on the T300U. Ignore all references to these in the T300/T300M

Operators Manual (P/N 06864) when operating the T300U.

• The set of available VARS is different (see Section 4.5).

• The set of submenus available under the DIAG menu is slightly different (see

Section 4.6).

• The set of signals available under the DIAG SIGNAL I/O submenu is different

(see Appendix A of this addendum).

• Because of the difference in how the analog output ranges are implemented

between the T300/T300M and the T300U, there are some differences in DIAG

ANALOG I/O CONFIGURATION submenu (see Section

4.7.1).

• There are no alarm outputs available of the T300U. Ignore Sec ti on 5.10 of the

T300/T300M Operators Manual (P/N 06864).

• There is an additional STATUS OUTPUT related to the A-REF cycle (see Section

3.3.2).

• The default Hessen protocol gas ID and status flag list is different from that of the

T300/T300M (see Secti on 4.7.4).

Page 28

T300U Operating Instructions Teledyne API - T300U Addendum to T300/T300M Manual

26 06867D DCN7970

4.2. OPERATING MODES

The information found in Section 4 of the T300/T300M Operators Manual (P/N 06864)

is applicable to the T300U with the following exception(s).

The following table supersedes Table 4-1 of the T300/T300M Operators Manual (P/N

06864).

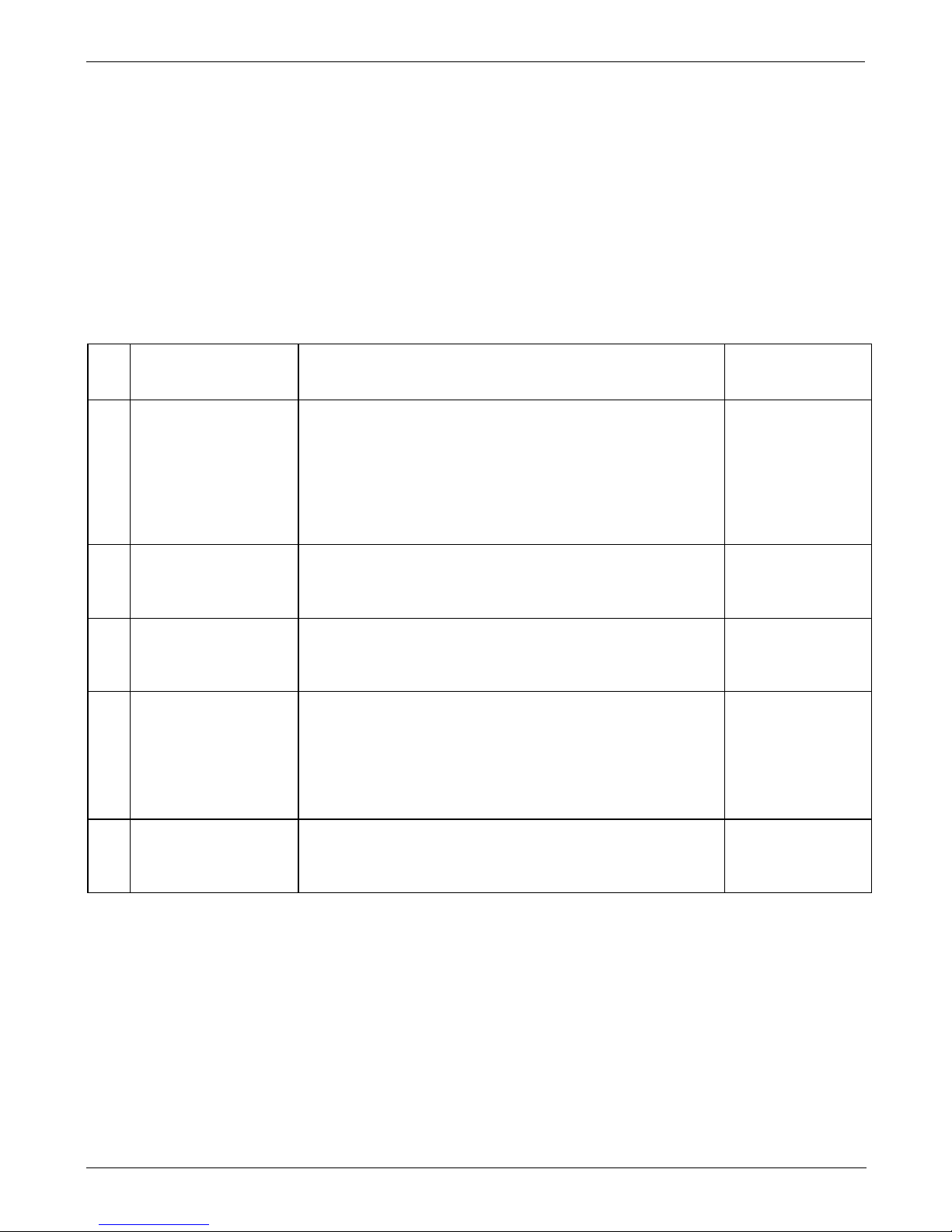

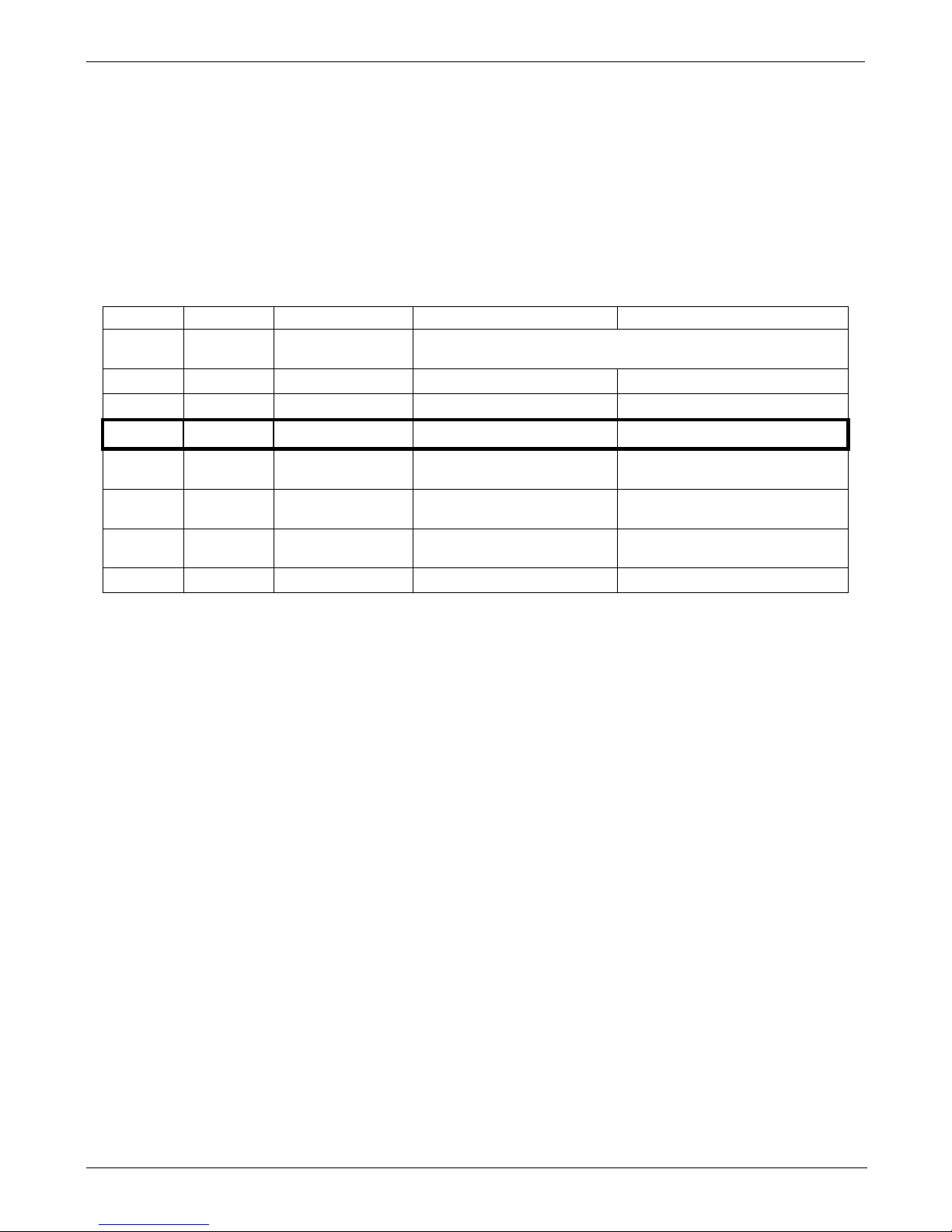

Table 4-1: T300U Operating Modes

MODE

MEANING

A-REF

The analyzer is currently recording values for CO MEAS and CO ref, while the

sample gas stream is being routed through the CO scrubber of the autoreference gas path.

DIAG

One of the analyzer’s diagnostic modes is being utilized.

M-P CAL

This is the basic, multi-point calibration mode of the instrument and is activated by pressing the

CAL key.

SAMPLE

Sampling normally, flashing indicates adaptive filter is on.

SAMPLE A

Indicates that unit is in

SAMPLE

Mode and

AUTOCAL

feature is activated.

SETUP

SETUP mode is being used to configure the analyzer (CO sampling will continue during this

process as well as data collection and output).

SPAN CAL A

1

Unit is performing span cal procedure initiated automatically by the analyzer’s AUTOCAL

feature.

SPAN CAL M1

Unit is performing span cal procedure initiated manually by the user.

SPAN CAL R1

Unit is performing span cal procedure initiated remotely via the RS-232, RS-4485 or digital i/o

control inputs.

ZERO CAL A1

Unit is performing zero cal procedure initiated automatically by the analyzer’s AUTOCAL

feature.

ZERO CAL M1

Unit is performing zero cal procedure initiated manually by the user.

ZERO CAL R1

Unit is performing zero cal procedure initiated remotely via the RS-232, RS-4485 or digital I/O

control inputs.

1

The various CAL modes allow calibration of the analyzer. Because of their importance, these modes are described

separately in Section 9 of the T300/T300M Operators Manual (P/N 06864).

Page 29

Teledyne API - T300U Addendum to T300/T300M Manual T300U Operating Instructions

06867D DCN7970 27

4.2.1. AUTO-REFERENCE MODE (A-REF)

One of the most significant differences between the T300/T300M and the T300U

analyzers is the auto-reference measurement feature. In this mode, the analyzer makes

special measurements and calculations that are applied to the CO concentration

calculation to dramatically improve interferent rejection as well as compensate for

changes in ambient temperature of the sample gas and age related drift of the optical

bench components (see Section 8.1.1 for detailed information about how and when this

A-REF feature occurs).

When in A-REF mode, the analyzer:

• Freezes the CO concentration reading displayed on the front panel and output via

the analog outputs or COM Ports.

• Displays AUTO-REF in the Mode field of the analyzer’s front panel (see menu chart,

Figure 4-1).

• Sets the A-REF status output (pin-7 on the status output connector) to high.

Figure 4-1: Display during A-REF Mode

Note

Initiating a calibration through either the front panel touchscreen, the COM

ports or digital control inputs terminates the A-REF mode.

Also, when the instrument is in Calibration Mode, the A-REF mode is

suppressed until the instrument exits Calibration Mode.

See Section 4.4 for information about changing the A-REF cycle time or manually

initiating an auto-reference measurement.

Page 30

T300U Operating Instructions Teledyne API - T300U Addendum to T300/T300M Manual

28 06867D DCN7970

4.2.2. TEST FUNCTIONS

The information found in Section 4.1.1 of the T300/T300M Operators Manual (P/N

06864) is applicable to the T300U with the exception that the following table supersedes

Table 4-2 of the T300/T300M Operato rs Manu al (P/N 06864).

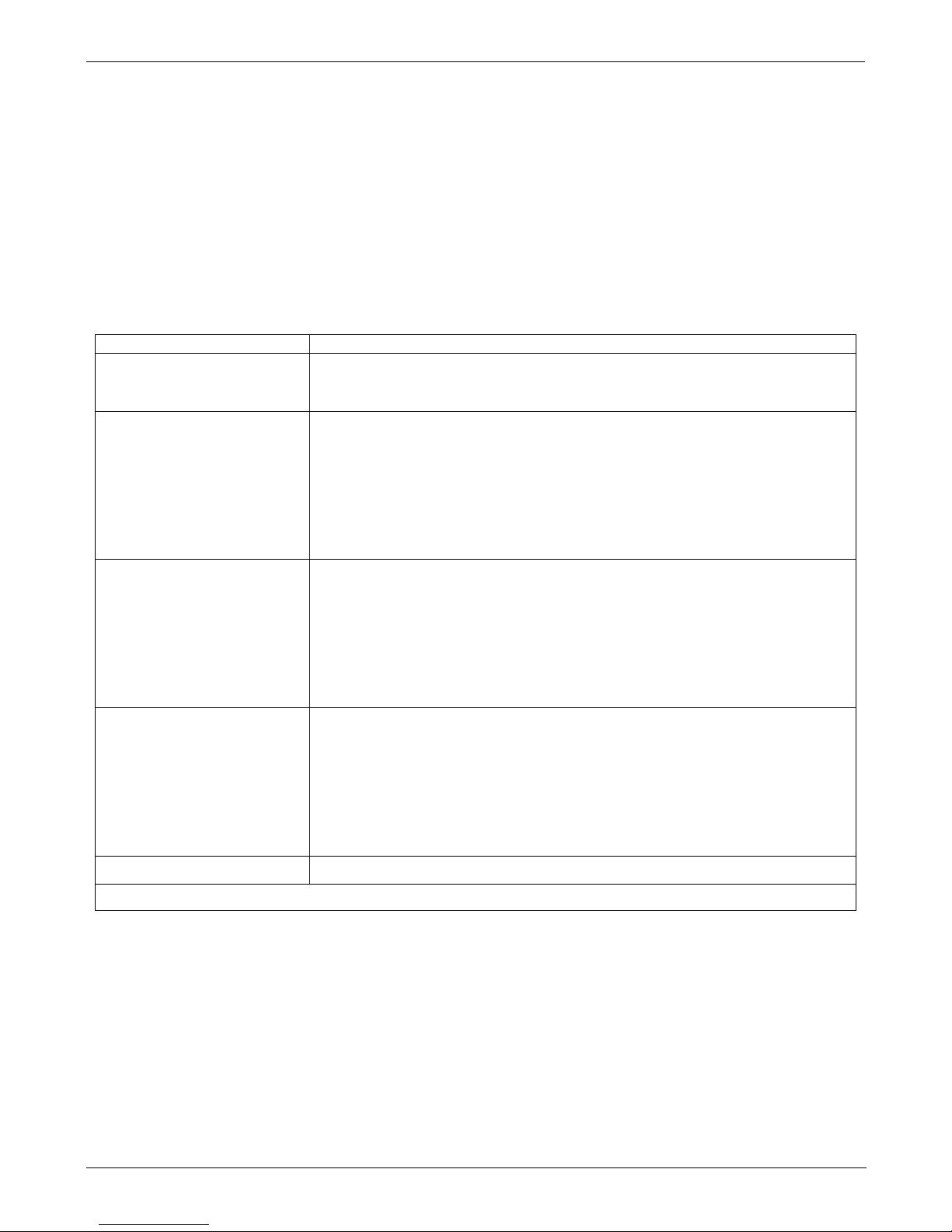

Table 4-2: Test Functions Defined

Parameter Display Title

Units

Meaning

RANGE

- RANGE1

RANGE2

RANGE

PPB, PPM

UGM, MGM

The full-scale limit at which the output range of the analyzer’s Analog

Outputs is currently set.

• THIS IS NO T t he Physic al Range of the instrument. See Section 4.3.2

for more information.

If DUAL or AUTO Range modes have been selected, two RANGE functions

will appear, one for each range.

Stability

STABIL

PPB, PPM

UGM, MGM

Standard deviation of CO concentration readings. Data points are recorded

every ten seconds using the last 25 data points. This function can be reset

to show O

2

or CO2 stability in instruments with those sensor options

installed.

CO Measure

MEAS

MV

The demodulated, peak IR detector output during the measure portion of the

GFC Wheel cycle.

CO Reference

REF

MV

The demodulated, peak IR detector output during the reference portion of

the GFC wheel cycle.

Measurement /

Reference Ratio

MR Rat io

-

The result of CO MEAS divided by CO REF based on readings taken during

the normal sample measurement portion of the A-REF cycle.

This ratio is the primary value used to compute CO concentration. The

value displayed is not linearized.

Auto-Reference

Ratio

AZERO RATIO -

The result of CO MEAS divided by CO REF based on readings

taken during the zero-reference portion of the A-REF cycle.

This ratio is the used to compute a reference correction factor

for computing the CO concentration. The value displayed is

not linearized.

Sample Pressure

PRES

In-Hg-A

The absolute pressure of the Sample gas as measured by a pressure

sensor.

Sample Flow

SAMPLE FL

cm3/min

Sample mass flow rate as measured by the flow rate sensor in the sample

gas stream,

Sample

Temperature

SAM P TEMP

°C

The temperature of the gas inside the sample chamber.

Bench

Temperature

BENCH TEMP

°C

Optical bench temperature.

Wheel

Temperature

WHEEL TEMP

°C

GFC wheel temperature.

Box Temperature

BOX TEMP

°C

The temperature inside the analyzer chassis.

Oven

Temperature

OVEN TEMP

2

°

C

The current temperature of the circulating air inside the T300U’s

convection oven area.

Photo-detector

Temp. Control

Voltage

PHT DRIVE

mV

The drive voltage being supplied to the thermoelectric coolers of the IR

photo-detector by the sync/demod Board.

Slope

SLOPE

-

The sensitivity of the instrument as calculated during the last calibration

activity. The SLOPE parameter is used to set the span calibration point of

the analyzer.

Offset

OFFSET

-

The overall offset of the instrument as calculated during the last calibration

activity. The OFFSET parameter is used to set the zero point of the

analyzer response.

Test Channel

Output

TEST

mV

The raw voltage being output on the analyzer’s A4 analog output. Only

appears when the test channel is assigned a function.

Current Time

TIME

-

The current time. This is used to create a time stamp on DAS readings, and

by the AUTOCAL feature to trigger calibration event s.

Page 31

Teledyne API - T300U Addendum to T300/T300M Manual T300U Operating Instructions

06867D DCN7970 29

4.3. SETUP RNGE: ANALO G OU TP UT REPORTING RANGE

CONFIGURATION

4.3.1. PHYSICAL R ANGE VERSU S ANALOG OUTPUT REPORTING

RANGES

Functionally, the T300U analyzer has one hardware “physical range” that is capable of

determining CO concentrations between 0 ppb and 100,000 ppb. This architecture

improves reliability and accuracy by avoiding the need for extra, switchable, gainamplification circuitry. Once properly calibrated, the analyzer’s front panel will

accurately report concentrations along the entire span of its physical range. T300U

analyzer’s physical range can create data resolution problems for most analog recording

devices. For example, in an application where the expected concentration of CO is

typically less than 1000 ppb, the full scale of expected values is only 1% of the

instrument’s 100,000 ppb physical range. Unmodified, the corresponding output signal

would also be recorded across only 1% of the range of the recording device.

The T300U solves this problem by allowing the user to select a scaled reporting range

for the analog outputs that only includes that portion of the physical range relevant to the

specific application.

Note

Only the reporting range of the analog outputs is scaled.

Both the DAS values stored in the CPU’s memory and the concentration

values reported on the front panel are unaffected by the settings chosen for the

reporting range(s) of the instrument.

4.3.2. ANALOG OUTPUT RANGES FOR CO CONCENTRATION

The analyzer has two active analog output signals related to CO concentration that are

accessible through a connector on the rear panel.

Not Used

ANALOG OUT

A1 A2 A3 A4

+

- + - + - + -

CO concentration

outputs

HIGH range when DUAL

mode is selected

Test Channel

Output

LOW range when DUAL

mode is selected

Figure 4-2: Analog Output Connector Pin Out

Page 32

T300U Operating Instructions Teledyne API - T300U Addendum to T300/T300M Manual

30 06867D DCN7970

The A1 and A2 channels output a signal that is proportional to the CO c oncent ratio n of

the sample gas. They can be configured:

• With independent reporting ranges reporting a “single” output signal (SNGL Mode,

see Section 4.3.3).

• Be to operate completely independently (DUAL mode, see Section 4.3.4). In this

mode the user can set the measure span and signal scale of each output in a

variety of combinations (but not the units of measure).

EXAMPLE:

A1 OUTPUT: Output Signal = 0-5 VDC representing 0-1000 ppb concentration

values

A2 OUTPUT: Output Signal = 0-10 VDC representing 0-500 ppb concentration

values.

• Or to automatically switch between the two ranges dynamically as the concentration

value fluctuates (AUTO modes, see Section 4.3.5).

Both the A1 and A2 outputs can be:

• Configured full scale outputs of: 0 - 0.1 VDC; 0 - 1VDC; 0 - 5VDC or; 0 - 10VDC.

• Equipped with optional 0-20 mADC current loop drivers and configured for any

current output within that range (e.g. 0-20, 2-20, 4-20, etc.).

The user may also add a signal offset independently to each output (see Section 4.7.1) to

match the electronic input requirements of the recorder or data logger to which the

output is connected.

DEFAULT SETTINGS

The default setting for these the reporting ranges of the analog output channels A1 and

A2 are:

• SNGL mode

• 0 to 500.0 ppb

• 0 to 5 VDC

Reporting range span may be viewed via the front panel by viewing the RANGE test

function. If the DUAL or AUTO modes are selected, the RANGE test function d will

be replaced by two separate functions, RANGE1 & RANGE2. Reporting range status

is also available as output via the external digital I/O status bits.

Note

Upper span limit setting for the individual range modes are shared. Resetting

the span limit in one mode also resets the span limit for the corresponding

range in the other modes as follows:

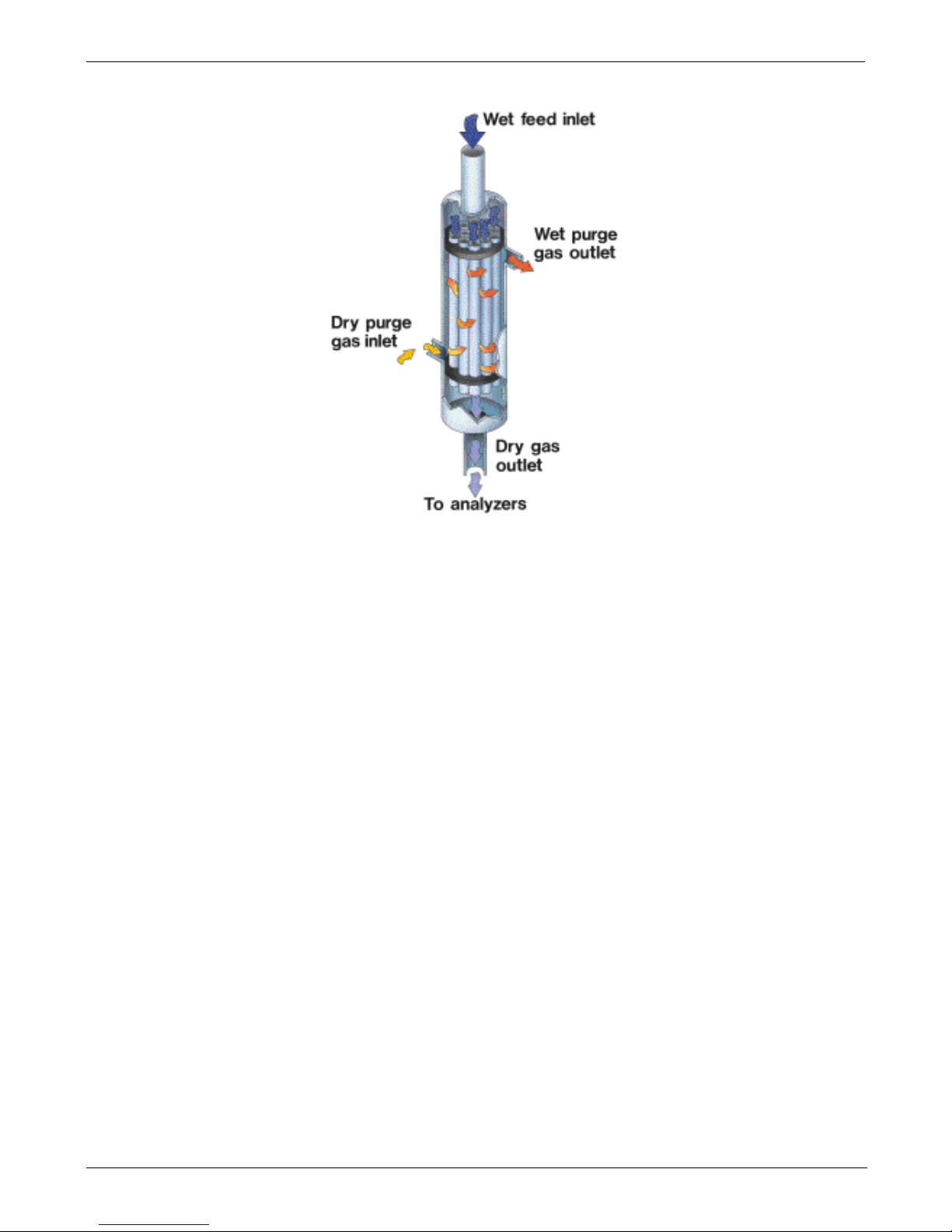

SNGL DUAL AUTO

Range

Range1 (Low)

Low Range

Range2 (Hi)

High Range

Page 33

Teledyne API - T300U Addendum to T300/T300M Manual T300U Operating Instructions

06867D DCN7970 31

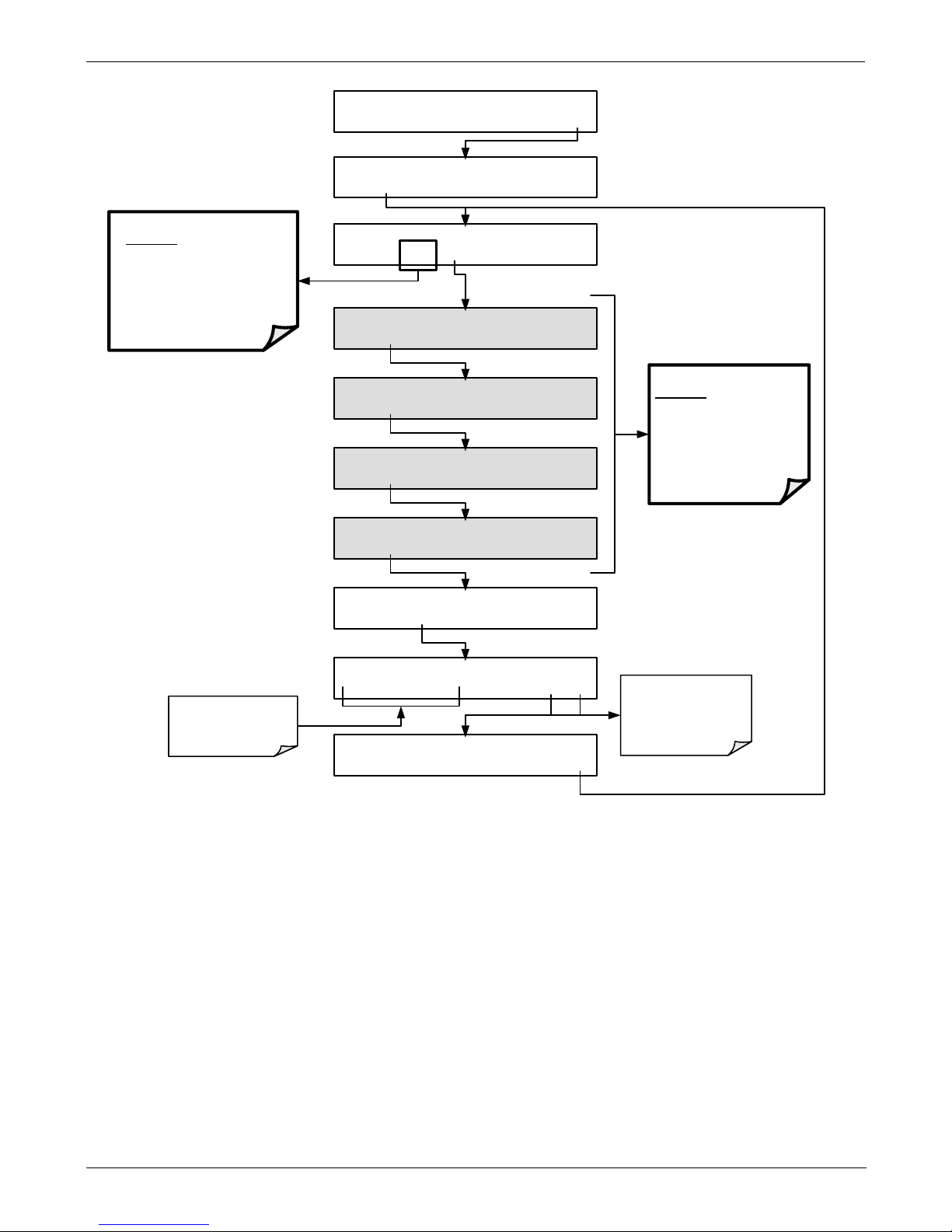

4.3.3. RNGE MODE SNGL: CONFIGURING THE T300U ANALYZER

FOR SINGLE RANGE MODE

The single range mode sets a single maximum range for the both the A1 and A2 analog

outputs. If the single range is selected both outputs are slaved together and will

represent the same reporting range span (e.g. 0-50 ppm), however, their electronic signal

levels may be configured for different ranges (e.g. 0-10 VDC vs. 0-0.1 VDC.

This Reporting range can be set to any value between 0.1 ppb and 10,000 ppb. To select

SINGLE range mode and set the upper limit of the reporting range, press:

SETUP PRIMARY SETUP MENU

CFG

DAS

RNGE PASS CLK

MORE

EXIT

SAMPLE

RANGE

=50.000 PPM CO= XXXX

<TST TST> CAL SETUP

SETUP

RANGE MODE MENU

MODE SET UNIT EXIT

SETUP

RANGE MODE

:SNGL

SNGL DUAL AUTO ENTR EXIT

SETUP RANGE MODE

:SNGL

SNGL DUAL AUTO ENTR EXIT

SETUP RANGE MODE MENU

MODE SET UNIT EXIT

SETUP RANGE

:500.0 Conc

0 0 5 0 0 .0 ENTR EXIT

Toggled these buttons

to select the upper

SPAN limit for the

reporting range

EXIT

discards the new

setting

ENTR accepts the

new setting

Note

This is the default reporting range mode for the analyzer.

Page 34

T300U Operating Instructions Teledyne API - T300U Addendum to T300/T300M Manual

32 06867D DCN7970

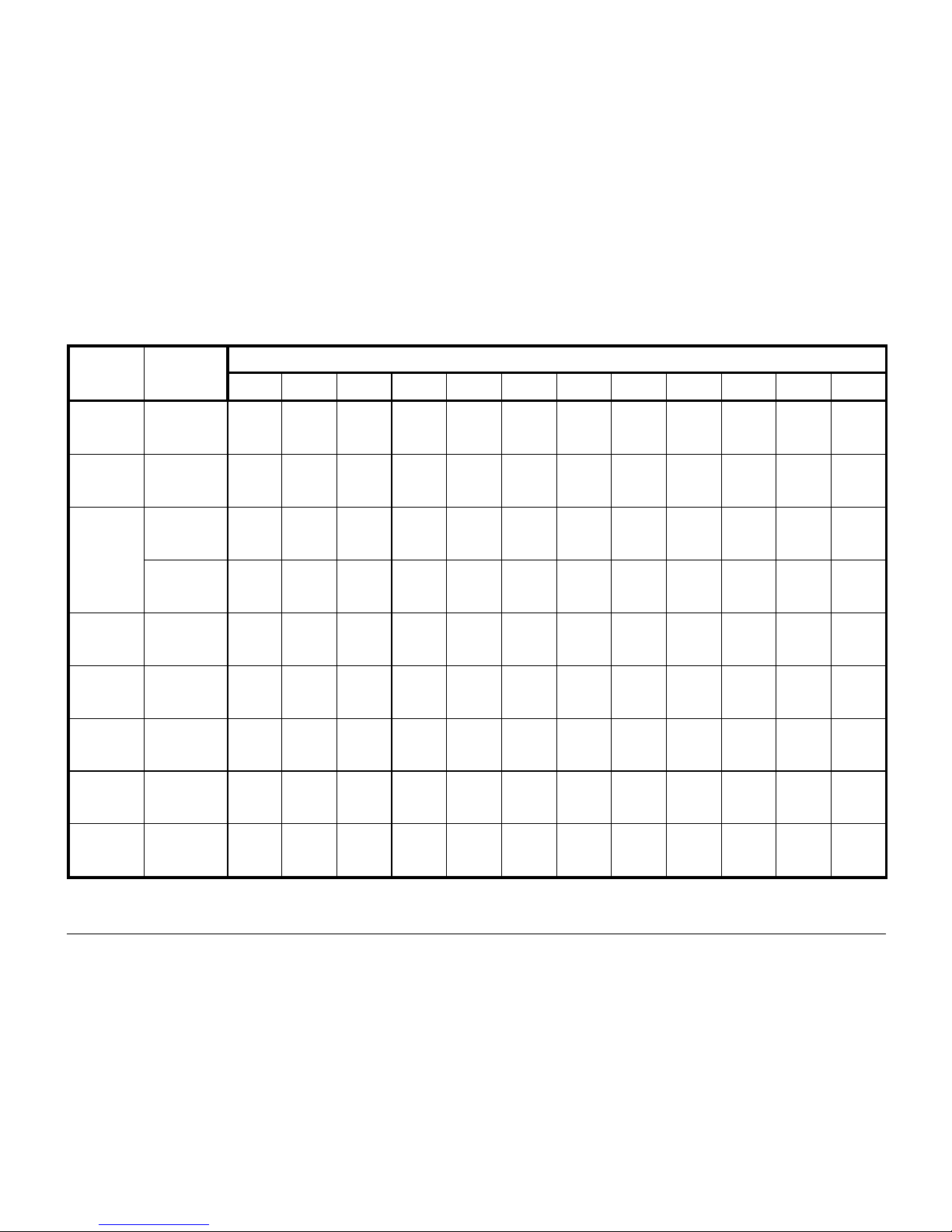

4.3.4. RNGE MODE DUAL: CONFIGURING THE T300U ANALYZER

FOR DUAL RANGE MODE

DUAL range mode allows the A1 and A2 outputs to be configured with separate

reporting range spans as well as separate electronic signal levels. The analyzer software

calls these two ranges LOW and HI.

• The LOW range setting corresponds with the analog output labeled A1 on the rear

panel of the instrument and is viewable via the test function RANGE 1.

• The HIGH range setting corresponds with the A2 output and is viewable via the test

function R ANGE 2.

• While the software labels these two ranges as LOW and HI, when in DUAL mode

their upper limits need not conform to that convention. The upper span limit of the

LOW/RANGE1 can be a higher number than

that of HI/RANGE 2

To set the ranges press:

.

SETUP PRIMARY SETUP MENU

CFG DAS RNGE PASS CLK MORE EXIT

SAMPLE RANGE=50.000 PPM CO= XXXX

<TST TST> CAL SETUP

SETUP RANGE MODE MENU

MODE SET UNIT EXIT

SETUP RANGE MODE:SNGL

SNGL DUAL AUTO ENTR EXIT

SETUP RANGE MODE:SNGL

SNGL DUAL AUTO ENTR EXIT

SETUP RANGE MODE MENU

MODE SET UNIT EXIT

SETUP HIGH RANGE:500.0 Conc

0 0 5 0 0 .0 ENTR EXIT

Toggle these buttons

to select the upper

SPAN limit for the

reporting range

EXIT discards the new

setting

ENTR accepts the

new setting

SETUP LOW RANGE:100.0 Conc

0 0 1 0 0 .0 ENTR EXIT

The LOW and HIGH

ranges have separate

slopes and offsets for

computing the CO

concentration.

The two ranges must

be independently

calibrated

.

EXIT discards the

new setting

ENTR accepts the

new setting

Page 35

Teledyne API - T300U Addendum to T300/T300M Manual T300U Operating Instructions

06867D DCN7970 33

4.3.5. RNGE MODE AUTO: CONFIGURING THE T300U ANALYZER

FOR AUTO RANGE MODE

AUTO range mode gives the analyzer to ability to output data via a LOW range

(displayed on the front panel as RANGE1) and HIGH range (displayed on the front

panel as RANGE2) on a single analog output.

When the AUTO range mode is selected, the analyzer automatically switches back and

forth between user-selected LOW & HIGH ranges depending on the level of the CO

concentration.

• The unit will move from LOW range to HIGH range when the CO concentration

exceeds to 98% of the LOW range span limit.

• The unit will return from HIGH range back to LOW range once the CO concentration

falls below 75% of the LOW range span limit.

Page 36

T300U Operating Instructions Teledyne API - T300U Addendum to T300/T300M Manual

34 06867D DCN7970

To set the ranges press:

SETUP PRIMARY SETUP MENU

CFG DAS

RNGE PASS CLK MORE EXIT

SAMPLE RANGE=50.000 PPM CO= XXXX

<TST TST> CAL SETUP

SETUP RANGE MODE MENU

MODE SET UNIT EXIT

SETUP RANGE MODE:SNGL

SNGL DUAL AUTO ENTR EXIT

SETUP RANGE MODE:SNGL

SNGL DUAL AUTO ENTR EXIT

SETUP RANGE MODE MENU

MODE SET UNIT EXIT

SETUP HIGH RANGE:200.0 Conc

0 0 2 0 0 .0 ENTR EXIT

Toggled these buttons

to select the upper

SPAN limit for the

reporting range

EXIT discards the new

setting

ENTR accepts the

new setting

SETUP LOW RANGE:50.0 Conc

0 0 0 5 0 .0 ENTR EXIT

The LOW and HIGH

ranges have separate

slopes and offsets for

computing the CO

concentration.

The two ranges must

be independently

calibrated

.

EXIT discards the

new setting

ENTR accepts the

new setting

IMPORTANT IMPACT ON READINGS OR DATA

Avoid accidentally setting the LOW range (RANGE 1) of the instrument with a

higher span limit than the HIGH range (RANGE 2). This will cause the unit to

stay in the low reporting range perpetually and defeat the function of the AUTO

range mode.

Page 37

Teledyne API - T300U Addendum to T300/T300M Manual T300U Operating Instructions

06867D DCN7970 35

4.3.6. SETUP RNGE UNIT: SETTING THE REPORTING RANGE UNIT

TYPE

The T300U can display concentrations in ppb, ppm, ug/m3, mg/m3 units. Changing units

affects all of the COM port values, and all of the display values for all reporting ranges.

To change the units of measure press:

SETUP CONC UNITS

:PPB

PPB PPM UGM MGM ENTR EXIT

SETUP PRIMARY SETUP MENU

CFG DAS RNGE PASS CLK MORE EXIT

SAMPLE RANGE=50.000 PPM CO= XXXX

<TST TST> CAL SETUP

SETUP RANGE MODE MENU

MODE SET UNIT EXIT

Toggle these buttons

to select the units of

measure for the

reporting ranges

EXIT discards the new

setting

ENTR accepts the

new setting

Note

Concentrations displayed in mg/m3 and ug/m3 use 0C, 760 mmHg for

Standard Temperature and Pressure (STP). Consult your local regulations for

the STP used by your agency.

Note

Once the units of measurement have been changed, the unit MUST be

recalibrated, as the “expected span values” previously in effect will no longer

be valid. Simply entering new expected span values without running the entire

calibration routine is not sufficient.

The following equations give approximate conversions between volume/volume units

and weight/volume units:

CO ppb x 1.25 = CO ug/m

3

CO ppm x 1.25= CO mg/m3

Page 38

T300U Operating Instructions Teledyne API - T300U Addendum to T300/T300M Manual

36 06867D DCN7970

4.4. SETUP MORE AREF: CONFIGURING AND

PERFORMING AUTO-REFERENCE MEASUREMENTS

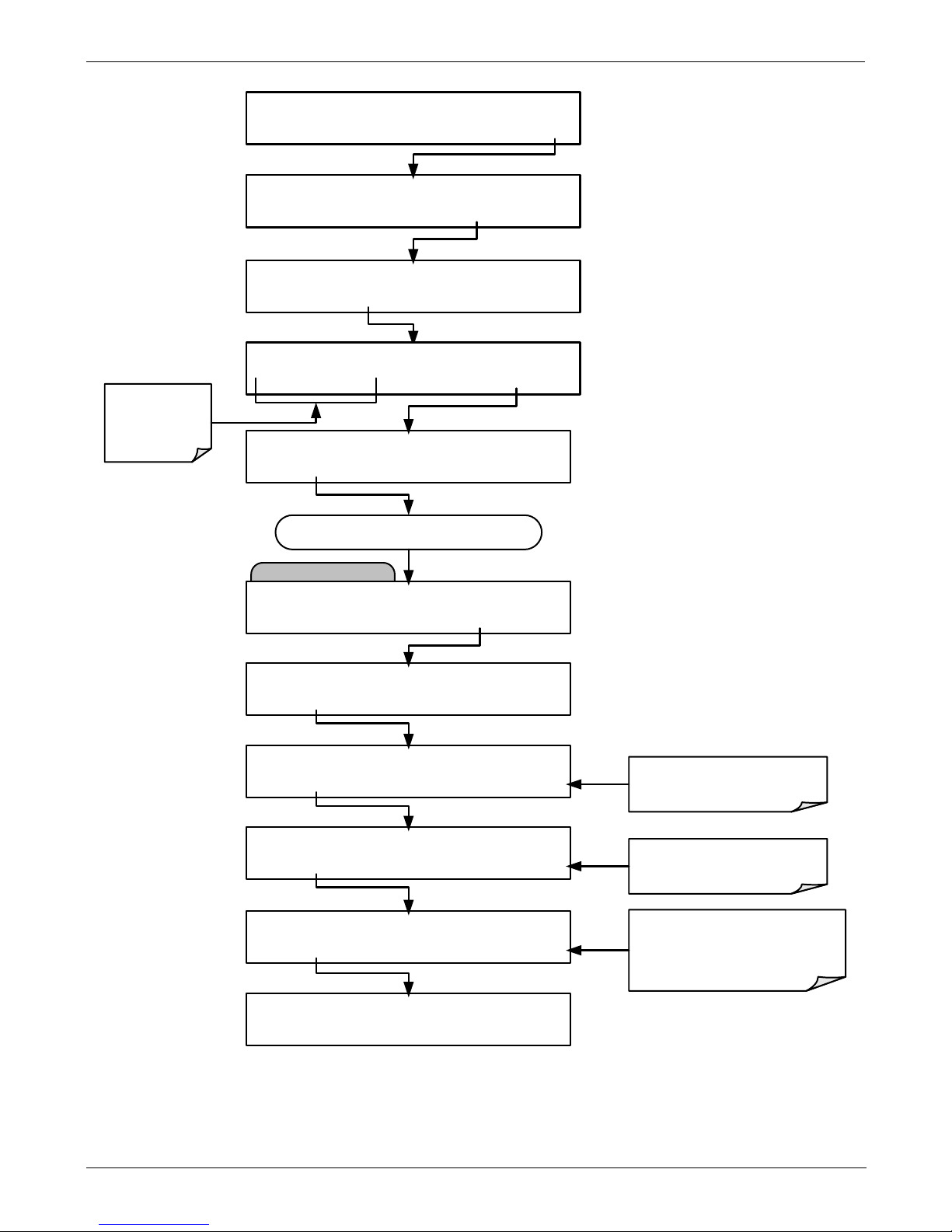

4.4.1. ADJUSTING THE A-REF MODE CYCLE TIME

The auto-reference measurement feature is initiated by the T300U at regular intervals

(see Section 8.1.1). It is triggered by the timer feature of the analyzers ACAL system,

which uses the instrument’s internal clock.

All T300U analyzers are shipped from the factory the ACAL system enabled (even on

instruments without calibration valve options installed) and the first ACAL sequence

already programmed and activated with the DELTA TIME parameter set for 4 hours

(for a more detailed discussion of the ACAL system see Section 9.4 of the T300/T300M

Operators Manual).

This interval time can be changed to fit the specific application in which the T300U is

being used. To change the A-REF interval, press:

Page 39

Teledyne API - T300U Addendum to T300/T300M Manual T300U Operating Instructions

06867D DCN7970 37

SETUP PRIMARY SETUP MENU

CFG ACAL DAS RNGE PASS CLK MORE EXIT

SAMPLE RANGE=50.000 PPM CO= XXXX

<TST TST> CAL SETUP

SETUP SEQ1) AUTO-REF,0:04:00

PREV NEXT MODE SET EXIT

NOTE

DO NOT

change the MODE.

Changing to mode to anything

other than AUTO-REF will

disable the A-REF feature and

seriously compromise the

accuracy of the T300U’s CO

measurements

SETUP TIMER ENABLE:ON

<SET SET> EDIT EXIT

SETUP STARTING DATE:01=JAN-07

<SET SET> EDIT EXIT

SETUP STARTING TIME:00:00

<SET SET> EDIT EXIT

SETUP DELTA DAYS:0

<SET SET> EDIT EXIT

SETUP DELTA TIME:04:00

<SET SET> EDIT EXIT

SETUP DELTA TIME:04:00

0 4 :0 0 ENTR EXIT

SETUP DELTA TIME:04:00

<SET SET> EDIT EXIT

Toggle these buttons

to change the A-REF

start interval.

EXIT discards the new

setting

ENTR accepts the

new setting

NOTE

DO NOT

change any of the

settings. Altering these

setting may disable the

A-REF feature and

seriously compromise the

accuracy of the T300U’s

CO measurements

Page 40

T300U Operating Instructions Teledyne API - T300U Addendum to T300/T300M Manual

38 06867D DCN7970

4.4.2. FORCING AN AUTO-REFERENCE MEASUREMENT

Sometimes it is advisable to perform an auto-reference measurement at other times such

as just before calibrating the analyz er.

To manually start an auto-reference measurement cycle, press:

YES initiates an new

A-REF cycle

NO aborts the A-REF

cycle

SETUP PRIMARY SETUP MENU

CFG DAS RNGE PASS CLK MORE EXIT

SAMPLE RANGE=50.000 PPM CO= XXXX

<TST TST> CAL SETUP

SETUP SECONDARY SETUP MENU

COMM VARS DIAG AREF EXIT

SETUP RESET AUTO-REFERENCE?

YES NO

Page 41

Teledyne API - T300U Addendum to T300/T300M Manual T300U Operating Instructions

06867D DCN7970 39

4.5. SETUP MORE VARS: VARIABLES SETUP AND

DEFINITION

The information found in Section 5.8 of the T300/T300M Operators Manual (P/N

06864) is applicable to the T300U with the following exception(s):

• There is no STABIL_GAS variable available under the VARS menu of the T300U.

• The following table supersedes Table 5-3 of the T300/T300M Operators Manual

(P/N 06864).

Table 4-3: T300U VARS Menu

NO. VARIABLE DESCRIPTION

ALLOWED

VALUES

0

DAS_HOLD_OFF

Changes the internal data acquisition system (DAS) hold-off

time, which is the duration when data are not stored in the

DAS because the software considers the data to be

questionable. That is the case during warm-up or just after

the instrument returns from one of its calibration modes to

SAMPLE mode. DAS_HOLD_OFF can be disabled entirely

in each DAS channel.

Can be between 0.5

and 20 minutes

Default=15 min.

1

CONC_PRECISION

Allows the user to set the number of significant digits to the

right of the decimal point display of concentration and

stability values.

AUTO, 1, 2, 3, 4

Default=AUTO

2

DYN_ZERO

Dynamic zero automatically adjusts offset and slope of the

CO response when performing a zero point calibration

during an AutoCal (Section 7).

ON/OFF

3

DYN_SPAN

Dynamic span automatically adjusts slope and slope of the

CO response when performing a zero point calibration

during an AutoCal (Section 7).

Note that the DYN_ZERO and DYN_SPAN features are not

allowed for applications requiring EPA equivalency.

ON/OFF

4

CLOCK_ADJ

Adjusts the speed of the analyzer’s clock. Choose the +

sign if the clock is too slow, choose the - sign if the clock is

too fast.

-60 to +60 s/day

Page 42

T300U Operating Instructions Teledyne API - T300U Addendum to T300/T300M Manual

40 06867D DCN7970

4.6. SETUP MORE DIAG: DIAGNOSTICS FUNCTIONS

The information found in Section 5.9 of the T300/T300M Operators Manual (P/N

06864) is applicable to the T300U with the following exception(s):

• There is no DISPLAY SEQUENCE CONFIGURATION submenu available under

the DIAG menu of the T300U.

• The following table supersedes Table 5-4 of the T300/T300M Operators Manual

(P/N 06864).

Table 4-4: T300U Diagnostic (DIAG) Submenus

DIAGNOSTIC FUNCTION AND MEANING

Front Panel

Mode Indicator

SIGNAL I/O: Allows observation of all digital and analog signals in the

instrument. Allows certain digital signals such as valves and heaters

to be toggled ON and OFF.

DIAG I/O

See

T300/T300M

Manual

ANALOG OUTPUT: When entered, the analyzer performs an analog

output step test. This can be used to calibrate a chart recorder or to

test the analog output accuracy.

DI AG AOU T

See

T300/T300M

Manual

ANALOG I/O CONFIGURATION: This submenu allows the user to

configure the analyzer’s four analog output channels, including

choosing what parameter will be output on each channel. Instructions

that appear here allow adjustment and calibration the voltage signals

associated with each output as well as calibration of the analog to

digital converter circuitry on the motherboard.

DI AG AIO

4.7.1

ELECTRIC TEST: The analyzer is performing an electric test. This test

simulates IR detector signal in a known manner so that the proper

functioning of the sync/demod board can be verified.

DIAG OPTIC

See

T300/T300M

Manual

DAR K CALIBRATION: The analyzer is performing a dark calibration

procedure. This procedure measures and stores the inherent dc

offset of the sync/demod board electronics.

DIAG ELEC

See

T300/T300M

Manual

PRESSURE CALIBRATION: The analyzer records the current output

of the sample gas pressure sensor. This value is used by the CPU to

compensate the CO concentration.

DIAG PCAL

See

T300/T300M

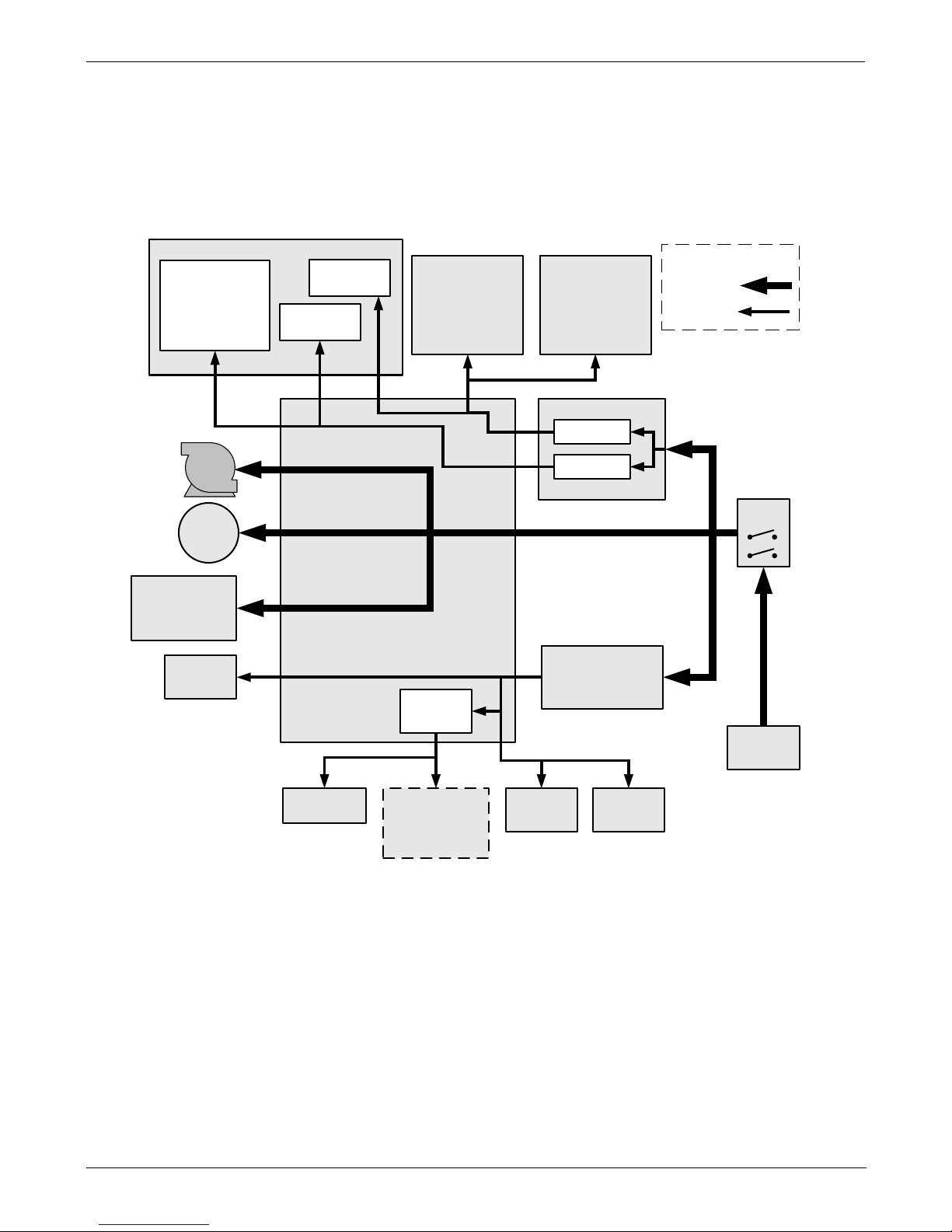

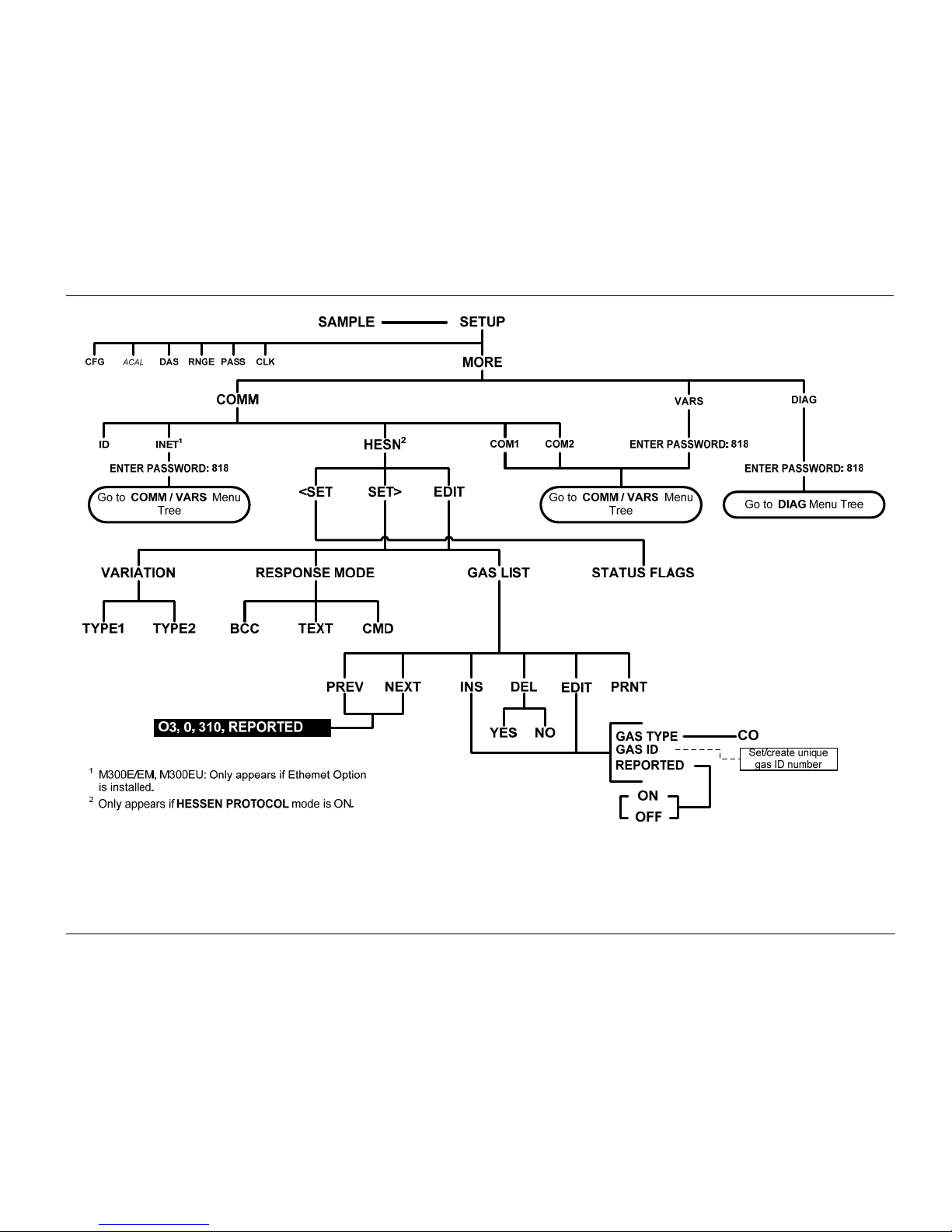

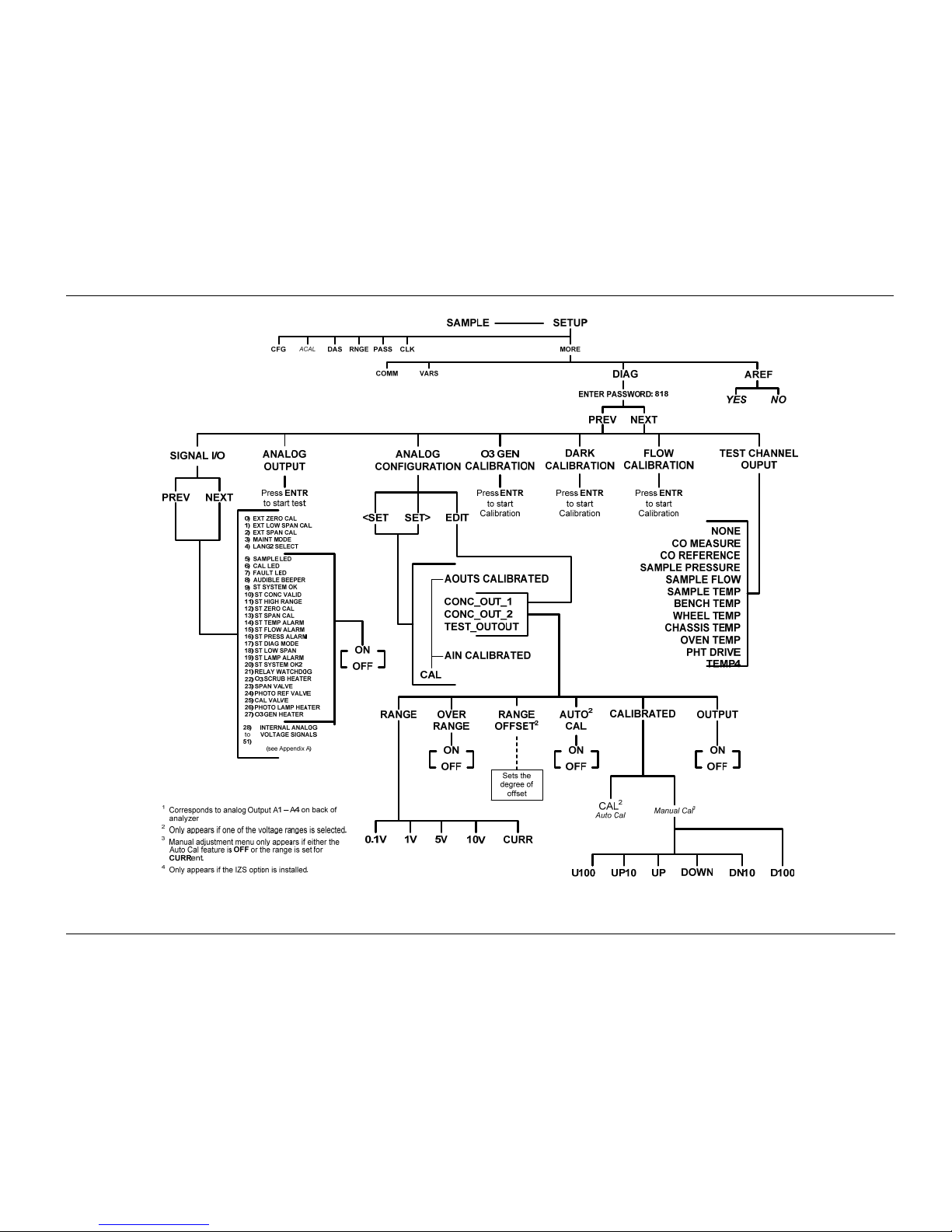

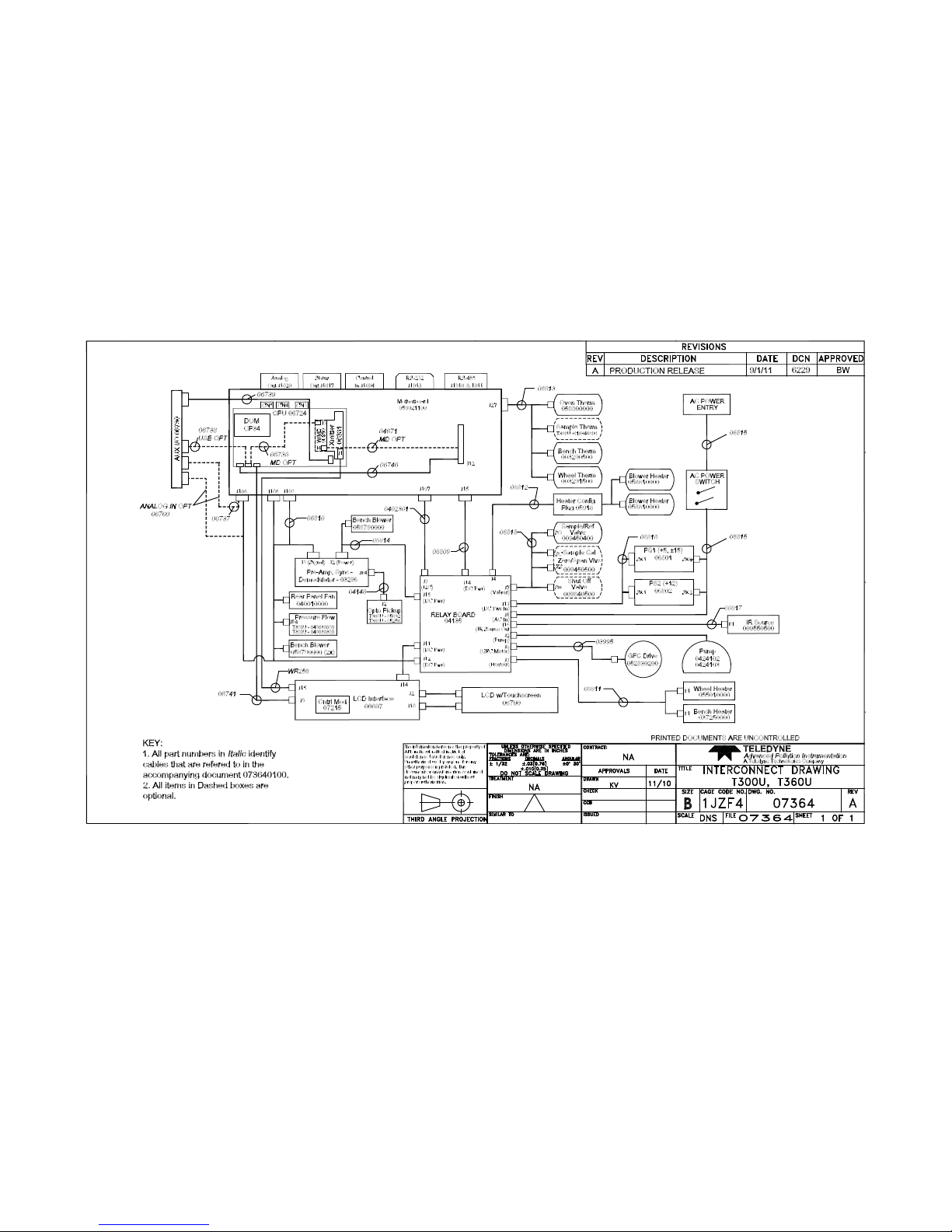

Manual