Page 1

USER MANUAL

MODEL 465H

OZONE MONITOR

©2007-2018 TAPI 06161H DCN7969

Teledyne API 21 August 2018

Teledyne API (TAPI)

9970 Carroll Canyon Road

San Diego, CA 92131-1106

Toll-Free: 800-324-5190

Phone: +1 858-657-9800

FAX: +1 858-657-9816

Email: api-sales@teledyne.com

Website: http://www.teledyne-api.com/

Page 2

Page 3

SAFETY MESSAGES

Important safety messages are provided throughout this manual for the purpose of avoiding

personal injury or instrument damage. Please read these messages carefully. Each safety

message is associated with a safety alert symbol and placed throughout this manual and inside the

instrument. The symbols with messages are defined as follows:

WARNING: Electrical Shock Hazard

HAZARD: Strong oxidizer

GENERAL WARNING/CAUTION: Read the accompanying message for

specific information.

CAUTION: Hot Surface Warning

Do Not Touch: Touching some parts of the instrument without protection or

proper tools could result in damage to the part(s) and/or the instrument.

Technician Symbol: All operations marked with this symbol are to be

performed by qualified maintenance personnel only.

Electrical Ground: This symbol inside the instrument marks the central

safety grounding point for the instrument.

CAUTION

GENERAL SAFETY HAZARD

This instrument should only be used for the purpose and in the

manner described in this manual. If you use it in a manner other

than that for which it was intended, unpredictable behavior could

ensue with possible hazardous consequences.

NEVER use any gas analyzer to sample combustible gas(es).

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual i

Page 4

CONSIGNES DE SÉCURITÉ

Des consignes de sécurité importantes sont fournies tout au long du présent manuel dans

le but d’éviter des blessures corporelles ou d’endommager les instruments. Veuillez lire

attentivement ces consignes. Chaque consigne de sécurité est représentée par un

pictogramme d’alerte de sécurité; ces pictogrammes se retrouvent dans ce manuel et à

l’intérieur des instruments. Les symboles correspondent aux consignes suivantes :

AVERTISSEMENT : Risque de choc électrique

DANGER : Oxydant puissant

AVERTISSEMENT GÉNÉRAL / MISE EN GARDE : Lire la consigne

complémentaire pour des renseignements spécifiques

MISE EN GARDE : Surface chaude

Ne pas toucher : Toucher à certaines parties de l’instrument sans

protection ou sans les outils appropriés pourrait entraîner des dommages

aux pièces ou à l’instrument.

Pictogramme « technicien » : Toutes les opérations portant ce symbole

doivent être effectuées uniquement par du personnel de maintenance

qualifié.

Mise à la terre : Ce symbole à l’intérieur de l’instrument détermine le

point central de la mise à la terre sécuritaire de l’instrument.

MISE EN GARDE

Cet instrument doit être utilisé aux fins décrites et de la manière décrite dans

ce manuel. Si vous utilisez cet instrument d’une autre manière que celle pour

laquelle il a été prévu, l’instrument pourrait se comporter de façon

imprévisible et entraîner des conséquences dangereuses.

NE JAMAIS utiliser un analyseur de gaz pour échantillonner des gaz

combustibles!

ii Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 5

WARRANTY

WARRANTY POLICY (02024J)

Teledyne API (TAPI), a business unit of Teledyne Instruments, Inc.,

provides that:

Prior to shipment, TAPI equipment is thoroughly inspected and tested.

Should equipment failure occur, TAPI assures its customers that prompt

service and support will be available. (For the instrument-specific warranty

period, please refer to the “Limited Warranty” section in the Terms and

Conditions of Sale on our website at the following link:

http://www.teledyne-api.com/terms_and_conditions.asp).

COVERAGE

After the warranty period and throughout the equipment lifetime, TAPI

stands ready to provide on-site or in-plant service at reasonable rates similar

to those of other manufacturers in the industry. All maintenance and the first

level of field troubleshooting are to be performed by the customer.

NON-TAPI MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by TAPI is warranted and will be

repaired to the extent and according to the current terms and conditions of

the respective equipment manufacturer’s warranty.

Product Return

Failure to comply with proper anti-Electro-Static Discharge (ESD) handling

and packing instructions and Return Merchandise Authorization (RMA)

procedures when returning parts for repair or calibration may void your

warranty. For anti-ESD handling and packing instructions please refer to the

manual, Fundamentals of ESD, PN 04786, in its “Packing Components for

Return to Teledyne API’s Customer Service” section. The manual can be

downloaded from our website at http://www.teledyne-api.com. RMA

procedures can also be found on our website.

All units or components returned to Teledyne API should be properly

packed for handling and returned freight prepaid to the nearest designated

Service Center. After the repair, the equipment will be returned, freight

prepaid.

The complete Terms and Conditions of Sale can be reviewed at

http://www.teledyne-api.com/terms_and_conditions.asp

CAUTION – Avoid Warranty Invalidation

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual iii

Page 6

THIS PAGE IS INTENTIONALLY LEFT BLANK

iv Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 7

TABLE OF CONTENTS

1. INTRODUCTION......................................................................................................... 8

2. SPECIFICATIONS AND AGENCY APPROVALS ................................................. 9

2.1. SPECIFICATIONS ................................................................................................................................... 9

2.2. APPROVALS ........................................................................................................................................ 10

2.2.1. Safety ....................................................................................................................................... 10

2.2.2. EMC ........................................................................................................................................ 10

2.2.3. Other Type Certifications ....................................................................................................... 10

3. PRINCIPLE OF OPERATION ................................................................................. 11

4. GETTING STARTED ................................................................................................ 13

4.1. MECHANICAL INSTALLATION (FOR MONITORS IN NEMA 4X ENCLOSURES) ..................................... 13

4.1.1. Ventilation Clearance ............................................................................................................. 13

4.2. MECHANICAL INSTALLATION (19” RACK VERSION) ........................................................................... 14

4.2.1. Ventilation Clearance ............................................................................................................. 14

4.3. AC POWER CONNECTION (FOR MONITORS IN NEMA 4X ENCLOSURE) ............................................. 15

4.3.1. Wiring Requirements for NEMA Enclosures .......................................................................... 15

4.3.2. Wiring Instructions ................................................................................................................. 15

4.4. PNEUMATIC CONNECTIONS ................................................................................................................ 17

4.4.1. Installing Flow Control Assemblies ........................................................................................ 18

4.4.2. Ozone Inlet Connection ........................................................................................................... 19

4.4.3. Zero Gas Connection .............................................................................................................. 19

4.4.4. Exhaust Connection ................................................................................................................ 19

4.5. ELECTRICAL I/O CONNECTIONS ......................................................................................................... 21

4.5.1. Location of I/O Connectors in the NEMA Configuration ....................................................... 21

4.5.2. Analog Output ......................................................................................................................... 22

4.5.3. Status Outputs ......................................................................................................................... 22

4.5.4. Hi-Current Relay Outputs ....................................................................................................... 23

4.5.5. Digital Serial Interfaces .......................................................................................................... 24

5. FREQUENTLY ASKED QUESTIONS .................................................................... 25

6. HARDWARE AND SOFTWARE OPTIONS ............................................................... 26

6.1. RACK MOUNT SLIDES ......................................................................................................................... 26

6.2. ETHERNET (MODBUS

®

TCP/IP) ....................................................................................................... 26

7. OPERATION .............................................................................................................. 27

7.1. FRONT PANEL OVERVIEW ................................................................................................................... 27

7.1.1. Ozone Concentration Display ................................................................................................. 27

7.1.2. Menu Navigation Keypad ....................................................................................................... 27

7.1.3. Concentration Alarm Status/Reset .......................................................................................... 28

7.1.4. Status LED’s ........................................................................................................................... 28

7.2. FRONT PANEL MENUS ........................................................................................................................ 29

7.2.1. Menu Navigation Basics ......................................................................................................... 29

7.2.2. Editing Numeric Values .......................................................................................................... 29

7.2.3. SETUP-ALARM Menu ............................................................................................................ 32

7.2.4. SETUP-VARS Menu ................................................................................................................ 33

7.2.5. DIAG Menu ............................................................................................................................. 34

7.2.6. VIEW Menu ............................................................................................................................. 37

7.2.7. CONFIG Menu ....................................................................................................................... 38

7.3. ANALOG OUTPUT ............................................................................................................................... 38

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual v

Page 8

8. DIGITAL COMMUNICATIONS ............................................................................. 39

8.1. DIGITAL COMMUNICATIONS OVERVIEW ............................................................................................ 39

8.2. CHANGING COM PORT HARDWARE CONFIGURATION ....................................................................... 39

8.3. RS-232 CONFIGURATION ................................................................................................................... 41

8.4. RS-485 CONFIGURATION ................................................................................................................... 42

8.5. ETHERNET CONFIGURATION .............................................................................................................. 43

8.5.1. Hardware Setup for Configuring the Ethernet Module .......................................................... 43

8.5.2. Verifying Network Hardware Connection .............................................................................. 43

8.5.3. Determining a Dynamically Assigned IP Address (DHCP Mode) ......................................... 44

8.5.4. Manually Assigning a Static IP Address ................................................................................ 44

8.6. MODBUS

8.6.1. Notes on MODBUS® registers ............................................................................................... 45

8.6.2. Real-Time Concentration and Status Registers (Read Only) ................................................. 46

8.6.3. Instrument Setup and Configuration Registers (Read / Write) ............................................... 46

®

REGISTER MAPS ............................................................................................................. 45

9. MAINTENANCE ........................................................................................................ 47

9.1. MAINTENANCE SCHEDULE ................................................................................................................. 47

9.2. INSTRUMENT LAYOUT ....................................................................................................................... 48

9.3. REPLACING INTERNAL PARTICULATE FILTER .................................................................................... 50

9.4. UV LAMP ADJUSTMENT .................................................................................................................... 51

9.5. UV LAMP REPLACEMENT .................................................................................................................. 52

9.6. REPLACING THE AUTO-ZERO VALVE ................................................................................................. 52

9.7. CONFIGURING THE ANALOG OUTPUT ................................................................................................ 53

9.8. CLEANING EXTERIOR SURFACES OF THE 465H .................................................................................. 54

9.9. BOOT LOADER OPERATION ................................................................................................................ 54

9.9.1. Boot Loader – Hardware Setup ............................................................................................. 54

9.9.2. Boot Loader – Software Setup ................................................................................................ 55

10. TROUBLESHOOTING ........................................................................................... 58

10.1. REFERENCE DRAWINGS ................................................................................................................... 58

10.1.1. Pneumatic Diagram ............................................................................................................. 58

10.1.2. Interconnect Diagram .......................................................................................................... 58

10.2. TROUBLESHOOTING USING FRONT PANEL STATUS LED’S OR STATUS OUTPUTS ............................ 60

10.2.1. Sensor OK ............................................................................................................................ 60

10.2.2. Invalid Reading .................................................................................................................... 61

10.2.3. Check Lamp ......................................................................................................................... 61

10.2.4. Pneumatic Error .................................................................................................................. 61

11. CALIBRATION ........................................................................................................ 63

11.1. FACTORY CALIBRATION .................................................................................................................. 63

12. TECHNICAL ASSISTANCE .................................................................................. 64

FIGURES

Figure 4-1: 465H Mounting Hole Locations and Dimensions ...................................................... 14

Figure 4-2. NEMA AC Power Connection to Monitor ................................................................. 16

Figure 4-3: Pneumatic Connections, Rack Mount Configuration ................................................. 17

Figure 4-4: Pneumatic Connections, NEMA Configuration ......................................................... 18

Figure 4-5: Rear Panel Electrical I/O Connections ....................................................................... 20

Figure 4-6: NEMA Electrical I/O Connections ............................................................................ 20

vi Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 9

Figure 4-7: NEMA I/O Label ....................................................................................................... 21

Figure 4-8: Status Output Schematic ............................................................................................ 22

Figure 7-1: Front Panel Display .................................................................................................... 27

Figure 7-2: Front Panel Menu Diagram ........................................................................................ 3 0

Figure 7-3: Front Panel Menu Diagram ........................................................................................ 3 1

Figure 7-4: Span Cal Menu ........................................................................................................... 37

Figure 8-1: COM Configuration Jumper Settings (SW3) ............................................................. 40

Figure 9-1: Instrument Layout, Rack Mount Configuration ......................................................... 48

Figure 9-2: Instrument Layout, NEMA Configuration ................................................................. 49

Figure 9-3: Internal Particulate Filter Replacement ...................................................................... 51

Figure 9-4: Mainboard – Analog Output Configuration ............................................................... 53

Figure 10-1: Pneumatic Diagram .................................................................................................. 58

Figure 10-2: Interconnect Diagram ............................................................................................... 59

TABLES

Table 4-1: 465H Ventilation Clearances, NEMA Version ............................................................ 13

Table 4-2: 465H Ventilation Clearances, Rack Mount Version .................................................... 14

Table 4-3: Status Output Definitions ............................................................................................ 23

Table 4-4: Relay Functions ........................................................................................................... 23

Table 7-1: Alarm LED’s ............................................................................................................... 28

Table 7-2: Status LED’s ................................................................................................................ 28

Table 7-3: Alarm Configuration Properties .................................................................................. 32

Table 7-4: VARS List ................................................................................................................... 33

Table 7-5: Analog Step Test Values ............................................................................................. 34

Table 7-6: Signal I/O List ............................................................................................................. 35

Table 7-7: VIEW Menu Parameters.............................................................................................. 3 7

Table 8-1: RS-232 Connector Details ........................................................................................... 41

Table 8-2: RS-232 Port Setup ....................................................................................................... 41

Table 8-3: RS-485 Connector Details ........................................................................................... 42

Table 8-4: RS-485 Port Setup ....................................................................................................... 42

Table 8-5: Ethernet LED Definitions ............................................................................................ 43

Table 9-1: Maintenance Schedule ................................................................................................. 47

Table 9-2: Required Software ....................................................................................................... 55

Table 10-1: Status LED/Output Definitions ................................................................................. 60

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual vii

Page 10

1. INTRODUCTION

Teledyne API’s Model 465H (465H) Ozone Monitor measures high concentration ozone;

this microprocessor-controlled instrument provides fast response times with minimal zero

drift, and has built in tests and diagnostics to allow maximum uptime.

We at Teledyne API will be pleased to provide you with any support required so that you

may utilize our equipment to the fullest extent. Our full time technical support

department is always available to answer your questions.

Teledyne API, Technical Support,

9970 Carroll Canyon Road

San Diego, California 92131-1106 USA

Toll-free Phone:

Phone:

Fax:

Email:

Website:

800-324-5190

+1 858-657-9800

+1 858-657-9816

api-techsupport@teledyne.com

http://www.Teledyne-API.com

8 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 11

N

2. SPECIFICATIONS AND AGENCY

APPROVALS

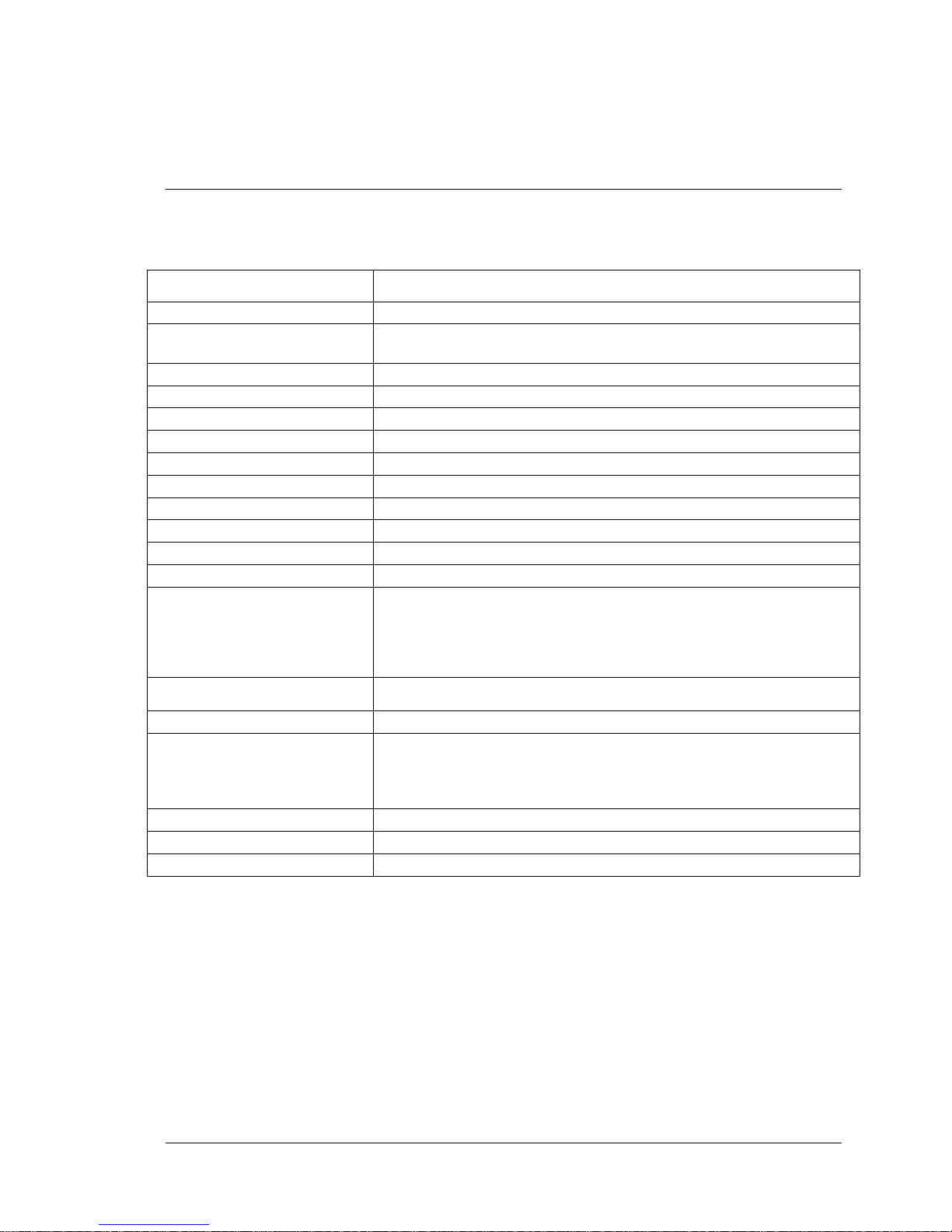

2.1. Specifications

PARAMETER DESCRIPTION

Measuring principle UV absorption (Beer Lambert Law)

Ranges

Measurement Units WT%, g/Nm3

Accuracy ± 1% of Full Scale

Precision/Repeatability ± 0.5% of Full Scale

Display Resolution 0.01 WT%, 0.1 g/Nm3

Response Time (95%) < 5 seconds to 95%

Compensation Pressure, Temperature (NTP = 273.15K, 760 mmHg)

Gas Inlet Pressure Range 3.0-30.0 psig

Sample Flow Rate 0.2-2.0 LPM

Humidity Range 10-90% RH, non-condensing

Temperature Range 5-45o C

Dimensions

(H x W x D)

Weight

Power 100-240 V~, 47-63 Hz, 74 W

Environmental

Analog Output (Bi-polar) 0-5V, 4-20 mA isolated output

Status Outputs System OK, Invalid Reading, Check Lamp, Pneumatic Error

RS-232 (optional RS-485) 57.6 Kbaud, DB-9 connector

0-5 WT% to 0-25 WT%

0-100 g/Nm

5.22” x 19.0" x 15.3" (3U RETMA Panel)

(133 mm x 483 mm x 388 mm)

In NEMA 4X enclosure, typical product envelope:

16.85" x 15.60 (±0.25)" x 6.65"

(428mm x 396 (±6)mm x 169mm)

Rack Mount – 13.6 lbs (6.17 kg)

EMA 4X enclosure – 15.3 lbs (6.94 kg)

in

Installation Category II

Pollution Degree 2

For Indoor Use Only

Maximum Operating Altitude 2000 meters

3

to 0-400 g/Nm3

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 9

Page 12

2.2. Approvals

This section presents Safety and Electromagnetic Compatibility (EMC) compliance

approvals for the Model 465H monitor.

2.2.1. Safety

IEC 61010-1:2001 (3rd Edition), Safety requirements for electrical

equipment for measurement, control, and laboratory use.

CE: 2006/95/EC, Low-Voltage Directive

2.2.2. EMC

EN 61326-1 (IEC 61326-1), Class A Emissions/Industrial

Immunity

EN 55011 (CISPR 11), Group 1, Class A Emissions

FCC 47 CFR Part 15B, Class A Emissions

CE: 2004/108/EC, Electromagnetic Compatibility Directive

2.2.3. Other Type Certifications

For additional certifications, please contact Technical Support:

Toll-free: 800-324-5190

Phone: +1 858-657-9800

Fax: +1 858-657-9816

Email: api-techsupport@teledyne.com

10 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 13

T

P

3. PRINCIPLE OF OPERATION

The detection of ozone molecules is based on absorption of 254 nm UV light due to an

internal electronic resonance of the O3 molecule. The 465H uses a mercury lamp

constructed so that a large majority of the light emitted is at the 254nm wavelength. Light

from the lamp shines down a hollow quartz tube that is alternately filled with sample gas,

then filled with gas scrubbed to remove ozone. The ratio of the intensity of light passing

through the scrubbed gas to that of the sample forms a ratio I/Io. This ratio forms the

basis for the calculation of the ozone concentration.

The Beer-Lambert equation, shown below, calculates the concentration of ozone from the

ratio of light intensities.

C

6

10

O

3

L

273

psi

695.14

n

o

Where:

I = Intensity of light passed through the sample

Io = Intensity of light through sample free of ozone

= absorption coefficient

L = path length

= concentration of ozone in parts per million

C

O

3

= sample temperature in Kelvin

= pressure in pounds per square inch (absolute)

As can be seen the concentration of ozone depends on more than the intensity ratio.

Temperature and pressure influence the density of the sample. The density of the gas

changes the number of ozone molecules in the absorption cell which impacts the amount

of light removed from the light beam. These effects are addressed by directly measuring

temperature and pressure and including their actual values in the calculation. The

absorption coefficient is a number that reflects the inherent ability of ozone to absorb 254

nm light. Most current measurements place this value at 308 cm-1 atm-1 at STP. The

value of this number reflects the fact that ozone is a very efficient absorber of UV

radiation which is why stratospheric ozone protects the life forms lower in the

atmosphere from the harmful effects from solar UV radiation. Lastly, the absorption path

length determines how many molecules are present in the column of gas in the absorption

cell.

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 11

Page 14

The intensity of light is converted into a voltage by the detector/preamp module. The

voltage is converted into a number by a high resolution A/D (analog-to-digital) converter.

The digitized signal, along with the other variables, is used by the CPU to compute the

concentration using the above formula.

12 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 15

4. GETTING STARTED

The 465H is shipped with the following standard equipment:

Power cord (Rack mount version only.)

Instruction manual.

Flow Control Assemblies (2X.)

Upon receiving the 465H, verify that there is no apparent shipping damage. (If damage

has occurred please advise shipper first, then Teledyne API.)

CAUTION

Connect the exhaust fitting on the rear panel to a

suitable vent outside the monitor area.

4.1. Mechanical Installation (for Monitors in

NEMA 4X Enclosures)

Mount the enclosure securely to a vertical surface.

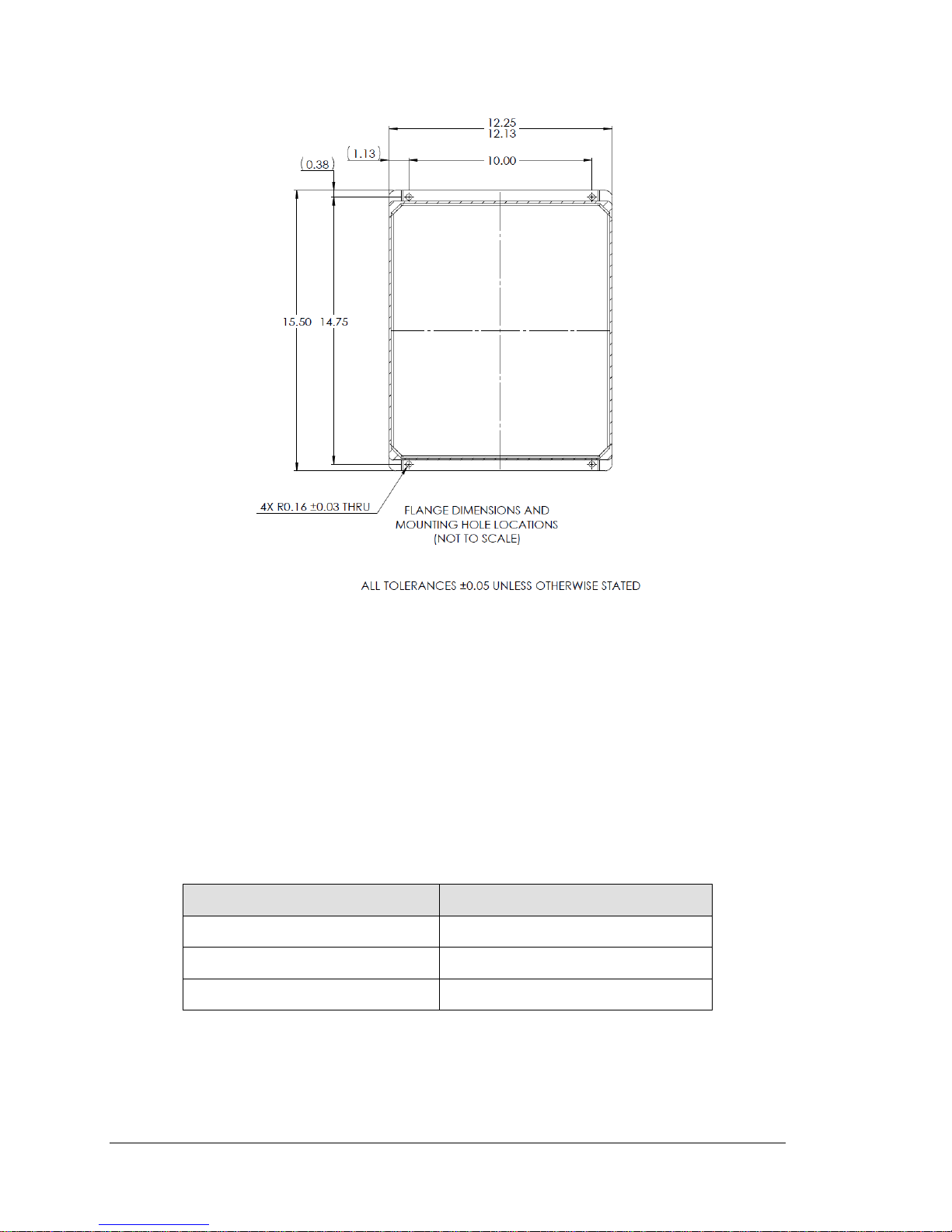

Figure 4-1 shows the locations of the four mounting holes, which are 0.32”

(8.128 mm) diameter.

All four mounting holes should be used to secure the monitor.

Use stainless steel, 5/16” (8 mm) diameter bolts.

4.1.1. Ventilation Clearance

When installing the 465H be sure to leave sufficient ventilation clearance.

Table 4-1: 465H Ventilation Clearances, NEMA Version

Area Minimum required clearance

Back of the monitor None

Sides of the monitor 1 inch

Above and below the monitor 1 inch

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 13

Page 16

Figure 4-1: 465H Mounting Hole Locations and Dimensions

4.2. Mechanical Installation (19” Rack Version)

The Rack Mount version of the 465H was designed to be operated as a bench-top monitor

or to be mounted in a standard 19” RETMA instrumentation rack. For rack installations,

the four mounting feet should be removed from the bottom of the monitor.

4.2.1. Ventilation Clearance

When installing the 465H be sure to leave sufficient ventilation clearance.

Table 4-2: 465H Ventilation Clearances, Rack Mount Version

Area Minimum required clearance

Back of the monitor 3 inches

Sides of the monitor 1 inch

Above and below the monitor 1/2 inch

14 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 17

4.3. AC Power Connection (for Monitors in

NEMA 4X Enclosure)

WARNING: Electrical Shock Hazard

Disconnect power to the AC mains before making or removing

A proper earth ground connection must be made to the

receptacle labeled “Earth Ground” on the 3 pin AC connector.

Failure to do so may result in a shock hazard and malfunction

4.3.1. Wiring Requirements for NEMA Enclosures

Use appropriate wiring rated for this type of equipment, ensuring that it meets local and

national safety and building requirements.

any electrical connections to the 465H.

WARNING: Electrical Shock Hazard

of the monitor

Ensure that overcurrent protection is used (a 5 A circuit breaker is recommended), and

that it fulfills the following requirements:

belocatedasneartotheinstrumentaspossible

quicklyandeasilyaccessible

clearlylabeledasthedisconnectingdeviceforthisinstrument

4.3.2. Wiring Instructions

1. Install a ½” conduit fitting for routing the electrical wiring into the monitor

through the hole provided in the bottom face of the NEMA enclosure; an

appropriate sealed conduit connector should be used.

2. Attach the leads of the power line to the AC power connector (see Figure 4-6).

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 15

Page 18

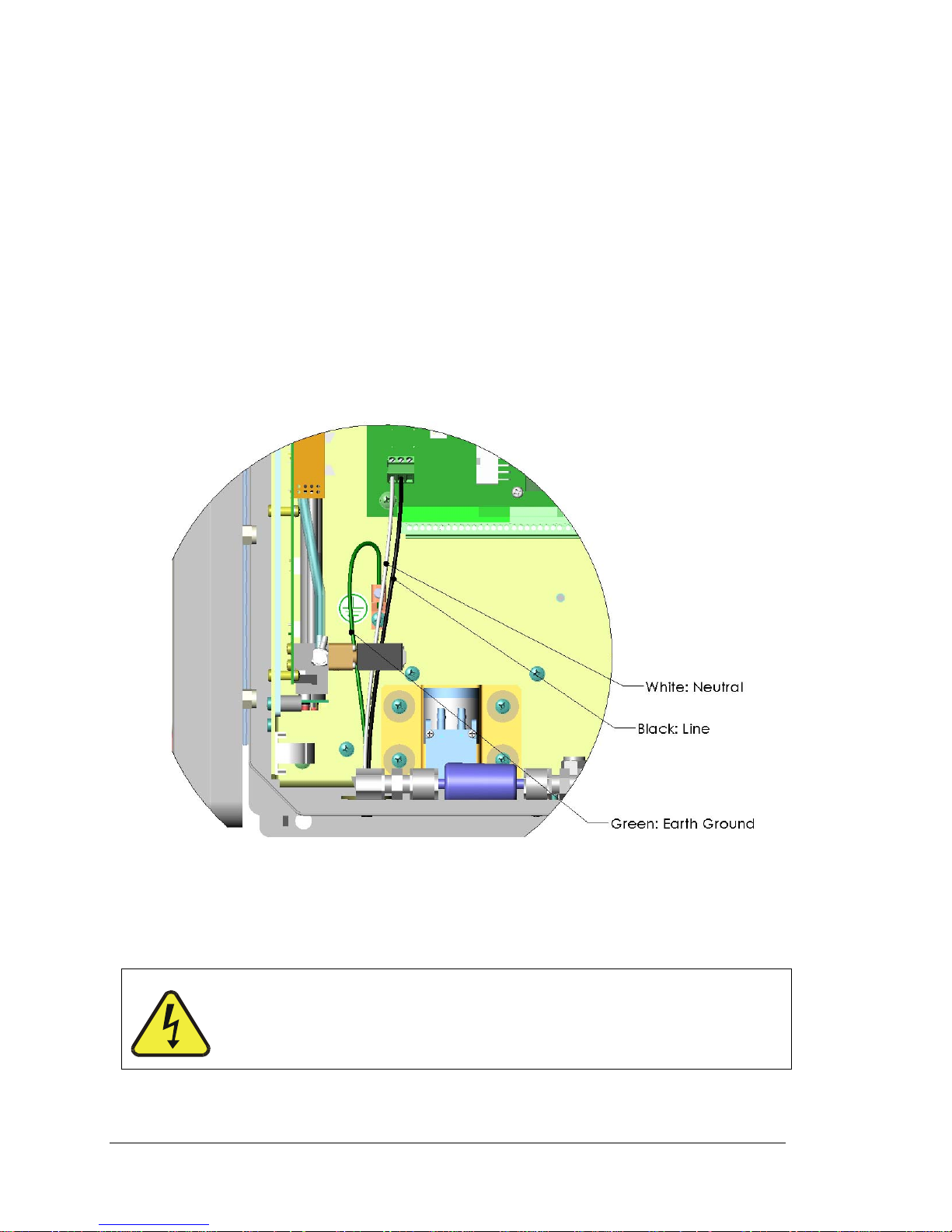

3. For the NEMA configuration, the electrical connection must be hard-wired to the

3-pin connector on the mainboard labeled J23. AC power connection to the

monitor should be made with 12-14 AWG stranded copper wire, connected to the

monitor as follows:

a. Earth Ground (green): Connect the earth ground wire to the screw terminal lug on

the chassis as shown in the Figure below. Do not connect

the earth ground wire directly to the PCB connector on the

mainboard PCB.

b. Line (Black): Connect the Line wire to the connector on the mainboard

PCB labeled “Line”.

c. Neutral (White): Connect the Neutral wire to the connector on the

mainboard PCB labeled “Neutral”.

Figure 4-2. NEMA AC Power Connection to Monitor

4. Connect the power cord to an appropriate power outlet (see the serial number tag

for correct voltage and frequency).

Verify that the instrument is set up for proper line voltage and

frequency. Observe local electrical codes when connecting

power to the monitor.

16 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

WARNING

Page 19

5. Turn on the 465H by switching the switch on the left side of the rear panel, or

applying power to the monitor (NEMA configuration.) The front panel display

should light with a sequence of messages, including the instrument serial number

and software revision. (When the instrument first powers up, the display will

show ‘xxxx’, indicating that the instrument is in start-up mode, waiting for the

UV detector readings to stabilize).

After the start-up period, the instrument will begin displaying the ozone concentration

and the optional stream selector will begin operating, if installed.

4.4. Pneumatic Connections

Figure 4-3: Pneumatic Connections, Rack Mount Configuration

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 17

Page 20

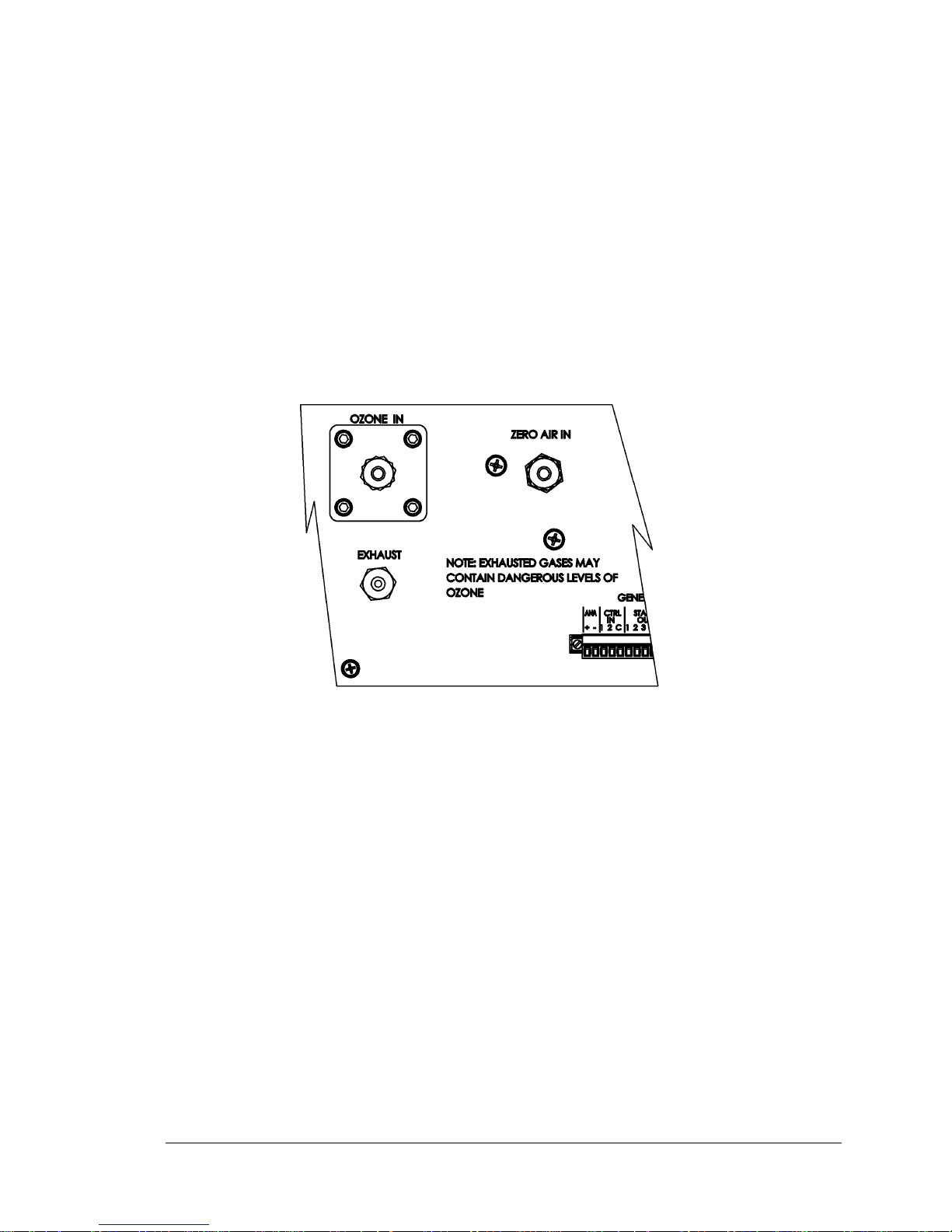

Figure 4-4: Pneumatic Connections, NEMA Configuration

4.4.1. Installing Flow Control Assemblies

Two (2) Flow Control assemblies are supplied separately from the monitor, these are

used to control the flow into the monitor. These Flow Control Assemblies will supply a

fixed flow into the monitor that is dependent on gas supply pressure.

Alternately, customer supplied needle valves can be used in place of these Flow Control

Assemblies if an adjustable flow control is desired. Use only needle valves that are

constructed of materials compatible with high concentrations of ozone, such as stainless

steel and Teflon.

Attach the Flow Control Assemblies by screwing them onto the threaded fittings of the

ozone inlet and the zero gas inlet (see Figure 9-1 and Figure 9-2).

Hand-tighten orifice assemblies until snug.

With a 9/16” open-end wrench, tighten each orifice assembly 1/8–1/4 turn. Use a

1/2” back-up wrench to anchor the fittings of the zero gas and ozone inlet ports in

place.

Do not over tighten the fittings.

NOTE

Both flow control assemblies are identical and interchangeable.

18 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 21

4.4.2. Ozone Inlet Connection

Connect the ozone delivery line to the Flow Control Assembly (See Section 4.4.1) on the

“Ozone Inlet” on the bottom face of the enclosure (See Figure 4-3 and Figure 4-4.) The

ozone delivery should be regulated between 5-30psig.

NOTE

Customers who wish to attach their own flow control devices

(e.g. needle valves) should attach their hardware directly to the

¼” fitting (Swagelok compatible) of the ozone inlet and the zero

gas inlet.

1/4" O.D. FEP (Teflon) or Stainless Steel tubing is recommended to connect the sample

source to the monitor. Any fittings used in the sample lines should also be constructed of

Stainless Steel.

A Flow Control assembly is provided with the monitor, see Section 4.4.1.

4.4.3. Zero Gas Connection

Connect the oxygen or other dry zero gas sources to the to the Flow Control Assembly

(See Section 4.4.1) on the ‘Zero Gas Inlet.’ Zero Gas supply pressure should be regulated

between 5 and 30 psig.

4.4.4. Exhaust Connection

Connect a ¼” OD vent line to the “Exhaust” fitting on the rear panel. This line must be

vented outdoors or to an appropriate discharge system capable of handling ozone. Local

regulations regarding the discharge of ozone to the atmosphere must be observed.

NOTE

The monitor may be equipped with an internal ozone scrubber for

removal of ozone from the exhaust stream. For safety reasons,

the exhaust port must still be vented appropriately as described

above.

CAUTION

Exhaust gas from the 465H may contain dangerous

levels of ozone! Do not vent this gas into enclosed or

occupied areas.

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 19

Page 22

Figure 4-5: Rear Panel Electrical I/O Connections

Figure 4-6: NEMA Electrical I/O Connections

20 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 23

4.5. Electrical I/O Connections

4.5.1. Location of I/O Connectors in the NEMA

Configuration

In the NEMA configuration of the 465H, the I/O connectors are located internally in the

instrument. See Figure 4-6 for their location. Connection to these terminals is usually

made via a conduit connection to the NEMA enclosure. A standard conduit penetration

may be added to one of the walls of the enclosure for this purpose, or the existing

penetration may be used.

The I/O label inside the NEMA cover provides information on the functions of the

connectors. See Figure 4-7 below for the location of the I/O Label.

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 21

Figure 4-7: NEMA I/O Label

Page 24

4.5.2. Analog Output

The analog output is located at the “General I/O” connector (See Figure 4-3.) and is

labeled “ANA.” The analog output can be configured for 0-5V voltage or 4-20 mA

current output. See Section 7.2.5.1 to automatically step-test the analog output.

The analog output is automatically scaled to the range of the instrument, i.e. if the

monitor range is 100 g/Nm3, then 5V would correspond to 100 g/Nm3 and 0V would

correspond to 0 g/Nm3. See Section 7.2.4 for information on changing the range of the

monitor.

4.5.3. Status Outputs

There are four instrument status outputs located at the “General I/O” connector. These

status outputs mirror the state of the four diagnostic LED’s on the front panel. If any of

these status outputs are in a different state than shown in Table 4-3 then some adjustment

or troubleshooting should be performed. See Section 10.2 for more detailed information.

Electrically these outputs are SPST dry contact relay closures with a common contact,

labeled ‘C’ on the rear panel. They are capable of switching up to 50 VDC, 250mA

maximum current. There are no polarity requirements, so the outputs can be used to sink

or source current from the ‘C’ pin, within the maximum voltage and current specified.

Schematically, the outputs look as shown in Figure 4-8 below:

Figure 4-8: Status Output Schematic

22 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 25

The outputs are defined as follows:

Table 4-3: Status Output Definitions

Status

Output #

Name Normal Operating

State

1 Sensor OK On

2 Invalid Reading Off

3 Check Lamp Off

4 Pneumatic Error Off

4.5.4. Hi-Current Relay Outputs

Three form C relay outputs are provided on the rear panel on the nine pin connector (see

Figure 4-5). The relays are labeled “Relay 1,” “Relay 2,” and “Relay 3.”

The relays are dry contact type form C (SPDT) relays with Normally Open (N.O.),

Normally Closed (N.C.) and Common (COM) contacts. The relays are capable of driving

loads of up to 250VAC, 5A. For maximum contact life, the relays should only be used to

drive resistive loads. Contact life may be dramatically shortened if inductive loads are

driven without any provision for minimizing a high voltage “inductive kick” that can

occur. See Section 7.2.3 to configure the alarms.

Table 4-4: Relay Functions

Relay # Function Normal

Operating State

1 System OK Diagnostic

On

(Identical to Sensor OK

status output as

described in Table 4-3)

2 Hi Alarm Off

3 Hi-Hi Alarm Off

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 23

Page 26

4.5.5. Digital Serial Interfaces

There is one external communications port that can be configured for either the RS232,

RS485 (Half Duplex,) or Ethernet (10Mbit.) This section provides only a brief overview

of the digital serial connections. For more detailed information on configuring and using

the digital serial interfaces, see Section 8.

4.5.5.1. RS232 Connection

With the instrument configured for RS232, connection can be made to the DB-9

connector, labeled “RS232/485”, or to the three “COM” pins on the “General I/O”

connector. See Section 8.2 for additional details.

When using RS232, a 9-pin serial cable (TAPI P/N WR77) can be used to connect the

instrument to a standard PC (personal computer) serial port.

4.5.5.2. RS485 Connection

With the instrument configured for RS485, connection can be made to the DB-9

connector, labeled “RS232/485”, or to the three “COM” pins on the “General I/O”

connector. See Section 8.2 for additional details.

4.5.5.3. Ethernet Connection

With the instrument configured for Ethernet, connection should be made to the RJ-45

port labeled “Ethernet.” Connection can be made using a standard Category 5 or better

network patch cable. See Section 8.2 for additional details. TAPI can provide an

appropriate cable.

24 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 27

5. FREQUENTLY ASKED QUESTIONS

6. Q: How long does the UV Lamp last?

A: The typical lifetime is about 2-3 years.

The lamp output will steadily decrease until lamp adjustment can no longer be

performed. The "Check Lamp" warning LED will tell the operator when this

adjustment should be attempted. When this adjustment can no longer be

performed, the lamp should be replaced. See Chapter 1 for more information.

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 25

Page 28

6. HARDWARE AND SOFTWARE OPTIONS

6.1. Rack Mount Slides

Rack mount slides can be attached to the sides of the instrument, allowing it to slide

completely out of a RETMA rack, facilitating maintenance activities.

6.2. Ethernet (MODBUS

The Ethernet option consists of a converter that provides a MODBUS® TCP/IP interface

to the monitor.

®

TCP/IP)

26 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 29

7. OPERATION

7.1. Front Panel Overview

The 465H front panel provides a number of functions in addition to displaying the current

ozone concentration being measured. Figure 7-1 below shows the display and keypad

portion of the front panel.

Figure 7-1: Front Panel Display

7.1.1. Ozone Concentration Display

The 4-character LED display in the center of the front panel normally shows the current

ozone concentration being measured by the 465H. While displaying concentration, one

of the unit-of-measure indicators (i.e. WT%, or g/Nm3) should be backlit, indicating the

current measurement units. If none of these indicators are backlit, then the display is in

Menu mode or Startup mode and is not displaying the concentration. If the display is in

Menu mode, the display can be returned to Concentration mode by repeatedly pressing

the CFG button until one of the unit-of-measure indicators is lit.

NOTE

Even when the display is in Menu mode, normal measurement

and stream selector operation will continue in the background.

7.1.2. Menu Navigation Keypad

The menu navigation keypad (CFG, ENT and UP/DOWN buttons) is used to navigate

the various menu items available on the 465H. The menus allow the operator to view

operational parameters of the instrument as well as view and modify the configuration of

the instrument. See Section 7.2 for more detailed information.

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 27

Page 30

7.1.3. Concentration Alarm Status/Reset

The 465H front panel displays the concentration alarm status of the sample gas. The

LED labeled ‘ALARM STATUS’ shows the alarm status as follows:

Table 7-1: Alarm LED’s

Alarm Status LED Color Alarm State

Green No alarm active

Amber ‘HI’ alarm active

Red ‘HI-HI’ alarm active

If the alarms are configured for latching operation, then the RESET button can be used to

attempt to reset all alarms.

NOTE

Alarms can only be reset if the concentration measured has

subsequently dropped below the alarm limit.

If the alarms are configured for non-latching operation, they will be automatically cleared

when the concentration falls below the alarm threshold. The RESET button has no effect

when the alarms are configured for non-latching operation.

See Sections 7.2.3 and 4.5.4 for additional details on concentration alarms.

7.1.4. Status LED’s

There are four Status LED’s on the front panel to the right of the concentration display.

These LED’s provide a quick view of the instrument’s Status and provide indication of

any problems that may exist. The normal state for these LED’s after the initial warm-up

period is as follows:

Table 7-2: Status LED’s

Status LED Normal State

Sensor OK ON

Invalid Reading OFF

Check Lamp OFF

Pneumatic Error OFF

If any of these LED’s are in a different state than shown above, then some adjustment or

troubleshooting should be performed. See Section 10.2 for more detailed information.

28 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 31

7.2. Front Panel Menus

The 465H has an interactive menu structure that can be operated from the front panel.

From within this menu structure, the operator can view real-time parameters such as

temperature and pressure, view configuration information, and edit setup parameters such

as alarm limits.

Figure 7-2 and Figure 7-3 below show the menu structure as well as the buttons that are

used to navigate it.

Starting with the display in Concentration mode, press CFG to enter Menu mode. At this

point the unit-of-measure LED should turn off and the first level of the Menu tree will be

active. Pressing the UP/DOWN arrows will now select from the items available at this

menu level. Press ENT to enter one of these sub-menus or press CFG to back out of this

menu level back to Concentration mode.

7.2.1. Menu Navigation Basics

1. Press CFG from Concentration mode to enter Menu mode.

2. Once in Menu mode, CFG will move backwards one level in the menu structure

and ENT will move forward.

3. Each menu level contains an EXIT selection. Selecting EXIT and pressing ENT

will exit the Menu mode and return the display to Concentration mode.

7.2.2. Editing Numeric Values

At certain places in the menu structure the operator can edit numeric values. The menu

buttons behave somewhat different when in this mode.

Press CFG to select a digit to edit. The selected digit will blink. Next press the

UP/DOWN arrows to increment/decrement the selected digit. Press CFG again to select

another digit. Pressing CFG at the last digit will wrap back to the first digit.

Once all the digits have been edited, press ENT to accept the new value.

To abort the editing process without changing the original value, press and hold the CFG

button until the display returns to the previous menu level.

NOTE

Limit checking is enforced, while editing values and changes that

would result in invalid values are ignored.

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 29

Page 32

Figure 7-2: Front Panel Menu Diagram

30 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 33

DIAG

VIEW

ENT

ENT

SEE PREVIOUS

PAGE

SEE PREVIOUS

PAGE

ANALOG

STEP TEST

SIGNAL I/O

MEMORY

RESET

ZERO CAL

SPAN CAL

STORE

VARS

RESTORE

VARS

EXIT

MEAS

REF

ENT

ENT

ENT

ENT

ENT

ENT

ENT

See Section

6.2.5.1

See Section

6.2.5.2

See Section

6.2.5.3

See Section

6.2.5.4

See Section

6.2.5.5

Unavailable

Unavailable

CFG

M465H-Front Panel Menu Diagram, Rack Mount

ENT

SEE PREVIOUS

Figure 7-3: Front Panel Menu Diagram

PAGE

PRESSURE

LAMP

TEMP

SAMPLE

TEMP

FLOW

EXIT

S/N

COMM

ADDRESS

REV

BOOT

EXIT

See Section

6.2.6

See Section

6.2.7

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 31

Page 34

7.2.3. SETUP-ALARM Menu

The ALARM menu gives the option of enabling/disabling the HI, and HI-HI alarms, as

well as setting the concentrations at which they are triggered. The options available:

Table 7-3: Alarm Configuration Properties

Property Meaning Default Value Range

HI ALARM HI alarm trigger value 1.00 WT%,

1.00 g/Nm3

HIHI ALARM HI-HI alarm trigger value 1.02 WT%,

1.02 g/Nm3

ON/OFF HI

ALARM

ON/OFF HI HI

ALARM

HI alarm enable, enables HI alarm

operation

HI-HI alarm enable, enables HI-HI

alarm operation

ON ON/OFF

ON ON/OFF

0.02%-25.0%

0.02-400 g/Nm3

0.02%-25.0%

0.02-400 g/Nm3

32 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 35

7.2.4. SETUP-VARS Menu

The VARS menu allows viewing and editing of various global setup variables that effect

how the 465H operates. These variables are stored in the instrument’s non-volatile

memory. Table 7-4 lists these variables and their function.

Table 7-4: VARS List

VAR Meaning Default

ALARM MODE Controls the latching behavior of

the concentration alarms. See

Section 7.1.3 for additional details.

ALARM DELAY Number of readings above alarm

limit required to trigger alarms

BC FILT SIZE Boxcar filter’s length for

concentration filter. Higher values

will smooth out the concentration

readings but will also increase the

response time.

FLOW SWITCH

ENABLE

COMM ADDRESS MODBUS® address for COM

UNIT Concentration unit-of-measure

Enables/disables operation of

optional flow switch

ports.

setting.

Range

Value

LATCHING LATCHING,

NONLATCHING

5 1 - 20

30 1-30

OFF ON, OFF

1 1 - 247

g/Nm3 WT%, g/Nm3

SCROLL DELAY Character delay for the front panel

display.

AZERO ENABLE Enables/Disengages zero

calibration

AZERO

INTERVAL

GAS CARRIER

WEIGHT

ANALOG RANGE Voltage range corresponding to

Interval at which zero calibration is

performed. (minutes)

Weight of gas without ozone, used

in %Weight measurement

ozone concentration.

20 6-100

ON ON/OFF

720 3-1440

32.00 20.0-40.0

20 5 – 50 g/Nm3

0.5 – 25.0 wt%

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 33

Page 36

7.2.5. DIAG Menu

The DIAG menu (See Figure 7-2 and Figure 7-3) contains functions that are useful for

calibration and I/O testing.

7.2.5.1. Analog Step-Test

When placed in this mode, the instrument will automatically step the analog output

through 5 points from 0 to 100 % and display the current value on the front panel. The

operator can suspend the automatic cycling and manually control the stepping by pressing

either one of the UP / DOWN arrow buttons. To resume automatic cycling, exit the

function by pressing CFG and re-enter by pressing ENT.

The 5 points will correspond to the following analog output values depending on whether

the output is configured for 0-5V or 4-20mA:

Table 7-5: Analog Step Test Values

Point 0-5V Output 4-20 mA Output

0% 0.00 V ± 0.02 4 mA ± 0.02

25% 1.25 V ± 0.02 8 mA ± 0.02

50% 2.50 V ± 0.02 12 mA ± 0.02

75% 3.75 V ± 0.02 16 mA ± 0.02

100% 5.00 V ± 0.02 20 mA ± 0.02

Press CFG to exit from the Analog Step-Test function.

7.2.5.2. Signal I/O

The Signal I/O menu allows the operator to manually control the various relay outputs

and control inputs available on the rear panel of the 465H. This function is useful for

testing or debugging external control systems (i.e. data-loggers or PLC’s) to which the

instrument may be connected.

See Section 4.5 for additional details on making connections to these I/O signals on the

rear panel.

See Figure 7-2 and Figure 7-3 for additional details on entering the Signal I/O menu.

34 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 37

Table 7-6: Signal I/O List

Signal Name Rear Panel Label Function

AUX 1 IN CTRL IN - 1 UNDEFINED

AUX 2 IN CTRL IN - 2 UNDEFINED

RELAY 1 RELAY 1 SENSOR OK

RELAY 2 RELAY 2 HI ALARM

RELAY 3 RELAY 3 HI-HI ALARM

STAT OUT 1 STATUS OUT – 1 SENSOR OK

STAT OUT 2 STATUS OUT – 2 INVALID READING

STAT OUT 3 STATUS OUT – 3 CHECK LAMP

STAT OUT 4 STATUS OUT – 4 PNEUMATIC ERROR

STAT AUX 1 AUX OUT – 1 UNDEFINED

STAT AUX 2 AUX OUT – 2 UNDEFINED

7.2.5.3. Memory Reset

This function is currently disabled.

7.2.5.4. Zero Calibration

This function performs a zero calibration based on gas from the “Zero In” port.

If the Auto Zero calibration is enabled, the internal ozone offset factor will automatically

be adjusted every 720 minutes. If the zero calibration is disabled, then manual calibration

is necessary based on the customer’s applications. For normal applications, the Auto Zero

is not necessary.

The zero calibration allows the instrument to calibrate its internal ozone offset factor.

This should only be done with a source of zero air connected to the “Zero In” port of the

465H. Allow the instrument to stabilize on the zero air source before attempting to zero

the instrument. This normally takes 10-15 minutes.

When entering the Zero Calibration menu, the prompt “ENT TO CAL” appears on the

display. Simply confirm the calibration by pressing the ENT button to perform the

calibration (to abort the calibration, press and hold the CFG button to return to the

previous menu level.) After pressing ENT, the instrument will automatically exit the

menu mode and return to Concentration mode. The concentration reading should quickly

go to zero.

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 35

Page 38

NOTE

While measuring zero air, a certain amount of noise or

“dithering” of the concentration about the zero point will occur

and is normal. This noise is typically 0.01-0.02 Wt% in

magnitude.

7.2.5.5. Span Calibration

The Span Calibration also allows the instrument to calibrate its internal ozone offset

factor. The Span Calibration however, is done with some controlled concentration gas

connected to the “Sample In” port of the 465H. It is recommended that a span gas is

concentrated to around 80% of the operating range. Set the SPAN VALUE to the

measured concentration of your calibration gas. This normally takes 10-15 minutes.

NOTE

A Span Calibration should only be performed with a stable

source of Ozone and a reference monitor measuring the same gas

supply.

If you are unsure regarding the suitability of a particular source

of calibration gas, contact Technical Support at Teledyne API for

assistance (see Section 0.)

See Figure 7-4 shows the Span Cal menu. After the instrument has stabilized on the

source of span gas, navigate to the Span Cal menu (See Figure 7-2 and Figure 7-3) and

Press ENT. Next enter the Span Target concentration (the actual concentration of ozone

being supplied to the monitor) and press ENT. The display will next show a

confirmation menu, ENT TO SPAN. Press ENT to perform the Span Calibration, or

CFG to abort back to the start. If the calibration is successful, the display will return to

the concentration menu and the monitor reading should change adjust to read very close

to the target value. If the calibration cannot be performed, an OUT OF RANGE error

will be displayed. Press ENT to confirm and the display will return to the start of the

Span Cal menu.

If the OUT OF RANGE error occurs, it means the Span Cal cannot be performed

because it would result in an out of range slope value for the monitor. This means that

either the sensor in the monitor is malfunctioning, causing improper readings, or the

actual ozone concentration being supplied to the monitor is different than the target value

being entered.

36 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 39

Figure 7-4: Span Cal Menu

7.2.6. VIEW Menu

The VIEW menu allows the operator to view various measurement parameters in realtime. This can be useful for diagnosing various instrument or system problems.

NOTE

These values are updated in real-time as they are repeatedly

scrolled on the display.

Table 7-7: VIEW Menu Parameters

Parameter Meaning Units Normal Range*

MEAS UV detector reading, measure cycle mV 250 – 1230

REF UV detector reading, reference

cycle

PRESSURE Sample pressure psia 9.0 – 18.0

LAMP

UV lamp temperature ºC 50.0 – 52.0

TEMP

SAMPLE

Sample temperature ºC 5.0 –50.0

TEMP

mV 250 – 1230

FLOW Flow Switch State ** ON/OFF ON

*After initial 20 minute warm-up period.

** Only available if Flow Switch Option is installed.

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 37

Page 40

7.2.7. CONFIG Menu

The CONFIG menu displays important information about the instrument. The Serial

Number, COMM address settings, and the latest revision of software installed are

information available in the CONFIG menu. Settings can be changed under other menus

(see sections 7.2.3, 7.2.4, and 7.2.5); however the CONFIG menu just contains

instrument-specific information.

7.3. Analog Output

The 465H provides an analog output of the current O3 reading on the rear panel (see

Section 4.5.2). The output can be configured for 0-5V or 4-20mA isolated current output.

The analog output provides a scaled, real-time output of the current ozone concentration

being measured by the instrument. See Section 7.2.4 for details on changing the analog

output range. See Section 9.6 for details on configuring the output for 0-5 V or 4-20 mA.

38 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 41

8. DIGITAL COMMUNICATIONS

8.1. Digital Communications Overview

The 465H comes equipped with a digital communications (COM) port that can be

connected to a computer or digital data acquisition system. This COM port uses the

standardized MODBUS® protocol and can be configured for RS232, RS485, or Ethernet

(10 Mbit,) allowing for connections to a wide variety of devices and networks. See

Section 8.2 for more information on configuring the COM port.

The COM port can be used for data acquisition, alarm triggering, and instrument

configuration. All the functions that are available at the front panel of the instrument can

also be performed over the COM port.

NOTE

The APICOM software provided by Teledyne API does not currently

support communications with the 465H. Contact TAPI for more

information on compatible MODBUS® software that can be used

with the 465H.

8.2. Changing COM Port Hardware

Configuration

The operations outlined in this section are to be performed by

The COM port can be configured for RS232, RS485, or Ethernet. To change the COM

port hardware configuration, perform the following steps:

1. Disconnect power from the 465H.

2. Remove the six screws and the top cover.

3. Locate the DIP switches labeled SW3 on the rear portion of the mainboard.

4. Turn ON the switches specified for the desired COM configuration (See Figure

8-1.) All other switches on SW3 should be OFF.

WARNING: Electrical Shock Hazard

qualified maintenance personnel only!

5. Locate SW2 (DTE-DCE switch) on mainboard.

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 39

Page 42

6. For RS-232 operation, set SW2 to either DTE or DCE (See Section 8.3.) For RS-

485 operation, set SW2 to DCE.

7. Re-install the instrument cover.

8. Re-connect power to the instrument.

9. The software portion of the COM port configuration will now automatically be

completed after the next instrument boot-up.

SW3

3

4

21

765

1098

RS232 Configuration

ETHERNET

SW3

RS485

Close Indicated Positions Only

3

4

21

765

RS232

1098

RS485 Configuration

ETHERNET

SW3

RS485

Close Indicated Positions Only

1234

567

RS232

8910

Ethernet Configuration

ETHERNET

RS485

Close Indicated Positions Only

Figure 8-1: COM Configuration Jumper Settings (SW3)

RS232

40 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 43

8.3. RS-232 Configuration

The RS-232 configuration is usually used when making a one-to-one connection between

the instrument and a single computer or PLC. The communications protocol used for the

RS-232 configuration is MODBUS

specification, please see http://www.modbus.org/.

With the instrument configured for RS-232, connection can be made to the DB-9

connector, labeled “RS232/485”, or to the three “COM” pins on the “General I/O”

connector. Only one of these connections should be used, the other must be left unconnected. Table 8-1 below details the pinouts of these two connectors:

Table 8-1: RS-232 Connector Details

®

RTU. For details on the MODBUS® RTU

Function DB-9

Connector Pin

(SW2 – DTE)

DB-9

Connector Pin

(SW2 – DCE)

General I/O

Connector

Transmit (Tx) 3 2 ‘T’

Receive (Rx) 2 3 ‘R’

Ground 5 5 ‘G’

NOTE

A DTE-DCE switch is provided so that the instrument can be

connected to another device using either a straight-through or

crossover (Null-Modem) cable. See Section 8.2 for details on

changing this configuration.

The serial port setup for RS-232 configuration is shown in Table 8-2 below:

Table 8-2: RS-232 Port Setup

Property Value

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 41

Baud Rate 57600

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

Page 44

8.4. RS-485 Configuration

RS-485 is commonly used for factory automation busses with a computer or PLC acting

as a master. The communications protocol used for the RS-485 configuration is

MODBUS

http://www.modbus.org/.

With the instrument configured for RS-485, connection can be made to the DB-9

connector, labeled “RS232/485”, or to the three “COM” pins on the “General I/O”

connector. Table 8-3 below details the pinouts of these two connectors:

®

RTU. For details on the MODBUS® RTU specification, please see

Table 8-3: RS-485 Connector Details

Function DB-9

Connector Pin

General I/O

Connector

(SW2 – DCE)

RS485 - A 2 ‘T’

RS485 - B 3 ‘R’

Ground 5 ‘G’

NOTE

For RS-485 configuration, the DTE-DCE switch should always

be set to DCE. See Section 8.2 for details on changing this

configuration.

The serial port setup for RS-485 configuration is shown in Table 8-4 below:

Table 8-4: RS-485 Port Setup

Property Value

Baud Rate 57600

42 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

Page 45

8.5. Ethernet Configuration

Ethernet is commonly used for factory automation busses with a computer or PLC acting

as a master. The communications protocol used for the Ethernet configuration is

MODBUS

http://www.modbus.org/.

A Windows software application, DeviceInstaller, is available for configuring the

Ethernet module used in the 465H. This application is available for download here:

http://www.lantronix.com/device-networking/utilities-tools/device-installer.html

8.5.1. Hardware Setup for Configuring the Ethernet

To make the first-time configuration of the Ethernet module as easy as possible, the

module comes from the factory with DHCP enabled. The 465H can simply be plugged

into a network with a DHCP server and an IP Address should be automatically assigned

to, and stored in, the device.

A simple network can easily be constructed for this purpose by using a small broadband

router commonly used for home networks. The 465H and a PC can then be connected to

the router and the router’s DHCP server will assign IP Addresses to both the PC and the

465H, enabling them to communicate.

®

TCP/IP. For details on the MODBUS® TCP/IP specification, please see

Module

8.5.2. Verifying Network Hardware Connection

With the 465H connected to a network and powered up, check the status of the two

LED’s on the Ethernet connector on the rear panel. The left-hand LED should be lit;

either amber or green indicating link status and the right-hand led should blink

periodically, indicating activity on the network. See Table 8-5 below for more details on

the status LED’s.

If neither of the LED’s are lit, then the Ethernet module may not be powered up or the

instrument may not be connected to a valid network. Check the COM port configuration

per Section 8.2 and make sure that it is set to “Ethernet.”

Table 8-5: Ethernet LED Definitions

Link LED (Left Side) Activity LED (Right Side)

Color Meaning Color Meaning

Off No Link Off No Activity

Amber 10 Mbps Connection Amber Half-Duplex

Green 100 Mbps Connection Green Full-Duplex

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 43

Page 46

8.5.3. Determining a Dynamically Assigned IP Address

(DHCP Mode)

The DeviceInstaller software application (See Section 8.5) can be used to search a

network for instruments and determine the IP Address assigned by a DHCP server.

1. Click Start->Programs->Lantronix DeviceInstaller->DeviceInstaller. If

your PC has more than one network adapter, a message displays. Select an

adapter and click OK.

2. Click on the Search icon. After a moment a list of instruments on the network

will be displayed. The 465H should be listed as an XPORT-IAP type device.

3. Double-click on the device in the right-hand section of the DeviceInstaller

window; a list of configuration parameters will be shown, including the IP

Address. If multiple devices are shown, the correct one can be determined by

matching the Hardware Address shown with the address printed on the label of

the Ethernet module in the 465H.

NOTE

The instrument cover must be removed to inspect this address in

the instrument.

8.5.4. Manually Assigning a Static IP Address

For applications where the IP Address must remain constant, a static IP Address can be

manually assigned to the instrument and the DHCP function must be disabled.

1. Click Start->Programs->Lantronix DeviceInstaller->DeviceInstaller. If

your PC has more than one network adapter, a message displays. Select an

adapter and click OK.

NOTE

If the unit already has an IP address (e.g., DHCP has assigned an

IP address), click the Search icon and select the unit from the list

of Lantronix device servers on the local network.

2. Click the Assign IP icon.

3. If prompted, enter the hardware address (on the product label) and click Next.

4. Select Assign a specific IP address and click Next.

44 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 47

5. Enter the IP address. The Subnet mask displays automatically based on the

IP address; if desired, you may change it. On a local network, you can leave the

Default gateway blank (all zeros). Click Next.

6. Click the Assign button and wait several seconds until a confirmation message

displays. Click Finish.

7. Select the device from the main window list and select Ping from the Tools

menu. The Ping Device dialog box shows the IP address of the selected unit.

8. From the Tools menu, click the Ping button. The results display in the Status

window. Click the Clear Status button to clear the window so you can ping the

device again.

NOTE

If you do not receive “Reply” messages, make sure the unit is

properly attached to the network and that the IP address assigned

is valid for the particular network segment you are working with.

If you are not sure, check with your systems administrator.

9. Click the Close button to close the dialog box and return to the main window.

8.6. MODBUS

8.6.1. Notes on MODBUS

Concentration values in the MODBUS® registers are always expressed in terms of the

desired 465H settings, whether in %WT or g/Nm3.

®

Register Maps

®

registers

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 45

Page 48

8.6.2. Real-Time Concentration and Status Registers

(Read Only)

Decimal

Address Description Register Type

1 Stream Concentration Float Inverse 0 32

3 Hi Alarm Status Byte 0 8

3 Hi Hi Alarm Status Byte 8 8

4 Gas Flow (cc/min) Float Inverse 0 32

19 Sensor Reference Value Float Inverse 0 32

21 Sensor Measure Value (mV) Float Inverse 0 32

23 Sensor Pressure Value (mV) Float Inverse 0 32

25 Sensor Gas Temperature (K) Float Inverse 0 32

27 Sensor UV Lamp Temperature (oC) Float Inverse 0 32

Start

Bit # Bits

8.6.3. Instrument Setup and Configuration Registers

(Read / Write)

Decimal

Address Description

1030 Hi Alarm Value (WT%) Float Inverse 0 32

1032 Hi Hi Alarm Value (WT%) Float Inverse 0 32

1034 Hi Alarm Enable (WT%) Byte 0 8

1034 Hi Hi Alarm Enable (WT%) Byte 8 8

1035 Alarm Latch Mode Byte 0 8

1038 Analog Range (WT%) Float Inverse 0 32

Register

Type

Start

Bit # Bits

46 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 49

9. MAINTENANCE

The operations outlined in this section are to be performed by

WARNING: Electrical Shock Hazard

qualified maintenance personnel only!

9.1. Maintenance Schedule

Table 9-1 outlines the suggested maintenance procedures and intervals for ensuring the

465H continues to operate accurately and reliably.

Table 9-1: Maintenance Schedule

Maintenance Item Recommended Interval Section

Replace particulate filter 6 months 9.3

Adjust UV lamp As Indicated by ‘Check Lamp’

LED or status output

Replace lamp As required; when adjustment can

no longer be performed.

Replace Auto Zero Valve Annually 9.6

Rebuild cell, replace orings

3 Years Return

9.4

9.5

to

Factory

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 47

Page 50

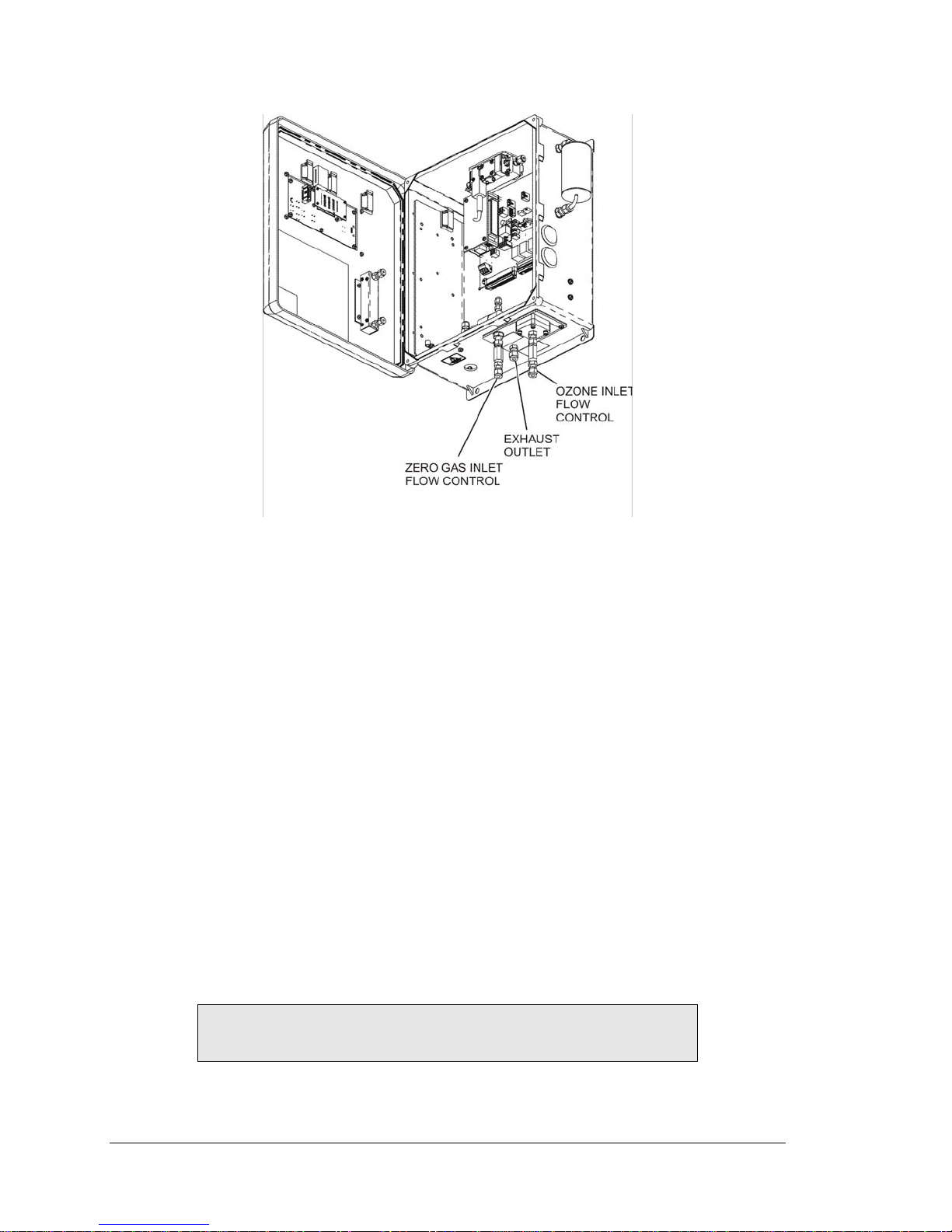

9.2. Instrument Layout

Figure 9-2 show the instrument layout of the 465H. These figures will be referenced in

the procedures that follow.

Figure 9-1: Instrument Layout, Rack Mount Configuration

48 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 51

Figure 9-2: Instrument Layout, NEMA Configuration

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 49

Page 52

9.3. Replacing Internal Particulate Filter

1. Disconnect power from the 465H.

2. Loosen the six screws from the top cover (Rack Mount Configuration, see Figure

9-1) or open front panel (NEMA Configuration, see Figure 9-2.)

3. Remove the six screws and top cover from the instrument.

4. Locate the particulate housing filter on the rear panel (Rack Mount Configuration,

see Figure 9-1) or the bottom panel (NEMA Configuration, see Figure 9-2.)

5. Loosen the four screws on the sample filter body (see Figure 9-3.)

6. Remove the fours screws, the four washers and the sample filter body from the

sample filter base.

7. Remove the o-ring and inspect for any cracks or deformities. If there are no

cracks or deformities, place the o-ring back in the sample filter body.

NOTE

If the o-ring is cracked or deformed, discard the o-ring and

replace with a new one.

8. Remove the two sample filter retainers and glass fiber filter element from the

sample filter body.

9. Discard the glass fiber filter element.

10. Place a new glass fiber filter element in between the two sample filter retainers

and place in the sample filter body.

11. Place the sample filter body on the sample body base and secure with the four

screws and fours washers.

12. Reinstall the top cover on the instrument and secure with the six screws or close

the front panel.

50 Teledyne API Model 465H O3 Monitor User Manual 06161H DCN7969

Page 53

Figure 9-3: Internal Particulate Filter Replacement

9.4. UV Lamp Adjustment

1. Instrument should be running and warmed up for at least 20 minutes.

2. With instrument running, remove the six screws and the top cover (Rack Mount

Configuration) or open front panel (NEMA Configuration.)

3. Locate the Reference UV Detector adjustment pot, PR3, on the Mainboard PCA

(see Figure 9-1 or Figure 9-2.)

4. Navigate the front panel menu to VIEW menu and scroll to REF display and press

ENT. At this point there should be a scrolling display similar to “REF = XXXX

MV.” See Section 7.2 for details on menu navigation.

5. While observing the REF value on the display, slowly turn the pot to adjust the

value. The target adjustment range is as high as possible within the range of 800

– 1150 mV.

6. Locate the Measure UV Detector adjustment pot, PR4, on the mainboard PCA

(see Figure 9-1 or Figure 9-2.)

7. Navigate the front panel menu to VIEW menu and scroll to MEAS display and

press ENT. At this point there should be a scrolling display similar to “MEAS =

XXXX MV.” See Section 7.2 for details on menu navigation.

8. While observing the MEAS value on the display, slowly turn the pot to adjust the

value. The target adjustment range is as high as possible within the range of 800

– 1150 mV.

06161H DCN7969 Teledyne API Model 465H O3 Monitor User Manual 51

Page 54

9. If the required adjustment cannot be achieved by adjusting the UV Detector pot

alone, then additional adjustment can be made by loosening the two UV lamp

setscrews on the UV lamp housing (see Figure 9-1 or Figure 9-2) and rotating the

lamp. Rotate the lamp very slowly while observing the REF or MEAS value on

the display. Make sure the lamp does not pull out and remains seated in the

housing while it is being rotated. Re-tighten the two setscrews when a desired

point has been reached.

10. If necessary, additional “fine tuning” can now be done with the UV Detector

adjustment pots per steps 4-8.

11. Re-Install instrument cover and observe REF and MEAS values on display for a

couple minutes to verify it does not drift out of the adjustment range.

9.5. UV Lamp Replacement

1. Disconnect power from the 465H.

2. Remove the six screws and the top cover (Rack Mount Configuration) or open

front panel (NEMA Configuration.)

3. Loosen the two UV lamp setscrews on the UV lamp housing (see Figure 9-1 or

Figure 9-2.)

4. Unplug the lamp power cord from the connector labeled J18 on the mainboard

PCA.

5. Carefully slide the lamp out of housing.

6. Install the new lamp, seating it in the lamp housing until it stops.

7. Re-tighten the two UV lamp setscrews.

8. Plug the lamp power cord into J18 on the mainboard PCA.

9. Reconnect power to the instrument and turn on power switch. Let instrument

warm up for at least 20 minutes.

10. Perform UV lamp adjustment procedure per Section 9.4.

9.6. Replacing the Auto-Zero Valve

1. Disconnect power from the 465H.

2. Remove the six screws and the top cover (Rack Mount Configuration) or open