Page 1

USB3.0 Serial Data

Operator’s Manual

917719 Revision A – December, 2009

Relating to the Following Release

Versions:

Software Option Rev. 6.0

USB3 Script Rev. 1.0

Style Sheet Rev. 1.2

Page 2

LeCroy Corporation

700 Chestnut Ridge Road

Chestnut Ridge, NY, 10977-6499

Tel: (845) 578-6020, Fax: (845) 578 5985

Internet: www.lecroy.com

© 2009 by LeCroy Corporation. All rights reserved.

LeCroy and other product or brand names are trademarks or requested trademarks of their respective holders.

Information in this publication supersedes all earlier versions. Specifications are subject to change without notice.

917719 Rev A

Page 3

QPHY-USB3-Tx-Rx Software Option

TABLE OF CONTENTS

INTRODUCTION ...................................................................................................................................... 6

Compatibility................................................................................................................................................... 6

Additional Options Equipment Available from LeCroy ........................................................................................6

QualiPHY Compliance Test Platform ................................................................................................................7

Oscilloscope Option Key Installation ................................................................................................................9

Typical (Recommended) Configuration.............................................................................................................9

Remote (Network) Configuration ......................................................................................................................9

Oscilloscope Selection ................................ ................................................................ ....................................9

Accessing the QPHY-USB3-Tx-Rx Software using QualiPHY ..........................................................................10

Customizing QualiPHY................................................................................................................................ ..12

Creating Custom Configurations ....................................................................................................................13

QPHY-USB3-Tx -Rx Operation .......................................................................................................................15

GUIDE TO OPERATION ...................................................................................................................... 16

Transmitter Testing .......................................................................................................................................16

Receiver Testing ...........................................................................................................................................16

Transmitter and Receiver Testing ...................................................................................................................16

Using QPHY-USB3-Tx-Rx .............................................................................................................................16

Oscilloscope Only ................................................................................................ ..................................16

Oscilloscope and PeRT3 ................................................................................................ .........................17

Oscilloscope and PeRT3 with RF Switch ................................ ................................................................ ..17

OPERATING THE PERT3 MANUALLY ............................................................................................. 17

LFPS Ping using the PeRT3...........................................................................................................................18

Loopback Mode using the PeRT3 ................................................................................................ ...................18

Receiver Test Calibration using the PeRT3......................................................................................................18

QPHY-USB3-TX-RX TEST CONFIGURATIONS ............................................................................. 20

Empty Template ............................................................................................................................................20

Pre-Test (Scope PeRT3) ...............................................................................................................................20

Demo of Device Transmitter Tests................................................................................................ ..................20

Device Scope Only (Host TX Tests)................................................................................................ ................20

Device Scope PeRT3 (Host RX Tests)............................................................................................................20

Device Scope PeRT3 (Host TX and RX Tests) ................................................................................................21

Device Scope PeRT3 (Host TX Tests) ............................................................................................................21

Device Scope PeRT3 RF Switch (Host RX Tests)............................................................................................ 21

Device Scope PeRT3 RF Switch (Host TX and RX Tests) ................................................................................22

Device Scope PeRT3 RF Switch (Host TX Tests) ................................................................ ............................22

Host Scope Only (Host TX Tests) ...................................................................................................................22

Host Scope PeRT3 (Host RX Tests) ...............................................................................................................23

Host Scope PeRT3 (Host TX and RX Tests) ...................................................................................................23

Host Scope PeRT3 (Host TX Tests) ...............................................................................................................23

Host Scope PeRT3 RF Switch (Host RX Tests) ...............................................................................................24

Host Scope PeRT3 RF Switch (Host TX and RX Tests) ...................................................................................24

Host Scope PeRT3 RF Switch (Host TX Tests) ...............................................................................................24

QPHY-USB3-TX-RX TEST DESCRIPTIONS ................................................................................... 26

Pre-Test .......................................................................................................................................................26

Test 1.1 Low Frequency Periodic Signaling (LFPS) ................................................................ .........................26

Test 1.2 Spread Spectrum Tests ................................................................ ..................................................... 27

Test 1.3 Jitter & Eye Diagram Test .................................................................................................................28

Test for Ping.LFPS Support ............................................................................................................................................................ 26

Test 1.3.1 Jitter ......................................................................................................................................28

Test 1.3.2 Phase Jitter Slew Rate ...........................................................................................................29

Test 1.3.3 SigTest Jitter................................................................ .......................................................... 30

Test 1.3.4 Eye Diagram ................................................................................................ ..........................31

Test 1.3.5 SigTest Eye Diagram..............................................................................................................32

917719 Rev A 3

Page 4

Test 1.4 AC and DC Common Mode Voltage Tests ..........................................................................................34

Test 1.5 Differential Voltage & De-emphasis Test ............................................................................................34

Receiver Test Calibration................................................................ ............................................................... 36

Test 2.1 Jitter Tolerance Test .........................................................................................................................37

QPHY-USB3-TX-RX VARIABLES...................................................................................................... 38

Always Reconnect PUT ..........................................................................................................................38

Cable S-Parameters File ........................................................................................................................38

De-embed Cables ..................................................................................................................................38

Demo Mode................................................................ ................................................................ ...........38

RF Switch GPIB Address........................................................................................................................ 38

Maximum PeRT3 retries ................................ ................................................................ .........................38

Disable Connection Diagrams .................................................................................................................38

Product Type ................................................................................................................................ .........38

Saved Waveform Path............................................................................................................................38

Save Individual Runs..............................................................................................................................38

S-Parameter Files Path ..........................................................................................................................39

SSC ................................ ................................................................ ......................................................39

Stop On Test to review results ................................................................................................................ 39

Test Mode ................................................................ ................................................................ .............39

Use PeRT3................................................................................................................................ ............39

Use RF Switch .......................................................................................................................................39

PeRT3 Setup................................................................................................ ................................................39

PeRT3 Hostname or IP Address ................................ ................................................................ .............39

PeRT3 SSC Enabled..............................................................................................................................39

Transmitter Tests ..........................................................................................................................................39

Deskew measure mode ..........................................................................................................................39

Deskew value in picoseconds ................................................................................................ .................40

PeRT3 Amplitude...................................................................................................................................40

PeRT TX Init Mode................................................................................................ .................................40

Jitter & Eye Diagram Tests ..................................................................................................................... 40

Common Mode Voltage Tests ................................................................................................ .................40

Differential Voltage & De-emphasis Test................................ ................................................................ ..40

Receiver Tests ..............................................................................................................................................40

Use Compliance Chanel ......................................................................................................................... 40

Jitter Tolerance Test ..............................................................................................................................40

QPHY-USB3-TX-RX LIMITS................................................................................................................ 41

MANUAL CALIBRATION PROCEDURES ....................................................................................... 43

Cable Deskewing using the Fast Edge Output (WavePro 7 Zi and WaveMaster 8Zi only) ..................................43

Cable Deskewing without using the Fast Edge Output.....................................................................................46

4 917719 Rev A

Page 5

QPHY-USB3-Tx-Rx Software Option

FIGURES

Figure 1 - TF-USB3 Fixture Se t .....................................................................................................................6

Figure 2. Report me nu in QualiPHY General Setup.......................................................................................7

Figure 3. The Test Report include s a summary table with links to the detailed test results ..........................8

Figure 4. QualiPHY main me nu and complian ce test Standard selection menu..........................................10

Figure 5. QualiPHY configuration selection menu ...................................................................................... 11

Figure 6. QualiPHY test item selection menu ..............................................................................................12

Figure 7. Variable Setup and Limits Manager window s...............................................................................14

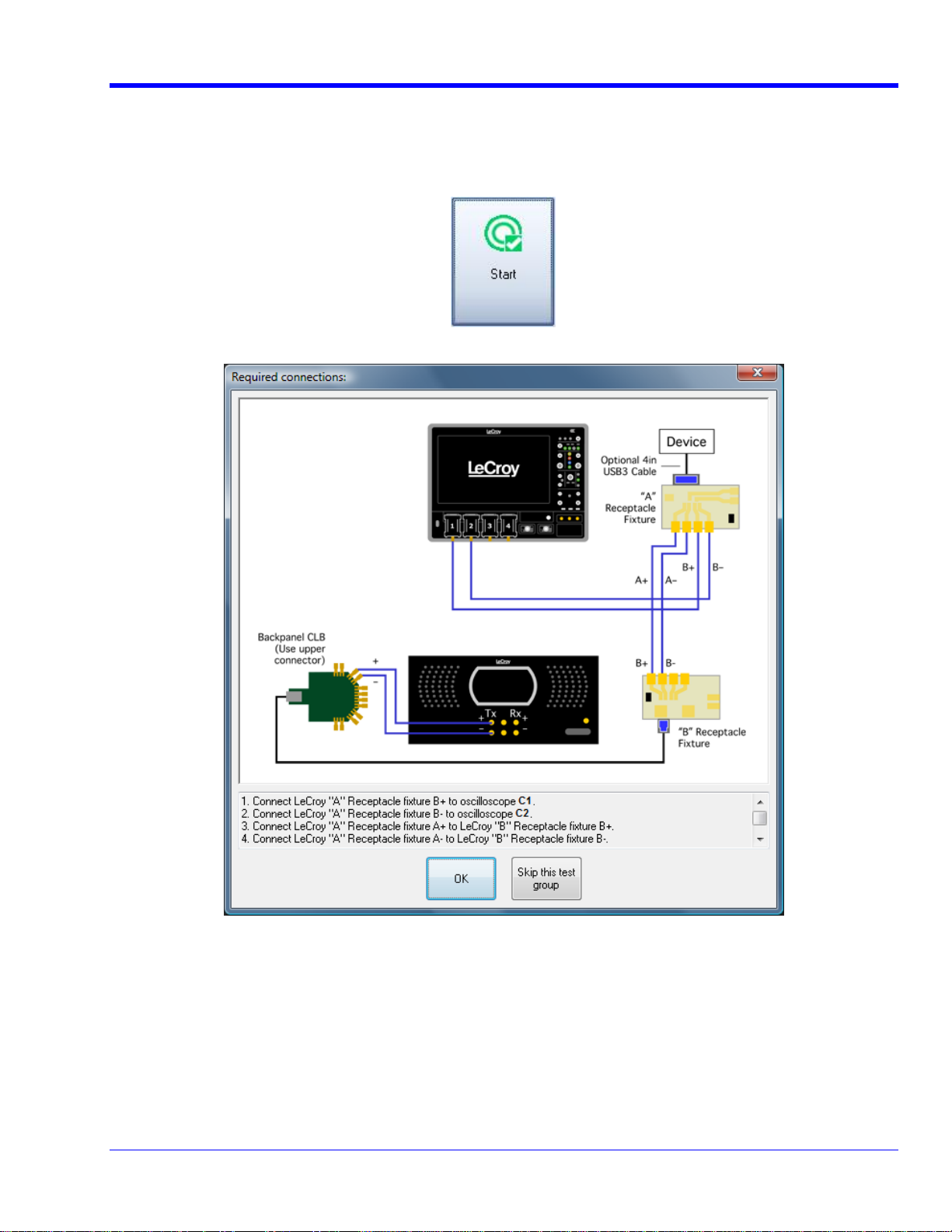

Figure 8. Start button ..................................................................................................................................15

Figure 9. Example of pop-up connection diagram and dialog box..............................................................15

Figure 10 - Oscilloscope Configuration a fter LFPS Test .............................................................................26

Figure 11 - Test Report from LFPS Te sts .....................................................................................................27

Figure 12 - Oscilloscope Configuration a fter SSC Tests .............................................................................27

Figure 13 - Test Report from SSC Tests ......................................................................................................28

Figure 14 - Oscilloscope Configuration a fter CP1 Ji tter Test ......................................................................28

Figure 15 - Oscilloscope Configuration a fter CP0 Ji tter Test ......................................................................29

Figure 16 - Test Report from Jitter Tests .....................................................................................................29

Figure 17 - Oscilloscope Configuration a fter Phase Jitter Slew Rate Test ..................................................30

Figure 18 - Test Report from Phase Jitter Slew Rate Test ...........................................................................30

Figure 19 - Oscilloscope Configuration a fter SigTest CP1 Jitter Test .........................................................31

Figure 20 - Test Report from SigTest Jitter Te st ..........................................................................................31

Figure 21 - Oscilloscope Configuration a fter Eye Diagram Te st..................................................................32

Figure 22 - Test Report from Eye Diagram Test ...........................................................................................32

Figure 23 - Oscilloscope Configuration a fter SigTest Eye Diagram Test .....................................................33

Figure 24 - Test Report from SigTest Eye Test ............................................................................................33

Figure 25 - Oscilloscope Configuration a fter AC and DC Common Mode Test ...........................................34

Figure 26 - Test Report from AC and DC Common Mode Test ....................................................................34

Figure 27 - Oscilloscope Configuration a fter Differential Voltage & De-emphasi s Te st on CP7 ..................35

Figure 28 - Oscilloscope Configuration a fter Differential Vol tage & De-emphasi s Te st on CP8 ..................36

Figure 29 - Test Report from Differential Voltage & De-emphasi s Test........................................................36

Figure 30 - Test Report from Jitter Tolerance Test ......................................................................................37

Figure 31 - QualiPHY Limits Manager .........................................................................................................41

Figure 32 - Timebase Setting s for Deskew with the Fast Edge Output .......................................................43

Figure 33 - Channel Pre -Processing Settings for Deskew with the Fast Edge Output ................................43

Figure 34 - Trigger Settings for Deskew with the Fast Edge Output ...........................................................44

Figure 35 - Measurement Settings for De skew with the Fast Edge Output .................................................44

Figure 36 - Adjusted Timebase Se ttings for De skew ...................................................................................44

Figure 37 - Save Waveform Settings for Deskew w ith the Fast Edge Output ..............................................45

Figure 38 - Final Screen with Channel 2 and 3 Deskewed...........................................................................45

Figure 39 - The Skew pa rameter right side dialog, Skew clock 2 tab, showing default setup .....................47

917719 Rev A 5

Page 6

INTRODUCTION

QPHY-USB3-Tx -Rx is a software package designed to capture, analyze, and report measurements in

conformance with SuperSpeed USB electrical specification standard. A copy of the specification can be found at

www.usb.org.

Compatibility

QPHY-USB3-Tx -Rx is a software option compatible with the following LeCroy X-Stream oscilloscopes:

WM813Zi, SDA813Zi, DDA813Zi (4x40 GS/s, 2x80GS/s) and higher bandwidth equivalents.

SDA II and Eye Doctor II software is required.

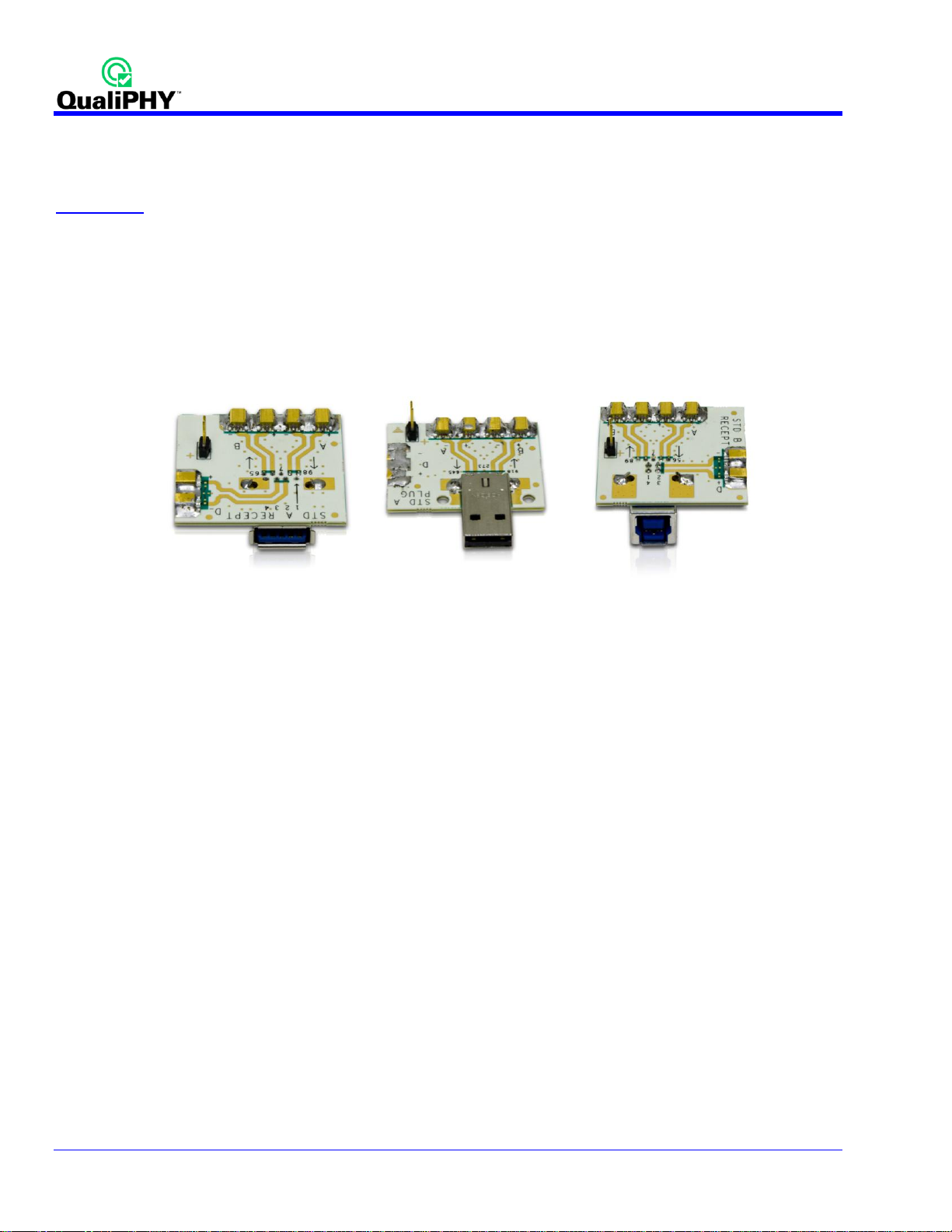

The TF-USB3 test fixture set is required for QPHY-USB3-Tx-Rx. This fixture set includes an A-Plug, A-Receptacle

and B-Receptacle fixtures. The Tx+, Tx-, Rx+ and Rx- signals are routed via low loss traces to SSMP connectors.

Eight 2 inch SSMP to SMA cables are provided with the TF-USB3 kit.

Figure 1 - TF-USB3 Fixture Set

Additional Options Equipment Available from LeCroy

Eagle PeRT3 System (1 channel) – PER-R006-S01-X

o Eagle Receiver Tolerance Test Suite – PER-R006-008-A

o Eagle USB 3.0 Receiver Test Suite – USB-R006-001-A

Keithley S46 RF-Microwave Switch System with 8 SPDT Relays – RF-Switch-8-SPDT

Pair of +/- 1ps phase matched cables (8 inches) – Matched-SMA-Cables-8inch-Pair

Pair of +/- 1ps phase matched cables (12 inches) – Matched-SMA-Cables-12inch-Pair

Pair of +/- 1ps phase matched cables (18 inches) – Matched-SMA-Cables-18inch-Pair

Pair of +/- 1ps phase matched cables (24 inches) – Matched-SMA-Cables-24inch-Pair

GPIB Host Option for LeCroy Oscilloscope – GPIB-HOST

6 917719 Rev A

Page 7

QPHY-USB3-Tx-Rx Software Option

QualiPHY Compliance Test Platform

QualiPHY is LeCroy’s unique compliance test framework which leads the user through the compliance tests.

QualiPHY displays connection diagrams to ensure tests run properly, automates the oscilloscope setup, and

generates full compliance reports.

QualiPHY makes USB 3.0 compliance testing easy and fast.

The QualiPHY software application automates the test and report generation.

Figure 2. Report menu in QualiPHY General Setup

917719 Rev A 7

Page 8

See the QualiPHY Operator’s Manual for more information on how to use the QualiPHY framework.

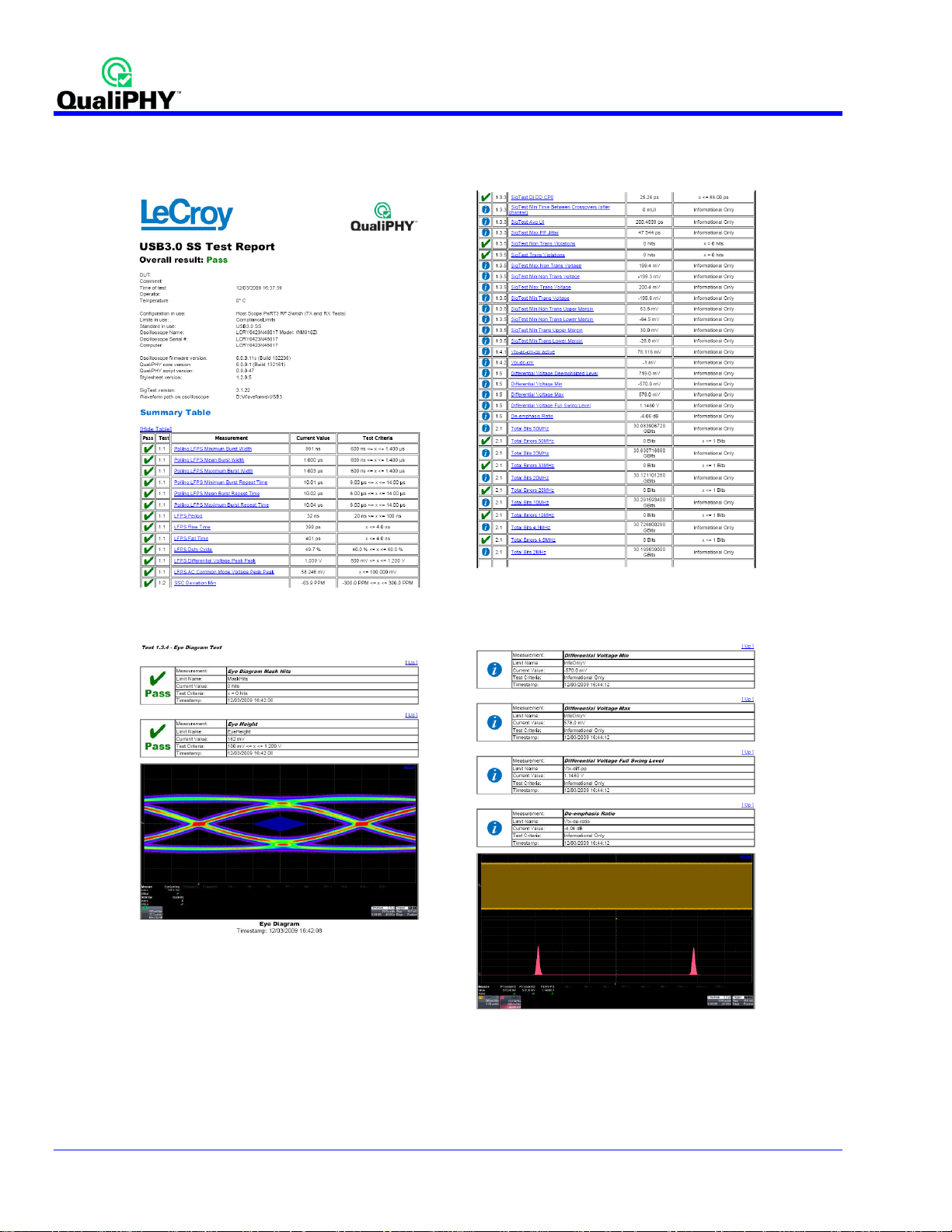

Figure 3. The Test Report includes a summary table with links to the detailed test results

8 917719 Rev A

Page 9

QPHY-USB3-Tx-Rx Software Option

Oscilloscope Option Key Installation

An option key must be purchased to enable the QPHY-USB3 option. Call LeCroy Customer Support to place an

order and receive the code.

Enter the key and enable the purchased option as follows:

1. From the oscilloscope menu select Utilities Utilities Setup...

2. Select the Options tab and click the Add Key button.

3. Enter the Key Code using the on-screen keyboard.

4. Restart the oscilloscope to activate the option after installation.

Typical (Recommended) Configuration

QualiPHY software can be executed from the oscilloscope or a host computer. The first step is to install QualiPHY.

Please refer to the QualiPHY O perator’s Manual for installation instructions.

LeCroy recommends running QualiPHY on an oscilloscope equipped with Dual Monitor Display capability (Option

DMD-1 for oscilloscopes where this is not standard). This allows the waveform and measurements to be shown

on the oscilloscope LCD display while the QualiPHY application and test results are displayed on a second

monitor.

By default, the oscilloscope appears as a local host when QualiPHY is executed in the oscilloscope. Follow the

steps under Oscilloscope Selection (as follows) and check that the IP address is 127.0.0.1.

Remote (Network) Configuration

It is also possible to install and run QualiPHY on a host computer, controlling the oscilloscope with a Network/LAN

Connection.

The oscilloscope must already be configured, and an IP address (fixed or network-assigned) must already be

established.

Oscilloscope Selection

Set up the oscilloscope using QualiPHY over a LAN (Local Area Network) by doing the following:

1. Make sure the host computer is connected to the same LAN as the oscilloscope. If unsure, contact

your system administrator.

2. From the oscilloscope menu, select Utilities Utilities Setup…

3. Select the Remote tab.

4. Verify the oscilloscope has an IP address and the control is set to TCP/IP.

5. Run QualiPHY in the host computer and click the General Setup button.

6. Select the Connection tab.

7. Enter the IP address from step 4 (previous).

8. Click the Close button.

QualiPHY is now ready to control the oscilloscope.

917719 Rev A 9

Page 10

QualiPHY tests the oscilloscope connection after clicking the Start button. The system prompts you if there is a

connection problem. QualiPHY’s Scope Selector function can also be used to verify the connection. Please refer

to the QualiPHY Operator’s Manual for explanations on how to use Scope Selector and other QualiPHY

functions.

Accessing the QPHY-USB3-Tx-Rx Software using QualiPHY

This topic provides a basic overvi ew of QualiP HY’s capabilities. Please refer to the QualiPHY Operator’s Manual

for detailed information.

Access the QPHY-USB3-Tx-Rx software using the following steps:

1. Wait for the oscilloscope to start and have its main application running.

2. Launch QualiPHY from the Analysis menu if installed on the oscilloscope or from the desktop icon if

installed on a host computer.

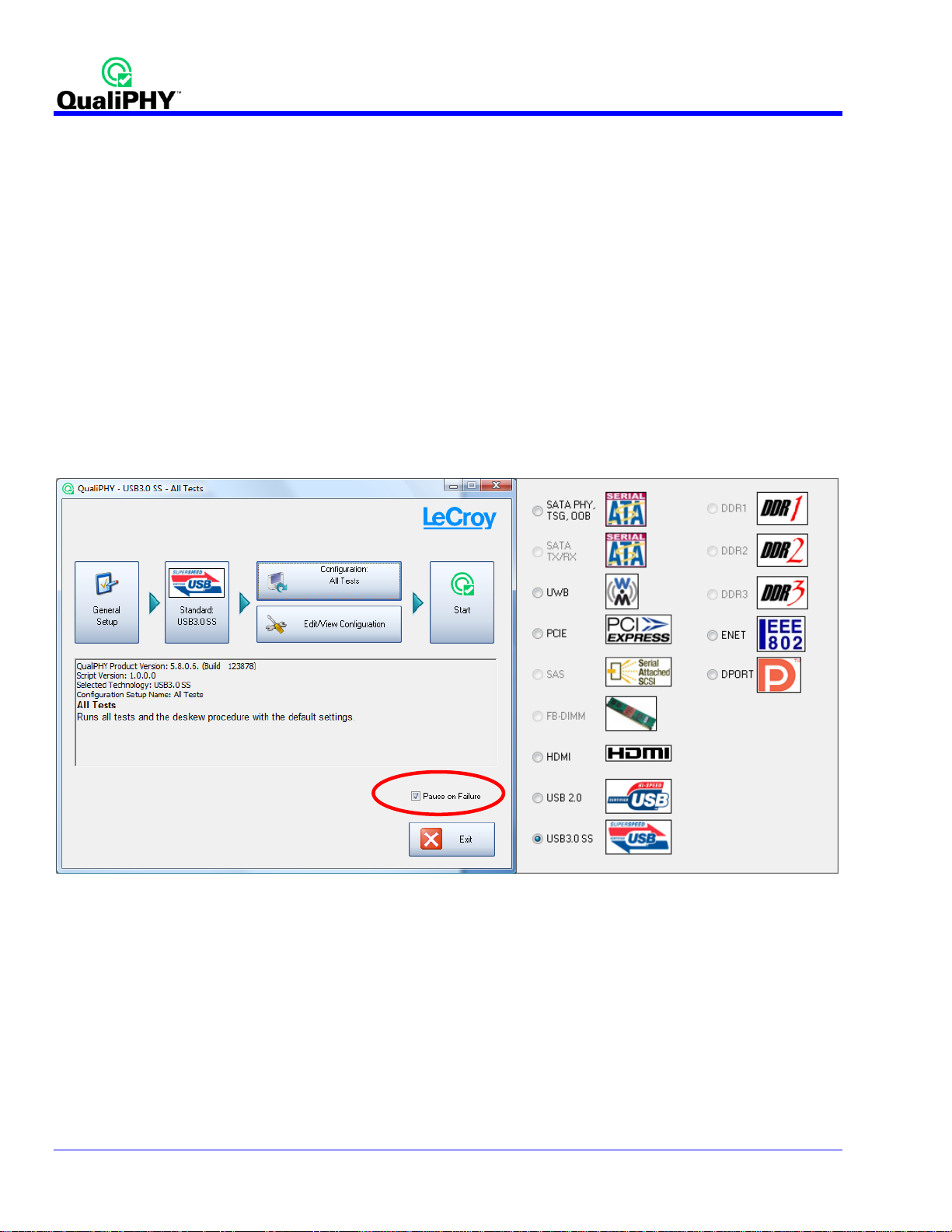

3. From the QualiPHY main window (as follows), select Standard, then USB3.0 SS from the pop-up menu

(if not already selected). If you check the Pause on Failure box (circled) QualiPHY prompts to retry the

measure whenever a test fails.

Figure 4. QualiPHY main menu and compliance test Standard selection menu

10 917719 Rev A

Page 11

QPHY-USB3-Tx-Rx Software Option

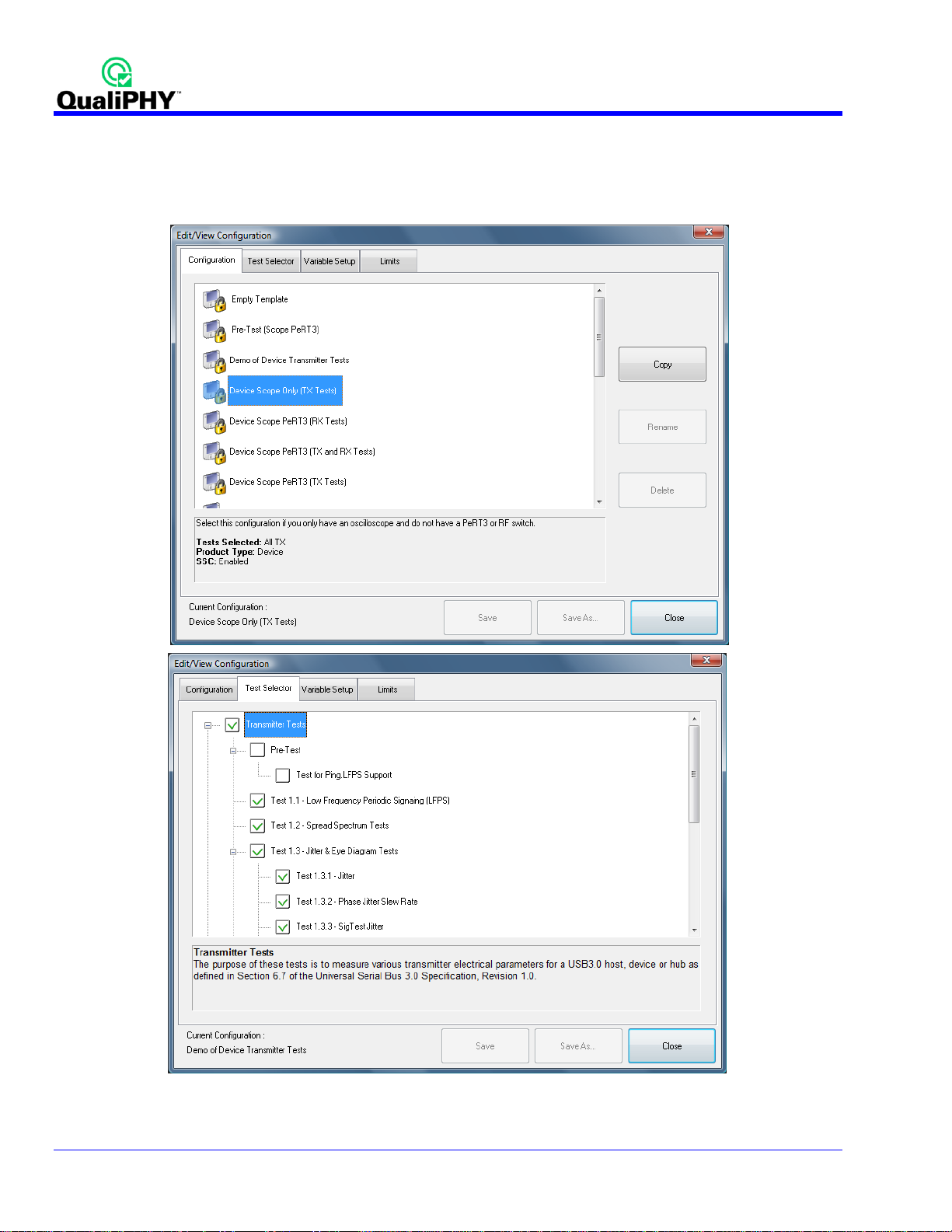

4. Click the Configuration button in the QualiPHY main menu.

5. Select a configuration from the pop-up menu. For addition information, please refer to the

QPHY-USB3-Tx -Rx Test Configurations section of this manual.

Figure 5. QualiPHY configuration selection menu

6. Click Start.

7. Follow the pop-up window prompts.

917719 Rev A 11

Page 12

Customizing QualiPHY

The predefined configurations in the Configuration screen can be modified but can only be saved as a new

configuration. You can also create your own test configurations by copying one of the standard test configurations

and making modifications. A description of the test is also shown in the description field when selected.

Figure 6. QualiPHY test item selection menu

12 917719 Rev A

Page 13

QPHY-USB3-Tx-Rx Software Option

Creating Custom Configurations

Beginning with any of the pre-loaded configurations,

1. Click on the Test Selector tab to change what tests you would like to be included in your new

configuration.

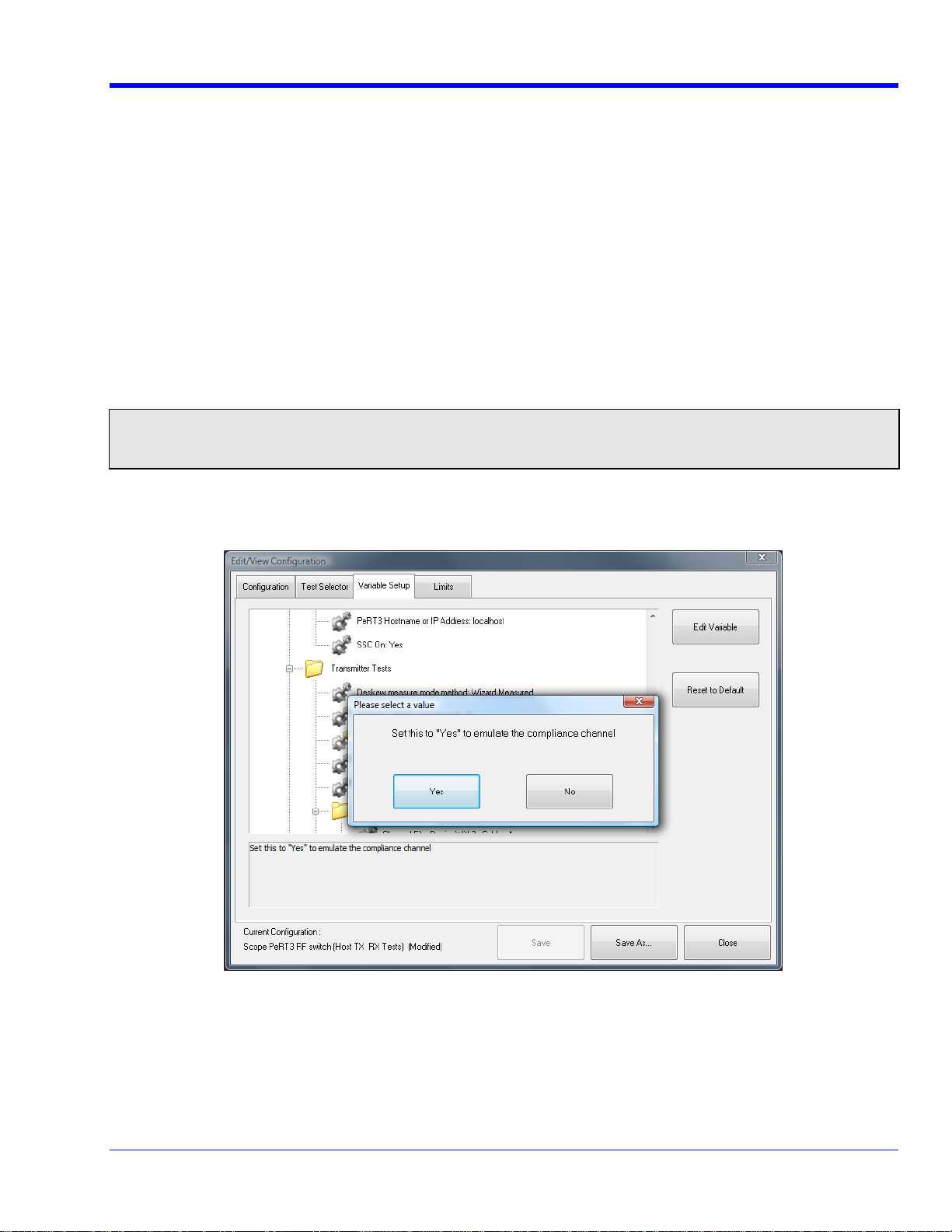

2. Click on the Variable Setup tab to change the variables for your new configuration.

For additional information, refer to the QPHY-USB3-Tx-Rx Variables section of this manual.

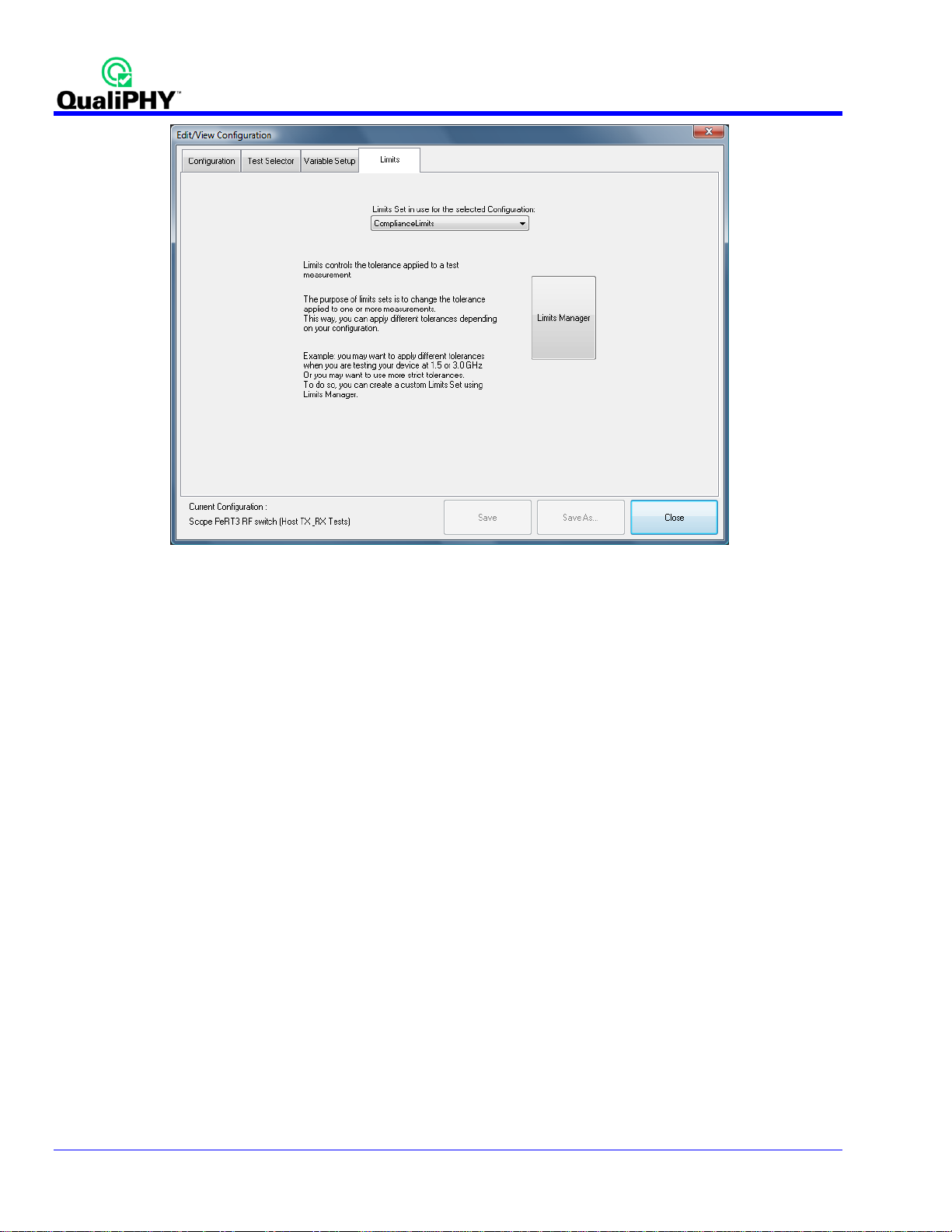

3. Click on the Limits tab to change which limit set should be used for your new configuration

For additional information, refer to the QPHY-USB3-Tx-Rx Limits section of this manual.

4. Once a change has been made to any of these sections, the Save As button is enabled at the bottom of

the dialog.

5. Clicking the Save As button prompts you for a new configuration name and description.

Note: If a Custom Configuration was used for the procedure, the Save button is also enabled on the bottom of the dialog. Clicking this button

updates the current configuration with new changes. Additionally, if the user does not wish to save their changes, they can chose to run

QualiPHY with the variables set as the want without saving. However, when the user attempts to switch to another configuration, the system

prompts to save or abandon the current configuration.

6. Once a custom configuration is defined, script variables and the test limits can be changed by using the

Variable Setup and Limits Manager from the Edit/View Configuration window.

917719 Rev A 13

Page 14

Figure 7. Variable Setup and Limits Manager windows

14 917719 Rev A

Page 15

QPHY-USB3-Tx-Rx Software Option

QPHY-USB3-Tx-Rx Operation

After pressing Start in the QualiPHY menu, the software instructs how to set up the test using pop-up connection

diagrams and dialog boxes. QualiPHY also instructs how to properly configure the Product Under Test (PUT) to

change test signal modes (when necessary).

Figure 8. Start button

Figure 9. Example of pop-up connection diagram and dialog box

917719 Rev A 15

Page 16

GUIDE TO OPERATION

QPHY-USB3-Tx -Rx was designed to utilize the features of the SDA 8Zi and the PeRT3. When using these 2

instruments together, there are many benefits that are not available when using either instrument independently. If

the user wishes to use the PeRT3 without the oscilloscope, the software for the PeRT3 must be used. One of the

many benefits of using the PeRT3 is its ability to stimulate the Product Under Test (PUT) to output the appropriate

compliance patterns required for transmitter testing. Additionally, QPHY-USB3-Tx -Rx can also utilize an RF Switch

to automate the switching of cables that would otherwise have to be manually configured by the user.

There are 2 types of electrical tests required by the SuperSpeed USB Electrical Test Specification: Transmitter

and Receiver tests.

Transmitter Testing

Transmitter testing requires the PUT to output specific compliance patterns and tests are performed on these

patterns. This can be done using only the oscilloscope. This requires the user to manually make the proper

connections between the PUT and the oscilloscope. Additionally, the user must be able to stimulate the PUT to

output the proper compliance pattern as required by QPHY-USB3-Tx-Rx.

If the oscilloscope and PeRT3 are being used together (and the PUT supports Ping.LFPS), then the PeRT3 can be

used to stimulate the PUT to enter compliance mode and transmit the proper compliance pattern. This makes

transmitter testing completely automated.

Receiver Testing

Receiver testing requires the PUT to be put into Loopback mode and the jitter tolerance of the receiver is

measured over 8 frequencies of sinusoidal jitter. When using the PeRT3 alone, receiver testing can be performed

manually using the PeRT3 software application. This requires the user to manually make the proper connections

between the PUT and the PeRT3. This is not supported by QPHY-USB3-Tx-Rx.

If the oscilloscope and PeRT3 are being used together (and the PUT supports Loopback mode), then the PeRT3

can be used to stimulate the PUT to enter loopback mode and then perform the jitter tolerance test as required.

Transmitter and Receiver Testing

When adding the RF Switch to the setup, fully automated transmitter and receiver testing is possible. The RF

Switch automatically routes the receiver of the PUT to the transmitter of the PeRT3 and the transmitter of the PUT

to the oscilloscope. In this configuration, all of the transmitter tests can be performed. When these tests are

complete, the RF Switch automatically switches in the compliance test channel in between the transmitter of the

PeRT3 and the receiver of the PUT. Additionally, the transmitter of the PUT is routed to the receiver of the PeRT3.

In this configuration, the jitter tolerance test can be performed.

Using QPHY-USB3-Tx-Rx

The QualiPHY software makes it easy to test a product for compliance. The extent to which QualiPHY can

automate the instruments and PUT depends on the equipment available and the capabilities of the product under

test. There are three supported hardware configurations in QPHY-USB3-Tx-Rx: Oscilloscope only, Oscilloscope

and PeRT3 and Oscilloscope and PeRT3 with RF Switch. For each hardware configuration there are

corresponding configurations in QualiPHY that are selectable in the top dialog. Refer to the QPHY-USB3-Tx-Rx

Test Configurations section of this manual for more information about selecting configurations.

Oscilloscope Only

Customers that do not have a PeRT3 sh ould select one of the “Scope Only ” configurations. These configurations

can also be selected for reduced automation and more hands-on testing, which can be useful for debugging or if

the PUT does not respond well to automation from the PeRT3. When using these configurations the QualiPHY

software automates the oscilloscope and sets up all the tests. At the appropriate time QualiPHY prompts the user

to make connections to the PUT and to control the PUT to output the proper test signals. Then QualiPHY resumes

the tests and continues to automate the oscilloscope.

16 917719 Rev A

Page 17

QPHY-USB3-Tx-Rx Software Option

Oscilloscope and PeRT3

With the addition of a PeRT3, the control of the PUT can also be automated. In the QualiPHY software there are

corresponding “Scope PeRT3” configurations that can be selected. There are three for devices and three for

hosts: transmitter tests (TX), receiver tests (RX) and both TX and RX tests.

For TX testing the PeRT3 can send an LFPS Ping to the PUT to cycle it through the different compliance patterns

CP0 – CP8. If the PUT does not support the LFPS Ping method of changing the compliance pattern and a

proprietary method must be used then the PeRT3 should not be used for TX testing. Instead use the Oscilloscope

Only configuration as described above. Alternatively, if the PUT supports loopback the TX tests can be run using

PeRT3 automation to place the PUT into loopback mode.

Note, that not all tests can be conducted correctly when using the loopback method. Therefore, the results should

be considered as informative and not used for compliance testing. In particular, the de-emphasis test requires a

compliance pattern that does not have de-emphasis. In loopback mode the de-emphasis in the PUT cannot be

disabled so the de-emphasis measurement cannot be done properly. Furthermore, in loopback mode there are

usually skips present in the data that may cause variations in the results when compared to using the LFPS Ping

mode.

Oscilloscope and PeRT3 with RF Switch

With the addition of an RF switch, QualiPHY can automate connection changes as well. As with the oscillosc ope

and PeRT3 configuratio n, the QualiPHY software has three “Scope PeRT3 RF Switch” configurations that can be

selected.

OPERATING THE PERT3 MANUALLY

The PeRT3 can be operated from the stand-alone PeRT3 application or from within the XStreamDSO application.

For instructions on using the stand-alone application please consult the PeRT3 documentation. In many situations

it is convenient to operate the PeRT3 from within the XStreamDSO application. The PeRT3 control dialog is

located under Analysis -> PeRT3. (The stand-alone PeRT3 application must be installed in order for the PeRT3

controls to appear on the Analysis menu.) When the dialog is first opened it looks as follows:

The first step is to setup the connection to the PeRT3 server. Set the IP Address / Hostname control to the IP

address or hostname of the machine that is physically connected to the PeRT3 via USB2 cable. The default value

is “localhost,” which is used when the PeRT

Server to establish communication with the PeRT3. The text below the Connect to PeRT Server button should

change to indicate the connection is being established and shortly after it should indicate that the PeRT3 is

connected. If the connection fails an error message is shown in the Status Message area at the bottom right of the

dialog. The connection fails if the PeRT3 is already being accessed from the PeRT3 stand-alone application or

from another oscilloscope or computer. After the connection is established a dialog tab is added for each PeRT3

channel.

After the connection is established, set the Protocol, Data Rate, Clock Out and SSC controls as desired and click

Configure PeRT. After a brief delay the text below those controls indicates that the PeRT3 is configured

successfully.

3

is connected to the oscilloscope. Next, click Connect to PeRT

At this point the PeRT3 is ready for use. Most of the controls on the PeRT3 dialogs correspond closely with the

controls in the stand-alone application. One exception is the Output ALIGN/SKP checkbox. When this checkbox

is unchecked the PeRT3 suppresses the symbols required to be inserted periodically (SKP for USB3, ALIGN for

SATA, etc). The default state is checked; however, you may disable those symbols for transmitter testing in

loopback or for receiver test calibration.

The remainder of this section specifically focuses on using the PeRT3 controls when testing USB3. The 3 key

operations are: LFPS Ping, Loopback and, receiver test calibration.

917719 Rev A 17

Page 18

LFPS Ping using the PeRT

To send an LFPS Ping from the PeRT3 the PeRT3 TX+ and TX- should be connected to RX+ and RX- of the PUT.

The PeRT3 controls should be set as follows:

Count Type: Bit Errors

Initialize: Custom Sequence

Custom Init Sequence: TX Test Init

Then click Connect to PUT. The TX Test Init sequence sets the PeRT3 output to electrical idle to prepare for

sending an LFPS Ping. (Some USB3 implementations have been observed to react to the TX Test Init as an LFPS

Ping.) Next, change the Custom Init Sequence to TX Test Ping. Then click Connect to PUT to send an LFPS

Ping. It is convenient to view the output of the PUT on the screen and watch the pattern change when the Ping is

sent.

Loopback Mode using the PeRT3

To place a USB3 product in loopback both the TX and RX of the PeRT3 must be connected to the PUT. The

PeRT3 controls should be set as follows:

Count Type: Bit Errors

Initialize: Loopback

Custom Init Sequence: No Disconnect Support (Default)

Output ALIGN/SKP: Checked

The PUT should be turned off. Click Connect to PUT. The PeRT3 sends out LFPS and waits to see LFPS from

the PUT. Next, turn on the PUT. For devices, VBUS power may need to be applied as well. The PUT should now

be connected.

3

Clicking the Main tab shows the following dialog:

The Termination controls how long a receiver test runs. The termination can be set separately for individual

channels or for all channels at once using the Termination For control. Verify the PUT is correctly in loopback by

setting the controls as follows:

Termination For: All Channels

Termination Type: Run Forever

Now, click the Start button. The Status Message should indicate that the PeRT3 is running and Pattern Locked

should appear in the top right with a green light next to it. It may take a few seconds to load the pattern the first

time Start is pressed before it changes to the Pattern Locked state. If the PeRT3 cannot obtain a pattern lock it

stops running after a short time. If this occurs, using other Initialize and Custom Init Sequence settings may

help debug the problem. Debugging loopback operation is beyond the scope of this manual. Please consult the

PeRT3 documentation for more guidance.

Receiver Test Calibration using the PeRT3

Receiver testing involves applying a fixed amount of jitter to a signal and controlling the amplitude and preemphasis. It is important that these be applied correctly and therefore it is desirable to measure the jitter,

amplitude and pre-emphasis of the PeRT3. Setup the PeRT3 to output the receiver test signal by setting the

controls on the PeRT3 dialog as follows:

Count Type: Bit Errors

Initialize: Loopback (blind / no handshake)

18 917719 Rev A

Page 19

QPHY-USB3-Tx-Rx Software Option

Custom Init Sequence: No Disconnect Support (Default)

Output ALIGN/SKP: unchecked

Click the Connect to PUT button. The Initialize setting Loopback (blind / no handshake) causes the PeRT3 to

skip through the LFPS handshake and behave as if the link is up. In this state the PeRT3 can be used to generate

USB3 signals without the RX inputs connected. By connecting the TX outputs to the oscilloscope the jitter,

amplitude and pre-emphasis can be measured.

Next, click on the CH1 tab and the following dialog is shown:

Adjust the controls on the dialog to apply the amplitude, pre-emphasis and jitter as desired. You can also choose

a pattern.

Note: The USB3 specification refers to de-emphasis, not pre-emphasis. They are effectively the same. However, for pre-emphasis the

amplitude refers to the amplitude of the bits before emphasis is added. For de-emphasis the amplitude refers to the amplitude of the bits

before emphasis is removed. Since the PeRT3 controls are for pre-emphasis the target amplitude is low er than the USB3 specification. For

example, if the desired amplitude of the emphasized bits is 750mV and the amount of emphasis is 3.5dB the amplitude setting f or the PeRT3 is

3.5dB less than 750mV, which is 500mV.

After setting up the channel controls click on the Main tab. Configure the controls as follows:

Termination For: All Channels

Termination Type: Run Forever

Now, click the Start button to begin sending out the pattern chosen with the applied jitter, amplitude and preemphasis.

917719 Rev A 19

Page 20

QPHY-USB3-TX-RX TEST CONFIGURATIONS

Configurations include variable settings and limit sets as well, not just test selections. For more information, refer

to the QPHY-USB3-Tx-Rx Test Descriptions and QPHY-USB3-Tx-Rx Variables sections of this manual.

Empty Template

This confi guration is intentionally left blank so it can easily be copied and configured to the user’s custom

configuration. The limit set in use is ComplianceLimits. All of the variables are set to their default settings.

Pre-Test (Scope PeRT3)

This configuration is meant to be run prior to running any other configuration. This configuration runs the

Ping.LFPS Support Test to determine if the Product under test supports the necessary modes to fully automate

the running of the remaining tests. A PeRT3 is required for this configuration.

Demo of Device Transmitter Tests

This configuration runs all transmitter tests using saved waveforms located on the oscilloscope in the

D:\Waveforms\USB3\Demo directory on the oscilloscope. This configuration is meant to easily demonstrate the

QPHY-USB3-Tx -Rx capabilities when live signals cannot be tested.

Device Scope Only (Host TX Tests)

This configuration is meant to run all of the transmitter tests for a user that does not have a PeRT3 or the RF

Switch. All of the variables are set to default except Product Type is set to “Device” and Channel File is set to

“Host11inWith3mCable.s4p.” The limit set is use is ComplianceLimits. The tests that are run are:

Test 1.1 – Low Frequency Periodic Signaling

Test 1.2 – Spread Spectrum Tests

Test 1.3 – Jitter & Eye Diagram Tests

o Test 1.3.1 – Jitter

o Test 1.3.2 – Phase Jitter Slew Rate

o Test 1.3.3 – SigTest Jitter

o Test 1.3.4 – Eye Diagram

o Test 1.3.5 – SigTest Eye Diagram

Test 1.4 – AC & DC Common Mode Test

Test 1.5 – Differential Voltage & De-emphasis Test

Device Scope PeRT3 (Host RX Tests)

This configuration is meant to run all of the receiver tests for a user that has a PeRT3 but not the RF Switch. All of

the variables are set to default except Product Type is set to “Device”, Use PeRT3 is set to “Yes” and Channel

File is set to “Host11inWith3mCable.s4p.” The limit set used is ComplianceLimits. The test run are:

Test 2.1. – Jitter Tolerance Test

20 917719 Rev A

Page 21

QPHY-USB3-Tx-Rx Software Option

Device Scope PeRT3 (Host TX and RX Tests)

This configuration is meant to run all of the transmitter and receiver tests for a user that has a PeRT3 but not the

RF Switch. All of the variables are set to default except Product Type is set to “Device”, Use PeRT3 is set to

“Yes” and Channel File is set to “Host11inWith3mCable.s4p.” The limit set used is ComplianceLimits. The tests

that are run are:

Test 1.1 – Low Frequency Periodic Signaling

Test 1.2 – Spread Spectrum Tests

Test 1.3 – Jitter & Eye Diagram Tests

o Test 1.3.1 – Jitter

o Test 1.3.2 – Phase Jitter Slew Rate

o Test 1.3.3 – SigTest Jitter

o Test 1.3.4 – Eye Diagram

o Test 1.3.5 – SigTest Eye Diagram

Test 1.4 – AC & DC Common Mode Test

Test 1.5 – Differential Voltage & De-emphasis Test

Test 2.1. – Jitter Tolerance Test

Device Scope PeRT3 (Host TX Tests)

This configuration is meant to run all of the transmitter tests for a user that has a PeRT3 but not the RF Switch. All

variables are set to default except Product Type (set to “Device”), Use PeRT3 (set to “Yes”) and Channel File

(set to “Host11inWith3mCable.s4p”). The limit set used is ComplianceLimits. The tests that are run are:

Test 1.1 – Low Frequency Periodic Signaling

Test 1.2 – Spread Spectrum Tests

Test 1.3 – Jitter & Eye Diagram Tests

o Test 1.3.1 – Jitter

o Test 1.3.2 – Phase Jitter Slew Rate

o Test 1.3.3 – SigTest Jitter

o Test 1.3.4 – Eye Diagram

o Test 1.3.5 – SigTest Eye Diagram

Test 1.4 – AC & DC Common Mode Test

Test 1.5 – Differential Voltage & De-emphasis Test

Device Scope PeRT3 RF Switch (Host RX Tests)

This configuration is meant to run all of the transmitter tests for a user that has a PeRT3 and the RF Switch. All

variables are set to default except Product Type (set to “Device”), Use PeRT3 (set to “Yes”), Use RF Switch (set

to “Yes”), Channel File (set to “Host11inWith3mCable.s4p”) , De-embed Cables (set to “Yes”) and Cable S-

Parameters File (set to “green24white12.s4p”). The green24white12.s4p file is installed with QualiPHY and is

appropriate for de-embedding the 24inch green cables and 12 inch silver cables with white label that are included

as part of the USB3-TX-RX bundle. The limit set used is ComplianceLimits. The tests that are run are:

Test 2.1. – Jitter Tolerance Test

917719 Rev A 21

Page 22

Device Scope PeRT3 RF Switch (Host TX and RX Tests)

This configuration is meant to run all of the transmitter tests for a user that has a PeRT3 and the RF Switch. All

variables are set to default except Product Type (set to “Device”), Use PeRT3 (set to “Yes”), Use RF Switch (set

to “Yes”), Channel File (set to “Host11inWith3mCable.s4p”) , De-embed Cables (set to “Yes”) and Cable S-

Parameters File (set to “green24white12.s4p”). The green24white12.s4p file is installed with QualiPHY and is

appropriate for de-embedding the 24inch green cables and 12 inch silver cables with white label that are included

as part of the USB3-TX-RX bundle. The limit set used is ComplianceLimits. The tests that are run are:

Test 1.1 – Low Frequency Periodic Signaling

Test 1.2 – Spread Spectrum Tests

Test 1.3 – Jitter & Eye Diagram Tests

o Test 1.3.1 – Jitter

o Test 1.3.2 – Phase Jitter Slew Rate

o Test 1.3.3 – SigTest Jitter

o Test 1.3.4 – Eye Diagram

o Test 1.3.5 – SigTest Eye Diagram

Test 1.4 – AC & DC Common Mode Test

Test 1.5 – Differential Voltage & De-emphasis Test

Test 2.1. – Jitter Tolerance Test

Device Scope PeRT3 RF Switch (Host TX Tests)

This configuration is meant to run all of the transmitter tests for a user that has a PeRT3 and the RF Switch. All

variables are set to default except Product Type (set to “Device”), Use PeRT3 (set to “Yes”), Use RF Switch (set

to “Yes”), Channel File (set to “Host11inWith3mCable.s4p”) , De-embed Cables (set to “Yes”) and Cable S-

Parameters File (set to “green24white12.s4p”). The green24white12.s4p file is installed with QualiPHY and is

appropriate for de-embedding the 24inch green cables and 12 inch silver cables with white label that are included

as part of the USB3-TX-RX bundle. The limit set used is ComplianceLimits. The tests that are run are:

Test 1.1 – Low Frequency Periodic Signaling

Test 1.2 – Spread Spectrum Tests

Test 1.3 – Jitter & Eye Diagram Tests

o Test 1.3.1 – Jitter

o Test 1.3.2 – Phase Jitter Slew Rate

o Test 1.3.3 – SigTest Jitter

o Test 1.3.4 – Eye Diagram

o Test 1.3.5 – SigTest Eye Diagram

Test 1.4 – AC & DC Common Mode Test

Test 1.5 – Differential Voltage & De-emphasis Test

Host Scope Only (Host TX Tests)

This configuration is meant to run all of the transmitter tests for a user that does not have a PeRT3 or the RF

Switch. All of the variables are set to default. The limit set used is ComplianceLimits. The tests that are run are:

22 917719 Rev A

Page 23

QPHY-USB3-Tx-Rx Software Option

Test 1.1 – Low Frequency Periodic Signaling

Test 1.2 – Spread Spectrum Tests

Test 1.3 – Jitter & Eye Diagram Tests

o Test 1.3.1 – Jitter

o Test 1.3.2 – Phase Jitter Slew Rate

o Test 1.3.3 – SigTest Jitter

o Test 1.3.4 – Eye Diagram

o Test 1.3.5 – SigTest Eye Diagram

Test 1.4 – AC & DC Common Mode Test

Test 1.5 – Differential Voltage & De-emphasis Test

Host Scope PeRT3 (Host RX Tests)

This configuration is meant to run all of the receiver tests for a user that has a PeRT3 but not the RF Switch. All

variables are set to default except Use PeRT3 is set to “Yes.” The limit set used is ComplianceLimits. The tests

that are run are:

Test 2.1. – Jitter Tolerance Test

Host Scope PeRT3 (Host TX and RX Tests)

This configuration is meant to run all of the transmitter and receiver tests for a user that has a PeRT3 but not the

RF Switch. All of the variables are set to default except Use PeRT3 is set to “Yes.” The limit set used is

ComplianceLimits. The tests that are run are:

Test 1.1 – Low Frequency Periodic Signaling

Test 1.2 – Spread Spectrum Tests

Test 1.3 – Jitter & Eye Diagram Tests

o Test 1.3.1 – Jitter

o Test 1.3.2 – Phase Jitter Slew Rate

o Test 1.3.3 – SigTest Jitter

o Test 1.3.4 – Eye Diagram

o Test 1.3.5 – SigTest Eye Diagram

Test 1.4 – AC & DC Common Mode Test

Test 1.5 – Differential Voltage & De-emphasis Test

Test 2.1. – Jitter Tolerance Test

Host Scope PeRT3 (Host TX Tests)

This configuration is meant to run all of the transmitter tests for a user that has a PeRT3 but not the RF Switch. All

of the variables are set to default except Use PeRT3 is set to “Yes.” The limit set is used is ComplianceLimits.

The tests that are run are:

Test 1.1 – Low Frequency Periodic Signaling

Test 1.2 – Spread Spectrum Tests

917719 Rev A 23

Page 24

Test 1.3 – Jitter & Eye Diagram Tests

o Test 1.3.1 – Jitter

o Test 1.3.2 – Phase Jitter Slew Rate

o Test 1.3.3 – SigTest Jitter

o Test 1.3.4 – Eye Diagram

o Test 1.3.5 – SigTest Eye Diagram

Test 1.4 – AC & DC Common Mode Test

Test 1.5 – Differential Voltage & De-emphasis Test

Host Scope PeRT3 RF Switch (Host RX Tests)

This configuration is meant to run all of the transmitter tests for a user that has a PeRT3 and the RF Switch. All of

the variables are set to default except Use PeRT3 (set to “Yes”), Use RF Switch (set to “Yes”), De-embed

Cables (set to “Yes”) and Cable S-Parameters File (set to “green24white12.s4p”). The green24white12.s4 p file is

installed with QualiPHY and is appropriate for de-embedding the 24inch green cables and 12 inch silver cables

with white label that are included as part of the USB3-TX-RX bundle. The limit set used is ComplianceLimits.

The tests that are run are:

Test 2.1. – Jitter Tolerance Test

Host Scope PeRT3 RF Switch (Host TX and RX Tests)

This configuration is meant to run all of the transmitter tests for a user that has a PeRT3 and the RF Switch. All of

the variables are set to default except Use PeRT3 (set to “Yes”), Use RF Switch (set to “Yes”), De-embed

Cables (set to “Yes”) and Cable S-Parameters File (set to “green24white12.s4p”). The green24white12.s4 p file is

installed with QualiPHY and is appropriate for de-embedding the 24inch green cables and 12 inch silver cables

with white label that are included as part of the USB3-TX-RX bundle. The limit set used is ComplianceLimits.

The tests that are run are:

Test 1.1 – Low Frequency Periodic Signaling

Test 1.2 – Spread Spectrum Tests

Test 1.3 – Jitter & Eye Diagram Tests

o Test 1.3.1 – Jitter

o Test 1.3.2 – Phase Jitter Slew Rate

o Test 1.3.3 – SigTest Jitter

o Test 1.3.4 – Eye Diagram

o Test 1.3.5 – SigTest Eye Diagram

Test 1.4 – AC & DC Common Mode Test

Test 1.5 – Differential Voltage & De-emphasis Test

Test 2.1. – Jitter Tolerance Test

Host Scope PeRT3 RF Switch (Host TX Tests)

This configuration is meant to run all of the transmitter tests for a user that has a PeRT3 and the RF Switch. All of

the variables are set to default except Use PeRT3 (set to “Yes”), Use RF Switch (set to “Yes”), De-embed

Cables (set to “Yes”) and Cable S-Parameters File (set to “green24white12.s4p”). The green24white12.s4 p file is

24 917719 Rev A

Page 25

QPHY-USB3-Tx-Rx Software Option

installed with QualiPHY and is appropriate for de-embedding the 24inch green cables and 12 inch silver cables

with white label that are included as part of the USB3-TX-RX bundle. The limit set used is ComplianceLimits.

The tests that are run are:

Test 1.1 – Low Frequency Periodic Signaling

Test 1.2 – Spread Spectrum Tests

Test 1.3 – Jitter & Eye Diagram Tests

o Test 1.3.1 – Jitter

o Test 1.3.2 – Phase Jitter Slew Rate

o Test 1.3.3 – SigTest Jitter

o Test 1.3.4 – Eye Diagram

o Test 1.3.5 – SigTest Eye Diagram

Test 1.4 – AC & DC Common Mode Test

Test 1.5 – Differential Voltage & De-emphasis Test

917719 Rev A 25

Page 26

QPHY-USB3-TX-RX TEST DESCRIPTIONS

Pre-Test

Test for Ping.LFPS Support

By utilizing the PeRT3, this test checks to see if the Product under test supports the required Ping.LFPS mode

that the PeRT3 uses to stimulate the PUT to generate the appropriate compliance patterns for each test. The

PeRT3 sends the Init.LFPS command to the PUT to stimulate the PUT to enter compliance mode. Then, the

PeRT3 sends a Ping.LFPS command to the PUT and the oscilloscope checks that the appropriate CP0 pattern is

being transmitted by the PUT. Then, another Ping.LFPS command is sent and the oscilloscope checks that the

appropriate CP1 pattern is being transmitted by the PUT. This is repeated for all compliance patterns.

Test 1.1 Low Frequency Periodic Signaling (LFPS)

The purpose of this test group is to verify the voltage and timing parameters of the Low Frequency Periodic

Signaling (LFPS) are within the specification limits.

At the completion of the Low Frequency Periodic Signaling Test the oscilloscope is in the following configuration:

Figure 10 - Oscilloscope Configuration after LFPS Test

On this screen there are 4 traces visible. F1 is the result of the subtraction of C1 and C2. This is the differential

LFPS trace. F2 is the result of the addition of C1 and C2 divided by 2. This is the common mode LFPS trace. F3

shows only the first 6 bursts of the differential LFPS trace and F4 shows only the first 6 bursts of the common

mode LFPS trace.

The burst width is measured in parameter P1. P2 is used to measure the time between the bursts (tRepeat). P3

measures the period of the signal within the burst. P4 and P5 measure the 20-80% rise time and 80-20% fall time

of the pulses within the burst. P6 and P7 measure the duty cycle and amplitude of the signals within the burst. P8

measures the peak-to-peak amplitude of the Common Mode Trace.

26 917719 Rev A

Page 27

QPHY-USB3-Tx-Rx Software Option

Figure 11 - Test Report from LFPS Tests

Test 1.2 Spread Spectrum Tests

The purpose of this test is to measure the spread spectrum modulation frequency and deviation and verify that

they are within the specification limits.

At the completion of the Spread Spectrum Tests the oscilloscope is in the following configuration:

Figure 12 - Oscilloscope Configuration after SSC Tests

917719 Rev A 27

Page 28

On this screen (shown previously) 1 trace is visible. This is the SSCTrack of the captured waveform.

The minimum and maximum of the SSC Track is measured in P1 and P2. The frequency of the SSC Track is

measured in P3.

Figure 13 - Test Report from SSC Tests

Test 1.3 Jitter & Eye Diagram Test

Test 1.3.1 Jitter

The purpose of this test group is to verify that the jitter is within the specification limits. For compliance testing the

measurements are made after a compliance channel after applying the reference Continuous Time Linear

Equalizer (CTLE) function. Measuring the jitter is a multiple step process. First, the jitter must be measured while

the PUT is transmitting the CP1 (101010) pattern. Then, the jitter is measured while the PUT is transmitting the

CP0 (scrambled D0.0) pattern, however the random jitter (Rj) that was measured during the jitter test of CP1 must

be injected into this measurement. This simplifies the separation of random (Rj) and deterministic jitter (Dj) since

there is no data depending jitter (DDj, a component of Dj) when CP1 is transmitted.

At the completion of the CP1 Jitter Test the oscilloscope is in the following configuration:

Figure 14 - Oscilloscope Configuration after CP1 Jitter Test

On this screen there are 2 traces visible. They are the TIE Histogram and the Bathtub Curve. Also, the Tj, Rj

(spectral) and Dj (spectral) are displayed in the SDA Jitter section.

Additionally the minimum pulse width in the acquired waveform is measured in P1.

28 917719 Rev A

Page 29

QPHY-USB3-Tx-Rx Software Option

At the completion of the CP0 Jitter Test the oscilloscope is in the following configuration:

Figure 15 - Oscilloscope Configuration after CP0 Jitter Test

On this screen there are 2 traces visible. They are the TIE Histogram and the Bathtub Curve. Again, the Tj, Rj

(spectral) and Dj (spectral) are displayed in the SDA Jitter section. However, as per the USB 3.0 SuperSpeed

Electrical Compliance Test Specification, the Rj that was measured on CP1 is injected into this measurement.

Additionally the minimum pulse width in the acquired waveform is measured in P1. Average UI is not shown on

the screen, but is reported with the other results.

Figure 16 - Test Report from Jitter Tests

Test 1.3.2 Phase Jitter Slew Rate

The purpose of this test group is to verify that the jitter slew rate is within the specification limits . This is a

measure of how fast the PLL in a USB3.0 receiver has to change in order to keep up with changes in the clock

frequency. Performing this test requires calculation of the first derivative of the PLL Track. The PLL Track is a

waveform that shows the phase change that the PLL was able to follow and track out of the signal. By taking the

first derivative of the PLL Track we can easily measure the minimum and maximum phase jitter slew rate on the

derivative waveform.

917719 Rev A 29

Page 30

At the completion of the Phase Jitter Slew Rate Test the oscilloscope is in the following configuration:

Figure 17 - Oscilloscope Configuration after Phase Jitter Slew Rate Test

On this screen there are 2 traces visible. These are the PLLTrack of the captured waveform and the first

derivative of the PLLTrack is show in F1.

The minimum and maximum of the derivative of the PLL Track is measured in P1 and P2. The Tj, Rj and Dj value

are also on by default when looking at any jitter trace (the PLL Track in this case).

Figure 18 - Test Report from Phase Jitter Slew Rate Test

Test 1.3.3 SigTest Jitter

The purpose of this test group is to verify that the jitter is within the specification limits using the SigTest DLL

provided by the USB-IF and integrated into the oscilloscope software. The test is performed in the same manner

that Test 1.3.1 is performed, with the exception of that the SigTest DLL is used for analysis, not the SDA II

software. For compliance testing the measurements are made after a compliance channel after applying the

reference Continuous Time Linear Equalizer function. The SigTest DLL currently implements the CTLE function,

however, it does not implement the channel emulation. For this reason, the channel emulation is still performed in

Eye Doctor II before the signal is seen by SigTest. Measuring the jitter is a multiple step process. First, the jitter

must be measured while the PUT is transmitting the CP1 (101010) pattern. Then, the jitter is measured while the

PUT is transmitting the CP0 (scrambled D0.0) pattern, however the Rj that was measured during the jitter test of

CP1 must be injected into this measurement. This simplifies the separation of Rj and Dj since there is no DDj

when CP1 is transmitted.

30 917719 Rev A

Page 31

QPHY-USB3-Tx-Rx Software Option

At the completion of the CP1 SigTest Jitter Test the oscilloscope is in the following configuration:

Figure 19 - Oscilloscope Configuration after SigTest CP1 Jitter Test

There are no traces shown on the screen at this time. The parameters displayed are the Tj, Rj and Dj calculated

by SigTest. Additionally, the Maximum Peak-to-peak Jitter, the Average UI, the Bit Rate, and the Minimum

Crossing time are also displayed.

Figure 20 - Test Report from SigTest Jitter Test

Test 1.3.4 Eye Diagram

The purpose of this test group is to verify that the eye diagram is within the specification limits. For compliance

testing the measurements are made after a compliance channel after applying the reference Continuous Time

Linear Equalizer function.

917719 Rev A 31

Page 32

At the completion of the Eye Diagram Test the oscilloscope is in the following configuration:

Figure 21 - Oscilloscope Configuration after Eye Diagram Test

Shown on the screen is the Eye Diagram measured while the PUT is transmitting CP0. Also, the compliance mask

is displayed. The parameters that are shown are the Number of Mask Hits, and the Eye Opening.

Figure 22 - Test Report from Eye Diagram Test

Test 1.3.5 SigTest Eye Diagram

The purpose of this test group is to verify that the eye diagram is within the specification limits using the SigTest

DLL provided by the USB-IF and integrated into the oscilloscope software. The test is performed in the same

manner that Test 1.3.4 is performed, with the exception of that the SigTest DLL is used for analysis, not the SDA

II software. For compliance testing the measurements are made after a compliance channel after applying the

reference Continuous Time Linear Equalizer function. The SigTest DLL currently implements the CTLE function,

however, it does not implement the channel emulation. For this reason, the channel emulation is still performed in

Eye Doctor II before the signal is seen by SigTest.

32 917719 Rev A

Page 33

QPHY-USB3-Tx-Rx Software Option

At the completion of the SigTest Eye Diagram Test the oscilloscope is in the following configuration:

Figure 23 - Oscilloscope Configuration after SigTest Eye Diagram Test

Shown on the screen are the SigTest Non-Transition and Transition Eye Diagrams along with the compliance

mask. The parameters that are shown are the number of Mask Violations, the Minimum Voltage, the Maximum

Voltage, the difference between the minimum high voltage and the mask (MinHMargin), and the difference

between the maximum low voltage and the mask (MinLoMargin). These parameters are shown for both the NonTransition Eye (NT) and the Transition Eye (T).

Figure 24 - Test Report from SigTest Eye Test

917719 Rev A 33

Page 34

Test 1.4 AC and DC Common Mode Voltage Tests

The purpose of this test group is to verify that the AC and DC common mode voltages are within the specification

limits. The AC Common Mode Voltage is defined as the peak-to-peak Voltage of the common mode signal and

the DC Common Mode Voltage is defined as the mean voltage of the common mode signal.

At the completion of the AC and DC Common Mode Voltage Test the oscilloscope is in the following

configuration:

Figure 25 - Oscilloscope Configuration after AC and DC Common Mode Test

On this screen there are 2 traces visible. In F1, the 2 input channels are added together and divided by 2 to

yield the common mode trace. In Z1, we show a zoom of this trace. The AC Common mode is calculated by

measuring the peak-to-peak value of this zoom trace (P1). The DC Common mode measurement is made over a

longer interval of time and is calculated by measuring the mean value of F1, the complete trace (P2).

Figure 26 - Test Report from AC and DC Common Mode Test

Test 1.5 Differential Voltage & De-emphasis Test

The purpose of this test is to verify that the Differential Voltage and De-emphasis are within the specification

limits. These 2 tests are performed together in 2 steps. The first step acquires the CP7 compliance pattern. This

pattern consists of 50-250 1’s followed by 50-250 0’s with de-emphasis applied to the signal. Once this acquisition

is performed, a histogram is created from the data. The difference between the 2 modes of the histogram is

calculated and is the amplitude of the de-emphasized bits.

34 917719 Rev A

Page 35

QPHY-USB3-Tx-Rx Software Option

At the completion of this part of the Differential Voltage & De-emphasis Test the oscilloscope is in the following

configuration:

Figure 27 - Oscilloscope Configuration after Differential Voltage & De-emphasis Test on CP7

On the screen are 2 visible traces. The first is the result of the acquisition of the CP7 signal after (optional) cable

de-embedded has been performed. The second is the histogram created from this signal. P1 and P2 are the 2

modes of the histogram. These 2 parameters only differ in the measurement gates that have been set. P3 is the

difference of the 2 modes.

Then this is repeated on the CP8 pattern. This pattern consists of the same 50-250 1’s followed by 50-250 0’s

without de-emphasis applied to the signal. The histogram is created and the difference between the 2 modes is

calculated. This result is the differential voltage (without de-emphasis). The differential voltage and the amplitude

of the de-emphasized bits are then used to calculate the de-emphasis ratio.

917719 Rev A 35

Page 36

At the completion of this part of the Differential Voltage & De-emphasis Test the oscilloscope is in the following

configuration:

Figure 28 - Oscilloscope Configuration after Differential Voltage & De-emphasis Test on CP8

On the screen are 2 visible traces. The first is the result of the acquisition of the CP8 signal after (optional) cable

de-embedded has been performed. The second is the histogram created from this signal. P1 and P2 are the 2

modes of the histogram. These 2 parameters only differ in the measurement gates that have been set. P3 is the

difference of the 2 modes.

Figure 29 - Test Report from Differential Voltage & De-emphasis Test

Receiver Test Calibration

As of the release of this version of QPHY-USB3-Tx-Rx, the receiver test calibration portion of the specification has

not yet been fully defined. For this reason, this test gives the user the ability to manually set their own jitter

parameters that the PeRT3 uses during each of the 8 points of the jitter tolerance test. The existing calibration

settings are loaded for the user. These values can be verified using the SDA II software and modified as

necessary. If the user modifies the values, they are saved for future use. For additional information, refer to the

Receiver Test Calibration section of this manual.

36 917719 Rev A

Page 37

QPHY-USB3-Tx-Rx Software Option

Test 2.1 Jitter Tolerance Test

The purpose of this test is to verify that the jitter tolerance test is within specification limits. To do this the PeRT3

output must first be calibrated. Specified previously, as of the release of this version of QPHY-USB3-Tx -Rx, the

receiver test calibration portion of the specification has not yet been finalized. Once, the PeRT3 output is

calibrated, the PeRT3 sets the PUT into loopback mode and performs the jitter tolerance test on the 8 required

points: 50MHz, 33MHz, 20MHz, 10MHz, 4.9MHz, 2MHz, 1MHz and 500kHz.

Figure 30 - Test Report from Jitter Tolerance Test

917719 Rev A 37

Page 38

QPHY-USB3-TX-RX VARIABLES

The variable settings in QualiPHY give the user the ability to customize their QualiPHY configurations. These

variables control what connection diagrams are displayed, what additional equipment can be used, filenames for

external files, address, etc. Detailed descriptions of each variable contained within

QPHY-USB3-Tx -Rx are explained as follows:

Always Reconnect PUT

This variable gives the user the ability to force the PeRT3 to always reconnect to the PUT after each run. The

default value for the variable is “No.” In this state, the PeRT3 determines if the PUT is in the correct mode

(compliance or loopback) for the next set of tests. When set to “Yes” the PeRT3 always disconnects and

reconnects to the PUT on every run.

Cable S-Parameters File

This variable allows the user to specify the S-Parameter filename (s4p) used when de-embedding the cables and

fixtures associated with their setup. This variable is only used if the De-embed Cables variable is set to “Yes.” By

default this variable is blank.

De-embed Cables

This variable allows the user to de-embed the cables and/or fixturing associated with their setup. Select “Yes” to

de-embed cables and/or fixturing using the S-Parameter file (s4p) specified in the Cable S-Parameters File

variable. The default value for this variable is “No.”

Demo Mode

This variable allows the user to run the tests in demo mode. When you set this value to “Yes,” you can run the

tests in demonstration mode using saved waveforms. The waveforms must be located in the Saved Waveform

Path. During demo mode, the user is still prompted with connection diagrams based on their other variable

selections. This allows the user to experience running the test as it would be run on live signals. The default value

for this variable is “No.”

RF Switch GPIB Address

This variable allows the user to select the GPIB address for the Keithley S46 RF Switch that can optionally be

used with this system. The default value for this variable is “7.” (This is the default value for the Keithley S46 RF

Switch).

Maximum PeRT3 retries

This variable allows the user to select the maximum number of times for the PeRT3 to retry to connect the link

before aborting. The default value for this variable is “3.”

Disable Connection Diagrams

This variable allows the user to disable the display of connection diagrams. The default for this variable is “No.”

Product Type

This variable allows users to specify if they are testing a Device, Host or Hub. The default for this variable is

“Host.”

Saved Waveform Path

This variable allows the user to specify the path that saved waveforms are recalled from when running in demo

mode or when TestMode is “Use Saved Data.” The default value for this variable is “D:\Waveforms\USB3.”

Save Individual Runs

This variable allows the user to specify if they would like to save the waveforms from multiple runs in the saved

waveform path. When this value is set to “Yes” waveforms are saved in a separate folder each time the test is run

- for example: D:\Waveforms\USB3\[Product under test]\Run1. When set to “No” waveforms are overwritten on

every run and saved in: “D:\Waveforms\USB3\[Product under test].”

38 917719 Rev A

Page 39

QPHY-USB3-Tx-Rx Software Option

S-Parameter Files Path

This variable allows the user to specify the path on the oscilloscope that contains the S-Parameter files used for

emulation and/or de-embedding. The default for this variable is “D:\Applications\EyeDr\USB3.”

SSC

This variable allows the user to specify whether or not Spread Spectrum Clocking (SSC) is enabled on the

Product Under Test. The SigTest Average UI test has different limits based on whether or not SSC is enabled. By

setting this variable, the correct limit for this test can be used. Select “Enabled” if Spread Spectrum Clocking is

enabled, otherwise select “Disabled.” The default is “Enabled” because SSC is required by the USB 3.0

Specification.

Stop On Test to review results

This variable gives the user the option to enable Stop on Test mode. When set to “Yes”, the testing pauses after

each test allowing the user to review the results. The setup is saved so oscilloscope settings can be modified by

the user. When execution is resumed, the setup is recalled. Note that any new acquisition completed while the

testing is paused may cause the testing to misbehave. The default value for this variable is “No.”

Test Mode

This variable allows the user to decide whether the tests should be run on newly acquired data or if previously

saved waveforms should be used. The choices for this variable are “Acquire New Data” and “Use Saved Data.” If

“Use Saved Data” is selected, the waveforms are recalled from the location specified in the Saved Waveform

Path variable. The default value for this variable is “Acquire New Data.”

Use PeRT3

This variable allows the users to select if they would like QualiPHY to automate the PeRT3 to configure the

Product under test for each test. If this variable is set to “No”, the user must have the ability to stimulate their

Product under test to transmit the required test patterns for transmitter testing. The default setting for this variable

is “No.”

Use RF Switch

This variable allows the users to specify whether or not they have an RF Switch. If this variable is set to “Yes,” the

oscilloscope communicates with the RF Switch and makes the required connections without any user interaction.

If this variable is set to “No,” the user must connect their signals when prompted. The default value for this

variable is “No.”

PeRT3 Setup

PeRT3 Hostname or IP Address

This variable allows the user to enter the hostname or IP Address of the PeRT3 Server (the machine that the

PeRT3 is connected to via USB). If QualiPHY is running from a remote PC and not from the oscilloscope,

“localhost” refers to the oscilloscope. The default value for this variable is “localhost.”

PeRT3 SSC Enabled

This variable allows the user to enable SSC on the PeRT3’s clock output. This is required for receiver testing. The

default for this variable is “Yes.”

Transmitter Tests

Deskew measure mode

This variable allows the user to select the method for deskewing their cables. The choices for this variable are

“Wizard Method” and “User Defined.” “Wizard Measured” is used to launch the automated deskew measurement.

“User Defined” is used if the user would like to set the Deskew value in picoseconds variable when the deskew

value is already known. The default value for this variable is “Wizard Method.”

917719 Rev A 39

Page 40

Deskew value in picoseconds

This variable allows the user to specify the channel + cable deskew between channels C1 and C2. The value is in

picoseconds and is applied to the channel C1. This value is only applied to C1 if “User Defined” is selected for the

Deskew measure mode variable.

PeRT3 Amplitude

This variable allows the user to control the amplitude of the PeRT3 during testing. The default for this variable is

0.8mV.

PeRT TX Init Mode

This variable controls the way the PeRT3 configures the product under test to output test patterns. The choices

are “Loopback” or Low Frequency Periodic Signaling (“LFPS”). LFPS mode brings the Product under test into

Compliance Mode and outputs a Ping.LFPS signal to prompt the Product under test to switch to the next

compliance pattern. Loopback mode places the Product under test in Loopback Mode, and then outputs the

required Compliance Test Pattern. This mode does not produce valid compliance test results because the Product

under test outputs SKP symbols into the data. The recommended choice is “LFPS” if it is supported.

Jitter & Eye Diagram Tests

The variables in this section allow the users to decide whether or not they would like the oscilloscope to perform

channel emulation and equalization as described by the specification. If yes, the user also has the ability to

specify the s-parameter file of the channel to emulate. Additionally the user can decide the location of the 2 poles,