Page 1

QPHY-HDMI

Operator’s Manual

Revision A – December, 2013

Relating to the following release versions:

Software Version Rev. 7.3.x.x

Script HDMI.IRT

Style Sheet Rev. 1.2

Page 2

700 Chestnut Ridge Road

Chestnut Ridge, NY, 10977-6499

Tel: (845) 425-2000, Fax: (845) 578 5985

teledynelecroy.com

© 2013 Teledyne LeCroy, Inc. All rights reserved.

Teledyne LeCroy and other product or brand names are trademarks or requested trademarks of their

respective holders. Information in this publication supersedes all earlier versions. Specifications are

subject to change without notice.

922540 Rev A

December, 2013

Page 3

QPHY-HDMI Operator’s Manual

Table of Contents

Introduction ............................................................................................................................... 1

About QualiPHY ............................................................................................................................................ 1

About QPHY-HDMI ....................................................................................................................................... 1

Required Hardware ....................................................................................................................................... 1

Test Fixtures .................................................................................................................................................. 2

Required Host Com puter S yst em ................................................................................................................. 2

Installation and Setup ............................................................................................................... 3

Install Base Application ................................................................................................................................. 3

Activate Components .................................................................................................................................... 3

Set Up Dual Monitor Display ......................................................................................................................... 3

Set Up Remote Control ................................................................................................................................. 4

Configure Oscilloscope for Remote Control .......................................................................................... 4

Add Connection to QualiPHY ................................................................................................................ 4

Select Connection .................................................................................................................................. 4

Using QualiPHY ......................................................................................................................... 5

Accessing the Software ................................................................................................................................. 5

General Setup ............................................................................................................................................... 6

Connection tab ....................................................................................................................................... 6

Session Info tab ..................................................................................................................................... 6

Report tab .............................................................................................................................................. 6

Advanced tab ......................................................................................................................................... 6

About tab ................................................................................................................................................ 6

QualiPHY Test Process ................................................................................................................................. 7

Set Up Test Session .............................................................................................................................. 7

Run Tests ............................................................................................................................................... 8

Run Reports ........................................................................................................................................... 9

Customizing QualiPHY ................................................................................................................................ 10

Copy Configuration .............................................................................................................................. 10

Select Tests ......................................................................................................................................... 10

Edit Variables ....................................................................................................................................... 11

Edit Test Limits .................................................................................................................................... 12

X-Replay Mode ........................................................................................................................................... 13

QPHY-HDMI Testing ................................................................................................................ 14

Test Preparation .......................................................................................................................................... 14

Required Test Modes .......................................................................................................................... 14

Physical Setup ..................................................................................................................................... 14

Deskew ................................................................................................................................................ 14

QPHY-HDMI Test Configurations ................................................................................................................ 15

Clock and Data0 Basic Tests ............................................................................................................... 15

Clock and Data0 Tests at All Standard Frequencies ........................................................................... 15

Data0 & Data1 & Data2 Inter-Pair Skew (7-6) ..................................................................................... 15

Clock and Data0 Tests at Custom Frequency (340 MHz) ................................................................... 15

Demo of All Tests................................................................................................................................. 15

QPHY-HDMI Test Descriptions ................................................................................................................... 16

Test7-2: TMDS-VL ............................................................................................................................... 16

Test7-4: TMDS TRise, TFall ................................................................................................................ 17

Test7-5: TMDS Over/Undershoot ........................................................................................................ 17

Test7-6: TMDS Inter-P air S kew ........................................................................................................... 18

Test7-7: TMDS Intra-P air S kew ........................................................................................................... 19

Test7-8: TMDS Clock Duty Cycle ........................................................................................................ 20

922540 Rev A i

Page 4

Test7-9: TMDS Clock Jitter .................................................................................................................. 21

Test7-10: TMDS Data Eye Diagram .................................................................................................... 22

QPHY-HDMI Variables ................................................................................................................................ 23

Specific to “Test7-2: TMDS-VL” Group ................................................................................................ 24

Specific to “Test7-4: TMDS TRise, TFall” Group ................................................................................. 24

Specific to “Test7-6: TMDS Inter-Pair Skew” Group ............................................................................ 24

Specific to “Test7-7: TMDS Intra-Pair Skew” Group ............................................................................ 25

Specific to “Test7-8: TMDS Clock Duty Cycle” Group ......................................................................... 25

Specific to “Test7-9: TMDS-Clock Jitter” Group .................................................................................. 25

Specific to “Test7-10: TMDS-Data Eye Diagram” Group ..................................................................... 26

QPHY-HDMI Limit Sets ............................................................................................................................... 26

Manual Deskewing Procedures.............................................................................................. 27

Cable Deskewing Using the Fast Edge Output........................................................................................... 27

Cable Deskewing Using the DUT Signal .................................................................................................... 30

Error Messages ....................................................................................................................... 32

Table of Figures

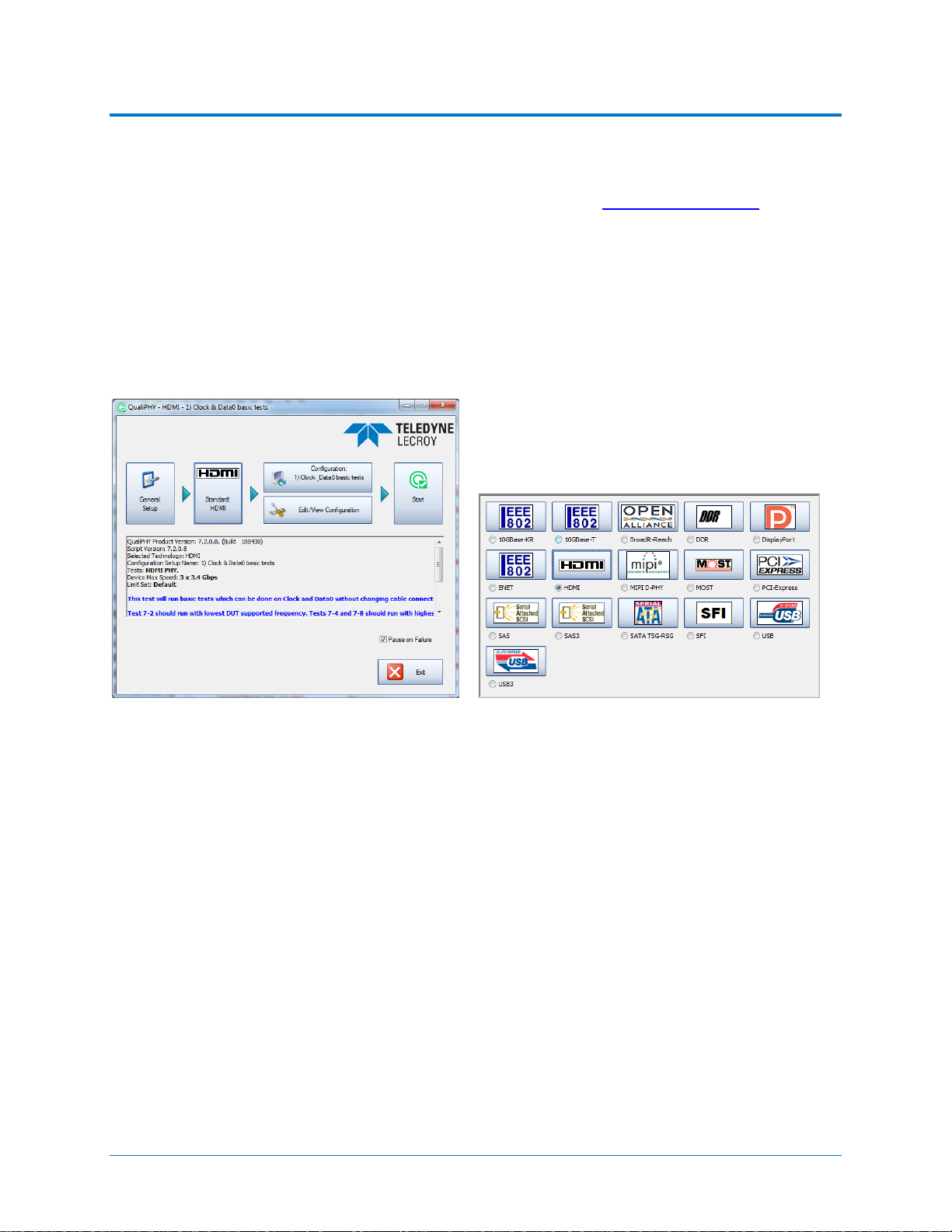

Figure 1 - QualiPHY framework dialog and Standard selection menu. ................................................. 5

Figure 2 - The Test Report Summary Table and Detail page. ................................................................. 9

Figure 3 – X-Replay Mode window. ......................................................................................................... 13

Figure 4 - The Skew parameter right side dialog, Skew clock 2 tab, showing default setup. ........... 31

About This Manual

This manual assumes that you are familiar with using an oscilloscope−in particular the Teledyne

LeCroy oscilloscope that will be used with QualiPHY−and that you have purchased the QPHYHDMI software option. Some of the images in this manual may show QualiPHY products other

than QPHY-HDMI, or were captured using different model oscilloscopes, as they are meant to

illustrate general concepts only. Rest assured that while the user interface may look different

from yours, the functionality is identical.

ii 922540 Rev A

Page 5

QPHY-HDMI Operator’s Manual

Introduction

About QualiPHY

QualiPHY is highly automated compliance test software meant to help you develop and validate

the PHY (physical-electrical) layer of a device, in accordance with the official documents

published by the applicable standards organizations and special interest groups (SIGs). You can

additionally set custom variables and limits to test compliance to internal standards.

QualiPHY is composed of a “framework” application that enables the configuration and control

of separate tests for each standard through a common user interface. Features include:

• Multiple Data Source Capability: Connect to your X-Stream oscilloscope via LAN or

other interfaces.

• User-Defined Test Limits: Tighten limits to ensure devices are well within the passing

region, even if subsequently measured with different equipment.

• Flexible Test Results Reporting that includes XML Test Record Generation.

Understand a device performance distribution, or obtain process related information from

the devices under test.

About QPHY-HDMI

QPHY-HDMI is an automated test package performing all the normative, real-time oscilloscope

tests for sources in accordance with version 1.4 of the High Definition Multimedia Interface

Compliance Test Specification (HDMI).

The software can be run on any Teledyne LeCroy oscilloscope with at least 8 GHz bandwidth

(for testing clock rates above 148.5 MHz). The oscilloscope must also have the QualiPHY

software installed and the QPHY-HDMI software option activated.

Required Hardware

• Real-time Teledyne LeCroy oscilloscope with all required software installed.

Note: QPHY-HDMI tests are designed to run on WavePro/SDA/DDA 7Zi/ZI-A,

WaveMaster/SDA/DDA Zi/Zi-A, LabMaster 9Zi/Zi-A Series oscilloscopes with minimum

8GHz bandwidth. The HDMI test specification requires 8 GHz bandwidth for testing clock

rates above 148.5 MHz.

• SDAII or SDAIII oscilloscope software option. (SDAII / SDIII is standard on SDA model

oscilloscopes)

• 8 SMA Male to SMA Male cables

• 4 TF-HDMI-3.3V test adapters

• HDMI test fixtur e

For the most complete and up-to-date list, see the HDMI SIG website: http://www.hdmi.org

922540 Rev A 1

Page 6

Test Fixtures

Teledyne LeCroy recommends using the Wilder Technologies HDMI-TPA-P (plug test adapter)

used in conjunction with HDMI-TPA-E (EDI D board with EEPROM). This equipment is available

from Wilder Technologies individually or as part of the HDMI-TPA-PRRCE Test Adapter Kit. The

HDMI-TPA-PRRCE test adapter kit provides a very high bandwidth, low noise evaluation vehicle

that enables high-performance characterization of both plug and receptacle HDMI™ devices

with bandwidth greatly exceeding the 340 MHz (10.2 Gbps) of the latest v1.4b HDMI

specification.

Required Host Computer System

Usually, the oscilloscope is the host computer for the QualiPHY software, and all models that

meet the acquisition requirements will also meet the host system requirements. However, if you

wish to run the QualiPHY software from a remote computer, these minimum requirements apply:

• Operating System:

o Windows 2000 Professional with service pack 4

o Windows XP Professional with service pack 2

o Windows VISTA with service pack 1

o Windows 7 Professional

• 1 GHz or faster processor

• 1 GB (32-bit) or 2 GB (64-bit) of RAM

• Ethernet (LAN) network capability

• Hard Drive:

o At least 100 MB free to install the framework application

o Up to 1GB per standard installed to store the log database (each database grows

from a few MB to a maximum of 1 GB)

See Set Up Remote Control

for configuration instructions.

2 922540 Rev A

Page 7

QPHY-HDMI Operator’s Manual

Installation and Setup

QualiPHY is a Windows-based application that can be configured with one or more serial data

compliance components. Each compliance component is purchased as a software option.

Install Base Application

Download the latest version of the QualiPHY software from:

teledynelecroy.com/support/softwaredownload under Oscilloscope Downloads > Software Utilities.

If the oscilloscope is not connected to the Internet, copy the installer onto a USB memory stick,

then transfer it to the oscilloscope desktop or a folder on a D:\ drive to execute it.

Run QualiPHYInstaller.exe and follow the installer prompts. Choose all the components you

plan to activate. If you omit any components now, you will need to update the installation to

activate them later.

By default, the oscilloscope appears as local host when QualiPHY is executed on the

oscilloscope. Follow the steps under Add Connection to QualiPHY

is 127.0.0.1.

to check that the IP address

Activate Components

The serial data compliance components are factory installed as part of the main application in

your oscilloscope and are individually activated through the use of an alphanumeric code

uniquely matched to the oscilloscope’s serial number. This option key code is what is delivered

when purchasing a software option.

To activate an option on the oscilloscope:

1. From the menu bar, choose Utilities > Utilities Setup.

2. On the Options tab, click Add Key.

3. Use the Virtual Keyboard to Enter Option Key, then click OK.

If activation is successful, the key code now appears in the list of Installed Option Keys.

4. Restart the oscilloscope application by choosing File > Exit, then double-clicking the

Start DSO icon on the desktop.

Set Up Dual Monitor Display

Teledyne LeCroy recommends running QualiPHY on an oscilloscope equipped with Dual

Monitor Display capability. This allows the waveform and measurements to be shown on the

oscilloscope LCD display, while the QualiPHY application and test results are displayed on a

second monitor.

See the oscilloscope Operator’s Manual or Getting Started Manual for instructions on setting up

dual monitor display.

922540 Rev A 3

Page 8

Set Up Remote Contr ol

QualiPHY software can be executed from a remote host computer, controlling the oscilloscope

through a LAN Connection. To set up remote c ontrol:

• The oscilloscope must be connected to a LAN and assigned an IP address (fixed or

dynamic).

• The host computer must be on the same LAN as the oscilloscope.

Note: LXI, GPIB, LSIB, and USBTMC remote control is available for some model instruments.

Follow the same procedure, selecting the appropriate connection type on the oscilloscope and

in QualiPHY.

Configure Oscilloscope for Remot e Cont rol

1. From the menu bar, choose Utilities Utilities Setup...

2. Open the Remote tab and set Remote Control to TCP/IP.

3. Verify that the oscilloscope shows an IP address.

Add Connection to QualiPHY

1. On the host PC, download and run QualiPHYInstaller.exe.

2. Start QualiPHY and click the General Setup button.

3. On the Connection tab, click Scope Selector.

4. Click Add and choose the connection type. Enter the oscilloscope IP address from Step

3 above. Click OK.

5. When the oscilloscope is properly detected, it appears on the Scope Selector dialog.

Select the connection, and click OK.

QualiPHY is now ready to control the oscilloscope.

Select Connection

Multiple oscilloscopes may be accessible to a single remote host. In that case, go to General

Setup and use the Scope Selector at the start of the QPHY session to choose the correct

connection.

QualiPHY tests the oscilloscope connection when starting a test. The system warns you if there

is a connection problem.

4 922540 Rev A

Page 9

QPHY-HDMI Operator’s Manual

Using QualiPHY

This section provides an overview of the QualiPHY user interface and general procedures. For

detailed information about the QPHY-HDMI software option, see QPHY-HDMI Testing

Accessing the Softw ar e

Once QualiPHY is installed and activated, it can be accessed from the oscilloscope menu bar

by choosing Analysis > QualiPHY, or by double-clicking the QualiPHY desktop icon on a

remote computer.

The QualiPHY framework dialog illustrates the overall software flow, from general set up

through running individual compliance tests. Work from left to right, making all desired settings

on each sub-dialog.

.

Figure 1 - QualiPHY framework dialog and Standard selection me nu.

The sub-dialogs are organized into tabs each containing configuration controls related to that

part of the process. These are described in more detail in the following sections.

If Pause on Failure is checked, QualiPHY prompts to retry a measure whenever a test fails.

Report Generator launches the manual report generator dialog.

The Exit button at the bottom of the framework dialog closes the QualiPHY application.

922540 Rev A 5

Page 10

General Setup

The first sub-dialog contains general system settings. These remain in effect for each session,

regardless of Standard, until changed.

Connection ta b

Shows IP Address of the test oscilloscope (local host 127.0.0.1 if QualiPHY is run from the

oscilloscope). The Scope Selector allows you to choose the oscilloscope used for testing when

several are connected to the QualiPHY installation. See Set Up Remote Control

Session Info tab

Optional information about the test session that may be added to reports, such as: Operator

Name, Device Under Test (DUT), Temperature (in °C) of the test location, and any additional

Comments. There is also an option to Append Results or Replace Results when continuing a

previous session.

To optimize report generation, enter at least a DUT name at the beginning of each session.

Report tab

Settings related to automatic report generation. Choose:

• Reporting behavior of:

for details.

o “Ask to generate a report after tests,” where you’ll be prompted to create a new

file for each set of test results.

o “Never generate a report after tests,” where you’ll need to manually execute the

Report Generator to create a report.

o “Always generate a report after tests,” to autogenerate a report of the latest test

results.

• Default report output type of XML, HTML, or PDF.

• A generic Output file name, including the full path to the report output folder.

Optionally, check Allow style sheet selection in Report Generator to enable the use of a

custom .css when generating reports. The path to the .css is entered on the Report Generator

dialog.

Report Generator launches the Report Generator dialog, which contains the same settings as

the Report tab, only applied to individual reports.

Advanced tab

This tab launches the X-Replay Mode dialog. See X-Replay Mode.

About tab

Information about your QualiPHY installation.

6 922540 Rev A

Page 11

QPHY-HDMI Operator’s Manual

QualiPHY Test Process

Once general system settings are in place, these are the steps for running test sessions.

Set Up Test Session

1. Connect the oscilloscope to the DUT. See QPHY-HDMI Testing Physical Setup.

2. Access the QualiPHY software to display the framework dialog.

3. If running QualiPHY remotely, click General Setup and open the Scope Selector to

select the correct oscilloscope connection.

4. If you have more than one component activated, click Standard and select the desired

standard to test against. Otherwise, your one activated component will appear as the

default selection.

Note: Although all the QualiPHY components appear on this dialog, only those selected

when installing QualiPHY are enabled for selection.

5. Click the Configuration button and select the test configuration to run. These preloaded configurations are set up to run all the tests required for compliance and provide

a quick, easy way to begin compliance testing. See QPHY-HDMI Test Configurations

a description of your configurations.

You can also create custom configurations for internal compliance tests by copying and

modifying the pre-loaded configurations. See Customizing QualiPHY

6. Close the Edit/View Configuration dialog to return to the framework dialog.

for de tails.

for

922540 Rev A 7

Page 12

Run Tests

1. On the framework dialog, click Start to begin testing.

When tests are in progress, this button changes to Stop. Click it at any time to stop the

test in process. You’ll be able to resume from the point of termination or from the

beginning of the test.

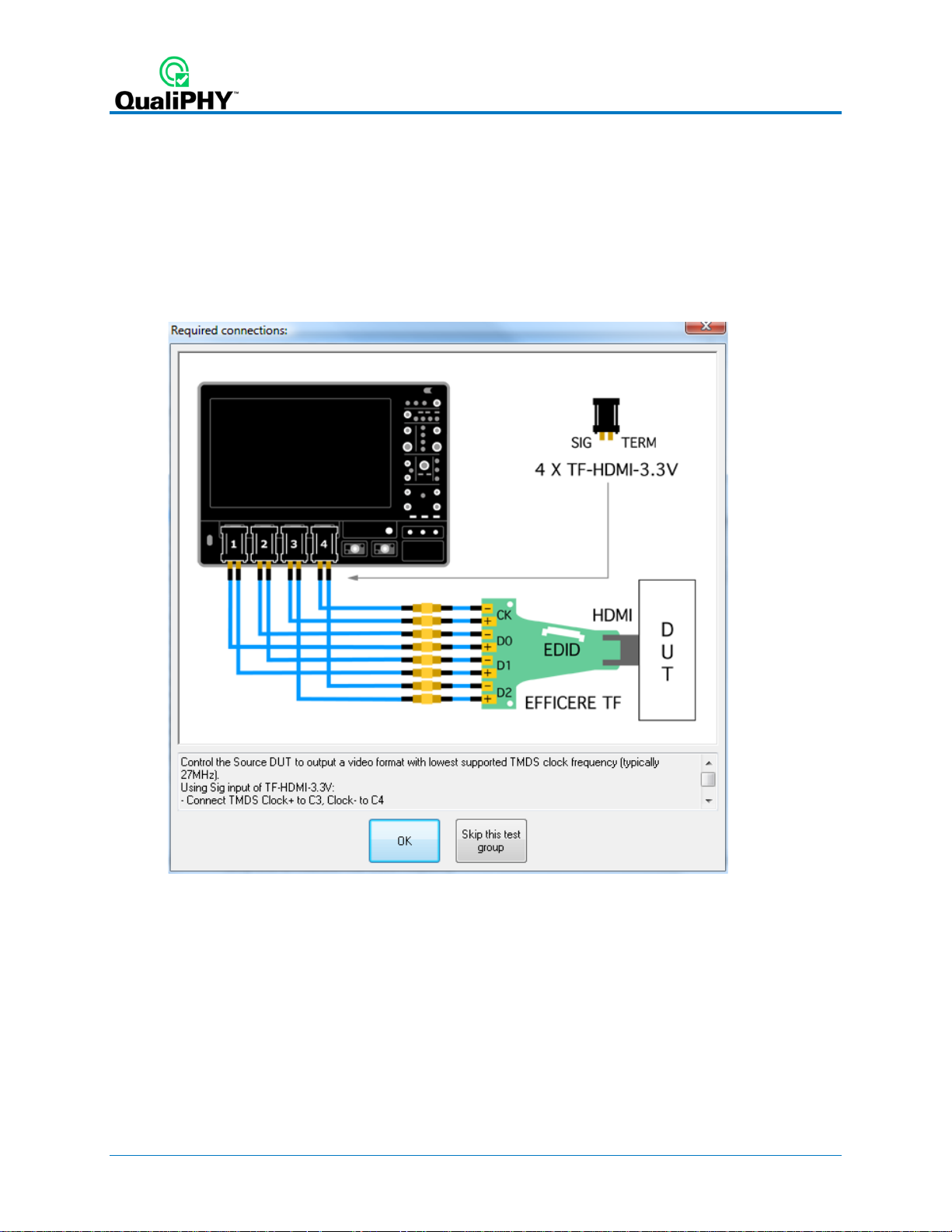

2. Follow the pop-up window prompts. QualiPHY guides you step-by-step through each of

the tests described in the standard specification, including diagrams of the connection to

the DUT for each required test mode.

3. When all tests are successfully completed, both progress bars on the framework dialog

are completely green and the message “All tests completed successfully” appears. If

problems are encountered, you’ll be offered options to:

• Retry the test from the latest established point defined in the script

• Ignore and Continue with the next test

• Abort Session

8 922540 Rev A

Page 13

QPHY-HDMI Operator’s Manual

Run Reports

The QualiPHY software automates report generation. On the framework dialog, go to General

Setup > Report to pre-configure reporting behavior. You can also manually launch the Report

Generator from the framework dialog once a test is run.

The Report Generator offers the same selections as the Report tab, only applied to each report

individually, rather than as a system setting. This enables you to save reports for each test

session, rather than overwrite the generic report file. There are also options to link a custom

style sheet (.xslt) to the report, or to Exclude Informative Results.

The Test Report includes a summary table with links to the detailed test result pages.

Figure 2 - The Test Report Summary Table and Detail page.

Reports are output to the base installation folder *\LeCroy\XReplay\Reports.

You can add your own logo to the report by replacing the file

*\LeCroy\XReplay\StyleSheets\CustomerLogo.jpg.

The recommended maximum size is 250x100 pixels at 72 ppi, 16.7 million colors, 24 bits. Use

the same file name and format.

922540 Rev A 9

Page 14

Customizing QualiPHY

The pre-loaded configurations cannot be modified. However, you can create your own test

configurations by copying one of the standard test configurations and modifying it.

Copy Configuration

1. Access the QualiPHY framework dialog and select a Standard.

2. Click Edit/View Configuration and select the configuration upon which to base the new

configuration. This can be a pre-loaded configuration or another copy.

3. Click Copy and enter a name and description. Once a custom configuration is defined, it

appears on the Configuration tab followed by “(Copy).”

4. Select the new, custom configuration and follow the procedures below to continue

making changes.

Note: If any part of a configuration is changed, the Save As button becomes active on

the bottom of the dialog. If a custom configuration is changed, the Save button will also

become active to apply the changes to the existing configuration.

Select Tests

On the Test Selector tab, select/deselect the tests that make up the configuration. Each test is

defined by the HDMI standard. A description of each test is displayed when it is selected.

To loop any of the tests in this configuration, select the test from the list, then choose to loop

indefinitely until stopped or enter the number of repetitions.

10 922540 Rev A

Page 15

QPHY-HDMI Operator’s Manual

Edit Variables

The Variable Setup tab contains a list of test variables. See QPHY-HDMI Variables for a

description of each.

To modify a variable:

1. Select the variable on the Var iable Setup tab, then click Edit Variable. (You can also

choose to Reset to Default at any time.)

2. The conditions of this variable appear on a pop-up. Choose the new condition to apply.

922540 Rev A 11

Page 16

Edit Test Limits

The Limits tab shows the Limit Set currently associated with the configuration. Any limit set can

be associated with a custom configuration by selecting it in this field.

The Limits Manager shows the settings for every test limit in a limit set. Those in the default set

are the limits defined by the standard.

To create a custom limit set:

1. On the Limits tab, click Limits Manager.

2. With the default set selected, click Copy Set and enter a name.

Note: You can also choose to copy and/or modify another custom set that has been

associated with this configuration.

3. Double click the limit to be modified, and in the pop-up enter the new values.

You can also Import Limits from a .csv file. Navigate to the f ile location after clicking the

button.

Tip: Likewise, Export Limits creates a .csv file from the current limit set. You may wish to

do this and copy it to format the input .csv file.

12 922540 Rev A

Page 17

QPHY-HDMI Operator’s Manual

X-Replay Mode

The X-Replay mode window is an advanced (“developer”) view of QualiPHY. The tree in the

upper-left frame enables you to navigate to processes in the HDMI test script, in case you need

to review the code, which appears in the upper-right frame.

Two other particularly useful features are:

• A list of recent test sessions in the lower-left frame. While you can only generate a

report of the current test session in the QualiPHY wizard, in X-Replay Mode you can

generate a report for any of these recent sessions. Select the session and choose

Report > Create Report from the menu bar.

• An event log is shownn the bottom-right frame. The frame can be split by dragging up

the lower edge. The bottom half of this frame now shows the raw Python output, which

can be useful if ever the script needs debugging.

Figure 3 – X-Replay Mode window.

922540 Rev A 13

Page 18

QPHY-HDMI Testing

Test Preparation

Before beginning any test or data acquisition, the oscilloscope should be warmed for at least 20

minutes.

Calibration is automatic under software control and no manual calibration is required. The

calibration will be run again if the temperature of the oscilloscope changes by more than a few

degrees.

Required Test Modes

The QPHY-HDMI script requires that you place the DUT (Device Under Test) in the required test

modes. The script will prompt you to do so before each specific test, but it is recommended that

you ensures the DUT is capable of being placed in the required test modes before beginning

testing.

Physical Setup

The T el edyne LeCroy direct measurement solution uses SMA cables to connect two differential

signals at one time to the oscilloscope channels through the TF-HDMI-3.3V SIG input. SMA

cables are also used to terminate the unused signal onto specific TERM inputs.

See the description of each test configuration for specific set up information.

Deskew

HDMI signals are properly probed using two separate channels on the oscilloscope connected

to the appropriate SMA jacks on the test fixture. The highest measurement accuracy is achieved

when the timing skew between the two channels is calibrated.

The configurations will guide you through an initial deskew procedure. See the end of this

manual for two approaches to deskew. For optimal results, we recommend that you always first

deskew channels 2 and 3, then channels 1 and 2, followed by channels 3 and 4.

14 922540 Rev A

Page 19

QPHY-HDMI Operator’s Manual

QPHY-HDMI Test Configurations

Test configurations include variable settings, limit sets, and test selections. All ut ilize the Default

limit set. See QPHY-HDMI Variables

See the QPHY-HDMI Limit Sets for more information about the default test limits.

Clock and Data0 Basic Tests

This configuration runs all Clock and Data0 tests that can be run without changing cable.

Maximum device speed is 3 x 3.4 Gbps. Test 7-2 should run with lowest DUT supported

frequency . Tests 7-4 and 7-8 should run with highest DUT supported frequency.

These tests do not require the use of the “FindScale” variable to increase precision. Change the

variable “TMDS Data pair to test” to Data1 and Data2.

Clock and Data0 Tests at All Standard Frequencies

This configuration runs all Clock and Data0 tests that can be run without changing cable

connections at all frequencies. Maximum device speed is 3 x 3.4 Gbps. Tests 7-7 should run

with highest DUT supported frequency. Tests 7-9 and 7-10 are configured to run at all DUT

standard frequencies (27 MHz, 74.25 MHz, 148.5 MHz, and 222.75 MHz).

These tests require the use of the “FindScale” variable to increase precision. Change the

variable ‘TMDS Data pair to test” to Data1 and Data2.

for a description of each variable and its default value.

Data0 & Data1 & Data2 Inter-Pair Skew (7-6)

This configuration runs the Data Inter-Pair Skew (7-6) tests for all data lane combinations (D0D1, D0-D2, D1-D2). Maximum device speed is 3 x 3.4 Gbps. The tests require several cable

connections and disconnections. Test 7-6 should run with highest DUT supported frequency.

Clock and Data0 Tests at Cust om F re que nc y (340 MHz)

This configuration runs Clock Jitter and Eye Diagram tests (7-9 and 7-10) on Clock and Data0 at

a custom frequency (340 MHz). Maximum device speed is 3 x 3.4 Gbps. This combination is

useful when highest DUT supported frequency is not a standard frequency.

You can test other custom frequencies using the variable “DUT TMDS Clock Alternate

Frequencies” in groups 7-9 and 7-10. Change the variable “TMDS Data pair to test” to Data1

and Data2.

Demo of All Tests

This configuration runs all the tests in index order using stored waveforms in D:\HDMI\Demo

and the Default limit set. This configuration is meant to easily demonstrate the QPHY-HDMI

capabilities when live signals cannot be tested. You will see dialogs and connection diagrams

similar to what you would see during an actual test.

922540 Rev A 15

Page 20

QPHY-HDMI Test Descriptions

These are the standard HDMI compliance tests.

Test7-2: TMDS-VL

This test confirms that DC voltage levels on the HDMI link are within specified limits for each

TMDS signal.

R

EQUIREMENT

Single-ended, low level output voltage, VL:

If attached Sink supports only <=165MHz : (AVcc - 600mVolts) ≤ VL ≤ (AVcc - 400mVolts)

If attached Sink supports >165MHz : (AVcc - 700mVolts) ≤ VL ≤ (AVcc - 400mVolts)

Reference: [HDMI: Table 4-15] Source DC Characteristics at TP1

ETHODOLOGY

M

1. Connect TP A-P adapter to Source DUT HDMI output connector.

2. Connect TF-HDMI-3.3V to TMDS_DATA0+.

3. Configure the EDID to indicate only 27MHz formats (480p and 576p, no Deep Color

support) with the 640x480p Established Timings bit set.

4. Control the Source DUT to output a video format with lowest supported TMDS clock

frequency (typically 27MHz).

5. Capture 1000 or more repetitions, triggered at the vertical mid-point of the High-to-Low

transition of a H-L-L-L bit sequence. Each capture must be of duration 3*TBIT.

6. Display the voltage (vertical) histogram on the scope, with the histogram data

accumulated only from the last 2-bits of the H-L-L-L sequence.

7. Read the VL value as the most common low-level voltage shown on the histogram. If (VL

> 2.90V) OR (VL < 2.70V) then

8. Capture 10,000 repetitions, triggered at mid-point of waveform, of duration ≥ 2*TBIT to

get proper histograms.

9. Display the voltage (vertical) histogram on the scope. If (VL > 2.90V) OR (VL < 2.70V)

then FAIL

10. Repeat the test for all eight TMDS signals.

11. If CDF field Source_Above_165 , then switch to an EDID that additionally indicates:

a. Support for 1080p50Hz and 60Hz

b. Deep Color 36-bits/pixel

c. Max_TMDS_Clock of 225MHz (value = 225/5 = 45)

12. Repeat t est sequence above still using lowest clock rate format. If (VL > 2.90V) OR (VL

< 2.60V) then FAIL.

13. Repeat the test for all eight TMDS signals.

16 922540 Rev A

Page 21

QPHY-HDMI Operator’s Manual

Test7-4: TMDS TRise, TFall

This test confirms that the rise times and fall times on the TMDS differential signals fall within

the limits of the specification.

R

EQUIREMENT

75psec ≤ Rise Time or Fall Time

Reference: [HDMI: Table 4-16] Source AC Characte ristics at TP1

ETHODOLOGY

M

1. Connect TP A-P adapter to Source DUT HDMI output connector.

2. Configure Source DUT to output a video format and pixel size with highest supported

TMDS clock frequency .

3. Accumulate at least 10,000 triggered waveforms.

4. Measure TRISE as the mode of the sampled edge times from 20% to 80% of the

differential swing voltage rising edge.

5. Measure TF ALL as the mode of the sampled edge times from 80% to 20% of the

differential swing voltage on the falling edge.

If (TRISE < 75ps) then FAIL.

If (TFALL < 75ps) then FAIL.

6. Repeat the test for all remaining TMDS clock and data pairs.

Test7-5: TMDS Over/Undershoot

This test confirms that the differential TMDS signals do not have overshoot or undershoot

beyond that allowed by the specified limits (HDMI 1.0 only).

922540 Rev A 17

Page 22

Test7-6: TMDS Inter-Pair Skew

This test confirms that that any skew between the differential pairs in the TMDS portion of the

HDMI link does not exceed the limits in the specification.

R

EQUIREMENT

Inter-pair skew must not exceed 0.20*TPIXEL.

Reference: [HDMI: T able 4-16] Source AC Characteristics at TP1

ETHODOLOGY

M

1. Connect TP A-P adapter to Source DUT HDMI output connector.

2. Connect the first TF-HDMI-3.3V to TMDS_DATA0.

3. Connect the second TF-HDMI-3.3V to TMDS_DATA1.

4. Configure Source DUT to output an HDMI signal with a video format and pixel size with

highest supported TMDS clock frequency.

5. Capture (trigger) or find a sequence of Control Period encoded characters. Either 10-bit

or 20-bit trigger may be used. For 10-bit trigger:

6. Find the first bit of the TMDS character on the two TMDS channels. The CTL encoding

pattern 1101010100 corresponds to:

a. TMDS_DATA0: HSYNC=1, VSYNC=0

b. TMDS_DATA1: CTL0=1, CTL1=0 (any Preamble)

c. T MDS_DATA2: CTL2=1, CTL3=0 (Data Island Preamble)

If it is difficult to capture using the above patterns, then any of the following (Control

Period) patterns may be used:

a. 0010101011

b. 1101010100

c. 0010101010

d. 1101010101

7. Examine second channel for any valid CTL code and measure TIPSKEW between

channels.

8. For 20-bit trigger, find the first bit of the following 20-bit sequence on the TMDS

channels.

a. For Channel 0: 0010101011 0011001101

b. For Channel 0: 0010101010 0011001101

c. For Channel 0: 1101010101 0011001101

d. For Channel 1: 0010101010 1100110010

e. For Channel 2: 0010101011 0011001101

9. Examine second channel for the appropriate sequence and measure TIPSKEW between

channels. If TSKEW > 0.2*TCHARACTER then FAIL.

10. Repeat the test for remaining combinations of TMDS_DATAx pairs.

18 922540 Rev A

Page 23

QPHY-HDMI Operator’s Manual

Test7-7: TMDS Intra-Pair Skew

This test confirms that any skew within any one differential pair in the TMDS portion of the HDMI

link does not exceed the limits in the specification.

R

EQUIREMENT

Intra-pair skew between TMDS DATA pairs must not exceed 0.15*TBIT.

Reference: [HDMI: T able 4-16] Source AC Characteristics at TP1

ETHODOLOGY

M

1. Connect TP A-P adapter to the Source DUT HDMI output connector.

2. Connect the first TF-HDMI-3.3V to TMDS_DATA0+.

3. Connect the second TF-HDMI-3.3V to TMDS_DATA0-.

4. Configure Source DUT to output a video format and pixel size with highest supported

TMDS clock frequency.

5. Set the trigger on TMDS_DATA0+ rising edge.

6. Display the waveform of TMDS_DATA0+ and DATA0-. Accumulate 10,000 or more

triggers. Find the closest falling edge of DATA0- (either preceding or following DATA0+

rising edge) and determine the most common 50% crossing point of that TMDS_DATA0falling edge using a horizontal (time) Histogram method.

7. Measure skew from trigger point to most common 50% crossing point of TMDS_DATA0-.

If (skew > 0.15*TBIT) then FAIL.

8. Repeat the test for all remaining TMDS differential pairs.

922540 Rev A 19

Page 24

Test7-8: TMDS Clock Duty Cycle

This test confirms that the duty cycle of the differential TMDS clock does not exceed the limits

allowed by the specification.

R

EQUIREMENT

Clock duty cycle must be at least 40% and not more than 60%.

Reference: [HDMI: T able 4-16] Source AC Characteristics at TP1

ETHODOLOGY

M

1. Connect TP A-P adapter to Source DUT HDMI output connector.

2. Configure Source DUT to output a video format and pixel size with highest supported

TMDS clock frequency .

3. Connect TF-HDMI-3.3V to TMDS Clock.

4. Display the waveform of 1 clock period.

5. Configure the Digital Oscilloscope: trigger source is the TMDS Clock rising edge, turn on

infinite persistence, measurement is duty cycle, capture at least 10,000 or more triggers.

6. Measure minimum duty cycle as earliest crossing of TMDS_CLOCK falling edge. If

(TDUTY(MIN) < 40%, then FAIL.

7. Measure maximum duty cycle as latest crossing of TMDS_CLOCK falling edge.) If

(TDUTY(MAX) > 60%, then FAIL.

20 922540 Rev A

Page 25

QPHY-HDMI Operator’s Manual

Test7-9: TMDS Clock Jitter

This test confirms that the TMDS Clock does not carry excessive jitter.

R

EQUIREMENT

TMDS differential clock jitter must not exceed 0.25*TBIT, relative to the ideal Recovery Clock.

Reference: [HDMI: T able 4-16] Source AC Characteristics at TP1

EST METHODOLOGY

T

1. Connect TP A-P adapter to the Source DUT HDMI output connector.

2. Connect two TF-HDMI-3.3V test fixtures to each line of the TMDS Clock pair.

3. Configure oscilloscope and CRU: evaluate 16M samples per channel (can be acquired

with a single or with multiple smaller captures).

4. Configure Source DUT to output one video format for each of the following TMDS Clock

frequencies if that frequency is supported by the DUT: 27MHz (or 25MHz), 74.25MHz,

148.5MHz, and 222.75MHz. For each of these test frequencies, perform the following:

a. Capture the waveform and process it with the Digital Oscilloscope.

b. If test frequency is <=165MHz, then set Sampling Rate ≥10GSa/s

If test frequency is >165MHz, then set Sampling Rate ≥20GSa/s

c. Measure Clock jitter as difference between farthest left sampling point and

farthest right sampling point, at Vertical setting = VC = 0V ± 20mV. If Clock jitter

exceeds 0.25*TBIT then FAIL.

5. Repeat the test for remaining supported test frequencies. Only one video format/pixelsize combination is required per TMDS clock rate.

922540 Rev A 21

Page 26

Test7-10: TMDS Data Eye Diagram

This test confirms that the differential signal on each TMDS differential data pair has an “eye

opening” (region of valid data) that meets or exceeds the limits on eye opening in the

specification.

R

EQUIREMENT

Refer to the “Eye Diagram Mask at TP1 for Source Requirements.

Reference: [HDMI: Figure 4-18] Eye Diagram Mask at TP1

ETHODOLOGY

M

1. Connect TP A-P-TDR to Source DUT HDMI output connector.

2. Connect the first TF-HDMI-3.3V to TMDS Clock, and configure as trigger.

3. Connect the second TF-HDMI-3.3V to TMDS_DATA0.

4. Connect 50 ohm pull-ups to each of the non-probed TMDS lines to 3.3V.

5. Configure Source DUT to output one video format for each of the following TMDS Clock

frequencies if that frequency is supported by the DUT: 27MHz (or 25MHz), 74.25MHz,

148.5MHz, and 222.75MHz, and, if not already covered, the highest DUT-supported

frequency. For each of these test frequencies, perform the following.

6. Capture the waveforms on the Digital Oscilloscope. Process with the CRU to display the

data eye diagram.

a. Set memory length to 16M samples per-channel.

b. If test frequency is <=165MHz then set Sampling Rate ≥10GSa/s

If test frequency is >165MHz then set Sampling Rate ≥20GSa/s

7. Compare the data eye to the TP1 Eye Diagram Mask. If any part of the waveform

exceeds either the high or low maximum voltage (+/- 780mV), then FAIL.

8. Shift the mask left or right through one entire TBIT to determine if any horizontal position

has no capture points within eye mask. No vertical shifting is allowed. If no shifted

position exists where no part of the waveform touches or crosses into the data eye, then

FAIL.

9. Measure the data jitter at the zero crossing point. Measurement box vertical setting: 0V

±5mV. If data jitter > 0.3*TBIT then FAIL.

10. Repeat the test for remaining TMDS_DATA pairs.

11. Repeat the test for remaining supported test frequencies. Only one video format/pixelsize combination is required per TMDS clock rate.

22 922540 Rev A

Page 27

QPHY-HDMI Operator’s Manual

QPHY-HDMI Variables

EXECUTION ORDER MODE

Choose between CablingOrdered and IndeOrdered to define how the tests will be run. Currently

only IndexOrdered is available.

D

EMO MODE

Select demonstration mode. When enabled, previously stored HDMI waveforms will be used.

HDMI

VERSION TESTED

Select HDMI Compliance test version. There are two versions available: 1.4 and 1.3.

N

UMBER OF SWEEPS ACQUIRED FOR A MEASURE

Increase the number of sweeps to increase precision. Decrease for speed. Choose between 1,

5 or 10. Default is 10.

U

SER DEFINED SIGNAL VERTICAL GAIN

If set to default (or negative value), the script will initiate an automated find scale to determine

the gain and offset. If set to a positive value, it will be used to set the gain of all signals and the

"Re-use vertical settings" variable will be ignored. Default is 0.

U

SER DEFINED SIGNAL VERTICAL OFFSET

If variable is defined (> 0), this offset will be used for the signal and trigger levels.

R

E-USE VERTICAL SETTINGS

Enable re-use of memorized vertical settings (to speed up test). Choose between Yes and No.

Default is No (disabled) to ensure gain and offset are correctly set. This variable is ignored if

"User defined signal vertical gain" > 0.

S

AVE ACQUIRED WAVEFORMS

Saved waveforms can be used later in demonstration or optimized version of script. Choose

between Yes or No. Default is No. This setting is ignored (no save) if using stored waveforms is

enabled and in Demo mode.

S

ILENT MODE CONTROL

Turn on/off user interaction. Useful to let the test run repetitively in the background. Choose

between Yes or No. Default is No.

TMDS

DATA PAIR TO TEST

Define which Data Pair to test. Connect TMDS DATA + to C1 and DATA - to C2. Choose

between D0, D1, D2 or D1,D2,D3. The last option is the default and will test all Data Pairs.

U

SE STORED TRACE FOR PIXEL CLOCK MEASURE OPTIMIZATION

Use to measure the pixel clock frequency only once. Choose between Yes and No, Default is

No.

922540 Rev A 23

Page 28

WAVEFORM PATH

Specify the path on the oscilloscope to save/recall waveforms. When not in Demo Mode and

Save acquired waveforms is enabled, the waveforms will be saved in this folder. When set to

Demo Mode or Use stored trace for pixel clock measure, saved waveforms should be available

in this folder. Default is "D:\Waveforms\HDMI".

Specific to “Test7-2: TMDS-VL” Group

NUMBER OF SEGMENTS ACQUIRED IN SEQUENCE

HDMI specification requires 10'000 segments. For debugging only, r educe the number of

segments to speed-up processing. Choose between 10’000, 1000, 500 or 50. Default is 10’000.

R

ECALLED WAVEFORM FILE INDEX (5 DIGITS)

Enter the 5 digits number corresponding to the index of the file you want to recall. Default is

00000.

S

UPPORT OF TMDS FREQUENCY >= 165 MHZ

Choose between Yes or No. Default is No. If attached Sink device supports only <=165MHz,

limit is: (AVcc - 600mVolts) ≤ VL ≤ (AVcc - 400mVolts). If attached Sink device supports

>165MHz, limit is: (AVcc - 700mVolts) ≤ VL ≤ (AVcc - 400mVolts).

Specific to “Test7-4: TMDS TRise , TFal l” Grou p

RECALLED WAVEFORM FILE INDEX (5 DIGITS)

Enter the 5 digits number corresponding to the index of the file you want to recall. Default is

00000.

U

SE INTERNAL PEAK IF SIGNAL HAS TWO PEAKS

Default is No. Choose Yes to debug specific signal shape. HDMI signals can have two peaks in

amplitude. Classic measure of rise/fall time at 20-80% doesn't give stable results in this case.

So if two peaks are detected, we can use the internal one to determine rise/fall levels. But we

have observed signals with "faked" internal peaks. These additional peaks give inaccurate (too

short) rise/fall time. So disabling the use of internal peaks allows forcing usage of the highest

peaks.

Specific to “Test7-6: TMDS Inter -Pair Skew” Group

DATA-DATA TEST COMBINATIONS

Choose the combination of Data Pair to be tested between D0-D2 or D0-D1 or D2-D1 or D0D2,D0-D1,D2-D1. The last option is the default and will test all Data Pairs.

R

ECALLED WAVEFORM FILE INDEX (5 DIGITS)

Enter the 5 digits number corresponding to the index of the file you want to recall. Default is

00000.

24 922540 Rev A

Page 29

QPHY-HDMI Operator’s Manual

Specific to “Test7-7: TMDS I n tra-Pair Skew” Group

NUMBER OF SEGMENTS ACQUIRED IN SEQUENCE

HDMI specification requires 10'000 segments. For debugging only, r educe the number of

segments to speed-up processing. Choose between 10’000, 1000, 500 or 50. Default is 10’000.

Recalled Waveform File Index (5 digits)

Enter the 5 digits number corresponding to the index of the file you want to recall. Default is

00000.

Specific to “Test7-8: TMDS Clock Duty Cy cle” Group

NUMBER OF SEGMENTS ACQUIRED IN SEQUENCE

HDMI specification requires 10'000 segments. For debugging only, r educe the number of

segments to speed-up processing. Choose between 10’000, 1000, 500 or 50. Default is 10’000.

R

ECALLED WAVEFORM FILE INDEX (5 DIGITS)

Enter the 5 digits number corresponding to the index of the file you want to recall. Default is

00000.

Specific to “Test7-9: TMDS-Clock Jitter” Group

DUT TMDS CLOCK STANDARD FREQUENCIES

Configure Source DUT to output one video format for each of the following TMDS Clock

frequencies if that frequency is supported by the DUT: 27MHz (or 25MHz), 74.25MHz,

148.5MHz, 222.75MHz. Use DUT TMDS Clock Alternate Frequencies if the highest DUTsupported frequency is not in this list or if you wish to define custom frequencies.

DUT

TMDS CLOCK ALTERNATE FREQUENCIES

If different than 0, this value will be used as the maximum DUT TMDS Clock frequency in

addition to the standard frequencies selected. The frequency must be entered in scientific

format (e.g., 340 MHz as 340e6). You can enter a list of values using the “,” separator. Default

value is 0.

T

IMEBASE USED TO CREATE EYE DIAGRAM

Increase/decrease the number of points acquired to create Eye Diagram. 100us/div gives

enough samples to fulfill the 16 MS/Channel HDMI requirement.

R

ECALLED WAVEFORM FILE INDEX (5 DIGITS)

Enter the 5 digits number corresponding to the index of the file you want to recall. Default is

00000.

922540 Rev A 25

Page 30

Specific to “Test7-10: TMDS-Data Eye Diagram” Group

DUT TMDS CLOCK STANDARD FREQUENCIES

Configure Source DUT to output one video format for each of the following TMDS Clock

frequencies: 27MHz (or 25MHz), 74.25MHz, 148.5MHz, 222.75MHz and, if not already covered,

the highest DUT-supported frequency. Use alternate frequency if the highest DUT-supported

frequency is not already covered.

DUT

TMDS CLOCK ALTERNATE FREQUENCIES

If different than 0, this value will be used as the maximum DUT TMDS Clock frequency in

addition to the standard frequencies selected. The frequency must be entered in scientific

format, e.g. 340MHz as 340e6. The default value is 0.

R

ECALLED WAVEFORM FILE INDEX (5 DIGITS)

Enter the 5 digits number corresponding to the index of the file you want to recall. Default is

00000.

T

IMEBASE USED TO CREATE EYE DIAGRAM

Increase/decrease the number of points acquired to create Eye Diagram. 100us/div gives

enough samples to fulfill the 16 MS/Channel HDMI requirement.

QPHY-HDMI Limit Sets

The default installation of QPHY-HDMI contains only one limit set, called “HDMI_Default.” In

this script, limits are only used to convey Unit labels. The actual limits for each value tested are

encoded in or computed by the script and cannot be changed. The default limits used by QPHYHDMI are specified in version 1.4 of the High Definition Multimedia Interface Compliance Test

Specification (HDMI) .

26 922540 Rev A

Page 31

QPHY-HDMI Operator’s Manual

Manual Deske wing Procedures

This section is only applicable to the oscilloscope and the cables connecting to the oscilloscope

channels.

Cable Deskewing Using the Fast Edge Output

The following procedure demonstrates how to manually deskew two oscilloscope channels and

cables using the fast edge output, with no need for any T connector or adapters.

Note: Fast Edge output is available only on some models. If your oscilloscope does not have

Fast Edge output, see Cable Deskewing Using the DUT Signal.

This can be done once the temperature of the oscilloscope is stable. The oscilloscope must be

warmed up for at least a half-hour before proceeding. This procedure should be run again if the

temperature of the oscilloscope changes by more than a few degrees.

For the purpose of this procedure, the two channels being deskewed are referred to as Channel

X and Channel Y. The reference channel is Channel X and the channel being deskewed is

Channel Y.

1. Begin by recalling the Default Oscilloscope Setup.

2. Configure the oscilloscope as follows:

• Timebase

i. Fixed Sample Rate

ii. Set the Sample Rate to 40 GS/s

iii. Set the Time/Division to 1 ns/div

• Channels

i. Turn on Channel X and Channel Y.

ii. Set V/div for Channel X and Channel Y to 100mV/div.

iii. Set the Averaging of Channel X and Channel Y to 500 sweeps.

iv. Set the Interpolation of Channel X and Channel Y to Sinx/x.

922540 Rev A 27

Page 32

• Trigger

i. Configure to Source to be FastEdge.

ii. Set the Slope to Positive.

• Parameter Measurements:

i. Set the source for P1 to CX and the measure to Delay.

ii. Set the source for P2 to CY and the measure to Delay.

iii. Set the source for P3 to M1 and the measure to Delay.

3. Set the display to Single Grid.

• Click Display Single Grid.

4. Using the appropriate adapter, connect Channel X to the Fast Edge Output of the

oscilloscope.

5. Adjust the Trigger Delay so that the Channel X signal crosses at the center of the

screen.

6. Change the Timebase to 50 ps/div.

7. Fine tune the Trigger Delay so that the Channel X signal crosses at the exact center of

the screen.

8. Press the Clear Sweeps button on the front panel to reset the averaging.

9. Allow multiple acquisitions to occur until the waveform is stable on the screen.

28 922540 Rev A

Page 33

QPHY-HDMI Operator’s Manual

10. Save Channel X to M1.

• Click File Save Waveform.

• Set Save To Memory.

• Set the Source to CX.

• Set the Destination to M1.

• Click Save Now.

11. Disconnect Channel X from the Fast Edge Output and connect Channel Y to the Fast

Edge Output.

12. Press the Clear Sweeps button on the front panel to reset the averaging.

13. Allow multiple acquisitions to occur until the waveform is stable on the screen.

14. From the Channel Y menu, adjust the Deskew of Channel Y until Channel Y is directly

over the M1 trace.

15. Ensure that P3 and P2 are reasonably close to the same value. (Typically < 5ps

difference)

922540 Rev A 29

Page 34

Cable Deskewing Using the DUT Signal

This procedure does not require a Fast Edge output. Its other advantages are:

• It does not require adapters.

• You can de-skew at the same V/div settings you'll use to capture your data (because you

are capturing your data for this procedure).

• If the differential data signal has higher speed edges than the oscilloscope's AUX OUT, it

is easier to get good timing measurements with the faster edges. This is definitely the

case for HDMI.

Note: This procedure demonstrates how to deskew channels 2 and 3. For optimal results, this

method should be followed for channels 2 and 3, and then channels 1 and 2, followed by

channels 4 and 3 to insure that all channels are deskew appropriately.

1. Connect a differential data signal to C2 and C3 using two approximately matching

cables. Set up the oscilloscope as you plan to use it. Set the timebase to capture a few

repetitions of the compliance test pattern (at least a few dozen edges). Press Auto to

start acquisition.

2. On the C3 dialog, check Invert. Now C2 and C3 should look the same.

3. On the Measure dialog, set P1 to measure the Skew of C2, C3. Turn on Statistics.

Write down the mean skew value after it stabilizes. This mean skew value is the addition

of Data skew + cable skew + channel skew.

4. Swap the cable connections on the Data source side (on the test fixture), and then press

the Clear Sweeps button on the oscilloscope (to clear the accumulated statistics; since

we changed the input).

5. Write down the mean skew value after it stabilizes. This mean skew value is the addition

of (-Data skew) + cable skew + channel skew.

6. Add the two mean skew values and divide the sum in half:

The above formula simplifies to:

[cable skew + channel skew]

30 922540 Rev A

Page 35

QPHY-HDMI Operator’s Manual

7. Set the resulting value as the Deskew value in C2 menu.

8. Restore the cable connections to their Step 1 settings (previous). Press the Clear

Sweeps button on the oscilloscope. The mean skew value should be approximately zero

- that is the data skew. Typically, r esult s are <1ps given a test fixture meant to minimize

skew on the differential pair.

9. On the C3 dialog, un-check the Invert checkbox and turn off the parameters.

Now that the oscilloscope inter-channel skew and cable skew is compensated for, you

are ready to test.

The procedure as given above relies on the default setup of the Skew parameter (which is:

detecting positive edges on both signals, at 50%). C3 was inverted in order to make C2 and C3

both have positive edges at the same time. The default setup of any parameter is in effect at the

time it is set up.

Figure 4 - The Skew parameter right side dialog, Skew clock 2 tab, showing default setup.

922540 Rev A 31

Page 36

Error Messages

These messages may appear when using QualiPHY.

“Warning, no valid technology package has been found…” This message appears if none

of the QualiPHY components have been activated on the oscilloscope before launching the

QualiPHY application. See Activate Components.

“No devices connected to the application or device not alive…” This message appears if

you are running QualiPHY from a remote PC, but a) you have not connected any oscilloscopes

to the installation, or b) the oscilloscopes are offline. See Set Up Remote Control

oscilloscope.

“This test requires Firmware version x.x.x.x or higher.” The test oscilloscope firmware

needs to be updated. Go to teledynelecroy.com/support/softwaredownload under Oscilloscope

Downloads > Firmware Update to download the latest firmware.

“An <oscilloscope model> or better is required for <test>.” The test cannot be run with this

oscilloscope. If using remote control, you may be able to choose another connected

oscilloscope.

“This test requires the <name> option.” Besides installing the QualiPHY software, you must

purchase and activate the named software option on the oscilloscope.

to connect an

32 922540 Rev A

Page 37

Loading...

Loading...