Page 1

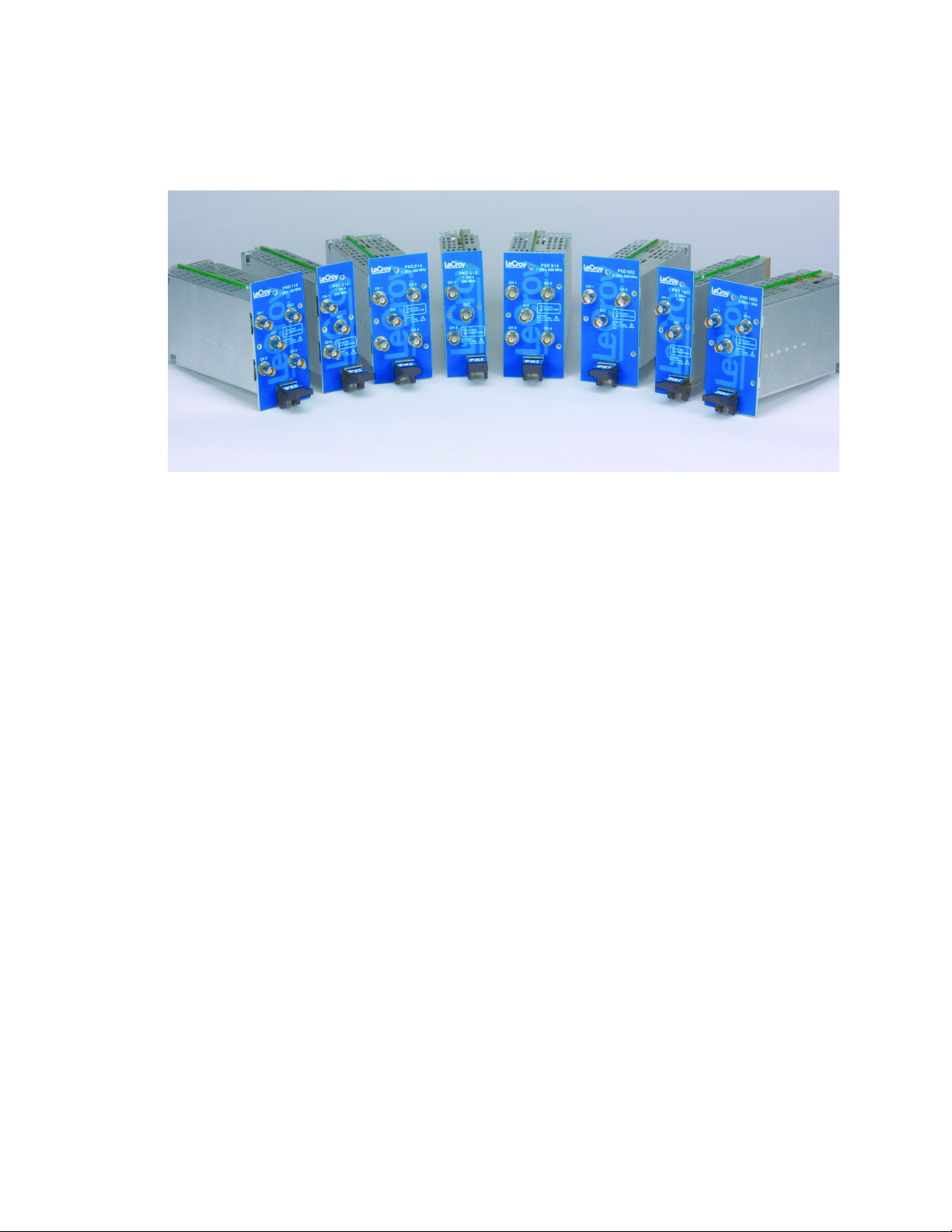

PXD DIGITIZER SERIES

OPERATOR’S MANUAL

MARCH 2003

Page 2

LeCroy Corporation

700 Chestnut Ridge Road

Chestnut Ridge, NY 10977-6499

Tel: (845) 578 6020, Fax: (845) 578 5985

Internet: www.lecroy.com

© 2003 by LeCroy Corporation. All rights reserved.

LeCroy, ActiveDSO, ProBus, SMART Trigger, WavePro, and Waverunner are registered

trademarks of LeCroy Corporation. JitterTrack, WaveMaster, and X-Stream are trademarks of

LeCroy Corporation. Information in this publication supersedes all earlier versions. Specifications

subject to change without notice.

901217-01

Page 3

Table of Contents

Table of Contents

First Things...First................................................................................................1

WHEN YOUR DIGITIZER IS DELIVERED .................................................1

Check That You Have Everything..........................................................................1

Be Sure To Read This Warranty............................................................................1

Take Advantage Of Maintenance Agreements ...................................................... 1

Obtain Assistance..................................................................................................2

Return a Product for Service or Repair.................................................................. 2

Stay Up-to-Date ..................................................................................................... 2

SAFETY INFORMATION...................................................................3

Safety Symbols......................................................................................................3

Operating Environment.......................................................................................... 3

Power Requirements ............................................................................................. 4

Cooling Requirements ........................................................................................... 4

Grounding Requirements.......................................................................................4

Calibration ............................................................................................................. 5

Abnormal Conditions ............................................................................................. 5

Cleaning ................................................................................................................ 5

INSTALL AND POWER UP THE DIGITIZER..............................................6

Introduction............................................................................................................ 6

Install NI Software Components ............................................................................ 6

Install PXD Device Driver ...................................................................................... 7

Install the PXI Digitizers......................................................................................... 7

Install PXD IVI Application Software.................................................................... 11

Copy Complementary Files onto Your Hard Drive (optional)...............................15

Install PXD IVI Driver........................................................................................... 16

Copy Complementary Files onto Your Hard Drive (optional)...............................20

Install Complementary files onto Your Hard Drive (optional) ...............................21

Operation............................................................................................................25

Introduction.......................................................................................................... 25

Acquisition Modes ...............................................................................................25

Trigger Modes...................................................................................................... 27

PXD SERIES DIGITIZER QUICK START APPLICATION SOFTWARE ...29

Soft Front Panel................................................................................................... 30

USING THE PXD SERIES DIGITIZER IVI INSTRUMENT DRIVERS ......32

PXD Digitizer Specifications......................................................................33

901217-01 ISSUED: March 2003 i

Page 4

PXD Series Digitizer

BLANK PAGE

ii ISSUED: March 2003 901217-01

Page 5

WHEN YOUR DIGITIZER IS DELIVERED

CHECK THAT YOU HAVE EVERYTHING

Verify receipt of all items on the packing list or invoice copy. The following is shipped with the standard PXD Series Digitizer:

• Performance or Calibration Certificate

• Quick Reference Guide

• CD ROM

NOTE: The warranty below replaces all other warranties, expressed or implied, including but not

limited to any implied warranty of merchantability fitness, or adequacy for any particular

purpose or use. LeCroy shall not be liable for any special, incidental, or consequential

damages, whether in contract or otherwise. The customer is responsible for the

transportation and insurance charges for the return of products to the service facility.

LeCroy will return all products under warranty with transport prepaid.

Contact the nearest LeCroy customer service center or national distributor if anything is missing or

damaged immediately. LeCroy is not responsible for replacement if not contacted immediately.

BE SURE TO READ THIS WARRANTY

The PXD Series Digitizer is warranted for normal use and operation, within specifications, for a

period of one year from shipment. LeCroy will either repair or, at LeCroy option, replace any product returned to one of our authorized service centers within warranty period after verification that

the product is found to be defective due to workmanship or materials, and not due to misuse,

neglect, accident, or abnormal conditions or operation by the purchaser.

Spare and replacement parts, and repairs all have a 90-day warranty.

The Digitizer’s firmware has been thoroughly tested and is presumed to be functional. Products

not made by LeCroy are covered solely by the warranty of the original equipment manufacturer.

TAKE ADVANTAGE OF MAINTENANCE AGREEMENTS

LeCroy offers a variety of services under the heading of Maintenance Agreements. These provide

an extended warranty for after the initial one-year warranty has expired. Installation, training,

enhancements, and on-site repairs — among other services — are available through special supplemental support agreements. Inquire at your LeCroy customer service center or national distributor.

901217-01 ISSUED: March 2003 1

Page 6

PXD Series Digitizer

OBTAIN ASSISTANCE

Help with installation, calibration, and the use of your PXD Series Digitizer scope in a range of

applications is also available from your customer service center.

RETURN A PRODUCT FOR SERVICE OR REPAIR

Identify returned LeCroy product(s) by model and serial numbers.

Describe the defect or failure, and provide name and contact

number.

For factory returns, use a Return Authorization Number (RAN),

obtainable from customer service. Clearly mark this number on the

outside of the shipping package to ensure rapid forwarding within

LeCroy.

Return those products requiring only maintenance to the nearest

customer service center. Defective or damaged products should be

returned directly to our factory. Contact our customer service for the

return address.

Transportation charges to the factory are the responsibility of the customer, while products under

warranty will be returned with transport prepaid by LeCroy. Outside the warranty period, provide a

purchase order number prior to repair or replacement. The customer is responsible for parts and

labor related to repair work, and return shipping charges.

Prepay return shipments. LeCroy cannot accept COD (Cash On Delivery) or Collect Return shipments. We recommend using air freight.

NOTE: Use the original

shipping carton when

returning Digitizer for

repair or replacement. If

this is not possible, the

carton used should be

rigid. The Digitizer

should be packed so that

it is surrounded by a

minimum of four inches

(10 cm) of shock absorbent material.

STAY UP-TO-DATE

To maintain the PXD Series Digitizer’s performance within specifications, LeCroy recommends

calibration at least once a year. LeCroy offers state-of-the-art technology by continually refining

and improving the instrument’s capabilities and operation. We frequently update both firmware and

software during service, provided free of charge during warranty.

2 ISSUED: March 2003 901217-01

Page 7

SAFETY INFORMATION

SAFETY SYMBOLS

The following symbols appear on the Digitizer’s front cover or in this manual and alert the customer to important safety considerations.

Refer to the accompanying information or documents in order to protect

against personal injury or damage to the instrument.

This symbol is used to denote the measurement ground connection.

The CAUTION sign indicates a potential hazard. It calls attention to a proce-

CAUTION

WARNING

dure, practice or condition which, if not followed, could possibly cause damage to equipment. If a CAUTION is indicated, do not proceed until its

conditions are fully understood and met.

The WARNING sign indicates a potential hazard. It calls attention to a procedure, practice, or condition which, if not followed, could possibly cause bodily

injury or death. If a WARNING is indicated, do not proceed until its conditions

are fully understood and met.

Installation (Overvoltage) Category rating per EN 61010-1 safety standard

CAT I

and is applicable for the Digitizer’s panel measuring terminals. CAT I rated

terminals must only be connected to source circuits in which measures are

taken to limit transient voltages to an appropriately low level.

OPERATING ENVIRONMENT

The Digitizer is intended for operation within a PXI chassis as a plug-in module. Ensure that the

PXI chassis being used to host the Digitizer fully conforms to the latest PXI specifications.

The Digitizer is intended for indoor use and should be operated in a clean and dry environment.

WARNING

The Digitizer must not be operated in explosive, dusty, or wet atmospheres.

901217-01 ISSUED: March 2003 3

Page 8

PXD Series Digitizer

The design of the Digitizer has been verified to conform to EN 61010-1 safety standard per the following limits:

Installation (Overvoltage) Category I: Refers to signal level, which is applicable for equipment

measuring terminals that are connected to source circuits in which measures are taken to limit

transient voltages to an appropriately low level.

Pollution Degree 2: Refers to an operating environment where normally only dry non-conductive

pollution occurs. Occasionally a temporary conductivity caused by condensation must be

expected.

POWER REQUIREMENTS

The Digitizer operates from within a PXI chassis. Power requirements depend on the Digitizer

model as indicated in the PXD Series Digitizer Specifications section of this manual. DC voltages

are supplied to the instrument from the PXI backplane. The instrument requires a variety of DC

currents/voltages as outlined in the Specifications section.

CAUTION

Disconnect power to the PXI Chassis before installing or removing the

Digitizer.

COOLING REQUIREMENTS

The Digitizer relies on externally supplied forced air cooling for proper operation. A minimum airflow of 5 cfm (PXD212, 512,1021) or 15 cfm (PXD114, 214, 514, 522, 1022) to the Digitizer’s air

inlet at a temperature between 0 °C and 40 °C must be provided by the PXI chassis. The user

should ensure that the PXI chassis can satisfy these airflow requirements.

GROUNDING REQUIREMENTS

To conform to the applicable safety and EMC requirements, ensure that the Digitizer instrument

panel and the PXI chassis are "earth" grounded.

CAUTION

The outer shells of the front panel terminals (CH1, CH2, CH3, CH4, EXT) are

connected to the instrument’s chassis and, therefore, to the safety ground.

4 ISSUED: March 2003 901217-01

Page 9

CALIBRATION

The recommended calibration interval is one year. Calibration should be performed by qualified

personnel only.

ABNORMAL CONDITIONS

Operate the Digitizer only as intended by the manufacturer. If you suspect the Digitizer has been

impaired, remove it from the PXI Chassis and secure against any unintended operation. The Digitizer is likely to be impaired, if for example, the instrument fails to perform the intended measurements or shows visible damage.

WARNING

Any use of the Digitizer in a manner not specified by the manufacturer may impair

the instrument and cause an unsafe condition to develop.

CLEANING

Clean only the exterior of the Digitizer, using a damp, soft cloth. Do not use chemicals or abrasive

elements. Under no circumstances allow moisture to penetrate the instrument.

CAUTION

No operator serviceable parts inside. Refer servicing to qualified personnel.

901217-01 ISSUED: March 2003 5

Page 10

PXD Series Digitizer

INSTALL AND POWER UP THE DIGITIZER

INTRODUCTION

Prior to inserting the Digitizer into your chassis, install the necessary software components on your

system. The list of components to install depends on the NI components you have already

installed:

• If you have LabWindows/CVI 6.0 and/or LabView 6.1 installed, you don't need to install any

additional NI components. You can skip the INSTALL NI SOFTWARE COMPONENTS section.

• If you are using an older version of LabWindows/CVI and/or LabView, first check the NI Web site

for compatibility issues.

• If you have neither Lab/Windows nor LabView installed, verify that you have the following NI

components installed:

NI VISA Engine v 2.6.0 or later

NI IVI Engine v 1.83 or later

NI CVI Runtime engine 6.0 or later

INSTALL NI SOFTWARE COMPONENTS

For detailed information about installing NI software, please visit the National Instruments Web

site: http://www.ni.com.

The IVI Engine software is necessary when you are using IVI drivers. Visit http://www.ni.com/ivi

and http://www.ivifoundation.org for more information about the IVI standard.

You also must have an IVI.INI in your directory \VXIpnp\WinNT\niivi. If not, create one with the

following default content:

[IviLogicalNames]

[LogicalName->SampleScope]

Description = "Sample Oscilloscope Logical Name"

1. Each component is protected by copyright © 2001 by National Instruments Corporation, all rights reserved.

1

6 ISSUED: March 2003 901217-01

Page 11

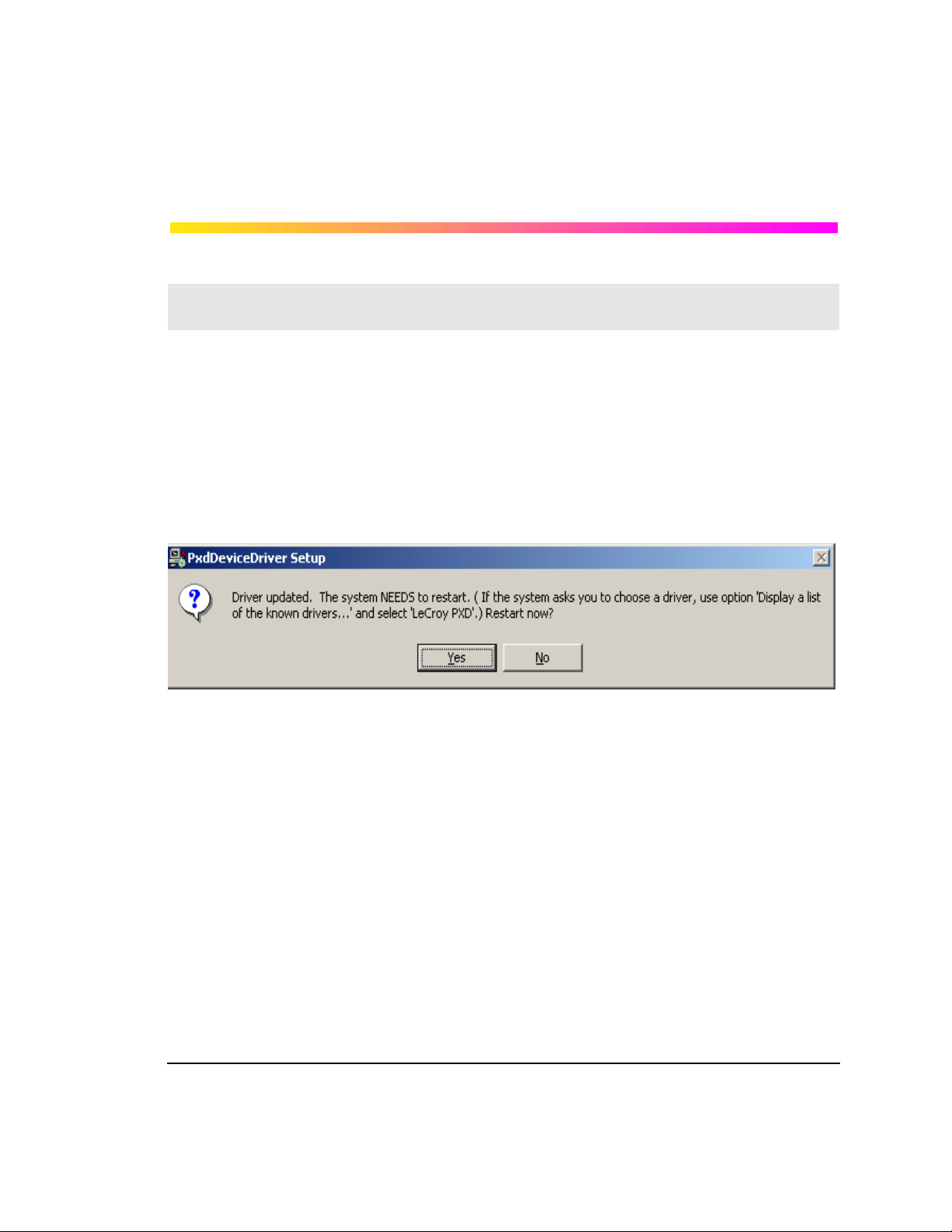

INSTALL PXD DEVICE DRIVER

Note: It is best to install the device driver with the Digitizer already installed in the

chassis.

The Installation process is divided into five parts.

I. Install the PXD Device Drivers onto the controller.

II. Turn Power off and install the PXD Module hardware into the PXI mainframe.

III. Repower and Run the Found New Hardware Wizard.

IV. Install the PXD IVI Application software.

V. Install the PXD IVI Driver. The following section will guide you step by step in this process.

• Run the PxdDeviceDriver.exe file from the PXD Series Driver sub-directory on the CD ROM.

The following dialog box will appear:

• Click No, then turn computer off and install Digitizer hardware.

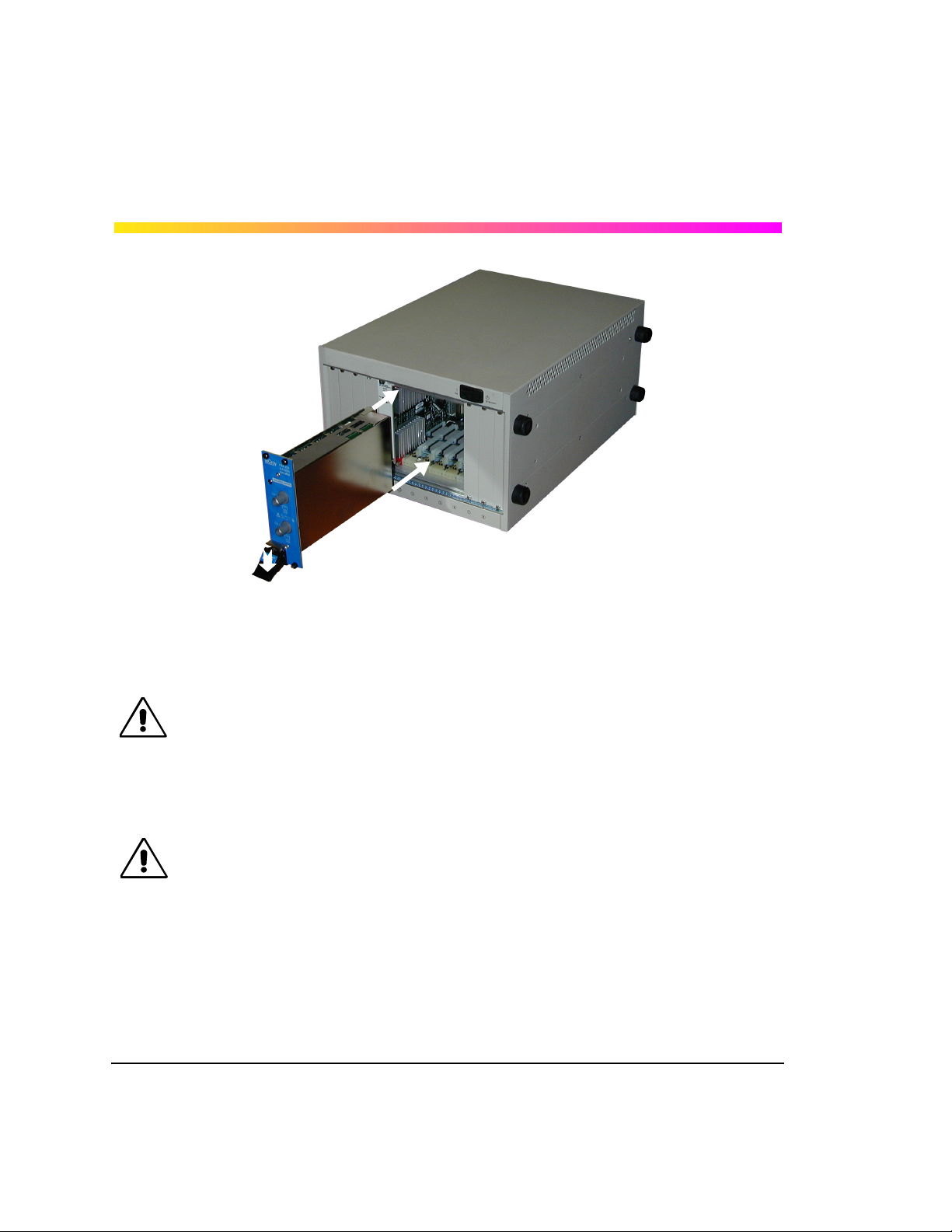

INSTALL THE PXI DIGITIZERS

• Shut down the instrument and install the Digitizer in the PXI chassis slot by first inserting the

Digitizer’s card edge into the front module guides (top and bottom). Slide the Digitizer to the

rear of the mainframe with the injector/ejector handle pushed down.

• When the Digitizer is securely in place, push up on the injector/ejector handle to fully seat the

Digitizer in the chassis.

• Secure the Digitizer to the front panel of the chassis with the mounting screws.

• Cover any open slots in the PXI chassis to ensure proper air flow.

901217-01 ISSUED: March 2003 7

Page 12

PXD Series Digitizer

• Power up the chassis. (If you are connecting to the chassis via an MXI-3 connection, power up

the computer after powering up the chassis.

CAUTION

Overheating will result if any slots in the PXI chassis remain open. Cover all open

slots to ensure proper air flow. Chassis fans should be at maximum speed. Chassis

cooling will vary from manufacturer to manufacturer. A minimum airflow of 5 cfm

through the PXD 212, 512, and 1021; and 15 cfm through the PXD 114, 214, 514, 522,

and 1022 to the Digitizer’s air inlet at a temperature between 0 °C and 40 °C must be

provided.

CAUTION

Static-sensitive parts. Proper handling, including a grounded wrist strap, should be

observed at all times.

8 ISSUED: March 2003 901217-01

Page 13

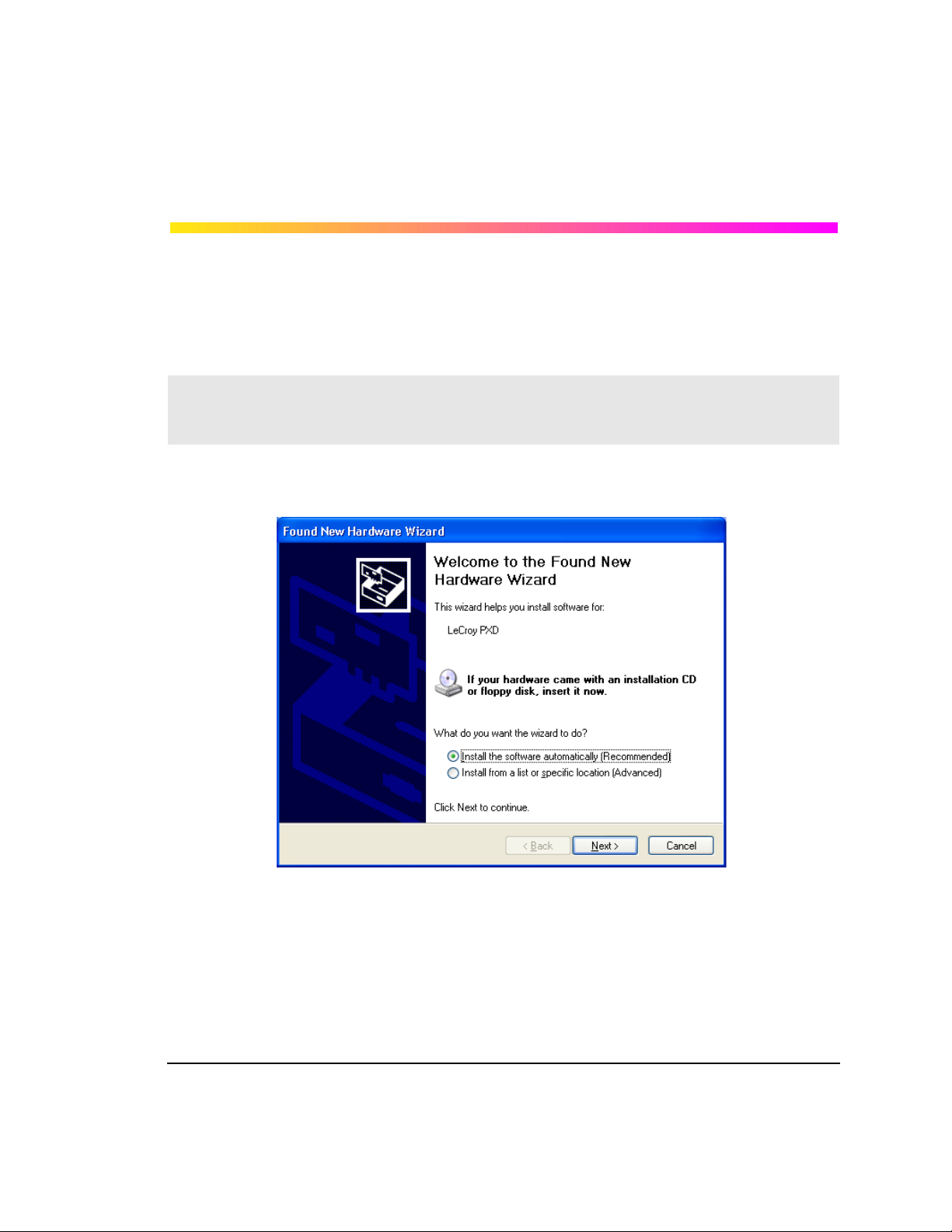

• Windows 2000 will recognize that you have a new PCI device installed and will also install the

device drivers automatically.

• Windows XP will recognize that you have a new PCI device installed, and will prompt you for

instructions on installing the device driver.

• After restart, you will see the "Found New Hardware" box, confirming that the hardware has

been recognized.

NOTE: Windows XP ad Win2000 users can confirm that the PXI Digitizer is properly

recognized by the OS by viewing the Device Manager. This can be found within the

"System" control panel option.

• Windows XP will start the New Hardware Wizard.

Click "Install the software automatically"

901217-01 ISSUED: March 2003 9

Page 14

PXD Series Digitizer

• Click on Next to finish the installation.

10 ISSUED: March 2003 901217-01

Page 15

INSTALL PXD IVI APPLICATION SOFTWARE

This software is intended to be a tool to test operation of the module, and for simple triggering and

viewing of signals.

Note: Before you install PXD IVI Application and Driver software, uninstall the previous

version using Windows Add/Remove programs.

Demo program will not run until installation of IVI Driver is complete. Complete the

next section before attempting to run application software.

• Run PXDIVIapplication.exe from the PXDIVI application subdirectory on the CD-ROM.

• Click on Next button to begin the installation.

901217-01 ISSUED: March 2003 11

Page 16

PXD Series Digitizer

• Enter Name and Organization information. Select option for single or multiple users. You must

have administrator rights to install the settings for all users.

• Click on the Next button.

12 ISSUED: March 2003 901217-01

Page 17

• Files for LeCroy PxiDigitizer IVI Application will be located in C:\ProgramFiles\LeCroy\

destination folder. To install into a different folder, click on Browse and select new folder

destination.

• Click on the Next button.

901217-01 ISSUED: March 2003 13

Page 18

PXD Series Digitizer

• Click on the Next button to install the application.

14 ISSUED: March 2003 901217-01

Page 19

• Click on the Finish button. Installation is complete.

901217-01 ISSUED: March 2003 15

Page 20

PXD Series Digitizer

INSTALL PXD IVI DRIVER

• Run PXDIVIdriver.exe from the PXDIVI driver subdirectory on the CD-ROM.

• Click on Next button to begin the installation.

16 ISSUED: March 2003 901217-01

Page 21

• Enter Name and Organization information. Select option for single or multiple users. You must

have administrator rights to install the settings for all users.

• Click on the Next button.

901217-01 ISSUED: March 2003 17

Page 22

PXD Series Digitizer

• Files for LeCroy PxiDigitizer IVI Driver are installed in the following folder. To install into a

different folder, click on Browse and select new folder destination.

• Click on the Next button.

18 ISSUED: March 2003 901217-01

Page 23

• Click Next to begin installation.

901217-01 ISSUED: March 2003 19

Page 24

PXD Series Digitizer

• Installation is complete. Run application program.

20 ISSUED: March 2003 901217-01

Page 25

INSTALL COMPLEMENTARY FILES ONTO YOUR HARD DRIVE (OPTIONAL)

In order to run the example programs provided, you have to generate a LabView driver from the

CVI driver:

1. Start LabView.

2. Select menu Import CVI Instrument Driver:

3. Select file LcPXD1xxx.fp in directory VXIpnp\winnt\LcPXD1xxx. If you have LabWindows/CVI

installed, this file is in directory C:\Program Files\National Instruments\MeasurementStudio\CVI\instr.

4. Select CVI driver DLL LcPXD1xxx_32.dll from VXIpnp\WINNT\bin.

901217-01 ISSUED: March 2003 21

Page 26

PXD Series Digitizer

5. Click OK

6. Open the example file provided (LcPXD1xxx Getting Started.vi) and start running:

7. Click the Exit button.

22 ISSUED: March 2003 901217-01

Page 27

8. Wait until execution is finished.

9. Exit from LabView.

§ § §

901217-01 ISSUED: March 2003 23

Page 28

PXD Series Digitizer

BLANK PAGE

24 ISSUED: March 2003 901217-01

Page 29

Operation

INTRODUCTION

This section provides information about the standard acquisition, triggering, and measurement

features of the PXD Series Digitizer. LeCroy PXD digitizers are IVI compliant which means that the

structure of commands for setting up, capturing, and reading out waveforms follows the structure

defined in Section 4 of the IVI Foundation specification (www.IVIfoundation.org). It is recommended that you review this section prior to programming the PXD modules. Detailed descriptions

of LeCroy commands are included in the Driver Help file.

ACQUISITION MODES

The Digitizer has three modes of operation: NORMAL, RIS (Random Interleaved Sampling), and

Sequence. These are defined as follows:

Normal

In Normal mode, the Digitizer will input the signals during a specified time window and create a

data array with the digitized data, which can be read out by the controller. The user programs the

number of points as well as the time window to be digitized on repetitive signals. LeCroy PXD Digitizers come with 256 kpoints of memory as standard. For storing longer single-shot signals, optimal memory of 4 Mpoints or 8 Mpoints/channel can be added. The maximum sample rate is 2 GS/

s, and will vary depending on the specific model and the time window setting.

RIS – For Higher Sample Rates

RIS (Random Interleaved Sampling) is an acquisition technique that allows effective sampling

rates higher than the maximum single-shot sampling rate. It is used on repetitive waveforms with a

stable trigger. The maximum effective Digitizer sampling rate of 50 GS/s can be achieved with RIS

by making 100 single-shot acquisitions at 500 MS/s. The bins thus acquired are positioned

approximately 20 ps apart. The process of acquiring these bins and satisfying the time constraint

is a random one. The relative time between ADC sampling instants and the event trigger provides

the necessary variation, measured by the timebase to 5 ps resolution.

The Digitizer requires multiple triggers to complete an acquisition. The number depends on the

sample rate: the higher the sample rate, the more triggers are required. It then interleaves these

segments to provide a waveform that is up to 50x faster than the single-shot sampling rate. However, the real-time interval over which the Digitizer collects the waveform data is much longer, and

depends on the trigger rate and the amount of interleaving required. The digitizer is capable of

acquiring approximately 40,000 RIS acquisitions per second.

901217-01 ISSUED: March 2003 25

Page 30

PXD Series Digitizer

Segment 1

Segment 2

Segment 3

Final capture

Sequence – Working With Segments

In sequence mode, the complete waveform consists of a number of fixed-size segments acquired

in single-shot mode. Select the number of segments to be captured, then select each segment

individually. Each trigger fills a new segment.

Sequence offers a number of unique capabilities. With it, dead time is limited between trigger

events for consecutive segments. The Digitizer can capture in fine detail complicated sequences

of events over large time intervals, while ignoring the uninteresting periods between the events.

Time measurements can be made between events on selected segments using the full precision

of the acquisition timebase.

Trigger time stamps of 1 ns resolution are given for each of the segments in the Text & Times Status menu. Each individual segment can be read out by the controller.

The Digitizer uses the sequence timebase setting to determine the capture duration of each segment: 10 x time/div. The digitizer uses this setting — with the desired number of segments, maximum segment length and total available memory — to determine the actual number of samples or

segments, and time or points.

26 ISSUED: March 2003 901217-01

Page 31

Operation

T

Segment 1

Segment 2

Segment 2

Trigger

Trigger

rigger

TRIGGER MODES

In all acquisition modes, capturing the signal requires an edge trigger or a trigger generated from

the controller. An edge trigger occurs when the trigger crosses the specified trigger level with the

specified slope. Trigger setup is IVI compliant and is shown in example programs on the PXD-CD.

PXD IVI CAPABILITY

Group Name Supported

Base Yes

Continuous Acquisition Yes

SampleMode (RIS) Yes

Average Acquisition Yes

Trigger Modifier AUTO and NORMAL Trigger

Interpolation No

TVTrigger No

RuntTrigger No

901217-01 ISSUED: March 2003 27

Page 32

PXD Series Digitizer

GlitchTrigger No

WidthTrigger No

AcLineTrigger No

WaveformMeasurement No

MinMax Waveform No

ProbeAutoSense No

AutoSetup No

For more information and for LeCroy specific extensions see the header file

c:\Vxipnp\WINNT\include\LcPXDIxxx.h, which contains all the instrument driver declarations.

28 ISSUED: March 2003 901217-01

Page 33

PXD SERIES DIGITIZER QUICK START APPLICATION SOFTWARE

Operation

The Quick Start Application software provides an efficient way to view and verify PXD module performance. The simple control panel allows for amplitude adjustment, memory depth and triggering,

and a simple logging function. It is intended as a verification tool to ensure that the module installation has been completed.

901217-01 ISSUED: March 2003 29

Page 34

PXD Series Digitizer

SOFT FRONT PANEL

The Digitizer Quick Start Application software has the following features for one to four channel

modules:

• Graphic display with independent vertical axis for each digitizer input channel

• Acquisition section including autosetup and reset

• Channels section with independent control of probe attenuation, Volts/Div, Offset,

Bandwidth limit, and coupling

• Timebase section including Time/Div, Delay, and acquisition type as well as indicators for

the number of points per acquisition and the sample rate

• Trigger section with source, coupling, slope, type, and level selectors

• Data Logger section to store waveforms to hard drive

Acquisition: The "Acquisition" indicator is green when data is being acquired and red when the

acquisition is stopped.

HINT: Typing values in the Offset fields is easier than using the knob.

CH1 and CH2: The channel 1 and channel 2 buttons are used to turn on and off channels 1 and 2.

The color of the buttons matches the color of the trace.

V/Div CH1 and CH2: Set the volts per division for each input independently by using the V/Div

arrows or by selecting a value from the V/Div field.

30 ISSUED: March 2003 901217-01

Page 35

Operation

Offset CH1 and CH2: Set the Offset for each input independently using the Offset knob or by typing a value in the Offset field. The Offset knob will change color depending on the channel

selected: yellow when channel 1 is selected and red when channel 2 is selected. These colors

also match the trace colors in the graphics display.

Bandwidth Limit CH1 and CH2: To suppress high frequency noise on waveforms, limit the bandwidth of the digitizer by selecting a 20 MHz or 200 MHz filter. This function smooths the displayed

waveform by blocking frequencies above the filter’s limit.

Coupling CH1 and CH2: Each channel of the digitizer is set to DC coupling by default so that AC

and DC signals appear on the display. Select AC coupling (in the Trigger control section) to view

the AC signal only. Clicking the switch control toggles the selection.

T/Div: The time per division is set by using the T/Div arrows or by selecting a value from the T/Div

field. The Digitizer automatically adapts itself to use the maximum sampling rate whenever the

timebase is changed.

Delay: Turn the Delay knob to adjust the horizontal position and the amount of pre-trigger, as

desired.

Number of Points: This is an indicator that displays the number of points in each acquisition. This

will vary automatically depending on the T/Div.

Sample Rate: This is an indicator that displays the sample rate for each acquisition. This will vary

automatically depending on the T/Div.

901217-01 ISSUED: March 2003 31

Page 36

PXD Series Digitizer

Source: The trigger source for the digitizer may be either of the input channels or the PXI Trigger

and Star Trigger lines on the PXI backplane.

Coupling: This sets the trigger coupling for the input channels. DC is used when all the signal

components (AC and DC) are coupled to the trigger circuit. When AC is selected, the signal is

capacitively coupled, DC levels are rejected, and frequencies below 50 Hz are attenuated.

Level: Defines the source voltage at which the trigger circuit will generate an event.

Slope: Determines the direction of the trigger voltage transition used to generate a particular trig-

ger event.

Modifier: In NORM mode the digitizer will acquire while there is a valid trigger. In AUTO mode the

trace will automatically be displayed regardless of a valid trigger. When a valid trigger is present in

Auto mode, the Digitizer will behave as if in Normal mode.

On/off: Turns datalogging on and off.

Directory: Sets the directory for storing waveforms. Entering a period sets the current directory of

the Quick-Start Demo; entering another value (e.g., "Test 1") creates a new folder called "Test1"

referenced from the current directory.

Filename: Sets prefix for the filename.

Index: An auto-incrementing index is appended to the filename. When the datalogger is turned on,

and the program is in Continuous Acquisition mode, each waveform will be stored.

USING THE PXD SERIES DIGITIZER IVI INSTRUMENT DRIVERS

The CD-ROM includes several example programs written in LabWindows/CVI using the PXD

Series IVI driver. Even if you are not using CVI, the ".c" files provide practical examples that will

help you learn how to program the Digitizer.

§ § §

32 ISSUED: March 2003 901217-01

Page 37

PXD SERIES DIGITIZER SPECIFICATIONS

ACQUISITION SYSTEM

Table 1. One and Two Channel Models

Model PXD512 PXD212 PXD522 PXD1022 PXD1021

Bandwidth 500 MHz 250 MHz 500 MHz 1 GHz 1 GHz

NOTE: Specifications are subject to

change without notice.

Maximum Single Shot

Sample Rate

Maximum Repetitive

Sample Rate

Channels 2 2 2 2 1

3U PXI Slots 2 2 3 3 2

Acquisition Memory

Standard

Acquisition Memory

Option 1

Acquisition Memory

Option 2

Single Shot Capture

Window

Repetitive Capture

Window

Sequential Mode Max.

Segments

Power Consumption 41 W 41 W 57 W 57 W 35 W

1 GS/s 1 GS/s 2 GS/s 2 GS/s 2 GS/s

50 GS/s 50 GS/s 50 GS/s 50 GS/s 50 GS/s

256k 256k 256k 256k 256k

4M 4M 4M 4M 4M

N/A N/A 8M 8M 8M

10 ns –

10,000 s

5 ns –

10µs

4096 4096 8192 8192 8192

10 ns –

10,000 s

5 ns –

10µs

10 ns –

10,000 s

5 ns – 10

µs

10 ns –

10,000 s

2 ns –

10µs

10 ns –

10,000 s

2 ns –

10µs

901217-01 ISSUED: March 2003 33

Page 38

PXD Series Digitizer

Model PDX514 PDX214 PDX114

Bandwidth 500 MHz 250 MHz 150 MHz

Table 2. Four Channel Models

Maximum Single Shot Sample

Rate

Maximum Repetitive Sample

Rate

Channels 4 4 4

3U PXI Slots 3 3 3

Acquisition Memory Standard 256k 256k 256k

Acquisition Memory Option 1 4M 4M 4M

Single Shot Capture Window

Repetitive Capture Window 5 ns – 10µs 5 ns – 10µs 5 ns – 10µs

Sequential Mode Max

Segments

Power Consumption Maximum 70 W 70 W 70 W

1 GS/s 1 GS/s 1 GS/s

50 GS/s 50 GS/s 50 GS/s

10 ns –

10,000s

4096 4096 4096

10 ns –

10,000s

10 ns –

10,000s

Table 3. Typical Input Current (Amps) for Different Modules

PXI Chassis

Voltage (V)

PXD114/214/

514 (A)

PXD522/1022

(A)

PXD212/512

(A)

PXD1021 (A)

5 7.3 6.6 4.2 3.86

3.3 5.8 4.4 3.7 3.0

12 0.28 0.14 0.11 0.08

-12 0.35 0.25 0.22 0.17

Bandwidth Limiter: 20 MHz and 200 MHz

Sensitivity: 40 mV to 8 V full scale range

Scale Factors – volts (calibrated): 0.04, 0.08, 0.16, 0.4, 0.8, 1.6, 4, 8 FSR

Full Scale Range: 8 major divisions

34 ISSUED: March 2003 901217-01

Page 39

Offset Range:

±1 V (40 mV to 792 mV FSR, 50 ohms only)

±10 V (800 mV to 8 V FSR, 50 ohms only)

±1 V (40 mV to 800 mV FSR, 1 Mohms only)

±20 V (816 mV to 8 V FSR, 1 Mohms only)

Variable Gain Range: 0.1 to 1.0 of full scale

Variable Gain Resolution: 0.1% of full scale

Input Coupling:

Zin = 50 ohms DC, GND

Zin = 1 Mohms AC, DC, GND

AC Coupled Lower Cutoff:

< 10 Hz, frequency -3 dB

Input Impedance:

Zin = 50 ohms ±1.5%

Zin = 1 Mohms ±1.5% || 16 ± 2 pF

DC Accuracy: ±(2% full scale + 1.6% offset setting + 1 mV) @ gain >= 80 mV FSR

Vertical Resolution: 8 bits

Maximum Input Voltage:

Zin = 50 ohms, 5 V

(including DC)

rms

Zin = 1 Mohms, 100 V (DC + pk AC, frequency <=5kHz)

Input Connector(s): BNC (grounded)

ACQUISITION MODES

Single Shot: For transient and repetitive signals: 1 GS/s for models 114, 214, 514, 212, 512; 2 GS/s for

models 1021, 1022, 522

Sampling period settable in 1-2-4 sequence.(e.g., PXD512 period: 1 ns/pt, 2 ns/pt, 4 ns/pt, etc.)

Random Interleaved Sampling (RIS): For repetitive signals: up to 50 GS/s

Sequence: Stores multiple events, each of them time stamped (1 ns resolution) in segmented acquisition

memory.

Minimum Segment Length: 256 samples

Maximum Segment Length: 1 million samples

TIMEBASE SYSTEM

Capture Window at Maximum Sample Rate: up to 4 ms

Clock Accuracy: 10 ppm

901217-01 ISSUED: March 2003 35

Page 40

PXD Series Digitizer

TRIGGER SYSTEM

Modes: Normal, Auto, Single, and Stop

Slope: Positive, Negative

Coupling: DC, AC, LFREJ, HFREJ

AC Cutoff (low freq.): 7.5 Hz (typical)

HFREJ, LFREJ Cutoff: 50 kHz typical (6 dB/octave)

TRIGGER DELAY

Pre-Trigger Recording: 0 –100% of horizontal full scale (adjustable in 1% increments)

Post-Trigger Delay: 0 –10,000 divisions (adjustable in 0.1 division increments)

Sources: All data channels, EXT (Slope, level, and coupling are unique for each source. PXI triggering

capabilities are described below.)

EXTERNAL TRIGGER

Range: ±0.5 V (± 2.5 V with Ext/5 selected)

Input Impedance: 50 ohms ±1.5%, 1 Mohms ±3% || 20 pF ±10%

Maximum Input:

Zin = 50 ohms, 5 V

Zin = 1 Mohms, 100 V (DC + pk AC, f <= 5 kHz)

Input Connector: BNC

Trigger Outputs: PXI (see below)

(including DC)

rms

MULTI-MODULE SYNCHRONIZATION

The PXD digitizers support PXI extensions to the PCI bus for the following backplane clock and trigger

capabilities:

• External clock input for module synchronization to the 10 MHz TTL clock provided by the PXI backplane

(PXI_CLK10).

• Trigger inputs to support an asynchronous low skew (1–5 ns) trigger source broadcast on the PXI star

trigger bus.

• Asynchronous trigger I/O to support a single-line broadcast on the PXI trigger bus. The trigger input may

come from an external source, or from a digitizer module. Digitizer modules provide a tri-stated output to

support this mode, with high impedance guaranteed on power-up.

Software Compatibility:

The PXD hardware is compatible with the following software environments:

Operating Systems: Windows 2000/XP

36 ISSUED: March 2003 901217-01

Page 41

Supported Drivers:

• IVI-Scope Driver

• LeCroy PXD Getting Started Application Program

• ActiveX Control

• LabView Driver

UPDATE RATE

Supports PCI Bus transfer rates up to 100 MB/s peak data rates.

GENERAL

Auto-Calibration: Ensures specified DC and timing accuracy.

Auto-Calibration Time: < 500 ms

Recommended Factory Calibration Interval: one year

Temperature

Operating: 0 to 40 °C when installed in a PXI chassis with a minimum airflow of 5 cfm (PXD 212, 512, 1021)

or 15 cfm (PXD 114, 214, 514, 522, 1022) provided to the air inlet of the Digitizer

Storage (Non-Op): -40 to +71°C

Humidity

Operating: 5 to 80% RH (non-condensing). Upper limit derates to 50% RH above 30 °C.

Storage (Non-op): 5 to 95% RH (non-condensing). Upper limit derates to 75% RH above 30 °C and 45% RH

above 40 °C.

Altitude

Operating: Up to 3,048 m (10,000 ft) at or below 25 °C

Storage (Non-op): Up to 12,192 m (40,000 ft)

Vibration

Operating: Random vibration, 0.31 g

Non-operating: Random vibration, 2.4 g

Functional Shock: 30 g

, half sine, 11 ms, 3 shocks (positive and negative) in each of 3 orthogonal axes,

peak

, 5 to 500 Hz, 15 minutes in each of 3 orthogonal axes

rms

, 5 to 500 Hz, 15 minutes in each of 3 orthogonal axes

rms

18 shocks total

Electromagnetic Compatibility: Conforms to EN 61326-1:1998 (Emissions and Immunity)

Safety: Conforms to EN 61010-1:2001 (Installation Category I, Pollution Degree 2)

Certifications: CE Approved

901217-01 ISSUED: March 2003 37

Page 42

PXD Series Digitizer

Mechanical Dimensions:

PXD512 and PXD212 occupy 2 3U PXI slots.

PXD514, PXD214 and PXD114 occupy 3 3U PXI slots.

Recommended Factory Calibration Interval: 1 year

Warranty: 1 year

SERVICE

LeCroy is committed to customer success, regardless of the number of LeCroy products owned. Call your

local service representative to discuss specific requirements.

We offer:

• Extended warranty packages

• Annual calibration maintenance

• Prompt, personalized warranty and nonwarranty repair at service offices

§ § §

38 ISSUED: March 2003 901217-01

Loading...

Loading...