Page 1

PXD 222 DIGITIZER

OPERATOR’S MANUAL

NOVEMBER 2001

Page 2

LeCroy Corporation

700 Chestnut Ridge Road

Chestnut Ridge, NY 10977-6499

Tel: (845) 578 6020, Fax: (845) 578 5985

Internet: www.lecroy.com

© 2001 by LeCroy Corporation. All rights reserved. Information in this publication supersedes all earlier

versions. Specifications subject to change.

LeCroy, ProBus and SMART Trigger are registered trademarks, and ActiveDSO, ScopeExplorer,

WaveAnalyzer and WavePro are trademarks, of LeCroy Corporation. Centronics is a registered trademark of

Data Computer Corp. Epson is a registered trademark of Epson America Inc. Mathcad is a registered

trademark of MATHSOFT Inc. MATLAB is a registered trademark of The MathWorks, Inc. Microsoft, MS and

Microsoft Access are registered trademarks, and Windows and NT trademarks, of Microsoft Corporation.

PowerPC is a registered trademark of IBM Microelectronics. DeskJet, ThinkJet, QuietJet, LaserJet, PaintJet,

HP 7470 and HP 7550 are registered trademarks of Hewlett-Packard Company.

PXD222-OM-E Rev A 1101

Page 3

Table of Contents

Table of Contents

First Things...First ................................................................................................1

WHEN YOUR DIGITIZER IS DELIVERED.................................................1

Check That You Have Everything .........................................................................1

Be Sure To Read This Warranty ...........................................................................1

Take Advantage Of Maintenance Agreements......................................................2

Obtain Assistance..................................................................................................2

Return a Product for Service or Repair..................................................................2

Stay Up-to-Date .....................................................................................................2

SAFETY INFORMATION ..................................................................3

Safety Symbols......................................................................................................3

Warnings ...............................................................................................................4

If Safety Features Are Impaired.............................................................................5

Care and Maintenance ..........................................................................................5

INSTALL AND POWER UP THE DIGITIZER.............................................6

Install NI Software Components ............................................................................6

Install LcPXD222 Instrument Driver.......................................................................7

Install the PXD 222 Digitizer..................................................................................9

Launch Measurement and Automation Explorer (MAX)......................................14

Install Quick-Start Application Software ...............................................................15

Copy Complementary Files onto Your Hard Drive (optional)...............................15

Install LcIVIScopeDemo (optional) ......................................................................16

Operation..............................................................................................................9

INTRODUCTION.......................................................................................17

A. Acquisition Modes...........................................................................................17

B. Run Modes ......................................................................................................20

C. Trigger Modes.................................................................................................20

D. PXD 222 Digitizer Waveform Measurements..................................................21

PXD 222 QUICK START APPLICATION SOFTWARE ............................22

Soft Front Panel ...................................................................................................22

USING THE PXD 222 DIGITIZER IVI INSTRUMENT DRIVERS .............26

PXD 222 Digitizer Specifications......................................................................27

VERTICAL SYSTEM.......................................................................27

PXD222-OM-E Rev A ISSUED: November 2001 iii

Page 4

PXD 222 Digitizer

HORIZONTAL SYSTEM...........................................................................27

TRIGGER..................................................................................................28

PHYSICAL DIMENSIONS ........................................................................30

POWER REQUIREMENTS......................................................................30

ENVIRONMENTAL CONDITIONS...........................................................30

SAFETY ..........................................................................................31

CERTIFICATIONS ..........................................................................33

iv ISSUED: November 2001 PXD222-OM-E Rev A

Page 5

First Things...First

AFirst Things...First

WHEN YOUR DIGITIZER IS DELIVERED

Check That You Have Everything

Verify that all items on the packing list or invoice copy have been shipped to you. (The items are

also listed below.) Contact your nearest LeCroy customer service center or national distributor if

anything is missing or damaged. If there is something missing or damaged, and you do not contact

us immediately, we cannot be responsible for replacement.

The following is shipped with the standard PXD 222 Digitizer:

• Performance or Calibration Certificate

• Quick Reference Guide

• CD ROM

NOTE: The warranty below

replaces all other warranties,

expressed or implied, including

but not limited to any implied

warranty of merchantability, fitness, or adequacy for any particular purpose or use. LeCroy

shall not be liable for any special, incidental, or consequential damages, whether in

contract or otherwise. The customer is responsible for the

transportation and insurance

charges for the return of products to the service facility.

LeCroy will return all products

under warranty with transport

prepaid.

Be Sure To Read This Warranty

The PXD 222 Digitizer is warranted for normal use and operation, within specifications, for

a period of one year from shipment. LeCroy will either repair or, at our option, replace any

product returned to one of our authorized service centers within this period. However, in

order to do this we must first examine the product and find that it is defective due to workmanship or materials and not due to misuse, neglect, accident, or abnormal conditions or

operation.

Spare and replacement parts, and repairs, all have a 90-day warranty.

The digitizer’s firmware has been thoroughly tested and is presumed to be functional. Neverthe-

less, it is supplied without warranty of any kind covering detailed performance. Products not made

by LeCroy are covered solely by the warranty of the original equipment manufacturer.

PXD222-OM-E Rev A ISSUED: November 2001 1

Page 6

PXD 222 Digitizer

Take Advantage Of Maintenance Agreements

We offer a variety of services under the heading of Maintenance Agreements. These give

extended warranty and allow you to budget maintenance costs after the initial one-year warranty

has expired. Installation, training, enhancements, and on-site repairs — among other services —

are available through special supplemental support agreements. Inquire at your LeCroy customer

service center or national distributor.

Obtain Assistance

Help with installation, calibration, and the use of your PXD 222 Digitizer scope in a range of applications is also available from your customer service center.

Return a Product for Service or Repair

If you do need to return a LeCroy product, identify it by its model

and serial numbers. Describe the defect or failure, and provide your

name and contact number.

For factory returns, use a Return Authorization Number (RAN),

obtainable from customer service. Attach it so that it can be clearly

seen on the outside of the shipping package to ensure rapid forwarding within LeCroy.

NOTE: If you need to return

your digitizer, use the original shipping carton. If this

is not possible, the carton

used should be rigid. The

digitizer should be packed

so that it is surrounded by a

minimum of four inches

(10cm) of shock absorbent

material.

Return those products requiring only maintenance to your customer

service center.

Within the warranty period, transportation charges to the factory will be your responsibility, while

products under warranty will be returned to you with transport prepaid by LeCroy. Outside the warranty period, you will have to provide us with a purchase order number before the work can be

done. You will be billed for parts and labor related to the repair work, as well as for shipping.

You should prepay return shipments. LeCroy cannot accept COD (Cash On Delivery) or Collect

Return shipments. We recommend using air freight.

Stay Up-to-Date

To maintain your PXD 222 Digitizer’s performance within specifications, have us calibrate it at

least once a year. LeCroy offers state-of-the-art technology by continually refining and improving

the instrument’s capabilities and operation. We frequently update both firmware and software during service, free of charge during warranty.

2 ISSUED: November 2001 PXD222-OM-E Rev A

Page 7

First Things...First

SAFETY INFORMATION

Safety Symbols

Where the following symbols appear on the PXD 222 Digitizer’s front or rear covers, or in this

manual, they alert you to important safety considerations.

WARNING Incorrect operation or failure to heed warnings may result in death or serious

injury. If a WARNING is indicated, do not proceed until its conditions are

understood and met.

CAUTION Incorrect operation or failure to heed cautions may result in injury or damage

to equipment. If a CAUTION is indicated, do not proceed until its conditions

are understood and met.

Refer to accompanying documents (for safety related information).

See elsewhere in this manual whenever this symbol is present, as indicated

in the Table of Contents.

Earth (Ground) Terminal

PXD222-OM-E Rev A ISSUED: November 2001 3

Page 8

PXD 222 Digitizer

Warnings

WARNING

To avoid electrical shock or fire if the digitizer input is connected to more that 42 V peak

(30 V rms) or on circuits of more than 4800 VA:

• Use only insulated voltage probes, test leads, and adapters.

• Before use, inspect voltage probes, test leads, and accessories for mechanical

damage and replace when damaged.

• Remove all probes, test leads, and accessories that are not in use.

• Do not connect the ground spring to voltages higher than 42 V peak (30 V rms) from

earth ground.

• When measuring in a CAT II environment, do not apply to any input voltages that differ

by more than 300 V from earth ground.

• When measuring in a CAT II environment, do not apply to the isolated inputs voltages

that differ by more than 300 V from each other.

• Do not apply input voltages above the rating of the instrument. Use caution when

using 1:1 test leads because the probe tip voltage will be directly transmitted to the

test tool.

• Do not use exposed metal BNC or banana plug connectors.

• Do not insert metal objects into connectors.

• Before connecting any input voltages, the unit must be properly installed in the PXI

rack.

• Disconnect the applied voltage(s) before disconnecting probes, BNC leads, test leads,

or accessories.

• Always use the digitizer only in the manner specified

Voltage ratings mentioned in the warnings are given as limits for "working voltage." They represent

VAC rms (50–60 Hz) for AC sine wave applications and as VDC for DC applications.

Overvoltage Category II refers to local distribution level, which is applicable to appliances and portable equipment.

The terms "isolated" and "electrically floating" are used in this manual to indicate a measurement

in which the digitizer input BNC or banana jack is connected to a voltage different from earth

ground.

The isolated input connectors have no exposed metal and are fully insulated to protect against

electrical shock.

4 ISSUED: November 2001 PXD222-OM-E Rev A

Page 9

First Things...First

The BNC connectors can be independently connected to a voltage above earth ground for isolated

(electrically floating) measurements and are rated up to 300 V rms (CAT II) above earth ground.

If Safety Features are Impaired

Whenever it is likely that safety has been impaired, the digitizer must be shut down, the PXI chassis disconnected from the line power, and the digitizer removed from the PXI chassis. The matter

should then be referred to qualified personnel. Safety is likely to be impaired if, for example, the

digitizer fails to perform the intended measurements or shows visible damage. Before use, inspect

the test leads for mechanical damage and replace damaged test leads!

WARNING

Use of the digitizer in a manner not specified may impair the protection provided by the

equipment.

Care and Maintenance

The exterior of the digitizer should be cleaned only with a soft cloth moistened with water or isopropyl alcohol.

The use of abrasive agents, strong detergents, or other solvents may damage the probe.

Ensure that the input receptacles are free of debris before inserting connection accessories.

All repair and maintenance should be referred to qualified service personnel.

Do not use the digitizer if any part is damaged.

PXD222-OM-E Rev A ISSUED: November 2001 5

Page 10

PXD 222 Digitizer

INSTALL AND POWER UP THE DIGITIZER

Prior to inserting the PXD 222 Digitizer into your chassis, you should install the necessary

software components on your system. To use the PXD 222 IVI driver, you will need to install the

following:

• IVI Engine (v1.65 or greater)

• NI-VISA (v2.5 Runtime version)

• PXD 222 IVI Instrument Driver

To run examples provided on the PXD 222 CDROM (including the Quick-Start demo and LabWindows™/CVI Getting Started Examples) you should also install:

• Measurement and Automation Explorer (included with NI-DAQ™ 6.8.1)

• LabWindows™/CVI Run-time Engine (included with the Quick-Start demo installation)

All of these components are included on the CDROM. Use the following instructions to install

these components on any Windows operating system in order to run the LeCroy Quick Start Demo

and Example programs.

Install NI Software Components

Install the following NI software components.1 For detailed information about installing this software, please visit the National Instruments Web site, http://www.ni.com and search for NI-DAQ™

6.8.1 in their Downloads section

1. Install NI-DAQ™ version 6.8.1

Installing this software will also install National Instrument’s Measurement and Automation

Explorer (MAX). We do not suggest using NI-DAQ™ 6.9.2 because it includes a bug that can

prevent recognition of the PXD 222 and other PXI instruments. After installation, confirm that

you have a MAX icon on your desktop. According to the “About Max…” dialog box, the MAX

version should be version 2.0.3.17.

2. Install NI-VISA Run-time version 2.5

Installing this software will also install the LabWindows™/CVI Run-Time Engine, which is a

necessary component.

3. Install IVI Engine 1.8.3

The IVI Engine software is necessary when you are using IVI drivers. Visit http://www.ni.com/

ivi and http://www.ivifoundation.org for more information about the IVI standard.

1. Each component is protected by copyright © 2001 by National Instruments Corporation, all rights reserved.

6 ISSUED: November 2001 PXD222-OM-E Rev A

Page 11

First Things...First

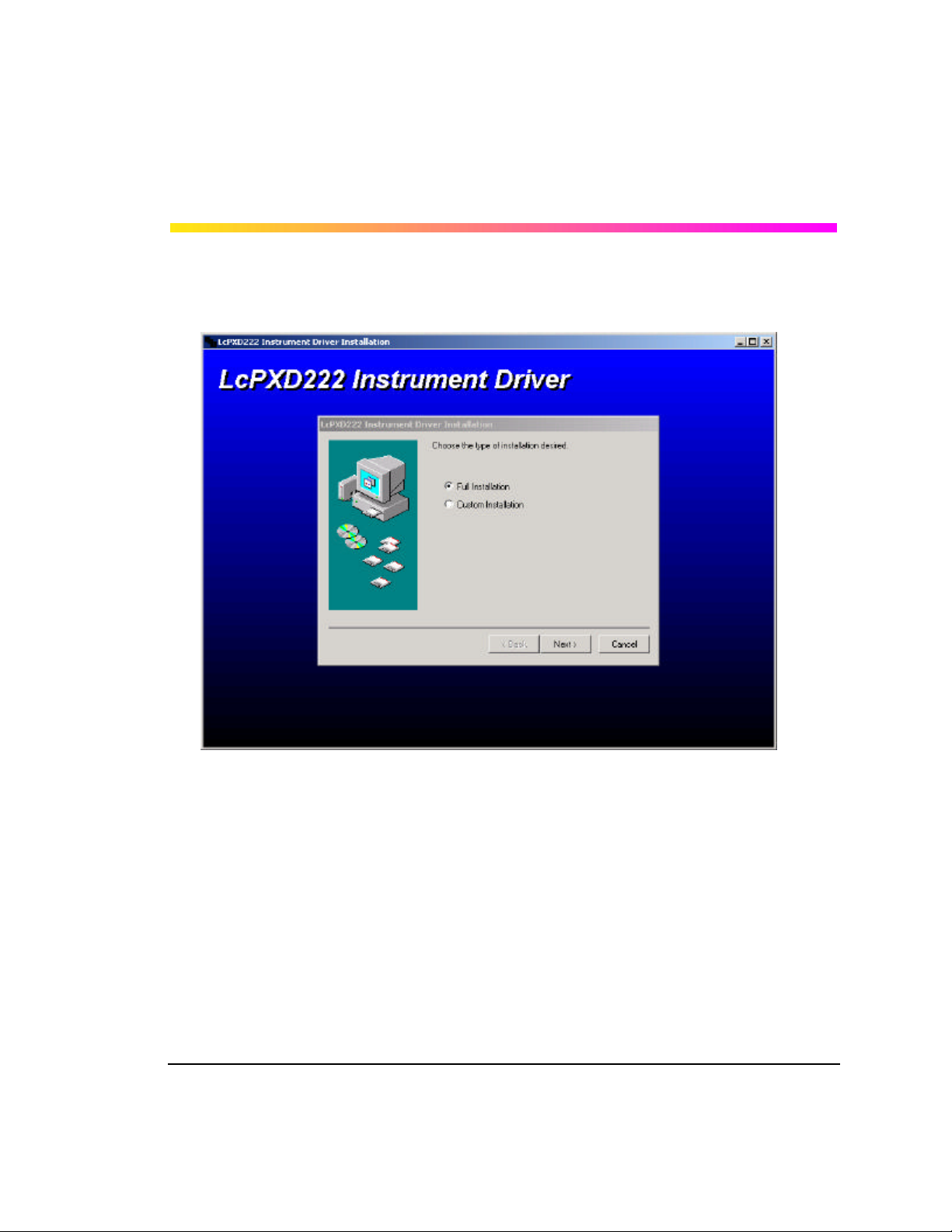

Install LcPXD222 Instrument Driver

1. Run the setup.exe file from the PXD 222 Instrument Driver directory on the CDROM. The fol-

lowing screen appears:

PXD222-OM-E Rev A ISSUED: November 2001 7

Page 12

PXD 222 Digitizer

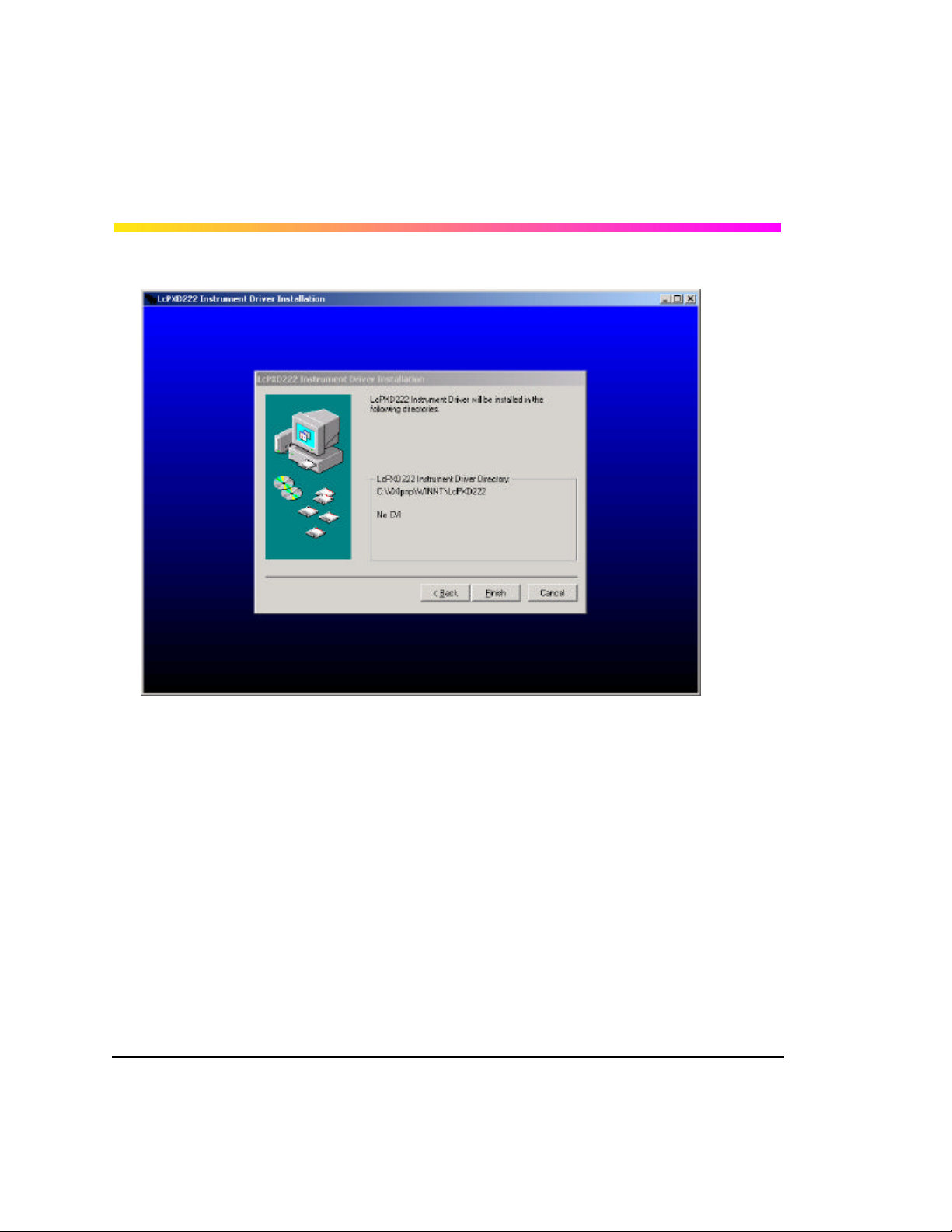

2. Full Installation is the suggested option. After you select OK, the following screen appears:

3. If Labwindows™/CVI is loaded on your computer, the installation program will put the driver

files within the standard CVI directory structure.

4. Click Finish to complete the Instrument Driver Installation. You are now ready to proceed with

the installation of the PXD 222 Digitizer.

8 ISSUED: November 2001 PXD222-OM-E Rev A

Page 13

First Things...First

Install the PXD 222 Digitizer

1. Shut down the instrument and install the digitizer in the PXI chassis slot by first inserting the

digitizer’s card edge into the front module guides (top and bottom). Slide the digitizer to the

rear of the mainframe with the injector/ejector handle pushed down.

2. When you begin to feel resistance, push up on the injector/ejector handle to fully seat the digitizer in the chassis.

3. Secure the digitizer to the front panel of the chassis with the mounting screws.

4. Cover any open slots in the PXI chassis to ensure proper air flow.

5. Power up the chassis. (If you are connecting to the chassis via an MXI-3 connection, power up

the computer after powering up the chassis.

CAUTION

Overheating will result if any slots in the PXI chassis remain open. Cover all open slots to

ensure proper air flow.

PXD222-OM-E Rev A ISSUED: November 2001 9

Page 14

PXD 222 Digitizer

6. Windows 9x, Win2000, and NT5.0 will recognize that you have a new PCI device installed,

and will prompt you for instructions on installing the device driver. (NT4.0 users should follow

the procedure described below). Choose to search manually for the device driver for your

operating system; it can be found on the CDROM, within a subfolder under “PXD 222 Device

Drivers.” When prompted, navigate to the folder for your operating system. Windows will install

the device driver, and the PXD 222 should at this point be visible in the Device Manager

screen for your operating system. For Windows9x users, you will see the following sequence

of dialog boxes.

10 ISSUED: November 2001 PXD222-OM-E Rev A

Page 15

First Things...First

PXD222-OM-E Rev A ISSUED: November 2001 11

Page 16

PXD 222 Digitizer

12 ISSUED: November 2001 PXD222-OM-E Rev A

Page 17

First Things...First

7. Windows 9x, NT5, and Win2000 users can confirm that the PXD 222 Digitizer is properly recognized by the OS by viewing the Device Manager. This can be found within the "System"

control panel option.

8. Windows NT4.0 Users: Copy the file “PXD222 Device Drivers\winNt4.0\LcPXD222_NT4.inf” to

the WinNT\inf directory. Right-click on the file, and select "Install” to install the driver.

PXD222-OM-E Rev A ISSUED: November 2001 13

Page 18

PXD 222 Digitizer

Launch Measurement and Automation Explorer (MAX)

1. Launch Measurement and Automation Explorer, and refresh the device list by pressing F5.

2. If the PXD 222 Digitizer is not found, or there is no “PXI System” list within the “Device and

Interfaces” folder, select “Update MAX driver support…” from the Tools menu.

3. Reboot when prompted, launch MAX, and refresh again by pressing F5. The PXD 222 Digitizer will now appear in the list.

Note: the string “PXI0::19::INSTR” in the illustration below is the VISA Resource Name MAX

has assigned to the PXD 222 Digitizer. The actual name assigned will vary based on the PCI

bus number and slot where the PXD 222 Digitizer is installed.

Measurement and Automation Explorer with PXD 222 Digitizer recognized

14 ISSUED: November 2001 PXD222-OM-E Rev A

Page 19

First Things...First

Install Quick-Start Application Software

This software is intended to be a tool for you to test operation of the module, and for simple triggering and viewing of signals. This application is described in the “Operation” section of this manual.

Copy Complementary Files onto Your Hard Drive (optional)

These files include the Getting Started LabWindows™/CVI example programs, and the driver help

files for CVI and VisualBasic.

PXD222-OM-E Rev A ISSUED: November 2001 15

Page 20

PXD 222 Digitizer

Install LcIVIScopeDemo (optional)

This LcIVIScopeDemo program illustrates the use of the Basic IVI Scope Class Drivers to control

the PXD 222 Digitizer. To use this demo, you will need to install the BICDSetup.exe installation

program provided on the CD-ROM (also currently available from National Instruments at no

charge). Then you will need to create a new “IVI Instruments” setup in MAX using the Logical

Names wizard. This process modifies the IVI.INI file; examples of the file for Win98 and Win2000

systems are provided on the CD-ROM. Make a backup of your existing IVI.INI file and copy the

example file into the VXIPNP/niivi directory. Perform a Refresh (F5) in MAX to see the new IVI

Instrument setup.

Prior to running the IVIScope demo program, make sure that the link to the PXD 222 DLL is correct. Open MAX, and right-click on the LcPXD 222 Digitizer selection under “IVI Instruments ?

Instrument Drivers.” This will open up the properties window for the driver. Verify that the “File”

selection is set to the LcPXD222_32.dll file. (The parser in MAX may not have read the directory

structure accurately.) Click “Browse” and navigate to the location of the DLL on your system. Most

installations will place this file within the VXIPNP/Win**/Bin directory path, where “**” is either “95”

or “NT”.

Once the set-up is correct, you can use the IVIScope demo program. This program is similar to the

Quick-Start Demo but uses the basic IVI class driver subroutine names. For more information

about the IVI architecture and IVI class drivers, visit http://www.ni.com/ivi.

§ § §

16 ISSUED: November 2001 PXD222-OM-E Rev A

Page 21

Operation

AOperation

INTRODUCTION

This section is intended to give you an understanding of the standard acquisition, triggering, and

measurement features of the PXD 222 Digitizer. Detailed descriptions of how to operate the

PXD222 Digitizer can be found in the Driver Help file.

A. Acquisition Modes

The PXD 222 Digitizer has two modes of operation NORMAL and MIN/MAX. These are defined as

follows:

NORMAL: In Normal mode, the PXD 222 Digitizer operates as a typical digitizer. The module will

digitize the input signals during a specified time window and create a data array with the digitized

data that can be read out by the controller. The user programs the number of points (maximum of

1000) as well as the time window to be digitized. The maximum sample rate is 2.5 GS/s, and will

vary depending on the time window setting. Table 1 gives the sample rates that are achieved.

MIN/MAX: There are two MIN/MAX modes, which are referred to as Glitch Capture and Scope

Record. In these modes, the PXD 222 Digitizer outputs two arrays; a MIN array with the minimum

values detected during each sample interval, and a MAX array with the maximum value detected

during each sample interval. Here’s how it works. In MIN/MAX mode, the time window is divided

into sampling intervals. During each interval, the digitizer oversamples the input at high speed (see

tables 2 and 3 on the following pages) and stores the MIN and MAX values in data arrays. This

technique allows you to detect and record glitches in the waveform that would not be found if only

1 sample were taken during each sampling interval. The Acquisition type is programmed by

means of the function LcPXD222_ConfigureAcquisitionType. (Note: This mode is sometimes

also referred to as a Peak Detect mode.)

When in Min/Max mode, and for time windows of 10 seconds or less, the digitizer is in Glitch Capture Mode, and will record MIN/MAX arrays of roughly 255 points. For time ranges of 11 seconds

and higher, the digitizer is in Scope Record Mode, and will store min-max arrays of roughly 27kpts.

Understanding the difference between Normal and MIN/MAX modes

Take an example where the time window is set to 1 ms. In Normal mode, the time between samples would be 1 µs (1 ms/1000 = 1 µs), corresponding to a sample rate of 1 MS/s because exactly

one sample is acquired per sample interval in this mode.

When setting the time window to 1 ms in MIN/MAX mode, the sampling interval is approximately

4 µs. This is roughly 4X longer than the corresponding value in Normal mode because 255 points

are stored instead of 1000. The PXD 222 Digitizer, however does not take only 1 sample in this 4

µs time interval, but instead samples at the higher speed of 20 MS/s. Of the 80 samples that are

taken (20MS/s * 4 µs = 80), the min and max points are retained. This is done for each of the 255

time intervals to create the Min and Max data arrays.

PXD222-OM-E Rev A ISSUED: November 2001 17

Page 22

PXD 222 Digitizer

Table 1: Normal Mode Time Windows, Intervals, and Sample Rates

Time Window Sampling Time

Interval for Each

Point

100 ns 400 ps 2.5 GS/s 250

200 ns 400 ps 2.5 GS/s 500

500 ns 2 ns 500 MS/s 250

1 µs 2 ns 500 MS/s 500

2 µs 2 ns 500 MS/s 1000

5 µs 10 ns 100 MS/s 500

10 µs 10 ns 100 MS/s 1000

20 µs 20 ns 50 MS/s 1000

50 µs 50 ns 20 MS/s 1000

100 µs 200 ns 5 MS/s 500

200 µs 200 ns 5 MS/s 1000

500 µs 500 ns 2 MS/s 1000

1 ms 1 µs 1 MS/s 1000

2 ms 2 µs 500 kS/s 1000

5 ms 5 µs 200 kS/s 1000

10 ms 10 µs 100 kS/s 1000

20 ms 20 µs 50 kS/s 1000

50 ms 50 µs 20 kS/s 1000

100 ms 100 µs 10 kS/s 1000

200 ms 200 µs 5 kS/s 1000

500 ms 500 µs 2 kS/s 1000

1 s 1 ms 1 kS/s 1000

2 s 2 ms 500 S/s 1000

5 s 5 ms 200 S/s 1000

10 s 10 ms 100 S/s 1000

Real Time

Sampling Rate

Nominal # of

Samples

a

a. # of points will vary slightly from the nominal value

18 ISSUED: November 2001 PXD222-OM-E Rev A

Page 23

Operation

Table 2: Glitch Capture Mode Time Windows, Intervals, and Sample Rates

Time Window Sampling Time

100 ns 400 ps 2.5 GS/s

200 ns 800 ps 2.5 GS/s

500 ns 2 ns 2.5 GS/s

1 µs 4 ns 2 GS/s

2 µs 8 ns 1 GS/s

5 µs 20 ns 200 MS/s

10 µs 40 ns 100 MS/s

20 µs 80 ns 50 MS/s

50 µs 200 ns 20 MS/s

100 µs 400 ns 20 MS/s

200 µs 800 ns 20 MS/s

500 µs 2 µs 20 MS/s

1 ms 4 µs 20 MS/s

2 ms 8 µs 20 MS/s

5 ms 20 µs 20 MS/s

10 ms 40 µs 20 MS/s

20 ms 80 µs 20 MS/s

50 ms 200 µs 20 MS/s

100 ms 400 µs 20 MS/s

200 ms 800 µs 20 MS/s

500 ms 2 ms 20 MS/s

1 s 4 ms 20 MS/s

2 s 8 ms 20 MS/s

5 s 20 ms 20 MS/s

10 s 40 ms 20 MS/s

Interval for Each

Point

Sampling Rate

Real Time

a

a. Waveform is oversampled at the real time sampling rate. Within

each time interval, the minimum and maximum values are

stored. A total of roughly 27 kpts are stored in the MIN and MAX

arrays.

PXD222-OM-E Rev A ISSUED: November 2001 19

Page 24

PXD 222 Digitizer

Table 3: Scope Record Mode Time Windows, Intervals, and Sample Rates

Time Window Sampling Time Interval

for Each Point

11 s 400 µs 20 MS/s

22 s 800 µs 20 MS/s

55 s 2 ms 20 MS/s

110 s 4 ms 20 MS/s

220 s 8 ms 20 MS/s

9 min 20 ms 20 MS/s

18 min 40 ms 20 MS/s

36 min 80 ms 20 MS/s

90 min 200 ms 20 MS/s

3 h 400 ms 20 MS/s

6 h 800 ms 20 MS/s

9 h 1200 ms 20 MS/s

18 h 2400 ms 20 MS/s

36 h 4800 ms 4 MS/s

a. Waveform is oversampled at the real time sampling rate. Within each time

interval, the minimum and maximum values are stored.

Real Time Sampling

Rate

a

B. Run Modes

The digitizer can be set to run in either Continuous or Single-shot mode. This is done through

the function LcPXD222_ConfigureInitiateContinuous.

C. Trigger Modes

The PXD 222 Digitizer supports the following trigger types: EDGE, GLITCH, WIDTH, TV, and

IMMEDIATE.

EDGE: An edge trigger occurs when the trigger signal crosses the specified trigger level with the

specified slope. The trigger level and slope are configured with the function

LcPXD222_ConfigureEdgeTriggerSource.

GLITCH: A glitch trigger occurs when the trigger signal has a pulse width that is less than the

glitch width. The trigger does not actually occur until the edge of the pulse that corresponds to the

specified glitch width and polarity crosses the trigger level. The trigger level is configured with the

function LcPXD222_ConfigureGlitchTriggerSource .

20 ISSUED: November 2001 PXD222-OM-E Rev A

Page 25

Operation

WIDTH: A width trigger occurs when the oscilloscope detects a positive or negative pulse width

between or, optionally, outside the width thresholds. The trigger does not actually occur until the

edge of a pulse that corresponds to the specified width thresholds and polarity crosses the trigger

level. The width thresholds, whether to trigger on pulse widths that are within or outside the width

thresholds, the polarity of the pulse, and the trigger level are configured with the function

LcPXD222_ConfigureWidthTriggerSource .

TV: The PXD 222 Digitizer can trigger on NTCS, PAL and SECAM video signals. The TV signal

type, the field and line number on which to trigger, and the signal polarity are configured with the

function LcPXD222_ConfigureTVTriggerSource .

IMMEDIATE: In this mode, the oscilloscope does not wait for trigger event and instead immediately begins the digitization process.

D. PXD 222 DIGITIZER WAVEFORM MEASUREMENTS

The PXD 222 Digitizer performs the following waveform measurements:

Mean Voltage LCPXD222_VAL_VOLTAGE_AVERAGE

RMS Voltage (AC) LCPXD222_VAL_VOLTAGE_RMS

True RMS Voltage (AC+DC) LCPXD222_VAL_VOLTAGE_TRUE_RMS

Peak to Peak voltage LCPXD222_VAL_VOLTAGE_PEAK_TO_PEAK

Maximum Peak voltage LCPXD222_VAL_VOLTAGE_MAX

Minimum Peak voltage LCPXD222_VAL_VOLTAGE_MIN

Neg Duty Cycle percentage LCPXD222_VAL_DUTY_CYCLE_NEG

Pos Duty Cycle percentage LCPXD222_VAL_DUTY_CYCLE_POS

Frequency LCPXD222_VAL_FREQUENCY

Neg Pulse Width LCPXD222_VAL_WIDTH_NEG

Pos Pulse Width LCPXD222_VAL_WIDTH_POS

Phase Difference LCPXD222_VAL_PHASE

To read out a waveform measurement, use the LcPXD222_ReadWaveformMeasurement func-

tion. To read back both the measurement and the waveform, call the function.

LcPXD222_FetchWaveform after calling LcPXD222_ReadWaveformMeasurement.

PXD222-OM-E Rev A ISSUED: November 2001 21

Page 26

PXD 222 Digitizer

PXD 222 DIGITIZER QUICK START APPLICATION SOFTWARE

Soft Front Panel

The PXD 222 Digitizer Quick Start Application software has the following features:

• Graphic Display with independent vertical axis for each digitizer input channel

• Acquisition section including autosetup and reset

• Channels section with independent control of probe attenuation, Volts/Div, Offset,

Bandwidth limit, and coupling

• Timebase section including Time/Div, Delay and acquisition type as well as indicators for

the number of points per acquisition and the sample rate

• Trigger section with source, coupling, slope, type, and level selectors

• Data Logger section

22 ISSUED: November 2001 PXD222-OM-E Rev A

Page 27

Operation

Acquisition: The "Acquisition" indicator is green when data is being acquired and red when the

acquisition is stopped.

AutoSetup: The AutoSetup feature lets the digitizer display complex, unknown signals automatically. This function optimizes the position, range, time base, and triggering.

Reset: The Reset feature will reset the PXD 222 Digitizer hardware and the software application

to a default state.

Hint: Typing values is easier that using the knob.

En CH1 and En CH2: The enable channel 1 and enable channel 2 buttons are used to turn on and

off channels 1 and 2 respectively. The color of the buttons matches the color of the trace.

CH1 and CH2 Probes: The BNC inputs to the digitizer do not include automatic probe sensing.

The CH1 and CH2 Probe switch should be set to 10 when a 10:1 probe is connected to the channel input, but it should be set to 1 when there is a direct connection.

V/Div. CH1 and CH2: Set the volts per division for each input independently by using the V/Div

knob or by typing a value in the V/Div control box. The V/Div knob will change color depending on

the channel selected: yellow when channel 1 is selected and red when channel 2 is selected.

These colors also match the trace colors in the graphic display.

PXD222-OM-E Rev A ISSUED: November 2001 23

Page 28

PXD 222 Digitizer

Offset CH1 and CH2: Set the Offset for each input independently using the Offset knob or by typing a value in the Offset control box. The Offset knob will change color depending on the channel

selected: yellow when channel 1 is selected and red when channel 2 is selected. These colors

also match the trace colors in the graphics display.

Bandwidth Limit CH1 and CH2: To suppress high frequency noise on waveforms, you can limit

the bandwidth of the digitizer by selecting a 10 kHz or 20 MHz filter. This function smooths the displayed waveform by blocking frequencies above the filter’s limit.

Coupling CH1 and CH2: Each channel of the digitizer is set to DC coupled by default so that AC

and DC voltages appear on the display. Select AC coupling when you wish to observe a small sig-

nal that rides on a DC signal. Clicking the switch control toggles the selection.

T/Div: The time per division is set by using the T/Div knob or by typing a value in the T/Div control

box. The digitizer automatically adapts itself to use the maximum sampling rate whenever the

timebase is changed.

Delay: Turn the Delay knob to adjust the horizontal position and the amount of pre-trigger, as

desired.

Acquisition Type: In NORMAL type, each acquisition is a fixed number of points depending on

the timebase; and the time between points is the inverse of the sample rate. In Mn-Max type an

oversampling technique is used to detect peaks. This acquisition type is useful for detecting

glitches on slow timebase settings. See the Operation chapter for more information.

Number of Points: This is an indicator that displays the number of points in each acquisition. This

will vary automatically depending on the T/Div and Acquisition type.

Sample Rate: This is an indicator that displays the sample rate for each acquisition. This will vary

automatically depending on the T/Div and Acquisition type.

24 ISSUED: November 2001 PXD222-OM-E Rev A

Page 29

Operation

Source: The trigger source for the digitizer may be either of the input channels or the PXI Trigger

and Star Trigger lines on the PXI backplane.

Coupling: This sets the trigger coupling for the input channels. DC is used when all the signal frequency components are coupled to the trigger circuit. When AC is selected the signal is capaci-

tively coupled, DC levels are rejected, and frequencies below 50 Hz are attenuated. NOISE Reject

is a filter that will help reduce jitter when triggering on noisy waveforms.

Level: Defines the source voltage at which the trigger circuit will generate an event.

Slope: Determines the direction of the trigger voltage transition used to generate a particular trig-

ger event.

Modifier: In NORM mode the digitizer will acquire while there is a valid trigger. In AUTO mode the

trace will automatically be displayed regardless of a valid trigger. When a valid trigger is present in

auto mode, the digitizer will behave as if in normal mode.

Type: Edge type requires a valid trigger edge. IMMEDIATE type will force a trigger even if the trig-

ger conditions are not met.

On/off: turns datalogging on and off.

Directory: Sets the directory for storying waveforms. Entering a period sets the current directory

of the Quick-Start Demo; entering another value (e.g., "Test 1") creates a new folder called "Test1"

referenced from the current directory.

Filename: Sets prefix for filename.

Index: An auto-incrementing index is appended to the above filename. When the datalogger is

turned on, and the program is in continuous Acquisition mode, each waveform will be stored.

PXD222-OM-E Rev A ISSUED: November 2001 25

Page 30

PXD 222 Digitizer

USING THE PXD 222 DIGITIZER IVI INSTRUMENT DRIVERS

Your CD-ROM includes several example programs written in LabWindows/CVI using the PXD 222

IVI driver. Even if you are not using CVI, the ".c" files provide practical examples that will help you

learn how to program the PXD 222 Digitizer.

§ § §

26 ISSUED: November 2001 PXD222-OM-E Rev A

Page 31

ASpecifications

PXD 222 DIGITIZER SPECIFICATIONS

NOTE: Specifications are subject to

change without notice.

VERTICAL SYSTEM

Bandwidth (DC coupled): 200 MHz (–3dB)

Lower Frequency Limit (AC coupled):

with 10:1 probe ...........................< 2 Hz (–3dB)

direct (1:1)..................................< 5 Hz (–3dB)

Rise Time: 1.7 ns

Analog Bandwidth Limiters: 20 MHz and 10 kHz

Input Coupling: AC, DC

Full Scale ranges:

direct (1-2-5 sequence)..............40 mV to 800 V

with 10:1 probe ...........................400 mV to 8000 V

Positioning (% of full range): 100%

Input Impedance on BNC:

DC Coupled ................................1 M?ohms (±1%) // 15 pF (±2 pF)

Max. Input Voltage

with 10:1 probe ...........................1000 V CAT II

direct (1:1)..................................300 V CAT II

(For detailed specifications, see “SAFETY”)

Vertical Accuracy: ±2% of full range

Digitizer Resolution: 8 bits, separate digitizer

Specifications

HORIZONTAL SYSTEM

Maximum Time Base Speed: 400 ps/sample

Minimum Time Base Speed: 4.8 s/sample (scope record mode)

Real Time Sampling Rate (for both inputs simultaneously):

400 ps to 80 ns/S.......................up to 2.5 GS/s

PXD222-OM-E Rev A ISSUED: November 2001 27

Page 32

PXD 222 Digitizer

40 ns to 2.4 s/S ..........................20 MS/s

4.8 s/S ........................................4 MS/s

(See the chapter on Operation for more information.)

Acquisition Modes: Real Time, Single Sweep

Normal Acquisition Mode:

Record size................................up to 1000 samples/ch

Record time span.......................100 ns to 10 s

Glitch Capture Mode:

Record size................................250 points (Min. and Max data arrays returned)

Recorded time span...................50 µs to 10 s; detects glitches as fast as 50 ns by

oversampling waveform

Sample rate................................up to 2.5 GS/s

Scope Record Size:

Record size................................27 points (Min. and Max data arrays returned)

Sample rate................................up to 20 MS/s

TRIGGER

Trigger Modes: Automatic, Edge, Video, Pulse Width

Trigger Delay: up to +25000 samples

Pre Trigger View: 2500 samples

Max. Delay: 10 s

Edge Trigger:

Mode ..........................................On Trigger, Single Shot

Source........................................Ch1, Ch2, PXI_TRIG[0,1,2…7],PXI_STAR[0,1,2…7]

Slope..........................................Positive, Negative

Trigger Level Control Range:

Input Ch1, Ch2...........................100% of full range

PXI_TRIG[0,1,2…7]...................fixed C-mos Cpci-level

PXI_STAR[0,1,2…7] ..................fixed C-mos Cpci-level

28 ISSUED: November 2001 PXD222-OM-E Rev A

Page 33

Specifications

Trigger Sensitivity Ch1 and Ch2:

DC to 5 MHz ...............................5 mV or 6.25% of full range

@ 200 MHz ...............................12.5% of full range

@ 250 MHz ...............................25.0% of full range

Video Trigger:

Standards ...................................PAL, PAL+, NTSC, SECAM

Modes ........................................Lines, Line Select, Field 1, or Field 2

Source........................................Ch 2

Polarity.......................................Positive, Negative

Sensitivity (sync level)................8.75% of full range

Pulse Width Trigger:

Screen Update ...........................On Trigger, Single Shot

Trigger Conditions......................< T, > T, approximately equal to T (±10%), not equal to T

(±10%)

Source........................................Ch2

Polarity.......................................Positive or negative pulse

Pulse Time Adj. Range..............0.25 to 10 samples with a maximum resolution of 50 ns

Auto Set/ Range:

Autoranging attenuators and timebase; automatic triggering with automatic source selection. The

autorange must be switched on or off.

If autorange is on, all auto functions are active until an autorange off command is executed.

Modes:

Normal........................................15 Hz to max. bandwidth

Low Frequency ...........................1 Hz to max. bandwidth

Minimum Amplitude Ch 1, Ch 2

DC to 1 MHz ...............................20 mV

1 MHz to max. bandwidth...........40 mV

PXD222-OM-E Rev A ISSUED: November 2001 29

Page 34

PXD 222 Digitizer

PHYSICAL DIMENSIONS

Height.........................................3 U (13.3 cm, 5.25 in.)

Width..........................................2 slots (3.9 cm, 1.56 in.)

Weight ........................................0.77 kg (1.7 lb.)

POWER REQUIREMENTS

Input voltage at cPCI connector....... 5 V ±10%

Input current ..................................... 1.6 A

ENVIRONMENTAL CONDITIONS

Temperature

Operating...................................0 °C to 50 °C (32 °F to 122 °F) with specified cooling of PXI

rack (indoor use only)

Non-Operating ...........................–40 °C to +71 °C

Humidity

Operating...................................5% to 95% max. RH (non-condensing) up to 30 °C; upper

limit derates to 45% RH (non-condensing) at 40 °C (104 °F)

Non-operating............................5% to 95% max. RH (non-condensing) up to 30 °C; upper

limit derates to 45% RH (non-condensing) at 60 °C (140 °F)

Altitude

Operating...................................4600 m (15,092 ft.)

Non-operating............................12,000 m (39,377 ft.)

Altitude

Conforms to MIL-PRF-28800 Class 3

30 ISSUED: November 2001 PXD222-OM-E Rev A

Page 35

Specifications

SAFETY

CAUTION

Safety specifications are only valid if

the unit is properly grounded, as

described in the Installation procedure.

The LeCroy PXD 222 Digitizer is designed for measurements on 300 V Category II Installations,

Pollution Degree 2, per:

EN 61010-1:1993 + A2:1995

CAN/CSA-C22.2 No.1010.1-92

UL3111-1

Max. Input Voltages:

Input Ch 1 and Ch 2 directly....................300 V CAT II

Input Ch 1 and Ch 2 via 10:1 probe........1000 V CAT II

Max. Floating Voltage:

From any terminal to ground ...................300 V CAT II

Between any terminal..............................300 V CAT II

Voltage ratings are given as “working voltage.” They should be read as VAC rms (50–60 Hz) for

AC sine wave applications and as VDC for DC applications.

PXD222-OM-E Rev A ISSUED: November 2001 31

Page 36

PXD 222 Digitizer

Input 2 &1

Max. Input Voltage v.s. Frequency

Safe Handling: Max. Input Voltage between Scope References 1and 2 and between Scope

References and safety ground

32 ISSUED: November 2001 PXD222-OM-E Rev A

Page 37

Specifications

CERTIFICATIONS

CE approved, UL & cUL recognized

CE Declaration of Conformity: The PXD 222 Digitizer meets requirements of the EMC Directive 89/336/

EEC for Electromagnetic Compatibility and Low Voltage Directive 73/23/EEC for Product Safety.

EMC Directive:

Electromagnetic Emissions: EN55022:1998, Class B Radiated emissions

Electromagnetic Immunity:

* Meets Performance Criteria “B” limits – during the disturbance, product undergoes a temporary degrada-

tion or loss of function of performance which is self recoverable.

EN 61326-1:1997 +A1:1998

EMC requirements for electrical equipment for measurement, control, and

laboratory use.

EN 61000-4-2:1995 +A1:1998* Electrostatic Discharge

EN 61000-4-3:1996 +A1:1998* RF Radiated Electromagnetic Field

EN 61000-4-4:1995* Electrical Fast Transient/Burst

EN 61000-4-5:1995* Surges

EN 61000-4-6:1996* RF Conducted Electromagnetic Field

CAUTION

EMC specifications are only valid if the unit is properly installed in a CE compliant PXI

chassis, as described in the Installation procedure.

PXD222-OM-E Rev A ISSUED: November 2001 33

Page 38

PXD 222 Digitizer

Low Voltage Directive: EN 61010-1:1993 +A2:1995

Safety requirements for electrical equipment for measurement, control, and laboratory use.

The PXD 222 Digitizer has been qualified to the following

EN61010-1 category:

300 V Installation (Overvoltage) Category II

Pollution Degree 2

Protection Class I

UL and cUL Recognized: UL Standard: UL 3111-1

Canadian Standard: CSA-C22.2 No. 1010.1-92

§ § §

34 ISSUED: November 2001 PXD222-OM-E Rev A

Loading...

Loading...