214579 REV C ECO 18776 03/26/2019

Teledyne Paradise Datacom Phone: (814) 238-3450

328 Innovation Blvd., Suite 100 Fax: (814) 238-3829

State College, PA 16803 USA Web: www.paradisedata.com

Email: sales@paradisedata.com

PowerMAX

SSPA System

Operations Manual

PowerMAX is covered by

U.S. Patent No. 8,189,338 B2

2 214579 REV C PowerMAX SSPA System Operations Manual

Teledyne Paradise Datacom, a division of Teledyne Defense Electronics LLC, is a single source for high

power solid state amplifiers (SSPAs), Low Noise Amplifiers (LNAs), Block Up Converters (BUCs), and

Modem products. Operating out of two primary locations, Witham, United Kingdom, and State College,

PA, USA, Teledyne Paradise Datacom has a more than 20 year history of providing innovative solutions

to enable satellite uplinks, battlefield communications, and cellular backhaul.

Teledyne Paradise Datacom Teledyne Paradise Datacom Ltd.

328 Innovation Blvd., Suite 100 2&3 The Matchyns, London Road, Rivenhall End

State College, PA 16803 USA Witham, Essex CM8 3HA England

(814) 238-3450 (switchboard) +44 (0) 1376 515636

(814) 238-3829 (fax) +44 (0) 1376 533764 (fax)

Information in this document is subject to change without notice. The latest revision of this document

may be downloaded from the company web site: http://www.paradisedata.com.

Use and Disclosure of Data

The items described herein are controlled by the U.S. Government and authorized for export only to the

country of ultimate destination for use by the ultimate consignee or end-user(s) herein identified. They

may not be resold, transferred, or otherwise disposed of, to any other country or to any person other

than the authorized ultimate consignee or end-user(s), either in their original form or after being incorporated into other items, without first obtaining approval from the U.S. government or as otherwise authorized by U.S. law and regulations.

Proprietary and Confidential

The information contained in this document is the sole property of Teledyne Paradise Datacom. Any reproduction in part or as a whole without the written permission of Teledyne Paradise Datacom is prohibited.

All other company names and product names in this document are property of the respective companies.

© 2018-2019 Teledyne Paradise Datacom

Printed in the USA

PowerMAX SSPA System Operations Manual 214579 REV C 3

Section 1: General Information ............................................................................................................. 11

1.0 Introduction ............................................................................................................................ 11

1.1 Theory of Operation .............................................................................................................. 11

1.1.1 Four-Module Systems ........................................................................................... 14

1.1.2 Eight-Module Systems .......................................................................................... 15

1.1.3 16-Module Systems ............................................................................................... 16

1.2 Specifications ........................................................................................................................ 17

1.3 Inspection .............................................................................................................................. 17

1.4 Shipment ............................................................................................................................... 17

1.5 Safety Considerations ........................................................................................................... 18

1.5.1 High Voltage Hazards ........................................................................................... 18

1.5.2 High Current Hazards ............................................................................................ 18

1.5.3 RF Transmission Hazards ..................................................................................... 19

1.5.4 Electrical Discharge Hazards ................................................................................ 19

1.5.5 Tipping Hazard ...................................................................................................... 20

1.5.6 High Potential for Waveguide Arcing .................................................................... 20

1.6 Waveguide Pressurization and Dehydration ......................................................................... 20

Section 2: System Components ........................................................................................................... 23

2.0 Introduction ............................................................................................................................ 23

2.1 PowerMAX SSPA Chassis .................................................................................................... 23

2.1.1 Front Panel Features ............................................................................................. 23

2.1.1.1 Fault Condition LEDs ............................................................................ 23

2.1.1.2 Master/Slave Indicator........................................................................... 24

2.1.1.3 Front Panel Display ............................................................................... 24

2.1.1.4 Navigation Keys .................................................................................... 24

2.1.1.5 Main Menu Key .................................................................................... 24

2.1.1.6 Local/Remote Key ................................................................................ 24

2.1.1.7 Mute/Unmute Key ................................................................................. 24

2.1.1.8 Output Sample Port [Type N (F)] .......................................................... 24

2.1.1.9 Removable Fan Assembly .................................................................... 24

2.1.1.10 Removable Face Plate ........................................................................ 25

2.1.2 Rear Panel Features ............................................................................................. 25

2.1.2.1 RF Input Port (J1) [Type N (F)] ............................................................. 25

2.1.2.2 RF Output Port (J2) [Band specific] ...................................................... 25

2.1.2.3 Switch Port (J3) [6-pin MS-type] ........................................................... 26

2.1.2.4 Serial Main (J4) [DB9 (F)] ..................................................................... 26

2.1.2.5 Serial Local (J5) [DB9 (M)] .................................................................... 26

2.1.2.6 Program Port (J6) [DB25 (M)] ............................................................... 27

2.1.2.7 Parallel I/O (J7) [DB37 (F)] .................................................................... 27

2.1.2.7.1 Hardware Mute (Tx Enable) ............................................................... 27

2.1.2.8 Link Port (J8) [DB9 (F)] ......................................................................... 27

2.1.2.9 Ethernet Port (J9) [RJ45] ...................................................................... 29

2.1.2.10 Power Supply M&C/Alarm (J12) [DB9 (M)] ......................................... 29

2.1.2.11 Removable Rear Fan Assembly ......................................................... 29

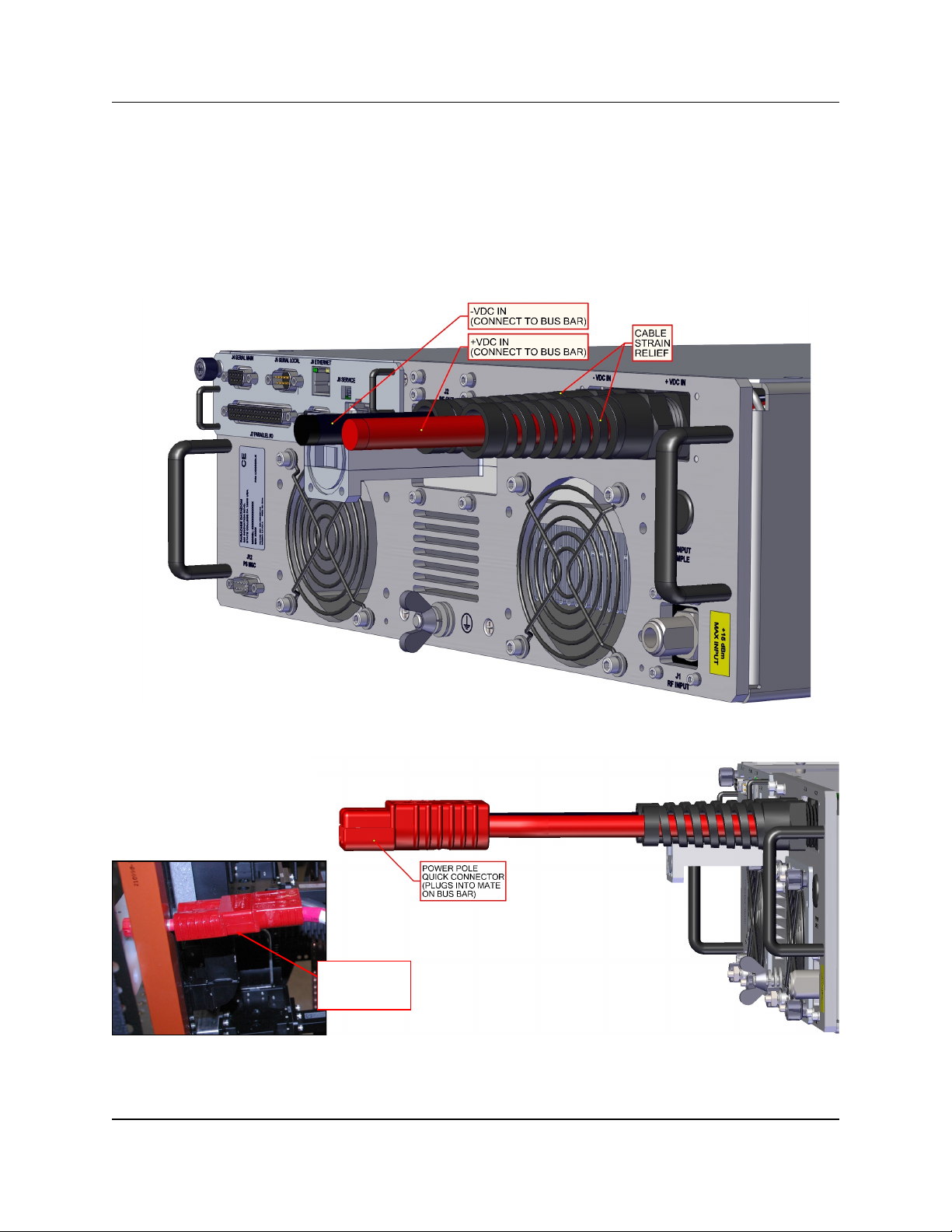

2.1.2.12 DC Input Port [bus bars] ...................................................................... 30

2.2 Power Supply Chassis .......................................................................................................... 31

2.2.1 AC Distribution Panel ............................................................................................ 33

2.2.2 DC Distribution Panel ............................................................................................ 34

2.3 RF Distribution Panel ............................................................................................................ 35

2.3.1 J1 to J8 RF Out - SSPA # [Type N (F)] ................................................................ 35

2.3.2 J9 RF In [Type N (F)] ............................................................................................. 32

2.3.3 J10 Sample [Type N (F)] ....................................................................................... 35

Table of Contents

4 214579 REV C PowerMAX SSPA System Operations Manual

2.3.4 J11 RF Input Sample [Type N (F)] ........................................................................ 35

2.3.5 J12 RF Output Sample [Type N (F)] ..................................................................... 36

2.3.6 J13 RF Out [SMA] ................................................................................................. 36

2.3.7 J14 4-Way Input [SMA] ......................................................................................... 36

2.3.8 J15 8-Way Input [SMA] ......................................................................................... 36

2.3.9 J16 8-Way Output [SMA] ....................................................................................... 36

2.3.10 Phase Adjusters, SSPA 2-4 and SSPA 6-8 ........................................................ 36

2.4 Ethernet Switch (Optional) .................................................................................................... 37

2.4.1 Ethernet Switch Specifications .............................................................................. 37

2.5 Forward/Reflected Power Detector ....................................................................................... 38

2.5.1 Reflected Power Alarm .......................................................................................... 38

2.5.2 J40 Forward RF Sample In [SMA (F)] .................................................................. 39

2.5.3 J41 Reflected RF Sample In [SMA (F)] ................................................................ 39

2.5.4 J42 RF Sample Out [SMA (F)] .............................................................................. 39

2.5.5 J43 +12V Input [Pin] .............................................................................................. 39

2.5.6 J44 RS-485 Connector [DB9 (F)] .......................................................................... 39

Section 3: System Installation .............................................................................................................. 41

3.0 Introduction ............................................................................................................................ 41

3.1 System Installation ................................................................................................................ 42

3.1.1 Uncrating the Equipment ....................................................................................... 42

3.1.1.1 Uncrate the System Cabinet ................................................................. 42

3.1.1.2 Uncrate the SSPA Module/Heatsink Assemblies, Power Supplies ...... 43

3.1.2 Setting Cabinet Upright ......................................................................................... 44

3.1.3 Inspect Waveguide ................................................................................................ 45

3.1.4 Inspect Cables ....................................................................................................... 45

3.1.4.1 RF Input Cables .................................................................................... 46

3.1.5 Install SSPA Module/Heatsink Assemblies ........................................................... 47

3.1.6 Install Power Supply Modules ............................................................................... 51

3.1.7 Cabinet I/O Connectors ......................................................................................... 52

3.1.10 Apply Power ........................................................................................................ 52

3.2 Cabinet Exhaust Option ........................................................................................................ 53

3.2.1 Rotate Impeller Housing for Eight-Module Systems with Exhaust Option ............ 54

3.3 Four-module to Eight-module Upgrade Paths ....................................................................... 55

3.3.1 Four-module to Eight-module PowerMAX Upgrade, Maximum Output Power ... 56

3.3.2 Four-module to Eight-module PowerMAX Upgrade, Hitless Operation ............... 57

3.3.3 System Gain and Power vs. Number of Modules in System ................................ 59

Section 4: Troubleshooting and Maintenance .................................................................................... 67

4.0 Troubleshooting Faults .......................................................................................................... 67

4.0.1 Summary Fault ...................................................................................................... 67

4.0.2 Voltage Fault ......................................................................................................... 67

4.0.3 Temperature Fault ................................................................................................. 67

4.0.4 Current Fault ......................................................................................................... 68

4.0.5 Power Supply Fault ............................................................................................... 69

4.0.6 Fan Fault ............................................................................................................... 69

4.0.7 Low RF Fault ......................................................................................................... 70

4.1 Modular SSPA Architecture ................................................................................................... 71

4.1.1 Removable Fans (intake and exhaust) ................................................................. 71

4.1.1.1 Fan and Heatsink Maintenance ............................................................ 72

4.1.2 SSPA Module/Heatsink Removal/Replacement ................................................... 74

4.1.3 Power Supply Module Removal ............................................................................ 76

4.1.4 Removable Controller Card (Rear Panel) ............................................................. 78

4.1.5 Firmware Upgrade Procedure ............................................................................... 79

4.1.5.1 Required Hardware ............................................................................... 79

4.1.5.2 Required Software ................................................................................. 79

4.1.5.3 Web Upgrade Procedure ...................................................................... 80

4.1.5.4 USB Port Upgrade Procedure ............................................................... 82

PowerMAX SSPA System Operations Manual 214579 REV C 5

4.2 Phase Adjustment ................................................................................................................. 83

4.2.1 Adjusting Phase After Replacing SSPA 1, 2, 3 or 4 .............................................. 83

4.2.2 Adjusting Phase After Replacing SSPA 5, 6, 7 or 8 .............................................. 85

4.3 Changing N+1 Hierarchy ....................................................................................................... 87

4.3.1 Changing Hierarchical Order of Slave Units ......................................................... 87

4.3.2 Exchange N+1 Privileges Between Master and Slave Units ................................ 87

4.3.3 Add SSPA Unit to the System ............................................................................... 88

Section 5: Front Panel Operation ......................................................................................................... 89

5.0 Operational Basics ................................................................................................................ 89

5.0.1 Selecting the Master Unit ...................................................................................... 89

5.0.2 Controlling System Operation ............................................................................... 90

5.0.3 N+1 Addressing ..................................................................................................... 90

5.0.4 Adjust System Gain ............................................................................................... 91

5.0.5 N+1 Automatic Gain Control Option ...................................................................... 91

5.0.6 N+1 RF Power Measurements .............................................................................. 91

5.0.7 N+1 Fault Detection............................................................................................... 92

5.0.8 Automatic Fan Speed Control ............................................................................... 92

5.1 Menus .................................................................................................................................... 93

5.1.1 System Information Sub-Menu .............................................................................. 94

5.1.1.1 Sys Info Page 1 ..................................................................................... 95

5.1.1.1.1 Clear Faults Menu ................................................................. 95

5.1.1.2 Sys Info Page 2 ..................................................................................... 96

5.1.1.3 Sys Info Page 3 ..................................................................................... 96

5.1.1.4 Sys Info Page 4 ..................................................................................... 96

5.1.1.5 Sys Info Page 5 ..................................................................................... 97

5.1.1.6 Sys Info Page 6 ..................................................................................... 97

5.1.1.7 Sys Info Page 7 ..................................................................................... 98

5.1.1.8 Sys Info Page 8 ..................................................................................... 98

5.1.1.9 Sys Info Page 9 (version 6.00) .............................................................. 98

5.1.1.10 Sys Info Page 10 (version 6.00) .......................................................... 99

5.1.1.11 IP Info Page 1 .................................................................................... 100

5.1.1.12 IP Info Page 2 .................................................................................... 100

5.1.1.13 IP Info Page 3 .................................................................................... 100

5.1.1.14 IP Info Page 4 .................................................................................... 101

5.1.1.15 Firmware Info Page 1 ........................................................................ 101

5.1.1.16 Firmware Info Page 2 (version 4.0) ................................................... 101

5.1.1.17 Firmware Info Pages 3, 4, 5, 6 and 7 (version 4.0) ........................... 101

5.1.1.18 Hardware Info Page 8 (version 6.00) ................................................ 101

5.1.1.19 HPA Local Time Page 9 (version 6.00) ............................................. 102

5.1.1.20 HPA Run Time Page 10 (version 6.00) ............................................. 102

5.1.1.21 N+1 Master Info Page 1 .................................................................... 102

5.1.1.21.1 Clear Faults Menu ............................................................. 103

5.1.1.22 N+1 Slave Info Page ......................................................................... 103

5.1.1.22.1 Clear Faults Menu ............................................................. 103

5.1.1.23 N+1 Master Info Page 2 .................................................................... 104

5.1.1.24 N+1 Master Info Page 3 .................................................................... 104

5.1.2 Communication Setup Sub-Menu ....................................................................... 105

5.1.2.1 Protocol ............................................................................................... 105

5.1.2.2 Baud Rate ........................................................................................... 105

5.1.2.3 System Address .................................................................................. 106

5.1.2.4 Interface .............................................................................................. 106

5.1.2.5 IP Setup ............................................................................................... 106

5.1.2.5.1 More (SNMP, IP and Web Settings) ................................... 107

5.1.2.5.2 More (Traps and Time Settings) ......................................... 108

5.1.2.6 N+1 Control (Floating Master Mode) ................................................... 109

5.1.3 Operation Setup Sub-Menu................................................................................. 111

5.1.3.1 Info....................................................................................................... 111

6 214579 REV C PowerMAX SSPA System Operations Manual

5.1.3.2 Buzzer ................................................................................................. 111

5.1.3.3 Mute..................................................................................................... 111

5.1.3.4 Sys. Mode ........................................................................................... 111

5.1.3.5 Attenuation .......................................................................................... 112

5.1.3.6 RF Units .............................................................................................. 112

5.1.4 Fault Monitoring Setup Sub-Menu ...................................................................... 113

5.1.4.1 BUC Fault ............................................................................................ 113

5.1.4.2 Auxiliary Faults .................................................................................... 113

5.1.4.3 RF Switch Faults ................................................................................. 114

5.1.4.4 Fault Latch ........................................................................................... 114

5.1.4.5 Forward RF / Automatic Level Control ................................................ 114

5.1.4.5.1 Disable ................................................................................ 114

5.1.4.5.2 Low RF ................................................................................ 114

5.1.4.5.3 High RF ............................................................................... 115

5.1.4.5.4 ALC On (Automatic Level Control) ...................................... 115

5.1.4.5.5 Set Level ............................................................................. 116

5.1.4.5.6 Back .................................................................................... 116

5.1.5 Options Sub-Menu .............................................................................................. 117

5.1.5.1 Backup User Settings .......................................................................... 117

5.1.5.2 Restore ................................................................................................ 117

5.1.5.3 Lamp Test ........................................................................................... 118

5.1.5.4 Password ............................................................................................. 118

5.1.5.5 Fan Speed ........................................................................................... 118

5.1.5.6 Reset ................................................................................................... 119

5.1.6 Redundancy Sub-Menu ....................................................................................... 121

5.1.6.1 Switching ............................................................................................. 121

5.1.6.2 Standby Select .................................................................................... 121

5.1.6.3 Standby Mode ..................................................................................... 121

5.1.6.4 Status .................................................................................................. 121

5.1.6.5 Priority ................................................................................................. 122

5.1.6.6 N+1 System Operation Parameters .................................................... 122

5.1.6.6.1 N+1 Array Size .................................................................... 122

5.1.6.6.2 N+1 Address ....................................................................... 122

5.1.6.6.3 Auto Gain Control ................................................................ 122

5.1.6.6.4 N+1 Info ............................................................................... 123

5.1.6.6.5 Module Eject ........................................................................ 124

5.1.6.6.6 Back .................................................................................... 124

Section 6: Remote Control Interface .................................................................................................. 125

6.0 Overview .............................................................................................................................. 125

6.1 Remote Control - Parallel ................................................................................................... 127

6.1.1 Control Outputs .................................................................................................. 127

6.1.2 Control Inputs ..................................................................................................... 127

6.2 Serial Communication Protocol ........................................................................................... 128

6.2.1 Header Sub-Packet ............................................................................................. 128

6.2.1.1 Frame Sync Word ............................................................................... 128

6.2.1.2 Destination Address ............................................................................ 128

6.2.1.3 Source Address ................................................................................... 128

6.2.2 Data Packet ......................................................................................................... 129

6.2.2.1 Protocol ID ........................................................................................... 129

6.2.2.2 Request ID .......................................................................................... 129

6.2.2.3 Command ............................................................................................ 129

6.2.2.4 Data Tag .............................................................................................. 130

6.2.2.5 Error Status / Data Address ................................................................ 130

6.2.2.6 Data Length ......................................................................................... 131

6.2.2.7 Data Field ............................................................................................ 131

6.2.3 Trailer Packet ...................................................................................................... 132

6.2.3.1 Frame Check ....................................................................................... 132

PowerMAX SSPA System Operations Manual 214579 REV C 7

6.2.4 Timing issues ...................................................................................................... 132

6.2.5 Serial Communications Protocol ......................................................................... 133

6.3 Access SSPA Subsystem through Packet Wrapper Technique ......................................... 139

6.4 Example 1 Check SSPA settings ........................................................................................ 140

6.5 Terminal Mode Serial Protocol for Paradise Datacom SSPA ............................................. 142

6.6 Ethernet Interface ................................................................................................................ 144

6.6.1 IPNet Interface .................................................................................................... 144

6.6.1.1 General Concept ................................................................................. 144

6.6.1.2 Setting IPNet interface ........................................................................ 146

6.6.1.3 Using the Rack Mount Web Interface ................................................. 147

6.6.2 SNMP Interface ................................................................................................... 149

6.6.2.1 Interface .............................................................................................. 149

6.6.2.2 SNMP V3 Issues in Teledyne Paradise Datacom SSPAs .................. 149

6.6.2.3 SNMP MIB Tree .................................................................................. 152

6.6.2.4 Description of MIB Entities .................................................................. 153

6.6.2.5 Configuring RM SSPA Unit to Work with SNMP Protocol ................... 154

6.6.2.6 Connecting to a MIB Browser ............................................................. 159

6.6.3 Extended SNMP Operation ................................................................................. 161

6.6.3.1 Extended SNMP MIB Tree .................................................................. 162

6.6.3.2 Extended SNMP MIB Tree Elements in Detail .................................... 164

Section 7: RM SSPA Control with Universal M&C ............................................................................ 167

7.0 Download the Universal M&C Application ........................................................................... 167

7.1 Add Each RM SSPA to the Universal M&C ....................................................................... 167

7.2 Add PowerMAX System to the Universal M&C ................................................................... 168

7.3 Universal M&C Overview .................................................................................................... 169

Appendix A: Ethernet Interface Quick Set-Up ................................................................................... 177

Appendix B: 10/100 Base-T Ethernet Cable Wiring .......................................................................... 181

Appendix C: Documentation ............................................................................................................... 185

8 214579 REV C PowerMAX SSPA System Operations Manual

Figures

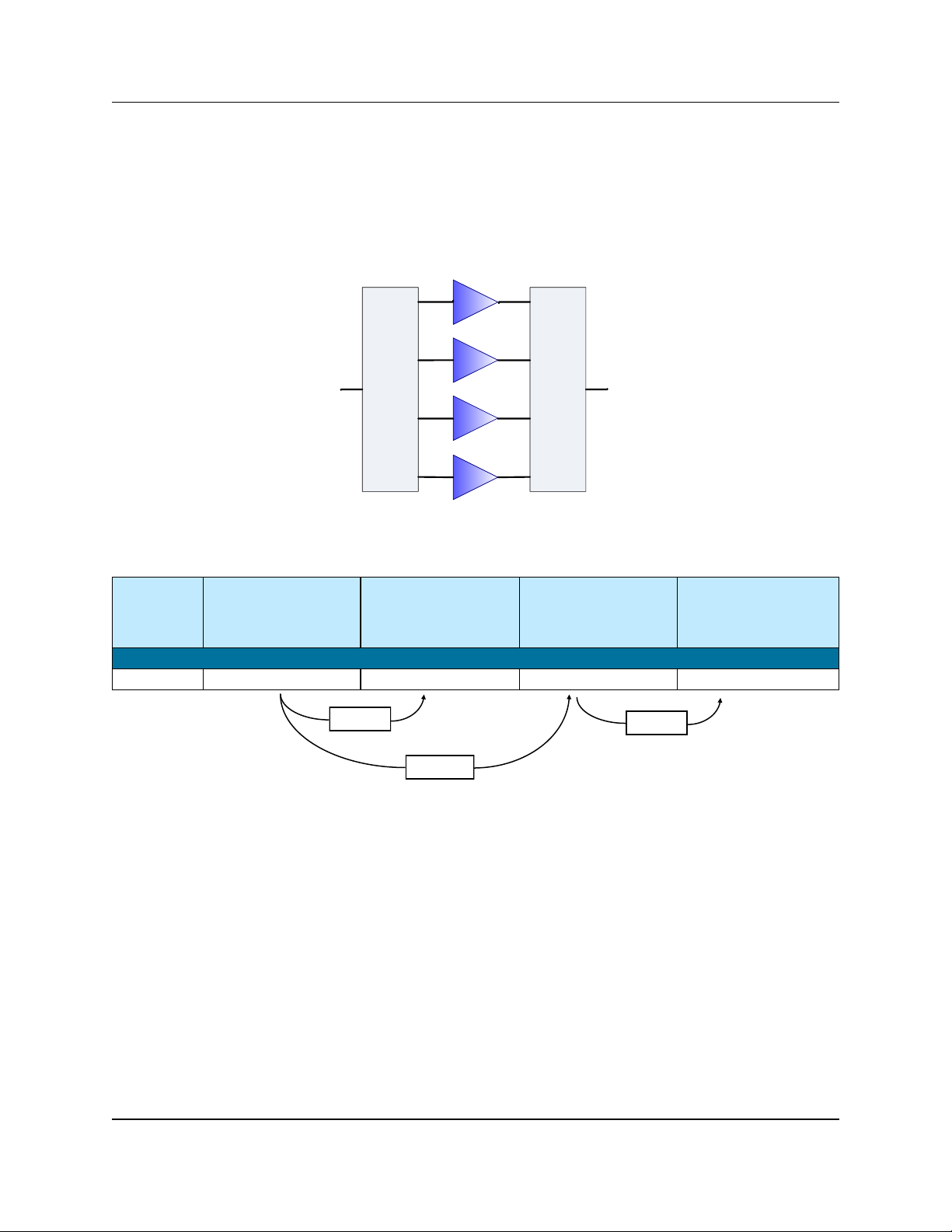

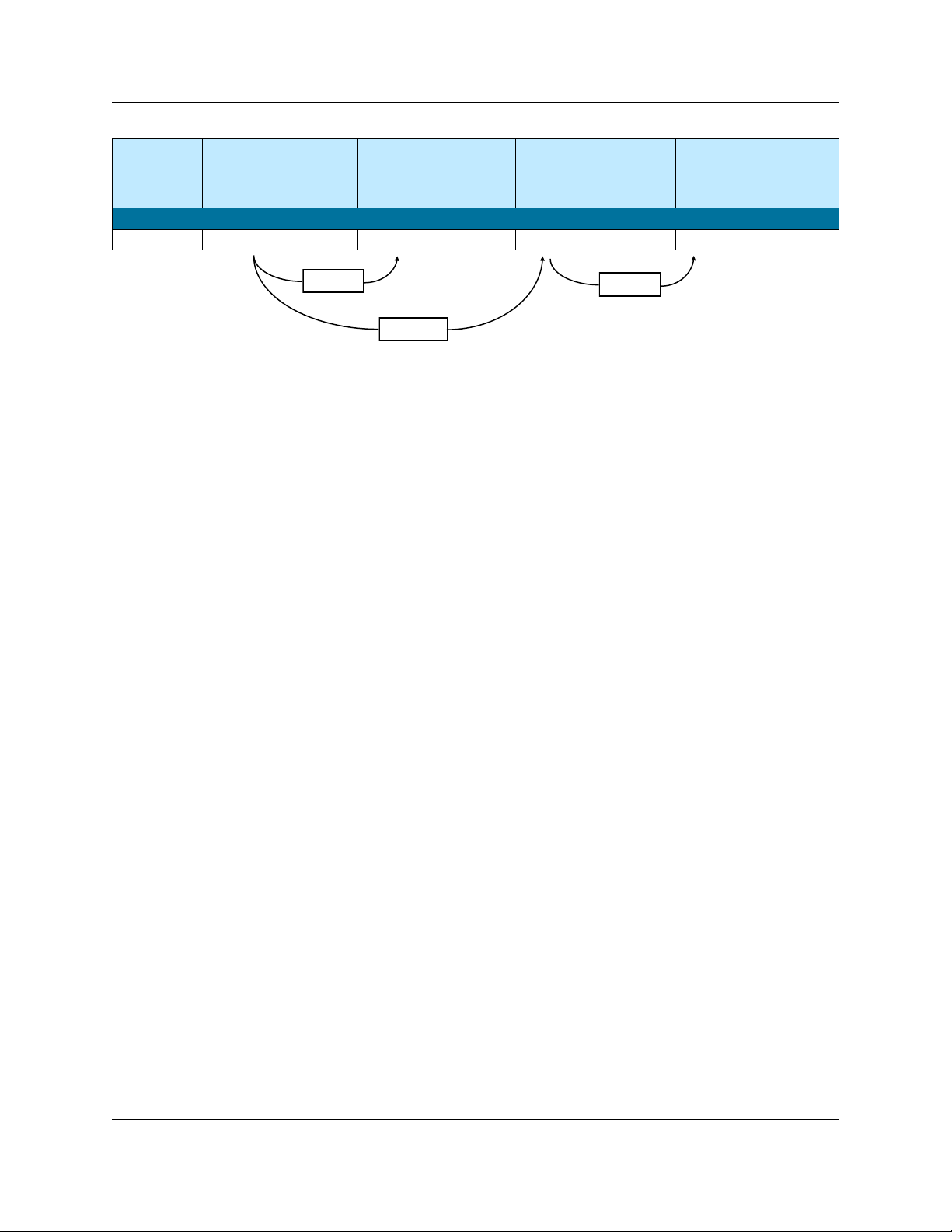

Figure 1-1: System Block Diagrams, PowerMAX Systems ......................................................... 13

Figure 1-2: Block Diagram of 4-Module PowerMAX System ...................................................... 14

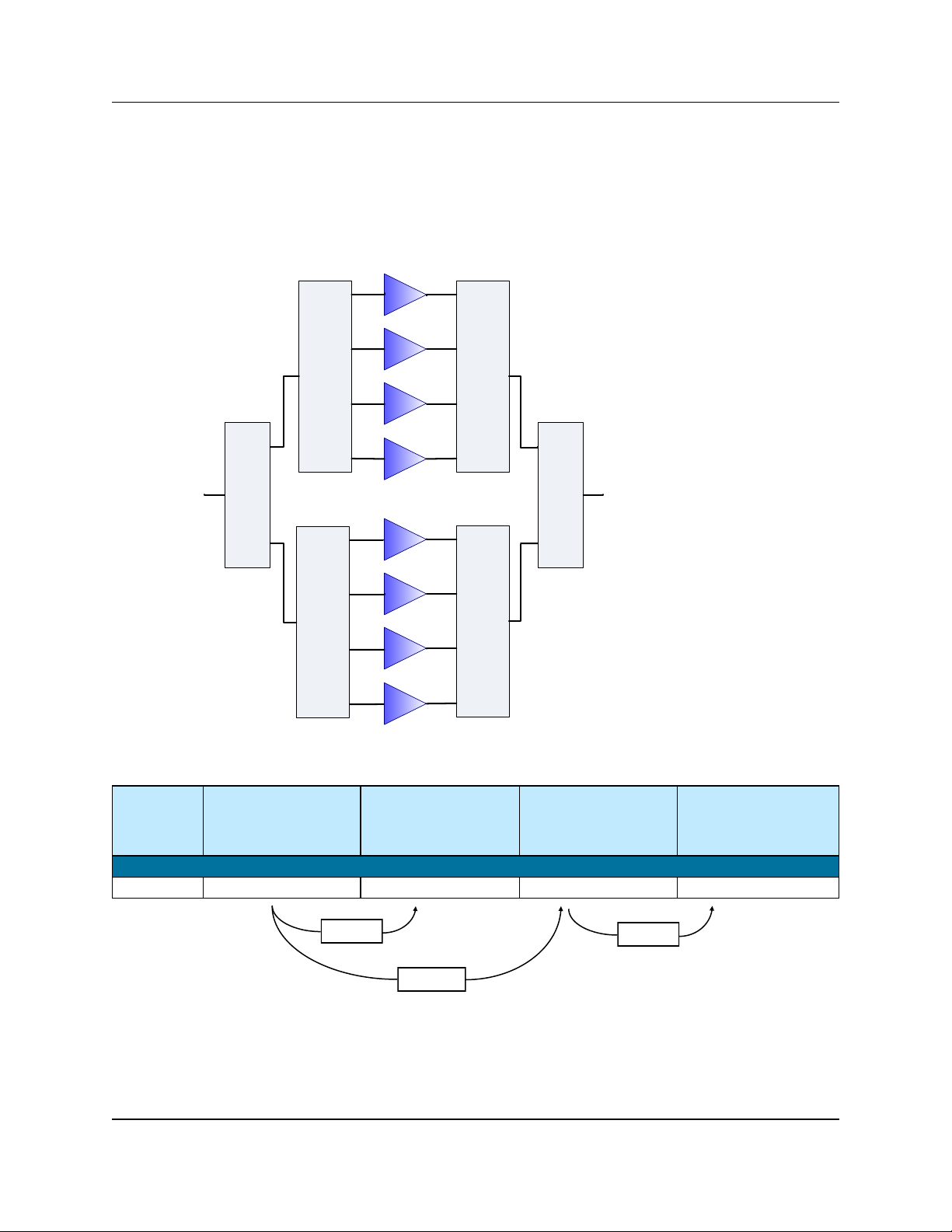

Figure 1-3: Block Diagram of 8-Module PowerMAX System ...................................................... 15

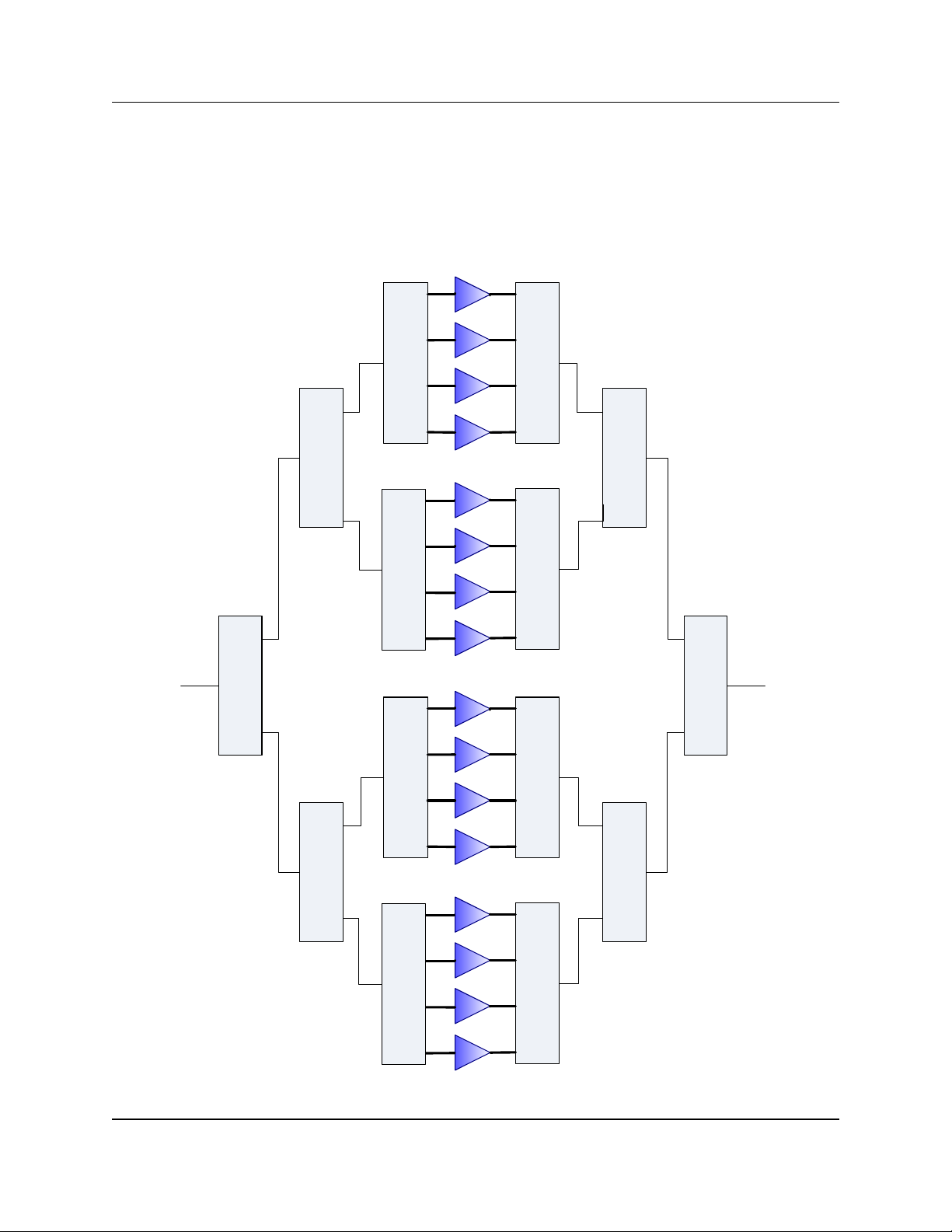

Figure 1-4: Block Diagram of 16-Module PowerMAX System .................................................... 16

Figure 1-5: Degradation of Breakdown Power by VSWR ........................................................... 22

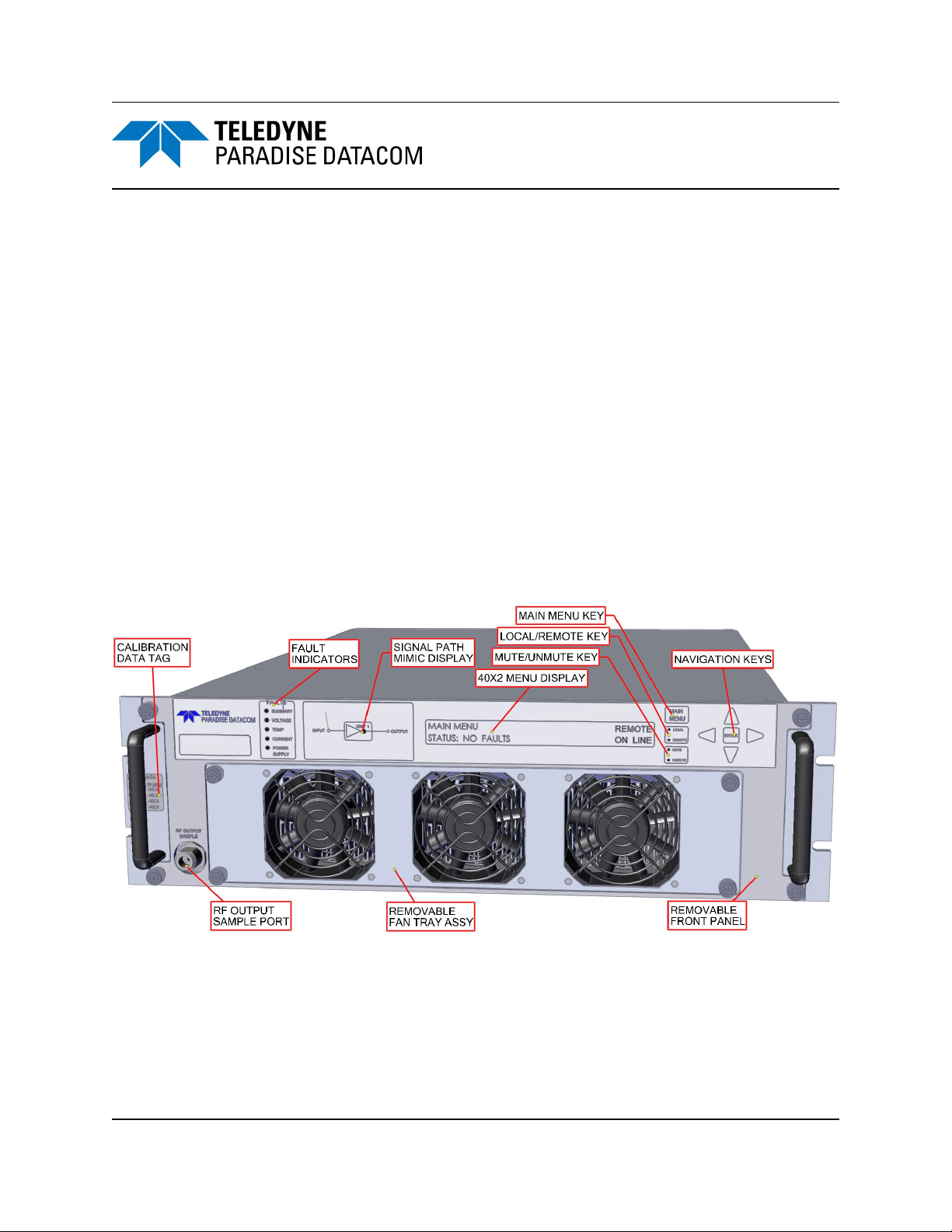

Figure 2-1: PowerMAX SSPA Chassis Front Panel .................................................................... 23

Figure 2-2: C-Band SSPA Rear Panel ........................................................................................ 25

Figure 2-3: Plastic Safety Cover; Bus Bar Connections .............................................................. 30

Figure 2-4: Connect Power Cables Between SSPA and Bus Rail .............................................. 30

Figure 2-5: 1RU Power Supply Module Insertion/Extraction ....................................................... 31

Figure 2-6: 1RU Power Supply AC Line Inputs/Outputs ............................................................. 32

Figure 2-7: Connect Cables to Power Supply DC Output Bus Bar ............................................. 32

Figure 2-8: Connect Cables to System Bus Bar ......................................................................... 32

Figure 2-9: AC Terminal Block, Example .................................................................................... 33

Figure 2-10: AC Distribution Panel .............................................................................................. 33

Figure 2-11: DC Distribution Panel.............................................................................................. 34

Figure 2-12: RF Distribution Panel, Front and Rear Views ......................................................... 35

Figure 2-13: Phase Adjustment Screws (Under Thumb Screws) ............................................... 36

Figure 2-14: Ethernet Switch ....................................................................................................... 37

Figure 2-15: Forward/Reflected RF Power Detector Box............................................................ 38

Figure 3-1: 4-Chassis (Left) and 8-Chassis PowerMAX System Configurations ........................ 41

Figure 3-2: Remove and Save Shipping Brackets ...................................................................... 42

Figure 3-3: Remove Crate Side Walls ......................................................................................... 43

Figure 3-4: Slide Cabinet so Base Hangs Over Edge of Crate Base .......................................... 44

Figure 3-5: Lift Near Top of Cabinet to Tilt Cabinet Upright ........................................................ 44

Figure 3-6: RF Input Cables ........................................................................................................ 46

Figure 3-7: Extend Rack Slides ................................................................................................... 47

Figure 3-8: Move Cables Out of Way to Install Module/Heatsink Assembly ............................... 47

Figure 3-9: Install SSPA Module/Heatsink into Rack Slides ....................................................... 48

Figure 3-10: Slide SSPA Module/Heatsink into Enclosure.......................................................... 48

Figure 3-11: Close Compression Latches ................................................................................... 48

Figure 3-12: Open-End Wrench Secured to Front, Top of Cabinet ............................................ 49

Figure 3-13: Connect RF In Connector and Power Cables ........................................................ 49

Figure 3-14: Connect M&C Cables to Fan Boost Board ............................................................. 50

Figure 3-15: Tuck Cables into Enclosure and Re-Seat Front Panel ........................................... 50

Figure 3-16: Install Power Supply Modules ................................................................................. 51

Figure 3-17: System I/O Panel .................................................................................................... 52

Figure 3-18: AC Terminal Block .................................................................................................. 52

Figure 3-19: Hinge Pin ................................................................................................................ 53

Figure 3-20: Impeller Mounting ................................................................................................... 53

Figure 3-21: Impeller Power ........................................................................................................ 53

Figure 3-22: Cabinet Exhaust, as Shipped ................................................................................. 54

Figure 3-23: Remove Bolts to Rotate Housing ............................................................................ 54

Figure 3-24: Block Diagram, Four-way PowerMAX system ........................................................ 55

Figure 3-25: Eight-module PowerMAX systems with (8) and (4) modules ................................. 56

Figure 3-26: Four Module PowerMAX with 1, 2, and 3 Modules ................................................ 59

Figure 3-27: Eight Module PowerMAX Systems with 7 and 6 Modules ...................................... 60

Figure 3-28: Eight Module PowerMAX Systems with 5 and 4 Modules ...................................... 61

Figure 3-29: Eight Module PowerMAX Systems with 3 and 2 Modules ...................................... 62

Figure 3-30: 16 Module PowerMAX Systems with 15 Modules .................................................. 63

Figure 3-31: 16 Module PowerMAX Systems with 14 Modules .................................................. 64

Figure 3-32: 16 Module PowerMAX Systems with 13 Modules .................................................. 65

Figure 3-33: 16 Module PowerMAX Systems with 12 Modules .................................................. 66

Figure 4-1: Front Panel Fault Display .......................................................................................... 67

Figure 4-2: Unscrew Thumbscrews ............................................................................................. 71

Figure 4-3: Unplug Power Plug ................................................................................................... 71

Figure 4-4: Unscrew Thumbscrews ............................................................................................. 71

PowerMAX SSPA System Operations Manual 214579 REV C 9

Figure 4-5: Unplug Connector .................................................................................................... 71

Figure 4-6: Example of Dust Blocking Heatsink Fins .................................................................. 72

Figure 4-7: Heatsink Fins Cleared of Debris ............................................................................... 73

Figure 4-8: Unplug M&C Cables ................................................................................................ 74

Figure 4-9: Unplug RF In Cable .................................................................................................. 74

Figure 4-10: Toggle Release Levers to Remove Module from Rack Slides ............................... 74

Figure 4-11: Install New SSPA Module ....................................................................................... 75

Figure 4-12: Reinstall Front Panel ............................................................................................... 75

Figure 4-13: Slide Power Supply Module from the Chassis ........................................................ 76

Figure 4-14: Loosen Retaining Thumbscrews ............................................................................ 78

Figure 4-15: Slide M&C Card Out to Remove ............................................................................. 78

Figure 4-16: Web Upgrade Authentication Window .................................................................... 80

Figure 4-17: Firmware Upload Form ........................................................................................... 80

Figure 4-18: Proceed With Upgrade Prompt ............................................................................... 81

Figure 4-19: Upload Process Message ....................................................................................... 81

Figure 4-20: Upload Completed Message .................................................................................. 81

Figure 4-21: Windows Device Manager > Ports .......................................................................... 82

Figure 4-22: Command Window Showing Program Prompts ..................................................... 82

Figure 4-23: Front Panel Display of System RF Power .............................................................. 83

Figure 4-24: Phase Adjusters for SSPA 2, SSPA 3 and SSPA 4 ............................................... 83

Figure 4-25: Adjust 8-Way Phase Trimmer ................................................................................. 84

Figure 4-26: Adjusting Phase of SSPA 6, SSPA 7 and SSPA 8 ................................................. 85

Figure 4-27: Adjust 8-Way Phase Trimmer ................................................................................. 86

Figure 5-1: Front Panel Display, Master Unit (Online LED Illuminated) ...................................... 89

Figure 5-2: Front Panel Display, Slave Unit (Online LED Dark).................................................. 89

Figure 5-3: Front Panel Menu Structure ...................................................................................... 93

Figure 5-4: System Information Menu Structure ......................................................................... 94

Figure 5-5: Slave Unit Display ................................................................................................... 103

Figure 5-6: Communication Setup Sub-Menu ........................................................................... 104

Figure 5-7: Operation Setup Sub-Menu .................................................................................... 111

Figure 5-8: Fault Setup Sub-Menu ............................................................................................ 113

Figure 5-9: Options Sub-Menu .................................................................................................. 117

Figure 5-10: Redundancy Sub-Menu ........................................................................................ 121

Figure 5-11: N+1 Info Menu ...................................................................................................... 123

Figure 6-1: SSPA Remote Control Interface Stack ................................................................... 125

Figure 6-2: Parallel I/O Form C Relay ...................................................................................... 127

Figure 6-3: Basic Communication Packet ................................................................................. 128

Figure 6-4: Header Sub-Packet ................................................................................................. 128

Figure 6-5: Data Sub-Packet ..................................................................................................... 129

Figure 6-6: Trailer Sub-Packet .................................................................................................. 132

Figure 6-7: Packet Wrapper Technique .................................................................................... 139

Figure 6-8: Terminal Mode Session Example ........................................................................... 143

Figure 6-10: UDP Redirect Frame Example.............................................................................. 145

Figure 6-10: Web Interface Login Window ................................................................................ 147

Figure 6-11: RM SSPA Web Interface, Status Tab ................................................................... 148

Figure 6-12: GetIF Application Parameters Tab ....................................................................... 159

Figure 6-13: GetIF MBrowser Window, with Update Data in Output Data Box......................... 159

Figure 6-14: Getif MBrowser Window, Setting settingValue.5 to a Value of ‘1’ ........................ 160

Figure 7-1: Select Rackmount SSPA ........................................................................................ 166

Figure 7-2: Add Rackmount SSPA Dialog Window ................................................................... 166

Figure 7-3: Select ‘N+1 System’ ................................................................................................ 168

Figure 7-4: Add N+1 System Dialog Window ............................................................................ 168

Figure 7-5: Status Screen ......................................................................................................... 169

Figure 7-6: Settings Screen ....................................................................................................... 170

Figure 7-7: Faults Screen .......................................................................................................... 171

Figure 7-8: IP Setup Screen ...................................................................................................... 172

Figure 7-9: N+1 Screen (Master)............................................................................................... 173

Figure 7-10: N+1 Screen (Slave)............................................................................................... 173

10 214579 REV C PowerMAX SSPA System Operations Manual

Figure 7-11: PowerMAX System Overview ............................................................................... 174

Figure 7-12: Mouse-over Unit # for Condition Synopsis ........................................................... 175

Figure A-1: TCP/IP Properties Window ..................................................................................... 177

Figure B-1: Modular Plug Crimping Tool ................................................................................... 181

Figure B-2: Transmission Line .................................................................................................. 181

Figure B-3: Ethernet Cable Pin-Outs ......................................................................................... 182

Figure B-4: Ethernet Wire Color Code Standards ..................................................................... 183

Figure B-5: Wiring Using 568A Color Codes ............................................................................. 183

Figure B-6: Wiring Using 568A and 568B Color Codes ............................................................ 183

Tables

Table 1-1: PowerMAX Output Power Reduction ......................................................................... 12

Table 1-2: Four-Module PowerMAX System Output Power Example ........................................ 14

Table 1-3: Eight-Module PowerMAX System Output Power Example ........................................ 15

Table 1-4: 16-Module PowerMAX System Output Power Example ............................................ 17

Table 1-5: Recommended Output Power Thresholds for W/G System Pressurization .............. 21

Table 1-6: De-rating of Popular Waveguide Components Relative to Straight Waveguide ........ 21

Table 2-1: Switch Port (J3) pin outs ............................................................................................ 26

Table 2-2: Serial Main (J4) pin outs ............................................................................................ 26

Table 2-3: Parallel I/O (J7) pin outs ............................................................................................. 28

Table 2-4: Ethernet Port (J9) pin outs ......................................................................................... 29

Table 2-5: Prime Input Power Example (400W GaN C-Band SSPA Module) ............................ 31

Table 3-1: RF Input Cable Connections ...................................................................................... 46

Table 6-1: Interfaces Enabled Based on Chosen Interface Setting Selection .......................... 126

Table 6-2: Command Byte Values ............................................................................................ 129

Table 6-3: Data Tag Byte Values .............................................................................................. 130

Table 6-4: Error Status Byte Values .......................................................................................... 131

Table 6-5: Request Frame Structure ......................................................................................... 133

Table 6-6: Response Frame Structure ...................................................................................... 133

Table 6-7: System Setting Details ............................................................................................. 134

Table 6-8: System Threshold Addressing Details (Read Only) ................................................ 136

Table 6-9: System Conditions Addressing Details .................................................................... 137

Table 6-10: OSI Model for RM SSPA Ethernet IP Interface ..................................................... 145

Table 6-11: SNMP Detailed Settings ......................................................................................... 155

Table 6-12: SNMP Detailed Thresholds .................................................................................... 157

Table 6-13: SNMP Detailed Conditions..................................................................................... 158

PowerMAX SSPA System Operations Manual 214579 REV C 11

1.0 Introduction

The PowerMAX technology is the preeminent system technology in High Power

Amplifier (HPA) redundancy. PowerMAX is the only purely parallel redundant amplifier

system. All aspects of the system’s active components are parallel redundant including

SSPA modules, monitor and control circuitry, power supplies, and fans. In addition to

being parallel redundant all of the active components are hot-swap removable from

either the front or rear panels. Once installed there is never a need to remove a solid

state power amplifier (SSPA) chassis from the cabinet. All active components are

easily spared on site making the PowerMAX the easiest amplifier system to maintain.

The PowerMAX system architecture is based on a single SSPA module per chassis.

This allows PowerMAX systems to be configured with a large variety of output power

levels. For example, C-Band output power levels range from 400W to 10.0kW.

Furthermore, PowerMAX is a scalable amplifier system. For example, a PowerMAX

system may be initially configured with four modules and later upgraded to eight or 16

modules in the field. There is never a need to return any part of the system to the

factory as the upgrades are easily installed in the field. This provides a tremendous

protection of investment in the amplifier system. The system can easily grow with

future power and bandwidth demands.

1.1 Theory of Operation

PowerMAX is a purely parallel redundant, modular HPA system. It can be populated

with any number of modules between three and sixteen. For maximum RF efficiency it

is recommended to power combine binary arrays of four, eight, or sixteen modules. A

modular system is used either as an extremely high output power amplifier or as a selfredundant amplifier system. Parallel architecture systems make excellent redundant

systems. The PowerMAX system concept is purely parallel throughout all aspects of

the design. The failure of a power supply module, fan, or monitor and control card has

no effect on the system operation. Full output power capability is maintained as well as

remote communications and control of the amplifier system. The system will issue a

minor alarm and indicate precisely which component has failed. The maintenance

technician can then perform the replacement of the failed component without removing

the amplifier from service. This is referred to as hot-swap component replacement.

These components can be replaced without the need to remove an amplifier chassis

from the equipment cabinet.

When used as a self-redundant amplifier system, the PowerMAX should be configured

such that there is one module’s worth of excess output power capacity. In this way a

failure of one SSPA module will still allow the system to provide the minimum output

power necessary. This type of architecture is referred to as n+1 redundant, meaning

that there is one additional RF module then required for normal system operation.

Section 1: General Information

12 214579 REV C PowerMAX SSPA System Operations Manual

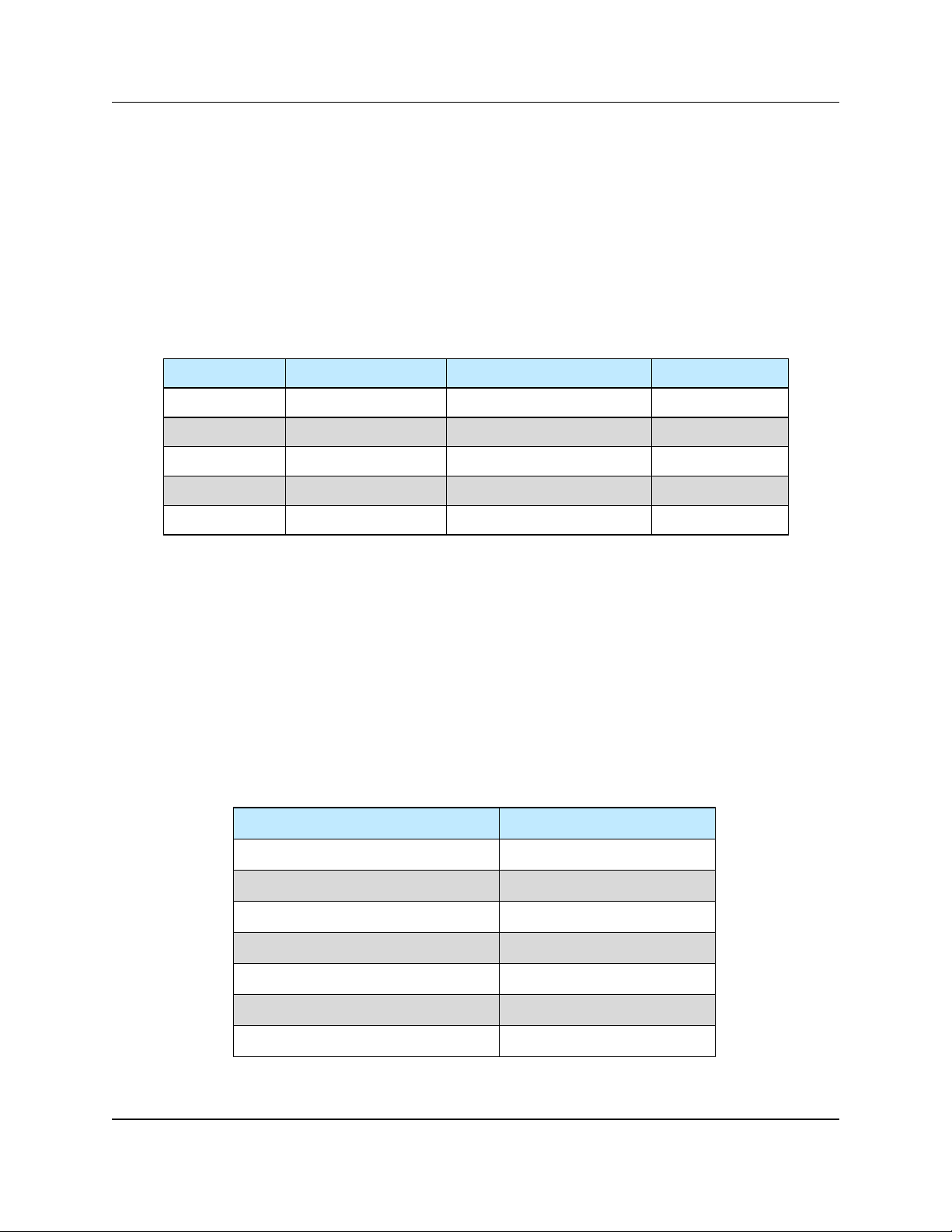

When configuring n+1 redundant system output power with binary array systems the

output power guideline shown in Table 1-1 should be followed.

Parallel architecture redundant systems have a distinct advantage over traditional

systems with their absence of transfer switching. Microwave transfer switches used in

traditional redundant systems have an inherent break-before-make characteristic. This

means that there is a finite period of time in which the RF output of the system is

completely dropped. This time can vary between hundreds of milliseconds to seconds

depending on the system design. Many satellite communication links are adversely

affected by a complete loss of carrier even for 100 milliseconds. Because there is no

transfer switch used in the PowerMAX system, there is never a complete loss of output

power for any period of time. The system will only lose a percentage of its output power as shown in the system configuration tables (Tables 1-2, 1-3 and 1-4). Under normal

operation (i.e., when output power levels are a few dB backed off from

maximum output power) there is no noticeable change in operation with a failure of an

SSPA module. The system gain of the PowerMAX will automatically compensate for

the failed module resulting in no change in the operating output power level.

The sophisticated firmware design of the PowerMAX permits the system to operate as

if it were a single chassis amplifier. There is no need to communicate directly with each

individual amplifier chassis, whether operating the system by remote link or locally via

the front panel. The system maintains a hierarchy of control whereby one of the n

modules in a system becomes the master control point. If the master amplifier were to

fail, control is automatically passed on to the next amplifier in the array. The master

amplifier is easily identified in the array by the front panel display.

The firmware design also provides for power savings operation. Any number of the

chassis can be placed in mute mode during periods in which full output power is not

required. This will make significant savings in electricity costs required to operate the

system. Otherwise the system provides 20dB of gain adjustment in 0.5dB increments

as well as optional ALC operation.

The system output power is measured with true rms power detection. Unlike peak

detection circuits common in many HPA systems, true rms detection gives a very

accurate measurement of the system’s output power in the presence of multiple

carriers and modulation types.

Table 1-1: PowerMAX Output Power Reduction

System Configuration Loss of One (1) Module Reduction in Output Power

4-Module 3 of 4 modules operating -2.4 dB

8-Module 7 of 8 modules operating -1.2 dB

16-Module 15 of 16 modules operating -0.6 dB

PowerMAX SSPA System Operations Manual 214579 REV C 13

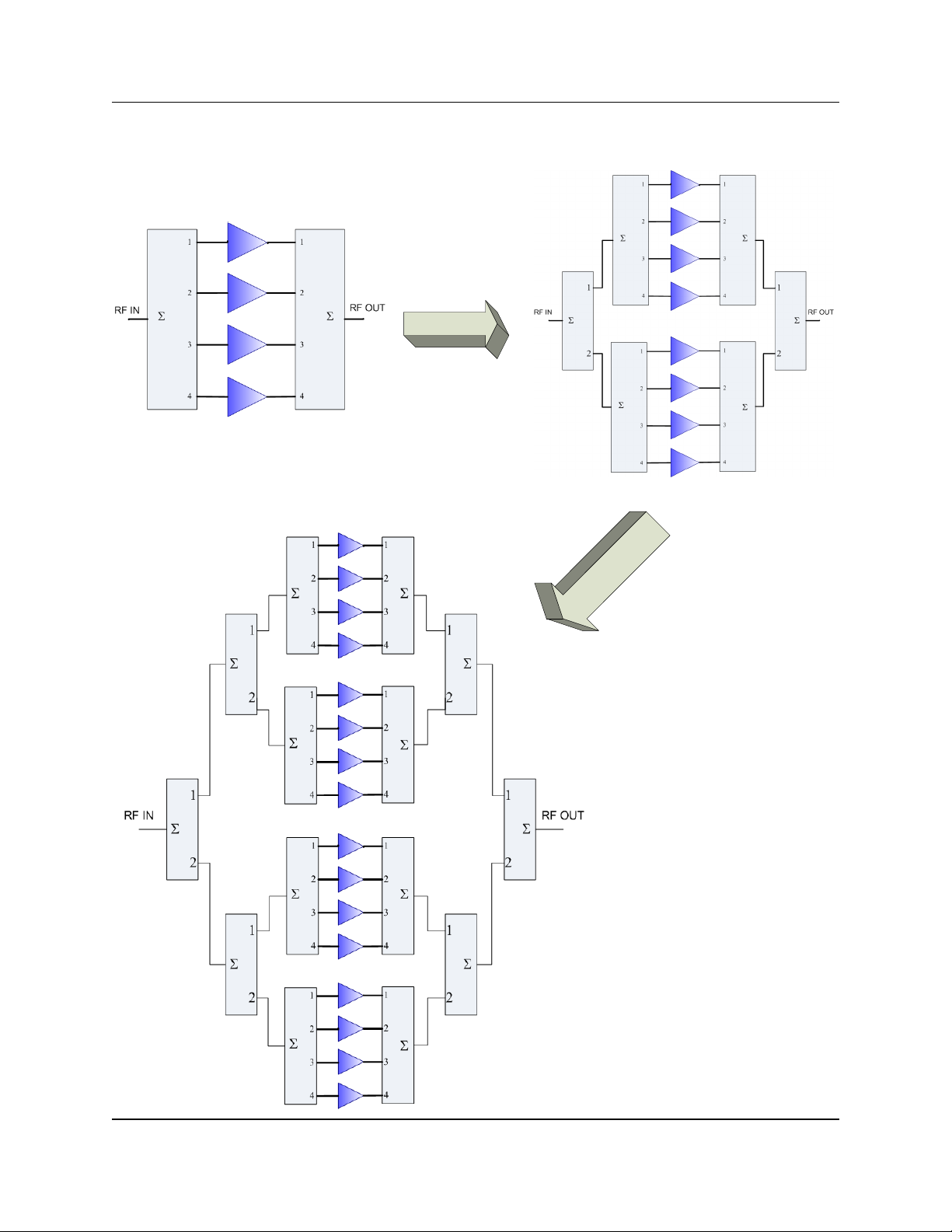

Figure 1-1 shows a simplified block diagram of the various system configurations.

Figure 1-1: System Block

Diagrams of 4-Module,

8-Module and 16-Module

PowerMAX Systems

4-Module System

8-Module System

16-Module System

14 214579 REV C PowerMAX SSPA System Operations Manual

1.1.1 Four-Module Systems

Figure 1-2 displays a simple block diagram of a Four -Module PowerMAX system.

Table 1-2 shows an example of maximum and redundant output powers at P

sat

and P

Linear

for Four-Module PowerMAX systems. Refer to the specification sheet in Ap-

pendix C for a full list of available power levels and output powers in the Four-Module

configuration.

2

1

3

4

2

1

3

4

RF IN

RF OUT

Table 1-2: Four-Module PowerMAX System Output Power Example

SSPA

Module

Power

Level

Typical Maximum

Output Power

4-modules, P

sat

Maximum

Output Power

4-modules, P

Linear

Typical Redundant

Output Power

3-modules, P

sat

Redundant

Output Power

3-modules, P

Linear

C-Band

400 W GaN

61.5 dBm (1.4 kW) 58.5 dBm (700 W) 59.1 dBm (800 W) 56.1 dBm (400 W)

Figure 1-2: Block

Diagram of 4-Module

PowerMAX System

- 3 dBm

- 2.4 dBm

- 3 dBm

A four-module PowerMAX system which experiences a failure

in one module will have a 2.4 dBm reduction in output power.

PowerMAX SSPA System Operations Manual 214579 REV C 15

1.1.2 Eight-Module Systems

Figure 1-3 displays a simple block diagram of a Eight -Module PowerMAX system.

Table 1-3 shows an example of maximum and redundant output powers at P

sat

and P

Linear

for Eight-Module PowerMAX systems. Refer to the specification sheet in Ap-

pendix C for a full list of available power levels and output powers in the Eight-Module

configuration.

2

1

3

4

2

1

3

4

2

1

2

1

3

4

2

1

2

1

3

4

RF IN RF OUT

Table 1-3: Eight-Module PowerMAX System Output Power Example

SSPA

Module

Power

Level

Typical Maximum

Output Power

8-modules, P

sat

Maximum

Output Power

8-modules, P

Linear

Typical Redundant

Output Power

7-modules, P

sat

Redundant

Output Power

7-modules, P

Linear

C-Band

400 W GaN

64.3 dBm (2.6 kW) 61.3 dBm (1.3 kW) 63.1 dBm (2.0 kW) 60.1 dBm (1.0 kW)

Figure 1-3: Block

Diagram of 8-Module

PowerMAX System

- 3 dBm

- 1.2 dBm

- 3 dBm

An eight-module PowerMAX system which experiences a failure

in one module will have a 1.2 dBm reduction in output power.

16 214579 REV C PowerMAX SSPA System Operations Manual

1.1.3 16-Module Systems

Figure 1-4 displays a simple block diagram of a 16-Module PowerMAX system. Table 1-4 shows an example of maximum and redundant output pow ers at P

sat

and

P

Linear

for 16-Module PowerMAX systems. Refer to the specification sheet in Appendix

C for a full list of available power levels and output powers in the 16-Module configura-

tion.

2

1

3

4

2

1

3

4

2

1

3

4

2

1

3

4

2

1

3

4

2

1

3

4

2

1

3

4

2

1

3

4

2

1

2

1

2

1

2

1

2

1

2

1

RF IN RF OUT

Figure 1-4: Block Diagram of 16-Module PowerMAX System

PowerMAX SSPA System Operations Manual 214579 REV C 17

1.2 Specifications

Refer to the specification sheet in Appendix C for complete specifications.

1.3 Inspection

When the unit is received, an initial inspection should be completed. First ensure that

the shipping container is not damaged. If it is, have a representative from the shipping

company present when the container is opened. Perform a visual inspection of the

equipment to make sure that all items on the packing list are enclosed. If any damage

has occurred or if items are missing, contact:

Teledyne Paradise Datacom

328 Innovation Blvd., Suite 100

State College, PA 16803 USA

Phone: +1 (814) 238-3450

Fax: +1 (814) 238-3829

1.4 Shipment

To protect the SSPA Chassis during shipment, use high quality commercial packing

methods. When possible, use the original shipping container and its materials. Reliable

commercial packing and shipping companies have facilities and materials to adequately repack the instrument.

Table 1-4: 16-Module PowerMAX System Output Power Example

SSPA

Module

Power

Level

Typical Maximum

Output Power

16-modules, P

sat

Maximum

Output Power

16-modules, P

Linear

Typical Redundant

Output Power

15-modules, P

sat

Redundant

Output Power

15-modules, P

Linear

C-Band

400 W GaN

67.0 dBm (5.0 kW) 64.0 dBm (2.5 kW) 66.4 dBm (4.3 kW) 63.4 dBm (2.1 kW)

- 3 dBm

- 0.6 dBm

- 3 dBm

A 16-module PowerMAX system which experiences a failure

in one module will have a 0.6 dBm reduction in output power.

18 214579 REV C PowerMAX SSPA System Operations Manual

1.5 Safety Considerations

Potential safety hazards exist unless proper precautions are observed when working

with this unit. To ensure safe operation, the user must follow the information, cautions

and warnings provided in this manual as well as the warning labels placed on the unit.

1.5.1 High Voltage Hazards

High Voltage, for the purpose of this section, is any voltage in excess of 30V. Voltages

above this value can be hazardous and even lethal under certain circumstances. Care

should be taken when working with devices that operate at high voltage.

All probes and tools that contact the equipment should be

properly insulated to prevent the operator from coming in

contact with the voltage.

The work area should be secure and free from non-

essential items.

Operators should never work alone on high voltage de-

vices. There should always be another person present in

the same work area to assist in the event of an emergency.

Operators should be familiar with procedures to employ in the event of an

emergency, i.e., remove all power, CPR, etc.

An AC powered unit will have 115 VAC or 230 VAC entering through the

AC power connector. Caution is required when working near this con-

nector, the AC circuit breaker, or the internal power supply.

1.5.2 High Current Hazards

Many high power devices are capable of producing large surges of current. This is true

at all voltages, but needs to be emphasized for low voltage devices. Low voltage

devices provide security from high voltage hazards, but also require higher current to

provide the same power. High current can cause severe injury from burns and

explosion. The following precautions should be taken on devices capable of

discharging high current:

Remove all conductive personal items (rings, watches,

medals, etc.)

The work area should be secure and free of non-essential

items.

Wear safety glasses and protective clothing.

Operators should never work alone on high risk devices.

There should always be another person present in the

same area to assist in the event of an emergency.

Operators should be familiar with procedures to employ in the event of an

emergency, i.e., remove all power, CPR, etc.

HIGH

CUR-

PowerMAX SSPA System Operations Manual 214579 REV C 19

Large DC currents are generated to operate the RF Module inside of the enclosure.

EXTREME CAUTION IS REQUIRED WHEN THE ENCLOSURE IS OPEN AND THE

AMPLIFIER IS OPERATING. DO NOT TOUCH ANY OF THE CONNECTIONS ON

THE RF MODULES WHEN THE AMPLIFIER IS OPERATING. CURRENTS IN EXCESS OF 60 AMPERES MAY EXIST ON ANY ONE CONNECTOR.

1.5.3 RF Transmission Hazards

RF transmissions at high power levels may cause eyesight damage and skin burns.

Prolonged exposure to high levels of RF energy has been linked to a variety of health

issues. Please use the following precautions with high levels of RF power.

Always terminate the RF input and output connector prior

to applying prime AC input power.

Never look directly into the RF output waveguide

Maintain a suitable distance from the source of the trans-

mission such that the power density is below recommended guidelines in ANSI/IEEE C95.1. The power density specified in ANSI/IEEE C95.1-1992 is 10 mW/cm2.

These requirements adhere to OSHA Standard 1910.97.

When a safe distance is not practical, RF shielding should be used to

achieve the recommended power density levels.

1.5.4 Electrical Discharge Hazards

An electric spark can not only create ESD reliability problems, it can also cause serious

safety hazards. The following precautions should be followed when there is a risk of

electrical discharge:

Follow all ESD guidelines

Remove all flammable material and solvents from the area.

All probes and tools that contact the equipment should be proper-

ly insulated to Prevent electrical discharge.

The work area should be secure and free from non-essential

items.

Operators should never work alone on hazardous equipment.

There should always be another person present in the same work area to

assist in the event of an emergency.

Operators should be familiar with procedures to employ in the event of an

emergency, i.e., remove all power, CPR, etc.

1.5.5 Tipping Hazard

To avoid risk of bodily injury, follow all instructions for maintaining the stability of the

equipment during transport, installation and maintenance.

RF

SIGNAL

20 214579 REV C PowerMAX SSPA System Operations Manual

The PowerMAX system is designed to be installed on a level

surface. Any attempt to install the cabinet on an uneven surface

may cause the cabinet to tip over, which may result in bodily

injury.

If the system includes the optional cabinet exhaust fans, do not

remove any of the SSPA chassis from the cabinet while the

exhaust fan door is open unless the cabinet is secured to the floor.

1.5.6 High Potential for Waveguide Arcing

As with all systems which utilize high power signals within

waveguide, the potential exists for an electric arc to form.

To minimize this risk, Teledyne Paradise Datacom requires all waveguide be pressurized and dehydrated.

1.6 Waveguide Pressurization and Dehydration

When working with high power amplifier systems that operate into waveguide, the inadvertent creation of arcs is always a concern. An arc in waveguide is the air discharge

breakdown due to the ionization of the air molecules by electrons. This breakdown in

waveguide occurs when the rate of electron production becomes greater than the loss

of electrons to diffusion to the surrounding walls.

It is extremely difficult to precisely predict the power levels at which the breakdown occurs. It is dependent on a variety of factors but the primary factors are:

Waveguide temperature and atmospheric pressure

Components in the Waveguide Transmission System such as: Flanges,

Bends, Tees, Combiners, Filters, Isolators, etc.

Load VSWR presented to the amplifier.

When operating such a high power amplifier system it is imperative that the waveguide

transmission system be dehydrated and pressurized. Operation with an automatic air

dehydrator will provide dry pressurized air to ensure that condensation cannot form in

the waveguide. Also the higher the pressure that can be maintained in the waveguide;

the higher the power handling is in the waveguide system. Most commonly available

air dehydrators are capable of providing pressures of 0.5 to 7.0 psig (25-362 mmHg).

At low power levels (uniform field distribution), low pressure can give good results. For

non-uniform conditions, highly localized breakdown can occur. In this case the wave-

guide system will require much higher pressure. This occurs with bends, waveguide

flange joints. If line currents flow across a small gap introduced by poor tolerances,

flange mismatch, poorly soldered bends, field strengths in excess of that in the main

line can occur in the gap. Pressurization with air or high dielectric gases can increase

the power handling by factors of 10 to 100.

PowerMAX SSPA System Operations Manual 214579 REV C 21

In High Power Amplifier systems an arc will travel from where it is ignited back to the

amplifier. Typical arc travel speed is on the order of 20 ft/sec. Increasing the waveguide pressure can reduce the speed of arc travel. It is difficult to get an accurate calculation of the amount of pressurization needed, but it is a good practice to get as

much pressure as your system can handle. All high power systems that meet the criteria of Table 1-5 are pressure tested at the factory to 1.5 psig. As a guide we rec-

ommend using the power levels in Table 1-5 as the threshold levels w here special

attention be given to dehydration and the overall simplification of waveguide system

design.

It is a common misconception to look up the maximum theoretical power handling of a

particular type of waveguide and assume that this is the maximum power handling.

This may be the case for a straight waveguide tube with ideal terminations but these

values must be significantly de-rated in practical systems. Phase combined amplifier

systems can be particularly sensitive to the potential for waveguide arcing. This is due

to the numerous bends, magic tees, multiple waveguide flange joints, and other wave-

guide components. Table 1-6 shows the power handling capability of some popu-

lar waveguide components normalized to the waveguide power rating. From this table,

we can see how a practical waveguide system’s power handling will de-rate significantly.

Table 1-6: Relative De-rating of Popular Waveguide

Components Relative to Straight Waveguide

Waveguide Component Relative Power Rating

H Plane Bend 0.6 to 0.9

E Plane Bend 0.97

90o Twist 0.8 to 0.9

Magic Tee 0.80

E-Plane Tee 0.06

H-Plane Tee 0.80

Cross Guide Coupler 0.21

Table 1-5: Recommended Output Power Thresholds

for Waveguide System Pressurization

Satcom Band Frequency Range Amplifier Output Power Waveguide

S Band 1.7-2.6 GHz > 10 kW WR430

C-Band 5.7 - 6.7 GHz > 2 kW WR137

X-Band 7.9-8.4 GHz > 1kW WR112

Ku-Band 13.75-14.5 GHz > 500W WR75

Ka-Band 27-31 GHz > 100W WR28

22 214579 REV C PowerMAX SSPA System Operations Manual

Most waveguide systems have many of these components integrated before reaching

the antenna feed. It is not uncommon for a Satcom waveguide network to de-rate to

5% of the straight waveguide power rating.

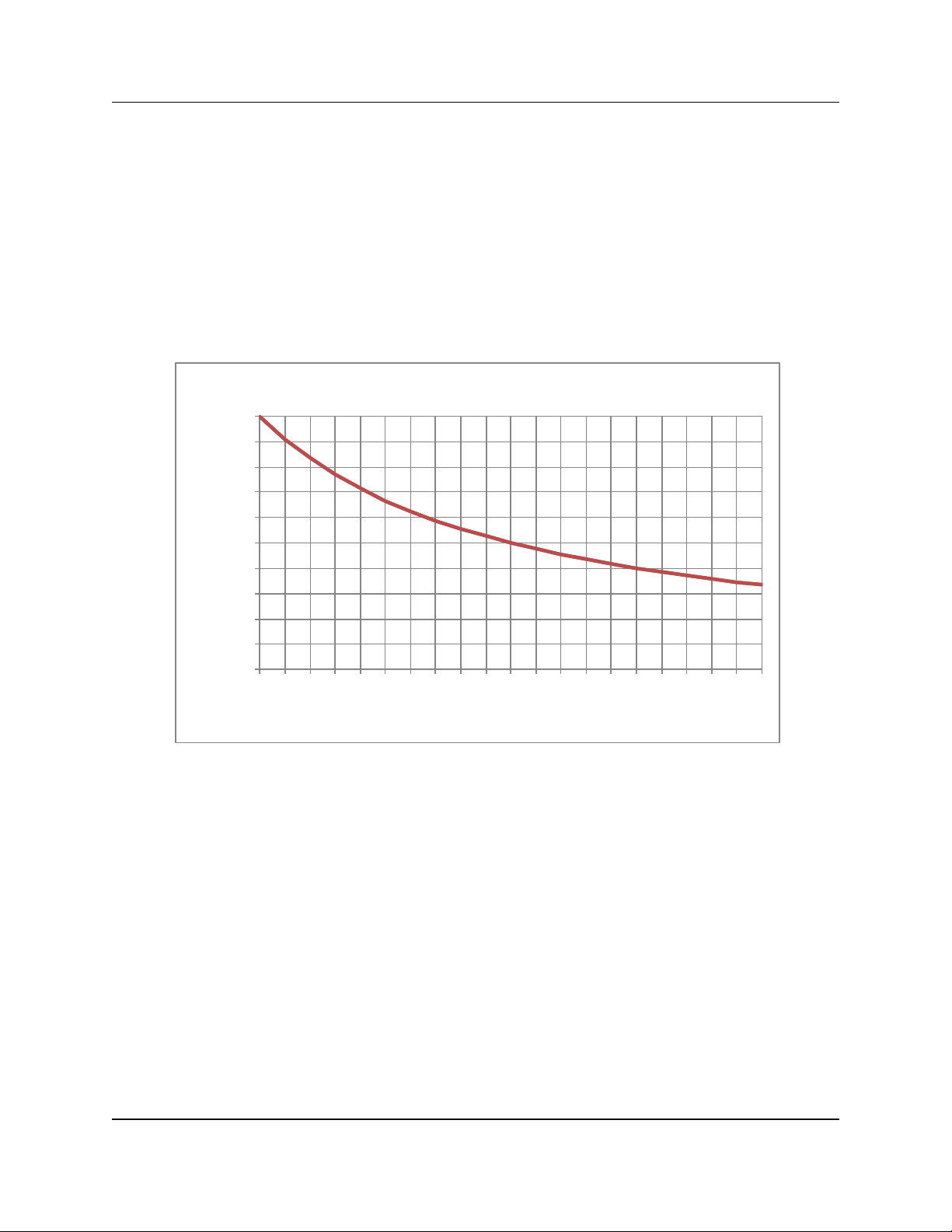

The load VSWR also has an impact on the breakdown threshold in waveguide networks. Standing waves degrade the power handling of any transmission line network.

The graph of Figure 1-5 shows the rapid degradation of waveguide breakdown vs.

load VSWR. The chart shows that for a 2.0:1 load VSWR, the breakdown potential will

be half of what it would be with a perfectly matched load. This can degrade even more

when high Q elements such as band pass filters are included in the waveguide network.

There are many factors to consider with high power amplifier systems in terms of the

output waveguide network. Especially when using HPA systems with output power

levels of Table 1-5, it is imperative to ensure that the output waveguide network is

pristinely clean and dry. An appropriate dehydrator should be used with capability of

achieving adequate pressure for the system’s output power. Take extra precaution to

make sure that any waveguide flange joints that are not already in place at the factory

are properly cleaned, gasket fitted, and aligned. A properly designed and maintained

waveguide network will ensure that no arcing can be supported and will provide many

years of amplifier service life.

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

3.0

Power Degradation Ratio

Load VSWR

Degradation of Breakdown Power by VSWR

Figure 1-5: Degradation of Breakdown Power by VSWR

PowerMAX SSPA System Operations Manual 214579 REV C 23

2.0 Introduction

This section contains descriptions of the various components of a PowerMAX SSPA

System. These include the SSPA Chassis, the Power Supply Chassis, the RF Distribution Panel, the optional AC Distribution Box and optional Ethernet Switch.

2.1 PowerMAX SSPA Chassis

The PowerMAX SSPA Chassis is a rack-mountable unit designed to fit in a standard

19” (483 mm) wide EIA rack. Each unit is 3 rack units or 5.22 inches (133 mm) high by

25.25 inches (641 mm) deep.

2.1.1 Front Panel Features

Figure 2-1 shows an illustration of the front panel view of a standard 3RU Rack

Mount chassis. The front panel features five (5) fault condition LEDs, a master/slave

indicator, a 40x2 character display, navigation keys, removable fan assembly and RF

sample port. The entire front panel may be removed to access the SSPA module.

2.1.1.1 Fault Condition LEDs

The RM SSPA has five fault condition LEDs on left side of the front panel which reflect

some of the HPA major faults plus the summary fault state.

Section 2: System Components

Figure 2-1: PowerMAX SSPA Chassis Front Panel

24 214579 REV C PowerMAX SSPA System Operations Manual

2.1.1.2 Master/Slave Indicator

When in N+1 Mode, pressing this key will put the designated HPA into Master Mode.

The LED beside this key will light when the HPA is in Master mode. If the LED is not

lit, the unit is in Slave Mode.

2.1.1.3 Front Panel Display

The front panel 40x2 character display allows the user to get detailed information

about state of the HPA and provides easy customization of operation through an

inter-active menu structure. See Section 5 for a full description of the menu structure

available through the front panel display.

2.1.1.4 Navigation Keys

The Up Arrow (▲), Down Arrow (▼), Left Arrow (◄), Right Arrow (►) and Enter

keys on the right side of the front panel allow the user to navigate through the menu

selections displayed on the front panel display.

2.1.1.5 Main Menu Key

Provides a shortcut to the SSPA main menu. See Section 5 for a complete description

of the menu selections and operation.

2.1.1.6 Local/Remote Key

Allows the user to disable or enable the local control keypad console. If the SSPA is in

"Remote Only" mode, the unit will not react on any keystrokes except the "Local/

Remote" key.

2.1.1.7 Mute/Unmute Key

Provides an easy way to change the Mute state of the SSPA. Muting the amplifier via

the front panel requires 100 msec maximum (50 msec minimum).

2.1.1.8 Output Sample Port [Type N (F)]

The Output RF Sample Port connector is located on the right lower corner of the HPA

front Panel. This provides a coupled sample of the RF output signal. A calibration tag

is located above the N-type (f) connector.

2.1.1.9 Removable Fan Assembly

The front panel fan assembly can be removed for maintenance. See Section 4 for

more details. The three-fan assembly operates at 20 VDC.

PowerMAX SSPA System Operations Manual 214579 REV C 25

2.1.1.10 Removable Face Plate

The entire front panel of the SSPA chassis is removable in order to access the SSPA

module. See Section 4, Troubleshooting and Maintenance for details on removing the

SSPA module from the chassis.

2.1.2 Rear Panel Features

Figure 2-2 shows the rear panel view of a standard DC input Rack Mount chas-