Platinum/Optima

CVE Pocket Guide

Platinum/Optima

CVE Refrigerated

Sampler

Pocket Guide

This pocket guide is not intended to replace

the instruction manual. Read the instruction

manual thoroughly before operating the

sampler.

COPYRIGHT © 2018 by

Teledyne ISCO

4700 Superior St.,

Lincoln, Nebraska, U.S.A. 68504

Phone: (402) 464-0231

Toll Free: (800) 228-4373

FAX: (402) 465-3022

Part Number: 69-2303-214

Released: October 2018

Information contained herein is classified as EAR99 under the U.S. Export

Administration Regulations. Export, reexport or diversion contrary to U.S.

law is prohibited.

Use and Disclosure of Data

Platinum/Optima

CVE Refrigerated

Sampler

Pocket Guide

Table of Contents

1. Introduction

1.1 Features .......................1-1

1.2 Specifications ...................1-6

2. Installation

2.1 Sampler Installation Overview .....2-1

2.2 Positioning the Sampler ..........2-2

2.3 Connecting Power ...............2-5

2.4 Installing a Bottle Kit ............2-7

2.4.1 24-1 Liter ................2-9

2.4.2 4-15 Liter (Platinum only). . 2-10

2.4.3 12-2.5 Liter ..............2-11

2.4.4 Single Bottle Configuration . 2-12

2.5 Attaching the Suction Line .......2-13

2.5.1 Vinyl Suction Line ........2-14

2.5.2 PTFE-lined Suction Line . . . 2-15

2.6 Attaching a Strainer ............2-16

2.6.1 Alternative to Strainers ....2-17

2.6.2 Max Unanchored Length . . . 2-17

2.7 Routing Suction Line and Strainer . 2-18

2.8 External Devices ...............2-19

iii

2.8.1 Other Device Connections . . 2-20

2.9 Configure and Program the Sampler . . .

2-24

2.10 Locking the Sampler ............2-24

2.11 Quick Start Guide ..............2-25

2.11.1 Program Ready Screen .....2-25

2.11.2 Program Configuration ....2-25

2.11.3 Sample Interval ..........2-27

2.11.4 Time Option .............2-27

2.11.5 Bottle Options ............2-27

3. Programming

3.1 Control Panel Description .........3-1

3.2 Getting Started .................3-3

3.3 Configuring the Sampler ..........3-4

3.3.1 Set Clock .................3-5

3.3.2 Bottle Configuration ........3-6

3.3.3 Suction Line ..............3-7

3.3.4 Rinse Cycle ...............3-8

3.3.5 Liquid Detector and Recycle . 3-9

3.3.6 Float Input ..............3-10

3.3.7 Output Pins ..............3-10

3.3.8 Refrigeration .............3-12

3.3.9 Program Lock ............3-13

3.3.10 Language Selection ........3-14

3.3.11 Set Unit ID ..............3-15

3.3.12 Diagnostics ..............3-16

3.3.13 Exit Configuration ........3-16

3.4 Sampling Program Overview .....3-16

3.4.1 Program Configuration ....3-18

3.4.2 Sampling Cycle

........................3-18

3.4.3 Sample Interval ..........3-21

3.4.4 Bottle Configuration

........................3-22

3.4.5 Program Run Options

........................3-24

3.4.6 Program Events

iv

Table of Contents

3.5 Programming Steps .............3-28

3.5.10 Flow Pulses, Analog Input . . 3-34

3.5.11 Composite Samples .......3-34

3.5.12 Pressurized Line ..........3-35

3.5.13 Timed Delay .............3-35

3.5.14 Auto Re-Run .............3-37

3.5.15 Timed Stop/Max Run Time . 3-37

........................3-27

3.5.1 Sample Pacing ...........3-28

3.5.2 Time Paced ..............3-29

3.5.3 Flow Paced ..............3-29

3.5.4 Bottles per Sample Event . . 3-30

3.5.5 Switch on Time Indexing . . . 3-31

3.5.6 Real Time Indexing .......3-31

3.5.7 Samples Per Bottle ........3-32

3.5.8 Run Continuously .........3-33

3.5.9 Sample Second ...........3-34

4. Operation

4.1 Start a Sampler Program .........4-1

4.1.1 Sample Calibration .........4-2

4.1.2 Start Time Delay ..........4-3

4.1.3 The Run State .............4-3

4.1.4 Completed Program ........4-4

4.2 Pause or Stop a Running Program . . 4-5

4.3 Post Sampling Activities ..........4-6

4.3.1 View the Log ..............4-6

4.3.2 User Interface Icon ........4-10

4.3.3 Sample Bottle Removal ....4-12

4.4 Grab Samples ..................4-13

4.5 Velocity Control Valve ..........4-14

5. Maintenance

5.1 Periodic Maintenance Checklist ....5-1

5.2 Fuse ..........................5-2

5.3 Cleaning the Sample Chamber .....5-3

5.3.1 Sample Chamber Removal . . . 5-3

5.3.2 Sample Chamber Installation 5-4

5.3.3 Installing the Tubing .......5-4

v

5.3.4 Sample Chamber Parts .....5-8

5.4 Compressor/Vacuum Pump .......5-10

5.5 Clean or Replace Wetted Parts ....5-11

5.5.1 Sampler Cleaning Guidelines . . .

5-11

vi

Platinum/Optima

CVE Refrigerated

Sampler

Section 1 Introduction

1.1 Features

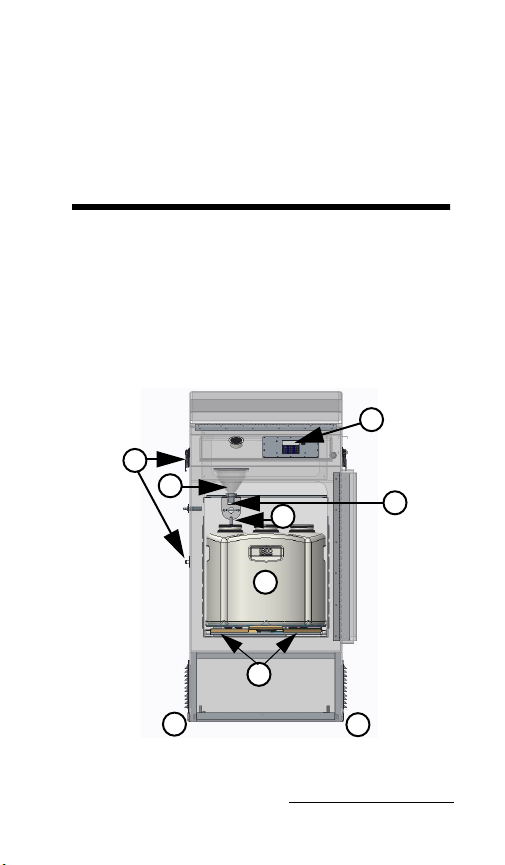

The sampler features are identified in Figures

1-1 through 1-4 and described in Table 1-1.

2

8

4

3

5

10

6

9

Figure 1-1 Sampler features (Front)

9

1-1

Platinum/Optima CVE Refrigerated Sampler

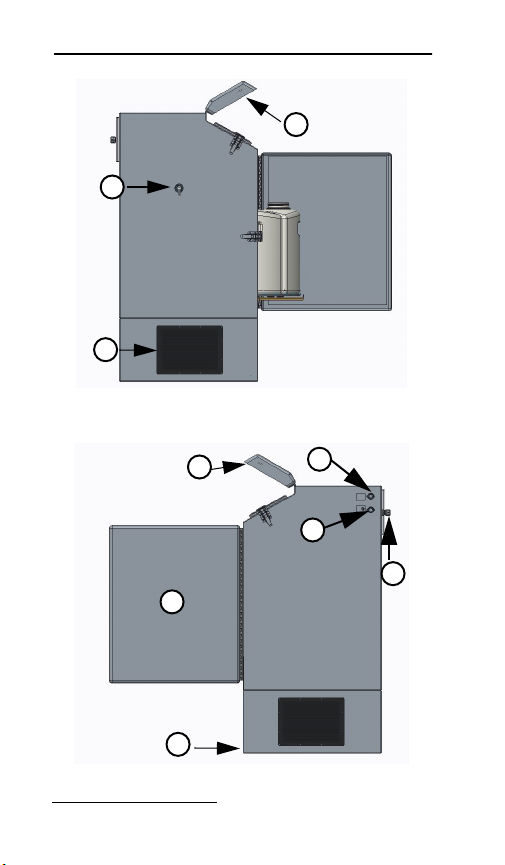

1

15

16

Figure 1-2 Sampler features (left side)

1

7

13

12

17

Figure 1-3 Sampler features (right)

1-2

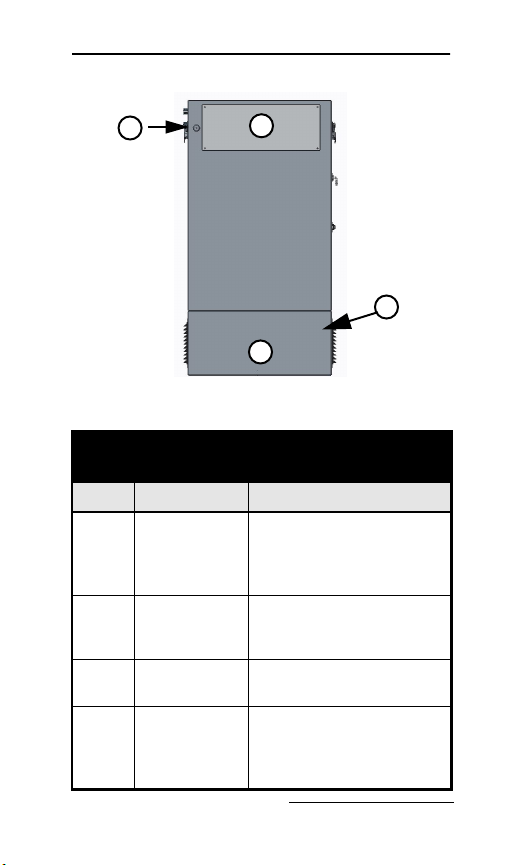

14

Section 1 Introduction

14

18

11

Figure 1-4 Sampler features (back)

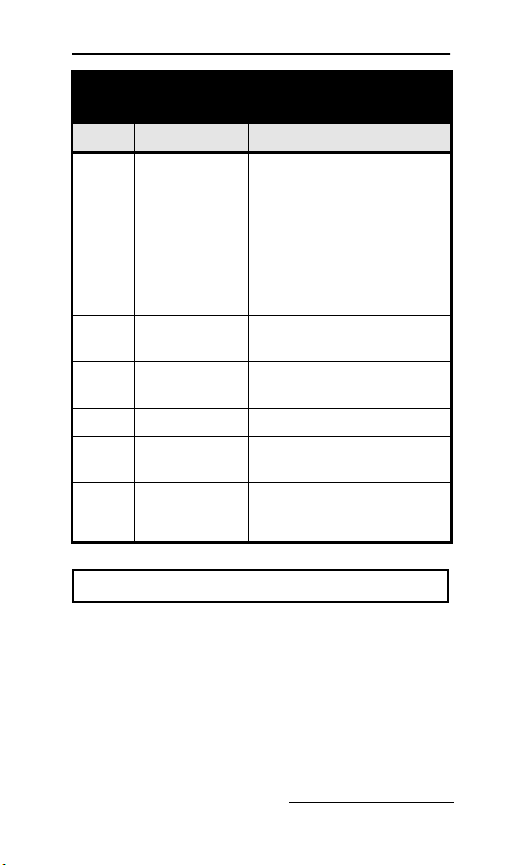

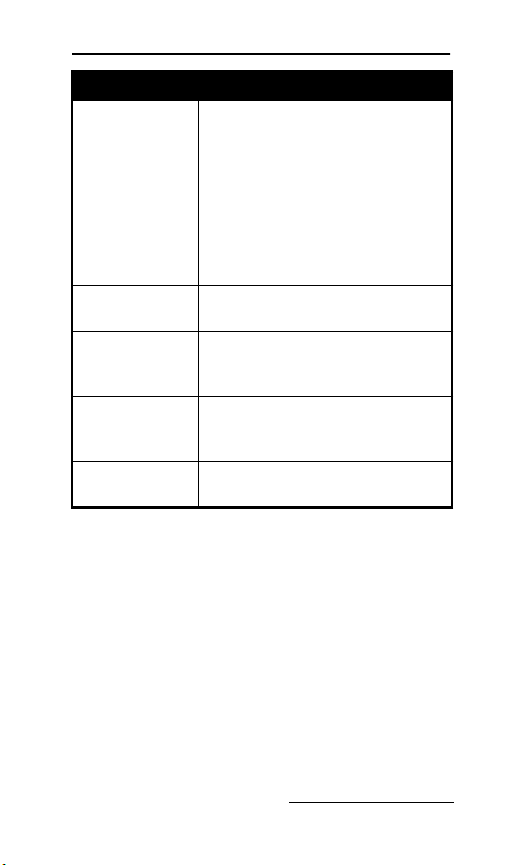

Table 1-1 Sampler Features

Item Name Description

1 Control

Panel Cover

2 Control

Panel

3 Discharge

Tube

4 Sample

Chamber

Protects the control panel

display and keypad. Can

be locked with user

supplied padlock.

Supports user control and

programming of sampler

operation.

Carries liquid to the

sample bottle.

Sample is measured and

collected in the chamber

then discharged into

sample container.

13

inside

1-3

Platinum/Optima CVE Refrigerated Sampler

Table 1-1 Sampler Features

(Continued)

Item Name Description

5 Bottles Hold the collected

6 Sequential

Ta ble

7 Refrigerator

Door

8 Latch Secures the door. The

9Level

Adjustment

Feet

10 Liquid

Detector

11 Lower Back

Cover

12 External

Device

Connection

samples.

Rotates the bottles.

Protects the collected

samples inside the

refrigerated

compartment.

latch mechanism may be

locked with a

user-supplied padlock.

The sampler includes four

level adjustment feet, one

at each corner. Use these

to keep the sampler

leveled.

The liquid-sensing

electrodes detect fluid in

the sample chamber.

Access to Refrigeration

Module.

Supports connections to

external devices such as

a flow meter for sample

pacing or 4-20mA.

1-4

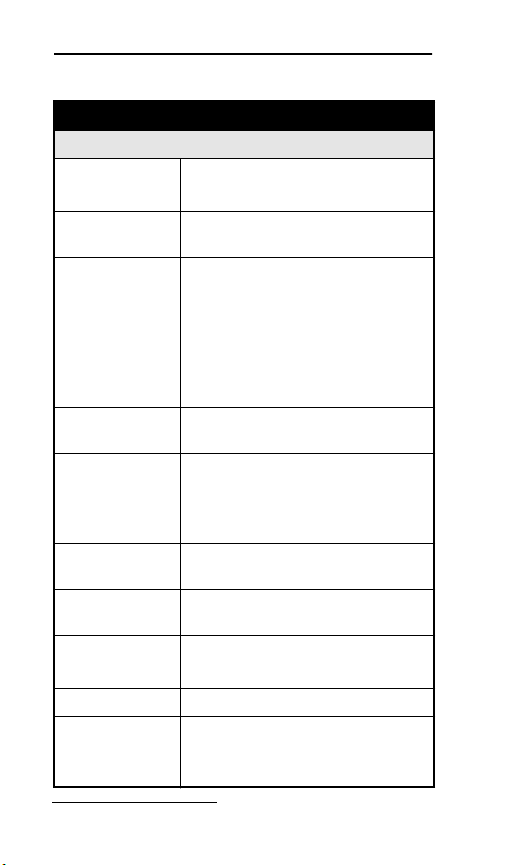

Section 1 Introduction

Table 1-1 Sampler Features

(Continued)

Item Name Description

13 Refrigeration

Module

14 AC Mains

Line Cord

15 Sample Line

intake

16 Air Vents Refrigeration air vents

17 Aux. Outputs Alarm, Fl. Star t, Fl.

18 Top Back

Cover

Modular,

corrosion-resistant

refrigeration assembly

cools the refrigerated

compartment to a

user-selected.

Temperature of 2 to 5 °C

(35 to 41°F).

Connects to AC power

source.

The sample intake line

connects here.

Start/Stop Run Status.

Access to the vacuum

pump, fuses, and

electrical components.

CAUTION

When lifting the sampler, cautiously lift with 2 people

(one on each side) with the door closed and latched.

Recommend using a lifting device.

1-5

Platinum/Optima CVE Refrigerated Sampler

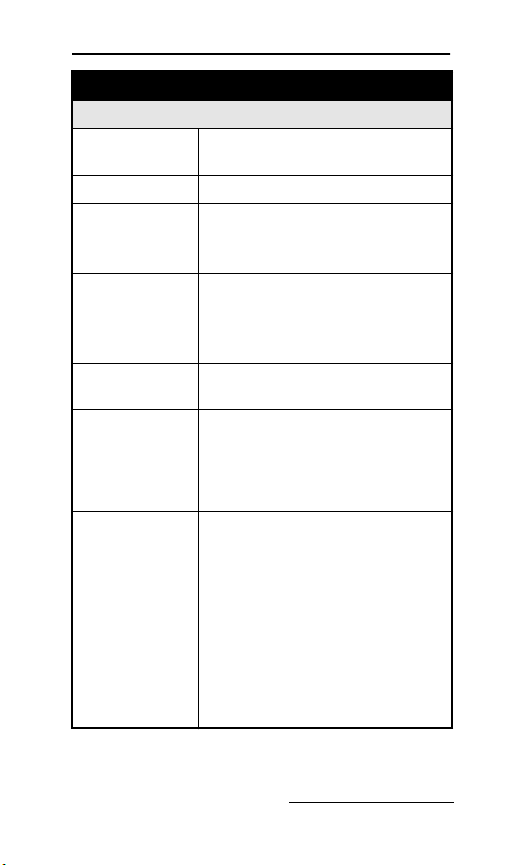

1.2 Specifications

Table 1-2 Specifications

General

Size

(H×W×D):

Weight

(empty):

Bottle

Configuration:

Refrigerator

Body:

Powe r

Requirements:

Installation

Category:

Pollution

Degree:

Maximum

Altitude:

Humidity: 0 to 100%

Operational

Temperature:

49 x 25.5 x 25.5 inches

124.4 x 64.7 x 64.7 cm

97 kg

214 lbs.

6 configurations available:

24, 1-liter PP

12, 2.5-liter PP

4, 15-liter PP

1, 20-liter PE

1, 10-liter PE or glass

Molded fiberglass with UV

resistant gel coat.

115 VAC ±10%, 60 Hz

Running current 12 amperes

230 VAC ±10%, 50 Hz

Running current 6 amperes

II

3

2,000 meters

6,562 feet

–29 to 49 °C

–20 to 120 °F

1-6

Section 1 Introduction

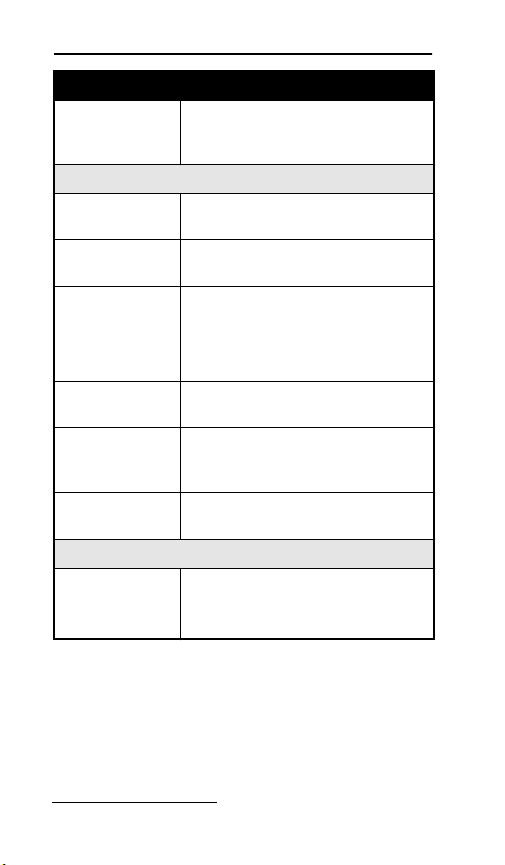

Table 1-2 Specifications (Continued)

Tubing

Intake Suction

Tubing Length:

Material: Vinyl or PTFE-lined polyethylene

Inside

Diameter:

1to45m

3 to 150 feet

3

8 inch (9 mm)

1

2 inch (12mm)

Maximum

Suction Lift:

Typical

Repeatability:

Typical Line

Velocity at

Head Height:

115VAC/60Hz

28 ft. lift Pump

Typical Line

Velocity at

Head Height:

230 VAC/50Hz

28 ft. lift Pump

28 ft. (8.5 m) with38 inch suction

line

22 ft. (7.0 m) with ½ inch suction

line

±5 ml or ±5%

3

8 inch suction line

3ft: 9.84ft/s

10ft: 7.38ft/s

20ft: 4.50ft/s

3

8 inch (9 mm) suction line

1 m: 2.04 m/s (6.70 ft/s)

4 m: 2.10 m/s (6.89 ft/s)

7 m: 1.52 m/s (4.99 ft/s)

½ inch (12 mm) suction line

1 m: 1.74 m/s (5.71 ft/s)

3 m: 1.60 m/s (5.25 ft/s)

7 m: 1.33 m/s (4.36 ft/s)

1-7

Platinum/Optima CVE Refrigerated Sampler

Table 1-2 Specifications (Continued)

Liquid

Presence

Detector:

Controller

Enclosure

Rating:

Program

Memory:

Flow Meter

Signal Inputs:

Digital Alarms: 1 output, with 5 alarm

Number of

Composite

Samples:

Internal Clock

Accuracy:

Software

Sample

Frequency:

Wetted Liquid-sensor electrodes.

NEMA 4X

IP66

Non-volatile ROM (Flash)

Pulses (dry contacts)

4-20 mA

0-5 VDC

0-10 VDC

configurations

Programmable from 1 to 999

samples.

1 minute per month at 25 °C

1 to 9999 minutes, in 1-minute

increments

1 to 9,999 flow pulses

1-8

Section 1 Introduction

Table 1-2 Specifications (Continued)

Sampling

Modes:

Sample

Volumes:

Sample

Retries:

Rinse Cycles: Rinsing of suction line up to 4

Controller

Diagnostics:

Constant Time, Constant Volume

Variable Time, Constant Volume

Constant Flow, Constant Volume

Variable Flow, Constant Volume

Time and Flow Based Sampling

(refer to manual for more info)

Incremental Time per Bottle

Incremental Flow per Bottle

20 to 400 ml

If no sample reaches the

liquid-sensor electrodes, recycle

will activate up to 4 attempts.

rinses for each sample

collection.

Live diagnostics while sampling.

1-9

Platinum/Optima CVE Refrigerated Sampler

1-10

Platinum/Optima

CVE Refrigerated

Sampler

Section 2 Installation

2.1 Sampler Installation Overview

The following sections provide general

instructions for placing the sampler into

operation. In typical applications, the steps are:

1. Positing the sampler (Section 2.2)

2. Connecting power. (Section 2.3)

3. Installing a bottle kit. (Section 2.4)

4. Attaching the suction line. (Section 2.5)

5. Attaching a strainer. (Section 2.6)

6. Routing the suction line and strainer.

(Section 2.7)

7. Connecting the sampler to external devices.

(Section 2.8)

8. Configuring and programming the sampler.

(Section 2.9)

9. Locking the sampler. (Section 2.10)

2-1

Platinum/Optima CVE Refrigerated Sampler

2.2 Positioning the Sampler

There are a few considerations when selecting a

site for the sampler. The foremost concern

should be personal safety.

The installation and use of this product may

subject you to dangerous working conditions

that can cause you serious or fatal injuries.

Take any necessary precautions before entering

the work site. Install and operate this product

in accordance with all applicable safety and

health regulations, and local ordinances.

WARNING

If this product is used in a manner not specified

in this manual, the protection provided by the

equipment may be impaired.

WARNING

This product has not been approved for use in

hazardous locations as defined by the National

Electrical Code.

WARNING

The sampler is heavy. When lifting, use a

two-person lift from the right and left sides. When

possible, move the sampler using a two-wheeled

hand cart from the side. To prevent damage to the

refrigeration system, do not tip the sampler more

than 45°.

2-2

Section 2 Installation

Dangerous Locations – If you must enter a

manhole, confined space, or other dangerous

location to install the suction line and strainer,

observe standard safety precautions.

Support – The sampler should be installed on

a surface capable of safely supporting the

sampler, full liquid containers, and personnel.

AC Power – The mains line cord is the

disconnect device should you need to remove

power. Therefore, the electrical power outlet

should be accessible.

Environmental – The sampler is designed for

outdoor use. Refer to Table 1-2 for

environmental specifications. When possible,

avoid subjecting the sampler to chemical

attacks and direct sunlight.

Avoid Submersion – The sampler is rated

NEMA 4x (IP66), which does not protect from

submersion. In the event of submersion, liquid

entering the refrigeration system could

permanently damage the sampler; liquid

entering the bottle compartment could

contaminate the collected samples. Liquid

entering the electrical compartment for the

refrigeration system could result in a short

circuit and possible shock hazard.

Liquid Sample Collection Point – It is best

to keep the distance between the sampler pump

and the collection point as short as possible.

Also, the pump inlet should be located above

the liquid surface to be sampled with no liquid

traps. Gravity will aid suction line rinses and

allow the line to drain, thereby reducing the

2-3

Platinum/Optima CVE Refrigerated Sampler

possibility of sample cross-contamination. Refer

to Table 1-2 for maximum suction line lengths

and suction head heights.

Security – The sample compartment and

control panel have a padlock feature, but the

location may need additional security to

prevent tampering or vandalism.

Accessibility – The sampler must be installed

in a location where personnel can easily

exchange bottles and perform routine service.

The sampler requires about 2600 square

centimeters (925 in

2

) of floor space. Additional

space must be allowed in front of the sampler,

at its left and right sides, and above the

sampler. Do not block access to these areas.

Obstructions will make routine servicing

activities difficult or impossible.

The back of the sampler may be placed against

a wall. Allow free air flow on both right and left

sides of the sampler, particularly at the vents.

Unrestricted air flow behind and around the

sampler will allow the refrigeration system to

work efficiently.

Level Surface – The sampler should be placed

on a level surface and the feet on the

refrigerator body should be adjusted to prevent

tipping or spills. If the sampler is not level, the

sample liquid may miss the bottle mouth.

To level the sampler, place a bubble level on the

top of the refrigerated compartment.

2-4

Section 2 Installation

CAUTION

Do not tip the sampler on its side or back. Tipping

the sampler more than 45° might cause oil to run

into the compressor inlet, which can permanently

damage the refrigeration system.

2.3 Connecting Power

WARNING

Before connecting the sampler to an AC power

source, be familiar with the Electrical

Requirements listed at the front of the Installation

and Operation manual.

The factory assembles the sampler for either

115 VAC/60 Hz, or 230 VAC/50 Hz. The serial

number label located inside the control cover

identifies the AC power configuration of your

sampler. You cannot convert the sampler in the

field.

• The mains power cord for 115 VAC

samplers is equipped with a NEMA 5-15P

plug for standard North American

outlets.

• The mains power cord for 230 VAC

samplers is equipped with an EU 1-16P

plug for standard CEE 7-7 European

outlets.

• For other types of outlets that supply

compatible AC power, convert the mains

2-5

Platinum/Optima CVE Refrigerated Sampler

power cord plug with a locally-purchased

adapter.

Plug the mains power cord into the outlet. The

sampler control panel will briefly show this

start up display.

Note

The refrigeration system must sit for 24 hours before

powering up. This allows the compressor oil to drain

back into the compressor if the unit was tipped on its

side any time dur ing shipment or during installation.

2-6

Section 2 Installation

2.4 Installing a Bottle Kit

The sampler can hold 1, 4, 12, and 24 bottles.

Each of these bottle configurations are supplied

as a kit (see Table 2-1), which is normally

ordered with the sampler or when you desire to

change the bottle configuration.

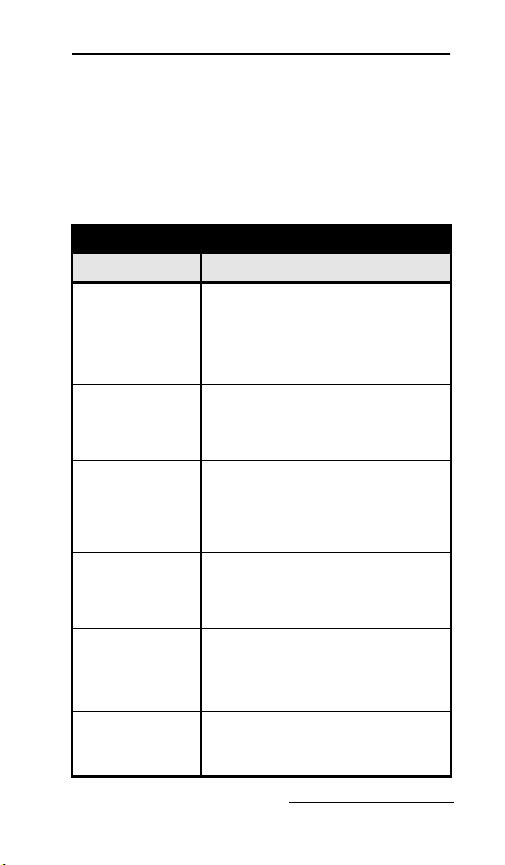

Table 2-1 Bottle K its

Part Number Description

602320001 24-bottle Configuration. Includes

602320003 4-bottle Configuration. Includes

602320002 12-bottle Configuration. Includes

682320026 1-bottle Configuration. Includes

682320025 1-bottle Configuration. Includes

299001306 1-bottle Configuration. Includes

complete bottle rack with 24

polypropylene 1-liter wedge

shaped bottles with caps and

discharge tube.

bottle rack with 4 polypropylene

15-liter wedge shaped bottles

with caps.

complete bottle rack with 12

polyethylene 2.5-liter wedge

shaped bottles with caps and

discharge tube.

one polyethylene 3-gallon

(11-liter) container, lid, and full

bottle shutoff switch.

one polyethylene 5-gallon

(18.5-liter) container, lid, and full

bottle shutoff switch.

one polyethylene 5.5-gallon

(20.5-liter) round bottle and cap.

2-7

Platinum/Optima CVE Refrigerated Sampler

Refer to the instructions for your selected bottle

configuration:

•

Bottle Configuration: 24-1L – Section

2.4.1

• Bottle Configuration: 4-15L – Section

2.4.2

• Bottle Configuration:12-2.5L – Section

2.4.3

If you have selected a single (composite) bottle

kit, refer to the instructions in Section 2.4.4.

For first-time use of the sampler, or if you have

changed the bottle kit, be sure to configure the

program for the new bottle kit (Section 3.3.2).

Note

An incorrectly installed discharge tube can cause the

sample to miss the bottle. Do not try to manually rotate

the sequential table. This may damage the drive

system.

2-8

Section 2 Installation

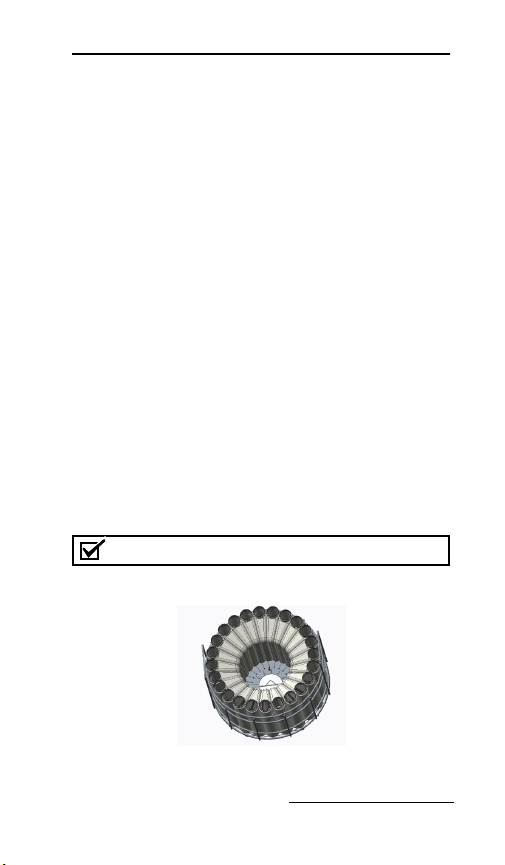

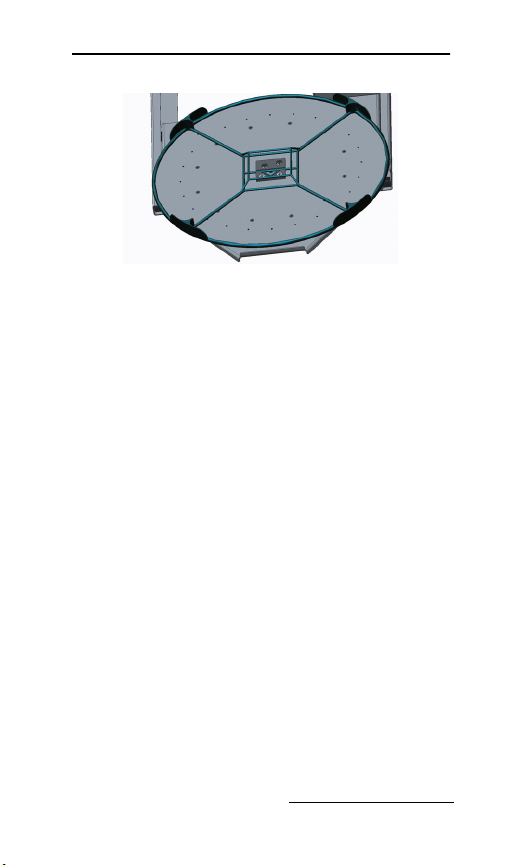

2.4.1 24-1 Liter

The 24 bottle configurations use a rack to hold

and align the containers. To install the bottles

in the refrigerator using the rack:

1. Place the uncapped bottles into the rack.

Install bottle retaining ring and fasten with

the 3 bungee cords.

2. Pull the sequential table forward. (Platinum

only).

3. Locate the arrow in center of the rack and

align it with the center block located on the

turn table.

4. Roll the sequential table back into the

sampler. (Platinum only).

5. Activate the program to R

UN and the table

will turn to locate #Bottle 1. After the table

has stopped make sure the discharge tube is

centered on the bottle. If the discharge tube

is not centered, rotate/adjust the discharge

tube to the center of the bottle.

Note

Bottle caps can be stored in the center of the bottle

rack.

Figure 2-1 Bottle rack with 24-1 liter bottles

2-9

Platinum/Optima CVE Refrigerated Sampler

Note

Align the arrow in the center of the rack with center

block located on the table (Figure 2-2).

Figure 2-2 Locating center block

2.4.2 4-15 Liter

(Platinum only).

To install the rack and bottles:

1. Pull the sequential table forward.

2. Place the four bottles on the sequential

table using the alignment rack to position

the bottles. Remove the bottle caps.

3. To load or unload the sample bottles there is

a table jog feature. When the program is not

in the run mode, the jog feature is available

by pushing the 0 button on the keypad. The

table will jog 90° each time 0 is pushed.

4. When the bottles are loaded, slide the

sequential table back into place.

2-10

Section 2 Installation

Figure 2-3 The 4-15 liter bottle rack

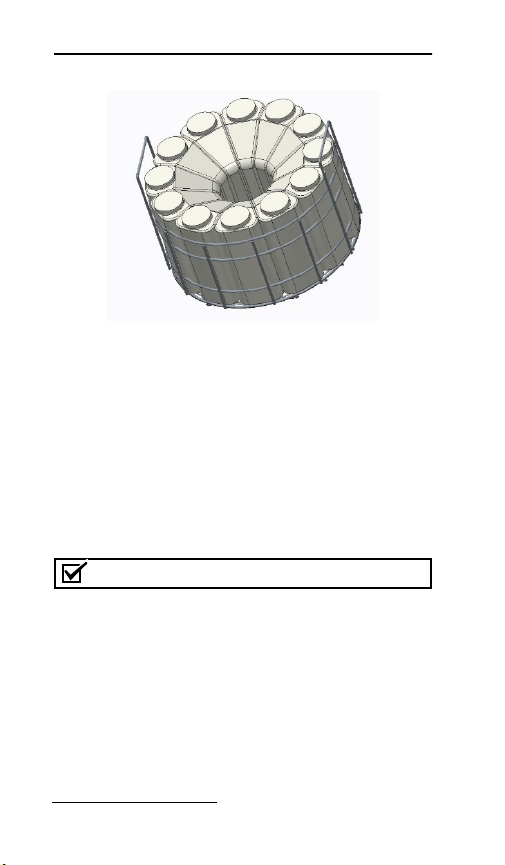

2.4.3 12-2.5 Liter

The 12 bottle configuration uses a rack to hold

and align the bottles. To install the bottles into

the sampler:

1. Place the uncapped bottles into the rack.

2. Roll the sequential drive out.

3. Locate the arrow in the center of the rack

and align it with the center block located at

the center of the drive table.

4. Roll the sequential table back into the

refrigerated compartment.

5. Activate the program to R

UN and the table

will turn to locate #Bottle 1. After the table

has stopped make sure the discharge tube is

centered in the bottle. If the discharge tube

is not centered, rotate/adjust the tube to the

center of the bottle.

2-11

Platinum/Optima CVE Refrigerated Sampler

Figure 2-4 Bottle rack and 12-2.5 liter

2.4.4 Single Bottle Configuration

If your sampler is configured for composite

sampling simply place the discharge tube in the

center of the sample bottle.

Composite Bottle Installation

1. Install the discharge tube (if needed).

Remove bottle cap and position the bottle

under the discharge tube.

Note

Make sure the discharge does not contact the bottle in

any way.

2. Go to BOTTLE OPt. in the menu and select

OMPOSITE and then select your bottle size.

C

2-12

Section 2 Installation

Figure 2-5 One 20 Liter PE Bottle

2.5 Attaching the Suction Line

Note

The suction line is the tubing from the sampling point to

the sampler intake fitting. The sampler typically uses a

3

/8inch ID (9 mm) suction line of lengths from 3 to 150

feet. Teledyne ISCO offers vinyl or PTFE-lined suction

lines. The PTFE-lined tubing has a polyethylene jacket

to protect it from kinks and abrasions.The vinyl suction

line contains a very low parts-per-million level of

phenols. If phenol content affects your sample analysis,

use the PTFE-lined suction line.

2-13

Platinum/Optima CVE Refrigerated Sampler

Teledyne ISCO ships suction line in standard

lengths of 3.0 m (10 ft) or 7.6 m (25 ft). Either

length should be cut to the shortest length

feasible for the installation. When installed, the

line should run the shortest possible distance

from the collection point to the sampler,

preferably with a gradual upward slope. Excess

suction line should be cut, not coiled. Coiled

suction line will hold liquid between sample

events which could cross-contaminate samples

or freeze in cold climates. If the standard

lengths are too short, or if you are cutting

3

compatible

/8inch ID suction line from a bulk

spool, you can use lengths up to 45 m (150 ft).

2.5.1 Vinyl Suction Line

The sampler inlet fitting is on the left side of

the samplers.

fittings are available to choose from. The

sample line is

3

/4” clear PVC tubing which is connected to the

1

/2” and3/8” stainless steel barbed

3

/8”x5/8” (I.D. x O.D.) or1/2” and

a right-angle barbed fitting.

Figure 2-6 Left side of the sampler

2-14

Section 2 Installation

2.5.2 PTFE-lined Suction Line

Inserting a tube coupler into PTFE-lined

suction line will damage the thin lining.

Instead, refer to Figure 2-7 and the instructions

below to attach PTFE-lined suction line to the

sample tube:

1. Slide a short piece of silicone tubing over

the inlet fitting and install a hose clamp (B).

2. Push about 20 mm of the PTFE-lined

suction line into the end of the silicone tube

(A).

3. Slide the clamp over the union and tighten.

Do not overtighten; this might cause the

tubing to collapse or restrict the flow.

A

B

Figure 2-7 Connecting PTFE-lined suction

line (A) silicone tube (B)

2-15

Platinum/Optima CVE Refrigerated Sampler

2.6 Attaching a Strainer

To select the right strainer for your application,

refer to Figure 2-8 and the table that follows.

øA

Low Flow

Weighted

60-9004-367

69-2903-138

CPVC

60-3704-066

øB

C

Figure 2-8 Strainers

To attach the strainer to the suction line,

carefully screw the strainer’s threaded

connector into the suction line. If attaching the

strainer to an PTFE-lined suction line, heat the

suction line end before threading the strainer

2-16

Section 2 Installation

into the line. Warming PTFE-lined tubing will

make it more pliable to avoid damage.

2.6.1 Alternative to Strainers

When sampling from high velocity streams

with heavy suspended solids, some field

investigations suggest that more

representative samples are obtained without

the strainer. Consider attaching a short piece of

thin walled aluminum tubing to the end of the

suction line; anchor the tubing so that the inlet

opens upstream. The aluminum tubing’s thin

wall will not disturb the flow stream, and most

sample analyses disregard aluminum ions.

Under most conditions, a pre-sample line rinse

removes any debris over the tubing entrance.

2.6.2 Max Unanchored Length

During a pre or post-sample purge or line rinse,

the suction line is filled with air which might

cause the suction line and strainer to float. If

the length of the suction line and strainer

exceeds the listed value, securely anchor the

strainer.

Even if the maximum length is not exceeded, it

is a good idea to anchor the suction line and

strainer when sampling from high velocity or

turbulent flow streams.

2-17

Platinum/Optima CVE Refrigerated Sampler

2.7 Routing Suction Line and Strainer

Route the suction line so that it has a

continuous slope from the liquid source to the

sampler. This helps to drain the line during pre

and post-sample line purges and rinses. If a

suction line exposed to freezing climates does

not fully drain, there is a risk of liquid in the

suction line becoming frozen. Frozen liquid will

cause the sample collection to fail. A warm

sampling source can usually prevent this,

provided there are no traps or low spots in the

suction line. Some extreme situations may

require more protective measures, such as

insulating the suction line or applying heat

tape or adding a pump heater.

For representative samples, place the strainer

in the main current of the flow stream, not in

an eddy or at the edge of flow. Placing a strainer

at the bottom may produce samples with excess

heavy solids and no floating materials, while

placing it at the top may produce the opposite

conditions.

2-18

Section 2 Installation

2.8 External Devices

You can connect the sampler to an external

instrument (Figure 2-9) for a variety of reasons.

Typical reasons include:

• Receiving flow pulses from a flow meter

device for variable time.

Figure 2-9 External device connections are

located on the upper right side of the sampler

• Receiving an enable pin signal to enable

sampler operation once site conditions

warrant sample collection.

• Receiving a linear 4-20 mA analog or

pulse representation of the flow rate for

variable time.

• Sending alarm signals when sampling

events occur.

2-19

Platinum/Optima CVE Refrigerated Sampler

These types of connections can be categorized

as Standard ISCO device connections or other

device connections. Each type is discussed in

Sections 2.8.1.

2.8.1 Other Device Connections

You can connect the sampler to receive a

4-20 mA signal, 0-5 VDC, 0-10 VDC or pulses

from an external device.

CAUTION

Risk of equipment damage. Only experienced

electronic technicians should make the connections

to an external device.

To connect the external device, refer to Table

and select the appropriate pins. Connect the

2-2

wires by inserting the wires into the proper pin

number and tightening them. To complete the

connection, be sure to finish the connector

assembly.

Analog Flow Signal

(4 pin connector)

34

12

Pin 3+

Pin 4Pulses (Dry Contacts)

Pin 1

Pin 2

2-20

Section 2 Installation

(7 pin connector)

1

2

1&2 Float

Start-Orange

3&4 Run Status-Blue

6

3

5&6 Alarm-Red

45

Table 2-2 Input Connector (4 pin)

Pin Input

Signal

1 Pulses Dry

2 Pulses Dry

Signal

Name

Contact

Contact

Parameters/

Comments

Pulse input

Pulse input

2-21

Platinum/Optima CVE Refrigerated Sampler

Table 2-2 Input Connector (4 pin)

Pin Input

Signal

3 4-20

mA,0-5VD,010VDC

(+)

4 4-20

mA,0-5VDC,

0-10VDC

(-)

Signal

Name

Analog

Analog Input: Linear current

Parameters/

Comments

loop signal

representing

minimum flow rate at

4 mA, maximum flow

rate at 20 mA

(0-5VDC) 0-Minimum

(0-10VDC)

0-Minimum

10-Maximum

5-Maximum

2-22

Section 2 Installation

Table 2-3 I/O Connector (7 pin)

Pin Wire

Color

1 Orange Float Start

2 Orange Float Start

3 Blue Run

4 Blue Run

5 Red Alarm Dry contact

6 Red Alarm

Signal

Name

or

Float

Start/Stop

or

Start/Stop

Status

Status

Parameters/

Comments

Dry contact

Closed contact to

initialize program start

or close contact to start

program and open

stops program

Dry contact

Relay 250V 5 amp

rated, closed contact

during sample cycle

Relay 250V 5 amp

rated, closed contact

during a fault condition

or program done

2-23

Platinum/Optima CVE Refrigerated Sampler

2.9 Configure and Program the Sampler

To complete the installation, the sampler

software should be configured and

programmed. Refer to Section 3 for

programming instructions or Section 2.11 for

the quick start guide.

Configure the sampler to make sure that it

recognizes what bottle configuration is

installed. Program the sampler to specify how

and when the sampler should collect liquid

samples.

2.10 Locking the Sampler

Locking the sampler is an optional step that

can prevent tampering with the sampler

operation or collected samples.

To prevent tampering with the sampler

operation, the sampler has a P

When enabled, this software feature requires a

numeric password to access most of the control

panel functions. Refer to Section 3.3.9 to enable

this option.

To prevent tampering with the collected

samples, place a padlock on the refrigerator

door latch and control panel.

ROGRAM LOCK.

2-24

Section 2 Installation

2.11 Quick Start Guide

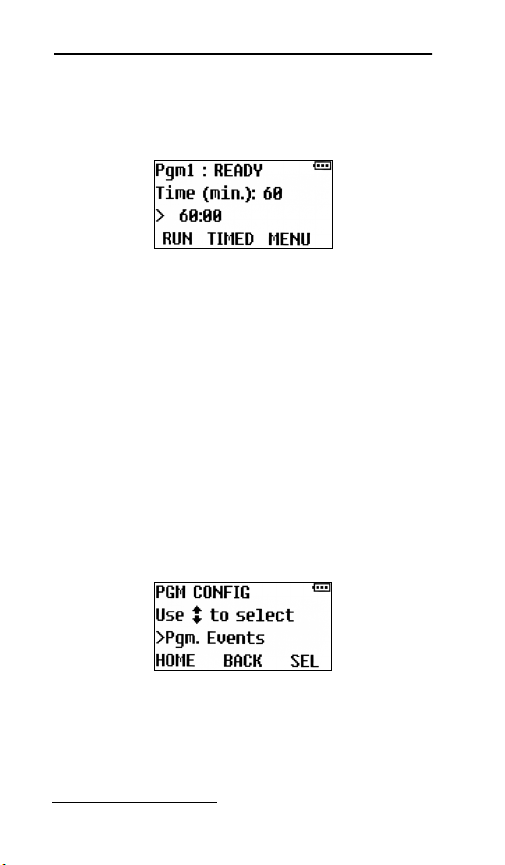

2.11.1 Program Ready Screen

At initial power up, the controller displays the

ROGRAM READY screen:

P

To run the displayed program, select F1 for

UN. Program timer begins and the program

R

runs as specified.

• Select F1 to S

point of the program running mode.

• Select F1 again to R

and go back to the P

To configure the program settings, select F3 for

ENU. Use the arrows to the right of the

M

display to scroll through the programs (1-6).

Press F3, or S

configure.

• Optionally scroll through the P

CONFIGURATION (PGM CONFIG) menu

using the arrow keys to select which

program setting to configure. The

following list displays all of the variable

sub-settings within each program

setting.

TOP the program at any

ESET the program

GM READY screen.

EL to select the program to

ROGRAM

2.11.2 Program Configuration

Cycle: Set the sampling parameters here.

Prepurge: Enter the number of seconds (0-99)

for the system to purge the intake lines prior to

sampling. Then press F3 to accept.

2-25

Platinum/Optima CVE Refrigerated Sampler

Sample Seconds: The sample size is set with

the adjustable intake tube. Set a sampling time

duration that is long enough to allow time for

the sample to fill the sample chamber and

touch the liquid sensing electrodes. Test this

and increase the time if no sample enters the

chamber. Press F3 to accept

.

Postpurge: Enter the number of seconds

(10-99) for the system to purge the intake after

the sample is taken. Press F3 to accept.

Num Rinses: Enter the number of times (0-4)

the intake line should be rinsed, prior to each

sample. Press F3 to accept. This option is to

precondition the sample line before taking a

sample.

Pressure Time: This menu item displays only

if the Number of Rinses is not zero. Type in the

number of seconds (0-99) each rinse should

pressurize the sampler chamber.

Vacuum Time: Enter the number of seconds

(0-99) each rinse should generate suction. The

time should be short enough that the sample

does not enter the sample chamber during the

rinse. Press F3 to accept.

Recycle: Use up and down arrows to enable or

disable the sample retry feature, or press F3 to

accept the setting. When the recycle feature is

enabled, the sampler makes a second attempt

to take the sample, if it failed to collect a

sample on the first try.

Consecutive SMPL: To draw just one sample

per interval, type 1 and press F3 to accept.

2-26

Section 2 Installation

2.11.3 Sample Interval

SMPL. Interval: Press F3 to select the

AMPLING INTERVAL setting. Use the up and

S

down arrows to scroll through the options and

select F3 to accept. Generally, the sampling

interval is a set time, in between samples.

2.11.4 Time Option

Use the up or down arrow keys to scroll to the

desired option (e.g. Time Fixed). Press F3 to

accept.

SMPL Min: Use the keypad to enter the

desired S

AMPLING TIME INTERVAL or leave as is,

then press F3 to accept.

2.11.5 Bottle Options

Sample Type: Use arrows to scroll and press

F3 to select C

ISCRETE/SEQUENTIAL SAMPLING type.

D

•IfD

the next menu is B

OMPOSITE or

ISCRETE SAMPLE TYPE was selected,

OTTLE CONFIG. Use

the arrows to scroll to the desired bottle

configuration that is installed in the

sampler, then press F3 to select.

Num. Bottles: Enter the number of bottles

that you want to use, otherwise press F3 to

accept the default setting to use all the bottles.

SAMPLS/Bottle: Enter the number of samples

that you want to collect in every bottle. Then

press F3 to accept this setting. Be sure to not

overfill the sample bottles.

2-27

Platinum/Optima CVE Refrigerated Sampler

Index Type: Use the arrows to scroll to the

desired indexing type. The A

FTER BOTTLE

setting is defaulted, which tells the program to

rotate to the next bottle, once all of the specified

samples are discharged into the current bottle.

Press F3 to accept this setting.

After entering these settings, the screen will

return to the P

GM CONFIG menu, indicating

that the program setup is complete. If you do

not wish to enable any P

ROGRAM RUN OPTIONS

(see manual for more detail), press F1 twice to

return to the P

ROGRAM READY screen.

2-28

Platinum/Optima

CVE Refrigerated

Sampler

Section 3 Programming

3.1 Control Panel Description

Figure 3-1 Control Panel

3-1

Platinum/Optima CVE Refrigerated Sampler

Table 3-1 Control Buttons

Icon Name Description

F1 HOME

F2 MAN

F3

Back Press this button to back

Enter Press this button to back

0-9 Keypad Keypad enter numbers

RUN

STOP

RESET

ESC

YES

TIMED

GRAB

BACK

MORE

MENU

SEL

PAUSE

RESTART

START

DETAIL

CONTINUE

NO

Go to home screen

Start the program

Stop the program

Reset the program

Go back to previous menu

Accept

Manual sample

Set a timed delay

Grab sample

Go back in the program

See more detail in log file

Go to menu

Select

Pause the program

Restart a program

Initiate sample

View log detail

Continue program

Reject

one space when entering

a number.

one space when entering

a number.

3-2

Section 3 Programming

3.2 Getting Started

Apply power to the sampler (see Section 2.8).

The start-up screens appear on the LCD

display.

Note

The refrigeration system may need to sit 24 hours

before star ting if the unit was tipped upside down during

shipment or installation. This will allow the oil in the

compressor to drain back.

After installing the sampler plug the power

cord into the proper receptacle. The display will

light up and programming can begin. The

program is ready to be configured.

Pgm 1: Ready: This screen displays three

menu options appear R

UN TIMED MENU.

If you have just installed the sampler, you will

first need to program the sampler (Section 3.5).

To program the sampler:

3-3

Platinum/Optima CVE Refrigerated Sampler

1. Pushing F3 located under MENU will

advance the program to M

2. Go to P

3. Press S

ROGRAM menu. Pushing F3 the menu

advances to P

GM SELECT PROGRAM 1).

ELECT to enter the PGM SELECT

AIN MENU.

menu.

This part of the menu will allow you to make

changes to the program.

• Cycle (Sampling settings)

• Smpl. Interval (Timed or Flow intervals)

• Bottles Opts. (Composite or Discrete)

• Pgm. Run Opts. (Run Options)

• Pgm. Events (Scheduled Events)

3.3 Configuring the Sampler

Before operating the sampler, configure the

sampler software. Doing so will set the time

and date, allow the sampler controller to

correctly use the hardware.

To begin from P

1. Press the Menu(F3) button, the screen will

advance to M

press SEL(F3).

2. The next screen is P

#1 push SEL(F3) the screen advances to PGM

CONFIG >CYCLE. In this configuration you

set the parameters.

GM1: READY

AIN MENU >PROGRAM MENU

GM SELECT >PROGRAM

You can step through the parameters using the

EL(F3) button. If a change was made to the

S

3-4

Section 3 Programming

program push SEL(F3) to enter the change or to

scroll thru the settings.

To return to the P

OME(F1) two or three times depending where

H

GM1: READY screen, push

you are in the program.

3.3.1 Set Clock

To set the clock:

1. Scroll to A

scroll until you see >S

F3(S

DMIN.MENU push SEL(F3) and

ET DST and push

EL). Use the up and down arrow to

scroll winter/summer.

2. Then push S

EL(F3) to select.

Setting the time and date allow the sampler

controller to correctly use the hardware. There

is an option to set the time for daylight saving

time (winter or summer).

3-5

Platinum/Optima CVE Refrigerated Sampler

Press the number buttons to type the current

date and hours (using 24-hour format). Press

NTER to accept the date and move to time.

E

When finished the screen will advance to

DJUST LCD screen.

A

3.3.2 Bottle Configuration

Select this option to specify the installed bottle

configuration (Section 2.3). The sampler uses

this setting to determine available bottle

options and control the operation of the

indexing table.

1.

3-6

Section 3 Programming

To select the bottle configuration press ENTER

or SEL(F3).

2.

To select C

up or down arrow and push S

OMPOSITE or DISCRETE sampling use

EL(F3).

Composite

Discrete

hen the bottle and sample size is set, make

W

sure not to overfill the bottles.

3.3.3 Suction Line

The intake tubing length is not entered into the

program. The sample time is set long enough

for the sample chamber to fill and the liquid to

touch the liquid sensor.

3-7

Platinum/Optima CVE Refrigerated Sampler

3.3.4 Rinse Cycle

You can use RINSE CYCLES to condition the

suction line and strainer before collecting a

sample. R

INSE CYCLES may also improve

sample volume repeatability by ensuring the

suction line is wetted before each sample.

The rinse setting is located in the C

YCLE MENU

after post purge. The maximum rinse cycles

and recycles is 4.

• 0 turns the Rinse cycle option

OFF.

• 1-4 Number of Rinses activates the

option:

• Enter RINSE VACUUM time. Be sure that

the vacuum cycle does not allow the fluid

to pump into the sample chamber. Test

and adjust the vacuum time as necessary.

3-8

Section 3 Programming

• Enter RINSE PRESSURE time. Pressure

time should be at minimum the entered

vacuum time.

WARNING

During the rinse cycle if the sample enters the

sample chamber and reaches the liquid-sensor

electrodes, the program will stop the vacuum time

and switch to purge.

3.3.5 Liquid Detector and Recycle

The liquid sensor electrodes are mounted at the

top of the sample chamber lid. If the sample

does not touch the electrodes, then S

FAILED will appear and RECYCLED will activate

if programmed.The liquid detection feature is

always on. The R

located in the C

INSE and RECYCLE option is

YCLE MENU after post purge.

The maximum number of rinse and recycle

cycles is four.

AMPLE

Turn recycle on or off

using the arrow keys

3-9

Platinum/Optima CVE Refrigerated Sampler

ON: If the sampler fails to detect liquid, it will

try again up 4 times to collect the sample.

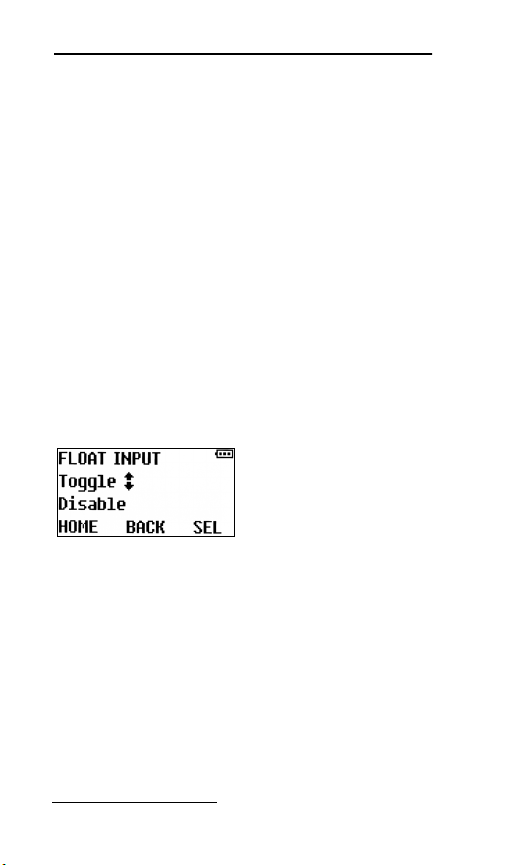

3.3.6 Float Input

Depending if the FLOAT INPUT options have

been factory-configured, enabling this input

will configure the sampling program to delay

sample collection until that circuit closes and

subsequently either:

• Float Start: continue sampling even if

the float circuit reopens,

• Float Start/Stop: toggle the collection of

samples on and off as the rising and

falling stream level closes and opens that

circuit. This feature may be used with

full bottle shut off for composite samples.

Toggle to change

Disable/ Enable

and press Enter.

If Disable the option

is turned off.

The sampler controller is D

ISABLED when pins

1 and 2 are open of the external 7 pin connector

(orange wires). The controller is E

NABLED when

pins 1 and 2 are closed.

3.3.7 Output Pins

An alarm output is based one of the following

events:

• Program Done: This event occurs when

a running sampling program has finished

3-10

Section 3 Programming

or full bottle. This alarm output stays on

as long as the run time display reads

PGM: DONE.

• Recycle: The collection of incomplete

samples by repeating the sampling cycle

as many as four times. To enable or

disable it.

• Temperature Error: The temperature

has been above its set temperature for

more than 30 minutes.

• Failed Sample: This event occurs when

the sampler failed to reach the

liquid-sensor electrodes. This may occur

if the intake line is plugged or the

vacuum time may need to be increased.

• Indexing Error: This event occurs when

the turntable has an indexing failure.

This condition must be corrected before

the sampling program can resume. This

alarm output stays on until the condition

is corrected.

(Alarm- 7 pin output connector using 2 red

wires pins5&6.)

• Run Status: This event occurs each time

a sample is taken. The output stays on

until the sample event is completed.

(2 blue wires pins 3&4)

• Float Start or Float Start/Stop:

*Float Start- If the FLT S

TART setting is

selected, the program will start with a

closed contact and the program will continue

3-11

Platinum/Optima CVE Refrigerated Sampler

sampling without interruption even if that

circuit reopens.

*Float Start/Stop- If the FLT S

TART/STOP

setting is selected, the program will reset its

sampling interval counters and not restart

them until the float circuit closes again (i.e.,

those counters will restart from zero when

the water level rises high enough to close

the float switch).

Note

The full bottle switch uses the float start/stop feature. If

float start or start/stop is being used as a remote start

the full bottle switch cannot be used.

3.3.8 Refrigeration

The sampler will display the interior cabinet

temperature. Scroll thru the run displays to

locate the temperature.

Setting the Refrigerator Temperature: The

thermostat is located on the lower right side of

the refrigeration module. Remove the air vent

to adjust the temperature by using the up and

down arrow on the display. To set the

temperature output 1 for refrigeration and

output 2 for the heater.

3-12

Section 3 Programming

3.3.9 Program Lock

Select this option to turn the PROGRAM LOCK

feature on or off, and to change the password.

When this security feature is enabled, the

sampler requires a numeric password before a

user can configure the program.

The program protection is

password is set to zero.

OFF when the

3-13

Platinum/Optima CVE Refrigerated Sampler

WARNING

DO NOT FORGET THE PASSWORD!

Should you forget the password, contact ISCO’s

Customer Service department for assistance.

3.3.10 Language Selection

Select this option to change the display

language.

1.

Press S

2.

3-14

EL(F3) or ENTER

Section 3 Programming

Scroll using the up and down arrow to select a

language (English, German, French, Spanish,

Italian, Polish, Danish, Swedish).

Press SEL (F3) or ENTER.

3.

If the language is correct at the top of the

screen press Y

ES, if it is wrong press NO.IfNO

was selected the language did not change.

3.3.11 Set Unit ID

Each sampler can be assigned a unique ID

number that will be included in its archival data

files.

Press SEL(F3)

3-15

Platinum/Optima CVE Refrigerated Sampler

3.3.12 Diagnostics

Each time a sample is taken, the program

checks the bottle location when in the

sequential sampling mode.

3.3.13 Exit Configuration

Pressing HOME (F1) the program will exit the

ROGRAM menu and return to PGM: READY.

P

Depending on what part of the P

ROGRAM menu

you are in it may take 2 or 3 times to exit the

ROGRAM menu completely.

P

3.4 Sampling Program Overview

The sampling program controls how often

sample events occur and what should take

place at each event. A sample event may

happen when:

• Starting a flow paced program that is

programmed to sample after a delay

(Section 3.5.13).

• A time paced program reaches the first

sample time and date.

• The programmed time interval has

elapsed.

• The programmed number of flow pulses

has been reached.

At each event, the sampler:

1. Resets the programmed flow or time pacing

interval after initializing a sample.

2. Purges the suction line (see Section 3.3.3).

3-16

Section 3 Programming

3. Sends a closed contact while sample is

taken. The sampler deposits the

programmed sample volume into the bottle.

If programmed to deposit a sample volume

in more than one bottle, the sampler:

a. Moves the table to the next bottle.

b. Deposits the programmed sample

volume into the bottle.

c. Repeats steps 3a and 3b until the

programmed number of bottles per event

is reached.

4. Purges the suction line (see Section 3.3.3

).

There are five categories of sampling program

instructions that control the above actions in an

event. These categories include:

• Cycle: Parameters that configure the

sampling cycle, purge, sample time, post

purge, rinse, recycle, and consecutive

samples.

• Sample Interval: Define what controls

the sample collection interval based on

Time or Flow.

• Bottle Option: Define which sampling

type (discrete/composite) and the bottle

configuration.

• PGM Run Options: Configure program

run options including auto rerun, delay

start, float, fault, timed stop, and bottle

limit.

3-17

Platinum/Optima CVE Refrigerated Sampler

• Program Events: Configure scheduled

events that start, stop, pause, halt, and

resume the program.

3.4.1 Program Configuration

The following are the Program setup categories

and their related programming screens:

Press F3/SEL

to advance

Press F3/SEL

to advance

3.4.2 Sampling Cycle

Press F3/SEL

3-18

Press F3/SEL

If Rinse is 0 program

advances to Recycle

Section 3 Programming

Press F3/SEL

Press F3/SEL

Press F3/SEL

3-19

Platinum/Optima CVE Refrigerated Sampler

Press F3/SEL

Press F3/SEL

Press F3/SEL

Press F3/SEL

3-20

3.4.3 Sample Interval

Section 3 Programming

Or

Press F3 (SEL) to enter the programmed

value and to advance to the next screen

3-21

Platinum/Optima CVE Refrigerated Sampler

3.4.4 Bottle Configuration

Press F3/SEL

3-22

Section 3 Programming

The INDEX TYPE can be configured to rotate to

the next bottle using the following indexing

criteria:

FTER BOTTLE- The table will advance

•A

after the bottle is serviced. If each bottle

was to receive 3 samples per bottle the

table would advance after the 3

rd

sample

in each bottle.

FTER SAMPLE- The table advances after

•A

each sample. If the program was for 2

samples per bottle and turn after the

sample, the table would make two full

revolutions.

FTER TIME- The turntable rotates each

•A

time a specified indexing interval

elapses.

EAL TIME- The turntable rotates at a

•R

fixed duration intervals stating at a

specified time of day.

3-23

Platinum/Optima CVE Refrigerated Sampler

3.4.5 Program Run Options

Press F3/SEL

•AUTO RERUN-If you configure a Start

Event to repeatedly start and stop the

sampler, enabling the Automatic Rerun

parameter will allow the program to

restart without having to reset.

AULT OPTION- Enable turns the Fault

•F

ON. The alarm condition displays

Option

the Alarm Icons, and also energizes a

relay, if a fault condition is detected.

EMPERATURE OPTION - If the Fault Option

-T

is Enabled, the Temperature Fault option is

displayed. This feature enables an alarm

when the enclosure temperature is out of

spec for more than 30 minutes. Toggle

between Enable or Disable.

3-24

Section 3 Programming

•DELAYED START- The program start time

can be delayed in minutes.

FLOAT INPUT- Enable turns the Float

•

ON. Refer to the manual for more

option

details.

•TIMED STOP- This parameter configures

the program to automatically stop a

specified number of hours or minutes

after program start. Select: None, 24

Hour, 12 Hour, 8 Hour or Custom.

3-25

Platinum/Optima CVE Refrigerated Sampler

•BOTTLE LIMIT:

-Program Stop: after discharging a specific

number of samples into a container the program stops and will have to be reset.

-Program Continue: the program will

draw samples indefinitely. You must replace

bottles as the program runs, to avoid bottle

overfill.

3-26

Section 3 Programming

3.4.6 Program Events

Each program’s scheduled events are defined by

a list that can be accessed via the P

ROGRAM

EVENTS group. Each event on that list has three

associated values:

• The type of event (start, stop, pause, halt,

resume or manually sample).

• The days of the week on which the event

will be executed.

3-27

Platinum/Optima CVE Refrigerated Sampler

• The time of day on those days at which

the event will be initiated.

Select the “End List” event when you have

programmed all the desired program events.

You can remove events by disabling the event

for each day of the week.

3.5 Programming Steps

To begin programming from the PGM READY

screen, use the menu F3 (SEL) button to select

ROGRAM. Press the F3 button to display the

P

first programming screen P

3.5.1 Sample Pacing

There are two pacing methods for sampling

programs, Time Paced and Flow Paced.

• Time Paced sampling programs use the

sampler’s internal clock to collect

samples at a constant time or variable

time interval. When you program the

sampler for time pacing, the sampler will

prompt you to enter the time between

sample events in minutes.

• Flow Paced sampling programs require

an electronic signal from a flow

measurement device. This electronic

signal is typically a dry contact (pulse)

that indicates some user-programmed

volume interval has passed through the

flow channel. Because each pulse

represents a volume interval, flow pacing

rates are proportional to the volume of

ROGRAM #1.

3-28

Section 3 Programming

water flowing through the channel. This

is sometimes called “Constant Volume

Variable Time (CVVT) sampling.” When

you program the sampler for flow pacing,

the sampler will prompt you to enter the

number of pulses to count before

collecting a sample.

All Teledyne ISCO flow meters provide a

compatible flow pulse. Non-ISCO flow

measurement devices may be used to paced the

sampler. Refer to Section 2.8– External Devices

for more details.

Use the F3(S

flow option, then press the E

EL) button to select the time or

NTER button.

3.5.2 Time Paced

Time Paced Only – Use the number buttons to

enter the time interval in minutes. The sampler

collects a sample each time this interval elapses

while the program is running.

3.5.3 Flow Paced

Flow Paced Only – Use the number buttons to

enter the flow interval as a number of pulses.

While the program is running the sampler

counts the flow pulses until this number is

reached. At this time the sampler collects a

sample and resets the interval to begin

counting again.

The volume that each flow pulse represents is a

fixed volume. Refer to the instruction manual of

the flow measurement device.

3-29

Platinum/Optima CVE Refrigerated Sampler

For example, consider an ISCO 4250 Flow

Meter programmed to send a flow pulse every

100 gallons. If you are required to collect a

sample every 10,000 gallons, you would enter

100 flow pulses. 10,000 gallons 100 gallons =

100 pulses.

If the flow measurement device sends flow rate

data via a 4-20 mA current loop instead of flow

pulses. The sample program needs to be

changed in the SMPL. I

NTERVAL menu. The

sampler assumes that the current is linear

from 4 mA at zero flow to 20 mA at the

full-scale flow rate.

1. Select the flow input type to 4-20mA.

2. Enter the maximum flow rate (MAX. LPM).

3. Enter the liters between each sample

(SMPL

LITERS).

Example: Consider a flow meter output to 20

mA at 1,000 liters per minute, the peak flow

rate of the channel. If you are required to collect

a sample every 5,000 liters, you would enter

5,000 in the SMPL. L

ITERS menu. The sampler

would totalize the flow base on the MAX LPM

and the flow signal. The sampler will totalize

the liters based on the flow signal. There are no

flow calculations needed, the sampler does that

for you.

3.5.4 Bottles per SampleEvent

Multiple Bottles Only – The sampler places a

sample volume in one bottle or sets of bottles at

each sample event. Use this screen to enter the

3-30

Section 3 Programming

number of bottles to repeat the sample volume

at each sample event. The effect of this number

is illustrated below.

Distribution scheme with

one bottle per sample event.

Samples events are

numbered.

Distribution scheme with

two bottles per sample

event.

Distribution scheme with

three bottles per sample

event.

3.5.5 Switch on Time Indexing

Multiple Bottles Only – The sampler can

switch bottles at regular time intervals. Use

timed indexing to switch Bottles/Sets based on

time.

Multiple Bottles Only – If you selected

Switch on Time, use the number buttons to

enter the desired time interval for bottle set

switches.

3.5.6 Real Time Indexing

Flow Paced, Multiple Bottles Only–If you

are switching bottles by time intervals, use this

3-31

Platinum/Optima CVE Refrigerated Sampler

screen to specify the first switch time. All other

bottle or bottle set switches will be relative to

this time. Press the number buttons to enter

the time of day in 24-hour format.

3.5.7 Samples Per Bottle

Multiple Bottles Only – The sampler places a

sample volume from one or more sample events

in a bottle. Use this screen to enter the number

of samples to be placed in a bottle. The

following diagrams illustrate the effect of this

number.

Distribution scheme with

one sample per bottle

Sample events are

numbered.

Distribution scheme with

two samples per bottle.

Distribution scheme with

three samples per bottle

This SAMPLES PER BOTTLE feature can be

combined with the BOTTLES PER SAMPLE

EVENT (Section 3.5.4) to build more complex

distribution schemes, sometimes known as

3-32

Section 3 Programming

multiple bottle compositing. The following

illustrates this example:

Distribution scheme with

three bottles per sample

event and three samples

.

per bottle. Sample events

are numbered

3.5.8 RunContinuously

Sample programs can run indefinitely or stop

by going to P

GM RUN OPTS and then to BOTTLE

LIMIT. Select PGM.CONTINUE to run the

program continuously or P

GM STOP to stop the

program when complete. Continuous sampling

resets the distribution when the distribution

sequence is complete. That is, when the last

bottle/set is reached, the next bottle/set is the

first bottle/set.

In this mode, the sampler assumes that any

filled bottles are replaced and ready to receive

samples while the program is running, thus the

pacing interval is never interrupted.

If you select PGM S

TOP, the sampler will run

until it completes the distribution sequence, at

which time it stops the program and reports

ROGRAM DONE. The sampler will wait in this

P

state until the bottles have been emptied and

the program is restarted.

If your sampler is configured for composite

sampling, refer to Section 3.5.14 for

instructions on continuous sampling.

3-33

Platinum/Optima CVE Refrigerated Sampler

3.5.9 Sample Second

Enter the number of seconds it will take to fill

the sample chamber and touch the

liquid-sensor electrodes. The sample seconds

must exceed the number of seconds to fill the

chamber. When the liquid-sensor is activated,

the timer stops and the program goes to post

purge.

3.5.10 Flow Pulses, Analog Input

Time Paced Only – If you are collecting

sample volumes dependent on flow (Section

3.5.11), select which type of flow rate input is

provided by the external flow measurement

device (see Section 2.8).

3.5.11 CompositeSamples

Single Bottle Only – Use the number buttons

to type the number of composite samples to

take. Press the E

NTER button to accept the

value.

The sampler does not calculate the maximum

number of samples. Use caution when selecting

the maximum number of samples per bottle so

they do not overfill.

• If you selected continuous in the B

OTTLE

LIMIT menu, the sampler collects samples

without regard for the total number of

samples.

• If you enter continuous, keep in mind

that the sampler might overfill the bottle.

3-34

Section 3 Programming

• If you enter STOP, the program will stop

when the program is done.

• The full bottle switch stops the sampler

from taking samples when the container

is full.

3.5.12 Pressurized Line

This sampler cannot be used in applications

that collect samples from a pressurized line,

without the pressurized line option. Attempting

this will fill the sampler with water and void

warranty. Teledyne ISCO offers a pressurized

line option for the sampler. Contact the factory

for more information.

3.5.13 Timed Delay

At this screen you have the option to start the

sampling program immediately when you press

the (F1) R

UN PROGRAM button, or delay the

sampling program until user-defined start time

is met.

To program the sampler to start immediately,

in the D

ELAY START menu enter 0. To enter a

program delay enter the desired minutes that

you want to delay the program from stating.

To set a start time and date can be made in two

different locations:

PMG Ready Screen:

On the P

labeled T

TART TIME and enter the M/D/Y the program

S

to start and the screen will advance to S

GM READY screen push the F2 button

IMED. The screen will advance to

TART

3-35

Platinum/Optima CVE Refrigerated Sampler

TIME to enter the time to start the program

H:M:S. Push the E

NTER button after making

each selection.

PMG Events:

Go to PGM E

then push S

VENTS and to START TIME and

ELECT. Enter the days of the week

that you want the sampler to start by pushing

the up or down arrow to highlight the day to

start the screen will advance to E

VENT TIME #1

enter the H:M:S to start the sampler. The

sampler can do weekly start and stop P

GM

READY screen push the F2 button labeled

IMED. The screen will advance to START TIME

T

and enter the M/D/Y the program to start and

the screen will advance to S

TART TIME to enter

the time to start the program h:m:s. Push the

NTER button after making each selection.

E

Go to PGM E

push S

VENTS and to START TIME and

ELECT. Enter the days of the week that

you want the sampler to start by pushing the

up or down arrow to highlight the day to start

The screen will advance to E

3-36

VENT TIME#1 enter

Section 3 Programming

the H:M:S to start the sampler. The sampler

can do weekly start and stop sampling with

pause and resume also. If the program is going

to run on a weekly basis, then set the A

UTO

RE-RUN to ENABLE.

3.5.14 Auto Re-Run

By default, the sampling program must be

manually reset each time it stops, which

indicates to the controller that the sample

containers have been emptied. If you configure

TART EVENT to repeatedly start and stop the

aS

sampler, enabling the A

UTOMATIC RERUN

parameter would enable the program to restart

without being reset.

Note

You should not enable this parameter unless you are

scheduling automatic start events.

3.5.15 Timed Stop/Max Run Time

This parameter configures the program to

automatically stop a specified number of hours

or minutes after it initiates its interval timers.

The choices are None, 24 HR,12 HR,8HR and

Custom. The custom feature allows you to enter

a shut of value that is not already in the

program.

3-37

Platinum/Optima CVE Refrigerated Sampler

This feature is useful for applications that

require the collection of a total sample volume

proportional to the flow volume over a specific

duration. An example of this would be a

flow-weighted composite sample representative

of the total daily flow volume (24 hours). If the

application does not limit the sample collection

to a specific duration, enter none.

3-38

Platinum/Optima

CVE Refrigerated

Sampler

Section 4 Operation

This section describes how to operate the

sampler. These instructions assume that the

sampler has been correctly installed (Section 2),

configured, and programmed (Section 3).

4.1 Start a Sampler Program

Before starting a program:

• Verify the sample tube is connected to the

sample.

• Place empty bottles in the rack and

install on the sequential drive table.

To start the program from the R

press the F1 R

the sampler will need to be calibrated (See

Section 4.1.1) to ensure volume accuracy.

If a sampler configured for multiple bottles was

previously stopped (see Section 4.2), the

sampler will rotate the bottles to number 1

position upon starting.

UN button. Upon initial setup,

EADY screen,

4-1

Platinum/Optima CVE Refrigerated Sampler

4.1.1 Sample Calibration

There are two ways to calibrate the sample:

1.

To properly calibrate the volume prior to

running a program, you must go to MAIN

MENU and scroll to find the CALIBRATE menu

item. Press F3 SEL to select the calibration

menu item.

• Calibrate #1 is displayed. Adjust the

intake tube to set the sample size:

a. Loosen the compression nut and slide the

tube down for a smaller sample and up

for more sample.

b. Tighten the compression nut.

c. Start (F3) to collect the Calibration #1

sample.

d. Check for volume accuracy, then discard

the sample and proceed to Calibrate #2 if

necessary.

e. When the volume accuracy is acceptable,

discard the calibration sample and press

OME (F1) to go to PROGRAM READY

H

screen.

2. If you skip the calibration steps, the

sampler will need to be calibrated in the

UN mode or GRAB mode.

R

4-2

Section 4 Operation

4.1.2 Start Time Delay

If the program is set for NO DELAY TO START

(Section 3.5.13), the sampler immediately

begins to operate according to its C

ONFIGURE

and PROGRAM settings.

If the program is set to use a start time, the

sampler will wait for the specified time and

date. During this delay, the display shows the

current time/date and program delay time/date.

When the programmed start time and date

match the sampler’s time and date, the sampler

program begins to run.

4.1.3 The Run State

Because the sampler operation is fully

automated, no user intervention is required.

Should there be a need to check on the running

program, you can view the sampler display. It

always reports the current state or operation

and the refrigerator temperature.

4-3

Platinum/Optima CVE Refrigerated Sampler

Typically, the display will count to the next

sample event. This screen may alternate with

other messages:

If the sampler is disabled by an external device,

1.

the display will show FLT. START

OPEN CLOSED.

2. If the sampler is currently taking a sample

the display will show the pre-purge screen.

If the sampler has encountered error

3.

conditions during the running program, the

display will show E

RRORS HAVE OCCURRED

and the alarm icon will show in the upper

right of the display, if the alarm function is

enabled.

4. If the sampler is programmed for TIMED

indexing the bottles (Section 3.5.5), the

display will show I

NDEX## min.:

• If any programmed sampler operations

are based on the sampler’s internal clock,

the display will show the current time

and date.

4.1.4 Completed Program

When the program is complete, the display will

ROGRAM DONE and number of samples

show P

can be viewed by scrolling through the run

displays using the arrow keys.

If the sampler encounters an error at any time

during the running program, an error message

4-4

Section 4 Operation

will appear along with the alarm icon if

enabled. See Table 4-1.

4.2 Pause or Stop a Running Program

Press F3 PAUSE button to pause a running

program. The sampler will display:

While paused, you can:

• View the log (see Section 4.3.1)

• Collect a Grab Sample (see Section 4.4)

• Stop the program — Press the S

button to S

TOP the program.

• Resume the program — Press the F3

ESUME button to resume the program.

R

• When in the R

UN mode the program can

be stopped by pushing the F1 S

While paused, the sampler skips sample events

that would have occurred otherwise.

TOP or F1

TOP.

4-5

Platinum/Optima CVE Refrigerated Sampler

4.3 Post Sampling Activities

Post-sampling activities include:

• Viewing the Log (Section 4.3.1)

• Retrieving the Refrigerator Temperature

Log (refer to the Installation and

operation guide)

• Removing the sample bottles (Section

4.3.3)

4.3.1 View the Log

The sampler records events during the running

program and summarizes them in a log. This

log is held in the sampler memory under

ARC:LOG:1. The current log file that is

running would be L

stopped or program done the current log file

goes to L

OG #2. The sampler will record and

display multiple log files.

To view the log after the completion of a

program, or in the run mode press the #5

button. To view different log files scroll using

the up and down arrows to access different file

numbers.

OG #1, once the sampler is

You can also view the log while a program is

paused.

4-6

Section 4 Operation

While viewing the log, you can:

• Step forward through the L

OG screens by

pressing the up or down buttons.

• Pressing the M

ORE and DETAIL buttons

will access the sampling data.

• Exit the log by pressing the B

ACK button.

The log generally contains the following

information:

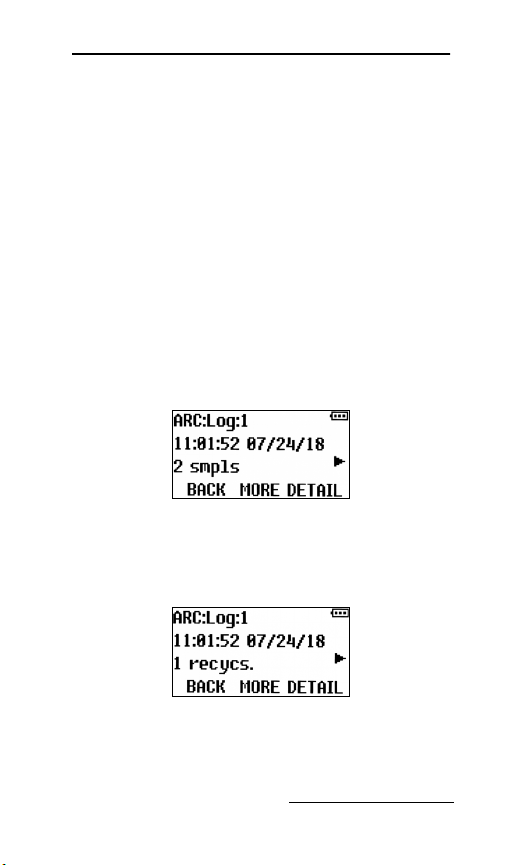

1. The number of samples collected (rc appears

only if some samples required recycling)—

this example indicates the sampling run

that commenced at 11:01 AM on July 24

collected 2 samples].

2. If recycle was activated, the log reports the

number recycles and the alarm output is

activated.

3. That archived data can be reviewed from

the user interface panel by pressing the 5

key when the selected program is running

4-7

Platinum/Optima CVE Refrigerated Sampler

(or waiting to be started), but not while the

DMINISTRATION or PROGRAM menu is

A

active. The first line of the resulting display

will indicate you are viewing log file 1, in

which data for the current (or pending)

sampling run is being (or will be) recorded.

4. Bottle type, number and size of the

containers to which those samples were

discharged.

5. If a log file’s fourth screen indicates one or

more exceptions were encountered, pressing

ETAIL [F3] key will display the

its D

timestamp and type of the first such

exception detected during that program

run. For example:

4-8

Section 4 Operation

If power was lost during the program, the log

reports the time of the power failure event and

the time the power was restored.

6. Pressing the D

ETAIL [F3] key while viewing

any sample container’s screen will display

the timestamp, as well as, the time needed

to collect the first sample that was

discharged to that container. You could then

display the same information for each of the

other samples in that container by pressing

the up and/or down keys.

The refrigerated cabinet temperature is logged

with each sample.

7. The log reports the average refrigerator

temperature and the minimum and

maximum recorded temperatures.

4-9

Platinum/Optima CVE Refrigerated Sampler

4.3.2 User Interface Icon

Table 4-1 User Interface Panel Icons

Message Description

Program is running.

Program is paused.

Time Start: program will

automatically start at a

specified time.

Time Stop: program will

automatically stop at a

specified time.

Sequence table is rotating.

4-10