Page 1

PROTOCOL SOLUTIONS GROUP

3385 SCOTT BLVD

SANTA CLARA, CA 95054

PETracer Summit™ and Summit T2-16

™

PCI Express Multi-Lane Protocol Analyzer

User Manual

For Software Version 6.7x

June 2013

Page 2

Summit User Manual

Document Disclaimer

The information in this document has been carefully checked and is believed to be

reliable. However, no responsibility can be assumed for inaccuracies that may not have

been detected.

Teledyne LeCroy reserves the right to revise the information in this document without

notice or penalty.

Trademarks and Servicemarks

Teledyne LeCroy, CATC Trace, PCI Express, PETracer Edge, PETracer EML, PETracer

ML, PETracer, PETrainer EML, PETrainer ML, PETracer Summit, Summit T2-16,

Summit Z2-16, Universal Protocol Analyzer System, UPAS, and BusEngine are

trademarks of Teledyne LeCroy.

Microsoft and Windows are registered trademarks of Microsoft Inc.

All other trademarks are property of their respective companies.

Copyright

© 2012 Teledyne LeCroy, Inc. All Rights Reserved.

This document may be printed and reproduced without additional permission, but all

copies should contain this copyright notice.

WEEE Program

Teledyne LeCroy

Page 3

Summit User Manual

TABLE OF CONTENTS

Section 1. General. . . . . . . . . . . . . . . . . . . . . 1

Chapter 1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 PETracer Analyzer Hardware and Software . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 CATC Trace Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Summit T2-16 Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 PETracer Gen2 Summit Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Other Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 2 Hardware Description . . . . . . . . . . . . . . . . . . . 9

2.1 System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Host Machine Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Summit T2-16 Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

LCD Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 PETracer Summit Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . 13

LCD Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5 Summit T2-16 Rear Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6 PETracer Summit Rear Panel Description . . . . . . . . . . . . . . . . . . . . . . . . 18

2.7 External Interface Breakout Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pin-Outs for the Data In/Out Connector . . . . . . . . . . . . . . . . . . . . . . . . 21

Prototype Rework Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Breakout Board Input and Output Signals. . . . . . . . . . . . . . . . . . . . . . . 22

Chapter 3 Installation and Setup . . . . . . . . . . . . . . . . . . 23

3.1 Installing the PETracer Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2 Setting Up the Summit T2-16 Analyzer using an Ethernet Connection. . . 25

Connecting to a Summit T2-16 Analyzer in the Local Network. . . . . . . 25

3.3 Setting Up the Summit T2-16 Analyzer using a USB Connection . . . . . . . 28

3.4 Setting Up the PETracer Summit Analyzer . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting to a PETracer Summit Analyzer in the Local Network. . . . 29

3.5 Interposers and Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.6 Using Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Example: Connecting the Summit T2-16 Analyzer to the Device Under

Test Using a Gen2 MidBus Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Example: Connecting the Summit T2-16 Analyzer to the Device Under

Test Using a Gen2 Multi-lead Probe for x1 and x4 . . . . . . . . . . . . . . . . 36

Example: Connecting the Summit T2-16 Analyzer to the Device Under

Test Using a Gen2 Multi-lead Probe for x8 and x16 . . . . . . . . . . . . . . . 38

3.7 Using Interposers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Example: Connecting the Summit T2-16 Analyzer to the Device Under

Test Using a Gen2 Passive Interposer . . . . . . . . . . . . . . . . . . . . . . . . . 40

Example: Connecting the Summit T2-16 Analyzer to the Device Under

Test Using a Gen2 Active Interposer. . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Teledyne LeCroy iii

Page 4

Summit User Manual

Section 2. PETracer Analyzer Software . . 45

Chapter 4 Software Overview . . . . . . . . . . . . . . . . . . . . 47

4.1 The PETracer Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2 Application Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.3 Using the Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Multi-Segment Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Toolbar Hide Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.4 Using the Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.5 Tool Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.6 Keyboard Shortcuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.7 Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.8 Making a PCI Express Recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.9 Recording Multi-Segmented CATC Traces . . . . . . . . . . . . . . . . . . . . . . . . 65

How to Create a Multisegment Recording . . . . . . . . . . . . . . . . . . . . . . 65

4.10 PETracer Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

CATC Trace Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Recording Options Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Display Options Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.11 Opening CATC Trace Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.12 Saving CATC Trace Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Using the Save As Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Saving a Portion of a CATC Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.13 Exporting a CATC Trace File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.14 Printing Data Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.15 Analyzer Chat Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Chapter 5 Reading CATC Traces . . . . . . . . . . . . . . . . . . 73

5.1 Viewing PCI Express CATC Traces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.2 Expand and Collapse Data Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.3 Resizing Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.4 Pop-up Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.5 View Data Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.6 Show Raw 10b Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.7 Show Header Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.8 Packet Cell Popup Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Packet Header R-> Cell Popup Menu. . . . . . . . . . . . . . . . . . . . . . . . . . 77

Packet Header G1 Cell Popup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.9 Set Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.10 Edit or Clear Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.11 Decoding Traffic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Packet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Split . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Chapter 6 Searching CATC Traces . . . . . . . . . . . . . . . . 83

6.1 CATC Trace Search Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.2 Go to Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.3 Go to Packet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.4 Go to Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

iv Teledyne LeCroy

Page 5

Summit User Manual

6.5 Go to Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

2. Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Markers Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Functionality of Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Attaching Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Adding an Attachment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5. Recording an Audio File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Video Files supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Attachment Types and Visualization . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Embedded Attachments to a Marker. . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Viewing Attachments of a Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Video . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

File Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

URL Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

YouTube Video . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Other Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Edit Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

All Markers Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.6 CATC Walk Playlist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Playlist Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Playback Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Playlist Playback Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.7 Go To Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.8 Search Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.9 Find . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Event Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.10 Search for the Next Packet Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Chapter 7 Display Options . . . . . . . . . . . . . . . . . . . . . . 109

7.1 Setting Display Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.2 Specifying General Display Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Analysis Tools Checkboxes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Configuration Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

7.3 Color, Format, and Hiding Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Setting Field Colors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Changing Field Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

7.4 Load a Previously Saved Display Options File . . . . . . . . . . . . . . . . . . . . 118

7.5 Saving Display Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Chapter 8 Recording Options . . . . . . . . . . . . . . . . . . . .119

8.1 Setting Recording Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

8.2 General Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Recording Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Buffer Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Target Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Trigger Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Trigger On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Teledyne LeCroy v

Page 6

Summit User Manual

Trace Filename and Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Options Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Save As MultiSegment Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Viewing Multisegmented Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Misc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Link for Summit and Summit T2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Saving and Loading Previously Saved Recording Options . . . . . . . . . 130

Setting Default Recording Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

8.3 Recording Rules Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Global State vs. Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

8.4 Recording Rules Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8.5 Creating Recording Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8.6 Recording Rules Logic: How Contradictory Rules are Resolved . . . . . . 136

Recording Rules Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

8.7 Properties Dialog Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

8.8 Event Properties Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Accessing the Properties Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Dialog Settings and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Error Properties Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Actions Properties Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

TLP Header Properties Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

TLP Prefix Properties Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Payload Properties Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

DLLP Packet Properties Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Ordered Set Properties Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

8.9 Counting Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

8.10 Creating a Payload Match . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

8.11 Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

8.12 Filter In and Filter Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Chapter 9 BitTracer Recording . . . . . . . . . . . . . . . . . . 155

9.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

PETracer Summit and Summit T2-16 Only. . . . . . . . . . . . . . . . . . . . . 155

9.2 Enabling BitTracer Recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

9.3 Trigger Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

9.4 Views Available for Captured Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

9.5 De-Skewing Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

9.6 Data Display Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

9.7 Color-Coding of BitTracer Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

9.8 Report and Analysis Windows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

9.9 Timing Measurements Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Markers Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

9.10 Errors Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

9.11 Symbols Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

9.12 Events Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

9.13 Packets Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

9.14 Decoding Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

9.15 Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

9.16 Link Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

9.17 Export of BitTracer Capture to CATC Trace Format . . . . . . . . . . . . . . . 169

Exports Involving Multiple Logical Links on One Physical Link. . . . . . 169

vi Teledyne LeCroy

Page 7

Summit User Manual

9.18 Compressing and Expanding the Data View . . . . . . . . . . . . . . . . . . . . . 169

9.19 Opening and Saving BitTracer Captures . . . . . . . . . . . . . . . . . . . . . . . . 169

Chapter 10 Reports and Tools . . . . . . . . . . . . . . . . . . . . 171

10.1 File Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

10.2 Error Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

10.3 Traffic Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Using the Traffic Summary Window to Search the CATC Trace . . . . . 174

Traffic Summary Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

10.4 Bus Utilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Bus Utilization Pop-up Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Bus Utilization Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

10.5 Link Tracker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Using the Link Tracker Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Link Tracker Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

10.6 Data Flow Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

10.7 Using the CATC Trace Navigator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Displaying the Navigator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Navigator Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Navigator Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Navigator Panes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

10.8 LTSSM Flow Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

10.9 Packet Header Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

10.10 Packet Data Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

10.11 Configuration Space View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

10.12 Using Unit Metrics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Show Metrics in the CATC Trace Display . . . . . . . . . . . . . . . . . . . . . . 200

Show Metrics in the Traffic Summary Window . . . . . . . . . . . . . . . . . . 202

Show Metrics in the Bus Utilization Window . . . . . . . . . . . . . . . . . . . . 204

10.13 Real-Time Statistics Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Real-Time Statistics Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Real-Time Statistical Monitor Pop-up Menu . . . . . . . . . . . . . . . . . . . . 210

Real-Time Statistics Graph Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

10.14 TC to VC Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

10.15 Timing and Bus Usage Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . 214

10.16 Running Verification Scripts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Chapter 11 Updates and Licensing . . . . . . . . . . . . . . . . 219

11.1 Updating the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

11.2 License Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

11.3 License Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Appendix A Configuration Space Decoding . . . . . . . . . 221

A.1 Mandatory Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

A.2 Mandatory Module Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

A.3 Configuration Register Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

A.4 Primitives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

A.5 Helper File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Appendix B China Restriction of Hazardous Substances

Table224

Teledyne LeCroy vii

Page 8

Summit User Manual

How to Contact Teledyne LeCroy . . . . . . . . . . . . . . . . . 225

Index 227

viii Teledyne LeCroy

Page 9

Summit User Manual Section 1

Section 1. General

Teledyne LeCroy 1

Page 10

Section 1 Summit User Manual

2 Teledyne LeCroy

Page 11

Summit User Manual Chapter 1: Overview

Chapter 1: Overview

Designed for developers and validators, the Teledyne LeCroy PETracer Summit™ and

Summit T2-16™ are Gen1/Gen2 PCI Express advanced verification systems.

By leveraging years of experience in protocol analysis tools for emerging markets,

PETracer Summit and Summit T2-16 blend sophisticated functionality with practical

features to speed the development of PCI Express™ IP cores, semiconductors, bridges,

switches, add-in boards, and systems.

1.1 PETracer Analyzer Hardware and Software

Features and Benefits

PETracer Summit and Summit T2-16 Analyzers have these features and benefits:

Features Benefits

Powerful and Intuitive

CATC Trace™ Analysis Software

Extensive Decoding Complete, accurate and reliable decoding of TLPs (Transaction

Monitoring and Link Utilization View link utilization and other performance measurements

Advanced Triggering Isolate important traffic, specific errors, or data patterns. Trigger

Hardware Filtering

Intelligent Reporting

Sophisticated Viewing View Packet, Link and Split Transaction levels of the PCI Express

Faster interpretation and debug of PCI Express traffic with

color-coded, clearly labeled protocol elements in a graphical

display. Reduces coding and deciphering.

Layer Packets), DLLPs (Data Link Layer Packets), and all

PCI Express Primitives

changing in real time.

condition setup is made simple with drag and drop tools to link

events to trigger or filter actions.

Analyze faster and understand transactions more clearly by

removing non-essential fields from the trace.

Quickly identify and track error rates and abnormal link or timing

conditions. Display configuration space and protocol specification

details.

protocol. Collapsible/expandable headers with Tool tip

explanations make it easy to navigate and interpret packet

contents, headers, and commands. View packets, transactions of

TLPs and DLLPs in classic CATC Trace™ format or in raw 10b

code for deeper analysis.

8 GB Recording Capacity,

4 GB in each direction

Teledyne LeCroy 3

Capture long recording sessions for analysis and problem solving

Page 12

Chapter 1: Overview Summit User Manual

Flexible Host Interface Summit T2-16: USB and GigE .

PETracer Summit: 10/100 MBps.

Downloadable CATC Trace

Viewer

Bidirectional x1-x16,

2.5 GBps to 5.0 GBps

recording support

Field-upgradeable firmware and

recording engine

Flexible probing options Active and passive slot interposers

External interface for probing

and monitoring auxiliary digital

signals

Share and annotate CATC Trace recordings within a development

team. Freely distributable PETracer software enables collaborative

analysis across sites and time zones.

Accurate and non-intrusive collection of PCI Express CATC Trace

data

Upgrades available for download direct from the Teledyne LeCroy

website

MidBus probe

Flying lead probe

Gen1 AMC interposer

Gen1 XMC interposer

Gen1 SIOM interposer

Gen1 Express card interposer

Enables cross triggering between other test instruments.

Dword to Transaction Level

Viewer

CRC checking Know that info being displayed is accurate.

View Dwords, Packet, Link and Split Transaction levels of the PCI

Express protocol.

1.2 CATC Trace Software

PETracer Summit and Summit T2-16 utilize the CATC Trace™ to assist users in

analyzing how PCI Express components work together, diagnose problems, and test for

interoperability and standards compliance.

The CATC Trace is a powerful and intuitive expert software system embedding detailed

knowledge of the protocol hierarchy and intricacies, as defined in the protocol

specification. The software allows the user to control the Analyzer and set specific

real-time triggering and filtering conditions. The CATC Trace utilizes a Windows-based

graphical display that has been optimized for fast and easy navigation through a captured

traffic session. Users are alerted as violations are detected at all levels of the protocol

layering and can easily drill down on areas of interest or collapse and hide fields that are

not relevant.

4 Teledyne LeCroy

Page 13

Summit User Manual Chapter 1: Overview

1.3 Summit T2-16 Analyzer

The Teledyne LeCroy Summit T2-16 is Teledyne LeCroy’s fourth-generation PCI Express

analyzer for customers in server, workstation, desktop, graphics, storage and network

card markets.

With advanced features such as support for PCI Express Spec 2.1, data rates of both 2.5

and 5 GBps, lane widths from x1 to x16, and a full 8 GB of trace (recording) memory, the

Summit T2-16 provides unmatched capability and flexibility for developers and users of

advanced PCI Express products. The Summit T2-16 is the most advanced and

sophisticated PCI Express Analyzer available in the market today.

As with other Teledyne LeCroy PCI Express analyzers, the Summit T2-16 leverages the

intuitive and powerful CATC Trace analysis software system, embedding a deep

understanding of the PCI Express protocol hierarchy and intricacies. The colorful,

intuitive and easy-to-use graphical display allows you to quickly capture and validate

PCI Express product designs. All Teledyne LeCroy PCI Express protocol analyzers

employ high-impedance, non-intrusive probing technology, thereby allowing fully

unaltered data pass-through.

In addition to a full suite of advanced hardware and software features, the Summit T2-16

introduces new user-convenience and analysis features, such as support for “lane

swizzling,” which allows a board developer to lay out a mid-bus probe pad with lanes in

non-standard order, simplifying the design of the board. Internally, the Summit T2-16

maps the lanes back into their correct order and accurately displays the embedded bus

traffic. Other new software features include enhanced error checking for automatic

identification of additional error types, more compact CATC Trace files that allow for

faster analysis of data, and the choice of simplified or advanced modes for setting up

recording options. An optional raw-recording mode allows bytes to be recorded as they

come across the link, allowing debugging of PHY layer problems and combining the

features of a logic analyzer format with a protocol analyzer format. The new

auto-sense-link feature monitors negotiation between devices of different lane widths.

The Summit T2-16 supports USB and GIGE host interfaces. By connecting over GIGE,

engineers can operate the system remotely (for example, install the client software on

their desktop systems to control an analyzer operating in a remote lab). Also, multiple

engineers working collaboratively can time-share use of a single analyzer, reducing the

need for an additional analyzer for each engineer and increasing the cost effectiveness

of the product.

Teledyne LeCroy 5

Page 14

Chapter 1: Overview Summit User Manual

Features

• Powerful and Intuitive CATC Trace Analysis Software System: The CATC Trace

embeds deep understanding of the PCI Express protocol hierarchy and intricacies.

This knowledge is presented in a colorful, intuitive and easy-to-use graphical

display, allowing you to quickly capture and validate PCI Express product designs.

• Protocol Hierarchical Viewing: Displays Packet, Transaction, and

Split Transaction levels of the PCI Express protocol, with increased drill-down detail

for PCI Express primitives, errors, payloads or individual packets.

• Advanced Triggering: Allows you to trigger on various PCI Express Events such

as Link Conditions, TLP Headers, DLLP Messages, and Data Payload.

• Lane-Reversal Compatible: Triggers, records, and displays PCI Express traffic

logically, regardless of the physical configuration of the lanes.

• Statistical and Error Reporting: Provides a quick summary of the CATC Trace file

to identify and track error rates and abnormal link or timing conditions.

• Raw Recording Mode (optional): Records the bytes exactly as they come across

the link, allowing debugging of PHY layer problems.

• Auto Speed detection: Follows link transitions through speed changes.

• Auto Polarity detection: Automatically detects lanes with inverted polarity.

• Auto Sense Lane Width: Analyzes all negotiation traffic between devices with

different lane widths, eliminating the need to set up lane widths before a trace.

• Lane Swizzling Support: Allows board developers to lay out lanes in a

non-standard order, simplifying board design.

• Powerful Real-time BusEngine Protocol Processor Technology: Sophisticated

triggering and filtering help you focus on critical protocol data and isolate important

protocol traffic, specific errors, or data patterns.

• Field-upgradeable Firmware and Engine: Positions you to receive the latest

PETracer enhancements and future additional capabilities. Allows field upgrades of

all system types.

• 8-GB Data Buffer: Capture long time windows for in-depth analysis and

identification of erratic problems.

• GIGE Ethernet Connectivity: Allows connection to an Ethernet network and

sharing of analyzer resources by multiple engineers.

• USB connectivity: Allows connection by USB cable.

6 Teledyne LeCroy

Page 15

Summit User Manual Chapter 1: Overview

1.4 PETracer Gen2 Summit Analyzer

The Teledyne LeCroy PETracer Gen2 Summit is Teledyne LeCroy’s first-generation

high-performance PCI Express analyzer for customers in server, workstation, desktop,

graphics, storage and network card markets.

With advanced features such as support for PCI Express Spec 2.0, data rates of both 2.5

and 5 GBps, lane widths from x1 to x16, and a full 8 GB of memory, the PETracer Gen2

Summit provides excellent capability and flexibility for developers and users of advanced

PCI Express products.

As with other Teledyne LeCroy PCI Express analyzers, the PETracer Gen2 Summit

leverages the intuitive and powerful CATC Trace analysis software system, embedding a

deep understanding of the PCI Express protocol hierarchy and intricacies. The colorful,

intuitive and easy-to-use graphical display allows you to quickly capture and validate

PCI Express product designs. All Teledyne LeCroy PCI Express protocol analyzers

employ high-impedance, non-intrusive probing technology, thereby allowing fully

unaltered data pass-through.

In addition to a full suite of advanced hardware and software features, the

PETracer Gen2 Summit supports “lane swizzling,” which allows a board developer to lay

out a mid-bus probe pad with lanes in non-standard order, simplifying the design of the

board. Internally, the PETracer Gen2 Summit maps the lanes back into their correct order

and accurately displays the embedded bus traffic. Other new software features include

enhanced error checking for automatic identification of additional error types, more

compact CATC Trace files that allow for faster analysis of data, and the choice of

simplified or advanced modes for setting up recording options. An optional Bit Tracer

mode allows bytes to be recorded as they come across the link, allowing debugging of

PHY layer problems and combining the features of a logic analyzer format with a protocol

analyzer format. The new auto-sense-link feature monitors negotiation between devices

of different lane widths.

The PETracer Gen2 Summit supports both a USB and a 10/100 MBps Ethernet LAN port

as standard features. By connecting over a LAN, engineers can operate the system

remotely (for example, install the client software on their desktop systems to control an

analyzer operating in a remote lab). Also, multiple engineers working collaboratively can

time-share use of a single analyzer, reducing the need for an additional analyzer for each

engineer and increasing the cost effectiveness of the product.

Teledyne LeCroy 7

Page 16

Chapter 1: Overview Summit User Manual

Features

• Powerful and Intuitive CATC Trace Analysis Software System: The CATC Trace

embeds deep understanding of the PCI Express protocol hierarchy and intricacies.

This knowledge is presented in a colorful, intuitive and easy-to-use graphical

display, allowing you to quickly capture and validate PCI Express product designs.

• Protocol Hierarchical Viewing: Displays Packet, Transaction, and

Split Transaction levels of the PCI Express protocol, with increased drill-down detail

for PCI Express primitives, errors, payloads or individual packets.

• Advanced Triggering: Allows you to trigger on various PCI Express Events such

as Link Conditions, TLP Headers, DLLP Messages, and Data Payload.

• Lane-Reversal Compatible: Triggers, records, and displays PCI Express traffic

logically, regardless of the physical configuration of the lanes.

• Statistical and Error Reporting: Provides a quick summary of the CATC Trace file

to identify and track error rates and abnormal link or timing conditions.

• Raw Recording Mode (optional): Records the bytes exactly as they come across

the link, allowing debugging of PHY layer problems.

• Auto Speed detection: Follows link transitions through speed changes.

• Auto Polarity detection: Automatically detects lanes with inverted polarity.

• Auto Sense Lane Width: Analyzes all negotiation traffic between devices with

different lane widths, eliminating the need to set up lane widths before a trace.

• Lane Swizzling Support: Allows board developers to lay out lanes in a

non-standard order, simplifying board design.

• Powerful Real-time BusEngine Protocol Processor Technology: Sophisticated

triggering and filtering help you focus on critical protocol data and isolate important

protocol traffic, specific errors, or data patterns.

• Field-upgradeable Firmware and Engine: Positions you to receive the latest

PETracer enhancements and future additional capabilities. Allows field upgrades of

all system types.

• 8-GB Data Buffer: Capture long time windows for in-depth analysis and

identification of erratic problems.

• 10/100 MBps Ethernet Connectivity: Allows connection to an Ethernet network

and sharing of analyzer resources by multiple engineers.

1.5 Other Documents

For more information, refer to the following documents:

• Teledyne LeCroy Analyzers File-based Decoding Manual

• PETracer/Trainer Automation Manual

• PETracer VSE Manual

• PETracer Gen2 Multi Lead Probe User Manual

• PETrainer Scripting Language Reference Manual

•PETracer Online Help

8 Teledyne LeCroy

Page 17

Summit User Manual Chapter 2: Hardware Description

Chapter 2: Hardware Description

The PCI Express™ system features Summit Analyzers.

2.1 System Components

•PETracer Summit system:

•PETracer Gen2 Summit™ analyzer box

• Breakout Board with cable

•PETracer Software program CD-ROM

• Active or Passive interposer (optional)

• Active or Passive interposer card with 12V power supply

• One or two (for x8 or x16 recording) Mid Box assemblies

• Two or four (for x8 or x16 recording) Analyzer-to-Pod cables

• One or two (for x8 or x16 recording) iPass Y probe data cables

• MidBus probe (optional)

• One or two (for x8 or x16 recording) PCI Express Midbus Pods with

12-volt power supplies

• One or two (for x8 or x16 recording) MidBus probe assemblies

• Two or four (for x8 or x16 recording) Analyzer-to-Pod cables

• Summit T2-16 system:

• Summit T2-16™ analyzer box

• AC Power Cable

• One or two (for x8 or x16 recording) iPass Y probe data cables

• Breakout Board with cable

•PETracer Software program CD-ROM

• Active interposer with Power Supply (optional)

• Passive interposer with Power Supply (optional)

• MidBus probe (optional)

• One or two (for x8 or x16 recording) MidBus probe assemblies

• One or two (for x8 or x16 recording) T2 MidBus Pods

2.2 Host Machine Requirements

PETracer Summit and Summit T2-16 connect to a host machine. Please consult the

readme file on the installation CD for the latest host machine requirements.

Teledyne LeCroy 9

Page 18

Chapter 2: Hardware Description Summit User Manual

2.3 Summit T2-16 Front Panel Description

When powered on, the Summit T2-16 activates the user-accessible controls and LEDs

on the front and rear panels.

Warning! Do not open the enclosure. There are no operator serviceable parts inside.

Refer servicing to Teledyne LeCroy.

The controls and LEDs are:

• Power Switch (black): 1 = On and 0 = Off.

• LCD Menus: Allows you to set up the Summit T2-16 and view status. See “LCD

Menus” on page 11.

• Up Arrow (top blue button): Move up in the LCD menu.

• Select (middle blue button): Select or change an option.

• Down Arrow (bottom blue button): Move down in the LCD menu.

• Record LED: Lights when the Summit T2-16 is recording.

• Trigger LED: Lights when the Summit T2-16 triggers on an event.

• Status LED: Displays Analyzer status: blue = good or red = error.

• Manual Trigger (right blue button): Forces a trigger.

• UPSTREAM [15:8] and UPSTREAM [7:0] connectors: Connection to the probe or

MidBus module for the capture of upstream direction of the link.

• DOWNSTREAM [15:8] and DOWNSTREAM [7:0] connectors: Connection to the

probe or MidBus module for the capture of downstream direction of the link.

• REF CLK IN (Reference Clock In): Provides an optional alternative connection

from an external reference clock source to the Summit T2-16 analyzer.

Note: In standard configuration, the Summit T2-16 analyzer uses the reference

clock from a probe cable.

10 Teledyne LeCroy

Page 19

Summit User Manual Chapter 2: Hardware Description

LCD Menus

The Summit T2-16 has a front LCD panel that displays menus with commands for

configuring the device.

Boot Sequence

The boot sequence for the analyzer takes a few seconds. As the analyzer boots, it

initializes itself, beeps, and shows the status on the LCD panel. If the analyzer boots

successfully, the LCD panel Root menu appears.

During initialization, the LCD panel displays boot status messages.

Booting from Boot-Code

If the analyzer does not boot successfully, or if it becomes non-responsive, you can boot

from default settings called boot-code.

Boot-code is a simplified version of Summit firmware. It allows the analyzer to boot to the

point where it can communicate with the Summit software application. After

communication is established between the analyzer and software application, you can

download a different version of firmware and BusEngine files to the analyzer.

To boot from boot-code:

Step 1 Press and hold the Manual Trigger button on the analyzer front panel.

Step 2 While holding the button DOWN, turn the box ON.

After you complete these steps, download the new version of BusEngine and firmware

files, then reboot the analyzer from the LCD panel menu (Summit Setup > Reboot).

Root Menu

The Root menu appears after successful boot-up. The top line of the Root menu displays

the device status with the following:

• [PCI]: Indicates the hardware platform.

• Idle: Shows analyzer status.

Submenus

The Root menu has these options:

• Summit Setup menu: Allows setup using submenus.

• Platform Status menu: Shows the results for the power-on self-diagnostics.

Note: When lists of options are presented in a menu, the current selections are

indicated with an asterisk.

To navigate, use the Up Arrow and Down Arrow buttons (top and bottom blue buttons)

on the front of the unit.

To select or change an option, use the Select button (middle blue button).

Teledyne LeCroy 11

Page 20

Chapter 2: Hardware Description Summit User Manual

Summit T2-16 Setup Menu

Menu Submenu Command

IP Mode Static

Dynamic

IP Address If IP Mode = Dynamic, this field is ignored.

Subnet Mask Default is 0.0.0.0

Default Gateway Default is 0.0.0.0

Reboot Cancel

Confirm

Shutdown Cancel

Confirm

About Displays status on the following parameters:

Static = You assign an IP address.

Dynamic = A DHCP server assigns an IP address.

If IP Mode = Dynamic, this field is ignored.

If IP Mode = Dynamic, this field is ignored.

Selecting Confirm causes Summit to save the

current configuration and reboot.

Selecting Confirm causes Summit to save the

current configuration and shut down.

• Subnet Mask

• Default Gateway

• BootCode

•Firmware

• Bus Engine

• IP Mode: Dynamic or Static

Note: To go back to the previous menu, press the

Select button (middle button).

[Back] Returns to the Root menu.

12 Teledyne LeCroy

Page 21

Summit User Manual Chapter 2: Hardware Description

2.4 PETracer Summit Front Panel Description

When powered on, the PETracer Summit activates the user-accessible controls and

LEDs on the front and rear panels.

Warning! Do not open the enclosure. There are no operator serviceable parts inside.

Refer servicing to Teledyne LeCroy.

The controls and LEDs are:

• Power Switch (black): 1 = On and 0 = Off.

• LCD Menus: Allows you to set up the PETracer Summit and view status. See “LCD

Menus” on page 14.

• Up Arrow (top blue button): Move up in the LCD menu.

• Select (middle blue button): Select or change an option.

• Down Arrow (bottom blue button): Move down in the LCD menu.

• Record LED: Lights when the PETracer Summit is recording.

• Trigger LED: Lights when the PETracer Summit triggers on an event.

• Status LED: Displays Analyzer status: blue = good or red = error.

• Manual Trigger (right blue button): Forces a trigger.

• UPSTREAM 1 (lanes [7:0]) and UPSTREAM 2 (lanes [15:8]) connectors:

Connection to the Pod for the capture of upstream direction of the link.

• DOWNSTREAM 1 (lanes [7:0]) and DOWNSTREAM 2 (lanes [15:8]) connectors:

Connection to the Pod for the capture of downstream direction of the link.

Teledyne LeCroy 13

Page 22

Chapter 2: Hardware Description Summit User Manual

LCD Menus

The PETracer Summit has a front LCD panel that displays menus with commands for

configuring the device.

Boot Sequence

The boot sequence for the Summit box takes a few seconds. As the box boots, it

initializes itself, beeps, and shows the status on the LCD panel. If the box boots

successfully, the LCD panel Root menu appears.

During initialization, the LCD panel displays boot status messages.

Booting from Boot-Code

If the Summit box does not boot successfully, or if it becomes non-responsive, you can

boot from default settings called boot-code.

Boot-code is a simplified version of Summit firmware. It allows the box to boot to the point

where it can communicate with the Summit software application. After communication is

established between the box and software application, you can download a different

version of firmware and BusEngine files to the box.

To boot from boot-code:

Step 1 Press and hold the Manual Trigger button on the Summit box front

panel.

Step 2 While holding the button DOWN, turn the box ON.

After you complete these steps, download the new version of BusEngine and firmware

files, then reboot the box from the LCD panel menu (Summit Setup > Reboot).

Root Menu

The Root menu appears after successful boot-up. The top line of the Root menu displays

the device status with the following:

• [PCI]: Indicates the hardware platform.

• Idle: Shows analyzer status.

Submenus

The Root menu has these options:

• Summit Setup menu: Allows setup using submenus.

• Platform Status menu: Shows the results for the power-on self-diagnostics.

Note: When lists of options are presented in a menu, the current selections are

indicated with an asterisk.

To navigate, use the Up Arrow and Down Arrow buttons (top and bottom blue buttons)

on the front of the unit.

To select or change an option, use the Select button (middle blue button).

14 Teledyne LeCroy

Page 23

Summit User Manual Chapter 2: Hardware Description

PETracer Summit Setup Menu

Menu Submenu Command

IP Mode Static

Dynamic

IP Address If IP Mode = Dynamic, this field is ignored.

Subnet Mask Default is 0.0.0.0

Default Gateway Default is 0.0.0.0

Reboot Cancel

Confirm

Shutdown Cancel

Confirm

About Displays status on the following parameters:

Static = You assign an IP address.

Dynamic = A DHCP server assigns an IP address.

If IP Mode = Dynamic, this field is ignored.

If IP Mode = Dynamic, this field is ignored.

Selecting Confirm causes Summit to save the

current configuration and reboot.

Selecting Confirm causes Summit to save the

current configuration and shut down.

• Subnet Mask

• Default Gateway

• BootCode

•Firmware

• Bus Engine

• IP Mode: Dynamic or Static

Note: To go back to the previous menu, press the

Select button (middle button).

[Back] Returns to the Root menu.

Teledyne LeCroy 15

Page 24

Chapter 2: Hardware Description Summit User Manual

2.5 Summit T2-16 Rear Panel Description

From left to right, the Summit T2-16 rear panel contains the following components:

Figure 2.1 Summit T2-16 Rear Panel

Wide-range AC Connector Module

• Power on/off switch

• Enclosed 5x20 mm 2.0A 250 V fast acting glass fuse

• Power socket

Warning! For continued protection against fire, replace fuse only with the type and

rating specified above.

Sync In and Sync Out Connectors

(not currently active) These connectors allow multiple Summit T2-16 analyzers to send

synchronization and control messages to one another.

USB Type B Host Machine Computer Connector

This connector links an Analyzer to the host machine for the purpose of transmitting

commands from the host machine to the Analyzer and uploading traces from the

Analyzer’s recording memory to the PETracer software for viewing and analysis.

Note: For each Analyzer or Exerciser, use either USB or Ethernet, not both.

Ethernet Port

GIGE Connectivity allows connection to an Ethernet network and sharing of analyzer

resources by multiple engineers. Note: For each Analyzer or Exerciser, use either USB

or Ethernet, not both.

BNC Connectors Trigger In and Trigger Out

These BNC connectors allow the Analyzer to transmit or receive trigger event signals.

Triggering: The Ext. In can receive a signal from another device and use that signal to

trigger the end of the recording. Conversely, the Ext. Out connector can be used to send

an output signal from the Analyzer to another device.

The BNC connectors are not used for the PETrainer Exerciser.

16 Teledyne LeCroy

Page 25

Summit User Manual Chapter 2: Hardware Description

RS-232 25-pin Data Input/Output Connector

This connector links a 25 pin RS-232 cable to an external Breakout Board. The

Breakout Board allows signals to be sent from the Exerciser or Analyzer to an external

device such as an oscilloscope or from an external device to the Exerciser or Analyzer

for the purpose of triggering on an external input. You configure input/output through the

Recording Options dialog box. The Breakout Board use is described at the end of this

chapter.

Teledyne LeCroy Bus Connector

The Teledyne LeCroy Bus Connector is not currently active.

Teledyne LeCroy 17

Page 26

Chapter 2: Hardware Description Summit User Manual

2.6 PETracer Summit Rear Panel Description

From left to right, the PETracer Summit rear panel contains the following components:

Figure 2.2 PETracer Summit Rear Panel

Wide-range AC Connector Module

• Power socket

• Enclosed 5x20 mm 2.0A 250 V fast acting glass fuse

• Power on/off switch

Warning! For continued protection against fire, replace fuse only with the type and

rating specified above.

RS-232 25-pin Data Input/Output Connector

This connector links a 25 pin RS-232 cable to an external Breakout Board. The

Breakout Board allows signals to be sent from the Analyzer to an external device such

as an oscilloscope or from an external device to the Analyzer for the purpose of triggering

on an external input. You configure input/output signalling through the Recording Options

dialog box. The Breakout Board use is described at the end of this chapter.

USB Type B Host Machine Connector

This connector links the Analyzer to the host machine for the purpose of transmitting

commands from the host machine to the Analyzer and uploading traces from the

Analyzer’s recording memory to the PETracer software for viewing and analysis. Note:

May not be active on some Summit systems.

Ethernet Port

10/100 Mbps Ethernet Connectivity allows connection to an Ethernet network and

sharing of analyzer resources by multiple engineers.

18 Teledyne LeCroy

Page 27

Summit User Manual Chapter 2: Hardware Description

BNC Connectors Ext. In and Ext. Out

These BNC connectors allow the Analyzer to transmit or receive external signals.

External signaling, in turn, can serve two functions:

• Linking of Analyzers: On dual Analyzer systems, the BNC connectors are used to

create a loop for transmitting clocking information and commands between the

Analyzers. This linking allows the two Analyzers to function as a single, logical

Analyzer.

• Triggering: The Ext. In can receive a signal from another device and use that

signal to trigger the end of the recording. Conversely, the Ext. Out connector can be

used to send an output signal from the Analyzer to another device.

The Ext. In and Ext. Out connectors have the same function as the 25 pin RS-232

connector - i.e., they channel input and output signals but do not support the use of a

Breakout Board.

VHDCI Sync In and Sync Out Connectors

These connectors allow multiple PETracer Summit or Summit T2-16 analyzers to send

synchronization and control messages to one another.

Teledyne LeCroy 19

Page 28

Chapter 2: Hardware Description Summit User Manual

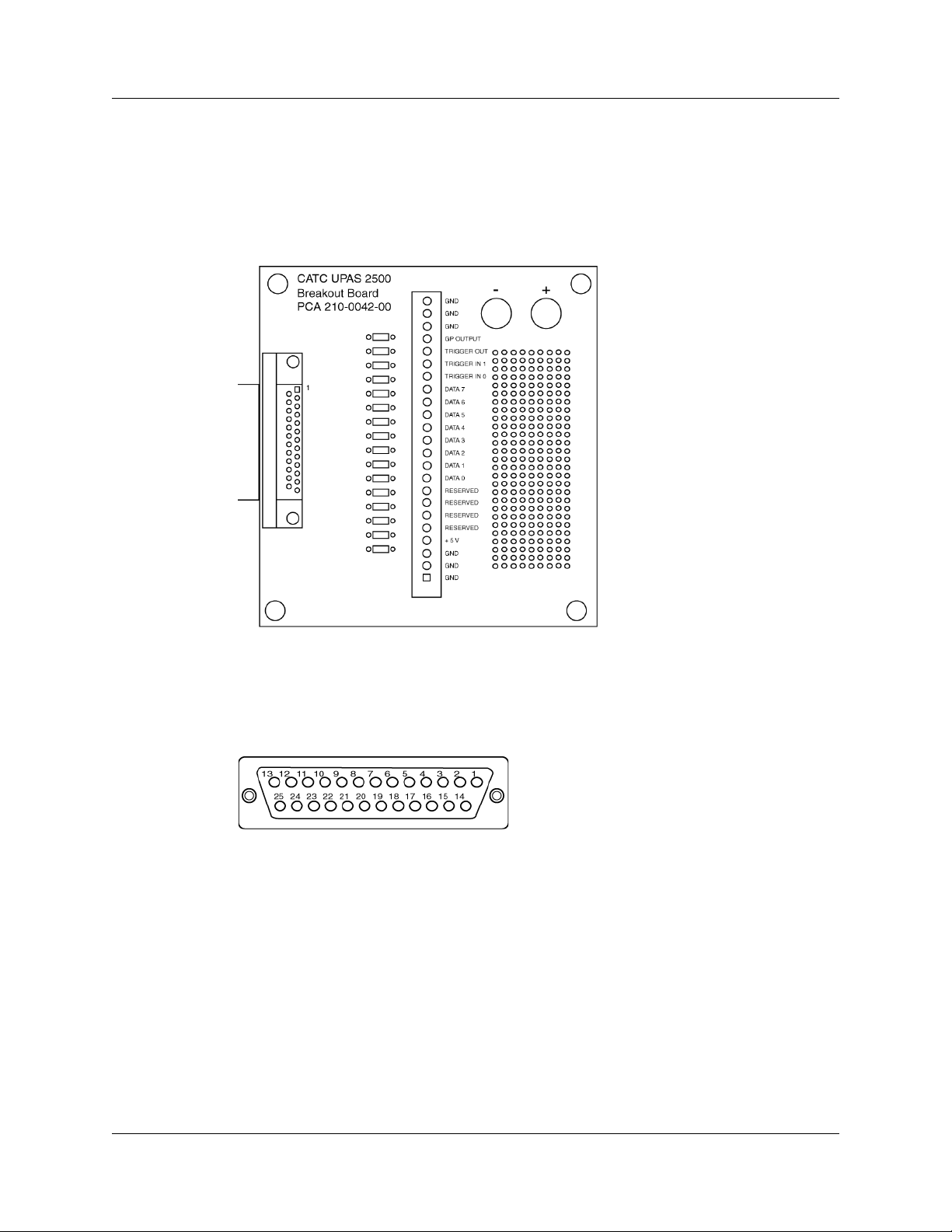

2.7 External Interface Breakout Board

With each Analyzer, Teledyne LeCroy includes an External Interface Breakout Board for

accessing several potentially useful standard, LV TTL output and input signals. The

Breakout Board also offers a simple way to connect logic Analyzers or other tools to the

Analyzer unit. Six ground pins and one 5-volt pin are provided.

The Breakout Board connects via a cable to the Data In/Out connector located on the

rear of the Analyzer unit. Each signaling pin is isolated by a 100 series resistor and a

buffer inside the Analyzer unit.

Data In/Out Connector (on cable)

20 Teledyne LeCroy

Page 29

Summit User Manual Chapter 2: Hardware Description

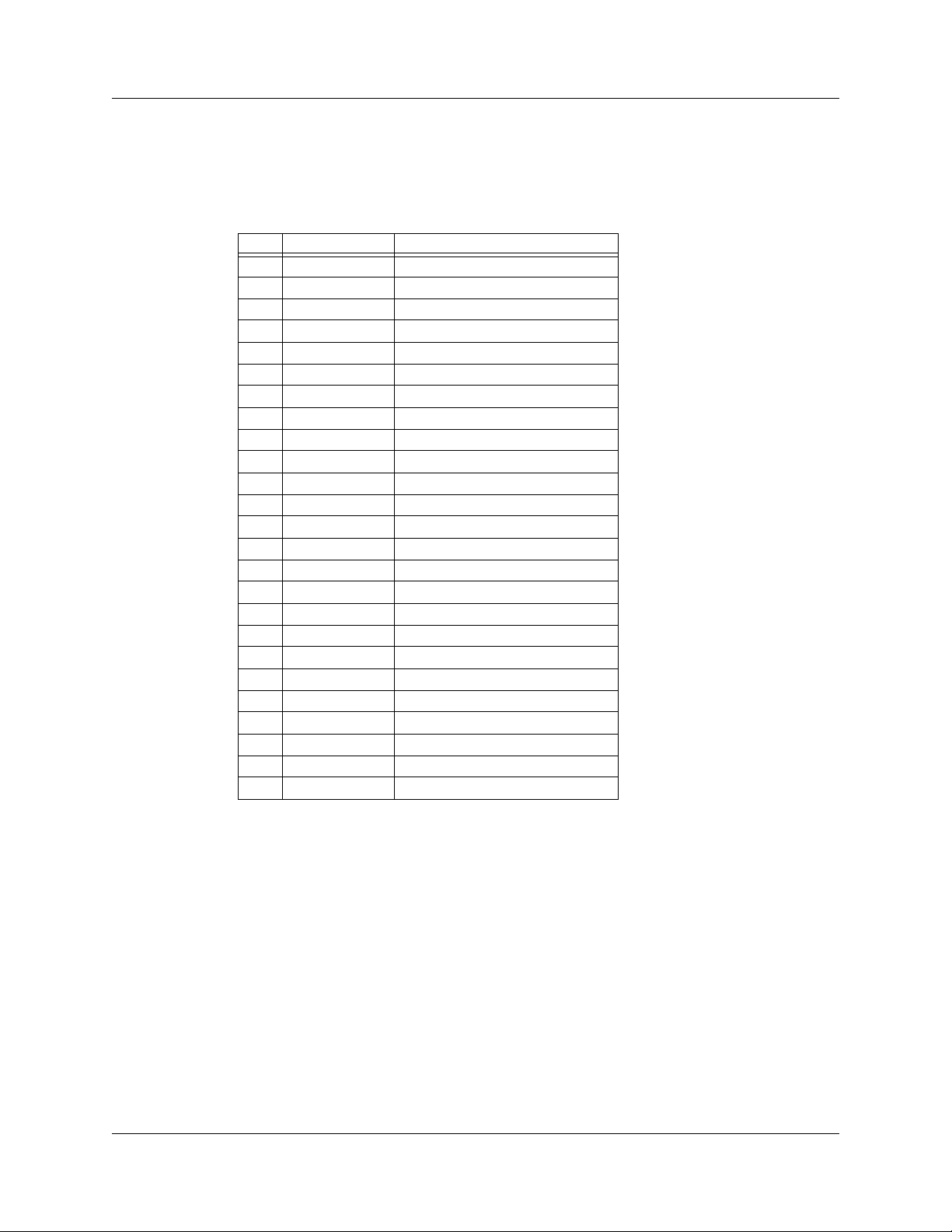

Pin-Outs for the Data In/Out Connector

The following table lists the pin-out and signal descriptions for the Data In/Out connector

on a cable that connects to the Breakout Board.

Data In/Out Connector – Pin-Out

Pin Signal Name Signal Description

1RSV Reserved

2 GND Ground

3 GP OUT General Purpose Output

4 TRG IN 1 Trigger In 1

5 GND Ground

6 DATA 6 Data 6

7 DATA 4 Data 4

8 DATA 3 Data 3

9 DATA 1 Data 1

10 GND Ground

11 RSV Reserved

12 RSV Reserved

13 +5V +5 Volts, 250 mA DC Source

14 RSV Reserved

15 GND Ground

16 TRG OUT Trigger Out

17 TRG IN 0 Trigger In 0

18 DATA 7 Data 7

19 DATA 5 Data 5

20 GND Ground

21 DATA 2 Data 2

22 DATA 0 Data 0

23 GND Ground

24 RSV Reserved

25 RSV Reserved

Note:

(*) Pins 4 and 17 have the same function: they allow external signals to be

used to cause triggering or recording. Pins 3 and 16 are used to transmit

output signals. Pins 6, 7, 8, 9, 18, 19, 21, and 22 (data pins) are used to

define data patterns for external input signals.

Note: All models of PETracer only support Data 0 - Data 3.

Prototype Rework Area

The Breakout Board contains a prototype rework area for making custom circuits for rapid

development. The area consists of plated-through holes, 20 columns wide by 27 rows

long. The top row of holes is connected to GND and the bottom row is connected to +5V.

The remaining holes are not connected. Use the rework area to insert custom

components and wire-wrap their respective signal, power, and ground pins.

Teledyne LeCroy 21

Page 30

Chapter 2: Hardware Description Summit User Manual

Breakout Board Input and Output Signals

A Breakout Board can be used to channel input signals into the Analyzer in order to cause

triggering. A Breakout Board can also be used to channel signals from the Analyzer to an

external source.

Drive strength for all outputs is about 30 mA high (@2 V) and 60 mA low (@0.5 V). Inputs

can handle 0 V to 5.5 V. Inputs above 2 V are detected as logic high; inputs below 0.8 V

are detected as logic low.

The Breakout Board connects via a cable to the Data In/Out connector on the rear of the

Summit systems.

External Recordable Signals

Breakout Board Data 0-3: These pins let you define a 4-bit Data Pattern that can be

recorded in a CATC Trace file.

External Input Triggers

You can use either an external input signal or the Trigger button on the front of the UPAS

to cause triggering. The following descriptions show what pins or buttons to use:

Breakout Board Data 3 - Data 0: Triggers on a 4-bit input pattern.

Breakout Board Trigger In 0: Selectable Edge triggered inputs. Triggers on any edge it

detects.

Breakout Board Trigger In 1: Selectable Edge triggered inputs. Triggers on any edge it

detects.

BNC Trigger (EXT IN): Selectable Edge triggered inputs. Triggers on any edge it detects.

Located on the back of the chassis.

Push Button Trigger: The Trigger button on the front of the UPAS can be pressed to

manually cause a trigger.

External Outputs

The Analyzer can be configured to send an external signal anytime a trigger and/or event

occurs. The following descriptions show the behavior of these output signals:

Breakout Board Trigger Out: Changes from low to high when Analyzer triggers

(one time per recording only)

Breakout Board G.P. Output: Programmable waveform (low or high pulse, toggle). Each

event can be programmed to enable this external signal.

BNC Output (EXT OUT): Same as Breakout Board G.P. Output. Located on the back of

the chassis.

Setting Recording Options to Support External Input/Output

Signaling

After a Breakout Board has been connected to a Summit system, the Analyzer must be

configured for external or internal input signaling.

22 Teledyne LeCroy

Page 31

Summit User Manual Chapter 3: Installation and Setup

Chapter 3: Installation and Setup

PETracer Summit™ and Summit T2-16™ are stand-alone systems.

You can begin making PCI Express™ recordings after following the steps in this chapter.

3.1 Installing the PETracer Software

PETracer software operates all of Teledyne LeCroy’s PCI Express protocol Analyzer and

Exerciser products:

The PETracer software is installed on a Microsoft

serves as the interface for the Analyzer.

To install the PETracer software on the host machine, before attaching the Analyzer to

the system:

Step 1 Insert the CD into the CD ROM drive of the host machine that will control

the Analyzer. The installation window opens and displays links to the

PETracer software, user manuals, a readme file, and Acrobat Reader.

Step 2 Select Install Software and follow the on-screen instructions.

®

Windows®-based host machine and

The PETracer software installs automatically on the host machine’s hard disk.

During installation, all necessary USB drivers are loaded automatically. Drivers

included in the installation are:

• summit.sys: Summit T2-16 driver

Note: PETracer Summit needs no driver installation.

Step 3 To start the application, launch the PETra c er program from the Start

menu:

Start > Programs > LeCroy > PETracer > LeCroy PETracer

Teledyne LeCroy 23

Page 32

Chapter 3: Installation and Setup Summit User Manual

The PETracer program opens:

Note: The software may be used with or without the Analyzer attached to the

system. When used without an Analyzer attached to the computer, the

program functions as a CATC Trace Viewer to view, analyze, and print

captured traffic.

24 Teledyne LeCroy

Page 33

Summit User Manual Chapter 3: Installation and Setup

3.2 Setting Up the Summit T2-16 Analyzer using an Ethernet Connection

Step 1 Remove the Analyzer from its shipping container.

Step 2 Connect the Analyzer to a 100-volt to 240-volt, 50 Hz to 60 Hz,

120 W power outlet using the provided power cord.

Note: The Analyzer is capable of supporting supply voltages between 100 volts

and 240 volts, 50 Hz or 60 Hz, thus supporting all known supply voltages around

the world.

Step 3 Connect the Ethernet cable between the Ethernet port on the back of the

Analyzer and a Ethernet port (hub, switch or wall) in your local network.

Continue with Step 4 below.

Note on USB: To connect using USB, see “Setting Up the Summit T2-16

Analyzer using a USB Connection” on page 28.

Step 4 Turn on the rear power switch and the front power switch.

Note: At power-on, the Analyzer initializes itself in approximately five seconds

and performs an exhaustive self-diagnostic that lasts about forty seconds. The

results are reflected by messages on the Summit T2-16 LCD display (see

“Summit T2-16 Front Panel Description” on page 10). If the LCD display indicates

failure, call Teledyne LeCroy Customer Support for assistance.

Connecting to a Summit T2-16 Analyzer in the Local Network

After you have installed the PETra c e r application software, perform the following

procedure to connect to a Summit T2-16 analyzer in the local network.

Step 1 Select the Setup > All connected devices… menu in the PETracer

application to display the Analyzer Devices dialog.

Teledyne LeCroy 25

Page 34

Chapter 3: Installation and Setup Summit User Manual

The PETracer software fills the list with devices that are connected over USB or

discovered on the Ethernet network. The discovery mechanism works only within

one network subnet. If a Summit is connected to the network on a different

subnet, you can manually add the subnet to the list by clicking the Add Device

button and specifying the IP address.

The Summit devices in the list are marked:

• Locked: Some other client on the network is already connected to that

device

• Ready to connect: Available for connection

Step 2 If a Summit device is marked Ready to Connect, you can select that

device and press the Connect button to execute the connection

procedure.

After the connection is established, the application displays the Connection

Properties dialog:

Step 3 Select an option:

• Automatically connect to the device: When the application is started or

when the named device is added to the network while the PETracer

application is running on this computer, the PETracer application will try to

connect to the named device.

• Ask if I want to connect to the device: When the application is started or

when the named device is added to the network while the PETracer

application is running on this computer, the PETracer application will display a

message box allowing you to connect to the named device.

• Take no action: When you start the application or when you add the named

device to the network while the PETracer application is running on this

computer, you must connect manually to use the named device.

Note: When you close the application on this computer (or you perform manual

disconnect), the application disconnects from the device.

26 Teledyne LeCroy

Page 35

Summit User Manual Chapter 3: Installation and Setup

Step 4 Press OK in the Connection Properties dialog.

After you finish the connect procedure, the Summit device to which you have

connected is marked as Ready and you can use it for recording:

Note: To disconnect from a device, display this dialog, select the device, and click

the Disconnect button.

Warning! Do not change from USB to Ethernet, or back, without power cycling

the analyzer.

Teledyne LeCroy 27

Page 36

Chapter 3: Installation and Setup Summit User Manual

3.3 Setting Up the Summit T2-16 Analyzer using a USB Connection

To set up the Analyzer using a USB connection:

Step 1 Remove the Analyzer from its shipping container.

Step 2 Insert and install the Installation CD.

Step 3 Connect the Analyzer to a 100-volt to 240-volt, 50 Hz to 60 Hz,

120 W power outlet using the provided power cord.

Note: The Analyzer is capable of supporting supply voltages between 100 volts

and 240 volts, 50 Hz or 60 Hz, thus supporting all known supply voltages around

the world.

Step 4 Connect the USB port to a USB port on the host machine using a USB

cable.

Note on Ethernet: To connect using Ethernet, see “Setting Up the Summit T2-16

Analyzer using an Ethernet Connection” on page 25.

Step 5 Turn on the rear power switch and the front power switch.

Note: At power-on, the Analyzer initializes itself in approximately five seconds

and performs an exhaustive self-diagnostic that lasts about forty seconds. The

results are reflected by messages on the Summit T2-16 LCD display (see

“Summit T2-16 Front Panel Description” on page 10). If the LCD display indicates

failure, call Teledyne LeCroy Customer Support for assistance.

Step 6 Click Next after you see the Add New Hardware Wizard window.

Step 7 Follow the Microsoft

for the automatic installation of the Analyzer as a USB device on your

analyzing host machine. (The required USB files are included on the

Installation CD and were installed on your system when you installed the

software CD.)

Step 8 Click Finish when you see the message that says “Windows has

finished installing the software that your new hardware requires” and the

file has been installed in your host machine.

Warning! Do not change from USB to Ethernet, or back, without power cycling

the analyzer.

®

Windows® on-screen Plug-and-Play instructions

28 Teledyne LeCroy

Page 37

Summit User Manual Chapter 3: Installation and Setup

3.4 Setting Up the PETracer Summit Analyzer

Step 1 Remove the Analyzer from its shipping container.

Step 2 Connect the Analyzer to a 100-volt to 240-volt, 50 Hz to 60 Hz,

120 W power outlet using the provided power cord.

Note: The Analyzer is capable of supporting supply voltages between 100 volts

and 240 volts, 50 Hz or 60 Hz, thus supporting all known supply voltages around

the world.

Step 3 Connect the Ethernet cable between the Ethernet port on the back of the

Analyzer and a Ethernet port (hub, switch or wall) in your local network.

Step 4 Turn on the rear power switch and the front power switch.

Note: At power-on, the Analyzer initializes itself in approximately five seconds

and performs an exhaustive self-diagnostic that lasts about fifteen seconds. The

results are reflected by messages on the PETracer Summit LCD display (see

“PETracer Summit Front Panel Description” on page 13). If the LCD display

indicates failure, call Teledyne LeCroy Customer Support for assistance.

Note: No driver installation is needed for the PETracer Summit device.

Connecting to a PETracer Summit Analyzer in the Local Network

After you have installed the PETra c e r application software, perform the following

procedure to connect to a PETracer Summit analyzer in the local network.

Step 1 Select the Setup > All connected devices… menu in the PETracer

application to display the Analyzer Devices dialog.

The PETracer software fills the list with devices that are connected over USB or

discovered on the Ethernet network. The discovery mechanism works only within

one network subnet. If a Summit is connected to the network on a different

subnet, you can manually add the subnet to the list by clicking the Add Device

button and specifying the IP address.

Teledyne LeCroy 29

Page 38

Chapter 3: Installation and Setup Summit User Manual

The Summit devices in the list are marked:

• Locked: Some other client on the network is already connected to that

device

• Ready to connect: Available for connection

Step 2 If a Summit device is marked Ready To Connect, you can select that

device and press the Connect button to execute the connection

procedure.

After the connection is established, the application displays the Connection

Properties dialog:

Step 3 Select an option:

• Automatically connect to the device: When the application is started or

when the named device is added to the network while the PETracer

application is running on this computer, the PETracer application will try to

connect to the named device.

• Ask if I want to connect to the device: When the application is started or

when the named device is added to the network while the PETracer

application is running on this computer, the PETracer application will display a

message box allowing you to connect to the named device.

• Take no action: When you start the application or when you want to add the

named device to the network while the PETracer application is running on this

computer, you must connect manually to use the named device.

Note: When you close the application on this computer (or you perform manual

disconnect), the application disconnects from the device.

30 Teledyne LeCroy

Page 39

Summit User Manual Chapter 3: Installation and Setup

Step 4 Press OK in the Connection Properties dialog.

After you finish the connect procedure, the Summit device to which you have

connected is marked as Ready and you can use it for recording:

Note: To disconnect from a device, display this dialog, select the device, and click

the Disconnect button.

Teledyne LeCroy 31

Page 40

Chapter 3: Installation and Setup Summit User Manual

3.5 Interposers and Probes

PETracer Summit and Summit T2-16 work with Interposers and Probes.

• Gen2 MidBus Probe: The Gen2 MidBus Probe is designed for use with the Summit

T2-16 Analyzer and supports lane widths from x1 to x16 at data rates of 2.5

GT/s (Gen1) or 5.0 GT/s (Gen2).

• Gen2 Multi-lead Probe: The Summit Multi-lead Probe is designed for use with the

Summit T2-16 Protocol Analyzer. The probe consists of 1 to 4 probe pods, which

are connected to the analyzer using either iPass Y-Cables (for x1 and x4) or straight

x4-to-x8 iPass cables (for x8 and x16). Each probe pod supports up to 8 Flex Tips,

with each Flex Tip connected via two coax cables.

•

Gen2 Passive Slot Interposer: The Gen2 Passive Slot Interposer is designed for use

with the Summit T2-16 Analyzer and supports lane widths from x1 to x16 at data

rates of 2.5 GT/s (Gen1) or 5.0 GT/s (Gen2). A separate interposer is used for each

lane width that you would like to probe. Lane reducers should NOT be used with the

Gen2 Passive Slot Interposer. For lane widths up to x8, one iPass Y-cable is

required. For x16 applications, two iPass Y-cables are required.

•

Gen2 Active Slot Interposer: The Gen2 Active Slot Interposer is designed for use

with the Summit T2-16 Analyzer and supports lane widths from x1 to x16 at data

rates of 2.5 GT/s (Gen1) or 5.0 GT/s (Gen2). Lane reducers/adapters may be used

with the Gen2 Active Slot Interposer. For lane widths up to x8, one iPass Y-cable is

required. For x16 applications, two iPass Y-cables are required.

The following sections describe how to set up probe systems.

32 Teledyne LeCroy

Page 41

Summit User Manual Chapter 3: Installation and Setup

3.6 Using Probes

Example: Connecting the Summit T2-16 Analyzer to the Device Under Test Using a Gen2 MidBus Probe

Components

• 1 or 2 iPass Y-cable

• 1 or 2 MidBus Probe pod

Teledyne LeCroy 33

Page 42

Chapter 3: Installation and Setup Summit User Manual

• 1 or 2 MidBus Probe Cable, Attachment Pad, and Header

• 1 or 2 Clock Cable

34 Teledyne LeCroy

Page 43

Summit User Manual Chapter 3: Installation and Setup

Connections Overview for Gen2 MidBus Probe

Use a 1-pod or 2-pod setup depending on the lane width of the recording:

• For x16 recordings, use the 2-pod setup.

• For all other lane width recordings, use a one-pod setup.

Use the iPass Y-cables to connect the probe data connectors on the Analyzer to the

MidBus pod(s).

On the other side of the pod, connect the MidBus probe assembly.

Connect the header on the MidBus probe assembly to the MidBus footprint on the

System Under Test (host platform/root complex). The following picture shows two midbus

footprints, with one connected to the MidBus probe assembly:

Connection Procedure

To connect the Summit T2-16 to the System Under Test (host platform/root complex):

Step 1 Connect the MidBus pods to the Analyzer using the iPass Y-cables.

Step 2 Connect the MidBus probe assemblies to the MidBus pods.

Step 3 Connect the MidBus probe assemblies to the MidBus footprints on the system

under test.

Step 4 Connect external reference clock signal to Mid-Bus External Clock In on

Mid-Bus probe pod, using external reference clock cable. For x16, you

need to chain the pods.

Teledyne LeCroy 35

Page 44

Chapter 3: Installation and Setup Summit User Manual

Example: Connecting the Summit T2-16 Analyzer to the

Device Under Test Using a Gen2 Multi-lead Probe for

and x4

x1

Components

• 1 iPass Y-cable for x1 and x4 (see “1 or 2 iPass Y-cable” on page 33)

• 1 Multi-lead Probe Pod for x1 and x4

• up to 16 MidBus Probe SSMP Cables, and up to 8 Flexible Leads, per pod

• 1 Clock Cable (see “1 or 2 Clock Cable” on page 34)

36 Teledyne LeCroy

Page 45

Summit User Manual Chapter 3: Installation and Setup