Page 1

Portable Emissions Analyzer

OPERATING INSTRUCTIONS FOR

PEM-9004

Portable Emissions Analyzer

P/N MPEM9004

ECO: XX-XXXX

DANGER

Toxic gases may be present in this monitoring system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist

for a time even after the power is turned off and disconnected.

Only authorized personnel should conduct maintenance and/or servicing.

Before conducting any maintenance or servicing, consult with authorized

supervisor/manager.

Teledyne Analytical Instruments i

Page 2

PEM-9004

Copyright © 2008 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by Teledyne or an authorized service center.

We assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its use r, an d serves as a tool b y whic h

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface, with the process being

measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of Teledyne at the

time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot accept

responsibility for conditions beyond its knowledge and control. No statement expressed or

implied by this document or any information disseminated by the manufacturer or its

agents, is to be construed as a warranty of adequate safety control under the user’s process

conditions.

Teledyne Analytical Instruments ii

Page 3

Portable Emissions Analyzer

Specific Model Information

It is not recommended that this instrument be used for analysis on

any other gas or gas mixture than that specified at the time of purchase.

Using this instrument to analyze any other gas mixture may result in

serious error. Consult the factory for additional information for gas

analysis not specified at the time of purchase.

Instrument Serial Number: _______________________

Teledyne Analytical Instruments iii

Page 4

PEM-9004

Important Notice

The PEM-9004 is a gas analysis computer for measuring and

computing the concentration of various gases in a combustion process.

Both toxic and combustible gasses may at times be present in and

around the analyzer. This instrument is designed to safely handle

specific combustible gas mixtures as outlined in the product

specification. Since Teledyne cannot control the end use of this

instrument, it is the responsibility of the user to establish whether or not

the total system of instrument, environment, alarm components, and any

other relevant devices actually will assure safety under the particular

circumstances of use.

Location of the equipment and sensors that will insure proper

operation is the responsibility of the user.

The safety checklist outlined below is only a guide. It is up to the

user to establish practical safety precautions given his/her own specific

circumstances. It is vital that the operator understand and test the

operation of the total system.

Safety Checklist

Verify that the instrument is powered correctly.

Verify that the instrument works properly (all functions).

Verify that measured values are correct.

Verify that unauthorized personnel cannot tamper with the

instrument or its auxiliary equipment.

Institute routine test/calibration procedures.

Identify and handle any potential problems in sampling or

location.

Train all operators to understand all operations and functions

of the analyzer and the system.

Identify and handle any environmental or other influences that

could affect the operation of the instrument.

Teledyne Analytical Instruments iv

Page 5

Portable Emissions Analyzer

Safety Messages

Your safety and the safety of others is very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the instructions

for details on the specific danger. These cautions warn of

specific procedures which if not followed could cause bodily

Injury and/or damage the instrument.

CAUTION: HOT SURFACE WARNING: This warning is

specific to heated components within the instrument. Failure

to heed the warning could result in serious burns to skin and

underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous

voltages appear within this instrument. This warning is

specific to an electrical hazard existing at or nearby the

component or procedure under discussion. Failure to heed this

warning could result in injury and/or death from

electrocution.

Technician Symbol: All operations marked with this symbol

are to be performed by qualified maintenance personnel only.

No

Symbol

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

NOTE: Additional information and comments regarding a

specific component or procedure are highlighted in the form

of a note.

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

Teledyne Analytical Instruments v

Page 6

PEM-9004

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

This manual provides information designed to guide you through

the installation, calibration operation and maintenance of your new

analyzer. Please read this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be peculiar to your

instrument.

Manuals do get lost. Additional manuals can be obtained from

Teledyne at the address given in the Appendix. Some of our manuals are

available in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Teledyne Analytical Instruments vi

Page 7

Portable Emissions Analyzer

Table of Contents

List of Figures................................................................................x

List of Tables................................................................................xi

Introduction ...................................................................................1

1.1 Overview 1

1.2 Features 3

1.3 Operator Interface 4

Operational Theory .......................................................................5

2.1 Introduction 5

2.2 Sensor Cell 5

2.3 Specific Sensor Network 6

2.4 Combustion Efficiency 6

2.4.1 Calculating the CO2 Composition of Exhaust Gas 6

2.4.2 Calculating the Waste Gas Loss 7

2.4.3 Calculating the Combustion Efficiency 7

2.4.4 Calculating Excess Air Value (Lambda) 8

2.4.5 Calculating Undiluted CO Concentration 9

2.5 Sample System 9

Installation ...................................................................................13

3.1 Unpacking the Analyzer 13

3.2 Attaching the Probe and Thermocouples 13

3.3 Initial Calibration 14

3.4 Battery Power 15

3.4.1 Charging the Battery 15

3.4.2 Battery Replacement 16

3.5 Sensor Replacement 16

Operation .....................................................................................17

Teledyne Analytical Instruments vii

Page 8

PEM-9004

4.1 User Interface 17

4.2 Startup Screen 19

4.3 Main menu 20

4.3.1 Status Line 20

4.3.2 Available Programs 20

4.4 Configure Menu 21

4.4.1 Display 21

4.4.2 Fuel 23

4.4.2.1 Remove a Fuel from the List 23

4.4.2.2 Reinstate a Previously Removed Fuel 23

4.4.2.3 Insert a New Fuel 24

4.4.3 Settings 26

4.4.3.1 Units for Draft and Pressure 26

4.4.3.2 Instrument Sound On/Off 26

4.4.3.3 Select Printer 27

4.4.3.4 User Address 27

4.4.3.5 Automatic Timer 28

4.4.4 Set Default 29

4.5 Measurement Screen 30

4.5.1 Flue Gas 31

4.5.1.1 Draft 32

4.5.1.2 Info 33

4.5.1.3 Draught Detection 34

4.5.1.4 Units 35

4.5.1.5 O

Referenece 36

2

4.5.1.6 Extended Data 36

4.5.1.7 Graphic 39

4.5.1.8 Fuel 40

4.5.1.9 Config 40

4.5.1.10 Program Macros 40

4.5.1.11 Hold 41

4.5.1.12 Zoom 42

Teledyne Analytical Instruments viii

Page 9

Portable Emissions Analyzer

4.5.1.13 CO Protect 43

4.5.1.14 Print 44

4.5.2 Temperature 45

4.5.3 Pressure 46

4.5.4 CO (O

) Measurement 47

2

4.6 Macro Start 48

4.7 Time-Date 49

4.8 Memory 51

4.9 USB-Interface 54

4.10 Charge Control 54

4.11 Battery / Line Voltage Operation 55

4.11.1 Charging the Battery 55

4.11.2 Battery Replacement 56

Maintenance.................................................................................57

5.1 Routine Maintenance 57

Appendix......................................................................................59

Specifications 59

Recommended Spare Parts List 62

Reference Drawings 63

Index.............................................................................................65

Teledyne Analytical Instruments ix

Page 10

PEM-9004

List of Figures

Figure 2-4: Gas Conditioning System ........................................... 10

Figure 3-1: PEM-9004 Front Panel ...............................................14

Figure 4-1: PEM-9004 Front Panel ...............................................17

Figure 4-2: Additional Functions Available from Flue Gas Menu...19

Figure 4-3: Data Memory Structure...............................................52

Figure 5-1 Water Trap and Filter...................................................58

Teledyne Analytical Instruments x

Page 11

Portable Emissions Analyzer

List of Tables

Table 1-1: Measurement Capabilities of the PEM-9004 Analyzer...2

Table 1-2: Parameters Calculated by the PEM-9004......................2

Table 4-1: Function Keys...............................................................18

Teledyne Analytical Instruments xi

Page 12

PEM-9004

DANGER

COMBUSTIBLE GAS USAGE

It is the customer's responsibility to ensure safety especially

when combustible gases are being analyzed since the

potential of gas leaks always exist.

The customer should ensure that the principles of operating

of this equipment is well understood by the user and that the

instrument as well as any approved support equipment is

properly installed. Misuse of this product in any manner,

tampering with its components, or unauthorized substitution

of any component may adversely affect the certification and

the safety of this instrument.

WARNING

Since the use of this instrument is beyond the control of

Teledyne, no responsibility by Teledyne, its affiliates, and

agents for damage or injury from misuse or neglect of this

equipment is implied or assumed.

Teledyne Analytical Instruments xii

Page 13

Portable Emissions Analyzer Introduction

Introduction

1.1 Overview

The Teledyne Analytical Instruments (TAI) Model PEM-9004 Gas

Analysis Computer is a multifunction analyzer with integrated

calculating functions. The system is ideally suited for monitoring

heaters, exhaust lines, and other flue gas installations.

The PEM-9004 analyzes the gaseous products of a combustion

process and provides critical information on the state of the effluent

stream. Information is available on-screen and via printed reports. Data

can also be output to a remote device via the USB communication port.

The system is battery operated, lightweight yet rugged so it can be

moved and rapidly setup at any location.

The analyzer measures and displays the O2, CO, and with the

appropriate option, SO2, and NO content of a gas. It also senses and

measures draft or pressure and the gas temperature at the sampling point

as well as the ambient temperature. An internal database of common

fuels supplies thermodynamic data for calculations that the monitor

performs on the sampled data, to determine the CO2 and NOx

concentrations when equipped with the appropriate optional sensors.

The instrument also calculates combustion efficiency, excess air and

other parameters critical in assessing efficiency in a combustion process.

Measured data and test results can be stored in a 100 record

database for later recall and printed on demand from the monitor’s

integral printer. Data can also be monitored remotely via an integral

USB communications port. Numerical data can be output in a variety of

units for customer reports.

Gas and electrical ports along with the display and all operator

controls are accessible from the front panel.

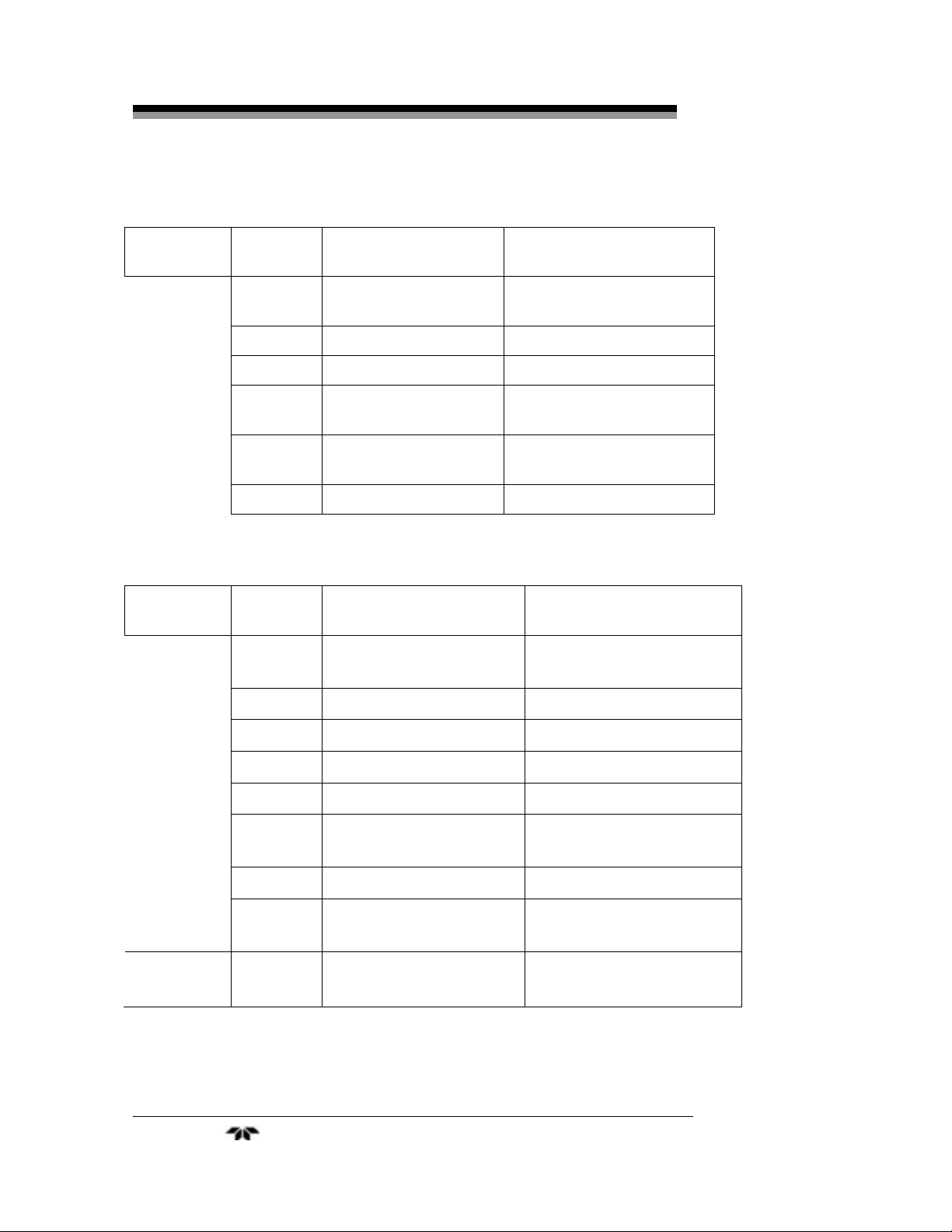

Table 1-1 and 1-2 highlight the PEM-9004 monitoring capability.

They show the actual measured parameters and derived (calculated)

values respectively.

Teledyne Analytical Instruments 1

Page 14

Introduction PEM-9004

Table 1-1: Measurement Capabilities of the PEM-9004 Analyzer

Measured

Values

T.Gas Waste or flue gas

temperature

T.Room Air or ambient

temperature

O2 Oxygen content % Volume

CO Carbon monoxide ppm-mg/mm3-mg/kWh

NO Nitrogen monoxide

(option)

SO2 Sulphur dioxide

(option)

Draft Draft or Pressure inches of H

°F or °C

°F or °C

ppm-mg/mm3-mg/kWh

ppm-mg/mm3-mg/kWh

Table 1-2: Parameters Calculated by the PEM-9004

Calculated

Values

CO2 Carbon dioxide % Volume

CO 0% Carbon monoxide,

undiluted

ppm

0 (iWC)

2

Effi. Combustion efficiency %

Ex.air Excess air value

qA Waste gas losses %

Dewpnt Fuel specific dewpoint °F or °C

T.Diff Differential temperature

°F or °C

(TG-TA)

NOx Nitrogen oxides (option) ppm-mg/mm3-mg/kWh

NOx ref. Nitric oxides, undiluted

ppm

(option)

SO2 ref. Sulphur dioxide,

ppm

undiluted (option)

Teledyne Analytical Instruments 2

Page 15

Portable Emissions Analyzer Introduction

1.2 Features

• Analysis Ranges: The PEM-9004 is available with the

following analysis ranges:

• O

2

0-20.9%

• CO 0-4000 ppm

(with H2 compensation)

• CO2 (calculated from O2 measurement)

0-CO2 max (fuel specific)

And optionally:

• CO 0-2% (0-20,000 ppm)

(without H2 compensation)

• NO 0-2000 ppm (optional)

• SO2 0-2000 ppm (optional)

• NO2 0-200 ppm

• CO Sensor Protection: The PEM-9004 incorporates a special

CO sensor protection feature utilizing a separate pump that

automatically flushes the CO sensor when an upper CO

threshold of 4000 ppm is exceeded.

• Pressure/Draft Measurement: A piezoresistive pressure

sensor with internal temperature compensation is installed for

measuring pressure up to ± 60 inches of water (iWC). A

convenient port is located on the front panel for positive or

negative pressure measurements.

• Temperature Measurement: Both ambient and gas

temperatures up to 1850°F (1000°C) are monitored using Ktype (NiCr-Ni) thermocouples. These parameters are used by

the internal processor in calculating combustion efficiency,

waste gas loses, excess air and undiluted CO concentration.

• Waste Gas Sampling: Via an external water separator and

filter, the waste gas is fed to the sensors by means of a gas

feed pump. It accepts either a one point measurement probe

(combi-probe) or multi-point measurement probe (multi-hole

probe).

Teledyne Analytical Instruments 3

Page 16

Introduction PEM-9004

• Unit Conversion: Gas, temperature and pressure information

is displayed and/or stored in several different units depending

on the user’s preference.

• Internal Infrared Thermal Printer: The PEM-9004 is

equipped with a printer for immediate hard copy of data. If

desired, the printed reports can contain a header with the

company name or other convenient designation.

• Display: Hi-res LCD module with 5 or 10 line text and

graphical display plus menu line.

• Data Communication: USB interface. Optional radio-

interface (Bluetooth).

• Memory: 100 memory blocks max. including dynamic

memory management and directory/file structure.

• Power: NiCd battery 6V/4Ah with external power adapter and

charger. Integral power management system controls battery

charging and prolongs battery life.

1.3 Operator Interface

All user controls and connections are accessible from the front

panel after opening the top case. Figure 1 shows the front panel of the

PEM-9004. There are 3 function buttons and 7 menu select buttons (also

referred to as keys) which control all operations of the analyzer. Chapter

4 describes in detail the use of the menu select and function buttons in

operating the analyzer. In addition to operator controls, gas and

thermocouple ports are installed and clearly identified on the front panel.

Teledyne Analytical Instruments 4

Page 17

Portable Emissions Monitor Operational Theory

Operational Theory

2.1 Introduction

The PEM-9004 uses state-of-the-art sensor technology for accurate

measurements of O

sensors employed are electrochemical cells specific for each component.

The instrument will measure and display the actual gas

concentration for O

the time of purchase, the PEM-9004 can also measure and display the

NO, CO (high), and SO2 concentration of a flue gas. The analyzer, based

on measurements of draft pressure, temperature, and data entered for the

combustion fuel plus pertinent thermodynamic data internally stored as

part of the instrument’s database, will calculate and display the

following combustion related information:

, CO/H2, CO-high and optionally, NO and SO2. The

2

and CO(H2). Depending on the options selected at

2

• CO2 concentration

• Non-diluted CO concentration

• Pressure and temperature differential

• Efficiency (Eta)

• Waste gas losses (qA)

• NOx concentration

• Dew point

• Eta combustion value

2.2 Sensor Cell

At the heart of the analyzer are the sensors. Up to 5 sensor cells are

installed depending on the options selected at the time of purchase. Each cell

is specific to a particular gaseous component.

Teledyne Analytical Instruments 5

Page 18

Operational Theory PEM-9004

2.3 Specific Sensor Network

The sensors employed in the PEM-9004 operate according to

Faraday's Law of Electrolysis: In an electrochem ical ce ll, the rate a t which

gas is produced at one pole is directly proportional to the quantity of

electric current flowing through the electrodes. Conversely, the current

produced by the cell is directly proportional to the consumption of gas at

the pole.

The PEM-9004 incorporates a network of up to five individual sensors

for analyzing oxygen, carbon monoxide, and optionally, sulphur dioxide,

and nitrogen oxides. The individual sensors are arranged on a sensor block

located underneath the front panel of the unit. Each sensor produces an

output current proportional to the consumption rate of the particular gas for

which it is sensitive. Typically, the sensor output is in the microampere

range. Cross-sensitivity between sensors is measured and corrected for,

using an internal algorithm. The sensor output is fast and stable and only

mildly affected by changes in relative humidity or temperature.

2.4 Combustion Efficiency

The PEM-9004 measures oxygen, combustion gas temperature,

draft pressure and ambient air temperature, and it contains an internal

database of the thermodynamic properties of several common fuels. It

uses these to calculate combustion efficiency as follows:

2.4.1 Calculating the CO2 Composition of Exhaust Gas

It first calculates the CO

basis using data extracted from the selected fuel. The following equation

is used to calculate the CO2 concentration in volume %.

Where: CO

is the fuel specific theoretical maximum CO

2MAX

concentration in volume %

O

is the measured oxygen concentration in volume %

2

20.9 is the oxygen content in air (volume %).

composition of the exhaust gas on a dry

2

O

22

MAX

⎛

1COCO

−×=

⎜

⎝

⎞

2

⎟

9.20

⎠

2

Teledyne Analytical Instruments 6

Page 19

Portable Emissions Monitor Operational Theory

=

2.4.2 Calculating the Waste Gas Loss

The analyzer uses the measured oxygen concentration and the

exhaust gas and ambient temperature of the stack to calculate the total

energy loss in the exhaust gas. The total energy loss is calculated by

adding in the work done to expand the exhaust gas against atmospheric

pressure and the heat required to vaporize the water generated in the

burning process.

The waste gas loss calculation involves multiplying the heat

capacity of each component by the difference in temperature between

ambient air and exhaust gas. The following equation is used to calculate

the waste gas loss (qA) in %:

2

+×= B

⎞

⎟

⎟

⎠

Where: T

T

gas

is the combustion ambient temperature in °F or °C

air

⎛

2

A

⎜

)T-(TqA

airgas

⎜

-O21

⎝

is the waste/flue gas temperature in °F or °C

A2 and B are fuel-specific factors stored internally in the

PEM-9004 database.

2.4.3 Calculating the Combustion Efficiency

The combustion efficiency of a combustion process is determined

from the relation:

Efficiency = (E

fuel

- E

lost

) 100

The instrument subtracts the waste gas loss as previously calculated

for a specific fuel from the total energy of the selected fuel to arrive at

the overall combustion efficiency (Eta). The PEM-9004 uses the

following equation:

qA-100Eta

Where: Eta is the combustion efficiency expressed as a

percentage.

qA is the heat loss calculated for the given fuel.

Teledyne Analytical Instruments 7

Page 20

Operational Theory PEM-9004

The calculation is done on a dry basis. This means that the term

representing the energy necessary to heat the water vapor from ambient

to exhaust temperature is omitted.

To obtain the precise value for combustion efficiency one must

account for many variables. The most important are:

• Radiative heat losses

• Variation in fuel composition

• Air that leaks into the flue gas mixture raising oxygen

reading

• Heat loss in ash

• Incomplete combustion

• Boiler blowdown.

The PEM-9004 necessarily makes simplifying assumptions in its

determination of efficiency. Therefore it must be considered a trend

indicator that will correctly show an increase or decrease in efficiency,

whereas the absolute value of the number applies to the ideal case only.

2.4.4 Calculating Excess Air Value (Lambda)

The minimum amount of air that supplies sufficient oxygen for the

complete combustion of a fuel is referred to as the theoretical or

stoichiometric amount of air. Most combustion processes involve an

amount of air different than stoichiometry requires. The differential is

called

excess air and can be a positive or negative amount. The

stoichiometric requirement for air depends on the type of fuel used and

to a lesser extent, the temperature and pressure of the reaction. Nitrogen

is normally considered unaltered in lower temperature reactions and

simply adds to the heat balance of the combustion process. As the

combustion temperature increases however, increasing amounts of

nitrogen oxides are formed which must be considered in the overall

chemical balance.

In the PEM-9004, the excess air (Lambda) value is calculated from

the ratio of CO

2max

to CO

Lambda

2observed

as follows:

CO

2MAX

==

CO

9.20

O9.20

−

22

Teledyne Analytical Instruments 8

Page 21

Portable Emissions Monitor Operational Theory

×

=

2.4.5 Calculating Undiluted CO Concentration

To calculate the uncompensated CO concentration the PEM-9004

uses the excess air as calculated above and the hydrogen compensated

value sensed by the CO electrochemical cell to arrive at an undiluted CO

concentration in ppm. The following equation is used:

LambdaCOCO(0%)

Where: Lambda is the excess air as calculated above.

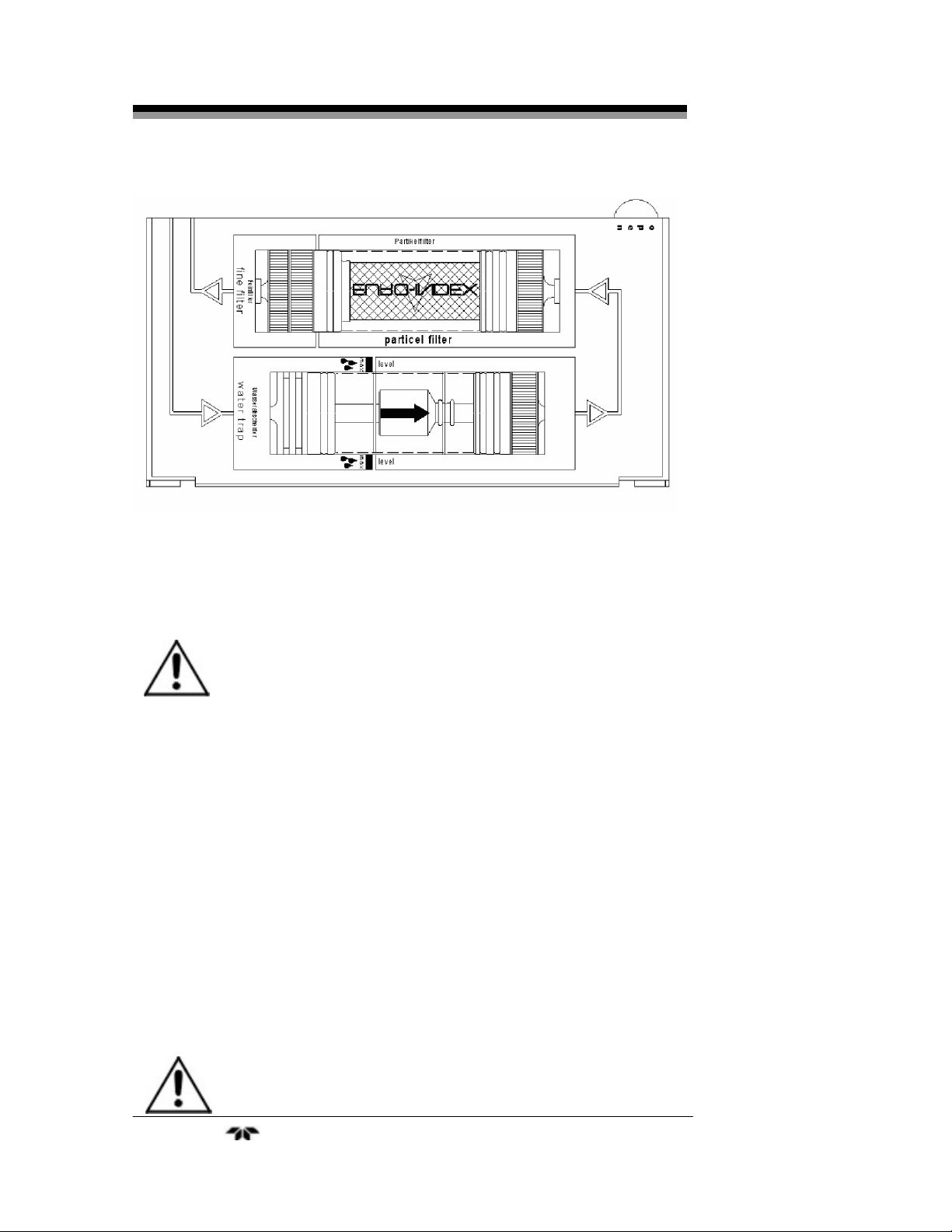

2.5 Sample System

The built-in sample system on the PEM-9004 can be though of as a

fully integrated data acquisition system. In addition to sampling the gas

stream and safely diverting a portion through the analyzer, it also gathers

data on pressure, temperature of the gas stream, and ambient

temperature.

The sample system is comprised of the following sections:

sample probe

•

•

sample and CO sensor protect pumps

•

gas conditioning section

temperature and pressure measurement

•

The probe is a steel tube connected to several feet of neoprene

tubing. It samples the exhaust gas stream and directs a portion into the

analyzer via the neoprene tubing. Integral with the sample probe are 2

type K (NiCr-Ni) thermocouples, one which measures the gas stream

temperature at the tip and the other sensing the air or ambient

temperature. A piezioresistive element is also contained within the probe

for converting pressure of the gas to an electronic signal used by the

microprocessor to determine the gas or draft pressure.

Waste gas is sampled through the probe and drawn into a filter

section in the analyzer by means of an 0.8 lpm pump through the Gas In

port on the front panel. Figure 2-4 shows the sample conditioning

section of the PEM-9004.

Teledyne Analytical Instruments 9

Page 22

Operational Theory PEM-9004

Figure 2-4: Gas Conditioning System

The gas is passed through a condensation trap to remove moisture

which would otherwise interfere with the measuring process.

CAUTION: THE WATER TRAP SHOULD BE EMPTIED AFTER

EACH USE. IF WATER IS ALLOWED TO COLLECT IN

THE TRAP IT COULD BACK FLOW INTO THE GAS

LINE AND DAMAGE THE PUMP AND SENSORS.

The sample gas is then drawn through a coarse particle filter in

series with a fine filter to remove any solid residue from the combustion

process prior to directing the gas to the sensor block.

The gas is fed to the sensor cells which are arranged in series. The

cell outputs a signal proportional to the concentration of the specific gas

it is sensitive to. Three to five cells are installed depending on the

options installed. A special purge line equipped with a separate pump is

installed to protect the CO sensor from prolonged exposure to high

concentration of oxygen such as atmospheric air. The pump is activated

automatically when the concentration exceeds 4000 ppm. It can also be

operated manually. See Section 4.5.1.13

CO Protect.

After traversing the sensor block, the sample gas is passed back out

through the Gas Out port on the front panel of the instrument.

CAUTION: BOTH TOXIC AND FLAMMABLE GASES ARE

PRESENT IN THE SAMPLE SYSTEM—INCLUDING

THE FILTERS! MAKE SURE THE EXHAUST LINE IS

Teledyne Analytical Instruments 10

Page 23

Portable Emissions Monitor Operational Theory

CONNECTED TO THE GAS OUT PORT AND VENTED

PROPERLY.

USE CAUTION WHEN CHANGING FILTER

ELEMENTS OR OTHERWISE OPENING ANY

PORTION OF THE SAMPLE SYSTEM. ALWAYS

PURGE THE SAMPLE SYSTEM TO REMOVE ANY

TOXIC OR FLAMMABLE GAS FROM THE LINES

BEFORE PERFORMING ANY MAINTENANCE ON

THIS INSTRUMENT.

Teledyne Analytical Instruments 11

Page 24

Operational Theory PEM-9004

Teledyne Analytical Instruments 12

Page 25

Portable Emissions Monitor Installation

Installation

Installation of the analyzer includes:

1.

Unpacking the system

2.

Connecting the Probe

3.

Making the gas and thermocouple connections

4.

Calibration and testing the installation

Also covered in this section are battery issues, and information

regarding battery replacement.

3.1 Unpacking the Analyzer

The TAI PEM-9004 Portable Emissions Monitor is generally

shipped fully functional and ready to work. Carefully unpack the

analyzer and inspect it for damage. Immediately report any damage to

the shipping agent. Note the probe and connectors and make sure there

is no shipping damage.

3.2 Attaching the Probe and Thermocouples

All connections are made on the front panel. Figure 2-1 illustrates

the front panel and identifies the connector locations.

Connect the exhaust gas thermocouple jack to the port labeled T Gas

•

•

Connect the ambient air thermocouple jack to the ambient air port

connector

Connect the gas line from the probe to the gas port

•

Connect the pressure sensor line to the port labeled P+ which is the

•

port for measuring a positive pressure.

NOTE: If you are monitoring a process which is below

atmospheric pressure, connect the pressure sensor to the

P- port.

Teledyne Analytical Instruments 13

Page 26

Installation PEM-9004

• Connect the gas out port to a suitable vent.

WARNING: TOXIC AND FLAMMABLE GASES ARE PRESENT IN

THIS INSTRUMENT. THESE GASES CAN BE

HARMFUL AND/OR FLAMMABLE EVEN AT LOW

CONCENTRATIONS. THE ANALYZER’S EXHAUST

PORT MUST BE VENTED TO A SAFE AREA.

PERSONAL PROTECTIVE EQUIPMENT MUST BE

WORN WHEN USING OR SERVICING THIS

INSTRUMENT.

AFTER EACH USE, BEFORE TURNING OFF THE

POWER OR DISCONNECTING ANY TUBING

CONNECTED TO THE ANALYZER, REMOVE THE

PROBE AND FLUSH THE UNIT WITH AIR FOR FIVE

MINUTES

Figure 3-1: PEM-9004 Front Panel

3.3 Initial Calibration

The instrument, when first powered up will go through a self-

diagnostic test routine and auto calibrate. For this reason, when

Teledyne Analytical Instruments 14

Page 27

Portable Emissions Monitor Installation

powering up for the first time or after a lengthy period of inactivity (1

week or longer) turn the analyzer on without the probe attached.

Ambient air will be drawn in through the gas in port and used to set a

zero reference for the sensors.

The front panel display will indicate any problems encountered

during the initial calibration. It will also display the battery status using

a series of 10 battery icons. Each filled battery icon indicates 10% of

full charge remaining. For instance, if 7 filled batteries are indicated, the

state of charge of the battery is 70%.

Note: The initial auto calibration with the probe and

thermocouples unattached will cause a temperature sensor

warning. The display will indicate a T-Room Sensor and TGas Sensor failure. This is normal if the thermocouples are

left unattached.

3.4 Battery Power

The PEM-9004 has a 6V NiCad battery installed and is designed to

operate only from battery power. Continuous monitoring (although not

recommended) for up to 36 hours is possible from a single charge. The

analyzer is equipped with a 120V 60 Hz AC battery charger for

recharging the battery. The unit should be OFF when the battery charger

is connected.

CAUTION: THE ANALYZER IS NOT DESIGNED TO OPERATE IN

MONITOR MODE WITH THE BATTERY CHARGER

CONNECTED. USE ONLY THE 6V NICAD BATTERY

TO POWER THIS INSTRUMENT.

3.4.1 Charging the Battery

When recharging is necessary, turn the instrument OFF and connect

the charger to the instrument at the port labeled CHARGE. Connect the

power end of the charger to 120VAC 60 Hz power source or 220VAC

50/Hz depending on your model.

The service life and capacity of the battery are considerably

affected by the way the instrument is charged and used. In order to make

handling safer, the instrument has a load management unit.

The load management feature is responsible for maintaining the

state of charge of the battery and monitors the temperature of the battery

Teledyne Analytical Instruments 15

Page 28

Installation PEM-9004

when charging. If a NiCad battery is always charged from 80% to 100%

i.e. the state of discharge of the battery never falls below 80% before the

battery is recharged, the battery will lose some of its capacity. This is

called “memory effect” and is a well-know problem in rechargeable

batteries. The battery remembers to what extent it is run down.

A part of this memory effect is suppressed by the load management

unit. It senses the state of discharge of the battery and will not allow

recharging until battery capacity has dropped below 60%.

Constant overcharging has adverse effects on the NiCad battery as

well. The load management feature monitors the state of charge, the

voltage, and the battery temperature. When predefined limits are

exceeded, the charging process is interrupted. After the appropriate

parameters are restored, the charging process is automatically restarted.

The service life of the NiCad battery can be significantly reduced

when the instrument is operated at temperatures below 40°F (5°C).

The graphic charge level indicator on the front panel display is

comprised of 10 battery symbols and is located in the one-line status

display during the calibration phase. The PEM-9004 load management

unit continuously monitors the incoming and outgoing current during

operation and charging. Under normal operating conditions, the

instrument should be operated until the battery is completely run down

(10 empty battery icons as opposed to dark, filled icons). When this is

routinely followed, the actual capacity of the NiCad battery is accurately

shown on the display.

3.4.2 Battery Replacement

Contact factory for battery replacement

3.5 Sensor Replacement

Up to 5 electrochemical cells are installed in the PEM-9004 analyzer

depending on the options ordered. When new cells are ordered, they are

packaged in a controlled atmosphere. The instrument is shipped with the

required sensor cells installed.

Teledyne Analytical Instruments 16

Page 29

Portable Emissions Monitor Operation

Operation

4.1 User Interface

Operation of the PEM-9004 is accomplished entirely from the front

panel using the 7 function keys on the right plus the 3 menu select keys

below the screen. The menu select keys take on additional functions

depending on the menu context. Figure 4-1 shows the location of the

function and menu select keys. Table 4-1 identifies each function key

and provides a brief description of its use.

Figure 4-1: PEM-9004 Front Panel

Teledyne Analytical Instruments 17

Page 30

Operation PEM-9004

Table 4-1: Function Keys

Key Function Action

ON/OFF switch Switches the power on or off

to the instrument.

Backlight key Turns the display backlight

on or off.

Change layout Used to alter the layout of

the menu specific F1, F2,

Change display Alters line by line the way the

and F3 keys.

display is arranged.

Pump ON/OFF switch Turns the gas feed pump on

or off.

Clear key Close/cancel/reset a

function, menu or display

Enter key Confirms an entry or action.

item.

The function buttons are used to select specific options from the

displayed menu. Some menus have numerous options to select from

such as the Flue Gas menu shown in Figure 4-2. In this case the

function buttons (F1, F2, F3) will correspond to the functions on the

selected line. For instance, if line 3 is selected by scrolling down with

the “Change Layout” key (

), then pressing F1 will select the “Save”

function, F2 will select “Draught detection”, and F3 will select “CO

protect”.

Note that the screen display will list: “Save”, “Draught detection”

and “CO protect” instead of F1, F2, and F3.

Teledyne Analytical Instruments 18

Page 31

Portable Emissions Analyzer Operation

Figure 4-2: Additional Functions Available from Flue Gas Menu

4.2 Startup Screen

• Press the ON/OFF button to turn the instrument ON.

The screen that appears includes information about the

version, part-no., hours in use, etc. This initial startup screen is

shortly replaced by the Main menu screen.

•

To hold this initial screen on the display press the ENTER

button during the startup routine.

Teledyne Analytical Instruments 19

Page 32

Operation PEM-9004

• Press the CLEAR button to close it.

You can switch the backlight on/off using the backlight button) but

the other buttons have no function in this initial menu.

4.3 Main menu

The Main menu screen appears automatically after the initial

startup screen. The Main menu includes a status line and a list of

available programs associated with the 3 function buttons.

4.3.1 Status Line

The status line appears at the top of most screens and continuously

updates and displays the status of certain information such as remaining

battery power, HOLD-function, sensor-alerts, operation of the pump,

chosen fuel, time, etc. It is context sensitive and depends on the

presently displayed screen.

4.3.2 Available Programs

Below the status line is a list of available programs accessible from

the Main menu. Each program is launched by the appropriate button

indicated to the right of the program name. In most cases additional

menus and additional screens will be available from within the selected

program.

Teledyne Analytical Instruments 20

Page 33

Portable Emissions Analyzer Operation

4.4 Configure Menu

The Configure menu is used to set up the analyzer for your specific

process. From this screen you can:

Change the display order so that the information on the screen

•

is in a convenient sequence.

Select a specific fuel from a list or add a new fuel to the list.

•

•

Change the general settings of the instrument.

Return to the default configuration of the instrument.

•

To enter the Configure menu press the F2 key from the Main menu.

The following screen appears:

4.4.1 Display

The sequence of the measured or calculated parameters can be

repositioned in any way to suit your preference. This is accomplished

from the Display screen. To rearrange the measurement screen:

From the Configuration menu press F1 to bring up the Display

•

screen. The following screen appears:

Teledyne Analytical Instruments 21

Page 34

Operation PEM-9004

•

Use the arrow keys to move the underline cursor to the line

you want to move. Then press OK to activate the line for

repositioning.

Move the selected line up or down using the arrow keys.

•

When it is in the chosen position, press OK. The following

screen shows the CO measurement line repositioned to the

second line from the top.

•

Press ENTER to save the setting or CLEAR to cancel the

move.

Note: The same line cannot be displayed more than once.

Teledyne Analytical Instruments 22

Page 35

Portable Emissions Analyzer Operation

4.4.2 Fuel

The Fuel menu is used to add or remove a fuel from the list of

available fuels stored in the analyzer’s memory. Up to five additional

fuels can be configured and stored in the list. To enter the Fuel menu

press F2 from the Configuration menu. The following screen appears:

From this screen you can remove a fuel from the list, add a fuel to

the list or include all the fuels programmed into the analyzer memory

including those that have been removed.

4.4.2.1 REMOVE A FUEL FROM THE LIST

• Press the button corresponding to “Remove”. The fuel that is

highlighted in the frame will be removed from the list.

Note: The removed fuel can be reinstated using the “Include all”

function.

4.4.2.2 REINSTATE A PREVIOUSLY REMOVED FUEL

• Press the button corresponding to “Include all”. Any

previously removed fuel will be reinstated in the fuel list.

It is possible to add up to 5 additional fuels to the preinstalled list of

fuels. In order to create a new fuel the first three fuel-specific factors

(CO

, A2 and B) have to be entered. If units than ppm or % are used

2max

additional factors must be entered in order to perform the conversion to

3

mg/m

, mg/kWh or MJ/m3 correctly.

Teledyne Analytical Instruments 23

Page 36

Operation PEM-9004

4.4.2.3 INSERT A NEW FUEL

• Press the button corresponding to “Insert”. The following

screen appears:

•

Use the arrow buttons to select where you want the fuel to be

added (Fuel 1, Fuel 2 . . . etc.). Press OK when the proper

location is highlighted. the following screen appears:

Press OK again to enter the editor screen. From this screen you can

enter or edit the name of the fuel.

Teledyne Analytical Instruments 24

Page 37

Portable Emissions Analyzer Operation

•

Use the arrow keys to scroll to the appropriate character and

then press OK to accept the letter. The character will appear

on screen and the position marker incremented to the next

letter position. If you make a mistake, continue pressing the

OK button until the cursor returns to the letter in error. Then

reselect the appropriate character using the arrow keys and

press OK once again to accept the new character.

Use the cycle button to toggle between all capital letters, lower

•

case and numerical input.

When the fuel name has been entered, save the input by

•

pressing ENTER or cancel the input by pressing CLEAR.

Once the fuel name has been input and accepted, the fuel properties

can be entered in the same fashion. Use the arrow keys to scroll the

highlighted line to the parameter you want to input and press OK.

Repeat the above procedures for editing each parameter required to

specify the fuel. The parameters include:

2max

CO

A2

B

HW (heating value without condensation)

BW (heating value with condensation)

H

O (water content)

2

Vatr (quantity of fuel gas, dry)

Teledyne Analytical Instruments 25

Page 38

Operation PEM-9004

4.4.3 Settings

The Settings screen is used to set the following instrument

parameters:

Units used for draft and pressure

•

Sound off/on

•

•

Printer

User address

•

Automatic shut down of the instrument and display

•

illumination

Pressing F3 from the Configuration menu brings up the Settings

screen.

4.4.3.1

UNITS FOR DRAFT AND PRESSURE

• Use the cycle button to highlight the Draft/Press line on the

screen.

•

Use the arrow keys to toggle between the available units.

When the desired unit appears, press OK.

4.4.3.2 INSTRUMENT SOUND ON/OFF

• Use the cycle button to highlight the Sound line on the screen.

Use the arrow keys to cycle between Yes (ON) and No (OFF).

•

Press OK to save the setting.

•

Teledyne Analytical Instruments 26

Page 39

Portable Emissions Analyzer Operation

4.4.3.3 SELECT PRINTER

Two printers are available in the the PEM-9004: EUROprinter

(Euro-Ir) and HP84420B (HP-Ir). To select the printer to use:

•

Use the cycle button to move the highlight to the Printer line.

Use the arrow keys to toggle between Euro-Ir and HP-Ir.

•

When the correct printer appears, press OK.

4.4.3.4 USER ADDRESS

The User address can be included in various reports printed by the

analyzer. To enter the user address:

•

Use the cycle button to highlight the User Address line on the

screen. Press OK and the following screen appears:

•

Use the arrow keys to move the highlight to the line you want

to edit. Press OK and the edit window appears.

Teledyne Analytical Instruments 27

Page 40

Operation PEM-9004

• Use the arrow keys to select the character to enter then press

OK. The cursor moves to the next position. Repeat the process

to enter or edit the correct address line. Each line is entered

separately. When the line is correct, press ENTER to save the

result or CLR to cancel the input. The editing screen

disappears.

Note: The cycle key can be used to toggle between caps, lower

case and numerical input.

• Use the arrow keys to move the highlight to the next line for

editing. Press OK and the editing window opens. Repeat the

above procedure to enter the user address line by line pressing

ENTER after each line is completed.

After the final line is entered and saved you will be returned to

•

the Settings screen.

4.4.3.5 AUTOMATIC TIMER

The PEM-9004 is equipped with automatic timers that will turn off

the display illumination and/or shut the instrument off to conserve

battery power. Both automatic features operate independently and

initiate if no key press is detected within the user-specified intervals.

To set the automatic power off feature:

Use the cycle button to highlight the Auto Off line on the

•

screen then press OK.

•

Use the arrow keys to increase or decrease the interval. Press

ENTER to save the setting or CLEAR to cancel the input.

Note: The Auto Off interval can be set in 5 minute intervals from

0 to a maximum 60 minutes.

The automatic shut off feature is disabled if an interval is

set to 0 minutes.

To set the automatic backlight off feature:

•

Use the cycle button to highlight the Illum. Off line on the

screen then press OK.

Teledyne Analytical Instruments 28

Page 41

Portable Emissions Analyzer Operation

• Use the arrow keys to increase or decrease the interval. Press

ENTER to save the setting or CLEAR to cancel the input.

Note: The Illum Off interval can be set from 0 to a maximum of

30 seconds in one second intervals.

The automatic illumination off feature is disabled if an

interval is set to 0 seconds.

4.4.4 Set Default

The Set Default function is used to return the instrument to the

initial factory programmed settings.

CAUTION: RESTORING THE INSTRUMENT TO FACTORY

DEFAULT SETTINGS WILL RESULT IN THE LOSS OF

ALL INDIVIDUAL SETTINGS AND CANNOT BE

UNDONE EXCEPT BY REENTERING THE USER

SETTINGS! THE DATA MEMORY IS NOT AFFECTED.

To restore the instrument to the default settings:

•

Press ENTER from the Configuration Main menu. The

following screen will appear:

•

Confirm the restoration operation by pressing ENTER or

cancel the request by pressing CLEAR.

Teledyne Analytical Instruments 29

Page 42

Operation PEM-9004

4.5 Measurement Screen

The Measurement screen is the main operation mode of the

instrument. It allows you to calibrate the specific flue gas for

measurement, perform gas measurements and calculations, and perform

pressure and temperature measurements.

In the Measurement menu the following button combinations are

available:

Cycle: Scroll line by line or toggle between

available options.

Change Layout: Change the layout of the function buttons.

Gas pump: Turn the sample gas pump on or off.

Backlight: Turn backlight on the display on or off.

Reset CO2max-value:

Enter a new value for the CO

(fuel specific).

To enter the Measurement screen press ENTER from the Main

menu. The following screen appears:

2max

value

Teledyne Analytical Instruments 30

Page 43

Portable Emissions Analyzer Operation

4.5.1 Flue Gas

To calibrate the instrument on a specific flue gas or change the

current flue gas, press the cycle button from the Measurement screen.

The following screen appears:

The instrument begins an automatic calibration cycle which takes

approximately 60 seconds from a cold start. If a restart is performed

from the Measurement screen, the calibration process only takes 10

seconds. The instrument probe should not be attached during this

calibration.

After the calibration the last used fuel appears on the screen as

shown below.

At this point, either the fuel in the framed box can be chosen or

any another fuel from the database of fuels in memory. The selected fuel

has to be in the framed box.

Teledyne Analytical Instruments 31

Page 44

Operation PEM-9004

• If the correct fuel is displayed, press ENTER to confirm the

selection.

•

If it is not correct press the cycle button to cycle through the

internal list of fuels.

Press ENTER when the desired fuel is displayed.

•

Once a fuel has been selected, a range of other functions are

available and assigned to the F1, F2, F3 function buttons as shown in

Figure 4-2.

Use the cycle button to scroll line by line through the available

functions. Note that the on screen representation of F1, F2 and F3

change appropriately to the named function.

It may be more convenient to alter the position of some functions

so that they appear on the same line. For instance, if you routinely

change fuels, make a measurement then , print and save the data, it may

be more efficient to have “fuel”, “print”, and “save” buttons on the same

line to avoid having to constantly scroll back and forth to the various

lines. Use the Change Layout button to move all three functions to the

same line.

4.5.1.1 DRAFT

This button is used to start a draft measurement. When pressed, the

following screen appears:

Hold (F1): Holds the reading for the draft measurement.

Set Zero (F2): Performs a zero calibration.

Teledyne Analytical Instruments 32

Page 45

Portable Emissions Analyzer Operation

Take (F3): Transfers the draft value to the Flue Gas menu.

Note: To determine the zero point in relation to the surrounding

air pressure, unplug the air tube (with the blue connector)

before every draft measurement. Then press the F2 button

and connect the air tube again.

Cycle button: Scroll line by line through the available

functions within the Flue Gas menu.

4.5.1.2 INFO

Pressing the Info button launches the Info screen which displays

important fuel parameters, current sensor status and the O

reference

2

value.

Function buttons active in this menu are:

Cycle: Change values in the various fields.

Change Layout: Opens the sensor status screen as shown below.

CLEAR: Close the Info screen

Teledyne Analytical Instruments 33

Page 46

Operation PEM-9004

Sensor quick-diagnosis:

O2-value > 50 %

Oxygen cell OK

CO- and H

CO- sen sor with 1-12-compensation OK *

-value: 0 to 1 %

2

CO%-value: 0 to 1 %

CO-senso r for upper range OK*

NO- and/or SO2-value: 0 to 1 %

NO- and/or SO

-value OK*

2

* indicates the respective sens or opti on is disabled.

Note: If any other values are displayed, the corresponding

sensor is either in need of service or the electrolyte is

depleted.

4.5.1.3 DRAUGHT DETECTION

The function "Draught detection" displays the flue gas temperature

graphically. Changes in the temperature of the flue gas are shown with a

black bar. No bar appears if the temperature is constant.

Press the Draught Detection button to open the Draught Detection

screen.

Teledyne Analytical Instruments 34

Page 47

Portable Emissions Analyzer Operation

Draught detection is only available for the measurement of the flue

gas temperature in the Flue Gas menu.

Function buttons active in this menu are:

Cycle: Change representation of readings in the Main

menu line by line.

4.5.1.4 UNITS

The PEM will automatically convert units to the specified type as

determined from the Units menu. Press the units button to display the

Units screen.

•

Use the arrow keys to select the desired units.

Press OK to confirm the selection.

•

Teledyne Analytical Instruments 35

Page 48

Operation PEM-9004

• Press ENTER to save the unit selection or CLEAR to cancel

the operation.

The data on the Flue Gas screen will be converted and updated to

the selected units. The units will remain in use until another unit is

selected.

4.5.1.5 O

REFERENECE

2

In some instances in order to correctly convert the measured gas

values it may be necessary to modify the O

reference value. For gas and

2

oil fuels a value of 3% is preset. For solid fuels a value of 13% is preset.

To change the O

reference value, press O2 Ref from the Flue Gas

2

menu. The following screen will appear:

•

Use the arrow keys to select the desired digit.

Press OK to confirm the selection.

•

•

Press ENTER to save the new value selection or CLEAR to

cancel the operation.

4.5.1.6 EXTENDED DATA

The following data can be entered and transferred to the

measurement protocol:

Smoke-no. (soot content according to the Bacharach scale).

•

Oil derivatives.

•

•

Temperature of boiler and heat carrier.

Teledyne Analytical Instruments 36

Page 49

Portable Emissions Analyzer Operation

To enter the data, press the Extended Data button from the Flue

Gas menu. The following screen appears:

Smoke-no. input menu

The value that was determined through the mechanical soot pump

can be entered using the function button F1.The following screen

appears:

•

Use the arrow keys to select the desired digit.

•

Press OK to confirm the selection.

Press ENTER to save the new value selection or CLEAR to

•

cancel the operation.

Oil derivatives input menu

Teledyne Analytical Instruments 37

Page 50

Operation PEM-9004

Pressing F2 from the Extended Data menu displays the Oil Derivates

Input screen. In this screen there is a choice between "Yes" (oil derivatives

exist) a nd "N o" (no oil derivatives exist).

•

Press F1 if oil derivatives are present.

•

Press F3 if oil derivatives are not present.

•

Press ENTER to save the result or CLEAR to cancel the

operation.

Temperature and heat carrier

Pressing F3 from the Extended Data menu displays the Boiler

Tempera t u r e s c r e en . I n t h i s s c r e en , t he measured temperature can be

entered through the editor.

Use the arrow keys to select the desired digit.

•

Press OK to confirm the selection.

•

•

Press ENTER to save the entered temperature or CLEAR to

cancel the operation.

Teledyne Analytical Instruments 38

Page 51

Portable Emissions Analyzer Operation

Note: When the input menu for the extended data (Smoke-no.,

oil derivatives and boiler temperature) is closed all data

that has been con fir me d with the ENTER button will be

stored in the measurement protocol. Inputs of data that

have been cancelled will be discarded.

4.5.1.7 GRAPHIC

The Graphic function uses a graphical display to show the

numerical values according to the chosen fuel. The remaining content

of oxygen (O

) and the calculated waste gas losses (qA) are thereby set

2

in a relation to the excess air value (λ) and to the classical combustion

diagram.

Press Graphic from the Flue Gas menu to bring up the graphic

display as shown below:

Teledyne Analytical Instruments 39

Page 52

Operation PEM-9004

Note: If both bars extend to the optimal fuel-air relation (the gap

indicated λopt) the firing facility in question is set

correctly.

Press ENTER to close the graphics display.

4.5.1.8 FUEL

The Fuel menu is used to select a fuel from the list of stored fuels

in memory.

Press the button corresponding to Fuel from the Flue Gas menu.

The following screen appears:

In order to select the new fuel it must appear in the framed box. To

change the current fuel:

•

Use the cycle button to scroll through line by line the available

fuels in memory.

When the desired fuel appears in the framed box, press

•

ENTER or press CLEAR to abort the operation and return the

previous fuel. Pressing either ENTER or CLEAR returns the

display back to the Flue Gas menu.

4.5.1.9 CONFIG

See Section 4.4.

4.5.1.10 PROGRAM MACROS

Up to three customized measuring configurations can be created

and stored as programmed macros. These macros can be started directly

Teledyne Analytical Instruments 40

Page 53

Portable Emissions Analyzer Operation

from the Main menu. The operation of these macros can be reduced to a

few button inputs only.

Program macros can have configurations as shown below:

•

Order of the readings that are shown on the screen

•

Font size of the readings (5 or 10 characters)

Predefined fuel

•

•

Preset measuring units

To enter a programmed macro:

•

Set the configuration to the desired state

Press Macro 1, Macro 2 or Macro 3 to inform the instrument

•

which button is to be assigned the macro configuration.

•

Press ENTER to save the configured macro to the assigned

macro button or CLEAR or abort the operation.

4.5.1.11 HOLD

The Hold function is used to temporarily freeze the screen keeping

the measured data from changing, When the HOLD function is activated

all displayed measured data at the time the button was pressed will be

kept.

Note: When the HOLD function is activated the alert "HOLD"

appears in the top left corner of the status line replacing

the name of the fuel.

Teledyne Analytical Instruments 41

Page 54

Operation PEM-9004

To initiate a Hold, press Hold from the Flue Gas menu. The

following screen is representative of a hold screen:

4.5.1.12 ZOOM

The Zoom function is used to change the displayed font size and

the number of lines capable of displaying on a single screen.

There are two fonts and therefore types of layout available:

•

10-line layout

The 10-lines layout is the default layout set at the factory.

Measured parameters are shown on the left whereas readings

and units are shown on the right.

5-line layout

•

This layout reduces the number of displayed lines and

increases the font size to facilitate the reading of the display

from a greater distance. In this layout, measured parameters

and units are on the left and readings only are on the right.

The zoom button toggles the screen display between the two

layouts as shown in the following screen displays.

Note: After the device is switched off and on again, the display

resets to the 10-lines layout automatically unless the 5lines layout was a measurement configuration activated by

a macro.

Teledyne Analytical Instruments 42

Page 55

Portable Emissions Analyzer Operation

10-Line Layout

5-Line Layout

4.5.1.13 CO PROTECT

The PEM-9004 is equipped with a second pump (CO-flushingpump) in order to protect the sensitive CO-sensors from CO-overload.

The CO-flushing-pump switches on automatically when necessary,

i.e. when the admitted CO-range is exceeded or it can be switched on

manually using the CO Protect button.

When the CO Protect button is pressed the CO pump will start.

Pressing CO Protect button again will turn the pump off as long as the

Teledyne Analytical Instruments 43

Page 56

Operation PEM-9004

CO concentration is below a factory preset threshold the value of which

depends on the sensor installed.

Whenever the CO pump is on (whether it is started automatically or

manually) a scored out CO-symbol appears in the status line as shown in

the screen display below.

.

If the CO-flushing-pump starts automatically due to an excess

concentration of CO it cannot be switched off manually until the COconcentration falls below a factory preset value.

Once the CO-concentration has reached the lower range the COflushing-pump will automatically shut off.

If the analyzer is equipped with two CO-sensors the result of the

higher range sensor will be displayed when the lower range sensor is

flushed.

The active CO-flushing-pump has no influence on any other

sensors within the analyzer.

4.5.1.14 PRINT

The measured data can be printed out by means of a wireless

infrared printer.

The printer in use can be selected from the Configuration menu.

See Section 4.4.3.3. The print speed depends on the printer selected.

Make sure the proper printer is activated to avoid possible failures while

printing.

Teledyne Analytical Instruments 44

Page 57

Portable Emissions Analyzer Operation

The PEM-9004 is capable of multi-tasking so the analyzer can be

taking measurements, performing calculations, etc during the printing

procedure. Printing takes place simultaneously in the background as

other analyzer operations are being performed.

To print a screen, press the Print button from the Flue Gas menu.

4.5.2 Temperature

The temperature program can be started by pressing F1 from the

Measurement screen.

The PEM-9004 supplies two temperature measurement channels

(T1 and T2). Measurement channel T1 is displayed with a resolution of

0.1°C whereas channel T2 has a resolution of 1°C.

The Temperature screen is shown below:

Available functions from within the temperature program are:

Hold: Freezes the current temperature readings.

Max/Min Reset: Resets the current temperature readings.

Print: Prints out the currently displayed temperature

screen

Cycle button: Change units (°C or °F).

Teledyne Analytical Instruments 45

Page 58

Operation PEM-9004

4.5.3 Pressure

The pressure program can be started by pressing F2 from the

Measurement screen.

Available functions from within the pressure program are:

Hold: Freezes the current pressure readings.

Max/Min Reset: Resets the current pressure readings.

Print: Prints out the currently displayed pressure screen

Cycle button: Change units (°C or °F).

ENTER button: Reset the pressure to zero.

The following units for pre s sure can be selected:

hPa,

mbar,

mmWC (millimeter water column)

mmHg (millimeter mercury column)

inWC (inches water column)

inHg (inches mercury column)

Psi (pounds per square inch)

Teledyne Analytical Instruments 46

Page 59

Portable Emissions Analyzer Operation

The conversion takes place in the active measurement program as

well as in the HOLD-mode.

4.5.4 CO (O2) Measurement

This is a reduced measurement (without temperature measurement)

for analyzing the flue gas. For this measurement program the same

keypad functions apply as described in Section 4.5.1

that the number of readings is reduced to five significant flue gas values.

Flue Gas except

The font size of the readings can be changed with the Zoom

function. See Section 4.5.1.12

Zoom.

Important notice concerninq measurement of

S02 and N02 (option)

Teledyne Analytical Instruments 47

Page 60

Operation PEM-9004

SO2 and NO2 gases have a high solubility in water. For

measurement of SO

and NO2 concentrations it is necessary to remove

2

the condensate residues form the gas filtration and drying system. These

residues can absorb SO

and NO2 which could cause erroneous

2

measurements.

Furthermore, when carrying out SO

and NO2 relevant

2

measurements no additional desiccant should be used. Even when dry

the dessicant can absorb a significant amount of SO

and NO2.

2

4.6 Macro Start

The Macro Start function launches configuration settings

previously programmed and saved as a macro. See Section 4.5.1.10.

Macros greatly facilitate the efficient operation of the PEM-9004

by loading and initiating convenient configuration settings using only a

few keystrokes. Up to three customized macros can be programmed and

used.

To launch a previously saved macro call the Macro Start function

by pressing the cycle button from the Main menu.

Teledyne Analytical Instruments 48

Page 61

Portable Emissions Analyzer Operation

Press F1, F2, or F3 to start a previously programmed and saved

macro.

When the macro is launched, the macro the settings it is based on

will be activated automatic a l l y after the calibr a t i o n p h as e a n d w i t h o u t

displaying the list of fuels.

If a Set Default operation (restore default settings) i s carried out, all

macro-settings will be lost. See Section 4.4.4. Without customized

settings, the settings for the fuel gas analysis will be used.

4.7 Time-Date

The integrated clock (time and date) can be set from the Time-Date

screen available from the Main menu.

To set the time and date, press F2 from the Main menu. The

following screen will appear:

Teledyne Analytical Instruments 49

Page 62

Operation PEM-9004

The time will be displayed in the top left corner of the status line if

not replaced by an alert or other superimposed information.

Time and date will be saved together with the corresponding data

and will appear on any print-outs of the measured data.

Note: The time value will not automatically adjust for daylight

savings changes but the date value will account for leap

years.

To set the time:

• Press F1 from the Time-Date screen. The following screen

will appear:

•

Use the arrow keys to select the desired digit.

Teledyne Analytical Instruments 50

Page 63

Portable Emissions Analyzer Operation

• Press OK to confirm the selection and move to the next digit.

•

Press ENTER to save the entered tim e or CLEAR to cancel the

operation.

Note: While setting the time, the clock in the editor window will be

stopped and will not restart until the new time is confirmed.

To set the date:

• Press F2 from the Time-Date screen. The following screen

will appear:

•

Use the arrow keys to select the desired digit.

•

Press OK to confirm the selection and move to the next digit.

Press ENTER to save the entered date or CLEAR to cancel the

•

operation.

4.8 Memory

The data memory is structured according to the menu structure

shown in Figure 4.3.

Teledyne Analytical Instruments 51

Page 64

Operation PEM-9004

Figure 4-3: Data Memory Structure

The organization of the memory is dynamic, i.e. only already existing

directories and files are available for saving data. Additional directories

and files can be created at any time.

Names of both directories and files can be defined by the user. Directories

could for instance be used for the names of clients or facilities (or client

numbers). Files could be named after the types of measurement.

The PEM-9004 instrument is shipped without preset directories and

files.

Memory is accessed from the Memory menu available by pressing

F3 from the Main menu. The following screen appears:

Teledyne Analytical Instruments 52

Page 65

Portable Emissions Analyzer Operation

From this menu you can:

•

Open an existing directory (F1)

•

Create a new directory (F2)

Erase an existing directory (F3)

•

To save a file to memory it must be saved to an existing directory.

To save a file to an existing directory:

Press F1 to bring up a list of available directories.

•

•

Use the arrow keys to move to the desired directory.

Press OK. The standard editor window will appear.

•

Use the arrow keys to select the character or digit. Use the

•

cycle button to toggle between all capital letters, lower case

and numerical input.

Press OK to accept the character and move to the next

•

position.

When the file name is correctly entered, press ENTER to save

•

the file or CLEAR to quit without saving.

To create a new directory:

•

Press F2 to open the directory editing window.

•

Use the arrow keys to select the character or digit. Use the

cycle button to toggle between all capital letters, lower case

and numerical input.

Teledyne Analytical Instruments 53

Page 66

Operation PEM-9004

• Press OK to accept the character and move to the next

position.

•

When the directory name is correctly entered, press ENTER to

create and save the directory or CLEAR to quit without

creating the directory.

To erase and existing file or directory:

•

Press F3 from the Memory menu.

Use the arrow keys to move to the directory or file.

•

•

Press OK to select the directory or file.

Press ENTER to erase the directory or file or press CLEAR to

•

abort the action.

4.9 USB-Interface

A USB connection port is provided for special service and data

communication via PC, laptop, notebook, etc. See Figure 3-1.

4.10 Charge Control

The battery is charged automatically when the analyzer is switched

on and off after the battery charger has been connected. The battery can

be recharged as well with the analyzer on. The charge control has both

an active phase and a passive phase.

During active recharging, parameters related to the battery and the

recharging process are displayed on the charge control screen.

Teledyne Analytical Instruments 54

Page 67

Portable Emissions Analyzer Operation

U batt. = current voltage

I Bat = current amperage

T Bat = measured battery temperature

Cap. = current battery capacity

To perform a measurement while charging, press ENTER from the

Charge Control menu. While in the measurement mode the battery will

be recharging and continuously monitored by the system.

When the battery is fully charged, the analyzer automatically

switches to the passive recharging mode (trickle charging) and the

charge control screen disappears.

When active recharging is finished the charger can remain

connected to the device without damaging the battery.

CAUTION: USE ONLY THE SUPPLIED OR FACTORY

AUTHORIZED

THE BATTERIES. ANY OTHER CHARGER MAY

CAUSE

DAMAGE TO THE BATTERY AND/OR

CHARGER UNIT FOR RECHARGING

THE ANALYZER.

4.11 Battery / Line Voltage Operation

Battery operation: Maximum of 36 hours of continuous

measuring (with backlight).

Battery charger: 95-135 VAC 60 Hz USA version

200-250 VAC European version

The analyzer employs Intelligent monitoring by means of an

integrated charge-management-system. To maintain the service life and

performance of the NiCd battery, please observe the following battery

charging instructions.

4.11.1 Charging the Battery

The PEM-9004 is equipped with an NiCd storage battery. The

service life and capacity of the battery are considerably affected by the

way the instrument is charged and used. In order to make the handling

Teledyne Analytical Instruments 55

Page 68

Operation PEM-9004

safer, the instrument has an efficient battery management system unit for

battery charging.

The service life of the NiCd battery can be significantly reduced

when the instrument is operated at temperatures below 5°C (40 °F).