Page 1

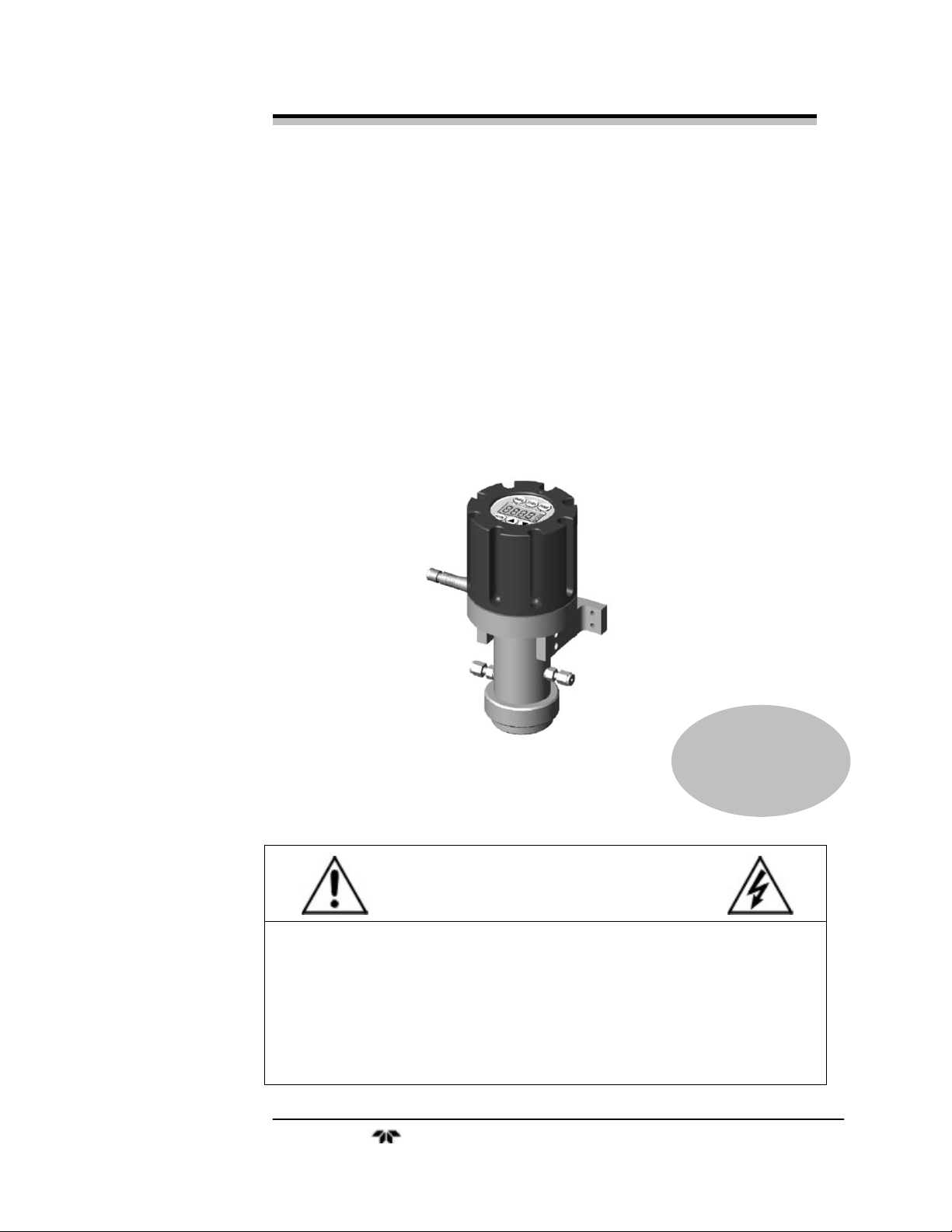

OPERATING INSTRUCTIONS FOR

INSTA-TRANS

Trace and Percent Oxygen

Transmitter

P/N M72103

08/02/10

DANGER

Toxic gases and or flammable liquids may be present in this monitoring system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist

for a time even after the power is turned off and disconnected.

Only authorized personnel should conduct maintenance and/or servicing.

Before conducting any maintenance or servicing, consult with authorized

supervisor/manager.

Teledyne Analytical Instruments

Page 2

Insta-Trans

Copyright © 2010 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by Teledyne or an authorized service center.

We assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, an d serves as a to ol by whic h

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface, with the process being

measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of Teledyne at the

time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot accept

responsibility for conditions beyond its knowledge and control. No statement expressed or

implied by this document or any information disseminated by the manufacturer or its

agents, is to be construed as a warranty of adequate safety control under the user’s process

conditions.

Teledyne Analytical Instruments ii

Page 3

Trace Oxygen Transmitter

Specific Model Information

The instrument for which this manual was supplied may

incorporate one or more options not supplied in the standard instrument.

Commonly available options are listed below, with check boxes. Any

that are incorporated in the instrument for which this manual is supplied

are indicated by a check mark in the box.

Instrument Serial Number: _______________________

Insta-Trans Transmitter Model: ____________

Cell Class:

A2C

A5

B1

B2C

L2C

B71875 Insta-Trace

B73016 Insta-Trace

Teledyne Analytical Instruments iii

Page 4

Insta-Trans

Table of Contents

Cell Class: ..................................................................................... iii

List of Figures .............................................................................. vi

Introduction ................................................................................... 1

1.1 Overview 1

1.2 Typical Applications 1

1.3 Main Features of the Transmitter 1

1.4 Operator Interface 2

Operational Theory ....................................................................... 5

2.1 Introduction 5

2.2 Micro-fuel Cell Sensor 5

2.2.1 Principles of Operation 5

2.2.2 Anatomy of a Micro-fuel Cell 6

2.2.3 Electrochemical Reactions 7

2.2.4 The Effect of Pressure 8

2.2.5 Calibration Characteristics 8

2.3 Sample System 10

2.4 Electronics and Signal Processing 11

Installation ................................................................................... 13

3.1 Unpacking the Transmitter 13

3.2 Mounting the Transmitter 13

3.3 Gas Connections 13

3.4 Electrical Connections 15

3.5 Installing the Micro-fuel Cell 16

3.6 Testing the System 17

Operation ..................................................................................... 19

4.1 Introduction 19

Teledyne Analytical Instruments iv

Page 5

Trace Oxygen Transmitter

4.2 The Range and Calibration Functions 19

4.3 Calibration 20

Maintenance ................................................................................. 23

5.1 Routine Maintenance 23

5.2 Cell Replacement 23

5.2.1 Storing and Handling Replacement Cells 23

5.2.2 When to Replace a Cell 24

5.2.3 Removing the Micro-fuel Cell 24

5.2.4 Cell Warranty 24

5.3 Insta-Trace Sensor 26

Appendix ...................................................................................... 29

Specifications 29

Recommended Spare Parts List 30

Drawings 32

Teledyne Analytical Instruments v

Page 6

Insta-Trans

List of Figures

Figure 1-1: Range Selection ............................................................ 3

Figure 2-1: Micro-fuel Cell ............................................................... 6

Figure 2-2: Cross Section of a Micro-fuel Cell ................................. 7

Figure 2-3: Characteristic Input/Output Curve for a Micro-fuel Cell ....... 9

Figure 2-4: Gas and Other Connections to the Transmitter .......... 10

Figure 2-5: Electronics Block Diagram .......................................... 12

Figure 3-1: Insta-Trans Connections and Mounting Dimensions ... 14

Figure 4-1: Insta-Trace Operation ................................................. 21

Figure 5-1: Cell Removal .............................................................. 26

Figure 5-2: Cell Removal Insta-Trace ........................................... 28

Teledyne Analytical Instruments vi

Page 7

Trace Oxygen Transmitter

DANGER

COMBUSTIBLE GAS USAGE

This is a general purpose instrument designed for usage in a

nonhazardous area. It is the customer's responsibility to

ensure safety especially when combustible gases are being

analyzed since the potential of gas leaks always exist.

WARNING

The customer should ensure that the principles of operating

of this equipment is well understood by the user. Misuse of

this product in any manner, tampering with its components,

or unauthorized substitution of any component may

adversely affect the safety of this instrument.

Since the use of this instrument is beyond the control of

Teledyne, no responsibility by Teledyne, its affiliates, and

agents for damage or injury from misuse or neglect of this

equipment is implied or assumed.

Teledyne Analytical Instruments vii

Page 8

Insta-Trans

Teledyne Analytical Instruments viii

Page 9

Trace Oxygen Transmitter Introduction

Introduction

1.1 Overview

The Teledyne Analytical Instruments Insta-Trans Trace Oxygen

Transmitter is a versatile instrument for detecting oxygen at the parts-per million (ppm) level in a variety of gases. This manual covers the Insta-Tr ans

Trace Oxygen Transmitter. These units are NEMA-4 rated and may be used

in hazardous environments. The Insta-Trans is also Factory Mutual approved

when installed in accordance with drawing D-73226 located in the back of

this manual.

1.2 Typical Applications

A few typical applications of the Insta-Trans are:

Monitoring inert gas blanketing

Air separation and liquefaction

Chemical reaction monitoring

Semiconductor manufacturing

Petrochemical process control

Quality assurance

Gas analysis certification.

1.3 Main Features of the Transmitter

The Insta-Trans Trace Oxygen Transmitter is sophisticated yet

simple to use. The main features of the analyzer include:

3½ digit LCD display with range and calibration

annunciators.

Six ranges: 0-10 ppm through 0-25%.

Stainless steel cell block.

Teledyne Analytical Instruments 1

Page 10

Introduction Insta-Trans

Simple push-button calibration and range selection.

Advanced Micro-fuel Cell, redesigned for trace analysis, has

a one year warranty and an expected lifetime of two years.

Air-calibration range for convenient spanning at 20.9 %.

True 2-wire 4-20 mA powered loop interface.

1.4 Operator Interface

The standard Insta-Trans is housed in a rugged NEMA-4 rated

metal case with all switches and the display accessible from the outside.

Figure 1-1 illustrates the Insta-Trans display and switches while Table 11 shows the decimal point (DP) location for the various ranges.

Function Keys: Six touch-sensitive membrane switches are used to set

the range and calibrate the transmitter.

RANGE Selects the Range mode and sets the desired range.

COARSE Selects the Coarse calibration mode.

FINE Selects the Fine calibration mode.

RUN Selects the Run mode.

▲ Used to adjust the calibration upward in Coarse

and Fine mode.

▼ Used to adjust the calibration downward in

Coarse and Fine mode.

DISPLAY 3 1/2 digit O

concentration LCD display with

2

annunciators

Table 1-1: Decimal Location for Selected Range

Range Decimal Location

0-10 PPM Decimal Point (DP) 2

0-100 PPM Decimal Point (DP) 1

0-1000 PPM No Decimal Point

0-1% Decimal Point (DP) 3

0-10% Decimal Point (DP) 2

0-25% Decimal Point (DP) 2

Teledyne Analytical Instruments 2

Page 11

Trace Oxygen Transmitter Introduction

Figure 1-1: Range Selection

Teledyne Analytical Instruments 3

Page 12

Introduction Insta-Trans

Teledyne Analytical Instruments 4

Page 13

Trace Oxygen Transmitter Operational Theory

Operational Theory

2.1 Introduction

The transmitter is composed of three subsystems:

1. Micro-fuel Cell Sensor

2. Sample System

3. Electronic Signal Processing, Display and Control

The sample system is designed to accept the sample gas and

transport it through the transmitter without contaminating or altering the

sample prior to analysis. The Micro-fuel Cell is an electrochemical

galvanic device that translates the amount of oxygen present in the

sample into an electrical current. The electronic signal processing,

display and control circuits simplify operation of the transmitter and

accurately displays the sampled data.

2.2 Micro-fuel Cell Sensor

2.2.1 Principles of Operation

The oxygen sensor used in the Insta-Trans series is a Micro-fuel

Cell designed and manufactured by Analytical Instruments. It is a sealed

plastic disposable electrochemical transducer.

The active components of the Micro-fuel Cell are a cathode, an

anode, and the 15% aqueous KOH electrolyte in which they are

immersed. The cell converts the energy from a chemical reaction into an

electrical current in an external electrical circuit. Its action is similar to

that of a battery.

There is, however, an important difference in the operation of a

battery as compared to the Micro-fuel Cell: In the battery, all reactants

are stored within the cell, whereas in the Micro-fuel Cell, one of the

reactants (oxygen) comes from outside the device as a constituent of the

sample gas being analyzed. The Micro-fuel Cell is therefore a hybrid

Teledyne Analytical Instruments 5

Page 14

Operational Theory Insta-Trans

between a battery and a true fuel cell. (All of the reactants are stored

externally in a true fuel cell.)

2.2.2 Anatomy of a Micro-fuel Cell

The Micro-fuel Cell is a cylinder only 1¼ inches in diameter and

1¼ inches thick. It is made of an extremely inert plastic, which can be

placed confidently in practically any environment or sample stream. It is

effectively sealed, although one end is permeable to oxygen in the

sample gas. The other end of the cell is a contact plate consisting of two

concentric foil rings. The rings mate with spring-loaded contacts in the

sensor block assembly and provide the electrical connection to the rest

of the analyzer. Figure 2-1 illustrates the external features.

Figure 2-1: Micro-fuel Cell

Refer to Figure 2-2, Cross Section of a Micro-fuel Cell, which

illustrates the following internal description.

At the top end of the cell is a diffusion membrane of Teflon,

whose thickness is very accurately controlled. Beneath the diffusion

membrane lies the oxygen sensing element—the cathode—with a

surface area almost 4 cm

2

. The cathode has many perforations to ensure

sufficient wetting of the upper surface with electrolyte, and it is plated

with an inert metal.

The anode structure is below the cathode. It is made of lead and has

a proprietary design which is meant to maximize the amount of metal

available for chemical reaction.

Teledyne Analytical Instruments 6

Page 15

Trace Oxygen Transmitter Operational Theory

Figure 2-2: Cross Section of a Micro-fuel Cell (not to scale)

At the rear of the cell, just below the anode structure, is a flexible

membrane designed to accommodate the internal volume changes that

occur throughout the life of the cell. This flexibility assures that the

sensing membrane remains in its proper position, keeping the electrical

output constant.

The entire space between the diffusion membrane, above the

cathode, and the flexible rear membrane, beneath the anode, is filled

with electrolyte. Cathode and anode are submerged in this common

pool. They each have a conductor connecting them to one of the external

contact rings on the contact plate, which is on the bottom of the cell.

2.2.3 Electrochemical Reactions

The sample gas diffuses through the Teflon membrane. Any

oxygen in the sample gas is reduced on the surface of the cathode by the

following HALF REACTION:

O

+ 2H2O + 4e– → 4OH– (cathode)

2

(Four electrons combine with one oxygen molecule—in the

presence of water from the electrolyte—to produce four hydroxyl ions.)

When the oxygen is reduced at the cathode, lead is simultaneously

oxidized at the anode by the following HALF REACTION:

Teledyne Analytical Instruments 7

Page 16

Operational Theory Insta-Trans

Pb + 2OH– → Pb+2 + H2O + 2e– (anode)

(Two electrons are transferred for each atom of lead that is

oxidized. Therefore it takes two of the above anode reactions to balance

one cathode reaction and transfer four electrons.)

The electrons released at the surface of the anode flow to the

cathode surface when an external electrical path is provided. The current

is proportional to the amount of oxygen reaching the cathode. It is

measured and used to determine the oxygen concentration in the gas

mixture.

The overall reaction for the fuel cell is the SUM of the half

reactions above, or:

2Pb + O2 → 2PbO

(These reactions will hold as long as no gaseous components

capable of oxidizing lead—such as iodine, bromine, chlorine and

fluorine—are present in the sample.)

The output of the fuel cell is limited by (1) the amount of oxygen in

the cell at the time and (2) the amount of stored anode material.

In the absence of oxygen, no current is generated.

2.2.4 The Effect of Pressure

In order to state the amount of oxygen present in the sample in

parts-per-million or a percentage of the gas mixture, it is necessary that

the sample diffuse into the cell under constant pressure.

If the total pressure increases, the rate that oxygen reaches the

cathode through the diffusing membrane will also increase. The electron

transfer, and therefore the external current, will increase, even though

the oxygen concentration of the sample has not changed. It is therefore

important that the sample pressure at the fuel cell (usually vent pressure)

remain relatively constant between calibrations.

2.2.5 Calibration Characteristics

Given that the total pressure of the sample gas on the surface of the

Micro-fuel Cell input is constant, a convenient characteristic of the cell

is that the current produced in an external circuit is directly proportional

to the rate at which oxygen molecules reach the cathode, and this rate is

directly proportional to the concentration of oxygen in the gaseous

Teledyne Analytical Instruments 8

Page 17

Trace Oxygen Transmitter Operational Theory

mixture. In other words it has a linear characteristic curve, as shown in

Figure 2-3. Measuring circuits do not have to compensate for

nonlinearities.

In addition, since there is zero output in the absence oxygen, the

characteristic curve has close to an absolute zero (within ± 0.5 ppm

oxygen).

Figure 2-3: Characteristic Input/Output Curve for a Micro-fuel Cell

Teledyne Analytical Instruments 9

Page 18

Operational Theory Insta-Trans

2.3 Sample System

The sample system delivers gases to the Micro-fuel Cell sensor

from the transmitter gas inlet. Depending on the mode of operation

either sample or calibration gas is delivered.

The Insta-Trans sample system is designed and fabricated to ensure

that the oxygen concentration of the gas is not altered as it travels

through the sample system. The sample encounters almost no dead

space. This minimizes residual gas pockets that can interfere with trace

analysis.

The sample system for the standard instrument incorporates 1/8

inch tube fittings for sample inlet and outlet connections. For metric

system installations, 6 mm adapters can be supplied with each

instrument to be used if needed (consult factory). The sample gas flows

through the transmitter as shown in Figure 2-4.

Figure 2-4: Gas and Other Connections to the Transmitter

Teledyne Analytical Instruments 10

Page 19

Trace Oxygen Transmitter Operational Theory

2.4 Electronics and Signal Processing

The Insta-Trans Trace Oxygen transmitter uses standard electronic

circuitry. Power is supplied via the 4-20 mA current loop.

The processing electronics are located inside the transmitter case.

Three boards are accessible after removing the top housing. Figure 2-5 is

a block diagram of the transmitter electronics.

In the presence of oxygen the cell generates a current. A current to

voltage amplifier converts this current to a voltage, which is amplified in

the second stage amplifier.

The second stage amplifier also supplies temperature compensation

for the oxygen sensor output. This amplifier circuit incorporates a

thermistor, which is physically located in the cell block. The thermistor

is a temperature dependent resistance that changes the gain of the

amplifier in proportion to the temperature changes in the block. This

change is inversely proportional to the change in the cell output due to

the same temperature changes. The result is a signal that is temperature

independent. The output from the second stage amplifier is sent to the

3 1/2 digit DVM/Display and voltage to current converter/driver.

The 3 1/2 digit DVM/Display provides a visual indication of the

oxygen concentration in ppm or % depending on the range selected.

Range selection and calibration information are entered from the key

pad and processed through the key pad control, the input range selection

and the calibration control circuits. All power needed to run the InstaTrans transmitter is derived from the signal current loop. Calibration

settings are maintained indefinitely when the signal current loop is

disconnected. Range settings are maintained for a minimum of 72 hours

through the use of a 0.1 Farad storage capacitor when the signal current

loop is disconnected. The transmitter always defaults to Run mode when

the signal current loop is connected.

Teledyne Analytical Instruments 11

Page 20

Operational Theory Insta-Trans

Figure 2-5: Electronics Block Diagram

Teledyne Analytical Instruments 12

Page 21

Trace Oxygen Transmitter Installation

Installation

Installation of the Insta-Trans Transmitter includes:

Unpacking

Mounting

Gas connections

Electrical connections

Installing the Micro-fuel Cell

Testing the system.

3.1 Unpacking the Transmitter

The transmitter is shipped with all the materials you need to install

and prepare the system for operation. Carefully unpack the transmitter

and inspect it for damage. Immediately report any damage to the

shipping agent.

3.2 Mounting the Transmitter

The Insta-Trans is intended for indoor or outdoor use.

The Insta-Trans transmitter is provided with a wall mount bracket.

Refer to Figure 3-1 for mounting information and dimensions. The

display and operator control switches are located on the top of the

transmitter. This should be taken into consideration when determining

mounting location. Mount the transmitter with the sensor housing

vertical and the cell holder on the bottom.

3.3 Gas Connections

The unit is manufactured with 1/8 inch tube fittings (consult

factory for other sizes). For a safe connection:

Teledyne Analytical Instruments 13

Page 22

Installation Insta-Trans

1. Insert the tube into the tube fitting, and finger-tighten the nut

until the tubing in the fitting cannot be rotated freely by hand.

(This may require an additional 1/8 turn beyond finger-tight.)

2. Hold the fitting body steady with a backup wrench, and with

another wrench rotate the nut another 1-1/4 turns.

Figure 3-1: Insta-Trans Connections and Mounting Dimensions

SAMPLE IN: Gas connections are made at the SAMPLE IN and

EXHAUST OUT connections.

The gas pressure in should be reasonably regulated. A flow control

device must be installed before the sample in port if the sample pressure

is above 0.5 psig.

Teledyne Analytical Instruments 14

Page 23

Trace Oxygen Transmitter Installation

If greater flow is required for improved response time (over 20

SCFH), install a bypass in the sampling system upstream of the analyzer

input.

EXHAUST OUT: Exhaust connections must be consistent with the

hazard level of the constituent gases. Check local, state, and federal

laws, and ensure that the exhaust stream vents to an appropriately

controlled area if required. The exhaust should be vented to atmospheric

pressure, through a short length of tubing (3'). The vent tubing should

not be less than 1/8".

3.4 Electrical Connections

The Insta-Trans analyzer requires two electrical connections. A

chassis ground connection should be made to the left side of the

mounting bracket. This is required to reduce the sensitivity to radio

frequency interference (RFI). An adequate ground connection is can be

established by mounting the analyzer to a metal structure, or attaching a

ground cable with lug (3/8") to the left side mounting bolt.

The signal and power are supplied by a single 4 pin electrical

connector on the left side of the analyzer. The Insta-Trans is supplied

with a twenty-four inch cable which mates with the power/signal

connector. Other cable lengths are available or the mating connector can

be supplied for customer use, see spare parts list in the rear of the

manual.

Wiring: The Insta-Trans is equipped with a four pin removable

connector (screw connections). The connector allows the user to easily

install or remove the analyzer. The connector should be wired per

B71625, interconnection is per A71629 (D73226 for FM approved

installation).

For Factory Mutual approved installations, the interconnection

cable must not exceed the following values:

GP AB 0.09 f and 3 mH inductance

GP C 0.3 f and 1 mH inductance

GP D 0.9 f and 3 mH inductance

The cable or wire required will depend on the specific application. A

shielded cable should be used when ever possible to improve resistance to

radio interference. The wire gage should be selected based on the length

Teledyne Analytical Instruments 15

Page 24

Installation Insta-Trans

of the cable. A minimum wire gage of 22 is recommended. The maximum

wire gage is limited by the size of the connector. A larger gage wire is

required for longer cable runs due to the voltage drop associated with the

cable resistance. A 1000 foot 22 gage cable will have a voltage drop of

0.59 VDC (29.5 ohms x 20ma) at full scale. A 1000 foot 18 gage cable

will have a voltage drop of 0.26 VDC (12.96 ohms x 20ma). The above

voltage will be added to the minimum voltage required for the transmitter.

A typical installation will include a load resistor. The value of the

resistor is dependent on the full-scale output voltage signal required. For a

full-scale output of 5 VDC the resistor value is 250 ohms (5V/20mA.).

For a full-scale output of 1 VDC the resistor value will be 50 ohms

(1V/20mA). The output voltage is also added to the minimum voltage for

the transmitter.

The operating voltage range of the transmitter is 9.3 – 30 VDC. The

wiring and load resistor voltage drops must be included in determining the

minimum voltage requirement. The minimum operating voltage required

with a 500 foot 20 gage cable and a 250 ohm load resistor is 14.4 VDC

(9.3V + (5.1 + 250) ohms x 20ma).

For Intrinsically Safe (IS) installation, special considerations are

required. The Insta-Trans analyzer has been designed to be Intrinsically

Safe when used with a properly selected and installed safety barrier. This

design utilizes redundant safety features to prevent the Insta-Trans from

becoming an ignition source in the event of a circuit failure. The user

should consult with the proper certifying agency prior to installation. Safety

barriers reduce the possibility of fires or explosion in hazardous locations

by limiting the energy available for ignition. Reference the FM

interconnection diagram D-73226.

3.5 Installing the Micro-fuel Cell

The Micro-fuel Cell is not installed in the cell block when the

instrument is shipped. It must be install before the analyzer is placed in

service.

Once it is expended, or if the cell (trace O

long, the Micro-fuel Cell will need to be replaced (B1 cells are designed

for use in % levels of O

such as air). The cell could also require

2

replacement if the instrument has been idle for too long.

) is exposed to air for too

2

Teledyne Analytical Instruments 16

Page 25

Trace Oxygen Transmitter Installation

When the Micro-fuel Cell needs to be installed or replaced, follow

the procedures in Chapter 5, Maintenance, for removing and installing

cells.

3.6 Testing the System

Before connecting the signal wires to the transmitter:

Check the integrity and accuracy of the gas connections.

Make sure there are no leaks.

Verify that the restriction device has been properly installed

(see section 3.3).

Check that inlet sample pressure is within the accepted range

(see section 3.3).

Connect the signal wires and energize the signal line, and test the

transmitter by performing the following:

1. Observe that the LCD display illuminates and that the

transmitter starts up in Run mode. If the transmitter is being

energizer for the first time or has been disconnected from the

power for a long period of time, wait about 60 seconds for

the 0.1 Farad storage capacitor to charge up before

attempting any tests.

2. If the right three digits of the LCD display are blank, the

transmitter is in an over range condition. Push the RANGE

button once to enter the Range Select mode. Observe that the

RNG annunciator illuminates. Push the RANGE button until

the transmitter displays an “in range” condition.

Note: Tthe transmitter can display a 99.9% over range condition,

so select a range where the left-most digit is blank.

3. Push the COARSE button. Observe that the CRS

annunciator illuminates on the display.

4. Push the ▲ and▼buttons. Observe that the gas

concentration reading goes up and down in rather coarse

increments as the buttons are pushed.

5. Push the FINE button.Observe that the CRS annunciator

goes out and the FIN annunciator illuminates on the display.

Teledyne Analytical Instruments 17

Page 26

Installation Insta-Trans

6. Push the ▲ and▼buttons. Observe that the gas

concentration reading goes up and down in fine increments

as the buttons are pushed.

7. Push the RUN button. Observe that the FIN and RNG

annunciators go out. The transmitter is now in Run mode.

Teledyne Analytical Instruments 18

Page 27

Trace Oxygen Transmitter Operation

Operation

4.1 Introduction

Once the transmitter has been installed, it must be configured to

your application. To do this you must:

Set the range.

Calibrate the instrument.

4.2 The Range and Calibration Functions

The transmitter is calibrated by using span gas.

Although the instrument can be spanned using air, a span gas with a

known oxygen concentration in the range of 70–90% of full scale of the

range of interest is recommended. Since the oxygen concentration in air

is 20.9% (209,000 ppm), the cell can take a long time to recover if the

instrument is used for trace oxygen analysis immediately following

calibration in air.

Connect the calibration gases to the transmitter according to the

instructions given in Section 3.3, Gas Connections, observing all the

prescribed precautions.

The gas supply should be off or set to a low flow before

connecting it to the transmitter, and be sure not to obstruct the

sample vent.

CAUTION: IN THE EVENT OF LOSS OF FLOW THROUGH THE

TRANSMITTER, IF THE VENT IS VENTED TO A

LOCATION OF HIGH OXYGEN CONTENT, OXYGEN

WILL BACK DIFFUSE THROUGH THE VENT LINE

AND IN MOST CASES QUICKLY SATURATE THE

CELL WITH OXYGEN WHICH CAN THEN REQUIRE A

LONG PURGE DOWN TIME FOR THE SENSOR

WHEN USED FOR LOW OXYGEN CONCENTRATION

MEASUREMENTS. IN THE EVENT THAT FLOW IS

INTERRUPTED INTO THE TRANSMITTER, IT IS

Teledyne Analytical Instruments 19

Page 28

Operation Insta-Trans

SUGGESTED THAT THE USER DO ONE OF THE

FOLLOWING:

1. Bag the sensor in nitrogen during this time

2. Install a shut off valve on the vent port of the

transmitter or somewhere within the users

sample system.

4.3 Calibration

Follow the following instructions to calibrate the Insta-Trans Trace

Oxygen Transmitter. Refer to figure 4-1.

1. Select range to be calibrated and enable calibration gas flow.

2. Wait until the display reading is stable before beginning the

span adjustment.

3. Once the reading is stable press COARSE to select the

Coarse mode.

4. Adjust the ‘COARSE’ range up or down using the ▲ and ▼

keys until the display reads the value that is closest to the

calibration gas oxygen concentration level.

5. When set to a value close to the calibration gas concentration

level press FINE to select the Fine mode.

6. Adjust the ‘FINE’ range up or down until the display reads

the value of the calibration gas oxygen concentration level. If

unable to reduce the Fine range lower, proceed to step 7. If

unable to increase the Fine range higher, proceed to step 8.

Else, proceed to step 9.

7. Set the transmitter into ‘COARSE’ mode and adjust the

Coarse range DOWN exactly 4 increments. Then, go back to

step 5.

8. Set the transmitter into ‘COARSE’ mode and adjust the

Coarse range UP exactly 4 increments. Then, go back to step

5.

9. Press RUN to complete calibration.

Teledyne Analytical Instruments 20

Page 29

Trace Oxygen Transmitter Operation

Figure 4-1: Insta-Trace Operation

Teledyne Analytical Instruments 21

Page 30

Operation Insta-Trans

Teledyne Analytical Instruments 22

Page 31

Trace Oxygen Transmitter Maintenance

Maintenance

5.1 Routine Maintenance

Aside from normal cleaning and checking for leaks at the gas

connections, routine maintenance is limited to replacing Micro-fuel

Cells and recalibration. For recalibration, see Section 4 Calibration.

WARNING: SEE WARNINGS ON THE TITLE PAGE OF THIS

MANUAL.

5.2 Cell Replacement

A Micro-fuel Cell is a sealed electrochemical transducer with no

electrolyte to change or electrodes to clean. When the cell reaches the

end of its useful life, it is replaced. The spent fuel cell should be

discarded according to local regulations. This section describes fuel cell

care as well as when and how to replace it.

5.2.1 Storing and Handling Replacement Cells

To have a replacement cell available when it is needed, TAI

recommends that one spare cell be purchased 9-10 months after

commissioning the Insta-Trans, or shortly before the end of the cell's

one year warranty period.

CAUTION: DO NOT STOCKPILE CELLS. THE WARRANTY PERIOD

STARTS ON THE DAY OF SHIPMENT.

The spare cell should be carefully stored in an area that is

not subject to large variations in ambient temperature

(75 °F nominal) or to rough handling.

WARNING: THE SENSOR USED IN THE INSTA-TRANS TRACE

OXYGEN TRANSMITTER USES ELECTROLYTES

WHICH CONTAIN TOXIC SUBSTANCES, MAINLY

Teledyne Analytical Instruments 23

Page 32

Maintenance Insta-Trans

LEAD AND POTASSIUM HYDROXIDE, THAT CAN BE

HARMFUL IF TOUCHED, SWALLOWED, OR

INHALED. AVOID CONTACT WITH ANY FLUID OR

POWDER IN OR AROUND THE UNIT. WHAT MAY

APPEAR TO BE PLAIN WATER COULD CONTAIN

ONE OF THESE TOXIC SUBSTANCES. IN CASE OF

EYE CONTACT, IMMEDIATELY FLUSH EYES WITH

WATER FOR AT LEAST 15 MINUTES. CALL

PHYSICIAN. (SEE APPENDIX, MATERIAL SAFETY

DATA SHEET.)

CAUTION: DO NOT DISTURB THE INTEGRITY OF THE CELL

PACKAGE UNTIL THE CELL IS TO ACTUALLY BE

USED. IF THE CELL PACKAGE IS PUNCTURED AND

AIR IS PERMITTED TO ENTER, THE CELL WILL

REQUIRE AN EXCESSIVELY LONG TIME TO REACH

ZERO AFTER INSTALLATION (1-2 WEEKS!).

5.2.2 When to Replace a Cell

The characteristics of the Micro-fuel Cell show an almost constant

output throughout its useful life and then falls off sharply towards zero

at the end. Cell failure in the Insta-Trans is usually characterized by the

inability to span or excessive offset when used on low ppm ranges.

Before replacing the cell:

1. Check your span gas to make sure it is within specifications.

2. Check for leaks downstream from the cell, where oxygen

may be leaking into the system.

If there are no leaks and the span gas is OK, replace the cell.

5.2.3 Removing the Micro-fuel Cell

Remove the Cell Holder by holding the bottom in place and

unscrewing the Collar until the Cell Holder falls out with the Cell.

Remove the new cell from its package, and carefully remove the

shorting clip. Place the cell on the cell holder with the screen side facing

down and tighten the cell holder onto the instrument. See Figure 5-1.

5.2.4 Cell Warranty

The Insta-Trace cell is the standard trace sensor for the Insta-Trans.

It is suitable for use in applications where the O

level is being measured

2

on a ppm range. The warranty period of the Insta-Trace is six months

Teledyne Analytical Instruments 24

Page 33

Trace Oxygen Transmitter Maintenance

from the date of shipment. This sensor has a life expectancy of eight

months when used in trace measurement applications.

The B1 cell is the standard percent sensor for use with Insta-Trans. It

is suitable for use when the analyzer will be used on a percent range. The

B1 has a warranty period of six months from the date of shipment and a

life expectancy of eight months in air.

The A2C cell is recommended for use in trace applications were

CO

is a major component of the sample gas. The warranty period of the

2

A2C is six months from the date of shipment. This sensor has a life

expectancy of eight months when used in trace measurement

applications.

The optional Class L2C Micro-fuel Cell can be used in the Insta-Trans.

This cell is a long life cell for use in trace (ppm) applications and is warranted

for 1 year from the date of shipment. Note any Addenda attached to the front

of this manual for special information applying to your instrument.

With regard to spare cells, warranty period begins on the date of

shipment. The customer should purchase only one spare cell (per section

5.2.1). Do not attempt to stockpile spare cells.

The B1, B2C, Insta-Trace, and L2C cells are not designed for

applications where CO2 is a major component in the sample,

however intermittent concentrations of 1,000 ppm or less will not

adversely effect the cell performance. Consult TAI for available options

for either intermittent or continuous CO2 exposure.

The A2C cell is recommended for trace applications when the

sample gas contains significant levels of CO

. The A2C cell is suitable

2

for CO2 concentration of 0 to 100%.

If a cell was working satisfactorily, but ceases to function before

the warranty period expires, the customer will receive credit toward the

purchase of a new cell.

If you have a warranty claim, you must return the cell in question to

the factory for evaluation. If it is determined that failure is due to faulty

workmanship or material, the cell will be replaced at no cost to you.

Teledyne Analytical Instruments 25

Page 34

Maintenance Insta-Trans

Figure 5-1: Cell Removal

5.3 Insta-Trace Sensor

Teledyne’s Insta-Trace Sensor (patent pending) provides rapid

sensor installation recovery time. The Insta-Trace system allows a new

sensor to be installed and working at low ppm (parts per million) in a

matter of minutes. The insta-Trace option includes the Insta-Trace

Sensor and a special Insta-Trace cell holder (the B2 cell adapter is not

used).

Teledyne Analytical Instruments 26

Page 35

Trace Oxygen Transmitter Maintenance

Any Insta-Trans can be converted to an Insta-Trace by substituting

the sensor and cell holder (see Spare Parts Listing in the Appendix).

The Insta-Trace system works by shielding the sensitive membrane

from air during the installation process. These special cells have an outer

membrane which seals the sensing membrane in a bath of N

until the

2

membrane is punctured during the installation. External gas can reach

the sensing membrane only after the external membrane is pierced. This

process prevents air from contaminating the sensor during installation

thus allowing rapid recovery to low ppm levels. For best results, the

proper installation must be followed.

To install the Insta-Trace:

The Insta-Trans transmitter must be purged with sample gas at a

flow rate of approximately 0.2 SCFH during installation.

Remove the Insta-Trace cell holder by unscrewing the collar (see

Figure 5-2).

Remove the Insta-Trace sensor from the double bags.

Remove the shorting plug from the rear of the sensor.

Install the sensor in the transmitter with the contact surface (two

concentric gold circles) facing up, and the membrane facing

down toward the cell holder.

Orient the cell holder to align the registration pin with the hole in

the cell holder.

Push the cell holder firmly in place while rotating the collar (see

Figure 5-2). The collar should be tightened finger-tight only.

Teledyne Analytical Instruments 27

Page 36

Maintenance Insta-Trans

Figure 5-2: Cell Removal Insta-Trace

Teledyne Analytical Instruments 28

Page 37

Trace Oxygen Transmitter Appendix

Appendix

Specifications

System Enclosure: Weather resistant, bulkhead mounted

Power Requirements: 15V nominal, reverse polarity protected.

9.3VDC-30VDC. V

safety barrier and/or load resistor used.

For Factory Mutual Approved Intrinsically

Safe Operation, an approved safety barrier

must be used. Ref. D-73226

dependent upon

min

Ranges: 0–10ppm through 0–25% Oxygen

Accuracy: ± 2% of full scale at constant temperature

and pressure (at the temperature and

pressure of calibration), except ± 1ppm on

0–10ppm range.

± 5% of full scale over operating

temperature range (once thermal

equilibrium has been reached), except ±

1ppm on 0–10ppm range.

Response Time (90%): Sensor Response Time + Electronic

Response Time = 40 seconds @ 77°F

(25°C)—(with standard cell)

Operating Temperature: 32–122°F (0–50°C)

Relative Humidity: 0-100% RH, NEMA-4 rated.

Stability: ± 1% in 24 hours (at constant temperature)

Reproducibility: ± 1% of full scale at constant temperature

Sensor Type: Micro-fuel Cell class B2C, L2C, B1, A2C,

Insta-Trace

Signal Output: 4–20 mA DC

Teledyne Analytical Instruments 29

Page 38

Appendix Insta-Trans

Recommended Spare Parts List

Qty. Part Number Description

1 B617 IS Safety Barrier MTL 7087+

1 B616 IS Safety Barrier MTL 787S+

1 B604 IS Safety Barrier(Galvanic MTL 5041

1 B70986 Standard Cell Holder

1 B71625A Power/Signal Cable 2 Ft.

1 B71625D Power/Signal Cable 25 ft (optional)

1 B66378 Cell Adapter (B1, B2, AC) Insta-Trace Option

1 D71159A PCB Display

1 D71159B PCB Logic Board

1 D71159C PCB I/O

1* C6689-A2C A2C Micro-fuel Cell

1* C6689-A5 A5 Micro-fuel Cell

1* C6689-B1 B1 Micro-fuel Cell

1* C6689-B2C B2C Micro-fuel Cell

1* B73016 Insta-Trans Sensor A-type

1* B71875 Insta-Trans Sensor B-type

1 CP2070 Connector, Power Signal

2 O290 O-Rings

1 B72087 Insta-Trace Cell Holder

* Application Dependant. Only 1 required

A minimum charge is applicable to spare parts orders.

Note: Orders for replacement parts should include the part

number (if available) and the model and serial number of

the instrument for which the parts are intended.

Teledyne Analytical Instruments 30

Page 39

Trace Oxygen Transmitter Appendix

Orders should be sent to:

TELEDYNE Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91749-1580

Phone (626) 934-1500, Fax (626) 961-2538

Web: www.teledyne-ai.com

or your local representative.

Teledyne Analytical Instruments 31

Page 40

Appendix Insta-Trans

Drawings

Teledyne Analytical Instruments 32

Loading...

Loading...