Falcon4 86M

Camera User’s Manual

FA-S0-86M16-01-R and FA-S1-86M16-00-R

sensors |

cameras

| frame grabbers | processors | software | vision solutions

03-032-20220-01

www.teledynedalsa.com

Notice

© 2017 Teledyne DALSA

All information provided in this manual is believed to be accurate and reliable. No

responsibility is assumed by Teledyne DALSA for its use. Teledyne DALSA reserves the right

to make changes to this information without notice. Reproduction of this manual in whole or

in part, by any means, is prohibited without prior permission having been obtained from

Teledyne DALSA.

Microsoft and Windows are registered trademarks of Microsoft Corporation in the United

States and other countries. Windows, Windows 7, Windows 8 are trademarks of Microsoft

Corporation.

All other trademarks or intellectual property mentioned herein belong to their respective

owners.

Document date: April 19, 2017

Document number: 03-032-20220-01

About Teledyne DALSA

Teledyne DALSA is an international high performance semiconductor and electronics

company that designs, develops, manufactures, and markets digital imaging products and

solutions, in addition to providing wafer foundry services.

Teledyne DALSA Digital Imaging offers the widest range of machine vision components in

the world. From industry-leading image sensors through powerful and sophisticated

cameras, frame grabbers, vision processors and software to easy-to-use vision appliances

and custom vision modules.

Contents

THE FALCON4 86M CAMERA ........................................................................... 4

DESCRIPTION ................................................................................................ 4

Key Features ......................................................................................... 4

Programmability ..................................................................................... 4

Applications ........................................................................................... 4

MODEL NUMBERS AND SOFTWARE REQUIREMENTS ..................................................... 5

CAMERA PERFORMANCE SPECIFICATIONS ................................................................ 5

ENVIRONMENTAL SPECIFICATIONS ........................................................................ 7

SENSOR COSMETIC SPECIFICATIONS ..................................................................... 7

RESPONSIVITY & QE ........................................................................................ 8

ANGLE OF INCIDENCE ....................................................................................... 9

FLASH MEMORY SIZE ....................................................................................... 9

CERTIFICATIONS & COMPLIANCE ........................................................................ 10

SHOCK & VIBRATION ..................................................................................... 10

SUPPORTED INDUSTRY STANDARDS .................................................................... 11

GenICam™ .......................................................................................... 11

Camera Link HS ................................................................................... 11

Camera Link HS ROI Characteristics ....................................................... 11

SENSOR BLOCK DIAGRAM & PIXEL READOUT ......................................................... 12

CAMERA SETUP ............................................................................................ 13

SYSTEM PRECAUTIONS & CLEANING .................................................................... 13

Precautions ......................................................................................... 13

Cleaning the Device .............................................................................. 13

Electrostatic Discharge and the CMOS Sensor .......................................... 13

SOFTWARE AND HARDWARE SETUP ............................................................ 14

RECOMMENDED SYSTEM REQUIREMENTS ............................................................... 14

SETUP STEPS: OVERVIEW ................................................................................ 14

Step 1: Install and Configure Frame Grabber and Software ........................ 14

Step 2: Connect Camera Link and Power Cables ....................................... 14

Power Connector .................................................................................. 15

Camera Link Data Connector ........................................................................ 16

Input Signals, Camera Link ........................................................................... 16

Frame Start Trigger (EXSYNC) ...................................................................... 16

LED Indicators ............................................................................................ 17

LED States on Power Up ............................................................................... 17

Step 3: Establish Communication between the frame grabber and the

camera .......................................................................................... 18

1. Power on the camera ............................................................................. 18

2. Connect to the frame grabber ................................................................. 18

3. Connect to the camera ........................................................................... 18

Check LED Status ........................................................................................ 19

Software Interface....................................................................................... 19

USING CAMEXPERT ...................................................................................... 21

CamExpert Panes ................................................................................. 21

CamExpert View Parameters Option .............................................................. 23

Falcon4 86M Cameras Contents 1

Creating a Camera Configuration File in the Host ...................................... 23

CAMERA OPERATION ................................................................................... 24

Factory Settings ................................................................................... 24

CHECK CAMERA AND SENSOR INFORMATION .......................................................... 24

Verify Temperature ............................................................................... 24

THERMAL MANAGEMENT .................................................................................. 25

Handling ............................................................................................. 25

SAVING AND RESTORING CAMERA SETTINGS ......................................................... 26

ACQUISITION AND TRANSFER CONTROL FEATURES ................................................... 27

TEST PATTERNS ............................................................................................ 28

GAIN AND BLACK LEVEL CONTROL DETAILS ........................................................... 29

EXPOSURE CONTROLS .................................................................................... 30

Internally Programmable Frame Rate and Internally Programmable

Exposure Time (Default) ......................................................................... 31

External Frame Rate and External Exposure Time (Trigger Width) ..................... 31

External Frame Rate, Programmable Exposure Time ........................................ 33

Exposure Time ..................................................................................... 33

Trigger Modes ...................................................................................... 33

Internal Frame Rate ............................................................................. 34

I/O Block Diagram ................................................................................ 34

Opto-Coupled Inputs ............................................................................ 34

Opto-Coupled Outputs .......................................................................... 35

FLAT FIELD CORRECTION AND DEFECTIVE PIXEL DETECTION OVERVIEW ......................... 36

Correction Function Block Diagram ......................................................... 36

Dark Row Subtract Algorithm ................................................................. 36

Flat Field Correction Algorithm Description ............................................... 37

General Notes on FFC calibration ................................................................... 37

An important note on window blemishes ................................................. 38

How to do an FFC Setup in the Camera ................................................... 38

Defective Pixel Detection and Replacement .............................................. 40

Single Pixel Replacement ....................................................................... 40

Defective Columns and Row Replacement ................................................ 40

Median Filter ........................................................................................ 41

File Access via the CamExpert Tool ......................................................... 41

TECHNICAL SPECIFICATIONS ...................................................................... 43

MECHANICALS.............................................................................................. 43

EC & FCC DECLARATION OF CONFORMITY ............................................................ 44

APPENDIX A: GENICAM COMMANDS ............................................................ 45

CAMERA INFORMATION CATEGORY ...................................................................... 45

Camera Information Feature Descriptions ................................................ 45

ACQUISITION AND TRANSFER CONTROL CATEGORY .................................................. 48

Acquisition and Transfer Control Feature Descriptions ............................... 48

SENSOR CONTROL CATEGORY ........................................................................... 48

Sensor Control Feature Descriptions ....................................................... 48

I / O CONTROL CATEGORY ............................................................................... 51

I/O Controls Feature Descriptions ........................................................... 51

ADVANCED PROCESSING CONTROL CATEGORY ........................................................ 55

Advanced Processing Control Feature Descriptions .................................... 55

IMAGE FORMAT CONTROLS CATEGORY ................................................................. 63

CLHS LINK TRANSPORT LAYER CATEGORY ............................................................ 65

Camera Link Transport Layer Feature Description ..................................... 65

2 Contents Falcon4 86M Cameras

FILE ACCESS CONTROL CATEGORY ..................................................................... 66

APPENDIX B: CAMERA, FRAME GRABBER COMMUNICATION ........................ 68

SETTING UP COMMUNICATION BETWEEN THE CAMERA AND THE FRAME GRABBER ............... 68

APPENDIX C: CLEANING THE SENSOR WINDOW .......................................... 69

Recommended Equipment ..................................................................... 69

Procedure ............................................................................................ 69

APPENDIX D: INTERNAL FLAT FIELD CALIBRATION ALGORITHMS .............. 70

Dark Row Subtract ............................................................................... 70

Offset (FPN) Calibration ........................................................................ 70

Gain (PRNU) Calibration ........................................................................ 70

Color Camera Gain (PRNU) Calibration .................................................... 71

APPENDIX E: FILE FORMAT ......................................................................... 74

FFC FILE FORMAT ......................................................................................... 75

CAMERA DEFECT MAP ..................................................................................... 76

CONTACT INFORMATION ............................................................................. 78

SALES INFORMATION...................................................................................... 78

TECHNICAL SUPPORT...................................................................................... 78

REVISION HISTORY ....................................................................................... 79

INDEX ......................................................................................................... 80

Falcon4 86M Cameras Contents 3

The Falcon4 86M Camera

Description

Teledyne DALSA‘s new generation of color and monochrome area scan cameras—the

Falcon4™ 86M—incorporate very large resolutions and fast frame rates, enabling high-speed image

capture with superb spatial resolution and excellent image quality. Global shuttering and correlated

double sampling ensure smear free and low noise images. These features make the Falcon4

cameras the best choices for applications where throughput, resolution and high pixel capacity

matter most.

Inside the Falcon4 camera is our leading-edge, global shutter CMOS sensor, which enables high

speed imaging at very large resolutions. Global shutter technology removes the need for

mechanical shutters which are limited in the number of open / shut operations.

The Falcon4 camera is compliant with GenICam™ and CameraLink HS™ (CLHS) specifications—

delivering 12 and 16 bits of data. In addition, the M95 thread opening allows for your choice of

lens.

Key Features

Global shutter and exposure control

Cross-track of 10,720 pixels

Faster frame rates through windowing

Good NIR response

Built-in FPN and PRNU correction

CLHS interface and GenICam compliant

Programmability

Adjustable digital gain and offset

12 and 16 bit output

Adjustable integration time and frame rate

Test patterns and camera diagnostics

Applications

Aerial imaging

Aerial reconnaissance

Surveillance

Machine vision

4 Contents Falcon4 86M Cameras

Model Number

Description

FA-S0-86M16-01-R

86M pixel monochrome, Camera Link HS.

FA-S1-86M16-00-R

86M pixel color, Camera Link HS.

Part Number

Description

AC-MS-00117-00-R

Fan mounting accessory. Allows a fan to be mounted on the camera case to direct air

flow over the heat sink.

Software

Product Number / Version Number

Camera firmware

Embedded within camera

GenICam™ support (XML camera description file)

Embedded within camera

Recommended: Sapera LT, including CamExpert GUI application and

GenICam for Camera Link imaging driver.

Version 7.50 or later

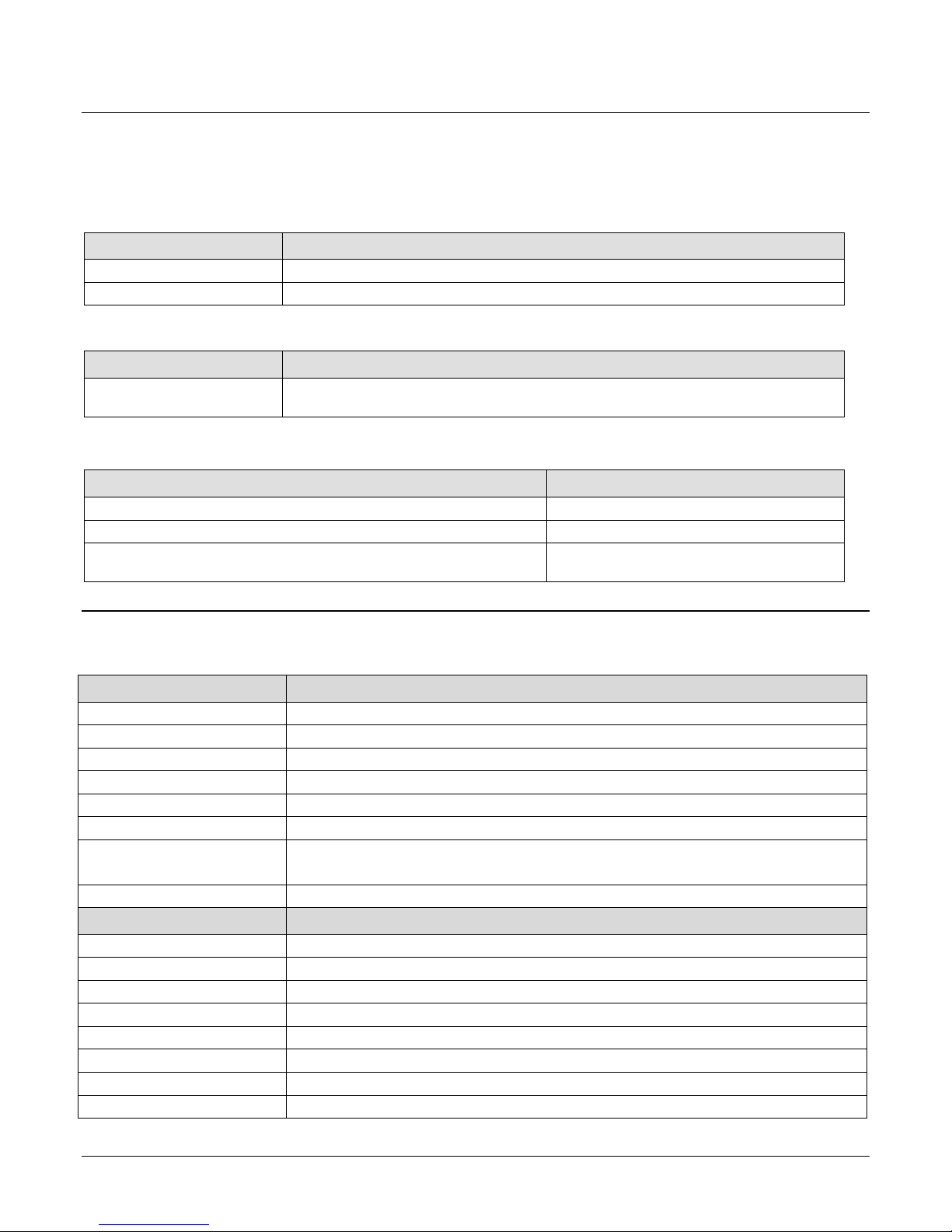

Specifications

Performance

Resolution

10720 (H) x 8064 (V)

Pixel Rate

1.38 Gpixel / s

Frame Rate

16 fps, maximum

Pixel Size

6 µm x 6 µm

Bit Depth

12 and 16 bits, selectable Camera Link HS

Exposure Time

100 µs minimum

Dynamic Range

53 dB (monochrome)

62 dB (monochrome)

Operating Temp

0 °C to +50 °C, front plate temperature

Connectors and Mechanicals

Size

100 mm (H) x 100 mm (W) x 67 mm (D)

Mass

< 1 kg

Data Connector

CLHS—single C2 7M1, CX4 connector

Power Connector

Hirose 12-pin circular

Supply Voltage

+ 12 V to + 24 V DC (± 5 %), 3.5 Amps

Power

< 35 W

Lens Mount

M95 x 1

Sensor Alignment

± 50 µm in X-Y directions

Model Numbers and Software Requirements

This manual covers the Falcon4 camera models summarized below. New models are added to this

manual as they are released by Teledyne DALSA.

Table 1: Camera Models Overview

Table 2: Camera Accessories

Table 3: Software

Camera Performance Specifications

Table 4: Camera Performance Specifications

Falcon4 86M Cameras Contents 5

Mono Operating Ranges

Units

Value

Notes

Noise and Non-Uniformity Performance

Full Well

e-

> 22, 000, global shutter

> 27, 000, rolling shutter

Dynamic Range

dB

53, global shutter

62, rolling shutter

Random Noise

DN rms

7.0, global shutter

3.2, rolling shutter

Maximum, FFC enabled

FPN (w/o correction), global

DN rms

48

PRNU (w/o correction), global

% rms

2.8

% measured signal level,

nominally 50% output.

FPN removed

Nominal Output Characteristics

Broad Band Responsivity

DN / (nJ / cm²)

137, global shutter mono

117, rolling shutter mono

64, global shutter color

73, rolling shutter color

FFC enabled

SEE

nJ / cm²

30, global shutter mono

35, rolling shutter mono

64, global shutter color

56, rolling shutter color

FFC enabled

NEE

pJ/cm²

64, global shutter mono

30, rolling shutter mono

133, global shutter color

44, rolling shutter color

FFC enabled

Antiblooming

> 600 x saturation

Integral non-linearity

% 3 From 10-90% of camera

saturation

*DN = digital number (12 bit)

Notes:

1) Mono Light source: broadband, quartz halogen, 3250 K with 700 nm IR cut-off filter.

2) Color Light source: broadband, quartz halogen, 3250K with BG38 filter.

3) Responsivity with FFC enabled

4) Mono camera PRNU w/o correction is measured at 50% output with FPN removed.

5) Integral non linearity = Deviation from best fit line 10 to 90%/4096

6 Contents Falcon4 86M Cameras

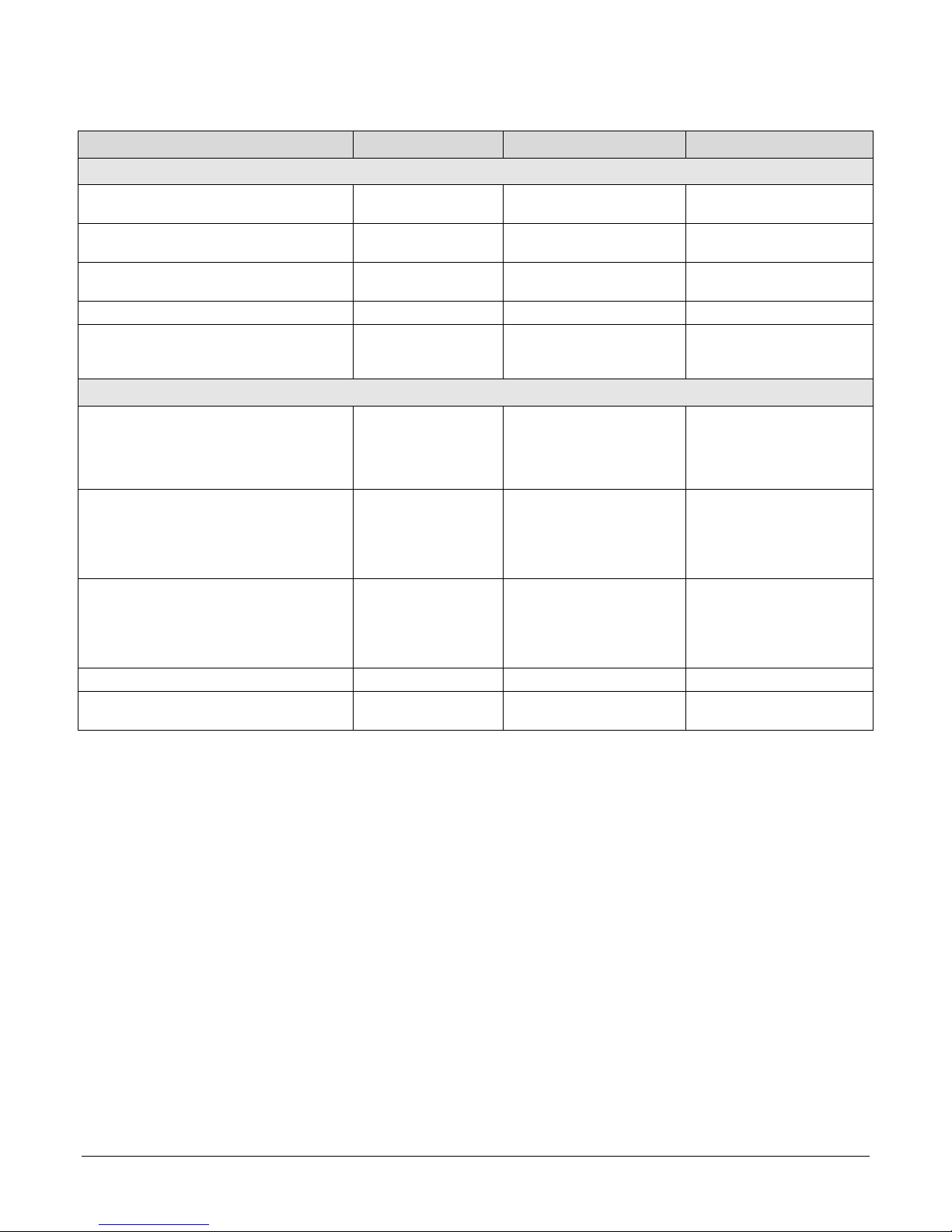

Specifications

Ranges

Storage temperature range

-20 °C to +80 °C

Humidity (storage and operation)

15% to 85% relative, non-condensing

MTBF (mean time between failures)

>100,000 hours, typical field operation

Description

Definition

# of Defects

Column defect

A group of more than 20 contiguous pixels along a single column that deviate from the

neighboring columns by:

More than ±15% at 50% saturation with Flat-field correction ON and 1x gain.

More than 20% of saturation in dark and 1x gain.

6

Row defect

A group of more than 20 contiguous pixels along a single row that deviate from the

neighboring columns by:

More than ±15% at 50% saturation with Flat-field correction ON and 1x gain.

More than 20% of saturation in dark and 1x gain.

6

Cluster defect

A grouping of 2 to 16 inclusive defective pixels at a given test condition. A defective

pixel is defined as 20% of saturation output when sensor is dark and ± 15% away from

the average of the neighboring pixels of the same color measured at 20% to 80% of

maximum output in steps of 10%.

The maximum cluster defect size is 16.

34

Uncorrectable

single defective

pixel

At dark: Pixel level is elevated beyond 20% of saturation.

At 50% saturation: Pixel level is ±15% away from its neighboring pixels with FFC on.

15,000

Environmental Specifications

Table 5: Environmental Specifications

Sensor Cosmetic Specifications

The following table lists the current cosmetic specifications for the Teledyne DALSA sensor used in

the cameras.

Table 6: Blemish Specifications

1. Cluster defects are separated by no less than one good pixel in any direction.

2. Column and row defects are separated by no less than two good columns and rows respectively.

Falcon4 86M Cameras Contents 7

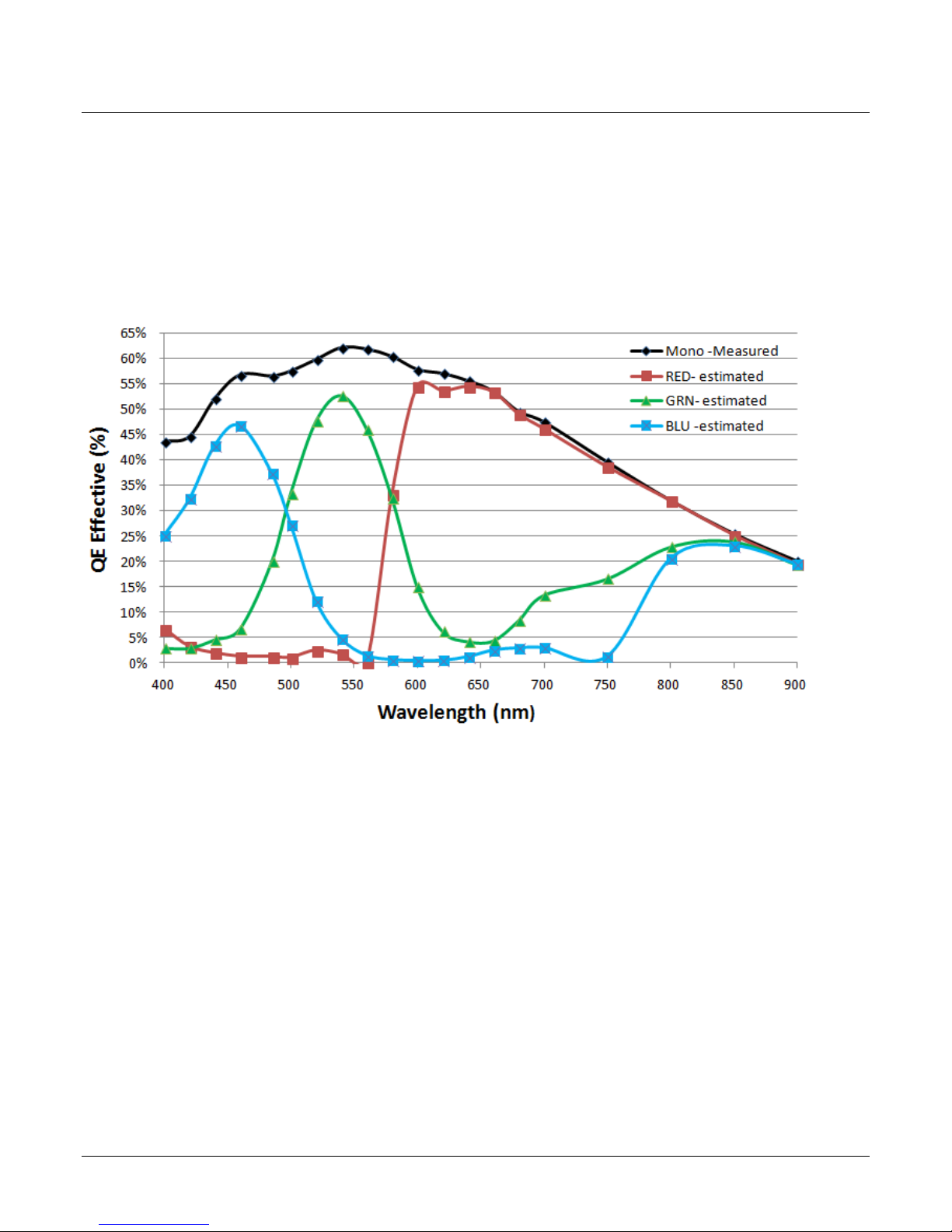

Responsivity & QE

The responsivity graph describes the camera‘s response to different wavelengths of light (excluding

lens and light source characteristics).

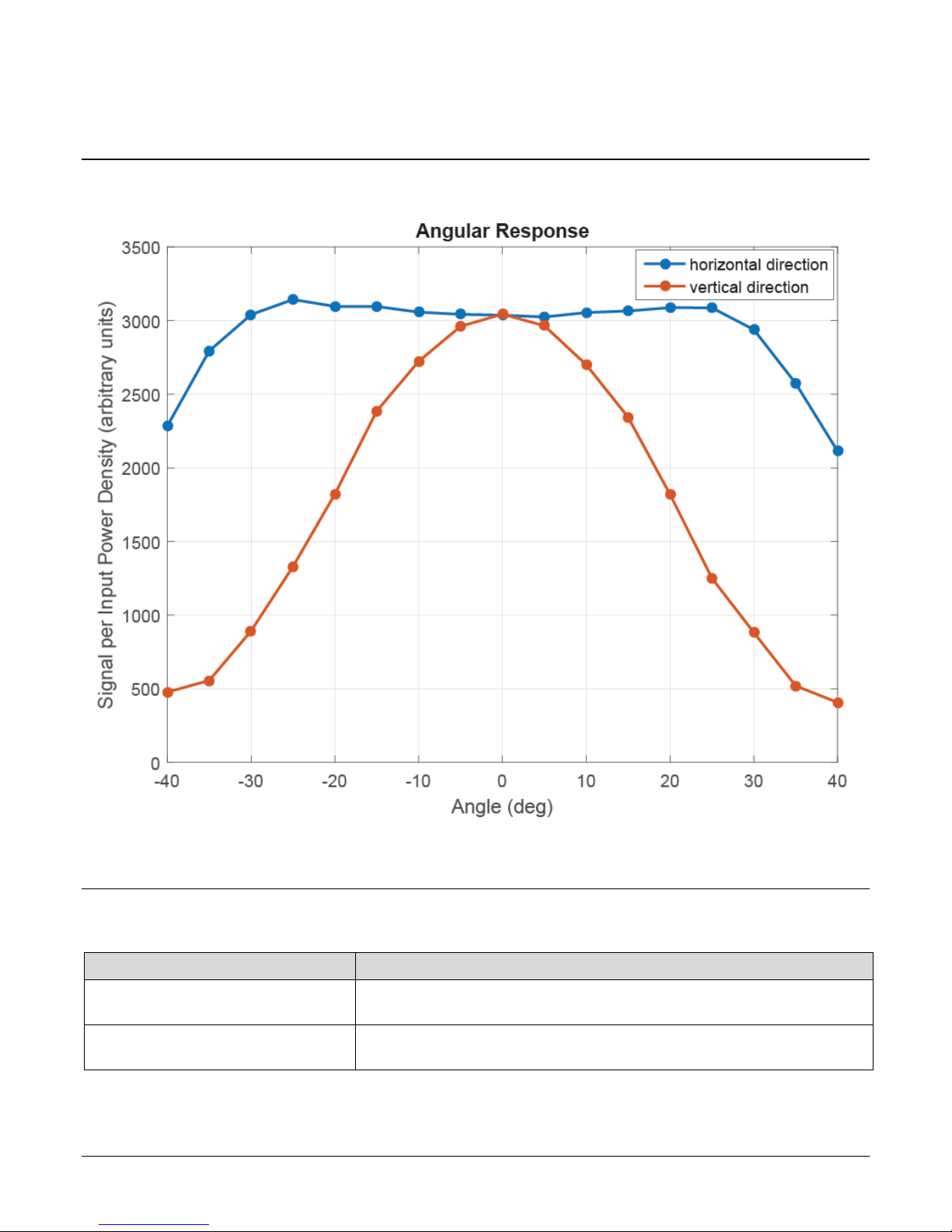

The image sensor includes micro lenses to improve the collection efficiency of the active pixel area.

The drawback to this is that the light collected varies with the angle of incidence, as shown in the

Angle of Incidence figure, below. Pixel Response Non Uniformity (PRNU) can be calibrated in the

field and takes into account the lighting and lens effects, and results in a more uniform output

level.

Figure 1: Camera Spectral Responsivity

8 Contents Falcon4 86M Cameras

Camera

Flash Memory Size

FA-S0-86M16-01-R

500 MByte program storage

8,000 MByte correction coefficients

FA-S1-86M16-00-R

500 MByte program storage

8,000 MByte correction coefficients

Angle of Incidence

Flash Memory Size

Falcon4 86M Cameras Contents 9

Figure 2: Angular Response

Table 7: Memory

Compliance

EN 55011, CISPR 11, EN 55022, EN 55032, CISPR 22, CISPR 32, FCC Part 15, and ICES-003 Class A Emissions

Requirements.

EN 55024, and EN 61326-1 Immunity to Disturbance.

Certifications & Compliance

Table 8: Radiated Emissions

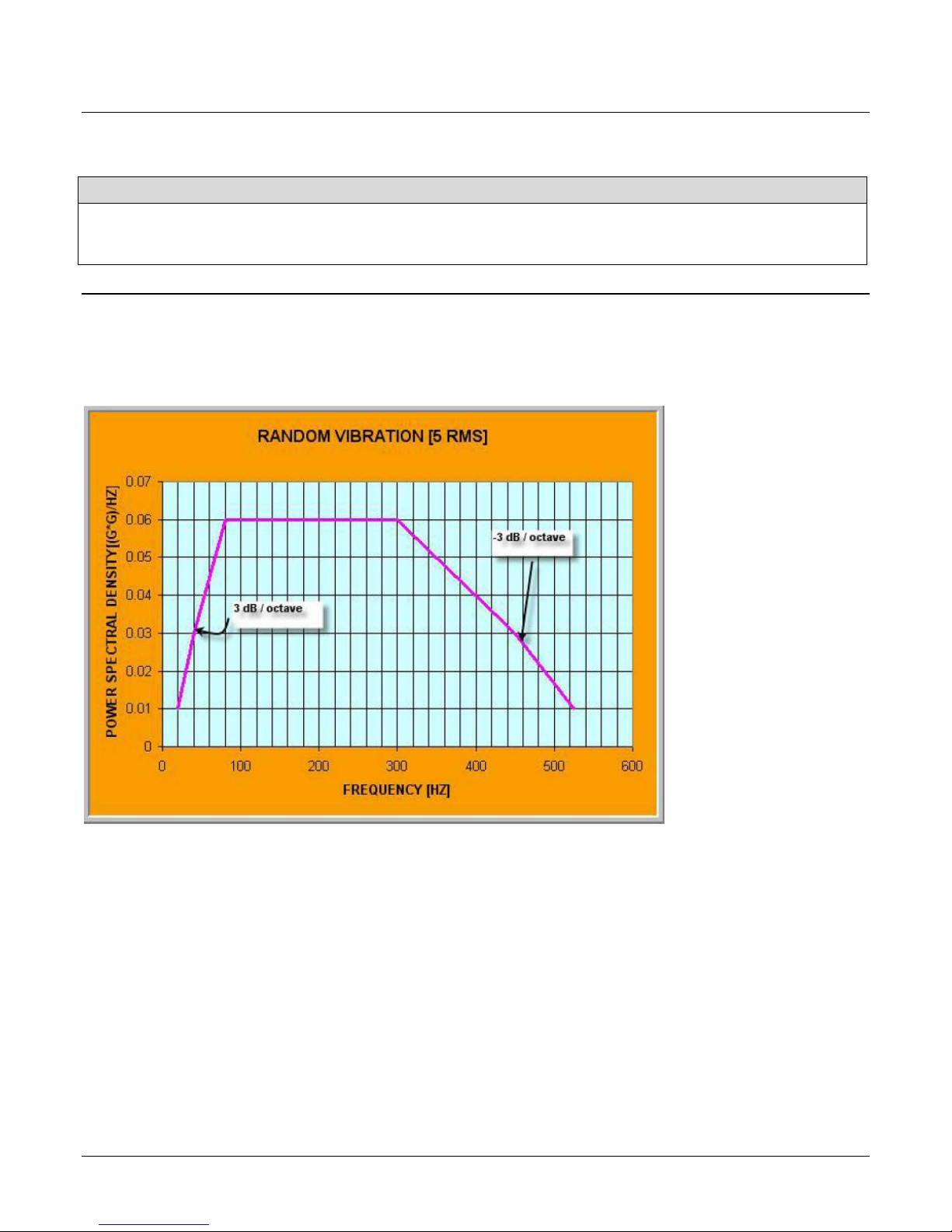

Shock & Vibration

The cameras meet or exceed the following specifications:

Random vibration per MIL-STD-810F at 25 G

Shock testing 75 G peak acceleration per MIL-STD-810F

2

/HZ [Power Spectral Density] or 5 RMS

10 Contents Falcon4 86M Cameras

RXC

TXC

TX1

TX2

TX3

TX4

TX5

TX6

TXC

RXC

RX1

RX2

RX3

RX4

RX5

RX6

Data Lane 6

Data Lane 0

Command

Channel

Video

Channel

Link

Camera

(C2,7M1)

Frame Grabber

(C2,7M1)

Supported Industry Standards

GenICam™

The camera is GenICam compliant and implements a superset of the GenICam Standard Features

Naming Convention specification V1.5.

This description takes the form of an XML device description file using the syntax defined by the

GenApi module of the GenICam specification. The camera uses the GenICam Generic Control

Protocol (GenCP V1.0) to communicate over the Camera Link HS command lane.

For more information see www.genicam.org.

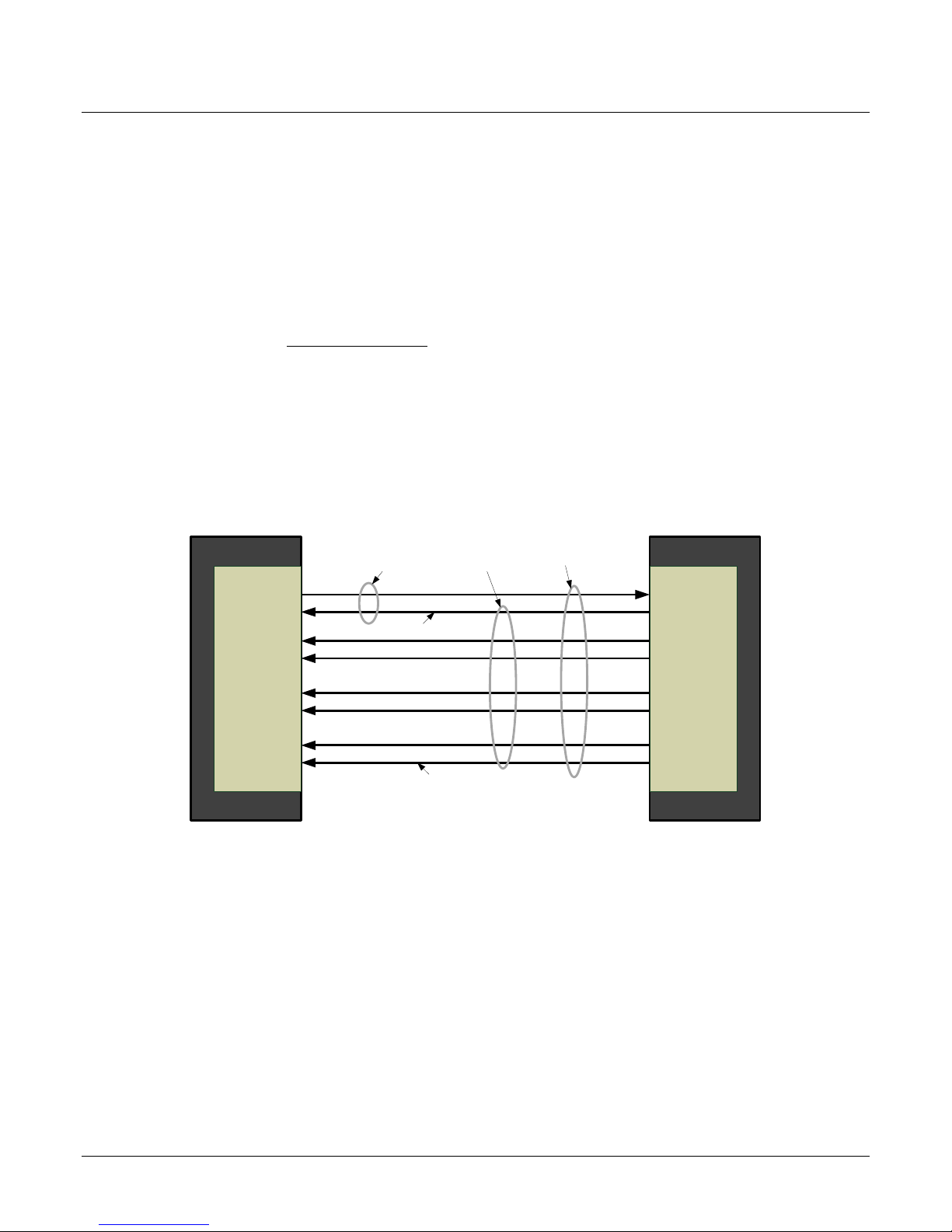

Camera Link HS

The camera is Camera Link HS version 1.0 compliant. Camera Link HS is the next generation of

high performance communications standards and is used where a digital industrial camera

interfaces with single or multiple frame grabbers with data rates exceeding those supported by

Camera Link. The camera includes a Camera Link HS connector capable of supporting data rates up

to 2.1 Gbytes / sec per second.

Figure 3. Single CLHS Connector Configuration

The command channel is used by the frame grabber to send command, configuration, and

programming data to the camera and to receive command responses, status, and image data from

the camera.

The designation C2, 7M1 defines the use of a SFF-8470 connector (C2) and up to 7 lanes of data

with 1 command channel using M-Protocol (8b/10b) at the default speed of 3.125 Gb/sec.

Camera Link HS ROI Characteristics

The single ROI is customer entered and transmitted across all seven data lanes. There is a

minimum of 96 pixels per data lane used.

Falcon4 86M Cameras Contents 11

CLHS limits the start and stop location of the ROI to a multiples of 32 pixels. The maximum line

rate is limited by the sensor when not limited by the CLHS cable or by the PCIe transfer. The sensor

is limited to a 125 kHz maximum line rate.

The CLHS cable has approximately 2.1 GByte / sec bandwidth for seven lanes. The XTIUM X8 frame

grabber has about 3.2 GByte / sec across the PCIe bus and can support the full frame rate of the

camera.

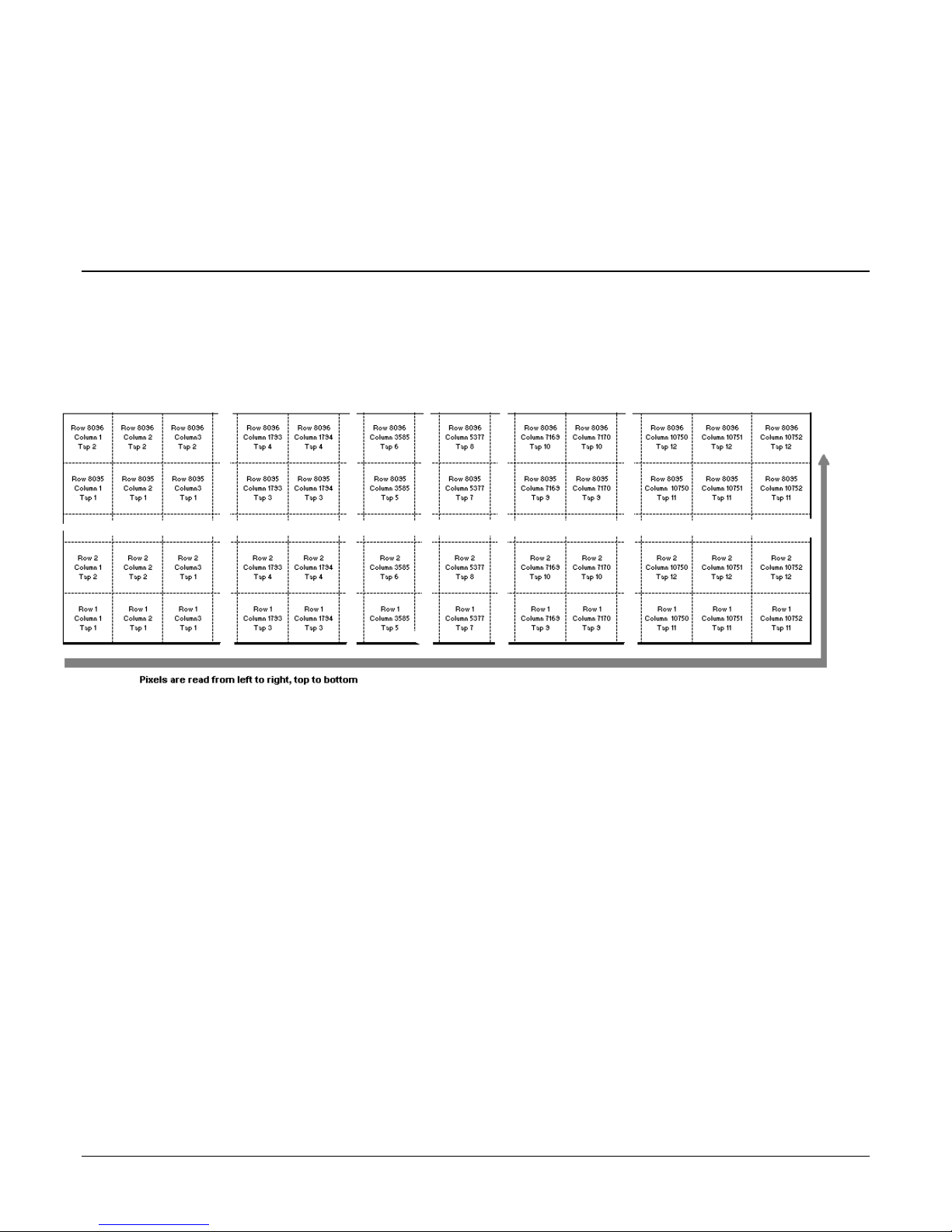

Sensor Block Diagram & Pixel Readout

Pixels are read from left to right, top to bottom. The data for each line is transferred from the

sensor to 7 CLHS data lanes. CLHS is a packet-based protocol therefore the concept of taps or tap

geometry does not apply; the frame grabber reconstructs the images based on the information

contained in the packet, regardless of which data lane is used for the transfer.

Figure 4: Pixel Readout of the Falcon 4 camera.

Note:

As viewed looking at the front of the camera without a lens. (The Teledyne DALSA logo on

the side of the case will be right-side up.)

12 Contents Falcon4 86M Cameras

Do not open the housing of the camera. The warranty is voided if the housing is

opened.

Camera Setup

System Precautions & Cleaning

Precautions

Read these precautions and this manual before using the camera.

Confirm that the camera‘s packaging is undamaged before opening it. If the packaging is

damaged please contact the related logistics personnel.

Keep the camera‘s front plate temperature in a range of 0 °C to 50 °C during operation. The

camera has the ability to measure its internal temperature. Use this feature to record the

internal temperature of the camera when it is mounted in your system and operating under

the worst case conditions. The camera will stop outputting data if its internal temperature

reaches 70 °C. Refer to section Verify Temperature for more information on the

‗Temperature‘ feature and thermal management.

Do not operate the camera in the vicinity of strong electromagnetic fields. In addition, avoid

electrostatic charging, violent vibration, and excess moisture.

Though this camera supports hot plugging, it is recommended that you power down and

disconnect power to the camera before you add or replace system components.

Cleaning the Device

To clean the device, avoid electrostatic charging by using a dry, clean absorbent cotton cloth

dampened with a small quantity of pure alcohol. Do not use methylated alcohol.

To clean the surface of the camera housing, use a soft, dry cloth. To remove severe stains use a

soft cloth dampened with a small quantity of neutral detergent and then wipe dry. Do not use

volatile solvents such as benzene and thinners, as they can damage the surface finish.

Electrostatic Discharge and the CMOS Sensor

Image sensors and the camera bodies housing are susceptible to damage from electrostatic

discharge (ESD). Electrostatic charge introduced to the sensor window surface can induce charge

buildup on the underside of the window. If this occurs, the charge normally dissipates within 24

hours and the sensor returns to normal operation.

Falcon4 86M Cameras Contents 13

Note: the use of cables types and lengths other than those specified may result in

increased emission or decreased immunity and performance of the camera.

Software and Hardware Setup

Recommended System Requirements

To achieve best system performance, the following minimum requirements are recommended:

High bandwidth frame grabber. For example, Teledyne DALSA Xtium PX8 CLHS series frame

grabber: http://www.teledynedalsa.com/imaging/products/fg/#digital-cameralink.

Operating systems: Refer to frame grabber documentation for supported platforms.

Setup Steps: Overview

Take the following steps in order to setup and run your camera system. They are described briefly

below and in more detail in the sections that follow.

1. Install and Configure Frame Grabber and Software.

2. Connect Camera Link and Power Cables.

3. Establish communication with the camera.

Step 1: Install and Configure Frame Grabber and Software

Teledyne DALSA recommends its Xtium PX8 CLHS series frame grabber or equivalent. Follow the

manufacturer‘s installation instructions.

A GenICam™ compliant XML device description file is embedded within the camera firmware

allowing GenICam™ compliant application to know the camera‘s capabilities immediately after

connection.

Installing Sapera LT gives you access to the CamExpert GUI, a GenICam™ compliant application.

Sapera LT is available free of charge for download from the Teledyne Dalsa website.

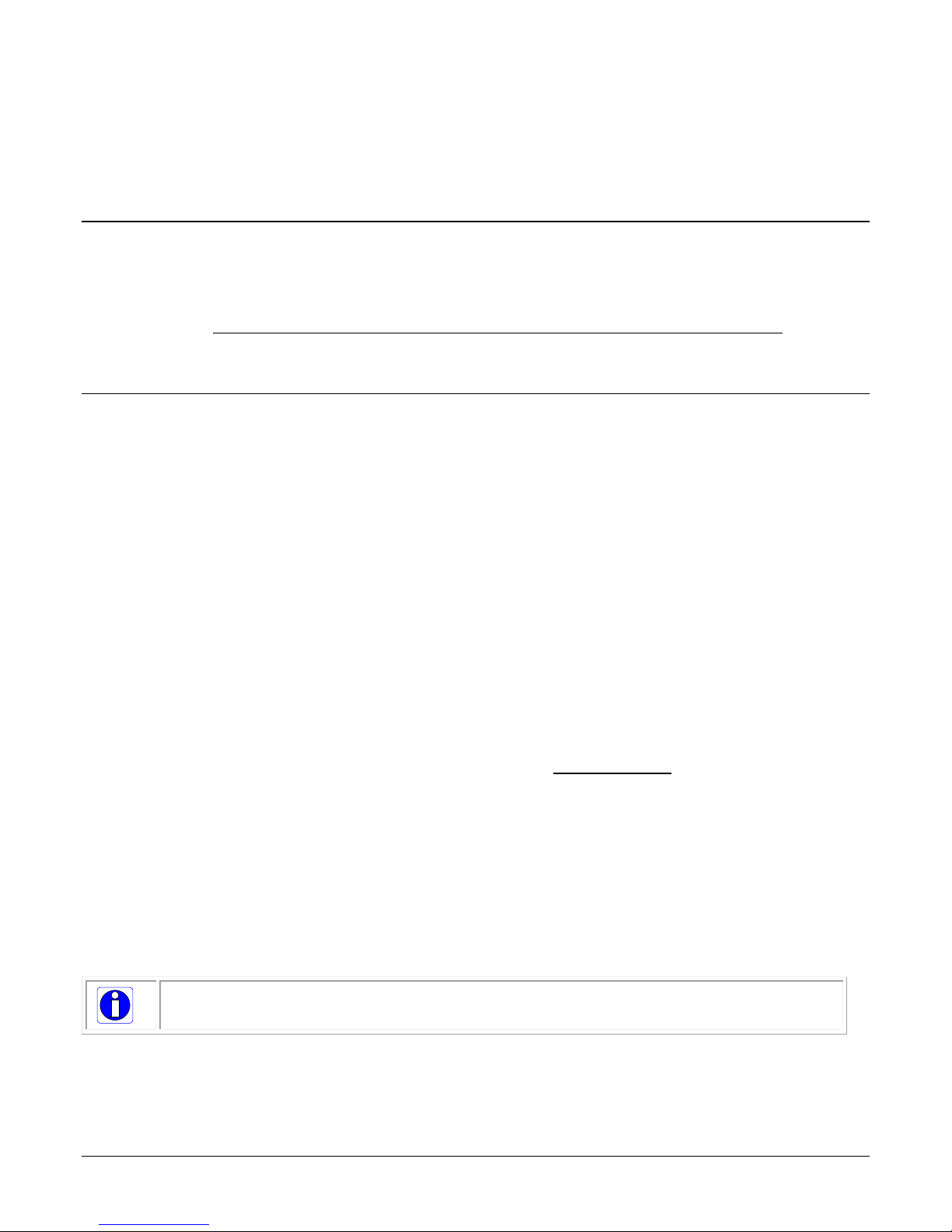

Step 2: Connect Camera Link and Power Cables

The camera uses a Camera Link HS SFF-8470 (CX4) cable and a Hirose connector for power and IO

connections.

Connect the required Camera Link HS cable from the camera to the frame grabber installed

on the computer.

Connect a power cable from the camera to a power supply that can provide a constant

voltage from +12 V to +24 V DC.

14 Contents Falcon4 86M Cameras

WARNING! Grounding Instructions

Static electricity can damage electronic components. It‘s critical that you discharge

any static electrical charge by touching a grounded surface, such as the metal

computer chassis, before performing handling the camera hardware.

WARNING: It is extremely important that you apply the appropriate voltages to

your camera. Incorrect voltages may damage the camera. Input voltage

requirement: +12 V to +24 V DC (± 5 %), 3.5 Amps. Before connecting power to

the camera, test all power supplies.

Figure 5: Input and Output, trigger, and Power Connectors

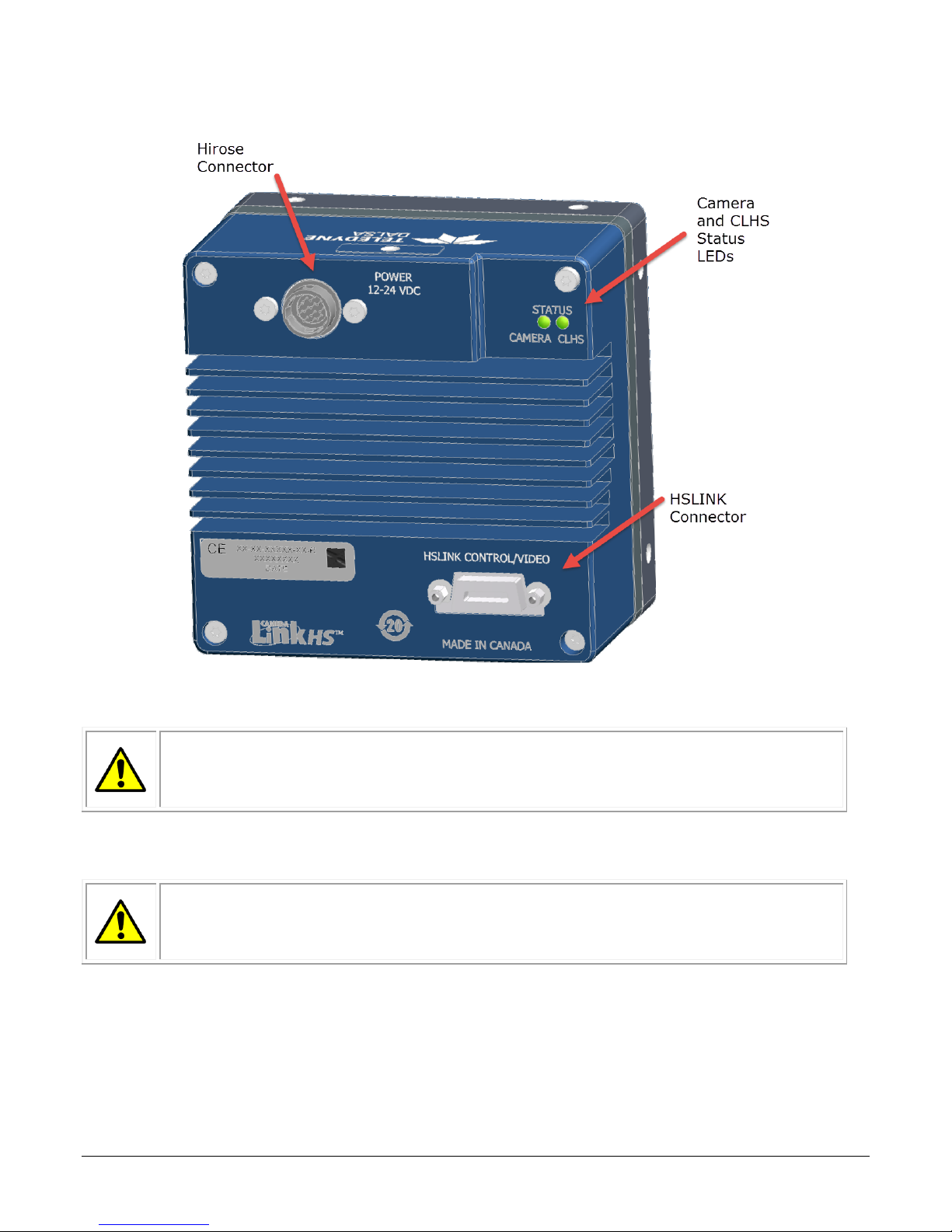

Power Connector

Falcon4 86M Cameras Contents 15

Pin

Description

Pin

Description

1

GND

7

OUT2+

2

+12 V to +24 V DC

8

OUT2-

3

OUT1-

9

NC 4 OUT1+

10

NC 5 IN1-/Trigger

11

IN2+/Trigger

6

IN1+/Trigger

12

IN2-/Trigger

WARNING: When setting up the camera‘s power supplies follow these guidelines:

Apply the appropriate voltages.

Protect the camera with a 3.5 amp slow-blow fuse between the power supply

and the camera.

Do not use the shield on a multi-conductor cable for ground.

Keep leads as short as possible in order to reduce voltage drop.

Use high-quality linear supplies in order to minimize noise.

Note: If your power supply does not meet these requirements, then the camera

performance specifications are not guaranteed.

1 2 3 4 6 7 8

9

10

11

12

Figure 6: 12-pin Hirose Circular Male Power Plug—Power Connector

Table 9. Power Plug Pinout

Camera Link Data Connector

The camera uses a Camera Link HS SFF-8470 (CX4) cable.

Input Signals, Camera Link

The camera accepts control inputs through the Camera Link HS SFF-8470(CX4) connector.

The camera ships (factory setting) in internal sync, and internally triggered integration.

Frame Start Trigger (EXSYNC)

The EXSYNC signal tells the camera when to integrate and readout the image. It can be either an

internally generated signal by the camera, or it can be supplied externally by a CLHS Pulse

Message software command or camera GPIO pin.

16 Contents Falcon4 86M Cameras

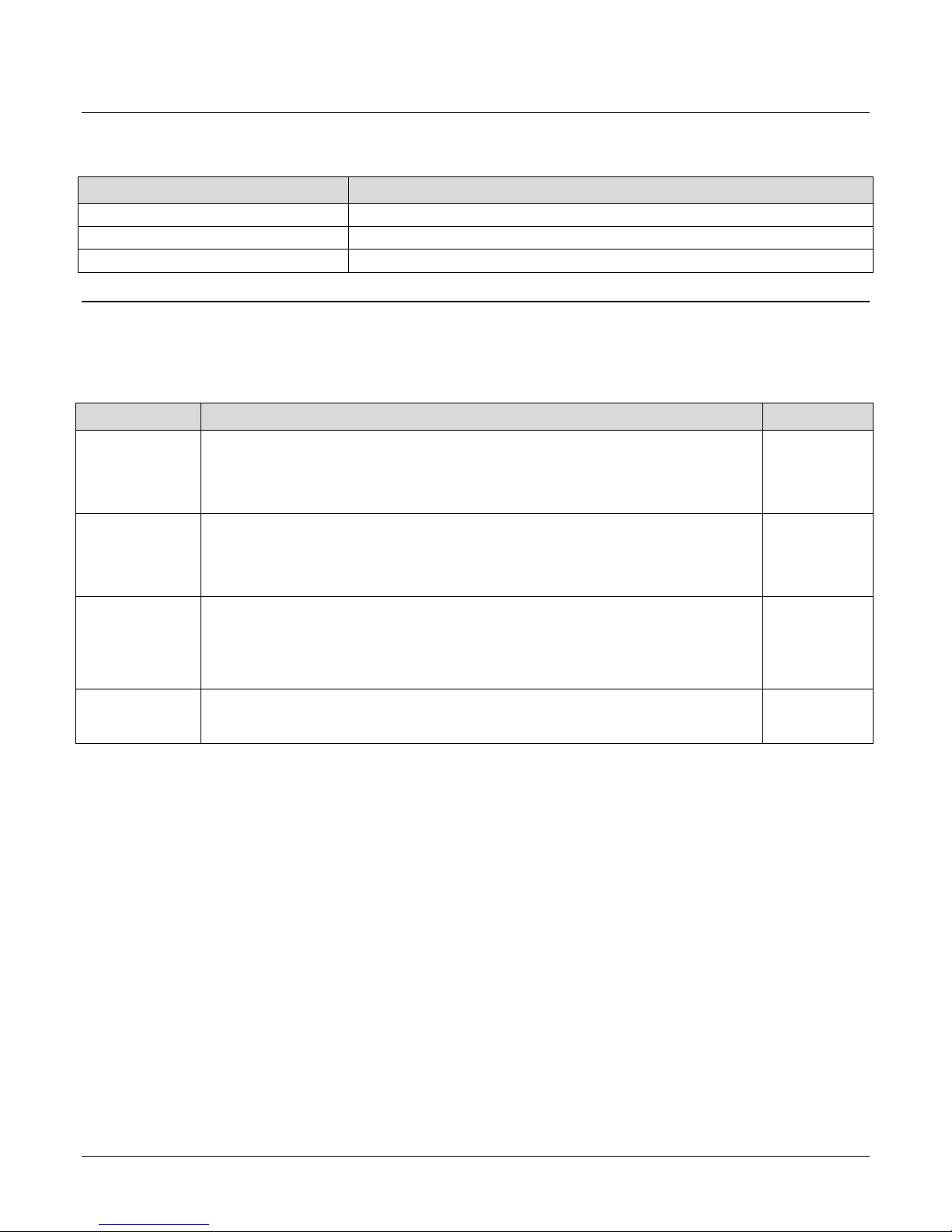

Color of Camera Status LED

Meaning

Off

No power or hardware malfunction

Red slow blinking

Camera in temporary shutdown (e.g. temperature). The communication channel is

maintained but imaging is disabled

Red solid

Fatal error state. Device is not functional

Blue fast blinking

Firmware upgrade, file transfer

Blue slow blinking

Camera waiting for warm up to complete (Camera initialization)

Blue solid

Upgrading internal firmware, when acquisition is disabled. This happens when changing a

camera feature that effects the image output (e.g. AOI, bit depth, etc.)

Green solid

Free-running acquisition

Green slow blinking

Calibration in progress

Orange slow blinking

Camera initializing

Color of CLHS Status LED

Meaning

Off

No power or hardware malfunction

Orange solid

The frame grabber is holding this device in reset preventing any communication

Orange slow blinking

The devices have established communication and determined that they are not

interoperable, and camera is initializing

Red solid

Fatal error state. Device is not functional.

Red slow blinking

Camera in temporary shutdown (e.g. temperature). The communication channel is

maintained but imaging is disabled

Red fast blinking

Camera has CLHS link error.

Green solid

Link established and data transfer may take place.

Green fast blinking

Camera is losing trigger

Green slow blinking

Looking for Link

Status

LED

CLHS

Status

LED

Initial power up

Camera initializing

(slow blinking)

Link established

Camera waiting for trigger

(fast blinking)

Initial power up

Camera initializing

(slow blinking)

Camera in free-running mode

Waiting for command

LED Indicators

The camera is equipped with 2 LEDs on the back to display the operational status of the camera.

The tables below summarize the operating states of the camera and the corresponding LED states.

When more than one condition is active, the LED indicates the condition with the highest priority.

LED States on Power Up

The following LED sequence occurs when the Falcon 4 is powered up connected to a CLHS frame

grabber.

Falcon4 86M Cameras Contents 17

Step 3: Establish Communication between the frame grabber and the

camera

To establish communication with the camera following these steps in order:

1. Power on the camera.

2. Connect to the frame grabber.

3. Connect to the camera.

1. Power on the camera

Turn on the camera‘s power supply. You may have to wait up to 60 seconds for the camera

to warm up and prepare itself for operation.

The camera must boot fully before it will be recognized by the GenCP compliant application.

In this ready-state, the CLHS LED will be green and the Camera LED will be green or blue (if

using a Teledyne DALSA frame grabber). You are now ready to connect the frame grabber,

step 2.

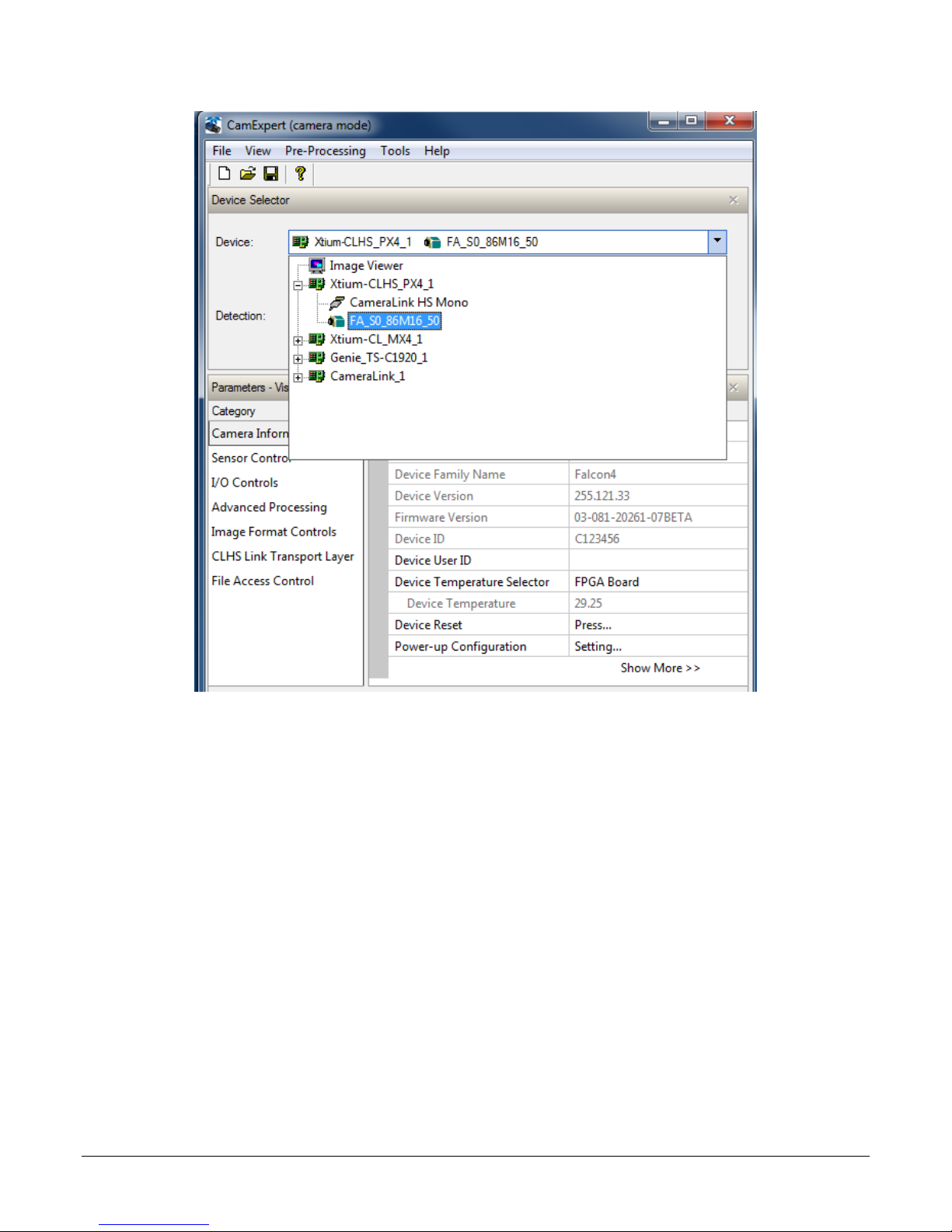

2. Connect to the frame grabber

Start Sapera CamExpert (or an equivalent GenCP-compliant interface) by double-clicking

the desktop icon created during the software installation.

CamExpert will search for Sapera devices installed on your system. In the Devices list area

on the left side of the GUI, the connected frame grabber will be shown. (See image below.)

Select the frame grabber device by clicking on its name.

Note: The first time you set up the camera you will need to establish a communication link between

the camera and frame grabber. Instructions are available in Appendix B: Camera, Frame Grabber

Communication.

3. Connect to the camera

Start a new Sapera CamExpert application (or equivalent Camera Link compliant interface)

by double-clicking the desktop icon created during the software installation.

Important: you need to have two interface windows open: one connected to and controlling

the frame grabber, and one connected to and controlling the camera. (See image below.)

CamExpert will search for Sapera devices installed on your system. In the Devices list area

on the left side of the GUI, the connected Falcon4 camera will be shown.

Select the Falcon4 camera device by clicking on the camera‘s user-defined name. By default

the camera is identified by its serial number.

18 Contents Falcon4 86M Cameras

Figure 7: Frame grabber and connected camera shown

Check LED Status

At this point, if the camera is operating correctly the LEDs will flash yellow for approximately 10

seconds and then turn solid green if acquisition is on, or camera LED stays blue, CLHS LED blinks

green to wait for trigger

Software Interface

All the camera features can be controlled through the GUI. For example, under the Sensor Control

menu in the camera window you can control the frame rate and exposure times.

Note: the camera uses two instances of CamExpert. One window controls the camera and one

displays the output received from the frame grabber.

Also Note: If CamExpert is running during a camera reset operation, then you will have to reload

the GUI window used to control the camera once the camera is powered up again. Do this by

either: 1) closing and reopening the CamExpert window, or 2) by going to ―Image Viewer‖ in the

―Device‖ tab and selecting the camera again.

Falcon4 86M Cameras Contents 19

Figure 8: Two CamExpert windows shown: one connected to the frame grabber and one connected to the

camera

At this point you are ready to start operating the camera in order to acquire images, set camera

functions, and save settings.

20 Contents Falcon4 86M Cameras

Note: The examples shown may not entirely reflect the features and parameters available from

the camera model and camera mode used in your application.

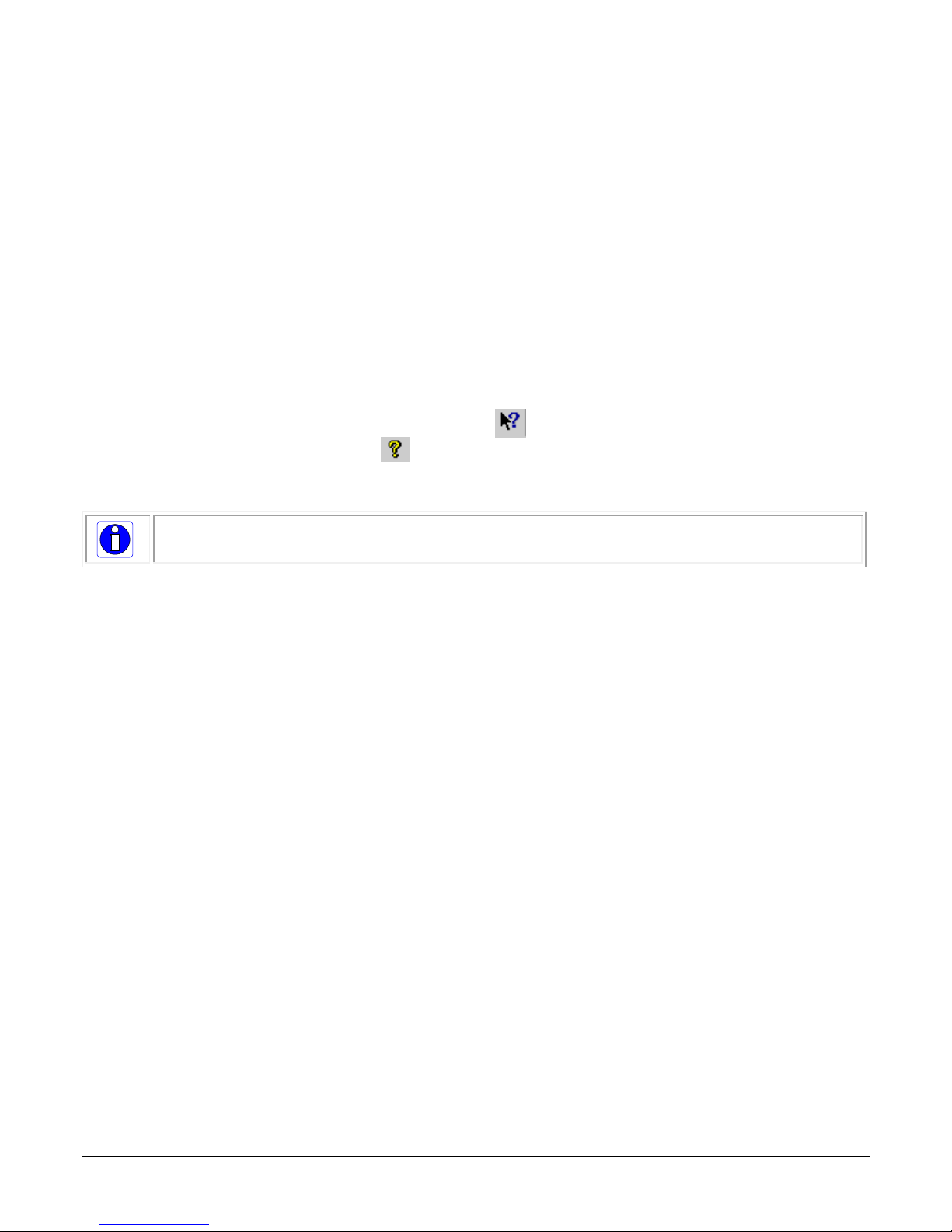

Using CamExpert

The Sapera CamExpert tool is the interfacing tool for GenCP compliant Camera Link cameras, and is

supported by the Sapera library and hardware. When used with a CLHS camera, CamExpert allows

a user to test most of the operating modes. Additionally, CamExpert is able to save and reload the

FG configuration to simplify repeated power-up system configuration. Similarly, the camera is able

to store the selected camera configuration in a user set which can be recalled each time the camera

is repowered.

An important component of CamExpert is its live acquisition display window which allows

immediate verification of timing or control parameters without the need to run a separate

acquisition program.

Click on any parameter and a short description is displayed below the Category pane. The same

context sensitive help is available by clicking on the button then click on a camera

configuration parameter. Click on the button to open the help file for more descriptive

information on CamExpert.

CamExpert Panes

The various areas of the CamExpert tool are described in the figure below. Device Categories and

Parameter features are displayed as per the device‘s XML description file. The number of

parameters shown is dependent on the View mode selected (Beginner, Expert, Guru – see

description below).

Falcon4 86M Cameras Contents 21

Device Selector pane: View and select from any installed Sapera acquisition device. After a

device is selected, CamExpert will only present parameters applicable to that device. Optionally

select a camera file included with the Sapera installation or saved by the user.

Parameters pane: Allows viewing or changing all acquisition parameters supported by the

acquisition device. CamExpert displays parameters only if those parameters are supported by

the installed device. This avoids confusion by eliminating parameter choices when they do not

apply to the hardware in use.

Display pane: Provides a live or single frame acquisition display. Frame buffer parameters are

shown in an information bar above the image window.

Control Buttons: The Display pane includes CamExpert control buttons. These are:

22 Contents Falcon4 86M Cameras

Acquisition control button:

Click once to start live grab, click again to stop.

Single frame grab:

Click to acquire one frame from device.

Software trigger button:

With the I/O control parameters set to Trigger Enabled / Software Trigger

type, click to send a single software trigger command.

CamExpert display controls:

(these do not modify the frame buffer data)

Stretch (or shrink) image to fit, set image display to original size, or zoom

the image to any size and ratio. This does not affect the acquisition.

Histogram / Profile tool:

Select to view a histogram or line/column profile during live acquisition.

Output pane: Displays messages from CamExpert.

CamExpert View Parameters Option

All camera features have a Visibility attribute which defines its requirement or complexity. The

states vary from Beginner (features required for basic operation of the device) to Guru (optional

features required only for complex operations).

CamExpert presents camera features based on their visibility attribute. CamExpert provides quick

Visibility level selection via controls below each Category Parameter list [ << Less More >> ]. The

user can also choose the Visibility level from the View ∙ Parameters Options menu.

Creating a Camera Configuration File in the Host

When using the Teledyne DALSA Sapera SDK – the CCF is created automatically via a save.

When using a 3

automatic. Simply follow the 3rd party Save Camera method as instructed.

If the SDK is based on GenAPI 2.3 or lower, the user must call the command

DeviceFeaturePersistenceStart before using the SDK Save Camera method and the command

DeviceFeaturePersistenceEnd at the end of the save function.

rd

party SDK application, if that SDK supports GenAPI 2.4, then the process is

Falcon4 86M Cameras Contents 23

Camera Operation

Factory Settings

The camera ships and powers up for the first time with the following factory settings:

Flat field coefficients enabled (calibrated in internal exposure mode, non-concurrent readout

and integration).

Defect concealment enabled.

Internal exposure mode (internal frame rate and exposure time).

12 Hz frame rate and 10 msec exposure time.

Dark row subtract enabled with the nominal background add value set

Check Camera and Sensor Information

Camera and sensor information can be retrieved via a controlling application—for example, the

CamExpert GUI shown in the following examples. Parameters such as camera model, firmware

version, sensor characteristics, and so forth, are read to uniquely identify the connected device.

The parameters used to select, load and save user sets are grouped together under the Camera

Information category.

Verify Temperature

To determine the temperature at the camera, use the Refresh Temperature feature. The Device

Temperature selector allows you to select which temperature sensor to read (FPGA, sensor board or

sensor). The temperature returned is the internal temperature in degrees Celsius. For proper

operation this value should not exceed 70 °C. If the camera exceeds the designated temperature it

will stop imaging and the LED will turn red. After you have diagnosed and remedied the issue use

the Device Reset function.

24 Contents Falcon4 86M Cameras

Warning! Depending on the mounting design and the operating conditions the

camera body could become hot. You must take precautions to ensure your

safety and avoid touching the camera directly during operation.

!

Thermal Management

The camera is designed to work with a maximum case temperature of 50 ºC. If the camera is left

powered on a bench, without lens, heat sinking, or forced air movement, the camera will become

very hot to the touch and will reduce its power dissipation by disabling the imaging function.

If this occurs, the LED turns red and communication with the camera is still available.

An accessory is available (part number AC-MS-00117-00-R, shown below) that mounts a fan to the

camera case to force air flow over the camera‘s heat sink. This accessory can be ordered from

Teledyne DALSA.

The fan‘s electrical connection is via 2 pigtail wires. The red wire is hooked to a +14 V to +24 V

supply @ 150 mA max, 100 mA typ. The black wire is the power return. With a +24 V supply, the

temperature on the sensor board will be about 25 degrees above ambient, as measured by the

sensor board temperature sensor. A +14 V supply results in an approximately +30 ºC temperature

rise above ambient.

Handling

Falcon4 86M Cameras Contents 25

Saving and Restoring Camera Settings

The Power-up Configuration parameter opens a dialog allowing you to specify the camera

configuration to use on power up and to save current parameter settings.

When the user changes a camera parameter, the settings are stored in the camera‘s volatile

memory and will be lost if the camera resets or is powered down. To save these settings for reuse,

they must be saved to the camera‘s non-volatile memory using the User Set Save parameter.

Previously saved user setting (User Set 1 to 3) or the factory settings can be restored using the

User Set Selector and User Set Load parameters.

Either the Factory or one of the User settings can be specified as the Default Set by selecting it in

the User Set Default Selector. The chosen set is automatically loaded when the camera is reset or

powered up. It should also be noted that the value of Default Selector will automatically get save in

non-volatile memory whenever it is changed.

26 Contents Falcon4 86M Cameras

The relationship between these three settings is illustrated here:

Figure 9: Relationship between the Camera Settings

NOTE: If a test pattern is active when you save the User Set, the camera will turn off all digital

processing upon restart. For example:

Set the test image selector to FPN Diagonal Pattern.

Do FPN Calibration and save the coefficient set.

Change the FFC mode to ActiveAll.

Set the default selector to UserSet1.

Save User Set 1.

Power cycle the camera.

Reconnect to the camera through CamExpert.

The FFC mode will be Off when it should be ActiveAll.

Acquisition and Transfer Control Features

Use the commands grouped under the Acquisition and Transfer Control category to choose the

acquisition mode, start and stop acquisitions, and to monitor the acquisition status.

The latest Teledyne DALSA frame grabber driver issues the acquisition start command by default.

Falcon4 86M Cameras Contents 27

Test Pattern

Description

Grey Horizontal Ramp

Image is filled horizontally with an image that goes from the

darkest possible value to the brightest. The ramp repeats every

4096 horizontal pixels.

Grey Vertical Ramp

Image is filled vertically with an image that goes from the

darkest possible value to the brightest. The ramp repeats every

4096 vertical pixels.

Purity

Image is filled with an image that goes from the darkest

possible value to the brightest by 1 DN increment per frame

(12-bit output).

Test Patterns

When setting test patterns, the camera set the digital gains to 1x, the digital offsets to 0, and

deactivates the flat field correction. This ensures that the test patterns appear as they should. At

the same time, the camera saves the last set of values that were used for video processing and

restores them when video output is restored.

Use CamExpert to easily enable and select any test pattern from the drop menu while the camera is

not in acquisition mode. Select live grab to see the pattern output.

The Test Pattern feature is available in the Image Format category:

28 Contents Falcon4 86M Cameras

Gray Diagonal Ramp

This test pattern is the sum of the horizontal and vertical test

patterns.

Static Value

All pixels are set to testImageStaticValue

PRNU

This is the 2 times the sum of a horizontal test pattern that

repeats every 64 pixels and a vertical test pattern that repeats

every 62 lines plus + testImageStaticValue. This test pattern

can be used to test FPN and PRNU correction.

Gain and Black Level Control Details

Gain and black level adjustments are available in the cameras. The analog black level and analog

gain are factory calibrated and not adjustable by the user. It is possible to optimize the image by

adjusting the digital offset controls and gain controls. The color camera features a per color gain

ahead of the system gain block. The user can evaluate gain and black level using CamExpert.

Note: The sensor digitizes at 12 bits and transfers the data across the link as 12 bit. If the data is

stored as 12 bit, then it is possible to optimize the image with post processing.

Falcon4 86M Cameras Contents 29

Description

Frame Rate

Exposure Time

Trigger Source

Internal frame rate and exposure

time

Internal, programmable

Internal programmable

Internal

External frame rate and exposure

time

Controlled by external

pulse

External

External

EXSYNC pulse controlling the frame

rate. Programmed exposure time.

Controlled by external

pulse

Internal programmable

External

Features and Limitations:

Analog Black Level offset is not available to the user.

Analog Gain is not available to the user.

[Digital Before FFC]Global FPN provides a constant component to the FPN Coefficients.

This value is calibrated in the factory but it can be adjusted relative to the factory setting (

factory setting). See the BlackLevel register‘s DigitalAll1 [Digital Before FFC] option. The

value is expressed as a floating point to allow for increased accuracy when processing a

frame sum of more than 1 frame.

[Digital After FFC] Background Subtract is a digital number that is used to reduce the

baseline pixel value. When combined with the system gain, this value is used to increase

contrast in the final output. See the BlackLevel register‘s DigitalAll2 [Digital After FFC]

option. The value is expressed as a floating point to allow for increased accuracy when

processing a frame sum of more than 1 frame.

System (Digital) Gain is expressed as a multiplication factor applied after the Color Gain

(color camera only) and any FFC stages. When combined with the background subtract, this

value is used to increase contrast in the final output.

Background Add is a number added to the image data before it is clipped at zero. This

value can be used to prevent the image clipping to zero. The factory uses the 2nd step FPN

algorithm for color cameras, where a small amount of light equal to (approximately 50 DN)

the least responsive channel is achieved and the FPN coefficient is recalculated. For a color

camera, the more responsive channels have about 130 DN output. The Background Add is

used to add this average level of signal back into the output value so that 0 light nominally

results in 0 output. The 2 step FPN is used to reduce errors in pixel values at low light level

due to nonlinear pixel behavior.

Exposure Controls

Exposure Control modes define the method and timing of how to control the sensor integration

period. The integration period is the amount of time the sensor is exposed to incoming light before

the video frame data is transmitted to the controlling computer.

Exposure control is defined as the start of exposure and exposure duration.

The start of exposure can be an internal timer signal (free-running mode), an external

trigger signal, or a software function call trigger.

The exposure duration can be programmable (such as the case of an internal timer) or

controlled by the external trigger pulse width.

The camera can grab images in one of three ways. The three imaging modes are determined using

a combination of the Exposure Mode parameters (including I/O parameters), Exposure Time and

Frame Rate parameters.

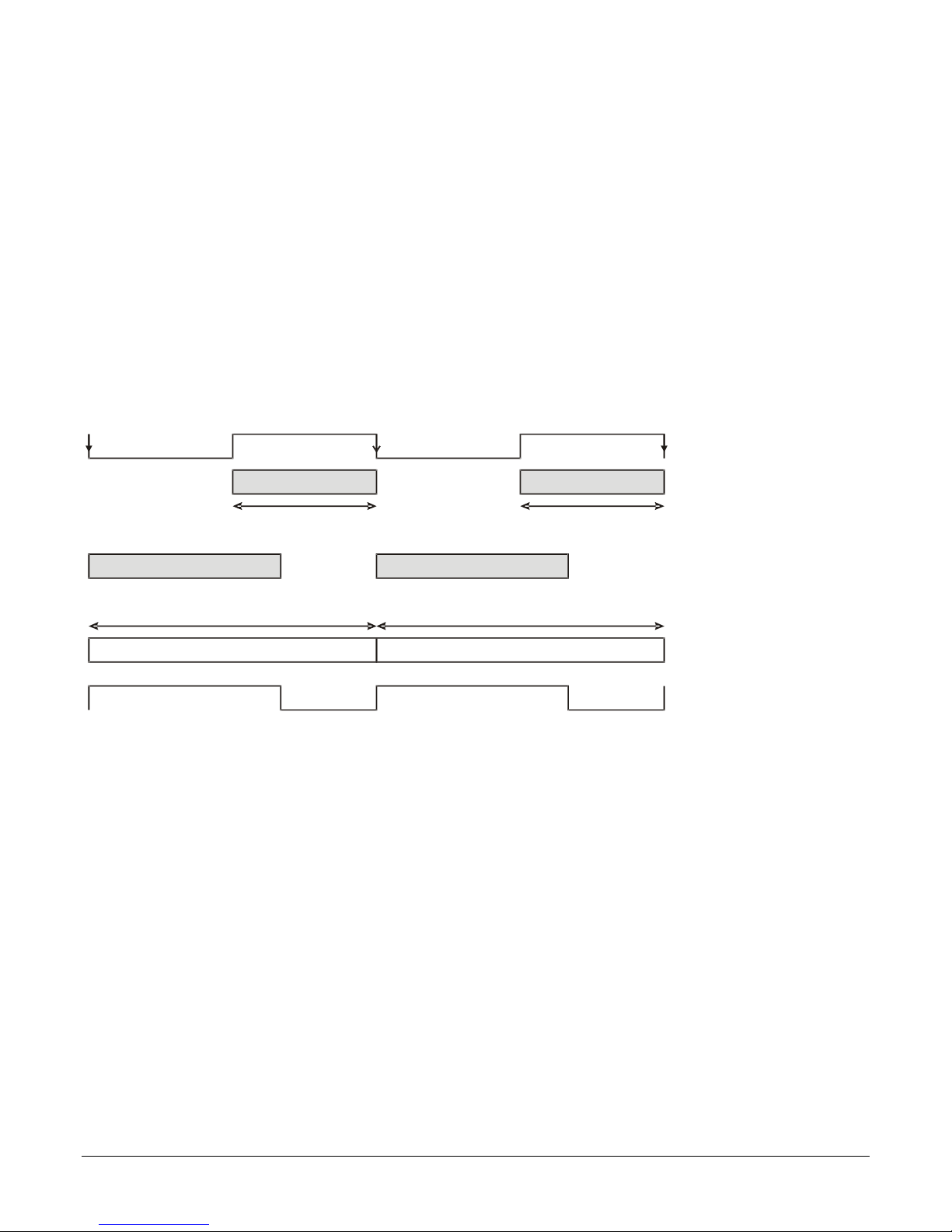

Figure 10: Exposure controls

30 Contents Falcon4 86M Cameras

Frame Time

Frame Time

Readout Time

Readout Time

Exposure Time

Exposure Time

Programmable

Programmable

Internally-generated

Exsync

Programmable

Programmable

FVAL

Internally Programmable Frame Rate and Internally Programmable Exposure

Time (Default)

Frame rate has priority over exposure time when adjusting the frame rate or exposure time. When

setting the frame rate, exposure time will decrease, if necessary, to accommodate the new frame

rate. When adjusting the exposure time the range is limited by the frame rate.

Note: The camera will not set frame periods shorter than the readout period and the frame rate is

limited to 12 Hz when sending 16 bit data and summing a single frame, due to cable bandwidth

limitations.

Camera Features:

TriggerMode = Off

AcquisitionFrameRate = 16 (for example)

ExposureMode = Timed

ExposureTime = 10000 (for example)

Figure 11: Internally Programmable Frame Rate and Internally Programmable Exposure Time (Default)

External Frame Rate and External Exposure Time (Trigger Width)

In this mode, EXSYNC sets both the frame period and the exposure time. The rising edge of

EXSYNC marks the beginning of the exposure and the falling edge initiates readout.

Camera Features:

TriggerMode = On

ExposureMode = Trigger Width

TriggerSource = GPIO Input 1

Falcon4 86M Cameras Contents 31

Frame Time Frame Time

Readout Time Readout Time

Exposure Time Exposure Time

User Exsync

FVAL

Figure 12: External Frame Rate and External Exposure Time (Trigger Width)

32 Contents Falcon4 86M Cameras

Frame Time

Frame Time

Readout Time

Exposure Time

Programmable

User Exsync

FVAL

Exposure Time

Programmable

Internally-generated Exsync

External Frame Rate, Programmable Exposure Time

In this mode, the frame rate is set externally with the falling edge of EXSYNC generating the rising

edge of a programmable exposure time.

Camera Features:

TriggerMode = On

ExposureMode = Timed

ExposureTime = 10000 (for example)

TriggerSource = GPIO Input 1

Figure 13: External Frame Rate, Programmable Exposure Time

Exposure Time

Exposure time is the amount of time that the sensor is allowed to accumulate charge before being

read. The user can set the exposure time when the ExposureMode feature is set to Timed. The

limitations on the maximum exposure time are listed below:

External Exposure Time: 100 µs (min) to 1 second (max).

Internal Exposure Time: (1 / frame rate) *0.95

Note: The maximum exposure time is dependent on the frame rate. To increase maximum

exposure time, decrease the frame rate. If using an internal exposure time with an external trigger,

it may be necessary to reduce exposure time to increase the frame rate.

Trigger Modes

The camera‘s image exposures are initiated by a trigger signal. The trigger event is either a

programmable internal signal used in free running mode, an external input used for synchronizing

exposures to external triggers, or a programmed function call message by the controlling computer.

These triggering modes are described below.

Free running (trigger disabled): The camera free-running mode has a programmable

internal timer for frame rate and a programmable exposure period.

Falcon4 86M Cameras Contents 33

External trigger: Exposures are controlled by an external trigger signal. The external trigger

signal can be either a Camera Link HS trigger message or a general purpose input (e.g.

GPIO [2 : 1]. General purpose inputs are isolated by an opto-coupler input with a time

programmable debounce circuit.

Software trigger: An exposure trigger is sent as a control command via the command

channel. Software triggers cannot be considered time accurate due to communications

latency and sequential command jitter.

Internal Frame Rate

The frame rate is dependent on the number of rows in read, and the summing mode. Frame rate

takes priority over exposure time. Maximum exposure time can be increased by lowering frame

rate.

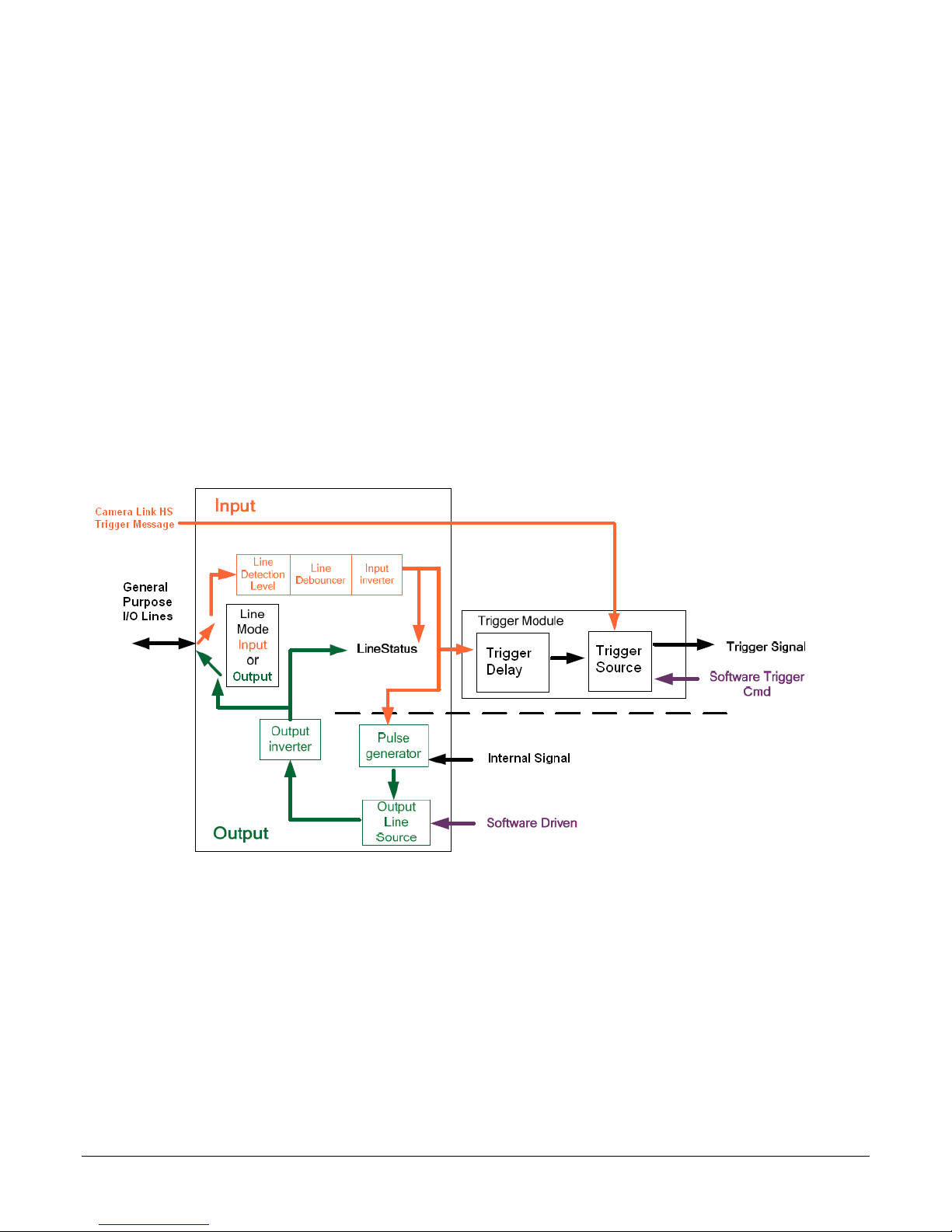

I/O Block Diagram

The following diagram describes the Input / Output features of the camera and how they are

related.

Opto-Coupled Inputs

The camera provides two sets of opto-isolated input signals. These can be used as external trigger

sources. The signals should be in range from 2.4 V to 24 V, 5 V typical. See the lineDetectionLevel

feature.

The delay between signals at the I / O pin and the internal timing core is a function of the signal

swing and the typical latency @ 5V swing is 3.5 µs.

34 Contents Falcon4 86M Cameras

Figure 14 I/O Module Block Diagram

Refer to Figure 6: 12-pin Hirose Circular Male Power Plug—Power Connector for the connector pin

out and electrical information. The cable shell and shield should electrically connect the camera

chassis to the computer chassis for maximum EMI protection.

Figure 15 Opto-coupled input

Each input incorporates a signal debounce circuit (following the opto-coupler) to eliminate short

noise transitions that could incorrectly be interpreted as a valid pulse. The duration is user

programmable from 1 µs to 255 µs using CamExpert.

Opto-Coupled Outputs

The outputs are unpowered devices and require external power. The simplified diagram below

demonstrates the need for a pull-up resistor (when using the outputs).

Figure 16: Simplified General Purpose Output Diagram

Falcon4 86M Cameras Contents 35

Flat Field Correction and Defective Pixel Detection

Overview

The Flat Field correction function consists of using two coefficients per pixel which correct the gain

and offset of the corresponding pixel. These corrections compensate for the Photo-response Nonuniformity (PRNU) and Fixed Pattern noise (FPN) attributes unique to each camera sensor. In

addition, the camera supports replacement of defective pixels (hot, dead, blinking) with a value

based on neighborhood pixels.

The Flat Field correction features are grouped in the Advanced Processing category:

Correction Function Block Diagram

The following simplified block diagram shows the processing chain that is applied to the image data

(the flat field and defective pixel blocks are highlighted). Note that each processing block can be

activated and deactivated independently. For example, the FPN and PRNU coefficients can be

applied independently or together using the flatfieldCorrectionMode.

Figure 17 Flat field and defective pixel processing

Dark Row Subtract Algorithm

The dark row subtract algorithm can be enabled, disabled, or set to off. The camera ships from the

factory with this feature enabled.

This algorithm improves the time stability of the FPN output from the sensor. The Dark Row

Subtract Mode Feature has 3 modes: Off, Disabled, Enabled.

36 Contents Falcon4 86M Cameras

When off, the dark rows from the image sensor are output in the first 32 rows of the image, the

image is shifted by 32 rows, and the top 32 rows of the image are not output. This mode is used to

measure and determine if any of the black rows are defective. Defective rows can be excluded

from the dark row subtract average using the Dark Row Defect Mask.

When disabled, the normal image is passed through this module without change.

When enabled, the average of the non-defective dark rows from the current and previous frame are

averaged on a per column basis and this average is subtracted from the raw sensor data. This

results in the average output of the column to be near zero and, as a result, the Dark Row Subtract

Digital Offset feature is used to add an offset back into the data so that no zero value clipping

occurs and FPN coefficients are correctly calculated. The camera ships with a value of 50 DN and

correction coefficients are calculated with the function enabled. Users need to ensure that the FPN /

PRNU coefficients in use were calculated with the current setting of the Dark Row Subtract

Algorithm.

Flat Field Correction Algorithm Description

Flat Field Correction Algorithm (feature: flatfieldCorrectionAlgorithm) applies the following FFC

formula for correcting pixel values:

newPixelValue

FFCGain

x,y

Where:

x & y are the Flat Field Correction Pixel coordinates. (See the

flatfieldCorrectionPixelXCoordinate and flatfieldCorrectionPixelYCoordinate features.)

newPixelValue is the pixel value after Flat Field Correction is applied.

sensorPixelValue is the pixel value before Flat Field correction is applied.

FFCOffsetBase is one offset coefficient value to subtract from the sensorPixelValue, this

value is measured at minimal exposure time.

FFCOffsetDelta is another offset coefficient value to subtract from the sensorPixelValue.

This value is measured at current exposure time, and is the deviation from FFCOffsetBase.

The normalization operation scales the stored FFCOffsetDelta by multiplying (current

integration time) / (calibration integration time). FFCOffsetDelta is measured immediately

after FFCOffsetBase.

FFCGain is the gain coefficient value that is multiplied with the sensorPixelValue.

The implementation of this formula requires that both the FPN and PRNU coefficient are stored in

32 bits. Internally in Falcon4, we reserve 9 bits for the FFCOffsetBase, 9 bits for FFCOffsetDelta

(FPN) coefficient and 14 bits for the FFCGain (PRNU) coefficient.

= (sensorPixelValue

x,y

– FFCOffsetBase

x,y

x,y – normalized

FFCOffsetDelta

x,y

) *

General Notes on FFC calibration

The camera comes calibrated with two factory sets, one for each shutter mode. In addition to the

factory calibrations, the camera provides three user configurable FFC sets. These can be calibrated

and saved in the camera.

Another option is to perform the flat field correction in the frame grabber.

In either case, we recommend that you repeat the correction when a temperature change of

greater than 10 °C occurs.

For best results, ensure that:

Falcon4 86M Cameras Contents 37

In camera flat field calibration can take up to 10 minutes. CamExpert has a default

timeout of 20 seconds per command, which is too short for the FFC calibration to run

fully. You can change the default timeout by setting a command line argument in the

short-cut:

Right click on the short-cut in the start menu and select properties.

Add –timeout 600 to increase the command timeout to 10 minutes (See

below)

Repeat for desktop short-cut

Gain (PRNU) calibration has a clean, white reference. The quality of this reference is

important for proper calibration. White paper is often not sufficient because the grain in the

white paper will distort the correction. White plastic or white ceramic will lead to better

balancing.

Ambient light flicker (e.g. fluorescent lights) is sufficiently low not to affect camera

performance and calibration results.

The average pixel should be at least 20 % below the target output. If the target is too close,

then some pixels may not be able to reach full swing due to correction applied by the

camera.

When 6.25 % of pixels from a single row within the region of interest are clipped to zero or

max value, flat field correction results may be inaccurate.

Correction results are valid only for the Dark Row Subtract settings for which the coefficients

were calculated. If you change this value, it is recommended that you recalculate your

coefficients.

Appendix D has more details.

An important note on window blemishes

When flat field correction is performed, window cleanliness is paramount. The figure below shows

an example of what can happen if a blemish is present on the sensor window when flat field

correction is performed. The blemish will cast a shadow on the wafer. FFC will compensate for this

shadow by increasing the gain. Essentially FFC will create a white spot to compensate for the dark

spot (shadow). As long as the angle of the incident light remains unchanged then FFC works well.

However when the angle of incidence changes significantly (i.e. when a lens is added) then the

shadow will shift and FFC will makes things worse by not correcting the new shadow (dark spot)

and overcorrecting where the shadow used to be (white spot). While the dark spot can be

potentially cleaned, the white spot is an FFC artifact that can only be corrected by another FFC

calibration.

How to do an FFC Setup in the Camera

38 Contents Falcon4 86M Cameras

Figure 18: Setting the camera’s timeout value

The calibration is performed in two steps. The offset FPN (base and Delta) is determined first by

performing an averaging without any light. This calibration determines exactly how much offset to

subtract per pixel in order to obtain flat output when the sensor is not exposed to light.

If the calibration finds any defective pixels, where its FPN base value is greater than Pixel

Replacement Offset Threshold, or its PRNU value is greater than Pixel Replacement Gain Threshold,

the pixel can be replaced if Pixel Replacement Mode is Active.

The gain (PRNU) calibration is performed next to determine the multiplication factors required to

bring each pixel to the required value (target) for flat, white output. For the monochrome cameras,

the target is determined by the user (See flatfieldCalibrationTarget).

It is important to do the FPN correction first. Results of the FPN correction are used in the PRNU

procedure.

Let‘s work through a flat field calibration example:

1. The camera is placed in internal exposure and frame rate. Ensure that the area of

interest (AOI) is set to the full window (i.e. Width = SensorWidth and Height =

SensorHeight). No other exposure mode or AOI configuration will allow FFC calibration. See

ExposureMode, TriggerMode, OffsetX, OffsetY, Width, Height.

2. Settings such as frame rate, exposure time, etc. are set as close as possible to the actual

operating conditions. Set system gain [All Digital] to 1 and background subtract to 0,

as these are the defaults during FFC calibration. See GainSelector, Gain, BlackLevelSelector,

and BlackLevel.

3. Select correction active set to user flat field x. Go to flat field correction mode, select

calibration. See flatfieldCorrectionCurrentActiveSet, and flatfieldCorrectionMode.

4. Clear existing coefficients. See flatfieldCalibrationClearCoefficient.

5. It is recommended to set Dark Row Subtract function Enabled as this corrects for column

offsets every frame and improves camera stability over time. The FPN coefficient calculation

result is impacted by the Dark Row Subtract. It is the user‘s responsibility to ensure the

coefficient set in use was calculated with the current setting of the Dark Row Subtract

function. When enabling the Dark Row Subtract function, the DarkRowSubtract Digital Offset

should be set to 50.

6. Place the camera in the dark (e.g. cover the lens), select FPN Calibration Step No as First

Step and run FPN Calibration. This performs the FPN correction and saves the FPN

coefficients to temporary memory. See flatfieldCalibrationFPN. FPNCalibrationStepNo

Calibration mode enables both FPN and PRNU correction. Verify signal output is close to 0

DN.

Falcon4 86M Cameras Contents 39

7. Illuminate the sensor to 65% saturation for monochrome cameras. For color cameras, try to

adjust the light level equally above and below 55% for the most and least responsive color.

Ensure a high quality white reference is used.

8. Set the Flat Field Calibration Algorithm to PRNU: Customer Target.

9. Set flat field target to 80 % saturation (monochrome only). For color cameras, set the flat

field target to 1.2x the average of the highest responding color. See

flatfieldCalibrationTarget.

10. Run Gain (PRNU) calibration. See flatfieldCalibrationPRNU.

A defective pixel will be replaced if Pixel Replacement Mode is Active. A defective pixel is

defined as a pixel whose FPN base value is greater than Pixel Replacement Offset Threshold

or / and whose PRNU value is greater than Pixel Replacement Gain Threshold.

11. Save the flat field calibration: flatfieldCalibrationSave.

More information is found in Appendix D.

Defective Pixel Detection and Replacement

The camera has three methods of replacing pixels. Single pixel replacement uses the FFC

coefficients to mark pixels that will be replaced. Defective columns or rows marked as defective use

the median filter algorithm to replace the defect pixel. The dynamic pixel replacement algorithm

uses a median filter to replace a given pixel value with the median value when its original value is

above / below a threshold when compared to adjacent pixels of the same color. These three

methods can be individually controlled.

Single Pixel Replacement

This is a technique for the elimination of dead or hot pixels.

The camera uses the FFC coefficients to indicate which pixels need to be replaced. If a pixel has a

Gain (PRNU) coefficient that is greater than the defectivePixelReplacementGainThreshold then the

pixel will be marked for replacement. Additionally, a pixel will be replaced if its Base Offset (FPN)

coefficient that is greater than the offset pixel replacement threshold

(defectivePixelReplacementOffsetThreshold ). Lowering these thresholds will remove more pixels

with high gain and offset coefficients.

Most hot and dead pixels will be identified when a FPN or PRNU calibration is performed in camera.

The user can also manually mark a pixel for replacement by setting its Pixel Base Offset to 511.

The replacement algorithm is shown below in the Median Filter section.

Defective Columns and Row Replacement

Defective rows and columns are marked during factory calibration but users can add or remove

defective rows and columns to / from the list. The Pixel Replacement Mode can be set to Off, which

does not replace the defective rows and columns, or Active to hide defective rows and columns. To

clear all rows and columns from the list, use the Pixel Replacement Clear function. To add a

defective Row or Column the following steps are used:

1) Select Row or Column using the Pixel Row or Column Selector.

2) Set the Row or Column Id using the Pixel Replacement Row or Column Number field.

3) The modified list can be saved in a user set.

40 Contents Falcon4 86M Cameras

The median filter algorithm, below, is used to replace defection rows and columns.

Median Filter

Enable the median filter by setting the medianFilter to Active (Image Format Controls). Setting this

filter to Off disables the medianFilter.

When the Median Filter is Active, then the Median Filter Threshold value controls the decision to

replace the pixel value. Replacement occurs when a pixel‘s current value differs from the median

value of a 3 x 3 kernel by more than the threshold value. The pixel is replaced by the median value

of a 3 x 3 kernel.

The algorithm is described below for monochrome cameras. Color cameras use the pixels of same

color in the matrix.

1. 3X3 2D median filter algorithm

a. First step calculation the 5 elements median value Pm1 and Pm2

P1 P2 P3 P1 P3

P4 P5 P6 => P5 => Med{P1, P3, P5, P7, P9} => Pmx;

P7 P8 P9 P7 P9

P1 P2 P3 P2

P4 P5 P6 => P4 P5 P6 => Med{P2, P4, P5, P6, P8} => Pmc;

P7 P8 P9 P8

b. Second step calculation the 3 elements median

Med{P5, Pmx, Pmc} => Pm;

c. Third step check the threshold(8bit value and default=255)

if (|P5 – Pm| > threshold) then

P5 output <= Pm;

else

P5 output <= P5;

end if;

2. Defect Pixel Replacement 3x3 2D Replacement

Each pixel with input defect flag associated if the flag is 1 the pixel will be do the 2D median

filter but without check threshold.

File Access via the CamExpert Tool

1. Click on the “Setting…” button to show the file selection menu.

Falcon4 86M Cameras Contents 41

Figure 19 Initial File Access Control Dialog

2. From the Type drop menu, select the file type that will be uploaded to the camera.

3. From the File Selector drop menu, select the camera memory location for the uploaded data. This menu

presents only the applicable data locations for the selected file type.

4. Click the Browse button to open a typical Windows Explorer window.

5. Select the specific file from the system drive or from a network location.

6. Click the Download button to execute the file transfer from the Falcon4.

7. Note that firmware changes require a device reset command.

42 Contents Falcon4 86M Cameras

Technical Specifications

Mechanicals

Falcon4 86M Cameras Contents 43

Teledyne DALSA inc.

605McMurray Road,

Waterloo, Ontario, Canada,

N2V 2E9

EN55032 (2012)

Electromagnetic compatibility of multimedia equipment —

Emission requirements

EN55011 (2009)

with A1(2010)

Industrial, scientific and medical equipment — Radiofrequency disturbance characteristics — Limits and methods

of measurement

EN 61326-1 (2013)

Electrical equipment for measurement, control and laboratory

use — EMC requirements — Part 1: General requirements

EN 55024 (2010)

Information technology equipment — Immunity

characteristics — Limits and methods of measurement

CFR 47

Part 15 (2008), subpart B, for a class A product. Limits for digital

devices

ICES-003

Information Technology Equipment (ITE) — Limits and Methods of

Measurement

CISPR 11

Industrial, scientific and medical equipment - Radio-frequency

disturbance characteristics - Limits and methods of measurement

CISPR 32

Electromagnetic compatibility of multimedia equipment - Emission

requirements

EC & FCC Declaration of Conformity

We:

Declare under sole legal responsibility that the following products conform to the protection

requirements of council directive 2004/108/EC (2014/30/EU after April 2016) on the approximation

of the laws of member states relating to electromagnetic compatibility and are CE-marked

accordingly:

FA-SO-86M16-01-R and FA-S1-86M16-00-R

The products to which this declaration relates are in conformity with the following relevant

harmonized standards, the reference numbers of which have been published in the Official Journal

of the European Communities:

Further declare under our sole legal responsibility that the product listed also conforms to the

following international standards:

Note: this product is intended to be a component of a larger system.

Waterloo, Canada. 2015 Apr.13

Hank Helmond

Director, Quality Assurance

44 Contents Falcon4 86M Cameras

Display Name

Feature & Values

Description

Standard & View

Device Vendor

Name

DeviceVendorName

Displays the device vendor name. (RO)

Beginner

Device Model

Name

DeviceModelName

Displays the device model name. (RO)

Beginner

Device Family

Name

DeviceFamilyName

Displays the device family product name.

(RO)

Beginner

Device Version

DeviceVersion

Displays the device version. This tag will

also highlight if the firmware is a beta or

custom design. This is an automatically

generated number that specifically

identifies the software build. (RO)

Beginner

Firmware Version

DeviceFirmwareVersion

Displays the currently loaded firmware

version number. Firmware files have a

unique number and have the .cbf file

extension. (RO)

Beginner

Device ID

DeviceID

Displays the device’s factory set camera

serial number. (RO)

Beginner

Device User ID

DeviceUserID

Feature to store a user-programmable

identifier of up to 15 characters. The default

factory setting is the camera serial number.

(RW)

Beginner

Appendix A: GenICam

Commands

This appendix lists the available GenICam camera features. Access these features using the

CamExpert interface.

Parameters in gray are read only, either always or due to another parameter being disabled.

Parameters in black are user set in CamExpert or programmable via an imaging application.