Teledyne FALCON GC Operation And Maintenance Manual

Teledyne Analytical Instruments

OPERATION AND MAINTENANCE

MANUAL FOR

FALCON GC

DANGER

Toxic and/or flammable gases or liquids may be present in this monitoring system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist for

a time even after the power is turned off and disconnected.

Only authorized personnel should conduct maintenance and/or servicing. Before

conducting any maintenance or servicing, consult with authorized

supervisor/manager.

P/N M

DATE 07/30/19

Information included herein is controlled by the Export Administration Regulations

(EAR) and requires an export license, license exception or other approval from the

appropriate U.S. Government agency before being exported from the United States

or provided to any foreign person. Diversion contrary to U.S. law is prohibited.

Falcon GC

ii Teledyne Analytical Instruments

Copyright © 2019 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91748.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by Teledyne or an authorized service center.

We assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by which

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface be properly trained in the

process being measured, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of Teledyne at the

time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot accept

responsibility for conditions beyond its knowledge and control. No statement expressed or

implied by this document or any information disseminated by the manufacturer or its

agents, is to be construed as a warranty of adequate safety control under the user’s process

conditions.

Teledyne Analytical Instruments iii

Safety Messages

Your safety and the safety of others is very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the

instructions for details on the specific danger. These

cautions warn of specific procedures which if not

followed could cause bodily Injury and/or damage the

instrument.

CAUTION: HOT SURFACE WARNING: This warning is

specific to heated components within the instrument.

Failure to heed the warning could result in serious burns

to skin and underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous

voltages appear within this instrument. This warning is

specific to an electrical hazard existing at or nearby the

component or procedure under discussion. Failure to heed

this warning could result in injury and/or death from

electrocution.

Technician Symbol: All operations marked with this

symbol are to be performed by qualified maintenance

personnel only.

NOTE: Additional information and comments regarding

a specific component or procedure are highlighted in the

form of a note.

STAND-BY: This symbol indicates that the instrument is

on Stand-by but circuits are active.

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

No

Symbol

Falcon GC

iv Teledyne Analytical Instruments

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

This manual provides information designed to guide you through the

installation, calibration and operation of your new analyzer. Please read

this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be specific to your

instrument.

Manuals do get misplaced. Additional manuals can be obtained from

Teledyne at the address given in the Appendix. Some of our manuals are

available in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Teledyne Analytical Instruments v

Additional Safety Information

DANGER

COMBUSTIBLE GAS USAGE

WARNING

This is a general purpose instrument designed for use in a

non-hazardous area. It is the customer's responsibility to

ensure safety especially when combustible gases are being

analyzed since the potential of gas leaks always exist.

The customer should ensure that the principles of operating

of this equipment are well understood by the user. Misuse of

this product in any manner, tampering with its components,

or unauthorized substitution of any component may

adversely affect the safety of this instrument.

Since the use of this instrument is beyond the control of

Teledyne, no responsibility by Teledyne, its affiliates, and

agents for damage or injury from misuse or neglect of this

equipment is implied or assumed.

WARNING: HYDROGEN GAS IS USED IN THIS INSTRUMENT AS

A FUEL AND PERHAPS AS A CARRIER GAS.

HYDROGEN IS EXTREMELY FLAMMABLE.

EXTREME CARE MUST BE USED WHEN WORKING

AROUND GAS MIXTURES CONTAINING

FLAMMABLE GASES.

A successful leak check was performed at TAI on the

sample system of this instrument prior to calibration,

testing and shipping. Ensure that there are no leaks

in the fuel supply lines before applying power to the

system.

Always purge the entire system before performing

any maintenance and always leak check the system

after removing any tubing or fittings on the sample

system. See the procedures for purging and leak

checking this instrument on the following pages.

Falcon GC

vi Teledyne Analytical Instruments

WARNING: THIS INSTRUMENT IS DESIGNED TO BE OPERATED

IN A NONHAZARDOUS AREA. THE ANALYZER USES

HYDROGEN GAS AND/OR OTHER COMBUSTIBLE

GASES IN ITS OPERATION. THIS EQUIPMENT, IF

NOT USED AND MAINTAINED PROPERLY CAN BE

AN EXPLOSION HAZARD. THE ANALYZER,

DEPENDING ON THE APPLICATION, MAY ALSO USE

TOXIC GASES. IT IS THEREFORE, THE

CUSTOMER'S RESPONSIBILITY TO ENSURE THAT

PROPER TRAINING AND UNDERSTANDING OF THE

PRINCIPLES OF OPERATION OF THIS EQUIPMENT

ARE UNDERSTOOD BY THE USER. SINCE THE USE

OF THIS INSTRUMENT IS BEYOND THE CONTROL

OF TELEDYNE, NO RESPONSIBILITY BY TELEDYNE,

ITS AFFILIATES AND AGENTS FOR DAMAGE OR

INJURY RESULTING FROM MISUSE OR NEGLECT

OF THIS INSTRUMENT IS IMPLIED OR ASSUMED.

MISUSE OF THIS PRODUCT IN ANY MANNER,

TAMPERING WITH ITS COMPONENTS OR

UNAUTHORIZED SUBSTITUTION OF ANY

COMPONENT MAY ADVERSELY AFFECT THE

SAFETY OF THIS INSTRUMENT.

CAUTION: WHEN OPERATING THIS INSTRUMENT, ALL

COVERS SECURELY FASTENED. THE GAUGES

MUST BE IN PROPER WORKING ORDER. DO NOT

OVERPRESSURIZE THE SYSTEM.

READ THIS MANUAL BEFORE OPERATING THE

INSTRUMENT AND ADHERE TO ALL WARNINGS

INCLUDED IN THIS MANUAL.

Teledyne Analytical Instruments vii

Table of Contents

Safety Messages ....................................................................... iii

Additional Safety Information ................................................... v

List of Figures ............................................................................ ix

Introduction ................................................................................ 1

Preparation ................................................................................. 3

2.1 Chromperfect File Types 3

Installation .................................................................................. 7

3.1 Preparation 7

3.2 Setup/Installation 8

3.2.1 User Connections 9

3.3 Configuring the Falcon GC 9

3.3.1 Setting the Falcon GC’s IP Address 10

3.4 Configuring Chromperfect 10

3.5 The Chromperfect Selection Tab 13

3.5.1 Claiming the Instrument and Setting the Data Directory

13

3.6 The Chromperfect Status Tab 14

3.7 Downloading a Method File 15

Operation .................................................................................. 17

4.1 Starting the GC 17

4.1.1 Turning on the GC Modules 17

4.1.2 Lighting the FID 18

4.1.3 Activating the TCD Filament 18

4.1.4 Starting a Run 18

4.2 Calibration 19

4.2.1 The Calibration File 19

4.2.2 Creating a New Calibration File 19

4.2.3 Updating a Current Calibration File 21

Maintenance & Troubleshooting ............................................. 23

5.1 Troubleshooting 24

5.2 Adjusting FID Pressures 25

Falcon GC

viii Teledyne Analytical Instruments

5.3 Outer Case Removal 29

5.4 FID Removal 35

5.5 Column Module Installation 38

5.6 Replacing the Glow Plug 47

Appendix ................................................................................... 51

A.1 Specifications: 51

A.2 Recommended Spare Parts List 51

A.3 Drawings 52

Teledyne Analytical Instruments ix

List of Figures

Figure 3-1: Instrument Connections ............................................. 9

Figure 5-1: Glow Plug Wire ........................................................ 48

Figure 5-2: FID Diagram ............................................................. 50

Falcon GC

x Teledyne Analytical Instruments

Blank Page

Falcon GC Introduction

Teledyne Analytical Instruments 1

Introduction

Teledyne Analytical Instruments Falcon GC is an ultrafast

programmed temperature gas chromatograph consisting of:

• Heated split/splitless injection port including septum purge and

350°C maximum operating temperature.

• Inlet accepts gas or liquid syringe injections or optionally an

automated gas or liquid sample valve.

• One or two column modules, for simultaneous detection on two

individual column types, and one or two detector modules.

• Plug and play, precalibrated and individually programmed

temperature column modules, enabling dual simultaneous

analysis on the same sample, using different separation media

and temperature profiles for maximum selectivity.

• Touchscreen user interface panel.

The Falcon GC uses a Windows equipped PC in conjunction with

the Chromperfect software. The computer connection can be made

through a shared ethernet cable via TCP. The ethernet connection from

PC to GC can either be direct or through a network.

This manual presents the standard operating procedure for the

general use of the Falcon GC. You should have a general working

knowledge of the Chromperfect software, as well as the Falcon GC

Introduction Falcon GC

2 Teledyne Analytical Instruments

before using this guide. Since this is a general SOP, more specialized

methods such as ASTM D7798 or D3710 will require additional

instruction not present in this document. This guide does not include

instruction on the operation of the Palarus or Talon autosamplers.

Falcon GC

Preparatio

n

Teledyne Analytical Instruments 3

Preparation

2.1 Chromperfect File Types

There are generally four key Chromperfect files that must work

together in order to ensure the effective operation of the Falcon GC.

Depending on the application, you may only need two or three of these

files. In some cases, even more files may be necessary. A method file

(.met) and a setpoint file (.mfl) are required for every application. Two

additional common file types are a calibration file (.cal) and a formatted

report file (.fmt). The folder destination for these files will vary from

user to user. Before getting started, check to make sure that the method

files have the correct pathnames defined for the files mentioned above.

This can be done by opening the method file in the File Editor Tab.

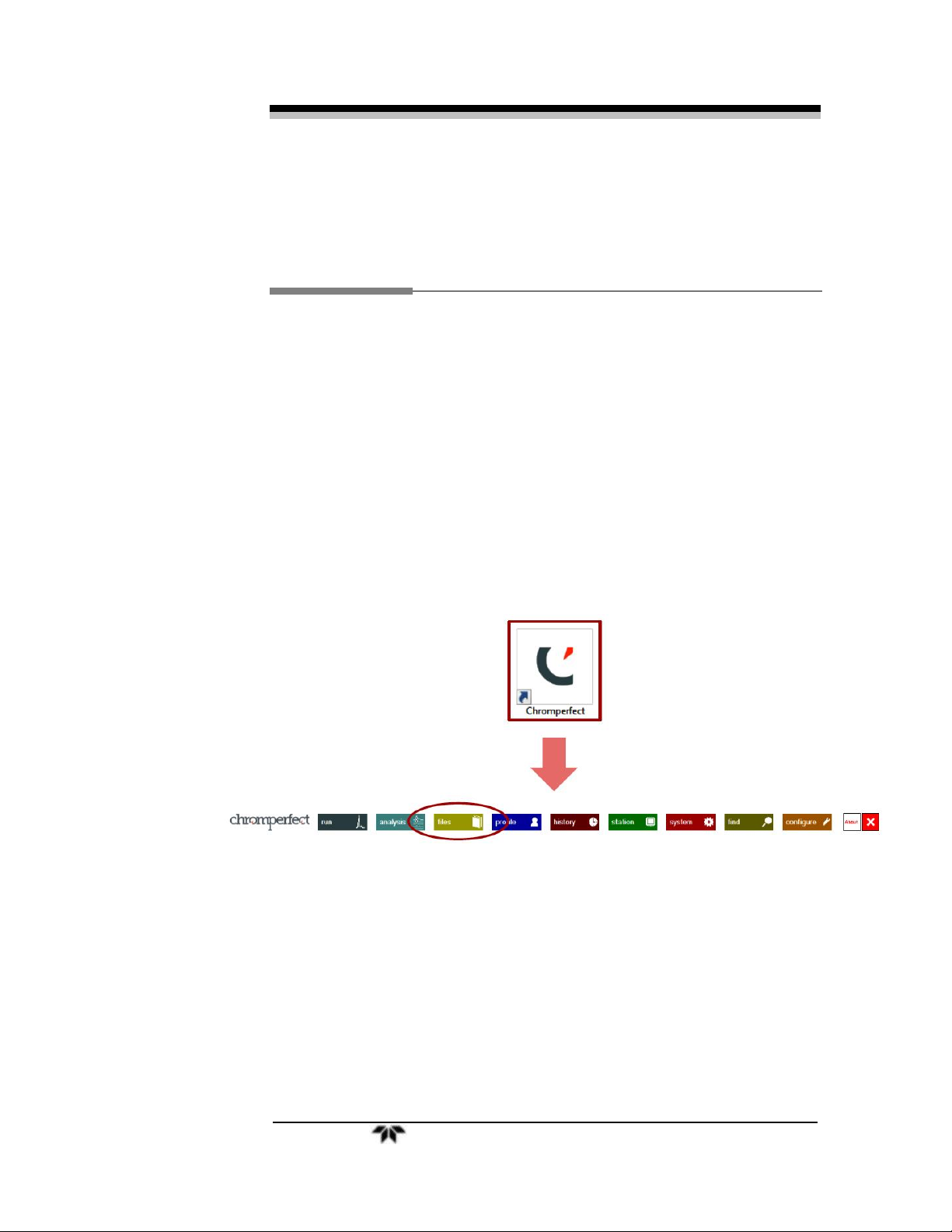

Click the “C” Chromperfect icon to open the Chromperfect banner and

then click on “Files”.

Here, click File→Open→Method and then click the “…” icon to

search for your method file.

Note: Depending on the current settings a pop-up window might

automatically open along with the File Editor program. If

that happens, just click Method from that window and then

click the “…” to select your method file.

Preparation Falcon GC

4 Teledyne Analytical Instruments

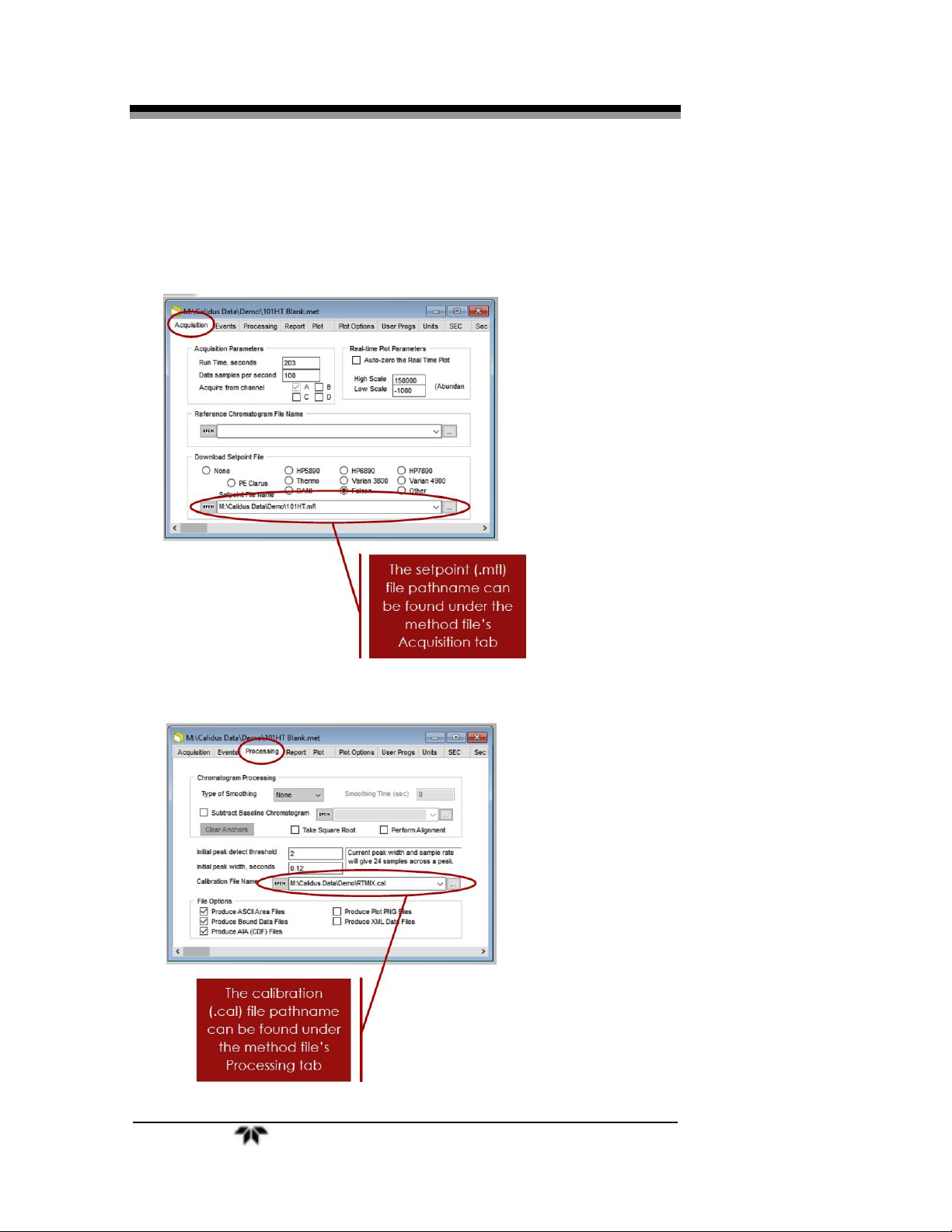

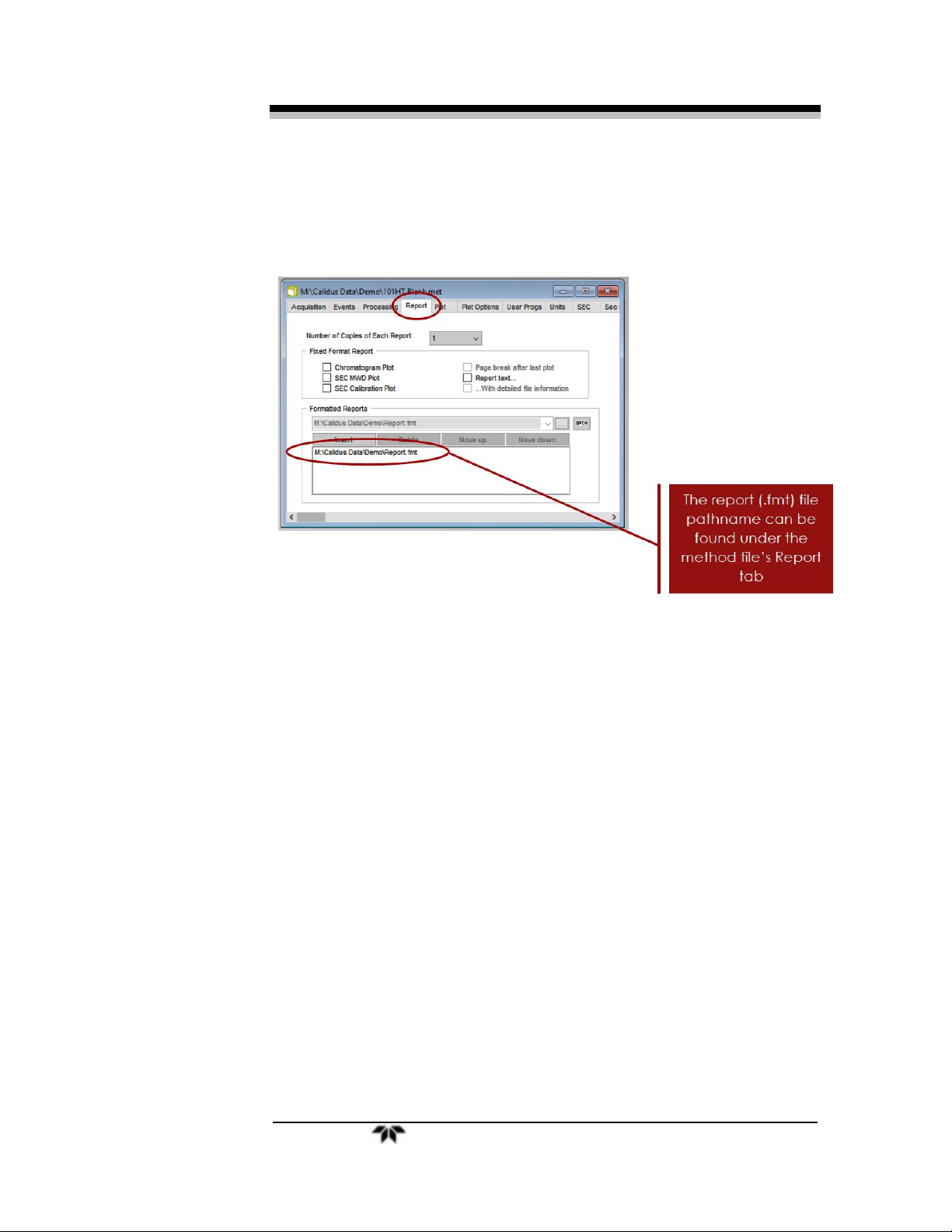

With the method file now open, click through the tabs to make sure

that all of your files are properly linked with the correct pathname.

Please note that your method may not require all these file types.

1. Click on Acquisition.

2. Click on Processing.

Falcon GC

Preparatio

n

Teledyne Analytical Instruments 5

3. Click on Report.

Preparation Falcon GC

6 Teledyne Analytical Instruments

Blank Page

Falcon GC Installation

Teledyne Analytical Instruments 7

Installation

3.1 Preparation

Installation of the Falcon GC will require:

• Carrier Gas

o Typically H

2

, but may also be He or N2 in special

circumstances.

Note: Hydrogen and air must be supplied if the instrument is

equipped with an FID (Flame Ionization Detector) or FPD

(Flame Photometric Detector).

o All gases should be ultra high purity (99.9995% pure) or

better.

o Hydrogen carrier gas is typically supplied from a

hydrogen generator or gas cylinders.

o Carrier gas must be regulated down to 60-80 psi before

entering the GC.

• Zero Air

o Must be hydrocarbon and moisture free.

o Air is typically supplied from a zero air generator and

compressor or gas cylinders.

o Zero air must be regulated down to 80-90 psi before

entering the GC.

• Tubing, Nuts, and Ferrules

o Connections and tubing are supplied with the Falcon

Startup Kit.

o Gas connections to the GC require 1/16” stainless steel

tubing.

▪ 1/16” Valco internal nuts and ferrules for carrier

gas and FID fuel.

▪ 1/16” Swagelock external nut and ferrule for air

input.

Installation Falcon GC

8 Teledyne Analytical Instruments

▪ Falcon CS units require 1/8” tubing with a

Swagelock external nut and ferrule for air (1/8”

tubing is NOT included in the Falcon GC Startup

Kit).

▪ 1/16” Valco internal nuts and ferrules must also

be used for SAMPLE IN and SAMPLE OUT on

gas sample valves and liquid sample valves.

▪ Optional: 1/16” Swagelock external brass nuts

and ferrules for split vent and septum purge vent.

• Ethernet Cable

o Used for TCP/IP communication directly from a PC to

the GC or from the GC to LAN.

• Power Supply

o 100-240VAC Power Source, 50-60Hz, either 240W or

320W.

o Auxiliary valve heating or sample valves require

auxiliary power cables that must be plugged into the

control panel or utility panel, respectively.

o Appropriate power supplies and cables are always

supplied with the Falcon GC.

• Wrenches

o Wrenches are supplied with the Falcon Startup Kit.

o 1/4” for internal nuts.

o 5/16” for external nuts.

o 7/16” for external 1/8” nuts.

3.2 Setup/Installation

The Falcon GC is shipped with all the materials needed to install and

prepare the system for operation (Calibration Samples excluded).

Carefully unpack the unit and inspect it for damage. Immediately report

any damage or shortages to the shipping agent.

The Falcon GC is a general-purpose instrument and as such is

designed with (non-sealed) enclosures. The GC can be operated within

temperatures ranging from 32ºF to 100ºF but for best results ambient T

should be within 60-80ºF. In areas outside these temperatures, auxiliary

Falcon GC Installation

Teledyne Analytical Instruments 9

heating/cooling may need to be supplied. Avoid locating the instrument

where extreme vibration may occur.

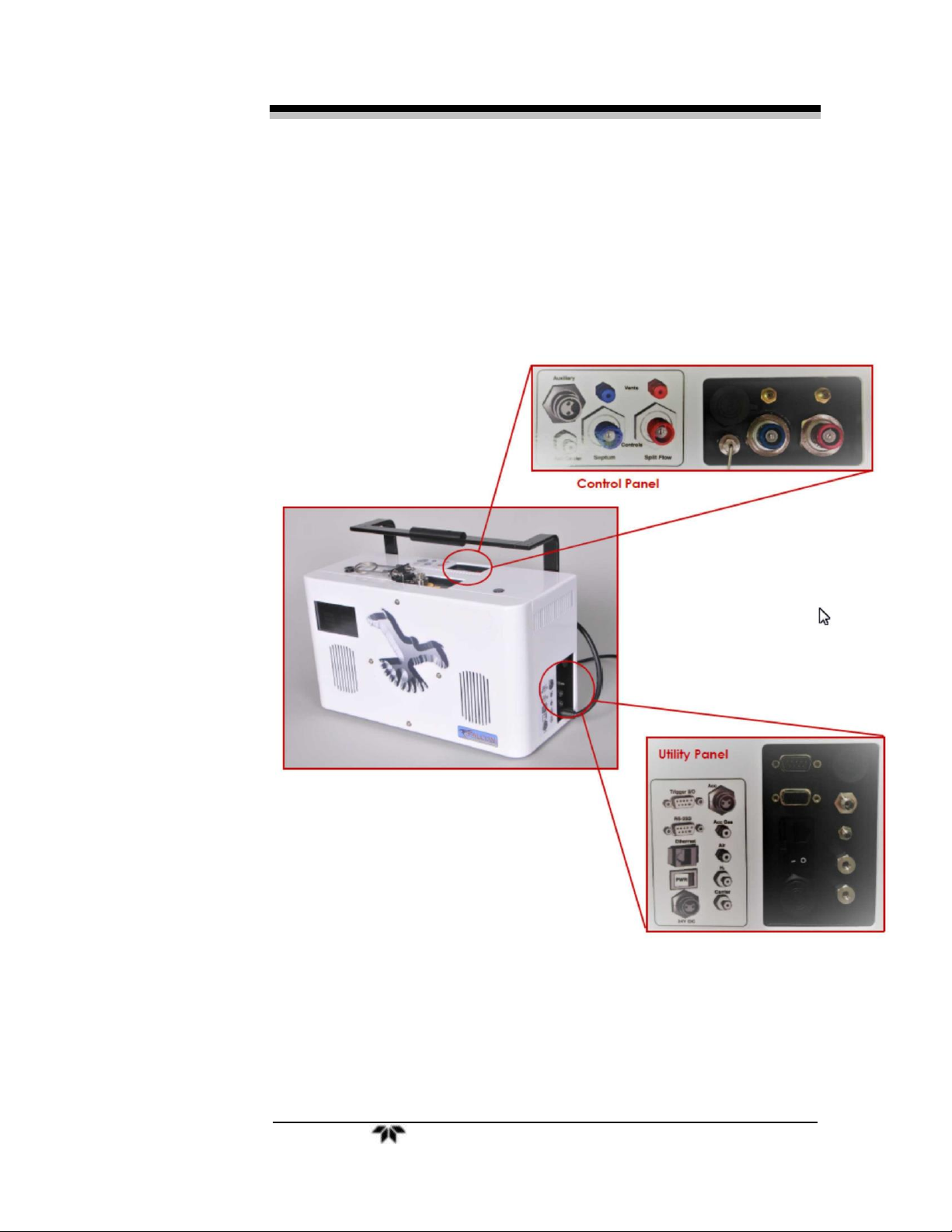

3.2.1 User Connections

Connect the appropriate tubing and cables according to the Control

Panel and Utility Panel diagrams located on the top of the instrument

and the right side of the instrument. See Figure 3-1 .

Figure 3-1: Instrument Connections

3.3 Configuring the Falcon GC

To properly use the Falcon GC you must connect the GC to a

Windows PC. This connection can be made through a shared ethernet

Installation Falcon GC

10 Teledyne Analytical Instruments

cable via TCP/IP. The ethernet connection from PC to GC can either be

direct or through a network.

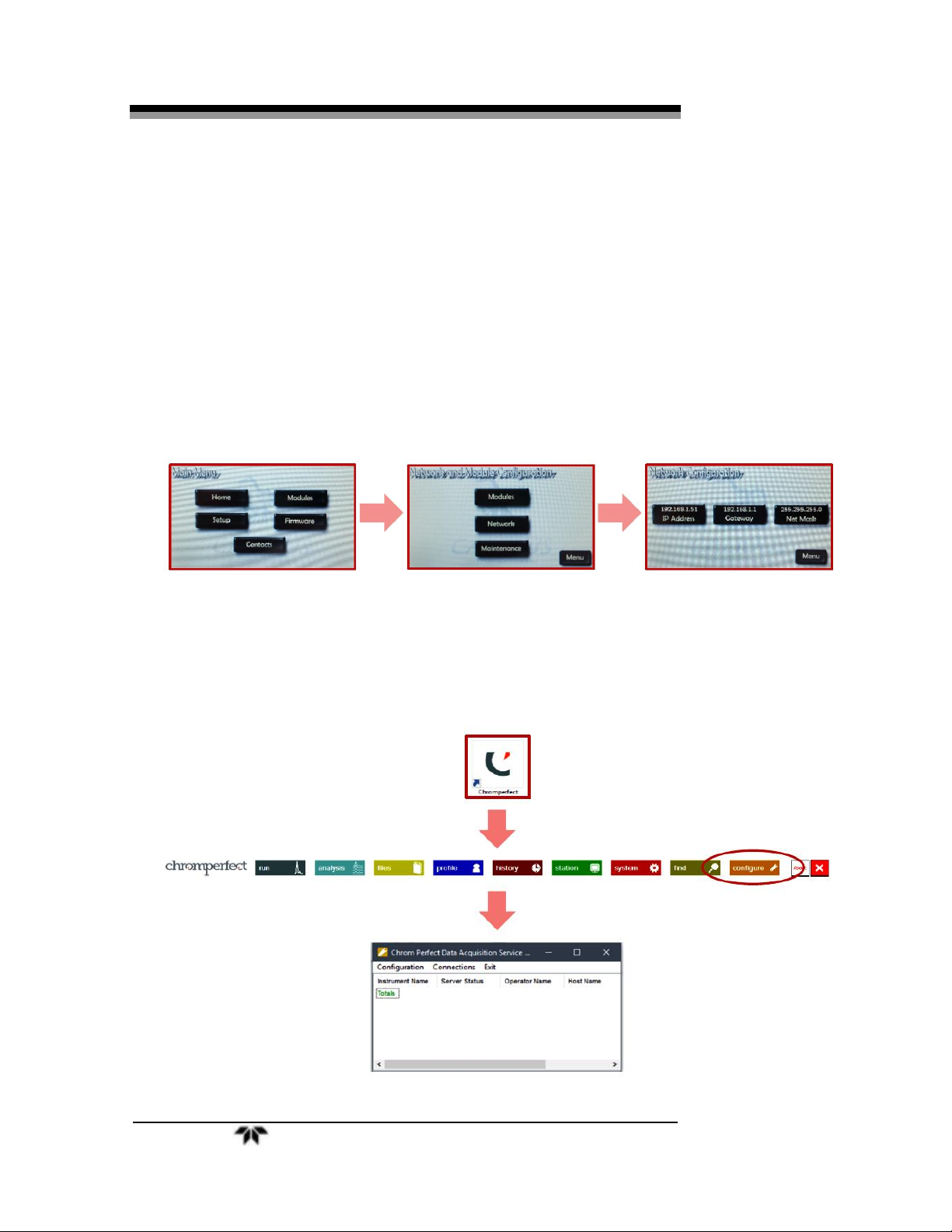

3.3.1 Setting the Falcon GC’s IP Address

To set the IP address, first, turn on the GC using the power toggle

switch on the Utility Panel.

On the Falcon touch screen press Menu→Setup→Network to access

the network options. From here you can view or change the GC’s IP

Address, Gateway, or Net Mask by pressing on their respective icons.

3.4 Configuring Chromperfect

1. Click on the “C” Chromperfect icon to open the Chromperfect

banner

2. Then click on Configure to open the configuration window.

Falcon GC Installation

Teledyne Analytical Instruments 11

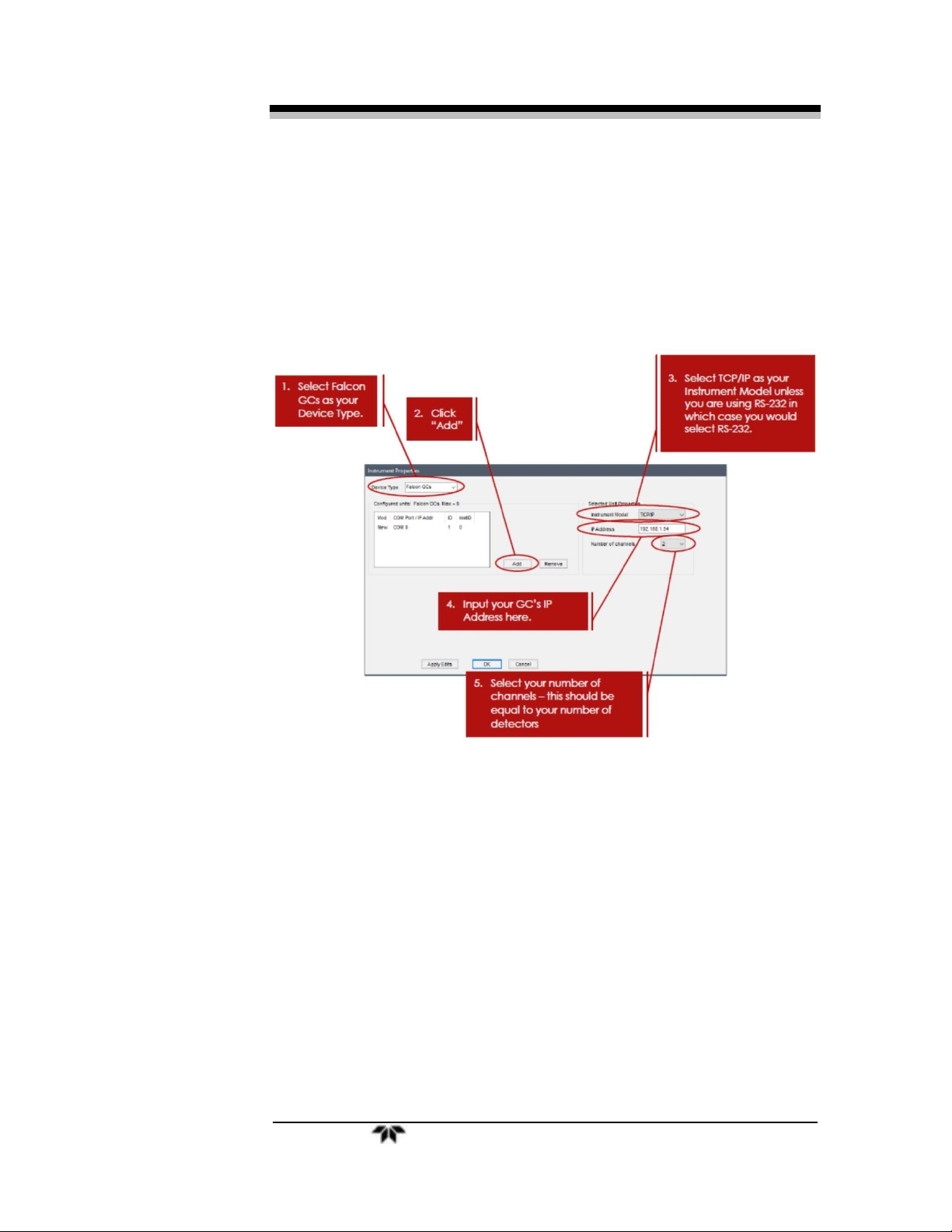

3. Click on Configuration at the top left of this new pop up

window. This will open the instrument properties pop-up

window.

4. After you have entered all the relevant information as seen

above, click on Apply Edits to apply your changes. Notice that

the small window where it says Mod and COM Port/IP Addr will

update with your current settings.

5. Click OK. A new pop-up window will appear with the title of

Instrument and Hardware Connections. Fill out the new pop-up

window as shown below:

Loading...

Loading...