Teledyne Echotrac MKIII Operator's Manual

ECHOTRAC MKIII

OPERATOR'S MANUAL

Version: 4.06

Teledyne Odom Hydrographic

Teledyne Marine

Fabriksvangen 13

3550 Slangerup

Denmark

Telephone: +45 47 38 00 22 Fax: +45 47 38 00 66

www.teledynemarine.com/odom-hydrographic/

Number of pages: 48

Date: 21 January 2019

Echotrac MKIII Operator's Manual 4.06

Page 2 of 48

January 21, 2019

Revision History

Version

Date

Author

Remarks

0.1

09-19-2002

P. Oostenrijk

Initial version – draft

1.0

01-28-2003

S.F. Apsey

1.1

03-27-2003

S.F. Apsey

Updated manual for firmware version 2.07;Changed default of

Tracking Gate. Added Skip Alarms. Added Grey shades.

1.2

09-09-2003

S.F. Apsey

Updated manual for firmware version 2.14: Added Subottom TVG,

SB TVG Range, Pre Amp Gain, Dual Light Shade parameters.

1.4

02-16-2005

S.F. Apsey

Changes from Echotrac MKIII 3.05 to 3.06:

1-When the Echotrac MKIII is set to read in heave through com4 it

will check to see if the first character in the string is an ‘R’ (remote

heave). If the first character is an ‘R’ the Echotrac will use the

remote heave value for corrections otherwise the Echotrac will use

the local heave.

2-Added a parameter called HEAVECORR. This parameter will

heave correct the chart when turned on or not heave correct the

chart if turned off. The selection of the ‘Heave Out’ serial string will

now no longer affect the heave correction on the chart.

3-The parameter DIGILINE will now have a range of

0,1,2,3,4,5,6,7,8,9,10 instead of on or off. When set to 0 the

digitizer line will not be printed. If set to any other number, the

digitizer line will be printed that many units above the raw bottom.

4-The parameter LIGHTSHADE will now have the selections Chnl2

Dark, Chnl1 Dark, Chnl2 Only and Chnl1 Only. This will reflect how

the data and what data will be printed when both channels are

turned on. If Chnl2 Dark is selected, Channel 2 will be printed

darker than Channel 1. If Chnl2 only is selected then only Channel

2 will be printed.

3.08

04-14-2005

P. Oostenrijk

Updated manual for firmware version 3.08

Added section on how to request parameter settings through the

serial port.

3.20

01-16-2006

P. Oostenrijk

Added UDP port, Hours of operation, Packet size 8/16 bits,

outputstring DESO DDV, print German Help.

3.22

02-28-2006

P. Oostenrijk

New optimized Deso command handling routines.

Re-enabled TVGgainref and Trackinggate in Echotrac Control

program. Improved annotation handling.

3.23

05-22-2006

P. Oostenrijk

Improved Echotrac Control program network detection interface.

Low Frequency pulse width increased to 256.

Corrected auto-scaling when draft and index are used.

Added support for Echotrac CVM.

3.25

08-03-2006

P. Oostenrijk

Fixed: Stopping the synchronization process disabled

communication with Echotrac.

Added compatibility check and warning for Echotrac Control

Program version and Echotrac firmware version.

If during synchronization a parameter is missing, the parameter

name is now displayed.

Improved version control in firmware and diagnostic window.

Added Echotrac and Subbottom mode to Control Program. This is

not supported on the MK3.

Added Datacheck for GPS and Heave.

Depth values are red in case of depth alarm.

Added transparency feature on depth monitor window.

Added support for CV100.

Added Power & Gain control to Depth Monitor window.

3.26

09-07-2006

P. Oostenrijk

Updated to 3.26 for Echotrac firmware version compliance.

Echotrac MKIII Operator's Manual 4.06

Page 3 of 48

January 21, 2019

Revision History

Version

Date

Author

Remarks

3.27

09-25-2006

P. Oostenrijk

When a menu parameter value is changed, only the value is

highlighted. But upon entering the edit mode for the menu value

almost instantly the entire menu row would be highlighted. The

problem appears when DESO_DDV+C is selected and Atlas Susy

sends event commands to the MK3.

3.28

01-10-2007

P. Oostenrijk

Improved verification of power settings when scale changes occur.

3.29

05-22-2007

P. Oostenrijk

Added description for Missed Returns and Mode on Setup tab.

Minor change in Grey Shades description. Updated COM port's

baudrate options to include 38400.

Removed chapter Overview Parameters and Settings. This is now

refers to the Technical Specification Ethernet Interface document.

4.00

02-19-2008

P. Oostenrijk

Updated Odom Title and Logo on cover page.

Updated Header and Footer according to new template.

Updated uploading firmware and upgrading DSP firmware.

4.01

02-25-2008

P. Oostenrijk

Updated document version to match software/firmware version.

4.02

03-18-2008

P. Oostenrijk

Added support of extra fine scale grid.

Added support for DESO DDV outputstring for all sounders.

4.03

05-23-2008

P. Oostenrijk

Updated Scale change functionality.

Updated CVM channel handling as 1 and 2 instead of 1 and 3.

4.04

19-12-2016

A. Moeller

Updated Odom logo and front page.

Updated header and footer format.

Updated 1.5 LCD Chart Panel.

Updated wording in 2.3.7 VGA.

4.05

A. Moeller

Contact details updated (page 1).

5.3.2.3: Expanded with two paragraphs and table of pulse widths at

certain frequencies.

Section 9.2: corrected numbered list (no. “13” was repeated).

App. A added with support and service details.

4.06

21-01-2019

A. Moeller

Updated support e-mail throughout document.

Warning, Caution, and Note boxes added throughout document

where relevant.

1.2 Echotrac MKIII Operator’s Manual – new section about the

purpose, scope, warnings and notes, etc.

4, 5, and 7: Somewhat rearranged, reworded.

App. A LCD15 Module. NEW.

App. B: AUX Modification for SILAS Output. NEW.

© TELEDYNE ODOM HYDROGRAPHIC, INC. 2016

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the

copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be

accurate and reliable, and may be subject to change without notice. The publisher will not accept any liability

for any consequence of its use. Publication thereof does not convey nor imply any license under patent- or

other industrial or intellectual property rights.

Echotrac MKIII Operator's Manual 4.06

Page 5 of 48

January 21, 2019

CONTENTS

1 Introduction......................................................................................................................................................7

1.1 Echotrac MKIII.............................................................................................................................................7

1.1.1 Dual Frequency Operation ...................................................................................................................7

1.1.2 Printer Mechanism ...............................................................................................................................7

1.1.3 Display .................................................................................................................................................7

1.1.4 LCD Chart Panel ..................................................................................................................................7

1.1.5 Keypad .................................................................................................................................................7

1.1.6 Receivers .............................................................................................................................................7

1.1.7 Transmitter ...........................................................................................................................................7

1.1.8 Communication Ports...........................................................................................................................8

1.2 Echotrac MKIII Operator’s Manual ..............................................................................................................8

1.2.1 Purpose................................................................................................................................................8

1.2.2 Scope ...................................................................................................................................................8

1.2.3 Warnings, Cautions, and Notes ...........................................................................................................8

1.2.4 Glossary ...............................................................................................................................................8

2 Installation........................................................................................................................................................9

2.1 Echotrac DF 3200 MKIII Recorder Installation ............................................................................................9

2.1.1 Power ...................................................................................................................................................9

2.1.2 Cabling .................................................................................................................................................9

2.1.3 Fuses ...................................................................................................................................................9

2.1.4 Chart Paper........................................................................................................................................10

2.2 Transducer Installation ..............................................................................................................................11

2.2.1 "THROUGH HULL" Installation ..........................................................................................................12

2.2.2 "SEA CHEST" Installation ..................................................................................................................12

2.2.3 "OVER-THE-SIDE" Transducer Installation .......................................................................................12

2.2.4 “HULL MOUNT” Installation ...............................................................................................................12

2.3 Echotrac MKIII Cable Connections ...........................................................................................................13

2.3.1 Serial 1 ...............................................................................................................................................13

2.3.2 Serial 2 ...............................................................................................................................................13

2.3.3 Serial 3 ...............................................................................................................................................13

2.3.4 Serial 4 ...............................................................................................................................................13

2.3.5 GPS In................................................................................................................................................13

2.3.6 GPS Out.............................................................................................................................................14

2.3.7 VGA....................................................................................................................................................14

2.3.8 LAN ....................................................................................................................................................14

2.3.9 Aux .....................................................................................................................................................14

2.3.10 TX1 .................................................................................................................................................15

2.3.11 TX2 .................................................................................................................................................15

2.3.12 DC ..................................................................................................................................................15

2.3.13 AC...................................................................................................................................................15

3 Quick Start Operating Procedures...............................................................................................................16

4 Chart Recorder Controls...............................................................................................................................17

4.1 ON/OFF.....................................................................................................................................................17

4.2 FEED.........................................................................................................................................................17

4.3 TAKE-UP...................................................................................................................................................17

4.4 LIGHT........................................................................................................................................................17

5 Display Panel Controls..................................................................................................................................18

5.1 Analog Controls.........................................................................................................................................18

5.1.1 POWER..............................................................................................................................................18

Echotrac MKIII Operator's Manual 4.06

Page 6 of 48

January 21, 2019

5.1.2 Transmitter and Receiver Controls ....................................................................................................19

5.1.3 MARK.................................................................................................................................................19

5.2 Parameter Entry System ...........................................................................................................................20

5.2.1 System Menu .....................................................................................................................................20

5.2.2 Setup Menu........................................................................................................................................22

5.2.3 Calibrate Menu...................................................................................................................................25

5.2.4 Chart Menu ........................................................................................................................................26

5.2.5 Communications Menu ......................................................................................................................28

5.2.6 Diagnostic Menu ................................................................................................................................29

6 Operating Procedures ...................................................................................................................................31

6.1 Shallow Water Operation ..........................................................................................................................31

6.2 Deep Water Operation ..............................................................................................................................31

6.3 Calibration .................................................................................................................................................32

7 Data I/O ...........................................................................................................................................................33

7.1 Serial Ports – Serial 1................................................................................................................................33

7.1.1 SERIAL OUTPUT STRING FORMATS .............................................................................................33

7.1.2 DESO DDV ........................................................................................................................................36

7.1.3 DESO COMMANDS...........................................................................................................................37

7.1.4 NMEA DBS ........................................................................................................................................37

7.2 Serial Data Input / Chart Annotation..........................................................................................................37

7.2.1 External Serial Control of Echotrac Parameters ................................................................................38

8 Overview parameters and settings ..............................................................................................................40

8.1 External Ethernet Control of Echotrac Parameters ...................................................................................40

8.2 Serial Ports – Serial 2................................................................................................................................40

8.3 Serial Ports – Serial 3................................................................................................................................40

8.4 Serial Ports – HEAVE................................................................................................................................40

8.5 ETHERNET Port .......................................................................................................................................40

9 Uploading Firmware ......................................................................................................................................41

9.1 Upgrading Motorola Processor Firmware..................................................................................................41

9.2 Upgrading DSP Firmware and Transceiver Processor Firmware .............................................................41

Appendix A – LCD15 Module................................................................................................................................43

A.1 Connections to the MKIIIE.........................................................................................................................43

A.1.1 Mouse and Keyboard Considerations ................................................................................................44

A.1.2 Starting and Shutting down the LCD15 Module .................................................................................44

A.1.3 Use of USB Memory Stick..................................................................................................................44

A.1.4 LCD15 Brightness Control .................................................................................................................44

A.2 Connecting to the MKIIIE...........................................................................................................................44

A.3 Making Changes To The Embedded Software Configuration ...................................................................45

A.3.1 Enhanced Write Filter.........................................................................................................................45

A.3.2 File Locations .....................................................................................................................................45

A.3.3 Installing Programs ............................................................................................................................45

Appendix B – AUX Modification for SILAS Output.............................................................................................46

Appendix C – Support and Service......................................................................................................................48

C.1 Support......................................................................................................................................................48

C.2 Returning Goods for Service.....................................................................................................................48

Echotrac MKIII Operator's Manual 4.06

Page 7 of 48

January 21, 2019

1 INTRODUCTION

1.1 Echotrac MKIII

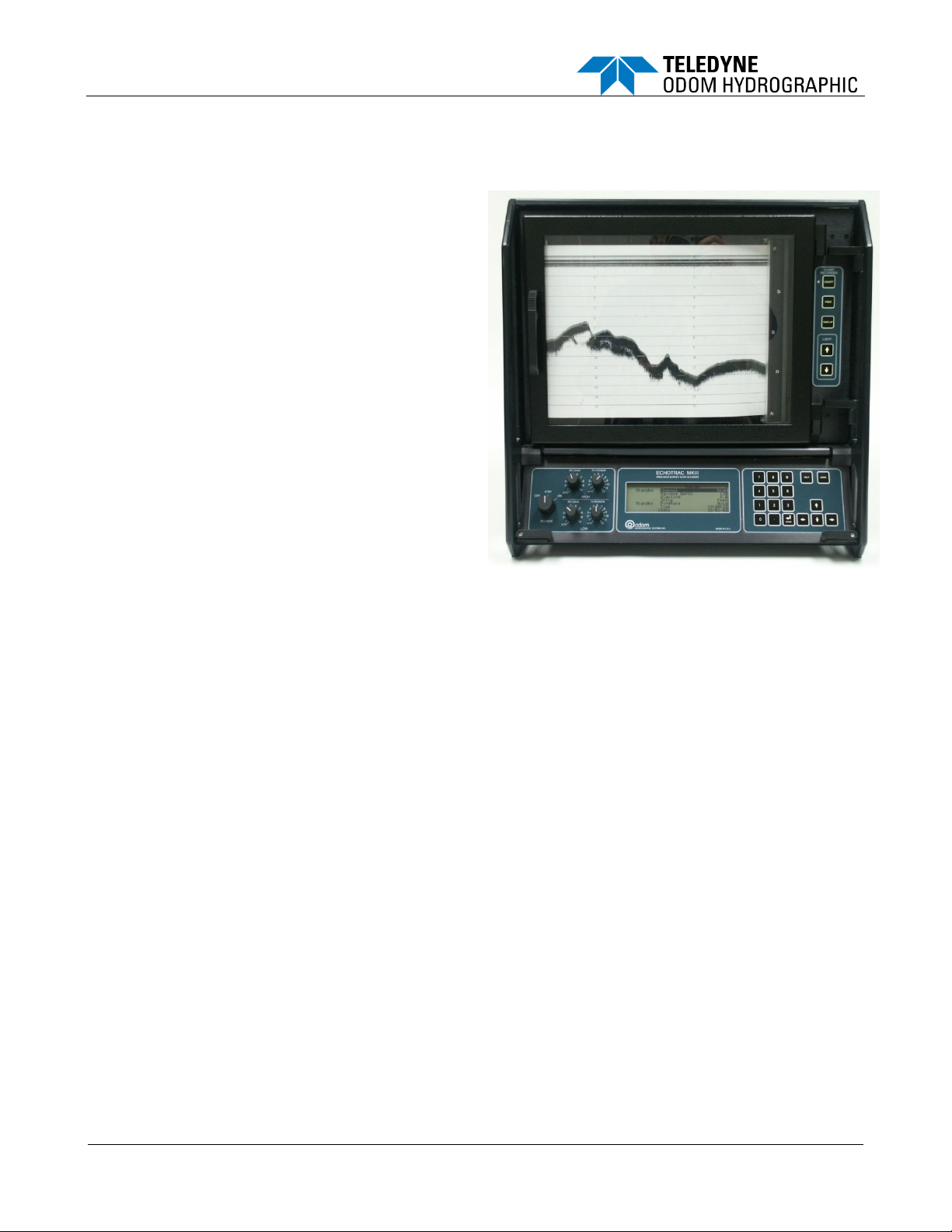

The Echotrac MKIII professional grade echo sounder

Recorder, Digitizer, Transceiver, utilizes multiple

processors including two dedicated Digital Signal

Processors (DSPs), working in concert to accomplish

specific analysis tasks while communicating effectively on a

real-time basis in order to assure accurate measurements

under difficult sea conditions and over all types of seabed.

1.1.1 Dual Frequency Operation

Two simultaneously transmitted frequencies are

selectable in 100 Hz steps in the following bands: High

Band - from 100 kHz to 1000 kHz and in the Low Band –

from 10 kHz to 50 kHz.

1.1.2 Printer Mechanism

The high-resolution thin-film thermal print head (216mm

(8.5") wide, 8 dots per mm (203/in.) is capable of printing

returns in up to 16 gray shades. Because of its construction,

the print head consumes very little power compared to

previous technologies. A stepper motor drives the print

mechanism while a DC motor and associated slipping-clutch mechanism re-winds the printed chart independently.

1.1.3 Display

Transflective, Back-lighted Graphical LCD Module (64 x 240 dots). The display shows six dot rows, has an on

board controller and LED backlighting. The transflective display was chosen because of its excellent visibility in all

light conditions from bright sun to darkened wheelhouse.

1.1.4 LCD Chart Panel

An alternative to the printer module is the LCD chart panel. It is a 1024x768 pixel color active matrix display with a

500 NIT back light. The LCD chart panel records echosounder data on internal drives. An export is possible via

the LCD chart panel’s USB interface or LAN interface.

1.1.5 Keypad

The 18 key-sealed micro-switch unit has good tactile feel and audible feedback. The keypad is used for direct

parameter value entry and functional control of the sounder from the front panel.

1.1.6 Receivers

The MKIII gives immediate control of Receiver Gain via continuously variable front panel mounted potentiometers.

The unit incorporates multiple, selectable TVG curves (10 log, 20 log, 30 log, and 40 log) and AGC as well.

1.1.7 Transmitter

Transmit frequencies are digitally synthesized and based on the stable frequency characteristics of a crystal

controlled clock oscillator. Transmitted power for both high and low channels is individually adjustable via front panel

mounted controls. Power is adjustable from the minimum of only 2 watts in high frequency shallow water

applications to over 2000 watts in low frequency deepwater uses. Transmit Pulse Width is variable either

automatically (actual value dependent on frequency and depth) or manually by keypad entry.

Echotrac MKIII Operator's Manual 4.06

Page 8 of 48

January 21, 2019

1.1.8 Communication Ports

Warnings alert the user to potential harm to personnel. Ignoring warnings may lead to

injury, health hazards, or death.

Cautions alert the user to improper use of the system. Ignoring cautions may lead to

accidental damage to the equipment or loss of data.

Notes provide additional system or operating information not related to the safety of personnel or

equipment.

The Echotrac MKIII has 4 serial ports that can be configured to interface with computers, positioning systems,

motion reference units and remote displays. The MKIII also has an Ethernet port that outputs the 16 bit samples

of the acoustic data for further processing or visualization.

1.2 Echotrac MKIII Operator’s Manual

1.2.1 Purpose

The purpose of this document is to explain the features and operation of the Echotrac MKIII.

1.2.2 Scope

The content of this document is focused on the end-user.

1.2.3 Warnings, Cautions, and Notes

Throughout the manual the following definitions apply and in the format shown.

If you require additional information or need clarification of any part of this document, please contact the customer

support hotline

Europe: +45 20 999 088

USA: +1 805 233 3900

E-mail: reson-support@teledyne.com

1.2.4 Glossary

DBS Depth Below Surface

DBT Dual Bottom Tracking

DSP Digital Signal Processor

NMEA National Marine Electronics Association

SBT Single Bottom Tracking

TVG Time Varied Gain

VDC Volts Direct Current

Echotrac MKIII Operator's Manual 4.06

Page 9 of 48

January 21, 2019

2 INSTALLATION

DC Fuses

DC Power Connector

AC Fuse Compartment

AC Power Conn.

2.1 Echotrac DF 3200 MKIII Recorder Installation

The Recorder is a flexible unit designed for tabletop, rack, or bulkhead mounting. Rack mounting can be

accommodated with the included special hardware, while bulkhead mounting requires ordering additional optional

hardware. Where tabletop mounting is preferred, it is highly recommended that the unit be secured with external

'tie-downs' for rough seas or heavy swells.

2.1.1 Power

The MKIII can be powered by either AC or DC power sources. Switch over between sources is automatic. DC

operation requires an input voltage between 18 and 29 VDC (nominal 24 VDC). Average power consumption is

approximately 75 watts. Frequently, power is derived from two 12 V lead-acid batteries connected in series. Two

"car" batteries (24V configuration), fully charged, and in good condition, can normally power a unit for a full day

without re-charging.

If using an AC source, the unit’s internal switcher accommodates either 110 or 230 VAC (50/60HZ) operation without

operator intervention. Regardless of the input source (AC or DC), the input power should be well regulated and

monitored closely for voltage transients, spikes, etc. Regulated DC supplies should be able to source a short

duration in-rush current spike of approximately 6 amps and an average current load of 3 amps. In the case of

"charger" type (unregulated) supplies, the output should be "floated" across a battery load and not connected solely

to the echo sounder’s DC input. Details of the power cable are given in section 2.3. Should the DC input voltage

polarity be applied in reverse, an audible alarm within the unit will sound regardless of the POWER switch setting. In

the event that the input voltage drops below the minimum threshold, the unit will automatically shut down.

2.1.2 Cabling

All cabling is via the connectors located in the recessed panel at the top rear of the unit. A view of the connector

arrangement is shown in Figure 2.1. Cable details are given in section 2.3. Care should be taken to route cables

using horizontal and vertical runs wherever possible. Avoid paths that run adjacent to transmitter feeder cables or

close to heat radiating elements such as steam pipes. For permanent installations, cables should be clamped at

regular intervals (1m) along their complete lengths.

Figure 1: Cabling

2.1.3 Fuses

For DC operation, both the positive and return lines are protected by fast blow standard glass tube (5-Amp/250

Volts) fuses. The two externally accessed fuses are mounted on the rear connector panel. The negative fuse

protects the unit from damage resulting from contact with external peripherals that do not share a common return

path potential. A 5-amp fuse is included in the AC input connector as well.

Echotrac MKIII Operator's Manual 4.06

Page 10 of 48

January 21, 2019

2.1.4 Chart Paper

Print Head release lever

Supply Door release lever

Take-Up Door release lever

2.1.4.1 General Paper Description

The Echotrac MKIII uses either thermal film or high quality thermal paper as the recording media for the analog

chart. The rolls are 216mm (8.5") wide and contain approximately 52m (170') of paper (film rolls are approximately

30m long). The inside diameter of the core is 12.7mm (½"), and the outside diameter of the roll is about 64mm (2.5").

Figure 2: Chart Paper

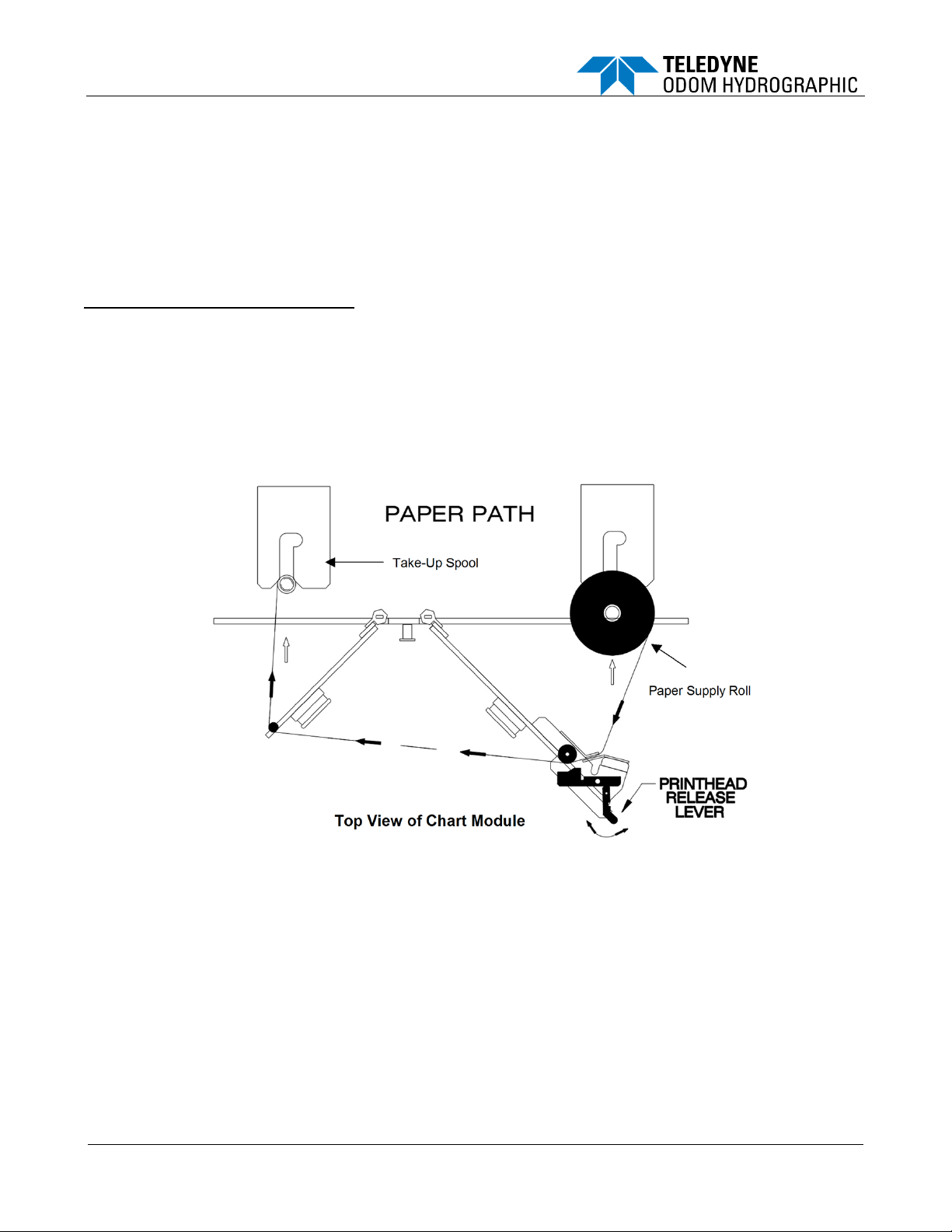

2.1.4.2 Loading paper

Loading paper is a multi-step process, but it need not be a difficult one if care is taken to assure that each step is

accomplished properly. As in almost all thermal recorders (including FAX machines), paper is sourced from a

supply roll, where it passes over a roller, which moves the paper past the thermal print head. A print head release

mechanism lifts the head away from the roller to assist in initial paper loading.

The Echotrac’s printed chart paper is taken up on a take-up spool behind the paper access door at the far left of

the chart panel. The motor that drives the take up spool does not advance the paper, as is the case in some echo

sounders. Movement of paper across the print head is accomplished by the stepper motor. In this configuration,

previously printed chart can be pulled from the take up assembly for review and simply re-wound without

disturbing the recording process.

Loading Paper Procedures:

1) Open the plexiglass chart door by pulling on the handle on the left side and remove it by lifting up on the hinged side.

2) If paper has been previously installed in the unit, place the power switch in the STANDBY position. Press the CHART

FEED switch until sufficient paper has been advanced to clear any previously recorded data. Cut the paper at some

point after the recorded data and press the Chart Take-up switch. This will allow the take-up mechanism to wind up

the recorded chart.

3) Locate the print head release lever on the right side of the print head. Move the lever to the right in order to lift the print

head away from the roller.

Echotrac MKIII Operator's Manual 4.06

Page 11 of 48

January 21, 2019

4) To gain access to the supply roll turn the supply side door release lever located on the lower right side of the chart

panel counter clockwise and pull the door open.

5) Remove any remaining paper from the paper path and remove the spent supply roll from the holder

mechanism by grasping the core and pushing it to the left and pulling out.

6) To gain access to the take-up roll turn the take-up door release lever located on the lower left side of the chart

panel clockwise and pull the door open.

7) Remove the take-up roll by grasping it, pushing it to the left, and pulling out. To remove the old paper from the

take up spool, spin the take-up spool in the opposite direction the paper is wound onto the take-up spool.

Remove the plastic end cap using a twisting motion and pull the paper off.

To Install a Fresh Paper Supply Roll:

8) Remove the source paper ends from the spent core and insert them into a new paper supply roll.

9) Insert the roll in the slots until it reaches the end and shift to the right, locking into place. Make sure the paper

is feeding from the right side of the roll.

10) Thread the paper past the print head and towards the take-up side as indicated in the paper path drawing.

11) The paper can be attached to the take-up spool either with a small piece of tape or by inserting the paper in the

slot of the take-up spool. Inserting the paper in the slot requires folding up the edges of the paper. Replace the

end cap to the take up spool and insert the take-up roll into the chart the same way as the supply roll.

12) Close both doors and press the feed button until the paper is aligned. Close the print head release lever. Now

the unit is ready for normal operation.

2.2 Transducer Installation

Proper mounting of the transducer is a crucial part of the installation of any "survey" echo sounder. An improperly

mounted transducer will result in poor system operation and unacceptable data quality.

In the case of temporary installations, the transducer may be mounted over-the-side. In permanent installations and

“class 1 surveys", hull mounts are generally preferred and often required. In either case, transducers should be

mounted at least 0.3 meters below the waterline. In cases where "over-the-side" mounts are exposed to wave action,

ensure that the transducer is mounted sufficiently deep so that it does not break the surface during vessel roll motions.

A preferred mounting location is near the keel of the vessel, in an area where the planning attitude of the hull at

speed, and the pitch and roll angles of the vessel in seas, have the least effect. The transducer should be mounted

far enough aft of the bow so that bubbles generated by the bow wave will not pass over the face of the unit.

Figure 3: Chart Module Top View

Echotrac MKIII Operator's Manual 4.06

Page 12 of 48

January 21, 2019

Transducers should be located away from sources of turbulence and cavitation bubbles such as propellers, bow

Care should be taken to protect the transducer from damage and turbulence by installing

a fairing with a sloping forward edge ahead of the unit.

The fairing has the dual effect of minimizing possible strike damage and smoothing the

flow of water over the face of the transducer.

Care should be taken to assure adequate protection for the transducer cable, particularly

at the point where the cable leaves the transducer body.

thrusters, and hull protrusions. Considerations should also be given to sources of mechanical noise generated within

the vessel (engines, props, pumps, generators, etc.). In some severe cases of mechanically coupled noise,

vibration-isolating mounts may be required to decouple the transducer from the hull.

Transducer mounting can be accomplished in many different ways. The following four sections show common

configurations.

2.2.1 "THROUGH HULL" Installation

The topside of the transducer is accessible from inside the vessel while the transducer face is directly exposed to

the water.

2.2.2 "SEA CHEST" Installation

In a "sea chest" mount, a fluid-filled enclosure large enough to contain the entire transducer is attached to the outer

hull of the vessel. The outer hull is removed within the area of the chest and replaced with an acoustically clear

"window", which is mounted flush with the hull immediately below the chest. Depending on construction, the material

selected for the acoustic window, and the draft of the vessel, access can often be gained to the transducer from

inside the hull without putting the vessel in dry-dock. In most installations, a water-filled standpipe is incorporated

into the "sea chest" design in order to provide hydrostatic pressure equalization. Transducer cables generally leave

these assemblies through “stuffing tubes” designed to maintain the watertight integrity of the chest.

2.2.3 "OVER-THE-SIDE" Transducer Installation

A temporary mount of this type is frequently constructed by welding a length of pipe to a flat plate that has been

drilled to accommodate the mounting points of the transducer. This length of pipe should be chosen to position

the transducer well below the waterline. A sturdy support on the vessel should be selected for the attachment

point of the pipe. Guy lines are usually attached at the transducer plate and run fore and aft to tie-points on the

gunnels. The guy lines and topside fixing point help to maintain a stable, horizontal transducer attitude.

2.2.4 “HULL MOUNT” Installation

Transducers that are “streamlined” and can be mounted directly to the outside of the hull or transducers that are fitted

into streamlined fairings welded or otherwise attached to the outside of the hull, often make for excellent installations.

The advantage here is that the radiating face of the transducer is generally below the “bubble stream” in clear water

and no acoustic window or transducer tank is involved to create extra reverberation (ringing). This type of installation

requires a stuffing tube to be installed in the hull in order to allow the transducer cable to penetrate the hull.

In all of the above installations, particular care should be taken to assure that the transducer radiating

face remains as parallel to the water surface as possible while the vessel is underway.

Echotrac MKIII Operator's Manual 4.06

Page 13 of 48

January 21, 2019

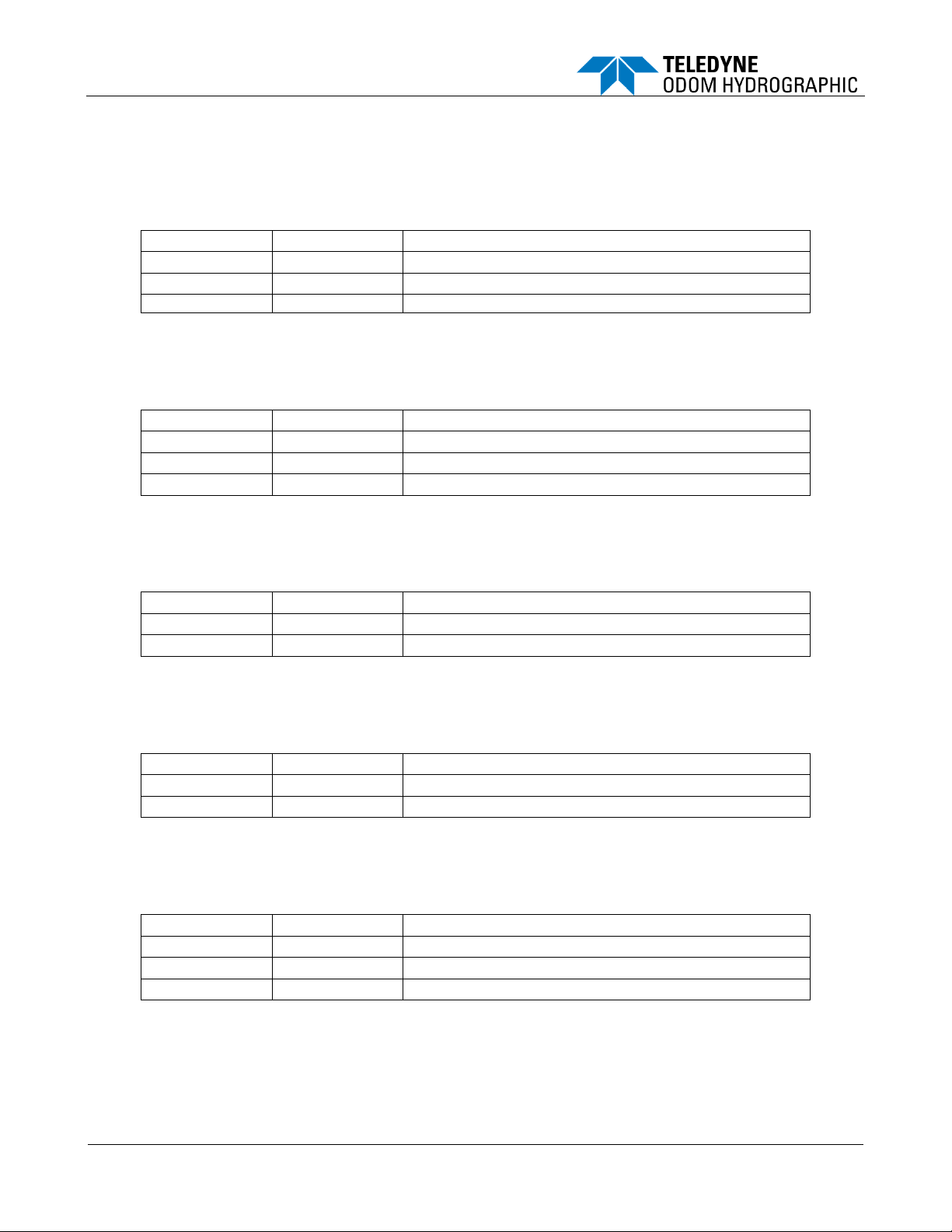

2.3 Echotrac MKIII Cable Connections

Connector PN

Pin Number

Signal Description

DB9 Male

2

Transmitted data from Echotrac MKIII

3

Received data to Echotrac MKIII

5

GND

Connector PN

Pin Number

Signal Description

DB9 Male

2

Transmitted data from Echotrac MKIII

3

Received data to Echotrac MKIII

5

GND

Connector PN

Pin Number

Signal Description

DB9 Male

3

Data from the positioning system to the Echotrac MKIII

5

GND

Connector PN

Pin Number

Signal Description

DB9 Male

3

Data from the motion sensor to the Echotrac MKIII

5

GND

Connector PN

Pin Number

Signal Description

DB9 Male

2

Transmitted data to the Internal GPS

3

Received data from the Internal GPS

5

GND

2.3.1 Serial 1

Serial 1 is the main communication port to and from the Echotrac MKIII. Use this port to receive depth values,

send annotation information, change parameters, and to upgrade the firmware.

2.3.2 Serial 2

Serial 2 is used for connecting a remote display to the Echotrac MKIII. Serial 2 is the only port that can be

configured as either RS232 or RS422.

2.3.3 Serial 3

Serial 3 is used for interfacing a positioning system to the Echotrac MKIII. The Echotrac MKIII will read NMEA

GLL or GGA sentences though this port.

2.3.4 Serial 4

Serial 4 is used for interfacing a motion reference sensor to the Echotrac MKIII. The Echotrac MKIII will read the

TSS1 string through this port.

2.3.5 GPS In

GPS In is only used when the Echotrac MKIII has a built in GPS unit. If the Echotrac MKIII has a built in GPS then

this is the configuration port for the GPS or can be used to input external RTCM correction to the GPS.

Echotrac MKIII Operator's Manual 4.06

Page 14 of 48

January 21, 2019

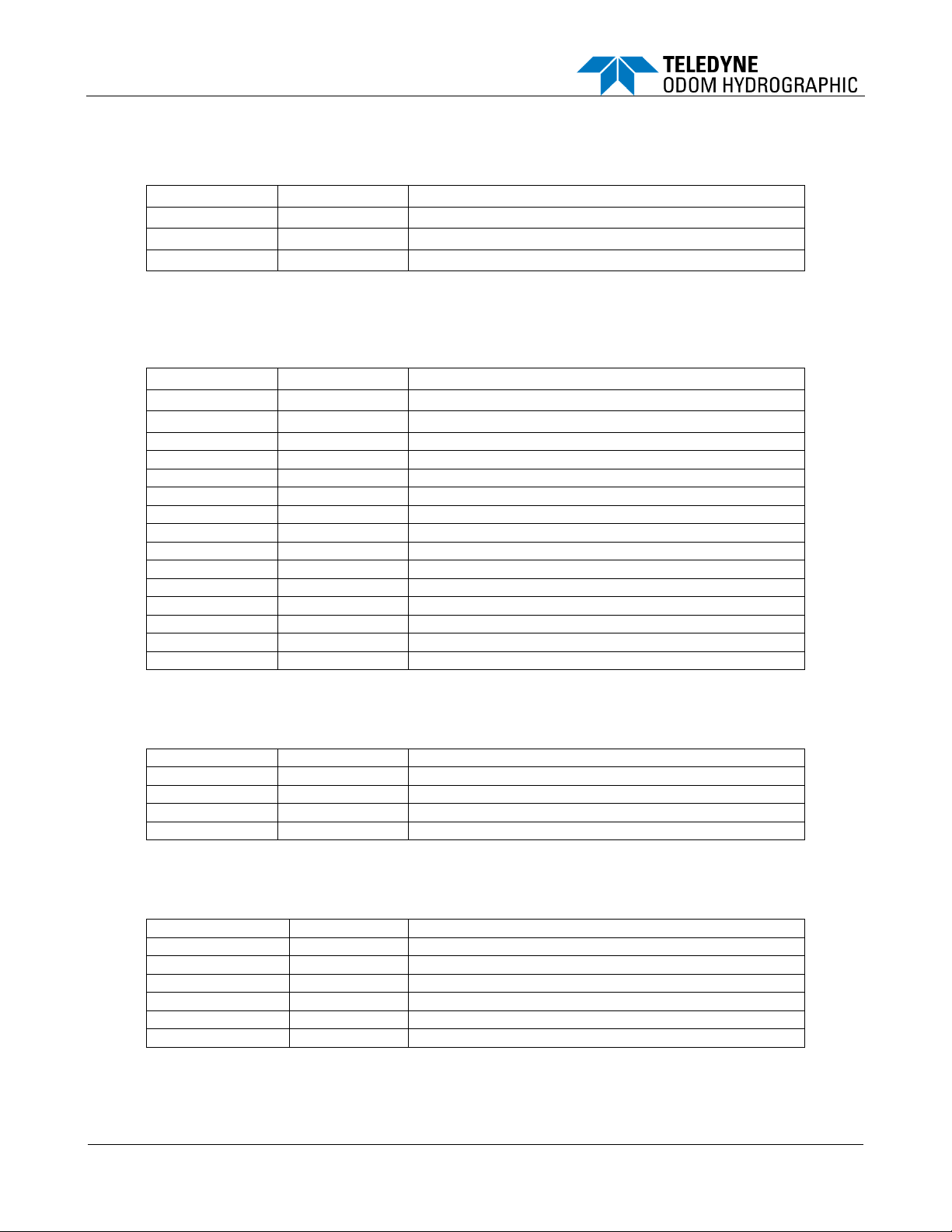

2.3.6 GPS Out

Connector PN

Pin Number

Signal Description

DB9 Male

2

Transmitted data to the Internal GPS

3

Received data from the Internal GPS

5

GND

Connector PN

Pin Number

Signal Description

VGA Male

1

Red2Green

3

Blue

4

ID25GND TEST

6

GND

7

GND

8

GND

9NC10

GND

11

ID012ID113HS14VS15ID3

Connector PN

Pin Number

Signal Description

10BASE-T

1

TX +

2

TX -3RX +

6

RX -

Connector PN

Pin Number

Signal Description

MS3116J10-6P

A

External Mark Input

B

External Trigger Input

C

TxRx or Start Signal

D

Reply signal for low frequency

E

Reply signal for high frequency

F

GND

GPS Out is only used when the Echotrac MKIII has a built in GPS unit. If the Echotrac MKIII has a built in GPS

then this is the output port for the GPS data.

2.3.7 VGA

VGA is only used when the Echotrac MKIII has an LCD module in place of the printer. The VGA connector allows

the user to connect a monitor to the Echotrac MKIII to see the same data that is in the LCD display.

2.3.8 LAN

The LAN connection is the Ethernet port for the Echotrac MKIII.

2.3.9 Aux

The Auxiliary port is used for acquiring the analog signal from the Echotrac MKIII.

Echotrac MKIII Operator's Manual 4.06

Page 15 of 48

January 21, 2019

2.3.10 TX1

Connector PN

Pin Number

Signal Description

MS3116J14-5P

A

Shield

B

High Frequency

C

Low Frequency

D

Low Frequency

E

High Frequency

Connector PN

Pin Number

Signal Description

MS3116J14-5P

A

Shield

C

Low Frequency

D

Low Frequency

Connector PN

Pin Number

Signal Description

MS3116J12-3S

A

+ 24 Volt DC

C

GND

TX1 is the main transducer connection port for the Echotrac MKIII. If using Odom Hydrographic Systems, Inc.

normal dual frequency transducer or a signal frequency transducer connect the transducer here.

2.3.11 TX2

TX2 is used when there is a separate low frequency transducer from the high frequency transducer. The low

frequency transducer is connected here.

2.3.12 DC

The DC connector is used to supply DC input power. The range of the DC power is 18-30 VDC.

2.3.13 AC

The AC connector is used to supply AC input power. The range of the AC power is 100-230 VAC, 50-60 Hz. The

Echotrac MKIII power supply automatically senses the input range and adjusts to it.

Loading...

Loading...