Teledyne Deltaflow DF180 Operation And Maintenance Manual

DF180 GAS FLOW AND TEMPERATURE MONITOR

Operation and Maintenance Manual

Teledyne Monitor Labs

35 Inverness Drive East

Englewood, CO 80112

TML DOCUMENT 99702200

Revision A

www.teledyne-ml.com

This document contains information proprietary to Teledyne Monitor Labs and is furnished with the

Transfer of EAR99 technical

express condition that the information contained herein will not be used for second source procurement

or directly or indirectly in any way detrimental to the interests of Teledyne Monitor Labs.

information

Use and Disclosure of Data

Information contained herein is classified as EAR99 under the U.S. Export

Administration Regulations. Export, reexport or diversion contrary to U.S. law

is prohibited.

Please contact your local Teledyne Monitor Labs regional sales or service representative, or call our

home office, if you require assistance.

Sales 800-422-1499

Technical Support 800-846-6062

Parts 800-934-2319

January, 2018 Page 2

Table of Contents

Table of Contents .......................................................................................................................................... 3

Specifications ................................................................................................................................................ 6

1 System Description ............................................................................................................................... 7

1.1 Instrument Panel ........................................................................................................................... 7

1.1.1 Controller .............................................................................................................................. 7

1.1.2 Differential Pressure (DP) Transmitter.................................................................................. 9

1.1.3 Push Buttons ......................................................................................................................... 9

1.1.4 Valve Manifold Assembly ...................................................................................................... 9

1.1.5 Absolute Pressure Transmitter ........................................................................................... 10

1.1.6 Temperature Transmitter ................................................................................................... 10

1.1.7 Precision Differential Pressure Switch ................................................................................ 11

1.1.8 Sample Filters ...................................................................................................................... 12

1.1.9 Power Supplies .................................................................................................................... 12

1.1.10 Precision Regulator ............................................................................................................. 12

1.2 Probe ........................................................................................................................................... 13

1.3 Sample Line ................................................................................................................................. 13

2 Theory of Operation ............................................................................................................................ 14

3 Installation .......................................................................................................................................... 16

3.1 Pre-Installation Planning and Preparation .................................................................................. 16

3.2 Site Selection ............................................................................................................................... 16

3.2.1 Representative Sampling Location ...................................................................................... 16

3.2.2 Access to Sampling Location ............................................................................................... 16

3.2.3 Environmental Conditions at Instrument Panel Location ................................................... 17

4 Web Interface ..................................................................................................................................... 17

4.1 Data ............................................................................................................................................. 19

4.1.1 Data: Values ........................................................................................................................ 19

4.1.2 Data: Alarms ........................................................................................................................ 20

4.1.3 Data: Calibrations ................................................................................................................ 20

4.1.4 Data: Modbus Map ............................................................................................................. 20

January, 2018 Page 3

4.1.5 Data: Tools .......................................................................................................................... 21

4.2 Control ........................................................................................................................................ 22

4.3 Configuration .............................................................................................................................. 23

4.3.1 Configuration: General ........................................................................................................ 23

4.3.2 Configuration: Inputs .......................................................................................................... 24

4.3.2.1 Configuration: Inputs: Analog ......................................................................................... 24

4.3.2.2 Configuration: Inputs: Modbus ....................................................................................... 25

4.3.2.3 Configuration: Inputs: Digital .......................................................................................... 25

4.3.2.4 Configuration: Inputs: Temperature ............................................................................... 25

4.3.3 Configuration: Outputs ....................................................................................................... 25

4.3.3.1 Configuration: Outputs: Computed ................................................................................ 25

4.3.3.1.1 Configuration: Outputs: Computed: Raw Velocity ................................................... 25

4.3.3.1.2 Configuration: Outputs: Computed: Velocity ........................................................... 25

4.3.3.1.3 Configuration: Outputs: Computed: Actual Volumetric Flow................................... 26

4.3.3.1.4 Configuration: Outputs: Computed: Standard Volumetric Flow .............................. 26

4.3.3.2 Configuration: Outputs: Analog ...................................................................................... 27

4.3.4 Configuration: Calibrations ................................................................................................. 27

4.3.4.1 Configuration: Calibrations: Timing ................................................................................ 27

4.3.4.2 Configuration: Calibrations: Evaluations ......................................................................... 28

4.4 Administrator .............................................................................................................................. 29

5 Operation ............................................................................................................................................ 29

5.1 Calibration and Adjustment ........................................................................................................ 29

5.2 Interference Check ...................................................................................................................... 30

5.3 Creating a Correction Curve ........................................................................................................ 30

5.4 Long-Term Shutdown .................................................................................................................. 31

6 Maintenance ....................................................................................................................................... 32

6.1 Scheduled Preventative Maintenance Chart .............................................................................. 32

6.2 Pitot Tube Cleaning Procedure ................................................................................................... 32

6.3 Sample Line Cleaning Procedure ................................................................................................ 32

6.4 Filter Media Replacement Procedure ......................................................................................... 33

January, 2018 Page 4

6.5 System Leak Test Procedure ....................................................................................................... 33

7 Troubleshooting .................................................................................................................................. 34

Appendix A: Spare Parts .............................................................................................................................. 35

Appendix B: Drawings ................................................................................................................................. 36

January, 2018 Page 5

Specifications

Flow Measurement:

Range:

0-300ft/sec (0-91m/sec)

Long-Term Repeatability:

+/-0.3ft/sec (+/-0.1 m/sec)

Relative Accuracy:

(vs. EPA Test Method 2)

Site dependent, see Commercial Performance

Warranty. Typically <5% above 10 ft/sec

Response Time:

8 sec

Drift:

+/- 1.5% of span over operating temperature range of instrument panel

Media Conditions:

Temperature:

-40° to 1000°F (-40° to +343°C)

Pressure:

-2 to 2 psig (-13.8 to 13.8 kPa)

Moisture:

Dry to saturated, including condensed water

Particulate:

</=3000 mg/m3

Duct Size:

Diameter:

From 3 - 45 Ft. (0.9 – 14m) Dia.

Temperature

Measurement:

Accuracy:

+/- 6 °F (3.3°C)

Long-Term Repeatability:

+/- 0.5% of span per year

Power:

100-240 VAC, 50/60Hz, Single Phase, 70 VA Maximum

Environment:

Ambient Temp. Limits:

Probe Assembly: -40°F to +160°F (-40° to 71°C)

Instrument Enclosure: +20°F to 104°F (-7°C to +40°C)

Relative Humidity:

Probe Assembly: 5% to 100% humidity, condensing

Instrument Enclosure: 0 to 95% non-condensing

Instrument Enclosure

NEMA 4/IP66 is standard, Ex Py purge protection can be

Mounting:

Process Connection:

4” 150# ANSI flange

Sizes & Weights:

Instrument Enclosure

Size: 30H x 24W x 12D (inches)

Weight: 135 lbs. (61 kg)

Probe Assembly

Size: Application dependent

Weight: 26 lbs. (11.8 kg), typical, application dependent

I/O:

Communication Protocol:

Modbus TCP/IP

Analog Outputs:

Two Outputs, 4-20mA current, one for differential pressure

Digital Inputs:

4 Inputs, dry contact Inputs are configurable to initiate

Relay Outputs:

Four configurable Outputs, Form C, (Single Pole Double

Maximum Contact Current: 10 Amps AC

Ratings:

January, 2018 Page 6

added as an option for Class I Division 2, and Zone 2

applications.

76H x 61W x 30.5D (cm)

and one for temperature

blow back, calibrations, Unit On, etc.

Throw)

Contact Voltage: 120/240VAC

1 System Description

The DeltaFlow 180 is an EPA compliant Pitot tube based flow monitoring system. The three main

components of the system are the instrument panel, probe, and sample line. This section describes in

detail each of these components.

1.1 Instrument Panel

The Instrument panel is typically mounted in a climate controlled area, and can be provided with or

without an enclosure. All the electronics, indicators, and valves for the system are located here.

Fig. 1-1 Deltaflow Instrument Panel

1.1.1 Controller

Daily quality assurance checks, signal processing, and monitor configuration are all handled by the

controller. The controller module I/O consists of 8 relays and 8 digital inputs. The relays are used to

control solenoid valves located on the instrument panel during calibration checks, interference checks,

and blowback sequences. The digital inputs are used to initiate different modes such calibration,

interference check, blowback, and maintenance. These modes can be initiated by the buttons located

on the instrument panel or by external dry contact signals from a plant distributed control system (DCS)

that are wired to the Deltaflow instrument panel terminal blocks.

Fig. 1-2 Deltaflow Controller, Analog Module, and Form C Relay Module

January, 2018 Page 7

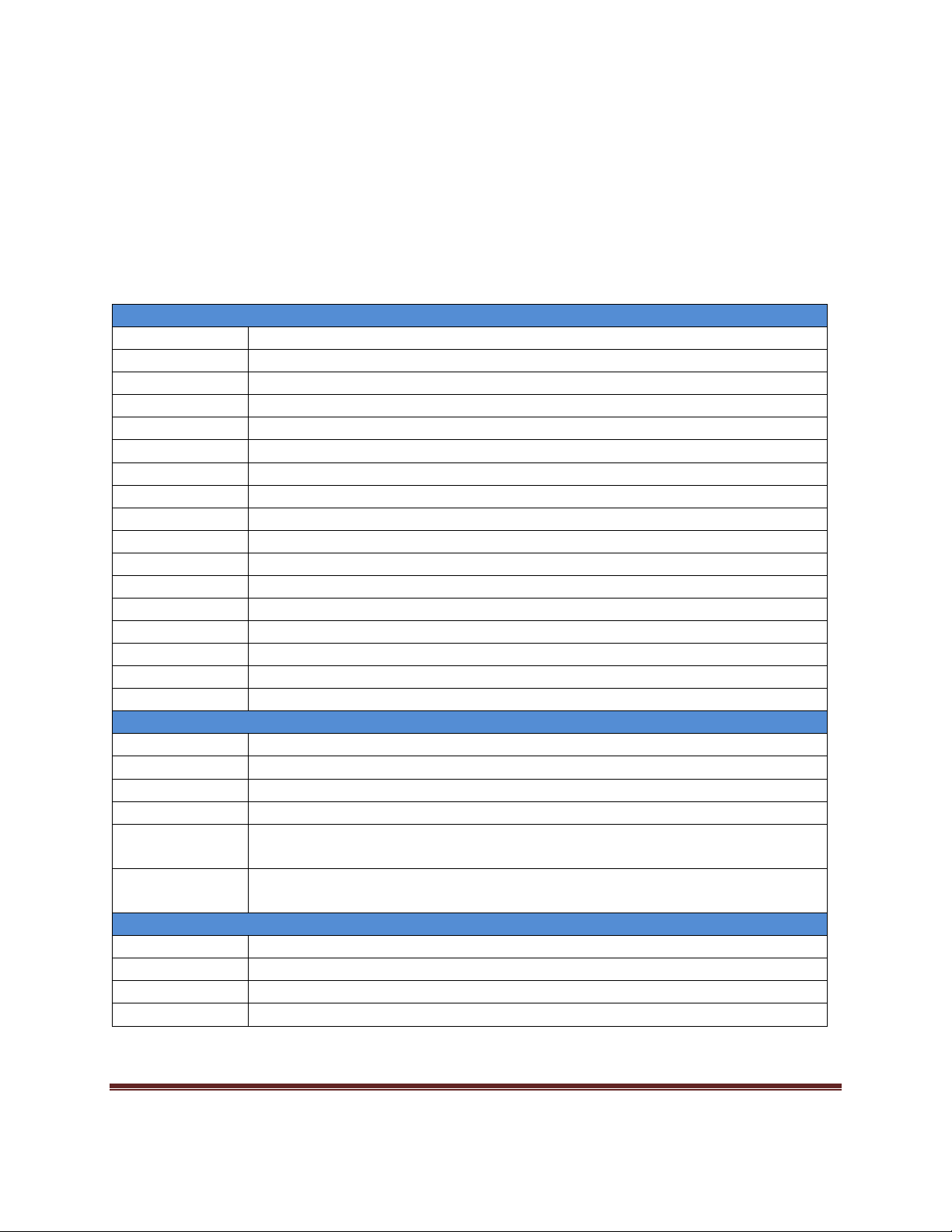

The controller has two external modules, the analog module and the form C relay module. The analog

Main Controller Module

Channel

Description

Relay 1

Solenoid Valve 1 – Impact Line Purge

Relay 2

Solenoid Valve 2 – Static Line Purge

Relay 3

Solenoid Valve 3 – Isolate DP Transmitter Low Side

Relay 4

Solenoid Valve 4 – Isolate DP Transmitter High Side

Relay 5

Solenoid Valve 5 – Span Calibration

Relay 6

Solenoid Valve 6 – Span Calibration (Low Pressure Instrument Air Delivery)

Relay 7

Solenoid Valve 7 – Span Calibration (Isolate DP Pressure Switch)

Relay 8

Not Used

Digital input 1

External Calibration Start

Digital input 2

External Interference Check Start

Digital input 3

External Blowback Start

Digital input 4

Maintenance

Digital input 5

Calibration Start

Digital input 6

Interference Check Start

Digital input 7

Blowback Start

Digital input 8

Not Used

Analog Module

Input 1

Differential Pressure

Input 2

Stack Temperature

Input 3

Stack Pressure

Input4

User defined

Output 1

Configurable – Differential Pressure, Stack Temperature, Stack Pressure, Velocity, Raw

Output 2

Configurable – Differential Pressure, Stack Temperature, Stack Pressure, Velocity, Raw

Form C Relay

Relay 1

In Calibration Mode

Relay 2

In Sample Mode

Relay 3

CEMS Fault (reverse logic, 1 = OK: 0 = Fault)

Relay 4

Value Based Alarm (e.g. based on user defined alarm limits)

module is used to take in 4-20mA signals from the various sensors on the instrument panel, and

transmit analog signals out of the instrument panel, such as velocity and temperature. The form C relay

module is used to relay status signals, such as fault or sample valid. Terminated on the form C relay

module is a temperature sensor that measures the ambient temperature of the instrument panel. Table

1-1 shows a complete I/O list for all the modules.

Table 1-1. Deltaflow Controller I/O list

Velocity, Actual Volumetric Flow, Standard Volumetric Flow, any user defined parameter

Velocity, Actual Volumetric Flow, Standard Volumetric Flow, any user define parameter

January, 2018 Page 8

1.1.2 Differential Pressure (DP) Transmitter

This device converts the pneumatic differential pressure signal measured by the probe to a 4-20mA

signal. It also provides a gauge style display to aid in troubleshooting the electrical signal. The gauge

needle can be zeroed and the 4-20mA signal can be calibrated at the display. Various ranges are

available; a TML Engineer selects the range based on process parameters of the application. See

Appendix A: Spare Parts for a complete list of all available ranges.

Fig. 1-3 Differential Pressure Transmitter with Display

1.1.3 Push Buttons

These buttons allow the user to start a blowback sequence, calibration check, interference check, or put

the Deltaflow into maintenance mode. Once pressed, the blowback sequence will start immediately.

Calibration and interference checks will start at the top of the next minute according to the controller

clock. Once pressed, the maintenance button will illuminate red and will put the Deltaflow into

maintenance mode until the button is pressed again. Maintenance mode causes the Deltaflow

controller to flag its’ data as invalid.

1.1.4 Valve Manifold Assembly

This assembly consists of 7 solenoid valves installed on a custom designed manifold. Static pressure,

impact pressure, and instrument air are directed through the manifold by the valves.

During normal sampling mode none of the valves are actuated; impact pressure and static pressure are

directed to the high and low sides of the differential pressure transducer, respectively. During a

blowback sequence or interference check, SV1 and SV2 send high pressure instrument air up the sample

line, while SV3 and SV4 isolate the differential pressure transmitter from the high pressure instrument

air.

The calibration check consists of a zero and span check. First, the DP transmitter high and low sides are

exposed to ambient pressure using SV3 and SV4. This provides a zero check. For the span check SV5,

SV6, and SV7 are activated. This allows low pressure instrument air to start pressurizing the DP

transmitter as well as the DP span set point switch. Once the DP span set point switch senses the correct

upscale pressure has been reached, it trips and shuts off SV6. This provides a stable upscale calibration

check. See the Plumbing & Instrumentation Diagram and the Timing Diagram in Appendix B for further

detail.

January, 2018 Page 9

Fig. 1-4 Solenoid Valve Manifold

1.1.5 Absolute Pressure Transmitter

Absolute stack pressure is needed to calculated velocity and standard volumetric flow. The DP

transmitter cannot continually measure stack pressure on its own. For this reason, the Deltaflow comes

standard with a 0-30 psia (61.1 inHg, 1551 mmHg) pressure transmitter. The transmitter is plumbed to

the static pressure line, and wired to input 3 of the analog module.

Fig. 1-5 Absolute Pressure Transmitter

1.1.6 Temperature Transmitter

Stack temperature is needed to calculated stack velocity and standard volumetric flow. The probe is

equipped with a type K thermocouple to accurately measure stack temperature. The thermocouple

signal is carried down to the instrument panel via thermocouple messenger cable in the sample line

where it is terminated on a DIN rail mounted transmitter. This device converts the thermocouple signal

to a 4-20mA signal that is wired to input 2 of the analog module.

The 4-20mA output range, and input type (RTD, TC, etc.) of the transmitter is adjustable using ProSense

XT-SOFT

software and a USB adapter cable (TML P/N 55000048-2).

January, 2018 Page 10

Fig. 1-6 Stack Temperature Transmitter

1.1.7 Precision Differential Pressure Switch

In order to provide a repeatable upscale differential pressure for daily calibration checks, a precision DP

switch is tied into the high side of the DP transmitter plumbing. During the beginning of a span check

this DP switch will shut off SV6 when it senses the correct pressure has been achieved on the high side

of the DP transmitter. This provides a repeatable and stable differential pressure to check the pneumatic

and electrical drift of the DP transmitter. The DP switch set point is adjustable via a screw at the left end

of the switch spring housing. These switches come in various ranges, see Appendix B: Spare Parts for a

complete list of all the available ranges.

Fig. 1-7 Precision Differential Pressure Switch

January, 2018 Page 11

1.1.8 Sample Filters

The differential pressure transmitter used in the Deltaflow is meant to only come in contact with clean

non- corrosive air. The Deltaflow purges the sample lines at a minimum of every 6 hours to ensure they

stay filled with clean instrument air. As added protection, each side of the DP transmitter has sample

filters that contain 13X molecular sieve, soda lime, and indicating Drierite®.

Fig. 1-7 Sample Filter

1.1.9 Power Supplies

Two power supplies are used. A 120W 24VDC power supply powers all the onboard Deltaflow

electronics, valves, and switches. A 10W 12 VDC power supply is used as loop power for the analog

outputs. Both power supplies’ inputs are rated 100-240VAC, 50/60Hz and are automatically adapting.

Both power supplies have “DC Voltage OK” indicating LEDs to aid in troubleshooting. The 24 VDC power

supply has a DC voltage output adjustment potentiometer.

1.1.10 Precision Regulator

In order to minimize the drift of the upscale differential pressure used during the daily cal checks, a

precision regulator is used that drops the instrument air supplied by the user from 50 psi down to 1.5

psi. This low pressure instrument air is bled into the high side plumbing of the DP transmitter by SV6 at

the beginning the of the daily upscale cal check.

Fig 1-8 Precision Regulator

January, 2018 Page 12

1.2 Probe

The Deltaflow Pitot tube probe assembly consists of an S type Pitot tube, a K type thermocouple, and a

4” mounting flange. All wetted components are constructed of Stainless steel. The Pitot tube comes in

various lengths, and the insertion depth is adjustable for easy installation. Once the desired insertion

depth is determined the Pitot tube is secured in place using a large compression fitting. The impact and

static sample lines are easily terminated on the probe using 3/8” compression fittings. The K type

thermocouple comes in various lengths and has a fixed insertion depth. The thermocouple wires from

the sample line are easily terminate in the head of the thermocouple assembly.

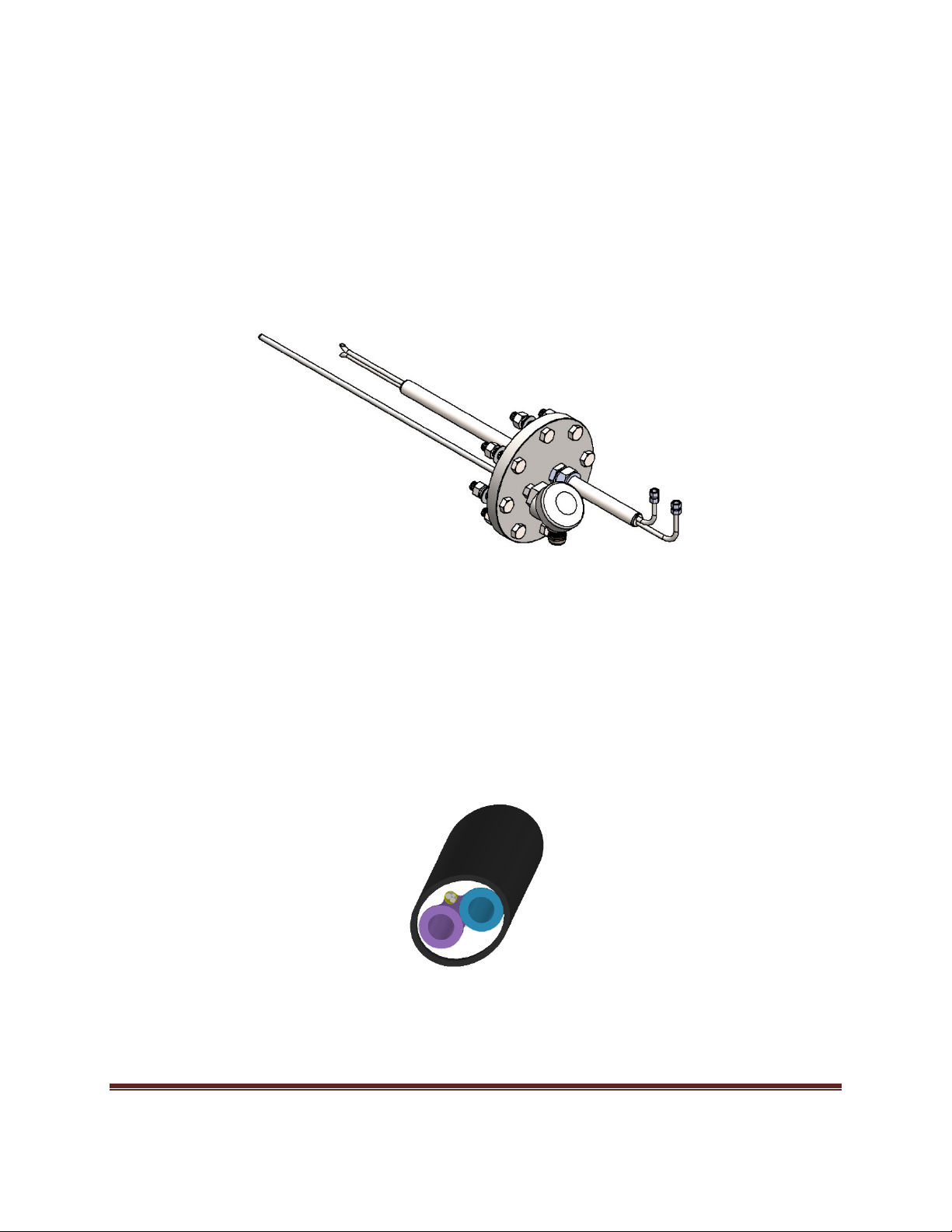

Figure 1-8 Deltaflow Probe

1.3 Sample Line

The Deltaflow sample line consists of a two 3/8” PFA Teflon sample lines, a K type thermocouple

messenger cable, a small amount of insulation, and a PVC jacket. The maximum recommended length

for the standard sample line is 430 feet. Line longer that this will require custom design. Custom sample

lines can be ordered with options such as stainless steel tubes, heaters, larger wires, or extra wires.

Fig. 1-9 Sample Line Cut Away

January, 2018 Page 13

Loading...

Loading...