Page 1

CANbus Trigger, Decode, and

Measure

Software Option

Operator's Manual

December, 2008

Page 2

Manufactured under an ISO

9000 Registered Quality

Management System.

Visit www.lecroy.com to view

the certificate.

This electronic product is subject to disposal and

recycling regulations that vary by country and region.

Many countries prohibit the disposal of waste

electronic equipment in standard waste receptacles.

For more information about proper disposal and

recycling of your LeCroy product, please visit

www.lecroy.com/recycle.

LeCroy Corporation

700 Chestnut Ridge Road

Chestnut Ridge, NY, 10977-6499

Tel: (845) 578-6020, Fax: (845) 578 5985

Warranty

LeCroy warrants this oscilloscope accessory for normal use and operation within specification for a period of one year

from the date of shipment. Spare parts, replacement parts and repairs are warranted for 90 days.

In exercising its warranty, LeCroy, at its option, will either repair or replace any assembly returned within its warranty

period to the Customer Service Department or an authorized service center. However, this will be done only if the

product is determined by LeCroy’s examination to be defective due to workmanship or materials, and the defect is not

caused by misuse, neglect, accident, abnormal conditions of operation, or damage resulting from attempted repair or

modifications by a non-authorized service facility.

The customer will be responsible for the transportation and insurance charges for the return of products to the service

facility. LeCroy will return all products under warranty with transportation charges prepaid.

This warranty replaces all other warranties, expressed or implied, including but not limited to any implied warranty of

merchantability, fitness or adequacy for any particular purposes or use. LeCroy shall not be liable for any special,

incidental, or consequential damages, whether in contract or otherwise.

Internet: www.lecroy.com

© 2008 by LeCroy Corporation. All rights reserved.

LeCroy, ActiveDSO, JitterTrack, WavePro, WaveMaster, WaveSurfer, WaveLink, WaveExpert, Waverunner, and WaveAce

are registered trademarks of LeCroy Corporation. Other product or brand names are trademarks or requested trademarks

of their respective holders. Information in this publication supersedes all earlier versions. Specifications are subject to

change without notice.

CANbus-TD-TDM-OM-E RevB

916940-00 RevA

Page 3

Operator's Manual

CANbus-TD-TDM-OM-E RevB

iii

TABLE OF CONTENTS

Introduction ............................................................................................................. 5

Overview ...................................................................................................................... 5

Compatibility................................................................................................................ 6

Assumptions ................................................................................................................ 6

The TD Series Software ............................................................................................. 6

The TDM Series Software .......................................................................................... 7

Using the CANbus Options ........................................................................................ 9

Accessing Serial Triggers .............................................................................................. 9

Creating a CANbus Trigger Condition ........................................................................ 10

CANbus Trigger Setup Detail...................................................................................... 10

CANbus Decode Setup Detail ..................................................................................... 14

Measuring CANbus Performance Using CANBUS TDM .............................................. 15

Overview of CANbus TDM (Trigger, Decode, Measure/Graph) ................................. 15

CANBUS TDM Parameters ......................................................................................... 16

CANbus TDM Graphing and Statistical Analysis ........................................................ 17

General Setup of CANbus TDM Parameters .............................................................. 18

CAN-to-Analog or Analog-to-CAN Measurement Parameter .................................... 22

CAN Message-to-CAN Message Measurement Parameter ....................................... 25

Extract CAN Message Data to a Decimal Value ......................................................... 27

CAN Bus Message Load Percent Measurement Parameter ...................................... 28

Time from Trigger Point to CAN Message Parameter ............................................... 30

Characterizing CANbus System Performance ............................................................ 30

System Performance Characterization Overview ...................................................... 30

Using Cursors ............................................................................................................. 32

Using Measurement Parameters ............................................................................... 34

Measurement Gating ................................................................................................. 35

Using Statistics and Graphing .................................................................................... 35

Pass/Fail Analysis with Measurement Parameters.................................................... 36

Page 4

CANbus Trigger, Decode, and Measure

iv

CANbus-TD-TDM-OM-E RevB

Isolating and Analyzing CANbus Activity .................................................................. 37

Isolate and Analyze Serial Bus Activity ...................................................................... 37

Reference ............................................................................................................... 45

CANbus TD and TDM Specifications .......................................................................... 45

Safety Requirements ................................................................................................. 47

Appendix A: External Trigger Hardware ................................................................... 48

CANbus TD Standard Hardware ................................................................................. 48

Accessories ................................................................................................................ 51

Connecting to a CANbus Circuit ................................................................................. 51

Trigger Setup .............................................................................................................. 62

Page 5

Operator's Manual

CANbus-TD-TDM-OM-E RevB

5

Introduction

Several communication protocol types are used in automotive applications. They are used to

send data from sensors to electronic control units (ECUs) or from one ECU to another. These

protocol types include Controller Area Network (CAN), Local Interconnect Network (LIN), and

FlexRay. LIN is a low-cost master/slave system designed for low-cost implementation in vehicles,

typically in what is commonly referred to as body electronics. FlexRay is a time-triggered

automotive communications bus designed for higher speeds and fault tolerance.

This manual focuses on the CANbus TDM and TD products. LeCroy also has separate LIN and

FlexRay products and manuals.

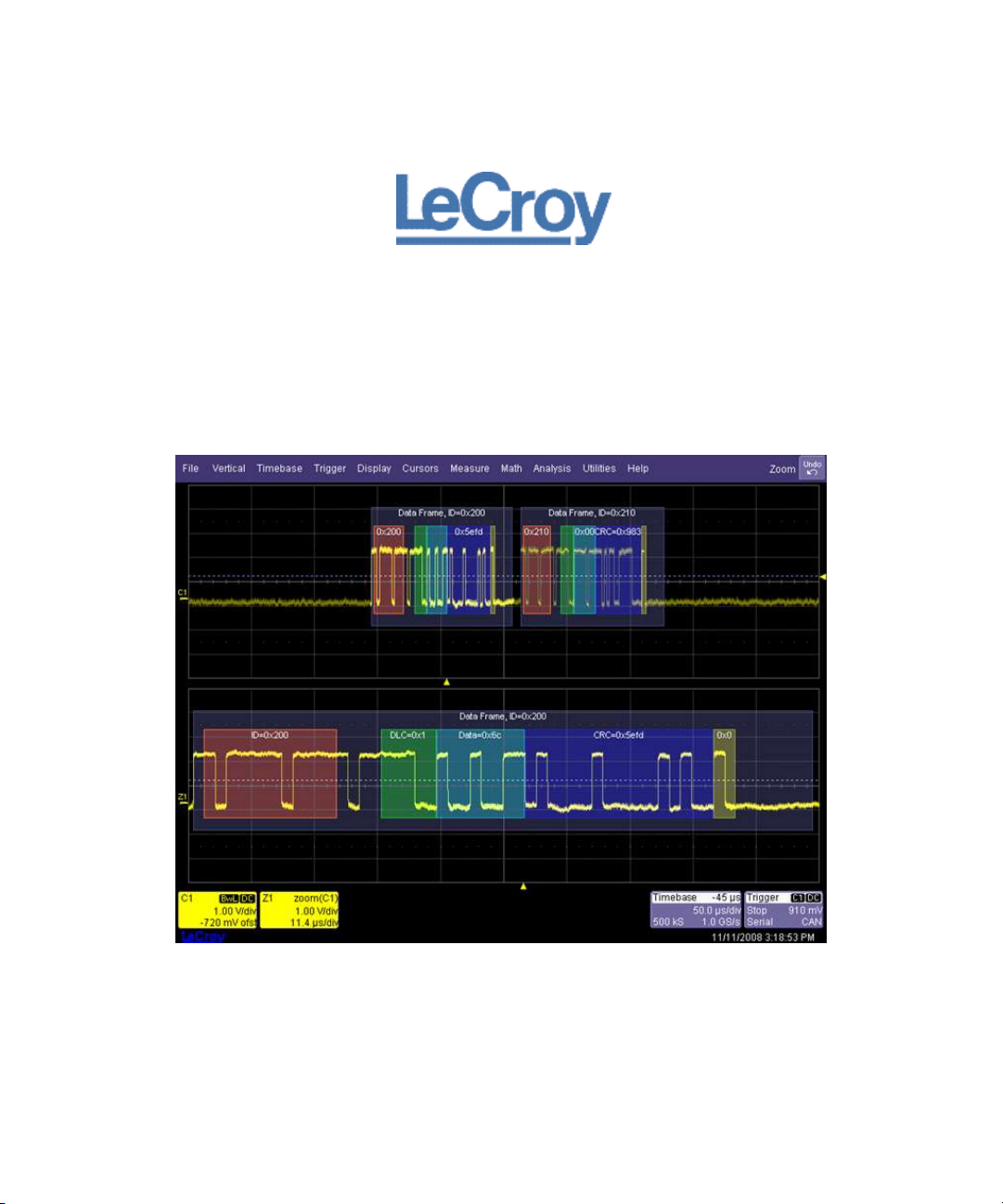

Overview

CANbus TDM and TD options contain powerful software algorithms which extract serial data

information from physical layer waveforms measured on your oscilloscope. The extracted

information is overlaid (annotated) on the actual physical layer waveforms, and color-coded to

provide fast, intuitive understanding.

The CANbus TD option allows triggering on CAN Frames and Errors. Frame triggering can be set

to trigger on any frame, one specific Frame ID, a range of Frame IDs, Remote Frames, and Errors.

Frame triggering and data triggering can be done for a single ID or message or a range of IDs and

data by using the conditional trigger capabilities. Other powerful and user-friendly features

included in CANbus TD include:

The ability to trigger and decode CAN at bit rates from 10 kb/s to 1 Mb/s.

The ability to create powerful, conditional Frame ID and Data triggers.

Triggering on CAN protocol errors and remote frames.

If you are unfamiliar or are just learning about CAN, start by using the simplest trigger conditions

(All Frames or Frame ID). Next, experiment with an ID and Data to trigger on a specific value.

Then, try a conditional ID + Data trigger (ID Greater Than or In Range).

The CANbus TDM and TD Serial Data options are unique oscilloscope tools from LeCroy which

greatly increase your ability to debug and analyze embedded controllers that use CAN. The TDM

product include Serial Trigger, Decode and Measure/Graph capabilities, the TD product include

Serial Trigger and Decode.

The CAN trigger is integrated into the oscilloscope - meaning no external hardware is used. It's

selected through the normal oscilloscope trigger menus. CAN signals are sent to the oscilloscope

using a differential probe like the ADP305 or AP033. Decoding is accessed from the Analysis

menu. The decoding is overlaid on top of the appropriate channel, and is intuitively presented

and color-coded for quick understanding. Measurement and graphing capabilities may be

accessed through the Measure/Graph tab in the Decode Setup or from the Measure menu. All

Page 6

CANbus Trigger, Decode, and Measure

6

CANbus-TD-TDM-OM-E RevB

packages contain Search capability for specific IDs, Data and Errors and a Table displays

summarized protocol data underneath the oscilloscope grid.

Compatibility

The CANbus TDM option is compatible for WavePro Zi and WaveRunner Xi oscilloscopes. The

CANbus TD option is compatible with the WavePro Zi, WaveRunner Xi and WaveSurfer Xs

oscilloscopes. CAN triggering is completely integrated with the oscilloscope and no external

hardware is required. Earlier versions of LeCroy’s CANbus TDM and TD options required the use

of an external trigger module, for documentation ion how to use the external trigger module

please see the appendix. The external trigger module is still available for use with WaveMaster

8000A, WavePro 7000A, and WaveRunner 6000A oscilloscopes.

Note: All references to Decode and Measure/Graph capabilities and functionality are identical

whether the external or internal CAN trigger is being used.

Assumptions

This manual assumes a basic understanding of the FlexRay standard physical layer and protocol

layer specifications, and knowledge of how FlexRay is used. Also, a basic understanding of

oscilloscope operation - specifically the LeCroy oscilloscope which the FlexRay trigger, decode,

and physical layer option is used with - is assumed. Wherever practical or necessary, details on

specific oscilloscope features have been included in this manual.

Note: LeCroy has a policy of frequently updating software. While screen images in this manual

may not exactly match what is seen on your oscilloscope display, be assured that the

functionality is nearly identical.

The TD Series Software

The TD option adds the following capability to the LeCroy oscilloscope software user interface

dialogs:

1. Serial Trigger Selection - If this is the first serial trigger option you have installed on your

oscilloscope, an additional icon is shown on your trigger dialog box. It allows a serial

trigger condition to be set from within the oscilloscope using an easy-to-understand

interface.

2. Serial Decode - If this is the first serial decode option you have installed on your scope, an

additional set of Serial Decode and Decode Setup dialog boxes are provided for setup of

Page 7

Operator's Manual

CANbus-TD-TDM-OM-E RevB

7

protocol format (as necessary) and decoding. These can be accessed from the Analysis

menu.

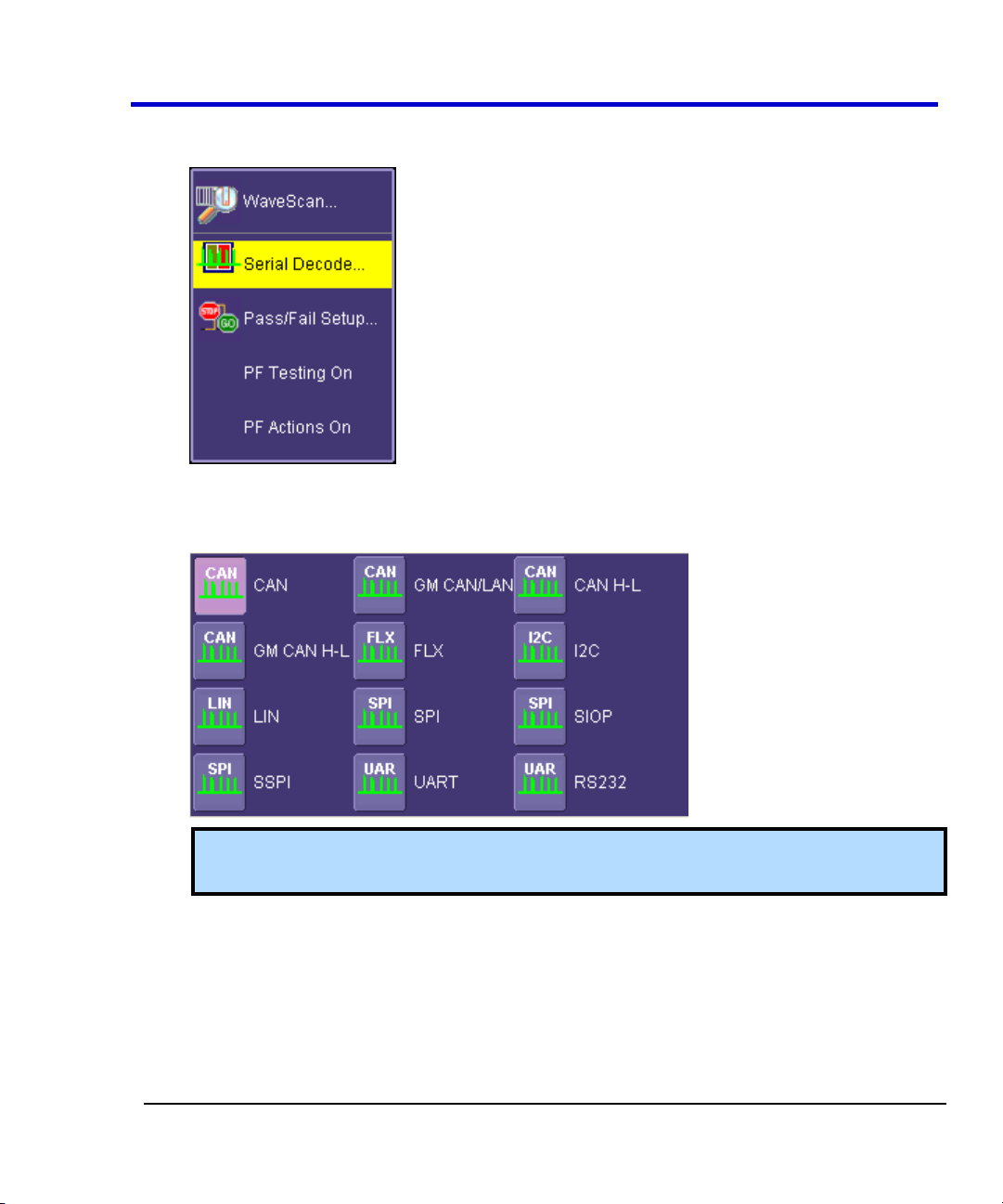

3. Decode Protocol Selections - As serial decode options are added to your oscilloscope,

additional protocol selections are available in a pop-up dialog box within the Serial

Decode dialog boxes.

Note: SIOP and SSPI are part of the SPIbus TD package. RS232 is part of the UARTRS232bus TD package.

The TDM Series Software

The TDP option adds the following capability to the LeCroy oscilloscope software user interface

dialogs:

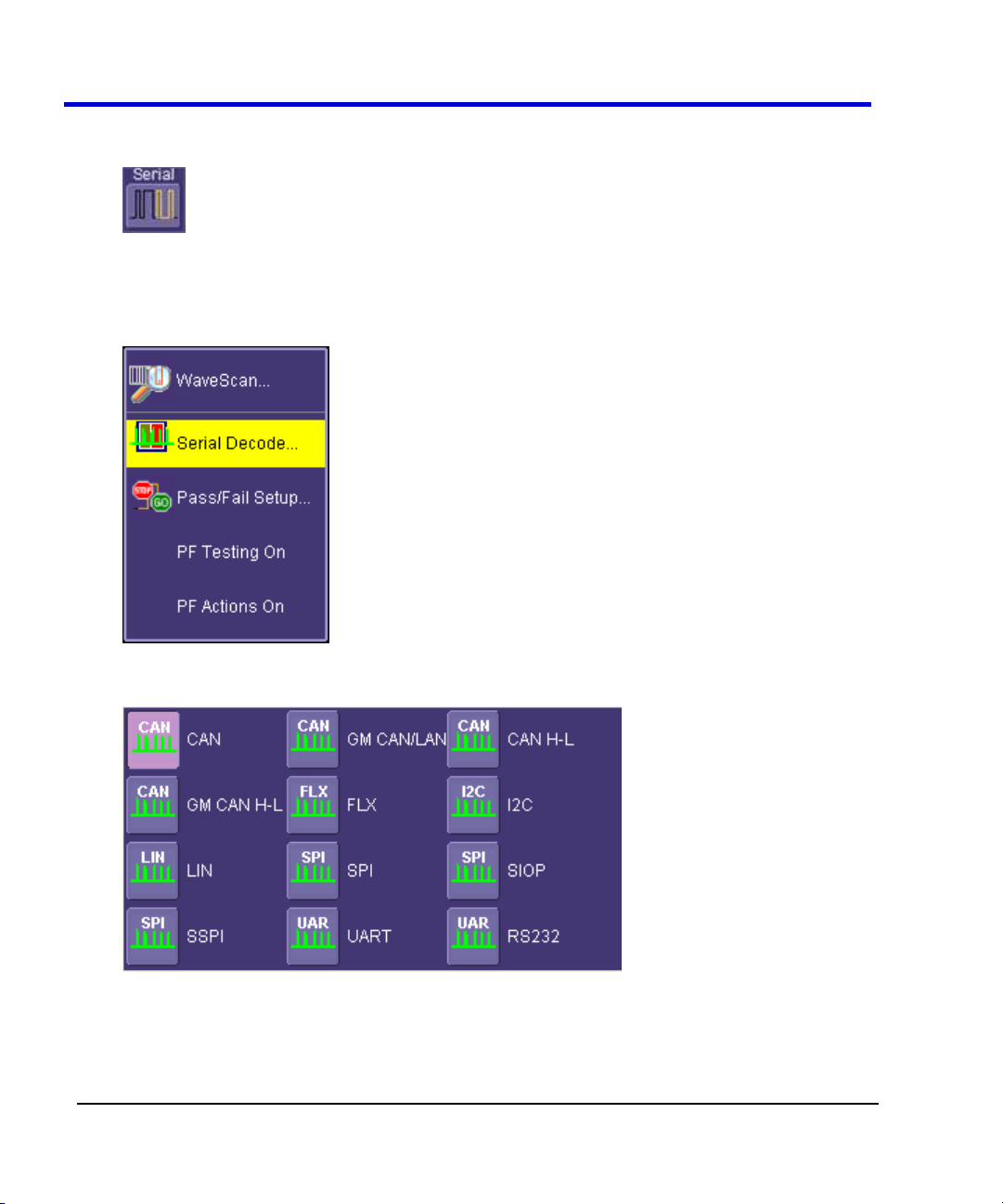

1. Serial Trigger Selection - If this is the first serial trigger option you have installed on your

oscilloscope, an additional icon is shown on your trigger dialog box. It allows a serial

Page 8

CANbus Trigger, Decode, and Measure

8

CANbus-TD-TDM-OM-E RevB

trigger condition to be set from within the oscilloscope using an easy-to-understand

interface.

2. Serial Decode - If this is the first serial decode option you have installed on your scope, an

additional set of Serial Decode and Decode Setup dialog boxes are provided for setup of

protocol format (as necessary) and decoding. These can be accessed from the Analysis

menu.

3. Decode Protocol Selections - CAN is one of several signal types that can be decoded by

the oscilloscope. Other standards include I2C, SPI, UART, RS-232, LIN, and FlexRay.

4. Measure/Graph Setup - CAN measurement and graphing functions are accessed through

the Serial Decode setup by selecting the Measure/Graph Setup tab.

Page 9

Operator's Manual

CANbus-TD-TDM-OM-E RevB

9

Using the CANbus Options

Overview of CANbus TD (Trigger and Decode)

The CANbus TD option contains powerful software algorithms to extract serial data information

from physical layer waveforms measured on your oscilloscope. The extracted information is

overlaid (annotated) on the actual physical layer waveforms, and color-coded to provide fast,

intuitive understanding.

The CANbus TD option allows triggering on CAN Frames and Errors. Frame triggering can be set

to trigger on any frame, one specific Frame ID, a range of Frame IDs, Remote Frames and Errors.

Frame triggering and data triggering can be done for a single ID or message or a range of IDs and

data by using the conditional trigger capabilities. Other powerful and user-friendly features

included in CANbus TD include:

The ability to trigger and decode CAN at bit rates from 10 kb/s to 1 Mb/s.

The ability to create powerful, conditional Frame ID and Data triggers.

Triggering on CAN protocol errors and remote frames.

If you are unfamiliar or are just learning about CAN, start by using the simplest trigger conditions

(All Frames or Frame ID). Next, experiment with an ID and Data to trigger on a specific value.

Then, try a conditional ID + Data trigger (ID Greater Than or In Range).

Accessing Serial Triggers

The CANbus serial trigger is accessed from the oscilloscope trigger dialog. Use one of the

following methods:

Touch the Trigger Descriptor Box in the lower right hand corner of the oscilloscope

display.

OR

Touch Trigger → Trigger Setup from the Menu Bar. On the Trigger dialog, touch Serial on

the Type section.

Select the appropriate serial trigger. The menu automatically changes to a different tab in

the Trigger dialog reflecting the selected standard.

Page 10

CANbus Trigger, Decode, and Measure

10

CANbus-TD-TDM-OM-E RevB

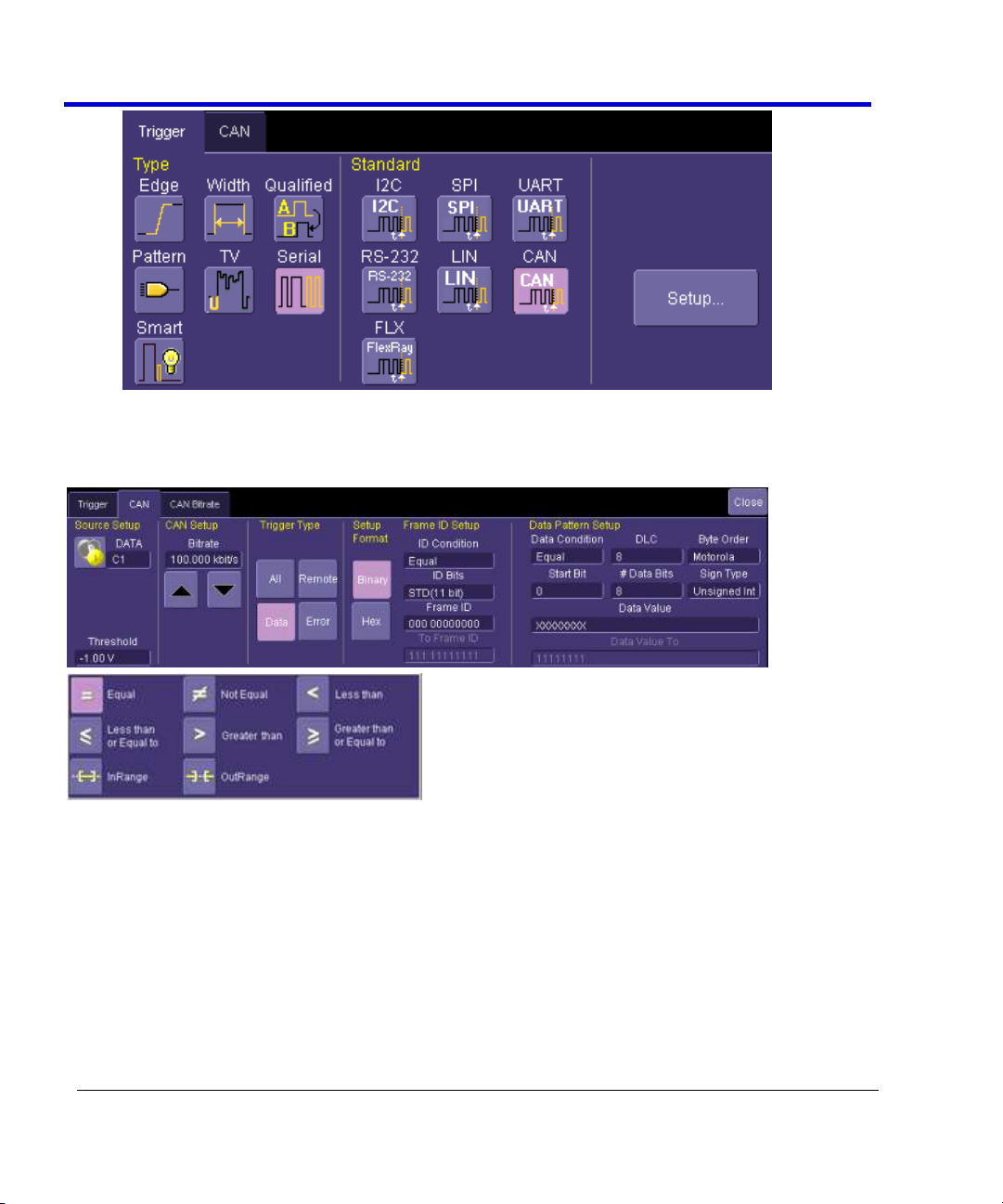

Creating a CANbus Trigger Condition

The CANbus Trigger dialog, with detail on some of the setup conditions, is shown in the

following topics.

CANbus Trigger Setup Detail

The following topics show the dialog selections for a CANbus Trigger.

Page 11

Operator's Manual

CANbus-TD-TDM-OM-E RevB

11

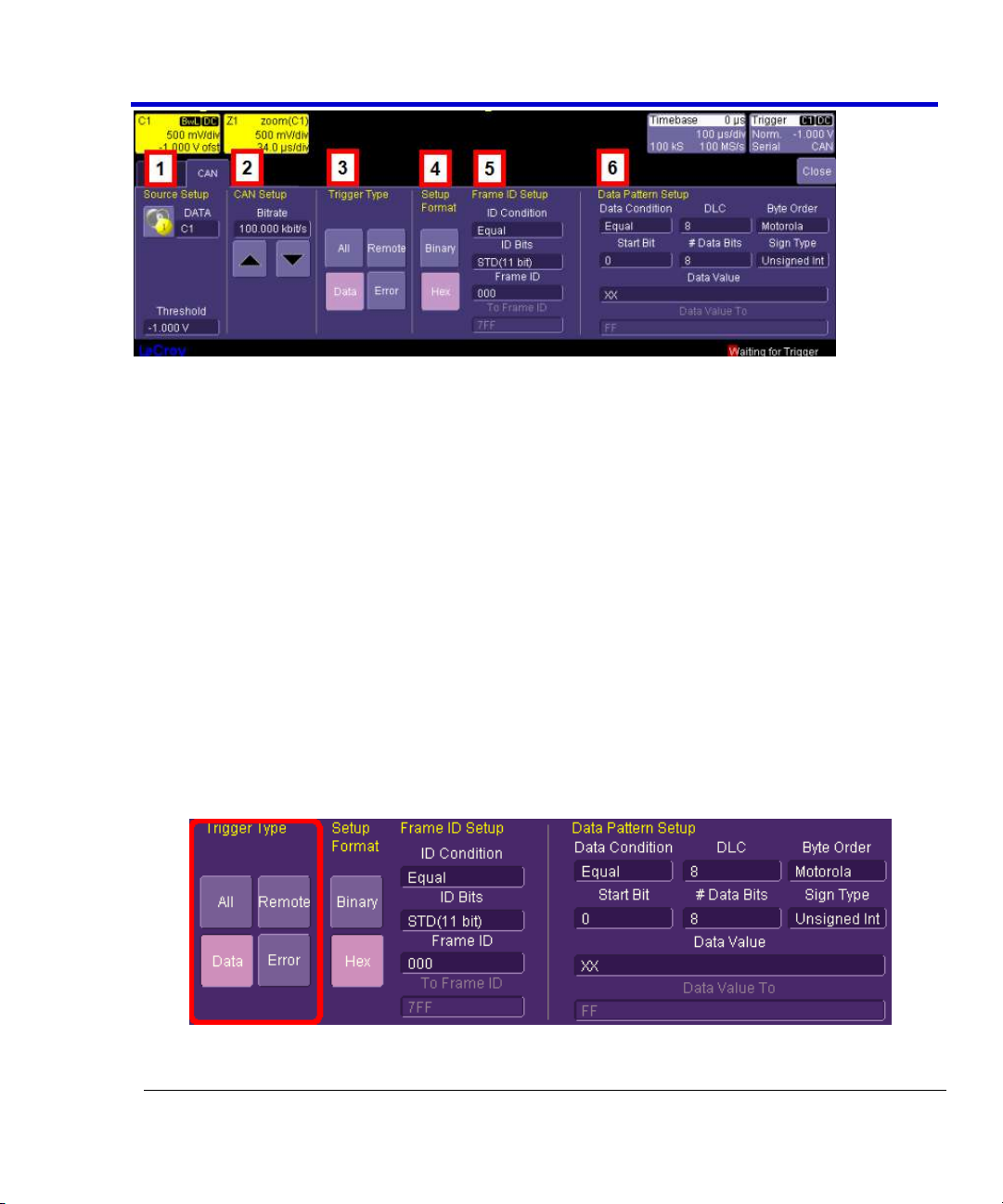

The previously numbered CANbus trigger sections correspond with the following explanations.

1. Source Setup

DATA - The DATA field's pop-up dialog is used to select the appropriate channel or EXT

input for each. Set this field up with caution or your trigger may not function correctly.

Use the Threshold field to adjust the vertical level for the trigger. Much like an Edge

trigger, a user must specify the level used in order to process the incoming signals and

determine whether the desired serial data pattern is meeting the set trigger condition.

2. CAN Setup

Bitrate - Use the Bitrate field to adjust the value and match the bus to which you are

connected. This bitrate selection is dynamically linked to the decoding bitrate (they are

always the same value). Use the arrows to move through standard bit rates (10, 25,

33.333, 50, 83.333, 100, 125, 250, 500, and 1000 kb/s) and make a selection. Or, touch

the number twice (with a finger, or using a mouse) and open a pop-up keypad and enter

the value directly.

3. Trigger Type

Trigger Type - Depending on your Trigger Type selection, certain Frame ID and Data

Pattern Setup fields are enabled or disabled as follows:

All - Triggers on all signals. No Frame ID and Data Pattern ID Setup fields are enabled.

Page 12

CANbus Trigger, Decode, and Measure

12

CANbus-TD-TDM-OM-E RevB

Remote - Only Frame ID Setup fields are enabled.

Data - Both Frame ID and Data Pattern ID Setup fields are enabled.

Error - Triggers only when an error signal occurs. No Frame ID and Data Pattern ID Setup

fields are enabled.

4. Setup Format

Select either Binary or Hexadecimal (Hex) setup mode. The mode selected propagates

through the entire CANbus trigger setup.

Try selecting Binary mode, and set up the Frame ID in binary format, then re-select HEX

mode and set up the data in hexadecimal format. Toggling back and forth between the

modes does not result in loss of information.

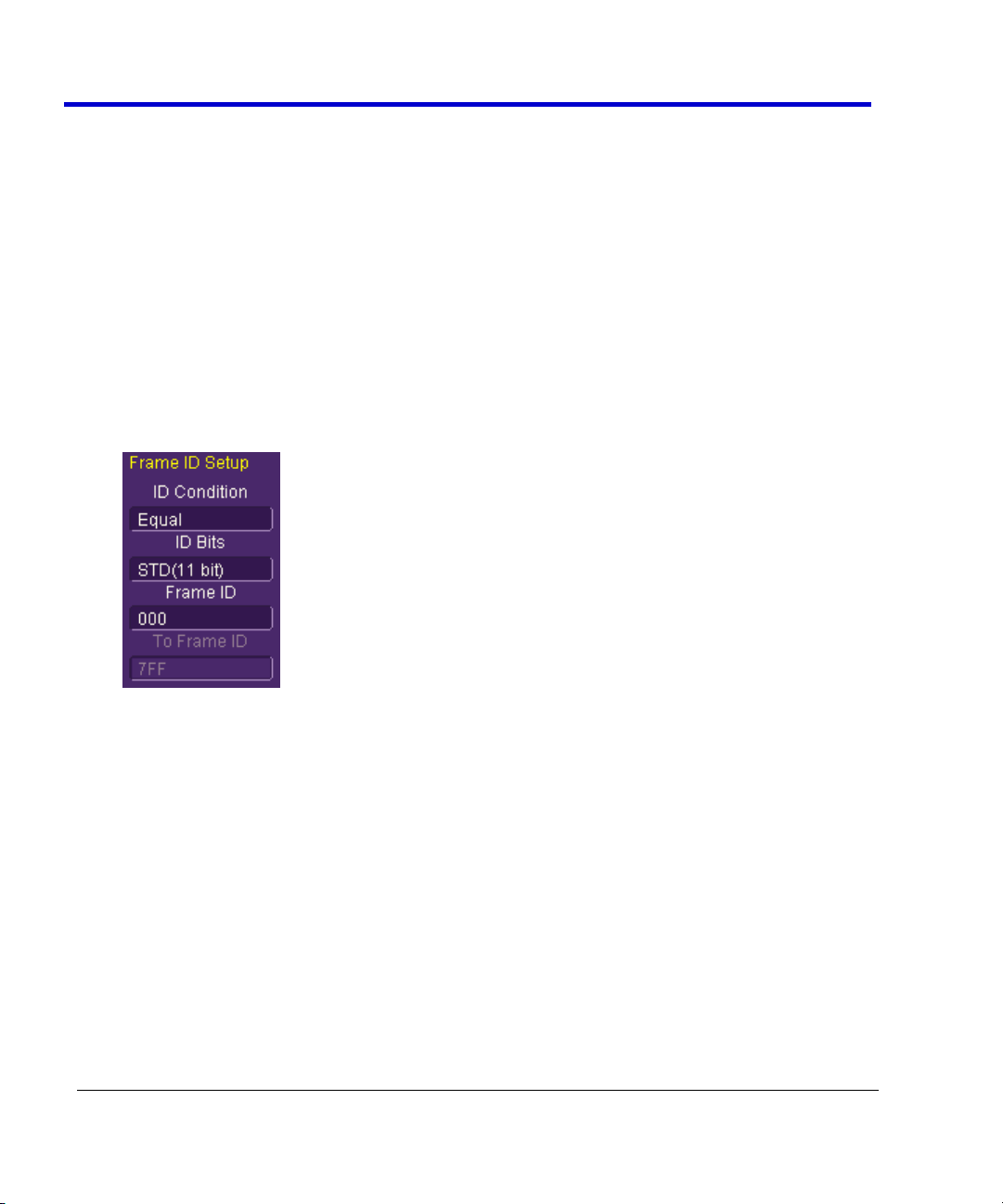

5. Frame ID Setup

Frame ID Setup is used to trigger on a specific Frame ID value with either 11 or 29 Bits.

When CANbus trigger selections are either Remote or Data, use the Frame ID Setup fields

as follows:

ID Condition - The ID condition can be set to many different values. If the ID condition is

set to “=”, then a data definition can also be set. Any other ID condition precludes setting

up a Data condition.

The ID condition can be set to <=, <, =, >, >=, not =, in a range, out of a range, or don’t

care.

ID Bits - The trigger can be set to trigger on CAN messages with either 11-bits (Standard

CAN) or 29-bits (Extended CAN). You can also set the trigger so that it triggers on a

message that meets a condition for either the 11-bit or 29-bit ID. For instance, there

might be an 11-bit ID value that is present in both an 11-bit and a 29-bit ID, and by

choosing ALL, you could trigger when that ID is present on either of those messages.

Frame ID - Specify the desired frame ID for triggering here.

Page 13

Operator's Manual

CANbus-TD-TDM-OM-E RevB

13

To Frame ID - When using an in range or out of range ID Condition (previous), specify a To

Frame ID value for triggering.

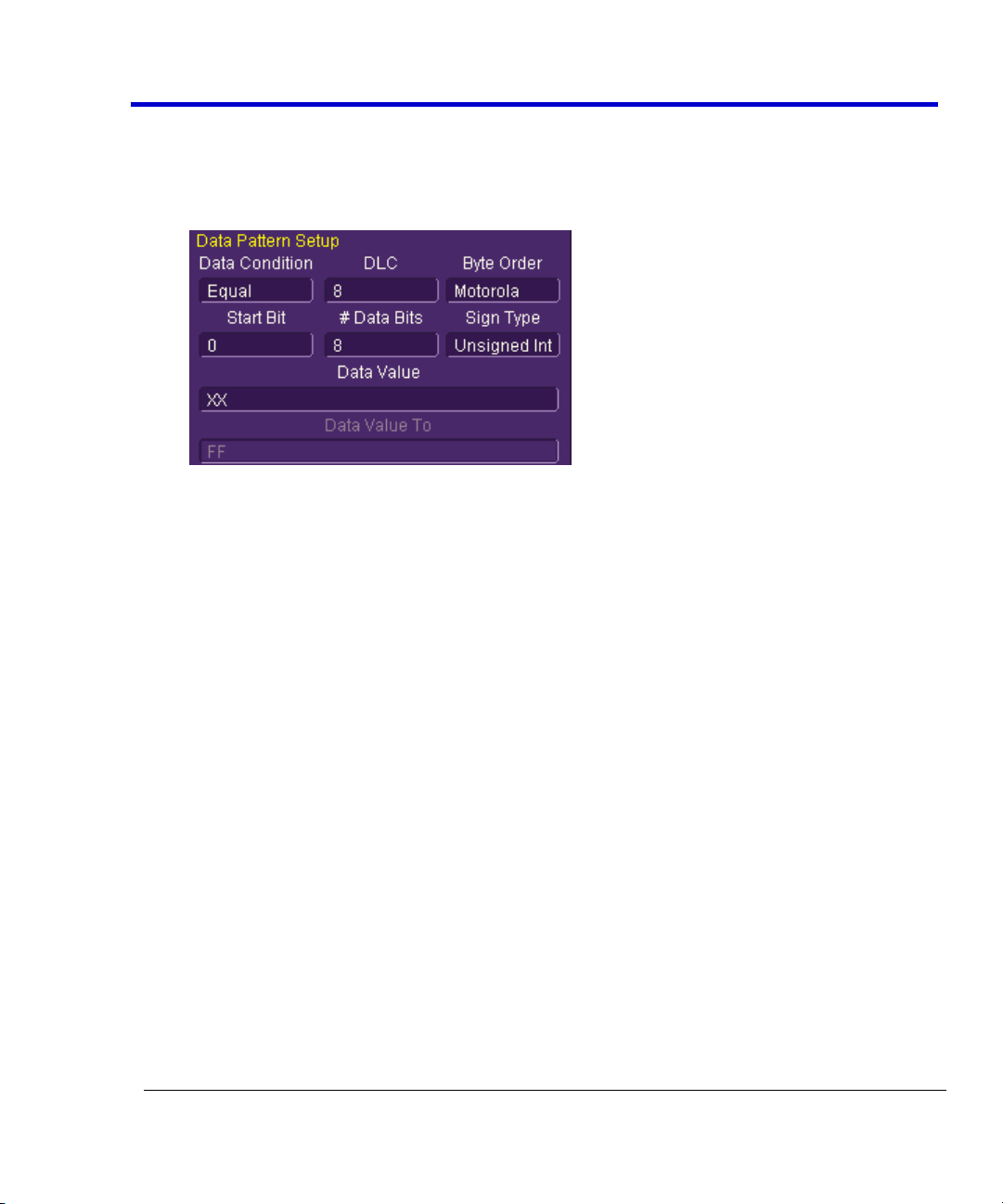

6. Data Pattern Setup

Fields on this section of the dialog are only enabled when using the Data trigger type.

Data Condition - The Data Condition can be set to many different values. The Data

condition can be set to <=, <, =, >, >=, not =, in a range, out of a range, or don’t care.

DLC - The DLC (data length code) can be set to any integer value from 0 to 8. It should

match the DLC of the CAN message you want to trigger on. If you set it to a value less

than 0, it will default to 0. If you set it to a value greater than 8, it will default to 8.

Byte Order - Choose from either Motorola (default) or Intel byte orders.

Start Bit and # Data Bits - The CANbus trigger allows you to trigger on up to 64

contiguous data bits (8 data bytes). This maximum 64-bit string can start at any location

in the CAN message data field - it is not limited to the start of a full byte or a nibble.

The Start Bit can be any value from 0 to 63. If you enter a value less than 0, it will default

to 0. If you enter a value more than 63, it will default to 63. The Start Bit value is always in

LSB format (i.e., the bit number as shown on the decoded waveform, with bit 0 being at

the far left and bit 63 being at the far right of the data string). Remember that the 1st

data byte is bits 0-7, the 2nd data byte is bits 8-15, etc. Also, make sure that your Start Bit

value makes sense in relation to the DLC Value. For instance, a Start Bit value of 32 with a

DLC Value of 4 is not going to result in a successful trigger.

The # Bits can be any value from 1 to 64. If you enter a value less than 1, it will default to

1. If you enter a value more than 64, it will default to 64.

Sign Type - Choose between signed and unsigned integer format.

Data Value and Data Value To - The Data Value is set in Binary or Hexadecimal format.

For Hexadecimal, if desired, you can precede the ID value with “0x”, but this is not

necessary. Be sure to enter a Data Value that matches the DLC Value.

Page 14

CANbus Trigger, Decode, and Measure

14

CANbus-TD-TDM-OM-E RevB

When using an in range or out of range Data Condition (previous), specify a Data Value

To value for triggering.

CANbus Decode Setup Detail

CANbus Decode Setup Right-Hand Dialogs are shown when CAN is selected as the decode

protocol. It provides detailed fields and setup conditions as follows:

Viewing - The decode format is displayed here as Hexadecimal for CANbus.

Bitrate - Adjust the bit rate value here to match the bit rate on the bus you are connected

to. This bit rate selection is dynamically linked to the decoding bit rate (they are always

the same value). Use the arrows to move through standard bit rates (10, 25, 33.333, 50,

83.333, 100, 125, 250, 500, and 1000 kb/s) and make a selection. Or, touch the number

twice (with a finger, or using a mouse) and open the pop-up keypad to enter the value

directly. Any value from 10-1000 kb/s may be entered in this way.

Show Stuff Bits – Use this checkbox to indicate whether you want stuff bits highlighted

on each CAN message frame.

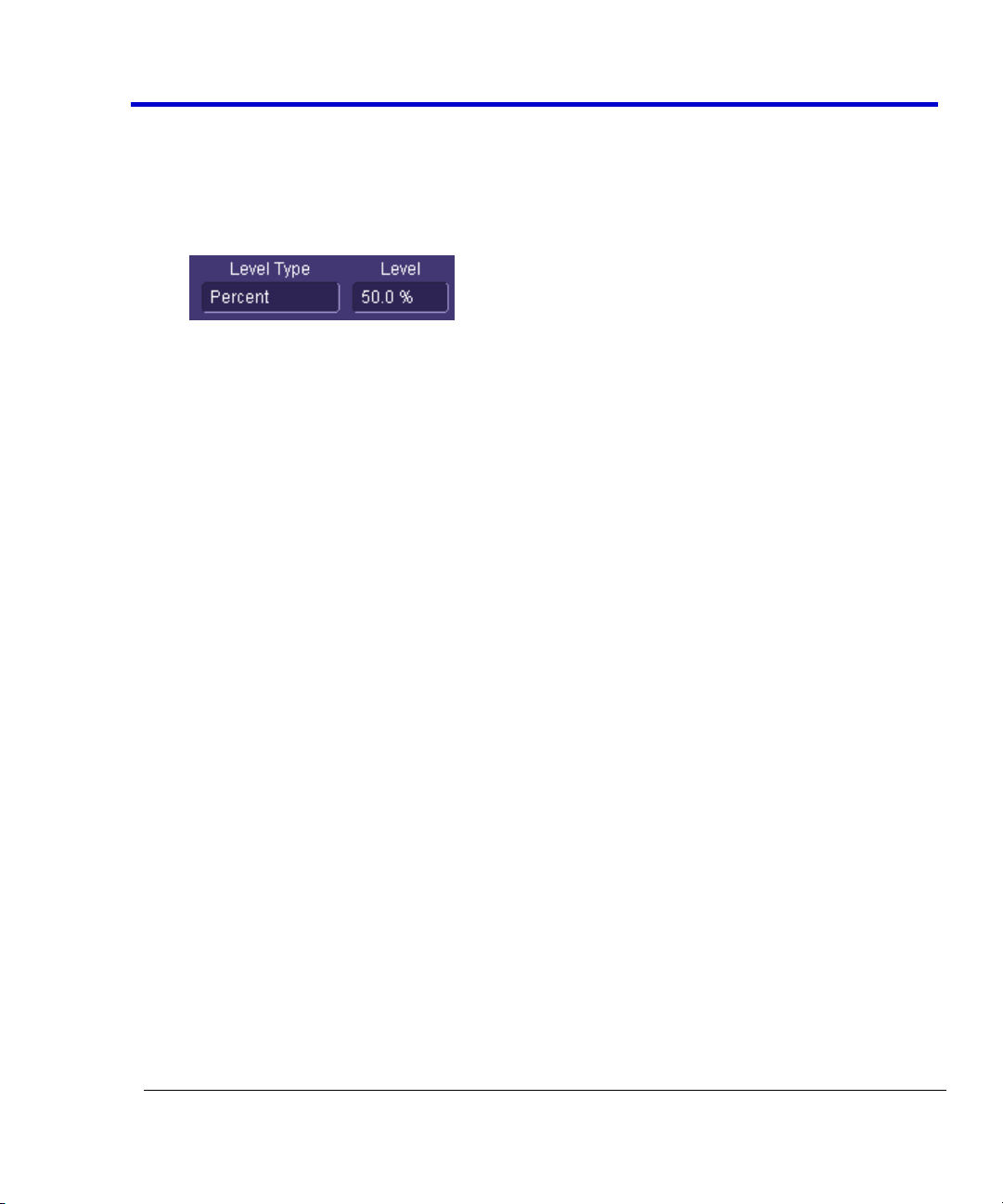

Level Type and Level - The message decoding algorithm setup is performed here. The

level is normally set up in %, and defaults to 50%. To adjust the level, touch inside the

number area to highlight the box title in yellow, then use the oscilloscope front panel

Page 15

Operator's Manual

CANbus-TD-TDM-OM-E RevB

15

Adjust knob to adjust. Or touch inside the number area twice and select a value using the

pop-up numeric keypad.

The set Level appears as a dotted horizontal line across the oscilloscope grid.

If your initial decoding indicates that there are a number of error frames, make sure that

the level is set to a reasonable value.

Measuring CANbus Performance Using CANBUS

TDM

Overview of CANbus TDM (Trigger, Decode, Measure/Graph)

Basic oscilloscope tools can be extremely helpful to understand single-shot events. However,

their utility in measuring performance of a CAN Bus system can be very limited. It is usually

necessary to obtain large quantities of data before you can be sure that system performance is

within specified limits. The following are typical examples of actions to assess CAN Bus system

performance:

Measure Timing Δ Between CAN and Analog Signals & Accumulate Statistics - Measure

the time difference between an analog signal and CAN signal generated in response to it

(or vice-a-versa). View the mean, minimum, and maximum timing values, the number of

samples, and the standard deviation of the measurements.

Measure Timing Δ Between Two CAN Messages & Accumulate Statistics - Same as

previous, but with two CAN signals.

Measure Timing Δ From the Trigger Point to a CAN Message - Same as previous, but the

trigger point can be anything - a CAN message, an Analog signal, a Pattern of signals, a

Dropout condition, etc.

Measure Timing, Accumulate Statistics, View Distribution - Instead of just looking at

numerical values, graph/plot the distribution as a histogram to better understand the

shape of the distribution, the quantity of extreme events, and determine underlying

cause.

Graph/Plot CAN Data Values from a Single Acquisition - Extract CAN Data values in

decimal format and compare them to an analog signal in a time-correlated fashion.

Graph/Plot CAN Data Values Over Multiple Acquisitions - Extract CAN Data values in

decimal format and graph/plot them over multiple acquisitions.

Measure CAN Bus Load, Graph/Plot - Understand how bus loading relates to other CAN

and Analog signal events.

Page 16

CANbus Trigger, Decode, and Measure

16

CANbus-TD-TDM-OM-E RevB

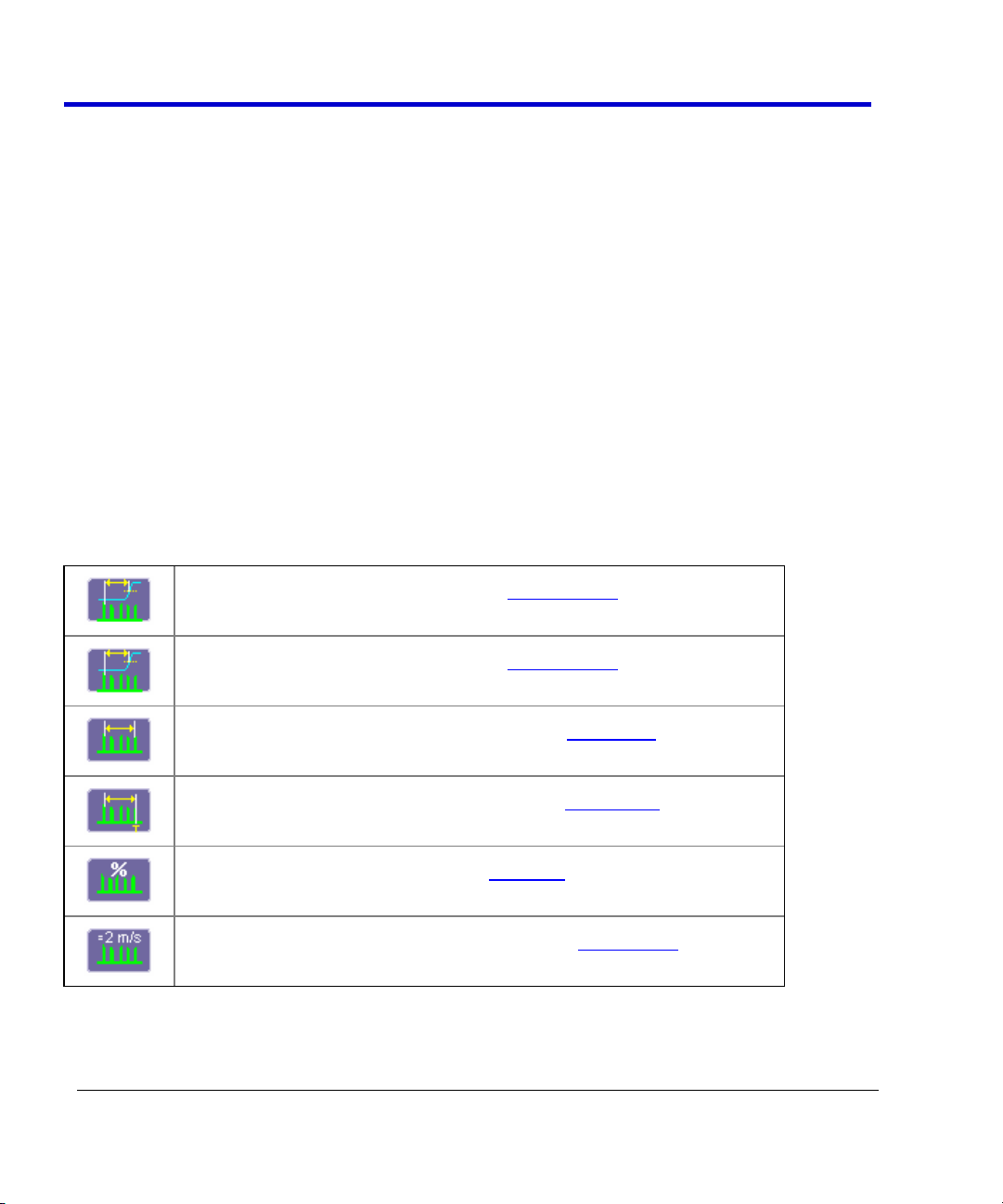

CAN Message to Analog Signal timing (CANtoAnalog)

Analog Signal to CAN Message timing (CANtoAnalog)

CAN Message to CAN Message Signal Timing (CANtoCAN)

Time from trigger to a specific CAN message (Time@CAN)

CAN Bus Message Load Percentage (CANLoad)

Extract CAN Message Data to a Decimal Value (CANtoValue)

Some of this information could be gathered using standard oscilloscope tools, but the

accumulation of the data would take hours or days. It is more likely that the engineer would

instead gather a very small sample set and skip the statistical evaluation in order to save time.

The result is reduced product quality and corresponding greater risk of shipping product that

functions incorrectly in some situations.

CANbus TDM contains specific CAN measurement parameters that allow you to quickly and

easily accumulate statistical information on a wide variety of events, and graphical display tools

to visualize the data on your oscilloscope screen. These sophisticated measurement and

graphical display tools are the “missing link” between standard oscilloscope and protocol

analyzer capability. The CANbus TDM tools provide the capability to trigger on defined CAN Bus

events, observe actions/reactions, measure timing among CAN and Analog signals, and view

results in a graphical fashion directly on the oscilloscope display with no complicated export of

data. Data on tens of thousands of events can be automatically and quickly gathered and

analyzed in a fraction of the time it takes to manually perform the same testing.

CANbus TDM contains additional CAN specific measurement, graphing, and statistical analysis

capability as the following topics explain.

CANBUS TDM Parameters

Page 17

Operator's Manual

CANbus-TD-TDM-OM-E RevB

17

CANbus TDM Graphing and Statistical Analysis

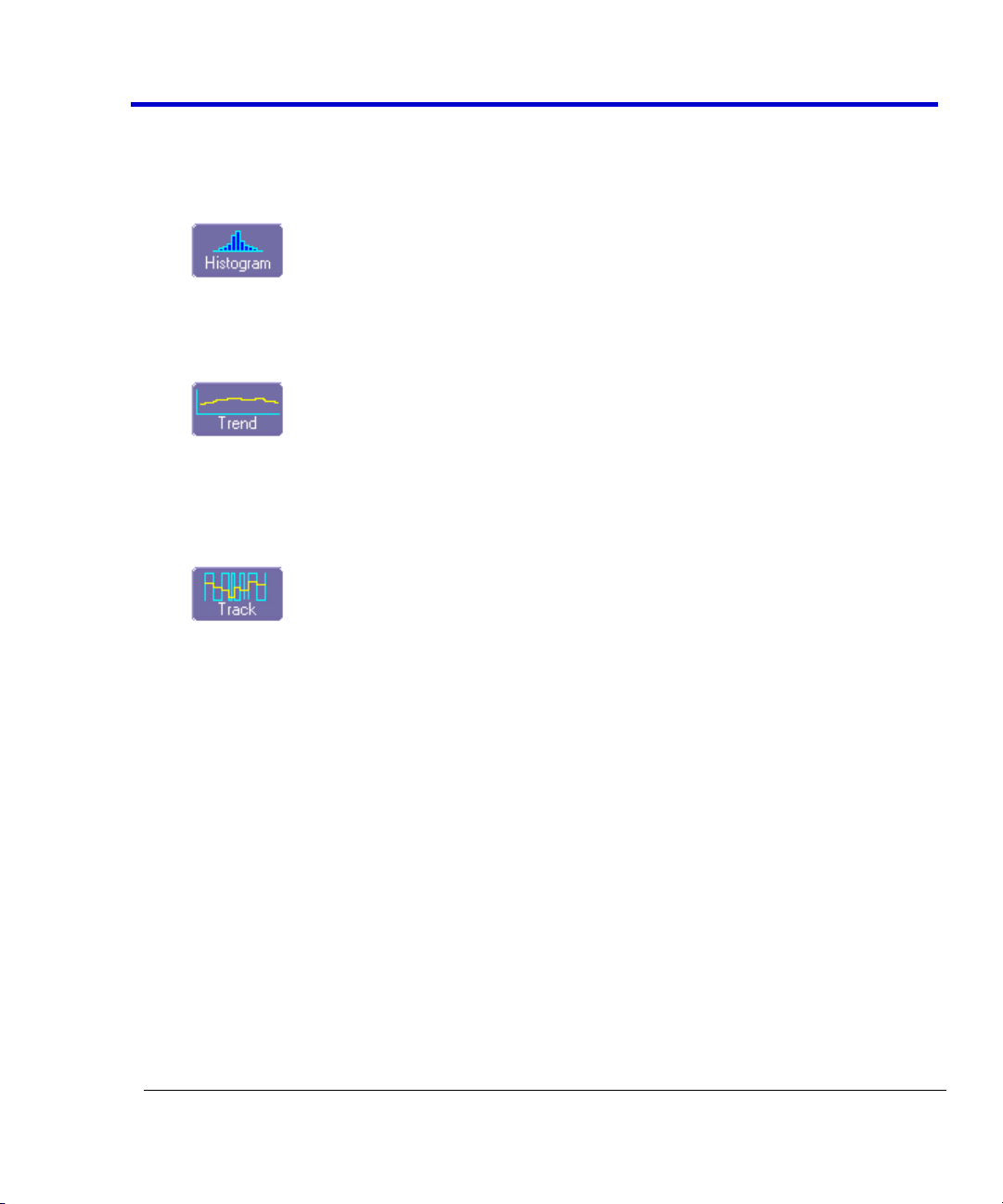

Histogram - The Histogram displays a statistical distribution of a measurement

parameter. Histogram is helpful to understand the modality of a measurement

parameter, and to debug the root cause of excessive variation.

Trend - The Trend statistical tool visualizes the evolution of a timing parameter over time

in the form of a line graph. The graph’s vertical axis is the value of the parameter; its

horizontal axis is the order in which values were acquired. Trend is typically used for a

multi-shot acquisition. Trend is analogous to a chart recorder.

Track - The Track displays a time-correlated accumulation of values for a single

acquisition. Track can be used to plot the values of CAN data and compare them to a

corresponding analog signal, or observe changes in timing. Track is typically used for a

single-shot acquisition. A long acquisition with many parameter measurements analyzed

with Track could provide information about the modulation of the parameter.

Page 18

CANbus Trigger, Decode, and Measure

18

CANbus-TD-TDM-OM-E RevB

In addition to the Histogram graphing capability, there are also 19 different measurement

parameters that apply specifically to Histograms. These are listed below (more information is

contained in Appendix D):

fwhm - full width (of largest peak) at half the maximum bin

fwxx - full width (of largest peak) at xx% the maximum bin

hist ampl - histogram amplitude between two largest peaks

hist base - histogram base or leftmost of two largest peaks

hist max - value of the highest (right-most) populated bin in a histogram

hist mean - average or mean value of data in the histogram

hist median - value of the x-axis of a histogram that divides the population into two

equal halves

hist min - value of the lowest (left-most) populated bin in a histogram

hist rms - rms value of data in histogram

hist sdev - standard deviation of values in a histogram

hist top - histogram top or rightmost of two largest peaks

max populate - population of most populated bin in histogram

mode - data value of most populated bin in histogram

percentile - data value in histogram for which specified `x'% of population is smaller

peaks - number of peaks in histogram

pop @ x - population of bin for specified horizontal coordinate

range - difference between highest and lowest data values

total pop - total population in histogram

x at peak - x-axis position of specified largest peak

These measurement parameters are available in the Statistics category in the measurement

selection pop-up dialog.

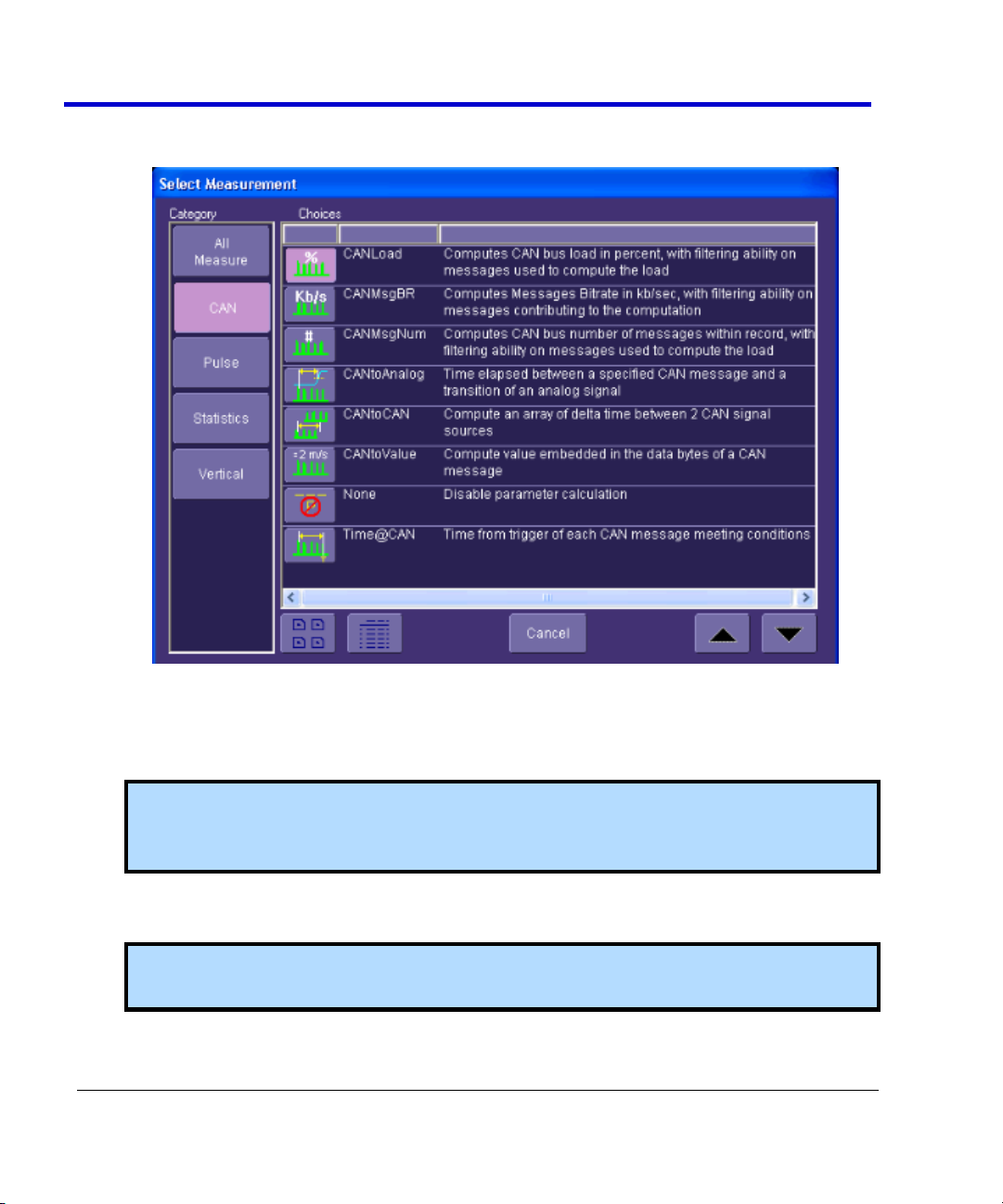

General Setup of CANbus TDM Parameters

There are two different ways to set up CAN related measurements. The easiest way is to use the

Measure tab in the CAN Analysis dialogs to access the CAN Measure dialog. This dialog is

specifically tailored to meet the needs of an engineer who is debugging CAN-based systems. It

contains different categories of CAN, pulse, statistical, etc. measurement parameters that are

commonly used to measure CAN system performance.

Setting Up CANbus Parameters using the Serial Decode option

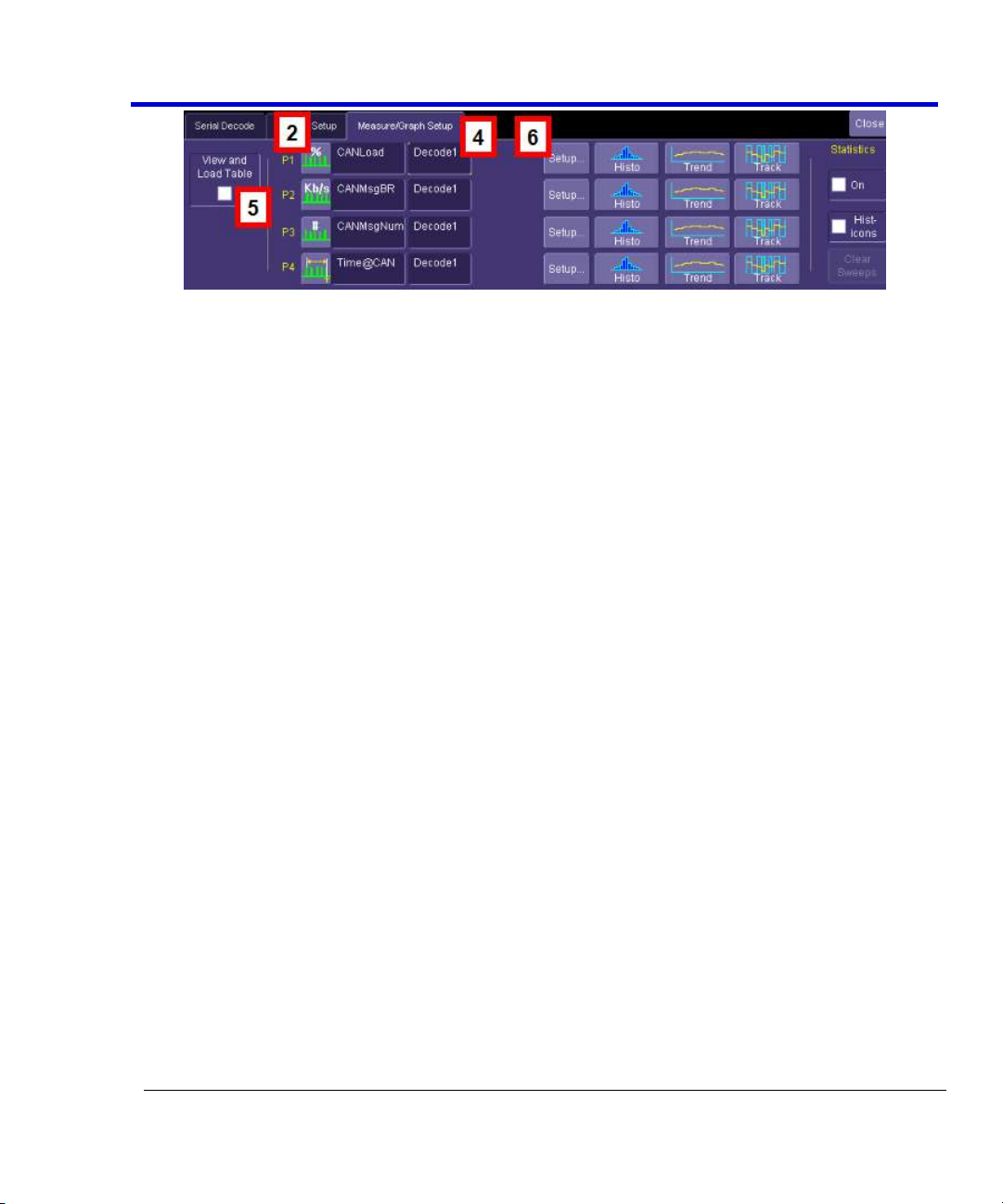

1. Touch the Measure/Graph Setup tab in the CAN Serial Decode dialogs. There are four

parameter measurements displayed (P1 through P4).

Page 19

Operator's Manual

CANbus-TD-TDM-OM-E RevB

19

Page 20

CANbus Trigger, Decode, and Measure

20

CANbus-TD-TDM-OM-E RevB

2. For a specific measurement parameter, touch the parameter icon or parameter name to

access the CAN Measurement Select pop-up dialog.

3. From the CAN Select Measurement window, choose a parameter. Touch an icon to select

the measurement.

4. Touch the source field to open the Select Source pop-up dialog. Select a category to

display the available sources, then select the appropriate source.

Note:The source for the CAN measurements should be Decode1, Decode2, Decode3 or

Decode4 depending on which serial data decode is being used to decode the bus you

are trying to measure.

5. The View and Load Table checkbox is checked automatically when you select your

parameters. Uncheck it to turn measurements OFF.

Note: Measurement parameter and source selections that are set up in the CAN

Measure menu are copied to the oscilloscope standard Measure menu.

Page 21

Operator's Manual

CANbus-TD-TDM-OM-E RevB

21

6. Many parameters (and all CAN-specific parameters) require some additional setup

information to be entered in order to work correctly. To access the setup dialog, touch

the Setup button.

Page 22

CANbus Trigger, Decode, and Measure

22

CANbus-TD-TDM-OM-E RevB

Setting Up CANbus Parameters using the Measure Setup option

You can also set up measurement parameters using the Measure menu as follows:

Touch Measure→Measure Setup. select the appropriate CAN or other parameter. For more

information, see Parameter Setup in the oscilloscope's Online Help or Operator's Manual.

Note: All CAN measurement parameters (with the exception of CAN Load %) calculate as many

values as possible during each acquisition. If there are 10 timing events that meet the set

condition during a specific acquisition, 10 timing event measurements will be returned.

However, the VALUE shown in the measurement table is the last measurement made. To view

statistical data (i.e., number of measurements made, mean, min, max, std. dev.), turn Statistics

ON.

CAN Load % returns only one value during each acquisition, since it is evaluating the load % for

the entire acquisition time.

CAN-to-Analog or Analog-to-CAN Measurement Parameter

CAN Message to Analog Signal timing (CANtoAnalog)

This measurement parameter is used to measure timing from either a CAN Message to an

Analog Signal, or from an Analog Signal to a CAN Message. The Frame Type, ID, DATA, etc.

conditions for the CAN message can be fully defined, as can the slope, level, etc. conditions for

the analog signal transition.

If measuring from CAN to Analog, the timing is always measured from the End of Frame of CAN

message to the analog signal transition. If measuring from Analog to CAN, the timing is always

measured from the analog signal transition to the Start of Frame of the CAN message.

Page 23

Operator's Manual

CANbus-TD-TDM-OM-E RevB

23

Note: Source 1 should always be defined as the CAN Decode source and Source 2 should

always be defined as your Analog Signal (either a channel, memory, etc.), regardless of

whether you wish to measure from CAN to Analog or Analog to CAN. Analog to CAN values will

simply be reported as negative values.

Page 24

CANbus Trigger, Decode, and Measure

24

CANbus-TD-TDM-OM-E RevB

CAN-to-Analog Parameter Setup

To access the setup dialog, touch Setup for that particular parameter on the CAN

Measure/Graph Setup dialog. The Px Parameter dialog will be displayed. On the right side of this

dialog box, there is an additional setup dialog:

The CAN Message tab defines the CAN Message Setup. The Analog Signal tab defines the Analog

Signal Setup.

Note: The CAN Message tab always defines the CAN Message Setup and the Analog Signal tab

always defines the Analog Signal setup even if you are measuring time from an Analog Signal

to a CAN Message. The CAN Message setup is nearly identical to the setup of the CAN message

in the CAN Trigger dialog, so details will not be repeated here.

The Analog Signal setup dialog is shown below:

Page 25

Operator's Manual

CANbus-TD-TDM-OM-E RevB

25

Select the measurement level as Percent or Absolute, and set a value. Then select the slope of

the edge to which you want to measure. The Hysteresis selection imposes a limit above and

below the measurement Level, which precludes measurements of noise or other perturbations

within this band. The width of the band is specified in milli-divisions. Guidelines for using

Hysteresis are as follows:

Hysteresis must be larger than the maximum noise spike you want to ignore.

The largest value of hysteresis usable is less than the distance from the level to the

closest extreme value of the waveform.

Unless you know the largest noise and closest extreme level that will ever occur on any

cycle, leave some margin on both sides of the level.

Note: Various pathological conditions can block the computation of the CANtoAnalog and

CANtoCAN parameters. In all cases, the cause of the condition can be viewed on the message

line by clicking on the yellow icon , below the measurement parameter values.

The simplest, and most common, reason for non-computation of the CAN timing parameters is

that none of the CAN Message or Analog Signal conditions defined in the right-hand dialog is

encountered in the whole record processed by the algorithm. In this case the error message

will be "Cannot find Start and/or End condition on input of CAN2CAN or CAN2Analog."

Another possible cause is that the time frames of the 2 inputs specified do not overlap at all.

The error message will be "No Common Time Span exists between inputs"

Finally, the sequence of occurrence of the CAN Message or Analog Signal conditions defined in

the right-hand dialog setup tab can lead to ambiguous results. (Too many CAN conditions for

each Analog condition, nested CAN and Analog conditions). In this case the message line will

show: "Ambiguous Start/End time relationship for CAN2CAN or CAn2Analog".

CAN Message-to-CAN Message Measurement Parameter

CAN Message-to-CAN Message timing (CANtoCAN)

This measurement parameter is used to measure timing values between two CAN Messages.

The Frame Type, ID, DATA, etc. conditions for the CAN message can be fully defined for both

CAN messages. The timing is always measured from the End of Frame of the first CAN message

to the Start of Frame (SOF) of the second CAN message.

Page 26

CANbus Trigger, Decode, and Measure

26

CANbus-TD-TDM-OM-E RevB

CANtoCAN Measurement Parameter Setup Detail

To access the setup dialog, touch Setup for that particular parameter on the CAN

Measure/Graph Setup dialog. The Px Parameter dialog is displayed. On the right side of this

dialog box, there is a setup dialog labeled with the measurement parameter name. Touch the

tab with the parameter name on it to access the following dialog:

The Start Message tab defines the first CAN Message Setup. The End Message tab defines the

second CAN Message Setup.

Note: The CAN Message setup is nearly identical to the setup of the CAN message in the CAN

Trigger dialog, so details will not be repeated here.

The two CAN message definitions can be different, or they can be the same. If they are different,

the time value measured will be from the first CAN message to the second, with a positive value

indicating that the second message occurred after the first message, and a negative value

indicating that the second message occurred before the first.

If you wish to measure the time between two identical CAN messages, the Data Condition must

be set to “Don’t Care.” Then, if there are “n” CAN messages that satisfy the condition, you will

get “n-1” measurements. Measurements would be made between all adjacent pairs that satisfy

the condition.

Note: Various pathological conditions can block the computation of the CANtoAnalog and

CANtoCAN parameters. In all cases, the cause of the condition can be viewed on the message

line by clicking on the yellow icon , below the measurement parameter values.

The simplest, and most common, reason for non-computation of the CAN timing parameters is

Page 27

Operator's Manual

CANbus-TD-TDM-OM-E RevB

27

that none of the Start or End condition defined in the right-hand dialog is encountered in the

whole record processed by the algorithm. In this case the error message will be "Cannot find

Start and/or End condition on input of CAN2CAN or CAN2Analog."

Another possible cause is that the time frames of the 2 inputs specified do not overlap at all.

The error message will be "No Common Time Span exists between inputs"

Finally, the sequence of occurrence of the Start or End conditions defined in the right-hand

dialog can lead to ambiguous results. (Too many Start conditions for each End condition,

nested Start and End conditions). In this case the message line will show: "Ambiguous

Start/End time relationship for CAN2CAN or CAn2Analog."

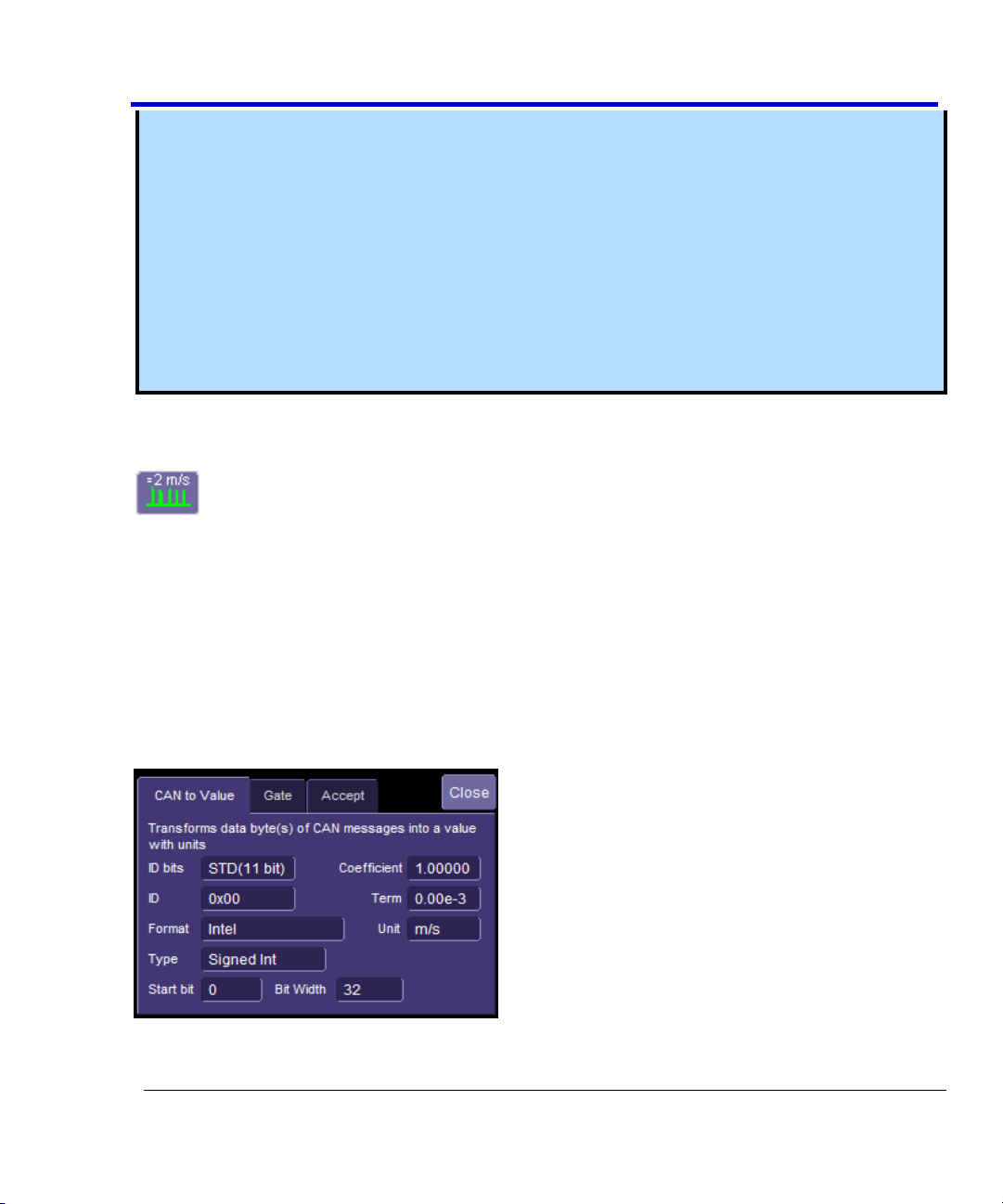

Extract CAN Message Data to a Decimal Value

Extract CAN Message Data to a Decimal Value (CANtoValue)

This measurement parameter is used to extract CAN message data in any sequential byte/bit

location and display it as a decimal value that is rescaled to specific operator set units of

measure. Essentially, it allows the conversion of a bit field embedded into a CAN message into a

value with user-definable units.

CANtoValue Measurement Parameter Setup Detail

To access the setup dialog, touch Setup for that parameter in the CAN Measure/Graph Setup

dialog. The Px Parameter dialog box is displayed. On the right side of this dialog box, there is a

setup dialog labeled with the measurement parameter name. Touch the tab with the parameter

name on it, and you will access the following dialog:

Page 28

CANbus Trigger, Decode, and Measure

28

CANbus-TD-TDM-OM-E RevB

You must specify the ID length and ID Value for the CAN Messages that you wish to extract data

from. The measurement parameter will process all messages meeting the ID condition in the

acquisition, and apply the same conversion to them.

The conversion process requires the Format in which the value is embedded (Intel or Motorola),

the Type of value (Integer of Float) and the bit window occupied by the value. The window is

specified with a Start Bit and a Bit Width for integers. Floating point values always use a Bit

Width of 32.

Finally, the last stage of the conversion process transforms the raw value into a physical value

with units, using a linear transformation of the type Parameter Value = Coefficient * Raw Value

+ Term. Units can be specified as well, provided they belong to the list given in "Rescaling and

Assigning Units" under Waveform Math. The unit specified here will propagate throughout the

system to the parameter value, subsequent Tracks and Trends, and cursor readout on any

derived function.

Note: The default coefficient and term will apply no transformation to units of the raw value.

All the entries required in this dialog are usually provided by sensor or actuator manufacturers,

or can be read out of commercially available tools using DBC files.

Using this measurement parameter, you can graph data using the Trend or Track function.

CAN Bus Message Load Percent Measurement Parameter

CAN Bus Message Load Percentage (CANLoad

This measurement parameter is used to measure total bus load within the captured record for

messages that meet a defined set of conditions. The “load” formula is the sum of the message

length(s) from SOF to EOF divided by total acquisition length.

CANLoad Measurement Parameter Setup Detail

To access the setup dialog, touch Setup for that parameter in the CAN Measure/Graph Setup

dialog. The Px Parameter dialog box is displayed. On the right side of this dialog box, there is a

setup dialog labeled with the measurement parameter name. Touch the tab with the parameter

name on it, and you will access the following dialog:

Page 29

Operator's Manual

CANbus-TD-TDM-OM-E RevB

29

Frame type can be ALL, Remote, Data, or Error type. ID conditions can be set, and IDs specified.

The operation is much the same as the CAN Trigger setup, so the detail will not be repeated

here.

Page 30

CANbus Trigger, Decode, and Measure

30

CANbus-TD-TDM-OM-E RevB

Time from Trigger Point to CAN Message Parameter

Time from Trigger Point to CAN Message (Time@CAN)

This measurement parameter is used to measure the time from the trigger point to the defined

CAN message. The trigger could be a CAN message, a simple edge trigger, or something more

complicated, like a Pattern or a Dropout SMART Trigger. This makes it a very powerful tool to

understand the time delay from the occurrence of a certain set of conditions to the start of a

CAN message.

Time@CAN Measurement Parameter Setup Detail

To access the setup dialog, touch Setup for that parameter in the CAN Measure/Graph Setup

dialog. The Px Parameter dialog box is displayed. On the right side of this dialog box, there is a

setup dialog labeled with the measurement parameter name. Touch the tab with the parameter

name on it, and you will access the following dialog:

Characterizing CANbus System Performance

System Performance Characterization Overview

The oscilloscope contains a number of built-in tools, such as cursors, measurement parameters,

statistics, and optional graphical analysis tools that you can use to characterize your CANbus

system’s performance. These can be used on the CAN Trace and CAN Zoom just like they are

used on any channel. In addition, you can use normal Edge or SMART Triggers on an analog

channel input to trigger the oscilloscope when a certain analog signal occurs, and then measure

to a particular CAN message.

Page 31

Operator's Manual

CANbus-TD-TDM-OM-E RevB

31

You can use cursors for making single-shot timing measurements, and measurement parameters

when you need to accumulate statistical data over many different acquisitions. In addition,

measurement parameters are helpful to determine the underlying integrity of the CAN physical

signal.

Page 32

CANbus Trigger, Decode, and Measure

32

CANbus-TD-TDM-OM-E RevB

For instance, take the example below of an analog signal creating a burst of CAN messages.

This data was acquired over a 500 ms duration. It is likely that you want to understand whether

the analog signal input to your electronic control unit (ECU) is creating the desired CAN message

output from the ECU. There are a number of ways that this could be done.

Using Cursors

Use horizontal cursors to mark locations on the waveform where the time measurement should

be done, then read the cursor values to establish the measurement. As necessary, adjust the

timebase or create zooms of the channels and the CAN Trace to view the signal with enough

detail. This is a good method for single-shot / single measurements.

Page 33

Operator's Manual

CANbus-TD-TDM-OM-E RevB

33

Page 34

CANbus Trigger, Decode, and Measure

34

CANbus-TD-TDM-OM-E RevB

Amplitude - Noise and overshoot resistant measurement of the amplitude of the signal

(measurement of amplitude from Top to Base).

Base - Value of the lowermost state in a bimodal waveform, such as a CAN Message.

Delay - Time from the trigger to the first transition at the 50% amplitude crossing.

Delta Delay - Time between the 50% crossing of the first transition of two waveforms.

Delta Time @ Level - Time between selectable levels of two waveforms.

Delta Trig Time - The time from last trigger to this trigger (usually used in Sequence

mode).

Fall (90-10), Fall 80-20, Fall@Level - Transition time on the falling edge. Three selections

are available for the user to determine at which vertical level the measurement is made.

Maximum - Highest value in the input waveform.

Mean - Average of all data values.

Minimum - Lowest value in the input waveform.

Overshoot Negative - Overshoot following a falling edge.

Overshoot Positive - Overshoot following a rising edge.

Using Measurement Parameters

You can use measurement parameters to make signal integrity or timing measurements of your

CAN Bus system. Basic parameters, such as Amplitude, Rise, Fall, Overshoot, etc. are ideal for

signal integrity checks. Timing parameters, such as Delay, Delta Delay, Delta Time @ Level, etc.,

are ideal for measuring timing from trigger to other signals (such as from a CAN Trigger to an

analog signal). Delta Trig Time is ideal for measuring the time between segments of a Sequence

Mode acquisition.

Page 35

Operator's Manual

CANbus-TD-TDM-OM-E RevB

35

Peak to Peak - Difference between the Maximum and Minimum data values.

Rise (10-90), Rise (20-80), Rise@Level - Transition time on the rising edge. Three

selections are available for the user to determine at which vertical level the

measurement is made.

Top - Value of the uppermost state in a bimodal waveform, such as a CAN Message.

Measurement Gating

Gating is available on each parameter to allow you to set a measurement window that the

parameter should be active in. This allows you to eliminate unwanted portions of the

acquisition from your measurement.

1. Touch the the appropriate measurement (P1, P2, etc.) or choose Measure→Measure

Setup and then touch the appropriate measurement tab (P1, P2, etc.).

2. Touch the Gate tab and enter the start and stop for the gate.

Using Statistics and Graphing

Statistics and Histicons are included with every LeCroy oscilloscope. They allow you to gather

numerical and visual information on the distribution of your various measurements.

You can turn on Statistics and Histicons separately in the Measure dialog. Touch the

appropriate box to place a checkmark and turn it ON, or touch it again to turn it OFF.

Page 36

CANbus Trigger, Decode, and Measure

36

CANbus-TD-TDM-OM-E RevB

In addition, some optional LeCroy programs add the capability to produce larger histograms and

trends of your measurement parameters. If you have this capability, then you can access it

through the Measurement Parameter setup dialog (the Px tab).

Pass/Fail Analysis with Measurement Parameters

Pass/Fail analysis using measurement parameters is simple to set up and powerful. For

instance, you can define a timing measurement, define the limits for the timing measurement,

and then run the oscilloscope in a Normal trigger mode, capturing thousands of measurement

events. Then, Pass/Fail can be used to save the waveform in the event of a Fail, or send an

email in the event of a fail.

Page 37

Operator's Manual

CANbus-TD-TDM-OM-E RevB

37

Touch Analysis→Pass/Fail Setup to set up pass/fail conditions.

Isolating and Analyzing CANbus Activity

Isolate and Analyze Serial Bus Activity

The combination of Serial Data Triggering, Decoding, and normal oscilloscope features is a

powerful combination of tools that can make it very easy to find latent Serial Data HW or SW

problems in your circuit. No longer is the oscilloscope a tool just for the hardware engineer.

Now the software engineer can also easily visualize the Serial Data signals and relate it to

programming code and operation. The TD options can enable the HW Engineer and SW Engineer

to “speak the same language” when it comes to system debugging and performance checking.

Some common Serial Data analysis needs and methods are discussed below:

Capture Long Pre-Trigger Time

LeCroy oscilloscopes are available with optional very long acquisition memory. For instance, the

WaveRunner Xi Series oscilloscopes can capture up to 12.5 Mpts on 4 channels, or 25 Mpts on 2

channels. If your Serial Data signals are 1 Mb/s, and you sample at the minimum required and

available sample rate (5 MS/s, you would be able to capture 5 seconds of Serial Data traffic. If

you wish, this can be 100% pre-trigger, 100% post-trigger, or something in between.

1. Adjust Pre-Trigger and Post-Trigger time by adjusting the Delay knob on the oscilloscope’s

front panel.

Page 38

CANbus Trigger, Decode, and Measure

38

CANbus-TD-TDM-OM-E RevB

2. Optimize your Sample Rate or Memory Length by accessing the Horizontal Dialog in your

oscilloscope and selecting either Set Max Memory mode or Fixed Sample Rate mode.

3. Touch Set Maximum Memory to decrease the memory usage in order to not sample at

rates you specify as being too high (high sample rates can slow down the decoding

algorithm). Then adjust your time timebase setting to the length needed to capture the

event.

Note: Make sure your combined timebase and memory length settings do not result in

too low of a sample rate. Otherwise, adequate capture and decode is not performed.

4. Touch Fixed Sample Rate to specify a fixed rate. It's common to fix the sample rate to a

specified value so you have the necessary oversampling to capture your Serial Data

messages (at least 4X the bit rate). This also allows for a high enough sample rate to

capture transients you may want to see on your Serial Data and analog signals (at least 2X

the frequency of any expected transients, preferably 10X).

Reference your oscilloscope’s Online Help for more information on these common settings.

Trigger Repeatedly, Save Data to a Hard Drive

You may want to set up your oscilloscope to capture a short or long memory acquisition for a

certain trigger condition, then save data to a hard drive or memory stick whenever the trigger

condition is met. This can be easily done in most LeCroy oscilloscopes. However, there is

significant trigger “dead time” when using this method. To minimize dead time, use the method

described inTrigger Repeatedly, Store all Triggers (Sequence Mode).

1. Set up your desired serial data (or other) trigger condition.

2. Choose File →Save Waveform from the menu bar. A dialog is shown where you can set

Save Waveform conditions as follows:

OFF - No Auto Saving occurs

WRAP - Auto Save occurs until the hard drive is filled, then discards the oldest data to

write the newest data

Page 39

Operator's Manual

CANbus-TD-TDM-OM-E RevB

39

FILL - Auto Save occurs until the hard drive is filled

PLEASE NOTE THE FOLLOWING:

Choose a Binary file format if you want to recall the traces into a LeCroy oscilloscope for

later analysis.

Even though the LeCroy oscilloscope hard drives are very large, it is a good idea to make

sure that your trigger condition is set correctly before beginning your acquisitions.

This method is not guaranteed to capture all of your trigger events, since there is a large

amount of “dead time” between triggers as the acquisition is captured, displayed, and

stored to the hard drive before the scope is re-armed for a new trigger. Minimize dead

time by using Sequence Mode.

Trigger Repeatedly, Store all Triggers (Sequence Mode)

LeCroy oscilloscope’s have a powerful capability called Sequence Mode that allows you to store

all triggered events by minimizing the dead time between triggers to < 800 nanoseconds. This is

ideal for finding repetitive causes of problems on your serial data buses or associated signals.

(Not available in WaveSurfer Series).

Sequence Mode uses long acquisition memory that is divided into “segments.” As triggered

events are acquired, they are stored in acquisition “segments” to be recalled at a later date. The

length of each sequence mode acquisition segment and the total number of segments allowed is

roughly determined by the total acquisition memory in the oscilloscope. For instance, a

WaveRunner Xi with VL memory can acquire 10,000 segments each a maximum of 625 samples

long or 10 segments each a maximum of 1.25 megasamples long, or something in between.

Different acquisition memory lengths have different ranges of segments and segment lengths.

You can define any number of segments from 2 to the maximum for that memory length

(reference your oscilloscope’s on-line Help), and any length of segment (as long as there is

sufficient acquisition memory). After acquisition of all segments is complete, you can recall them

one-by-one and view them in decoded format on the oscilloscope screen.

Page 40

CANbus Trigger, Decode, and Measure

40

CANbus-TD-TDM-OM-E RevB

Acquisition dead time is kept to a minimum because there are no operations performed during

the acquisition. All data for each triggered event is written only into high-speed acquisition

memory. Until the entire sequence is completed, there is no updating of the oscilloscope

display, or other operations that cause unnecessary dead time. This is ideal for situations when

you cannot take a chance on losing data.

In the example shown below, we have only acquired Channel 1 (the CAN signal) in sequence

mode. We could also acquire additional analog or other signals as desired or as necessary to do

a proper analysis.

1. Touch the Timebase descriptor box to open the Timebase dialog.

2. In the Sampling Mode area, select Sequence Mode. Touch the Sequence tab.

3. On the Sequence tab, select the Display Mode. Select the Number of Segments Displayed

at one time.

4. If you have acquired more segments than you can display at one time, you can choose

the segment at which to start the display.

5. Set up the Serial Trigger to capture an event. For instance, you might want to trigger on a

specific address or data value, and capture long pre-trigger time to determine what

precedes that message. In this example, we’ve used a simple I2C Start trigger. To begin

the sequence mode acquisition, press the front panel SINGLE trigger button. Each time

the trigger condition is met, the TRIG’D light on the front panel flashes. When you’ve

acquired the set number of segments, the trigger STOPS and the following display is

shown (this is a 50 segment acquisition in Mosaic display mode).

Page 41

Operator's Manual

CANbus-TD-TDM-OM-E RevB

41

6. Display an individual segment separately from the main channel display by selecting

Math→Math Setup from the menu bar. Then, choose a math trace to define as a

Segment (here we’re defining F1 as a Segment of C2).

Page 42

CANbus Trigger, Decode, and Measure

42

CANbus-TD-TDM-OM-E RevB

Use the channel the serial data was acquired on as a source (in this case Channel 2).

Check the TRACE ON checkbox to display the trace. Select a segment to view by touching

the Select tab and use either the pop-up keypad or the front panel adjust knob.

7. Set up the Decode to use the Math trace as the source for Data in order to view decoded

data on the individual segment (in this case F4 is the source).

Page 43

Operator's Manual

CANbus-TD-TDM-OM-E RevB

43

To change the decoded segment, select a new segment from the Math trace dialog (as

shown in the preceding step).

8. Conserve display space, by turning off the Channel and selecting only the segment you

want to view.

Page 44

CANbus Trigger, Decode, and Measure

44

CANbus-TD-TDM-OM-E RevB

9. View the timestamps for each segment by selecting Vertical→Channels Status on the

menu bar. On the Show Status portion of the dialog, select Time. A display of timestamp

information for each segment in the sequence acquisition is shown.

10. Ten timestamps fit on the display at a time. You can choose which 10 to display by using

the Select Segment control. You can also page through the segments one at a time by

using the Adjust knob on the front panel.

Page 45

CANbus-TD-TDM-OM-E RevB

45

Reference

Definition

CANbus TD and TDM

Protocol Setup

Select Bitrate (10, 25, 33.333, 50, 83.333, 100, 125, 250, 500, 1000 kb/s

or user-defined between 10-1000 kb/s).

Decode Capability

CANbus TD and TDM

Format

Hexadecimal

Decode Setup

Threshold definition required. Default is to Percent amplitude. Select

BitRate.

Decode Input

Any analog Channel, Memory or Math trace.

Number of Decoded

Waveforms

Up to 4 buses may be decoded at one time.

In addition, zooms can be displayed (with decoded information).

Location

Overlayed over DATA waveform, on Grid.

(Use multi-grid if there is more than one decoder ON)

Visual Aid

Color Coding for FRAME, ID, DLC, DATA, CRC, Ack, Stuff Bits and Errors.

Decode information is intelligently annotated based on timebase setting.

Trigger Capability

CANbus TD and TDM

Format

Hexadecimal or Binary

Trigger Setup

Trigger on All Frames, Frame ID, ID with Data, Remote Frames, or Error

Frames.

Address (ID)

Condition Setup

Specify one Frame ID or a range of Frame IDs. Frame ID trigger can be

combined with Data.

Conditional Trigger

Setup

Conditional Frame ID and Conditional Data triggering available. Choose

from <=, <, =, >, >=, <>, in range, out of range or don’t care conditions.

Data Setup

Hexadecimal:

CANbus TD and TDM Specifications

Note: Specifications are subject to change without notice.

Operator's Manual

Page 46

CANbus Trigger, Decode, and Measure

46

CANbus-TD-TDM-OM-E RevB

Trigger Capability

CANbus TD and TDM

# Data Bytes = 0 to 8. Data can be defined by nibble. Triggers on that

data pattern regardless of position.

Binary:

Any combination of 0,1, or X for 1-64 bits. Triggers on that data pattern

regardless of position.

Bit Rates

10, 25, 33.333, 50, 83.333, 100, 125, 250, 500, 1000 kb/s or user-defined

between 10-1000 kb/s.

Trigger Input

Any analog Channel or the EXT input.

Trigger Design

Internal to oscilloscope, settable like any other oscilloscope trigger.

Search Capability

CANbus TD and TDM

Search Options

Search for Any Frame, Any Error or Frame ID in Hexadecimal format.

Measure and Graph

Capability

CANbus TD

CANbus TDM

CAN Timing

Measurements

Not Applicable

CAN-CAN, CAN-Analog, Time@CAN,

CAN Message Bitrate.

CAN Data Extraction

Not Applicable

CAN-Value.

CAN Bus Load

Measurements

Not Applicable

CAN Bus Load %.

Graphing Functions

Not Applicable

Track, Trend and Histogram of CAN

measurements.

Page 47

Operator's Manual

CANbus-TD-TDM-OM-E RevB

47

Safety Requirements

WARNING

To avoid personal injury and to prevent damage to this product or any products connected to it, review

the following safety precautions. To avoid potential hazards, use this product only as specified.

Before using the CANbus TD, ensure that its operating environment will be maintained within these

parameters:

Operation: In-door Use

Temperature: 5 to 40 oC

Humidity: < 80% RH (non-condensing)

WARNING

To avoid fire or personal injury, comply with the following:

Do not use the CANbus TD Series hardware in wet or explosive atmospheres.

Do not use the CANbus TD Series hardware if any part is damaged. All maintenance should be

referred to qualified service personnel.

Use of the CANbus TD Series hardware and/or the oscilloscope it is connected to in a manner

other than specified may impair the protection mechanisms.

Page 48

CANbus Trigger, Decode, and Measure

48

CANbus-TD-TDM-OM-E RevB

Qty. 1: Trigger Module -- The Trigger Module is basically a

CAN Node that is set to filter (and provide a triggering

signal) when certain conditions are met. It contains a 32bit, 64 MHz microcontroller and two Philips SJA1000 CAN

controllers. A Trigger Coupler (CAN transceiver) needs to

be installed in the trigger module to connect to the

appropriate bus. A 251 Trigger Coupler is provided

standard on input 1, and a second can be installed on input

2. As necessary, the trigger couplers can be interchanged

to suit your specific needs. The Trigger Module receives

triggering instructions, as defined in the CAN Trigger dialog,

through the USB2.0 cable (connected to the LeCroy

oscilloscope), and outputs a trigger pulse through the 3-pin

connector when the CAN trigger condition is met. The

trigger pulse is a negative going edge from 5 V to 0 V.

Qty. 1: Oscilloscope Interface Module -- This module

connects to the Trigger Module via the 3-pin connector.

The module is LeCroy ProBus® compatible. When plugged

into a LeCroy oscilloscope, it is automatically recognized

and proceeds with appropriate setup for CAN triggering.

The OIM can be connected to any channel, but is more

commonly connected to the EXT input (to reserve a channel

for an analog signal). Once connected, it sets the following:

sets the oscilloscope trigger to a negative going Edge

with a trigger level of 3 V (to trigger on the output

pulse when the CAN trigger condition is met) and no

trigger holdoff condition.

displays the CAN trigger dialog

applies a skew correction to all channels (to ensure

that the trigger point aligns with the EOF point of the

Appendix A: External Trigger Hardware

CANbus TD Standard Hardware

The Standard Hardware consists of the following items:

Page 49

Operator's Manual

CANbus-TD-TDM-OM-E RevB

49

triggered CAN message.

sets the horizontal settings to real-time sample

mode using 4 channels.

if connected to a channel, it also resets various

channel settings (interpolation, variable gain, scale

and offset, averaging, etc.) to a default value.

Qty. 1: USB2.0 Cable -- Provides power to the Trigger

Module. Also downloads CAN trigger conditions from the

oscilloscope’s CAN Trigger dialog to the Trigger Module.

Qty. 2: 120 Terminations -- A 9-pin to 9-pin DSUB

connector with an internal 120 termination between pins

2 and 7 (to convert a low-speed cable to a high-speed

cable).

Qty. 1: CAN Bus Connection Cable (High-speed)

Page 50

CANbus Trigger, Decode, and Measure

50

CANbus-TD-TDM-OM-E RevB

Qty. 1: CAN Bus Connection Cable (Low-speed and SingleWire)

Qty. 1: Quick Reference Guide

Qty. 1: Operator’s Manual

Qty. 1: Carrying Case

Page 51

Operator's Manual

CANbus-TD-TDM-OM-E RevB

51

Accessories

Various accessories are also available to use with the CANbus TD. These are listed below:

Trigger Couplers – Trigger Couplers are CAN Transceivers. The Trigger Coupler in the

Trigger Module must match the CAN transceiver in the circuit that you are connecting the

Trigger Module to. Trigger Couplers can be easily interchanged in the Trigger Module as

the need requires. The following Trigger Couplers are available from LeCroy:

o CAN 251 High-speed (Included with Trigger Module)

o CAN 1050 High-speed

o CAN 1041 High-speed (Wake-Up)

o CAN 1054 Low-speed

o CAN 5790c Single-Wire

All Trigger Couplers are optically isolated and feature optical decoupling between the

CANbus TD Trigger Module and the CAN Bus. Galvanic isolation of the transceiver

voltage supply is realized using a DC/DC converter.

Note: ISO 11992-1 prescribes at least a 16 V voltage supply (VS) for 24 V systems. Therefore, it

is required to use the TC 10011OPTO Trigger Coupler with an external voltage supply. This

voltage supply should be between 16 V and 36 V, and applied to pin 9. No other trigger

couplers require an external voltage supply.

Cables – A variety of connection cable sets for high-speed and low-speed CAN are

available. These cable sets provide all that is needed to connect to 9-pin terminated CAN

in many situations. In addition, a low-speed Y-connection cable is also available, which

makes it easy to connect to a third-party CAN simulation or analysis tool, such as Vector’s

CANalyzer or CANoe.

Connecting to a CANbus Circuit

Overview

The CANbus TD/TDM Trigger Module operates as a “node” on the CAN Bus. It contains a

Microcontroller, CAN controller, and Transceiver (Trigger Coupler) and interfaces to the CAN

circuit just like any other node on the bus. However, the Trigger Module only provides triggering

capability. In order to “view” the actual CAN physical signal on the oscilloscope display, you

must also probe the CANH and CANL signals with single-ended probes, or a differential probe

(such as the LeCroy ADP305 or AP033) and input this probe signal(s) to an oscilloscope channel.

Page 52

CANbus Trigger, Decode, and Measure

52

CANbus-TD-TDM-OM-E RevB

1. Connect the USB2.0 Cable to one of the

instrument’s PC-USB ports.

2. Connect the other end of the USB2.0 Cable

to the CANbus TD/TDM Trigger Module.

Connecting the Trigger Module to the Oscilloscope

Connect the CANbus TD/TDM Trigger Module and Oscilloscope Interface Module (OIM) to the

instrument as follows:

Page 53

Operator's Manual

CANbus-TD-TDM-OM-E RevB

53

3. Connect the CANbus TD/TDM Oscilloscope

Interface Module (OIM) to the EXT input of

the instrument. Make sure that the top

(OIM labeled side) is facing up.

Note: Make sure that the OIM is at a right angle

to the connector.

4. Connect the 3-pin plug end of the OIM to

the Trigger Module.

1. Open the CAN Trigger dialog by touching the Trigger descriptor

box (or by pushing the front panel “Bus Analysis” push button

on Vehicle Bus Analyzers, and then selecting the CAN Trigger

Installing Trigger Couplers

UNDERSTANDING WHICH TRIGGER COUPLER IS INSTALLED IN THE TRIGGER MODULE

The Trigger Coupler is a CAN Transceiver. Therefore, the Trigger Coupler in the Trigger Module

must match the transceiver in the CAN circuit you wish to connect to. If it does not match, the

CAN trigger will not function properly.

To identify the coupler(s) that are installed, do the following:

Page 54

CANbus Trigger, Decode, and Measure

54

CANbus-TD-TDM-OM-E RevB

dialog). With the Trigger Module connected to the instrument,

the Trigger Dialog will default to the CAN Trigger tab.

2. On the right hand side of the CAN Trigger dialog, there is a

listing of Trigger Couplers. Note the Input # and the Type. If

the correct Type of Trigger Coupler is installed, make sure you

connect that Trigger Module Input to your circuit using the

appropriate cable.

3. Trigger Module Input (and hence, Trigger Coupler) used for

triggering may be selected from the CAN Trigger dialog “Input”

selection.

1. Unplug the USB2.0 and OIM cable (if they are

plugged in).

INSTALLING OR REMOVING A TRIGGER COUPLER

You will probably only need to use one or two different Trigger Couplers, so this will probably be

something that you only have to do once, or very infrequently. In any case, it is simple to do.

The CANbus TD/TDM Trigger Module housing can be opened easily. Follow the instructions

below to open the Trigger Module and install or remove a Trigger Coupler.

Page 55

Operator's Manual

CANbus-TD-TDM-OM-E RevB

55

2. The housing is shipped with two of the plastic

end caps (that cover the screws) uninstalled. If

these have been installed by you or someone

else, you will need to remove them with a small

screwdriver or knife.

3. Unscrew the screws on the DSUB-9 connector

side of the Trigger Module using a Philips #1

screwdriver.

4. Slide the tray out of the housing (you may have

to pull with some force if it has not been opened

before).

Page 56

CANbus Trigger, Decode, and Measure

56

CANbus-TD-TDM-OM-E RevB

Note: Be sure to avoid touching the bottom or top of the Trigger Couplers or the Trigger Module

main boards. If you are unsure, use normal static grounding techniques.

5. The Trigger Coupler is held down with a screw

and locknut. Use a Philips #1 screwdriver to

remove them. If necessary, carefully remove a

Trigger Coupler from the main board, taking

care not to touch the bottom of the Trigger

Coupler. Store the Trigger Coupler in one of the

static sensitive boxes (provided).

6. Install a new Trigger Coupler, making sure that

the two-row connector and one-row connector

are properly aligned and that the pins are fitting

correctly. Refasten screw and locknut.

Page 57

Operator's Manual

CANbus-TD-TDM-OM-E RevB

57

7. Slide the tray back into the housing, making

sure that when the tray is re-installed the USB

connector is showing.

8. Push the tray and the housing together, with

light pressure. Tighten the screws firmly but not

excessively.

Cable Part Number 902382-00

DSUB (9-pin) Pin #

Definition

Wire Color

2

CANL

White

3

GND (low-speed) or VB- (single-

wire)

Brown

Connecting the Trigger Module to the CAN Bus

Since the Trigger Module is a “node” on the CAN Bus, all of the normal connection rules apply.

The bus must be terminated correctly, and CANH, CANL, GND, etc. must be connected to the

correct locations. If you don’t make corrections to the bus correctly, the CANbus TD/TDM

Trigger Module may generate error frames, may load down your signal, and will not trigger.

Fortunately, LeCroy provides a number of standard cables to enable you to easily make

connections to high-speed, low-speed, and single-wire CAN Buses. These cables have 9-pin

DSUB socket connectors with 2 or 4 wires that are stripped and may be connected to in-circuit

wiring, banana plugs, alligator clips, etc., as necessary to connect to the CAN Bus circuit. The

part numbers for these cables are 902381-00 and 902382-00. They are usable for most

applications.

First, understand whether your CAN circuit is low-speed, high-speed, or single-wire. Then, plug

the correct cable’s 9-pin DSUB connector into the Trigger Module, and connect the wires to the

CANH, CANL, and other (as necessary).

Reference the tables below for information on the cables:

Page 58

CANbus Trigger, Decode, and Measure

58

CANbus-TD-TDM-OM-E RevB

7

CANH

Yellow

8

VB+ or VB

BATT

Red

Notes:

Connect Pin 3 as necessary, depending on whether it is low sped or single-wire CAN

Use for low-speed (1054) or single-wire (GM-LAN, 5790c) CAN

(ISO 11898-3, ISO 11519, SAE J2411)

Cable Part Number 902381-00

DSUB (9-pin) Pin #

Definition

Wire Color

2

CANL

White 7 CANH

Yellow

Notes:

A 120 ohm terminating resistor is connected across pins 2 and 7, in accordance with IS0

11898.

Use for high-speed (251, 1050, 1041) CAN

(ISO 11898-2)

LED

Indication

RX

Flashes when messages are being

received

VERIFYING PROPER TRIGGER MODULE CONNECTION TO THE CAN BUS

The CANbus TD/TDM Trigger Module has several LEDs on the front of the module. These LEDs

will light to indicate CAN message direction and error frame activity. There is one set of LEDs for

each input (or Trigger Coupler). The LEDs will light as follows:

Page 59

Operator's Manual

CANbus-TD-TDM-OM-E RevB

59

TX

Flashes when messages are being

transmitted

Err

Flashes when errors occur on the bus

If you see either or both of these error messages (shown in the picture

to the right) in the CAN Trigger dialog, then you need to re-examine the

connections to the Trigger Module and make sure that they are correct.

This message will be replaced by Trigger Module attributes and trigger

coupler information when the Trigger Module is properly connected.

If the RX or TX light is flashing when there is CAN traffic on the bus, then you can assume that

the Trigger Module connection to the bus is correct.

If the Err light is flashing, or if there are no lights flashing, then there is something wrong with

the connection of the Trigger Module to the bus. Re-examine your wiring connection, make

sure that you are using the correct cable and/or correct termination, and make sure that the bit

rate is set correctly in the CAN Trigger dialog.

There are also optional cable sets that may be purchased for both high-speed and low-speed

CAN. These cables have 9-pin DSUB to 9-pin DSUB connectors, and are useful if your embedded

controller has a 9-pin connection for CAN. It is also simple to build these cables. The cables and

cable sets are described below (schematic detail is provided in Appendix A)

Page 60

CANbus Trigger, Decode, and Measure

60

CANbus-TD-TDM-OM-E RevB

Cable Set Part Number 902329-00

Quantity

Description

1

0.3 m cable with 9-pin DSUB socket connectors on each

end, and with pins 2 and 7 connected, including 120 ohm

terminations on each end.

1

2 m cable with 9-pin DSUB socket connectors on each end,