Teledyne BVS-SP-1280M-IDE, BVS-SP-0640M-IDS, BVS-SP-0640M-IDE, BVS-SP-1280M-IDS Quick Start Manual

BOA Spot ID

Quick Start Guide

BOA Spot ID Quick Start

1

Ver sion 1.2; 2017-11-20

Notice

BOA Spot ID Quick Start Guide

Document Number 405-00064-00

Copyright © 2016 Teledyne DALSA Incorpor ated.

All rights reser ved.

All copyrights in this manual, and the hardware and software described in it, are the

exclusive property of Teledyne DALSA Incorporated and its licensors.

Claim of copyright does not imply waiver of Teledyne DALSA Incorporated or its licensors

other rights in the work. See the following Notice of Proprietary Rights.

NOTICE OF PROPRIETAR Y RIGHTS

This manual and the related hardware and software are confidential trade secrets and the

property of Teledyne DALSA Incorporated and its licensors. Use, examination,

reproduction, copying, transfer and/or disclosure to others of all or any part of this manual

and the related documentation are prohibited except with the express written consent of

Teledyne DALSA Incorporated.

The information in this document is subject to change without notice. Teledyne DALSA

Incorporated makes no representations or warranties with respect to the contents of this

manual and specifically disclaims any implied warranties of merchantability or fitness for a

particular purpose. Teledyne DALSA Incorporated assumes no responsibility for errors or

omissions in this document.

Teledy ne DALSA logo is a trademark of Tel edyne DALSA Incorporat ed. All other

trademarks ar e the pr oper ty of their respective owners.

Teledy ne DALSA Industrial Products

Information: info.ipd@teledyne.com

Support: support.ipd@teledyne.com

Web: http://www.teledynedalsa.com/visionsystems

700 Technolo gy Park Drive

Billerica, MA, USA 01821

Tel 1.978.670.2002 Fax 1.978.670.2010

2

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

Certifications

Declaration of Conformity

Manufacturer Teledyne DALSA Industrial Products Incorporated

CE We declare that this product has been tested to comply with the

FCC We declare that this product has been tested and found to

700 Technology Park Drive

Billerica MA 01867

USA

EC Directive for a class A digital device in accordance with

EN55022/CISPR22.

comply with the limits for a class A digital device, pursuant to

Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference in a

residential installation.

This equipment generates, uses and can radiate radio frequency

energy and may cause harmful interference to radio

communication.

Other Certifications

IP67 This product meets the requirements for industrial applications

that require IP67 wash down protection - requires fitted sealing

lens cover and sealing plugs on unused connectors.

CFR 21 Part 11 This product provides the tools needed for users to implement

an auditing program that could be in compliance with CFR 21

Part 11. These tools include:

• System or software backup and restore

• System software security (password login and access limits)

• Protection of system backup files from modification.

• Time stamp information on data output.

3

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

Handling Precautions

Care should alway s be exer cised w hen handling and operati ng y our BOA Spot Vision

Sensor . Even though the system is encased wi thi n a rugged, industrial enclosure,

incorrect use or handling can resul t i n damag e to your investment. To prevent this, we

recommend follow ing these pr ecaution s:

• Do not look directly into the LED ring light during operati on! The light is extremely

bright and may cause pain or damage y our vision.

• Avoid “hot-pl ug g i ng ” cables and dev ice s. Always shut the system down and r emov e

power before connecting or disconnecting anything to it.

• Do not use in a Free-standing operation. Mount the B OA Spot properly to prevent it

from falling accidentall y. Mounting holes are provided on each side of the BOA Spot.

• Always use the BOA Spot sensor w ithin its recommended operati ng condit ions.

Refer to the complete specifications on page 25.

• Do not install BOA Spot in a loca ti on that will expose i t to excessive heat, humidity,

vibration, impact, corrosive substances, flammable substances, static electricity or

Electro Static Discharg e (ESD ).

• Never expose the internal electr onics by opening the enclosure.

• Do not attempt to modify the BOA Spot or open the case. This unit has no fiel dreplaceable co mponents ( beyond repl acing the Lens or Ring-lig ht). Tamper ing wi th

the unit will void the product war ranty.

Warranty

Teledy ne D ALSA warr ants the BOA Spot Vision Sensor ag ainst defects in material s and

workmanship for a period of twenty four (24) months from the date of delivery. T eledy ne

DALSA and its representatives expressl y disclaim any and all other warranties.

Your sole remedy shall be repair or replacement of the BOA Spot Vision Sensor pr oduct

and associated optional co mponents, pr ovided t hat the defective product is returned

within the warranty period.

If you need to return the BOA Spot Vision Sensor, you must co ntact the Teledyne DALSA

representative w ho sold y ou the product. Do not return your product to Teledyne DALSA

without prior authoriz ation.

Teledy ne DALSA assumes no li abi l it y for damag es resulting from the use of thi s manual.

4

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

Table Of Contents

Introduction Product Overview …………………….......................... 6

Code Reading Considerations …………………….......................... 7

Code Variability …………………….......................... 8

Inspection Capabilities …………………….......................... 9

Components …………………….......................... 10

Lens, Cover & Light Options …………………….......................... 11

FOV and Reading Distances …………………….......................... 12

Installation Connections & Pin-outs …………………….......................... 17

Cable Configurations …………………….......................... 19

Mounting Options …………………….......................... 22

Dimensional Drawings …………………….......................... 23

Specifications General Specifications …………………….......................... 25

Input Specifications …………………….......................... 26

Output Specifications ……………………......................... 28

PL-101 Specifications ………………………………………. 30

PL-101 Wiring Diagrams ………………………………………. 31

Serial Port Connection ………………………………………. 32

Software Setup How to Access BOA Spot …………………….......................... 33

Configure Client PC …………………….......................... 34

Configure BOA Spot ………………………………………. 38

iDiscover Utilit y …………………….......................... 39

BOA Spot Web Server …………………….......................... 40

Firmware Upgrading …………………….......................... 41

Application Settings …………………….......................... 42

Application Interface ………………………………………. 43

Getting Started ………………………………………. 44

Emulator Software Complementary Programs ……………………………………… 51

Troubleshooting Common Startup Issues ……………………..........................

..

5

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

53

Introduction

BOA Spot ID Overview

BOA Spot is a fully integrated vision sensor t hat has been designed for i ndustr i al ID

(Barcode, 2D Matrix and T ext ) applications. Packaged complete w ith application

software, BOA Spot ID offers a robust, easy-to-deploy fixed code reader and inspection

tool for the factory floor . BOA Spot is compatible w ith Windows 7, 8.1 and 10. BOA Spot

is not compatible with Windows XP.

BOA Spot Vision Sensor s are rugged dev i ces that can be integrated into existing

production l ines, mach iner y or moving equi pment. They are su ppor ted by standard

industrial M 12 cables to further simpl ify and r educe i mplementat ion cost s.

Rated for IP67 deployment w hen fitted w ith the M12 lens and lens cov er, BOA Spot

vision sensors can be mounted in w ash down factory envir onments w it hout the need for

additional protect iv e enclosures. The product is also available w ith a C-mount lens

option for greater imag e quali ty, operating distance and li ghti ng flexi bili ty.

BOA Spot ID Models

• BVS-SP-0640M-IDS-XXX-Y – 640x480 senso r w ith standard reader tools

• BVS-SP-1280M-IDS-XXX-Y – 1280x960 senso r with standard reader tools

• BVS-SP-0640M-IDE-XXX-Y – 640x480 sensor with expanded tool set

• BVS-SP-1280M-IDE-XXX-Y – 1280x960 sensor wi th expanded tool set

In addition to reading barcodes, the IDE model offers advanced capabilities for reading

printed tex t, veri fyi ng the posi ti on and content of labels, or verifying the presence,

absence and integrity of features on parts.

Upgrading from IDS to the IDE:

The IDS model can be field upgraded vi a a license to support the IDE advanced

features. The upgr ade can be purch ased t hrough our local r eseller and w ill require

sending the serial number and MAC ID of the device. The upgrade license is entered in

the highlighted field on the Applicati ons page of the w eb se r v er (as shown below). More

information on this is provided later in this document.

6

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

Code Reading Considerations

BOA Spot ID offers fast decoding of 1D and 2D codes pri nted or directly marked on a

variety of surfaces, including paper, plast ic and metal. The decoder is robust and able

to read poorly printed, w orn or environmenta lly degr aded codes i n any orientation .

Guidelines for reliable code reading are as follows:

1D Codes

• M ini mum distance between bars = 1.5 pixel s (2.5 pi x el s for low contrast)

• M ini mum bar width = 1.5 pixel s ( 2.5 pi xels for low contrast)

2D Codes

• M ini mum cell size = 2 x 2 pixels

• M ini mum dot diameter = 2 pix el s

All Codes

• Non-DPM = Maximum ROI size = 1280 x 960

• D PM = Maximum ROI area = 614,400 pix els (i .e. 1280 x 480, 1024 x 600, 960 x 640,

800 x 768 and anything smaller, such as 640 x 480)

• U se “Invert” preprocessor to decode light-on-dark barcodes

• With the excepti on of “low contrast”, the control parameters descr ibed on the next

page are mutually exclusive. Onl y one can be enabl ed at a time.

General deployment guidel ines:

• Choose a lens that satisfies the FOV and minimum bar/module size

• Adjust wor ki ng distance to maximize the code FOV wher ever possible

• BOA Spot ID with integrated lig ht is a good choice for high contr ast codes pr inted on

non-reflective surfaces

• BOA Spot ID with external dar k field li ght is better for dot peen codes

• BOA Spot ID with external di ffuse of f-axi s l i g ht is better for cur ved or highly reflective

surfaces.

• Increase li g ht and r educe shutter time to stop motion for fast moving applicati on s

7

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

Compensating for Code Variability

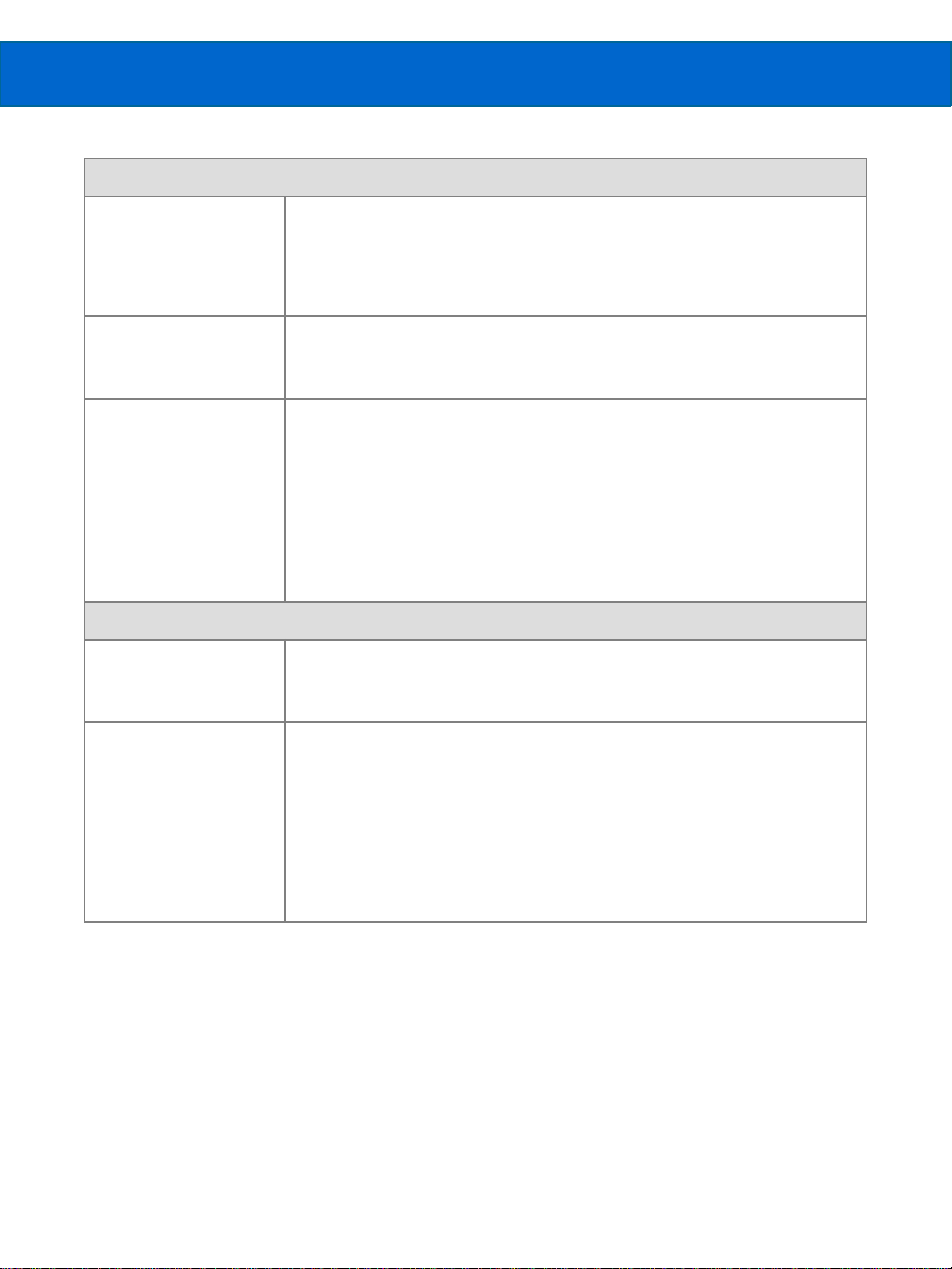

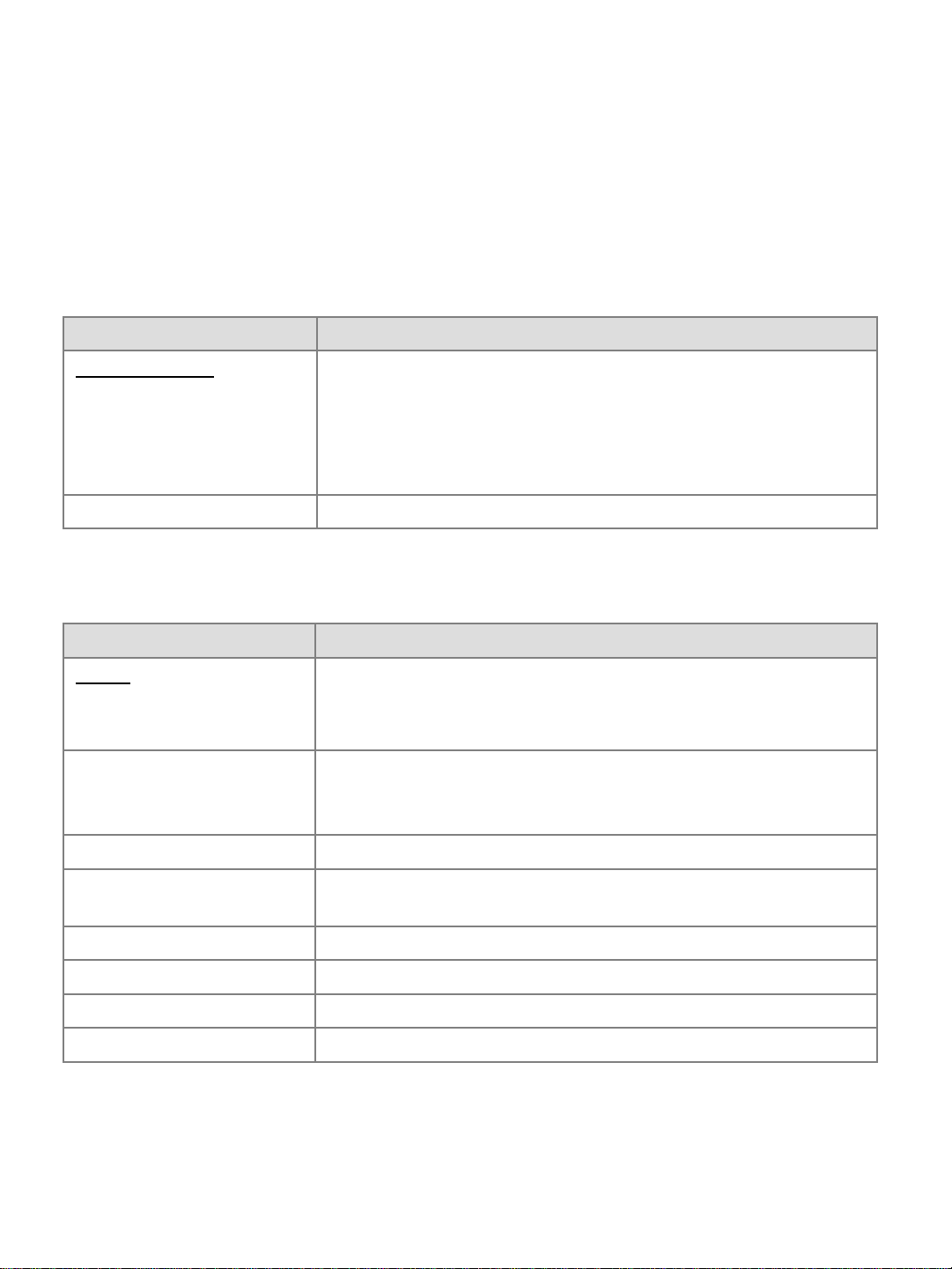

Control Parameter Model Description

Low Contrast IDS/IDE

Enable decoding of low contrast 1D codes (D-on-L or Lon-D) with a minimum module size of 2.5 pixels.

Enhance Contrast IDS/IDE

Enable contrast enhancement preprocessor to

improve readability of 1D or 2D.

1D Security Level IDS/IDE

Helps improve 1D decoding when print quality is poor

or module size is marginal.

Basi c Etch IDS/IDE

Enable decoding of basic laser/chemical etch DPM

codes

Basi c Dots IDS/IDE

Enable decoding of basic dots DPM codes, including

inkjet marks.

Basi c Inkjet IDS/IDE

Enable decoding of poor quality inkjet DPM codes.

Basi c Perspective IDS/IDE

Enables decoding of good quality, centered codes

with severe perspective distortion

Dot peen D-on-L IDE

Enables robust algorithm for decoding dark on light

dot peened codes

Dot peen L-on-D IDE

Enables robust algorithm for decoding light on dark

dot peened codes

Laser & Chemical Etch IDE

Enables robust algorithm for decoding laser and

chemi cally etched codes

DPM Ti m e out IDE

Total time in ms that the advanced algorithm is

allowed to run. A value "0" indicates no timeout

The variability between surface type and printing method can result in significant

changes in code appearance from par t to part. The IDS and IDE models includes imag e

filters and contr ol par ameter s to enhance readabi li ty for poor print q ual i ty or direct part

marking (DPM). The IDE model also includes advanced algor ithms speci fically

designed for challenging DPM applications.

8

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

BOA Spot ID Inspection Capabilities

The following table shows the tools available in the IDS & IDE models. Detailed

information about each of the tools is avail able in the on-line help.

Icon Tool Description Model

Use to decode: Code 11, 32, 39, 93, 128,

Barcode

IDS & IDE

I25, UPC-A/E, EAN-8/13, Databar,

BC412, Pharmacode and more

2D Matrix

Count

Point

Preprocessor

Edge Count

Verify

OCR

Graphics

Match

IDS & IDE

IDS & IDE

IDS & IDE

IDS & IDE

IDE

IDE

IDE

IDE

IDE

Use to decode: Data matrix, QR Code,

PDF417, MicroPDF and more

Use to count characters or features on a

label or part.

Use to detect a single edge point for

position measurement or as a locator for

aligning other tools

Use to enhance picture qual ity to

accentuate features of interest.

Use to find or count edge transitions for

determining label position and or

alignment

Use to verify product features, such as

labels or logos. Trains on a series of good

samples to learn acceptable variation.

Use to read printed, stamped or etched

characters on labels or parts.

Use to add text or draw shapes, to label or

highlight tool result s or features in the

image area

Use to train and match features for

inspection or tool alignment. Supports

multiple matches and 360° orientation.

9

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

BOA Spot Components

BOA Spot V isi on Sensors are shipped w ith the components li sted below. Take a few

moments to veri fy that ev er y t hing has arrived in good co ndit ion. If your product has

been visibly damaged during shipment or is missing parts, please contact your Teledyne

DALSA representative i mmediately.

Standard componen ts (ship w it h ever y BOA Spot Vision Sensor):

Component Description

BOA Spot Sensor

BVS-SP-0640M-IDL-TFF-C

BVS-SP-1280M-IDL-TFF-C

Mounting Screw Kit M4 screws for mounting the BOA Spot (Qty 4)

* Lens and ring-light are only specified for the M12 version, not available with C Mount lens.

BOA Spot Fully integrated vision system with 640x480 or 1280x960

monochrome sensor, lens, processing engine, embedded software,

communications and light control.

(L= feature level: S or E); (T = lens type: M= M12, C=C Mount);

(FF* = focal length in mm: 06, 08, 12, 16); (C= Ring-Light Color:

R=red, B=blue, W=white*)

Optional components (sold separately) :

Component Description

Cables

A-BVS-E8S-X

A-BVS2-IO12S-X

BVS-PL-101

A-BVS-PL101S-X

BVS-PL-100 Panel Link breakout module for Passive Power on Ethernet

M12-RJ45 Ethernet cordset (X= length: 5=5 m, 10=10 m)

M12 single-ended IO cordset (X= length: 5=5 m, 10=10 m)

Panel Link breakout module. Provides convenient panel access to

BOA Spot I/O and serial port

M12 IO cordset to PL-101 (X= length: 5=5 m, 10=10 m)

A-BVS-SP-LCG-45 Lens Cover for C Mount lens option. Required for IP67 compliance.

(45 mm internal lens length)

A-BVS-M12-P M12 plug for IP67 compliance

A-BVS-SP-M12-LKIT M12 lens kit (includes 6, 8, 12 & 16 mm lenses)

Lights Various Lighting options available from Teledyne DALSA

Filters Various C-Mount filters available from Teledyne DALSA

10

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

Lens, Cover, and Light Options

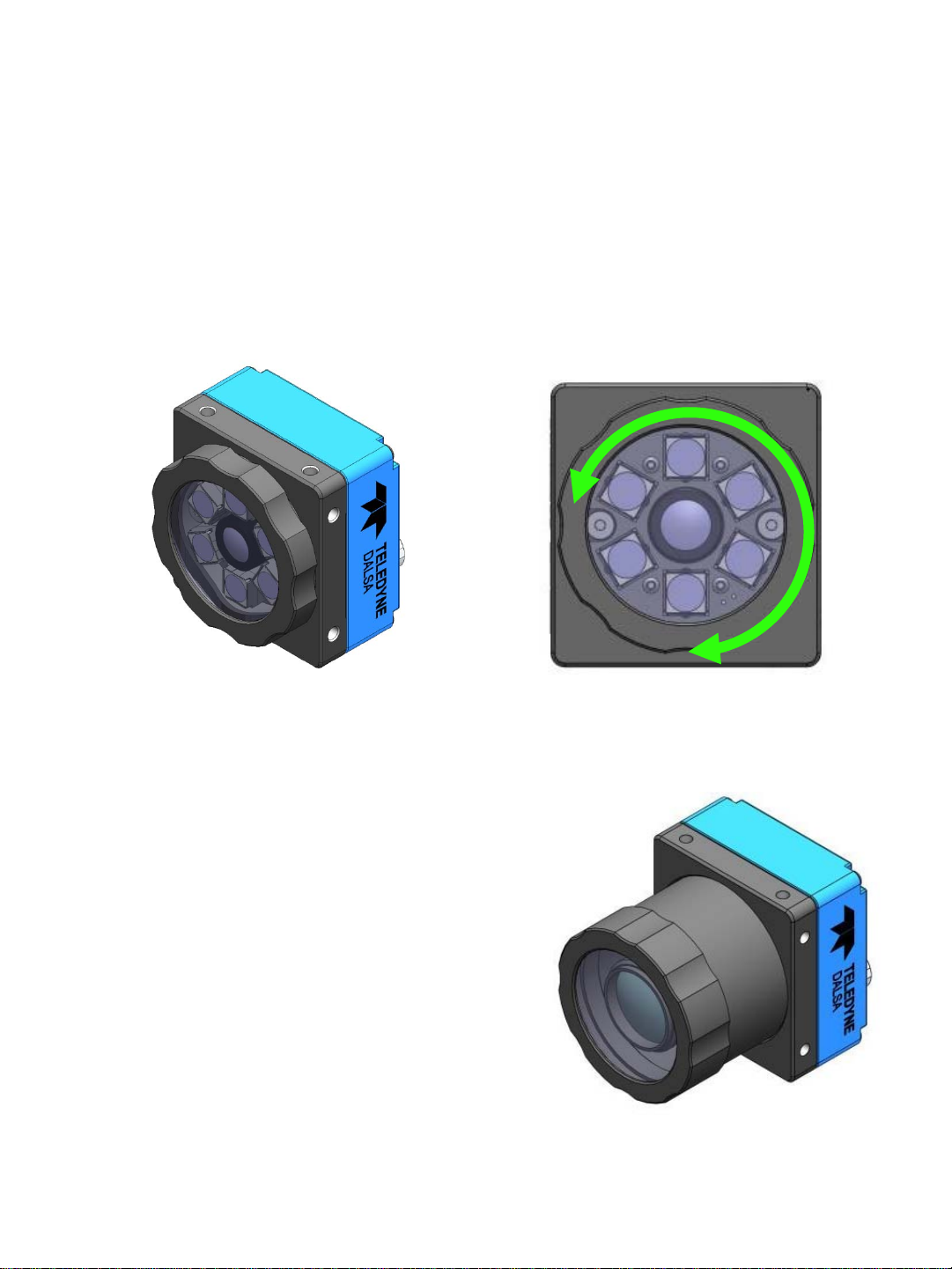

M12 Lens

The BOA Spot Vi sion Sensor can be ordered w ith an M12 lens in several focal leng ths

(6, 8, 12, 16 mm). The M12 option comes with a special IP67 cover, that allows you to

change focus wi thout removi ng the cov er.

The M12 Lens and cover support an LED ring-light that is mounted inside the cover.

The ring-light is availabl e in White, Red, or Blue and specified at time of order.

C-Mount Lens

The BOA Spot Vision Senso r can be ordered

with support for a C-Mount lens. Lenses are sold

separately.

There is an optional IP67 Lens cov er that may be

ordered separately.

There is no internal light option with the C-Mount

lens.

Optional filter s ca n be or der ed separately for use

with the C-Mount lens.

11

M12 cover rotates to adjust focus M12 Lens, Cover, and LED ring

C-Mount Lens

shown with Optional Cover

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

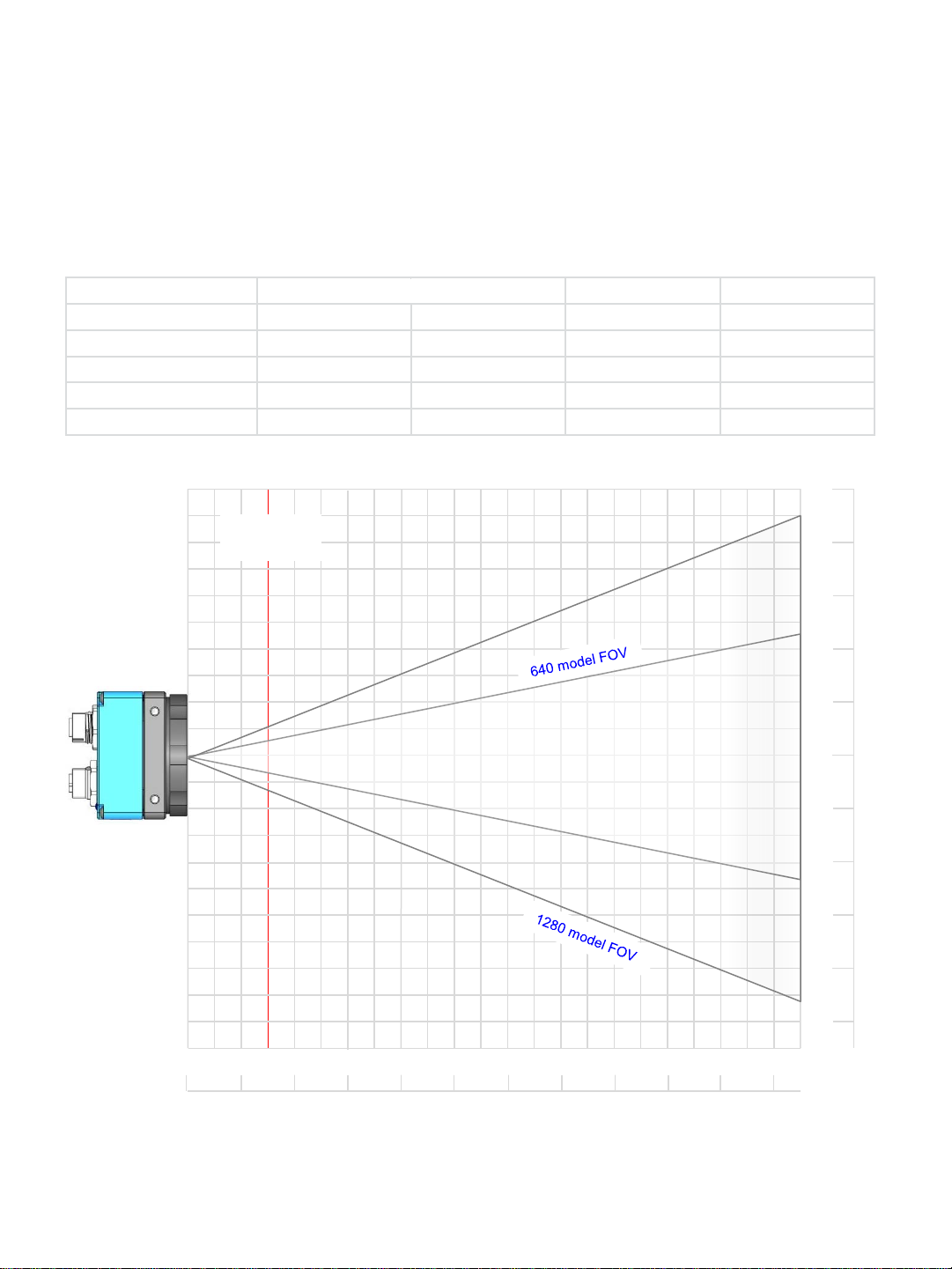

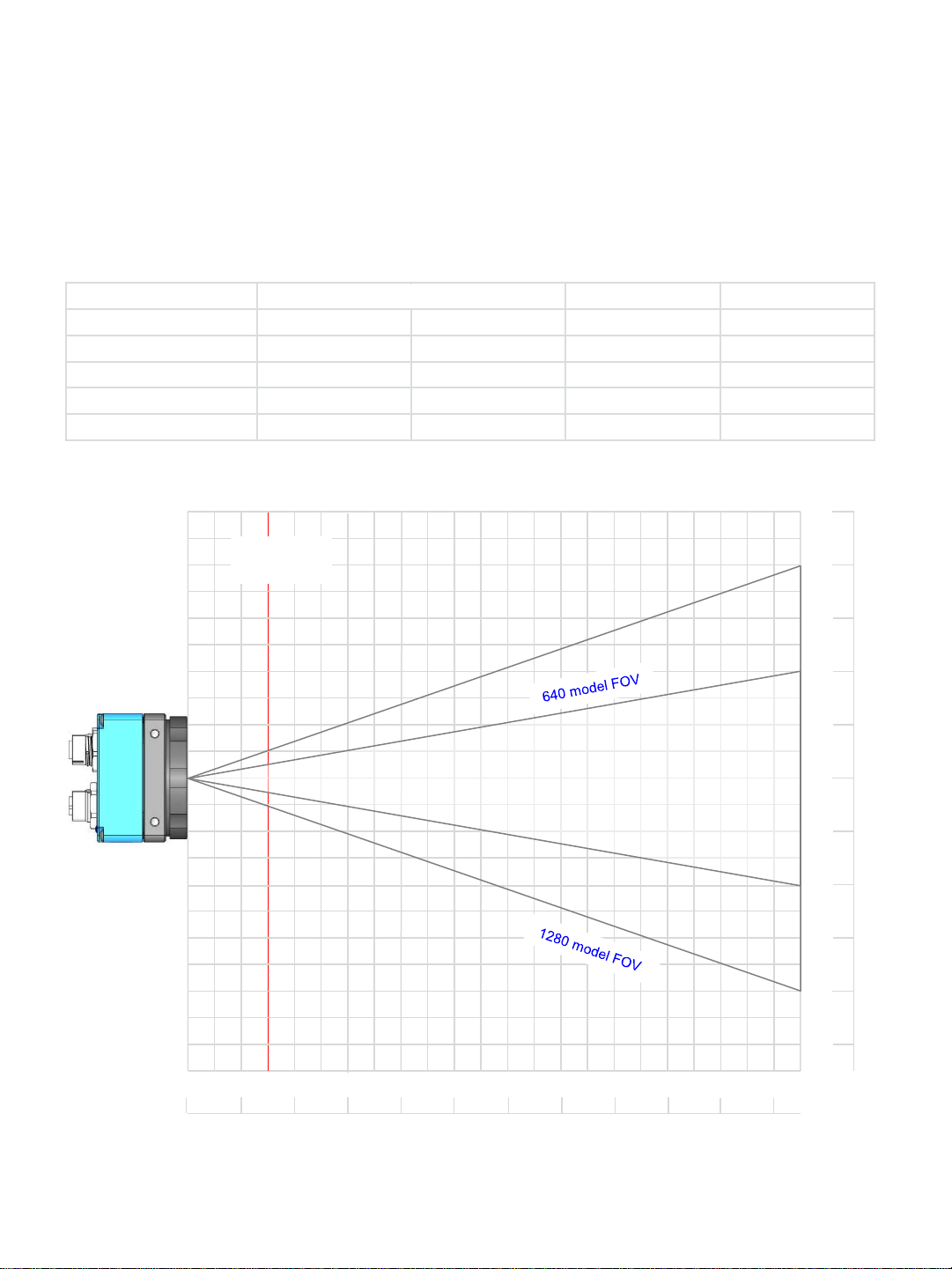

Field Of View (FOV) and reading Distances

Distance in mm 2D min cell (mil) 1D min bar (mil)

640 Model 1280 Model

65 25 x 19 50 x 38 3 2.5

82 32 x 24 64 x 48 4 3

103 40 x 30 80 x 60 5 4

205 81 x 61 162 x 122 10 7.5

Approx FOV (mm)

6 mm Lens

The following table show s the field of view (FOV) widths of the 6 mm lens focused to

205 mm at various working distances for the M640 & M1280 model sensors.

100

Min Focus

Distance

60 80

40

mm

20

0

40 60

80

100

120

140

160

180

200

220

12

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

0

80 60 40 20 20

100

mm

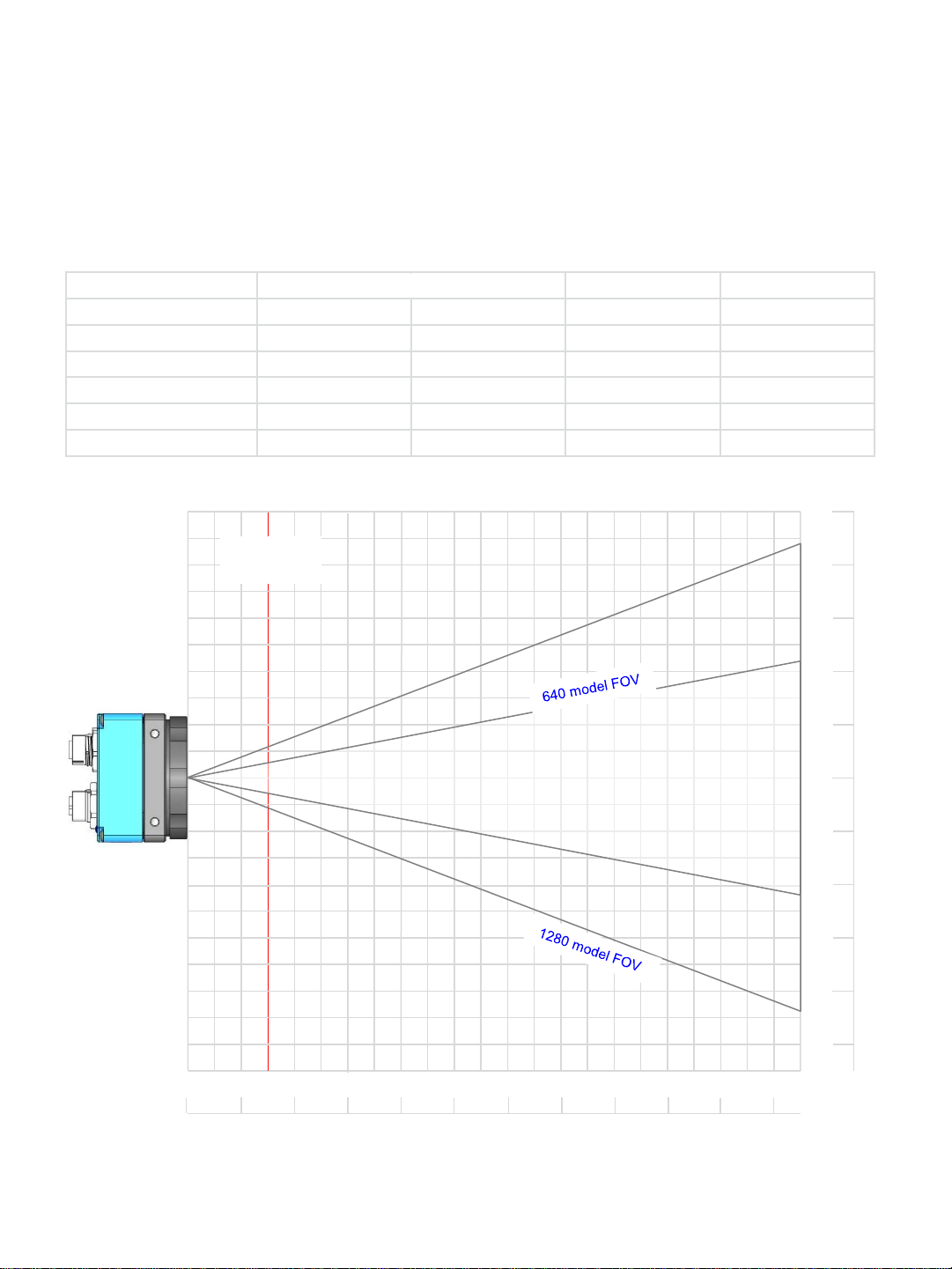

Field Of View (FOV) and reading Distances

Distance in mm 2D min cell (mil) 1D min bar (mil)

640 Model 1280 Model

50 16 x 12 32 x 24 2 1.5

103 32 x 24 64 x 48 4 3

210 40 x 30 80 x 60 5 4

415 80 x 60 160 x 120 10 7.5

Approx FOV (mm)

8 mm Lens

The following table show s the field of view (FOV) widths of the 8 mm lens focused to

415 mm at various working distances for the M640 & M1280 model sensors.

100

Min Focus

Distance

60 80

20

0

mm

60 100

140

160

200

240

280

320

360

400

13

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

40

0

80 60 40 20 20

100

mm

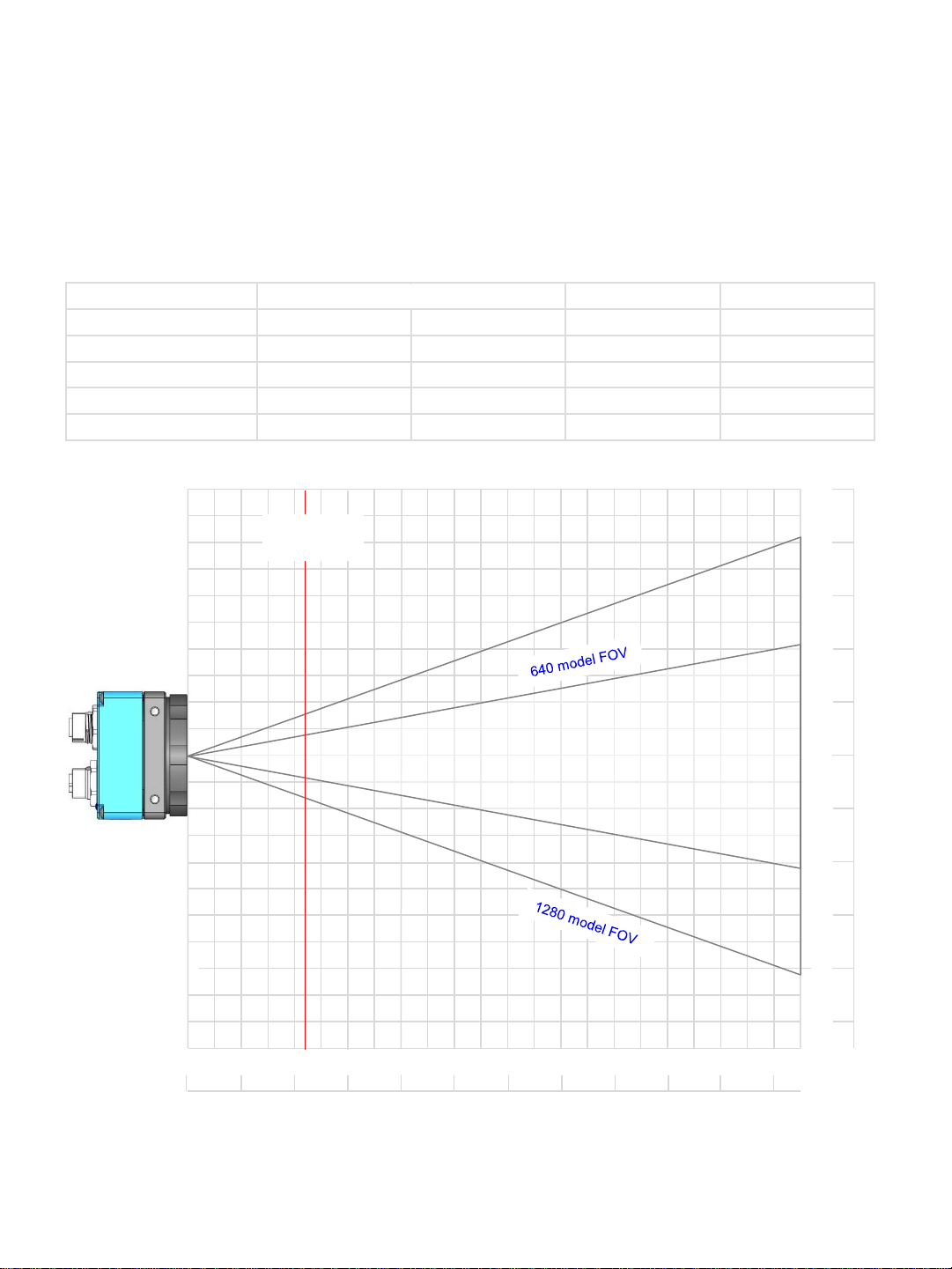

Field Of View (FOV) and reading Distances

Distance in mm 2D min cell (mil) 1D min bar (mil)

640 Model 1280 Model

90 16 x 12 32 24 2 1.5

130 24 x 18 48 x 36 3 2.5

170 32 x 24 64 x 48 4 3

210 40 x 30 80 x 60 5 4

410 80 x 60 160 x 120 10 7.5

Approx FOV (mm)

12 mm Lens

The following table show s the field of view (FOV) widths of the 12 mm lens focused to

410 mm at various working distances for the M640 & M1280 model sensors.

100

Min Focus

Distance

60 80

40

0

mm

80 120

160

200

240

280

320

360

400

440

14

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

40

0

80 60 40 20 20

100

mm

Field Of View (FOV) and reading Distances

Distance in mm 2D min cell (mil) 1D min bar (mil)

640 Model 1280 Model

120 16 x 12 32 x 24 2 1.5

225 32 x 24 64 x 48 4 3

280 40 x 30 80 x 60 5 4

550 80 x 60 160 x 120 10 7.5

Approx FOV (mm)

16 mm Lens

The following table show s the field of view (FOV) widths of the 16 mm lens focused to

550 mm at various working distances for the M640 & M1280 model sensors.

100

Min Focus

Distance

60 80

40

mm

50

0

100 150

200

250

300

350

400

450

500

550

15

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

0

80 60 40 20 20

100

mm

Product Support

In addition to this Qui ck Star t G uide, the foll owing information is available:

1. On-line help: Finger tip help i s availabl e on ev ery screen (panel) of the BOA Spot

Software User Interface.

2. Additional manuals and documentation are included on the CD that ships with the

product.

3. Factory support is availabl e by email at: support.ipd@teledyne.com.

4. Call, fax or email your local representati ve w ho sold y ou the product.

16

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

Installation

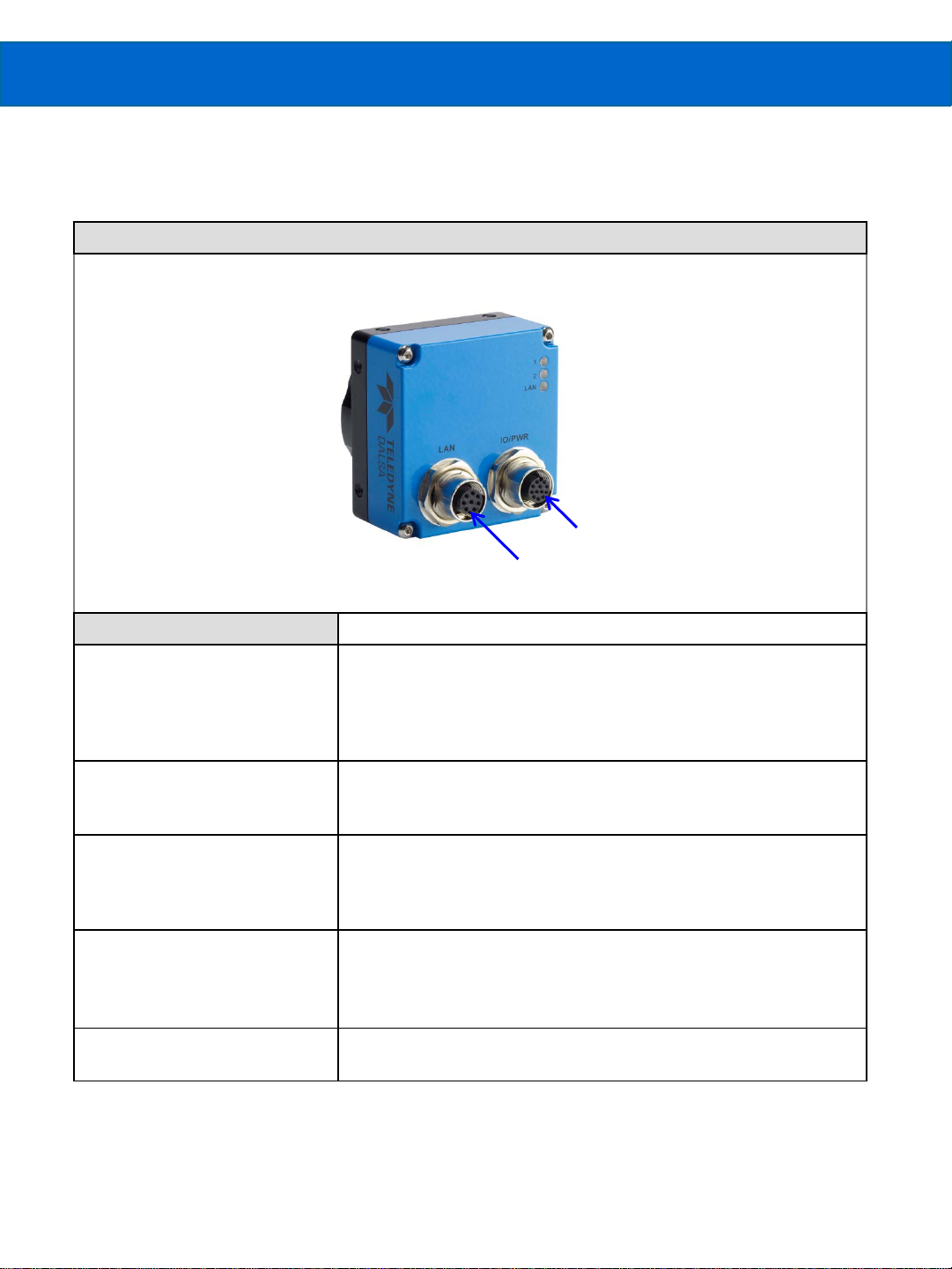

Connecting the BOA Spot Vision Sensor

This section details how to connect the BOA Spot Vision Sensor w ith its associated

components and factory environment.

Camera Connectors and Indicators

I/O PWR 12 Pin

LAN 8 Pin

Definitions Designator

LAN

I/O PWR

LED 1 Blue Solid = Sensor booted, not configured (no Solution file)

LED 2 Blue blink = Booting (should stop after 20 seconds)

LED LAN Blue = Warm reset or reboot

10/100 BaseT Ethernet connection. Provides the primary

interface for configuring the sensor, developing the application

and monitoring results.

Note: The BOA Spot can be powered from the Ethernet cable

directly (Passive Power over Ethernet or PPoE).

Provides access to the sensor I/O – 3 IN, 3 OUT, RS-232. Also

provides PWR input (24-30V). Note: The power is common to

both connectors.

Green Solid = Solution loaded, ready to run

Green blink = Solution loaded & running, acquisition in process

Red = Sensor Fault

Green = Inspection Pass (runtime decision result)

Blue = Inspection Recycle (runtime decision result)

Red = Inspection Fail (runtime decision result)

Red/Green/Yellow = Network activity

NOTE: The BOA Spot does not support the IEEE 802.3af standar d Pow er over Etherne t

(PoE) and should not be directly connected to a PoE supported rout er.

17

Ver sion 1.2; 2017-11-20 BOA Spot ID Quick Start

Loading...

Loading...