Page 1

BioOptix™ 10

Installation and Operation Guide

#69-5203-150

Copyright © 2004 Teledyne Isco, Inc.

All rights reserved.

Revision B, September 20, 2005

Page 2

Page 3

Foreword

This instruction manual is designed to help you gain a thorough understanding of the

operation of the equipment. Teledyne Isco recommends that you read this manual

completely before placing the equipment in service.

Although Teledyne Isco designs reliability into all equipment, there is always the possibility of a malfunction. This manual may help in diagnosing and repairing the malfunction.

If the problem persists, call or e-mail the Teledyne Isco Technical Service Department

for assistance. Simple difficulties can often be diagnosed over the phone.

If it is necessary to return the equipment to the factory for service, please follow the

shipping instructions provided by the Customer Service Department, including the

use of the Return Authorization Number specified. Be sure to include a note

describing the malfunction. This will aid in the prompt repair and return of the

equipment.

Teledyne Isco welcomes suggestions that would improve the information presented in

this manual or enhance the operation of the equipment itself.

Teledyne Isco is continually improving its products and reserves the right to

change product specifications, replacement parts, schematics, and instructions without notice.

Customer Service

Phone: (800) 228-4373 (USA, Canada, Mexico)

Fax: (402) 465-3022

Email: IscoCSR@teledyne.com

Technical Service

Phone: (800) 775-2965 (Analytical)

Email: IscoService@teledyne.com

Return equipment to: 4700 Superior Street, Lincoln, NE 68504-1398

Other Correspondence

Mail to: P.O. Box 82531, Lincoln, NE 68501-2531

Email: IscoInfo@teledyne.com

Web site: www.isco.com

Contact Information

(402) 464-0231 (Outside North America)

(800) 228-4373 (Samplers and Flow Meters)

Revised September 15, 2005

Page 4

Page 5

BioOptix™ 10

Safety

BioOptix™ 10

Safety

General Warnings Before installing, operating, or maintaining this equipment, it is

imperative that all hazards and preventive measures are fully

understood. While specific hazards may vary according to location

and application, take heed in the following general warnings:

WARNING

Liquids associated with this instrument may be classified

as carcinogenic, biohazardous, flammable, or radioactive.

Should these liquids be used, it is highly recommended that

this application be accomplished in an isolated

environment designed for these types of materials in

accordance with federal, state, and local regulatory laws,

and in compliance with your company’s chemical/hygiene

plan in the event of a spill.

AVERTISSEMENT

Eviter de répandre des liquides dangereux. Les liquides qui

sont analysés dans cet instrument peuvent être

cancérigènes, hasards biologiques, inflammables, ou

radioactifs. Si vous devez utiliser tels liquides, il est très

recommandé que vous le faites à l'intérieur d'un

environnement isolé conçu pour tels liquides. Cet

environnement isolé devrait être construit selon les

règlements fédéraux, provinciaux, et locaux, aussi que le

plan de votre compagnie qui concerne l'évènement d'un

accident avec les matières hasardeuses.

WARNING

Avoid hazardous practices! If you use this instrument in

any way not specified in this manual, the protection

provided by the instrument may be impaired.

AVERTISSEMENT

Éviter les usages périlleux! Si vous utilisez cet instrument

d’une manière autre que celles qui sont specifiées dans ce

manuel, la protection fournie de l’instrument peut être

affaiblie; cela augmentera votre risque de blessure.

WARNING

If this system uses flammable organic solvents, Teledyne

Isco recommends that you place this system in a

well-ventilated environment, designed for these types of

materials. This environment should be constructed in

accordance with federal, state, and local regulations. It

should also comply with your organization’s plan

concerning chemical and hygiene mishaps. In all cases use

good laboratory practices and standard safety procedures.

iii

Page 6

BioOptix™ 10

Safety

AVERTISSEMENT

Ce système peut utiliser des dissolvants organiques

inflammables. Pour réduire le péril qui peut être causé par

l'accumulation des vapeurs explosives, Teledyne Isco

recommande que vous installez ce système dans un

environnement bien-aéré qui est conçu pour les matières

hasardeuses. Cet environnement devrait être construit

selon les règlements fédéraux, provinciaux, et locaux.

Aussi, il devrait se conformer au plan de votre organisation

qui concerne les mésaventures de l'hygiène ou de

chimique. En tout cas, utilisez toujours de pratiques

bonnes de la laboratoire et des procédures standardes de

la sûreté.

Hazard Severity Levels This manual applies Hazard Severity Levels to the safety alerts.

Three levels of severity are described in the sample alerts below.

CAUTION

Cautions identify a potential hazard, which if not avoided, may

result in minor or moderate injury. This category can also warn

you of unsafe practices, or conditions that may cause property

damage.

WARNING

Warnings identify a potentially hazardous condition, which

if not avoided, could result in death or serious injury.

DANGER

DANGER – limited to the most extreme situations

to identify an imminent hazard, which if not

avoided, will result in death or serious injury.

iv

Page 7

BioOptix™ 10

Hazard Symbols The equipment and this manual use symbols used to warn of

hazards. The symbols are explained below.

Hazard Symbols

Warnings and Cautions

The exclamation point within the triangle is a warning sign alerting you of

important instructions in the instrument’s technical reference manual.

The lightning flash and arrowhead within the triangle is a warning sign alerting you of “dangerous voltage” inside the product.

Symboles de sécurité

Ce symbole signale l’existence d’instructions importantes relatives au produit dans ce manuel.

Ce symbole signale la présence d’un danger d’électocution.

Safety

Warnungen und Vorsichtshinweise

Advertencias y Precauciones

Das Ausrufezeichen in Dreieck ist ein Warnzeichen, das Sie darauf

aufmerksam macht, daß wichtige Anleitungen zu diesem Handbuch

gehören.

Der gepfeilte Blitz im Dreieck ist ein Warnzeichen, das Sei vor “gefährlichen

Spannungen” im Inneren des Produkts warnt.

Esta señal le advierte sobre la importancia de las instrucciones del manual

que acompañan a este producto.

Esta señal alerta sobre la presencia de alto voltaje en el interior del

producto.

v

Page 8

BioOptix™ 10

Safety

vi

Page 9

BioOptix™ 10

Table of Contents

Section 1 Introduction

1.1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 System Controls and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.1 BioOptix 10 Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.2 BioOptix 10 Left-side Controls and Connections . . . . . . . . . . . . . . . . . . . . . 1-4

1.3.3 BioOptix 10 Right-side Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.3.4 BioOptix 10 Rear Panel Controls and Connections . . . . . . . . . . . . . . . . . . . 1-6

Section 2 Installation

2.1 Unpacking the BioOptix 10 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 BioOptix 10 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2.1 BioOptix 10 Location and Space Requirements . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2.2 Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.3 Assembling the BioOptix 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.4 Assembling the Foxy 200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.2.5 Fluid Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.2.6 Windows PC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.3 BioOptix 10 Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.3.1 Configuring BioOptix 10 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.4 BioOptix 10 System Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Section 3 Operation

3.1 Sample Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Column Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.1 Column Tubing and Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 BioOptix 10 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4 Gradients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4.1 Defining a Gradient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.4.2 Saving the Gradient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.5 Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.5.1 Equilibrate Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.5.2 Load Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.5.3 Wash Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.5.4 Elute Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.5.5 Flush Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.5.6 Saving the Method File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.6 Experiments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.6.1 Setting up the Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.6.2 Editing the Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.6.3 Saving the Experiment File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.7 Running the Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.7.1 System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.7.2 Operation Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.7.3 Suspending System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

vii

Page 10

BioOptix™ 10

Table of Contents

3.8 Post-experiment Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.8.1 Pump Flush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.8.2 Saving Run Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.8.3 AutoReports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Section 4 System Maintenance

4.1 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Piston Seal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 Deuterium Lamp Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.5 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.5.1 Operating Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.5.2 Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.5.3 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.5.4 Inaccessible Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.5.5 Inaccessible Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.6 Service Department . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.7 How to Ship Returns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Appendix A Method Templates

A.1 Opening the Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.2 Modifying the Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

A.2.1 General Editing Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

A.2.2 [Blocks] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

A.2.3 [Blockn] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

A.2.4 [Other] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Appendix B Fluid Path Diagrams

B.1 Fluid-type Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.2 Load-type Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B.3 Gradient-type Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B.4 Pump Flush. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

B.5 Plumbing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Appendix C Replacement Parts Lists

C.1 Detector Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

C.2 Column Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

C.3 Pump Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-11

viii

Page 11

BioOptix™ 10

Table of Contents

List of Figures

1-1 BioOptix 10 front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2 BioOptix 10 left-side connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-3 BioOptix 10 right-side connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-4 BioOptix 10 rear panel controls and connections . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

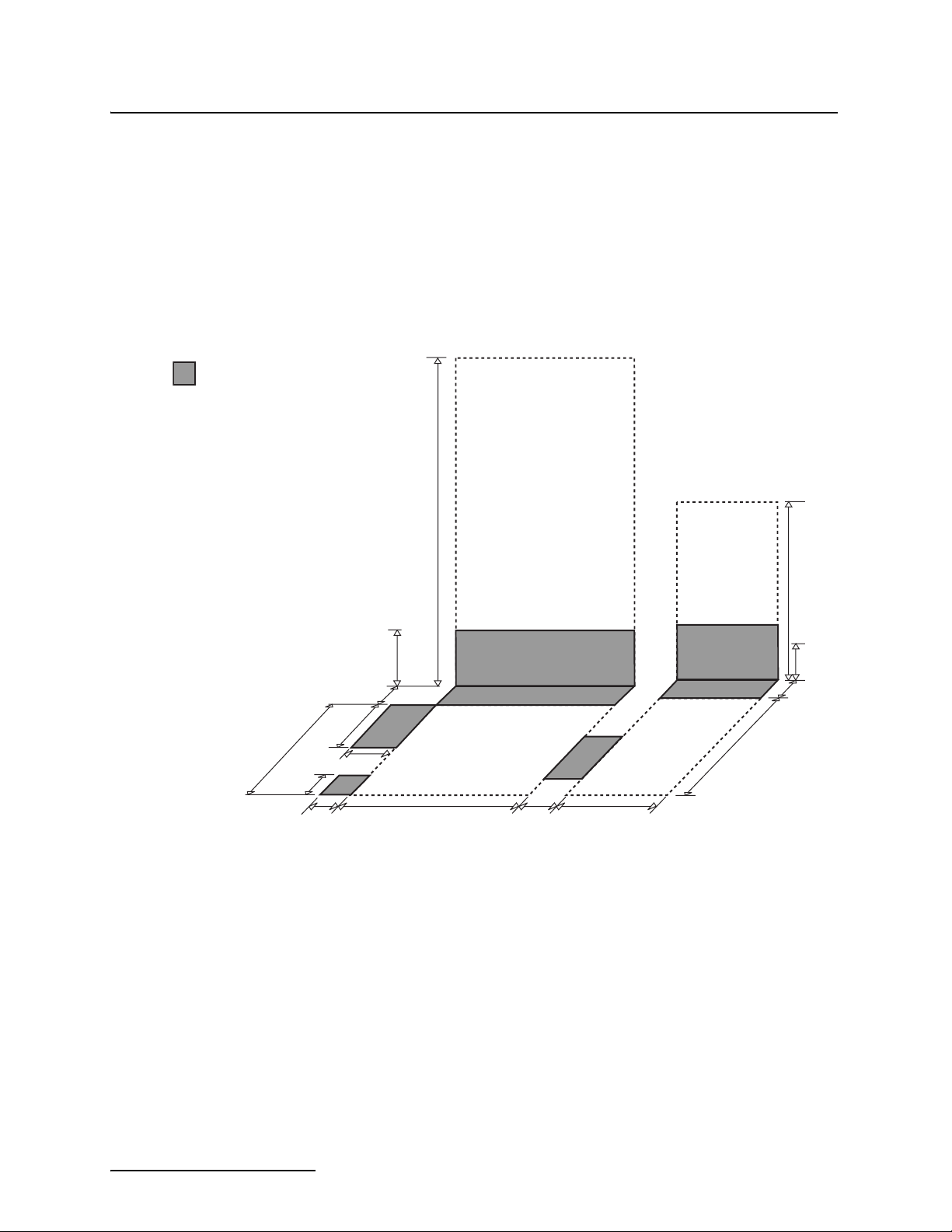

2-1 System space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

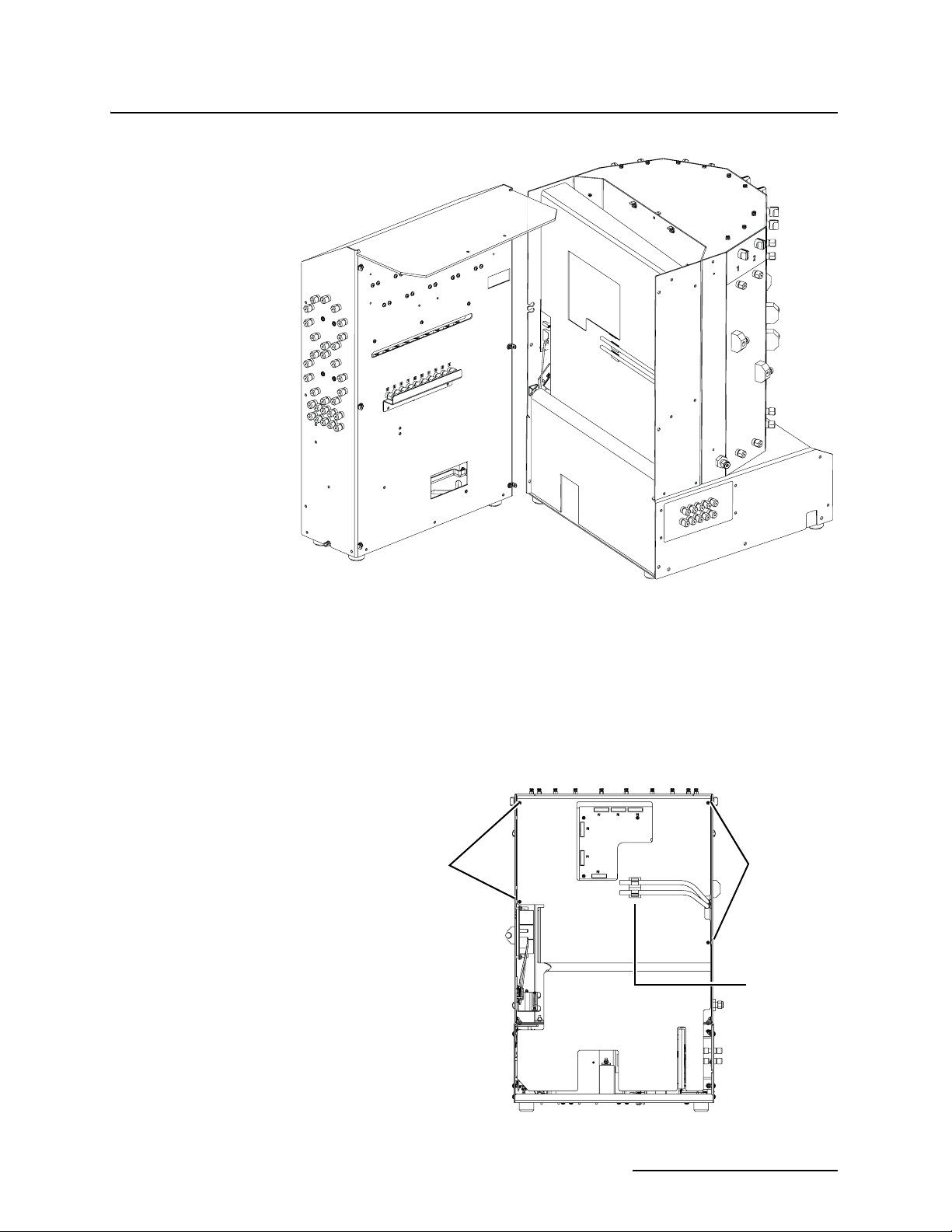

2-2 Accessing pump and column module internal connections . . . . . . . . . . . . . . . . . . 2-3

2-3 Removing the column module back plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

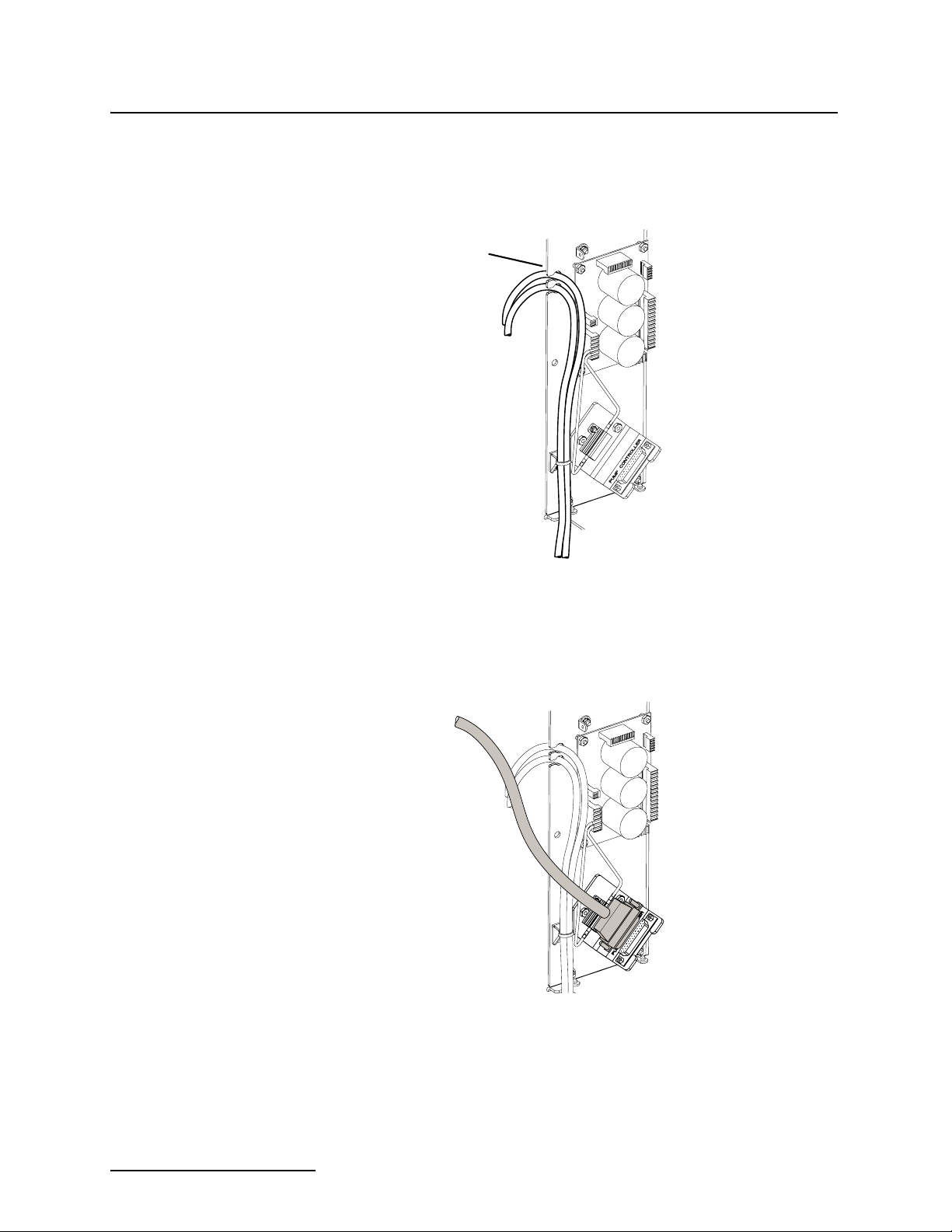

2-4 Routing the Sample Out lines (column module) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-5 Pump controller connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

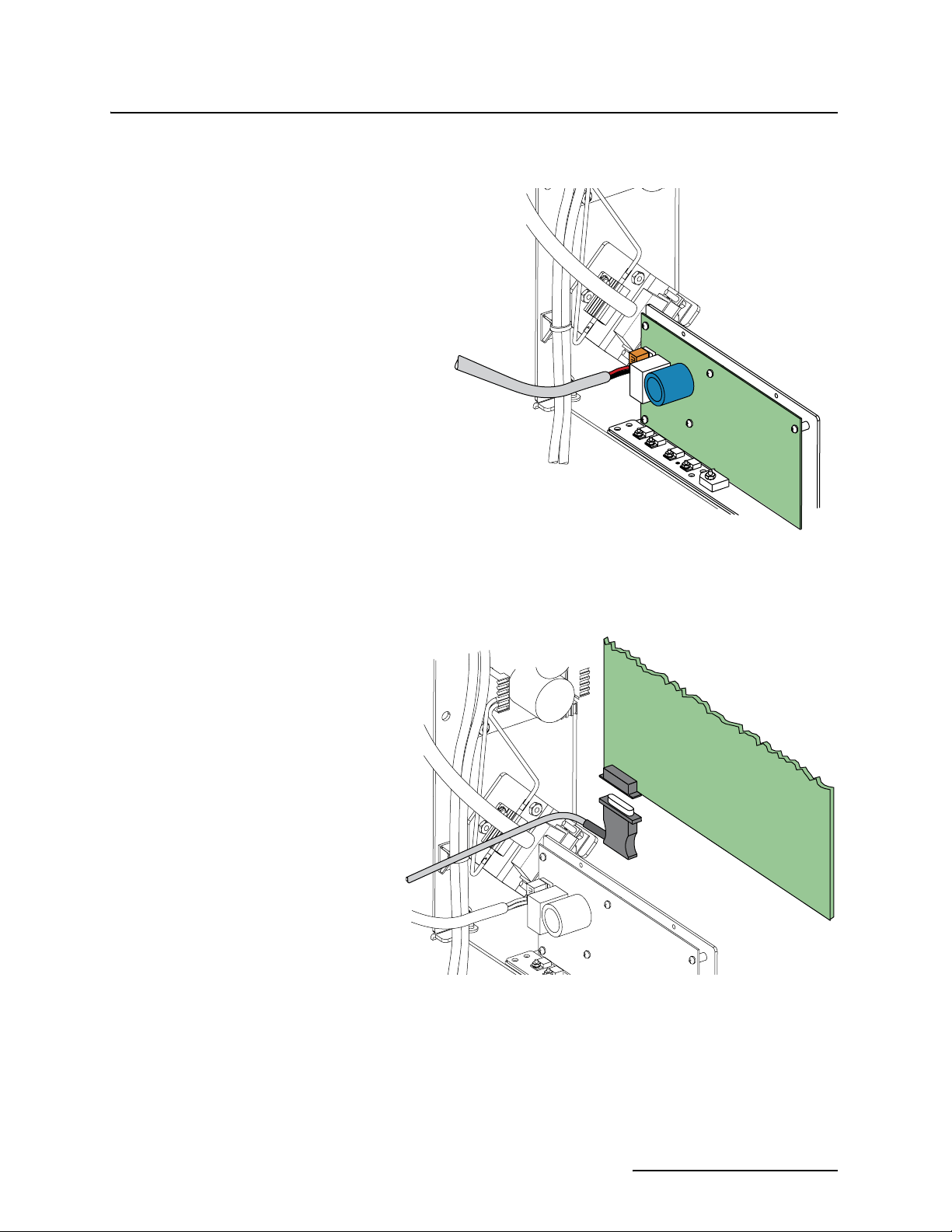

2-6 P110 Connection on BD3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-7 J106 Connection on BD1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-8 AC power connection from pump module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-9 Ribbon cable connections

(top half of column module shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-10 Liquid connections

(pump module shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-11 Aligning the fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-12 Column clamps inserted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-13 Foxy arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2-14 Buffer assembly routes a common solution to all ten channels . . . . . . . . . . . . . 2-11

2-15 Buffer assemblies installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-16 Foxy 200 tubing connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2-17 Adhesive retainers attached . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2-18 Column bypass tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2-19 Mode control knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2-20 BioOptix 10 Manual Hardware Control window . . . . . . . . . . . . . . . . . . . . . . . . 2-17

3-1 Gradient File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-2 Equilibrate tab settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-3 Load tab settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-4 Wash tab settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-5 Elute tab settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-6 Flush tab settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-7 Experiment File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-8 BioOptix 10 Operation Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-9 Pause at end of block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3-10 Pump flush option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3-11 Flush window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

4-1 Flush window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 Access the pump assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-3 Pump assembly components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-4 Attach seal to push rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-5 Waste port mounting plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4-6 Deuterium lamp location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4-7 Circuit breaker location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4-8 Thermal breaker location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

A-1 Installed Standard.tpl file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A-2 Customizable values in the Standard.tpl file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

B-1 Fluid path for Fluid-type blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B-2 Inactive channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B-3 Fluid path for Load-type blocks -

Pump injections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B-4 Fluid path for Load-type blocks -

Manual injections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B-5 Fluid path for Gradient-type blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B-6 Pump flush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

B-7 BioOptix 10 Plumbing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

ix

Page 12

BioOptix™ 10

Table of Contents

List of Tables

1-1 BioOptix 10 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 BioOptix 10 Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 BioOptix 10 Left-side Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-4 BioOptix 10 Right-side Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-5 BioOptix 10 Rear Panel Controls and Connections . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2-1 Tubing Color chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2-2 Windows

3-1 Operation Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

4-1 Common Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

®

PC Minimum Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

x

Page 13

BioOptix™ 10

Section 1 Introduction

1.1 Product Overview The BioOptix™ 10 system performs automated protein purifi-

cation on as many as ten liquid samples simultaneously. The

system has ten independent pumps that keep flow rates properly

regulated in each channel, and ten independent detectors so that

you can monitor the separation in every channel. The purified

sample is collected by a fraction collector — up to 300 fractions

per sample for unattended operation, or unlimited fractions for

attended purification runs. BioOptix 10 control software lets you

quickly locate the fractions of interest.

System highlights include:

• Individual detector on each channel.

• Unique gradient conditions can be used for each

channel— great for scouting ideal gradient conditions.

• Repeatable, uniform flow for each sample, regardless of

buffer gradient or sample consistency. Ten independent

precision pumps provide flow rates from 0.5 to 12

mL/min for each channel.

• Fast and easy sample loading—individual sample introduction lines for each channel.

• Compact size gives you maximum capability in

minimum bench space.

• High fraction capacity —

❍ collect up to 300 fractions per sample completely

unattended,

❍ or unlimited fractions by manually replacing filled

racks during a run.

• Pumps designed for salt buffers and common solvents

ensure long life, low maintenance, no seal rinse fluid

needed.

1-1

Page 14

BioOptix™ 10

Section 1 Introduction

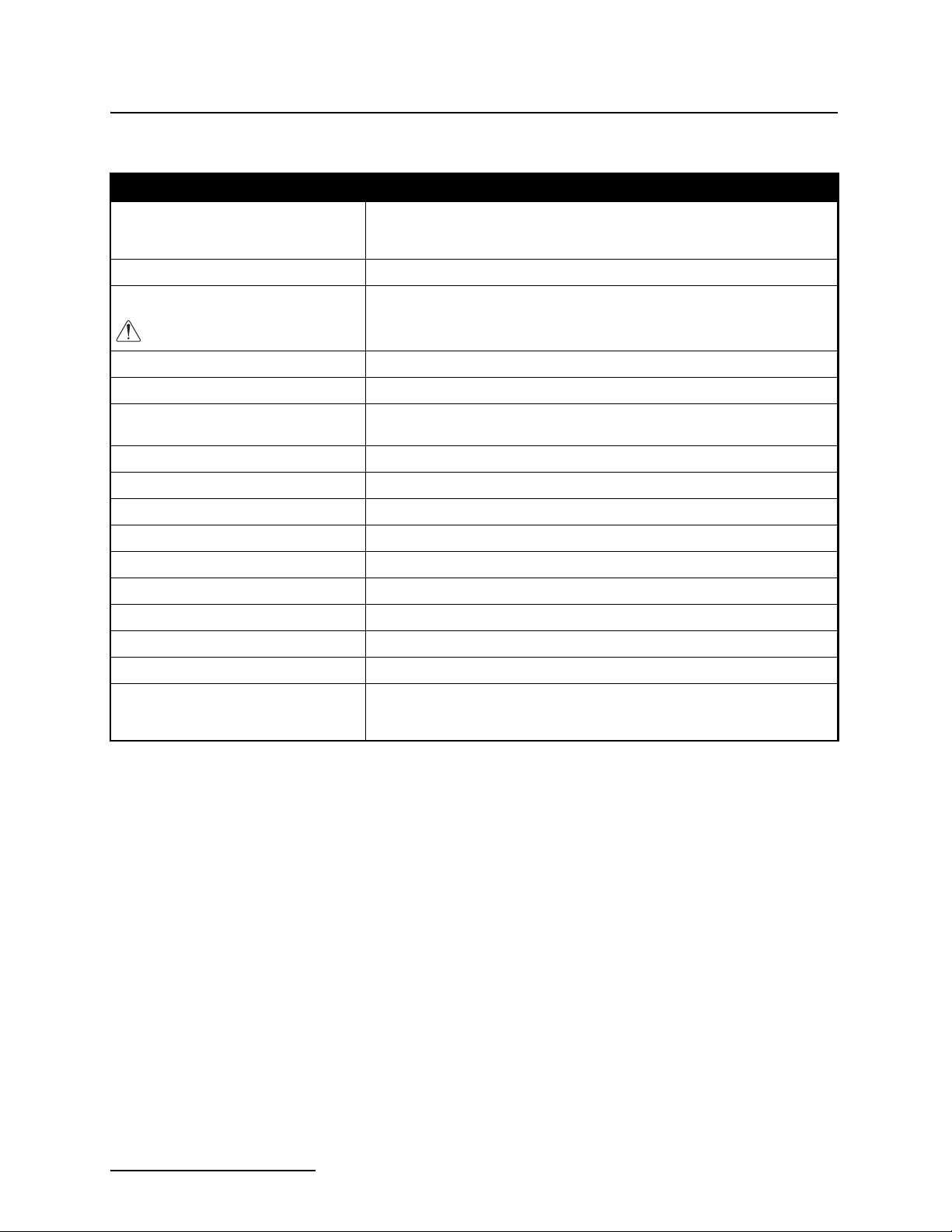

1.2 System Specifications Table 1-1 lists the BioOptix 10 specifications.

Table 1-1 BioOptix 10 Specifications

Dimensions

Weight

Power Requirement

Line Frequency 50 or 60 Hz

Operating Temperature

Humidity

Gradient Flow Rate Range 0.5 to 12 mL/min

Flow Rate Accuracy ± 5% full scale (using water)

Gradient Accuracy ± 5% full scale (using water)

Gradient Linearity ± 5% full scale (using water)

Operating Pressure 0 to 6.895 bar (0 to 100 psi)

a

a,b

a,c

The power switch is the

disconnect device.

a

a

Height: 69 cm

Width: 72 cm

Depth: 61 cm

210 kg

100 VAC ±10%, 2.0 Amps

117 VAC ±10%, 2.0 Amps

234 VAC ±10%, 1.0 Amps

5 to 40°C

When connected to mains power, 95% relative humidity maximum at 5 to

40°C

Flow Cell Path Length 2 mm

Detector Wavelength 190 to 360 nm

-4

Detector Noise 5 × 10

Detector Drift 1 × 10

CE Conformity Specifications

a,d

Pollution Degree: 2

AU

-3

AU/hr

Installation Category: II

Maximum Altitude: 2000 meters

a. Excludes Foxy 200 Fraction Collector and Windows PC Controller. Refer to the respective manuals for these additional

specifications.

b. Dry weight of the BioOptix 10, excluding connection cables, tubing, and user-supplied buffer containers.

c. Operating voltage of the BioOptix 10 is factory set.

d. Refer to the CE Declaration of Conformity, at the back of this manual, for applicable standards and test results.

1-2

Page 15

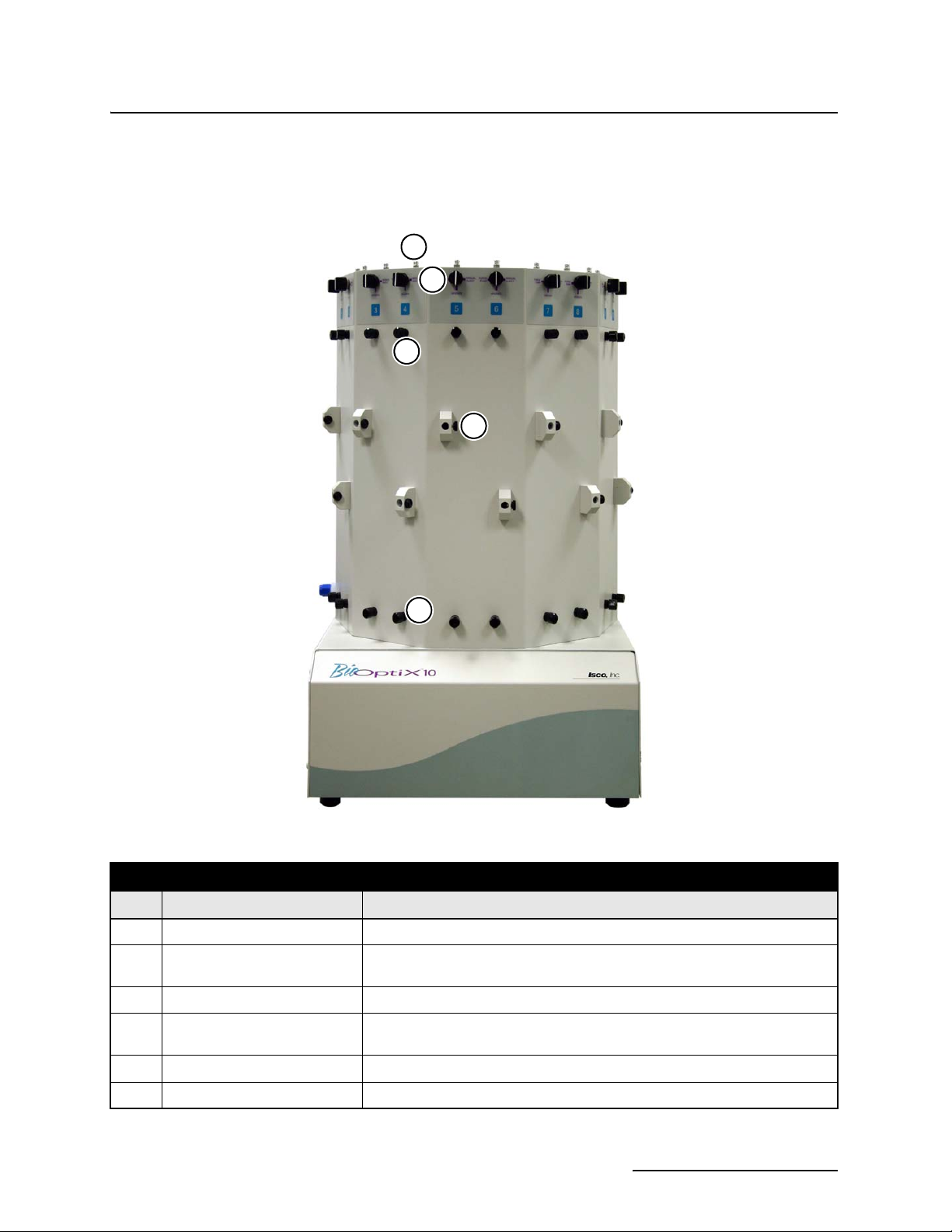

1.3 System Controls and Connectors

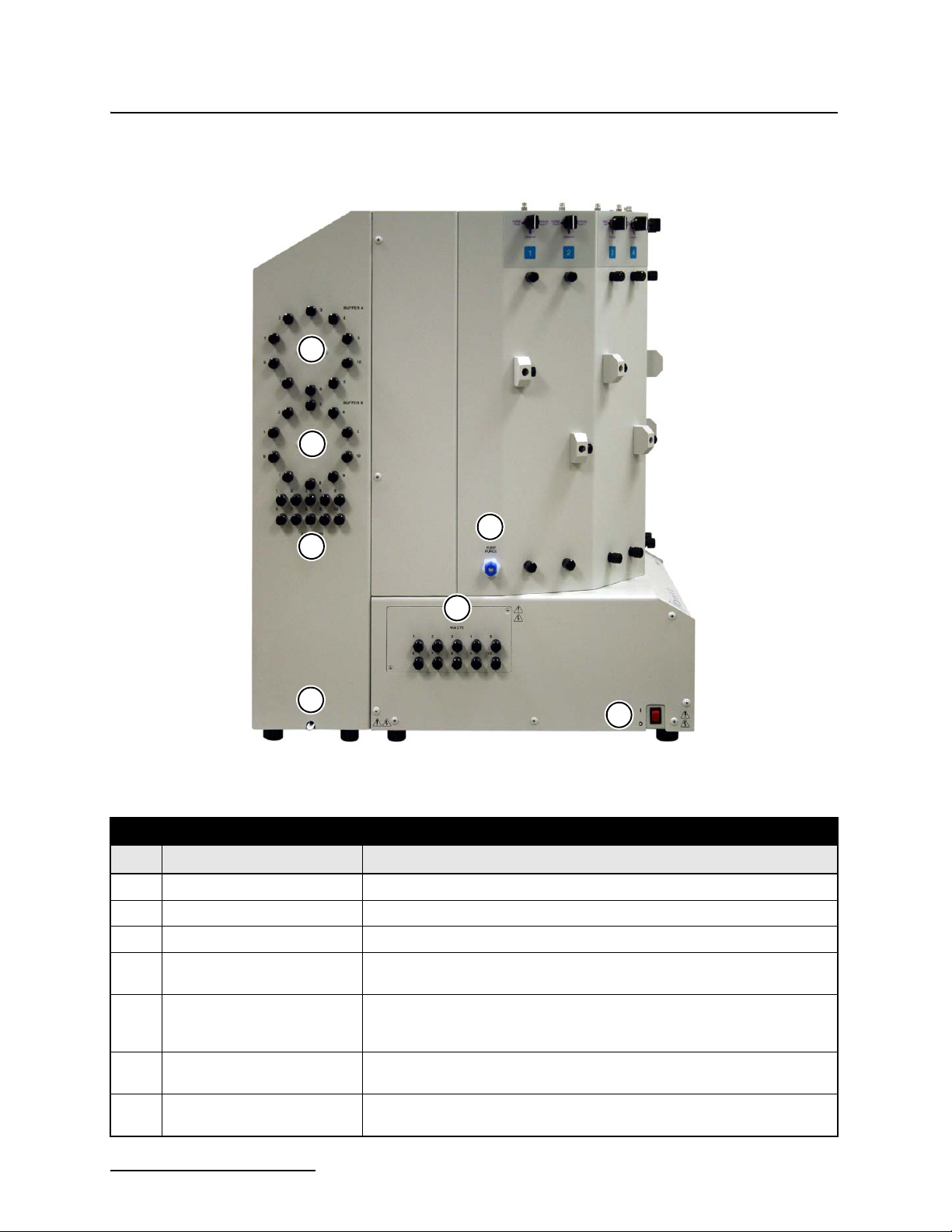

1.3.1 BioOptix 10 Front Panel Controls

BioOptix™ 10

Section 1 Introduction

1

2

3

4

5

Figure 1-1 BioOptix 10 front panel

Table 1-2 BioOptix 10 Front Panel Controls

Item Name Description

1 Manual Sample Inject Port Injection port for syringe-injected liquid samples.

2 Mode Knob Configures fluid path for purging, manual sample injection, or purification

operation.

3 Column Inlet Port Allows connection of tubing to column inlet.

4 Column Clamp Position Adjust Secures column clamp and allows for horizontal and rotational positioning of

columns.

5 Column Outlet Port Allows connection of tubing from column outlet.

6 Column Clamp (Not shown) Tightens to secure the chromatography column.

1-3

Page 16

BioOptix™ 10

Section 1 Introduction

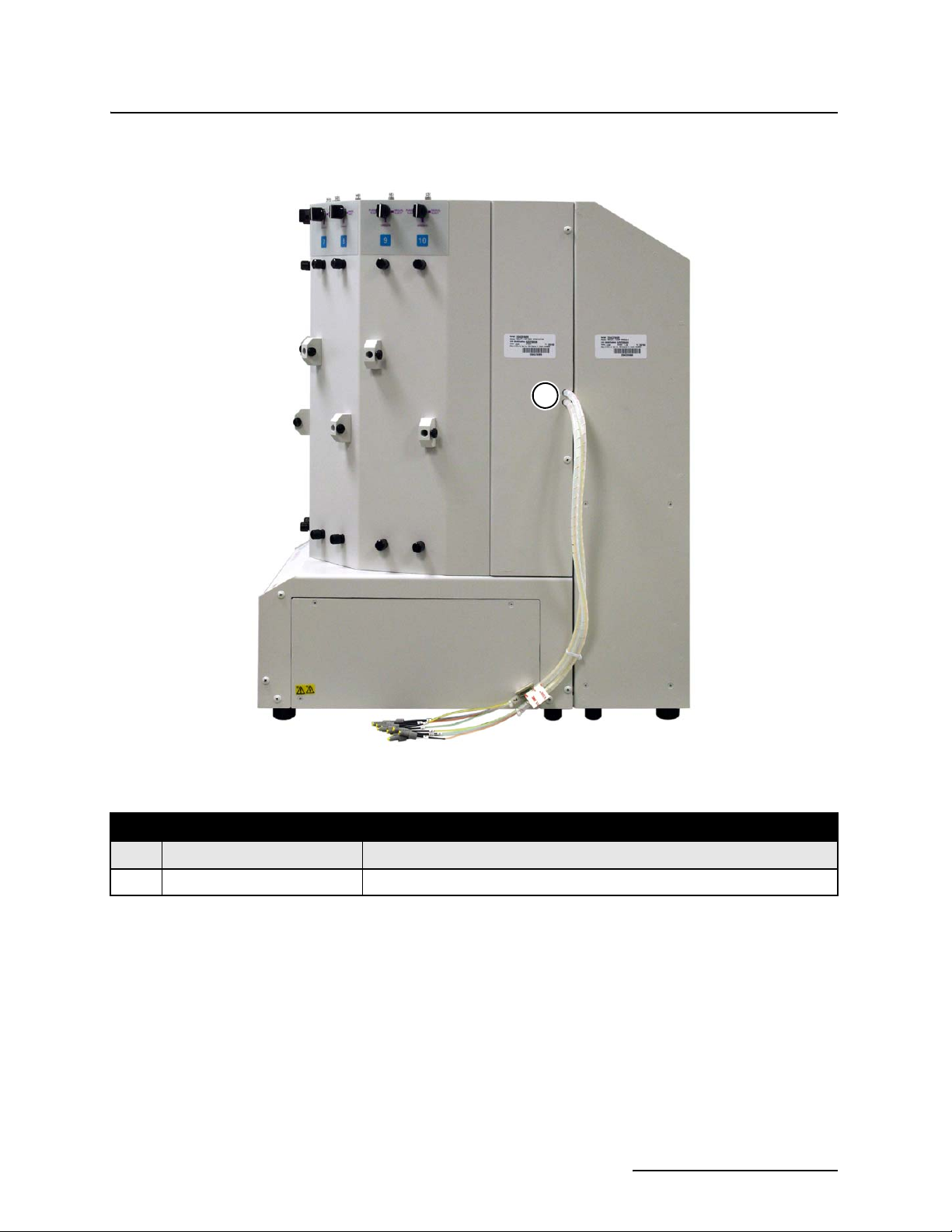

1.3.2 BioOptix 10 Left-side Controls and Connections

1

2

4

3

5

6

7

Figure 1-2 BioOptix 10 left-side connections

Table 1-3 BioOptix 10 Left-side Connections

Item Name Description

1 Buffer A Inlet Ports Ports to accept Buffer A solution for each channel.

2 Buffer B Inlet Ports Ports to accept Buffer B solution for each channel.

3 Sample In Ports Ports to accept sample for each channel.

4 Pump Purge Port When the Mode Knob is in the Purge Pump position, pumped fluids are

diverted to this port, bypassing the column, detection, and collection.

5 Waste Ports Connects to waste collection container(s). Connecting to separate contain-

ers allows isolation of waste buffers by each channel, which could be beneficial should a purified sample fail to collect.

6 Internal Drain Fluid from internal leaks exit the case through this opening. Internal leaks

are the result of pump seal failures due to neglected routine maintenance.

7 Power Switch I = On

0= Off

1-4

Page 17

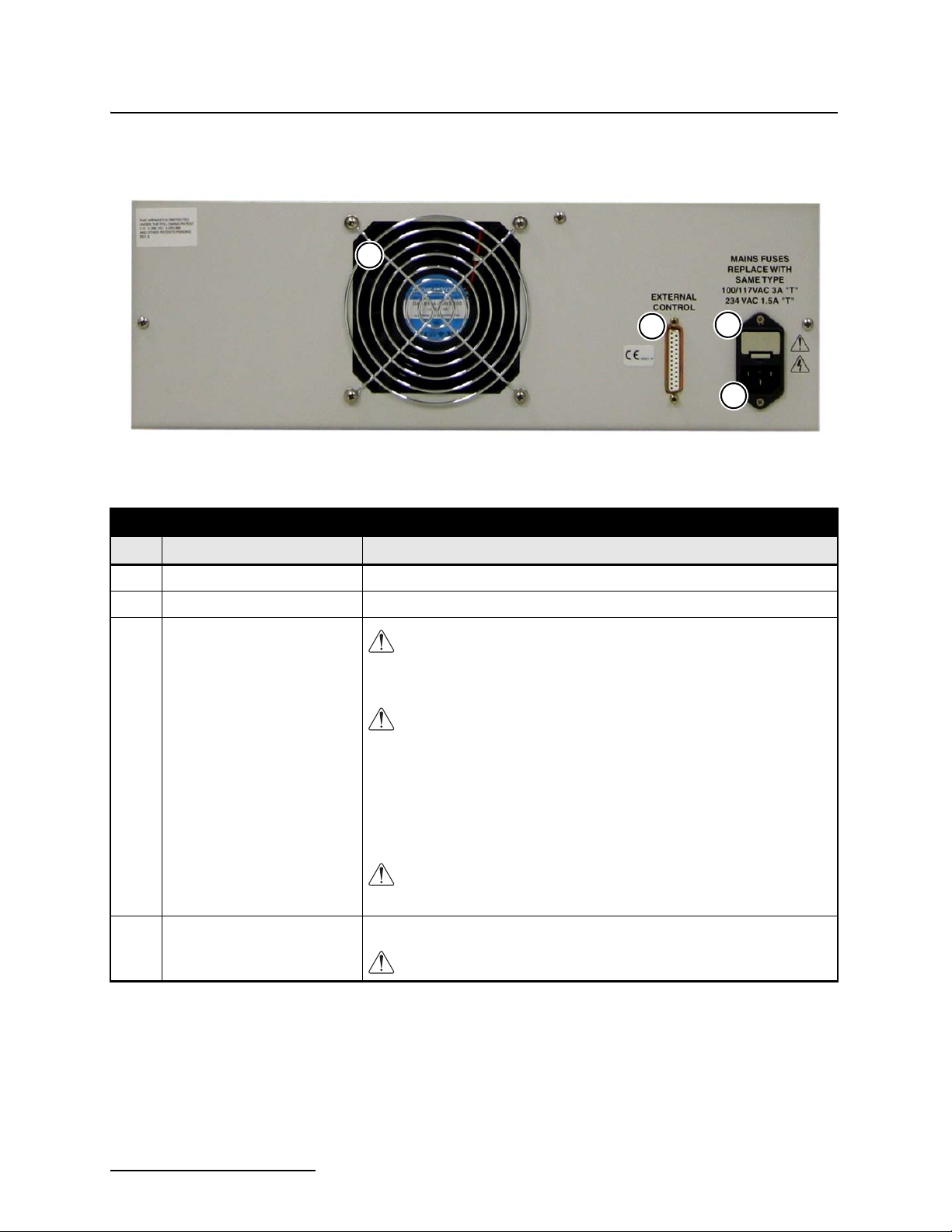

1.3.3 BioOptix 10 Right-side Connections

BioOptix™ 10

Section 1 Introduction

1

Figure 1-3 BioOptix 10 right-side connections

Table 1-4 BioOptix 10 Right-side Connections

Item Name Description

1 Purified Sample Outlet Channels 1 through 10 which connect to the Foxy 200 Fraction Collector.

1-5

Page 18

BioOptix™ 10

Section 1 Introduction

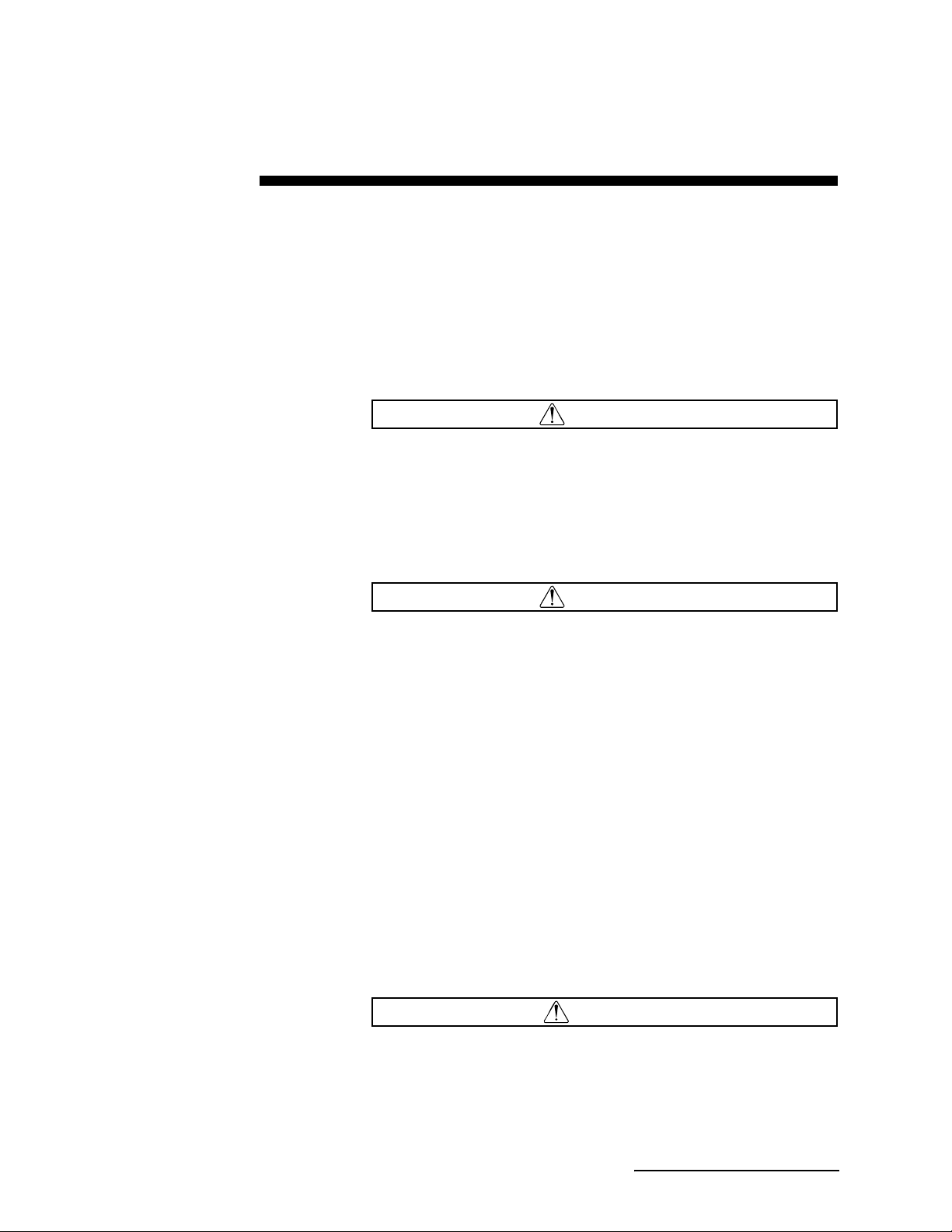

1.3.4 BioOptix 10 Rear Panel Controls and Connections

1

2

Figure 1-4 BioOptix 10 rear panel controls and

connections

Table 1-5 BioOptix 10 Rear Panel Controls and Connections

Item Name Description

1 Cooling Fan Ventilates the BioOptix 10 case and cools internal components.

2 External Control Connector Connects to the Foxy 200 Fraction Collector and computer.

3 Fuses Rear Panel Accessible Fuses.

Must always be replaced with same type fuses:

100/117 VAC — 3 amp “T” type fuse

234 VAC — 1.5 amp “T” type fuses

Internal fuses are not accessible to the user and should only be

replaced by a trained service technician.

Pump Drive Board F101 — 4.0 amp “T” type fuse.

Power One PS F1 — Not Serviceable.

Lamp Drive Board F1 — .375 amp “T” type fuse.

Case Bottom Assy F4 — Not Serviceable (T2 primary).

F5 — Not Serviceable (T2 secondary).

F6 — Not Serviceable (T2 secondary).

3

4

The Column Module has an internal 1.2 amp circuit breaker and a thermal breaker that should only be reset by a trained service technician.

4 AC Power Connector Connects to AC power source. A dedicated power source is recommended.

Mains power cord is the disconnect device.

1-6

Page 19

BioOptix™ 10

Section 2 Installation

This section provides instructions for installing the system and

preparing it for operation.

The BioOptix 10 system consists of a BioOptix 10 unit, a

Foxy 200 Fraction Collector, and a Windows PC running

BioOptix 10 software.

The system is heavy. Use a two-person lift to prevent injury.

WARNING

2.1 Unpacking the BioOptix 10 System

2.2 BioOptix 10 Installation

2.2.1 BioOptix 10 Location and Space Requirements

Carefully unpack the shipment and inspect the contents to verify

receipt of all components against the packing list. If there is any

damage to the shipping carton or any components, contact the

shipping agent and Teledyne Isco (or its authorized representative) immediately.

WARNING

If there is any evidence that the system has been damaged

in shipping, do not plug it into the power line. Contact

Teledyne Isco or its authorized representative for advice.

Compare the contents of the boxes with the enclosed packing slip.

If there are any shortages, contact Teledyne Isco immediately.

The system should be installed on a work surface capable of supporting the system, and buffer, sample, and waste containers.

The system is designed for ambient temperature and cold-room

operation. Refer to Table 1-1 for environmental specifications.

The BioOptix 10 unit requires about 3350 square centimeters

(520 in

2-1. Space must be left behind the unit for case ventilation and

electrical connections. The left side of the unit should be kept

clear to access the power switch and for fluid connections.

2

) of bench space. Space requirements are shown in Figure

CAUTION

Ensure there is at least 10 cm (4 inches) of air space on its left

side so that the disconnect device (power switch) may be easily accessed in an emergency.

2-1

Page 20

BioOptix™ 10

Section 2 Installation

= Keep area clear for instrument

connections, ventilation and to

access On/Off Switch.

To keep tubing length at a minimum, buffer, sample, and waste

collection containers should be placed to the left of the unit. The

containers may also be kept behind the unit as long as the containers are accessible.

The Foxy 200 should be installed to the right of the BioOptix 10.

The fraction collector requires about 1800 square centimeters

(275 in

2

) of bench space. Ensure that the full motion of the

fraction collector arm is not obstructed.

The Windows PC may be placed anywhere within 2 meters of the

BioOptix 10 unit (the length of the serial control cable).

100 cm

16 cm

8 cm

33 cm

56 cm

13 cm

10 cm

10 cm

Figure 2-1 System space requirements

2.2.2 Electrical Requirements

The operating voltage of the BioOptix 10 is factory set. Refer to

the serial number label on the right side panel to determine the

electrical requirements.

Teledyne Isco recommends that the BioOptix 10 system runs on

a dedicated AC circuit to prevent abnormal conditions that may

be caused by high current or electrical noise. The BioOptix 10

and Foxy 200 should be connected to the same circuit to prevent

ground loop anomalies.

(Rear)

BioOptix

(Front)

44 cm 29 cm

12 cm

Foxy 200

50 cm

16 cm

8 cm

61 cm

2.2.3 Assembling the BioOptix 10

2-2

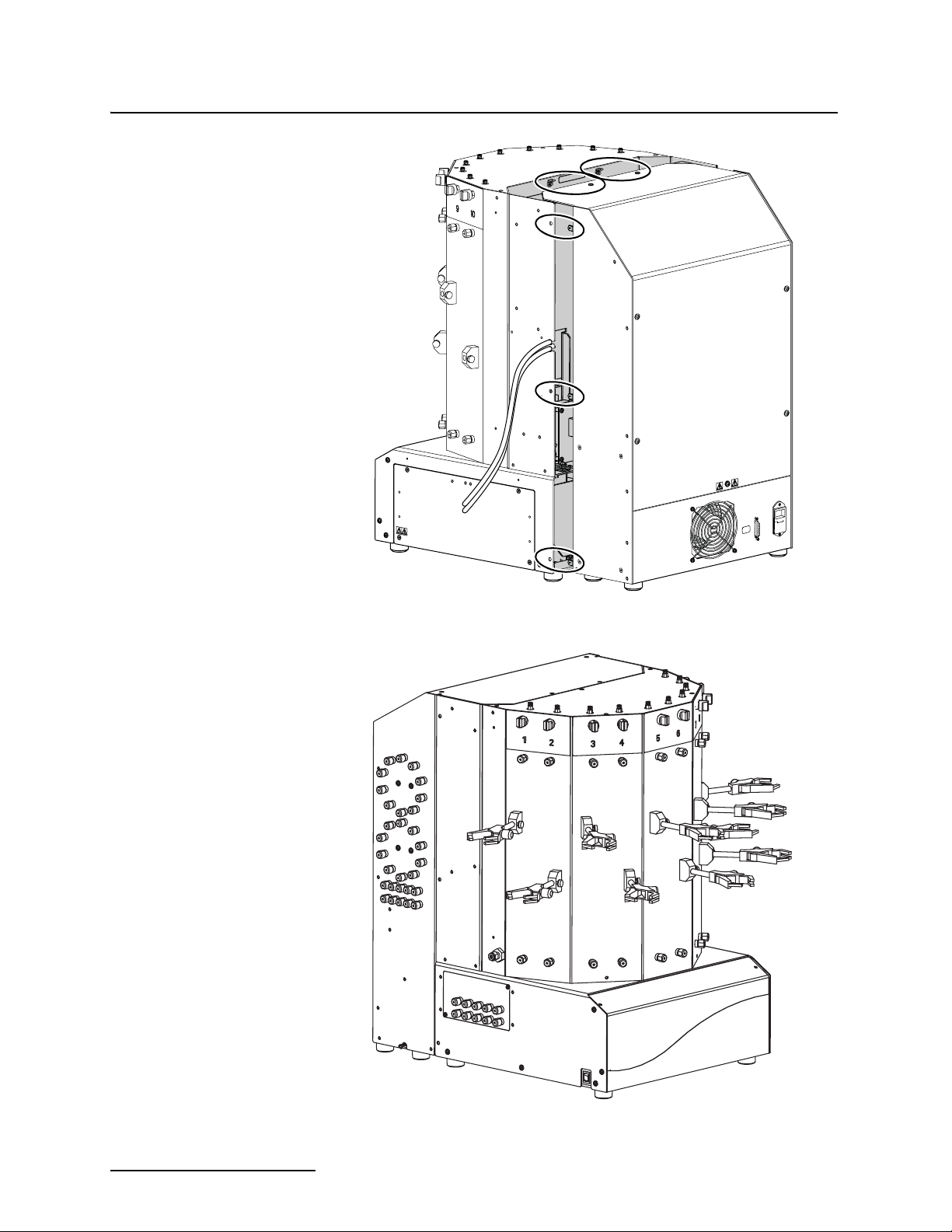

The BioOptix 10 is shipped in two pieces— a column module and

a pump module. After unpacking and inspecting the modules

place them as shown in Figure 2-2 on a sturdy work surface. This

will allow access to the internal electrical and fluid connections.

Page 21

Section 2 Installation

Pump Module Column Module

BioOptix™ 10

Figure 2-2 Accessing pump and column module internal

connections

To complete the connections:

1. Release the two sets of tubes from the retaining clips (Figure 2-3).

2. Remove the four screws securing the back metal plate on

the column module (Figure 2-3). Then, lift and remove the

plate.

Screws Screws

Retaining

Clips

Figure 2-3 Removing the column module back plate

2-3

Page 22

BioOptix™ 10

Section 2 Installation

3. While facing the back of the column module, locate the two

liquid tubing bundles secured to the lower-left inside case

panel. Route these two bundles through the slots at the

edge of the panel (Figure 2-4).

Route tubing

through slots

To

Foxy 200

Figure 2-4 Routing the Sample Out lines (column

module)

4. Connect the beige 25-pin connector from the pump module

to the column module connector labeled Pump Controller.

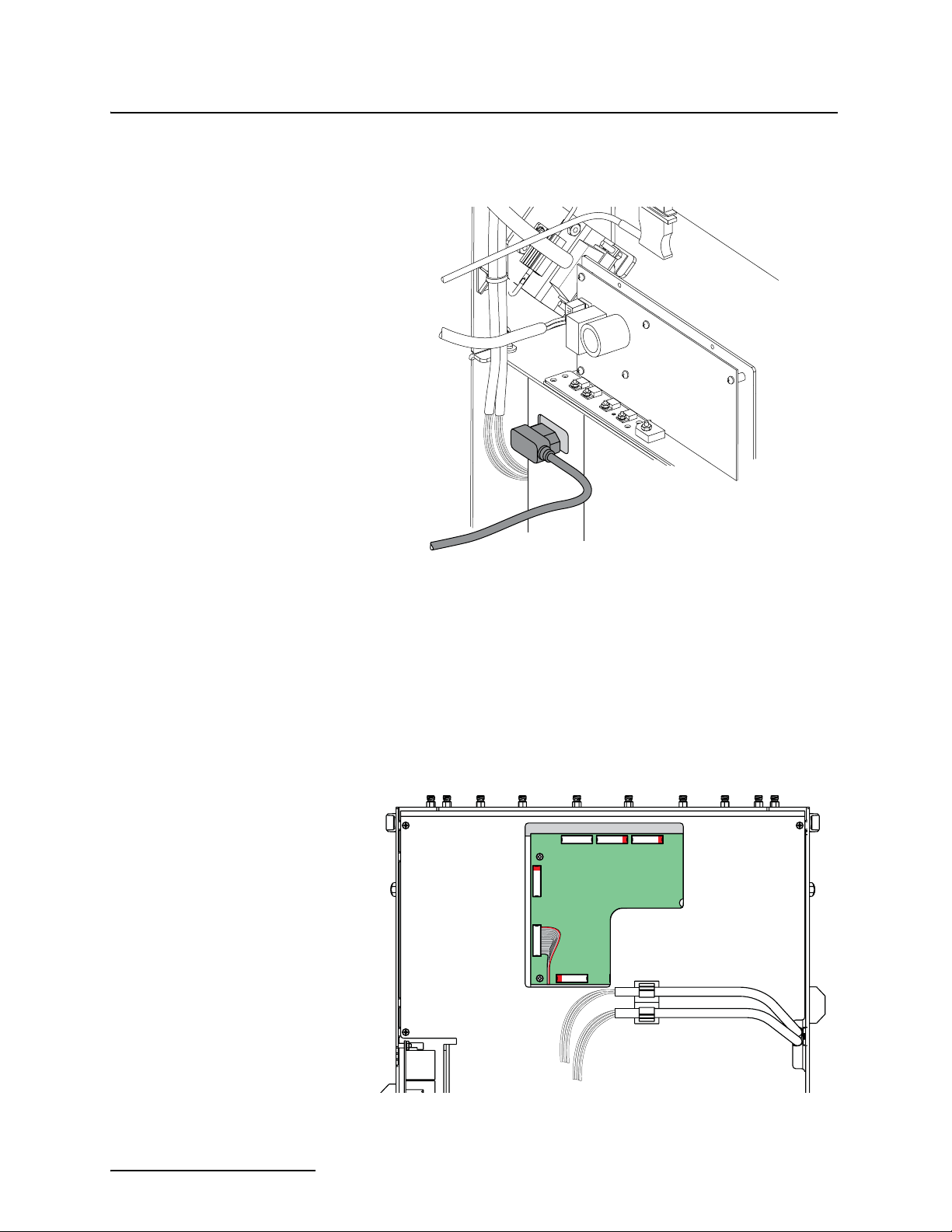

Refer to Figure 2-5.

From Pump

Module

Figure 2-5 Pump controller connection

2-4

Page 23

BioOptix™ 10

Section 2 Installation

5. Connect the orange connector labeled BD3 P110 to P110 on

the Power Drive Circuit Board (Figure 2-6).

From Pump

Module

Figure 2-6 P110 Connection on BD3

Figure 2-7 J106 Connection on BD1

6. Connect the plug labeled BD1 J106 to J106 on the Controller Circuit Board (Figure 2-7).

From

Pump

Module

2-5

Page 24

BioOptix™ 10

Section 2 Installation

7. Plug the black power cord from the pump module into the

receptacle at the lower part of the column module (Figure

2-8).

From

Pump

Module

Figure 2-8 AC power connection from pump module

8. Before completing the remaining cable connections, replace

the back metal plate on the column module. The openings

in the plate will fit around the connections made in steps 3

through 7. Secure the plate with the four screws (Figure

2-3). Then, reattach the tubing to the retaining clips.

9. The remaining ribbon cable connections are routed from

the top of the pump module through the opening on the

back plate of the column module. Refer to Figure 2-9 and

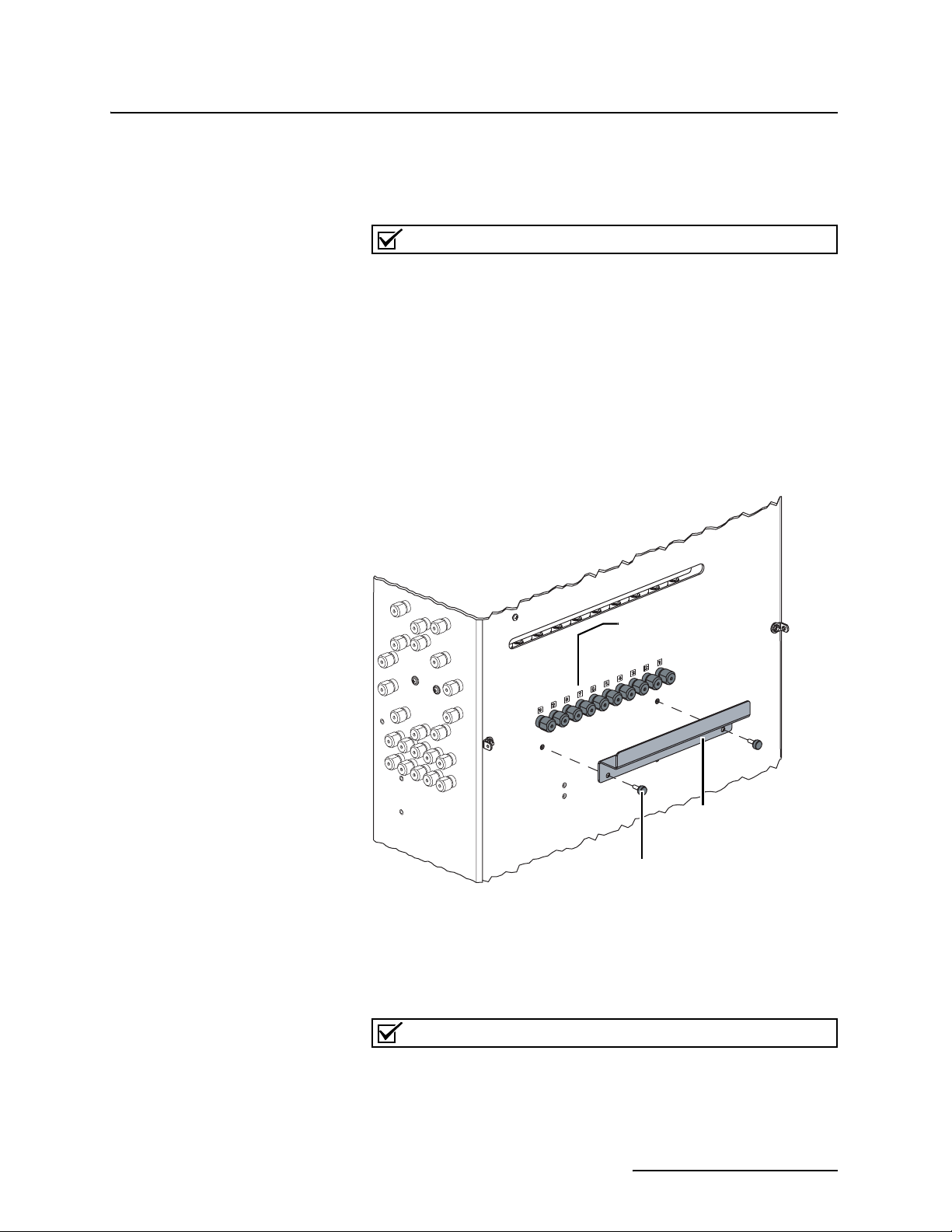

complete the connections, matching the connector labels.

P6

Not

Used

P12

P8 P11

Figure 2-9 Ribbon cable connections

(top half of column module shown)

2-6

Tubing to pump

module

Page 25

BioOptix™ 10

Section 2 Installation

10. Connect the tubing from the column module to the pump

module. Refer to Figure 2-10.

a. Remove the two thumbscrews securing the splash

guard to the pump module. Set aside the splash guard.

Note

The tubing numbers from the column module match the numbers above the compression fittings on the pump module. (The

tubing is visible in Figure 2-9; the compression fittings are visible in Figure 2-10.)

b. Loosen the nut on the compression fitting, insert the

tubing fully into the fitting and finger-tighten the nut.

Then, use a wrench to tighten the nut an additional full

turn. Repeat for all ten channels.

c. Replace the splash guard so that the tubing is routed

up and over the guard.

Figure 2-10 Liquid connections

(pump module shown)

Fittings for column

module tubing

Splash Guard

Thumbscrew

11. Slide the two modules together (Refer to Figure 2-11).

Align the eight holes on the upper and side case panels,

and secure with screws.

Note

Use care to avoid damaging internal tubing and cables. Do not

pinch or crimp tubing or cables between modules.

2-7

Page 26

BioOptix™ 10

Section 2 Installation

Figure 2-11 Aligning the fasteners

Figure 2-12 Column clamps inserted

2-8

Page 27

BioOptix™ 10

Section 2 Installation

12. Ensure the Power Switch is in the Off (“0”) position. Then,

connect the AC power cord to the back of the Pump Module. Connect the other end of the power cord to an outlet

meeting the electrical requirements listed on the serial

number label.

13. Locate the Serial “Y” cable, P/N 60-1020-241 in the Accessories Kit. Connect the 25-pin connector labeled First

Instrument Optix to the External Control port on the back of

the Pump Module.

The BioOptix 10 may now be positioned on the bench as

shown in Figure 2-1.

WARNING

The system is heavy. Use a two-person lift to prevent injury.

14. Insert the ten column clamps into the BioOptix 10. Secure

the clamps by tighten the thumbscrews against the stainless steel shafts (Figure 2-12).

2.2.4 Assembling the Foxy 200

Drop former height

thumbscrews

10-channel drop

former assembly

1. Refer to section 2 of the Foxy 200 X-Y Fraction Collector

instruction manual. Unpack the Foxy 200 and assemble

the arm.

Note

To prevent damage to the ground wire on the fraction collector

arm, attach the ten-channel drop former to the arm before proceeding with the arm assembly instructions.

2. Loosen the two thumbscrews and raise the ten-channel

drop former assembly to its highest position (Figure 2-13).

Retighten the thumbscrews.

Figure 2-13 Foxy arm

3. Load collection tubes into the racks. Place the racks on the

Foxy 200.

4. Loosen the two thumbscrews and lower the ten-channel

drop former assembly so that it will clear the collection

tubes (Figure 2-13). Retighten the thumbscrews.

2-9

Page 28

BioOptix™ 10

Section 2 Installation

5. Connect the AC power cord to the back of the Foxy 200.

Connect the other end of the power cord to an outlet meeting the electrical requirements listed on the serial number

label.

6. Connect the “Y” Serial Cable end labeled Second Instru-

ment Foxy to the RS-232-C port on the back of the Foxy

200.

7. Place the Foxy 200 to the right of the BioOptix 10 (Figure

2-1). Ensure that the full motion of the fraction collector

arm is not obstructed, especially near column positions 9

and 10 on the BioOptix 10.

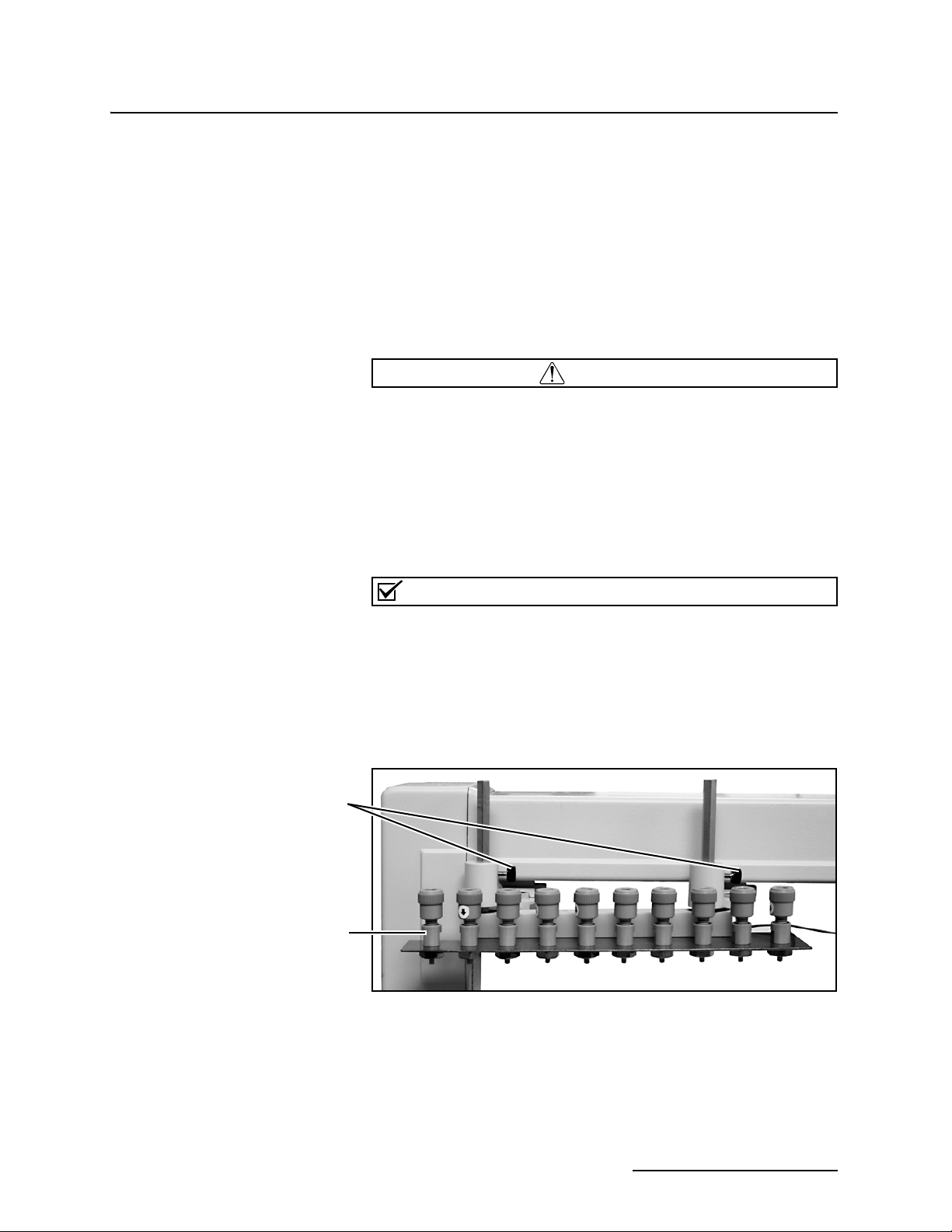

2.2.5 Fluid Connections Fluid line connections include Buffers, Samples, Waste, Pump Purge, and Foxy. Tubing for the fluid connections is located in the accessory kit, P/N 60-5209-002. The kit includes enough tubing to complete a standard installation. Standard tubing lengths are noted in the following instructions for each connection. This kit also includes a tubing cutter.

Except as noted on the Foxy connections, use the following steps

for tubing connections:

1. Loosen the nut on the compression fitting.

2. Insert the tubing fully into the fitting.

3. Finger-tighten the nut.

4. Using a wrench, tighten the fitting an additional full turn.

Buffer A – These inlet ports are located on the left side of the

BioOptix 10. The ferrules on these inlet ports accept the

0.125" OD tubing, P/N 023-0503-02, found in the accessories kit.

Note

Larger or smaller outside diameter tubing will require different

ferrules.

Buffer A solutions may be unique to each channel, or a single

solution may be routed to all ten channels.

• If unique buffers will be used on each channel, cut the

tubing to length (standard length is 60" or 152 cm) and

route the tubing to the buffer solution containers.

• If a common buffer solution will be used for all ten

channels, install the Buffer Assembly (P/N

60-5204-064), found the accessory kit. Figure 2-14 illustrates the Buffer Assembly parts. Figure 2-15 shows the

buffer assembly installed on the BioOptix 10.

2-10

Page 29

BioOptix™ 10

Section 2 Installation

Mounting

Block

Figure 2-14 Buffer assembly routes a common solution to

all ten channels

Common Buffer Inlet

Manifold

Figure 2-15 Buffer assemblies installed

To connect the Buffer Assembly:

a. Remove the two screws located in the center of the

Buffer A inlet ports. (The two exposed holes are used to

mount the Buffer Assembly.)

b. Attach the mounting block to the two holes using the

hex head screws.

c. Attach the manifold to the mounting block with the

Phillips screws and lock washers.

d. Connect the ten Teflon tubes (each 3" long by 0.085 ID)

from the manifold to the Buffer A inlet ports.

e. Cut to length a section of 0.250" OD Teflon tubing (P/N

023-0508-01) from the accessory kit and route the

buffer solution to the common inlet. The standard

length is 60" or 152 cm.

2-11

Page 30

BioOptix™ 10

Section 2 Installation

Buffer B – To form gradient buffers during purification, connect

Buffer B solution(s) to these ten inlet ports. Perform the steps

described in Buffer A above to complete these fluid connections.

Sample In – The ferrules on these inlet ports accept the

0.063" OD tubing. The accessory kit contains Teflon tubing of

this size in five different colors. Cut the tubing to length

(standard length is 36" or 91 cm), insert one end into a Sample In

port, and route the other end to the sample container.

Note

Although not critical for operation, installing the colored tubing

according the chart below may be helpful should there be a

later need to trace the lines or monitor system performance.

Table 2-1 Tubing Color chart

Channel Numbers Color Part Number

1, 6 Blue 023-0505-06

2, 7 Yellow 023-0505-04

3, 8 Orange 023-0505-03

4, 9 Green 023-0505-05

5, 10 Clear 023-0505-09

Waste Out – The ferrules on these inlet ports accept the

0.063" OD tubing listed in Table 2-1, found in the accessories kit.

Cut the tubing to length (standard length is 36" or 91 cm). Then,

while observing the color-coded channel numbers, insert one end

into a Waste Out port, and route to a suitable collection point.

If there might be a need to recover waste fluid (e.g. undetected

purified sample), a collection container for each channel is recommended. Isolating waste fluid for each channel can simplify

sample recovery.

Pump Purge – This port is used when the pumps clears any

fluid remaining in the pump. This fluid is cleared before a run is

started or during system maintenance. Connect a length of

0.250" OD Teflon tubing (P/N 023-0508-01) and use it to route

the pump purge fluid to a suitable collection container. The

standard length of tubing is 60" or 152 cm.

Column Positions – For initial operation, and when channels

are unused during operation, tubing must be inserted between

the Column Inlet and Outlet ports. Use the column bypass tube

(P/N 60-5203-170) or pieces of clear 0.063" ID tubing (P/N

023-0505-09) from the bulk roll in accessory kit.

Foxy – The two bundles of tubing on the right side of the

BioOptix 10 connect to the Foxy 200 Fraction Collector. Each

color-coded tube is labeled with its channel number and finished

with a threaded fitting.

2-12

Page 31

Section 2 Installation

Blue

Yellow

Orange

Green

Clear

Blue

Yellow

Orange

Green

12345678910

10

1

BioOptix™ 10

Clear

Figure 2-16 Foxy 200 tubing connections

Refer to Figure 2-16 and complete the tubing connections

between the BioOptix 10 and the Foxy 200. Thread and

finger-tighten the fittings into the ten-channel drop former

assembly. After connecting the tubing, peel the adhesive backing

from each retainer. Then, attach each retainer to the top of the

Foxy 200 arm (Figure 2-17).

Retainers with

adhesive backing

Figure 2-17 Adhesive retainers attached

2-13

Page 32

BioOptix™ 10

Section 2 Installation

2.2.6 Windows PC Connection

®

The Windows

personal computer (PC) must meet the following

minimum requirements:

Table 2-2 Windows® PC Minimum Requirements

Processor: Pentium, 133 MHz

RAM 32 MB

Hard Drive 20 MB available space

®

Operating System Windows

Communication Port One available RS-232 port

CD-ROM 16×

Monitor VGA or better (640×480 or higher resolution)

95, 98, 2000, NT, or XP

The PC should be set up according the manufacturer’s instructions. After the PC is fully operational, place it on the workbench

within 2 meters of the BioOptix 10.

Note

Greater lengths are possible with a user-supplied DB9 Serial

Extension Cable. Total length should not exceed 10 meters.

2.3 BioOptix 10 Software Installation

2.3.1 Configuring BioOptix 10 Software

Connect the “Y” Serial Cable end labeled Computer Serial to the

RS-232 Serial Port on the PC.

Install the BioOptix 10 Software on the Windows PC.

1. Locate the BioOptix 10 Software CD that was shipped with

the system.

2. After turning on the PC, insert the CD into the CD-ROM

drive.

3. Using Windows Explorer, locate and open the file named

setup.exe on the CD-ROM drive.

4. Follow the on-screen instructions to complete the software

installation.

After installing the BioOptix 10 software on the PC, the software

should be configured to match the hardware of the BioOptix 10

system. To configure the software:

1. Start BioOptix 10 software.

The software installation routine placed an icon on the

desktop. Double click this icon to start. Or, you can start

the software from the Windows Start button, navigating

through Programs>BioOptix 10>BioOptix 10.

2. From the BioOptix 10 menu, select Tools>Configure….

3. Match the Configuration dialog box settings to the hardware.

❍ Rack – select the rack size/type that is installed on

the system.

2-14

Page 33

BioOptix™ 10

Section 2 Installation

❍ Rack Change Bell – When this option is enabled, the

system provides an audible signal while it is waiting

for the operator to change the tube rack.

❍ Com Port – select the Com Port number to which the

“Y” Serial cable is connected to the PC. Refer to the

documentation provided with your PC.

❍ Fraction Size – type or select the desired fraction size

to be collected by the Foxy 200.

❍ Stroke Volume – type or select the desired stroke

volume of the pump.

A larger stroke volume will reduced the number of

Fill/pump cycles. However, this will limit the possible

sample and pumped volumes to a multiple of the stroke

volume. A stroke volume of 1 mL allows sample and

pumped volumes in increments of 1 mL.

❍ Refill Rate – type or select the desired Refill Rate in

mL/minute.

❍ Pressure Limit – type or select the desired operating

pressure limit, in psi. When exceeded, the system

will reduce the flow rate until the pressure returns to

the normal range.

This empirical value will vary according to the properties of the stationary and mobile phase. Select a value

low enough to limit the flow rate when a column or tubing blockage may be indicated, but high enough to

avoid false indications when higher column operating

pressures may be the norm.

❍ Default Data Directory – Click the Browse button to

select a default data directory.

4. Click the Save button to accept the configuration settings

and close the dialog box.

2.4 BioOptix 10 System Preparation

The system preparation assumes that the instructions in sections 2.1 through 2.3 have been completed. System preparation

primes the tubing with buffer solution to ready the BioOptix 10

for a system verification test run.

To prepare the system:

1. Ensure that BioOptix 10 software is configured and running on the connected Windows PC.

2. Turn the Power switch on the left side of the BioOptix 10 to

On.

3. Press the Power button on the Foxy 200.

4. Place the Buffer A inlet line(s) into two liters of solution

(such as HPLC-grade water or other appropriate buffer

solution).

5. Place the Buffer B inlet line(s) into two liters of solution

(such as HPLC-grade water or other appropriate buffer

solution).

2-15

Page 34

BioOptix™ 10

Section 2 Installation

6. Ensure that each channel on the BioOptix 10 has

0.125" OD bypass tubing between the Column Inlet and

Outlet ports (Figure 2-18).

Column Inlet

Figure 2-18 Column bypass tubing

Figure 2-19 Mode control knob

Column Outlet

7. For each channel, set the mode control knobs to Purge (Figure 2-19).

2-16

8. From the BioOptix 10 software menu, select Tools>Manual

Control. The BioOptix 10 Manual Hardware Control win-

dow is displayed (Figure 2-20).

Page 35

Figure 2-20 BioOptix 10 Manual Hardware Control

window

BioOptix™ 10

Section 2 Installation

9. In the Columns section of this window, check each channel

number that should be primed. Configure the remaining

settings to match those shown in Figure 2-20.

10. Click the Start Pump button. Observe the following for each

enabled channel:

❍ Buffer B solution movement should be visible at the

inlet ports on the left side of the BioOptix 10.

❍ After passing through the internal pump and valves,

Buffer B solution should be visible at the Pump Purge

port.

11. Continue to manually pump Buffer B solution through the

system and inspect the tubing connections.

If any connections are leaking, use a wrench to tighten the

fitting

1

/4 turn, then check again for leaks. Repeat as neces-

sary.

If no leaks are found, proceed with step 12.

12. Click the Stop Pump button.

13. Change the %B setting to 0 percent.

14. Click the Start Pump button. Monitor the flow of Buffer A

through the system. Correct leaks as needed.

15. Click the Stop Pump button.

16. Click the Done button.

The system is ready for operation (Section 3).

2-17

Page 36

BioOptix™ 10

Section 2 Installation

2-18

Page 37

BioOptix™ 10

Section 3 Operation

This section provides an introduction to preparing the system

and creating files necessary for a purification run. The instructions assume that the system has been set up according to

Section 2.

3.1 Sample Preparation The Sample In lines for each channel should be placed into a

vessel holding the liquid sample mixture. Sample In lines can be

placed into a common sample vessel, or in multiple vessels when

unique samples are to be introduced on each channel.

3.2 Column Installation The BioOptix 10 system uses versatile column clamps to hold a

variety of columns. The clamps are adjustable, holding column

sizes as large as 45 mm (1

Note

User-supplied clamps and apparatus may be used on the system. The mounting holes on the side of the BioOptix 10 accept

9.5 mm (

3

/8 in) mounting stems.

3

/4 in).

3.2.1 Column Tubing and Adapters

To install a column, insert the column into the clamp and turn

the knob to close the clamp and secure the column.

When inserting any column be sure to observe the flow direction

if noted on the column. Orient the column with the inlet at the

top and the outlet at the bottom.

Because of the variety of columns that may be used on the

BioOptix 10, the system does not include standard fittings. All

column fittings and tubing are user-supplied to fit the selected

columns.

To install the column tubing:

1. Remove the bypass tubing that was installed to

prime/purge the pumps.

2. At each column position, insert a tube with a fitting at the

upper column inlet port. Then, connect the fitting to the

top of the column.

3. At each column position, insert a tube with a fitting at the

lower column outlet port. Then, connect the fitting to the

bottom of the column.

3-1

Page 38

BioOptix™ 10

Section 3 Operation

3.3 BioOptix 10 Software

Note

Refer to On-line Help for specific BioOptix 10 software operating instructions.

3.3.1 Overview The operation of the BioOptix 10 system is directed by three files:

• Gradient – these files define how a gradient is to be

formed from Buffer A and B solutions.

• Method – these files contain the settings that direct the

operation of each channel of the system. A method file

will reference the settings in a gradient file.

• Experiment – These files contain settings that direct the

operation of all channels. Experiment files are based on

method file settings. The BioOptix 10 system operation

can be started after the experiment settings are defined.

Sections 3.4 through 3.6 describe these files in detail.

3.4 Gradients A gradient file can be created by:

• selecting the File>New>Gradient menu command,

• pressing the Ctrl+G keyboard buttons,

•or by clicking the G toolbar button.

A new gradient file displays an empty two-column table and a

plot area (Figure 3-1). The table contains inflection points—

points at which the rate of gradient formation change.

The Initial volume row in the table defines the starting mixture,

expressed as percent B.

Figure 3-1 Gradient File

3-2

Page 39

Note

The percent B value is the amount of Buffer B solution mixed

with Buffer A. A value of zero percent B (0 %B) pumps only

Buffer A. Conversely, a value of 100 %B pumps only Buffer B.

All other rows in the table define the %B that will be reached

after pumping the listed volume. The system forms a linear gradient between inflection points. This can be observed in Figure

3-1. After pumping the initial 5 mL of 0 %B, a linear gradient is

formed, reaching 80 %B after pumping an additional 20 mL.

A gradient file may contain as many as 9 inflection points.

3.4.1 Defining a Gradient To define a gradient:

• Using the table, enter the %B value and the pumped

Volume in mL over which that value will be reached. Or,

• Click in the plot area to add inflection points to the right

of the plot. After adding a point you can click and drag

the inflection point to change it.

Note that whenever the table or plot area is edited, both are

updated.

The buttons below the table modify the table of inflection points.

• Insert Row – adds a row above the selected row.

• Delete Row – removes the selected row from the table.

• Add Row – adds a row to the end of the table.

Sharp changes can be made in the gradient by entering a row

with 0 mL as the pumped volume, followed by another row with

the new %B and volume. Pairing rows such as these can be used

to form step gradients.

BioOptix™ 10

Section 3 Operation

3.4.2 Saving the Gradient To be used in method and experiment files, the gradient file must be saved. Save the gradient by selecting the File>Save menu command. Use a descriptive file name so that it can be located later.

3.5 Methods A method file can be created by:

• selecting the File>New>Method menu command,

• pressing the Ctrl+M keyboard buttons,

•or by clicking the M toolbar button.

A new method file displays a series of tabs. Each tab contains the

settings for each block of the method. A block is a segment of the

method that pumps buffer solution, loads a sample, or forms a

gradient.

About Method Templates When creating a new method, the BioOptix 10 software con-

figures the blocks of the method file according to a template

file—standard.tpl. This template file can be modified to suit your

applications, allowing up to ten blocks or tabs. Refer to Appendix

A for instructions.

3-3

Page 40

BioOptix™ 10

Section 3 Operation

The default method file contains five blocks that are appropriate

for use with affinity column purification:

• Equilibrate – conditions the column.

• Load – loads the sample onto the column.

• Wash – washes compounds from the column that do not

bind to the column media.

• Elute – pumps a buffer solution to release the purified

compounds from the column.

• Post Run– flushes any remaining compounds from the

column to prepare the column for the next purification

run, storage, or disposal.

3.5.1 Equilibrate Settings This block conditions the column and fills the column with the desired buffer solution for starting the purification.

Figure 3-2 Equilibrate tab settings

3-4

The Equilibrate tab (Figure 3-2) contains the following:

• Fluid, %B – Enter the desired mix of buffer fluid as a

percentage of Buffer B.

• Flow Rate, mL/min – Enter the desired flow rate, from 0.5

to 12 mL/min.

• Volume, mL – Enter the total amount of Buffer fluid to

pump during this block.

• Collect Effluent – Select the desired action for effluent

fluid as it comes off the column. Selecting No diverts the

effluent to a channel waste port. Selecting Ye s sends the

fluid to the fraction collector. If Ye s is selected, enter a

fraction size in mL. The fraction collector will advance to

the next row of tubes after collecting the entered

volume.

• Pause at End – Select Ye s to have the system wait for

operator intervention after completing this block. Select

No to automatically advance to the next block.

Page 41

Pausing at the end of a block allows for buffer changes or

other mechanical adjustments before proceeding with the

next block.

• Wavelength – Type or select the desired wavelength from

190 to 360 nm to be used for UV detection. Note that all

blocks use the same wavelength.

Note

The Equilibrate tab is a “Fluid” block type. See Appendix A.

3.5.2 Load Settings This block loads the sample onto the column.

BioOptix™ 10

Section 3 Operation

Figure 3-3 Load tab settings

The Sample Load tab (Figure 3-3) contains the following:

• Injection – Select Pump to pump liquid sample from the

Sample In ports onto the column. Select Manual to inject

the sample from the manual injection ports (located on

the top of the BioOptix 10) onto the column. Note that

selecting Manual disables the flow rate and volume

settings.

• Flow Rate, mL/min – If a Pump injection is selected, enter

the desired flow rate in mL/min.

• Volume – If a Pump injection is selected, enter the

desired volume in mL.

• Collect Effluent – Select the desired action for effluent

fluid as it comes off the column. If Ye s is selected, enter

the desired fraction size.

• Pause at End – Select Ye s to have the system wait for

operator intervention after completing this block. Select

No to automatically advance to the next block.

Note

The Load tab is a “Load” block type. See Appendix A.

3-5

Page 42

BioOptix™ 10

Section 3 Operation

3.5.3 Wash Settings This block flushes compounds that did not bind to the affinity media. The Wash tab is a fluid block type, therefore the settings displayed on this tab are the same as the Equilibrate tab. Refer to section 3.5.1 for a discussion on the settings for this tab.

Figure 3-4 Wash tab settings

3.5.4 Elute Settings This block pumps the buffer solutions through the column. The mixture and quantity of buffer solution is defined by the gradient file.

Figure 3-5 Elute tab settings

3-6

The Elute tab (Figure 3-5) contains the following:

• Gradient – Click the Browse button to select a gradient

file.

• Volume, mL – This is reported by the gradient file.

• Flow Rate mL/min – type or select the desired flow rate.

Page 43

BioOptix™ 10

Section 3 Operation

• Collect Effluent – Select the desired action for effluent

fluid as it comes off the column. If Ye s is selected, enter

the desired fraction size.

Note

The Elute tab is a “Gradient” block type. See Appendix A.

3.5.5 Flush Settings This block pumps fluid to flush remaining sample from the column and system tubing. This step can prepare the column for the next purification run, storage, or disposal.

The Flush tab is a fluid block type, therefore the settings displayed on this tab are the same as the Equilibrate and Wash

tabs. Refer to section 3.5.1 for a discussion on the settings for this

tab.

Figure 3-6 Flush tab settings

3.5.6 Saving the Method File To be used in an experiment file, the method file must be saved. Save the method by selecting the File>Save menu command. Use a descriptive file name so that it can be located later.

3.6 Experiments An experiment file can be created by:

• selecting the File>New>Experiment menu command,

• pressing the Ctrl+E keyboard buttons,

•or by clicking the E toolbar button.

Before building and displaying the experiment file, you must

select a method file that will be used for all ten channels. In the

Select a Method for Experiment dialog box, locate and highlight

the method file, then click the Open button.

An experiment file displays operating parameters in a table.

Many of the columns in the table are determined by the template

file used to create the method file. (Refer to Appendix A for more

details on the template file.) Default values will be assigned to

the table cells from the method file you’ve chosen.

3-7

Page 44

BioOptix™ 10

Section 3 Operation

3.6.1 Setting up the

Experiment

Before proceeding, determine which BioOptix 10 channel positions will be used during the purification run. Channels that will

be in use require that the corresponding rows in the table be

completed. Note that to use these positions they should have

samples prepared (section 3.1) and columns installed (3.2).

Table rows for unused channels must remain empty.

To set up the experiment:

1. Position the cursor in the Sample Name table cell of the

first channel position in use. Enter a descriptive name for

the sample. This activates the channel for use in the experiment.

Because the Sample Name also is used as a filename for

post-run data, the text you enter in this field must be a

Windows-compatible file name.

2. Advance the cursor to the next cell to the right.

BioOptix 10 completes the remaining cells in the row using

the settings from the method file as defaults.

3. Repeat steps 1 and 2 for all channel positions that will be

in use.

The table now is populated with default settings for each channel

position in use.

Figure 3-7 Experiment File

3.6.2 Editing the Experiment The table can be edited to create unique purification parameters for each channel. To edit any cell in the table, position the cursor in a cell and enter the new value. You can also select different gradient files by clicking on the [...] button and browsing for the new file. When editing the table note the following:

• Load type values (such as the “Load Column in Figure

3-7) must be a multiple of the stroke volume. Stroke

volume is discussed in section 2.3.1.

• If selecting a different gradient file, note that the total

volume pumped be the same for all channels in the

experiment.

3-8

Page 45

BioOptix™ 10

Section 3 Operation

3.6.3 Saving the Experiment File

3.7 Running the Experiment

Save the experiment by selecting the File>Save menu command.

Use a descriptive file name so that it can be located for later use.

With the experiment file open, some BioOptix 10 operation

buttons along the bottom of the window are active (Figure 3-8).

Buttons will be active or inactive according to the current state of

the system.

Figure 3-8 BioOptix 10 Operation Buttons

Button Description

Play Click to begin the experiment run. If the Stop

Stop Click to suspend the run activity. From this state

Stop

Fast

Forward

Next

TubePlay

Table 3-1 Operation Buttons

button was clicked during the run, clicking the

Play button will resume the run.

you click Play to resume the run, or click Fast

Forward to skip to the next block or abort the

run.

Fast Forward Click the Fast Forward to skip to the next block

Next Tube Click this button to advance the fraction collector

AutoZero The baseline absorbance trace may shift if

Show Run Window Click this button to bring the experiment window

or abort the run.

to the next row. This is useful when there is a

need to isolate effluent.

buffer solutions are changed mid-run. Click this

button to re-zero the absorbance trace.

for the run in progress to the foreground. If you

have several other files (e.g. previous experiments or new methods) open in the BioOptix 10

window this button lets you quickly return to the

running experiment.

3.7.1 System Operation To start the experiment, click the Play button. The system begins operation with the first block and proceeds according to the experiment and method files.

Referring to Figure 3-7, this first block would be “Equilibrate”

and use the operating parameters specified by the method file

(Figure 3-2). The system would pump 0 %B (100% of buffer A) at

5.0 mL/min. The system would pump 50 mL and then pause

(Figure 3-9). Similarly, the BioOptix 10 would proceed through

the Sample Load, Wash, Elute, and Flush blocks.

3-9

Page 46

BioOptix™ 10

Section 3 Operation

Figure 3-9 Pause at end of block

If the block is set to collect effluent (Figure 3-4), the fraction collector will deposit the fluid in the collection tubes. If a peak is

detected, the fraction collector automatically advances to the

next row to isolate the fluid. The fraction collector will also automatically advance to the next row of tubes whenever the specified fraction size has been collected.

If the block is not set to collect effluent (Figure 3-2), the

BioOptix 10 diverts all pumped fluids to the waste ports.

3.7.2 Operation Displays The window displayed during the run has several features that let you monitor the operation.

At the start of a run, the plot area displays the gradient as a blue

line (right Y-axis). The X-axis displays the volume pumped.

Below the X-axis is a progress bar. As the run progresses, the

absorbance traces is plotted as a red line (left Y-axis).

Zoom and pan To the right of the plot area are several controls that can modify

the display. The Pan/Zoom switch specifies which action to take

when you use the cursor to click and drag across the plot area. In

Zoom mode, clicking and dragging across part of the plot area

will zoom in on the selected region. In Pan mode, clicking and

dragging moves the plot area under the cursor to a new position.

The view can be returned to the default view by clicking the

Reset Graph button.

Absorbance trace In addition to the zoom feature which scales the plot area both

horizontally and vertically, the scale of the absorbance trace can

be modified alone. To change the left Y- a x i s S c a l e , click and select

a new value from the pull-down list.

Channel positions Channel positions can be displayed in the plot area individually

or collectively. Highlight the channels you wish to display. If multiple absorbance traces and gradients are selected, they will be

overlaid in the plot area. This can be useful when comparing

channels, especially when desiring to monitor the effects of any

experimental interventions.

Status bar The status bar is located at the bottom edge of the BioOptix 10

window. The fields in this bar display system information and

messages during the run.

3.7.3 Suspending System

Operation

3-10

The system automatically stops after completing all blocks.

However, the experiment can be paused at any time by clicking

the Stop button. This stops the pumps which allows you to refill

or change buffers, or make other mechanical adjustments to the

system. Click the Play button to resume the experiment.

Page 47

BioOptix™ 10

Section 3 Operation

The Fast Forward button is active after clicking the Stop button.

The Fast Forward button allows you to skip to the next block in

the experiment or abort the run.

3.8 Post-experiment Operation

3.8.1 Pump Flush At the completion of the experiment, the BioOptix 10 provides

the option to flush the pumps (Figure 3-10). The pump flush will

pass a wash fluid through the pumps to prevent salts from crystallizing in the system.

CAUTION

Salts will cause premature wear to the internal components

and eventually pump failure.

Figure 3-10 Pump flush option

Flush the pumps for

storage

Figure 3-11 Flush window

If another experiment will be started immediately, this flush can

be skipped. Otherwise, if the system will remain idle for a few

hours or even overnight, the pump flush is recommended.

1. Click the Ye s option to flush the pumps. This opens the

BioOptix 10 flush window (Figure 3-11).

2. Select the channels to be flushed.

3-11

Page 48

BioOptix™ 10

Section 3 Operation

3. Select a wash fluid. The wash fluid must be compatible

with the buffer system and of sufficient strength to dissolve salts. If this solution is different than the buffers,

move the Buffer In lines to the wash fluid container.

4. For all selected channel positions, turn the Mode knob to

the purge pump position.

5. Click the Start button to begin the flush routine.

The BioOptix 10 flushes the pumps.

6. When the routine is finished, return the Mode knobs to the

Operate position.

The flush routine can be modified to meet your application’s

needs. To modify the pump flush select the Tools>Edit Pump Flush

menu command. This command opens a window that allows you

to change the flush volume, flow rate, Buffer A and B mixing, and

the stroke volume. Click the Save button to save your changes.

3.8.2 Saving Run Data The BioOptix 10 software automatically saves the run data and chromatograms using the experiment name as the filename. Two types of files are saved: “.lst” and “.run” files.

This run data can be retrieved and viewed at a later time using

BioOptix 10 software. To do so, select the File>Open menu

command or click the Open toolbar button. Multiple channels

from the experiment can be opened by select the “.lst” file. Individual channels can be viewed by opening a “.run” file.

Viewing the run data and chromatograms is very similar to the

operation displays described in section 3.7.2.

The run data and chromatograms displayed in the active window

may be exported in various formats for archiving and sharing.

• Hard copies can be produced by selecting the File>Print

menu command or clicking the Print toolbar button.

Before printing you can also change the page setup

(File>Page Setup…) and preview the page (File>Print

Preview).

• Other file formats can be produced using the File>Save

As menu command. These formats are:

❍ DOC– Microsoft Word format that includes the run

data and chromatogram.

❍ RTF– Rich Text Format that includes the run data

and chromatogram. This format can be opened with

many word-processing programs.

❍ PDF– Portable Document Format that is an

electronic file similar in appearance to the hard copy

output. Viewing PDF files require Adobe’s Acrobat

Reader, a free download from www.adobe.com.

❍ TXT– Text-only format that lists the run parameters

and history. This format does not support

chromatogram data.

3-12

Page 49

BioOptix™ 10

Section 3 Operation

3.8.3 AutoReports After the run the BioOptix 10 can automatically print the purification run results or save the file in a format listed in section

3.8.2. To automatically receive the hard copies or save the files,

select the Tools>AutoReport menu command and modify the set-

tings.

3-13

Page 50

BioOptix™ 10

Section 3 Operation

3-14

Page 51

BioOptix™ 10

Section 4 System Maintenance

4.1 Periodic Maintenance The BioOptix 10 system’s internal components have been

selected for long life and low maintenance. To maintain the

system, the only required periodic maintenance is to flush the

pumps daily. The pump flush passes a wash fluid through the

pumps to prevent salt buffers from crystallizing in the system.

CAUTION

Salts will cause premature wear to the internal components

and eventually equipment failure. Flush the pumps daily to prevent damage.

The BioOptix 10 system provides the option to flush the pump at

the end of a purification run (see section 3.8). If the system will

remain idle for a few hours or even overnight, a pump flush following the run is recommended.

The pump flush can also be initiated from a menu command.

Daily Pump Flush 1. Select Tools>Edit Pump Flush and review the settings. Save

any changes you’ve made.

2. Ensure the Buffer In lines are placed in containers of wash

fluid.

Figure 4-1 Flush window

Note

Select a wash fluid that is strong enough to dissolve salts. The

wash fluid must also be miscible with buffer solution remaining

in the system from the previous run.

3. Select the To o l s > P u m p F l u s h menu command. This opens

the BioOptix 10 flush window (Figure 4-1).

4. Check the pump channels to be flushed. Then, click the

Start button.

4-1

Page 52

BioOptix™ 10

Section 4 System Maintenance

The BioOptix 10 system pumps the wash fluid, flushing the

Buffer In lines, gradient formation components, pump, and purge

lines. (See Figure B-6 in Appendix B.)