Page 1

Oxygen Analyzer

OPERATING INSTRUCTIONS FOR

MM

MM

OO

OO

DD

DD

Oxygen Analyzer

33

33

EE

EE

00

00

LL

LL

00

00

BB

BB

00

00

DD

DD

SS

SS

P/N M71903

11/30/01

ECO # 01-

DANGER

Tox ic g a se s a nd o r fla mma ble liq uids ma y be pr es e nt in this mon itor ing s y stem.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist

for a time even after the power is turned off and disconnected.

Only authorized personnel should conduct maintenance and/or servicing.

Teledyne Analytical Instruments i

Page 2

BDS 3000

Before conducting any maintenance or servicing, consult with authorized

supervisor/manager.

Teledyne Analytical Instruments ii

Page 3

Oxygen Analyzer

Copyright © 2000 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by Teledyne or an authorized service center.

We assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

T hi s in str ument p ro v id es measur ement read in g s to it s user, an d serv es as a to o l b y w h i c h

v al uabl e d at a can b e g at h er ed . The i n fo rmat i on p r ov id ed by t h e in st r umen t may assi st th e user

i n el imi nati n g po ten ti al hazard s cau sed b y his p r ocess; ho wev er , it is essent ial t hat all

p er so nn el in v ol ved in th e u se o f t he in st ru men t or it s int er f ace, wi th t h e pr ocess b ein g

measu red , be pr op er l y tr ain ed i n t he pr ocess i tself , as well as all in s t r u m e n t a t io n rel at ed to i t .

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of Teledyne at the

time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot accept

responsibility for conditions beyond its knowledge and control. No statement expressed or

implied by this document or any information disseminated by the manufacturer or its

agents, is to be construed as a warranty of adequate safety control under the user’s process

conditions.

Teledyne Analytical Instruments iii

Page 4

BDS 3000

Specific Model Information

The instrument for which this manual was supplied may

incorporate one or more options not supplied in the standard instrument.

Commonly available options are listed below, with check boxes. Any

that are incorporated in the instrument for which this manual is supplied

are indicated by a check mark in the box.

Instrument Serial Number: _______________________

Options Included in the Instrument with the Above Serial Number:

• BDS 3000-V: Instrument configured for Vacuum Service

• 19" Rack Mnt: The 19" Relay Rack Mount units are

available with one BDS 3000 series

analyzers installed in a standard 19" panel

and ready to mount in a standard rack.

Teledyne Analytical Instruments iv

Page 5

Oxygen Analyzer

Safety Messages

Your safety and the safety of others is very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the

instructions for details on the specific danger. These cautions

warn of specific procedures which if not followed could cause

bodily Injury and/or damage the instrument.

CAUTION: HOT SURFACE WARNING: This warning is

specific to heated components within the instrument. Failure

to heed the warning could result in serious burns to skin and

underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous

voltages appear within this instrument. This warning is

specific to an electrical hazard existing at or nearby the

component or procedure under discussion. Failure to heed this

warning could result in injury and/or death from

electrocution.

Technician Symbol: All operations marked with this symbol

are to be performed by qualified maintenance personnel only.

NOTE: Additional information and comments regarding a

specific component or procedure are highlighted in the form

of a note.

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

Teledyne Analytical Instruments v

Page 6

BDS 3000

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

This manual provides information designed to guide you through

the installation, calibration and operation of your new analyzer. Please

read this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be peculiar to your

instrument.

Manuals do get lost. Additional manuals can be obtained from

Teledyne at the address given in the Appendix. Some of our manuals are

available in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Teledyne Analytical Instruments vi

Page 7

Oxygen Analyzer

Table of Contents

Safety Messages ...........................................................................v

Table of Contents ........................................................................ vii

List of Figures................................................................................ x

List of Tables ............................................................................... xii

Introduction ...................................................................................1

1.1 Overview 1

1.2 Typical Applications 1

1.3 Main Features of the Analyzer 1

1.4 Front Panel (Operator Interface) 2

1.5 Rear Panel (Equipment Interface) 5

Operational Theory .......................................................................7

2.1 Introduction 7

2.2 BDS Sensor 7

2.2.1 Principles of Operation 7

2.2.2 Gas Flow Rate 10

2.2.3 Gas Pressure 11

2.2.4 Temperature effect 11

2.2.5 Recovery from High Level Oxygen Exposure 11

2.2.6 Background gas compatibility 12

2.2.7 Stability 13

2.2.8 Maintenance 13

2.3 Sample System 14

2.4 Electronics and Signal Processing 15

Installation ................................................................................... 19

3.1 Unpacking the Analyzer 19

3.2 Mounting the Analyzer 19

3.3 Rear Panel Connections 21

Teledyne Analytical Instruments vii

Page 8

BDS 3000

3.3.1 Gas Connections 21

3.3.2 Electrical Connections 22

3.3.2.1 Primary Input Power 22

3.3.2.2 50-Pin Equipment Interface Connector 23

3.4 Electrolyte Refill of BDS Sensor 28

3.5 Testing the System 30

3.6 Sensor Protection Mode 30

Operation ..................................................................................... 33

4.1 Introduction 33

4.2 Using Data Entry and Function Buttons 34

4.3 The System Function 36

4.3.1 Tracking Oxygen During Cal and Alarm Delay 37

4.3.2 Setting up an Auto-Cal 38

4.3.3 Password Protection 39

4.3.3.1 Entering the Password 40

4.3.3.2 Installing or Changing the Password 41

4.3.4 Logout 43

4.3.5 System Self-Diagnostic Test 43

4.3.6 Version Screen 44

4.3.7 Filter Function 44

4.3.8 Negative Value Display 45

4.3.9 The Gas Correction Factor 45

4.3.10 Troubleshooting Screen 46

4.3.11 Temperature 47

4.3.12 Extended Analog Output Function 47

4.3.13 Zero Baseline Temperature Compensation 48

4.4 Calibration of the Analyzer 49

4.4.1 Zero Cal 50

4.4.1.1 Auto Mode Zeroing 50

4.4.1.2 Manual Mode Zeroing 51

4.4.2 Span Cal 52

4.4.2.1 Auto Mode Spanning 52

Teledyne Analytical Instruments viii

Page 9

Oxygen Analyzer

4.4.2.2 Manual Mode Spanning 53

4.4.3 Span Failure 54

4.5 The Alarms Function 54

4.6 The Range Function 57

4.6.1 Setting the Analog Output Ranges 58

4.6.2 Fixed Range Analysis 58

4.7 The Analyze Function 59

4.8 Signal Output 59

Maintenance................................................................................. 65

5.1 Routine Maintenance 65

5.2 Adding Water to the BDS Sensor 65

5.3 Fuse Replacement 66

5.4 System Self Diagnostic Test 67

5.5 Major Internal Components 68

5.6 Cleaning 70

5.7 Troubleshooting 70

Appendix...................................................................................... 73

A-1 Specifications 73

A-2 Recommended 2-Year Spare Parts List 75

A-3 Drawing List 76

A-4 19-inch Relay Rack Panel Mount 76

A-5 Application notes 77

A-6 Material Safety Data Sheet 79

Teledyne Analytical Instruments ix

Page 10

BDS 3000

List of Figures

Figure 1-1: BDS-3000 Front Panel.................................................. 3

Figure 1-2: Model BDS 3000 Rear Panel........................................ 5

Figure 2.1: Cross Section of the BDS Oxygen Sensor................... 9

Figure 2.2: BDS sensor output at different gas flow rate............... 10

Figure 2-3: BDS Sample System .................................................. 11

Figure 2.4 Typical Purge-down Curve After Air Saturation............ 12

Figure 2.5: Adding DI Water to the BDS Sensor .......................... 13

Figure 2-6: Flow Diagram.............................................................. 14

Figure 2-7: Electronic Component Location .................................. 16

Figure 2-8: BDS 3000 Electronics Block Diagram......................... 17

Figure 3-1: Model BDS 3000 Front Panel ..................................... 20

Figure 3-2: Required Front Door Clearance................................. 20

Figure 3-3: Rear Panel of the Model Ultra Trace 3000................. 21

Figure 3-4: Equipment Interface Connector Pin Arrangement ...... 23

Figure 3-5: Remote Probe Connections........................................ 28

Figure 3-6: FET Series Resistance ............................................... 29

Figure 3.7: Adding Electrolyte to the BDS Sensor......................... 29

Figure 4-2: Analyzer Power-up Sequence .................................... 62

Figure 4-3: Analyzer Span Sequence ........................................... 63

Figure 4-4: Analyzer Zero Sequence ............................................ 64

Teledyne Analytical Instruments x

Page 11

Oxygen Analyzer

Figure 5.1 Adding water into the BDS sensor................................ 66

Figure 5-2: Removing Fuse Block from Housing ........................... 67

Figure 5-3: Installing Fuses ........................................................... 67

Figure 5-4: Rear Panel Screws .....................................................69

Figure 5-5: Vacuum Degassing for the BDS Oxygen Sensor........ 71

Figure A-1: Single 19" Rack Mount (dimensions in mm) ............... 76

Teledyne Analytical Instruments xi

Page 12

BDS 3000

List of Tables

Table 3-1: Analog Output Connections ......................................... 24

Table 3-2: Alarm Relay Contact Pins ............................................ 25

Table 3-3: Remote Calibration Connections ................................. 26

Table 3-4: Range ID Relay Connections....................................... 27

Table 4-1: Characters Available for Password Definition: ............ 42

Table 4-2: Linear Output for a 0-100 ppm O2 Range................... 59

Table 4-3: Range ID Output .......................................................... 61

Table 5-1: Self-Test Failure Codes ............................................... 68

Teledyne Analytical Instruments xii

Page 13

Oxygen Analyzer

DANGER

COMBUSTIBLE GAS USAGE

WARNING

This is a general purpose instrument designed for usage in a

nonhazardous area. It is the customer's responsibility to

ensure safety especially when combustible gases are being

analyzed since the potential of gas leaks always exist.

The customer should ensure that the principles of operating

of this equipment is well understood by the user. Misuse of

this product in any manner, tampering with its components,

or unauthorized substitution of any component may

adversely affect the safety of this instrument.

Since the use of this instrument is beyond the control of

Teledyne, no responsibility by Teledyne, its affiliates, and

agents for damage or injury from misuse or neglect of this

equipment is implied or assumed.

Teledyne Analytical Instruments xiii

Page 14

Page 15

Oxygen Analyzer Introduction

Introduction

1.1 Overview

The Teledyne Analytical Instruments Model BDS 3000 Trace

Oxygen Analyzer is a versatile microprocessor-based instrument for

detecting oxygen at the parts-per-billion (ppb) level in a variety of gases.

This manual covers the Model BDS 3000 General Purpose flush-panel

and/or rack-mount units only. These units are for indoor use in a nonhazardous environment.

1.2 Typical Applications

A few typical applications of the Model BDS 3000 are:

• Monitoring inert gas blanketing

• Air separation and liquefaction

• Chemical reaction monitoring

• Semiconductor manufacturing

• Petrochemical process control

• Quality assurance

• Gas analysis certification.

1.3 Main Features of the Analyzer

The Model BDS 3000 Oxygen Analyzer is sophisticated yet simple

to use. The main features of the analyzer include:

• A 2-line alphanumeric vacuum fluorescent display (VFD)

screen, driven by microprocessor electronics. The screen

continuously prompts and informs the operator.

• High resolution, accurate readings of oxygen content from

low ppb levels through 100 ppm. Large, bright, meter

readout.

• New BDS Sensing technology, Patent pending.

Teledyne Analytical Instruments 1

Page 16

Introduction BDS 3000

• Versatile analysis over a wide range of applications.

• Microprocessor based electronics: 8-bit CMOS

microprocessor with 32 kB RAM and 128 kB ROM.

• Three user definable output ranges (from 0-100 ppb through

0-100 ppm) allow best match to users process and

equipment, plus a fixed 100 ppm over range.

• Auto Ranging allows analyzer to automatically select the

proper preset range for a given measurement. Manual

override allows the user to lock onto a specific range of

interest.

• Two adjustable concentration alarms and a system failure

alarm.

• Extensive self-diagnostic testing, at startup and on demand,

with continuous power-supply monitoring.

• Two way RFI protection.

• RS-232 serial digital port for use with a computer or other

digital communication device.

• Four analog outputs: two for measurement (0–1 VDC and

Isolated 4–20 mA DC) and two for range identification.

• Convenient and versatile, steel, flush-panel or rack-

mountable case with slide-out electronics drawer.

1.4 Front Panel (Operator Interface)

The standard BDS 3000 is housed in a rugged metal case with all

controls and displays accessible from the front panel. See Figure 1-1.

The front panel has thirteen buttons for operating the analyzer, a digital

meter, an alphanumeric display, and a window for viewing the sample

flowmeter.

Function Keys: Six touch-sensitive membrane switches are used to

change the specific function performed by the analyzer:

• Analyze Perform analysis for oxygen

content of a sample gas.

Teledyne Analytical Instruments 2

Page 17

Oxygen Analyzer Introduction

Figure 1-1: BDS-3000 Front Panel

• System Perform system-related tasks

(described in detail in chapter 4,

Operation.).

• Span Span calibrate the analyzer.

• Zero Zero calibrate the analyzer.

• Alarms Set the alarm setpoints and

attributes.

• Range Set up the 3 user definable ranges

for the instrument.

Data Entry Keys: Six touch-sensitive membrane switches are used to

input data to the instrument via the alphanumeric VFD display:

• Left & Right Arrows

Select between functions currently

displayed on the VFD screen.

Teledyne Analytical Instruments 3

Page 18

Introduction BDS 3000

• Up & Down Arrows

Increment or decrement values of

functions currently displayed.

• Enter Moves VFD display on to the next

screen in a series. If none remains,

returns to the

Analyze

screen.

• Escape Moves VFD display back to the

previous screen in a series. If none

remains, returns to the

Analyze

screen.

Digital Meter Display: The meter display is a Light Emitting Diode

(LED) device that produces large, bright, 7-segment numbers that are

legible in any lighting. It produces a continuous readout from 0-999.9

ppb and then switches to a continuous ppm readout from 0-100.00 ppm.

It is accurate across all analysis ranges without the discontinuity inherent

in analog range switching.

Alphanumeric Interface Screen: The VFD screen is an easy-to-use

interface from operator to analyzer. It displays values, options, and

messages that give the operator immediate feedback.

Flowmeter: Monitors the flow of gas past the sensor. Readout is 0.1 to

2.0 standard liters per minute (SLPM) of nitrogen

Standby Button: The Standby turns off the display and outputs, but

circuitry is still operating.

CAUTION: THE POWER CABLE MUST BE UNPLUGGED TO

FULLY DISCONNECT POWER FROM THE

INSTRUMENT. WHEN CHASSIS IS EXPOSED OR

WHEN ACCESS DOOR IS OPEN AND POWER

CABLE IS CONNECTED, USE EXTRA CARE TO

AVOID CONTACT WITH LIVE ELECTRICAL

CIRCUITS.

Access Door: For access t o the BDS S ensor , the front panel swi ngs open

when the l at ch in t he upper r ight corner of t he panel i s pressed al l the way

i n wi th a nar row gauge t ool . Accessi ng the mai n cir cuit boar d requir es

unf astening rear panel screws and sl i di ng t he uni t out of the case.

Teledyne Analytical Instruments 4

Page 19

Oxygen Analyzer Introduction

1.5 Rear Panel (Equipment Interface)

The rear panel, shown in Figure 1-2, contains the gas and electrical

connectors for external inlets and outlets. Some of those depicted are

optional and may not appear on your instrument. The connectors are

described briefly here and in detail in Chapter 3 Installation.

Figure 1-2: Model BDS 3000 Rear Panel

• Power Connection Universal AC power source.

• Gas Inlet and Outlet One inlet and one exhaust out.

• Analog Outputs 0–1 VDC oxygen concentration

plus 0-1 VDC range ID, and

isolated 4–20 mA DC oxygen

concentration plus 4-20 mA DC

range ID.

Teledyne Analytical Instruments 5

Page 20

Introduction BDS 3000

• Alarm Connections 2 concentration alarms and 1

system alarm.

• RS-232 Port Serial digital concentration signal

output and control input.

• Remote Probe Used in the BDS 3000 for

controlling external solenoid

valves only.

• Remote Span/Zero Digital inputs allow external

control of analyzer calibration.

• Calibration Contact To notify external equipment that

instrument is being calibrated and

readings are not monitoring

sample.

• Range ID Contacts Four separate, dedicated, range

relay contacts. Low, Medium,

High, Cal.

• Network I/O Serial digital communications for

local network access. For future

expansion. Not implemented at this

printing.

Note: If you require highly accurate Auto-Cal timing, use external

Auto-Cal control where possible. The internal clock in the

Model BDS 3000 is accurate to 2-3 %. Accordingly,

internally scheduled calibrations can vary 2-3 % per day.

Teledyne Analytical Instruments 6

Page 21

Oxygen Analyzer Operational Theory

Operational Theory

2.1 Introduction

The analyzer is composed of three subsystems:

• BDS Sensor

• Sample System

• Electronic Signal Processing, Display and Control

The sample system is designed to accept the sample gas and

transport it through the analyzer without contaminating or altering the

sample prior to analysis. The BDS Sensor is an electrochemical device

that translates the amount of oxygen present in the sample into an

electrical current. The electronic signal processing, display and control

subsystem simplifies operation of the analyzer and accurately processes

the sampled data. The microprocessor controls all signal processing,

input/output and display functions for the analyzer.

2.2 BDS Sensor

2.2.1 Principles of Operation

The BDS oxygen sensor technology developed at Teledyne

Analytical Instruments is a result of TAI’s heavy investment on R&D

and expertise established during the half-century’s manufacturing of

electrochemical oxygen sensor. It stands for Bipotentiostat Driven

Sensor. A BDS oxygen sensor accurately translates the oxygen level in

the sample gas into to an electrical current signal.

A potentiostat contains three electrodes: a working electrode, a

reference electrode and a counter electrode. A Bipotentiostat is a

combination of two potentiostats that share the reference electrode and

the counter electrode. The potential at the working electrode is precisely

controlled with respect to the

is used to carry the current that flow through the sensor. A potentiostat is

typically constructed with several operational amplifiers. The three

electrodes in an electrochemical cell and the operational amplifiers in

Teledyne Analytical Instruments 7

reference electrode. The counter electrode

Page 22

Operational Theory BDS 3000

the potentiostat constitute a feedback-control loop. The potentiostat

technology has been well accepted in the field of electrochemistry, and

proven effective in eliminating polarization of the reference electrode

and automatic compensating electric resistance in the cell.

In a BDS oxygen sensor, the sensing electrode is a working

electrode that is under precise potential control as discussed above. A

stable sensing electrode potential is very critical for an oxygen sensor to

achieve high stability, low noise and large dynamic range. The reference

electrode in a BDS sensor is a Ag/Ag

O electrode which is well known

2

for its stable electrode potential and compatibility with the KOH

electrolyte in an oxygen sensor. The counter electrode is made of a

Platinum wire.

The sensing process involves electrochemical reactions inside the

sensor. At the sensing electrode, oxygen is reduced at the controlled

potential:

+ 2H2O + 4e

O

2

-

— > 4OH

-

(1)

There is no net electrochemical reaction at the reference electrode

since it is connected to the high impedance input of the operation

amplifier.

The electrochemical reaction at the counter electrode is:

4OH- — > O2 + 2H2 O + 4e

-

It is noteworthy that reaction (2) is reverse of the reaction (1). It is

indicative of a net change of zero inside a BDS sensor throughout the

sensing process. This feature produces a long-term stability for the BDS

sensor.

There are two resources of oxygen being reduced at the sensing

electrode: from the sample gas and dissolved oxygen within the

electrolyte. The oxygen molecules in the sample gas diffuse to the

sensing electrode through a diffusion barrier (controlled diffusion) to

produce a current signal which is proportional to the oxygen level in the

sample gas. However, the dissolved oxygen in the electrolyte also

diffuses through the electrolyte. It is reduced at the sensing electrode and

produces a background current. This background current represents the

detection limit of an oxygen sensor.

The main advantage of the BDS technology lies in the unique

second potentiostat. It is designed to remove dissolved oxygen and other

( 2)

Teledyne Analytical Instruments 8

Page 23

Oxygen Analyzer Operational Theory

impurities in the electrolyte. It eliminates the internal background

current which previously limited the detection process.

The second potentiostat is located adjacent to the sensing electrode.

It uses a novel material, Reticulated Vitreous Carbon (RVC) and precise

control of the potential to remove the dissolved oxygen and impurities in

the electrolyte efficiently. As the result, the BDS sensor achieves an

outstanding feature of absolute zero output in the absence of oxygen.

Figure 2.1: Cross Section of the BDS Oxygen Sensor

Figure 2.1 shows the schematic of a BDS oxygen sensor. The

sample gas enters the sensor through the gas inlet port and exits at the

gas outlet. A portion of oxygen in the sample gas diffuses through the

diffusion barrier to be reduced at the sensing electrode to form OH- in

the electrolyte. OH- can move freely through the porous 2nd working

electrode. At the Counter Electrode, OH- is oxidized back to oxygen.

While the 2nd working electrode allows OH- to move through, it

prevents the dissolved oxygen from the top portion of the sensor to reach

Teledyne Analytical Instruments 9

Page 24

Operational Theory BDS 3000

the sensing electrode. The reference electrode provides a potential

reference for both the sensing electrode and the 2nd working electrode.

NOTE: BDS technology and sensor is a patent pending

technology of Teledyne Analytical Instruments in the

United State of America as well as many foreign countries.

To learn more about BDS technology, please visit TAI’s web page at

http://www.Teledyne-AI.com

To learn more about potentiostat, visit Electochemical Society’s web

page at http://www.electrochem.org

2.2.2 Gas Flow Rate

The output from a BDS oxygen sensor is relatively insensitive to

change of gas flow rate if operated in the range of 1 - 3 SCFH (in

nitrogen). The output drops when the flow rate is below 1 SCFH. Figure

2.2 is a typical curve showing the sensor outputs at different flow rate.

Figure 2.2: BDS sensor output at different gas flow rate

Teledyne Analytical Instruments 10

Page 25

Oxygen Analyzer Operational Theory

2.2.3 Gas Pressure

The analyzer is equipped with a flow restriction tube (from the

back panel of the analyzer to the left side of the BDS sensor) as shown

in Figure 2-3. The sensor is not affected by pressure as long as the

analyzer vents to atmosphere. If the analyzer is not vented to

atmosphere, the downstream pressure must not exceed 10 inch of water.

A clogged or restricted vent or excessive pressure will force gas into the

electrolyte and cause damage to the BDS sensor.

Figure 2-3: BDS Sample System

2.2.4 Temperature effect

The raw output from a BDS oxygen sensor has a temperature

coefficient about 0.25% / °C. This temperature effect is compensated by

the software throughout the operation temperature range (5 – 40°C).

2.2.5 Recovery from High Level Oxygen Exposure

The ambient air contains about 210,000,000 ppb (2.1 x 108)

oxygen. Figure 2.4 is a typical purge-down curve for a new BDS sensor

which had been air saturated. It is normal to take several hours, even

days for an air saturated BDS to purge down to a low ppb level.

Teledyne Analytical Instruments 11

Page 26

Operational Theory BDS 3000

Figure 2.4 Typical Purge-down Curve After Air Saturation

S h or t e n i ng t h e ai r exp o s u r e wi l l al l o w a f a s t e r se ns o r r ec o v e r y.

A ty p i c a l BD S se n s o r wi l l re c o v e r t o 1 pp m i n ap p r ox i m a t el y 25

m i nu t e s , t o 10 0 pp b af t e r 80 m i n , an d 10 pp b i n ab ou t 8 ho u r s , af t e r

s u f f e r i n g a t e n m i n u t e ex p os u r e to ai r .

2.2.6 Background gas compatibility

T he BDS oxygen sensor wi l l work in i ner t gas backgr ounds,

i ncludi ng ni t rogen, hydr ogen, ar gon, heli um and ethane. The sensor

out put, however, i s dif fer ent in di ff erent backgr ound gases. For exam pl e,

t he sensor output i n a hydr ogen background is twi ce as much as it woul d

be in a ni tr ogen background. Therefor e, i t is recom mended to cali br ate t he

analyzer wit h an oxygen standar d that has a sim il ar background as the

sam pl e gas. If an oxygen st andar d is unavai l able for a par ti cul ar

background, a Gas F act or which is det er mi ned at TAI coul d be used t o

cor rect the sensor out put in dif f er ent backgr ound (see sect ion 4.3.9) .

Note: the gas flow meter in the analyzer is calibrated for air. The

error for measuring nitrogen is usually negligible. But for

hydrogen, it reads 100% lower. For example, when the

float ball in the flow meter is at 0.5 SLPM, the actual flow

rate of hydrogen is about 1 SLPM.

Teledyne Analytical Instruments 12

Page 27

Oxygen Analyzer Operational Theory

The BDS oxygen sensor can tolerate exposure to acidic gases. Up

to 0.2% CO

has no effect to ppb level oxygen measurement.

2

2.2.7 Stability

The BDS sensor is essentially drift free. Typically a BDS sensor

requires no re-calibration over an entire year period. However, there

may be some intrusion to the zero during the maintenance. See next

section for details.

2.2.8 Maintenance

The only maintenance required on the BDS sensor is to replenish

distilled or de-ionized water every three to four months. It is not

necessary to take the analyzer out of service while adding water to the

sensor but caution should be taken to avoid spilling water on the PC

boards or other area inside the analyzer.

Figure 2.5: Adding DI Water to the BDS Sensor

There is a Max line and Min Line clearly marked on the BDS

sensor body. It is a good practice to check the electrolyte level every

month and add de-ionized water into the sensor whenever it is

convenient.

When running dry gas through the sensor, the gas carries out

moisture from the sensor. Therefore, the electrolyte (10% KOH in

Teledyne Analytical Instruments 13

Page 28

Operational Theory BDS 3000

water) inside the sensor is gradually concentrated during the sensor

operation. It typically takes about four months for the electrolyte level to

drop from the Max line to Min line. When adding water to increase the

electrolyte level from the Min line to the Max line, it is typical that the

oxygen reading will drift down about 10 ppb in an hour. If the oxygen

content in the sample gas is very close to zero, the analyzer may display

a negative reading during this period. The sensor will recover by itself

during the following week. This drift-down then recover-back

phenomenon is caused by the quick dilution of the electrolyte and reestablishment of a new equilibrium inside the sensor. To minimize this

effect, add a small amount of water each time and do this before the

electrolyte level reaches the Min line.

2.3 Sample System

The sample system delivers gases to the BDS sensor from the

analyzer rear panel inlet. Depending on the mode of operation either

sample or calibration gas is delivered.

The Model BDS 3000 sample system is designed and fabricated to

ensure that the oxygen concentration of the gas is not altered as it travels

through the sample system.

The sampl e syst em for the standar d inst rument incor porates 1/4" VCR

fit tings for sample inl et and swagelock fittings for outl et tube connections at

the rear panel. The sample or cal ibrati on gas that flows through the system

is monitored by a flowmeter downstream from the sensor .

Figure 2-6 represents the flow diagram of the sampling system. In

the standard instrument, calibration gases can be connected directly to

the Sample In port by teeing to the port with appropriate valves.

Figure 2-6: Flow Diagram

Teledyne Analytical Instruments 14

Page 29

Oxygen Analyzer Operational Theory

2.4 Electronics and Signal Processing

T he Model BDS 3000 Oxygen Analyzer uses an 8031

m icrocontr ol l er wi th 32 kB of RAM and 128 kB of ROM to cont rol all

signal processi ng, i nput / output, and di splay functi ons f or the analyzer .

S ystem power is suppli ed fr om a universal power suppl y module desi gned

t o be compat i bl e wi t h any i nt er nat ional power source. F i gure 2- 7 shows

t he l ocati on of t he power suppl y and the mai n el ect roni c P C boards.

The signal processing electronics including the microprocessor,

analog to digital, and digital to analog converters are located on the

motherboard at the bottom of the case. The preamplifier board is

mounted on top of the motherboard as shown in the figure. These boards

are accessible after removing the back panel. Figure 2-8 is a block

diagram of the Analyzer electronics.

In the presence of oxygen the sensor generates a current. A current

to voltage amplifier converts this current to a voltage, which is further

amplified in the second stage amplifier.

The output from the second stage amplifier is sent to an 18 bit

analog to digital converter controlled by the microprocessor.

The digital concentration signal along with input from the control

panel is processed by the microprocessor, and appropriate control

signals are directed to the display, alarms and communications port. The

same digital information is also sent to a 12 bit digital to analog

converter that produces the 4-20 mA DC and the 0-1 VDC analog

concentration signal outputs, and the analog range ID outputs.

Signals from the power supply are also monitored, and through the

microprocessor, the system failure alarm is activated if a malfunction is

detected.

Teledyne Analytical Instruments 15

Page 30

Operational Theory BDS 3000

Figure 2-7: Electronic Component Location

Teledyne Analytical Instruments 16

Page 31

Oxygen Analyzer Operational Theory

Figure 2-8: BDS 3000 Electronics Block Diagram

Teledyne Analytical Instruments 17

Page 32

Operational Theory BDS 3000

Teledyne Analytical Instruments 18

Page 33

Oxygen Analyzer Installation

Installation

Installation of the Model BDS 3000 Analyzer includes:

• Unpacking

• Mounting

• Gas connections

• Electrical connections

• Filling the Sensor with Electrolyte.

• Testing the system.

3.1 Unpacking the Analyzer

Although the analyzer is shipped complete, certain parts, such as

the electrolyte, are wrapped separately to be installed on site as part of

the installation. Carefully unpack the analyzer and inspect it for damage.

Immediately report any damage or shortages to the shipping agent.

3.2 Mounting the Analyzer

The Model BDS 3000 is for indoor use in a general purpose area. It

is NOT for hazardous environments of any type.

T he standard model is designed for f l ush panel m ounti ng. F igur e 3-1

i s an i l lust r at ion of the BDS 3000 st andard fr ont panel and mount ing

bezel . There ar e four mount ing hol es—one in each corner of t he ri gi d

f rame. The dr awings sect i on i n the r ear of thi s manual contai ns out l ine

dim ensi ons and mount ing hol e spaci ng di agram s.

On special order, a 19" rack-mounting panel can be provided. For

rack mounting, one BDS 3000 series analyzer is flush-panel mounted on

the rack panel. See Appendix for dimensions of the mounting panel.

Teledyne Analytical Instruments 19

Page 34

Installation BDS 3000

Figure 3-1: Model BDS 3000 Front Panel

All operator controls are mounted on the control panel, which is

hinged on the left edge and doubles as the door that provides access to

the sensor and cell block inside the instrument. The door is spring

loaded and will swing open when the button in the center of the latch

(upper right corner) is pressed all the way in with a narrow gauge tool

(less than 0.18 inch wide), such as a small hex wrench or screwdriver

Allow clearance for the door to open in a 90-degree arc of radius 7.125

inches. See Figure 3-2.

Figure 3-2: Required Front Door Clearance

Teledyne Analytical Instruments 20

Page 35

Oxygen Analyzer Installation

3.3 Rear Panel Connections

Figure 3-3 shows the Model BDS 3000 rear panel. There are ports

for gas inlet and outlet, power, communication, and both digital and

analog concentration output.

Figure 3-3: Rear Panel of the Model Ultra Trace 3000

3.3.1 Gas Connections

The unit is manufactured with 1/4 inch VCR fittings. For a safe

connection:

SAMPLE IN: In the standard model, gas connections are made at the

SAMPLE IN and EXHAUST OUT connections. Calibration gases must be

tee'd into the sample inlet with appropriate valves. A VCR fitting is

provided for the inlet connection.

Teledyne Analytical Instruments 21

Page 36

Installation BDS 3000

The inlet gas pressure should be regulated to pressures between 11

to 16 psig to maintain a flow between 0.5 to 1.0 SLPM. If pressure is too

low, the flow will drop below 0.5 SLPM at which the output of the

sensor is sensitive (see section 2.2.2). If pressure is too high, it will force

gas into the electrolyte and cause damage to the sensor. A pressure

regulator must be used if sample pressure varies farther than the

recommended range.

If greater sample flow is required for improved response time,

install a bypass in the sampling system upstream of the analyzer input.

EXHAUST OUT: Exhaust connections must be consistent with the

hazard level of the constituent gases. Check Local, State, and Federal

laws, and ensure that the exhaust stream vents to an appropriately

controlled area, if required

3.3.2 Electrical Connections

For safe connections, no uninsulated wiring should be able to come

in contact with fingers, tools or clothing during normal operation.

CAUTION: USE SHIELDED CABLES. ALSO, USE PLUGS THAT

PROVIDE EXCELLENT EMI/RFI PROTECTION. THE

PLUG CASE MUST BE CONNECTED TO THE CABLE

SHIELD, AND IT MUST BE TIGHTLY FASTENED TO

THE ANALYZER WITH ITS FASTENING SCREWS.

ULTIMATELY, IT IS THE INSTALLER WHO ENSURES

THAT THE CONNECTIONS PROVIDE ADEQUATE

EMI/RFI SIELDING.

3.3.2.1 PRIMARY INPUT POWER

The power cord receptacle and fuse block are located in the same

assembly. Insert the power cord into the power cord receptacle.

CAUTION: POWER IS APPLIED TO THE INSTRUMENT'S

CIRCUITRY AS LONG AS THE INSTRUMENT IS

CONNECTED TO THE POWER SOURCE. THE RED

SWITCH ON THE FRONT PANEL IS FOR SWITCHING

POWER ON OR OFF TO THE DISPLAYS AND

OUTPUTS ONLY.

The universal power supply requires 85–250 VAC, 47-63 Hz power

source.

Teledyne Analytical Instruments 22

Page 37

Oxygen Analyzer Installation

Fuse Installation: The fuse block, at the right of the power cord

receptacle, accepts US or European size fuses. A jumper replaces the

fuse in whichever fuse receptacle is not used. Fuses are not installed at

the factory. Be sure to install the proper fuse as part of installation. (See

Fuse Replacement in chapter 5, maintenance.)

3.3.2.2 50-PIN EQUIPMENT INTERFACE CONNECTOR

Figure 3-4 shows the pin layout of the Equipment Interface

connector. The arrangement is shown as seen when the viewer faces the

rear panel of the analyzer. The pin numbers for each input/output

function are given where each function is described in the paragraphs

below.

Figure 3-4: Equipment Interface Connector Pin Arrangement

Analog Outputs: There are four DC output signal pins—two pins per

output. For polarity, see Table 3-1. The outputs are:

0–1 VDC % of Range: Voltage rises linearly with increasing

oxygen, from 0 V at 0 ppm to 1 V at

full scale ppm. (Full scale = 100% of

programmable range.)

0–1 VDC Range ID: 0.25 V = Low Range, 0.5 V = Medium

Range, 0.75 V = High Range, 1 V =

100ppm.

4–20 mA DC % Range: Current increases linearly with

increasing oxygen, from 4 mA at 0

ppm to 20 mA at full scale ppm. (Full

scale = 100% of programmable range.)

4–20 mA dc Range ID: 8 mA = Low Range, 12 mA = Medium

Range, 16 mA = High Range, 20 mA

= 100ppm.

Teledyne Analytical Instruments 23

Page 38

Installation BDS 3000

Table 3-1: Analog Output Connections

Pin Function

3+ Range ID, 4-20 mA, floating

4– Range ID, 4-20 mA, floating

5+ % Range, 4-20 mA, floating

6– % Range, 4-20 mA, floating

8+ Range ID, 0-1 V dc

23 – Range ID, 0-1 V dc, negative ground

24 + % Range, 0-1 V dc

7– % Range, 0-1 V dc, negative ground

Alarm Relays: The nine alarm-circuit connector pins connect to the

internal alarm relay contacts. Each set of three pins provides one set of

Form C relay contacts. Each relay has both normally open and normally

closed contact connections. The contact connections are shown in Table

3-2. They are capable of switching up to 3 amperes at 250 VAC into a

resistive load. The connectors are:

Threshold Alarm 1:

• Can be configured as high (actuates when concentration

is above threshold), or low (actuates when concentration

is below threshold).

• Can be configured as failsafe or nonfailsafe.

• Can be configured as latching or nonlatching.

• Can be configured out (defeated).

Threshold Alarm 2:

• Can be configured as high (actuates when concentration

is above threshold), or low (actuates when concentration

is below threshold).

• Can be configured as failsafe or nonfailsafe.

• Can be configured as latching or nonlatching.

• Can be configured out (defeated).

Teledyne Analytical Instruments 24

Page 39

Oxygen Analyzer Installation

System Alarm:

Actuates when DC power supplied to circuits is

unacceptable in one or more parameters. Permanently

configured as failsafe and latching. Cannot be defeated.

Actuates if self-test fails.

(Reset by pressing button to remove power. Then

press again and any other button EXCEPT System to

resume.

Further detail can be found in Chapter 4, Section 4-5.

Table 3-2: Alarm Relay Contact Pins

Pin Contact

45 Threshold Alarm 1, normally closed contact

28 Threshold Alarm 1, moving contact

46 Threshold Alarm 1, normally open contact

42 Threshold Alarm 2, normally closed contact

44 Threshold Alarm 2, moving contact

43 Threshold Alarm 2, normally open contact

36 System Alarm, normally closed contact

20 System Alarm, moving contact

37 System Alarm, normally open contact

Digital Remote Cal Inputs: Accept 0 V (off) or 24 V dc (on) inputs for

remote control of calibration. (See Remote Calibration Protocol below.)

See Table 3-3 for pin connections.

Zero:

Floating input. 5 to 24 V i nput across the + and – pins puts

the analyzer into the Zero mode. Either side may be

grounded at the source of t he signal. 0 to 1 volt across the

ter minals allows Zero mode to ter minate when done. A

synchronous signal must open and close the external zero

val ve appropriately. See Remote P robe Connect or. (T he –C

opt ion internal valves oper ate automati cally) .

Teledyne Analytical Instruments 25

Page 40

Installation BDS 3000

Span:

Floating input. 5 to 24 V input across the + and – pins

puts the analyzer into the Span mode. Either side may be

grounded at the source of the signal. 0 to 1 volt across the

terminals allows Span mode to terminate when done. A

synchronous signal must open and close external span

valve appropriately. See Figure 3-5 Remote Probe

Connector. (The –C option internal valves operate

automatically.)

Cal Contact:

This relay contact is closed while analyzer is spanning

and/or zeroing. (See Remote Calibration Protocol below.)

Table 3-3: Remote Calibration Connections

Pin Function

9+ Remote Zero

11 – Remote Zero

10 + Remote Span

12 – Remote Span

40 Cal Contact

41 Cal Contact

Remote Calibration Protocol: To properly time the Digital Remote Cal

Inputs to the Model BDS 3000 Analyzer, the customer's controller must

monitor the Cal Relay Contact.

When the contact is OPEN, the analyzer is analyzing, the Remote

Cal Inputs are being polled, and a zero or span command can be sent.

When the contact is CLOSED, the analyzer is already calibrating. It

will ignore your request to calibrate, and it will not remember that

request.

Once a zero or span command is sent, and acknowledged (contact

closes), release it. If the command is continued until after the zero or

span is complete, the calibration will repeat and the Cal Relay Contact

(CRC) will close again.

Teledyne Analytical Instruments 26

Page 41

Oxygen Analyzer Installation

For example:

1) Test the CRC. When the CRC is open, Send a zero command

until the CRC closes (The CRC will quickly close.)

2) When the CRC closes, remove the zero command.

3) When CRC opens again, send a span command until the

CRC closes. (The CRC will quickly close.)

4) When the CRC closes, remove the span command.

When CRC opens again, zero and span are done, and the sample is

being analyzed.

Note: The Remote Valve connections (described below) provides

signals to ensure that the zero and span gas valves will be

controlled synchronously.

Range ID Relays: Four dedicated Range ID relay contacts. The first

three ranges are assigned to relays in ascending order—Low range is

assigned to Range 1 ID, Medium range is assigned to Range 2 ID, and

High range is assigned to Range 3 ID. The fourth range is reserved for

the Air Cal Range (25%). Table 3-4 lists the pin connections.

Table 3-4: Range ID Relay Connections

Pin Function

21 Range 1 ID Contact

38 Range 1 ID Contact

22 Range 2 ID Contact

39 Range 2 ID Contact

19 Range 3 ID Contact

18 Range 3 ID Contact

34 Range 4 ID Contact (Air Cal)

35 Range 4 ID Contact (Air Cal)

Network I/O: A serial digital input/output for local network protocol.

At this printing, this port is not yet functional. It is to be used for future

options to the instrument. Pins 13 (+) and 29 (–).

Teledyne Analytical Instruments 27

Page 42

Installation BDS 3000

Remote Valve Connections: The Ultra Trace 3000 is a single-chassis

instrument, which has no Remote Valve Unit. Instead, the Remote Valve

connections are used as a method for directly controlling external

sample/zero/span gas valves. See Figure 3-5.

Figure 3-5: Remote Probe Connections

The voltage from these outputs is nominally 0 V for the OFF and

15 V dc for the ON conditions. The maximum combined current that can

be pulled from these output lines is 100 mA. (If two lines are ON at the

same time, each must be limited to 50 mA, etc.) If more current and/or a

different voltage is required, use a relay, power amplifier, or other

matching circuitry to provide the actual driving current.

In addition, each individual line has a series FET with a nominal

ON resistance of 5 ohms (9 ohms worst case). This can limit the

obtainable voltage, depending on the load impedance applied. See

Figure 3-6.

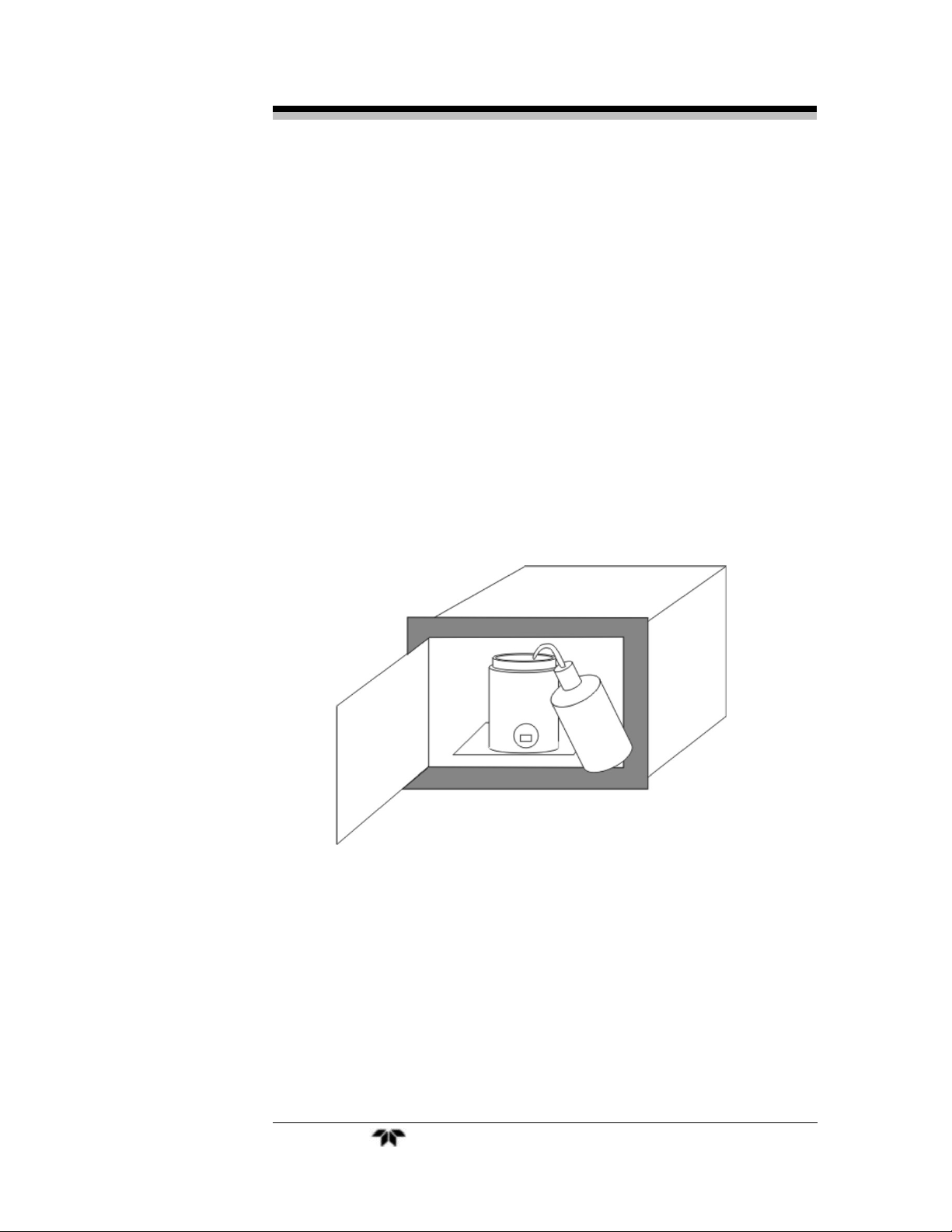

3.4 Electrolyte Refill of BDS Sensor

The BDS sensor was shipped dry. It must be filled with the

electrolyte before operation. The electrolyte is a caustic solution (10%

KOH), supplied in five 50 ml bottles. Review the Material Safety Data

Sheet (MSDS) in Section A-6 before handling the electrolyte.

Teledyne Analytical Instruments 28

Page 43

Oxygen Analyzer Installation

Figure 3-6: FET Series Resistance

To refill the BDS sensor:

1. Open the front door and swing it open.

2. Unscrew the sensor cap and disconnect sensor cable from the

BDS sensor.

3. Pour the electrolyte from the five small bottles into a larger

container.

4. Sparge the electrolyte with nitrogen gas at a flow of 100 CCM

for about 1/2 hour then pour into the provided wash bottle.

5. Ref. to Figure 3.7 for the method of adding electrolyte to the

sensor. It is important that as the sensor is being filled with the

electrolyte, filling is accomplished without trapping gas bubbles

in the lower part of the sensor.

Figure 3.7: Adding Electrolyte to the BDS Sensor

Teledyne Analytical Instruments 29

Page 44

Installation BDS 3000

Squirt electrolyte content into the sensor. Do it slowly until the

bottom parts of the sensor are fully immersed in the electrolyte.

4. Pour the rest of the electrolyte into the sensor. Gas bubbles in the

top portion of the sensor would not affect the sensor

performance. One bottle of electrolyte is sufficient to rise the

electrolyte level to the MAX line. For the rest of sensor life, no

further electrolyte addition is needed.

5. Install the sensor cap,

6. Do not connect the sensor's electric connector at this stage.

3.5 Testing the System

Before plugging the instrument into the power source:

• Check the integrity and accuracy of the gas connections.

Make sure there are no leaks.

• Check the integrity and accuracy of the electrical

connections. Make sure there are no exposed conductors

• Purge the system for 3 minutes. Make sure the gas flow rate

is within 0.5-1 SLPM.

Power up the system, and conduct the Self-Diagnostic Test as

described in Chapter 4, Section 4.3.5. It takes two minutes for the

microprocessor to test various sections of the analyzer.

3.6 Sensor Protection Mode

The BDS sensor is a very sensitive device for measuring ultra trace

levels of oxygen. When the oxygen level in the gas exceeds 100 ppm (in

nitrogen background) for one minute, the analyzer will enter a selfprotection mode and show temporary shut down on the display. It

indicates a high level oxygen intrusion into the system. Check the gas

line and other related parts, and fix them if there is any leaks found.

The analyzer will try to reconnect with the sensor in one minute. If

it is still over range for one minute, the analyzer will enter a temporary

shut down mode again for three minutes. The analyzer will try the third

time to reconnect the sensor, and will enter a System Shut Down mode

to protect the sensor if it is still over range.

Pressing the ESCAPE key will return the analyzer to operation.

Teledyne Analytical Instruments 30

Page 45

Oxygen Analyzer Installation

For operations frequently encountering oxygen levels above 100

ppm, TAI’s Micro-Fuel-Cell type of oxygen sensor is recommended.

The maximum working range with a background of nitrogen gas is

100 ppm. The maximum working range is different for other gas

backgrounds. See Section 4.3.9.

Teledyne Analytical Instruments 31

Page 46

Installation BDS 3000

Teledyne Analytical Instruments 32

Page 47

Oxygen Analyzer Operation

Operation

4.1 Introduction

Once the analyzer has been installed, it can be configured for your

application. To do this you will:

• Set system parameters:

• Establish a security password, if desired, which will require

the operator to log in.

• Establish and start an automatic calibration cycle, if desired.

• Calibrate the instrument.

• Define the three user-selectable analysis ranges, then choose

autoranging or select a fixed range of analysis, as required.

• Set alarm setpoints, and modes of alarm operation (latching,

failsafe, etc).

Before you configure your BDS 3000, these default values are in

effect:

Ranges: LO = 100ppb ppm, MED = 1000

ppb, HI = 10 ppm.

Auto Ranging: ON

Alarm Relays: Defeated, Alarm 1 at10.000 ppm,

Alarm 2 at 1.000 ppm HI, Not

failsafe, Not latching.

Zero: Auto, every 0 days at 0 hours.

Span: Auto, at 008.00 ppm, every 0 days

at 0 hours.

If you choose not to use password protection, the default password

is automatically displayed on the password screen when you start up,

and you simply press ENTER for access to all functions of the analyzer.

Teledyne Analytical Instruments 33

Page 48

Operation BDS 3000

4.2 Using Data Entry and Function Buttons

Data Entry Buttons: The __ arrow buttons select options from the

menu currently being displayed on the VFD screen. The selected option

blinks.

When the selected option includes a modifiable item, the __ arrow

buttons can be used to increment or decrement that modifiable item.

The ENTER button is used to accept any new entries on the VFD

screen. The ESCAPE button is used to abort any new entries on the VFD

screen that are not yet accepted by use of the ENTER button.

Figure 4-1 shows the hierarchy of functions available to the

operator via the function buttons. The six function buttons on the

analyzer are:

• Analyze. This is the normal operating mode. The analyzer

monitors the oxygen content of the sample, displays the

percent of oxygen, and warns of any alarm conditions.

• System. The system function consists of several subfunctions

that regulate the internal operations of the analyzer:

• Auto-Cal setup

• Password assignment

• Self -Test initiation

• Checking software version

• Logging out

• Show negative readings

• Set digital filter

• Zero. Used to set up a zero calibration.

• Span. Used to set up a span calibration.

• Alarms. Used to set the alarm setpoints and determine

whether each alarm will be active or defeated, HI or LO

acting, latching, and/or failsafe.

• Range. Used to set up three analysis ranges that can be

switched automatically with auto-ranging or used as

individual fixed ranges.

Teledyne Analytical Instruments 34

Page 49

Oxygen Analyzer Operation

Figure 4-1: Hierarchy of Functions and Subfunctions

Teledyne Analytical Instruments 35

Page 50

Operation BDS 3000

Any function can be selected at any time by pressing the

appropriate button (unless password restrictions apply). The order as

presented in this manual is appropriate for an initial setup.

Each of these functions is described in greater detail in the

following procedures. The VFD screen text that accompanies each

operation is reproduced, at the appropriate point in the procedure, using

ARIAL NARROW bolded type style. Pushbutton names are printed in

Oblique type.

4.3 The System Function

The subfuctions of the System function are described below.

Specific procedures for their use follow the descriptions:

• Auto-Cal: Used to define an automatic calibration sequence

and/or start an Auto-Cal.

• PSWD: Security can be established by choosing a 5 digit

password (PSWD) from the standard ASCII character set. (See

Installing or Changing the Password, below, for a table of ASCII

characters available.) Once a unique password is assigned and

activated, the operator MUST enter the UNIQUE password to

gain access to set-up functions which alter the instrument's

operation, such as setting the instrument span or zero setting,

adjusting the alarm setpoints, or defining analysis ranges.

After a password is assigned, the operator must log out to

activate it. Until then, anyone can continue to operate the

instrument without entering the new password.

Only one password can be defined. Before a unique password

is assigned, the system assigns TETAI by default. This allows

access to anyone. After a unique password is assigned, to defeat

the security, the password must be changed back to TETAI.

• Logout: Logging out prevents unauthorized tampering with

analyzer settings.

• More: Select and enter More to get a new screen with

additional subfunctions listed.

• Self–Test: The instrument performs a self-diagnostic test to

check the integrity of the power supply, output boards and

amplifiers.

Teledyne Analytical Instruments 36

Page 51

Oxygen Analyzer Operation

• Version: Displays Manufacturer, Model, and Software

Version of instrument.

• Xout: This function provides the capability for the analog

output to track negative readings, by introducing an offset on

the zero baseline.

• Neg: The operator selects whether display can show

negative oxygen readings or not.

• TRAK/HLD: The oper ator sets whether the instrument analog

out puts t rack t he concentration change during calibration and

set s a ti me del ay for the concentration alar ms aft er cal ibrati on.

• Filter: This is to set the response time of the digital filter in

the LO range.

• GasBkgn: Set the gas correction factor. This function adjusts

the calibration of the sensor when the background gas is changed.

• Trbsht: Displays useful information for troubleshooting

purposes.

• TempComp: Compensates the zero baseline temperature

drift by setting the temperature coefficient of the sensor in

ppb/degrees C.

• Temperature: Displays sensor temperature.

4.3.1 Tracking Oxygen Readings During

Calibration and Alarm Delay

The user has the option of setting the preference as to whether the

analog outputs track the display readings during calibration or not. To

set the preference, press the System key once and the first System menu

will appear in the VFD display:

TRAK/HLD Auto-Cal

PSWD Logout More

TRAK/HLD

the ENTER key once:

should be blinking. To enter this system menu press

Output Sttng: TRACK

Alarm Dly: 10 min

Teledyne Analytical Instruments 37

Page 52

Operation BDS 3000

Or

Output Sttng: HOLD

Alarm Dly: 10 min

In the first line, TRACK or HOLD should be blinking. The operator

can toggle between

When

TRACK is selected, the analog outputs (0-1 VDC and 4-20 mA)

TRACK and HOLD with the Up or Down keys.

and the range ID contacts will track the instrument readings during

calibration (either zero or span). TRACK is the factory default.

When HOLD is selected, the analog outputs (0-1 VDC and 4-20

mA) and the range ID contacts will freeze on their last state before

entering one of the calibration modes. When the instrument returns to

the Analyze mode, either by a successful or an aborted calibration, there

will be a three-minute delay before the analog outputs and the range ID

contacts start tracking again.

The concentration alarms freeze on their last state before entering

calibration regardless of selecting HOLD or TRACK. But, when HOLD

is selected the concentration alarms will remain frozen for the time

displayed in the second line of the

TRAK/HLD menu after the analyzer

returns to the Analyze mode.

The factory default is three minutes, but the delay time is

programmable. To adjust to delay time use the Left or Right arrow keys.

When the time displayed on the second line blinks, it can be adjusted by

Pressing the Up or Down keys to increase or decrease its value. The

minimum delay is 1 minute, the maximum is 30.

This preference is stored in non-volatile memory so that it is

recovered if power is removed from the instrument.

4.3.2 Setting up an Auto-Cal

When proper automatic valving is connected (see Chapter 3,

Installation), the Analyzer can cycle itself through a sequence of steps

that automatically calibrates the instrument.

Note: If you require highly accurate Auto-Cal timing, use external

Auto-Cal control where possible. The internal clock in the

Model BDS 3000 is accurate to 2-3 %. Accordingly,

internally scheduled calibrations can vary 2-3 % per day.

To setup an Auto–Cal cycle:

Teledyne Analytical Instruments 38

Page 53

Oxygen Analyzer Operation

CAUTION: FREQUENT ZERO ADJUSTMENTS OF THE CELL IS

NOT RECOMMENDED. A NEWLY INSTALLED CELL

MAY TAKE 7-10 DAYS OF OPERATION TO REACH A

STEADY ZERO (TYPICALLY LESS THAN 5 PPB). IF

REQUIRED, THE INSTRUMENT MAY BE ZEROED

AFTER THIS INITIAL STABILIZING PERIOD AND MAY

BE CHECKED AGAIN AFTER AN ADDITIONAL 7-10

DAY PERIOD. THE FREQUENCY OF ZERO

ADJUSTMENT IS AT THE DISCRETION OF THE

USER (ONCE A MONTH IS SUGGESTED).

Choose System from the Function buttons. The LCD will display

five subfunctions.

TRAK/HLD Auto—Cal

PSWD Logout More

Use < > arrows to blink Auto—Cal, and press Enter. A new screen

for Span/Zero set appears.

Span OFF Nxt: 0d 0h

Zero OFF Nxt: 0d 0h

Press < > arrows to blink Span (or Zero), then press ENTER again.

(You won’t be able to set OFF to ON if a zero interval is entered.) A

Span Every ... (or Zero Every ...) screen appears.

Span Every 0 d

Start 0 h from now

Use __ arrows to set an interval value, then use __ arrows to move

to the start-time value. Use DÑ arrows to set a start-time value.

To turn ON the Span and/or Zero cycles (to activate Auto-Cal):

Press System again, choose

Auto—Cal, and press ENTER again. When

the Span/Zero values screen appears, use the < > arrows to blink the

Span (or Zero) OFF/ON field. Use _ arrows to set the OFF/ON field to

ON. You can now turn these fields ON because there is a nonzero span

interval defined.

4.3.3 Password Protection

If a password is assigned, then setting the following system

parameters can be done only after the password is entered: span and zero

settings, alarm setpoints, analysis range definitions, switching between

autoranging and manual override, setting up an auto-cal, and assigning a

Teledyne Analytical Instruments 39

Page 54

Operation BDS 3000

new password. However, the instrument can still be used for analysis or

for initiating a self-test without entering the password.

If you have decided not to employ password security, use the

default password TETAI. This password will be displayed automatically

by the microprocessor. The operator just presses the ENTER key to be

allowed total access to the instrument’s features.

Note: If you use password security, it is advisable to keep a copy

of the password in a separate, safe location.

4.3.3.1 ENTERING THE PASSWORD

To install a new password or change a previously installed

password, you must key in and ENTER the old password first. If the

default password is in effect, pressing the ENTER button will enter the

default TETAI password for you.

Press System to enter the System mode.

TRAK/HLD Auto—Cal

PSWD Logout More

Use the __arrow keys to scroll the blinking over to PSWD, and

press ENTER to select the password function. Either the default TETAI

password or AAAAA place holders for an existing password will appear

on screen depending on whether or not a password has been previously

installed.

T E T A I

Enter PWD

or

A A A A A

Enter PWD

The screen prompts you to enter the current password. If you are

not using password protection, press ENTER to accept TETAI as the

default password. If a password has been previously installed, enter the

password using the < > arrow keys to scroll back and forth between

letters, and the __ arrow keys to change the letters to the proper

password. Press ENTER to enter the password.

If the password is accepted, the screen will indicate that the

password restrictions have been removed and you have clearance to

proceed.

Teledyne Analytical Instruments 40

Page 55

Oxygen Analyzer Operation

PSWD Restrictions

Removed

In a few seconds, you will be given the opportunity to change this

password or keep it and go on.

Change Password?

<ENT>=Yes <ESC>=No

Press ESCAPE to move on, or proceed as in Changing the

Password, below.

4.3.3.2 INSTALLING OR CHANGING THE PASSWORD

If you want to install a password, or change an existing password,

proceed as above in Entering the Password. When you are given the

opportunity to change the password:

Change Password?

<ENT>=Yes <ESC>=No

Press ENTER to change the password (either the default TETAI or

the previously assigned password), or press ESCAPE to keep the

existing password and move on.

If you chose ENTER to change the password, the password

assignment screen appears.

T E T A I

<ENT> To Proceed

or

A A A A A

<ENT> To Proceed

Enter the password using the __ arrow keys to move back and forth

between the existing password letters, and the __ arrow keys to change

the letters to the new password. The full set of 94 characters available

for password use are shown in Table 4-1 below.

When you have finished typing the new password, press Enter. A

verification screen appears. The screen will prompt you to retype your

password for verification.

A A A A A

Retype PWD To Verify

Teledyne Analytical Instruments 41

Page 56

Operation BDS 3000

Wait a moment for the entry screen. You will be given clearance to

proceed.

A A A A A

<ENT> TO Proceed

Table 4-1: Characters Available for Password Definition:

ABCDE F GHI J

KLMNOP QRS T

UVWXYZ[ ¥ ] ^

_` abcdefgh

ijklmnopqr

stuvwxyz{|

}®! "#$%&' (

)*+' -. /012

3456789: ; <

=>?@

Use the arrow keys to retype your password and press ENTER

when finished. Your password will be stored in the microprocessor and

the system will immediately switch to the Analyze screen, and you now

have access to all instrument functions.

If all alarms are defeated, the Analyze screen appears as:

0.0 ppm Anlz

Range: 0 — 100

If an alarm is tripped, the second line will change to show which

alarm it is:

0.0 ppm Anlz

AL—1

Note: If you log off the system using the logout function in the

system menu, you will now be required to re-enter the

password to gain access to Span, Zero, Alarm, and Range

functions.

Teledyne Analytical Instruments 42

Page 57

Oxygen Analyzer Operation

4.3.4 Logout

The Logout function provides a convenient means of leaving the

analyzer in a password protected mode without having to shut the

instrument off. By entering

instrument leaving the system protected against use until the password is

reentered. To log out, press the System button to enter the System

function.

Use the __ arrow keys to position the blinking over the Logout

function, and press ENTER to Log out. The screen will display the

message:

Logout, you effectively log off the

TRAK/HLD Auto—Cal

PSWD Logout More

Protected Until

Password Reentered

4.3.5 System Self-Diagnostic Test

The Model BDS 3000 has a built-in self-diagnostic testing routine.

Pre-programmed signals are sent through the power supply, output board

and sensor circuit. The return signal is analyzed, and at the end of the

test the status of each function is displayed on the screen, either as OK

or as a number between 1 and 3. (See System Self Diagnostic Test in

Chapter 5 for number code.)

The self diagnostics are run automatically by the analyzer

whenever the instrument is turned on, but the test can also be run by the

operator at will. To initiate a self diagnostic test during operation:

Press the System button to start the System function.

TRAK/HLD Auto—Cal

PSWD Logout More

Use the < > arrow keys to blink More, then press Enter.

Version Diag Xout

Neg-Y Filter-10 More

Use the __arrow keys again to move the blinking to the Self–Test

function. The screen will follow the running of the diagnostic.

RUNNING DIAGNOSTIC

Testing Preamp — 83

Teledyne Analytical Instruments 43

Page 58

Operation BDS 3000

During preamp testing there is a countdown in the lower right

corner of the screen. When the testing is complete, the results are

displayed.

Power: OK Analog: OK

Preamp: 3

The module is functioning properly if it is followed by OK. A

number indicates a problem in a specific area of the instrument. Refer to

Chapter 5 Maintenance and Troubleshooting for number code

information. The results screen alternates for a time with:

Press Any Key

To Continue . . .

Then the analyzer returns to the initial System screen.

4.3.6 Version Screen

Move the __arrow key to More and press Enter. With Version

blinking, press Enter. The screen displays the manufacturer, model, and

software version information.

4.3.7 Filter Function

The response time on the most sensitive range (ppb range) is user

definable from approximately 1-60 minutes. The adjustable filter allows

the user to tune the response of the analyzer to best balance sensor noise

and response time requirements. The factory default setting is 5 minutes.

The actual response time will depend on the user’s sample system (the

length and size the tubing of tubing as well as the sample flow rate).

The filter setting can be accessed by selecting SYSTEM on the

keypad followed by MORE on the display with the __keys. The filter

function is then selected and changed using the arrow keys. Press

ENTER and ANALYZE to return to analyze mode.

In the event of an over-range condition, the filter rate will

automatically switch to a faster setting (approximately 45 sec. response

time) for the duration of the over-range or upset condition. This feature

allows the analyzer to quickly respond to and track an upset condition.

Teledyne Analytical Instruments 44

Page 59

Oxygen Analyzer Operation

4.3.8 Negative Value Display

The operator is able to set the display not to show negative

readings. To access this option, Press the SYSTEM key and access the

second screen of the System menu:

Version Diag Xout

Neg-N Filter-5 More

By using the Left or Right keys, the Neg- field can be accessed.

Once that field is selected, use the Up or Down keys to toggle from

Y or Y to N. Setting to N means that when the reading of the sensor

N to

drifts negative, the display will stay at zero. To follow negative upsets,

set this field to Y. The default setting is N.

4.3.9 The Gas Correction Factor

When the background gas is changed. this function can adjust the

calibration of the instrument to compensate for the sensor change of

output. This is helpful when the gas background needs to be changed

and only a calibration bottle with nitrogen background is used. The

default setting is 1.00, for nitrogen gas background. To set this factor,

press the System key and access the third screen:

GasBkgnd TempComp

o

Trbsht temp: 21.0

C

Select GasBkgnd and press the ENTER key to see the function

screen:

Gas Background

Correction: 1.00

Use the Up or Down keys to adjust the value. The working range is

0.25 to 2.50. This factor will divide the output. For example if the factor

is set to 2.00, the output of the sensor, when read by the electronics will

be divided by two.

Special consideration on the working range: Changing the gas

correction factor has an effect on the maximum working range of the

analyzer, e.g.: if a gas factor of 2.00 is selected the maximum working

range of the analyzer is 50 ppm. Any reading above this, may saturate

the amplifier. The automatic sensor shutdown function will become

Teledyne Analytical Instruments 45

Page 60

Operation BDS 3000

active automatically when the reading goes over 50 ppm as described in

Section 3.6.

4.3.10 Troubleshooting Screen

This System function provides access to troubleshooting

information. This information will be helpful to TAI technical support

staff.

Note: To use this function, it is recommended that known span

gas be flowing through the system before entering this

function.

Once the span gas has been flowing for at least five minutes, Press

the SYSTEM key and access the

Trbsht on the third screen.

GasBkgnd TempComp

Trbsht