Reference Manual

Model CFA-24

Transparent Cable Farm

Automation Switch

Rev –

Version 7.7.1

Date of Publication: 02/22/2019

“Results You Can Count On”

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual TOC 1

Table of Contents

1.0 Introduction ......................................................................................................................................................... 1

1.1 Overview ......................................................................................................................................................... 1

1.2 Main Features .................................................................................................................................................. 3

1.3 Specifications .................................................................................................................................................. 4

2.0 About This Manual .............................................................................................................................................. 5

2.1 Chronological Order of Processes ................................................................................................................... 5

3.0 Before You Begin ................................................................................................................................................ 6

3.1 Establish CFA Network .................................................................................................................................. 6

3.2 Connecting Standalone CFA-24 to POE Adaptor ........................................................................................... 6

3.3 Connecting CFA-24 to POE Switch ............................................................................................................... 7

3.4 Changing Factory Default IP Address ............................................................................................................ 8

3.5 Proper Shut Down Procedure (for Systems purchased before 1/1/2016) ...................................................... 10

3.6 Reset Switch .................................................................................................................................................. 12

4.0 Definitions ......................................................................................................................................................... 13

4.1 Loop Segment ............................................................................................................................................... 14

4.2 Punch Down Block ....................................................................................................................................... 16

4.3 Input/Output Connectors ............................................................................................................................... 16

4.3.1 CPE Input/Output Connector .................................................................................................................... 16

4.3.2 CO Input/Output Connector ..................................................................................................................... 16

4.3.3 Custom Cable Set Example ...................................................................................................................... 17

4.3.4 Cabling Segment Extender Units .............................................................................................................. 18

4.4 Connector Segment ....................................................................................................................................... 19

4.5 Channel ......................................................................................................................................................... 19

4.6 Coordinates ................................................................................................................................................... 20

4.7 Coordinate Matrix ......................................................................................................................................... 20

4.8 Network Monitor ........................................................................................................................................... 20

5.0 Installation Configuration Management Process ............................................................................................... 21

5.1 Understanding Operational Modes ............................................................................................................... 21

5.1.1 Standalone Mode (applies to one-unit network) ....................................................................................... 21

5.1.2 Controller Mode (applies to multi-unit network)...................................................................................... 21

5.1.3 Extender Mode (applies to multi-unit network) ....................................................................................... 21

Relationship of Controller to Extender Units .................................................................................................... 21

Assigning Channel and Segment Numbers ....................................................................................................... 22

5.2 Steps in Installation Configuration Management Process ............................................................................. 23

5.3 Launching the CFA-24 Configuration Software ........................................................................................... 24

5.4 Configure Individual Units ........................................................................................................................... 24

5.4.1 Overview................................................................................................................................................... 24

5.4.2 Instructions for Linking Extender Units to the Controller ........................................................................ 25

Set/Change Static IP .......................................................................................................................................... 25

Set/Change Operational Mode .......................................................................................................................... 26

Configure Coordinate Matrix ............................................................................................................................ 28

Multiple Vectoring Groups (Configure MP Cables) ......................................................................................... 29

6.0 Display/Edit Network Monitoring Map ............................................................................................................ 35

7.0 Test Maintenance Process ................................................................................................................................. 38

7.1 Colocated and Non-Colocated Vectoring Groups ......................................................................................... 38

7.2 Instructions .................................................................................................................................................... 39

7.2.1 Accessing Test Maintenance .................................................................................................................... 39

8.0 Making Connections Process ............................................................................................................................ 41

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual TOC 2

8.1 Steps in Making Connections Process .......................................................................................................... 41

8.2 Rack Mounting (optional) ............................................................................................................................. 41

8.2.1 Placement of Rack-Mounting Brackets .................................................................................................... 42

8.2.2 Mounting on a 19” Rack ........................................................................................................................... 42

8.2.3 Using the CFA-24 without Rack Mounting .............................................................................................. 43

8.3 Segment Twisted-Pair Connection to Coordinate Punch Down Blocks ....................................................... 44

8.3.1 Segment to Punch Down Block Connection ............................................................................................. 44

8.3.2 Using the CFA-PDTOOL-KIT to Punch Down Wire .............................................................................. 46

Overview ........................................................................................................................................................... 46

Before You Begin .............................................................................................................................................. 46

Instructions for Top Row of Punch Down Blocks (punched from above connector) ....................................... 47

Instructions for All Other Punch Down Blocks (punched from below connector) ........................................... 47

8.3.3 Cable Shield Continuity ............................................................................................................................ 49

8.4 CFA-24 Signal and Chassis Ground ............................................................................................................. 51

8.5 Using Patch Panel (optional) ......................................................................................................................... 51

8.6 Cable CFA-24 Units Together to Extend Segments (optional) ..................................................................... 51

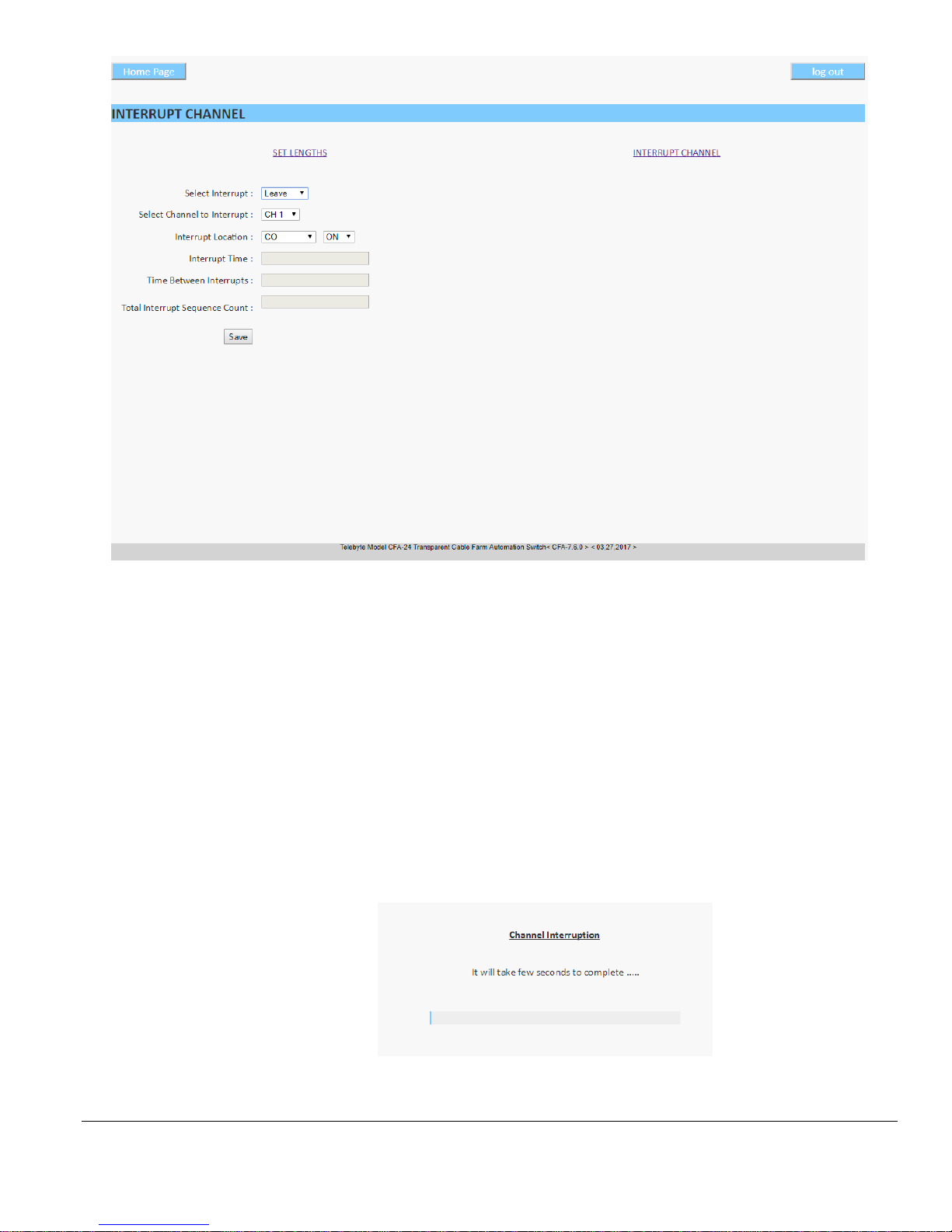

9.0 Set Line Lengths and Interrupts Process ........................................................................................................... 51

9.1.1 Steps in the Set Line Lengths and Interrupts Process ............................................................................... 51

9.1.2 Instructions ............................................................................................................................................... 52

Set Lengths ........................................................................................................................................................ 52

Set Mechanical Interruptions ............................................................................................................................. 53

10.0 User Management .............................................................................................................................................. 55

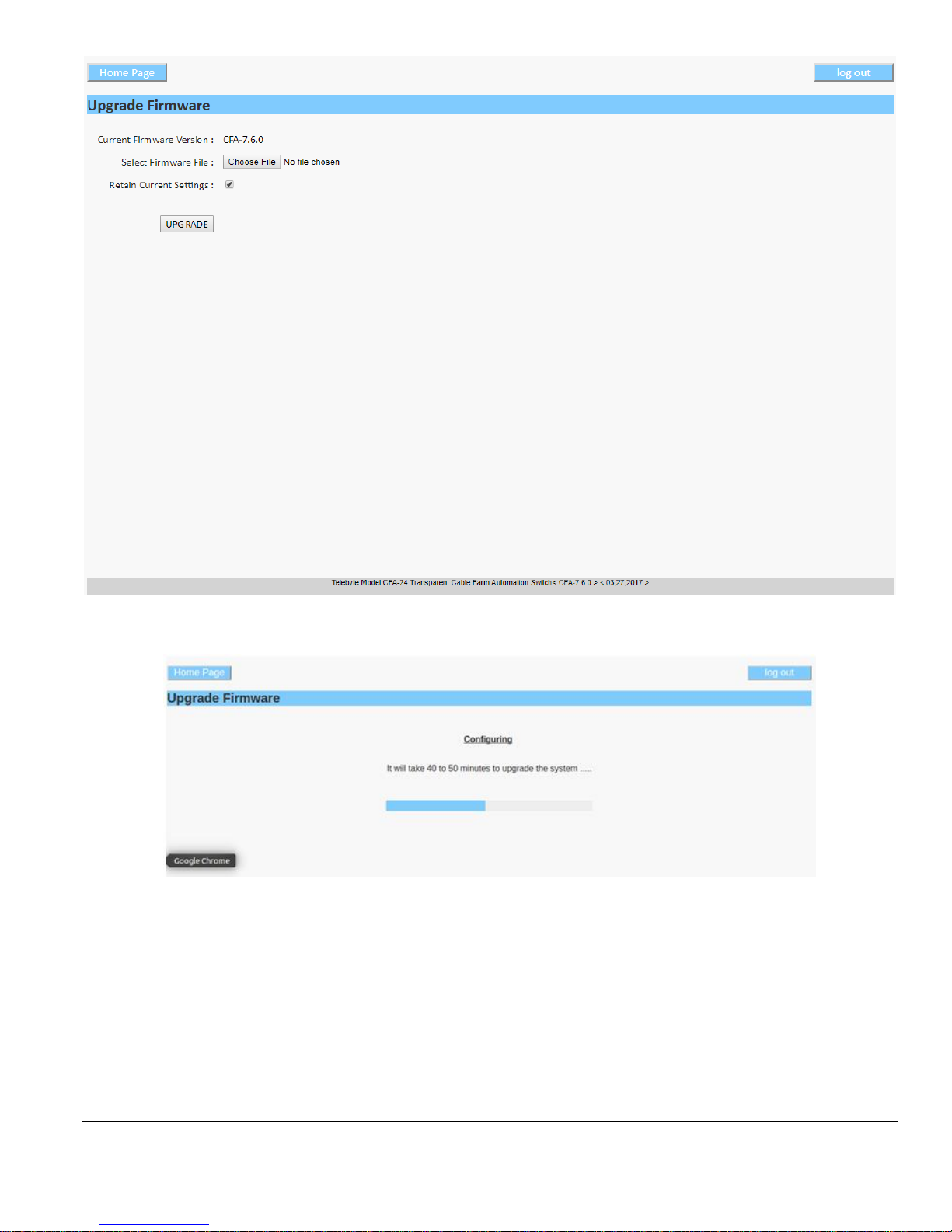

11.0 Upgrade Firmware ............................................................................................................................................. 57

12.0 Create Backup of Coordinate Matrix ................................................................................................................ 60

13.0 Technical Support .............................................................................................................................................. 61

Appendix A – Configuration Example Diagrams .......................................................................................................... 62

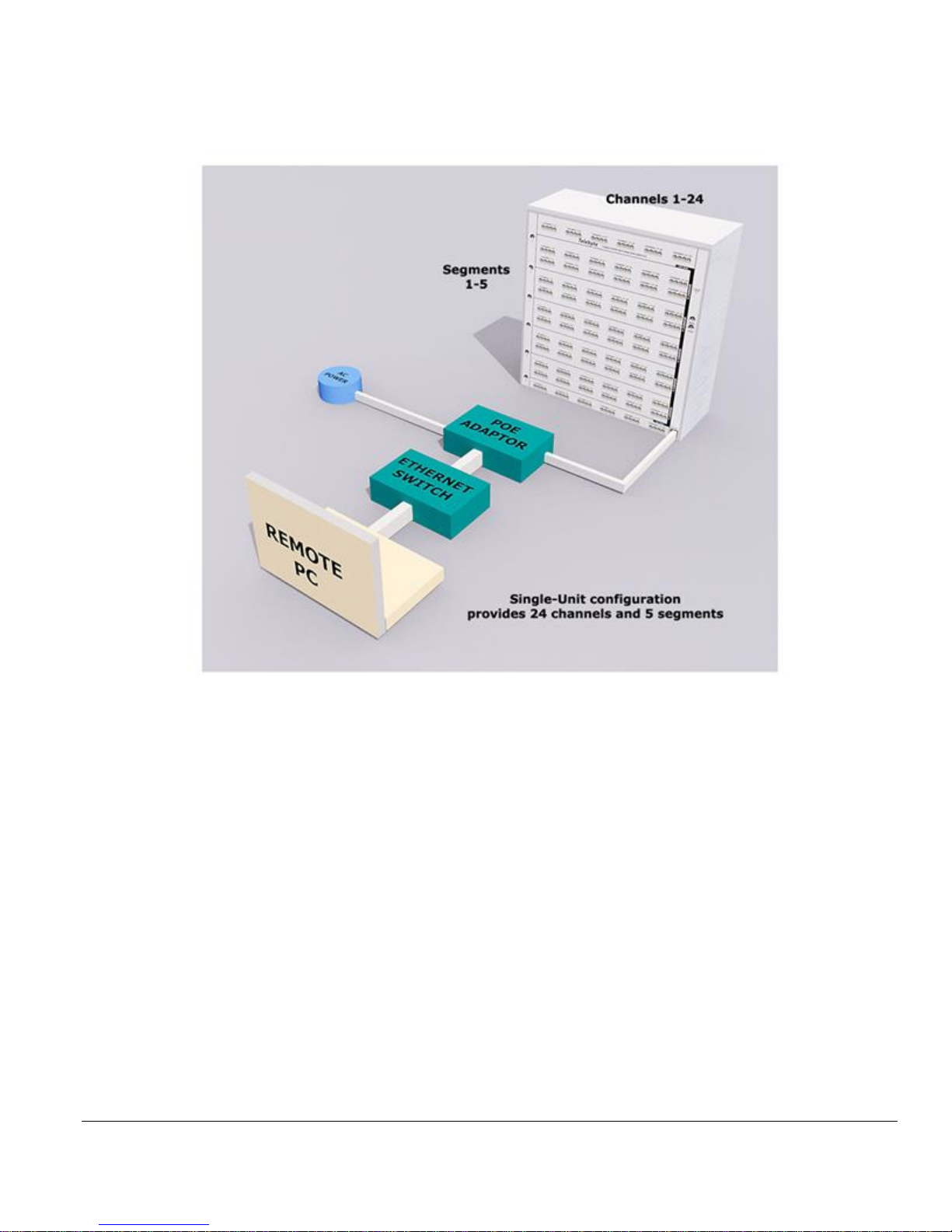

5 Segments/24 Channels ............................................................................................................................................ 62

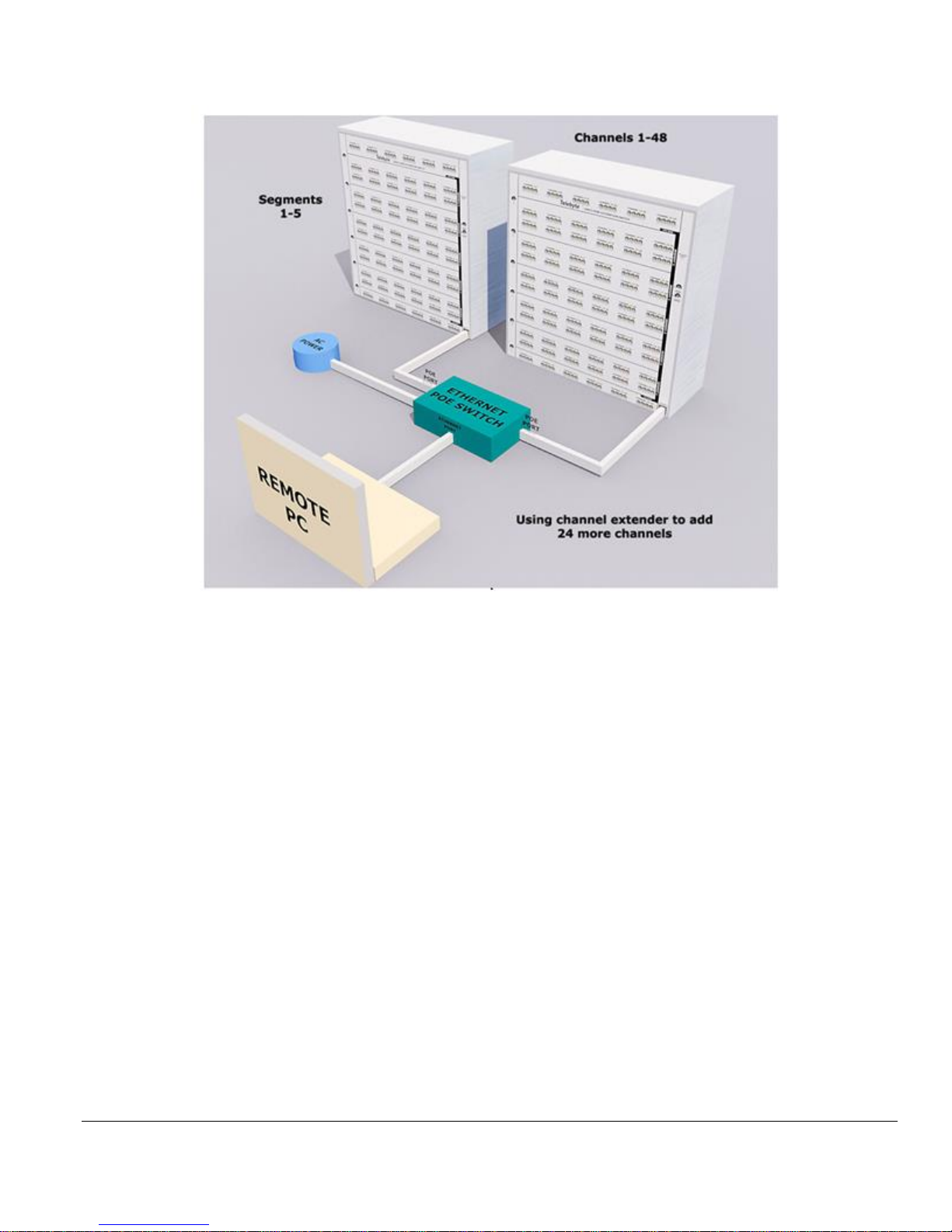

5 Segments/48 Channels ............................................................................................................................................ 63

10 Segments/48 Channels .......................................................................................................................................... 64

Appendix B - Remote Commands .................................................................................................................................. 65

Access via Remote Telnet and SSH Connections ...................................................................................................... 65

Shutdown via Remote Telnet and SSH Connections ................................................................................................. 65

shutdown ................................................................................................................................................................ 65

reboot ..................................................................................................................................................................... 65

Show Command ......................................................................................................................................................... 66

show -h................................................................................................................................................................... 66

show system netif .................................................................................................................................................. 66

show system software ............................................................................................................................................ 66

show length <line> ................................................................................................................................................ 66

show term <line> ................................................................................................................................................... 67

$ show ncl vg<n>................................................................................................................................................... 67

show leave <line> .................................................................................................................................................. 68

show allow <line>.................................................................................................................................................. 68

show vg details ...................................................................................................................................................... 69

Set Command ............................................................................................................................................................. 69

set -h....................................................................................................................................................................... 69

set length <line> <length> ..................................................................................................................................... 69

set term <line><yes|no> ........................................................................................................................................ 70

set termloc <line><co|cpe|both|none> ................................................................................................................... 70

set microcut <line> <location> <open time in ms> <period> <count> ................................................................. 71

set cut <line> <location> <open time in seconds> <period> <count> .................................................................. 72

set interrupt off ...................................................................................................................................................... 72

$ set leave <line> <location> <on|off> .................................................................................................................. 73

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual TOC 3

set cl <vectoring group> colocated <on|off> ......................................................................................................... 73

set ncl <vectoring group> <segment><checked|unchecked> ................................................................................ 74

Appendix C – ID-337 Screen Examples......................................................................................................................... 75

Example – Using Two Vectoring Groups, 4 Channels Each ..................................................................................... 75

Coordinate Matrix (8 Channels) ........................................................................................................................ 75

Configure MP Cables (2 Vectoring Groups) ..................................................................................................... 75

Test Maintenance (All Segments Selected) ....................................................................................................... 76

Set Lengths (2 Different Lengths for Each Vectoring Group) .......................................................................... 76

Appendix D –Recommended Cable Segment Lengths .................................................................................................. 77

ID-337 ........................................................................................................................................................................ 77

TR-249 ....................................................................................................................................................................... 77

Customer Care ................................................................................................................................................................ 78

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 1 of 76

1.0 Introduction

1.1 Overview

The Model CFA-24 Transparent Cable Farm Automation Switch is a transparent, electrically neutral, switching device

that allows up to twenty-four incoming cable farm lines (twisted pairs) to be switched to five different loop segments.

Operating in a frequency band up to 212 MHz, the CFA-24 is highly suited to lab-grade testing of next-gen devices

where live crosstalk is required (e.g., VDSL2 Vectoring or G.fast performance testing). Telebyte’s superior transparency

delivers excellent crosstalk accuracy. Ideal for ID-337 G.fast Certification and TR-249 VDSL2 Vectoring testing.

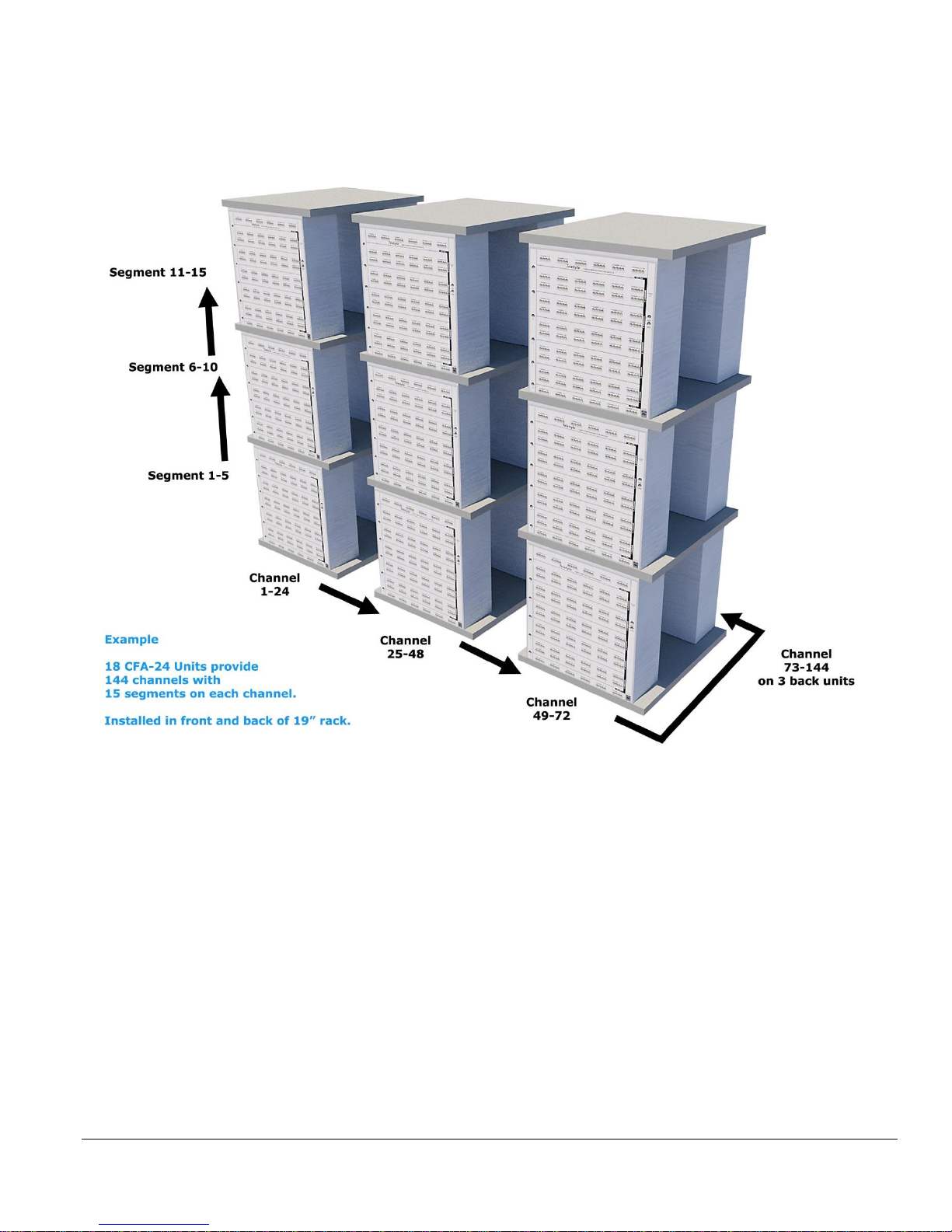

Configurations may be expanded by adding channel expander units, allowing users to scale the number of pairs that can

be switched from 24 to as many as needed, in groups of 24. In addition, segment extender units can be jumpered together

to add more line segments.

The CFA-24 Transparent Cable Farm Automation Switch.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 2 of 76

Configurations may be expanded by adding channel extender units, allowing users to scale the number of pairs that can

be switched from 24 to as many as needed, in groups of 24. In addition, segment extender units can be cabled together

to add more line segments.

The example above shows 18, CFA-24 units installed in three racks. This would provide 15 segments and 144

channels. A configuration can be as simple as one unit (with 5 segments and 24 channels) or extended

and expanded up to 15 segments and as many channels as needed. Installation in the front and back of a

19” rack reduces the amount of racks required.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 3 of 76

1.2 Main Features

• Ideal for Broadband Forum’s ID-337 G.fast Certification and TR-249 VDSL2 Vectoring Testing

• High performance transparent solution designed to automate testing of cable farms

• Use additional units to expand the number of segments and channels

• Multiple Vectoring groups per unit or across multiple units

• Colocated and non-colocated test configurations

• Connect cables once then switch programmatically

• Automatically terminates unused channels and/or segments

• Micro-Interruptions

• Supports Reverse Powering for G.fast

• Low crosstalk/low insertion Loss

• Control/Power via Power Over Ethernet (POE)

• Embed remote commands in scripts (e.g., TCL, Python)

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 4 of 76

1.3 Specifications

Specifications

Switching Capability

Switching of up to 5 loop segments for 24 local loops

(expandable by adding channel expanders and/or segment

extenders)

Insertion Loss across all 5 Segments

in Bypass (from CO side to CPE side)

• DC to 17 MHz: less than 0.3 dB

• 17 MHz to 30 MHz: less than 0.38 dB

• 30 MHz to 106 MHz: less than 0.57 dB

• 106 MHz to 212 MHz: less than 0.89 dB

Noise Floor

Less than -153 dBm/Hz

Channel-to-Channel Isolation

• DC to 17 MHz: minimum 81 dB

• 17 MHz to 30 MHz: minimum 76 dB

• 30 MHz to 106 MHz: minimum 68 dB

• 106 MHz to 212 MHz: minimum 63 dB

Impedance

100 ohms

Temperature

• Operating: 0°C to 50°C (32°F to 122°F)

• Storage: -20°C to 70 °C (-18°F to 158°F)

Operating Relative Humidity

0% to 95% relative humidity (non-condensing)

Connectors

• CO Input/Output: 6 x 8 Way Punch Down Blocks

• CPE Input/Output: 6 x 8 Way Punch Down Blocks

• Line Segments: 60 x 8 Way Punch Down Blocks

• Control: RJ45 (Power over Ethernet)

Conductors Accepted

• Diameters from 0.6 mm to 0.4 mm

• Solid conductors

• Shielded or unshielded

Dimensions

Overall: 17.50”H x 16”W x 6”D (10-U High)

Rack mountable (front and/or back) in 19” rack

Micro-Interruptions

Location: CO or CPE side - on any one channels

Interrupt Time: 5ms to 100ms in 1-ms increments

Power

POE per 802.3af standard

Cycles of Operation

1,000,000 Minimum

DC Rating Maximum Voltage Tip - Ring

220 VDC/250 VAC, 2 amperes maximum

Specifications are subject to change without notice. Made in USA.

Ordering Information

CFA-24

24-Channel Transparent Cable Farm Automation Switch (Controller, Channel or

Segment Extender)

RJ45x24-PP

24-channel female CAT6 RJ45 patch panel w/solid conductor, 6 feet; 1-U high, to

connect to CO and/or CPE side of test.

CFA-Custom Cable

Custom cable kit to connect to CO and/or CPE side of test.

CFA-CA-MGT

Cable Management Kit. Includes 6 rack-mountable cable-tie bars with cable ties.

CFA-POE-1

PHIHONG PSA16U-480(POE) 1-PoE Ethernet Adapter

CFA-POE-4

Linksys LGS108P 8-port switch with 4 PoE+ ports

CFA-POE-8

Linksys LGS116P 16-port switch with 8 PoE+ ports

CFA-POE-12

Linksys LGS124P 24-port switch with 12 PoE+ ports

CFA-PDTOOL

Punch down tool

CW1420-400

Spool of CW1420 400 m cable (4 pairs) for ID-337 testing

All switches verified and qualified for use with the CFA-24.

Contact Telebyte to request qualification of alternate switch for use with this product.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 5 of 76

2.0 About This Manual

This reference manual describes, and is organized by, the five basic processes required to set up and begin testing with

a CFA system. Each has its own level of complexity and requisite understanding of the cable farm, required test

configuration and simple running of tests. In addition, user management is available to restrict menu access to

appropriate personnel.

2.1 Chronological Order of Processes

➢ It is very important to follow this order of processes. In particular, establish the CFA network (Process 1) before

punching down any cables.

PROCESS

DESCRIPTION

1

Establish CFA Network

o The correct way to connect CFA-24 unit

o How to assign static IP address to each unit

o Powering the CFA network

2

Installation Configuration Management

o Overall set up of entire CFA system.

o Configure Multiple Vectoring Groups (Optional)

o Complexity is dependent upon the number of units in the system.

o Prepares the system for the Test Maintenance process

3

Test Maintenance

o Sets the line lengths available for selection during the Set Channel

Lengths/Interrupts process

o Set Colocated, Non-Colocated

4

Connect Cable Farm

o Connect cable farm to all CFA-24 punch down blocks

5

Set Channel Lengths/Interrupts

o Select channel lengths

o Configure and start micro-interruptions

A section on basic concepts precedes the Installation Configuration Management and Connect Cable Farm sections to

orient the reader involved in these processes. The basic concepts section is not required reading for the Test Maintenance

and Set Channel Lengths/Micro-Interruptions sections.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 6 of 76

3.0 Before You Begin

➢ Do not punch down cable to the CFA-24 until you have read this document and the reference manual. The last

step in setting up your system is punching down the cable.

➢ Always use the punch down tool approved by Telebyte.

3.1 Establish CFA Network

Do not connect CFA-24 units with the same IP address to the POE switch. The CFA-24 units do not

support DHCP. A default static IP address for each CFA-24 is configured at the factory and must be

changed if there is more than one unit in the CFA network. Connect only one unit at a time to the POE

switch while a new IP address is assigned through the web browser interface. This prevents IP address

conflicts which can prevent communication with the CFA-24.

3.2 Connecting Standalone CFA-24 to POE Adaptor

CFA-24 Default IP Settings:

IP:172.16.21.241

Subnet Mask: 255.255.255.0

When the CFA network consists of only one (Standalone) unit, the CFA-24 is most likely connected to power via

a POE adaptor (CFA-POE-1). The IP address for the Standalone unit may be changed from the factory default if

desired but this is not required. If the CFA network consists of two or more units, see Connecting CFA-24 to POE

Switch in the next section.

1. Plug the POE adaptor into a power source.

2. Configure the remote PC with an IP address in the same subnet of the CFA’s IP.

3. Connect a remote PC to the IN port of the POE adapter.

4. Connect the CFA to the OUT port of the POE adapter and wait at least 75 seconds for the CFA-24 to boot up.

An LED in the front of the unit turning from RED to GREEN indicates the system is ready.

5. From the remote PC, open a web browser and enter the factory default IP: 172.16.21.241 to communicate with

the CFA-24 unit.

6. The Main screen is displayed.

OUT IN

CFA

PC

!

IMPORTANT

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 7 of 76

Telebyte recommends the use of these web browsers:

Google Chrome v. 54.0.2840.71

Firefox Mozilla v. 49.0.2

Next Steps:

a. If changing the factory default IP address to a new static IP, proceed to Changing Factory Default IP

Address later in this document.

b. If powering down the unit, proceed to Proper Shut Down Procedure later in this document.

c. If ready to continue to the next step in configuring the Standalone unit, proceed to Definitions.

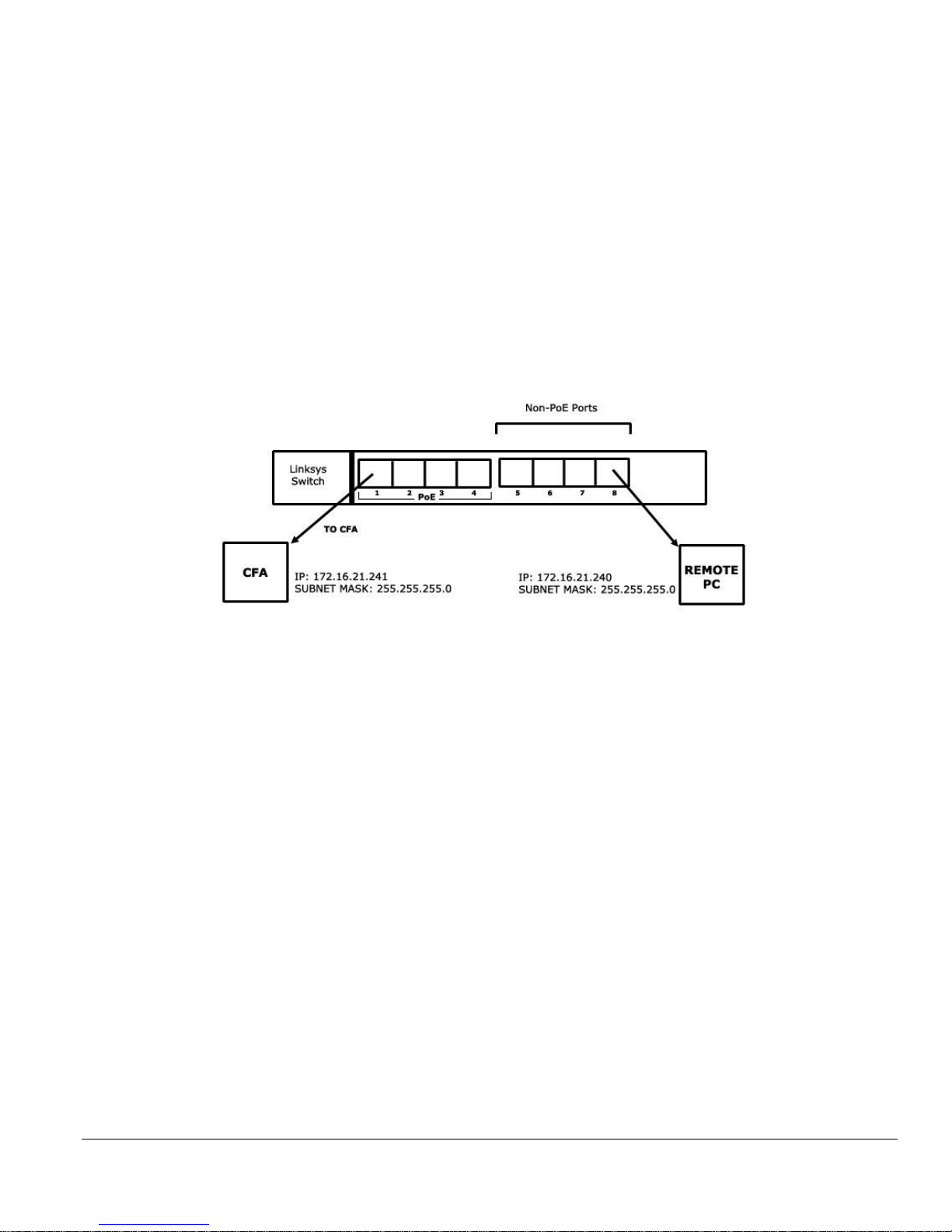

3.3 Connecting CFA-24 to POE Switch

Example shows the CFA-POE-4 (8-port version). User may have the 16 or 24-port version.

1. Plug the Linksys switch into a power source.

2. Configure the remote PC with an IP address in the same subnet of the CFA’s IP.

3. Connect a remote PC to the IN port of the POE adapter.

4. Connect the CFA-24 to the POE port. Note: When configuring the first unit, connect only that CFA-24

to a POE port as shown in the diagram above. After that, additional units may be plugged in providing

they have a different IP address from any other CFA connected.

5. Wait at least 75 seconds for the CFA-24 to boot up. An LED on the front of the unit turning from RED

to GREEN indicates the system is ready.

6. From the remote PC, open a web browser and enter the factory default IP: 172.16.21.241 to

communicate with the CFA-24 unit.

7. The Main screen is displayed.

8. unit.

9. The Main screen is displayed.

Next Steps:

a. Proceed to Changing Factory Default IP Address.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 8 of 76

3.4 Changing Factory Default IP Address

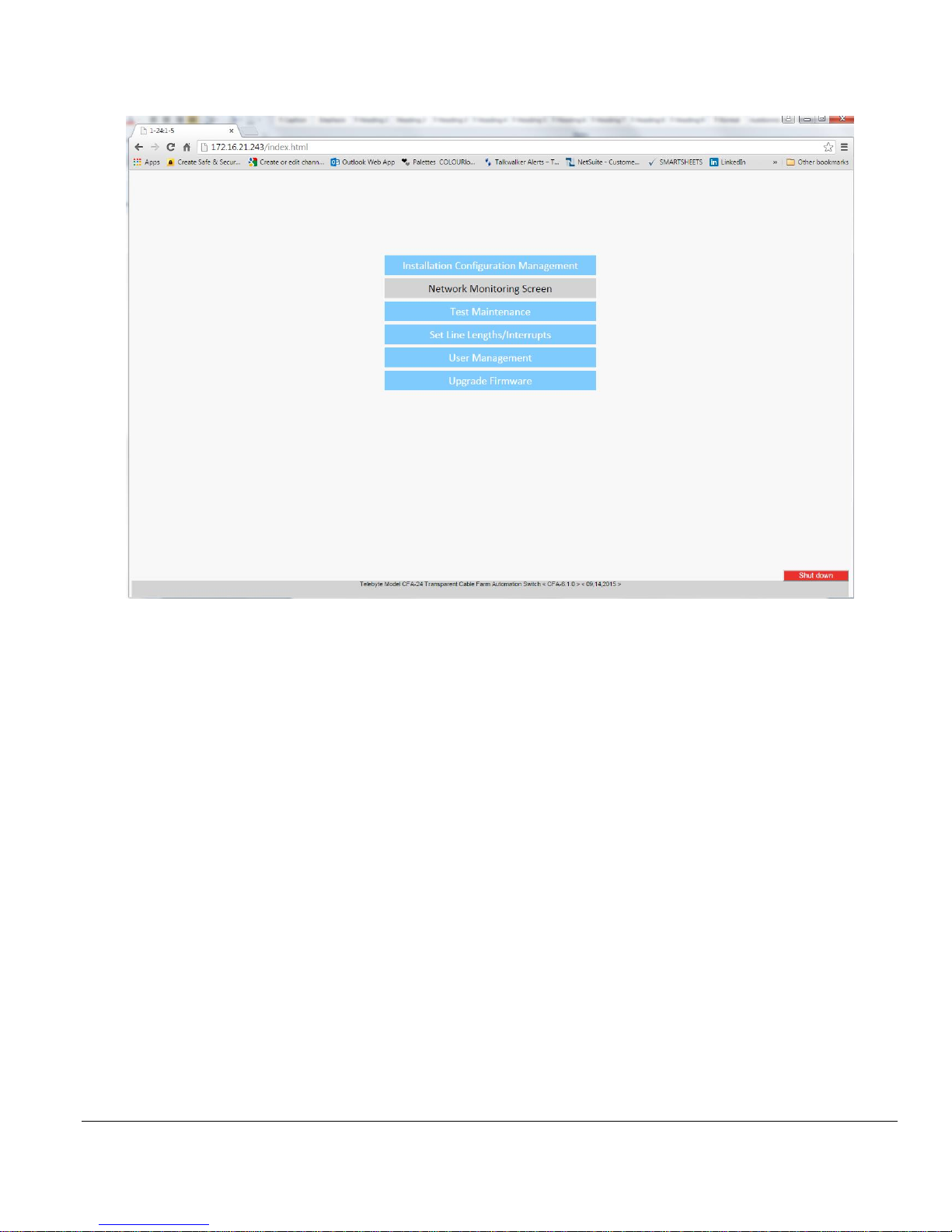

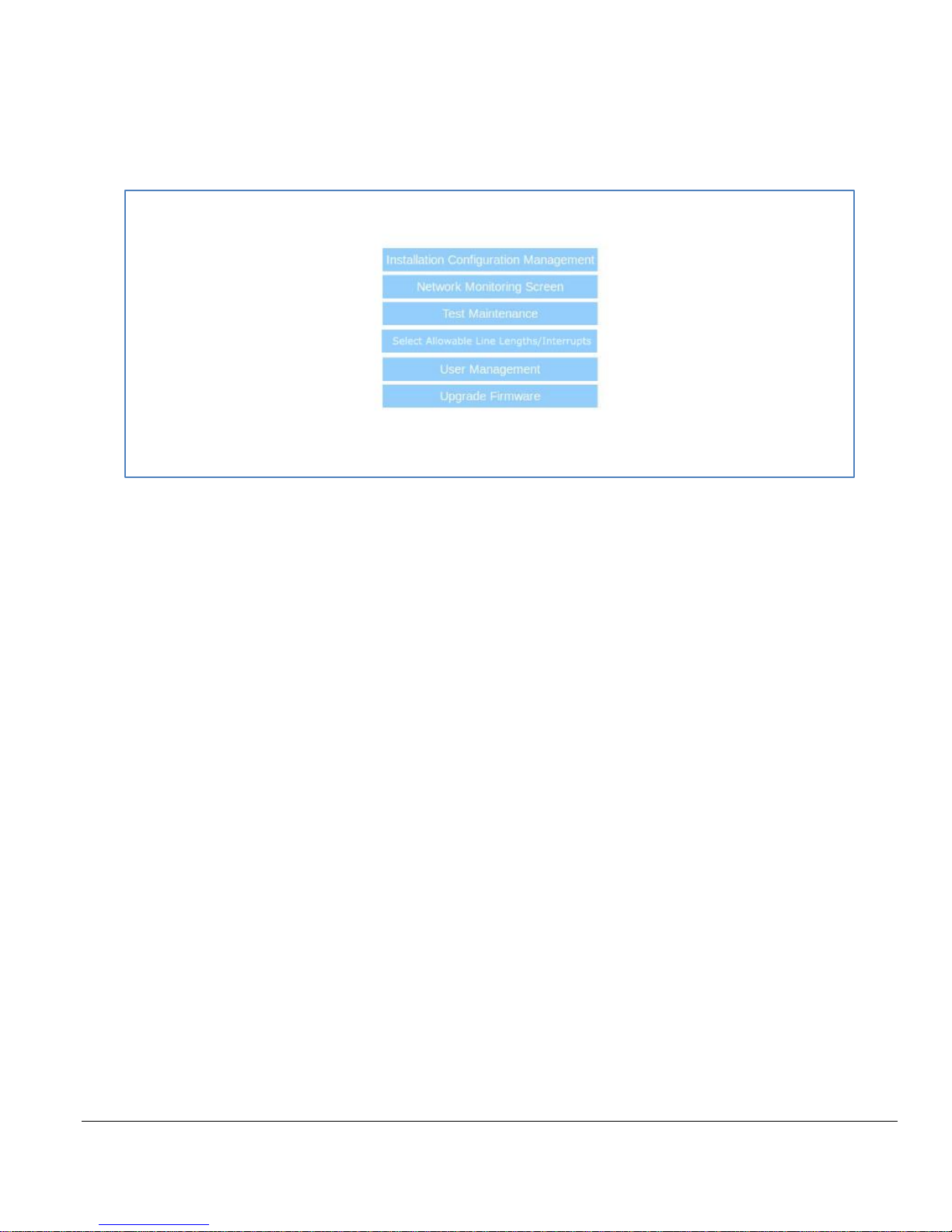

1. Select Installation Configuration Management from the Main screen.

Web Browser Main screen.

➢ Menu options that are grayed out are not available in the current Operational Mode. See Understanding

Operational Modes later in the document.

2. The Authentication Required dialogue box is shown. Depending on the browser, the look of this dialogue box

and the message displayed may vary.

3. Enter the following information in the Authentication Required dialogue box when prompted, and then click

OK (or Log In).

User Name: admin

Password: admin

The Installation Configuration Management screen is shown.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 9 of 76

Installation Configuration Management Screen

4. Change the default IP to the new static IP address of 172.16.21.231. Then click Submit.

➢ All subsequent units configured must be assigned a different IP address to avoid a conflict. After the set up

of the first unit, increment each IP address by 1 for each new CFA-24 unit being configured.

An error screen is displayed when the CFA-24 loses connectivity due to the IP address change. Depending on the

browser, this message may vary:

Next Steps:

a. Optional: To regain communication, enter the newly assigned IP address in the web browser. If any

issues arise, see Reset Switch later in this document.

b. Optional: While not required, the unit may be powered down at this time. If powering down the unit,

proceed to Proper Shut Down Procedure later in this document.

c. Optional: Return to Step 3 of Connecting CFA-24 to POE switch to configure more units.

d. If ready to continue with setting up the CFA network, proceed to Definitions.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 10 of 76

3.5 Proper Shut Down Procedure (for Systems purchased before 1/1/2016)

This procedure is always followed before the Ethernet cable is unplugged from the unit.

➢ For instructions on proper shut down using remote commands, see Appendix B – Remote Commands.

1. Enter the IP address of the unit (e.g., 172.16.21.231) in the web browser to connect. The Main screen is shown.

2. Click the Shut Down button in the lower-right corner of the Main screen.

Shut Down button in lower-right corner of Main screen.

3. When Prompted to shut down, click OK in the dialogue box.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 11 of 76

4. The CFA-24 connection is lost when the system shuts down.

The appearance of the message shown below may vary, depending on the browser.

➢ VERY IMPORTANT: Wait 30 seconds to allow the system to discharge completely before attempting to

reconnect the unit.

5. Unplug the CFA-24 Ethernet cable.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 12 of 76

3.6 Reset Switch

Should it become necessary to reset the IP address to the factory default, use the Ethernet Reset button as described

below.

The Ethernet Reset button is located in the upper-right-front side of the unit.

1. With the CFA-24 powered ON, insert a paperclip into the Ethernet Reset hole and depress the switch for one

second to restore the CFA-24 factory default Network Configuration.

2. Wait at least 2 minutes before attempting to establish a new Ethernet connection.

3. Enter 172.16.21.241 in the web browser from a pre-configured remote computer with the same Subnet Mask.

Factory Default Settings:

IP: 172.16.21.241

Subnet Mask: 255.255.255.0

Default Gateway: 172.16.21.1

4.0 Definitions

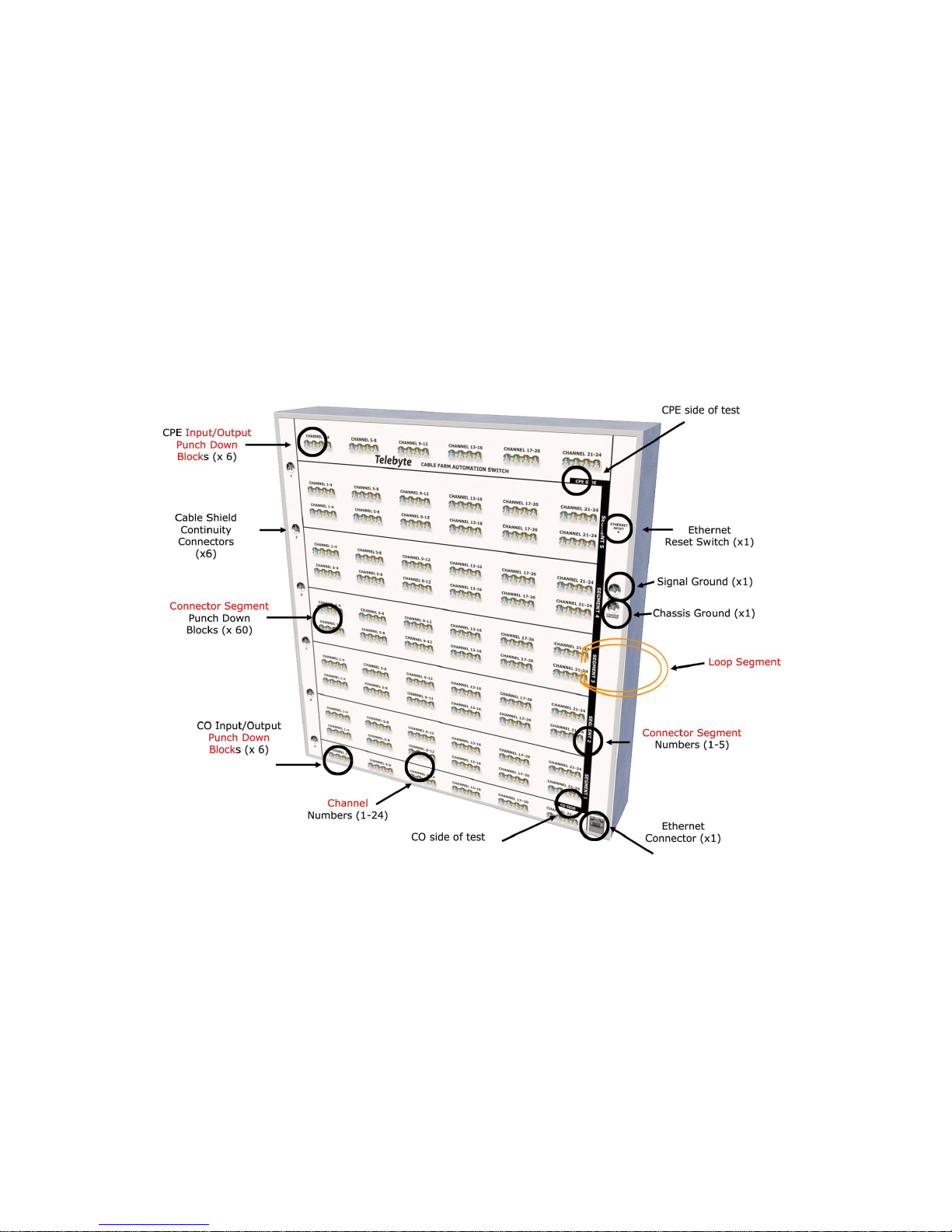

Refer to the diagram above when reading this section.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 14 of 78

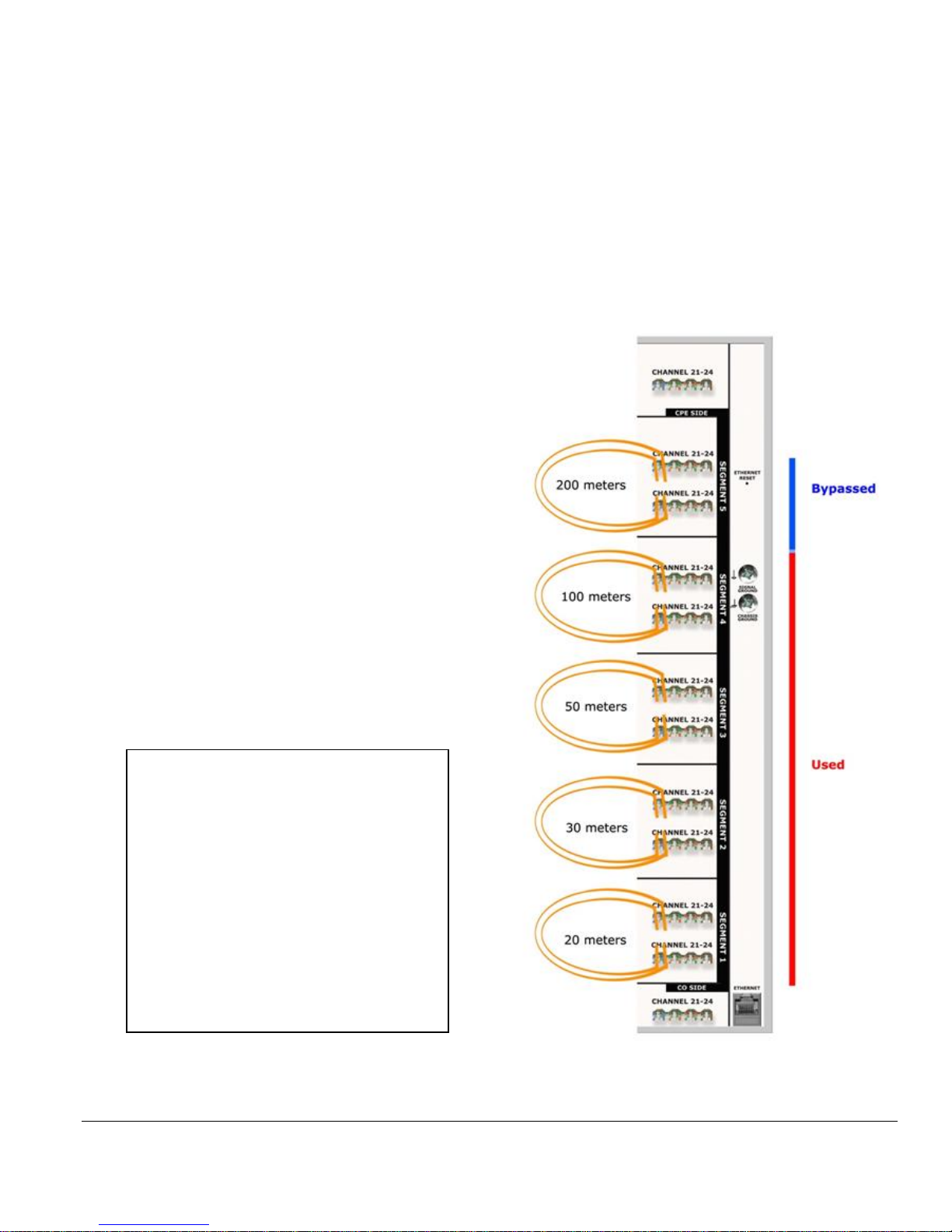

4.1 Loop Segment

A loop segment is a length of twisted-pair cable attached to the CFA-24. Loop segments may have different lengths. In

addition, loop segments may be connected and then, when required, bypassed programmatically.

➢ All crosstalk in a CFA system occurs between the cable farm wires. The CFA-24 is transparent.

Example ID-337 Test Setup

(Selection of 200 meters)

• Five loop segments of different

lengths of CW1420 are each attached

to one of five segments.

• The allowable loop lengths of this

non-colocated setup are 20, 50, 100,

200 and 400 meters.

• Segments 1, 2, 3, and 4 are used to

form the 200 meters. Segment 5 is

bypassed.

Recommended Cable Lengths

for ID-337

For ID-337 Telebyte recommends

installation of the following cable

segment lengths, in the order

shown:

Segment 5 200m

Segment 4 100m

Segment 3 50m

Segment 2 30m

Segment 1 20m

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 15 of 78

Example TR-249 Issue 1 Test Setup

(Selections of 150, 300, 450, 600 and 750 meters)

• Five 150-meter, 0.4mm loop

segments are each attached to

one of five segments.

• The allowable loop lengths of this

setup are 150, 300, 450, 600 and

750 meters.

• Segments 1, 2, 3 and 4 are used

to form the 600 meters. Segment

5 is bypassed. This configuration

represents the Medium Loop (17

MHz profile) per TR-249 Issue 1.

Recommended Cable Lengths

for TR-249

For TR-249 Telebyte recommends

installation of the following cable

segment lengths:

Segment 5 150m

Segment 4 150m

Segment 3 150m

Segment 2 150m

Segment 1 150m

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 16 of 78

4.2 Punch Down Block

Each punch down block accepts 4 twisted-pair AWG22-26 solid wire connections. There are a total of 72 punch down

blocks on the front of the unit. 60 are dedicated to loop segment connections (two per loop segment) while 12 (referred

to as input/output connectors) are used to connect to the CO or CPE side of the unit (6 on top and 6 on bottom).

AWG-Metric Wire Equivalent Table

AWG Size (mm)

AWG Dia. (in)

Metric Dia.

26

0.0159

0.405

24

0.0201

0.511

22

0.0644

0.253

The punch down block for the CPE-side input/output connections of channels 9-12 is shown above.

4.3 Input/Output Connectors

Punch down blocks provide connectivity for the input/output connectors located on the top and bottom rows of the

CFA-24.

4.3.1 CPE Input/Output Connector

The top row connects to the CPE side. These connectors may also be used to jumper to another unit, where applicable.

4.3.2 CO Input/Output Connector

The bottom row connects to the CO side. These connectors are also used to cable to another unit, where applicable. See

Using CFA-PDTOOL-KIT for instructions.

• Use short cables for CPE and CO jumpers to CFA-24 Extenders that are the same as the Segment cable wire.

Maintain the twists of the pair across the jumper length between the CFA-24 Extenders.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 17 of 78

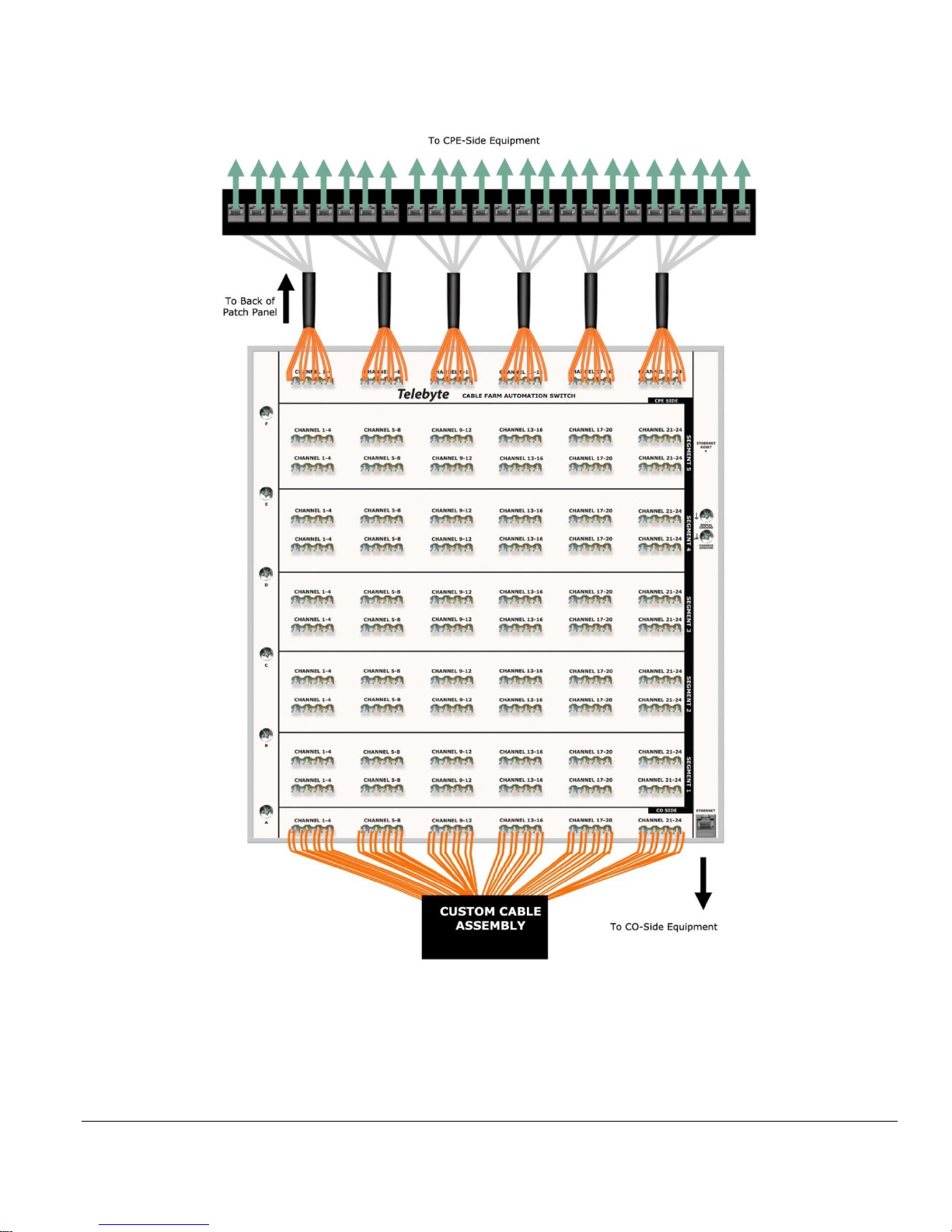

4.3.3 Custom Cable Set Example

The custom cable set usually consists of a patch panel and cables with custom lengths and terminations. This allows

the user to connect to the input/output punch down blocks once then use the patch panel to connect and disconnect

CO and CPE equipment. One custom cable set may be ordered for each side of the test. This illustration is conceptual

only and does not show other elements such as connections for shield ground continuity.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 18 of 78

4.3.4 Cabling Segment Extender Units

Multiple CFA-24 units can be used to extend the number of connector segments available. This requires a minimum of

two units to be cabled (jumpered) together such that the CO cable of one CFA-24 connects to the CPE of the other CFA-

24. The number assigned to a connector segment on more than one Extender unit will depend on the sequence in which

each unit is cabled.

Example of CO/CPE side cabling when using CFA-24’s as segment extenders. This illustration is conceptual only and

does not show other elements such as connections for shield ground continuity.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 19 of 78

4.4 Connector Segment

Connector segment numbers (1-5) are identified on the right side of the unit. Loop segments are connected to punch

down blocks (top and bottom) located within a given connector segment. Five vertical connector segments form a

channel.

4.5 Channel

A series of five vertical connector segments form a channel. Channels are numbered from 1 to 24, beginning on the left

side of the unit, unless there are multiple units. If so, the channel numbers will increment by 24 on each subsequent

CFA-24 used to extend the number of channels.

Channels can be grouped by Vectoring Groups (optional).

Channel 4 is highlighted above in red. It consists of 12 vertical punch down block connectors that make up five

connector segments and two input/output connectors.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 20 of 78

4.6 Coordinates

A coordinate is the physical location of two punch down block connections that form a specific connector segment

number and channel number combination. There are 120 coordinates in the Matrix of coordinates (5 connector segments

x 24 channels). This identification allows the channel/segment combination to be addressed during the configuration

process. A coordinate is further defined by length and type (see Matrix of Coordinates in the CFA-24 Configuration

section later in this manual).

4.7 Coordinate Matrix

The Coordinate Matrix is made up of the 120 coordinates (5 connector segments x 24 channels) physically located on

the front of a CFA-24 unit. These coordinates are defined by attributes such as coordinate type and coordinate length.

These definitions must match the cable farm lines physically attached to the unit. All Coordinate matrixes are combined

together by the CFA-24 software to form a Network Monitoring interface that allows the user to oversee the entire CFA

network.

4.8 Network Monitor

Once each CFA-24 unit is configured, multi-unit CFA systems may be viewed in their entirety via the Network Monitor

screen. The Network Monitor displays IP addresses and connection status for all units. The user may also add or remove

a unit from the CFA system or take a unit offline.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 21 of 78

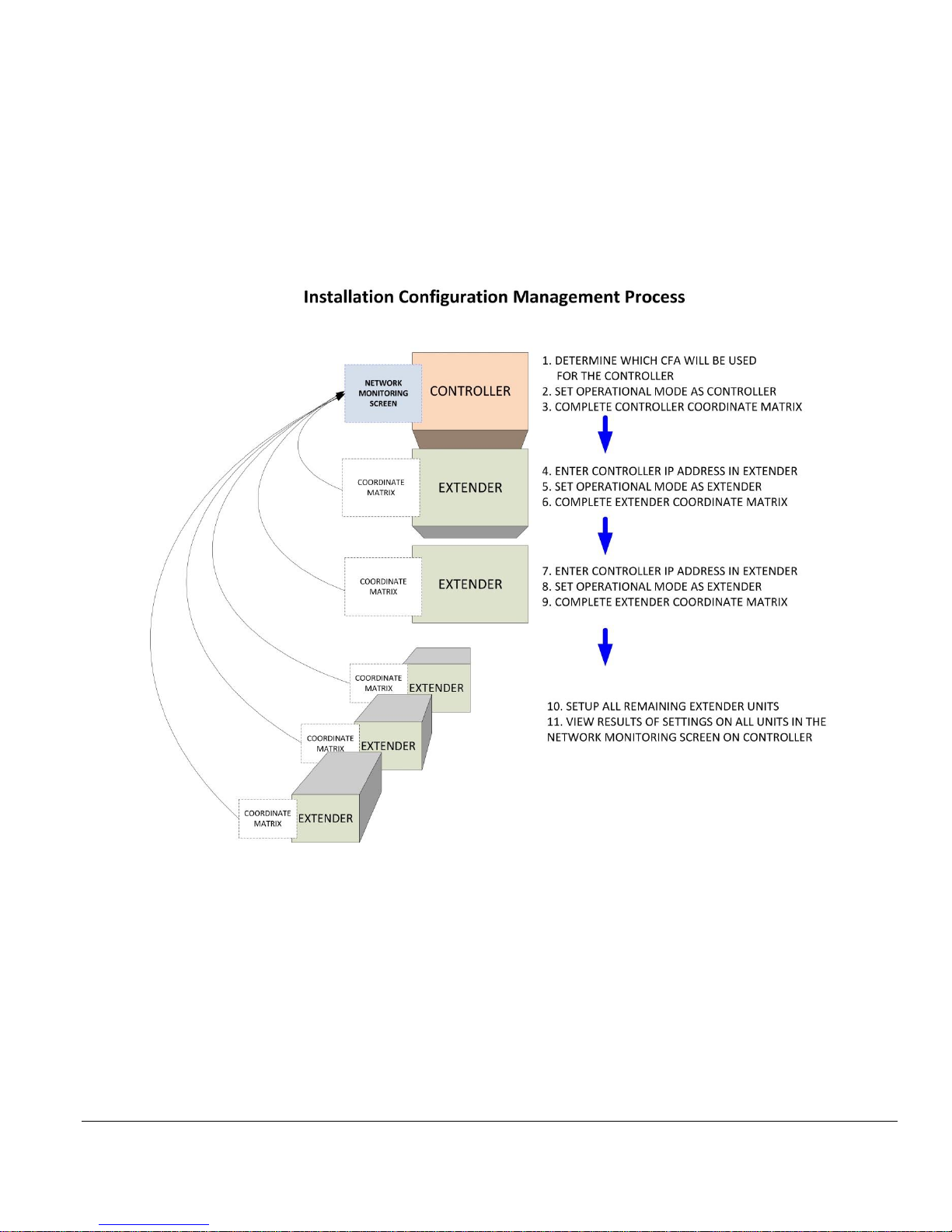

5.0 Installation Configuration Management Process

The following steps are required before the Test Maintenance Process can be initiated.

➢ It is assumed that the first process, Establish CFA-24 Network, has already been followed. If not, stop and go

to that section before proceeding.

5.1 Understanding Operational Modes

The Installation Configuration Management process establishes which units are in the CFA-24 network and how they

will behave. During the Installation Configuration Management Process, each CFA-24 is assigned one of three

Operational Modes. In the case of the one-unit network, the CFA-24 is always set to Standalone mode. In the multi-unit

network, one unit is set as the Controller and the others are set as a type of Extender (for channels 25 and higher or

segment 6 and higher).

5.1.1 Standalone Mode (applies to one-unit network)

The CFA-24 is set to Standalone mode when it is the only unit in the setup. Throughout this manual, the term “CFA-24

Network” refers to single and multi-unit setups.

5.1.2 Controller Mode (applies to multi-unit network)

The CFA-24 is set to Controller mode when it is used for channels 1-24 and segments 1-5 in a multi-unit network.

5.1.3 Extender Mode (applies to multi-unit network)

Extenders operate in one of three ways:

• Channel Extender: The CFA-24 is set to the Channel Extender mode when the unit extends only the number of

channels available. When used, the unit’s location in the channel numbering sequence is also assigned.

• Segment Extender: The CFA-24 is set to the Segment Extender mode when the unit extends only the number

of segments available. When used, the unit’s location in the segment numbering sequence is also assigned.

• Segment AND Channel Extender: The CFA-24 is set to the Segment AND Extender mode when the unit

extends the number of segments AND the number of channels available. When used, the unit’s location in the

segment AND channel numbering sequence is also assigned.

Relationship of Controller to Extender Units

In multi-unit CFA-24 Networks, all Extenders are associated with one Controller unit by entering the Controller’s IP

address during Extender configuration. Once all Extenders are configured, the Controller is the only unit accessed.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 22 of 78

Example of CFA-24 Operational Modes

Assigning Channel and Segment Numbers

All channel range and segment ranges must be unique for each CFA-24. The following shows the allowable

combinations:

CH range 1-24

CH range 25-28 or higher

Segment range

1-5

Standalone or Controller

Channel Extender

Segment range

6-10

Segment Extender

Segment & Channel Extender

Segment range

11-15

Segment Extender

Segment & Channel Extender

The begin the Installation Configuration Management process, the user sets the static IP address and Operational Mode

of each unit. This is required to populate the Coordinate Matrix screen which is used to identify all coordinates in the

network and their features. All of these activities result in a Network Monitoring Map. The Network Monitoring Map

allows units to be added and removed from the system and displays the current status of all units in the system.

➢ The CFA-24 is designed specifically for VDSL2 Vectoring and G.fast technologies; therefore, only those

options consistent with that type of testing are presented to the user.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 23 of 78

5.2 Steps in Installation Configuration Management Process

1. If configuring a multi-unit CFA network, determine which CFA-24 (and related IP address) will operate in

Controller mode.

2. Configure Coordinate Matrix of Controller (or Standalone) unit.

3. Add Controller’s IP address to Segment and/or Channel Extenders to link them to the Controller

4. Assign Operational Mode of remaining units including channel and/or segment range

5. Complete Coordinate Matrix of remaining units

6. Optionally, configure multiple Vectoring Groups (Multi-pairs) on Controller (or Standalone) unit

7. Display/edit Network Monitoring Map on Controller.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 24 of 78

5.3 Launching the CFA-24 Configuration Software

The CFA-24 is connected to a remote PC via an Ethernet POE switch or POE adaptor (connected to an Ethernet switch),

depending on the number of units in the CFA network.

• Enter the static IP address of the CFA-24 unit to access the CFA configuration software. The Main screen is

shown.

The Main Screen.

5.4 Configure Individual Units

5.4.1 Overview

Entering the IP address of a CFA-24 unit via a remote PC connected to the CFA-24 network launches the CFA-24

software.

➢ IP addresses are established during the first process, Establish CFA Network. If you have not done so, stop and

go to that section before proceeding.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 25 of 78

5.4.2 Instructions for Linking Extender Units to the Controller

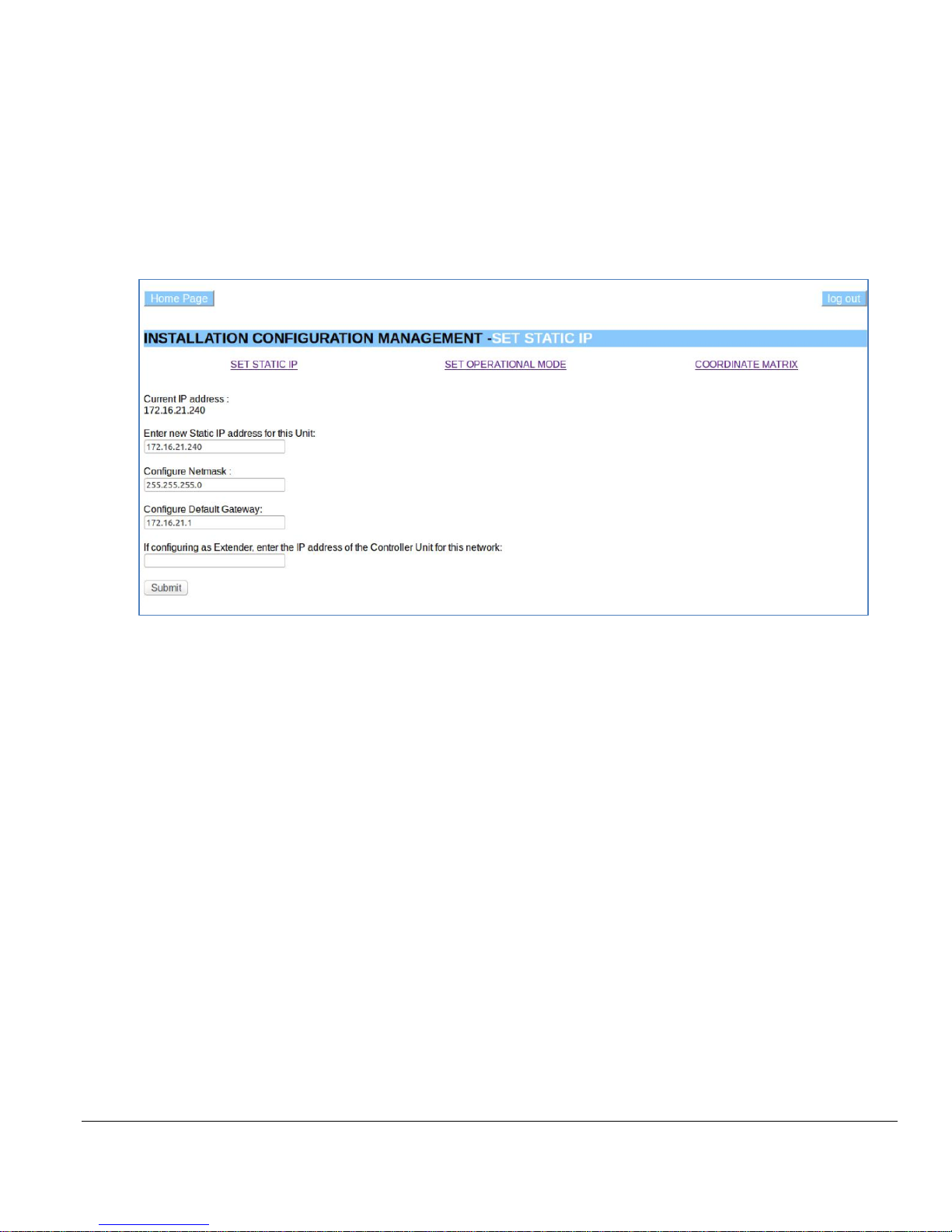

Set/Change Static IP

It is assumed the Establish CFA Network process has been completed and, if applicable, the IP address of the Controller

unit selected. The instructions that follow are used to enter the Controller IP address in the SET STATIC IP screen

when linking Extenders to the Controller. If the CFA system has only one unit, this section does not apply.

• Select Installation Configuration Management from the Main screen. The INSTALLATION

CONFIGURATION MANAGEMENT - SET STATIC IP screen is shown.

Set Static IP screen. The bottom field is used to enter the IP address of the Controller unit

to link an Extender unit to the Controller unit.

• If this unit is an Extender unit, enter the Controller IP address in the If configuring as Extender . . . field to

link this Extender to the Controller unit.

• Click Submit to update all fields. A confirmation screen is shown.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 26 of 78

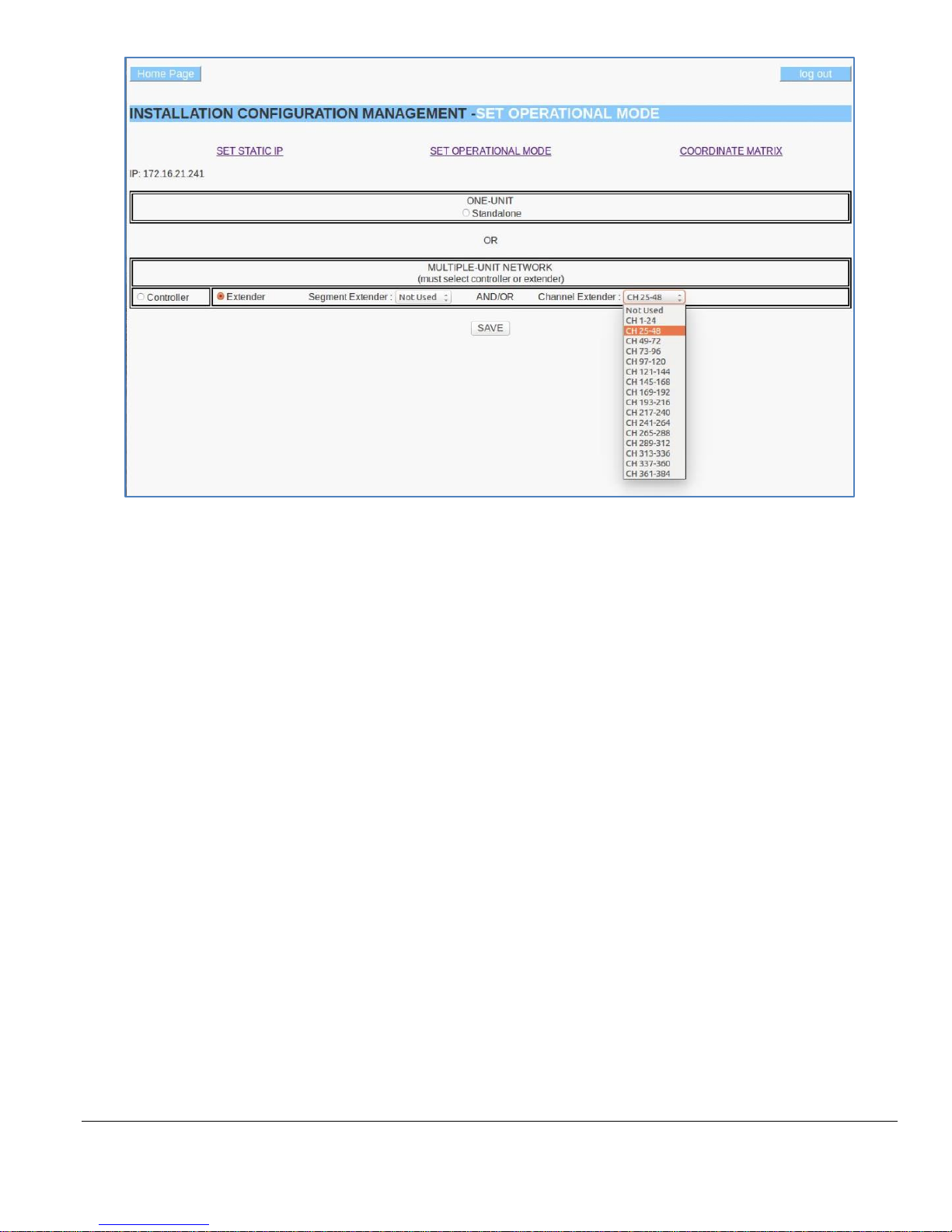

Set/Change Operational Mode

If not already connected, enter the IP address of a CFA-24 unit via a remote PC connected to the CFA-24 network to

launch the CFA-24 software.

• Select SET OPERATIONAL MODE from the INSTALLATION CONFIGURATION MANAGEMENT

screen.

The Set Operational Mode screen showing the selections for a Controller unit.

The Set Operational Mode screen showing the selections for a Segment Extender unit used for segments 6-10.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 27 of 78

The Set Operational Mode screen showing the selection for a Channel Extender unit used for channels 25-48.

• Single-Unit Networks

o Click the Standalone radio button.

o Click Save to update the target unit. A confirmation screen is shown.

• Multi-unit network

o Controller Unit

▪ Click the Controller radio button (the channel range is must also be 1-24 and the segment

range 1-5 for the Controller);

OR

o Extender Unit

▪ Click the Extender radio button

▪ For Segment Extenders, select the segment range for this unit (this range appears in the

Coordinate Matrix; AND/OR

▪ For Channel Extenders, select the channel range for this unit (this range appears in the

Coordinate Matrix).

o Click Save to update the target unit. A confirmation screen is shown.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 28 of 78

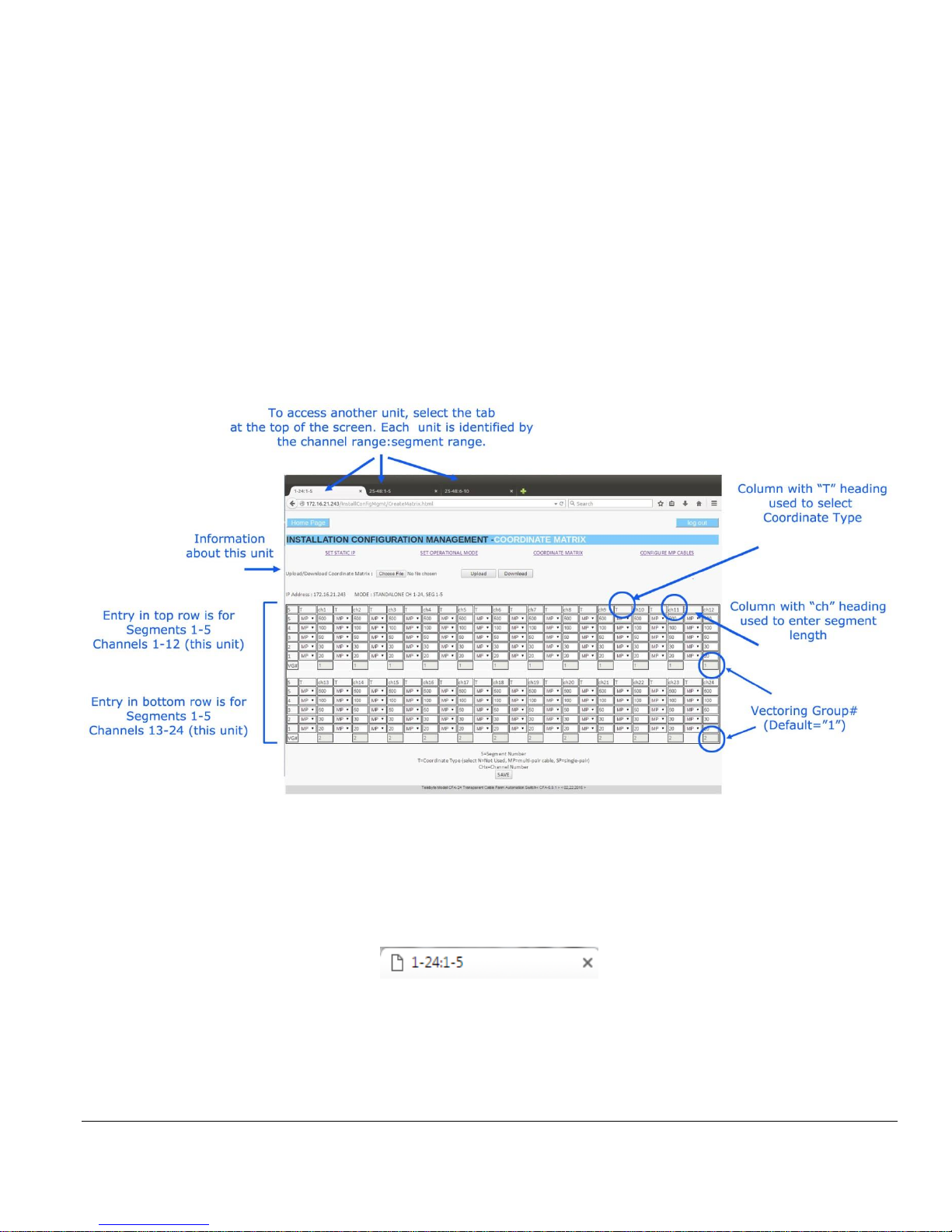

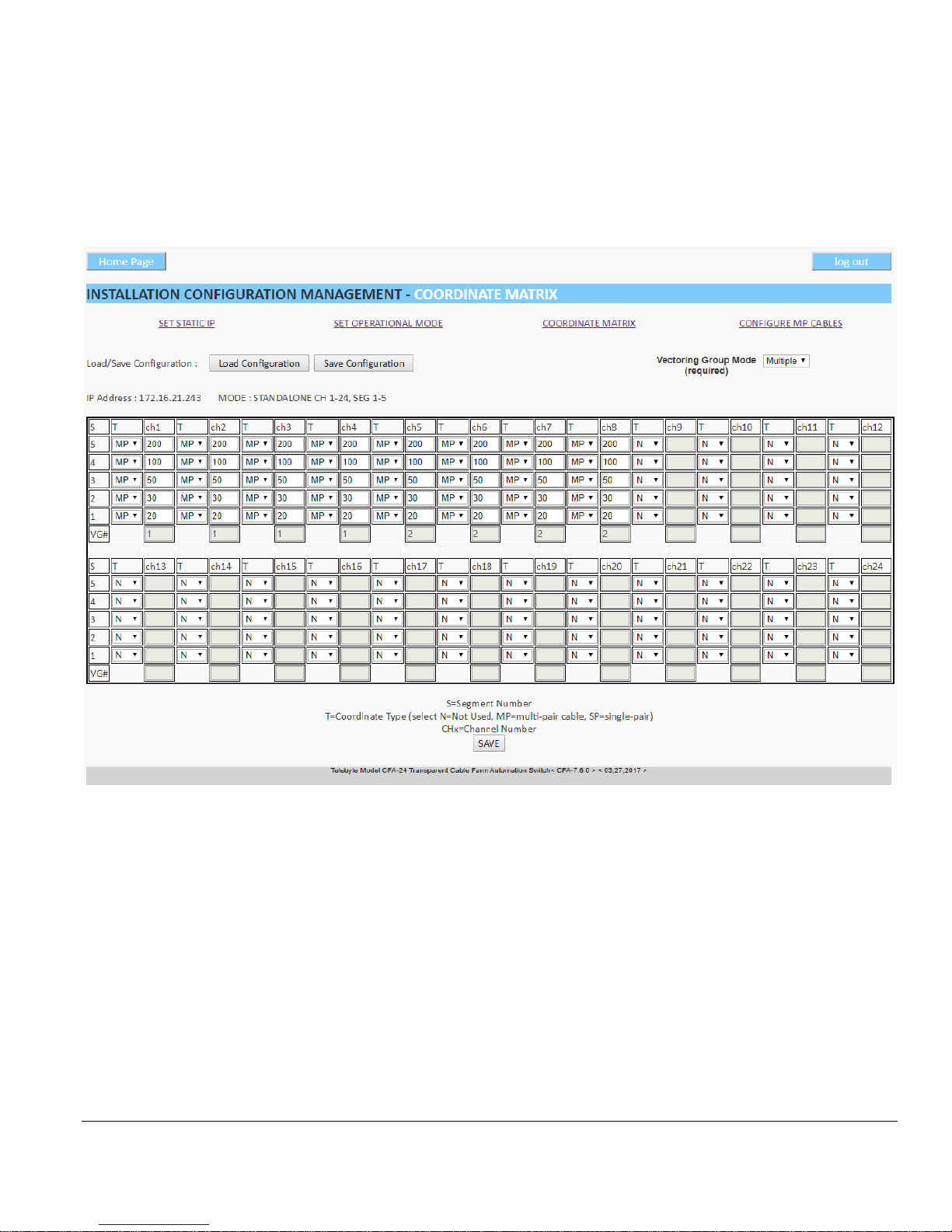

Configure Coordinate Matrix

The Coordinate Matrix defines the coordinate types and length for each segment:channel combination on the target

CFA-24. The selections for the coordinate type must match the physical cable attached to the CFA-24 segment:channel.

The information from each Coordinate Matrix combines with all others to form the overall characteristics of the CFA24 system.

Elements of the Coordinate Matrix screen

The Coordinate Matrix screen is divided into two rows, the topmost is for channels 1-12 and the bottommost for

channels 13-24. Both rows display the connector segment number on the left side. Columns with a “T” heading are used

to select the Connector Type. Columns with a “CHx” heading are used to enter a loop length for the channel. Vectoring

Group numbers (VG#) are shown at the bottom of each channel.

Connector Types are selected and loop lengths are entered directly. Vectoring Group numbers are configured through

the Configure MP Cable function. The resulting Vectoring Group number assignments are displayed on the Coordinate

Matrix screen. The Configure MP Cable function is only available on a Controller or Standalone unit as Vectoring

Groups are system-wide.

The Coordinate Matrix screen always shows a segment range of 1-5 and a channel range of 1-24 (on a unit basis). To

view the current unit’s channel:segment range in the complete CFA-24 system, view the tabs at the top of the screen to

see the actual channel:segment range (on a system-wide basis). For example, the tab below shows the current Coordinate

Matrix is for channels 1-24 and segments 1-5.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 29 of 78

Multiple Vectoring Groups (Configure MP Cables)

A Vectoring Group (VG) is used to identify a specific selection of channels for the purpose of setting independent

available line lengths for that selection. The available line lengths can be varied by including or excluding segments

independently from one VG to another. It is assumed all channels in a given Vectoring Group are connected to cables

between which there is crosstalk. In addition, a Vectoring Group may be designed as Colocated or Non-Colocated.

For example, the user may wish to attach two binders, each with four cables, to a CFA and have independent control of

the line lengths available for selection for each binder. In this example, the user would configure two Vectoring Groups

of four channels each.

Vectoring Groups apply to the entire CFA system; therefore, they are configured on the Controller or Standalone unit

only.

When using Multi-Pairs in the Coordinate Matrix, the CONFIGURE MP CABLES option must be used to configure

the Vectoring Groups.

List of Rules for defining a Vectoring Group:

• A minimum of 2 channels is required for any VG.

• All channels in the VG must contain at least one MP coordinate.

• The channels within a VG are not required to be sequential.

• The channels within a VG are not required to belong to the same CFA-24 unit.

The number of available Multiple Vectoring Groups is calculated by adding together all channels in the entire CFA

system that contain at least one MP coordinate. This number is then divided by two (a minimum of two channels are

required per VG) and, if necessary, rounded down to the next lowest whole number.

Once the number of VG’s is selected, each channel is assigned to a specific VG by the user. After each VG is established,

the user may include or exclude segments (if Non-Colocated) for any VG independently, allowing for different line

length settings per VG.

➢ The default number of Vectoring Groups is 1.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 30 of 78

Considerations When Selecting Coordinate Types and Lengths

The CFA-24 solution is designed for VDSL2 Vectoring and G.fast testing. Selections are verified to be certain they do

not deviate from the appropriate choices for this type of testing. In the event this occurs, the row containing the error is

highlighted.

Multi-pair vs Single-Pair Selections

There is a difference in the Allowable Line Lengths results in Test Maintenance when assigning coordinate types of

Multi-Pairs vs Single Pairs in the Coordinate Matrix screen:

• Multi-Pairs:

o Allowable Line Lengths results in Test Maintenance, for a particular channel, are determined by

adding each segment length, beginning with the CO side of the unit (on segment 1).

o The Test Maintenance screen is used to select which segments are included in the Allowable Line

Lengths computation.

o This coordinate type is required when enabling Multiple Vectoring Groups. All channels in a

Vectoring Group must contain at least one MP coordinate.

• Single-Pairs:

o Single-Pair segments are automatically included as part of the Allowable Line Lengths computation.

Rules

Multi-Pair Coordinate Type (referred to as MP’s below):

• When using MP’s on a particular channel, a minimum of two MP’s must be assigned to that channel.

• An MP must have the same length as all the other MP’s in the same segment row. This applies regardless

of how many Vectoring Groups are used.

• When configuring a series of MP’s on a particular channel, configure the first one (lowest numbered one)

beginning on the CO side. Any MP after that, on the same channel, must be assigned to a higher segment

number.

• If enabling multiple Vectoring Groups, the number of MP coordinates determines how many Vectoring

Groups are available for selection.

Single-Pair Coordinate Type (referred to as SP’s below):

• An SP can have any length.

• Multiple SP’s allowed per channel.

• Any SP segment number must be higher than any MP segment number on the same channel.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 31 of 78

Not Used (N) Coordinate Type:

• Any or all coordinates in a segment row may be designated as an N, even if that row has SP’s or MP’s.

• If a row has an MP and at least one N, then all channels that have an N in that particular row may only

have an N or SP above that point (i.e., in a higher segment number).

Example of Differences in Results

Using multi-pair coordinates only on all channels and segments:

CH1-24, Segment 1: 25

CH1-24, Segment 2: 50

CH1-24, Segment 3: 100

CH1-24, Segment 4: 200

CH1-24, Segment 5: 100

Potential available line lengths: 25, 75, 175, 375, 475

Using single-pair coordinates only on all channels and segments:

CH1-24, Segment 1: 25

CH1-24, Segment 2: 50

CH1-24, Segment 3: 100

CH1-24, Segment 4: 200

CH1-24, Segment 5: 100

Potential available line lengths: 25, 75, 100, 125, 150, 175, 200, 225, 250, 275, 300, 325, 350, 375,400, 425, 450, 475

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 32 of 78

• Select COORDINATE MATRIX from the INSTALLATION CONFIGURATION MANAGEMENT screen.

The Installation Configuration Management screen example for a standalone unit.

• Select Coordinate Type from the dropdown field, under the “T” column for the desired coordinate. See

Considerations When Selecting Coordinate Types and Lengths.

o N: Represents “Not Used.” Select N when no loop segment is attached to this coordinate.

o MP: Select MP (multi-pair) when the loop segment attached to this coordinate is part of the multi-pair

cable portion of the test setup. It is expected that crosstalk occurs between multi-pairs. When using

Multi-Pairs in the Coordinate Matrix, use CONFIGURE MP CABLES to set up the number of

Vectoring Groups.

o SP: Select SP (single pair) when the loop segment attached to this coordinate is used for the single-

pair portion of the test setup.

• Enter Coordinate Length. This field is mandatory when the Coordinate Type is MP or SP. The value entered

must match the length of physical twisted multi-pair cable connected to a connector segment.

• VG#: Display field showing the current Vectoring Group number assigned to the channel. A blank field

indicates there is one Vectoring Group (default). If this unit is a Controller or Standalone and MP’s are

configured, select CONFIGURE MP CABLES to configure Vectoring Groups.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 33 of 78

• Click SAVE to update the target CFA-24. The confirmation screen is displayed, showing the selections

made.

➢ Entries for Multi-Pair lengths are not validated by the Save function when there is only one

Vectoring Group. This validation is performed on the Test Maintenance screen.

• Select CONFIGURE MP CABLES from the COORDINATE MATRIX screen

The Configure Multiple Pair (MP) Cables screen is shown above. In this example 4 Vectoring Groups are selected.

• Number of Vectoring Groups: The values in this dropdown field are determined by the number of MP

coordinates assigned, in all the Coordinate Matrix screens, for all CFA’s in the CFA system. Select the

number of Vectoring Groups desired. Once selected, the number of Vectoring Groups is displayed in the

upper-left corner of the grid. Note that selecting 1 Vectoring Group simply returns the user to the Coordinate

Matrix screen.

• VG #: assign a Vectoring Group (VG) number to each channel.

• PREVIEW: click to see a preview of all assignments.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 34 of 78

In the example of the PREVIEW screen above, 24 channels are assigned to four Vectoring Groups.

• SAVE: Click to update the CFA system or Cancel to return to Test Maintenance without saving. Once the

CFA system is updated, all Coordinate Matrix screens in the CFA system display the new Vectoring Group

number assignments under each channel.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 35 of 78

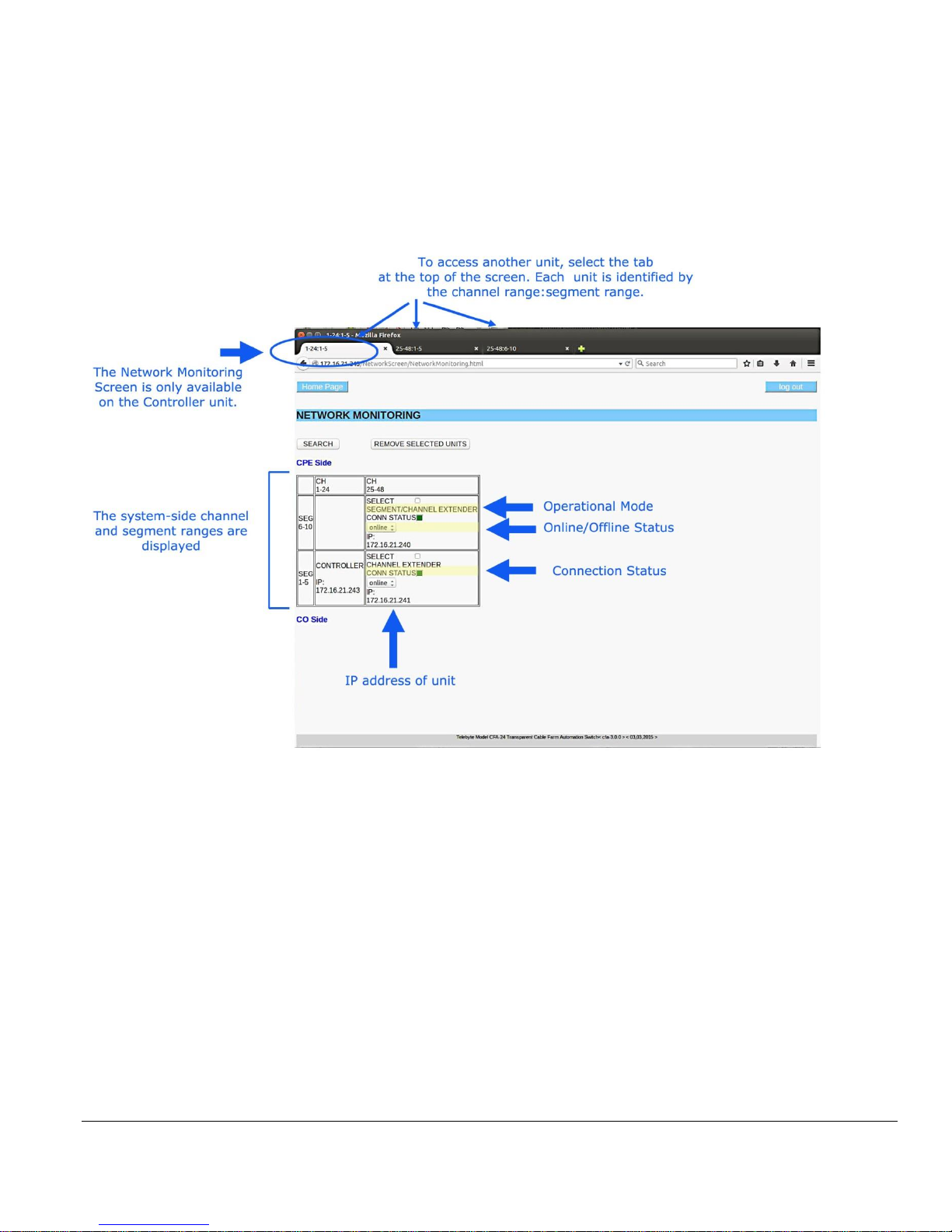

6.0 Display/Edit Network Monitoring Map

Once all Coordinate Matrixes are completed, the Network Monitoring Map may be viewed by accessing the Controller

unit.

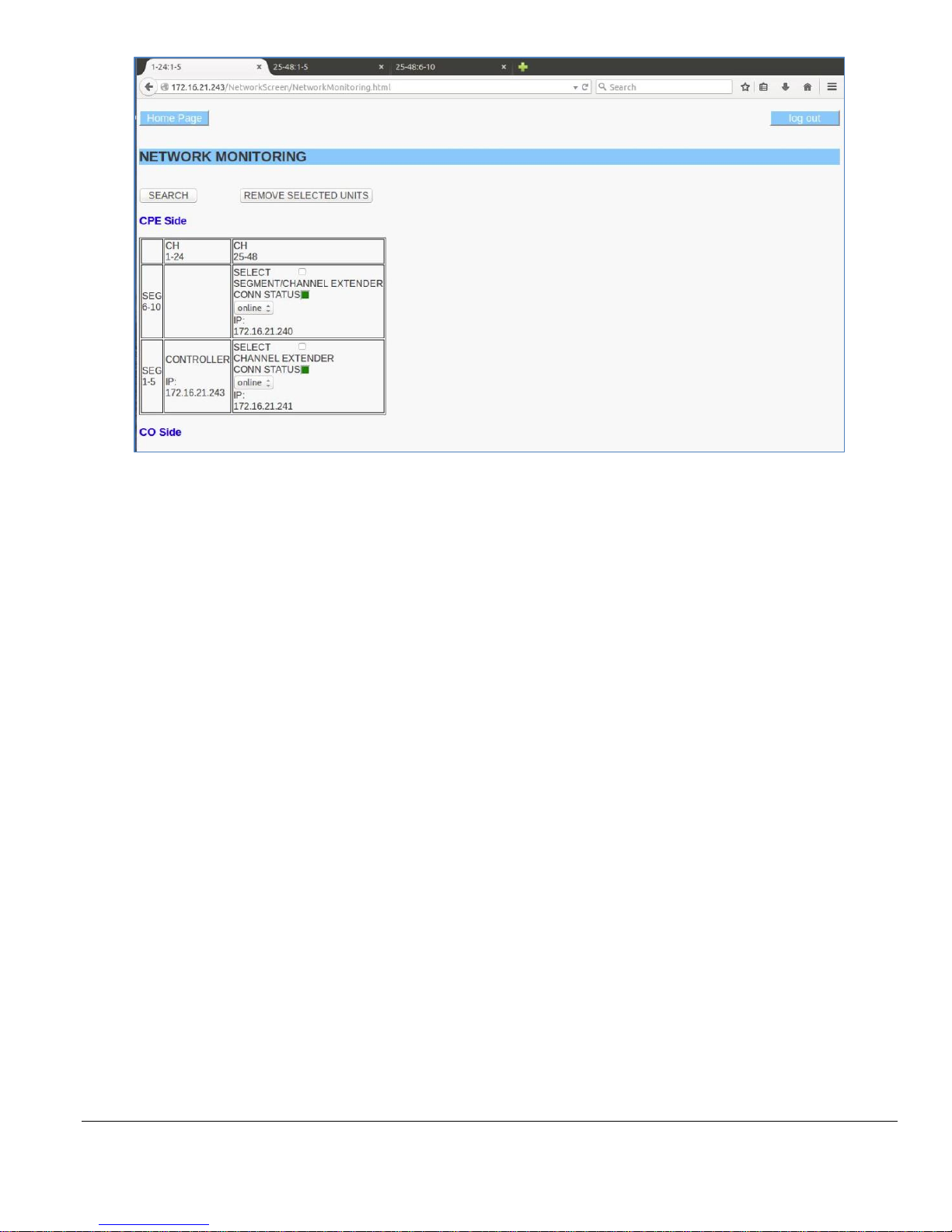

Elements of the Network Monitoring Screen

All information shown in the Network Monitoring screen is obtained from settings established during the previous

processes. In the example above, a system with a Controller, Channel Extender, and Segment/Channel Extender is

shown. Each unit is identified by its static IP address. Note the segment:channel ranges set during the Set Operational

Mode process are now all shown on a system-side basis.

The user may now manually place a unit off (or on) line, check the connection status, remove a unit from the system or

search to find units added to the system that are not yet shown.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 36 of 78

• Enter the IP address of the Controller unit. Select Network Monitoring Screen. The Network Monitoring screen

is displayed.

The Main Screen.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 37 of 78

The Network Monitor screen example shows a three-unit system.

Search: search the CFA-24 Network to discover all units where the Controller IP address value for that unit matches

the Controller’s IP address displayed on the Network Monitoring screen.

Remove Selected Units: any unit on the screen with the Select box checked is removed from CFA-24 Network when

this button is clicked. When the Search button is clicked, if the unit is still physically connected to the network and has

the same IP address as the Controller, it appears again in the Network Monitoring screen.

Select: checkbox used to select a unit for removal when the Remove Selected Units button is clicked.

Online/Offline: dropdown allows user to change the status of the related unit to online or offline. Online means the

unit should be included in the CFA-24 Network. Offline means that it should not be included in the CFA-24 Network.

This selection does not physically disconnect the unit.

• Manually taking a unit offline may cause other units to be taken offline also. For instance, taking the

unit using segments 1-5 (and channels 25-48) offline would force all units in a higher segment range

to be taken offline.

Conn (Connection) Status: A red LED appears when a unit is not communicating with the Controller. A green LED

appears when the unit is communicating with the Controller.

• A unit can have a connection status of “not connected” and still have an online status. This can occur

if the unit becomes physically disconnected but the user still wishes it to be in the CFA Network.

IP: shows the unique static IP address of the CFA unit.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 38 of 78

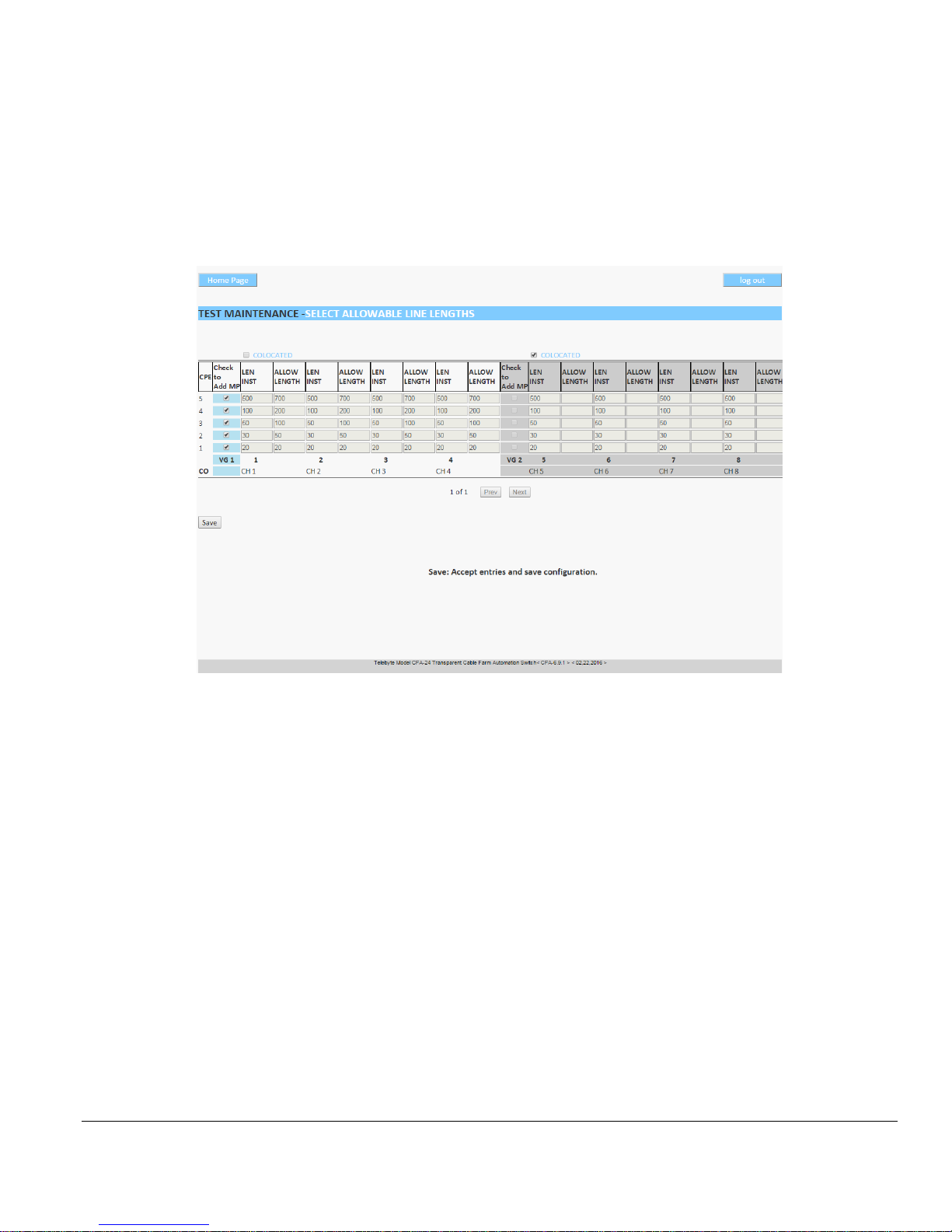

7.0 Test Maintenance Process

The Test Maintenance Process sets the line lengths that are allowed to be selected by the user during the Set Channel

Lengths/Micro-Interruptions process. The purpose is to control the available settings at the user level. All values shown

in the Test Maintenance screen are calculated based upon the configuration steps performed during the Installation

Configuration Management process.

7.1 Colocated and Non-Colocated Vectoring Groups

One or more Vectoring Groups may be designated as Colocated or Non-Colocated. The default is one Non-Colocated

Vectoring Group. The Colocated check box is used to make the designation.

Colocated:

• All segments selected automatically.

• Only MP’s are valid.

• SP’s are ignored.

• More line lengths available for selection.

Non-Colocated:

• Control over which segments are included.

• Both MP’s and SP’s are valid.

Understanding Colocated and Non-Colocated

This relates to the lengths of the twisted pair cables between the CO (DPU or DSLAM) and CPE’s in a vectoring

group. When the cable lengths in the vectoring group are equal, then the vectoring group will be colocated. When they

are unequal, then the vectoring group will be non-colocated.

Examples:

Colocated – The connection from the CO terminates at an MDU (multiple dwelling unit). All the cables in the binder

(vectoring group) are the same length.

Non-Colocated – Each CPE connected to the CO is located at a different distance from the CO. Cables terminate at

the various CPEs and leave the binder (vectoring group), resulting in unequal line lengths within the binder.

The behavior of FEXT (Far End Crosstalk) in a colocated vectoring group is different from that found in a noncolocated vectoring group. This is due, in part, to the fact that crosstalk is affected by the proximity of cables to each

other. When the lengths are different, the proximity varies. A colocated vectoring group might be used for testing

when the greatest FEXT is needed.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 39 of 78

7.2 Instructions

7.2.1 Accessing Test Maintenance

• Enter the IP address of the Controller unit to access the Main screen. Click TEST MAINTENANCE.

The SELECT ALLOWABLE LINE LENGTHS screen is shown.

The SELECT ALLOWABLE LINE LENGTHS screen allows the user to configure the line lengths available for

selection by checking off which segments to include.

For Colocated Vectoring Group

Colocated: check this box to designate the Vectoring Group as Colocated. If checked, the entire Vectoring Group is

grayed out.

For Non-Colocated Vectoring Group:

Check to Add MP: check this box to include the segment number (shown to the left of check box) and all related

lengths in that row for the range of channels on the screen. Each segment selected becomes a loop increment available

for selection. Note: Anytime the Coordinate Matrix is updated, confirm the Check to Add MP boxes of the Test

Maintenance page are correct and press Save before setting any line length in the “SET LENGTH” screen.

LEN INST: displays the length of the loop segment established during the Installation Configuration Management

process.

ALLOW LENGTH: displays the resulting length available to the user during the Set Lengths and Interrupts Process.

Note the values in this field are derived from the LEN INST values in the checked segments.

• Click SAVE to save this configuration and update the Test Maintenance screen.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 40 of 78

Use the Prev and Next buttons to navigate from one VG to another. This may be necessary when there are a large

number of VG’s.

➢ Anytime the Coordinate Matrix is updated, confirm the Check to Add MP boxes of the Test Maintenance screen

are correct and press Save before setting any line length in the “SET LENGTH” screen.

For the example screen on the previous page, the resulting available line lengths are:

VG1 (Channels 1-4): 0, 20, 50, 100, 200, 700

VG2 (Channels 5-8): 0, 20, 30, 50, 70, 80, 100, 120, 130, 150, 170, 180, 200, 500, 520, 530, 550, 570, 580, 600, 620,

630, 650, 670, 680, 700

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 41 of 78

8.0 Making Connections Process

8.1 Steps in Making Connections Process

1. Rack mounting (optional)

2. Segment twisted-pair loop segments connected to coordinate punch down blocks.

3. Connection of CO and CPE-side equipment

4. Establishing Cable Shield Continuity

5. Establishing proper grounding

6. Connecting Segment Extenders

8.2 Rack Mounting (optional)

To allow for dense installations, each unit may be installed in the front and/or back of a standard 19” rack. In addition,

three rack mount options make installation customizable.

➢ Care should be taken to leave space for easy access to the back of the unit. This

area contains an access door that may need to be used at some point.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 42 of 78

8.2.1 Placement of Rack-Mounting Brackets

There are two rack-mounting brackets on the CFA-24, one on each side. Each bracket is movable and may be

used to control the position of the unit in the rack.

• The standard position is for the CFA-24 to be flush with the rack.

• For the Protruding position, remove the mounting bracket screws holding the side rack-mounting

brackets, move the brackets toward the rear and re-install the mounting bracket screws into the new

position. The CFA-24 then protrudes 2” out from the rack.

• For the Recessed position remove the mounting bracket screws holding the side rack-mounting

brackets, move the brackets toward the front and re-install the mounting bracket screws into the new

position. The CFA-24 then recesses 2” into the rack.

➢ Care should be taken to leave space for easy access to the back of the unit. This

area contains an access door that may need to be used at some point.

8.2.2 Mounting on a 19” Rack

The rack-mounting brackets on each side of the unit contain six holes for mounting onto a 19” rack. The

bottom of the CFA-24 should align with the half of the 0.5” space pattern (of the rack holes) that is followed

by the two 0.625” hole pattern (as shown below). Use the four (4) cage nuts at the top and bottom rackmounting bracket holes in the rack (that have been determined for CFA-24 attachment) and insert a screw

(provided) through the CFA-24 top and bottom rack-mounting bracket holes into the cage nut and tighten the

CFA-24 to the rack. Note: typically, #10, #12 and M6 mounting hardware is used.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 43 of 78

8.2.3 Using the CFA-24 without Rack Mounting

When using the CFA-24 without the rack mounting option, the rack-mounting brackets may be retained on the CFA-24

or removed.

WARNING

For personnel safety when not mounted on a rack, the metal enclosure of the CFA-24 must be earth

grounded. Connect an AWG18 wire to the ring lug at the rear of the CFA-24 (shown below) and

connect the other side of the wire to a good earth ground.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 44 of 78

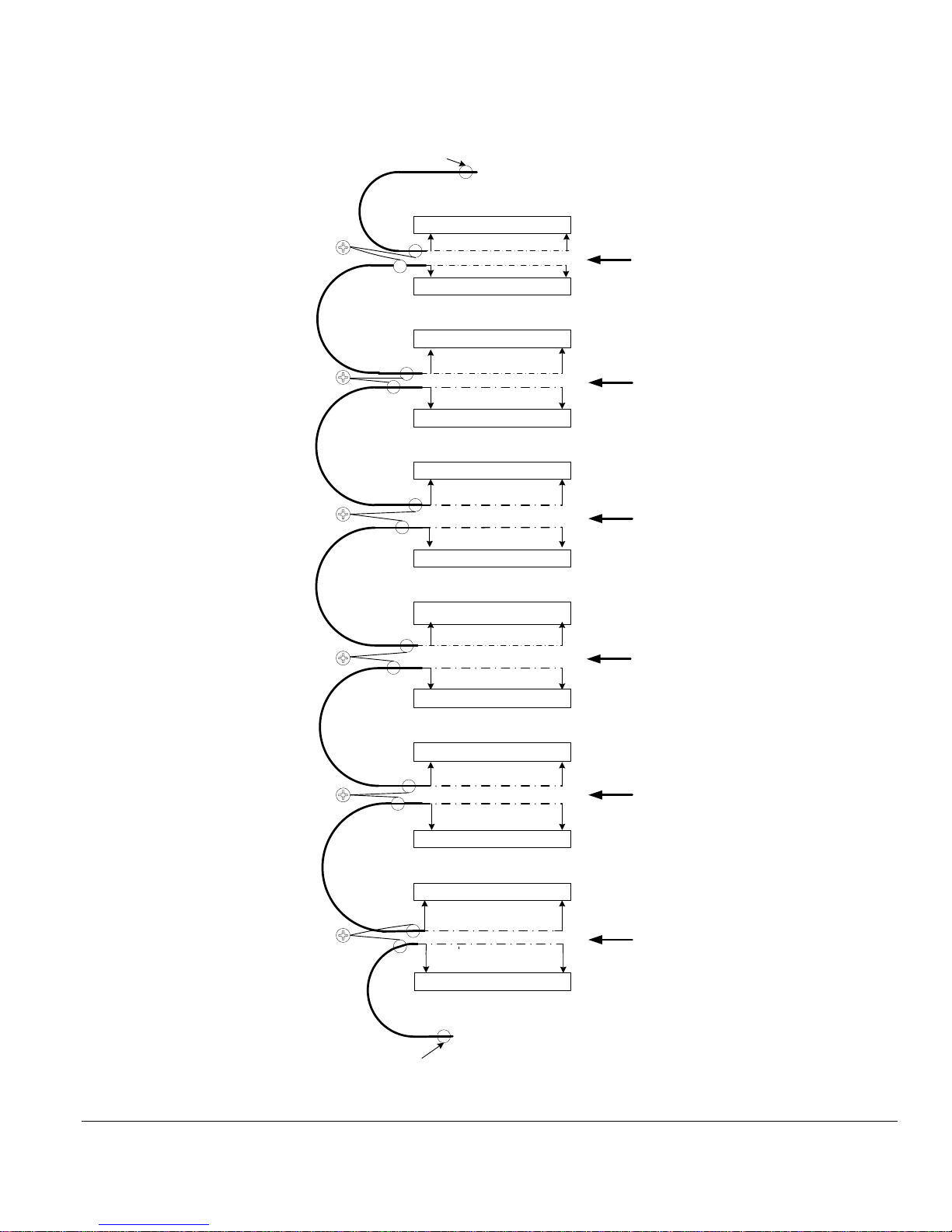

8.3 Segment Twisted-Pair Connection to Coordinate Punch Down Blocks

8.3.1 Segment to Punch Down Block Connection

Ø

Ø

Ø

Ø

Ø

Ø

Ø

Ø

Ø

Ø

Ø

CPE or Extender

SEG 5 in Punch Blocks

SEG 5 out Punch Blocks

CPE Punch Blocks

F

SEG 4 out Punch Blocks

E

Shield

Connector

Shield

Screw

SEG 4 in Punch Blocks

SEG 3 out Punch Blocks

Seg 3 in Punch Blocks

D

Ø

C

Seg 2 out Punch Blocks

Seg 2 in Punch Blocks

SEG 1 in Punch Blocks

SEG 1 out Punch Blocks

B

CO Punch Blocks

A

CO or Extender Cable

Shield

Screw

Shield

Screw

Shield

Screw

Shield

Screw

Cable Shield

CO or EXT IN

SEG 1 IN Tie

Bar

Seg 1

Seg 2

Seg 3

SEG 1 OUT

SEG 2 IN

Tie Bar

SEG 2 OUT

SEG 3 IN

Tie Bar

SEG 3 OUT

SEG 4 IN

Tie Bar

Seg 4

SEG 4 OUT

SEG 5 IN

Tie Bar

Seg 5

SEG 5 OUT

CPE or EXT

Tie Bar

Cable Shield

Segment Punch Down Block Connection Diagram

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 45 of 78

Segment Wire Connection to the Punch Down Blocks

The channel connections for the 24 wire pairs of each Cable Segment is arranged in a horizontal row with Channel 1

wire pair at the far left side and Channel 24 wire pair on the far right side of each row. Each punch down block contains

eight (8) connections for 4-channel wire pairs where the Tip wire (T) is connected to the left side of the pair and the

Ring wire (R) is connected to the right side of the pair, as defined in punch down block figure that follows. Each wire

pair must retain its twists up to their separation at the punch down block. The wire enters the block from the lower side

of the block.

• Maintain tip-ring twists to the punch block.

• Do not strip the insulation off the wire. The

punch block will make connection through the

insulation.

• See CFA-PDTOOL-KIT for instructions.

Starting on left side of the Punch Down Block

Blue

Blue

T pair 1

Blue

R pair 1

Green

Orange

T pair 2

Green

Orange

R pair 2

Orange

Green

T pair 3

Orange

Green

R pair 3

Brown

Brown

T pair 4

Brown

R pair 4

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 46 of 78

8.3.2 Using the CFA-PDTOOL-KIT to Punch Down Wire

Overview

The punch down blocks accept 22 AWG to 26 AWG solid wire. Due to the non-symmetrical nature of the punch down

blocks, the krone blade must be properly oriented to prevent damage to the connectors. The CFA-PDTOOL-KIT

contains the following tools for proper installation of the wires.

• Fluke Impact Tool

• Fluke Krone Blade

• Jonard Krone Blade

• Wire Cutter

Before You Begin

• When a connection is removed, the replacement wire must be the same AWG size or larger than the wire

removed. The punch down block is specified for 20 removals/replacements.

• Maintain tip-ring twists to the punch block.

• Do not strip the insulation off the wire. The punch down block itself will make connection through the

insulation.

The CFA-PDTOOL-KIT consists of a Fluke Impact Tool, Krone Impact Tool Blade, alternate Jonard Krone Blade and

a wire cutter. The Fluke Impact Tool is shipped with the Krone Impact Tool Blade already attached and the Jonard

Krone Blade stored inside the handle of Krone Impact Tool. To remove the Jonard Krone Blade, turn Release Blade.

To change from High Impact to Low Impact, turn LO HI IMPACT.

Correct orientation of the Jonard Krone Blade. Side view of the Krone Impact Tool Blade. Correct orientation.

Krone Impact Tool –

Blade and Handle

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 47 of 78

Jonard Krone Blade with protective cap to cover blade end. The blade must be oriented as shown above or it may cause

damage the punch down block. If resistance is felt, check the orientation as it should slide into the block easily. The

opposite end is used to push the wire into the punch down block and the separate wire cutter is used to cut the wire.

Keep the red cap on the blade end to protect fingers, especially when inserting into the Krone Impact Tool for storage.

Instructions for Top Row of Punch Down Blocks (punched from above connector)

Tools:

1. Fluke Impact Tool

2. Jonard Krone Blade

3. Wire cutter

➢ Important! Orient the Jonard Krone Blade as shown below to avoid damaging the punch down block.

The Jonard Krone Blade showing the wire being pushed into the punch down block.

Use the wire cutters to cut excess wires from below the punch down connector.

Instructions for All Other Punch Down Blocks (punched from below connector)

Tools:

1. Fluke Impact Tool

2. Krone Impact Tool Blade

Press the wire into the punch down block. This will also automatically cut the wire. For 24 AWG or 26 solid wire use

the Low Impact setting. For 22 AWG solid wire use the High Impact setting

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 48 of 78

Segment End Input and Output Side Pairing

To prevent punch down connection signal coupling, segment signals of equal level are retained near each other. For

Cable Management, a set of six (6) Segment Tie Bars are available, which mount to the 19” rack through the CFA Rack-

Mounting brackets, at positions that provide for pairing the cables as shown in the Segment Punch Down Block

Connection Diagram (referred to here as the Connection Figure). Each Segment Cable end is identified as an input or

output as shown in the Connection Figure. The input end is where a signal enters into a segment and the output end is

where the segment’s attenuated signal leaves the segment. As the output of a segment is at the same signal level as the

input to the next segment, these ends are placed on the same Segment Tie Bar (referred to here as a Tie Bar), which

prevents coupling from a stronger to a weaker signal end. Do not place other segment ends on the same Tie Bar as the

stronger signal end will couple into the weaker signal end.

As shown on the Connection Figure, the output of the CO cable and the input to SEG 1 cable are on the SEG 1 Tie Bar.

The CO wires are connected to the lower punch down blocks and the input to SEG 1 cable are connected to the second

punch down blocks. Similarly:

The output of SEG 1 and input to Seg 2 are on the same Tie Bar.

The output of SEG 2 and input to Seg 3 are on the same Tie Bar

The output of SEG 3 and input to Seg 4 are on the same Tie Bar

The output of SEG 4 and input to Seg 5 are on the same Tie Bar

The output of SEG 5 and input to the CPE Cable are on the same Tie Bar.

➢ To further minimize coupling it is recommended that the above cable segment pairs be alternated between the

left and right side of the CFA-24 rack to further increase the distance between weaker and stronger signals.

Example:

CO (or Extender) input and SEG 1 input on left side of rack

SEG 1 output and SEG 2 input on right side of rack.

SEG 2 output and SEG 3 input on left side of rack.

SEG 3 output and SEG 4 input on right side of rack.

SEG 4 output and SEG 5 input on left side of rack.

SEG 5 output and CPE (or Extender) output on right side of rack.

Model CFA-24 Transparent Cable Farm Automation Switch Reference Manual Page 49 of 78

8.3.3 Cable Shield Continuity

➢ Refer to the Segment Punch Down Block Connection Diagram ( see section 4.3 earlier in this text).

The CFA-24 includes Shield Continuity Connectors marked A-F located at the left side of the punch down blocks. The

A through F connection screws are isolated from each other and from signal and earth grounds. They provide a means

to “bond” the shield of a segment output end to the next segment input end. This provides for a continuous shield

connection from the CO to the CPE.

The CO cable shield is connected to Shield Continuity Connector “A” screw using a #10 ring lug. The SEG 1 input end

cable shield is also connected to the “A” screw which allows the SEG 1 cable shield to be connected to the CO shield.

In a similar manner, each output cable end and input cable end shield is connected to the same Shield Continuity

Connector as shown below. The Shield Continuity Connector screws are 10-32 size and the shield lugs are placed

between the stainless steel washer and screw-head to prevent damage to the pc board.

When less than five (5) segments are used the Shield Continuity Connectors must have jumpers connected to the Shield

Continuity Connector screws in order to maintain shield continuity to the CPE, as shown below.