TelCom Semiconductor Inc TC850CLW, TC850ILW, TC850IJL, TC850CPL Datasheet

15-BIT, F AST -INTEGRATING CMOS ANALOG-T O-DIGITAL

CONVERTER

1

TC850

2

FEATURES

■ 15-bit Resolution Plus Sign Bit

■ Up to 40 Conversions per Second

■ 12 Conversions per Second Guaranteed

■ Integrating ADC Technique

— Monotonic

— High Noise Immunity

— Auto-Zeroed Amplifiers Eliminate Offset

Trimming

■ Wide Dynamic Range ...................................... 96dB

■ Low Input Bias Current ................................... 30pA

■ Low Input Noise ...........................................30µV

■ Sensitivity....................................................... 100µV

■ Flexible Operational Control

— Continuous or On-Demand Conversions

— Data Valid Output

■ Bus Compatible, 3-State Data Outputs

— 8-Bit Data Bus

— Simple µP Interface

— Two Chip Enables

— Read ADC Result Like Memory

■ ± 5V Power Supply Operation ...................... 20mW

■ 40-Pin Dual-in-Line or 44-Pin PLCC Packages

FUNCTIONAL BLOCK DIAGRAM

C

R

INT

–

+

÷4

5

CONT/

DEMAND

BUF

25363439

BUFFER

INT

INT IN

TC850

7

L/H6OVR/

POL

INT OUT

–

+

INTEGRATOR

BUS INTERFACE

DECODE LOGIC

3

4RD1CS2

WR

2324

CE

22

COMPARATOR

+

–

6-BIT

UP/DOWN

COUNTER

DATA LATCH

OCTAL 2-INPUT MUX

3-STATE DATA BUS

. . . .

15

DB0

COMMON

+

REF

2

+

1

ANALOG

MUX

CONTROL

SEQUENCER

1

–

REF

A/D

18

OSC

2

REF

32

+

IN

31

–

IN

30

CLOCK

OSCILLATOR

17

OSC

+5V–5V

40

9-BIT

UP/DOWN

COUNTER

8

DB7

P-P

GENERAL DESCRIPTION

The TC850 is a monolithic CMOS analog-to-digital

converter (ADC) with resolution of 15-bits plus sign. It

combines a chopper-stabilized buffer and integrator with a

unique multiple-slope integration technique that increases

conversion speed. The result is 16 times improvement in

speed over previous 15-bit, monolithic integrating ADCs

(from 2.5 conversions per sec up to 40 per sec). Faster

conversion speed is especially welcome in systems with

human interface, such as digital scales.

The TC850 incorporates an ADC and a µP-compatible

digital interface. Only a voltage reference and a few noncritical passive components are required to form a complete 15bit plus sign ADC.

CMOS processing provides the TC850 with highimpedance differential inputs. Input bias current is typically

only 30pA, permitting direct interface to sensors. Input

sensitivity of 100µV per least significant bit (LSB) eliminates

the need for precision external amplifiers. The internal

amplifiers are auto-zeroed, guaranteeing a zero digital output

with 0V analog input. Zero adjustment potentiometers or

calibrations are not required.

The TC850 outputs data on an 8-bit, 3-state bus. Digital

inputs are CMOS compatible; outputs are TTL/CMOS compatible. Chip-enable and byte-select inputs combined with

an end-of-conversion output ensures easy interfacing to a

wide variety of microprocessors. Conversions can be performed continuously or on command. In continuous mode,

data is read as three consecutive bytes and manipulation of

address lines is not required.

Operating from ±5V supplies, the TC850 dissipates only

20mW. It is packaged in 40-pin plastic or ceramic dual-inline packages (DIPs) and in a 44-pin plastic leaded chip

carrier (PLCC), surface-mount package.

ORDERING INFORMATION

Part No. Package Temperature Range

TC850CLW 44-Pin PLCC 0°C to +70°C

TC850CPL 40-Pin Plastic DIP 0°C to +70°C

TC850IJL 40-Pin CerDIP – 25°C to +85°C

TC850ILW 44-Pin PLCC – 25°C to +85°C

3

4

5

6

7

TELCOM SEMICONDUCTOR, INC.

8

TC850-4 11/5/96

3-77

TC850

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

ABSOLUTE MAXIMUM RATINGS*

Positive Supply Voltage (VDD to GND)....................... +6V

Negative Supply Voltage (VSS to GND) .....................– 9V

Analog Input voltage (IN+ or IN–) .....................VDD to V

Voltage Reference Input

Logic Input Voltage ................ V

Current Into Any Pin.................................................10mA

Ambient Operating Temperature Range

ELECTRICAL CHARACTERISTICS: V

(REF

+

1

, REF

–

, REF

1

+

)..............................VDD to V

2

+ 0.3V to GND – 0.3V

DD

While Operating................................................100µA

C Device ................................................0°C to +70°C

I Device.............................................– 25°C to +85°C

= ±5V, f

S

Lead Temperature (Soldering, 10 sec) .................+300°C

Package Power Dissipation (TA ≤ 70°C)

CerDIP..............................................................2.29W

Plastic DIP ........................................................1.23W

SS

SS

CLK

Plastic PLCC ....................................................1.23W

*Static-sensitive device. Unused devices must be stored in conductive

material. Protect devices from static discharge and static fields. Stresses

above those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings only and functional

operation of the device at these or any other conditions above those

indicated in the operational sections of the specifications is not implied.

Exposure to Absolute Maximum Rating Conditions for extended periods

may affect device reliability.

= 61.44 kHz, VFS = 3.2768V, TA = 25°C, Fig. 1 Test Circuit,

unless otherwise specified.

Symbol Parameter Test Conditions Min Typ Max Unit

Zero-Scale Error VIN = 0V ±0.25 ±0.5 LSB

End Point Linearity Error –VFS ≤ VIN ≤ +V

FS

Differential Nonlinearity — ±0.1 ±0.5 LSB

I

IN

Input Leakage Current VIN = 0V, TA = 25°C — 30 75 pA

0°C ≤ T

≤ +70°C ———

A

– 25° ≤ TA ≤ +85°C — 1.1 3 nA

V

CMR

Common-Mode Voltage Range Over Operating Temperature Range VSS + 1.5 — VDD – 1.5 V

CMRR Common-Mode Rejection Ratio VIN = 0V, VCM = ±1V — 80 — dB

Full-Scale Gain Temperature External Ref Temperature

Coefficient Coefficient = 0 ppm/°C — 2 5 ppm/°C

0°C ≤ TA ≤ +70°C

Zero-Scale Error V

= 0V — 0.3 2 µV/°C

IN

Temperature Coefficient 0°C ≤ TA ≤ +70°C

Full-Scale Magnitude V

= ±3.275V — 0.5 2 LSB

IN

Symmetry Error

e

I

S

I

S

V

V

I

OP

V

IL

I

PU

I

PD

I

OSC

C

C

t

CE

t

RE

t

DHC

t

DHR

t

OP

N

+

–

OH

OL

IH

IN

OUT

Input Noise Not Exceeded 95% of Time — 30 — µV

Positive Supply Current — 2 3.5 mA

Negative Supply Current — 2 3.5 mA

Output High Voltage IO = 500 µA 3.5 4.9 — V

Output Low Voltage IO = 1.6 mA — 0.15 0.4 V

Output Leakage Current Pins 8 – 15, High-Impedance State — 0.1 1 µA

Input High Voltage Note 3 3.5 2.3 — V

Input Low Voltage Note 3 — 2.1 1 V

Input Pull-Up Current Pins 2, 3, 4, 6, 7; VIN = 0V — 4 — µA

Input Pull-Down Current Pins 1, 5; VIN = 5V — 14 — µA

Oscillator Output Current Pin 18, V

= 2.5V — 140 — µA

OUT

Input Capacitance Pins 1 – 7, 17 — 1 — pF

Output Capacitance Pins 8 – 15, High-Impedance State — 15 — pF

Chip-Enable Access Time CS or CE, RD = LOW (Note 1) — 230 450 nsec

Read-Enable Access Time CS = HIGH, CE = LOW (Note 1) — 190 450 nsec

Data Hold From CS or CE RD = LOW (Note 1) — 250 450 nsec

Data Hold From RD CS = HIGH, CE = LOW (Note 1) — 210 450 nsec

OVR/POL Data Access Time CS = HIGH, CE = LOW, RD = LOW (Note 1) — 140 300 nsec

— ±1 ±2 LSB

P-P

3-78

TELCOM SEMICONDUCTOR, INC.

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

ELECTRICAL CHARACTERISTICS (Cont.)

1

TC850

Symbol Parameter Test Conditions Min Typ Max Unit

t

LH

t

WRE

t

WRD

t

WWR

NOTES: 1. Demand mode, CONT/DEMAND = LOW. Figure 10 timing diagram. CL = 100pF.

Low/High Byte Access Time CS = HIGH, CE = LOW, RD = LOW (Note 1) — 140 300 nsec

Clock Setup Time Positive or Negative Pulse Width 100 — — nsec

RD Minimum Pulse Width CS = HIGH, CE = LOW (Note 2) 450 230 — nsec

RD Minimum Delay Time CS = HIGH, CE = LOW (Note 2) 150 50 — nsec

WR Minimum Pulse Width CS = HIGH, CE = LOW, Demand Mode 75 25 — nsec

Clock Setup Time Positive or Negative Pulse Width 100 — — nsec

2. Continuous mode, CONT/DEMAND = HIGH. Figure 12 timing diagram.

3. Digital inputs have CMOS logic levels and internal pull-up/pull-down resistors. For TTL compatibility, external pull-up resistors to VCC are

recommended.

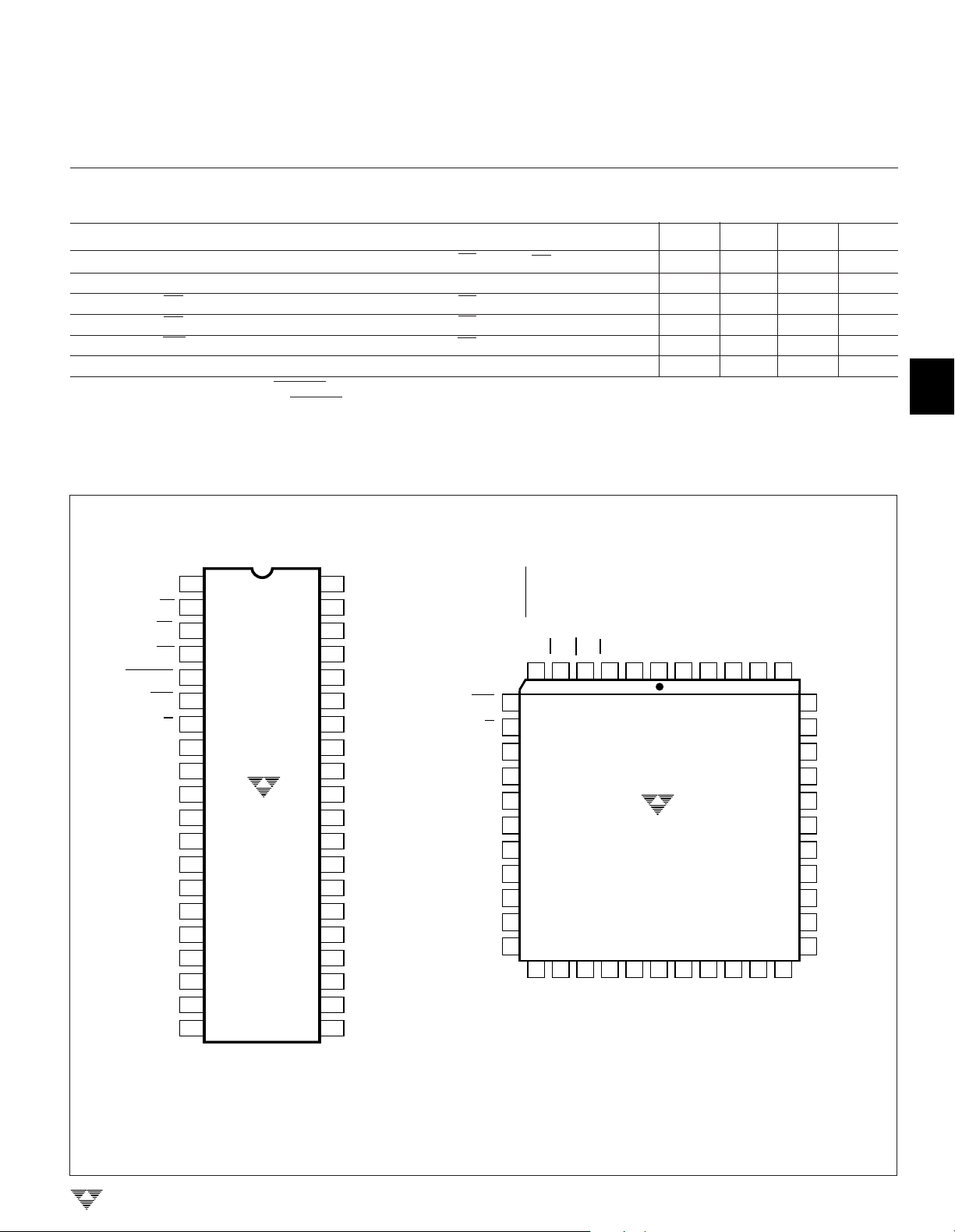

PIN CONFIGURATIONS

CS

CE

WR

RD

CONT/DEMAND

OVR/POL

L/H

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

BUSY

OSC

OSC

TEST

GND

1

2

3

4

5

6

7

8

9

10

TC850CPL

11

TC850IJL

12

13

14

15

16

17

1

18

2

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

V

DD

+

REF

1

+

C

REF1

–

C

REF1

–

REF

–

C

REF2

+

C

REF2

+

REF

2

+

IN

–

IN

COMMON

C

INTB

C

INTA

C

BUFA

C

BUFB

BUFFER

INT

IN

INT

OUT

V

SS

COMP

OVR/POL

L/H

DB7

DB6

DB5

NC

DB4

DB3

DB2

DB1

DB0

CONT/DEMAND

RD

6543 1442

7

8

9

10

11

12

13

18 19 20 21 23 24

OSC

BUSY

CE

WR

TC850CLW

TC850ILW

1

2

TEST

OSC

22

CS

GND

NC

NC

DD

V

COMP

1

+

43 42 41 40

25 26 27 28

REF

SS

V

+

REF1

C

OUT

INT

–

REF1

C

IN

INT

–

REF

39

38

37

36

35

34

33

3214

3115

3016

2917

BUFFER

–

C

REF2

+

C

REF2

+

REF

2

+

IN

–

IN

NC

COMMON

C

INTB

C

INTA

C

BUFA

C

BUFB

2

3

4

5

6

7

TELCOM SEMICONDUCTOR, INC.

NC = NO INTERNAL CONNECTION

8

3-79

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

TC850

PIN DESCRIPTIONS

40-Pin DIP

Pin No. Symbol Description

1 CS Chip select, active HIGH. Logically ANDed with CE to enable read and write inputs. (See

2 CE Chip enable, active LOW. (See note 5.)

3 WR Write input, active LOW. When chip is selected (CS = HIGH and CE = LOW) and in demand

4 RD Read input, active LOW. When CS = HIGH and CE = LOW, a logic LOW on RD enables the

5 CONT/DEMAND Conversion control input. When CONT/DEMAND = LOW, conversions are initiated by the WR

6 OVR/POL Overrange/polarity data-select input. When making conversions in the demand mode (CONT/

7 L/H Low/high byte-select input. When CONT/DEMAND = LOW, this input controls whether low-

8 DB7 Most significant data bit output. When reading the A/D conversion result, the polarity,

9 – 15 DB6–DB0 Data outputs DB6–DB0. 3-state, bus compatible.

16 BUSY A/D conversion status output. BUSY goes to a logic HIGH at the beginning of the deintegrate

17 OSC

18 OSC

1

2

19 TEST For factory testing purposes only. Do not make external connection to this pin.

20 DGND Digital ground connection.

21 COMP Connection for comparator auto-zero capacitor. Bypass to VSS with 0.1 µF.

22 V

23 INT

24 INT

SS

OUT

IN

25 BUFFER Output of the input buffer. Connect to R

26 C

27 C

28 C

29 C

BUFB

BUFA

INTA

INTB

30 COMMON Analog common.

31 IN

–

30 COMMON Analog common.

REF2

REF2

REF1

REF1

DD

+

2

+

–

–

–

+

+

1

33 REF

34 C

35 C

36 REF

37 C

38 C

39 REF

40 V

NOTES: 4. This pin incorporates a pull-down resistor to DGND.

5. This pin incorporates a pull-up resistor to VDD.

note 4.)

mode (CONT/DEMAND = LOW), a logic LOW on WR starts a conversion. (See note 4.)

3-state data outputs. (See note 5.)

input. When CONT/DEMAND = HIGH, conversions are performed continuously. (See note 4.)

DEMAND = LOW), OVR/POL controls the data output on DB7 when the high-order byte is

active. (See note 5.)

byte or high-byte data is enabled on DB0 through DB7. (See note 5.)

overrange, and DB7 data are output on this pin. (See text.)

phase and goes LOW when conversion is complete. The falling edge of BUSY can be used to

generate a µP interrupt.

Crystal oscillator connection or external oscillator input.

Crystal oscillator connection.

Negative power supply connection, typically – 5V.

Output of the integrator amplifier. Connect to C

Input to the integrator amplifier. Connect to summing node of R

INT

.

INT

INT

and C

INT

.

.

Connection for buffer auto-zero capacitor. Bypass to VSS with 0.1 µF.

Connection to buffer auto-zero capacitor. Bypass to VSS with 0.1 µF.

Connection for integrator auto-zero capacitor. Bypass to VSS with 0.1 µF.

Connection for integrator auto-zero capacitor. Bypass to VSS with 0.1 µF.

Negative differential analog input.

Positive input for reference voltage V

Positive connection for V

Negative connection for V

reference capacitor.

REF2

reference capacitor.

REF2

REF2

. (V

REF2

= V

REF1

/64)

Negative input for reference voltages.

Negative connection for V

Positive connection for V

Positive input for V

REF1

reference capacitor.

REF1

reference capacitor.

REF1

.

Positive power supply connection, typically +5V.

3-80

TELCOM SEMICONDUCTOR, INC.

15-BIT, FAST-INTEGRATING CMOS

ANALOG-TO-DIGITAL CONVERTER

1

TC850

THEORY OF OPERATION

The TC850 is a multiple-slope, integrating analog-todigital converter (ADC). The multiple-slope conversion process, combined with chopper-stabilized amplifiers, results

in a significant increase in ADC speed, while maintaining

very high resolution and accuracy.

Dual-Slope Conversion Principles

The conventional dual-slope converter measurement

cycle (shown in Figure 2A) has two distinct phases:

(1) Input signal integration

(2) Reference voltage integration (deintegration)

The input signal being converted is integrated for a fixed

time period, measured by counting clock pulses. An opposite polarity constant reference voltage is then integrated

until the integrator output voltage returns to zero. The

reference integration time is directly proportional to the input

signal.

In a simple dual-slope converter, complete conversion

requires the integrator output to "ramp-up" and "rampdown." Most dual-slope converters add a third phase, autozero. During auto-zero, offset voltages of the input buffer,

integrator, and comparator are nulled, thereby eliminating

the need for zero-offset adjustments.

Dual-slope converter accuracy is unrelated to the integrating resistor and capacitor values, as long as they are

stable during a measurement cycle. By converting the

unknown analog input voltage into an easily-measured

function of time, the dual-slope converter reduces the need

for expensive, precision passive components.

Noise immunity is an inherent benefit of the integrating

conversion method. Noise spikes are integrated, or averaged, to zero during the integration period. Integrating ADCs

are immune to the large conversion errors that plague

successive approximation converters in high-noise environments.

A simple mathematical equation relates the input signal,

reference voltage, and integration time:

t

SI

1

RC

VIN(t) dt = ,

∫

0

where: VR = Reference voltage

tSI = Signal integration time (fixed)

tRI = Reference voltage integration time (variable).

VR t

RC

RI

Multiple-Slope Conversion Principles

One limitation of the dual-slope measurement technique is conversion speed. In a typical dual-slope method,

the auto-zero and integrate times are each one-half of the

deintegrate time. For a 15-bit conversion, 214+214+2

(65,536) clock pulses are required for auto-zero, integrate,

and deintegrate phases, respectively. The large number of

clock cycles effectively limits the conversion rate to about

2.5 conversions per second, when a typical analog CMOS

fabrication process is used.

The TC850 uses a multiple-slope conversion technique

to increase conversion speed (Figure 2B). This technique

makes use of a two-slope deintegration phase and permits

15-bit resolution up to 40 conversions per second.

During the TC850's deintegration phase, the integration

capacitor is rapidly discharged to yield a resolution of 9 bits.

At this point, some charge will remain on the capacitor. This

remaining charge is then slowly deintegrated, producing an

2240

V

SS

COMMON

C

C

C

C

BUFFER

INT

C

BUFACBUFB

0.1

µF

–5V

REF

REF

REF

+

REF1

–

REF1

+

REF2

–

REF2

INT

OUT

TEST

IN

26

IN

100 MΩ

32

+

0.1

µF

31

30

39

33

36

38

37

34

35

25

24

23

19

0.01 µF INPUT

+1.6384V

+0.0265V

1 µF

1 µF

120 MΩ

R

INT

0.1µF

C

INT

NC

–

+

1

+

2

–

IN

+5V

20

V

DGND

DD

16

BUSY

8

DB7

9

DB6

10

DB5

11

DB4

12

DB3

13

DB2

14

DB1

15

DB0

1

CS

2

CE

3

WR

4

RD

5

CONT/DEMAND

6

OVR/POL

7

L/H

17

**

NOTES: Unless otherwise specified, all 0.1µF capacitors are film dielectric.

61.44 kHz

**

Ceramic capacitors are not recommended.

NC = No internal capacitors

*Polypropylene capacitors.

** 100pF Mica capacitors.

OSC

18

OSC

21

COMP

C

INTA

0.1

µF

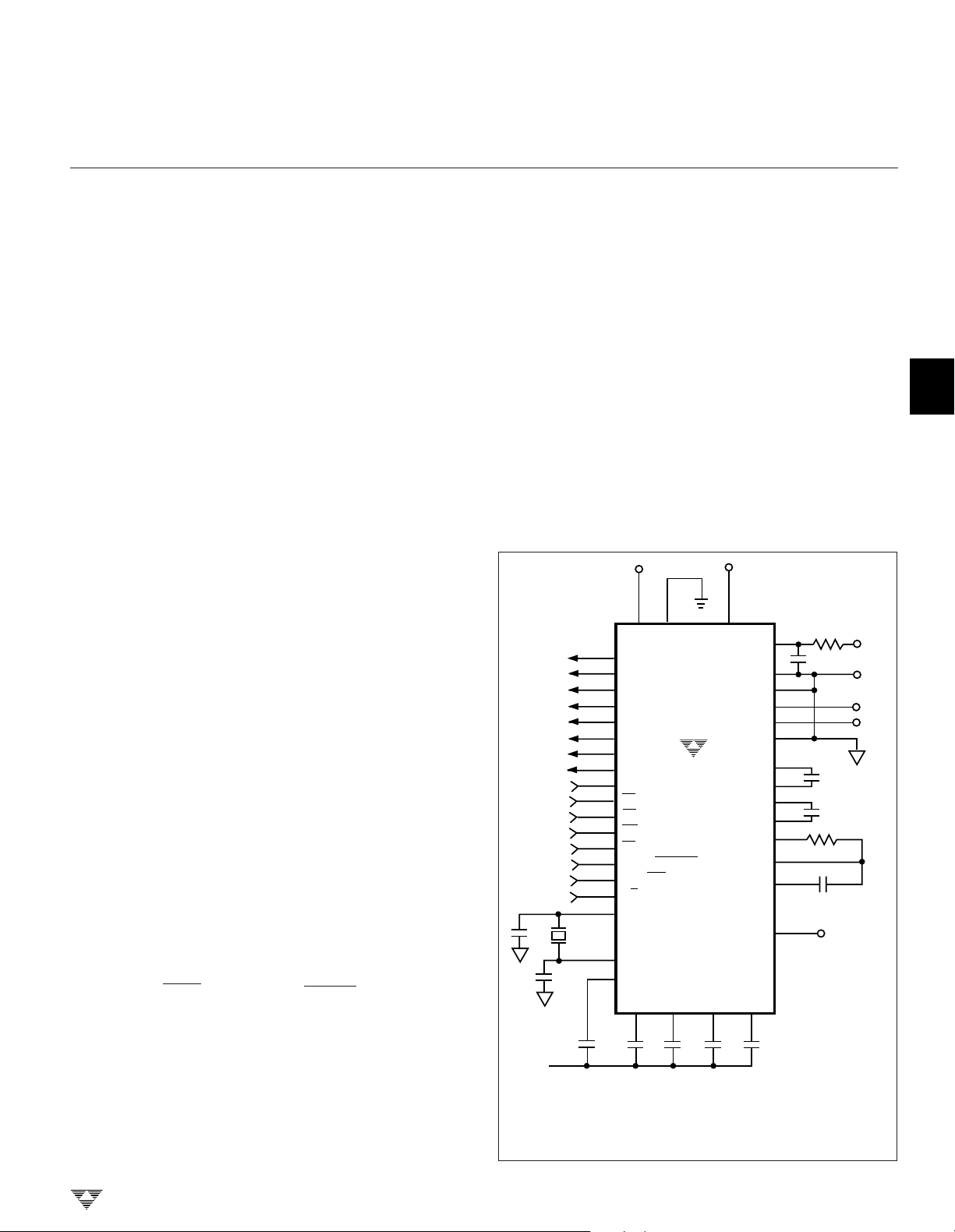

Figure 1. Standard Circuit Configuration

1

2

C

INTB

28 2729

0.1

µF

TC850

0.1

µF

15

*

*

2

3

4

5

6

7

8

TELCOM SEMICONDUCTOR, INC.

3-81

Loading...

Loading...