Datasheet TC7660MJA, TC7660IJA, TC7660EPA, TC7660EOA, TC7660CPA Datasheet (TelCom Semiconductor)

...

CHARGE PUMP DC-TO-DC VOLTAGE CONVERTER

EVALUATION

KIT

AVAILABLE

FEATURES

GENERAL DESCRIPTION

1

TC7660

2

■ Converts +5V Logic Supply to ±5V System

■ Wide Input Voltage Range ....................1.5V to 10V

■ Efficient Voltage Conversion.........................99.9%

■ Excellent Power Efficiency ...............................98%

■ Low Power Supply...............................80µA @ 5V

■ Low Cost and Easy to Use

— Only Two External Capacitors Required

■ RS232 Negative Power Supply

■ Available in Small Outline (SO) Package

■ Improved ESD Protection ....................... Up to 3kV

■ No Dx Diode Required for High Voltage Operation

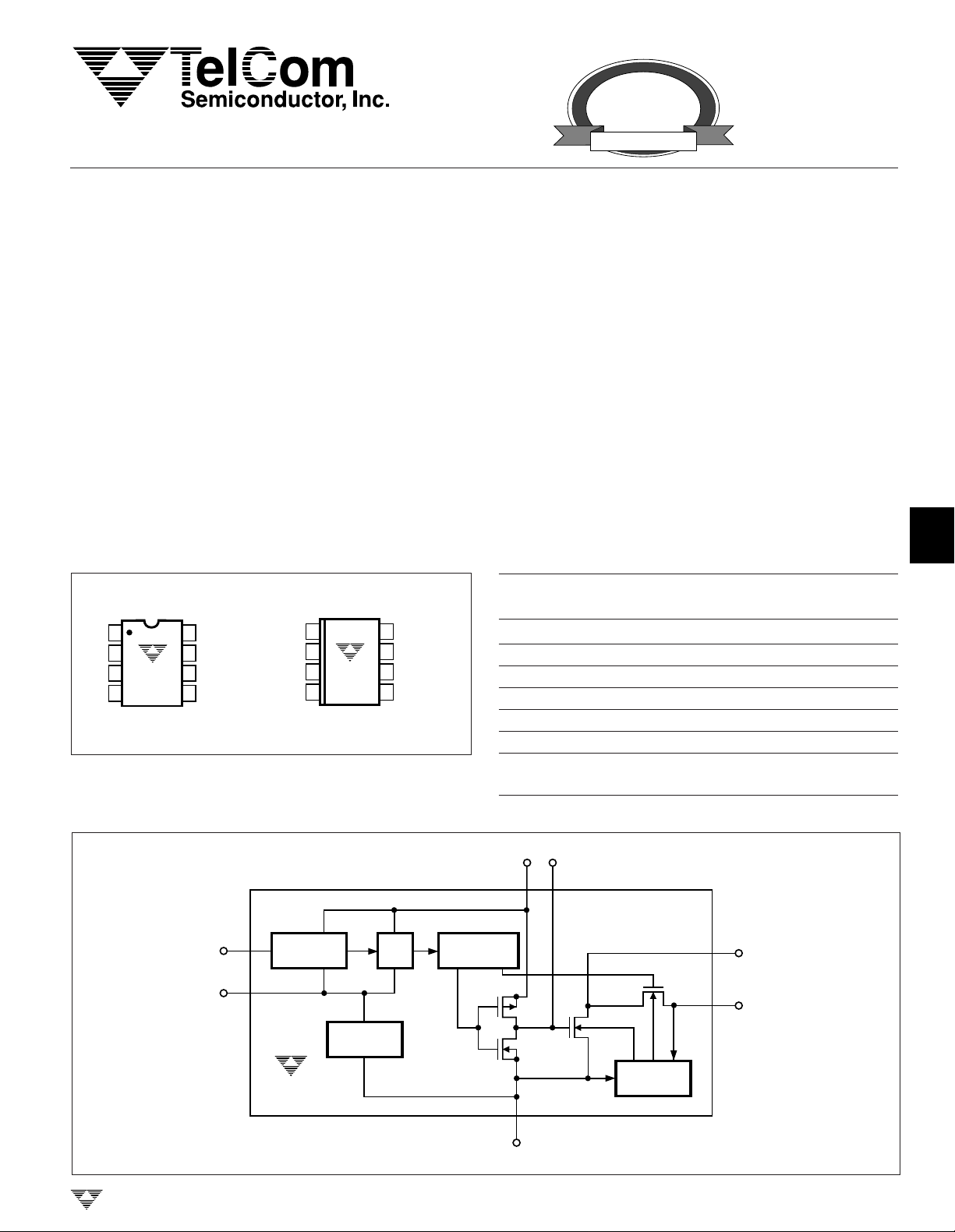

PIN CONFIGURATION (DIP and SOIC)

NC

CAP

GND

CAP

1

+

2

3

–

4

TC7660CPA

TC7660EPA

TC7660IJA

+

8

V

7

OSC

LOW

6

VOLTAGE (LV)

5

V

OUT

NC = NO INTERNAL CONNECTION

NC

CAP

GND

CAP

1

+

2

3

–

4

TC7660COA

TC7660CPA

+

8

V

OSC

7

LOW

6

VOLTAGE (LV)

V

5

OUT

The TC7660 is a pin-compatible replacement for the

Industry standard TC7660 charge pump voltage converter.

It converts a +1.5V to +10V input to a corresponding – 1.5V

to – 10V output using only two low-cost capacitors, eliminating inductors and their associated cost, size and EMI.

IN

The on-board oscillator operates at a nominal frequency of 10kHz. Operation below 10kHz (for lower supply

current applications) is possible by connecting an external

capacitor from OSC to ground (with pin 1 open).

The TC7660 is available in both 8-pin DIP and 8-pin

SOIC packages in commercial and extended temperature

ranges.

ORDERING INFORMATION

Temperature

Part No. Package Range

TC7660COA 8-Pin SOIC 0°C to +70°C

TC7660CPA 8-Pin Plastic DIP 0°C to +70°C

TC7660EOA 8-Pin SOIC – 40°C to +85°C

TC7660EPA 8-Pin Plastic DIP – 40°C to +85°C

TC7660IJA 8-Pin CerDIP – 40°C to +85°C

TC7660MJA 8-Pin CerDIP – 55°C to +125°C

TC7660EV Evaluation Kit for

Charge Pump Family

3

4

5

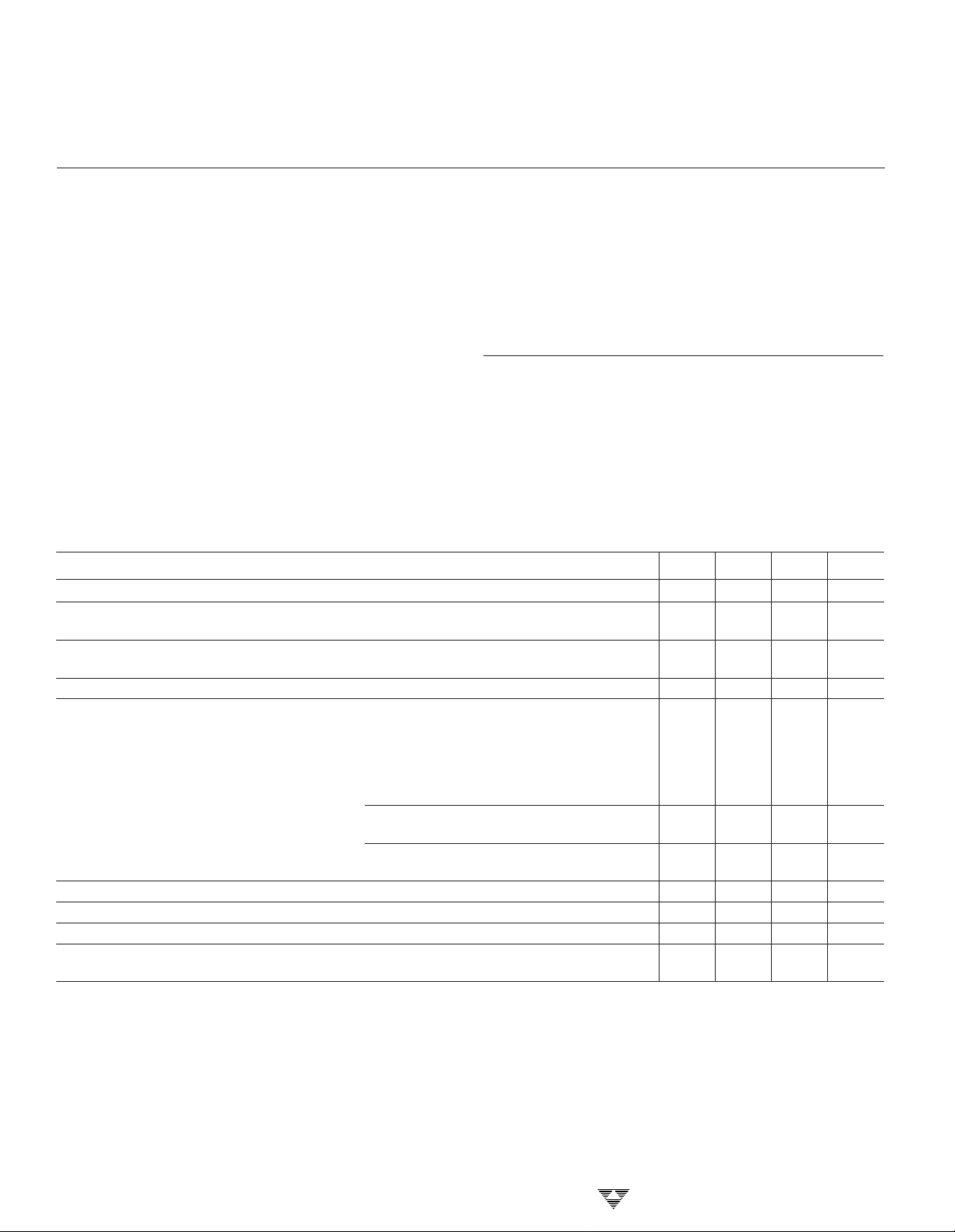

FUNCTIONAL BLOCK DIAGRAM

OSC

LV

TELCOM SEMICONDUCTOR, INC.

7

6

RC

OSCILLATOR

TC7660

INTERNAL

VOLTAGE

REGULATOR

÷ 2

VOLTAGE–

LEVEL

TRANSLATOR

V+CAP

82

3

GND

+

LOGIC

NETWORK

4

5

CAP

V

OUT

–

6

7

8

TC7660-7 9/30/96

4-51

TC7660

ABSOLUTE MAXIMUM RATINGS*

CHARGE PUMP DC-TO-DC

VOLTAGE CONVERTER

Supply Voltage ...................................................... +10.5V

LV and OSC Inputs

Voltage (Note 1) ........................ – 0.3V to (V+ + 0.3V)

for V+ < 5.5V

(V+ – 5.5V) to (V+ + 0.3V)

for V+ > 5.5V

Current Into LV (Note 1).....................20 µA for V+ > 3.5V

Output Short Duration (V

≤ 5.5V) .........Continuous

SUPPLY

Power Dissipation (TA ≤ 70°C) (Note 2)

CerDIP............................................................800mW

Plastic DIP ......................................................730mW

SOIC...............................................................470mW

Operating Temperature Range

C Suffix ..................................................0°C to +70°C

I Suffix............................................... – 25°C to +85°C

E Suffix ............................................. – 40°C to +85°C

M Suffix...........................................– 55°C to +125°C

Storage Temperature Range ................– 65°C to +150°C

Lead Temperature (Soldering, 10 sec) .................+300°C

*Static-sensitive device. Unused devices must be stored in conductive

material. Protect devices from static discharge and static fields. Stresses

above those listed under "Absolute Maximum Ratings" may cause permanent damage to the device. These are stress ratings only and functional

operation of the device at these or any other conditions above those

indicated in the operation sections of the specifications is not implied.

Exposure to absolute maximum rating conditions for extended periods

may affect device reliability.

ELECTRICAL CHARACTERISTICS: Specifications Measured Over Operating Temperature Range With,

V+ = 5V, C

Symbol Parameter Test Conditions Min Typ Max Unit

I

+

+

V

H

+

V

L

R

OUT

F

OSC

P

EFF

V

OUT EFF

Z

OSC

NOTES: 1. Connecting any input terminal to voltages greater than V+ or less than GND may cause destructive latch-up. It is recommended that no

Supply Current RL = ∞ — 80 180 µA

Supply Voltage Range, High Min ≤ TA ≤ Max, 3 — 10 V

RL = 10 kΩ, LV Open

Supply Voltage Range, Low Min ≤ TA ≤ Max, 1.5 — 3.5 V

RL = 10 kΩ, LV to GND

Output Source Resistance I

= 20mA, TA = 25°C — 70 100 Ω

OUT

I

= 20mA, 0°C ≤ TA ≤ +70°C — — 120 Ω

OUT

(C Device)

I

= 20mA, – 40°C ≤ TA ≤ +85°C — — 130 Ω

OUT

(I Device)

= 20mA, – 55°C ≤ TA ≤ +125°C — 104 150 Ω

I

OUT

(M Device)

+

V

= 2V, I

0°C ≤ TA ≤ +70°C

V+ = 2V, I

– 55°C ≤ TA ≤ +125°C (Note 3)

Oscillator Frequency Pin 7 open — 10 — kHz

Power Efficiency RL = 5 kΩ 95 98 — %

Voltage Conversion Efficiency RL = ∞ 97 99.9 — %

Oscillator Impedance V+ = 2V — 1 — MΩ

V+ = 5V — 100 — kΩ

inputs from sources operating from external supplies be applied prior to "power up" of the TC7660.

2. Derate linearly above 50°C by 5.5 mW/°C.

3. TC7660M only.

4. The TC7660 can be operated without the Dx diode over full temperature and voltage range.

= 0, Test Circuit (Figure 1), unless otherwise indicated.

OSC

= 3 mA, LV to GND — 150 300 Ω

OUT

= 3 mA, LV to GND — 160 600 Ω

OUT

4-52

TELCOM SEMICONDUCTOR, INC.

CHARGE PUMP DC-TO-DC

VOLTAGE CONVERTER

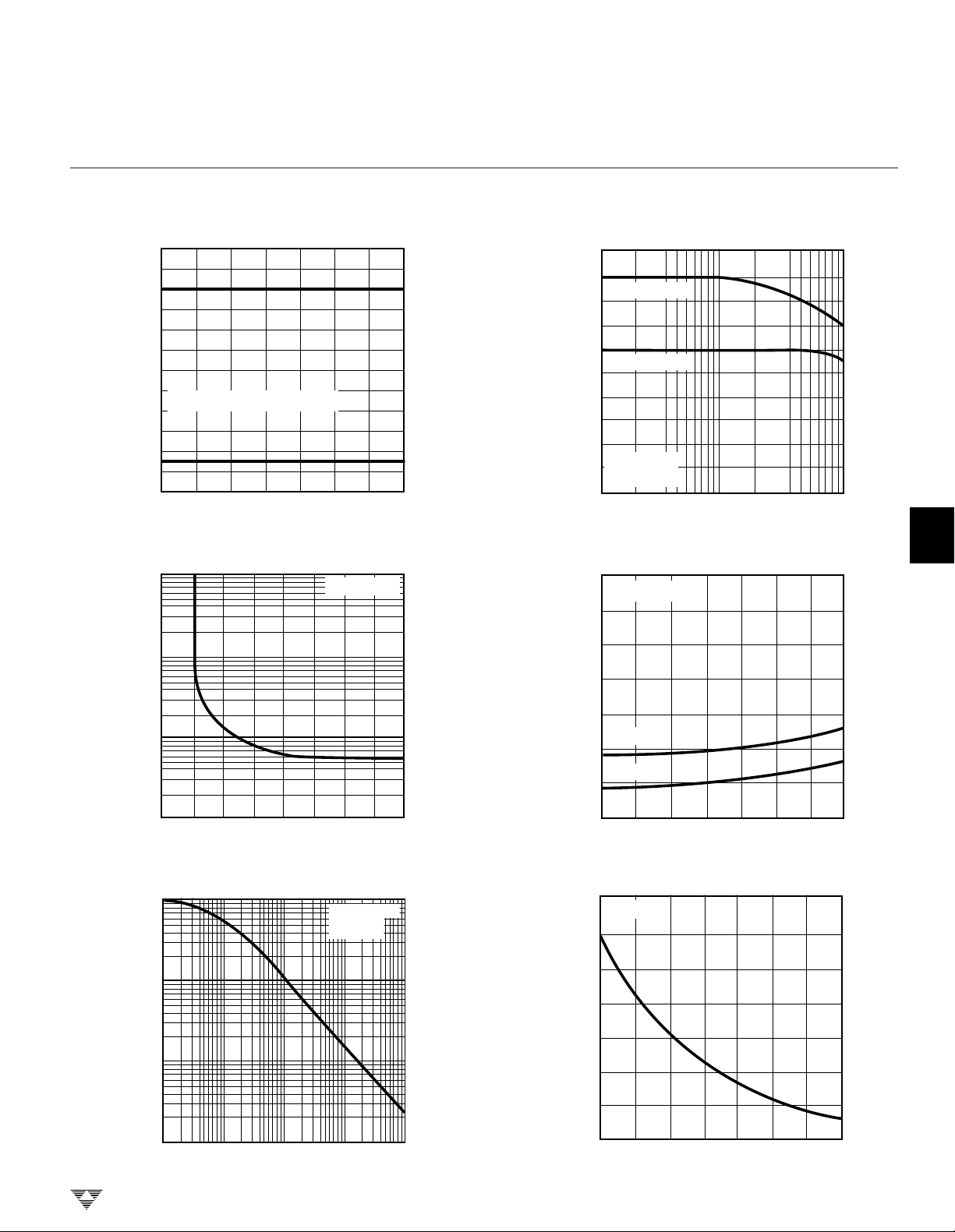

TYPICAL PERFORMANCE CHARACTERISTICS (Circuit of Figure 1)

1

TC7660

Operating Voltage vs. Temperature

12

10

8

6

SUPPLY VOLTAGE RANGE

4

SUPPLY VOLTAGE (V)

2

0

–25 0 +25 +75 +100 +125

–55

TEMPERATURE (°C)

Output Source Resistance vs. Supply Voltage

10k

1k

100Ω

OUTPUT SOURCE RESISTANCE (Ω)

10Ω

SUPPLY VOLTAGE (V)

+50

TA = +25°C

78

6543210

Power Conversion Eff. vs. Osc. Freq.

100

98

I

= 1 mA

OUT

96

94

92

I

= 15 mA

OUT

90

88

86

84

TA = +25°C

82

V+ = +5V

POWER CONVERSION EFFICIENCY (%)

80

100 1k 10k

OSCILLATOR FREQUENCY (Hz)

Output Source Resistance vs. Temperature

500

I

= 1 mA

OUT

450

400

200

150

V+ = +2V

100

V + = +5V

50

OUTPUT SOURCE RESISTANCE (Ω)

0

–55 –25 0 +25 +50 +75 +100 +125

TEMPERATURE (°C)

2

3

4

5

6

Freq. of Osc. vs. Ext. Osc. Capacitance

10k

1k

100

OSCILLATOR FREQUENCY (Hz)

10

1

TELCOM SEMICONDUCTOR, INC.

10 100 1000 10k

OSCILLATOR CAPACITANCE (pF)

TA = +25°C

V+ = +5V

Unloaded Osc. Freq. vs. Temperature

20

V+ = +5V

18

16

14

12

10

8

OSCILLATOR FREQUENCY (kHz)

6

–25 0 +25 +50 +75 +100 +125

–55

TEMPERATURE (°C)

7

8

4-53

TC7660

TYPICAL CHARACTERISTICS (Cont.)

CHARGE PUMP DC-TO-DC

VOLTAGE CONVERTER

Output Voltage vs. Output Current

0

–1

–2

–3

–4

–5

–6

–7

OUTPUT VOLTAGE (V)

–8

–9

–10

10 20 30 40 50 60 70 80 90 100

0

OUTPUT CURRENT (mA)

TA = +25°C

LV OPEN

Supply Current and Power Conversion Efficiency vs. Load Current

100

90

80

70

60

50

40

30

20

10

POWER CONVERSION EFFICIENCY (%)

0

1.5 3.0 4.5 6.0 7.5 9.0

LOAD CURRENT (mA)

TA = +25°C

V+ = 2V

20

18

16

14

12

10

8

6

4

SUPPLY CURRENT (mA) (Note)

2

0

Output Voltage vs. Load Current

5

TA = +25°C

4

V+ = +5V

3

2

1

0

–1

–2

OUTPUT VOLTAGE (V)

–3

–4

–5

10 20 30 40 50 60 70 80

0

100

90

80

70

60

50

40

30

20

10

POWER CONVERSION EFFICIENCY (%)

0

10 20 30 40 50 60

SLOPE 55Ω

LOAD CURRENT (mA)

TA = +25°C

V+ = +5V

LOAD CURRENT (mA)

100

90

80

70

60

50

40

30

20

SUPPLY CURRENT (mA) (Note)

10

0

2

1

0

–1

OUTPUT VOLTAGE (V)

–2

0

4-54

Output Voltage vs. Load Current

TA = +25°C

V+ = +2V

SLOPE 150Ω

123 4567 8

LOAD CURRENT (mA)

TELCOM SEMICONDUCTOR, INC.

CHARGE PUMP DC-TO-DC

VOLTAGE CONVERTER

I

*

C

2

10µF

S

+

V

(+5V)

I

L

R

L

V

O

1

2

+

C

1

10µF

NOTES: For large values of C

TC7660

3

4

*

of C1 and C2 should be increased to 100µF.

Figure 1. TC7660 Test Circuit

8

7

6

5

OSC

C

OSC

+

(>1000pF), the values

Detailed Description

The TC7660 contains all the necessary circuitry to

implement a voltage inverter, with the exception of two

external capacitors, which may be inexpensive 10 µF polarized electrolytic capacitors. Operation is best understood by

considering Figure 2, which shows an idealized voltage

inverter. Capacitor C1 is charged to a voltage, V+, for the half

cycle when switches S1 and S3 are closed. (Note: Switches

S2 and S4 are open during this half cycle.) During the second

half cycle of operation, switches S2 and S4 are closed, with

S1 and S3 open, thereby shifting capacitor C1 negatively by

V+ volts. Charge is then transferred from C1 to C2, such that

the voltage on C2 is exactly V+, assuming ideal switches and

no load on C2.

TC7660

The four switches in Figure 2 are MOS power switches;

S1 is a P-channel device, and S2, S3 and S4 are N-channel

devices. The main difficulty with this approach is that in

integrating the switches, the substrates of S3 and S4 must

always remain reverse-biased with respect to their sources,

but not so much as to degrade their ON resistances. In

addition, at circuit start-up, and under output short circuit

conditions (V

and the substrate bias adjusted accordingly. Failure to

accomplish this will result in high power losses and probable

device latch-up.

This problem is eliminated in the TC7660 by a logic

network which senses the output voltage (V

with the level translators, and switches the substrates of S

and S4 to the correct level to maintain necessary reverse

bias.

The voltage regulator portion of the TC7660 is an

integral part of the anti-latch-up circuitry. Its inherent voltage

drop can, however, degrade operation at low voltages. To

improve low-voltage operation, the LV pin should be

connected to GND, disabling the regulator. For supply

voltages greater than 3.5V, the LV terminal must be left

open to ensure latch-up-proof operation and prevent device

damage.

Theoretical Power Efficiency Considerations

In theory, a capacitive charge pump can approach

100% efficiency if certain conditions are met:

(1) The drive circuitry consumes minimal power.

(2) The output switches have extremely low ON

resistance and virtually no offset.

(3) The impedances of the pump and reservoir

capacitors are negligible at the pump frequency.

= V+), the output voltage must be sensed

OUT

) together

OUT

1

2

3

3

4

5

6

S

+

V

GND

Figure 2. Idealized Charge Pump Inverter

TELCOM SEMICONDUCTOR, INC.

1

S

3

S

2

S

4

C

2

V

OUT

= – V

IN

7

8

4-55

TC7660

CHARGE PUMP DC-TO-DC

VOLTAGE CONVERTER

The TC7660 approaches these conditions for negative

voltage multiplication if large values of C1 and C2 are used.

Energy is lost only in the transfer of charge between

capacitors if a change in voltage occurs. The energy lost

is defined by:

2

E = 1/2 C1 (V

1

– V

2

)

2

V1 and V2 are the voltages on C1 during the pump and

transfer cycles. If the impedances of C1 and C2 are relatively

high at the pump frequency (refer to Figure 2), compared to

the value of RL, there will be a substantial difference in

voltages V1 and V2. Therefore, it is not only desirable to

make C2 as large as possible to eliminate output voltage

ripple, but also to employ a correspondingly large value for

C1 in order to achieve maximum efficiency of operation.

Dos and Don'ts

• Do not exceed maximum supply voltages.

• Do not connect LV terminal to GND for supply voltages

greater than 3.5V.

• Do not short circuit the output to V+ supply for voltages

above 5.5V for extended periods; however, transient

conditions including start-up are okay.

• When using polarized capacitors in the inverting mode,

the + terminal of C1 must be connected to pin 2 of the

TC7660 and the + terminal of C2 must be connected to

GND Pin 3.

The output characteristics of the circuit in Figure 3 are

those of a nearly idea l voltage source in series with 70 Ω.

Thus, for a load current of – 10mA and a supply voltage of

+5V, the output voltage would be – 4.3V.

The dynamic output impedance of the TC7660 is due,

primarily, to capacitive reactance of the charge transfer

capacitor (C1). Since this capacitor is connected to the

output for only 1/2 of the cycle, the equation is:

2

XC = = 3.18Ω,

2πf C

1

where f = 10kHz and C1 = 10µF.

+

V

C

10µF

1

2

+

1

*

TC7660

3

4

1. V

= –n V+for 1.5V ≤ V+ ≤ 10VNOTES:

OUT

Figure 3. Simple Negative Converter

8

7

6

5

V

*

OUT

C

2

10µF

+

Simple Negative Voltage Converter

Figure 3 shows typical connections to provide a negative supply where a positive supply is available. A similar

scheme may be employed for supply voltages anywhere in

the operating range of +1.5V to +10V, keeping in mind that

pin 6 (LV) is tied to the supply negative (GND) only for supply

voltages below 3.5V.

4-56

Paralleling Devices

Any number of TC7660 voltage converters may be

paralleled to reduce output resistance (Figure 4). The reservoir capacitor, C2, serves all devices, while each device

requires its own pump capacitor, C1. The resultant output

resistance would be approximately:

R

(of TC7660)

R

OUT

=

OUT

n (number of devices)

TELCOM SEMICONDUCTOR, INC.

CHARGE PUMP DC-TO-DC

VOLTAGE CONVERTER

1

2

C

1

3

4

TC7660

"1"

8

7

6

5

1

TC7660

+

V

2

1

2

TC7660

C

1

3

"n"

4

8

R

7

6

5

L

Figure 4. Paralleling Devices Lowers Output Impedance

Cascading Devices

The TC7660 may be cascaded as shown (Figure 6) to

produce larger negative multiplication of the initial supply

voltage. However, due to the finite efficiency of each device,

the practical limit is 10 devices for light loads. The output

voltage is defined by:

V

= –n (VIN)

OUT

where n is an integer representing the number of devices

cascaded. The resulting output resistance would be approximately the weighted sum of the individual TC7660

R

values.

OUT

Changing the TC7660 Oscillator Frequency

It may be desirable in some applications (due to noise or

other considerations) to increase the oscillator frequency.

This is achieved by overdriving the oscillator from an external clock, as shown in Figure 6. In order to prevent possible

C

2

+

device latch-up, a 1kΩ resistor must be used in series with

the clock output. In a situation where the designer has

generated the external clock frequency using TTL logic, the

addition of a 10kΩ pull-up resistor to V+ supply is required.

Note that the pump frequency with external clocking, as with

internal clocking, will be 1/2 of the clock frequency. Output

transitions occur on the positive-going edge of the clock.

It is also possible to increase the conversion efficiency

of the TC7660 at low load levels by lowering the oscillator

frequency. This reduces the switching losses, and is achieved

by connecting an additional capacitor, C

Figure 7. Lowering the oscillator frequency will cause an

undesirable increase in the impedance of the pump (C1) and

the reservoir (C2) capacitors. To overcome this, increase the

values of C1 and C2 by the same factor that the frequency

has been reduced. For example, the addition of a 100pF

capacitor between pin 7 (OSC) and pin 8 (V+) will lower the

oscillator frequency to 1kHz from its nominal frequency of

10kHz (a multiple of 10), and necessitate a corresponding

increase in the values of C1 and C2 (from 10µF to 100µF).

, as shown in

OSC

3

4

5

6

1

2

10µF

NOTES:

*

1. V

TELCOM SEMICONDUCTOR, INC.

+

= –n V+for 1.5V V 10V

OUT

3

4

TC7660

"1"

+

≤≤

Figure 5. Increased Output Voltage by Cascading Devices

+

V

8

7

6

5

10µF

+

1

2

3

4

TC7660

"n"

8

7

6

5

+

10µF

V

OUT

*

7

8

4-57

TC7660

CHARGE PUMP DC-TO-DC

VOLTAGE CONVERTER

+

V

CMOS

GATE

V

OUT

10µF

+

+

V

C

OSC

V

OUT

C

2

10µF

C

+

V

1

2

+

3

TC7660

4

Figure 6. External Clocking

1

2

+

1

TC7660

3

4

Figure 7. Lowering Oscillator Frequency

8

1 kΩ

7

6

5

8

7

6

5

+

Positive Voltage Multiplication

The TC7660 may be employed to achieve positive

voltage multiplication using the circuit shown in Figure 8. In

this application, the pump inverter switches of the TC7660

are used to charge C1 to a voltage level of V+– VF (where V

is the supply voltage and VF is the forward voltage drop of

diode D1). On the transfer cycle, the voltage on C1 plus the

supply voltage (V+) is applied through diode D2 to capacitor

C2. The voltage thus created on C2 becomes (2 V+) – (2 VF),

or twice the supply voltage minus the combined forward

voltage drops of diodes D1 and D2.

The source impedance of the output (V

on the output current, but for V+ = 5V and an output current

of 10 mA, it will be approximately 60Ω.

+

V

1

2

3

4

TC7660

8

D

7

6

5

1

D

2

+

C

1

) will depend

OUT

V

OUT

(2 V+) – (2 VF)

+

C

2

=

Combined Negative Voltage Conversion

and Positive Supply Multiplication

Figure 9 combines the functions shown in Figures 3 and

8 to provide negative voltage conversion and positive voltage multiplication simultaneously. This approach would be,

for example, suitable for generating +9V and –5V from an

existing +5V supply. In this instance, capacitors C1 and C

perform the pump and reservoir functions, respectively, for

the generation of the negative voltage, while capacitors C

and C4 are pump and reservoir, respectively, for the multiplied positive voltage. There is a penalty in this configuration

which combines both functions, however, in that the source

impedances of the generated supplies will be somewhat

higher due to the finite impedance of the common charge

pump driver at pin 2 of the device.

+

V

1

2

TC7660

3

4

+

C

1

+

Figure 9. Combined Negative Converter and Positive Multiplier

8

7

6

5

+

C

2

+

D

1

V

OUT

(2 V+) – (2 VF)

D

2

+

Efficient Positive Voltage Multiplication/Conversion

Since the switches that allow the charge pumping operation are bidirectional, the charge transfer can be performed backwards as easily as forwards. Figure 10 shows

a TC7660 transforming –5V to +5V (or +5V to +10V, etc.).

The only problem here is that the internal clock and switchdrive section will not operate until some positive voltage has

been generated. An initial inefficient pump, as shown in

Figure 9, could be used to start this circuit up, after which it

will bypass the other (D1 and D2 in Figure 9 would never turn

on), or else the diode and resistor shown dotted in Figure 10

can be used to "force" the internal regulator on.

V

=

OUT

–(V+–VF)

C

3

=

C

4

3

2

4-58

Figure 8. Positive Voltage Multiplier

TELCOM SEMICONDUCTOR, INC.

CHARGE PUMP DC-TO-DC

VOLTAGE CONVERTER

V

= –V

OUT

C

10µF

1

2

+

1

3

4

TC7660

8

7

1 MΩ

6

5

–

V

–

INPUT

1

TC7660

+

V

50 µF

+

100 kΩ

+

–

1

2

3

4

TC7660

8

7

1 MΩ

6

5

V

R

L1

+

10µF

V

OUT

V+–V

R

L2

=

–

2

50 µF

50 µF

+

–

2

3

–

Figure 10. Positive Voltage Conversion

Voltage Splitting

The same bidirectional characteristics used in Figure 10

can also be used to split a higher supply in half, as shown in

Figure 11. The combined load will be evenly shared between the two sides. Once again, a high value resistor to the

LV pin ensures start-up. Because the switches share the

load in parallel, the output impedance is much lower than in

the standard circuits, and higher currents can be drawn from

the device. By using this circuit, and then the circuit of Figure

5, +15V can be converted (via +7.5V and –7.5V) to a nominal

–15V, though with rather high series resistance (~250Ω).

Figure 11. Splitting a Supply in Half

4

5

6

TELCOM SEMICONDUCTOR, INC.

7

8

4-59

Loading...

Loading...