Datasheet TC500COE, TC500ACPE, TC500ACOE, TC510CPF, TC510COG Datasheet (TelCom Semiconductor)

...

PRECISION ANALOG FRONT ENDS

EVALUATION

KIT

AVAILABLE

TC500

TC500A

TC510

TC514

1

FEATURES

■ Precision (up to 17 Bits) A/D Converter "Front End"

■ 3-Pin Control Interface to Microprocessor

■ Flexible: User Can Trade-Off Conversion Speed

for Resolution

■ Single Supply Operation (TC510/514)

■ 4 Input, Differential Analog MUX (TC514)

■ Automatic Input Voltage Polarity Detection

■ Low Power Dissipation ...........TC500/500A: 10mW

TC510/514: 18mW

■ Wide Analog Input Range .......±4.2V (TC500A/510)

■ Directly Accepts Bipolar and Differential Input

Signals

ORDERING INFORMATION

Part No. Package Temp. Range

TC500ACOE 16-Pin SOIC 0°C to +70°C

T

C500ACPE 16-Pin Plastic DIP (Narrow) 0°C to +70°C

TC500COE 16-Pin SOIC 0°C to +70°C

TC500CPE 16-Pin Plastic DIP (Narrow) 0°C to +70°C

TC510COG 24-Pin SOIC 0°C to +70°C

TC510CPF 24-Pin Plastic DIP (300 Mil.) 0°C to +70°C

TC514COI 28-Pin SOIC 0°C to +70°C

TC514CPJ 28-Pin Plastic DIP (300 Mil.) 0°C to +70°C

TC500EV Evaluation Kit for TC500/500A/510/514

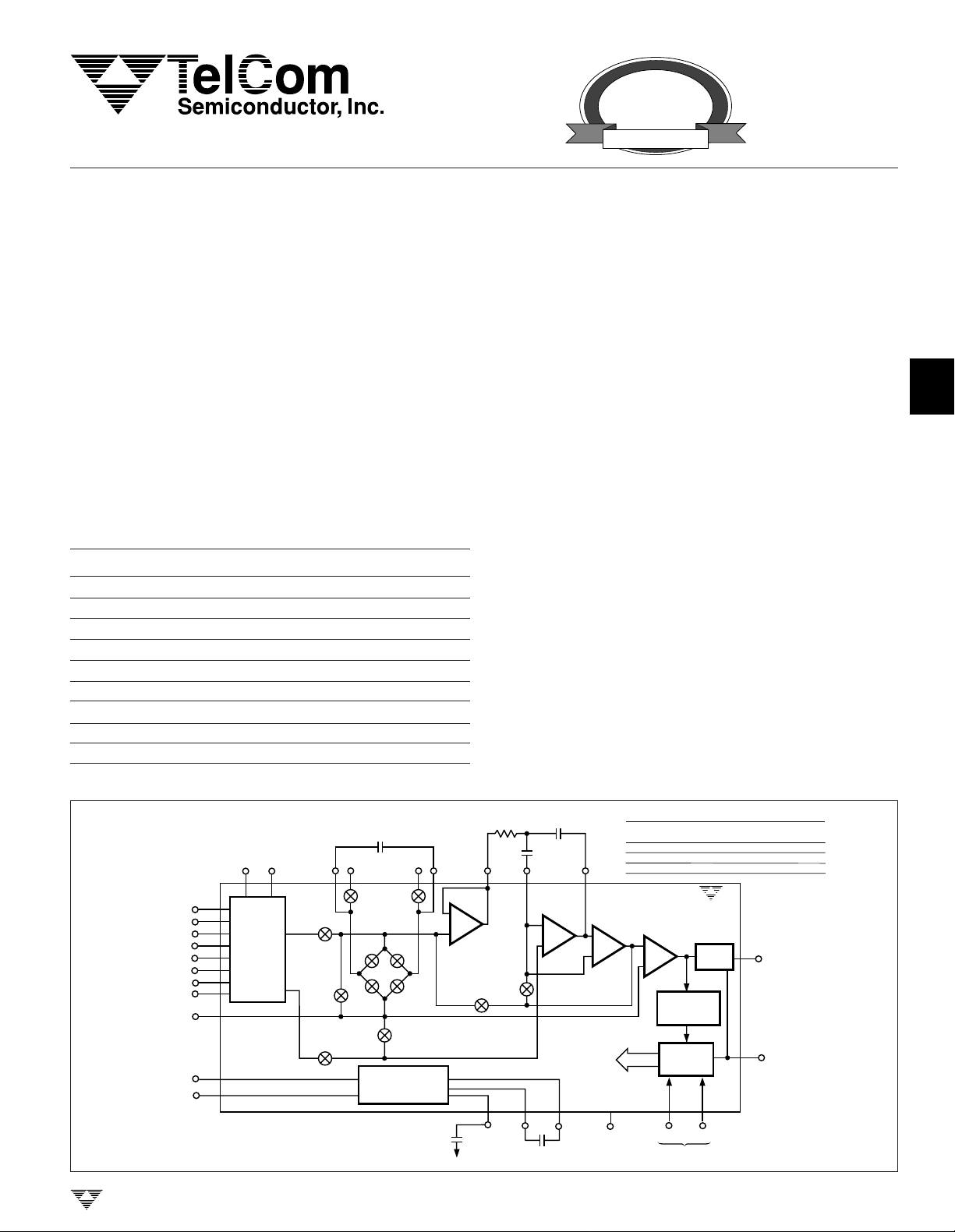

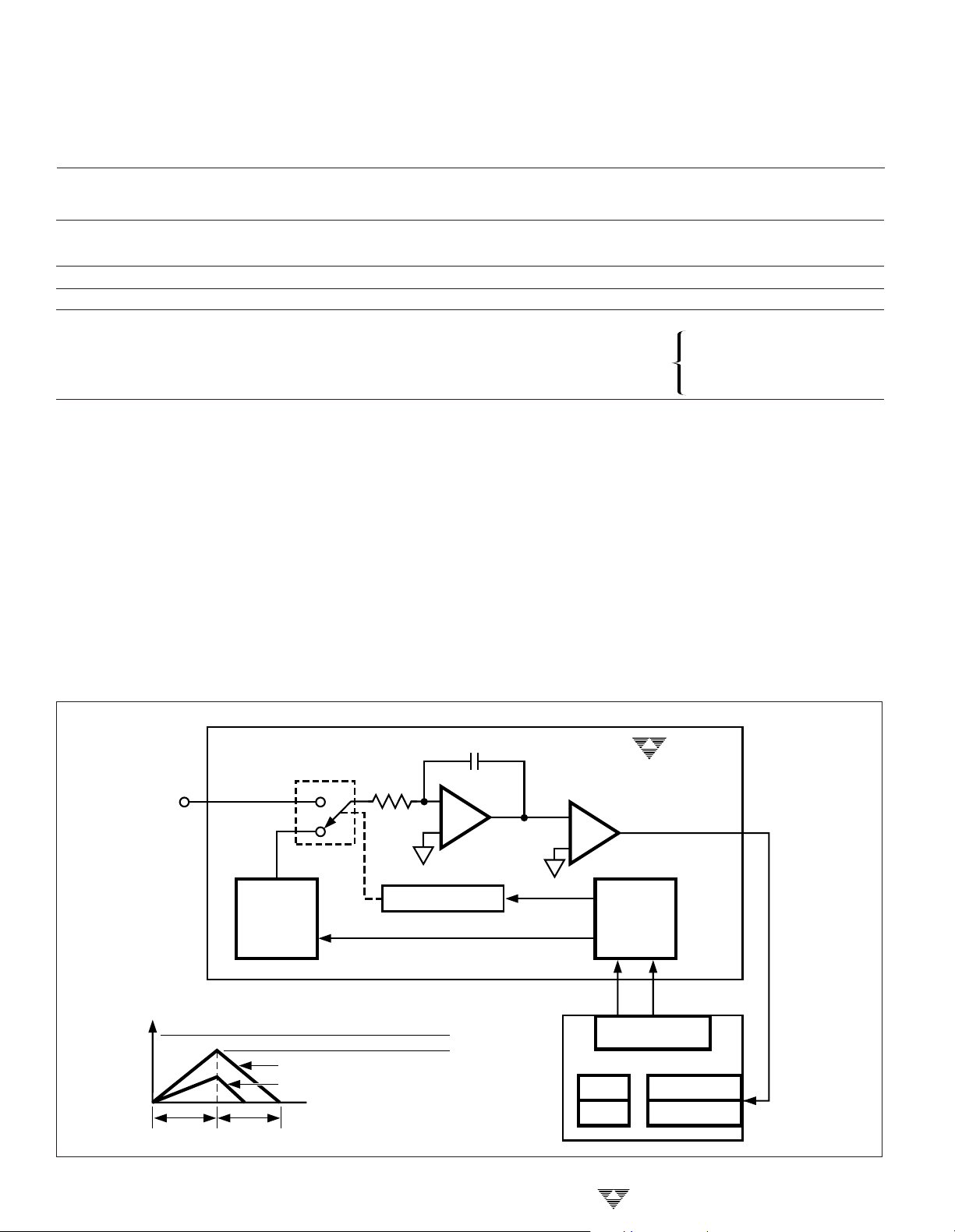

FUNCTIONAL BLOCK DIAGRAM

C

REF

CH1

CH2

CH3

CH4

CH1

CH2

CH3

CH4

ACOM

OSC

+

C

+

REF

SW

SW

SW

V

REF

SW

I

SW

Z

SW

I

A1

A0

+

+

+

+

–

–

–

–

V

S

DIF.

MUX

(TC514)

–

V

REF

SW

R

R

–

+

SW

RI

RI

–

+

SW

RI

RI

SW

1

DC-TO-DC

CONVERTER

(TC510 & TC514)

–

C

REF

BUFFER

–

+

GENERAL DESCRIPTION

The TC500/500A/510/514 family are precision analog

front ends that implement dual slope A/D converters having

a maximum resolution of 17 bits plus sign. As a minimum,

each device contains the integrator, zero crossing comparator and processor interface logic. The TC500 is the base

(16 bit max) device and requires both positive and negative

power supplies. The TC500A is identical to the TC500,

except it has improved linearity allowing it to operate to a

maximum resolution of 17 bits. The TC510 adds an onboard negative power supply converter for single supply

operation. The TC514 adds both a negative power supply

converter and a 4 input differential analog multiplexer.

Each device has the same processor control interface

consisting of 3 wires: control inputs A and B and zerocrossing comparator output (CMPTR). The processor manipulates A, B to sequence the TC5xx through four phases

of conversion: Auto Zero, Integrate, Deintegrate and Integrator Zero. During the Auto Zero phase, offset voltages in

the TC5xx are corrected by a closed-loop feedback mechanism. The input voltage is applied to the integrator during the

Integrate phase. This causes an integrator output dv/dt

directly proportional to the magnitude of the input voltage.

The higher the input voltage, the greater the magnitude of

the voltage stored on the integrator during this phase. At the

start of the Deintegrate phase, an external voltage reference

is applied to the integrator, and at the same time, the external

host processor starts its on-board timer.

CONTROL LOGIC

A B

0 0 ZERO INTEGRATOR OUTPUT

0 1 AUTO-ZERO

1 0 SIGNAL INTEGRATE

1 1 DEINTEGRATE

CMPTR 2

–

+

POLARITY

DETECTION

PHASE

DECODING

LOGIC

SW

INT

AZ

Z

–

C

INT

C

AZ

INTEGRATOR

–

+

CONTROL

–

CAP

CAP

C

INT

CMPTR 1

+

–

ANALOG

SWITCH

SIGNALS

+

R

C

BUF

SW

IZ

V

OUT

CONVERTER STATE

TC500

TC500A

TC510

TC514

LEVEL

SHIFT

The processor main-

CMPTR

OUTPUT

DGND

2

3

4

5

6

7

TELCOM SEMICONDUCTOR, INC.

1.0µF

C

–

OUT

1.0µF

V

SS

(TC500

TC500A)

CONTROL LOGIC

BA

8

TC500/A/510/514-3 10/3/96

3-19

TC500

TC500A

TC510

TC514

PRECISION ANALOG FRONT ENDS

GENERAL DESCRIPTION (Cont.)

tains this state until a transition occurs on the CMPTR output,

at which time the processor halts its timer. The resulting

timer count is the converted analog data. Integrator Zero

(the final phase of conversion) removes any residue remaining in the integrator in preparation for the next

conversion.

The TC500/500A/510/514 offer high resolution (up to 17

bits) superior 50Hz/60Hz noise rejection, low power operation, minimum I/O connections, low input bias currents and

lower cost compared to other converter technologies having

similar conversion speeds.

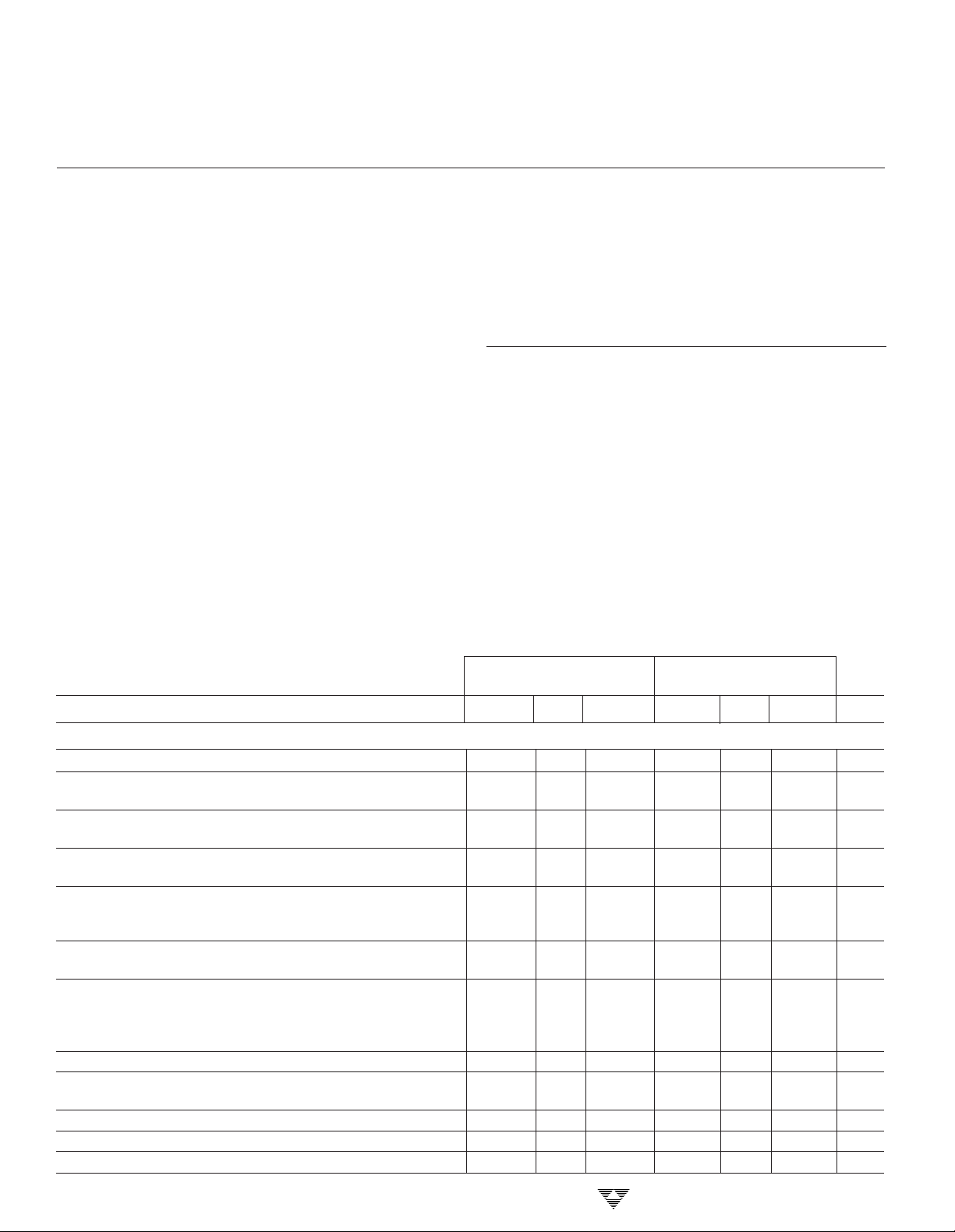

ABSOLUTE MAXIMUM RATINGS

*

TC510/514 Positive Supply Voltage

(VDD to GND) .................................................. +10.5V

TC500/500A Supply Voltage

(V

to VSS) ....................................................... +18V

DD

TC500/500A Positive Supply Voltage

(VDD to GND) ..................................................... +12V

ELECTRICAL CHARACTERISTICS: TC510/514: V

specified. CAZ = C

TC500/500A Negative Supply Voltage

(VSS to GND) ...................................................... – 8V

Analog Input Voltage (V

+

IN

_

or V

) ....................VDD to V

IN

Logic Input Voltage .................. VDD +0.3V to GND – 0.3V

Voltage on OSC ..... – 0.3V to (VDD +0.3V) for VDD < 5.5V

Ambient Operating Temperature Range ...... 0°C to +70°C

Storage Temperature Range ................ – 65°C to +150°C

Lead Temperature (Soldering, 10 sec) ................. +300°C

* Static-sensitive device. Unused devices must be stored in conductive

material. Protect devices from static discharge and static fields. Stresses

above those listed under "Absolute Maximum Ratings" may cause permanent damage to the device. These are stress ratings only and functional

operation of the device at these or any other conditions above those

indicated in the operation sections of the specifications is not implied.

Exposure to absolute maximum rating conditions for extended periods may

affect device reliability.

= +5V, TC500/500A: V

DD

= 0.47 µF

REF

= ±5V unless otherwise

S

SS

TA = +25°C TA = 0°C to +70°C

Symbol Parameter Test Conditions Min Typ Max Min Typ Max Unit

Analog

Resolution Note 1 60 — — — — — µV

ZSE Zero-Scale Error TC500/510/514 — — 0.005 — 0.005 0.012 % F.S.

with Auto Zero Phase TC500A — — 0.003 — 0.003 0.009

ENL End Point Linearity

NL Best Case Straight

Line Linearity

ZS

TC

SYE Full-Scale Symmetry Note 3 — 0.01 — — 0.03 — % F.S.

FS

TC

I

IN

V

CMR

V

REF

Zero-Scale Over Operating — — — 1 2 µV/°C

Temperature Temperature Range

Coefficient

Error (Roll-Over Error)

Full-Scale Temperature Over Operating — — — — 10 —

Coefficient Temperature Range

Input Current VIN = 0V — 6 — — — — pA

Common-Mode VSS +1.5 — VDD – 1.5 V

Voltage Range

Integrator Output Swing VSS +0.9 — VDD – 0.9 VSS +0.9 — VSS +0.9 V

Analog Input Signal RangeACOM = GND = 0V VSS +1.5 — VDD – 1.5 V

Voltage Reference Range V

TC500/510/514, Notes 1, 2,

TC500A

TC500/510/514, Notes 1, 2,

TC500A

External Reference

TC = 0ppm/°C

_

+

V

REF

REF

— 0.005 0.015 — 0.015 0.060

— — 0.010 — 0.010 0.045

— 0.003 0.008 — — —

— — 0.005 — — —

+1.5 — VDD – 1.5 V

SS

+1.5 — V

SS

V

+1 — VDD – 1 V

SS

+1 — VDD – 1 V

SS

+1.5 V

SS

% F.S.

% F.S.

% F.S.

% F.S.

ppm/°C

3-20

TELCOM SEMICONDUCTOR, INC.

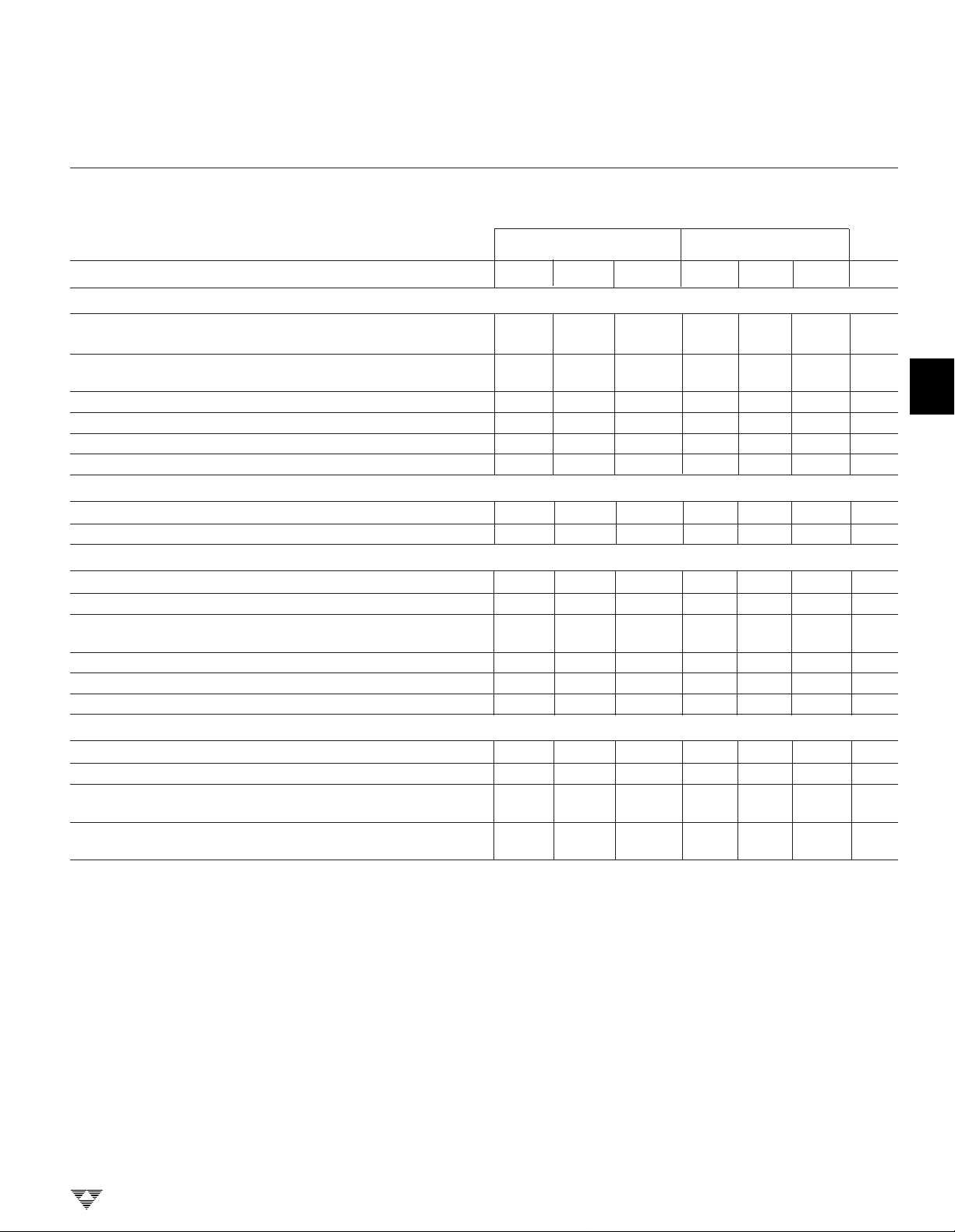

PRECISION ANALOG FRONT ENDS

ELECTRICAL CHARACTERISTICS: (Cont.)

TC500

TC500A

TC510

TC514

1

T

Symbol Parameter Test Conditions Min Typ Max Min Typ Max Unit

Digital

V

OH

V

OL

V

IH

V

IL

I

L

t

D

Multiplexer (TC514 Only)

R

DS

ON

Power (TC510/514 Only)

I

S

P

D

V

DD

R

OUT

I

OUT

Power (TC500/500A Only)

I

S

P

D

V

DD

V

SS

NOTES: 1. Integrate time ≥ 66msec, auto-zero time ≥ 66msec, V

Comparator Logic 1, I

Output High

Comparator Logic 0, I

Output Low

Logic 1, Input High Voltage 3.5 — — 3.5 — — V

Logic 0, Input Low Voltage — — 1 — — 1 V

Logic Input Current Logic 1 or 0 — — — — 0.3 — µA

Comparator Delay — 2 — — 3 — µsec

Maximum Input Voltage VDD = 5V – 2.5 — 2.5 – 2.5 — 2.5 V

Drain/Source ON Resistance VDD = 5V — 6 10 — — — kΩ

Supply Current VDD = 5V, A = 1, B = 1 — 1.8 2.4 — — 3.5 mA

Power Dissipation VDD = 5V — 18 — — — — mW

Positive Supply 4.5 — 5.5 4.5 — 5.5 V

Operating Voltage Range

Operating Source Resistance I

Oscillator Frequency (Note 3) — 100 — — — — kHz

Maximum Current Out VDD = 5V — — – 10 — — – 10 mA

Supply Current VS = ±5V, A = B = 1 — 1 1.5 — — 2.5 mA

Power Dissipation V

Positive Supply 4.5 — 7.5 4.5 — 7.5 V

Operating Voltage Range

Negative Supply – 4.5 — – 7.5 – 4.5 — – 7.5 V

Operating Voltage Range

2. End point linearity at ±1/4, ±1 /2, ±3/4 F.S. after full-scale adjustment.

3. Roll-over error is related to C

INT

, C

REF

= 400µA4——4——V

SOURCE

= 2.1mA — — 0.4 — — 0.4 V

SINK

= 10mA — 60 85 — — 100 Ω

OUT

= 5V, VSS = – 5V — 10 — — — — mW

DD

(peak) ≈ 4V.

INT

, CAZ characteristics.

= +25°C TA = 0°C to +70°C

A

2

3

4

5

6

TELCOM SEMICONDUCTOR, INC.

7

8

3-21

TC500

TC500A

TC510

TC514

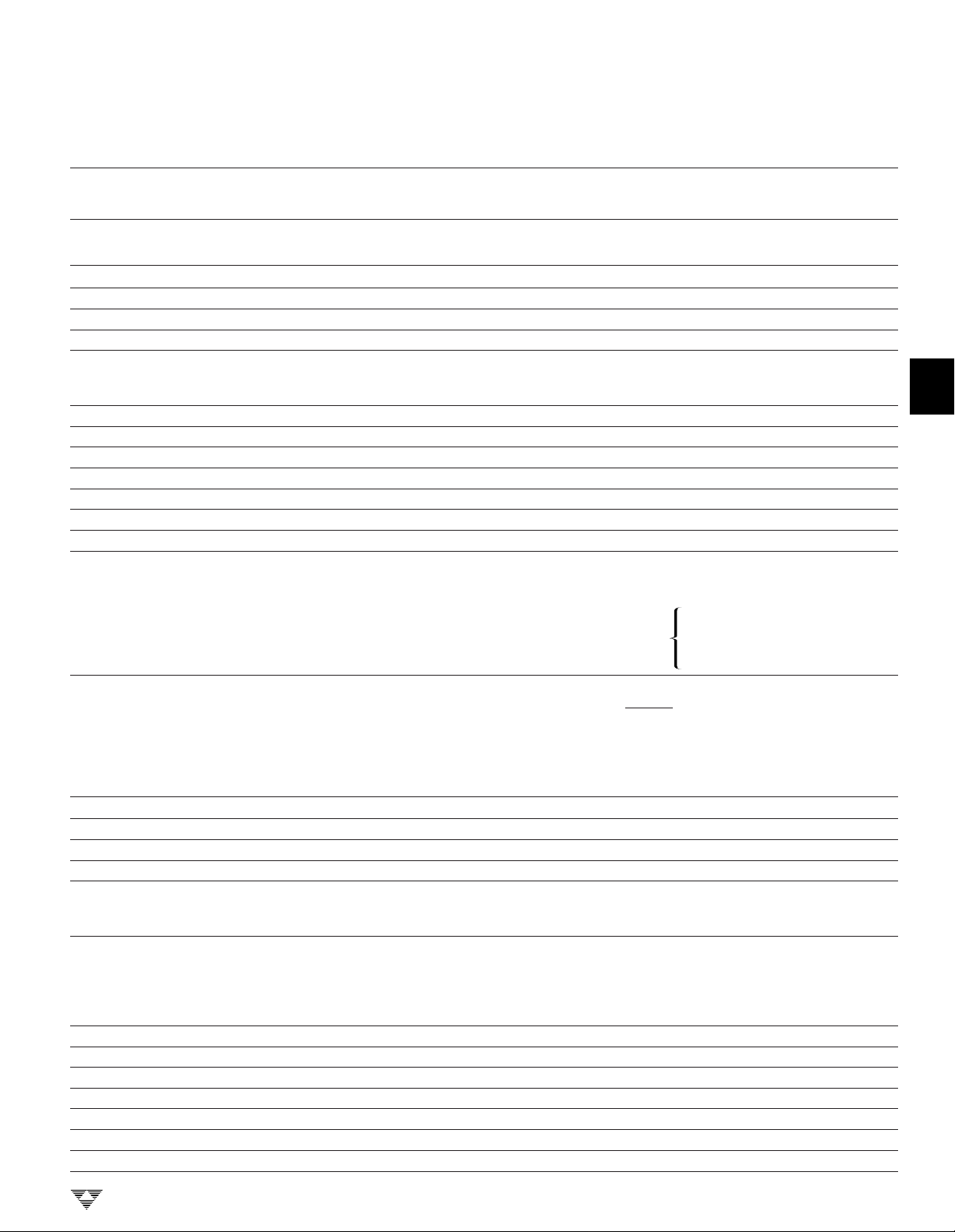

PIN CONFIGURATIONS

PRECISION ANALOG FRONT ENDS

C

V

C

ACOM

C

REF

C

REF

V

REF

–

V

OUT

C

INT

C

AZ

BUF

ACOM

–

C

REF

+

C

REF

–

V

REF

+

V

REF

N/C

N/C

N/C

INT

–

+

–

SS

AZ

1

2

3

4

5

6

7

8

1

2

3

4

5

6

TC510CPF

7

8

9

10

11

12

TC500/

TC500A

CPE

V

16

DD

15

DIGITAL GND

14

CMPTR OUT

B

13BUF

12

A

+

V

11

IN

–

V

10

IN

+

V

9

REF

24

CAP

23

DGND

22

CAP

V

21

DD

20

OSC

CMPTR OUT

19

A

18

17

B

+

V

16

IN

15

V

IN

14

N/C

13

N/C

C

INT

V

SS

C

AZ

BUF

ACOM

–

C

REF

+

C

REF

–

V

REF

–

–

+

V

C

OUT

INT

C

AZ

BUF

ACOM

–

C

REF

+

C

REF

–

V

REF

+

V

REF

–

N/C

N/C

N/C

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

TC500/

5

TC500A

COE

6

7

8

TC510COG

16

15

14

13

12

11

10

9

24

23

22

21

20

19

18

17

16

15

14

13

V

DD

DIGITAL GND

CMPTR OUT

B

A

+

V

IN

–

V

IN

+

V

REF

–

CAP

DGND

+

CAP

V

DD

OSC

CMPTR OUT

A

B

+

V

IN

–

V

IN

N/C

N/C

3-22

–

V

OUT

C

INT

C

AZ

BUF

ACOM

–

C

REF

+

C

REF

–

V

REF

+

V

REF

CH4

CH3

CH2

CH1

N/C

–

–

–

–

1

2

3

4

5

6

7

8

9

10

11

12

13

14

TC514CPJ

28

CAP

27

DGND

26

CAP

V

25

DD

24

OSC

CMPTR OUT

23

A

22

B

21

A0

20

A1

19

18

CH1

17

CH2

16

CH3

CH4

15

–

–

+

+

+

+

+

V

OUT

C

INT

C

AZ

BUF

ACOM

–

C

REF

+

C

REF

–

V

REF

+

V

REF

CH4

CH3

CH2

CH1

N/C

1

2

3

4

5

6

TC514COI

7

8

9

–

10

–

11

–

12

–

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

–

CAP

DGND

+

CAP

V

DD

OSC

CMPTR OUT

A

B

A0

A1

+

CH1

+

CH2

+

CH3

+

CH4

TELCOM SEMICONDUCTOR, INC.

PRECISION ANALOG FRONT ENDS

PIN DESCRIPTION

TC500

TC500A

TC510

TC514

1

Pin No Pin No Pin No

(TC500, 500A) (TC510) (TC514) Symbol Description

122C

2 Not Used Not Used V

333CAZAuto-zero input. The Auto-zero capacitor connection.

4 4 4 BUF Buffer output. The Integrator capacitor connection.

5 5 5 ACOM This pin is grounded in most applications. It is recommended that

666C

777C

888V

999V

10 15 Not Used V

11 16 Not Used V

12 18 22 A Input. Converter phase control MSB. (See input B.)

13 17 21 B Input. Converter phase control LSB. The states of A, B place the

14 19 23 CMPTR OUT Zero crossing comparator output. CMPTR is HIGH during the

15 23 27 DGND Input. Digital ground.

16 21 25 V

22 26 CAP

24 28 CAP

11V

20 24 OSC Oscillator control input. The negative power supply converter normally

18 CH1

13 CH1

17 CH2

12 CH2

16 CH3

11 CH3

15 CH4

INT

SS

–

REF

+

REF

–

REF

+

REF

–

IN

+

IN

DD

–

OUT

Integrator output. Integrator capacitor connection.

Negative power supply input (TC500/500A only).

–

–

or C

ACOM and the input common pin (V

analog common mode range (CMR).

Input. Negative reference capacitor connection.

Input. Positive reference capacitor connection.

Input. External voltage reference (–) connection.

Input. External voltage reference (+) connection.

Negative analog input.

Positive analog input.

TC5xx in one of four required phases. A conversion is complete

when all four phases have been executed:

Phase control input pins: AB =

Integration phase when a

and is LOW when a negative input voltage is being integrated. A

HIGH-to-LOW transition on CMPTR signals the processor that the

Deintegrate phase is completed. CMPTR is undefined during the

Auto-Zero phase. It should be monitored to time the Integrator Zero

phase (see text).

Input. Power supply positive connection.

+

Input. Negative power supply converter capacitor (+) connection.

–

Input. Negative power supply converter capacitor (–) connection.

Output. Negative power supply converter output and reservoir

capacitor connection. This output can be used to power other

devices in the circuit requiring a negative bias voltage.

runs at a frequency of 100kHz. The converter oscillator frequency can

be slowed down (to reduce quiescent current) by connecting an

external capacitor between this pin and VDD. (See Typical Characteristics Curves).

+

Positive analog input pin. MUX channel 1.

–

Negative analog input pin. MUX channel 1.

+

Positive analog input pin. MUX channel 2.

–

Negative analog input pin. MUX channel 2.

+

Positive analog input pin. MUX channel 3.

–

Negative analog input pin. MUX channel 3.

+

Positive analog input pin. MUX channel 4.

positive input voltage is being integrated

IN

00: Integrator Zero

01: Auto Zero

10: Integrate

11: Deintegrate

) be within the

HN

2

3

4

5

6

7

8

TELCOM SEMICONDUCTOR, INC.

3-23

TC500

TC500A

TC510

TC514

PIN DESCRIPTION (Cont.)

Pin No Pin No Pin No

(TC500/A) (TC510) (TC514) Symbol Description

10 CH4

20 A0 Multiplexer input channel select input LSB. (See A1).

19 A1 Multiplexer input channel select input MSB.

GENERAL THEORY OF OPERATION

Dual-Slope Conversion Principles (Figure 2)

Actual data conversion is accomplished in two phases:

input signal Integration and reference voltage Deintegration.

The integrator output is initialized to 0V prior to the start

of Integration. During Integration, analog switch S1 connects VIN to the integrator input where it is maintained for a

fixed time period (t

integrator output to depart 0V at a rate determined by the

magnitude of

VIN, and a direction determined by the

of VIN. The Deintegration phase is initiated immediately at

the expiration of t

). The application of VIN causes the

INT

.

INT

–

Negative analog input pin. MUX channel 4

Phase control input pins: A1, A0 =

polarity

PRECISION ANALOG FRONT ENDS

00 = Channel 1

01 = Channel 2

10 = Channel 3

11 = Channel 4

During Deintegration, S1 connects a reference voltage

(having a polarity opposite that of VIN) to the integrator input.

At the same time, an external precision timer is started. The

Deintegration phase is maintained until the comparator

output changes state, indicating the integrator has returned

to its starting point of 0V. When this occurs, the precision

timer is stopped. The Deintegration time period (t

measured by the precision timer, is directly proportional to

the magnitude of the applied input voltage.

A simple mathematical equation relates the Input

Signal, Reference Voltage and Integration time:

DEINT

), as

ANALOG

INPUT

(VIN)

OUTPUT

INTEGRATOR

T

INT

VOLTAGE

T

DEINT

REF

±

V

V

IN

IN

S1

' V

' 1/2 V

C

INT

R

INT

FULL SCALE

FULL SCALE

Figure 2. Basic Dual-Slope Converter

INTEGRATOR

–

+

SWITCH DRIVER

POLARITY

CONTROL

V

SUPPLY

V

INT

V

INT

–

+

PHASE

CONTROL

TC510

COMPARATOR

CONTROL

LOGIC

AB

I/O

MICROCOMPUTER

ROM

RAM

TIMER

COUNTER

CMPTR OUT

3-24

TELCOM SEMICONDUCTOR, INC.

PRECISION ANALOG FRONT ENDS

TC500

TC500A

TC510

TC514

1

1 t

R

INT CINT

where:

V

t

t

For a constant VIN:

The dual-slope converter accuracy is unrelated to the

integrating resistor and capacitor values as long as they are

stable during a measurement cycle.

An inherent benefit is noise immunity. Input noise spikes

are integrated (averaged to zero) during the integration

periods. Integrating ADCs are immune to the large conversion errors that plague successive approximation converters in high-noise environments.

Integrating converters provide inherent noise rejection

with at least a 20dB/decade attenuation rate. Interference

signals with frequencies at integral multiples of the integration period are, theoretically, completely removed since the

average value of a sine wave of frequency (1/t) averaged

over a period (t) is zero.

Integrating converters often establish the integration

period to reject 50/60Hz line frequency interference signals.

The ability to reject such signals is shown by a normal mode

rejection plot (Figure 4). Normal mode rejection is limited in

practice to 50 to 65dB, since the line frequency can deviate

by a few tenths of a percent (Figure 3).

= Reference Voltage

REF

= Signal Integration time (fixed)

INT

= Reference Voltage Integration time (variable)

DEINT

VIN = V

REF

80

∫

INT

0

t

DEINT

t

VIN (t) dt =

INT

V

R

REF tDEINT

INT CINT

30

T = MEASUREMENT

PERIOD

20

10

NORMAL MODE REJECTION (dB)

0

0.1/T 1/T 10/T

INPUT FREQUENCY

Figure 4.. Integrating Converter Normal Mode Rejection

TC500/500A/510/514 CONVERTER OPERATION

The TC500/500A/510/514 incorporates an Auto zero

and Integrator phase in addition to the input signal Integrate

and reference Deintegrate phases. The addition of these

phases reduce system errors and calibration steps, and

shorten overrange recovery time. A typical measurement

cycle uses all four phases in the following order:

(1) Auto zero

(2) Input signal integration

(3) Reference deintegration

(4) Integrator output zero

The internal analog switch status for each of these

phases is summarized in Table 1. This table is referenced

to the

Functional Block Diagram

sheet.

on the first page of this data

2

3

4

5

6

70

t = 0.1 sec

60

50

40

NORMAL

MODE

REJECTION

30

DEV = DEVIATION FROM 60 Hz

NORMAL MODE REJECTION (dB)

t = INTEGRATION PERIOD

20

0.01 0.1

LINE FREQUENCY DEVIATION FROM 60 Hz (%)

Figure 3. Line Frequency Deviation

TELCOM SEMICONDUCTOR, INC.

= 20 LOG

π

SIN 60 t (1 ± )

p

60 t (1 ± )

DEV

100

DEV

100

1.0

Auto-Zero Phase (AZ)

During this phase, errors due to buffer, integrator and

comparator offset voltages are nulled out by charging C

(auto-zero capacitor) with a compensating error voltage.

The external input signal is disconnected from the

internal circuitry by opening the two SWI switches. The

internal input points connect to analog common. The reference capacitor is charged to the reference voltage potential

through SWR. A feedback loop, closed around the integrator

and comparator, charges the CAZ capacitor with a voltage to

compensate for buffer amplifier, integrator and comparator

offset voltages.

AZ

3-25

7

8

PRECISION ANALOG FRONT ENDS

TC500

TC500A

TC510

TC514

Table 1. Internal Analog Gate Status

Internal Analog Gate Status

Conversion Phase SW

Auto-Zero (A = 0, B = 1) Closed Closed Closed

Input Signal Integration Closed

(A = 1, B = 0)

Reference Voltage Closed* Closed

Deintegration (A =1, B= 1)

Integrator Output Zero Closed Closed Closed

(A = 0, B = 0)

*Assumes a positive polarity input signal. SW

I

–

would be closed for a negative input signal.

RI

SW

+

RI

Analog Input Signal Integration Phase (INT)

The TC5xx integrates the differential voltage between

+

the (V

) and (V

IN

within the device's common-mode range V

–

) inputs. The differential voltage must be

IN

.

CMR

The input signal polarity is normally checked via software at the end of this phase: CMPTR = 1 for positive

polarity; CMPTR = 0 for negative polarity.

Reference Voltage Deintegration Phase (DINT)

The previously charged reference capacitor is connected with the proper polarity to ramp the integrator output

back to zero. An externally-provided, precision timer is used

to measure the duration of this phase. The resulting time

measurement is proportional to the magnitude of the applied

input voltage.

–

SW

RI

SW

Z

SW

R

SW

1

SW

IZ

voltage range, common-mode rejection is typically 80dB.

Full accuracy is maintained, however, when the inputs are

no less than 1.5V from either supply.

The integrator output also follows the common-mode

voltage. The integrator output must not be allowed to saturate. A worst-case condition exists, for example, when a

large, positive common-mode voltage with a near full-scale

negative differential input voltage is applied. The negative

input signal drives the integrator positive when most of its

swing has been used up by the positive common-mode

voltage. For these critical applications, the integrator swing

can be reduced. The integrator output can swing within 0.9V

of either supply without loss of linearity.

Analog Common

Integrator Output Zero Phase (IZ)

This phase guarantees the integrator output is at 0V

when the Auto Zero phase is entered and that only system

offset voltages are compensated. This phase is used at the

end of the reference voltage deintegration phase and MUST

be used for ALL TC5xx applications having resolutions of 12

bits or more. If this phase is not used, the value of the AutoZero capacitor (CAZ) must be about 2 to 3 times the value of

the integration capacitor (C

) to reduce the effects of

INT

charge-sharing. The Integrator Output Zero phase should

be programmed to operate until the Output of the Comparator returns "HIGH". The overall Timing System is shown in

Figure 8.

ANALOG SECTION

+

Differential Inputs (V

The TC5xx operates with differential voltages within the

input amplifier common-mode range. The amplifier common-mode range extends from 1.5V below positive supply

to 1.5V above negative supply. Within this common-mode

3-26

IN

, V

–

IN

)

Analog common is used as V

zero and reference deintegrate. If V

return during system-

IN

–

is different from analog

IN

common, a common-mode voltage exists in the system.

This signal is rejected by the excellent CMR of the converter.

In most applications, V

(i.e., power supply common). A common-mode voltage will

exist when V

–

is not connected to analog common.

IN

Differential Reference

–

will be set at a fixed known voltage

IN

+

REF

, V

–

REF

)

(V

The reference voltage can be anywhere within 1V of the

power supply voltage of the converter. Roll-over error is

caused by the reference capacitor losing or gaining charge

due to stray capacitance on its nodes. The difference in

reference for (+) or (–) input voltages will cause a roll-over

error. This error can be minimized by using a large reference

capacitor in comparison to the stray capacitance.

Phase Control Inputs (A, B)

The A, B unlatched logic inputs select the TC5xx operating phase. The A, B inputs are normally driven by a

microprocessor I/O port or external logic.

TELCOM SEMICONDUCTOR, INC.

PRECISION ANALOG FRONT ENDS

TC500

TC500A

TC510

TC514

1

Comparator Output

By monitoring the comparator output during the fixed

signal integrate time, the input signal polarity can be determined by the microprocessor controlling the conversion.

The comparator output is HIGH for positive signals and LOW

for negative signals during the signal-integrate phase (see

timing diagram).

During the reference deintegrate phase, the comparator

output will make a HIGH-to-LOW transition as the integrator

output ramp crosses zero. The transition is used to signal the

processor that the conversion is complete.

REFERENCE

DEINTEGRATE

ZERO

CROSSING

INTEGRATOR

OUTPUT

COMPARATOR

OUTPUT

SIGNAL

INTEGRATE

The internal comparator delay is 2µsec, typically. Figure

5 shows the comparator output for large positive and negative signal inputs. For signal inputs at or near zero volts,

however, the integrator swing is very small. If commonmode noise is present, the comparator can switch several

times during the beginning of the signal-integrate period. To

ensure that the polarity reading is correct, the comparator

output should be read and stored at the end of the signal

integrate phase.

The comparator output is undefined during the AutoZero Phase and is used to time the Integrator Output Zero

phase. (See

section).

INTEGRATOR

COMPARATOR

Integrator Output Zero Phase of System Timing

SIGNAL

INTEGRATE

OUTPUT

OUTPUT

REFERENCE

DEINTEGRATE

ZERO

CROSSING

2

3

4

5

TELCOM SEMICONDUCTOR, INC.

B. Negative Input SignalA. Positive Input Signal

6

Figure 5. Comparator Output

7

8

3-27

TC500

TC500A

TC510

TC514

PRECISION ANALOG FRONT ENDS

APPLICATIONS

Component Value Selection

The procedure outlined below allows the user to arrive

at values for the following TC5xx design variables:

(1) Integration Phase Timing

(2) Integrator Timing Components (R

(3) Auto Zero and Reference Capacitors

(4) Voltage Reference

Select Integration Time

Integration time must be picked as a multiple of the

period of the line frequency. For example, t

33msec, 66msec and 132msec maximize 60Hz line rejection.

D

and IZ Phase Timing

INT

The duration of the DINT phase is a function of the

amount of voltage stored on the integrator during TINT, and

the value of V

. The DINT phase must be initiated imme-

REF

diately following INT and terminated when an integrator

output zero-crossing is detected. In general, the maximum

number of counts chosen for DINT is twice that of INT (with

V

chosen at V

REF

Calculate Integrating Resistor (R

(max)/2).

IN

INT

The desired full-scale input voltage and amplifier output

current capability determine the value of R

and integrator amplifiers each have a full-scale current of

20µA.

The value of R

follows:

R

(in MΩ) =

INT

where: V

R

IN MAX

=Integrating Resistor (in MΩ)

INT

For loop stability, R

Select Reference (C

C

and C

REF

AZ

is therefore directly calculated as

INT

V

IN MAX

20

= Maximum input voltage (full count voltage)

should be ≥ 50kΩ.

INT

) and Auto Zero (CAZ) Capacitors

REF

must be low leakage capacitors (such as

polypropylene). The slower the conversion rate, the larger

the value C

and C

AZ

C

may also be used to limit roll-over errors.

REF

must be. Recommended capacitors for C

REF

are shown in Table 1. Larger values for CAZ and

, C

INT

)

INT

times of

INT

)

. The buffer

INT

REF

Table 1. C

REF

and C

Selection

AZ

Conversions Typical Value of Suggested *

Per Second C

REF

, C

(µF) Part Number

AZ

>7 0.1 WIMA MK12 .1/63/20

2 to 7 0.22 WIMA MK12 .22/63/20

2 or less 0.47 WIMA MK12 .47/63/20

*WIMA Corp. listing on the last page of this data sheet.

Calculate Integrating Capacitor (C

INT

)

The integrating capacitor must be selected to maximize

integrator output voltage swing. The integrator output voltage swing is defined as the absolute value of V

less 0.9V (i.e., V

– 0.9V or

DD

VSS +0.9V ). Using the 20µA

DD

(or

V

SS

buffer maximum output current, the value of the integrating

capacitor is calculated using the following equation.

(t

) (20 x 10 –6)

C

= (in µF) =

INT

where: t

INT

INT

(VS – 0.9)

= Integration Period

VS = Applied Supply Voltage

It is critical that the integrating capacitor has a very low

dielectric absorption. Polypropylene capacitors are an example of one such chemistry. Polyester and Polybicarbonate

capacitors may also be used in less critical applications.

Table 2 summarizes recommended capacitors for C

Table 2. Recommend Capacitor for C

INT

INT

.

Value Suggested Part Number*

0.1 WIMA MK12 .1/63/20

0.22 WIMA MK12 .22/63/20

0.33 WIMA MK12 .33/63/20

0.47 WIMA MK12 .47/63/20

*WIMA Corp. listing on the last page of this data sheet.

Calculate V

REF

The reference deintegration voltage is calculated

using:

V

REF

(in Volts) =

(VS – 0.9) (C

2(t

INT

INT

)

) (R

INT

)

)

3-28

TELCOM SEMICONDUCTOR, INC.

PRECISION ANALOG FRONT ENDS

TC500

TC500A

TC510

TC514

1

S

N

TH

INTEGRATOR

OUTPUT

COMPARATOR

OUTPUT COMP

INTEGRATE

PHASE

Low

REF

OVERSHOOT

DEINTEGRATE PHASE

Figure 7. Overshoot

S

30 µV

N

TH

Normal

V

V

SLOPE (S) = NTH = Noise Threshold

ZERO

CROSSING

INTEGRATOR

ZERO PHASE

REF

R

C

Figure 6. Noise

which a TC5xx is interfaced to a microcontroller. The

microcontroller drives the A, B inputs with I/O lines and

monitors the comparator output, CMPTR, using an I/O line

or dedicated timer-capture control pin. It may be necessary

to monitor the state of the CMPTR output in addition to

having it control a timer directly for the Reference Deintegration phase. (This is further explained below.)

timing in a real system depends on many system parameters

and component value selections. There are four critical

timing events (as shown in Figure 8): sampling the input

polarity; capturing the deintegration time; minimizing overshoot and properly executing the Integrator Output Zero

phase.

REF

Figure 8 shows the overall timing for a typical system in

The timing diagram in Figure 8 is not to scale as the

Auto-Zero Phase

S

2

N

TH

High

V

REF

3

4

5

DESIGN CONSIDERATIONS

Noise

The threshold noise (NTH) is the algebraic sum of the

integrator noise and the comparator noise. This value is

typically 30µV. Figure 6 shows how the value of the reference voltage can affect the final count. Such errors can be

reduced by increased integration times, in the same way

that 50/60Hz noise is rejected. The signal-to-noise ratio is

related to the integration time (t

constant (R

S/N (dB) = 20 Log

System Timing

To obtain maximum performance from the TC5xx, the

overshoot at the end of the Deintegration phase must be

minimized. Also, the Auto Zero phase must be terminated as

soon as the comparator output returns high. (See timing

diagram, Figure 8).

TELCOM SEMICONDUCTOR, INC.

INT)

(C

INT

) as follows:

(

30 x 10

) and the integration time

INT

V

IN

•

–6

(R

INT

t

INT

) • (C

INT

)

)

The length of this phase is usually set to be equal to the

Input Signal Integration time. This decision is virtually arbitrary since the magnitudes of the various system errors are

not known. Setting the Auto-Zero time equal to the Input

Integrate time should be more than adequate to null out

system errors. The system may remain in this phase indefinitely, i.e., Auto-Zero is the appropriate idle state for a TC5xx

device.

Input Signal Integrate Phase

The length of this phase is constant from one conversion

to the next and depends on system parameters and component value selections. The calculation of t

elsewhere in this data sheet. At some point near the end of

this phase, the microcontroller should sample CMPTR to

determine the input signal polarity. This value is, in effect,

the Sign Bit for the overall conversion result. Optimally,

CMPTR should be sampled just before this phase is terminated by changing AB from 10 to 11. The consideration here

is shown

INT

3-29

6

7

8

TC500

TC500A

TC510

TC514

PRECISION ANALOG FRONT ENDS

is that, during the initial stage of input integration when the

integrator voltage is low, the comparator may be affected by

noise and its output unreliable. Once integration is well

underway, the comparator will be in a defined state.

Reference Deintegration

The length of this phase must be precisely measured

from the transition of AB from 10 to 11 to the falling edge of

CMPTR. The comparator delay contributes some error in

timing this phase. The typical delay is specified to be 2µsec.

This should be considered in the context of the length of a

single count when determining overall system performance

and possible single-count errors. Additionally, Overshoot

will result in charge accumulating on the integrator after its

output crosses zero. This charge must be nulled during the

Integrator Output Zero phase.

TIME

CONVERTER

STATUS

INTEGRATOR

VOLTAGE

0

V

INT

AUTO -ZERO

INTEGRATE

FULL SCALE INPUT

Integrator Output Zero phase

The comparator delay and the controller's response

latency may result in Overshoot causing charge buildup on

the integrator at the end of a conversion. This charge must

be removed or performance will degrade. The Integrator

Output Zero phase should be activated (AB = 00) until

CMPTR goes high. It is absolutely critical that this phase be

terminated immediately so that Overshoot is not allowed to

occur in the opposite direction. At this point, it can be

assured that the integrator is near zero. Auto Zero should be

entered (AB = 01) and the TC5xx held in this state until the

next cycle is begun.

REFERENCE

DEINTEGRATE

OVERSHOOT INTEGRATOR

OUTPUT

ZERO

COMPARATOR

OUTPUT

AB INPUTS

CONTROLLER

OPERATION

NOTES

A

B

BEGIN CONVERSION

WITH AUTO-ZERO PHASE

TYPICALLY = t

(POSITIVE INPUT SHOWN)

The length of this phase

is chosen almost arbitrarily

but needs to be long enough

to null out worst case errors

(see text)

UNDEFINED

A = 0

B = 1

INT

0 FOR NEGATIVE INPUT

1 FOR POSITIVE INPUT

A = 1

B = 0

TIME INPUT

INTEGRATION

PHASE

SAMPLE INPUT POLARITY

t

INT

COMPARATOR DELAY

A = 1

B = 1

CAPTURE

DEINTEGRATION

TIME

I

NTEGRATOR

OUTPUT

ZERO PHASE

COMPLETE

COMPARATOR DELAY +

PROCESSOR LATENCY

A = 0

B = 0

READY FOR NEXT

CONVERSION

(AUTO-ZERO IS IDLE

STATE)

MINIMIZING OVERSHOOT

WILL MINIMIZE I.O.Z. TIME

3-30

Figure 8. Typical Dual Slope A/D Converter System Timing

TELCOM SEMICONDUCTOR, INC.

PRECISION ANALOG FRONT ENDS

TC500

TC500A

TC510

TC514

1

Design Example

Given: Required Resolution: 16 Bits (65,536 counts).

Maximum VIN: ±2V

Power Supply Voltage: +5V

60Hz System

Step 1: Pick integration time (t

line frequency:

1/60Hz = 16.6msec. Use 4x line frequency = 66msec

Step 2: Calculate R

R

(in MΩ) = V

INT

Step 3: Calculate C

output swing:

C

(in µF) = (t

INT

NOTE: TelCom recommended capacitor:

Step 4: Choose C

Conversions/sec

From which CAZ = C

INT

INMAX

for maximum (4V) integrator

INT

) (20 x 10 –6) / (VS – 0.9)

INT

= (.066) (20 x 10 –6) / (4.1)

= .32µF (use closest value: 0.33µF)

WIMA p/n: MK12 .33/63/10

and CAZ based on conversion rate

REF

= 1/(t

AZ

= 1

/(66msec + 66msec +132msec+2msec)

= 3.7 conversions/sec

) as a multiple of the

INT

/20 = 2/20 = 100kΩ

+ t

+ 2 t

INT

= 0.22µF (see Table 1)

REF

+ 2msec)

INT

USING THE TC510/514

Negative Supply Voltage Converter (TC510, TC514)

A capacitive charge pump is employed to invert the

voltage on VDD for negative bias within the TC510/514. This

voltage is also available on the V

bias elsewhere in the system. Two external capacitors are

required to perform the conversion.

Timing is generated by an internal state machine driven

from an on-board oscillator. During the first phase, capacitor

CF is switched across the power supply and charged to V

This charge is transferred to capacitor C

second phase. The oscillator normally runs at 100kHz to

ensure minimum output ripple. This frequency can be reduced by placing a capacitor from OSC to VDD. The relationship between the capacitor value is shown in the typical

characteristics curves at the end of this data sheet.

–

pin to provide negative

OUT

–

during the

OUT

Analog Input Multiplexer (TC514)

The TC514 is equipped with a four input differential

analog multiplexer. Input channels are selected using select

inputs (A1, A0). These are high-true control signals

(i.e., channel 0 is selected when (A1, A0 = 00).

EVALUATION KIT (TC500EV)

The TC500EV consists of a pre-assembled, 4 inch by 6

inch printed circuit board that connects to the serial port of

:

any PC or dumb terminal. Design software is also included.

TC500EV helps reduce design time and optimize converter

performance. Please contact your local TelCom representative for more information.

2

+

.

S

3

4

5

6

NOTE: TelCom recommended capacitor:

WIMA p/n: MK12 .22/63/10

Step 5: Calculate V

V

REF

TELCOM SEMICONDUCTOR, INC.

REF

(in Volts) = (VS – 0.9) (C

2(t

= (4.1) (0.33 x 10 –6) (105) / 2(.066)

= 1.025V

INT

)

INT

) (R

INT

7

)

8

3-31

TC500

TC500A

TC510

TC514

PRECISION ANALOG FRONT ENDS

TC05

R1

10k

+5V

R2

10k

R3, 10k

C1

0.01µF

1µF

C

REF

0.22µF

PC

PRINTER

PORT

PORT

0378

HEX

C

INT

0.33µF

C

AZ

0.22µF

R

INT

100k

+5V

2

3

10

4

5

6

7

9

8

1

2

3

–

V

OUT

C

INT

C

AZ

BUF

ACOM

–

C

REF

+

C

REF

+

V

REF

–

V

REF

TC510

CMPTR

CAP

DGND

CAP

V

DD

V

V

24

–

23

+

22

21

19

18

A

17

B

16

+

IN

–

15

IN

1µF

+5V

INPUT

INPUT

+

–

Figure 8. TC510 Design Example (See "Design Example")

121

V

OUT

TC510

DGND

–

ACOM

CAP

CAP

+

C

REF

–

C

REF

+

V

REF

–

V

REF

BUF

C

C

INT

V

V

AZ

24

–

+

22

7

6

9

8

100kΩ

4

0.22µF

3

2

+

16

IN

–

15

IN

5

23

18

17

19

A

B

CMPTR

V

DD

1µF

1µF

0.22µF

0.01µF

100kΩ

0.01µF

CONTROLLER

0.33µF

+5V

MICRO

10k

10k

+

INPUT

–

TYPICAL WAVEFORMS

PIN 2

+

V

IN

PIN 19

PIN 2

–

V

IN

PIN 19

10kΩ

TC04

3-32

Figure 9. TC510 to IBM Compatible Printer Port

TELCOM SEMICONDUCTOR, INC.

PRECISION ANALOG FRONT ENDS

TC500

TC500A

TC510

TC514

1

TC05

+5V

10k

10k

10k

1µF

C

REF

0.22µF

C1, .01µF

C

INT

0.33µF

C

AZ

0.22µF

R

INT

100k

2

4

5

6

7

9

8

1

3

–

V

OUT

C

INT

C

AZ

BUF

ACOM

–

C

REF

+

C

REF

+

V

REF

–

V

REF

TC514

CAP

DGND

CAP

V

DD

A0

A1

CMPTR

A

B

CH1

CH1

CH2

CH2

CH3

CH3

CH4

CH4

28

–

27

1µF

26

+

25

+5V

22

19

23

22

21

18

+

13

–

+

17

12

–

+

16

–

11

+

15

–

10

ANALOG

MUX LOGIC

INPUT 1

INPUT 1

INPUT 2

INPUT 2

INPUT 3

INPUT 3

INPUT4

INPUT4

+

–

+

–

+

–

+

–

+

5V

MICRO

CONTROLLER

Figure 10. TC514 Design Example (See "Design Example")

TYPICAL WAVEFORMS

PIN 2

+

V

IN

PIN 23

PIN 2

–

V

IN

PIN 23

2

3

4

+

INPUT 1

–

+

INPUT 2

–

+

INPUT 3

–

+

INPUT 4

–

ANALOG MUX

CONTROL LOGIC

IBM

PRINTER PORT

PORT

0378

HEX

+5V

25

18

+

CH1

–

13

CH1

17

+

CH2

12

CH2

16

+

CH3

11

–

CH3

15

+

CH4

–

10

CH4

20

A0

19

A1

22

2

3

10

21

23

A

B

CMPTR

1

–

V

V

OUT

DD

–

TC514

DGND

27

CAP

CAP

C

REF

C

REF

+

V

REF

–

V

REF

BUF

C

C

ACOM

+

–

INT

28

–

26

+

7

6

9

8

4

3

AZ

2

5

100kΩ

0.22µF

1µF

1µF

0.22µF

0.01µF

0.33µF

10k

10k

10kΩ

TC04

5

6

7

Figure 11. TC514 to IBM Compatible Printer Port

TELCOM SEMICONDUCTOR, INC.

8

3-33

PRECISION ANALOG FRONT ENDS

TC500

TC500A

TC510

TC514

TYPICAL PERFORMANCE CHARACTERISTICS OF INTERNAL DC-TO-DC CONVERTER

Output Voltage vs Load Current

5

TA = 25°C

4

V+ = 5V

3

2

1

0

–1

–2

OUTPUT VOLTAGE (V)

–3

–4

–5

200

175

150

125

100

Slope 60Ω

010203040

LOAD CURRENT (mA)

Output Ripple vs. Load Current

V+ = 5V, TA = 25°C

Osc. Freq. = 100kHz

CAP = 1µF

50

60 70 0 6 8 104214161812 2080

Output Voltage vs. Output Current

–0

TA = 25°C

–1

–2

–3

–4

–5

–6

OUTPUT VOLTAGE (V)

–7

–8

Output Source Resistance vs. Temperature

100

V+ = 5V

I

= 10mA

OUT

90

80

70

OUTPUT CURRENT (mA)

75

50

OUTPUT RIPPLE (mV PK-PK)

25

0

0 345612 78 910

Oscillator Frequency vs. Capacitance

100

10

OSCILLATOR FREQUENCY (kHz)

1

110

OSCILLATOR CAPACITANCE (pF)

CAP = 10µF

LOAD CURRENT (mA)

TA = +25°C

V+ = 5V

100

1000

60

50

OUTPUT SOURCE RESISTANCE (Ω)

40

–50

150

125

100

75

OSCILLATOR FREQUENCY (kHz)

50

–50

–25

Oscillator Frequency vs. Temperature

025

TEMPERATURE (°C)

025–25

TEMPERATURE (°C)

50 75 100

V+ = 5V

75 125100

50

3-34

TELCOM SEMICONDUCTOR, INC.

PRECISION ANALOG FRONT ENDS

WIMA Corporation Capacitor Representatives (Tables 1 and 2 in Applications Section)

TC500

TC500A

TC510

TC514

1

Australia:

ADILAM ELECTRONICS (PTY.) LTD.

P.O. Box 664

3 Nicole Close

Bayswater 3153

Tel.: 3-761-4466

Fax: 3-761-4161

Canada:

R-THETA INC.

130 Matheson Blvd. East, Unit 2

Mississauga, Ont. L4Z1Y6

Tel.: 905-890-0221

Fax: 905-890-1628

Hong Kong:

REALTRONICS CO. LTD.

E-3, Hung-On Building

2, King's Road

Tel.: 25-70-1151

Fax: 28-06-8474

India:

SUSAN AGENCIES

P.O. Box 2138

Srirampuram P.O.

Bangalore-560 021

Tel.: 080-332-0662

Fax: 080-332-4338

Israel:

M.G.R. TECHNOLOGY

P.O. Box 2229

Rehavot 76121

Tel.: 972-841-1719

Fax: 972-841-4178

Japan:

UNIDUX INC.

5-1-21, Kyonan-Cho

Musashino-Shi

Tokyo 180

Tel.: 04-2232-4111

Fax: 04-2232-0331

Malaysia:

MA ELECTRONICS (M) SDN BHD

346-B Jalan Jelutong

11600 Penang

Tel.: 604-281-4518

Fax: 604-281-4515

Singapore:

MICROTRONICS ASSOC. (PTE.) LTD.

8, Lorong Bakar Batu

03-01, Kolam Ayer Ind. Park

Singapore 1334

Tel.: 65-748-1835

Tlx: 34 929

Fax: 65-743-3065

South Africa:

KOPP ELECTRONICS LIMITED

P.O. Box 3853

2128 Rivonia

Tel.: 011-444-2333

Fax: 011-444-1706

South Korea:

YONG JUN ELECTRONIC CO.

#201, Sungwook Bldg.

1460-16, Seocho-Dong

Seocho-Ku

Seoul, Korea

Tel.: 25-231-8002

Fax: 25-231-803

Taiwan, R.O.C.:

SOLOMON TECHNOLOGY CORP.

7th Floor No. 2

Lane 47, Sec. 3

Nan Kang Road

Taipei

Tel.: 886-2788-8989

Fax: 886-288-8275

Thailand:

MICROTRONICS THAI LTD.

50/68 T.T. Court

Cheng Wattana Road

Amphur Pak-Kreed

Nonthaburi 11120

Tel.: 66-2584-5807, Ext. 102

Fax: 66-2583-3775

USA:

THE INTER-TECHNICAL GROUP, INC.

WIMA DIVISION

175 Clearbrook Road

P.O. Box 535

Elmsford, NY 10523-0535

Tel.: 914-347-2474

Fax: 914-347-7230

TAW ELECTRONICS, INC.

4215, W. Burbank, Blvd.

Burbank, CA, 91505

Tel.: 818-846-3911

Fax: 818-846-1194

Venezuela:

MAGNETICA, S.A.

Apartado 78117

Caracas 1074 A

Tel.: 58-2241-7509

Fax: 58-2241-5542

2

3

4

5

6

TELCOM SEMICONDUCTOR, INC.

7

8

3-35

Loading...

Loading...