Page 1

查询TC7109供应商

12-BIT µP-COMP ATIBLE ANALOG-TO-DIGITAL CONVERTERS

1

TC7109

TC7109A

FEATURES

■ Zero-Integrator Cycle for Fast Recovery From

Input Overloads

■ Eliminates Cross -Talk in Multiplexed Systems

■ 12-Bit Plus Sign Integrating A/D Converter With

Overrange Indication

■ Sign Magnitude Coding Format

■ True Differential Signal Input and Differential

Reference Input

■ Low Noise............................................ 15 µV

P-P

Typ

■ Input Current .............................................. 1 pA Typ

■ No Zero Adjustment Needed

■ TTL-Compatible, Byte-Organized Tri-State

Outputs

■ UART Handshake Mode for Simple Serial Data

Transmission

ORDERING INFORMATION

PART CODE TC7109X

A or blank*

Package Temperature

Code Package Range

CKW 44-Pin PQFP 0°C to +70°C

CLW 44-Pin PLCC 0°C to +70°C

CPL 40-Pin Plastic DIP 0°C to +70°C

IJL 40-Pin CerDIP –25°C to +85°C

* The "A" version has a higher I

on the digital lines.

OUT

GENERAL DESCRIPTION

The TC7109A is a 12-bit plus sign, CMOS low-power

analog-to-digital converter (ADC). Only eight passive components and a crystal are required to form a complete

dual-slope integrating ADC.

The improved VOH source current TC7109A has features that make it an attractive per-channel alternative to

analog multiplexing for many data acquisition applications. These features include typical input bias current of

1pA drift of less than 1µV/°C, input noise typically 15µV

and auto-zero. True differential input and reference allow

measurement of bridge-type transducers such as load

cells, strain gauges, and temperature transducers.

The TC7109A provides a versatile digital interface. In

the direct mode, chip select and HIGH/LOW byte enables

control parallel bus interface. In the handshake mode, the

TC7109A will operate with industry-standard UARTs in

controlling serial data transmission — ideal for remote

data logging. Control and monitoring of conversion timing

is provided by the RUN/HOLD input and STATUS output.

For applications requiring more resolution, see the

TC500, 15-bit plus sign ADC data sheet.

The TC7109A has improved overrange recovery performance and higher output drive capability than the original TC7109. All new (or existing) designs should specify

the TC7109A wherever possible.

P-P

2

3

,

4

5

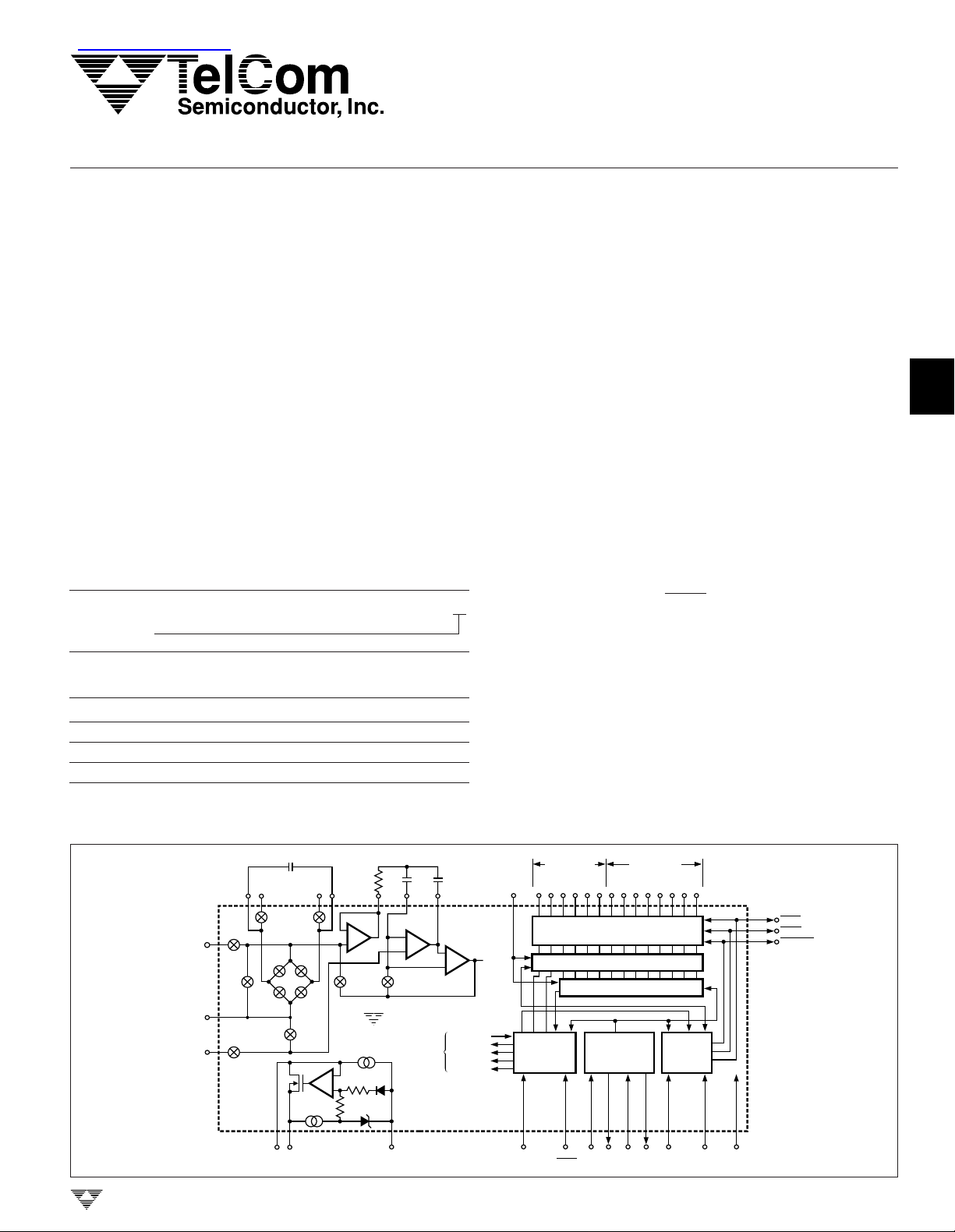

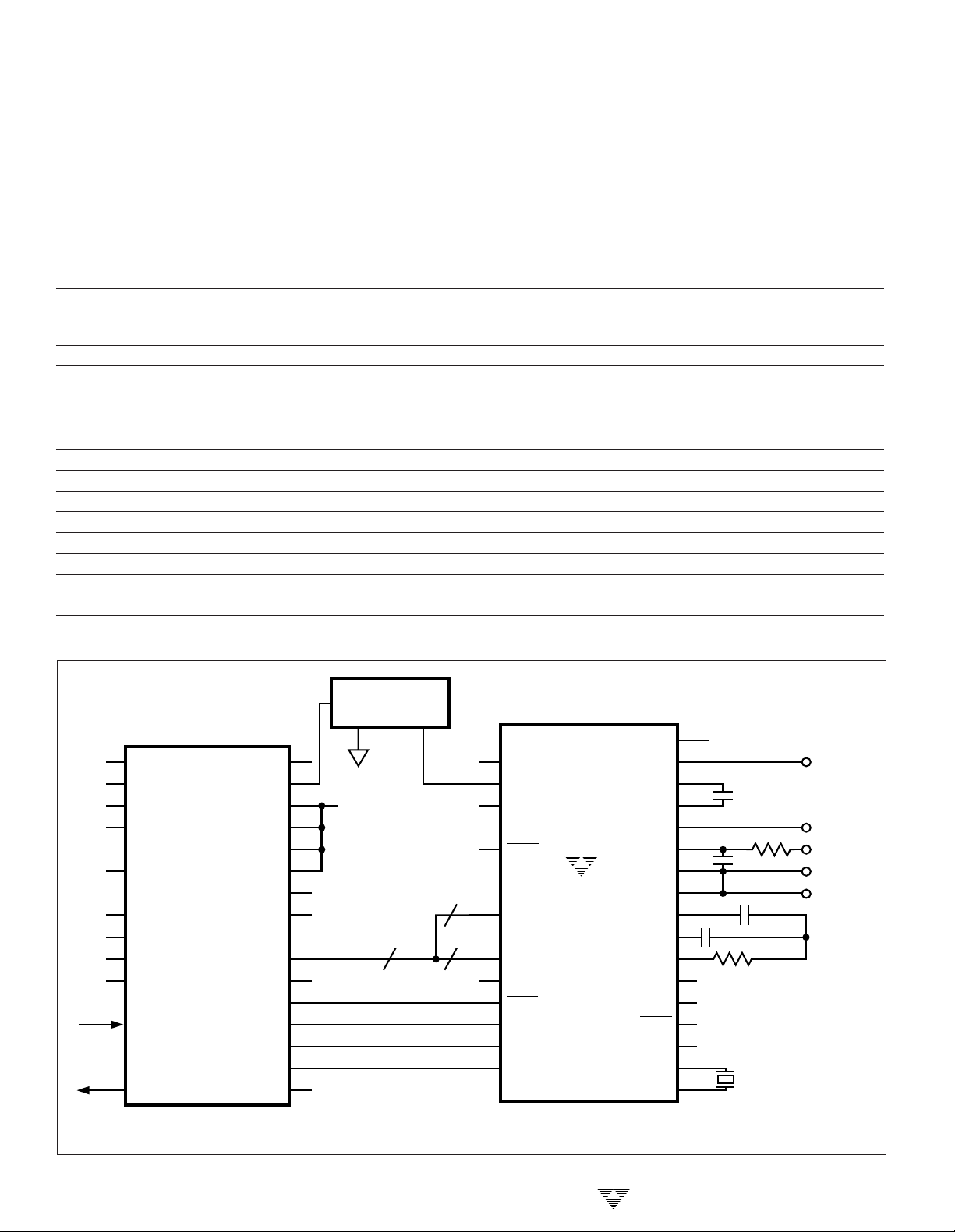

FUNCTIONAL BLOCK DIAGRAM

C

REF

REF

REF

+

IN

+

CAP

37 36

AZZIAZ

INT

35

INPUT

COMMON

INPUT

HI

33

INT

34

LO

DE

(–)DE(+)

AZ

DE

DE

(+)

(–)

AZ

DE (±)

ZI

29

28 40

–

REF

V

OUT

TELCOM SEMICONDUCTOR, INC.

HIGH-ORDER

R

REF

IN

ZI

INT

REF

–

–

CAP

3839

BUFFER

–

+

ZI

TC7109A

10 µA

–

+

6.2V

C

AZBUFF

3130

INTEGRATOR

–

+

AZ

ANALOG

SECTION

+

V

AZ

32

TO

C

INT

INT

COMPARATOR

COMP OUT

AZ

INT

DE (±)

ZI

COMP

OUT

BYTE OUTPUTS

B12B11B10B9B8B7B6B5B4B3B2B

POL

OR

TEST

17 3 4 5 6 7 8 9 10 11 12 13 14

16 THREE-STATE OUTPUTS

CONVERSION

CONTROL

LOGIC

226222324

OSC

STATUS

RUN/

HOLD

14 LATCHES

12-BIT COUNTER

LATCH

OSCILLATOR

AND CLOCK

CIRCUITRY

OSC

OSC

SEL

IN

OUT

LOW-ORDER

BYTE OUTPUTS

CLOCK

HANDSHAKE

21

25

BUF

MODE

OSC

OUT

15 16

LOGIC

1

27

SEND

1

GND

18

LBEN

19

HBEN

20

CE/LOAD

TC7109/A-7 11/6/96

6

7

8

3-91

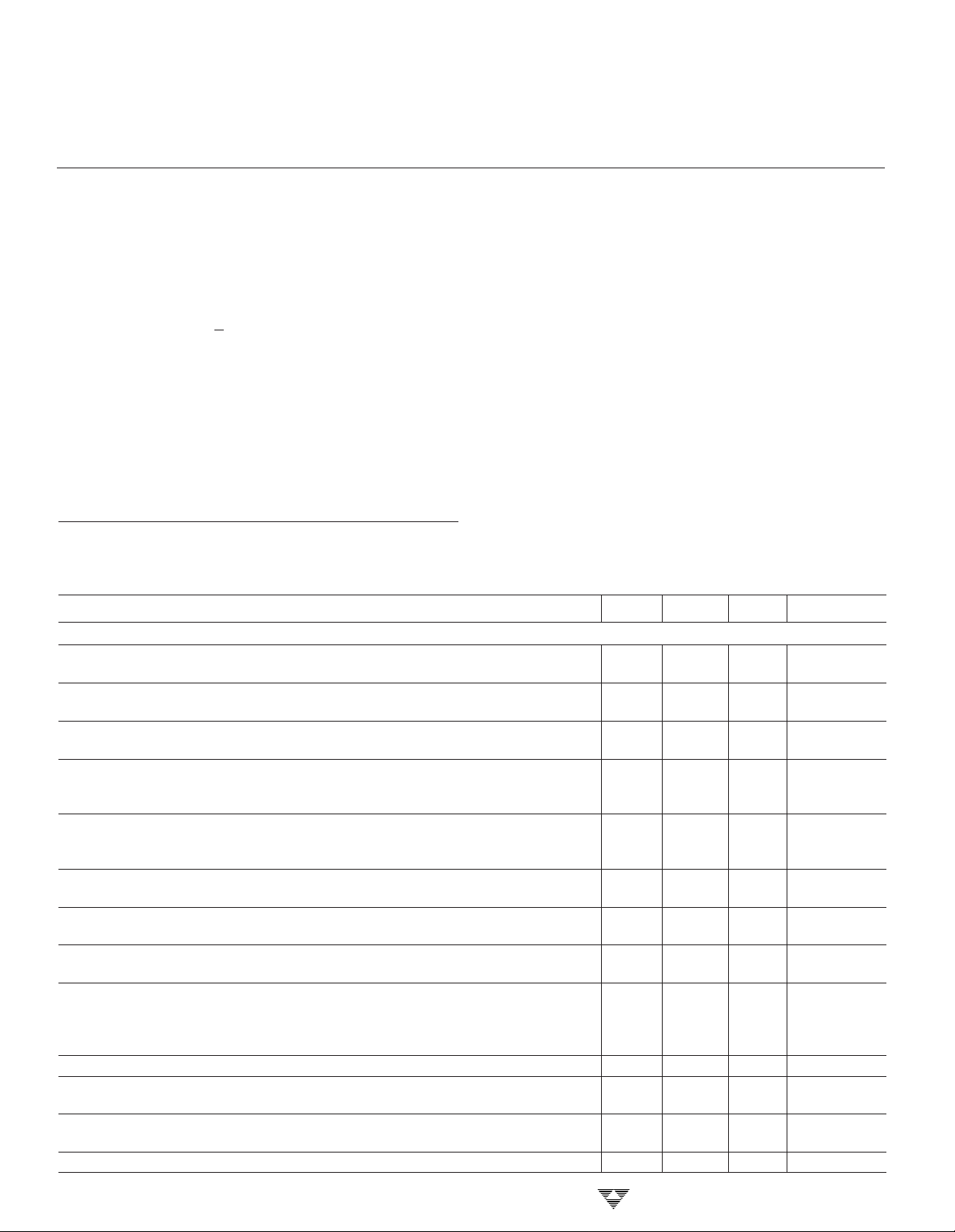

Page 2

TC7109

TC7109A

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

ABSOLUTE MAXIMUM RATINGS*

Positive Supply Voltage (GND to V+) ..................... +6.2V

Negative Supply voltage (GND to V–) ....................... –9V

Analog Input Voltage (Low to High) (Note 1).......V+ to V

Reference Input Voltage (Low to High (Note 1) ..V+ to V

Digital Input Voltage (Pins 2–27) (Note 2)..... GND –0.3V

Power Dissipation, TA < 70°C, (Note 3)

CerDIP............................................................. 2.29W

Plastic DIP....................................................... 1.23W

PLCC ............................................................... 1.23W

PQFP............................................................... 1.00W

Operating Temperature Range

Plastic Package (C)...............................0°C to +70°C

Ceramic Package (I)....................... – 25°C to +85°C

(M) ................... – 55°C to +125°C

Storage Temperature Range ............... – 65°C to +150°C

Lead Temperature (Soldering, 10 sec) .................+300°C

ELECTRICAL CHARACTERISTICS: All parameters with V

*Static-sensitive device. Unused devices must be stored in conductive

material. Protect devices from static discharge and static fields. Stresses

above those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings only and functional

–

operation of the device at these or any other conditions above those

–

indicated in the operational sections of the specifications is not implied.

Exposure to Absolute Maximum Rating Conditions for extended periods

may affect device reliability.

NOTES: 1. Input voltages may exceed supply voltages if input current is

limited to ±100 µA.

2. Connecting any digital inputs or outputs to voltages greater

than V+ or less than GND may cause destructive device latchup. Therefore, it is recommended that inputs from sources

other than the same power supply should not be applied to

the TC7109A before its power supply is established. In

multiple supply systems, the supply to the device should be

activated first.

3. This limit refers to that of the package and will not occur during

normal operation.

+

= +5V, V– = –5V, GND = 0V, TA = +25°C,

unless otherwise indicated.

Symbol Parameter Test Conditions Min Typ Max Unit

Analog

Overload Recovery Time — 0 1 Measurement

(TC7109A) Cycle

Zero Input Reading V

Ratio Metric Reading V

NL Nonlinearity (Max Deviation Full Scale = 409.6 mV to –1 ±0.2 +1 Count

From Best Straight Line Fit) 2.048V Over Full Operating

Roll-Over Error (Difference in Full Scale = 409.6 mV to –1 ±0.02 +1 Count

Reading for Equal Positive and 2.048V Over Full Operating

Negative Inputs Near (Full Scale) Temperature Range

CMRR Input Common-Mode V

Rejection Ratio Full Scale = 409.6 mV

V

CMR

Common-Mode Voltage Input High, Input Low, V–+1.5 — V+–1 V

Range and Common Pins

e

N

Noise (P-P Value Not VIN = 0V — 15 — µV

Exceeded 95% of Time) Full Scale = 409.6 mV

I

IN

TC

TC

ZS

FS

Leakage Current at Input VIN, All Packages: +25°C—110pA

Zero Reading Drift VIN = 0V — 0.2 1 µV/°C

Scale-Factor VIN = 408.9 mV = >7770

Temperature Coefficient Reading, Ext Ref = 0 ppm/°C

+

I

Supply Current VIN = 0V, Crystal Oscillator — 700 1500 µA

(V+ to GND) 3.58 MHz Test Circuit

I

S

Supply Current (V+ to V–) Pins 2–21, 25, 26, 27, 29 Open — 700 1500 µA

= 0V – 00008±00008+00008Octal Reading

IN

Full Scale = 409.6 mV

= V

IN

REF

V

= 204.8 mV 4000

REF

3777

3777840008Octal Reading

8

8

Temperature Range

±1V, VIN = 0V — 50 — µV/V

CM

C Device: 0°C ≤ T

I Device: –25°C ≤ T

≤ +70°C 20 100 pA

A

≤ +85°C 100 250 pA

A

M Device: –55°C ≤ TA ≤ +125°C25nA

8

—15µV/°C

3-92

TELCOM SEMICONDUCTOR, INC.

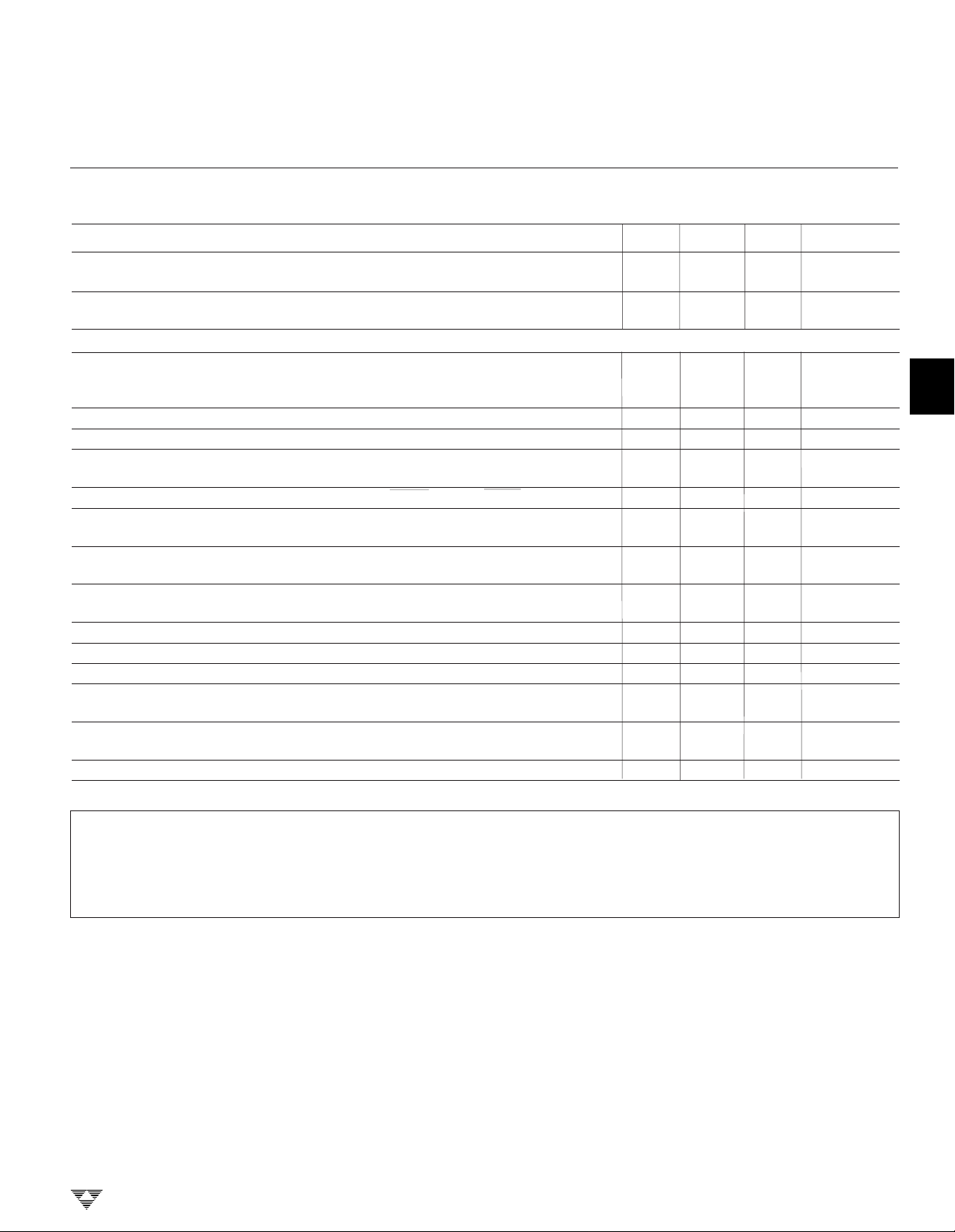

Page 3

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGIT AL CONVERTERS

ELECTRICAL CHARACTERISTICS (Cont.)

1

TC7109

TC7109A

Symbol Parameter Test Conditions Min Typ Max Unit

V

REF

TC

REF

Digital

V

OH

V

OL

V

IH

V

IL

t

W

Ref Out Voltage Referenced to V+, 25 kΩ – 2.4 – 2.8 – 3.2 V

Between V+ and Ref Out

Ref Out Temperature 25 kΩ Between V+ and Ref Out — 80 — ppm/°C

Coefficient 0°C ≤ TA ≤ +70°C

Output High Voltage TC7109: I

TC7109A: I

Pins 3–16, 18, 19, 20

Output Low Voltage I

Output Leakage Current Pins 3–16 High Impedance — ±0.01 ±1 µA

Control I/O Pins 18, 19, 20 V

Pull-Up Current Mode Input at GND

Control I/O Loading HBEN, Pin 19; LBEN, Pin 18 — — 50 pF

Input High Voltage Pins 18–21, 26, 27 2.5 — — V

Input Low Voltage Pins 18-21, 26, 27 — — 1 V

Input Pull-Up Current Pins 26, 27; V

Input Pull-Down Current Pin 21; V

Oscillator Output Current, High V

Oscillator Output Current, Low V

Buffered Oscillator Output V

Current, High

Buffered Oscillator Output V

Current, Low

Mode Input Pulse Width 60 — — nsec

= 1.6 mA — 0.2 0.4 V

OUT

Referenced to GND

Referenced to GND

Pins 17, 24; V

= 2.5V — 1 — mA

OUT

= 2.5V — 1.5 — mA

OUT

= 2.5V — 2 — mA

OUT

= 2.5V — 5 — mA

OUT

= 100 µA 3.5 4.3 — V

OUT

= 700 µA

OUT

= V+–3V — 5 — µA

OUT

= V+–3V — 5 — µA

OUT

= V+–3V 25 µA

OUT

= GND = +3V — 1 — µA

OUT

2

3

4

5

HANDLING PRECAUTIONS: These devices are CMOS and must be handled correctly to prevent damage. Package

and store only in conductive foam, anti-static tubes, or other conducting material. Use proper anti-static handling

procedures. Do not connect in circuits under "power-on" conditions, as high transients may cause permanent

damage.

TELCOM SEMICONDUCTOR, INC.

6

7

8

3-93

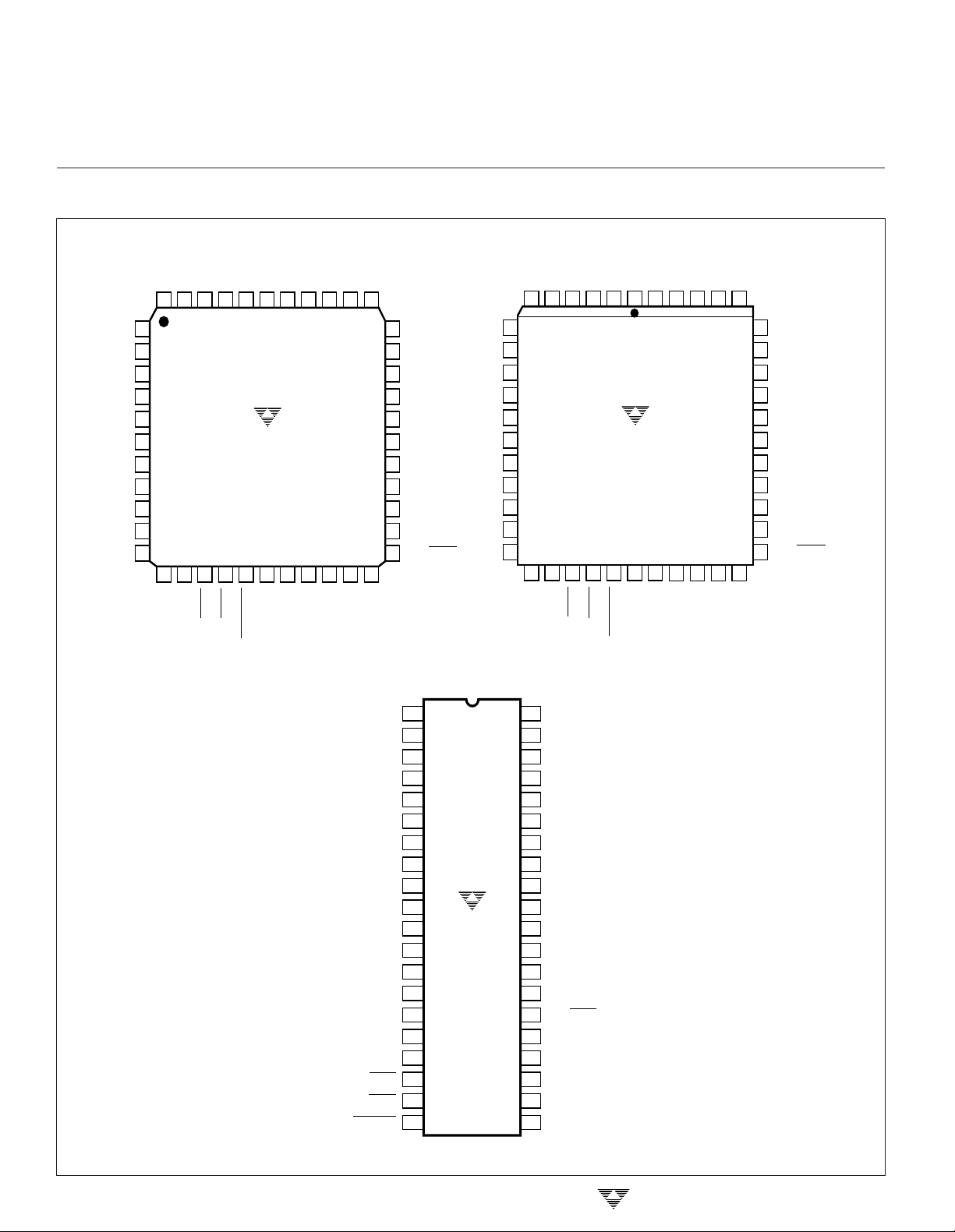

Page 4

TC7109

TC7109A

PIN CONFIGURATIONS

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

+

+

–

–

+

–

–

+

12

B

44 43 42 41 39 3840

B

1

11

B

2

10

B

3

9

B

4

8

B

5

7

6

NC

B

7

6

B

5

B

4

B

3

B

2

12 13 14 15 17 18

1

B

OR

TEST

POL

LBEN

STATUS

TC7109ACKW

TC7109CKW

HBEN

GND

(PQFP)

16

CE/LOAD

NC

NC

+

V

MODE

REF CAP

REF CAP

REF IN

37 36 35 34

19

20 21 22

OSC IN

OSC SEL

OSC OUT

STATUS

CE/LOAD

REF IN

33

32

31

30

29

28

27

268

259

2410

2311

BUFF

OSC OUT

GND

POL

OR

B

12

B

11

B

10

B

B

B

B

B

B

B

B

B

TEST

LBEN

HBEN

IN HI

IN LO

COMMON

INT

AZ

NC

BUFF

REF OUT

–

V

SEND

RUN/HOLD

1

2

3

4

5

6

7

9

8

9

8

7

10

6

11

12

5

13

4

14

3

2

15

1

16

17

18

19

20

B

B

10

B

B

B

NC

B

B

B

B

B

TC7109A

TC7109

(CPL, IJL,

MJL)

(PDIP)

(CerDIP)

12

OR

B

6543 1442

7

11

8

9

9

10

8

11

7

12

13

6

5

4

3

2

18 19 20 21 23 24

1

B

TEST

+

40

V

39

REF IN

38

REF CAP

37

REF CAP

36

REF IN

35

IN HI

IN LO

34

33

COMMON

32

INT

31

AZ

30

BUFF

REF OUT

29

–

28

V

27

SEND

26

RUN/HOLD

25

BUFF OSC OUT

24

OSC SEL

23

OSC OUT

22

OSC IN

21

MODE

STATUS

POL

TC7109ACLW

TC7109CLW

LBEN

HBEN

–

–

+

+

GND

(PLCC)

22

CE/LOAD

NC

NC

+

V

MODE

REF CAP

REF CAP

REF IN

43 42 41 40

25

26 27 28

OSC IN

OSC SEL

OSC OUT

REF IN

39

38

37

36

35

34

33

3214

3115

3016

2917

BUFF

OSC OUT

IN HI

IN LO

COMMON

INT

AZ

NC

BUFF

REF OUT

–

V

SEND

RUN/HOLD

3-94

NC = NO INTERNAL CONNECTION

TELCOM SEMICONDUCTOR, INC.

Page 5

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGIT AL CONVERTERS

TC7109/A PIN DESCRIPTION

1

TC7109

TC7109A

40-Pin PDIP

Pin Number Symbol Description

1 GND Digital ground, 0V, ground return for all digital logic.

2 STATUS Output HIGH during integrate and deintegrate until data is latched. Output LOW

when analog section is in auto-zero or zero-integrator configuration.

3 POL Polarity — High for positive input.

4 OR Overrange — High if overranged.

5B12Bit 12 (Most Significant Bit)

6B11Bit 11

7B10Bit 10

8B

9B

10 B

11 B

12 B

13 B

14 B

15 B

16 B

17 TEST Input High — Normal operation. Input LOW — Forces all bit outputs HIGH.

18 Low-Byte Enable — With MODE (Pin 21) LOW, and CE/LOAD (Pin 20) LOW,

19 High-Byte Enable — With MODE (Pin 21) LOW, and CE/LOAD (Pin 20) LOW,

20 Chip Enable/Load — With MODE (Pin 21) LOW, CE/LOAD serves as a master

21 MODE Input LOW — Direct output mode where CE/LOAD (Pin 20), HBEN (Pin 19), and

22 OSC IN Oscillator Input

23 OSC OUT Oscillator Output

24 OSC SEL Oscillator Select — Input HIGH configures OSC IN, OSC OUT, BUF OSC OUT as

25 BUF OSC OUT Buffered Oscillator Output

26 Input HIGH — Conversions continuously performed every 8192 clock pulses.

9

8

7

6

5

4

3

2

1

LBEN

HBEN

CE/LOAD

RUN/HOLD

Bit 9

Bit 8

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1 (Least Significant Bit)

Note: This input is used for test purposes only.

taking this pin LOW activates low-order byte outputs, B1–B8. With MODE (Pin 21)

HIGH, this pin serves as low-byte flag output used in handshake mode. See

Figures 7, 8, and 9.

taking this pin LOW activates high-order byte outputs, B9–B12, POL, OR. With

MODE (Pin 21) HIGH, this pin serves as high-byte flag output used in handshake

mode. See Figures 7, 8, and 9.

output enable. When HIGH, B1–B12, POL, OR outputs are disabled. When

MODE (Pin 21) is HIGH, a load strobe is used in handshake mode. See Figure 7,

8, and 9.

LBEN (Pin 18) act as inputs directly controlling byte outputs.

Input Pulsed HIGH — Causes immediate entry into handshake mode and output

of data as in Figure 9.

Input HIGH — Enables CE/LOAD (Pin 20), HBEN (Pin 19), and LBEN (Pin 18)

as outputs, handshake mode will be entered and data output as in Figures 7 and

8 at conversions completion.

RC oscillator — clock will be same phase and duty cycle as BUF OSC OUT. Input

LOW configures OSC IN, OSC OUT for crystal oscillator — clock frequency will

be 1/58 of frequency at BUF OSC OUT.

Input LOW — Conversion in progress completed; converter will stop in auto-zero

seven counts before integrate.

All Three-State Data Bits

2

3

4

5

6

7

8

TELCOM SEMICONDUCTOR, INC.

3-95

Page 6

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

TC7109

TC7109A

TC7109/A PIN DESCRIPTION (Cont.)

40-Pin PDIP

Pin Number Symbol Description

27 SEND Input — Used in handshake mode to indicate ability of an external device to

accept data.

Connect to V+ if not used.

28 V

29 REF OUT Reference Voltage Output — Nominally 2.8V down from V+ (Pin 40).

30 BUFFER Buffer Amplifier Output

31 AUTO-ZERO Auto-Zero Node — Inside foil of CAZ.

32 INTEGRATOR Integrator Output — Outside foil of C

33 COMMON Analog Common — System is auto-zeroed to COMMON.

34 INPUT LOW Differential Input Low Side

35 INPUT HIGH Differential Input High Side

36 REF IN + Differential Reference Input Positive

37 REF CAP + Reference Capacitor Positive

38 REF CAP – Reference Capacitor Negative

39 REF IN – Differential Reference Input Negative

40 V

NOTE: All digital levels are positive true.

–

+

Analog Negative Supply — Nominally –5V with respect to GND (Pin 1).

.

INT

Positive Supply Voltage — Nominally +5V with respect to GND (Pin 1).

+5V

GND

+5V

5–12

GND

SERIAL

INPUT

SERIAL

OUTPUT

1

V

2

OSC CONTROL

3

GND

4

RRD

RBR1–8

13

14

15

16

20

25

CMOS UART

PE

FE

OE

SFD

RR1

TRO

6403

*

Q11

RESET

+5V

CD4040B

CLK

1011

8

15

40

TRC

OSC IN

*TBR1–8

NOTE:

17

39

EPE

38

CLS1

37

CLS2

36

SBS

35

GND

PI

34

CRL

TRE

DRR

DR

TBRL

TBRE

MR

For lowest power consumption, TBR1–TBR8 inputs

should have 100kΩ pull-up resistors to +5V.

+5V

26–33

24

18

19

23

22

21

GND

GND

6

8

1

GND

25

BUFF OSC OUT

2

STATUS

19

HBEN

3–8

B9–B12,

POL, OR

9–16

B1–B8

17

TEST

18

LBEN

21

MODE

20

CE/LOAD

27

SEND

TC7109A

V

REF IN

REF CAP

REF CAP

REF IN

IN HI

IN LO

COM

INT

AZ

BUFF

REF OUT

V

RUN/HOLD

OSC SEL

OSC OUT

OSC IN

40

+

39

–

38

–

+

37

+

36

35

34

33

32

31

30

29

28

–

26

24

23

22

+5V

1µF

1MΩ

0.01µF

C

INT

0.15µF

C

AZ

0.33µF

R

20k

INT

–5V

+5V OR OPEN

GND

100kΩΩ

3.58MHz

CRYSTAL

–

EXTERNAL

REFERENCE

+

+

INPUT

–

ANALOG

GND

0.2V

REF

1V

REF

3-96

Figure 1. TC7109A UART Interface (Send Any Word to UART to Transmit Latest Result)

TELCOM SEMICONDUCTOR, INC.

Page 7

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGIT AL CONVERTERS

1

TC7109

TC7109A

+5V

GND

+5V

+5V

+5V

+5V

GND

23

1

TO

4

RESET

5

SS

6

INT

8748/8049

MICROCOMPUTER

7

EA

8

WR

9

PSEN

11

ALE

25

PROG

26

V

DD

39

TL

40

V

CC

20

GND

CMOS

XTAL2XTALI

P20–P27

P14–P17

P13

P12

P11

P10

DB0–DB7

RD

2

21–24,

35–38

31–34

30

29

28

27

12–19

10

8

5

OTHER I/O

8

40

+5V

GND

6

8

17

26

18

19

3–8

9–16

20

V

1

GND

TEST

RUN/HOLD

2

STATUS

LBEN

HBEN

B9–B12,

POL, OR

B1–B8

CE/LOAD

+

REF IN

REF CAP

REF CAP

REF IN

TC7109A

REF OUT

BUFF OSC OUT

OSC SEL

OSC OUT

IN HI

HI LO

COM

INT

AZ

BUFF

V

SEND

OSC IN

MODE

39

–

38

–

C

AZ

0.33µF

–5V

GND

1µF

1MΩ

0.01µF

C

INT

0.15µF

R

20k

10 kΩΩ

3.58MHz

CRYSTAL

37

+

36

+

35

34

33

32

31

30

29

28

–

27

25

24

23

22

21

INT

–

EXTERNAL

REFERNCE

+

+

INPUT

–

ANALOG

GND

0.2 V

REF

1 V

REF

2

3

4

Figure 2. TC7109A Parallel Interface With 8048/8049 Microcomputer

DETAILED DESCRIPTION

(All Pin Designations Refer to 40-Pin DIP)

Analog Section

The functional diagram shows a block diagram of the

analog section of the TC7109A. The circuit will perform

conversions at a rate determined by the clock frequency

(8192 clock periods per cycle), when the RUN/HOLD input

is left open or connected to V+. Each measurement cycle is

divided into four phases, as shown in Figure 3. They are:

(1) Auto-Zero (AZ), (2) Signal Integrate (INT), (3) Reference

Deintegrate (DE), and (4) Zero Integrator (ZI).

Auto-Zero Phase

The buffer and the integrator inputs are disconnected

from input high and input low and connected to analog

common. The reference capacitor is charged to the reference voltage. A feedback loop is closed around the system

to charge the auto-zero capacitor, CAZ, to compensate for

offset voltage in the buffer amplifier, integrator, and comparator. Since the comparator is included in the loop, the AZ

accuracy is limited only by the noise of the system. The offset

referred to the input is less than 10 µV.

Signal-Integrate Phase

The buffer and integrator inputs are removed from

common and connected to input high and input low. The

auto-zero loop is opened. The auto-zero capacitor is placed

in series in the loop to provide an equal and opposite

compensating offset voltage. The differential voltage between input high and input low is integrated for a fixed time

of 2048 clock periods. At the end of this phase, the polarity

of the integrated signal is determined. If the input signal has

no return to the converter's power supply, input low can be

tied to analog common to establish the correct commonmode voltage.

Deintegrate Phase

Input high is connected across the previously-charged

reference capacitor and input low is internally connected to

analog common. Circuitry within the chip ensures the capacitor will be connected with the correct polarity to cause

the integrator output to return to the zero crossing (established by auto-zero) with a fixed slope. The time, represented by the number of clock periods counted for the output

to return to zero, is proportional to the input signal.

5

6

7

8

TELCOM SEMICONDUCTOR, INC.

3-97

Page 8

TC7109

TC7109A

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

Zero-Integrator Phase

The ZI phase only occurs when an input overrange

condition exists. The function of the ZI phase is to eliminate

residual charge on the integrator capacitor after an overrange

measurement. Unless removed, the residual charge will be

transferred to the auto-zero capacitor and cause an error in

the succeeding conversion.

The ZI phase virtually eliminates hysteresis or "cross

talk" in multiplexed systems. An overrange input on one

channel will not cause an error on the next channel measured. This feature is especially useful in thermocouple

measurements, where unused (or broken thermocouple)

inputs are pulled to the positive supply rail.

During ZI, the reference capacitor is charged to the

reference voltage. The signal inputs are disconnected from

the buffer and integrator. The comparator output is connected to the buffer input, causing the integrator output to be

driven rapidly to 0V (Figure 3). The ZI phase only occurs

following an overrange and lasts for a maximum of 1024

clock periods.

Differential Input

The TC7109A has been optimized for operation with

analog common near digital ground. With +5V and –5V

power supplies, a full ±4V full-scale integrator swing maximizes the analog section's performance.

A typical CMRR of 86 dB is achieved for input differential

voltages anywhere within the typical common-mode range

of 1V below the positive supply to 1.5V above the negative

supply. However, for optimum performance, the IN HI and IN

LO inputs should not come within 2V of either supply rail.

Since the integrator also swings with the common-mode

voltage, care must be exercised to ensure the integrator

output does not saturate. A worst-case condition is near a

full-scale negative differential input voltage with a large

positive common-mode voltage. The negative input signal

drives the integrator positive when most of its swing has

been used up by the positive common-mode voltage. In

such cases, the integrator swing can be reduced to less than

the recommended ±4V full-scale value, with some loss of

accuracy. The integrator output can swing to within 0.3V of

either supply without loss of linearity.

reference for (+) or (–) input voltages will cause a roll-over

error. This error can be held to less than 0.5 count worst case

by using a large reference capacitor in comparison to the

stray capacitance. To minimize roll-over error from these

sources, keep the reference common-mode voltage near or

at analog common.

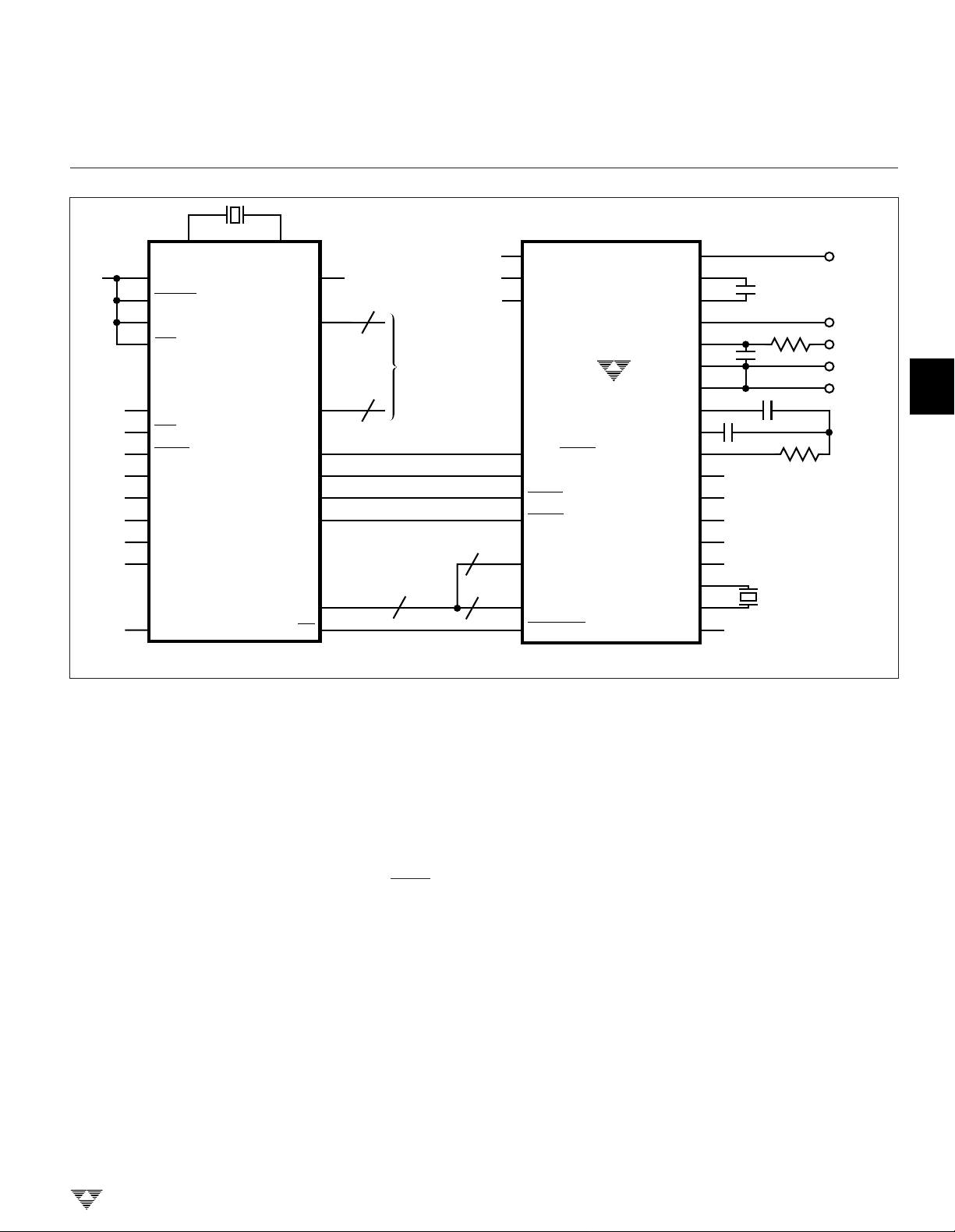

Digital Section

The digital section is shown in the block diagram (Figure 4) and includes the clock oscillator and scaling circuit,

a 12-bit binary counter with output latches and TTL compatible three-state output drivers, UART handshake logic,

polarity, overrange, and control logic. Logic levels are referred to as LOW or HIGH.

Inputs driven from TTL gates should have 3 kΩ to 5 kΩ

pull-up resistors added for maximum noise immunity. For

minimum power consumption, all inputs should swing from

GND (LOW) to V+ (HIGH).

STATUS Output

During a conversion cycle, the STATUS output goes

HIGH at the beginning of signal integrate and goes LOW

one-half clock period after new data from the conversion has

been stored in the output latches (see Figure 3). The signal

may be used as a "data valid" flag to drive interrupts, or for

monitoring the status of the converter. (Data will not change

while status is LOW.)

MODE Input

The output mode of the converter is controlled by the

MODE input. The converter is in its "direct" output mode,

when the MODE input is LOW or left open. The output data

is directly accessible under the control of the chip and byte

enable inputs (this input is provided with a pull-down resistor

to ensure a LOW Level when the pin is left open). When the

MODE input is pulsed high, the converter enters the UART

handshake mode and outputs the data in 2 bytes, then

returns to "direct" mode. When the MODE input is kept

HIGH, the converter will output data in the handshake mode

at the end of every conversion cycle. With MODE = 0 (direct

bus transfer), the send input should be tied to V+. (See

"Handshake Mode.")

Differential Reference

The reference voltage can be generated anywhere

within the power supply voltage of the converter. Roll-over

voltage is the main source of common-mode error, caused

by the reference capacitor losing or gaining charge due to

stray capacity on its nodes. With a large common-mode

voltage, the reference capacitor can gain charge (increase

voltage) when called upon to deintegrate a positive signal

and lose charge (decrease voltage) when called upon

to deintegrate a negative input signal. This difference in

3-98

RUN/HOLD Input

With the RUN/HOLD input high, or open, the circuit

operates normally as a dual-slope ADC, as shown in Figure

3. Conversion cycles operate continuously with the output

latches updated after zero crossing in the deintegrate mode.

An internal pull-up resistor is provided to ensure a HIGH

level with an open input.

TELCOM SEMICONDUCTOR, INC.

Page 9

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGIT AL CONVERTERS

1

TC7109

TC7109A

INTEGRATOR OUTPUT

FOR OVERRANGE INPUT

INTEGRATOR OUTPUT

FOR NORMAL INPUT

INTERNAL CLOCK

INTERNAL LATCH

STATUS OUTPUT

NUMBER OF COUNTS TO ZERO CROSSING

INTEGRATOR

SATURATES

AZ

PHASE I

2048

COUNTS

MIN

PROPORTIONAL TO V

Figure 3. Conversion Timing (RUN/HOLD Pin High)

PHASE II

COUNTS

INT

FIXED

2048

IN

ZI

AZ

ZERO INTEGRATOR

NO ZERO

CROSSING

ZERO CROSSING

OCCURS

ZERO CROSSING

DETECTED

DE

PHASE III

4096

COUNTS

MAX

AFTER ZERO CROSSING, ANALOG SECTION

WILL BE IN AUTO-ZERO CONFIGURATION

AZ

PHASE FORCES

INTEGRATOR

OUTPUT TO 0V

2

3

4

TO

ANALOG

SECTION

COMP OUT

AZ

INT

DE (±)

TEST17POL3OR

ZI

HIGH-ORDER

BYTE OUTPUTS

B

B

B

B

12

11

10

4

5

6

7

14 THREE-STATE OUTPUTS

CONVERSION

CONTROL

LOGIC

2262223242521

STATUS RUN/

HOLD

B

9

8

8

9

14 LATCHES

12-BIT COUNTER

OSCILLATOR

AND CLOCK

CIRCUITRY

OSCINOSC

OUT

LOW-ORDER

BYTE OUTPUTS

B

B

7

6

10

11

12

LATCH

CLOCK

OSC

BUFF

SEL

OSC

OUT

B

B

5

4

13

14

HANDSHAKE

MODE

B

3

15

LOGIC

B

2

B

1

16

27

SEND

1

GND

18

19

20

5

LBEN

HBEN

CE/LOAD

6

7

TELCOM SEMICONDUCTOR, INC.

Figure 4. Digital Section

8

3-99

Page 10

TC7109

TC7109A

INTEGRATOR OUTPUT

INTERNAL CLOCK

INTERNAL LATCH

STATUS OUTPUT

RUN/HOLD INPUT

*

NOTE:

ANALOG-TO-DIGITAL CONVERTERS

AUTO-ZERO

DETERMINATED

AT ZERO CROSSING

DETECTION

RUN/HOLD input is ignored until end of auto-zero phase.

Figure 5. TC7109A RUN/HOLD Operation

PHASE I

MIN 1790 COUNTS

MAX 2041 COUNTS

*

12-BIT

STATIC IN

HOLD STATE

µP-COMPATIBLE

INT

PHASE II

7 COUNTS

The RUN/HOLD input may be used to shorten conversion time. If RUN/HOLD goes LOW any time after zero

crossing in the deintegrate mode, the circuit will jump to

auto-zero and eliminate that portion of time normally spent

in deintegrate.

If RUN/HOLD stays or goes LOW, the conversion will

complete with minimum time in deintegrate. It will stay in

auto-zero for the minimum time and wait in auto-zero for a

HIGH at the RUN/HOLD input. As shown in Figure 5, the

STATUS output will go HIGH 7 clock periods after RUN/

HOLD is changed to HIGH, and the converter will begin the

integrate phase of the next conversion.

The RUN/HOLD input allows controlled conversion interface. The converter may be held at idle in auto-zero with

RUN/HOLD LOW. The conversion is started when RUN/

HOLD goes HIGH, and the new data is valid when the

STATUS output goes LOW (or is transferred to the UART;

see "Handshake Mode"). RUN/HOLD may now go LOW,

terminating deintegrate and ensuring a minimum auto-zero

time before stopping to wait for the next conversion. Conversion time can be minimized by ensuring RUN/HOLD goes

LOW during deintegrate, after zero crossing, and goes

HIGH after the hold point is reached. The required activity on

the RUN/HOLD input can be provided by connecting it to the

buffered oscillator output. In this mode, the input value

measured determines the conversion time.

Direct Mode

The data outputs (bits 1 through 8, low-order bytes; bits

9 through 12, polarity and overrange high-order bytes) are

accessible under control of the byte and chip enable terminals as inputs with the MODE pin at a LOW level. These

three inputs are all active LOW. Internal pull-up resistors are

provided for an inactive HIGH level when left open. When

chip enable is LOW, a byte-enable input LOW will allow the

outputs of the byte to become active. A variety of parallel

data accessing techniques may be used, as shown in the

"Interfacing" section. (See Figure 6 and Table 1.)

The access of data should be synchronized with the

conversion cycle by monitoring the STATUS output. This

prevents accessing data while it is being updated and

eliminates the acquisition of erroneous data.

t

CE/LOAD

AS INPUT

HBEN

AS INPUT

LBEN

AS INPUT

HIGH-BYTE

DATA

LOW-BYTE

DATA

t

BEA

t

DAB

Figure 6. TC7109A Direct Mode Output Timing

DATA

VALID

= HIGH IMPEDANCE

t

DAB

t

DAC

CEA

DATA

VALID

DATA

VALID

t

DHC

Table 1. TC7109A Direct Mode Timing Requirements

Symbol Description Min Typ Max Units

t

BEA

t

DAB

t

DHB

t

CEA

t

DAC

t

DHC

Byte Enable Width 200 500 nsec

Data Access Time 150 300 nsec

From Byte Enable

Data Hold Time 150 300 nsec

From Byte Enable

Chip Enable Width 300 500 nsec

Data Access Time 200 400 nsec

From Chip Enable

Data Hold Time 200 400 nsec

From Chip Enable

3-100

TELCOM SEMICONDUCTOR, INC.

Page 11

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

Handshake Mode

An alternative means of interfacing the TC7109A to

digital systems is provided when the handshake output

mode of the TC7109A becomes active in controlling the

flow of data instead of passively responding to chip and

byte enable inputs. This mode allows a direct interface

between the TC7109A and industry-standard UARTs with

no external logic required. The TC7109A provides all the

control and flag signals necessary to sequence the two

bytes of data into the UART and initiate their transmission

in serial form when triggered into the handshake mode.

The cost of designing remote data acquisition stations is

reduced using serial data transmission to minimize the

number of lines to the central controlling processor.

The MODE input controls the handshake mode. When

the MODE input is held HIGH, the TC7109A enters the

handshake mode after new data has been stored in the

output latches at the end of every conversion performed

(see Figures 7 and 8). Entry into the handshake mode may

be triggered on demand by the MODE input. At any time

during the conversion cycle, the LOW-to-HIGH transition of

a short pulse at the MODE input will cause immediate entry

into the handshake mode. If this pulse occurs while new

data is being stored, the entry into handshake mode is

delayed until the data is stable. The MODE input is ignored

in the handshake mode, and until the converter completes

the output cycle and clears the handshake mode, data

updating will be inhibited (see Figure 9).

When the MODE input is HIGH or when the converter

enters the handshake mode, the chip and byte enable

inputs become TTL-compatible outputs which provide the

output cycle control signals (see Figures 7, 8 and 9).

The SEND input is used by the converter as an indication of the ability of the receiving device (such as a UART)

to accept data in the handshake mode. The sequence of

the output cycle with SEND held HIGH is shown in Figure

7. The handshake mode (internal MODE HIGH) is entered

after the data latch pulse (the CE/LOAD, LBEN and HBEN

terminals are active as outputs since MODE remains HIGH).

The HIGH level at the SEND input is sensed on the

same HIGH-to-LOW internal clock edge. On the next LOWto-HIGH internal clock edge, the high-order byte (bits 9

through 12, POL, and OR) outputs are enabled and the CE/

LOAD and the HBEN outputs assume a LOW level. The

CE/LOAD output remains LOW for one full internal clock

period only; the data outputs remain active for 1-1/2 internal clock periods; and the high-byte enable remains LOW

for 2 clock periods. The CE/LOAD output LOW level or

LOW-to-HIGH edge may be used as a synchronizing signal to ensure valid data, and the byte enable as an output

may be used as a byte identification flag. With SEND

TC7109

TC7109A

remaining HIGH the converter completes the output cycle

using CE/LOAD and LBEN while the low-order byte outputs (bits 1 through 8) are activated. When both bytes are

sent, the handshake mode is terminated. The typical UART

interfacing timing is shown in Figure 8. The SEND input is

used to delay portions of the sequence, or handshake, to

ensure correct data transfer. This timing diagram shows an

industry-standard HD6403 or CDP1854 CMOS UART to

interface to serial data channels. The SEND input to the

TC7109A is driven by the TBRE (Transmitter Buffer Register Empty) output of the UART, and the CE/LOAD input of

the TC7109A drives the TBRL (Transmitter Buffer Register

Load) input to the UART. The eight transmitter buffer register inputs accept the parallel data outputs. With the UART

transmitter buffer register empty, the SEND input will be

HIGH when the handshake mode is entered after new data

is stored. The high-order byte outputs become active and

the CE/LOAD and HBEN inputs will go LOW after SEND is

sensed. When CE/LOAD goes HIGH at the end of one

clock period, the high-order byte data is clocked into the

UART transmitter buffer register. The UART TBRE output

will go LOW, which halts the output cycle with the HBEN

output LOW, and the high-order byte outputs active. When

the UART has transferred the data to the transmitter register and cleared the transmitter buffer register, the TBRE

returns HIGH. The high-order byte outputs are disabled on

the next TC7109A internal clock HIGH-to-LOW edge, and

one-half internal clock later, the HBEN output returns HIGH.

The CE/LOAD and LBEN outputs go LOW at the same

time as the low-order byte outputs become active. When

the CE/LOAD returns HIGH at the end of one clock period,

the low-order data is clocked into the UART transmitter

buffer register, and TBRE again goes LOW. The next

TC7109A internal clock HIGH-to-LOW edge will sense

when TBRE returns to a HIGH, disabling the data inputs.

One-half internal clock later, the handshake mode is cleared,

and the CE/LOAD, HBEN and LBEN terminals return

HIGH and stay active, if MODE still remains HIGH.

Handshake output sequences may be performed on

demand by triggering the converter into handshake mode

with a LOW-to-HIGH edge on the MODE input. A handshake output sequence triggered is shown in Figure 9. The

SEND input is LOW when the converter enters handshake

mode. The whole output sequence is controlled by the

SEND input, and the sequence for the first (high order) byte

is similar to the sequence for the second byte.

Figure 9 also shows that the output sequence can take

longer than a conversion cycle. New data will not be latched

when the handshake mode is still in progress and is therefore lost.

1

2

3

4

5

6

7

8

TELCOM SEMICONDUCTOR, INC.

3-101

Page 12

TC7109

TC7109A

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

INTEGRATOR

OUTPUT

INTERNAL CLOCK

INTERNAL LATCH

STATUS OUTPUT

MODE INPUT

INTERNAL MODE

SEND INPUT

CE/LOAD

HBEN

HIGH-BYTE DATA

LBEN

LOW-BYTE DATA

UART

NORM

ZERO CROSSING OCCURS

ZERO CROSSING DETECTED

MODE HIGH ACTIVATES

CE/LOAD, HBEN, LBEN

= DON'T CARE

SEND SENSED SEND SENSED

DATA VALID

DATA VALID

THREE-STATE

=

HIGH IMPEDANCE

THREE-STATE

=

WITH PULL-UP

TERMINATES

UART MODE

MODE LOW,

NOT IN

HANDSHAKE

MODE

DISABLES

OUTPUTS

CE/LOAD,

HBEN,

LBEN

INTEGRATOR OUTPUT

INTERNAL CLOCK

INTERNAL LATCH

STATUS OUTPUT

MODE INPUT

INTERNAL MODE

SEND INPUT (UART TBRE)

CE/LOAD OUTPUT (UART TBRL)

HBEN

HIGH-BYTE DATA

LBEN

LOW-BYTE DATA

Figure 7. TC7109A Handshake With SEND INPUT Held Positive

ZERO CROSSING OCCURS

ZERO CROSSING DETECTED

UART

NORM

SEND

SENSED

DATA VALID

SEND

SENSED

DATA VALID

SEND

SENSED

TERMINATES

UART MODE

3-102

= DON'T CARE

Figure 8. TC7109A Handshake — Typical UART Interface Timing

=

THREE-STATE HIGH IMPEDANCE

TELCOM SEMICONDUCTOR, INC.

Page 13

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

POSITIVE TRANSITION

CAUSES ENTRY INTO

UART MODE

INTERNAL CLOCK

INTERNAL LATCH

STATUS OUTPUT

STATUS OUTPUT UNCHANGED

IN UART MODE

DE PHASE III

ZERO CROSSING OCCURS

ZERO CROSSING DETECTED

LATCH PULSE INHIBITED

IN UART MODE

1

TC7109

TC7109A

2

MODE INPUT

INTERNAL MODE

SEND INPUT

CE/LOAD AS OUTPUT

HIGH-BYTE DATA

LOW-BYTE DATA

HBEN

LBEN

UART

NORM

SEND

SENSED

DATA VALID

= DON'T CARE

Figure 9. TC7109A Handshake Triggered by MODE Input

=

Oscillator

The oscillator may be overdriven, or may be operated as

an RC or crystal oscillator. The OSCILLATOR SELECT

input optimizes the internal configuration of the oscillator for

RC or crystal operation. The OSCILLATOR SELECT input

is provided with a pull-up resistor. When the OSCILLATOR

SELECT input is HIGH or left open, the oscillator is configured for RC operation. The internal clock will be the same

frequency and phase as the signal at the BUFFERED

OSCILLATOR OUTPUT. Connect the resistor and capacitor as in Figure 10. The circuit will oscillate at a frequency

given by f = 0.45/RC. A 100 kΩ resistor is recommended for

useful ranges of frequency. The capacitor value should be

chosen such that 2048 clock periods are close to an integral

multiple of the 60 Hz period for optimum 60 Hz line rejection.

With OSCILLATOR SELECT input LOW, two on-chip

capacitors and a feedback device are added to the oscillator.

In this configuration, the oscillator will operate with most

crystals in the 1 to 5 MHz range with no external components

(Figure 11). The OSCILLATOR SELECT input LOW inserts

TERMINATES

SEND

SENSED

DATA VALID

THREE-STATE

HIGH IMPEDANCE

a fixed 458 divider circuit between the BUFFERED OSCILLATOR OUTPUT and the internal clock. A 3.58 MHz TV

crystal gives a division ratio providing an integration time

given by:

t = (2048 clock periods) = 33.18 ms

The error is less than 1% from two 60 Hz periods, or

33.33 ms, which will give better than 40 dB, 60 Hz rejection.

The converter will operate reliably at conversion rates up

to 30 per second, corresponding to a clock frequency of

245.8 kHz.

When the oscillator is to be overdriven, the OSCILLA-

TOR OUTPUT should be left open, and the overdriving

signal should be applied at the OSCILLATOR INPUT. The

internal clock will be of the same duty cycle, frequency and

phase as the input signal. When the OSCILLATOR SELECT

is at GND, the clock will be 1/58 of the input frequency.

SEND

SENSED

THREE-STATE

=

WITH PULL-UP

3.58 MHz

UART MODE

58

3

4

5

6

7

TELCOM SEMICONDUCTOR, INC.

8

3-103

Page 14

TC7109

TC7109A

24

OSC

SEL

+

V OR OPEN

+

V

22

OSC

IN

f = 0.45/RC

OSC

Figure 10. TC7109A RC Oscillator

23

OSC

OUT

R

C

25

BUFFERED

OSC OUT

CLOCK

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

roll-over errors will be slightly worse than in the ±4V case.

For large common-mode voltage ranges, the integrator

output swing must be reduced further. This will increase both

noise and roll-over errors. To improve performance, ±6V

supplies may be used.

Integrating Capacitor

The integrating capacitor, C

give the maximum integrator output voltage swing that will

not saturate the integrator to within 0.3V from either supply.

A ±3.5V to ±4V integrator output swing is nominal for the

TC7109A, with ±5V supplies and analog common connected to GND. For 7-1/2 conversions per second (61.72

kHz internal clock frequency), nominal values C

are 0.15 µF and 0.33 µF, respectively. These values should

be changed if different clock frequencies are used to maintain the integrator output voltage swing. The value of C

given by:

, should be selected to

INT

and C

INT

INT

AZ

is

÷

58

GND

24

22

OSC

OSC

SEL

IN

CRYSTAL

Figure 11. TC7109A Crystal Oscillator

23

OSC

OUT

25

BUFFERED

OSC OUT

Test Input

The counter and its outputs may be tested easily. When

the TEST input is connected to GND, the internal clock is

disabled and the counter outputs are all forced into the HIGH

state. When the input returns to the 1/2 (V+–GND) voltage or

to V+ and one clock is input, the counter outputs will all be

clocked to the LOW state.

The counter output latches are enabled when the TEST

input is taken to a level halfway between V+ and GND,

allowing the counter contents to be examined anytime.

Component Value Selection

The integrator output swing for full-scale should be as

large as possible. For example, with ±5V supplies and

COMMON connected to GND, the nominal integrator output

swing at full-scale is ±4V. Since the integrator output can go

to 0.3V from either supply without significantly effecting

linearity, a 4V integrator output swing allows 0.7V for variations in output swing due to component value and oscillator

tolerances. With ±5V supplies and a common-mode voltage

range of ±1V required, the component values should be

selected to provide ±3V integrator output swing. Noise and

C

(2048 3 Clock Period) (20 µA)

=

INT

Integrator Output Voltage Swing

The integrating capacitor must have low dielectric absorption to prevent roll-over errors. Polypropylene capacitors give undetectable errors, at reasonable cost, up to

+85°C. Teflon® capacitors are recommended for the military

temperature range. While their dielectric absorption characteristics vary somewhat between units, devices may be

selected to less than 0.5 count of error due to dielectric

absorption.

Integrating Resistor

The integrator and buffer amplifiers have a class A

output stage with 100 µA of quiescent current. They supply

20 µA of drive current with negligible nonlinearity. The

integrating resistor should be large enough to remain in this

very linear region over the input voltage range, but small

enough that undue leakage requirements are not placed on

the PC board. For 2.048V full-scale a 100 kΩ resistor is

recommended and for 409.6 mV full-scale a 20 kΩ resistor

is recommended. R

may be selected for other values of

INT

full scale by:

R

Full-Scale Voltage

=

INT

20 µA

Auto-Zero Capacitor

As the auto-zero capacitor is made large, the system

noise is reduced. Since the TC7109A incorporates a zero

integrator cycle, the size of the auto-zero capacitor does not

affect overload recovery. The optimal value of the auto-zero

capacitor is between 2 and 4 times C

. A typical value for

INT

CAZ is 0.33 µF.

3-104

TELCOM SEMICONDUCTOR, INC.

Page 15

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

1

TC7109

TC7109A

The inner foil of CAZ should be connected to pin 31 and

the outer foil to the RC summing junction. The inner foil of

C

should be connected to the RC summing junction and

INT

the outer foil to pin 32 for best rejection of stray pickups. For

low leakage at temperatures above +85°C, use Teflon

capacitors.

Reference Capacitor

A 1 µF capacitor is recommended for most circuits.

However, where a large common-mode voltage exists, a

larger value is required to prevent roll-over error (e.g., the

reference low is not analog common), and a 409.6 mV scale

is used. The roll-over error will be held to 0.5 count with a 10

µF capacitor. For temperatures above +80°C use Teflon or

equivalent capacitors for their low leakage characteristics.

Reference Voltage

To generate full-scale output of 4096 counts, the analog

input required is VIN = 2 V

a reference of 204.8 mV. In many applications, where the

ADC is connected to a transducer, a scale factor will exist

between the input voltage and the digital reading. For

instance, in a measuring system, the designer might like to

have a full-scale reading when the voltage for the transducer

is 700 mV. Instead of dividing the input down to 409.6 mV,

the designer should use the input voltage directly and select

V

= 350 mV. Suitable values for integrating resistor and

REF

capacitor would be 34 kΩ and 0.15 µF. This makes the

system slightly quieter and also avoids a divider network on

the input. Another advantage of this system occurs when

temperature and weight measurements with an offset or tare

are desired for non-zero input. The offset may be introduced

by connecting the voltage output of the transducer between

common and analog high, and the offset voltage between

common and analog low, observing polarities carefully. In

processor-based systems using the TC7109A, it may be

more desirable to use software and perform this type of

scaling or tare subtraction digitally.

Reference Sources

A major factor in the absolute accuracy of the ADC is the

stability of the reference voltage. The 12-bit resolution of the

TC7109A is one part in 4096, or 244 ppm. Thus, for the onboard reference temperature coefficient of 70 ppm/°C, a

temperature difference of 3°C will introduce a one-bit absolute error. Where the ambient temperature is not controlled,

or where high-accuracy absolute measurements are being

made, it is recommended that an external high-quality

reference be used.

. For 409.6 mV full scale, use

REF

A reference output (pin 29) is provided which may be

used with a resistive divider to generate a suitable reference

voltage (20 mA may be sunk without significant variation in

output voltage). A pull-up bias device is provided which

sources about 10 µA. The output voltage is nominally 2.8V

below V+. When using the on-board reference, REF OUT

(pin 29) should be connected to REF– (pin 39), and REF

should be connected to the wiper of a precision potentiometer between REF OUT and V+. The test circuit shows the

circuit for a 204.8 mV reference, generated by a 2 kΩ

precision potentiometer in series with a 24 kΩ fixed resistor.

Interfacing

Direct Mode

Combinations of chip-enable and byte-enable control

signals which may be used when interfacing the TC7109A

to parallel data lines are shown in Figure 12. The CE/LOAD

input may be tied low, allowing either byte to be controlled

by its own enable (Figure 12A). Figure 12B shows the

HBEN and LBEN as flag inputs, and CE/LOAD as a master

enable, which could be the READ strobe available from

most microprocessors. Figure 12C shows a configuration

where the two byte enables are connected together. The

CE/LOAD is a chip enable, and the HBEN and LBEN may

be used as a second chip enable, or connected to ground.

The 14 data outputs will be enabled at the same time. In

the direct MODE, SEND should be tied to V+.

Figure 13 shows interfacing several TC7109A's to a

bus, ganging the HBEN and LBEN signals to several converters together, and using the CE/LOAD input to select

the desired converter.

Figures 14–19 give practical circuits utilizing the parallel three-state output capabilities of the TC7109A. Figure

14 shows parallel interface to the Intel MCS-48, -80 and 85 systems via an 8255 PPI, where the TC7109A data

outputs are active at all times. The 8155 I/O ports may be

used in an identical manner. This interface can be used in a

read-after-update sequence, as shown in Figure 15. The

data is accessed by the high-to-low transition of the STATUS driving an interrupt to the microprocessor.

The RUN/HOLD input is also used to initiate conversions under software control. Figure 16 gives an interface

to Motorola MC6800 or MOS Technology MCS650X system.

An interrupt is generated through the Control Register

B, CB1 line from the high-to-low transition of the STATUS

output. The RUN/HOLD pin is controlled by CB2 through

Control Register B, allowing software control of conversions.

2

+

3

4

5

6

7

TELCOM SEMICONDUCTOR, INC.

8

3-105

Page 16

TC7109

TC7109A

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

Direct interfacing to most microprocessor busses is

easily accomplished through the three-state output of the

TC7109A.

Figures 1, 17 and 18 are typical connection diagrams.

To ensure requirements for setup and hold times, minimum

met, it is necessary to carefully consider the system timing

in this type of interface. This type of interface is used when

the memory peripheral address density is low, providing

simple address decoding. Interrupt handling can be simplified by using an interface to reduce the component count.

pulse widths, and the drive limitations on long busses are

GND

A. B. C.

MODE CE/LOAD

B9–B12

POL, OR

6

GND

TC7109A

ANALOG

IN

B1–B8

RUN/HOLD

LBENHBEN

CONTROL

8

CONVERT

Figure 12. Direct Mode Chip and Byte Enable Combinations

ANALOG

IN

GND OR

CHIP SELECT 2

CHIP SELECT 1

MODE CE/LOAD

B1–B12

POL, OR

TC7109A

RUN/HOLD

LBENHBEN

14

CONVERT

GND

ANALOG

IN

CHIP SELECT

MODE CE/LOAD

B9–B12

POL, OR

TC7109A

B1–B8

RUN/HOLD

LBENHBEN

BYTE FLAGS

6

8

CONVERT

GND

ANALOG

MODE CE/LOAD

TC7109A

IN

CONVERTER

SELECT

B9–B12

POL, OR

B1–B8

RUN/HOLD

LBENHBEN

BYTE SELECT FLAGS

6

8

+5V

Figure 13. Three-Stating Several TC7109A's to a Small Bus

GND

ANALOG

IN

CONVERTER

SELECT

MODE CE/LOAD

B9–B12

POL, OR

TC7109A

B1–B8

RUN/HOLD

LBENHBEN

CONVERTER

SELECT

GND

MODE CE/LOAD

6

B9–B12

POL, OR

6

TC7109A

8

+5V

ANALOG

IN

B1–B8

RUN/HOLD

LBENHBEN

8

+5V

3-106

TELCOM SEMICONDUCTOR, INC.

Page 17

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

1

TC7109

TC7109A

GND

ANALOG

GND

ADDRESS BUS

2

CONTROL BUS

DATA BUS

3

MODE CE/LOAD

B9–B12

IN

TC7109A

POL, OR

RUN/HOLD

B1–B8

STATUS

LBENHBEN

Figure 14. Full-Time Parallel Interface to MCS-48, -80, -85 Microcomputers

6

+5V

8

SEE TEXT

RD WR D7–D0

PA5–PA0

8255

PB7–PB0

PC5

(MODE 0)

A0–A1

CS

87C48

8008, 8080,

8085, 8048, ETC.

4

GND

ANALOG

GND

5

ADDRESS BUS

CONTROL BUS

DATA BUS

6

MODE CE/LOAD

B9–B12

POL, OR

IN

TC7109A

RUN/HOLD

B1–B8

STATUS

LBENHBEN

6

8

STB

1µF

10kΩ

+5V

(SEE TEXT)

A

RD WR D7–D0

PA5–PA0

PC6

PB7–PB0

PC4

8255

A0–A1

CS

INTR

PC6 INTR

87C48

8008, 8080,

8085, 8048, ETC.

A

7

Figure 15. Full-Time Parallel Interface to MCS-48, -80, -85 Microcomputers With Interrupt

TELCOM SEMICONDUCTOR, INC.

8

3-107

Page 18

TC7109

TC7109A

ANALOG

IN

GND

MODE

TC7109A

CE/

LOAD

B9–B12

POL, OR

B1–B8

RUN/HOLD CB1

STATUS

LBEN

HBEN

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

PA–5

6

CRB - -11R-01

PB–7

8

CB2

MC6820

MC6800

OR

MCS650X

GND

ADDRESS

BUS

Figure 16. Full-Time Parallel Interface to MC6800 or MCS650X Microprocessor

ADDRESS BUS

A15A14

CONTROL BUS

RD

*

DATA BUS

LBEN

B9–B12

POL, OR

B1–B8

6

8

ANALOG

HBEN

IN

TC7109A

DATA

BUS

8008, 8080, 8085

CONTROL

BUS

3-108

CE/LOAD

RUN/HOLDMODE

+5VGND

Figure 17. TC7109A Direct Interface to 8080/8085

* MEMR or IOR for 8080/8228 system.

TELCOM SEMICONDUCTOR, INC.

Page 19

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

1

TC7109

TC7109A

ANALOG

GND

+5V

2

MODE

IN

TC7109A

RUN/HOLD

CE/LOAD

B9–B12

POL, OR

B1–B8

HBEN

LBEN

6

8

74C42

74C30

A0–A2

A15–A10

R/W, VMA

ADDRESS

BUS

DATA

BUS

CONTROL

BUS

MC6800

OR

MCS650X

3

4

Figure 18. TC7109A Direct Interface to MC6800 Bus

ADDRESS BUS

ANALOG

IN

TC7109A

CONTROL BUS

DATA BUS

A

A

PA7–PA0

PC4

PC5

PC

PC6

PC7

RD WR D7–D0

8255

(MODE 1)

B9–B12

POL, OR

B1–B8

CE/LOAD

SEND

RUN/HOLD

MODE

Figure 19. TC7109A Handshake Interface to MCS-48, -80, -85 Microcomputers

6

8

STB

IBF

A0–A1

CS

PC3

INTR

5

6

87C48

8008, 8080,

8085, 8048, ETC.

7

TELCOM SEMICONDUCTOR, INC.

8

3-109

Page 20

TC7109

TC7109A

Handshake Mode

The handshake mode provides an interface to a wide

variety of external devices. The byte enables may be used

as byte identification flags or as load enables and external

latches may be clocked by the rising edge of CE/LOAD. A

handshake interface to Intel microprocessors using an 8255

PPI is shown in Figure 19. The handshake operation with

the 8255 is controlled by inverting its Input Buffer Full (IBF)

flag to drive the SEND input to the TC7109A, and using the

CE/LOAD to drive the 8255 strobe. The internal control

register of the PPI should be set in MODE 1 for the port

used. If the 8255 IBF flag is LOW and the TC7109A is in

handshake mode, the next word will be strobed into the

port. The strobe will cause IBF to go HIGH (SEND goes

LOW), which will keep the enabled byte outputs active. The

PPI will generate an interrupt which, when executed, will

result in the data being read. The IBF will be reset LOW

when the byte is read, causing the TC7109A to sequence

into the next byte. The MODE input to the TC7109A is

connected to the control line on the PPI.

The data from every conversion will be sequenced in

two bytes in the system, if this output is left HIGH, or tied

HIGH separately. (The data access must take less time

than a conversion.) The output sequence can be obtained

on demand if this output is made to go from LOW to HIGH

and the interrupt may be used to reset the MODE bit.

Conversions may be obtained on command under software control by driving the RUN/HOLD input to the TC7109A

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

by a bit of the 8255. Another peripheral device may be

serviced by the unused port of the 8255. The 8155 may be

used in a similar manner. The MCS650X microprocessors

are shown in Figure 20 with MODE and RUN/HOLD tied

HIGH to save port outputs.

The handshake mode is particularly useful for directly

interfacing to industry-standard UARTs (such as Western

Digital TR1602), providing a means of serially transmitting

converted data with minimum component count.

A typical UART connection is shown in Figure 1. In this

circuit, any word received by the UART causes the UART

DR (Data Ready) output to go HIGH. The MODE input to

the TC7109A goes HIGH, triggering the TC7109A into

handshake mode. The high-order byte is output to the

UART and when the UART has transferred the data to the

Transmitter register, TBRE (SEND) goes HIGH again, LBEN

will go HIGH, driving the UART DRR (Data Ready Reset)

which will signal the end of the transfer of data from the

TC7109A to the UART.

An extension of the typical connection to several

TC7109A's with one UART is shown in Figure 21. In this

circuit, the word received by the UART (available at the

RBR outputs when DR is HIGH) is used to select which

converter will handshake with the UART. Up to eight

TC7109A's may interface with one UART, with no external

components. Up to 256 converters may be accessed on

one serial line with additional components.

ANALOG

3-110

+5V

MODE

IN

LBEN

RUN/HOLD

CRA - -100-01

TC7109A

CE/LOAD CA1

SEND

HBEN

Figure 20. TC7109A Handshake Interface to MCS-6800, MCS650X Microprocessors

PA0–PA7

CA2

MC6820

ADDRESS

BUS

DATA

BUS

CONTROL

BUS

MC6800

OR

MCS650X

TELCOM SEMICONDUCTOR, INC.

Page 21

12-BIT

µP-COMPATIBLE

ANALOG-TO-DIGITAL CONVERTERS

1

TC7109

TC7109A

ANALOG

IN

CE/

LOAD

TC7109A

RUN/HOLD

SENDMODE

B9–B12

POL, OR

B1-B8

LBENHBEN

SERIAL OUTPUT

6402 CMOS UART

TBRL DRR

6

8

Figure 21. Handshake Interface for Multiplexed Converters

TBRE RBR1–RBR8 SFD TBR1–TBR8

23

8-BIT DATA BUS

SENDMODE

CE/

LOAD

B9–B12

POL, OR

RUN/HOLD

LBENHBEN

+5V

ANALOG

IN

TC7109A

GND

B1–B8

SERIAL INPUT

6

8

+5V

ANALOG

2

3

SENDMODE

CE/

LOAD

B9–B12

POL, OR

IN

B1–B8

TC7109A

RUN/HOLD

LBENHBEN

6

8

+5V

4

5

Integrating Converter Features

The output of integrating ADCs represents the integral,

or average, of an input voltage over a fixed period of time.

Compared with techniques in which the input is sampled and

held, the integrating converter averages the effects of noise.

A second important characteristic is that time is used to

quantize the answer, resulting in extremely small nonlinearity

errors and no missing output codes. The integrating converter also has very good rejection of frequencies whose

periods are an integral multiple of the measurement period.

This feature can be used to advantage in reducing line

frequency noise (Figure 22).

30

t = MEASUREMENT

PERIOD

20

10

0

NORMAL MODE REJECTION PLAN

0.1/t 1/t 10/t

INPUT FREQUENCY

Figure 22. Normal Mode Rejection of Dual-Slope Converter as a

Function of Frequency

6

7

8

TELCOM SEMICONDUCTOR, INC.

3-111

Loading...

Loading...