TEL CP802, CP801, CP801, CP800, CP800 Datasheet

...

CP800 THRU CP808

SINGLE-PHASE SILICON BRIDGE

VOLTAGE - 50 to 800 Volts CURRENT - P.C. MTG 3A, HEAT-SINK MTG 8A

FEATURES

l Surge overload rating—200 Amperes peak

l Low forward voltage drop and reverse leakage

l Small size, simple installation

l Plastic package has Underwriter Laboratory

Flammability Classification 94V-O

l Reliable low cost construction utilizing molded

plastic technique

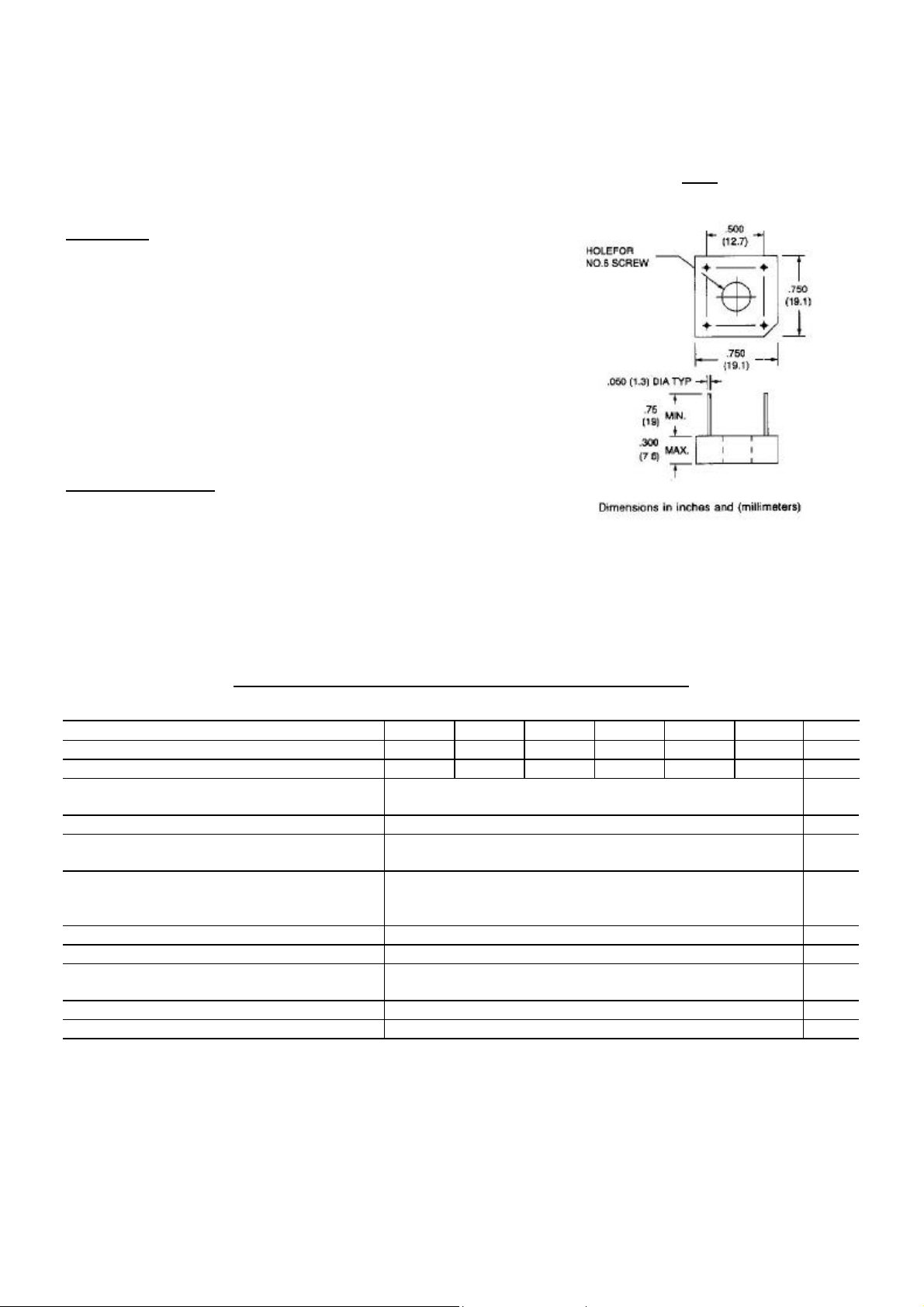

MECHANICAL DATA

Mounting position: Any

Weight: 0.24 ounce, 6.9 grams

Terminals: Leads solderable per MIL-STD-202,

Method 208

Mounting torque: Thro hole for #6 screw

CP-8

MACXIMUM RATINGS AND ELECTRICAL CHARACTERISTICS

At 25ambient temperature unless otherwise noted; resistive or inductive load at 60Hz .

Max Recurrent Peak Reverse Voltage 50 100 200 400 600 800 V

Max Bridge Input Voltage RMS 35 70 140 280 420 560 V

Max Average Rectified Output at TC=50*

See Fig. 2 at TA=40**

CP800 CP801 CP802 CP804 CP806 CP808 UNITS

8.0

3.0

Peak One Cycle Surge Overload Current 200 A

Max Forward Voltage Drop per element at

4.0A DC & 25. See Fig. 3

Max Rev Leakage at rated Dc Blocking

Voltage per element at 25

See Fig 4 at100

1.1

10.0

1.0

I2t Rating for fusing ( t<8.3ms) 166 A2Sec

Typical junction capacitance per leg (Note 4) CJ

Typical Thermal Resistance per leg (Note 3) RJA

Typical Thermal Resistance per leg (Note 2) RJL

200

21

6

Operating Temperature Range -55 TO +125

Storage Temperature Range -55 TO +150

NOTES:

1. Bolt down on heat-sink with silicon thermal compound between bridge and mounting surface

A

A

V

A

mA

F

P

/W

for maximum heat transfer with #6 screw.

2. Units Mounted on a 8.6”×8.6” ×24” thick (22×22×0.6cm) AL plate heatsink.

3. Units Mounted on P.C.B at 0.375”(9.5mm) lead length with 0.5×0.5”(12×12mm)copper pads.

4. Measured at 1.0MHZ and applied reverse voltage.

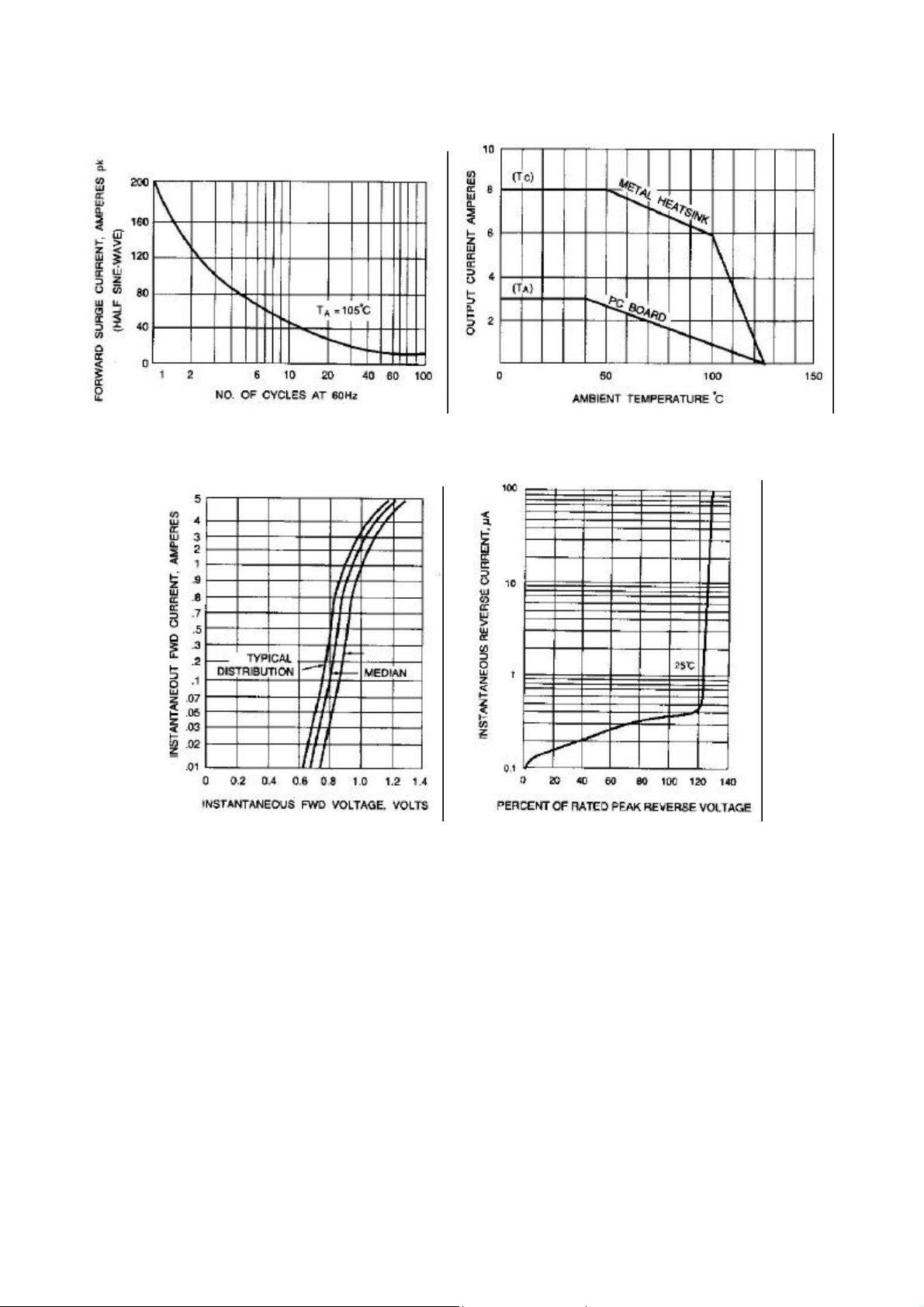

RATING AND CHARACTERISTIC CURVES

CP800 THRU CP808

Fig. 1-NON-RECURRENT SURGE RATING Fig. 2-DERATING CURVE FOR OUTPUT

RECTIFIED CURRENT

Fig. 3-TYPICAL FORWARD CHARACTERISTICS Fig. 4- TYPICAL REVERSE CHARACTERISTICS

Loading...

Loading...