TEL CP1008, CP1008, CP1001, CP1001, CP1000 Datasheet

...

CP1000 THRU CP1008

SINGLE-PHASE SILICON BRIDGE

VOLTAGE - 50 to 800 Volts CURRENT - P.C. MTG 3A, HEAT-SINK MTG 10A

FEATURES

l Surge overload rating—200 Amperes peak

l Low forward voltage drop and reverse leakage

l Small size, simple installation

l Plastic package has Underwriter Laboratory

Flammability Classification 94V-O

l Reliable low cost construction utilizing molded

plastic technique

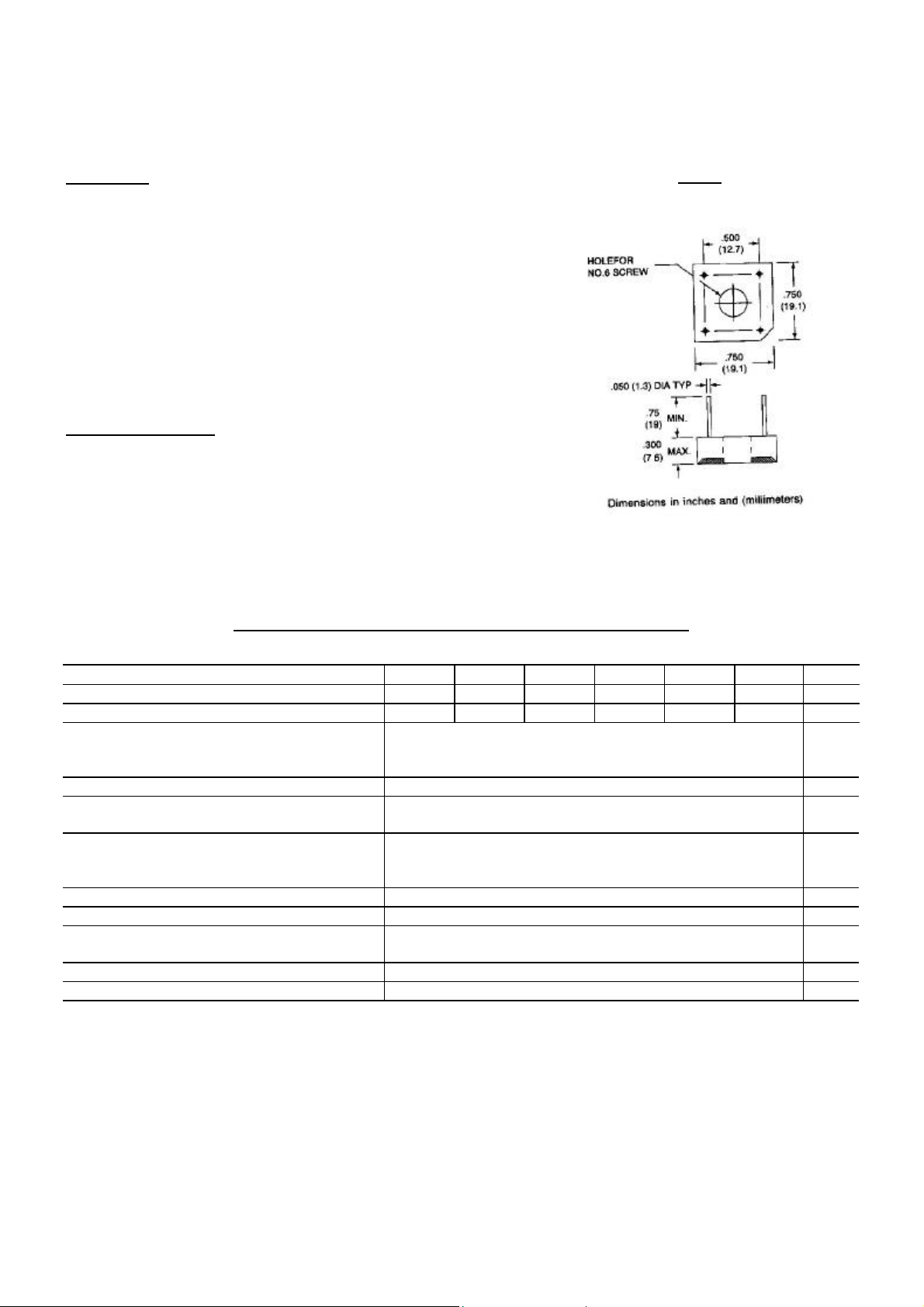

MECHANICAL DATA

Case: Molded plastic with heatsink integrally

mounted in the bridge encapsulation

Terminals: Leads solderable per MIL-STD-202,

Method 208

Weight: 0.21 ounce, 6.1 grams

MACXIMUM RATINGS AND ELECTRICAL CHARACTERISTICS

CP-10

At 25ambient temperature unless otherwise noted; resistive or inductive load at 60Hz .

Max Recurrent Peak Rev Voltage 50 100 200 400 600 800 V

Max Bridge Input Voltage RMS 35 70 140 280 420 560 V

Max Average Rectified Output at TC=50*

See Fig. 2 at TC=100*

at TA=50**

CP1000 CP1001 CP1002 CP1004 CP1006 CP1008 UNITS

10.0

3.0

3.0

Peak One Cycle Surge Overload Current 200 A

Max Forward Voltage Drop per element at

5.0A DC & 25. See Fig. 3

Max Rev Leakage at rated Dc Blocking

Voltage per element at 25

See Fig 4 at100

Typical junction capacitance per leg (Note 4) CJ

1.1

10.0

1.0

200

I2t Rating for fusing ( t<8.3ms) 164 A2S

Typical Thermal Resistance (Note 2) RJA

Typical Thermal Resistance (Note 3) RJC

25

5

Operating Temperature Range -55 TO +125

Storage Temperature Range -55 TO +150

NOTES:

* Unit mounted on metal chassis.

** Unit mounted on P.C. board.

A

A

V

A

mA

F

P

/W

1. Recommended mounting position is to bolt down on heatsink with silicone thermal compound

for maximum heat transfer with #6 screw.

2. Units Mounted in free air, no heatsink. P.C.B at 0.375”(9.5mm) lead length with 0.5×0.5”

(12×12mm)copper pads.

3. Units Mounted on a 3.0×3.0” ×0.11” thick (7.5×7.5×0.3cm) AL plate heatsink.

4. Measured at 1.0MHZ and applied reverse voltage of 4.0 volts.

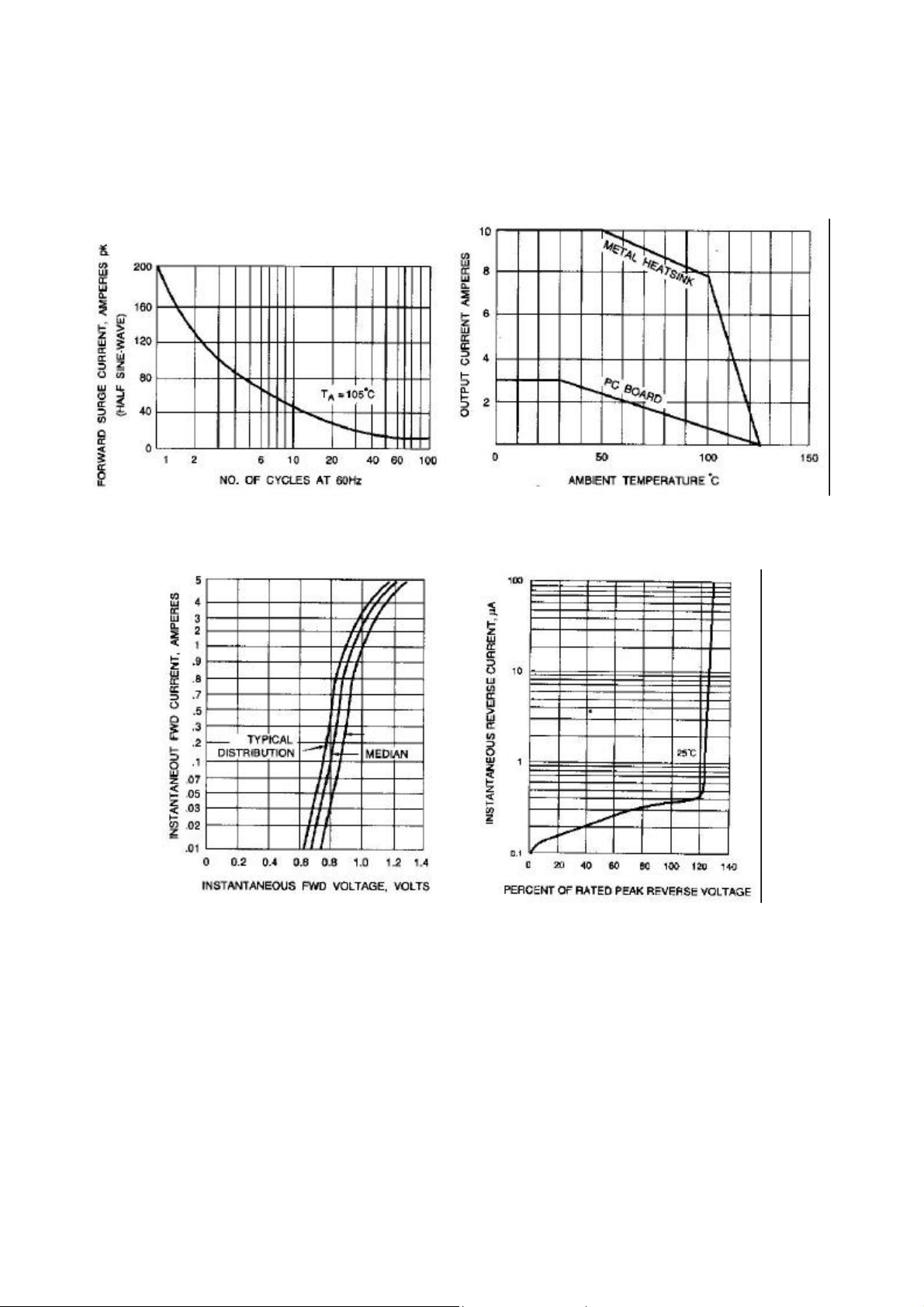

RATING AND CHARACTERISTIC CURVES

CP1000 THRU CP1008

Fig. 1-NON-RECURRENT SURGE RATING Fig. 2-DERATING CURVE FOR OUTPUT

RECTIFIED CURRENT

Fig. 3-TYPICAL FORWARD CHARACTERISTICS Fig. 4- TYPICAL REVERSE CHARACTERISTICS

Loading...

Loading...