DMM4040 and DMM4050

Digital Multimeter

077-0362-01

Technical Reference

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix

or its subsidiaries or suppliers, and are protected by national copyright laws and international

treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in

this publication supersedes that in all previously published material. Specifications and price

change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix, Inc.

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

- In North America, call 1-800-833-9200.

- Worldwide, visit www.tektronix.com

to find contacts in your area.

Table of Contents

Chapter Title Page

1 Introduction and Specifications ......................................................... 1-1

Introduction ........................................................................................................ 1-3

General Safety Summary ................................................................................... 1-4

To Avoid Fire or Personal Injury .............................................................. 1-4

Symbols and Terms ................................................................................... 1-7

Safety and Electrical Symbols .................................................................. 1-7

Description of IEC 61010 Measurement Categories ................................. 1-8

Organization of the Calibration Manual ............................................................ 1-8

Chapter 1 – Introduction and Specifications ................................................. 1-9

Chapter 2 – General Maintenance ................................................................. 1-9

Chapter 3 – Performance Test and Calibration.............................................. 1-9

Operating Instructions ........................................................................................ 1-9

Accessories ........................................................................................................ 1-9

General Specifications ....................................................................................... 1-11

Power ............................................................................................................. 1-11

Dimensions .................................................................................................... 1-11

Display ........................................................................................................... 1-11

Environment .................................................................................................. 1-11

Triggering ...................................................................................................... 1-11

Memory ......................................................................................................... 1-11

Math Functions .............................................................................................. 1-11

Electrical ........................................................................................................ 1-12

Remote Interfaces .......................................................................................... 1-12

Warranty ........................................................................................................ 1-12

Electrical Specifications .................................................................................... 1-12

DC Voltage Specifications ............................................................................ 1-12

Input Characteristics .................................................................................. 1-12

4050 Accuracy .......................................................................................... 1-13

4040 Accuracy .......................................................................................... 1-13

Additional Errors ....................................................................................... 1-13

AC Voltage Specifications ............................................................................ 1-13

Input Characteristics .................................................................................. 1-14

4040/4050 Accuracy ................................................................................. 1-14

Additional Low Frequency Errors............................................................. 1-15

Resistance ...................................................................................................... 1-15

i

DMM4040 and DMM4050

Technical Reference

DC Current .................................................................................................... 1-16

AC Current .................................................................................................... 1-18

Frequency ...................................................................................................... 1-20

Capacitance (4050 only) ................................................................................ 1-21

Temperature (4050 only) ............................................................................... 1-21

Additional Errors ........................................................................................... 1-21

Continuity ...................................................................................................... 1-21

Diode Test ..................................................................................................... 1-22

Measurement Rates (IEEE488[4]) ................................................................. 1-22

Measurement Uncertainty .................................................................................. 1-22

Interpreting Accuracy Specifications ................................................................. 1-23

24-Hour Accuracy ......................................................................................... 1-23

90-Day and 1-Year Accuracy ........................................................................ 1-23

Temperature Coefficients .............................................................................. 1-23

Configuring for Highest Accuracy Measurements ............................................ 1-23

DC Voltage, DC Current, and Resistance Measurements ............................. 1-23

AC Voltage and AC Current Measurements: ................................................ 1-23

Frequency and Period Measurements: ........................................................... 1-23

Input Characteristics .................................................................................. 1-15

4040/4050 Accuracy ................................................................................. 1-16

Additional Ohms Errors ............................................................................ 1-16

Input Characteristics .................................................................................. 1-16

Accuracy (4040/4050) ............................................................................... 1-17

Additional Current Errors ......................................................................... 1-17

Input Characteristics .................................................................................. 1-18

4040/4050 Accuracy ................................................................................. 1-19

Additional Low Frequency Errors............................................................. 1-20

4040/4050 Accuracy ................................................................................. 1-20

Gate Time vs. Resolution .......................................................................... 1-20

Additional Low Frequency Errors............................................................. 1-20

2 General Maintenance .......................................................................... 2-1

Introduction ........................................................................................................ 2-3

Warranty Repairs and Shipping Information ..................................................... 2-3

General Maintenance Information ..................................................................... 2-3

Required Equipment ...................................................................................... 2-3

Power Requirements ...................................................................................... 2-3

Static Safe Handling ...................................................................................... 2-3

Cleaning ............................................................................................................. 2-4

Fuse Replacement .............................................................................................. 2-4

Line-Power Fuse ............................................................................................ 2-4

Current-Input Fuses ....................................................................................... 2-5

If the Meter Does Not Turn On .......................................................................... 2-7

Display Tests ...................................................................................................... 2-7

Disassembly Procedures .................................................................................... 2-7

General Disassembly ..................................................................................... 2-7

Main Chassis Disassembly ............................................................................ 2-8

Front Panel Disassembly ............................................................................... 2-8

Assembly Procedures ......................................................................................... 2-8

3 Performance Test and Calibration ..................................................... 3-1

Introduction ........................................................................................................ 3-4

Required Equipment .......................................................................................... 3-4

Test Considerations ............................................................................................ 3-6

ii

Contents (continued)

Performance Tests .............................................................................................. 3-6

Volts DC Verification .................................................................................... 3-6

Volts DC Ratio Verification .......................................................................... 3-10

Volts AC and Frequency Verification ........................................................... 3-12

4-Wire Ohms Verification ............................................................................. 3-15

2-Wire Ohms Verification ............................................................................. 3-17

2X4 Test Lead Verification Steps ................................................................. 3-18

Rear Panel Terminal Verification Steps ........................................................ 3-19

Capacitance Verification Steps (DMM4050 only) ........................................ 3-21

DC Current Verification Steps ...................................................................... 3-23

AC Current Verification Steps ...................................................................... 3-25

Adjustment (Calibration) ................................................................................... 3-27

Unlocking the Meter for Adjustments (Calibration) ..................................... 3-27

Unlocking the Meter for Adjustments Over a Remote Interface ................... 3-27

Changing the Calibration Password .............................................................. 3-27

Resetting the Calibration Password ............................................................... 3-28

Changing the Calibration Date ...................................................................... 3-29

Equipment for Calibration ............................................................................. 3-29

Adjustment Process ....................................................................................... 3-29

Aborting a Calibration Process ...................................................................... 3-35

Sample Adjustment Program ......................................................................... 3-35

Appendices

A Verification Forms ...................................................................................... A-1

B Example Adjustment Program .................................................................... B-1

iii

DMM4040 and DMM4050

Technical Reference

iv

List of Tables

Table Title Page

1-1. Accessories ............................................................................................................. 1-9

2-1. Line Voltage to Fuse Rating................................................................................... 2-5

3-1. Required Test Equipment ....................................................................................... 3-4

3-2. DMM4050 DC Volts Verification Steps ................................................................ 3-8

3-3. DMM4040 DC Volts Verification Steps ................................................................ 3-9

3-4. DMM4050 DC Volts Ratio Verification Steps ...................................................... 3-11

3-5. DMM4040 DC Volts Ratio Verification Steps ...................................................... 3-11

3-6. DMM4040/4050 AC Volts Verification Steps ....................................................... 3-13

3-7. DMM4040/4050 AC Volts Frequency Verification Steps ..................................... 3-14

3-8. DMM4040/4050 4-Wire Ohms Verification Steps ................................................ 3-16

3-9. DMM4040/4050 2-Wire Ohms Verification Steps ................................................ 3-18

3-10. DMM4050 Rear-Panel Terminal Verification Steps (Optional Test) .................... 3-20

3-11. DMM4040 Rear-Panel Terminal Verification Steps (Optional Test) .................... 3-20

3-12. DMM4050 Capacitance Verification Steps ........................................................... 3-22

3-13. DMM4040/4050 DC Current Verification Steps ................................................... 3-24

3-15. DMM4040/4050 Adjustment Steps ....................................................................... 3-29

v

DMM4040 and DMM4050

Technical Reference

vi

List of Figures

Figure Title Page

1-1. IEC 61010 Measurement Category (CAT) Levels ................................................. 1-8

2-1. Line Fuse Replacement .......................................................................................... 2-5

2-2. Current Input Fuse Replacement ............................................................................ 2-6

3-1. DC Volts Test Equipment Setup with 5520A ........................................................ 3-7

3-2. DC Volts Ratio Test Equipment Setup with 5520A and 5720A ............................ 3-10

3-3. AC Volts Test Equipment Setup with 5520A ........................................................ 3-12

3-4. 4-Wire Ohms Test Equipment Setup ..................................................................... 3-15

3-5. 2-Wire Ohms Test Equipment Setup ..................................................................... 3-17

3-6. Rear-Panel Terminals Equipment Setup ................................................................ 3-19

3-7. Capacitance Equipment Setup ................................................................................ 3-21

3-8. 100 mA DC Current Equipment Setup .................................................................. 3-23

3-9. AC Current Equipment Setup ................................................................................ 3-25

3-10. Calibration Jumper Location .................................................................................. 3-28

vii

DMM4040 and DMM4050

Technical Reference

viii

Chapter 1

Introduction and Specifications

Title Page

Introduction ........................................................................................................ 1-3

General Safety Summary ................................................................................... 1-4

Organization of the Calibration Manual ............................................................ 1-8

Chapter 1 – Introduction and Specifications ................................................. 1-9

Chapter 2 – General Maintenance ................................................................. 1-9

Chapter 3 – Performance Test and Calibration.............................................. 1-9

Operating Instructions ........................................................................................ 1-9

Accessories ........................................................................................................ 1-9

General Specifications ....................................................................................... 1-10

Power ............................................................................................................. 1-10

Dimensions .................................................................................................... 1-10

Display ........................................................................................................... 1-10

Environment .................................................................................................. 1-10

Triggering ...................................................................................................... 1-10

Memory ......................................................................................................... 1-10

Math Functions .............................................................................................. 1-10

Electrical ........................................................................................................ 1-11

Remote Interfaces .......................................................................................... 1-11

Warranty ........................................................................................................ 1-11

Electrical Specifications .................................................................................... 1-11

DC Voltage Specifications ............................................................................ 1-11

AC Voltage Specifications ............................................................................ 1-

Resistance ...................................................................................................... 1-14

DC Current .................................................................................................... 1-15

AC Current .................................................................................................... 1-17

Frequency ...................................................................................................... 1-19

Capacitance (4050 only) ................................................................................ 1-20

Temperature (4050 only) ............................................................................... 1-20

Additional Errors ........................................................................................... 1-20

Continuity ...................................................................................................... 1-20

Diode Test ..................................................................................................... 1-21

Measurement Rates (IEEE488[4]) ................................................................. 1-21

Measurement Uncertainty .................................................................................. 1-21

Interpreting Accuracy Specifications ................................................................. 1-22

24-Hour Accuracy ......................................................................................... 1-22

12

1-1

DMM4040/4050

Technical Reference Manual

Configuring for Highest Accuracy Measurements ............................................ 1-22

90-Day and 1-Year Accuracy ........................................................................ 1-22

Temperature Coefficients .............................................................................. 1-22

DC Voltage, DC Current, and Resistance Measurements ............................. 1-22

AC Voltage and AC Current Measurements: ................................................ 1-22

Frequency and Period Measurements: ........................................................... 1-22

1-2

Introduction and Specifications

Introduction 1

Introduction

The DMM4040 and 4050 are 6-1/2 digit, dual-display multimeters designed for

bench-top, field service, and system applications. Their full complement of measurement

functions plus its RS-232, IEEE 488, and Ethernet Remote Interfaces makes these

multimeters ideal candidates for precision manual measurements and use in automated

systems. For portability, these multimeters include a carrying handle that also serves as a

bail for bench top operation.

There are a few additional features in the DMM4050 that are not present in the

DMM4040. These features will be identified with the annotation of “4050 Only” by each

feature that is found only in that model. Separate specification tables are also used to

clarify the differences between these two models.

The following is a list of some of the features and functions:

• Bright, large-digit, wide-viewing-angle display

• Dual display for displaying two properties of an input signal (e.g., ac voltage in one

display and frequency in the other).

• Remote operation via IEEE 488, RS-232, and Ethernet interface.

• Trigger in and measurement-complete out

• Front panel USB port for optional memory

• 6-1/2 digit resolution

• Half-rack width

• True rms ac

• 2 and 4-wire resistance measurements

• Extended 10 Ω and 1 GΩ ranges

• Frequency measurements to 1 MHz

• Capacitance measurements (4050 only)

• Temperature measurement (4050 only)

• 10 A current capability

• Decibels (dB and dBm) with variable reference impedance and audio power

measurement capability

• Input terminals on both front and rear panels of the meter

• Closed-case calibration (no internal calibration adjustments)

This technical reference manual focuses on performance verification and calibration of

the Tektronix DMM4040 and 4050 Digital Multimeters (hereafter referred to as the

Meter).

1-3

DMM4040/4050

Technical Reference Manual

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to this

product or any other products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system. Read the

safety sections of the other component manuals for warnings and cautions related to

operating the system.

This instrument has been designed and tested in accordance with the European standard

publication EN 61010-1:2001 and U.S./Canadian standard publications UL 61010-1 and

CAN/CSA-C22.2 No.61010-1-04. The instrument has been supplied in a safe condition.

This manual contains information and warnings that must be observed to keep the

instrument in a safe condition and ensure safe operation.

To use the instrument correctly and safely, read and follow the precautions in this section

and follow all the safety instructions or warnings given throughout this manual that relate

to specific measurement functions. In addition, follow all generally accepted safety

practices and procedures required when working with and around electricity.

CAT I equipment is designed to protect against transients from high-voltage, low-energy

sources, such as electronic circuits or a copy machine.

CAT II equipment is designed to protect against transients from energy-consuming

equipment supplied from the fixed installtion, such as TVs, PCs, portable tools, and other

houseshold appliances.

To Avoid Fire or Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Use Proper Voltage Setting. Before applying power, ensure that the line selector is in

the proper position for the source being used.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor of the

power cord. To avoid electric shock, the grounding conductor must be connected to earth

ground. Before making connections to the input or output terminals of the product, ensure

that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings information

before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that exceeds the

maximum rating of that terminal.

Power Disconnect. The power cord disconnects the product from the power source. Do

not block the power cord; it must remain accessible to the user at all times.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

1-4

Introduction and Specifications

General Safety Summary 1

Do Not Operate With Suspected Failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components when

power is present.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Keep Product Surfaces Clean and Dry.

Warning

To avoid possible electric shock, personal injury, or death, read

the following before using the Meter.

• Use the Meter only as specified in this manual, or the

protection provided by the Meter might be impaired.

• Do not use the Meter in wet environments.

• Inspect the Meter before using it. Do not use the Meter if it

appears damaged.

• Inspect the test leads before use. Do not use them if

insulation is damaged or metal is exposed. Check the test

leads for continuity. Replace damaged test leads before

using the Meter.

• Verify the Meter's operation by measuring a known voltage

before and after using it. Do not use the Meter if it operates

abnormally. Protection may be impaired. If in doubt, have

the Meter serviced.

• Whenever it is likely that safety protection has been

impaired, make the Meter inoperative and secure it against

any unintended operation.

• Servicing of the Meter should be performed by qualified

service personnel.

• Do not apply more than the rated voltage, as marked on the

Meter, between the terminals or between any terminal and

earth ground.

• While in IEC Measurement Category II environments, do not

apply voltages above 600 V ac to the input of the Meter. See

“Description of IEC 61010 Measurement Categories” later in

this manual.

• Always use the power cord and connector appropriate for

the voltage and outlet of the country or location in which

you are working.

• Always use a power cord with a ground connection and

ensure the ground is properly connected to the power

distribution system.

• Remove test leads from the Meter before opening the case.

• Never remove the cover or open the case of the Meter

without first removing it from the main power source.

1-5

DMM4040/4050

Technical Reference Manual

• Use caution when working with voltages above 30 V ac rms,

• Use only the replacement fuse(s) specified by the manual.

• Use the proper terminals, function, and range for your

• Do not operate the Meter around explosive gas, vapor, or

• When using probes, keep your fingers behind the finger

• When making electrical connections, connect the common

• Disconnect circuit power and discharge all high-voltage

42 V ac peak, or 42 V dc. These voltages pose a shock

hazard.

measurements.

dust.

guards.

test lead before connecting the live test lead; when

disconnecting, disconnect the live test lead before

disconnecting the common test lead.

capacitors before testing resistance, continuity, diodes, or

capacitance.

• Before measuring current, check the Meter's fuses and turn

OFF power to the circuit before connecting the Meter to the

circuit.

• When servicing the Meter, use only specified replacement

parts.

• To prevent damage to the Meter, do not change the position

of the Front/Rear switch while signals are applied to either

the front or rear input terminals.

1-6

Introduction and Specifications

Symbols and Terms

The following terms and safety and electrical symbols may appear in the manual or on

the product:

A Warning statement identifies conditions or practices that could result in injury

or death.

A Caution statement identifies conditions or practices that could result in damage to

the Meter or equipment to which it is connected.

Warning

To avoid electric shock, personal injury, or death, carefully read

the information under “General Safety Summary” before

attempting to install, use, or service the Meter.

Safety and Electrical Symbols

Symbol Description Symbol Description

General Safety Summary 1

Risk of danger. Important

information. See manual.

Hazardous voltage. Voltage > 30 V

dc or ac peak might be present.

AC (Alternating Current)

DC (Direct Current)

or

AC or DC (Alternating or Direct

Current)

Continuity test or continuity beeper

tone

Potentially hazardous voltage

Double insulat ed

Measurement Category II is for

CAT II

measurements performed on

circuits directly connected to the

low voltage installation.

CAT I

Display ON / OFF and Meter reset.

Earth ground

Capacitance

Diode

Fuse

Y

Digital signal

Maintenance or Service

Static awareness. Static discharge

can damage parts.

Measurement Category I is for

measurements not directly

connected to mains.

1-7

DMM4040/4050

Technical Reference Manual

Description of IEC 61010 Measurement Categories

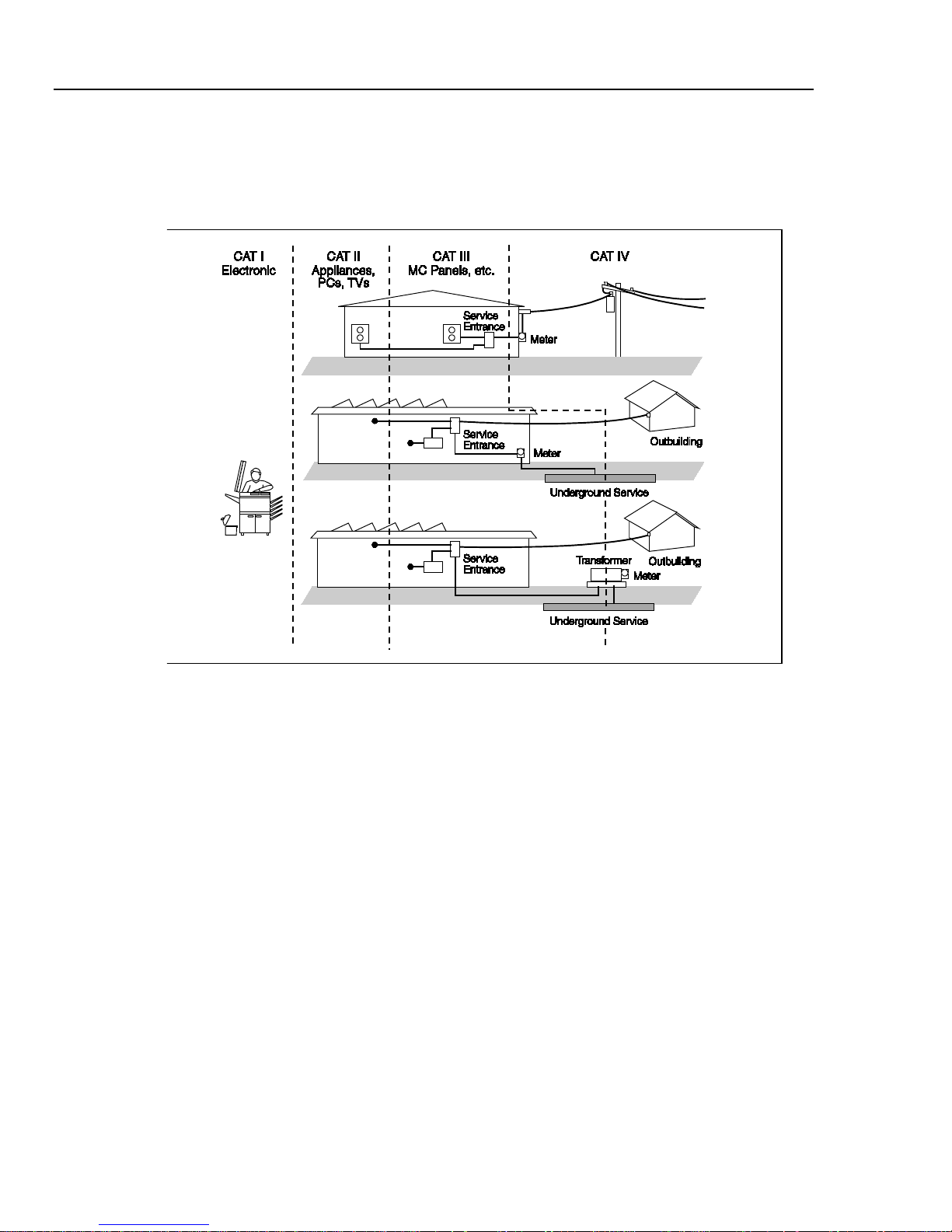

The IEC 61010 safety standard defines four Overvoltage (Installation) Categories (CAT I

to CAT IV) based on the magnitude of danger from transient impulses as shown in Figure

1-1.

Figure 1-1. IEC 61010 Measurement Category (CAT) Levels

The IEC 61010 Measurement CAT level indicates the level of protection the instrument

provides against impulse withstand voltage.

CAT I equipment is designed to protect against transients from high-voltage, low-energy

sources, such as electronic circuits or a copy machine.

CAT II equipment is designed to protect against transients from energy-consuming

equipment supplied from the fixed installation, such as TVs, PCs, portable tools, and

other household appliances.

CAT III equipment is designed to protect against transients in equipment in fixed

equipment installations, such as distribution panels, feeders and short branch circuits, and

lighting systems in large buildings.

CAT IV equipment is designed to protect against transients from the primary supply

level, such as an electricity meter or an overhead or underground utility service.

Organization of the Calibration Manual

This calibration manual is divided into the following chapters:

cat_levels.eps

1-8

Introduction and Specifications

Operating Instructions 1

Chapter 1 – Introduction and Specifications

This chapter introduces the Tektronix DMM4040 and 4050 Digital Multimeters,

describing their features, and accessories. This chapter also discusses use of the

Calibration Manual and the various conventions used in describing the meter’s circuitry

and presents a complete set of specifications.

Chapter 2 – General Maintenance

Chapter 2 provides maintenance information covering handling, cleaning, and fuse

replacement. Access and reassembly procedures are also explained in this chapter.

Chapter 3 – Performance Test and Calibration

This chapter provides performance verification procedures related to the specifications

presented in Chapter 1. To maintain these specifications, a full adjustment/calibration

procedure is also presented.

Operating Instructions

Full operating instructions are provided in the Tektronix DMM4040/4050 Users Manual.

Reference to these instructions may be necessary during some of the maintenance and

repair procedures presented in this Calibration Manual.

Accessories

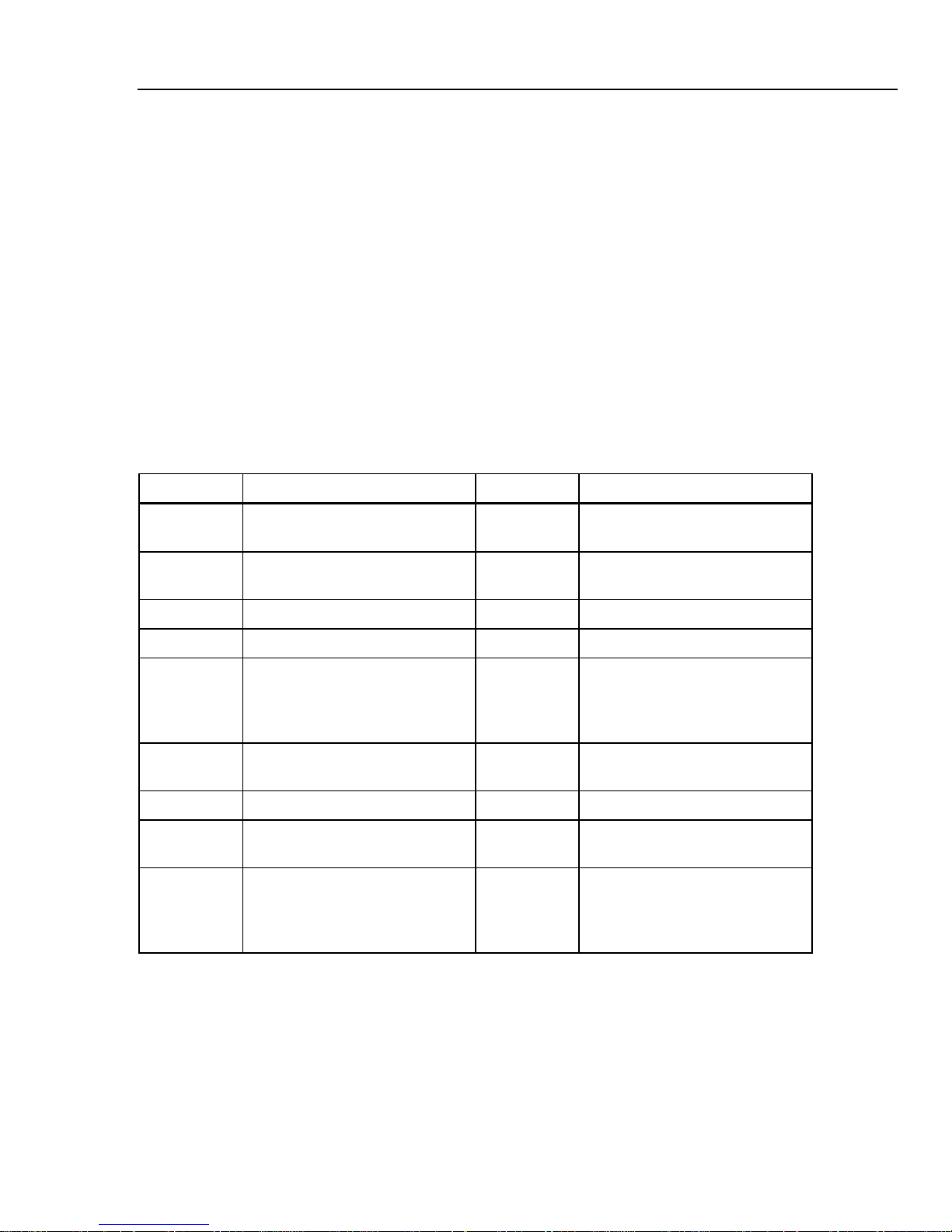

Table 1-1 lists the available accessories for the DMM4040 and 4050.

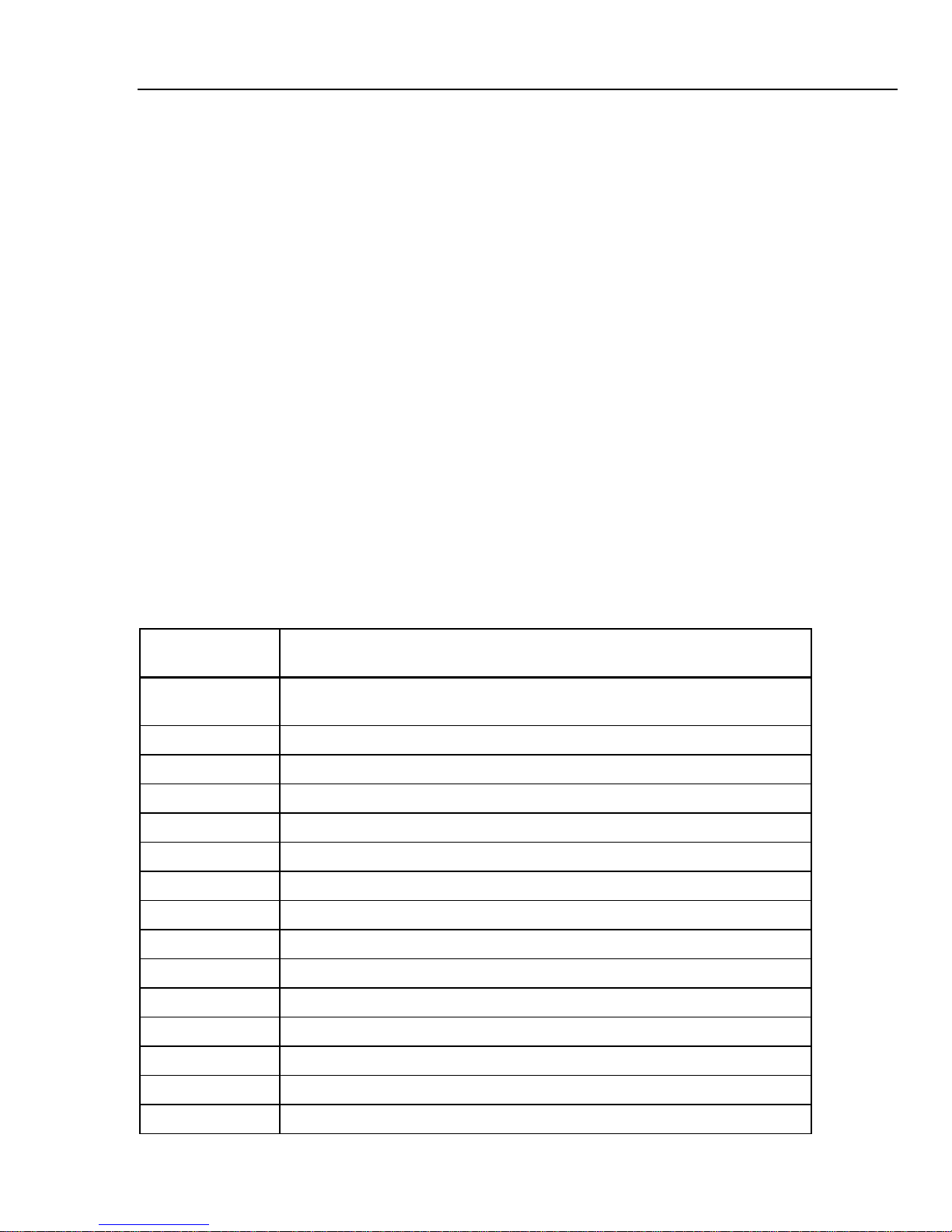

Table 1-1. Accessories

Model / Part

Number

TL710

196-3520-00

TP750 100 Ohm RTD Temperature Probe (DMM4050 only)

013-0369-00 Calibration fixture; 4 terminal shor ting bar

Y8846S Rack Mount Kit Single

Y8846D Rackmount Kit Dual

TL705 2X4 Wire Ohm Precision Test Leads

TL725 2X4 Wire Ohm Tweezers Test Leads

159-0487-00 F2, Fuse, 440 mA, 1000 V, Fast, .406X 1.375, Bulk

159-0488-00 F1, Fuse, 11 A, 1000 V, Fast, .406INX1.5IN, Bulk

174-5813-00 USB to RS-232 cable assembly

Premium Test Lead Set

Description

012-0991-01 GPIB cable; Low EMI; 1 meter

159-0187-00 Fuse, 0.25 A, 250 V AC, slow blow

159-0063-00 Fuse, 0.125 A, 250 V, slow blow

HCTEK4321 Hard case, plastic

AC4000 Soft case, nylon

1-9

DMM4040/4050

Technical Reference Manual

General Specifications

Power

Voltage

100 V Setting ...................................................... 90 V to 110 V

120 V Setting ...................................................... 108 V to 132 V

220 V Setting ...................................................... 198 V to 242 V

240 V Setting ...................................................... 216 V to 264 V

Frequency ............................................................... 47 Hz to 440 Hz. Automatically sensed at power-on.

Power Consumption................................................ 28 VA peak (12 Watt average)

Dimensions

Height ...................................................................... 88 mm (3.46 in.)

Width ....................................................................... 217 mm (8.56 in.)

Depth ...................................................................... 297 mm (11.7 in.)

Weight ..................................................................... 3.6 kg (8.0 lb)

Shipping Weight ...................................................... 5.0 kg (11.0 lb)

Display

Vacuum Fluorescent Display, dot matrix

Environment

Temperature

Operating ............................................................ 0 °C to 55 °C

Storage ............................................................... -40 °C to 70 °C

Warm Up ............................................................. 1 hour to full uncertainty specifications

Relative Humidity (non-condensing)

Operating ............................................................ 0 °C to 28 °C <90 %

Storage ............................................................... -40 °C to 70 °C <95 %

Altitude

Operating ............................................................ 2,000 Meters

Storage ............................................................... 12,000 Meters

Vibration and Shock ................................................ Complies with MIL-PRF-28800F Class 3.

28 °C to 40 °C <80 %

40 °C to 55 °C <50 %

Triggering

Samples per Trigger ........................................... 1 to 50,000

Trigger Delay ...................................................... 0 s to 3600 s; in 10 µS increments

External Trigger Delay ........................................ <1 mS

External Trigger Jitter ......................................... <500 µS

Trigger Input ....................................................... TTL Levels

Trigger Output ..................................................... 5 V maximum (open collector)

Memory

10,000 measurements, internal, and up to 2 Gigabyte capacity with USB memory module (available separately) through

front-panel USB port

Math Functions

Zero, dBm, dB, MX+B, Offset, DCV ratio and TrendPlot, Histogram, Statistics (min/max/average/standard deviation), and

Limit Test

1-10

Introduction and Specifications

Resolution

4½ Digits

5½ Digits

6½ Digits

100 mV

100.0000 mV

10 µV

1 µV

100 nV

10 MΩ or >10 GΩ

[1]

100 µV

10 µV

1 µV

10 MΩ or >10 GΩ

[1]

10 V

10.00000 V

1 mV

[1]

100 V

100.0000 V

10 mV

1 mV

100 µV

10 MΩ ±1%

10 MΩ ±1%

Electrical Specifications 1

Electrical

Input Protection ....................................................... 1000 V all ranges

Overrange ............................................................... 20 % on all ranges except 1000 V dc, 1000 V ac

Diode, and 10 A ranges

Remote Interfaces

RS-232C, DTE 9-pin, 1200 to 230400 baud (RS-232C to USB cable available to connect the Meter to a PC USB port.

See Accessories)

IEEE 488.2

LAN and “Ethernet 10/100 base T with DHCP (for IP_ADDRess) option”

Warranty

Three years

Electrical Specifications

Accuracy specifications are valid for 6½ digit resolution mode after at least a 1-hour warm-up with Auto Zero enabled.

24-hour specifications are relative to calibration standards and assume a controlled electromagnetic environment per

EN 61326-1:2000-11

DC Voltage Specifications

Maximum Input ....................................................... 1000 V on any range

Common Mode Rejection ....................................... 140 dB at 50 or 60 Hz ±0.1 % (1 kΩ unbalance)

Normal Mode Rejection .......................................... 60 dB for NPLC of 1 or greater with analog filter off and power line

Measurement Method ............................................. Multi-ramp A/D

A/D Linearity ........................................................... 0.0002 % of measurement +0.0001 % of range

Input Bias Current ................................................... <30 pA at 25 °C

Autozero Off Operation ........................................... Following instrument warm-up at calibration temperature ±1 °C and

Analog Filter ............................................................ When using the analog filter, specifications are relative to within one

DC Ratio ................................................................. Accuracy is +/- (Input accuracy + Reference accuracy), where Input

Settling Considerations ........................................... Measurement settling times are affected by source impedance, cable

frequency ±0.1 %

100 dB for NPLC of 1 or greater with analog filter on and power line

frequency ±0.1 %

less than 10 minutes, add error: 0.0002 % range additional error

+5 µV.

hour of using the ZERO function for that range and NPLC setting.

accuracy = DC Voltage accuracy for the HI to LO Input (in ppm of the

Input voltage), and Reference accuracy = DC Voltage accuracy for the

HI to LO (Sense) Reference (in ppm of the Reference voltage).

dielectric characteristics, and input signal changes.

Input Characteristics

Range Resolution

1 V 1.000000 V

1000 V 1,000.000 V 100 mV 10 mV 1 mV

[1] Inputs beyond ±14 V are clamped through 200 kΩ typical. 10 MΩ is default input impedance.

1-11

Input Impedance

100 µV 10 µV 10 MΩ or >10 GΩ

DMM4040/4050

±1 °

±5 °

±5 °

Temperature

Outside 18 to 28 °C

100 mV

0.0025 + 0.003

0.0025 + 0.0035

0.0037 + 0.0035

0.0005 + 0.0005

1 V

0.0018 + 0.0006

0.0018 + 0.0007

0.0025 + 0.0007

0.0005 + 0.0001

10 V

0.0013 + 0.0004

0.0018 + 0.0005

0.0024 + 0.0005

0.0005 + 0.0001

100 V

0.0018 + 0.0006

0.0027 + 0.0006

0.0038 + 0.0006

0.0005 + 0.0001

1000 V

0.0018 + 0.0006

0.0031 + 0.001

0.0041 + 0.001

0.0005 + 0.0001

±1 °

±5 °

±5 °

Temperature

Outside 18 to 28 °C

100 mV

0.003 + 0.003

0.004 + 0.0035

0.005 + 0.0035

0.0005 + 0.0005

1 V

0.002 + 0.0006

0.003 + 0.0007

0.004 + 0.0007

0.0005 + 0.0001

10 V

0.0015 + 0.0004

0.002 + 0.0005

0.0035 + 0.0005

0.0005 + 0.0001

100 V

0.002 + 0.0006

0.0035 + 0.0006

0.0045 + 0.0006

0.0005 + 0.0001

1000 V

0.002 + 0.0006

0.0035 + 0.0010

0.0045 + 0.0010

0.0005 + 0.0001

Digits

NPLC

Additional NPLC Noise Error

6½

100

0 % of range

5½

1

0.001 % of range

5½

.2

4½

0.02

0.017 % of range +17 µV

Technical Reference Manual

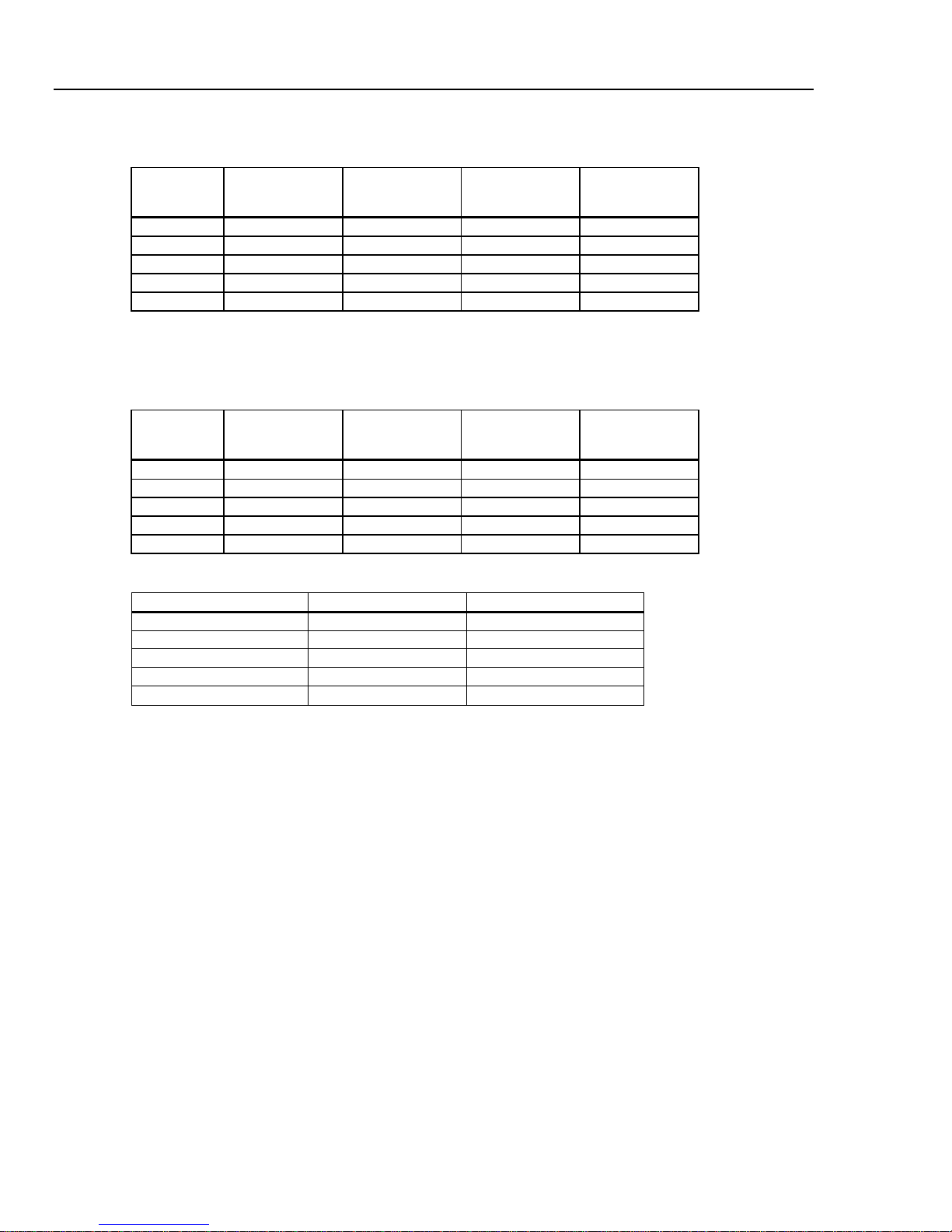

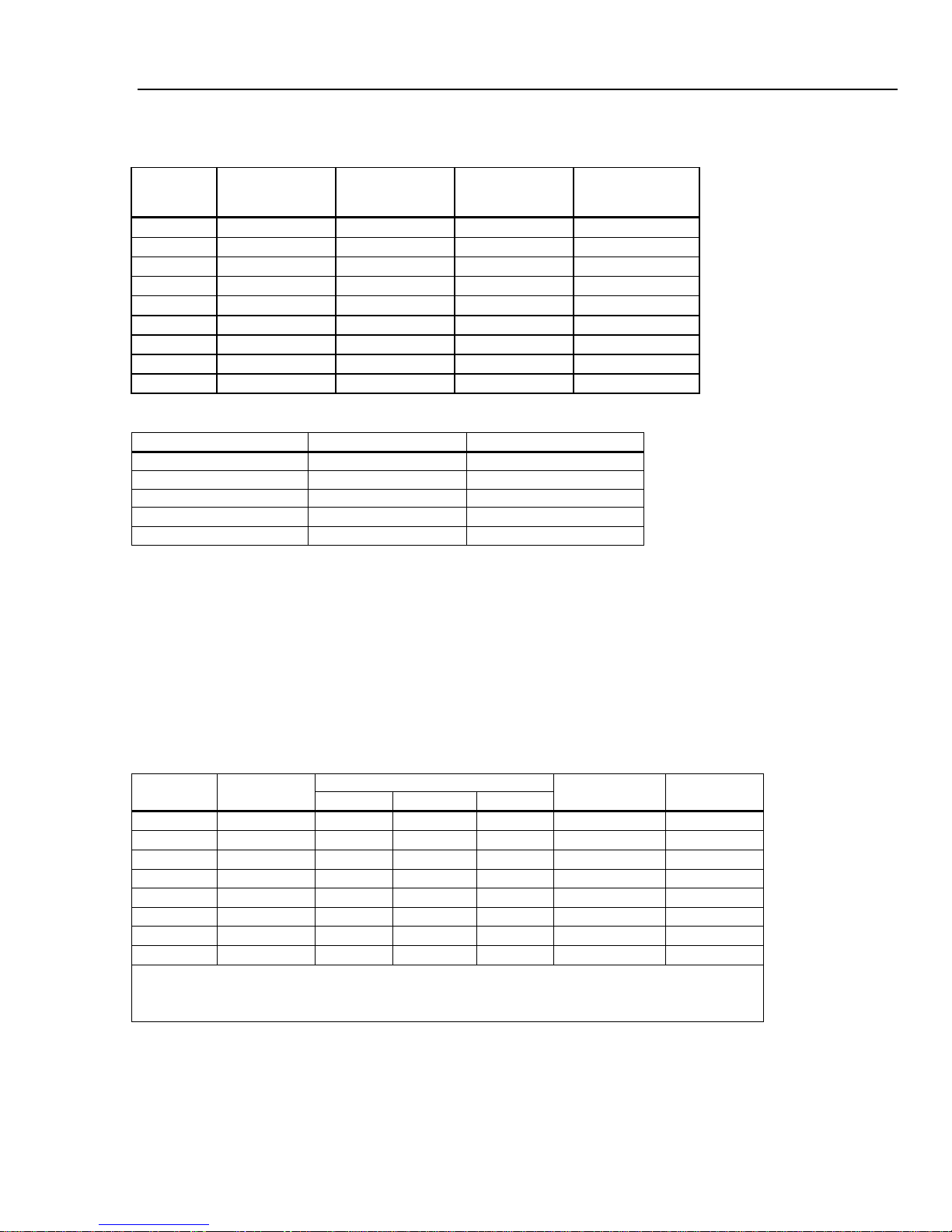

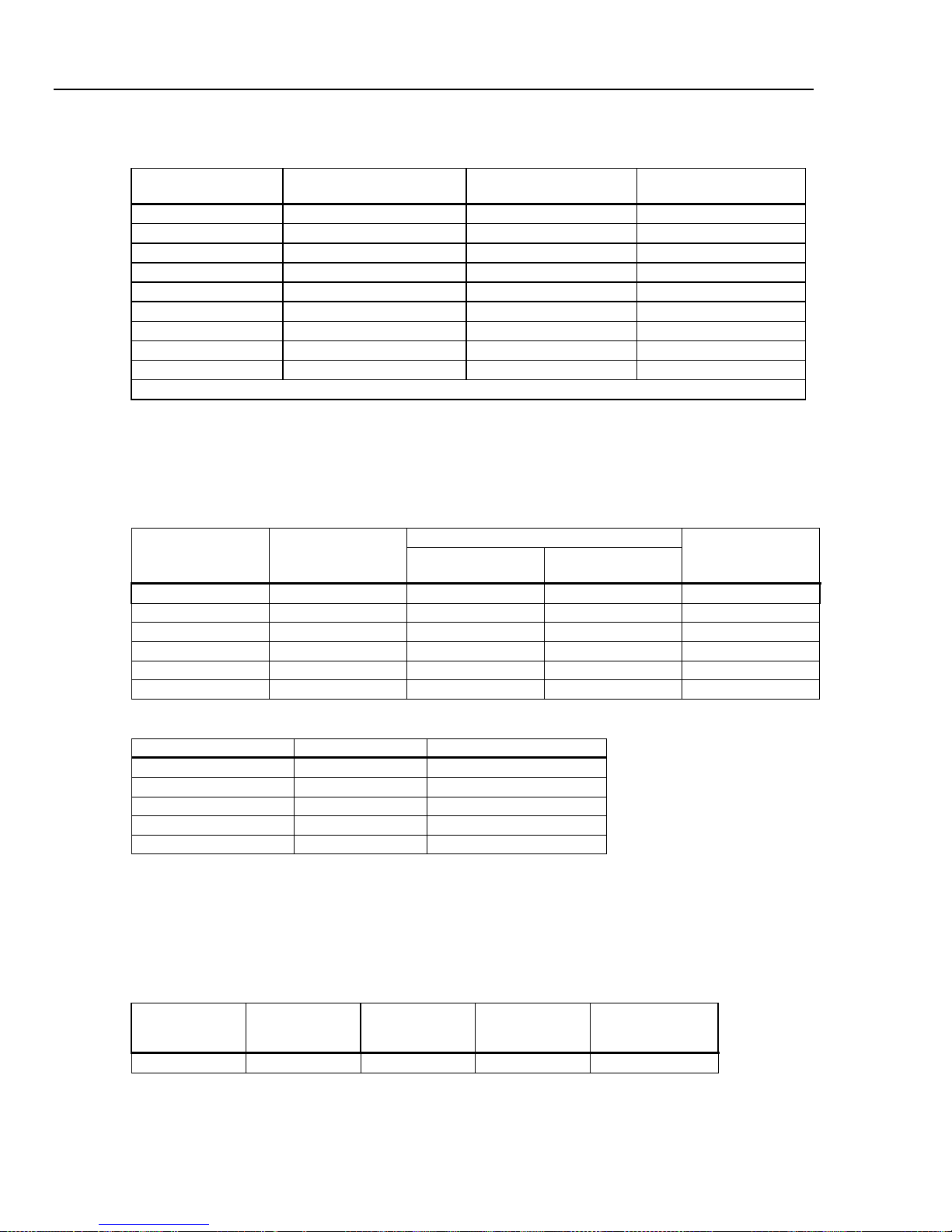

4050 Accuracy

Accuracy is given as ± (% measurement + % of range)

Range

24 Hour

(23

C)

90 Days

(23

C)

4040 Accuracy

Accuracy is given as ± (% measurement + % of range)

Range

24 Hour

(23

C)

90 Days

(23

C)

Additional Errors

1 Year

(23

1 Year

(23

C)

C)

Coefficient/ °C

Coefficient/ °C

6½ 10 0 % of range

0.0025 % of range +12 µV

AC Voltage Specifications

AC Voltage specifications are for ac sinewave signals >5 % of range. For inputs from 1 % to 5 % of range and <50 kHz,

add an additional error of 0.1 % of range, and for 50 kHz to 100 kHz, add 0.13 % of range.

Maximum Input ....................................................... 1000 V rms or 1414 V peak or 8 x 10

less) for any range.

Measurement Method ............................................. AC-coupled true-rms. Measures the ac component of input with up to

1000 V dc bias on any range.

AC Filter Bandwidth:

Slow .................................................................... 3 Hz – 300 kHz

Medium ............................................................... 20 Hz – 300 kHz

Fast ..................................................................... 200 Hz – 300 kHz

Common Mode Rejection ....................................... 70 dB at 50 Hz or 60 Hz ±0.1 % (1 kΩ unbalance)

Crest Factor Error (applies to non-sinusoidal waveforms only)

Maximum Crest Factor ....................................... 5:1 at Full Scale

Additional Crest Factor Errors (<100 Hz) ............ Crest factor 1-2, 0.05 % of full scale

Crest factor 2-3, 0.2 % of full scale

Crest factor 3-4, 0.4 % of full scale

Crest factor 4-5, 0.5 % of full scale

7

volts-Hertz product (whichever is

1-12

Introduction and Specifications

Resolution

4½ Digits

5½ Digits

6½ Digits

100 mV

100.0000 mV

10 µV

1 µV

100 nV

1 V

1.000000 V

100 µV

10 µV

1 µV

10 V

10.00000 V

1 mV

100 µV

1000 V

1,000.000 V

100 mV

10 mV

1 mV

±1 °

±5 °

±5 °

Temperature

Outside 18 to 28 °C

100 mV

3 – 5 Hz

1.0 + 0.03

1.0 + 0.04

1.0 + 0.04

0.1 + 0.004

5 – 10 Hz

0.35 + 0.03

0.35 + 0.04

0.35 + 0.04

0.035 + 0.004

100 – 300 kHz

[1]

4.0 + 0.50

4.0 + 0.50

4.0 + 0.50

0.20 + 0.02

3 – 5 Hz

1.0 + 0.02

1.0 + 0.03

1.0 + 0.03

0.1 + 0.003

5 – 10 Hz

0.35 + 0.02

0.35 + 0.03

0.35 + 0.03

0.035 + 0.003

10 Hz – 20 kHz

0.04 + 0.02

0.05 + 0.03

0.06 + 0.03

0.005 + 0.003

20 – 50 kHz

0.1 + 0.04

0.11 + 0.05

0.12 + 0.05

0.011 + 0.005

50 – 100 kHz

0.55 + 0.08

0.6 + 0.08

0.6 + 0.08

0.06 + 0.008

100 – 300 kHz

[1]

4.0 + 0.50

4.0 + 0.50

4.0 + 0.50

0.2 + 0.02

10 V

3 – 5 Hz

1.0 + 0.02

1.0 + 0.03

1.0 + 0.03

0.1 + 0.003

5 – 10 Hz

0.35 + 0.02

0.35 + 0.03

0.35 + 0.03

0.035 + 0.003

10 Hz – 20 kHz

0.04 + 0.02

0.05 + 0.03

0.06 + 0.03

0.005 + 0.003

20 – 50 kHz

0.1 + 0.04

0.11 + 0.05

0.12 + 0.05

0.011 + 0.005

50 – 100 kHz

0.55 + 0.08

0.6 + 0.08

0.6 + 0.08

0.06 + 0.008

100 – 300 kHz

[1]

4.0 + 0.50

4.0 + 0.50

4.0 + 0.50

0.2 + 0.02

100 V

3 – 5 Hz

1.0 + 0.02

1.0 + 0.03

1.0 + 0.03

0.1 + 0.003

5 – 10 Hz

0.35 + 0.02

0.35 + 0.03

0.35 + 0.03

0.035 + 0.003

10 Hz – 20 kHz

0.04 + 0.02

0.05 + 0.03

0.06 + 0.03

0.005 + 0.003

[1]

5 – 10 Hz

0.35 + 0.015

0.35 + 0.0225

0.35 + 0.0225

0.035 + 0.00225

10 Hz – 20 kHz

0.04 + 0.015

0.05 + 0.0225

0.06 + 0.0225

0.005 + 0.00225

20 – 50 kHz

0.1 + 0.03

0.11 + 0.0375

0.12 + 0.0375

0.011 + 0.00375

50 – 100 kHz

[2]

0.55 + 0.06

0.6 + 0.06

0.6 + 0.06

0.06 + 0.006

100 – 300 kHz

[1][2]

4.0 + 0.375

4.0 + 0.375

4.0 + 0.375

0.2 + 0.015

[2] 1000 Volt range is limited to 8 X 107 volt-Hertz

Electrical Specifications 1

Input Characteristics

Range Resolution

100 µV 10 µV

100 V 100.0000 V 10 mV 1 mV

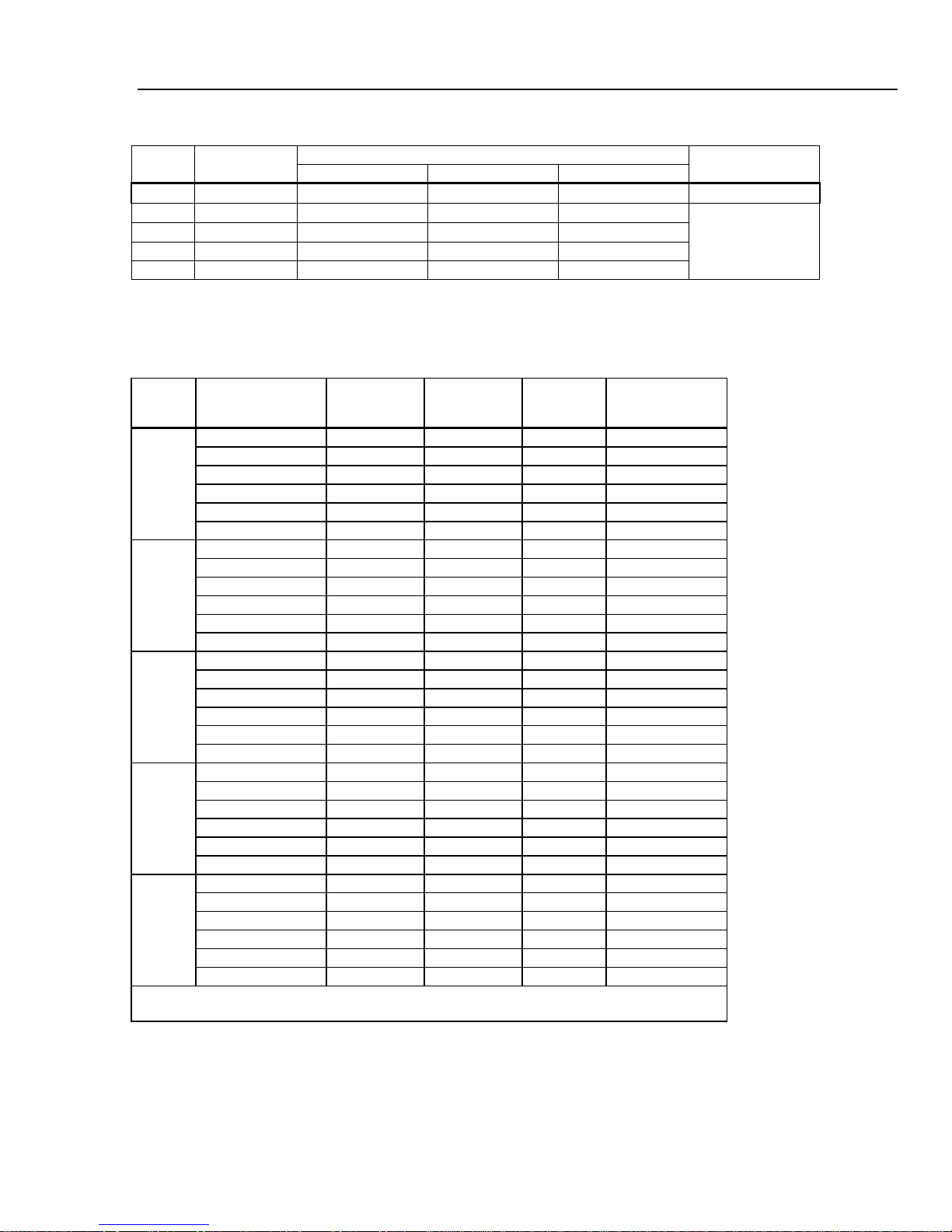

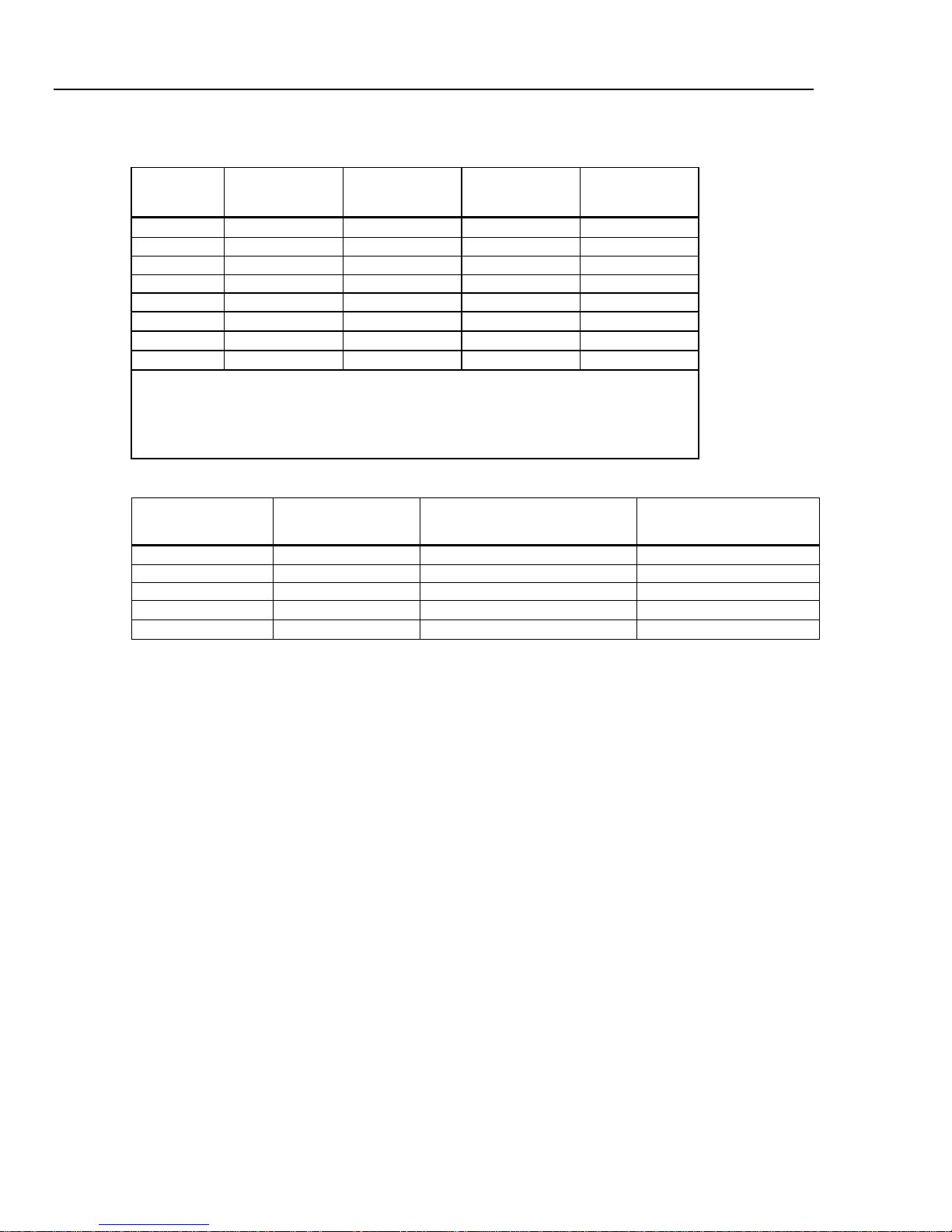

4040/4050 Accuracy

Accuracy is given as ± (% measurement + % of range)

Range Frequency

10 Hz – 20 kHz 0.04 + 0.03 0.05 + 0.04 0.06 + 0.04 0.005 + 0.004

20 – 50 kHz 0.1 + 0.05 0.11 + 0.05 0.12 + 0.05 0.011 + 0.005

50 – 100 kHz 0.55 + 0.08 0.6 + 0.08 0.6 + 0.08 0.06 + 0.008

1 V

24 Hour

(23

C)

90 Days

(23

C)

1 Year

(23

C)

Input Impedance

1 MΩ ±2 % shunted

by <100 pf

Coefficient/ °C

20 – 50 kHz 0.1 + 0.04 0.11 + 0.05 0.12 + 0.05 0.011 + 0.005

50 – 100 kHz 0.55 + 0.08 0.6 + 0.08 0.6 + 0.08 0.06 + 0.008

100 –- 300 kHz

1000 V 3 – 5 Hz 1.0 + 0.015 1.0 + 0.0225 1.0 + 0.0225 0.1 + 0.00225

[1] Typically 30 % reading error at 1 MHz

4.0 + 0.50 4.0 + 0.50 4.0 + 0.50 0.2 + 0.02

1-13

DMM4040/4050

AC Filter

3 HZ (slow)

20 HZ (medium)

200 HZ (fast)

20 – 40 Hz

0

0.02 – 40 – 100 Hz

0

0.01

0.55

200 Hz – 1 kHz

0 0 0.02

>1 kHz

0 0 0

Resolution

4½ Digits

5½ Digits

6½ Digits

10 Ω

10.00000 Ω

1 mΩ

100 µΩ

10 µΩ

100 Ω

100.0000 Ω

10 mΩ

1 mΩ

100 µΩ

1 kΩ

1.000000 kΩ

100 mΩ

10 mΩ

1 mΩ

10 kΩ

10.00000 kΩ

1 Ω

100 mΩ

10 mΩ

100 µA/6 V

1 MΩ

1.000000 MΩ

100 Ω

10 Ω

1 Ω

10 µA/13 V

10 MΩ

10.00000 MΩ

1 kΩ

100 Ω

10 Ω

1 µA/13 V

1.0 GΩ

1.000000 GΩ

100 kΩ

10 kΩ

1 kΩ

1 µA || 10 MΩ/10 V

Technical Reference Manual

Additional Low Frequency Errors

Error is stated as % of reading.

Frequency

10 – 20 Hz 0 0.25 –

100 – 200 Hz 0 0 0.2

Resistance

Specifications are for 4-wire resistance function, 2 x 4-wire resistance, or 2-wire resistance with zero. If zero is not used,

add 0.2 Ω for 2-wire resistance plus lead resistance, and add 20 mΩ for 2 x 4-wire resistance function.

Measurement Method ............................................. Current source referenced to LO input

Max. Lead Resistance (4-wire ohms) ..................... 10 % of range per lead for 10 Ω, 100 Ω, 1 kΩ ranges. 1 kΩ per lead on

Input Protection ....................................................... 1000 V on all ranges

Common Mode Rejection ....................................... 140 dB at 50 or 60 Hz ±0.1 % (1 kΩ unbalance)

Normal Mode Rejection .......................................... 60 dB for NPLC of 1 or greater with analog filter off and power line

Analog Filter ............................................................ When using the analog filter, specifications are relative to within one

all other ranges

frequency ±0.1 %

100 dB for NPLC of 1 or greater with analog filter on and power line

frequency ±0.1 %

hour of using the ZERO function for that range and NPLC setting.

Input Characteristics

Range Resolution

100 kΩ 100.0000 kΩ 10 Ω 1 Ω 100 mΩ 100 µA/13 V

100 MΩ 100.0000 MΩ 10 kΩ 1 kΩ 100 Ω 1 µA || 10 MΩ/10 V

Source Current

5 mA/13 V

1 mA/6 V

1 mA/6 V

1-14

Introduction and Specifications

±1 °

±5 °

±5 °

Temperature

Outside 18 to 28 °C

10 Ω

0.003 + 0.01

0.008 + 0.03

0.01+ 0.03

0.0006 + 0.0005

100 Ω

0.003 + 0.003

0.008 + 0.004

0.01 + 0.004

0.0006 + 0.0005

1 kΩ

0.002 + 0.0005

0.008 + 0.001

0.01 + 0.001

0.0006 + 0.0001

100 kΩ

0.002 + 0.0005

0.008 + 0.001

0.01 + 0.001

0.0006 + 0.0001

10 MΩ

0.015 + 0.001

0.02 + 0.001

0.04 + 0.001

0.003 + 0.0004

1 GΩ

1.0 + 0.01

1.5 + 0.01

2.0 + 0.01

0.6 + 0.0002

Digits

NPLC

Additional NPLC Noise Error

6½

100

0 % of range

6½

10

0 % of range

5½

0.2

0.003 % of range ±7 mΩ

0.017 % of range ±15 mΩ

Resolution

Shunt Resistance

4½ Digits

5½ Digits

6½ Digits

10 nA

1 nA

100 pA

100 Ω

10 mA

10.00000 mA

1 µA

100 nA

10 nA

1 Ω

<0.025 V

100 mA

100.0000 mA

100 nA

<0.25 V

400 mA

[3]

400.000 mA

100 µA

10 µA

1 µA

1 Ω

<0.50 V

[2]

100 µA

10 µA

1 µA

0.01 Ω

[1]

3.00000A

1 mA

<0.15 V

10 A

10.00000 A

1 mA

100 µA

10 µA

0.01 Ω

<0.5 V

Electrical Specifications 1

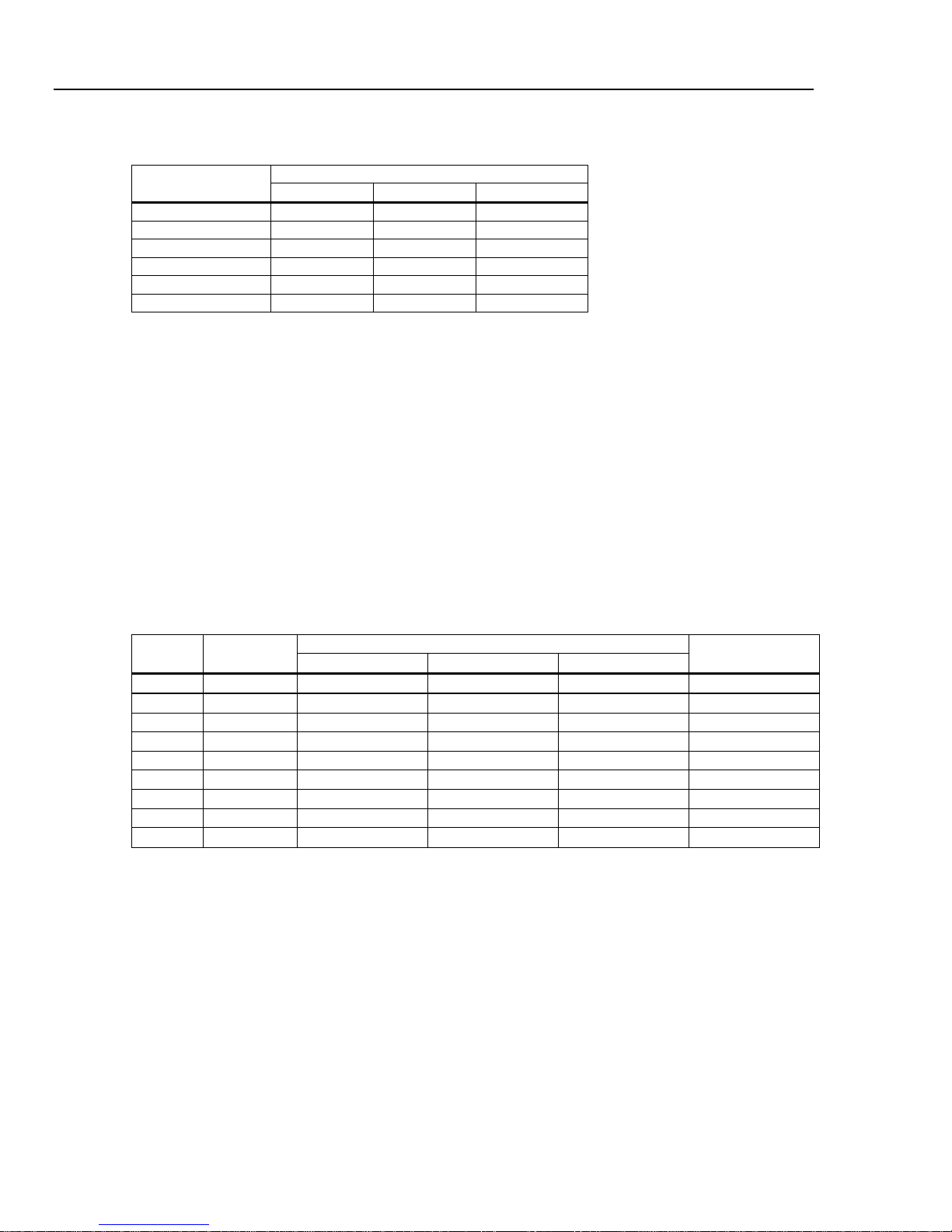

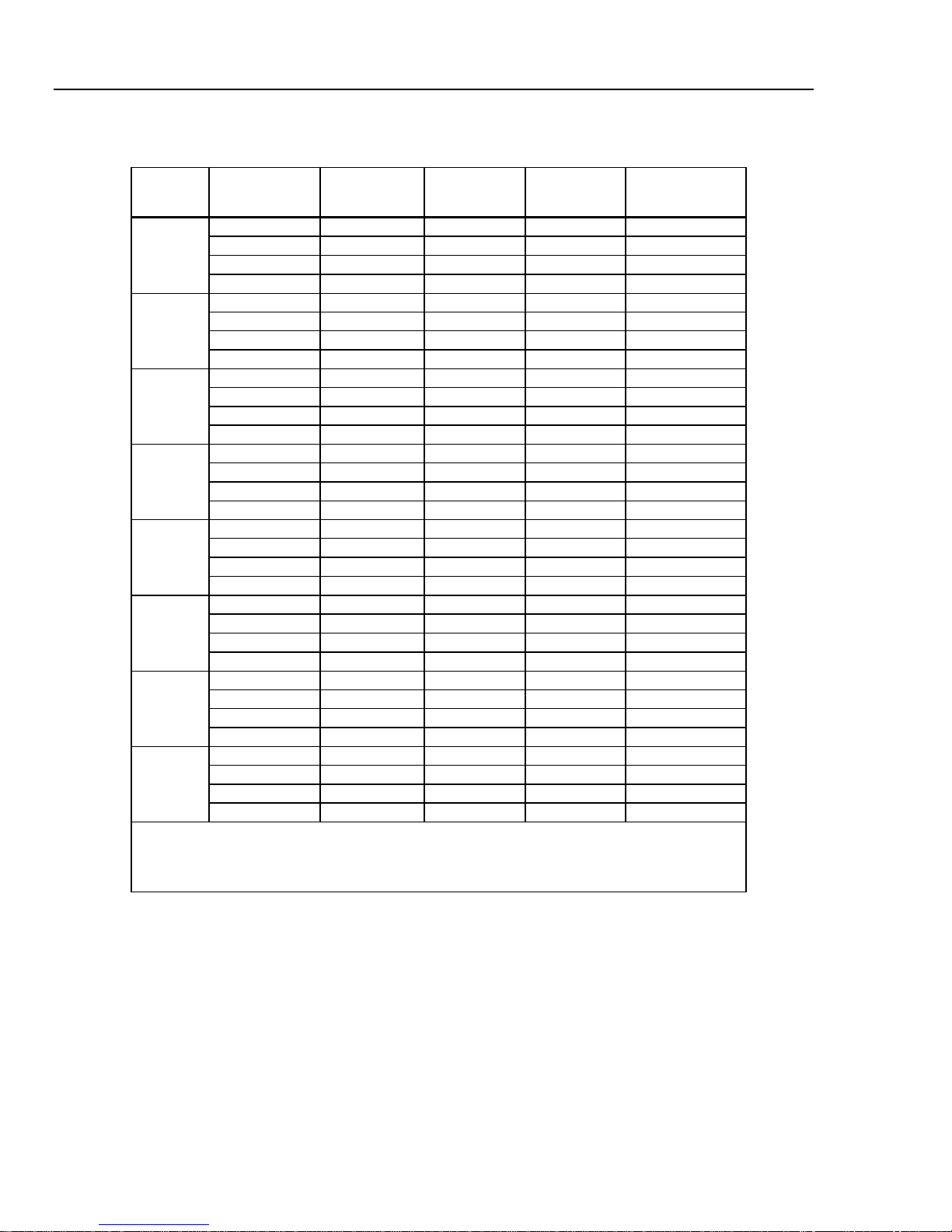

4040/4050 Accuracy

Accuracy is given as ± (% measurement + % of range)

Range

10 kΩ 0.002 + 0.0005 0.008 + 0.001 0.01 + 0.001 0.0006 + 0.0001

1 MΩ 0.002 + 0.001 0.008 + 0.001 0.01 + 0.001 0.001 + 0.0002

100 MΩ 0.3 + 0.01 0.8 + 0.01 0.8 + 0.01 0.15 + 0.0002

24 Hour

(23

C)

90 Days

(23

C)

1 Year

(23

C)

Coefficient/ °C

Additional Ohms Errors

5½ 1 0.001 % of range

4½ 0.02

DC Current

Input Protection ....................................................... Tool-accessible 11 A/1000 V and 440 mA/1000 V fuses, limits of

Common Mode Rejection ....................................... 140 dB at 50 or 60 Hz ±0.1 % (1 kΩ unbalance)

Normal Mode Rejection .......................................... 60 dB for NPLC of 1 or greater with analog filter off and power line

Analog Filter ............................................................ When using the analog filter, specifications are relative to within one

400 mA continuous 550 mA for 2 minutes on, 1 minute off.

frequency ±0.1 %

100 dB for NPLC of 1 or greater with analog filter on and power line

frequency ±0.1 %

hour of using the ZERO function for that range and NPLC setting.

Input Characteristics

Range Resolution

100 µA 100.0000 µA

1 mA 1.000000 mA 100 nA 10 nA 1 nA

1 A

1.000000 A

3 A

[1] Part of 10 A range.

[2] Available on the front panel terminal only.

[3] 400 mA continuously; 550 mA for 2 minutes on, 1 minute off.

1-15

10 µA 1 µA

100 µA 10 µA 0.01 Ω

(Ohms)

100 Ω

1 Ω

Burden Voltage

<0.015 V

<0.15 V

<0.05 V

DMM4040/4050

±1 °

±5 °

±5 °

Temperature

Outside 18 to 28 °C

100 µA

[4]

0.01 + 0.02

0.04 + 0.025

0.05 + 0.025

0.002 + 0.003

1 mA

0.007 + 0.005

0.030 + 0.005

0.05 + 0.005

0.002 + 0.0005

10 mA

[4]

0.007 + 0.02

0.03 + 0.02

0.05 + 0.02

0.002 + 0.002

100 mA

0.01 + 0.004

0.03 + 0.005

0.05 + 0.005

0.002 + 0.0005

[3]

1 A

[2]

0.03 + 0.02

0.04 + 0.02

0.05 + 0.02

0.005 + 0.001

[1][2]

10 A

[2]

0.1 + 0.008

0.12 + 0.008

0.15 + 0.008

0.005 + 0.0008

Additional NPLC Noise Error for

10 A

Additional NPLC Noise Error

6½

100

0 % of range

0 % of range

6½

10

0 % of range

0 % of range

5½

0.2

0.011 % of range ±4 µA

0.11 % of range ±4 µA

0.04 % of range ±4 µA

0.28 % of range ±4 µA

Technical Reference Manual

Accuracy (4040/4050)

Accuracy is given as ± (% measurement + % of range)

Range

400 mA

3 A

0.03 + 0.004 0.04 + 0.005 0.05 + 0.005 0.005 + 0.0005

0.05 + 0.02 0.08 + 0.02 0.1 + 0.02 0.005 + 0.002

[1] Part of 10 A range

[2] Available at front panel connectors only

[3] 400 mA continuously; 550 mA for 2 minutes on, 1 minute off.

[4] In RF fields of 3 V/m and frequencies of 1.7 GHz to 1.9 GHz, add 0.06% of range. With conducted RF

voltages of 3 Vrms and frequencies of 20 MHz to 50 MHz, add 0.08% of range.

24 Hour

(23

C)

90 Days

(23

C)

1 Year

(23

C)

Coefficient/ °C

Additional Current Errors

Digits NPLC

5½ 1 0.001 % of range 0.01 % of range

4½ 0.02

1 mA, 100 mA, 400 mA, 3 A an d

for 100 µA, 10 mA, 1 A

1-16

Introduction and Specifications

Resolution

4½ Digits

5½ Digits

6½ Digits

100 µA

100.0000 µA

10 nA

1 nA

100 pA

100 Ω

<0.015 V

1 mA

100 Ω

10 mA

10.00000 mA

1 µA

100 nA

10 nA

1 Ω

<0.025 V

100.0000 mA

10 µA

1 µA

100 nA

1 Ω

<0.25 V

[3]

100 µA

10 µA

1 µA

1 Ω

1 A

[2]

1.000000 A

100 µA

10 µA

1 µA

0.01 Ω

<0.05 V

[1][2]

3.00000 A

1 mA

<0.05 V

[2]

100 µA

10 µA

0.01 Ω

Electrical Specifications 1

AC Current

The following ac current specifications are for sinusoidal signals with amplitudes greater than 5 % of range. For inputs

from 1 % to 5 % of range, add an additional error of 0.1 % of range.

Input Protection ....................................................... Tool accessible 11 A/1000 V and 440 mA/1000 V fuses, limits of

Measurement Method ............................................. ac-coupled true-rms, dc-coupled to the fuse and shunt (no blocking

AC Filter Bandwidth

Slow .................................................................... 3 Hz to 10 kHz

Medium ............................................................... 20 Hz to 10 kHz

Fast ..................................................................... 200 Hz to 10 kHz

Crest Factor Error (applies to non-sinusoidal waveforms only)

Maximum Crest Factor ....................................... 5:1 at full scale

Additional Crest Factor Errors (<100 Hz) ............ Crest factor 1-2, 0.05 % of full scale

400 mA continuous 550 mA for 2 minutes on, 1 minute off.

capacitor)

Crest factor 2-3, 0.2 % of full scale

Crest factor 3-4, 0.4 % of full scale

Crest factor 4-5, 0.5 % of full scale

Input Characteristics

Range Resolution

Shunt Resistance

(Ohms)

Burden Voltage

1.000000 mA 100 nA 10 nA 1 nA

100 mA

400 mA

400.000 mA

3 A

10 A

10.00000 A 1 mA

[1] Part of 10 A range

[2] Available at front panel connectors only

[3] 400 mA continuously; 550 mA for 2 minutes on, 1 minute off; maximum crest factor 3:1 at 400 mA

100 µA 10 µA 0.01 Ω

<0.15 V

<0.50 V

<0.5 V

1-17

DMM4040/4050

±1 °

±5 °

±5 °

Temperature

Outside 18 to 28 °C

3 – 5 Hz

1.1 + 0.06

1.1 + 0.06

1.1 + 0.06

0.2 + 0.006

5 – 10 Hz

0.35 + 0.06

0.35 + 0.06

0.35 + 0.06

0.1 + 0.006

5 – 10 kHz

0.35 + 0.7

0.35 + 0.7

0.35 + 0.7

0.03 + 0.006

1 mA

3 – 5 Hz

1.0 + 0.04

1.0 + 0.04

1.0 + 0.04

0.1 + 0.006

5 – 10 Hz

0.3 + 0.04

0.3 + 0.04

0.3 + 0.04

0.035 + 0.006

10 Hz – 5 kHz

0.1 + 0.04

0.1 + 0.04

0.1 + 0.04

0.015 + 0.006

5 – 10 kHz

0.2 + 0.25

0.2 + 0.25

0.2 + 0.25

0.03 + 0.006

10 mA

3 – 5 Hz

1.1 + 0.06

1.1 + 0.06

1.1 + 0.06

0.2 + 0.006

10 Hz – 5 kHz

0.15 + 0.06

0.15 + 0.06

0.15+ 0.06

0.015 + 0.006

5 – 10 kHz

0.35 + 0.7

0.35 + 0.7

0.35 + 0.7

0.03 + 0.006

100 mA

3 – 5 Hz

1.0 + 0.04

1.0 + 0.04

1.0 + 0.04

0.1 + 0.006

5 – 10 Hz

0.3 + 0.04

0.3 + 0.04

0.3 + 0.04

0.035 + 0.006

10 Hz – 5 kHz

0.1 + 0.04

0.1 + 0.04

0.1 + 0.04

0.015 + 0.006

[3]

3 – 5 Hz

1.0 + 0.1

1.0 + 0.1

1.0 + 0.1

0.1 + 0.006

10 Hz – 1 kHz

0.1 + 0.1

0.1 + 0.1

0.1 + 0.1

0.015 + 0.006

1kHz – 10 kHz

0.2 + 0.7

0.2 + 0.7

0.2 + 0.7

0.03 + 0.006

[2]

3 – 5 Hz

1.0 + 0.04

1.0 + 0.04

1.0 + 0.04

0.1 + 0.006

5 – 10 Hz

0.3 + 0.04

0.3 + 0.04

0.3 + 0.04

0.035 + 0.006

5 – 10 kHz

0.35 + 0.7

0.35 + 0.7

0.35 + 0.7

0.03 + 0.006

3 A

[1][2]

3 – 5 Hz

1.1 + 0.06

1.1 + 0.06

1.1 + 0.06

0.1 + 0.006

5 – 10 Hz

0.35 + 0.06

0.35 + 0.06

0.35 + 0.06

0.035 + 0.006

10 Hz – 5 kHz

0.15 + 0.06

0.15 + 0.06

0.15 + 0.06

0.015 + 0.006

5 – 10 kHz

0.35 + 0.7

0.35 + 0.7

0.35 + 0.7

0.03 + 0.006

[2]

3 – 5 Hz

1.1 + 0.06

1.1 + 0.06

1.1 + 0.06

0.1 + 0.006

10 Hz – 5 kHz

0.15 + 0.06

0.15 + 0.06

0.15 + 0.06

0.015 + 0.006

5 – 10 kHz

0.35 + 0.7

0.35 + 0.7

0.35 + 0.7

0.03 + 0.006

Technical Reference Manual

4040/4050 Accuracy

Accuracy is given as ± (% measurement + % of range)

Range

100 µA

400 mA

1 A

Frequency

(Hz)

24 Hour

(23

C)

90 Days

(23

C)

1 Year

(23

C)

Coefficient/ °C

10 Hz – 5 kHz 0.15 + 0.06 0.15 + 0.06 0.15 + 0.06 0.015 + 0.006

5 – 10 Hz 0.35 + 0.06 0.35 + 0.06 0.35 + 0.06 0.1 + 0.006

5 – 10 kHz 0.2 + 0.25 0.2 + 0.25 0.2 + 0.25 0.03 + 0.006

5 – 10 Hz 0.3 + 0.1 0.3 + 0.1 0.3 + 0.1 0.035 + 0.006

10 Hz – 5 kHz 0.1 + 0.04 0.1 + 0.04 0.1 + 0.04 0.015 + 0.006

10 A

5 – 10 Hz 0.35 + 0.06 0.35 + 0.06 0.35 + 0.06 0.035 + 0.006

[1] Part of 10 A range

[2] Available only on front panel connectors

[3] 400 mA continuously; 550 mA for 2 minutes on, 1 minute off; maximum crest factor 3:1 at 400 mA; specification for

current above 329 mA is typical.

1-18

Introduction and Specifications

AC Filter

3HZ (slow)

20HZ (medium)

200HZ (fast)

20 – 40 Hz

0

0.02 – 40 – 100 Hz

0

0.01

0.55

200 Hz – 1 kHz

0 0 0.02

> 1 kHz

0 0 0

±1 °

±5 °

±5 °

Temperature

Outside 18 to 28 °C

100 mV to

3 – 5 Hz

0.1

0.1

0.1

0.005

5 – 10 Hz

0.05

0.05

0.05

0.005

10 – 40 Hz

0.03

0.03

0.03

0.001

40 Hz – 300 kHz

0.006

0.01

0.01

0.001

300 kHz – 1 MHz

0.006

0.01

0.01

0.001

Gate Time

Resolution

0.01

5½

0.1

6½

1.0

6½

Resolution

6½

5½

4½

5 – 10 Hz 0 0.17

0.17

10 – 40 Hz 0 0.2

0.2

40 – 100 Hz 0 0.06

0.21

100 – 300 Hz 0 0.03

0.21

300 Hz – 1 kHz 0 0.01

0.07

> 1 kHz 0 0

0.02

Electrical Specifications 1

Additional Low Frequency Errors

Error is stated as % of reading.

Frequency

10 – 20 Hz 0 0.25 –

100 – 200 Hz 0 0 0.2

Frequency

Gate Times ............................................................. Programmable to 1 s, 100 ms, and 10 ms

Measurement Method ............................................. Flexible counting technique. AC-coupled input using the ac voltage

Settling Considerations ........................................... When measuring frequency or period after a dc offset voltage change,

Measurement Considerations ................................. To minimize measurement errors, shield inputs from external noise

measurement function.

errors may occur. For the most accurate measurement, wait up to

1 second for the input blocking capacitor to settle.

when measuring low-voltage, low-frequency signals.

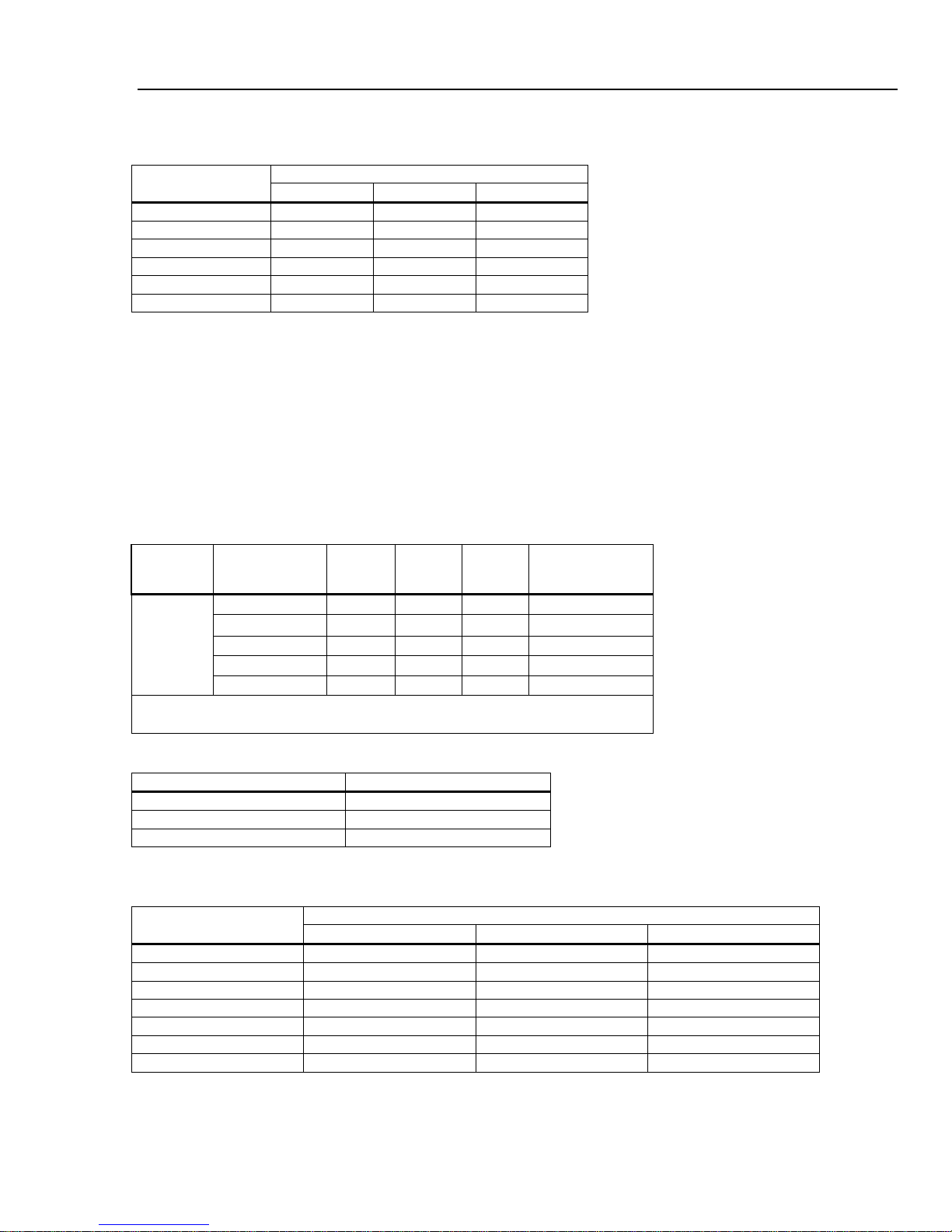

4040/4050 Accuracy

Accuracy is given as ± % measurement

Range Frequency

[1][2]

1000 V

[1] Input >100 mV. For 10 – 100 mV, multiply percent measurement error by 10.

[2] Limited to 8 X 10

7

volt-Hertz

24 Hour

(23

C)

90 Days

(23

C)

1 Year

(23

Coefficient/ °C

C)

Gate Time vs. Resolution

Additional Low Frequency Errors

Error stated as percent of measurement for inputs >100 mV. For 10 – 100 mV, multiply percent by 10.

Frequency

3 – 5 Hz 0 0.12 0.12

1-19

DMM4040/4050

[1]

(23 ±5 °C)

°C

Outside 18 to 28 °C

2% ± 2.5 %

10 nF

10 pF

0.05 + 0.01

1% ± 0.5 %

1 nF

0.01 + 0.01

10 µF

1% ± 0.5 %

100 µF

100 nF

1% ± 0.5 %

0.01 + 0.01

1 mF

1 µF

1% ± 0.5 %

0.01 + 0.01

10 mF

10 µF

1% ± 0.5 %

0.01 + 0.01

100 mF

100 µF

4% ± 0.2 %

0.05 + 0.05

Accuracy

Temperature

°

90 Days

(23 ±5 °C)

1 Year

(23 ±5 °C)

-200 °C

0.001 °C

0.06

0.09

0.0025

0 °C

0.001 °C

0.04

0.06

0.002

100 °C

0.001 °C

0.05

0.08

0.002

600 °C

0.001 °C

0.18

0.22

0.002

Digits

NPLC

Additional NPLC Noise Error

6 ½

100

6 ½

10

0 °C

0.03 °C

5 ½

0.2

0.12 °C

4 ½

0.02

±1 °

±5 °

±5 °

Temperature

Outside 18 to 28 °C

1000.0 Ω

0.002 + 0.01

0.008 + 0.02

0.01 + 0.02

0.001 + 0.002

Technical Reference Manual

Capacitance (4050 only)

Accuracy is stated as ±(% of measurement + % of range)

Range Resolution

1 Year Accuracy

Temperature Coefficient/

1 nF 1 pF

100 nF 100 pF

1 µF

10 nF

[1] Stated accuracy is attained when Zero function is used.

1% ± 0.5 %

1% ± 0.5 %

0.05 + 0.05

0.01 + 0.01

0.01 + 0.01

Temperature (4050 only)

Test Current ............................................................ 1 mA

Accuracy is stated as ± °C and is based on a Platinum RT100 (DIN IEC 751, 385 type) RTD with less than 10 ohms lead

resistance. The accuracy listed in the table below are valid only when using the 4-wire RTD measurement function.

Specifications do not include probe accuracy, which must be added.

Range Resolution

-100 °C 0.001 °C 0.05 0.08 0.002

Coefficient/ °C

Outside 18 to 28

C

300 °C 0.001 °C 0.1 0.12 0.002

Additional Errors

0 °C

5 ½ 1

0.6 °C

Continuity

Continuity Threshold ............................................... Selectable between 1 Ω and 1000 Ω

Test Current ............................................................ 1 mA

Response Time ....................................................... 300 samples/sec with audible tone

Accuracy is given as ± (% measurements + % of range)

Range

24 Hour

(23

C)

90 Days

(23

C)

1 Year

(23

C)

Coefficient/ °C

1-20

Introduction and Specifications

±1 °

±5 °

±5 °

Temperature

Outside 18 to 28 °C

10.0000 V

0.002 + 0.001

0.008 + 0.002

0.01 + 0.002

0.001 + 0.002

Measurements/Second

[1]

4040

4050

DC Volts, DC Current, and

6½

100 NPLC

1.67 (2) s

0.6 (0.5)

0.6 (0.5)

6½

10 NPLC

167 (200) ms

6 (5)

6 (5)

5½

1 NPLC

16.7 (20) ms

60 (50)

60 (50)

5½

0.2 NPLC

3.3 ms

270

270

4½

0.02 NPLC

500 us

995

995

[2]

6½

3 Hz 0.47

0.47

6½

20 Hz 1.64

1.64

6½

200 Hz

[3]

4.5

4.5

5½

100 ms 9.8

9.8

4½

10 ms 80

80

Capacitance

6½

NA

2

Measurement Uncertainty 1

Diode Test

Test Current ............................................................ 100 µA or 1 mA

Response Time ....................................................... 300 samples/sec with audible tone.

Accuracy is given as ± (% measurements + % of range)

Range

5.0000 V 0.002 + 0.002 0.008 + 0.002 0.01 + 0.002 0.001 + 0.002

24 Hour

(23

C)

90 Days

(23

C)

1 Year

(23

C)

Coefficient/ °C

Measurement Rates (IEEE488[4])

Function Digits Setting

Resistance

AC Voltage and AC Current

Frequency and Period 6½ 1 s 1 1

[1] Typical measurement rates with auto-zero off, delay = 0, display off, auto range off and math off.

[2] Maximum measurement rates for 0.01 % of ac step. Wh en dc input varies, additional settling delay is required.

[3] For remote operation or external trigger using default settling delay

[4] Speeds available in OutG SW 1.0.700.18 or higher. Note that the measurements rates for RS232 can vary depending on the

baud rate chosen. If the baud rate selected is 115,200, the maximum measurement rate is 711 measurement/s. The LAN bus

has a maximum measurement rate of 963 measurement/s.

Integration Time

60 Hz (50 Hz)

Measurement Uncertainty

The Meter's measurement uncertainties are expressed in the form ( % of reading + % of

range ). In addition to the reading error and range error, you may need to add additional

errors for certain operating conditions. If the Meter is operated outside the temperature

range specified, an additional temperature coefficient error must be applied. For dc

voltage, dc current, and resistance measurements, apply an additional reading-speed

error. For ac voltage and ac current measurements, apply an additional low frequency

error or crest factor error.

The "% of reading" error varies according to the input level on the selected range. This

error is expressed in percent of input measurement. The “% of range” error represents the

floor noise of the range and represents the lowest meaningful resolution for that range.

The following example shows the reading error applied to the Meter's 24-hour 10 Vdc

specification: 0.0013% of input + 0.0004% of range.

Assuming the Meter is set to the 10V range with an input voltage of 1 V, the

measurement uncertainty would be: +/- [(0.0013% x 1V) + (.0004% x 10V)].

Permissible High Value = 1 + 0.000053V = 1.000053 V

Permissible Low Value = 1 - 0.000053V = 0.999947 V

1-21

DMM4040/4050

Technical Reference Manual

Interpreting Accuracy Specifications

The following sections provide a clearer understanding of specifications over time and

with temperature variations.

24

-Hour Accuracy

The 24

measurement range for short time intervals and within a stable environment. Short

accuracy is usually specified for a 24

90

-Day and 1-Year Accuracy

The longer

±5 °C temperature range. These specifications include the initial calibration errors plus

the Meter's long

Temperature Coefficients

Accuracy is usually specified at the calibration temperature (T

range. This is a common temperature range for many operating environments. Add

additional temperature coefficient errors to the accuracy specification if the Meter is

operated outside the ±5 °C temperature range (the specification is per °C).

-hour accuracy specification indicates the Meter's relative accuracy over its full

-term

-hour period and for a ±1 °C temperature range.

duration accuracy specifications are valid at the calibration temperature (Tcal)

-term drift errors.

cal) ±5 °C temperature

Configuring for Highest Accuracy Measurements

The measurement configurations shown below assume that the Meter is in its power-on

or reset state. It is also assumed that auto-ranging is enabled to ensure proper full-scale

range selection.

DC Voltage, DC Current, and Resistance Measurements

Select NPLC and 100 (NPLCs) for highest instrument resolution and accuracy.

For the best dc voltage accuracy, set INPUT HIGH INPUT Z (impedance) to GOhm (for

the 100 mV, 1 V, and 10 V ranges).

For the best resistance measurement accuracy, use the 4

For 2

-wire ohms, dc voltage and dc current measurements, set AUTOZERO to ON to

remove thermal EMF and offset errors.

Zero the test lead resistance for 2

-wire and 4-wire ohms measurements and zero to

remove any interconnection offset for dc voltage measurements.

AC Voltage and AC Current Measurements:

Set the AC FILTER to 3 Hz: SLOW.

Frequency and Period Measurements:

Set the GATE TIME to 1 sec.

-wire ohms function (4W).

1-22

Chapter 2

General Maintenance

Title Page

Introduction .......................................................................................................... 2-3

Warranty Repairs and Shipping Information ....................................................... 2-3

General Maintenance Information ....................................................................... 2-3

Required Equipment ........................................................................................ 2-3

Power Requirements ........................................................................................ 2-3

Static Safe Handling ........................................................................................ 2-3

Cleaning ............................................................................................................... 2-4

Fuse Replacement ................................................................................................ 2-4

Line-Power Fuse .............................................................................................. 2-4

Current-Input Fuses ......................................................................................... 2-5

If the Meter Does Not Turn On ............................................................................ 2-7

Display Tests ........................................................................................................ 2-7

Disassembly Procedures ...................................................................................... 2-7

General Disassembly ....................................................................................... 2-7

Main Chassis Disassembly .............................................................................. 2-8

Front Panel Disassembly ................................................................................. 2-8

Assembly Procedures ........................................................................................... 2-8

2-1

DMM4040/4050

Technical Reference Manual

2-2

General Maintenance

Introduction 2

Introduction

This chapter provides handling, cleaning, fuse replacement, disassembly, and assembly

instructions for the Meter.

Warranty Repairs and Shipping Information

If your meter is still under warranty, see the warranty information at the front of this

manual for instructions on returning the unit. A Tektronix telephone number and the

website address can be found in the “Contacting Tektronix” section at the front of this

manual.

General Maintenance Information

The following sections describe how to maintain the Meter.

Required Equipment

Equipment required for calibration, troubleshooting, and repair of the Meter is listed in

Table 3-1.

Power Requirements

To avoid electric shock, connect the Meter’s power cord to a

power receptacle with earth ground.

The Meter operates on power distribution standards found throughout the world, and

must be set up to operate on the correct line voltage power it. The Meter is packed ready

for use with a line voltage determined at the time of ordering. If the selected line voltage

does not match the power the Meter will be plugged into, then the Meter’s line voltage

setting must be changed and the line fuse possibly replaced. See the DMM4040 and 4050

Safety and Installation Manual for information on switching the Meter’s line voltage.

If you have not already done so, plug the line cord into the connector on the rear of the

Meter.

Static Safe Handling

All integrated circuits, including surface mounted ICs, are susceptible to damage from

electrostatic discharge (ESD). Modern integrated circuit assemblies are more susceptible

to damage from ESD than ever before.

Integrated circuits today can be built with circuit lines less than one micron thick,

allowing more than a million transistors on a 1/4-inch square chip. These submicron

structures are sensitive to static voltages under 100 volts. This much voltage can be

generated on a dry day by simply moving your arm. A person can develop a charge of

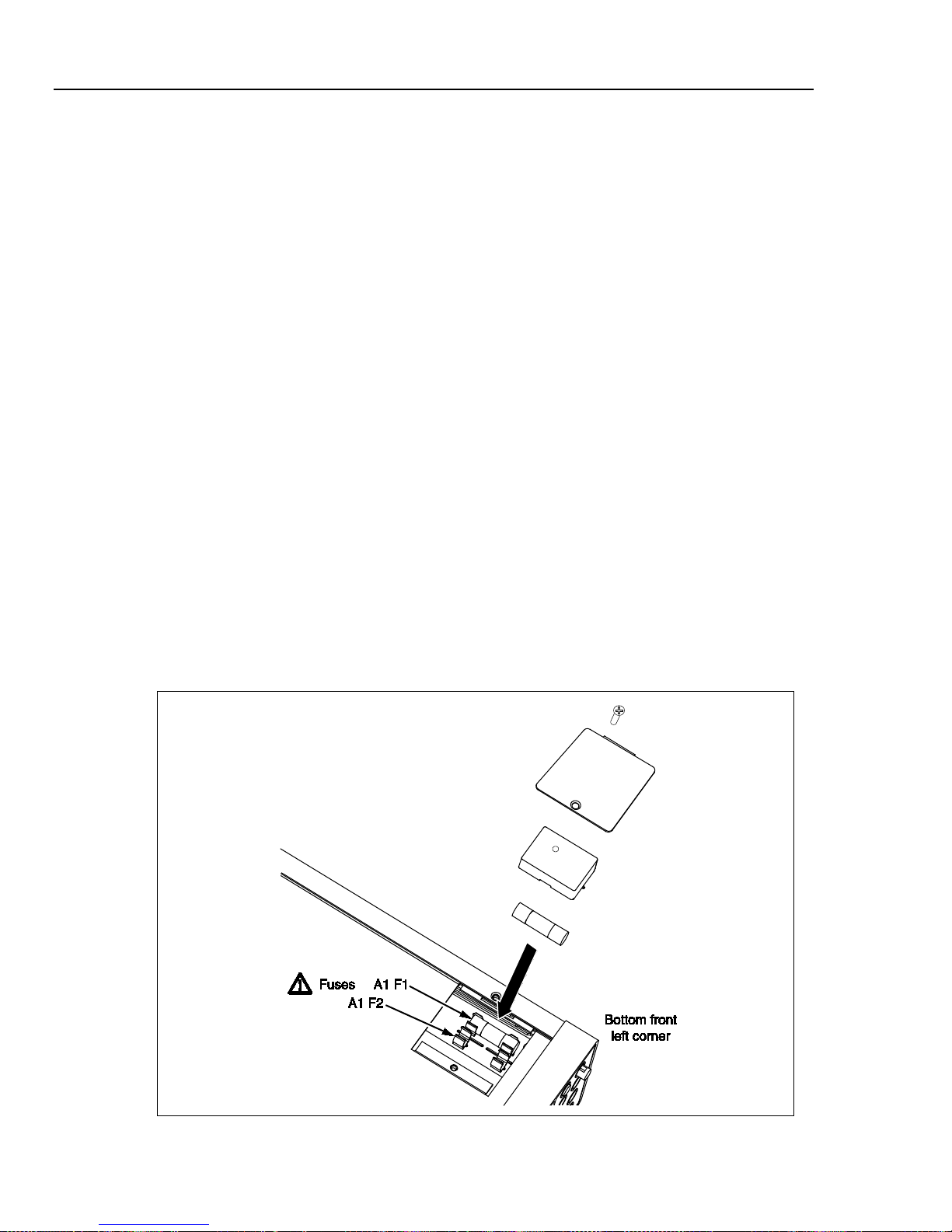

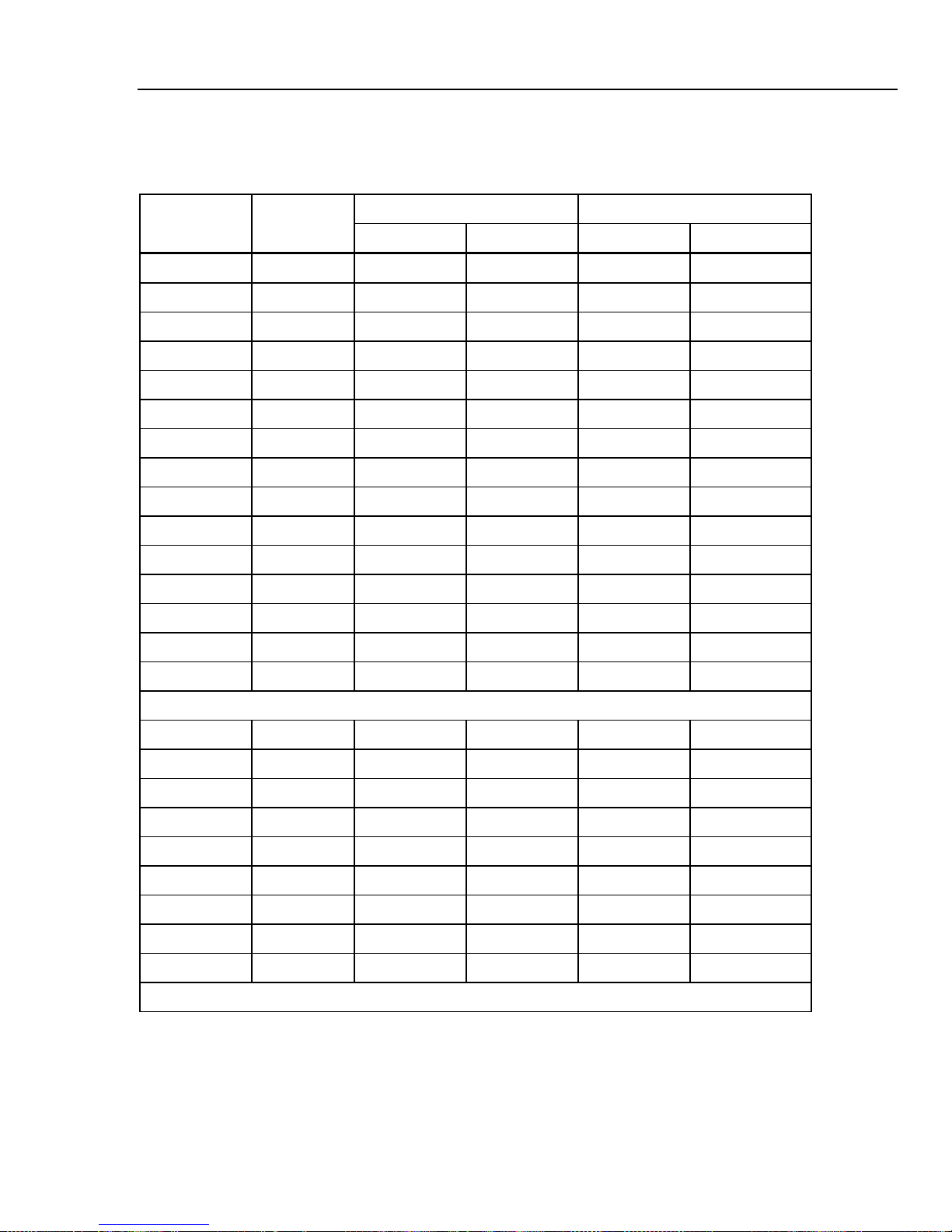

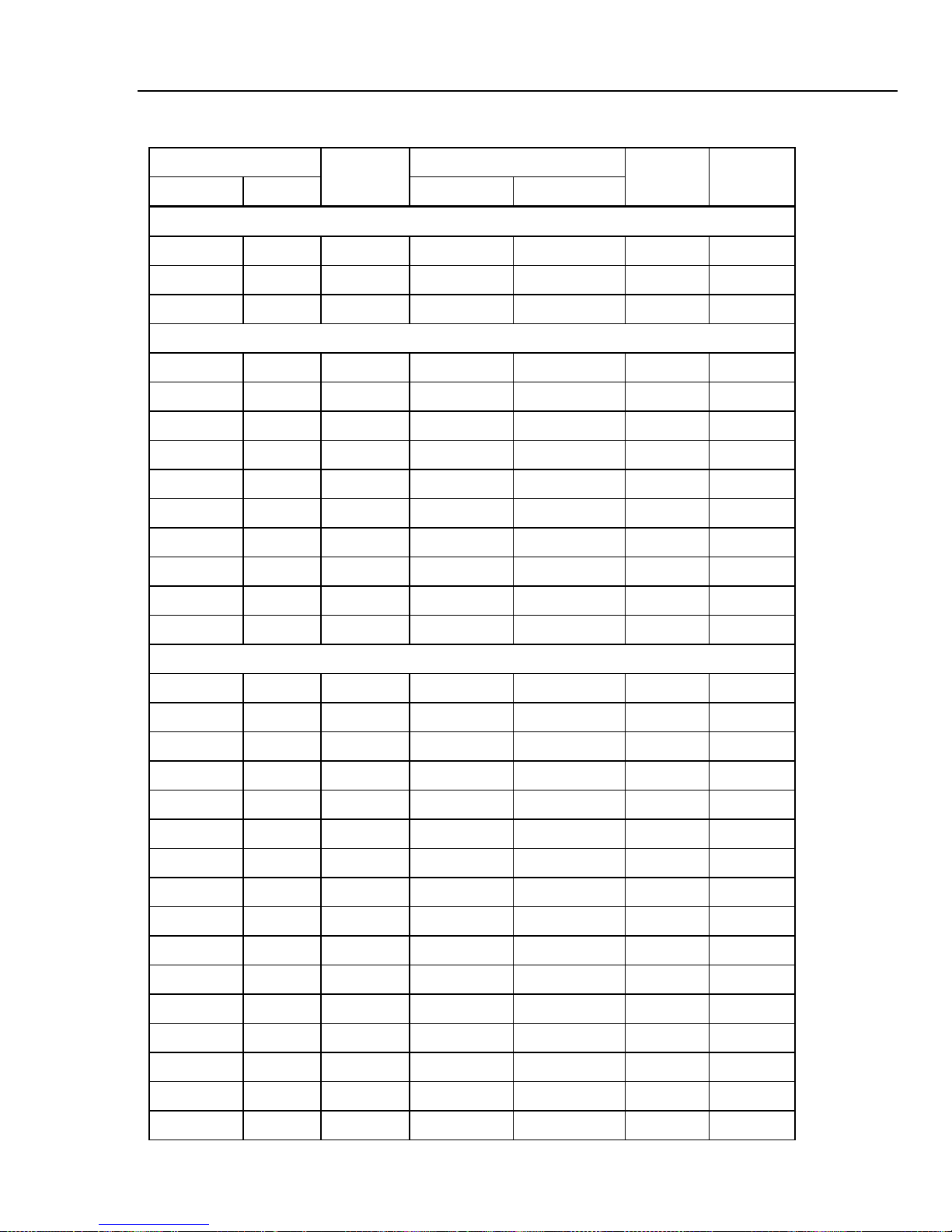

2,000 volts by walking across a vinyl tile floor, and polyester clothing can easily generate