Page 1

Instruction Manual

YT-1 / YT-1S

Chart Recorder

070-6270-04

NOTE: This manual is intended for YT-1/YT-1S

Chart Recorders serial numbers B030500 and

higher, or units that have been upgraded to that

level (to identify upgrade, see page 8-5 and note

frame cutout next to print head). For instruments

with serial numbers B030499 and lower that have

not been upgraded, please contact your local

Tektronix Customer Service Representative for

information regarding module exchange service.

First Printing: Oct. 1998

Page 2

Copyright E Tektronix, Inc. 1998. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and

pending. Information in this publication supercedes that in all

previously published material. Specifications and price change

privileges reserved.

Printed in the U.S.A.

Tektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX, TEK, and YT-1 / YT-1S are registered trademarks of

Tektronix, Inc.

Page 3

WARRANTY

Tektronix warrants that this product will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If any such

product proves defective during this warranty period, Tektronix, at its option,

either will repair the defective product without charge for parts and labor, or will

provide a replacement in exchange for the defective product.

In order to obtain service under this warranty , Customer must notify Tektronix of

the defect before the expiration of the warranty period and make suitable

arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by

T ektronix, with shipping charges prepaid. T ektronix shall pay for the return of the

product to Customer if the shipment is to a location within the country in which

the T ektronix service center is located. Customer shall be responsible for paying

all shipping charges, duties, taxes, and any other charges for products returned to

any other locations.

This warranty shall not apply to any defect, failure, or damage caused by improper

use or improper or inadequate maintenance and care. Tektronix shall not be

obligated to furnish service under this warranty a) to repair damage resulting from

attempts by personnel other than Tektronix representatives to install, repair, or

service the product; b) to repair damage resulting from improper use or

connection to incompatible equipment; or c) to service a product that has been

modified or integrated with other products when the effect of such modification or

integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO

THIS PRODUCT IN LIEU OF ANY OTHER WARRANTIES,

EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS

DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE

PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED

TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE

VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Table of Contents

General Safety Summary

Operator Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary viii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation and Repacking

Unpacking and Initial Inspection ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Source and Power Requirements ix. . . . . . . . . . . . . . . . . . . . . . .

Repacking for Shipment ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Instructions

Instructions for Use 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Replacement 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information and Specifications

Product Description 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standards, Documents, and References Used 2-1. . . . . . . . . . . . . . . . . . .

Characteristics and Specifications 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Performance Checks

Head Alignment Chart Diagnostic and Chart Quality 3-1. . . . . . . . . . . . .

Accessories and Options

Standard and Optional Accessories 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operations

Introduction 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Individual Write Command Operation 5-3. . . . . . . . . . . . . . . . . . . . . . . . .

Individual Read Command Operation 5-5. . . . . . . . . . . . . . . . . . . . . . . . .

Protocol 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface Information 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration

LCD Chart Diagnostic 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Check 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

YT-1 / YT-1S Chart Recorder

v

Page 6

Table of Contents

Maintenance

Required Tools 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part Removal/Replacement 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical 7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 7-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shipping Instructions 7-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Parts

Parts Ordering Information 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Replaceable Parts 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Replaceable Parts 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

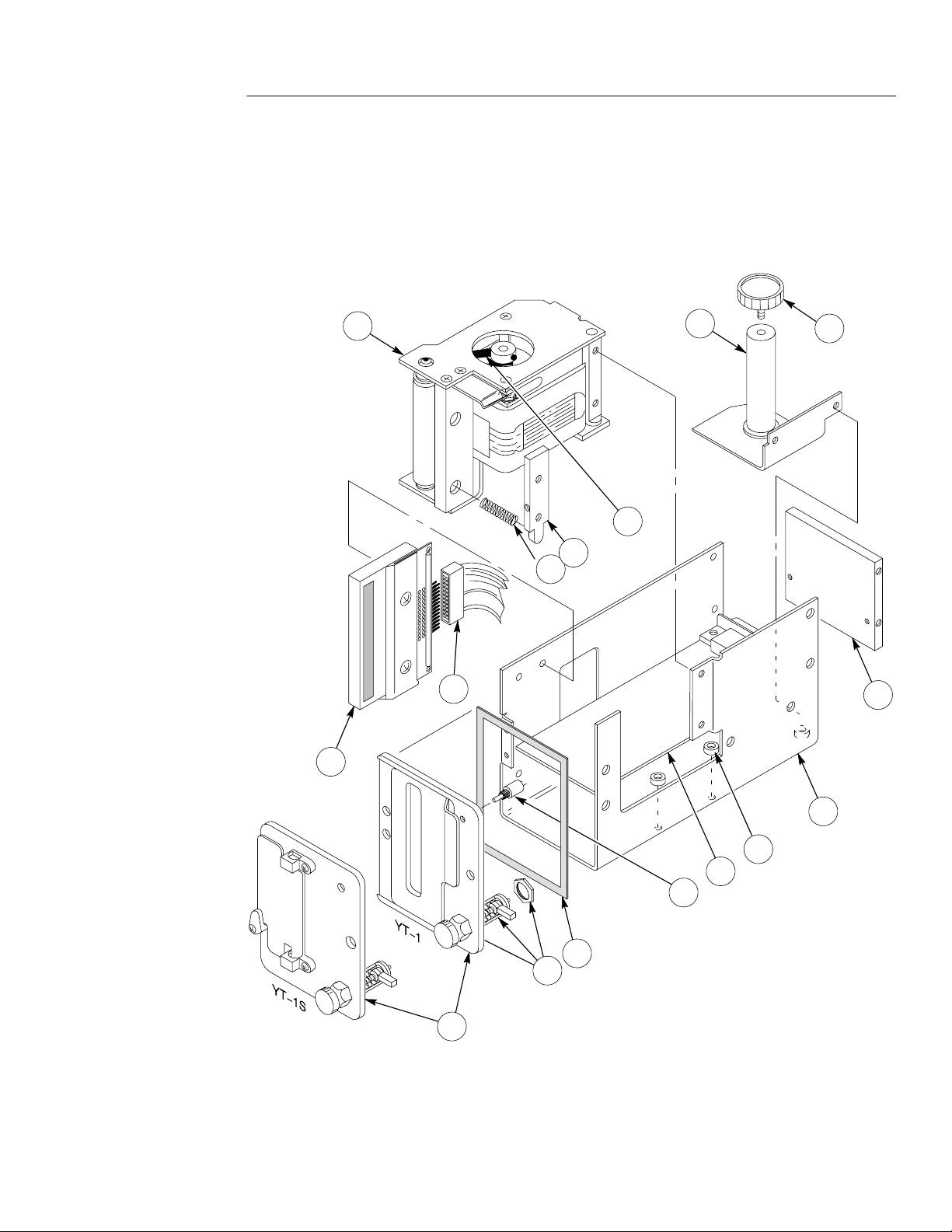

Exploded View Diagram 8-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

YT-1 / YT-1S Chart Recorder

Page 7

General Safety Summary

CAUTION. Do not operate this pr oduct without paper installed, or, if

operating when the paper runs out, shut the power off immediately .

Printing without paper might burn out the printhead.

Operator Safety Summary

Power Sources

This product is intended to operate from a power source supplied by

the parent instrument. Do not attempt to power this module by any

other means.

Grounding the Instrument

This product is grounded through the parent instrument. A protective

ground connection is essential for safe operation.

Danger Arising From Loss of Ground

Upon loss of the protective-ground connection, all accessible

conductive parts (including knobs and controls that appear to be

insulating) can render an electric shock.

Refer to connector changes to qualified service personnel.

Do Not Operate in Explosive Atmospheres

To avoid explosion, do not operate this product in an explosive

atmosphere unless it has been specifically certified for such

operation.

YT-1 / YT-1S Chart Recorder

vii

Page 8

General Safety Summary

Do Not Remove Covers or Panels

To avoid personal injury, do not remove the product covers or panels.

Do not operate the product without the covers and panels properly

installed.

Service Safety Summary

CAUTION. For qualified service personnel only. Refer also to the

preceding Operator Safety Summary.

Do Not Service Alone

Do not perform internal service adjustment of this product unless

another person capable of rendering first aid and resuscitation is

present.

Use Care When Servicing With Power On

Dangerous voltages exist at several points in this product. To avoid

personal injury, do not touch exposed connections and components

while power is on.

Disconnect power before removing protective panels, soldering, or

replacing components.

viii

YT-1 / YT-1S Chart Recorder

Page 9

Installation and Repacking

Unpacking and Initial Inspection

Before unpacking the YT-1/YT -1S from its shipping container or

carton, inspect for signs of external damage. If the carton is

damaged, notify the carrier . The shipping carton contains the basic

instrument and its standard accessories. Refer to the replaceable parts

list for a complete listing.

If the contents of the shipping container are incomplete, if there is

mechanical damage or defect, or if the instrument does not meet

operational check requirements, contact your local Tektronix Field

Office or representative. If the shipping container is damaged, notify

the carrier as well as Tektronix.

The instrument was inspected both mechanically and electrically

before shipment. It should be free of mechanical damage and meet or

exceed all electrical specifications. Procedures to check operational

performance are in the parent instruction service manual. Procedures

to check electrical and mechanical specifications are in the

Calibration section of this manual.

Power Source and Power Requirements

The YT-1/YT-1S is intended to be operated from the parent

instrument’s power supply. A protective ground connection by way

of proper installation in the parent instrument is essential for safe

operation.

Further information on the YT-1/YT-1S power requirements can be

found in the Operator Safety Summary and in the Operator section.

Repacking for Shipment

If the YT-1/YT-1S is to be shipped to a Tektronix Service Center for

service or repair, attach a tag showing the name and address of the

owner, name of the individual at your firm that can be contacted,

complete serial number , and a description of the service required. If

YT-1 / YT-1S Chart Recorder

ix

Page 10

Installation and Repacking

the original packaging is unfit for use or is not available, repackage

the instrument per the instructions near the end of the Maintenance

section in this manual.

x

YT-1 / YT-1S Chart Recorder

Page 11

Operating Instructions

Page 12

Page 13

Operating Instructions

Instructions for Use

Making permanent records with the 1500-Series is easy with the

Tektronix YT-1/YT1-1S Digital Chart Recorder.

CAUTION. Do not operate this pr oduct without paper installed, or, if

operating when the paper runs out, shut the power off immediately .

Printing without paper might burn out the printhead.

1. Make sure the desired waveform (or waveforms) is displayed on

the LCD.

2. Slide back the protective cover on the recorder. Push PRINT on

the front panel of the chart recorder.

3. When the chart recorder has finished, tear off the paper

recording, pulling the paper to the left. You may prefer to close

the door prior to tearing off the chart to facilitate a cleaner tear.

Making chart recordings with the YT-1/YT1-1S will reduce the

charge of the battery pack (if so equipped) in the parent instrument.

Read the appropriate battery information in the parent instrument

Operator section.

Paper Replacement

1. Turn the knurled knob on the front panel of the chart recorder

counter-clockwise until it loosens. Pull the unit from the parent

instrument. Set the YT-1/YT1-1S with the front panel to the right.

2. With your thumbs, push the frame surrounding the motor pulley.

Push until the motor assembly latch locks the motor assembly to

the side frame. This loosens the tension in the paper path,

allowing any remaining paper to be removed.

3. Remove the paper retaining knob. Remove any paper and the

empty paper core.

YT-1 / YT-1S Chart Recorder

1–1

Page 14

Operating Instructions

4. Following the diagram on the top of the recorder, place a fresh

roll of paper in the recorder so the paper unwinds off the right

side of the roll into the paper path (looking down on the recorder,

the paper unrolls clockwise). Tearing the end of the paper roll on

a slant will facilitate placing the paper in the slot.

5. Assure that the paper drops down into the paper path without

binding, and the paper protrudes through the slot in the front of

the instrument. Release the keeper from the frame, and the paper

drive mechanism will return to the operating position.

1–2

YT-1 / YT-1S Chart Recorder

Page 15

General Information and

Specifications

Page 16

Page 17

General Information and Specifications

Product Description

The Tektronix YT-1/YT-1S Chart Recorder is an optional accessory

for a parent instrument (e.g., the 1500B/C-series Metallic Time

Domain Reflectometers). It is designed to plug into the instrument in

the option port.

The YT-1/YT-1S has a water resistant door that covers the record

paper slot.

A chart recording is a permanent record. It can be of great service in

fault interpretation (e.g., a chart recording of a fault can be compared

to that of an acceptable test).

Standards, Documents, and References Used

Terminology used in this manual is in accordance with industry

practice. Abbreviations are in accordance with ANSI Y1.1-1972,

with exceptions and additions explained in parentheses in the test.

Graphic symbology is based on ANSI Y32.2-1975. Logic symbology

is based on ANSI Y32.14-1973 and manufacturer’s data books or

sheets. A copy of ANSI standards may be obtained from the Institute

of Electrical and Electronic Engineers, 345 47th Street, New York,

NY 10017.

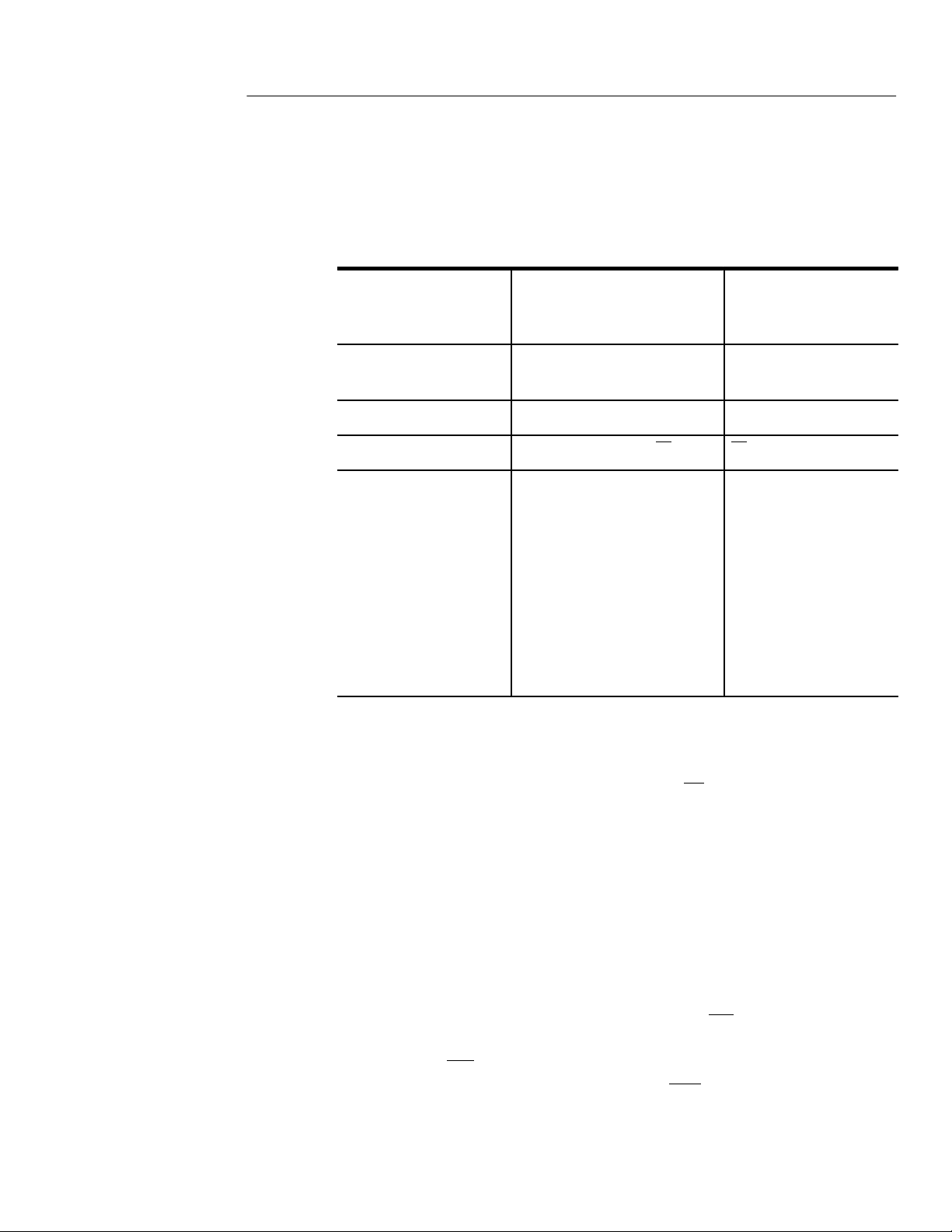

Characteristics and Specifications

The tables on the following pages list the electrica characteristics

and features that apply to the Tektronix YT-1/YT -1S Chart Recorder

when it is installed in a Tektronix 1500B/C-series TDR instrument

and after a 20 minute warm-up.

The Performance Requirement column describes the limits of the

characteristic and Supplemental Information column describes

features and typical values or information that might be helpful.

YT-1 / YT-1S Chart Recorder

2–1

Page 18

General Information and Specifications

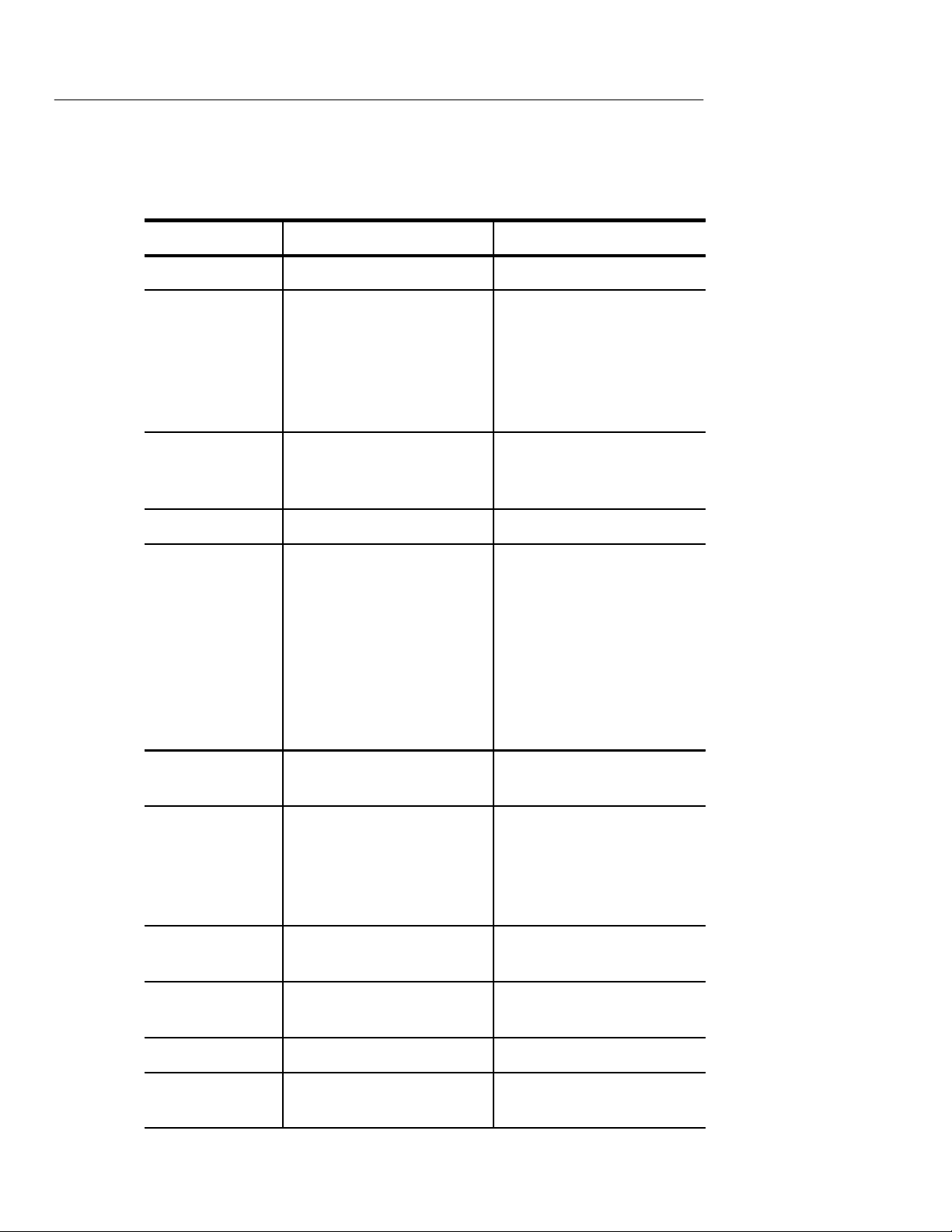

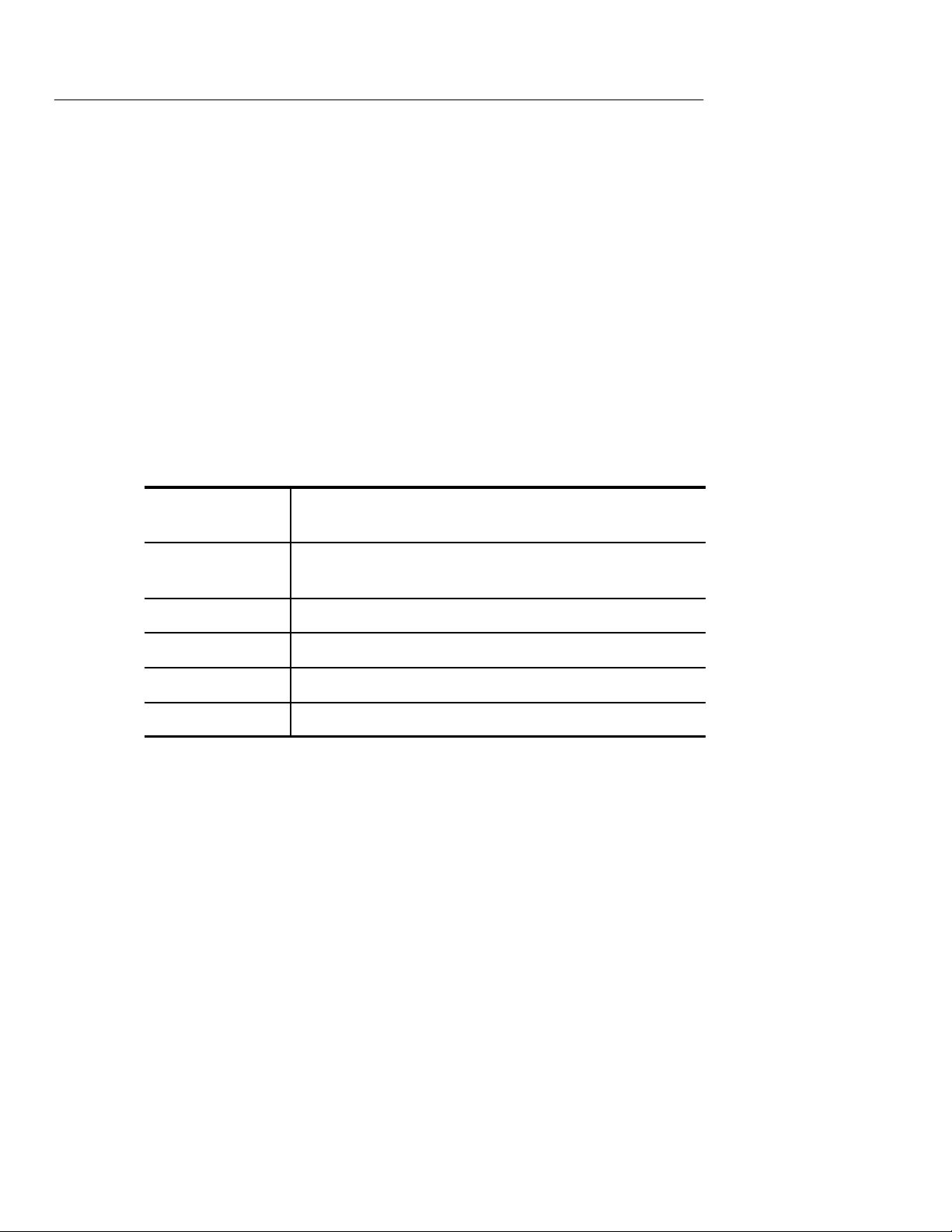

Printing Specifications

Characteristic Performance Required Supplemental Infor.

Writing method Direct thermal

Chart paper Roll type, 50mm. Outside

dia. 50mm max. Accept

15mm spindle. Thermal

coating facing inside roll.

Will allow recorder to meet

print density spec.

End-of-roll warning

Print color Black

Print density Solid black print pattern

Shall be marked by a red

line beginning 5 ft. from the

end of the roll.

shall measure at 1.1D on

Kodak Gray Scale.

Example: See Tektronix

part number in Accessories

section.

Pattern created by printing

40 element blocks three

times each until a 360 bit

wide by at least 200 bit long

(45mm by 25mm min.)

image is formed. Density

measurement made with an

appropriate Densitometer.

Patten print at 25°C ± 5°C.

2–2

Background density

Print drop-outs No more than 1% of the

Print element

width

Addressable print

elements

Print field width 48mm

Alignment of print

field

Less than 0.2 D when

stored at 70°C for 24 hours.

elements to be printed shall

fail to print. Adjacent failures shall number three or

less.

0.125mm

384 (48 8-bit bytes)

Entire print field must lie on

paper.

YT-1 / YT-1S Chart Recorder

Page 19

General Information and Specifications

Characteristic Supplemental Infor.Performance Required

Orthogonality of

print field

Paper movement

per ADVANCE

command

Record length 10.87 to 12.76 inches Algo-

Print time Typical 20 seconds Algo-

Power Specifications

A line printed across the

paper shall be perpendicular to the edge of the paper

within 1.0 degrees.

0.125mm, ± 0.01mm

rithm dependent

rithm dependent.

Characteristic Performance Required Supplemental Infor.

+5 Volts +5V ± 5%, 500mW max Power is applied to recorder

only while it is operating.

+16 Volts +16 Volts ± 10%. Average

Power = 12W max. Peak

current not to exceed 1.7A.

Mechanical Characteristics: YT-1/YT-1S plugs into the parent

instrument Option Port.

YT-1 / YT-1S Chart Recorder

2–3

Page 20

General Information and Specifications

Environmental Specifications: Apply when chart recorder is properly

installed in a 1500B/C-series TDR Option Port.

Temperature:

Operating

Non-operating

Humidity:

Operating

Non-operating

Altitude

Operating

Non-operating

Vibration 5 to 15Hz, 0.7g

Shock 30g, 11ms 1/2 sine wave-

–10°C to +55°C

–62°C to +85°C

0 to 100% RH, excluding

condensing

0 to 100% RH, including

condensation

To 15,000 ft above sea level

To 40,000 ft above sea level

MIL-T-28800C

15 to 25Hz, 1.3g

25 to 55Hz, 3.0g

form three shocks in each

direction on each axis.

Prolonged exposure to

temperatures above 70°C

might cause thermal paper

to darken.

Shock or vibration greater

than1g may cause temporary trace discontinuity.

Salt atmosphere 48 hours, 20% solution. Per

MIL-T-28800C.

Electromagnetic

compatibility

Electrostatic discharge

Water resistance Splash-proof and drip-proof

When operated in host

instrument, unit meets the

following requirements of

MIL-STD-461A: CE02,

CE04, CS02, CS06, RE02,

RE02.1, RS03, RS03.1.

3kV to 20kV, Tekronix standard 062–2862–XX

2–4

YT-1 / YT-1S Chart Recorder

Page 21

Operator Performance Checks

Page 22

Page 23

Operator Performance Checks

The following checks will confirm if the YT-1/YT-1S is operating

according to specification. They are found in the Chart Diagnostics

Menu in the Diagnostics Menu of the parent instrument.

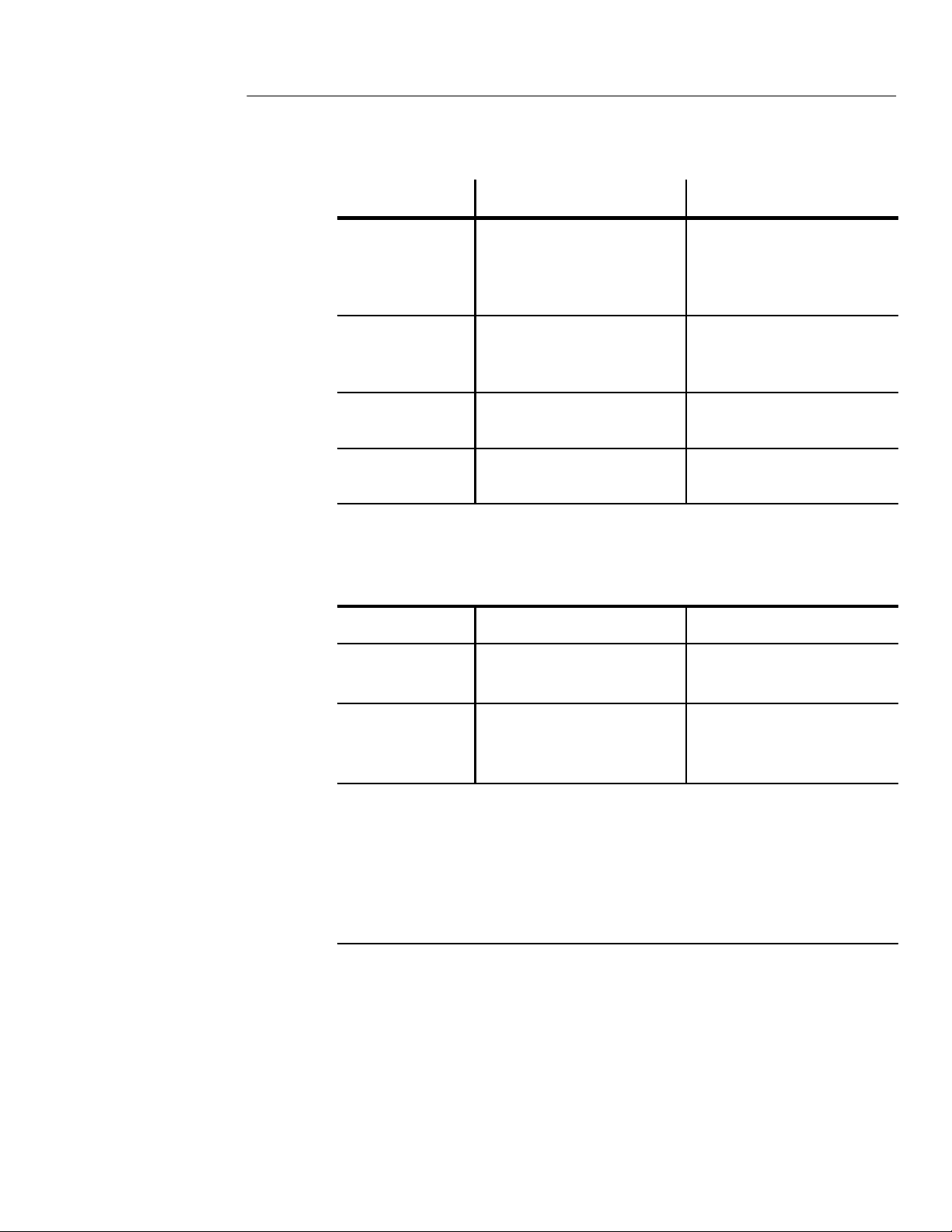

Head Alignment Chart Diagnostic

This test gives the chart recorder a rapid feed test as well as a test for

print dropouts, feed spacing, and alignment of the head. If the

YT-1/YT-1S is not operating properly, symptoms may include pixel

drop-out, washed-out print, ‘‘titled’’ chart, chart off the page, or

improper or erratic speed.

Chart Quality

1. Access the Head Alignment chart in the Chart Diagnostics menu

located under the Diagnostics Menu of the parent instrument.

2. Press MENU. The diagnostic chart that is printed should look like

the figure below and must meet the following criteria:

SOLID LINES

Equally Spaced Wide LinesEqually Spaced Narrow Lines

6 Inches 6 Inches

12 INCHES

a. The total chart from first printed line to last printed line

must measure between 10.87 to 12.76 inches.

YT-1 / YT-1S Chart Recorder

3–1

Page 24

Operator Performance Checks

b. There must be between 5.43 to 6.38 inches of narrow

spaced lines on the chart.

c. There must be between 5.43 to 6.38 inches of wide spaced

lines on the chart.

d. Fold the paper in half at the last narrow line. The two

halves of the chart should be equal in length.

e. The entire diagnostic should be printed within the

boundaries of the paper .

f. All vertical lines should be perpendicular relative to the

top and bottom of the chart within 1°.

g. The three solid vertical lines on the chart must be

complete with no missing dots.

h. All lines on the chart must be legible with no fading,

smearing, or irregularities in print blackness.

If your test chart does not meet the above criteria, send your chart

recorder and include the test chart.

3–2

YT-1 / YT-1S Chart Recorder

Page 25

Accessories and Options

Page 26

Page 27

Accessories and Options

Standard Accessories

Accessory Tektronix Part Number

Chart paper, single roll 006–7647–00

Optional Accessories

Accessory Tektronix Part Number

Chart paper, 25–roll quantity 006–7677–00

Chart paper, 100–roll quantity 006–7681–00

Options

There are no options for the YT-1/YT-1S Chart Recorder

YT-1 / YT-1S Chart Recorder

4–1

Page 28

Accessories and Options

4–2

YT-1 / YT-1S Chart Recorder

Page 29

W ARNING

The following servicing instructions are for use only by

qualified personnel. To avoid injury, do not perform any

servicing other than that stated in the operating instructions

unless you are qualified to do so. Refer to all safety

summaries before performing any service.

Page 30

Page 31

Theory of Operations

Page 32

Page 33

Theory of Operations

Introduction

The YT-1/YT-1S Chart Recorder is to be used with a parent

instrument, such as the 1502B/C or 1503B/C Time Domain

Reflectometer. This manual contains information on the YT-1/YT -1S

only. For related information on the parent instrument, see Option

Port Interface in the Circuit Description section of respective service

manual.

The YT-1/YT-1S consists of a drive motor assembly, a thermal

printhead, and an electronic circuit board.

More information can be found in the Specification section of this

manual. A block diagram of the Option Port can be found in the

parent manual in the Circuit Description section. See the following

figure for the block diagram of the YT-1/YT-1S Chart Recorder.

Controller Board

To

Option

Port

J1

6

Power

and

Ground

6

8

1

Interrupt

Switch

Address

and

Control

Data

Motor Assembly

Motor

Control

1

3

Decode

and

Control

1

Data

Latch

4

Status

3

2

1

1

Serial Word

Load

1

Power and

2

Ground

J3

4

1

7

J2

Drive Motor

Control

Printhead

Thermal Print

Assembly

Thermal

Printhead

YT-1 / YT-1S Chart Recorder

5–1

Page 34

Theory of Operations

Circuit Description

BitĆMap (Data Matrix) Operation

Bit-Map Description

Bit–map operation permits the host to control the 384 individual bits

(48 bytes) that make up the recorder print field. This allows any

combination of dots to be printed including alpha-numerical

characters and graphics. All print data should be sent in the form of

bytes (1 byte = 8 bits). The state of the dots printed is controlled by

the state of the data bits sent by the host to the recorder. A ‘‘0’’ will

turn an element off and a ‘‘1’’ will turn an element on when a row is

printed. The bit-mapping is done on rows of the page. There are 8

rows per millimeter and 48 bytes per row. The resolution is thus

1/8mm across the page.

Bit-Map Operation

The recorder uses a thermal printhead with 384 individual elements

(48 bytes). The bytes of digital data are shifted through the printhead

from left to right. As the new bytes of data are shifted in by the host,

the old bytes remaining from the previous line of print data are

shifted out one by one. To replace all the old data bytes with new

ones the host must completely refill the printhead each time a new

line is to be printed. If the host does not completely refill the

printhead with a new line of data before printing, the remaining old

data will be printed out with the new data. The new data will also be

shifted to the left of its proper print field.

The host should never attempt to turn on more than 25% of the dots

in the print field at one time. If the host’s desired pattern requires the

energizing of more that 25% of the dots on a single line, the solution

is to divide the pattern into smaller parts. These smaller parts can

then be loaded and printed one at a time until the complete pattern is

printed. The host can then move on to the next line of print data by

advancing the paper . Bits will be turned on as shown:

5–2

YT-1 / YT-1S Chart Recorder

Page 35

Theory of Operations

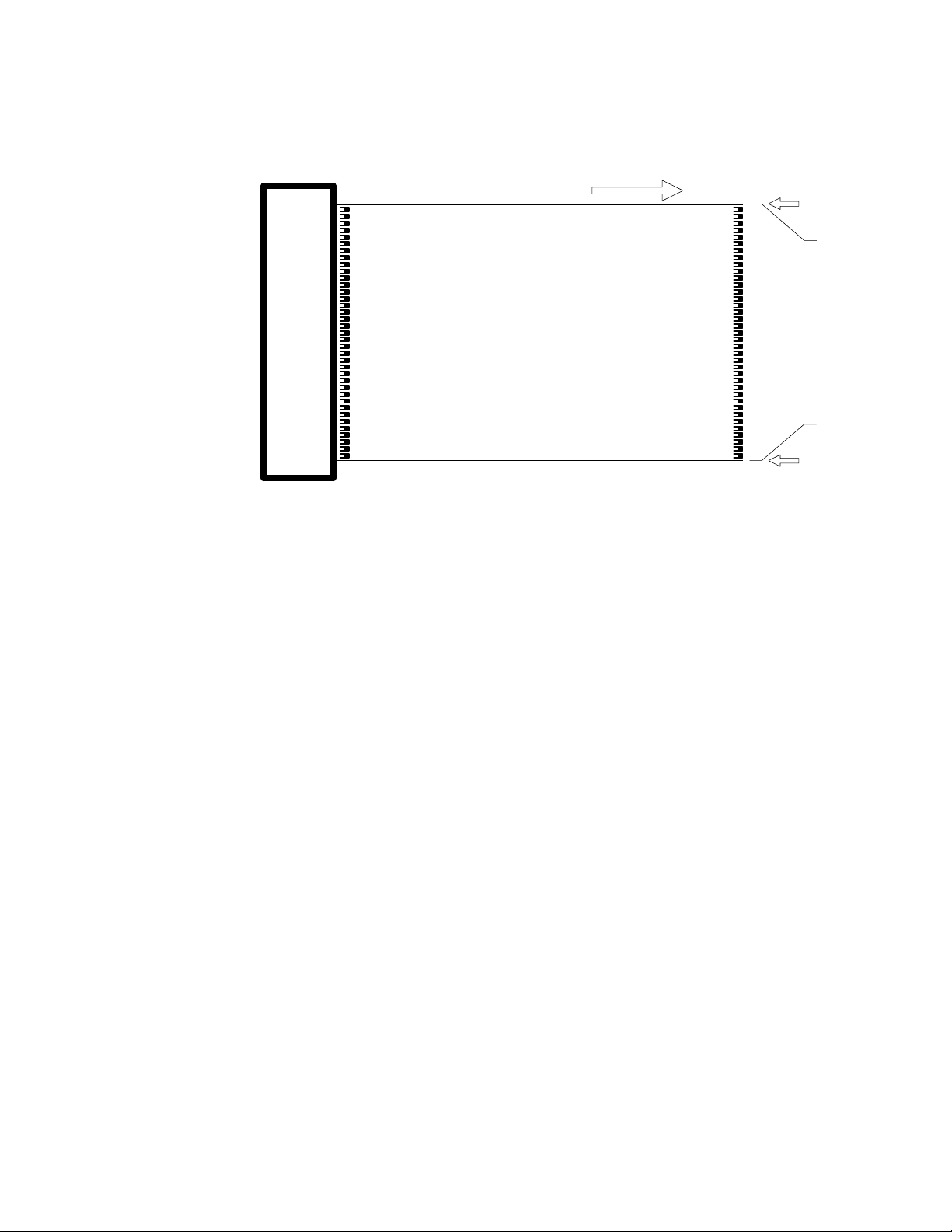

Direction of Paper Travel

Thermal Paper

Thermal

Printhead

Printed side of paper

Individual Write Command Operation

Load a Byte of Print Data

BYTE 1 on

this side

48 bytes wide

Host usable print field

BYTE 48 on

this side

When this write command operation is used the recorder will take

the data byte (8 bits) that the host has placed on the data bus and

shift it out to the recorder printhead. This command should only be

used when the recorder is ready to accept data (i.e. the Accept Data

status line D5 = 1). Use of this command will cause the Accept Data

status line to be disabled (D5 = 0). This status line will not be

re-enabled until the recorder is ready to accept another data byte. No

byte should be sent until this line goes high again (D5 = 1).

Latch a Line of Print Data

This write command operation should precede the print command.

When the host has completely finished loading the printhead with

data this command is used to latch that data into the printhead so that

it can be printed. This command should only be used when the

recorder is not printing or shifting data (i.e., both Print Ready and

Accept Data status lines are high D6 = 1, D5 = 1). Sending this

command while either of these status line is disabled could cause

faulty data to be printed out.

YT-1 / YT-1S Chart Recorder

5–3

Page 36

Theory of Operations

Print a Line of Data

This write operation causes the line of print data that the host has

loaded and latched into the printhead to be printed. This command

should only be used when the recorder is ready to print (i.e., the Print

Ready status line D6 = 1). This host should never attempt to turn on

more that 25% of the dots in the print field at one time. If the host’s

desired pattern requires the energizing of more than 25% of the dots

on a single line, the solution is to divide the pattern into smaller

parts. These smaller parts can then be loaded and printed one at a

time until the complete pattern is printed. The host can then move on

to the next line to print data by advancing the paper.

Advance Paper One Line

This write command operation causes the recorder to advance the

paper one line (1/8mm). This command can be used after printing to

move to the next print line or can be used without having printed to

create a blank line or print leader. This command should only be

used when the recorder is ready to advance (i.e., the Advance Ready

status line D4 = 1). Sending this command while the status line is

disabled will disrupt the recorder’s stepper motor and cause erratic

motor action to result.

5–4

Print a Line and Advance Paper One Line

This write command operation combines the print and advance

commands previously discussed. Upon receiving this command the

recorder will print the current line of print data and advance the

paper to the next line. This command should only be used when the

recorder is not printing or advancing the paper (i.e., both Print Ready

and Advance Ready status lines are high D6 = 1, D4 = 1). Sending

this command before the recorder is ready could cause printing errors

or erratic motor action.

Reset Recorder to Quiescent State

This write command resets the recorder to a quiescent state waiting

for the host to send a command. After reset the host should still

check the status lines before sending a command to insure the

recorder is ready.

YT-1 / YT-1S Chart Recorder

Page 37

Individual Read Command Operation

Read Recorder Identify Code

This read command operation allows the host to identify the recorder

and insure that it is properly inserted into the host unit. The recorder

has an identify code of (01H).

Read Recorder Status Codes

This read command operation allows the host to insure that the

recorder is ready to accept the desired command. The host must

always wait until the recorder is ready before sending a command.

By checking the corresponding status line or lines the host can

determine recorder readiness. There are status lines for Ready to

Print (D6), Ready to Advance (D4), Ready to Accept Data (D5), and

Recorder Fault (D7). Only send commands when the recorder is

ready.

Theory of Operations

Protocol

Introduction

This protocol is designed for the Tektronix YT-1/YT -1S bit map only

thermal dot matrix recorder.

The Tektronix YT-1/YT -1S chart recorder produces a hard copy

record on thermally activated paper of data provided through a

parallel digital interface. The bit map (dot matrix) data is provided

one byte at a time (1 byte = 8 bits) line by line (1 print line = 48

bits). This allows any combination of dots to be printed including

alpha-numeric characters and graphics. Each dot corresponds to one

element of a thermal printhead with a resolution of 200 dots per inch

(8 dots per mm). Printing is achieved by energizing the individual

elements of the printhead.

YT-1 / YT-1S Chart Recorder

5–5

Page 38

Theory of Operations

Interface Information

The YT-1/YT-1S chart recorder communicates to the host system via

the host’ s address and data bus. The interface includes four address

lines, eight data lines, one interrupt line, and three control lines. All

interface lines are 74HC compatible.

Inputs and Outputs

The following signal descriptions apply to the host-to-recorder

interface. Refer to the following table for pin designations (see

Interface Pin Structure).

A0 – A3 (INPUT): Address lines from the host for the read and write

operations to the recorder (all lines active high).

D0 – D7 (INPUT): Bidirectional data lines for the read and write operations

to the recorder (all lines active high).

(INPUT): Recorder select line from the host (active low).

(INPUT): Data read line from the host (active low).

(INPUT): Data write line from the host (active low).

(OUTPUT): Interrupt request line from the recorder (active low).

Interface Pin Structure

The interface pin structure table along with the associated waveforms

are in the Maintenance section of this manual. A 25-pin male D-shell

connector is used on the recorder . Information about the operation of

these pins is available under Option Port Interface in the Circuit

Description section of the 1502B and 1503B Service manuals.

5–6

YT-1 / YT-1S Chart Recorder

Page 39

Theory of Operations

Interface Characteristics

Characteristic Performance Required Supplemental Info

Connector 25-pin male D-shell (Holm-

berg HYM25A28AP or

equiv.)

Protocol As defined under heading:

Protocol

Logic Interface 74HC CMAS or equiv.

Print Initiation Ground Closure on IR IR = Pin 7

Command

Execution Times Print

Command

2.5ms typical. Measure from

time command sent to time

BUSY flag clears.

Advance

Load Data Byte

Latch Printhead Data

4ms typical

< 5µs typical

< 5µs typical

General Interrupt Operations

The recorder generates an interrupt request (IR

) each time the record

push button is depressed. This signal is active low. This signal does

not disable communication between the host and the recorder, thus

allowing read and write operations to continue even though an

interrupt request has been received.

General Command Operations

All commands are sent from the host to the recorder over the address

interface bus (A0 - A3). All commands are accompanied by a low

strobe of the recorder select line from the host (RS

). All read

commands are accompanied by a low strobe of the data read line

from the host (RD

strobe at the date write line from the host (WR

). All write commands are accompanied by a low

).

YT-1 / YT-1S Chart Recorder

5–7

Page 40

Theory of Operations

Read Command Operations

The recorder has the following read command operations:

Address 0H Identify code for recorder (Recorder = 01H)

Address 1H Status codes for recorder

Address 2H – FH Not used by recorder

The status code bits are formatted as follows:

D0 – D3 Not used by recorder

D4 Indicates recorder ready to accept advance command;

0 = Recorder not ready

D6 1 Indicates recorder ready to accept print command;

0 = Recorder not ready

D7 0 Indicates recorder fault exists;

1 = No fault exists

Write Command Operations

The recorder has the following write command operations:

Address 0H Reset recorder to quiescent state

Address 1H Advance paper one line with no printing

Address 2H Load a byte of print data (8 bits)

Address 3H Latch a line of print data

Address 4H Print a line and advance the paper one line

Address 5H Print a line with no advance of paper

5–8

Address 6H – FH Not used by recorder

YT-1 / YT-1S Chart Recorder

Page 41

Calibration

Page 42

Page 43

Calibration

The YT-1/YT-1S Chart Recorder has no electrical adjustments, and

few mechanical adjustments. Since the mechanical adjustments are

done at the factory, they are not included in the Calibration section.

The mechanical adjustments can be found in the Maintenance

section. The Performance Check will determine whether or not the

instrument is operating according to published specifications.

The YT-1/YT-1S Chart Recorder Performance Check is accomplished via a diagnostic test on the parent instrument (1500B/C-series)

LCD Chart Diagnostic

Technically this is not a diagnostic, but for assistance in troubleshooting, temporary adjust of the printing characteristics, and a

back-up for the PRINT push button.

For information on the troubleshooting aspects of LCD Chart, see the

Maintenance section of this manual.

The printing characteristics of the YT-1/YT-1S are designed to

provide chart recordings in environmental extremes under varying

conditions. If it does become necessary to change the chart

characteristics, it is possible from the front panel of the 1500B/C-series instrument.

The thermal printhead of the YT-1/YT-1S has 384 print elements.

Because of power economy, not all of the elements are turned on at

the same time. When printing, only 40 elements (or dots) of the

printhead are activated at a time. Forty dots equals a segment. If it is

intended to make the dots darker, elements can be turned on more

than once, analogous to a ‘‘double-strike’’ on a mechanical printer.

1. Using MENU and POSITION, access LCD chart in the Chart

Diagnostics menu.

YT-1 / YT-1S Chart Recorder

6–1

Page 44

Calibration

2. When adjusted, the left Vp knob will adjust the number of dots

the YT-1/YT-1S will print per segment, ranging from 13 to 41.

The effect of this adjustment is subtle.

3. When adjusted, the right Vp knob will adjust the number of prints

or ‘‘strikes’’ per segment. This adjustment is quite dramatic,

resulting in a much darker or lighter chart, and a corresponding

change in printer speed.

0.00 ft

auto

O

O

O

ac

F

F

F

F

F

F

When the parent instrument POWER is turned on, the printing

characteristics will default to 40 elements per segment and one print

per segment.

6–2

YT-1 / YT-1S Chart Recorder

Page 45

Calibration

This diagnostic also takes the place of the PRINT push button. If the

button should become defective, simply run the LCD chart

diagnostic and current screen will be printed.

Paper Skew

If the paper tends to run up to the top or down to the bottom of the

paper exit slot of the recorder, the paper skew may need adjustment.

Symptoms include information printed off the top or bottom of the

page and paper jamming.

Occasionally the paper may skew after the paper has been replaced.

This is due to improper setting of the paper in the feed path. This

will usually clear itself after a couple of charts. If it does not, the

paper still skews after a minimum of two charts, the paper guide

would be adjusted.

If the YT-1/YT-1S did not pass the Head Alignment Chart diagnostic,

refer to the Maintenance section of this manual.

Performance Check

The following checks will confirm if the YT-1/YT-1S is operating

according to specification. They are found under ‘‘Chart Diagnostics

Menu’’ in the ‘‘Diagnostics Menu’’.

Head Alignment Chart Diagnostic

This test gives the chart recorder a rapid feed test as well as a test for

print dropouts, feed spacing, and alignment of the head. If the

YT-1/YT-1S is not operating properly, symptoms may include pixel

drop-out, washed-out print, ‘‘tilted’’ chart, chart off the page, or

improper or erratic speed.

Chart Quality

1. Access Head Alignment chart in the Chart Diagnostics menu

located under Diagnostics Menu of the parent instrument.

2. Press MENU. The diagnostic chart that is printed must meet these

criteria:

YT-1 / YT-1S Chart Recorder

6–3

Page 46

Calibration

a. The total chart from first printed line to last printed line

must measure between 10.87 to 12.76 inches.

b. There must be between 5.43 to 6.38 inches of narrow

spaced lines on the chart.

c. There must be between 5.43 to 6.38 inches of wide spaced

lines on the chart.

d. Fold the paper in half at the last narrow line. The two

halves of the chart should be equal in length.

e. The entire diagnostic should be printed within the

boundaries of the paper .

f. All vertical lines should be perpendicular relative to the

top and bottom of the chart within 1 degree.

g. The three solid vertical lines on the chart must be

complete with no missing dots.

h. All lines on the chart must be legible with no fading,

smearing, or irregularities in print blackness.

SOLID LINES

Equally Spaced Wide LinesEqually Spaced Narrow Lines

6 Inches 6 Inches

12 INCHES

6–4

YT-1 / YT-1S Chart Recorder

Page 47

Maintenance

Page 48

Page 49

Maintenance

This section contains information of preventive and corrective

maintenance, troubleshooting, and shipping instructions.

CAUTION. We recommend that service be performed at an authorized

Tektronix Service Center, or by a technician skilled in digital

sampling techniques. The cir cuit board has SMT devices that require

special equipment to replace. If found defective, we recommend that

the ECB be replaced as an entire unit. We have included a majorparts/connectors locator as an aid to assist in troubleshooting.

Required Tools

This is a list of common tools needed to accomplish the maintenance

procedures that follow.

Oscilloscope (Tektronix 5440 or equivalent)

Option Port extension cable (174–0950–00)

3/8 inch hex nutdriver

1/2 inch hex nutdriver

0.050 hex wrench

Phillips head screwdriver

Straight blade screwdriver

Long-nosed pliers

Cotton swabs

Preventive Maintenance

Preventive maintenance includes cleaning and visual inspection. A

convenient time to perform preventive maintenance is during the

periodic performance check/calibration procedure. If the instrument

has been subjected to extreme environments or harsh handling, more

frequent preventive maintenance may be necessary.

YT-1 / YT-1S Chart Recorder

7–1

Page 50

Maintenance

Cleaning

CAUTION. Do not use chemical cleaning agents that contain benzene,

toluene, xylene, acetone, etc., because of possible damage to plastics

in the instrument.

The outside chassis and front panel should be cleaned gently with a

damp cloth.

The interior of the YT-1/YT-1S is protected from dirt and dust as

long as it is installed in the option port and the print door is closed.

However, if interior cleaning is necessary, blow off accumulated dust

with low-pressure air, and remove remaining dirt with a soft brush,

cotton swab or pipe cleaner moistened with isopropyl alcohol. The

paper must be removed before cleaning with alcohol.

The thermal printhead can be cleaned with a soft cotton swab dipped

in a little alcohol. Latch the motor assembly out of the way, remove

the paper, and carefully clean the printhead by swabbing the surface.

Any of the surfaces that are in the paper path should also be cleaned.

Lubrication

No lubrication is necessary. It is recommended, however, that the

YT-1/YT-1S be cleaned on a regular basis.

Visual Inspection

Obvious defects such as broken connectors, damaged board, frayed

cables, improperly seated components and heat-damaged components should be corrected first before attempting further troubleshooting. Heat damage usually indicates a deeper problem

somewhere in the circuitry, and should be traced and corrected

immediately.

We do not recommend electrical checks of individual components

because defective components will become evident during

instrument operation.

7–2

YT-1 / YT-1S Chart Recorder

Page 51

Re-calibration

After maintenance has been performed, the instrument should be

checked per procedures explained in the Calibration section of this

manual.

Parts Removal/Replacement

The YT-1/YT-1S can be disassembled by following these directions

in order. It can be assembled by reversing the order.

Front Panel Plate

1. Remove the three mounting screws (one on the right side of the

panel and two on the left) which secure the front panel to the

frame.

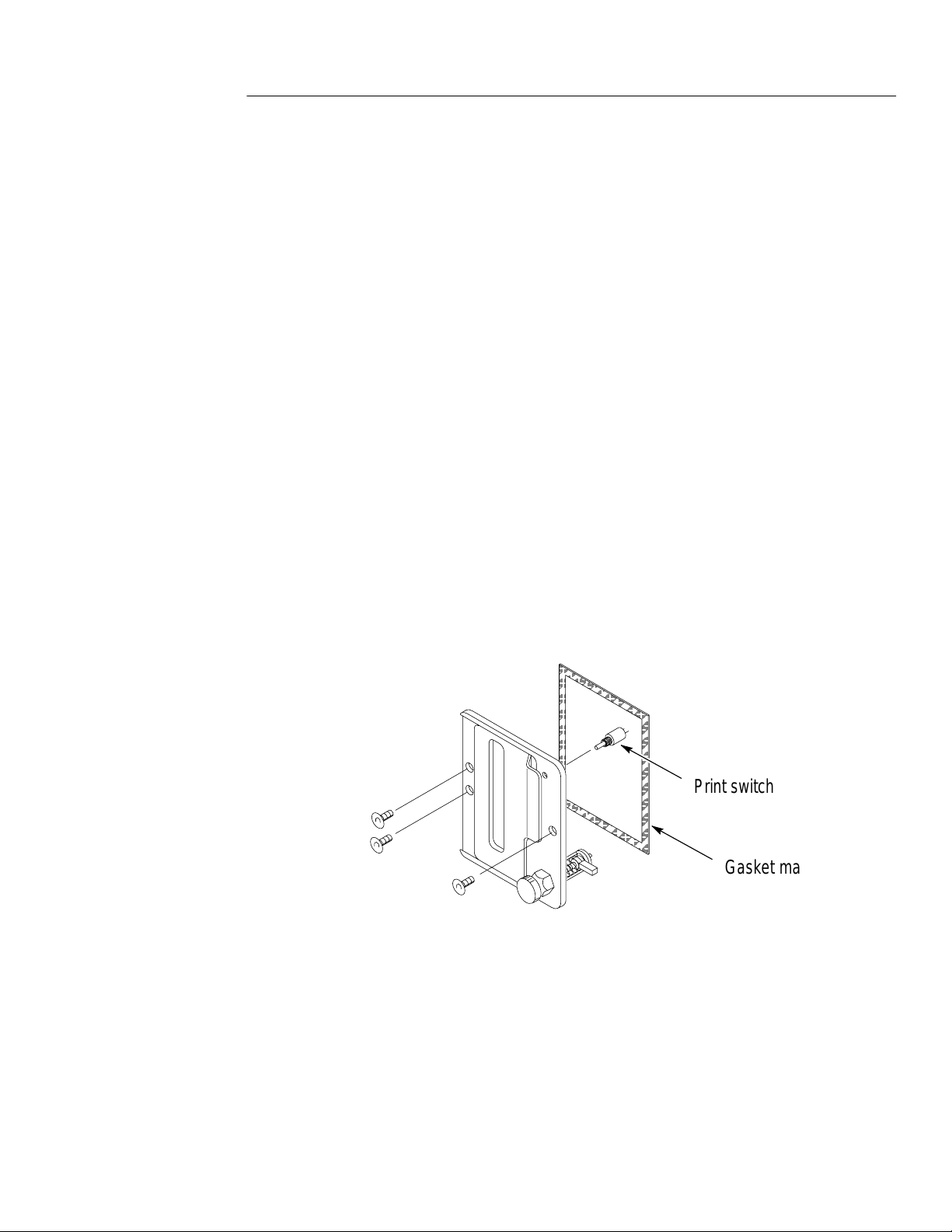

Maintenance

2. Remove the Print switch from the upper right corner of the front

panel (use care to not pull the wires loose from this switch).

Print switch

Gasket material

3. Inspect gasket material and replace if necessary (use Dow

Corning 3140 or equivalent to coat mating surface of gasket).

Paper Retaining Mandrel

4. Remove the two mounting screws on the right side panel that

attach the paper retaining mandrel assembly.

YT-1 / YT-1S Chart Recorder

7–3

Page 52

Maintenance

5. Remove the mandrel from the recorder .

Chart Drive Motor Assembly

6. Remove the two compression springs between the forward

support strut and motor drive assembly.

Drive

Motor

Springs

Compression

7. Remove the two mounting screws that hold the motor drive

assembly to the right side panel. They are located near the middle

of the right side panel.

7–4

YT-1 / YT-1S Chart Recorder

Page 53

Maintenance

8. With a long-nosed plier or screwdriver, remove the wire harness

connector from the ECB socket. Avoid scratching the printhead.

9. Remove the motor assembly through the top of the case.

Thermal Printhead

10.Remove the four mounting screws that attach the thermal

printhead to the left side panel.

Printhead

11. Carefully disconnect the thermal printhead from the ECB. Use an

IC puller or a long-nosed plier.

Controller Board

12.Remove three ECB mounting screws, washers and standoffs.

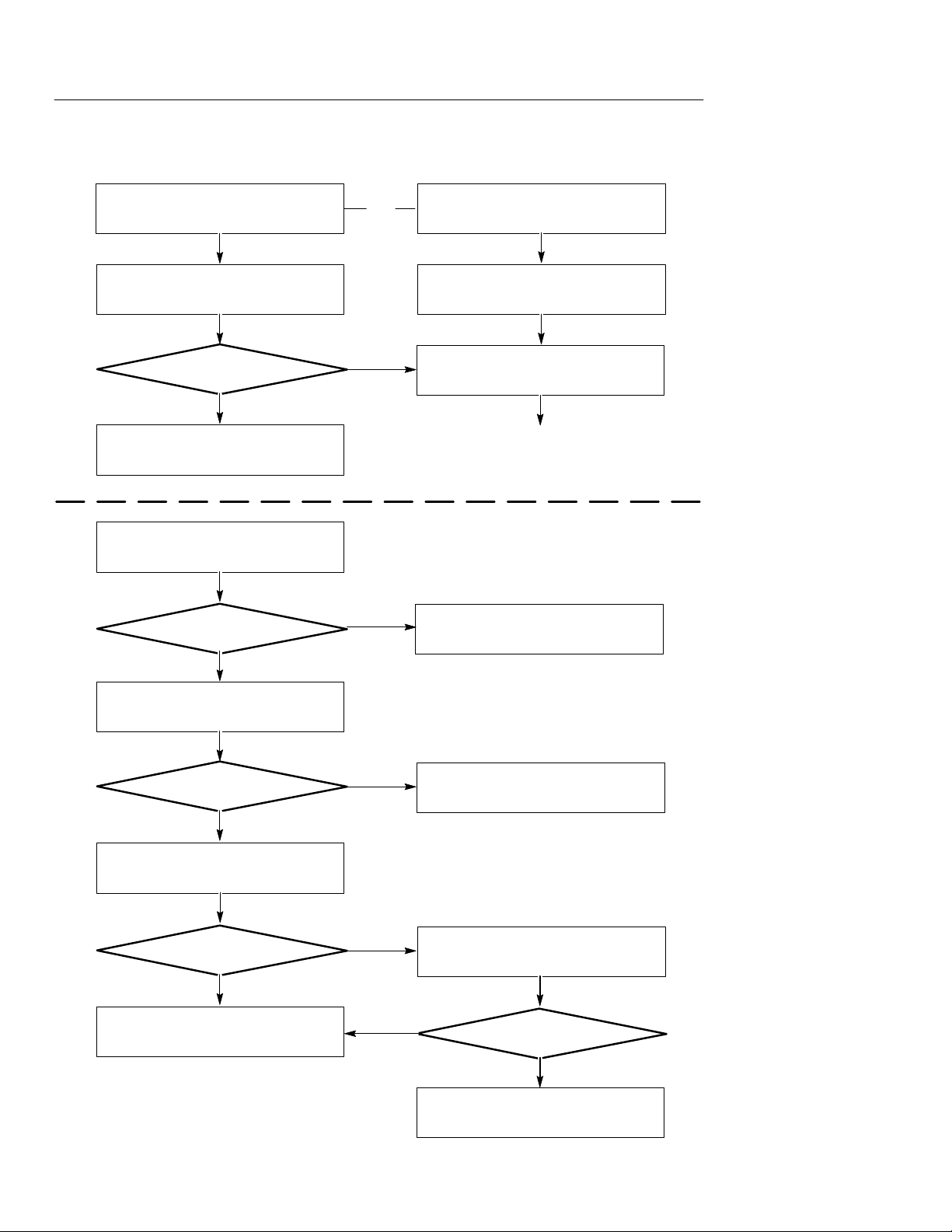

T roubleshooting

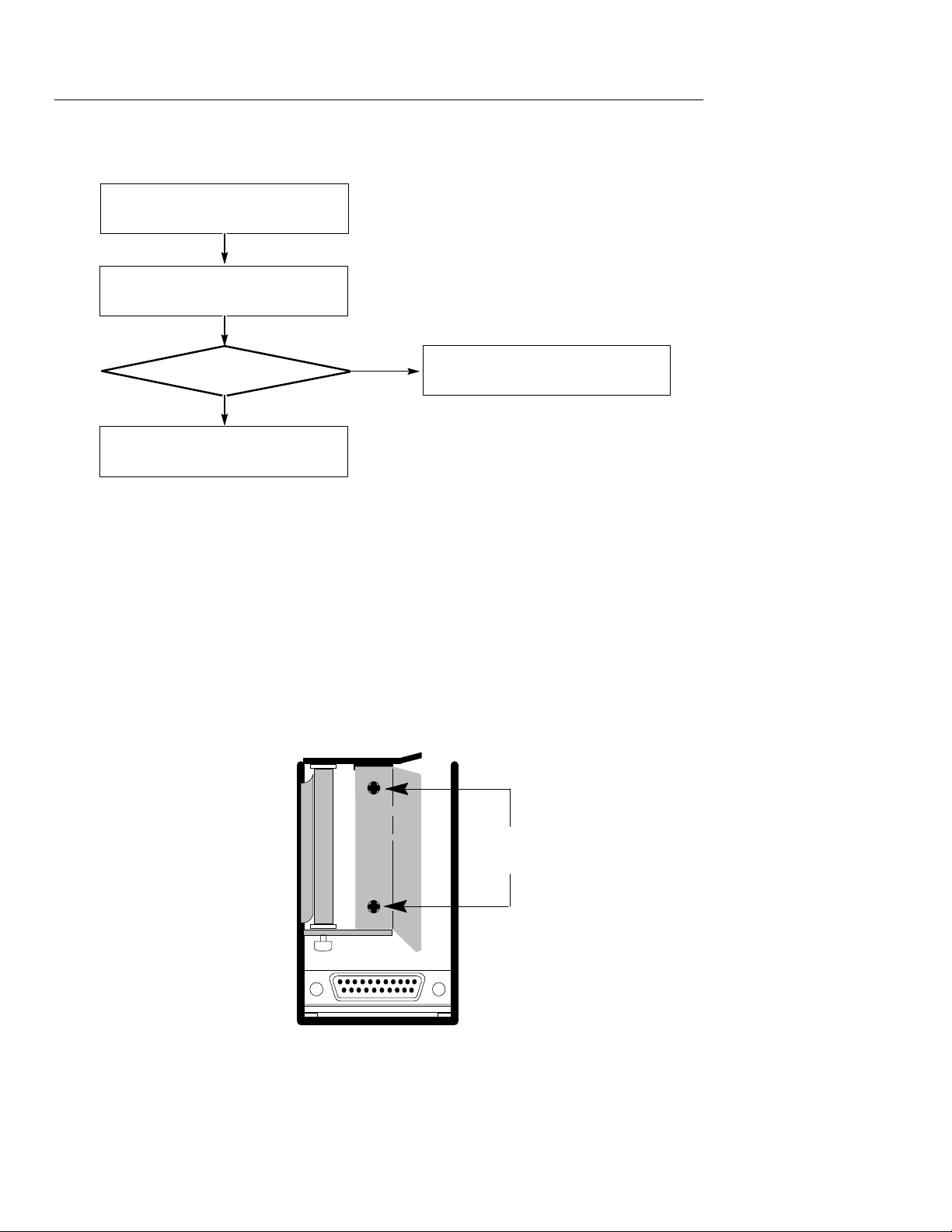

Troubleshooting Flow Charts

The following charts are provided to aid you in troubleshooting

electrical and mechanical problems with the YT-1/YT-1S. Additional

information follows the flow charts.

Nut

Spacer

ECB

Case

Back

Case

Bottom

YT-1 / YT-1S Chart Recorder

7–5

Page 54

Maintenance

Paper skews up or down when printer is

operated

Run recorder at least four times to allow

the paper to realign

Is it correct now ?

NO

See the paper skew adjustment in

the maintenance section

Instrument shuts down when PRINT

button is pressed

Is unit running off of

battery?

OR

YES

YES

Print is not square with the paper

See the orthogonality adjustment in

the maintenance section

Unit functions

Be sure the battery is charged or

use AC power

NO

Unplug J2

Unit still shuts down when

PRINT is pressed

YES

Plug J2 back in and unplug J3

Unit still shuts down when

PRINT is pressed

YES

Run recorder at least four times to allow

the paper to realign

NO

NO

YES

Replace the print head assembly

Measure resistance between P3.1 & P3.2

and between P3.3 & P3.4

Is resistance approx 10 ohms

NO

Replace the motor assembly

7–6

YT-1 / YT-1S Chart Recorder

Page 55

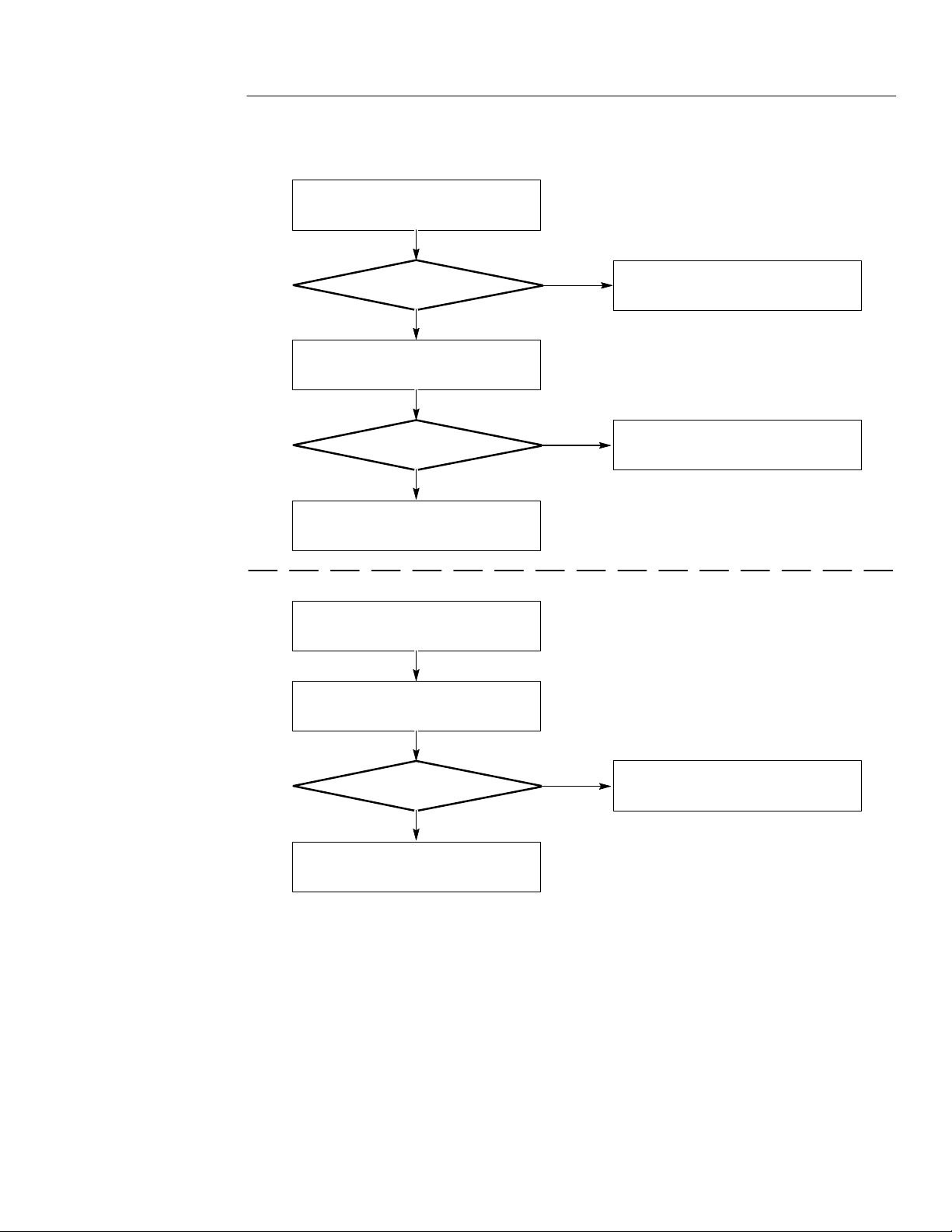

Motor advances but there is no print

Maintenance

Is the paper installed

correctly ?

YES

Check voltages and waveforms on

J2 on the ECB

Are they correct ?

YES

Replace the printhead assembly

The paper will not advance

Measure resistance between P3.1 & P3.2

and between P3.3 & P3.4

NO

Install the paper correctly

NO

Replace the ECB assembly

Is the resistance approx

10 ohms?

NO

Replace the motor assembly

YT-1 / YT-1S Chart Recorder

YES

Replace the ECB assembly

7–7

Page 56

Maintenance

Data garbled on the paper

Check voltages and waveforms on

Replace the printhead assembly

Mechanical

Paper Skew Adjustments

1. To adjust the paper guide, first remove the back panel, then the

paper and the paper retaining mandrel (see Part Removal/Replacement in this section).

J2 on the ECB

Are they correct ?

YES

NO

Replace the ECB assembly

7–8

Skew

Adjustment

2. The two screws holding the paper guide onto the motor assembly

must be loosened slightly (not too much!). Position the paper

guide as follows:

YT-1 / YT-1S Chart Recorder

Page 57

3. Paper Skews Downward

a. Move the top of the paper guide slightly away from the

printhead side of the instrument.

b. Tighten the two paper guide screws and replace the paper

retaining mandrel and the paper .

c. Run a minimum of two Print Head Alignment chart

diagnostics and check for proper paper tracking.

4. Paper Skews Upward

a. Move the top of the paper guide slightly closer from the

printhead side of the instrument.

b. Tighten the two paper guide screws and replace the paper

retaining mandrel and the paper .

Maintenance

If necessary, repeat the above procedure to fine tune the skew.

Electrical

ECB Inputs and Outputs

Accessing Connectors

To access J2 and J3, remove the ECB from the recorder. Disassemble

the chart recorder . Reconnect all wiring. Attach the Option Port

extension cable to the parent instrument’ s Option Port. Connect one

end of the cable to J2010 on the parent instrument Main Board and

the other end to J1 on the YT-1/YT-1S ECB.

c. Run a minimum of two Print Head Alignment chart

diagnostics and check for proper paper tracking.

YT-1 / YT-1S Chart Recorder

7–9

Page 58

Maintenance

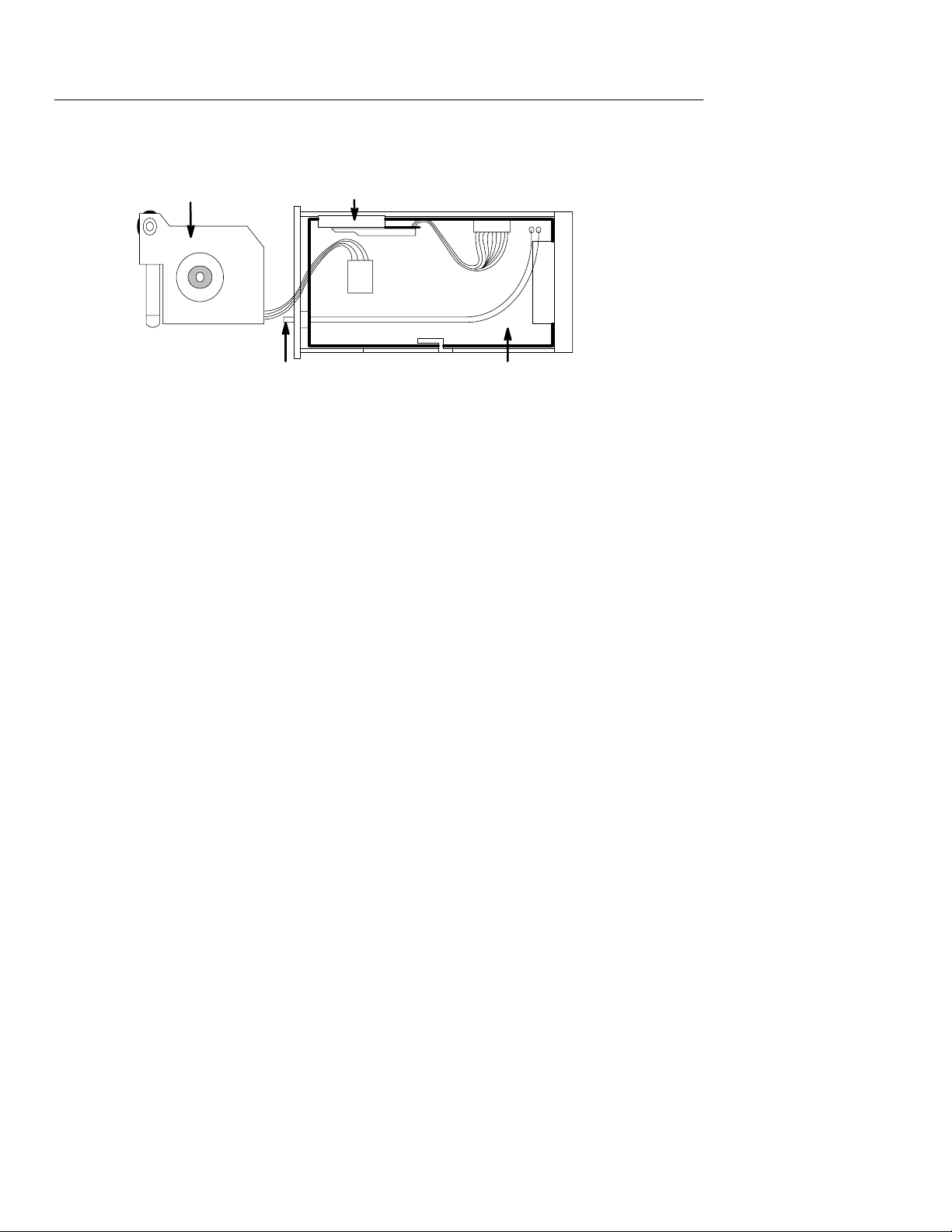

Motor

Printhead

J2

J3

J1

Chart Recorder CCASwitch

The illustration above shows the connector locations in the

YT-1/YT-1S. Each connector and the signals that should be found on

them are described in the following paragraphs and tables.

J1 on ECB – Data and Voltage Input

The Option Port Diagnostic creates a repeating pattern of signals at

the option port connector to allow service technicians to verify that

all signals are present and working correctly. This test does not

generate any output to the LCD display.

There are two ways to terminate this diagnostic: hold down the

MENU button until the Option Port menu reappears, or momentarily

pull the line low.

The purpose of the diagnostic is to exercise the data and control lines

at the option port by creating a repeating pattern of signals that can

be easily observed with an oscilloscope. The pattern on all data lines

is the same and the pattern on the four address lines is also the same.

Although the exact patterns on the read, write and enable lines vary,

the repetition interval is the same for all patterns (about 15

microseconds). The active low trigger line (pin14 on the 25-pin ‘‘D’’

connector) is unused in the diagnostic. The function of the line can

be tested by momentarily grounding it to exit the diagnostic and

return to the Option Port menu.

7–10

YT-1 / YT-1S Chart Recorder

Page 59

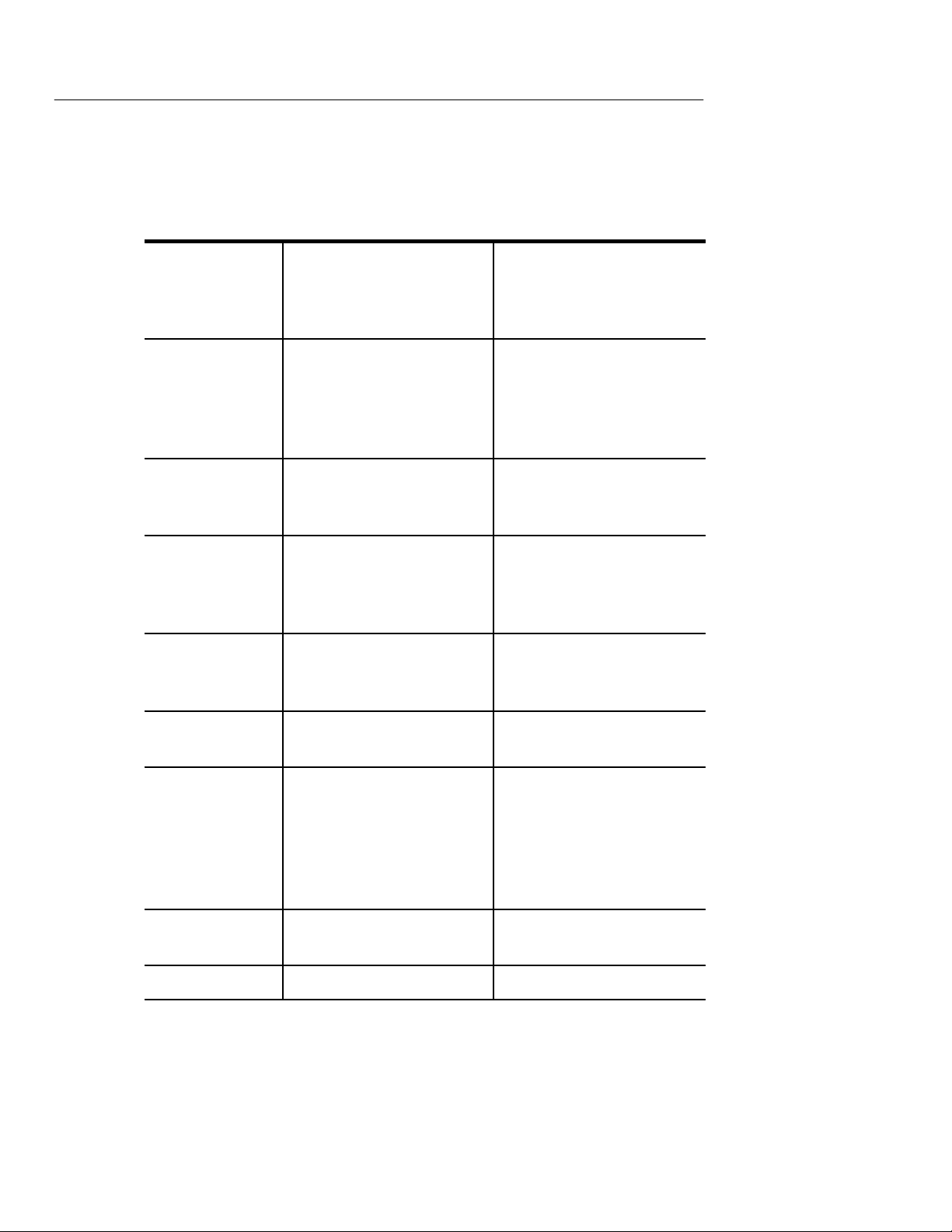

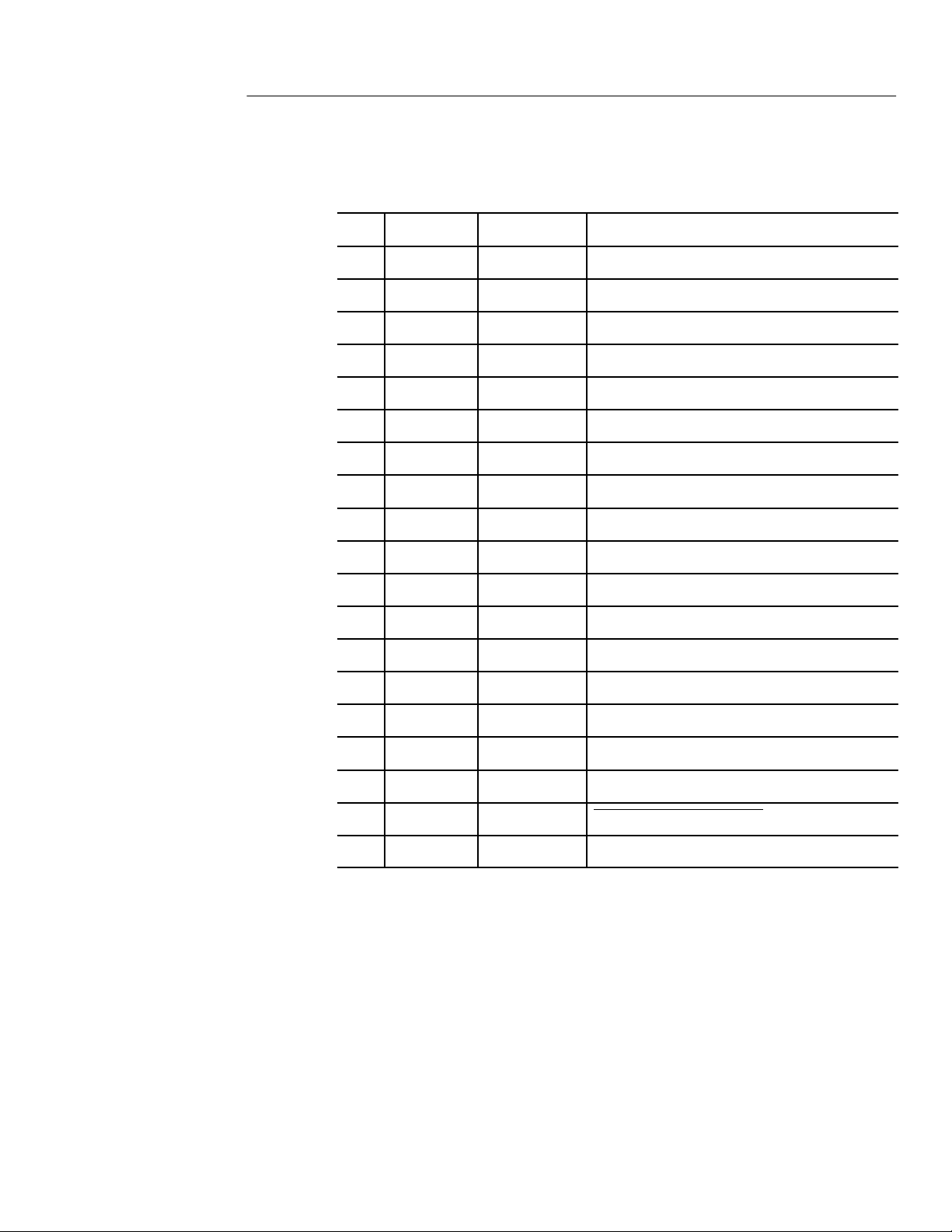

Pin In/Out Designation Function (Status)

25

In/Out D2 Data Line 2 (active high)

24 In/Out D3 Data Line 3 (active high)

23 In/Out D4 Data Line 4 (active high)

22 In/Out D5 Data Line 5 (active high)

21 In/Out D6 Data Line 6 (active high)

20 In/Out D7 Data Line 7 (active high)

19 Input A0 Address Line 0 (active high)

18 Input A1 Address Line 1 (active high)

17 Input A2 Address Line 2 (active high)

16 Input A3 Address Line 3 (active high)

Maintenance

15 –––– Reserved Reserved for host

14 –––– Reserved Reserved for host

13 Input +16 V +16 VDC Power (motor/print)

12 Input +16 V +16 VDC Power (motor/print)

11 –––– 16 V Return 16 VDC Return (Power GND)

10 –––– 16 V Return 16 VDC Return (Power GND)

9 Input +5 V +5 VDC Power (Logic)

8 –––– 5 V Return 5 VDC Return (logic GND)

7 Output IR INTERRUPT REQUEST (active low)

6 Not used

YT-1 / YT-1S Chart Recorder

7–11

Page 60

Maintenance

J2 on ECB – Thermal Printhead Output

Pin In/Out Designation Function (Status)

5

Input RS RECORDER SELECT (active low)

4 Input RD DATA READ (active low)

3 Input WR DATA WRITE (active low)

2 In/Out D0 Data Line 0 (active high)

1 In/Out D1 Data Line 1 (active high)

J2, Pin No. Data Present

1 +5 VDC ± 0.5 V

2 +16 VDC ± 1.5 V

3 +16 VDC ± 1.5 V

4 +5 VDC ± 0.5 V

5 Ground

6 Ground

7 5 V 500Hz Square Wave

8 5 V 500Hz Square Wave

9 5 V Data Stream

10 5 V Data Stream

11 5 V Data Stream

12 No connection

13 +5 VDC ± 0.5 V

14 +5 VDC ± 0.5 V

7–12

YT-1 / YT-1S Chart Recorder

Page 61

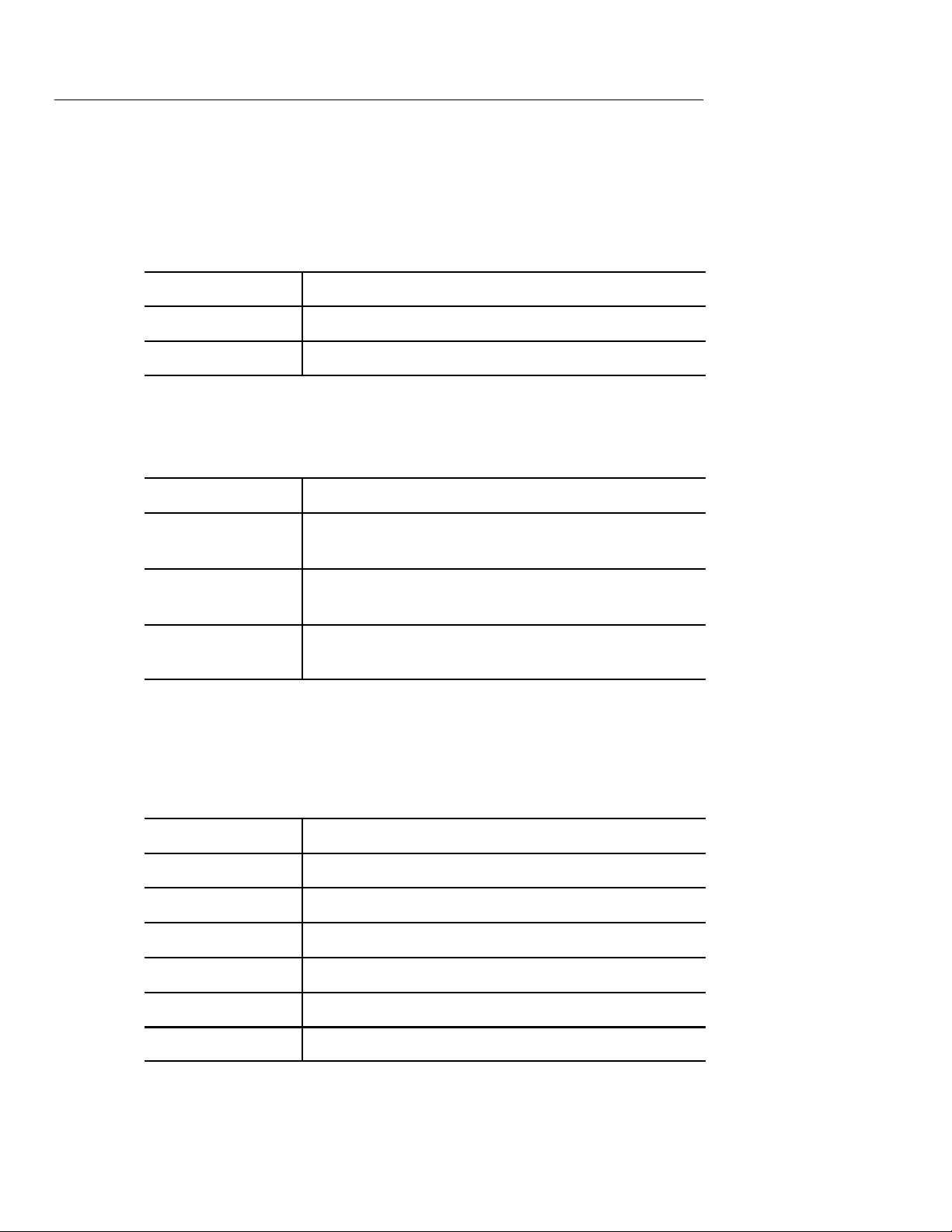

J3 on ECB – Motor Drive Connector

J3, Pin No. Data Present

1 16 V Data Stream

2 16 V Data Stream

3 16 V Data Stream

4 16 V Data Stream

Shipping Instructions

If possible, reuse the original packaging materials. If this is not

possible, use a carton with inside dimensions of no less than six

inches for cushioning materials, or obtain a shipping carton from an

authorized Tektronix Service Center.

Maintenance

Shipping Carton Test Strength

Gross Weight (lb) Carton Test Strength (lb)

0 – 10 200

10 – 30 275

30 – 120 375

120 – 140 500

140 – 160 600

1. Surround the instrument with polyethylene sheeting to protect the

finish of the instrument.

2. Cushion the instrument on all sides by tightly packing dunnage or

urethane foam between carton and instrument, allowing three

inches on all sides.

3. Seal carton with shipping tape or industrial stapler .

YT-1 / YT-1S Chart Recorder

7–13

Page 62

Maintenance

7–14

YT-1 / YT-1S Chart Recorder

Page 63

Replaceable Parts

Page 64

Page 65

Replaceable Parts List

This section contains a list or replaceable modules in the

YT-1/YT-1S. Use this list to identify and order replacement parts.

Parts Ordering Information

Replacement parts information is available from your Tektronix

Service Center or representative. Parts can be ordered through your

local Tektronix field office.

Changes to Tektronix instruments are sometimes made to accommodate improved components as they become available, and to provide

benefit of the latest circuit improvements developed by our

engineers.

When ordering parts, include the following information:

H Part number

H Instrument type or model number

H Instrument serial number

H Instrument modification number (if applicable)

Module Replacement

The YT-1/YT-1S is serviced by replacing defective modules. There

are three options you should consider:

Module Exchange

In some cases you may exchange the defective module for a

re-manufactured module. Re-manufactured modules cost significantly less than new modules, and meet the same factory specifications.

For more information about the module exchange program, call

1-800-832-3814.

YT-1 / YT-1S Chart Recorder

8–1

Page 66

Replaceable Parts

Module Repair

You may ship the defective module to Tektronix for repair. We will

repair and return the same module to you.

New Modules

New modules can be purchased like other replacement parts.

Using the Replaceable Parts List

The tabular information in the parts list is arranged for easy use.

The parts list is indented to indicate item relationships. The

following is an example of the indentation system used in the Name

and Description column:

Assembly and/or component

. Detail part of assembly or component

.. Parts of detail part

Abbreviations conform to American Nation Standards Institute

(ANSI) standard.

Tektronix Part Number

Use the part number when ordering a replacement part from

Tektronix.

Serial/Model No.

These columns show the serial numbers of the first and last

instruments in which a part was used. No entry in these columns

indicates that the part is used in all instruments.

Name and Description

In the parts list, an item name is separated from its description by a

color (:). Because of space limitations, an item name by be

8–2

YT-1 / YT-1S Chart Recorder

Page 67

Replaceable Parts

incomplete. For more name identification, refer to the U.S. Federal

Cataloging Handbook H6–1.

Mfr. Code and Mfg. Part Number

These columns list the code number of the manufacturer of the part,

and the manufacturer’s part number for the part. Refer to the Cross

Index, Mfg. Code Number to Manufacturer for names and addresses

of manufacturers.

CROSS INDEX – MFR. CODE NUMBER TO MANUFACTURER

Mfr. Code Manufacturer Address City, State, Zip Code

54318 ASTRO-MED INC 600 EAST GREENWICH AVE WEST WARWICK RI 02983–5446

80009 TEKTRONIX 14150 SC KARL BRAUN DR BEAVERTON OR 97007–0001

REPLACEABLE ELECTRICAL ASSEMBLIES

Fig

Tektronix

No.

Part No.

A1 118–7614–02 CIRCUIT BD ASSY:CONTROLLER W/ HARNESS 54318 32001–001

A2 118–7616–01 PRINTHEAD ASSY:THERMAL 54318 30995–014

Serial No.

Effective Dscont

Name & Description Mfg.

Code

Mfr. Part

No.

YT-1 / YT-1S Chart Recorder

8–3

Page 68

Replaceable Parts

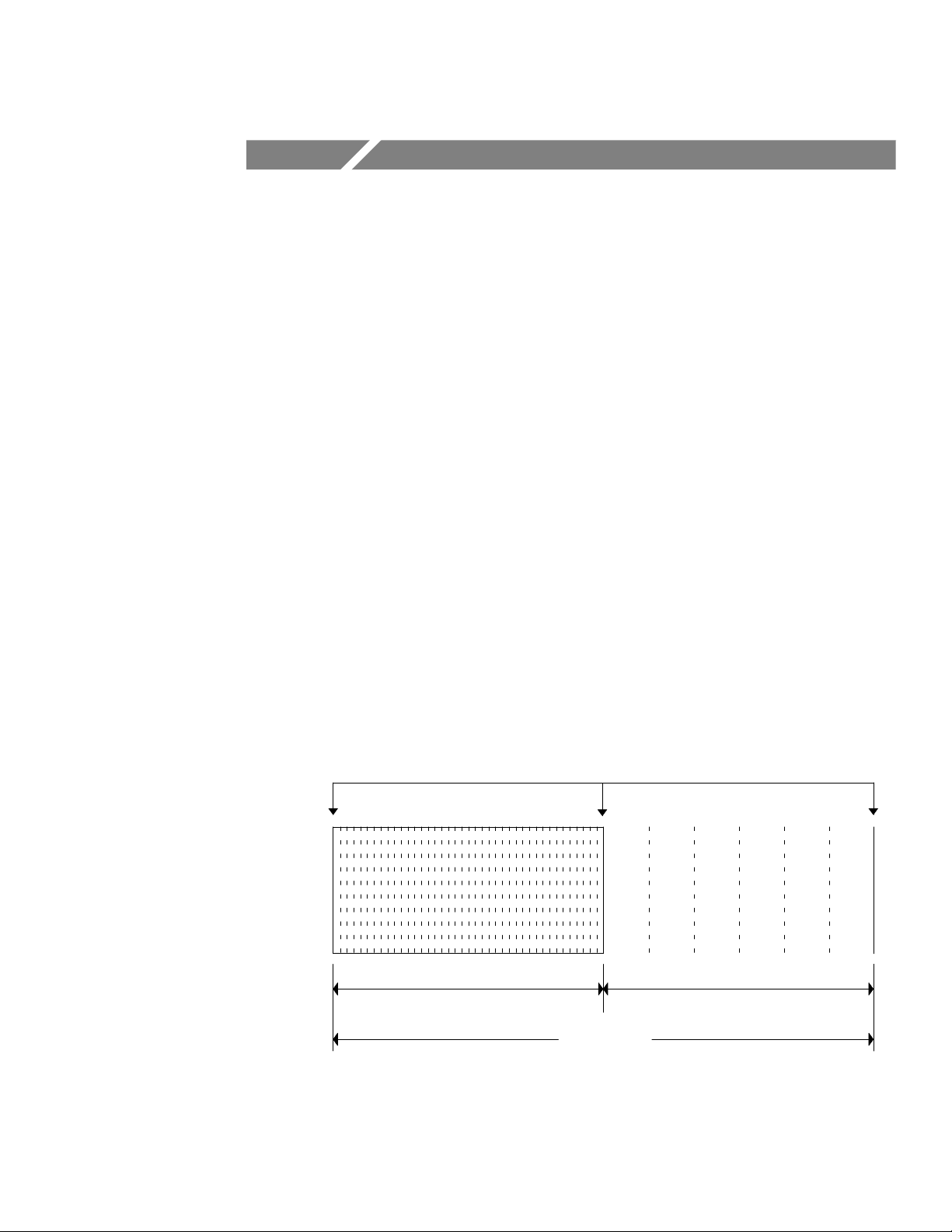

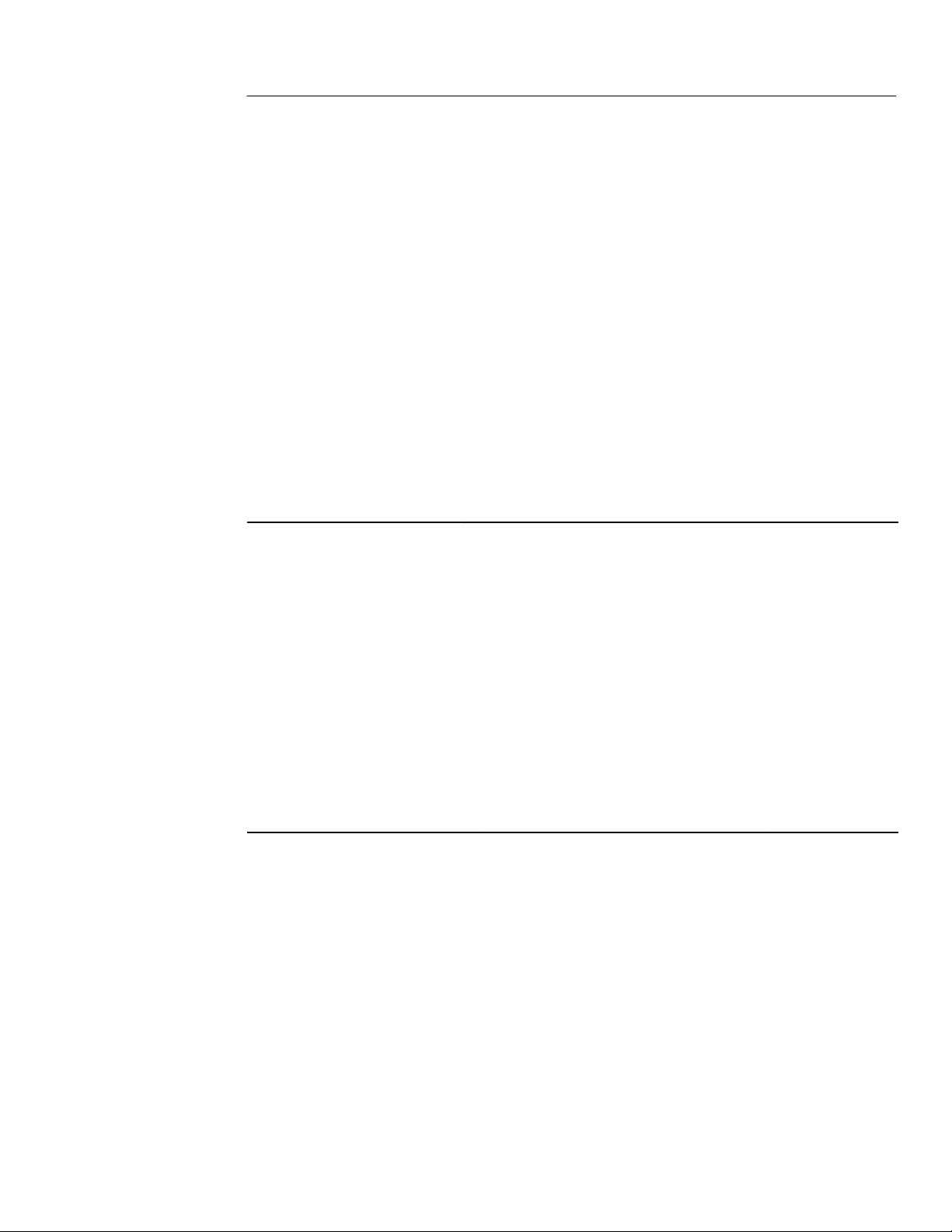

REPLACEABLE MECHANICAL ASSEMBLIES

Fig

Tektronix

No.

Part No.

1 118–7613–01 MOTOR:CHART DRIVE ASSY 54318 31310–000

2 118–8357–00 MANDREL PAPER:W/HARDWARE 54318 22976–010

3 118–7617–00 . KNOB:PAPER RETAINING 54318 12676–001

4 118–7623–00 PANEL,REAR:W/PINS 54318 22354–002

5 118–7622–03 FRAME,CASE: 54318 31268–20X

6 118–7633–00 (3) SPACER:NYLON 54318 10831–000

7 –––– –––– CKT BD ASSY:SEE A1 REPL

8 118–7620–00 WIRING HARNESS:PUSHBUTTON,RECORD 54318 12629–000

Serial No.

Effective Dscont

Name & Description Mfg.

Code

Mfr. Part No.

9 118–7621–01 PANEL,FRONT:W/LATCH YT-1 ONLY 54318 22764–000

200–3498–00 DOOR ASSY:YT -1S ONLY 54318 31927–000

10 118–7628–00 . LATCH,DOOR:YT-1/YT-1S 54318 22766–000

11 118–7624–02 . GASKET:YT-1/YT-1S 54318 22769–000

12 –––– –––– THERMAL PRINTHEAD ASSY:SEE A2 REPL

13 174–3241–00 CABLE ASSY:CHAR T RECORDER PRINT 54318 22745–952

14 118–7619–00 SPRING:COMPRESSION 54318 10475–001

15 118–7631–00 BLOCK:SPRING SUPPORT 54318 12541–001

16 214–4728–00 BELT,TIMING:1/8 INCH WIDE 54318 22110–048

8–4

YT-1 / YT-1S Chart Recorder

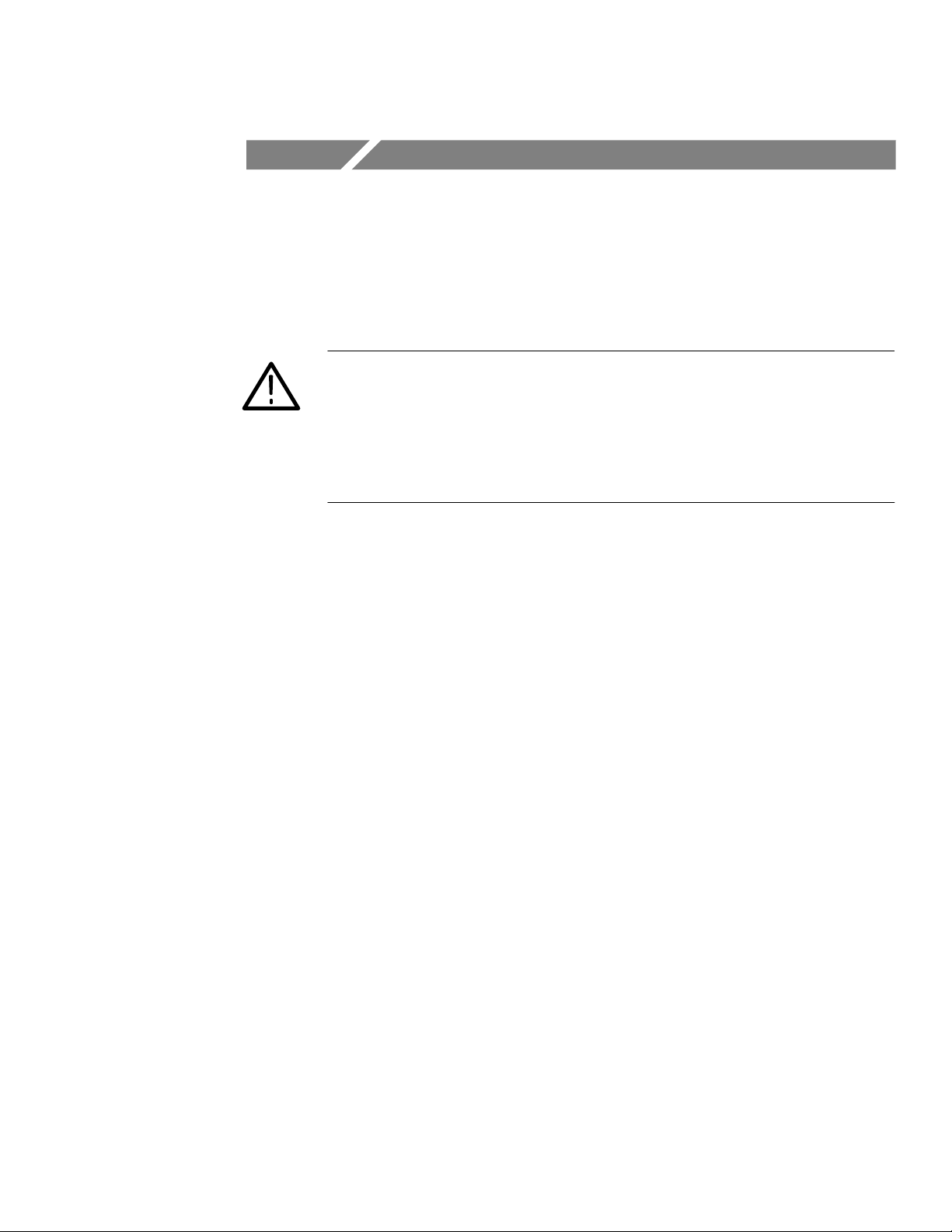

Page 69

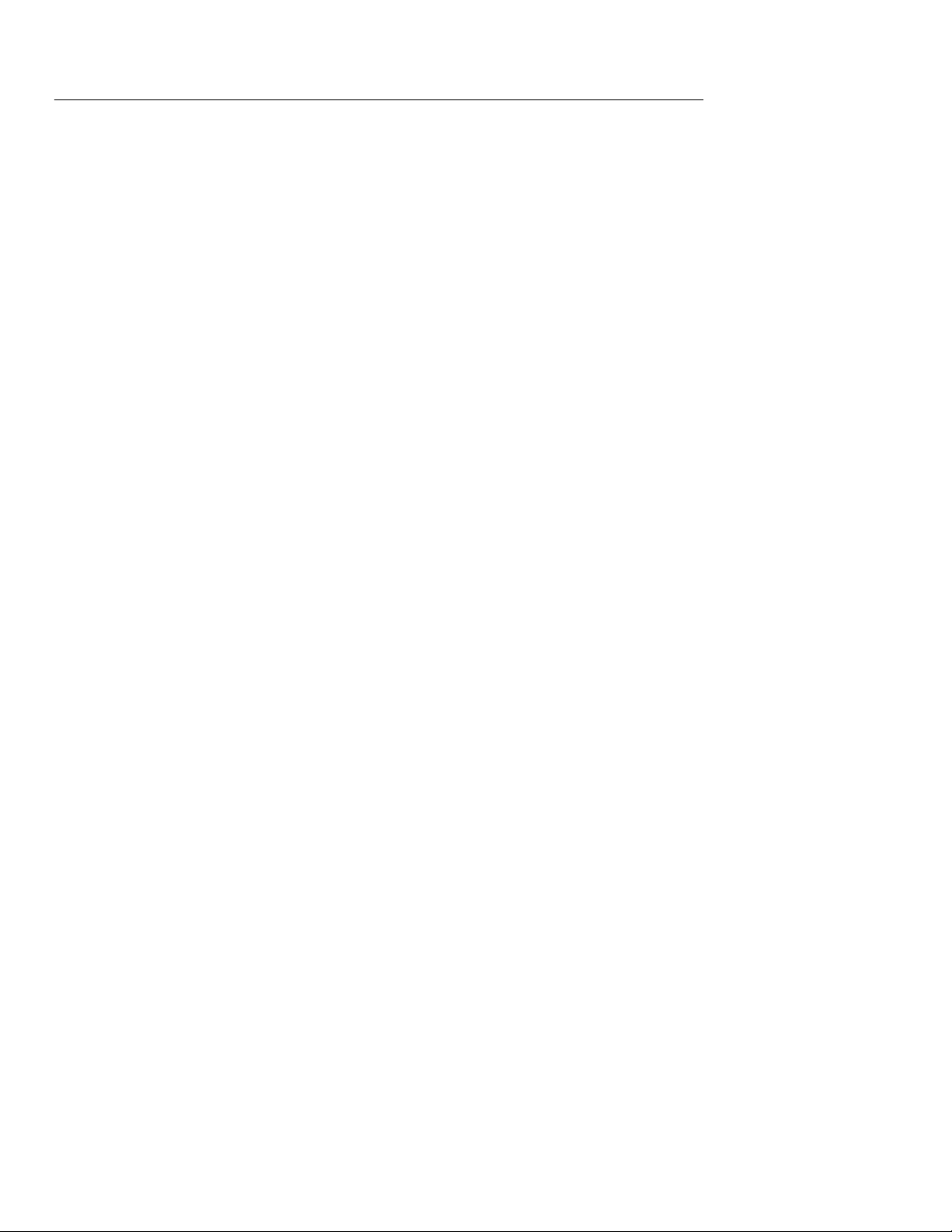

Replaceable Parts

A2

12

1

16

15

14

13

2

3

4

9

YT-1 / YT-1S Chart Recorder

10

11

5

6

7

8

A1

8–5

Page 70

Replaceable Parts

8–6

YT-1 / YT-1S Chart Recorder

Page 71

Page 72

Loading...

Loading...