Page 1

Y-l

bnART

RE

INSTRUCTION

ORDER

MANUAL

Page 2

---

COMMITTED

TO

EXCELLENCE

Tektronix, Inc.

P.O.

Box

500

Beaverton,

OR

970TI

PLEASE CHECK

FOR

CHANGE

INFORMATION AT THE REAR

OF

THIS MANUAL.

Y-T

CHART

RECORDER

INSTRUCTION MANUAL

First Printing

Revised

OCT

NOV

1987

1984

Page 3

Copyright

O

1984, 1985, 1986,

and

1987

Tektronix, Inc. All

rights reserved. Contents of this publication .may not be repro-

duced in any form without the written permission of Tektronix,

Inc.

Products of Tektronix, Inc. and its subsidiaries are covered by

U.S.

and foreign patents andtor pending patents.

TEKTRONIX, TEK. and

are registered trademarks of

Tektronix, Inc. TELEQUIPMENT is a registered trademark of

U.K.

Tektronix.

Limited.

Printed in U.S.A. Specification and price change privileges are

reserved.

Page 4

REV

DEC

1986

TABLE

List of

Safety Summary

Section 1 INTRODUCTION AND SPECIFICATION

Section

Installation

Stylus Alignment

Chart Paper Alignment

Record

Evaluation

Battery Operating Time

Installing Chart Recorder Paper

illustrations

2

OPERATING INSTRUCTIONS

..........................................................................................

................................................................................................

..........................................................................................

..............................................................................

..........................................

................................................................................

OF CONTENTS

.

.......................................................................

..........................................

.........................................................

................................

............................

Page

iv

v

2-1

2-1

2-1

2-1

2-2

2-2

2-2

Page 5

Y-T

Chart Recorder

TABLE

3

Section

Motor Voltage Control

Heater Vottage Regulator

Pen Drive Amplifier

Speed Sensing 3-2

Section 4 CALIBRATION

Calibration for

Calibration for

CIRCUIT DESCRIPTION

1500

Stylus Temperature and Gain Adjustment

Chart Recorder Checks

Motor Speed Control Adjustment

OF

Stylus Temperature and Gain Adjustment

Motor Speed Adjustment

Chart Recorder Checks 4-8

Linearity Checks

OF

CONTENTS

(cont)

......................................................................

...................................................................

.........................................................................

...................................................................................

TDR Series

........................................................

......................................

..................................................................

....................................................

TDR Series

...........................................................

......................................

...............................................................

..................................................................

..........................................................................

Page

3-1

3-1

3-2

4-1

4-2

4-3

4-6

4-7

4-7

4-8

4-9

REV DEC

1986

Page 6

LE

OF CONTENTS

5

Section

Chart Recorder Repair

Changing the Stylus

Replacing the Rubber Rollers

Repacking for Shipment

Section 6 OPTIONS

Section

Section

Y-T

Section 9 REPLACEABLE MECHANICAL PARTS

Section

MAINTENANCE

.......................................................................

...........................................................................

............................................................

.....................................................................

7

REPLACEABLE ELECTRICAL PARTS

8

DIAGRAMS

Chart Recorder Schematic

10

ACCESSORIES

..........................................................

(cont)

Page

5-1

5-1

5-3

5-5

8-4

Y-T

Chart

Recorder

REV DEC 1986

iii

Page 7

Y-T

Chart

Recorder

TABLE OF ILLUSTRATIONS

Title

Tektronix Y-T Chart Recorder

Chart Recorder Controls

Stylus Position Adjusted

Chart Recorder Motor

Motor Speed Control

Verifying Peak-to-Peak Signals

Aligning Chart Paper

Location of Chart Recorder Components

Correct Alignment of Stylus Assembly Connecting Wire

Y-T Chart Recorder Circuit Board

Motor Speed Control Circuit Board

Modified Circuit Board

Y-T Chart Recorder Exploded View

Accessories 9-13

.................................................................................

.................................................................

..................................................................

...................................................................

.................................................................

.....................................................

..............................................................

..............................................................

..................................................

....................................

.............

...............................................

..............................................

............................................

Page

2-3

4-4

4-4

4-5

4-5

4-9

4-10

5-2

5-4

8-6

8-7

8-8

9-12

REV

JUN

1987

Page 8

Y-T

Chart

Recorder

ERATOR

The general safety information in this part of the sum-

mary is for both operating and servicing personnel. which could result in personal injury or loss of life.

Specific warnings and cautions will be found throughout

the manual where they apply, but may not appear in this

summary.

TERMS

In This

CAUTION

which could result in damage to the equipment or other

Property.

REV

Manual

statements identify conditions or practices

DEC

1986

SAF

WARNING

As

Marked

CAUTION

ately accessible as one reads the marking, or a hazard

to property including the equipment itself.

DANGER

accessible as one reads the marking.

statements identify conditions or practices

on

Equipment

indicates a personal injury hazard not irnrnedi-

indicates a personal injury hazard immediately

Page 9

Y-T

Chart Recorder

SYMBOLS

In

This

Manual

This symbol indicates where applicable cau-

tionary or other information is to be found.

As

Marked on Equipment

b

@

DANGER-High Voltage

AlTENTION-refer to manual.

Protective ground (earth) terminal.

Power Source

This product is intended to operate from a power source

supplied by the parent instrument (fiber or metallic TDR).

Do not attempt to power this module by any other

means.

Grounding the Product

This product is grounded through the parent instrument.

A

protective ground connection is essential for safe

operation.

Danger Arising From Loss

Upon loss of the protective-ground connection, all acces-

sible conductive parts (including knobs and controls that

appear to

be

insulating) can render an electric shock.

of

Ground

REV DEC

1986

Page 10

Y-T

Chart

Recorder

Do Not Operate in Explosive

Atmospheres

To avoid explosion, do not operate this product in an

it

explosive atmosphere unless

certified for such operation.

has been specifically

Do Not Service Alone

Do not perform internal service or adjustment of this pro-

duct unless another person capable of rendering first aid

and resuscitation is present.

REV

DEC

1986

Use Care When Servicing With Power

On

Dangerous voltages exist at several points in this pro-

duct. To avoid personal injury, do not touch exposed

connections and components while power is on.

Disconnect power before removing protective panels,

soldering, or replacing components.

Do Not Remove Covers or Panels

To avoid personal injury, do not remove the product cov-

ers or panels. Do not operate the product without the

covers and panels properly installed.

vii

Page 11

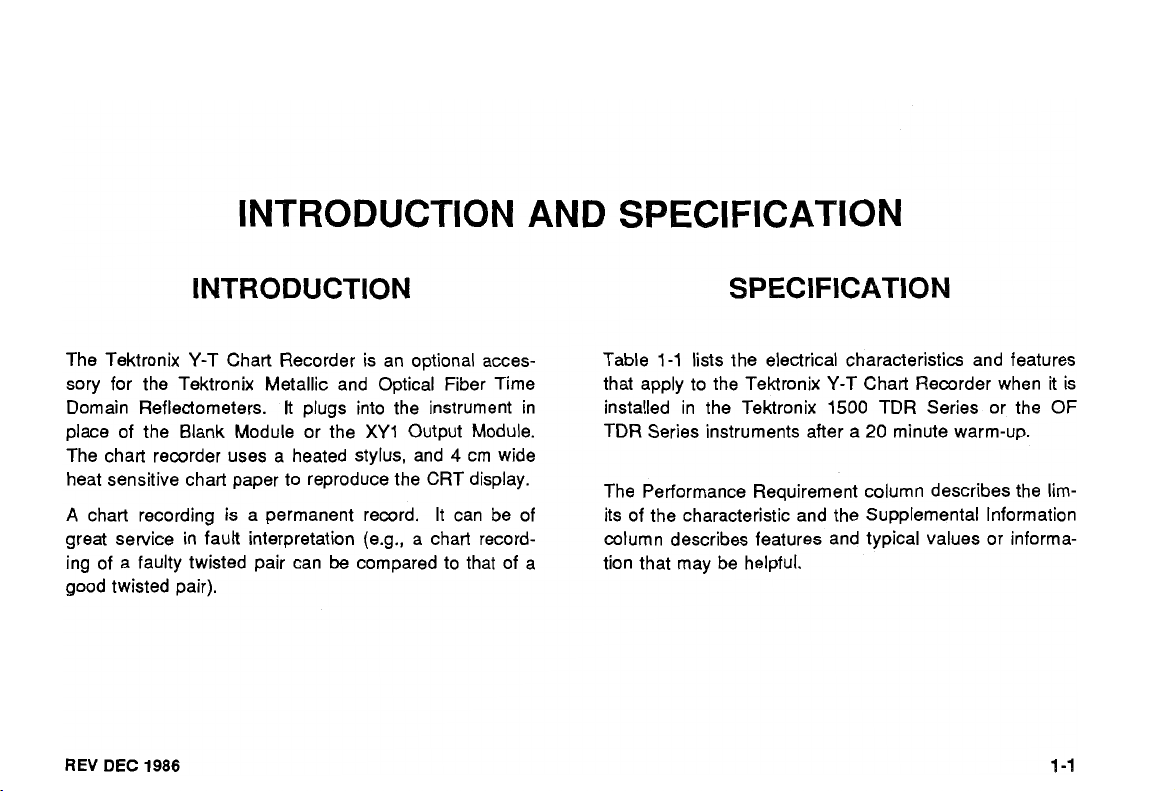

INTRODUCTION AND SPECIFICATION

INTRODUCTION

The Tektronix

sory for the Tektronix Metallic and Optical Fiber Time

Domain Reflectometers.

place of the Blank Module or the

The chart recorder uses a heated stylus, and

heat sensitive chart paper to reproduce the

A

chart recording is a permanent record. It can be of

great service in fault interpretation (e.g., a chart record-

ing of a faulty twisted pair can

good twisted pair).

REV

DEC

1986

Y-T

Chart Recorder is an optional acces-

It

plugs into the instrument in

XY1

Output Module.

CRT

be

compared to that of a

4

cm wide

display.

SPECIFICATION

Table

1-1

lists the electrical characteristics and features

that apply to the Tektronix Y-T Chart Recorder when it is

installed in the Tektronix

TDR Series instruments after a

The Performance Requirement column describes the lim-

its of the characteristic and the Supplemental Information

column describes features and typical values or informa-

tion that may be helpful.

1500

TDR Series or the OF

20

minute warm-up.

Page 12

Y-T

Introduction and Specification

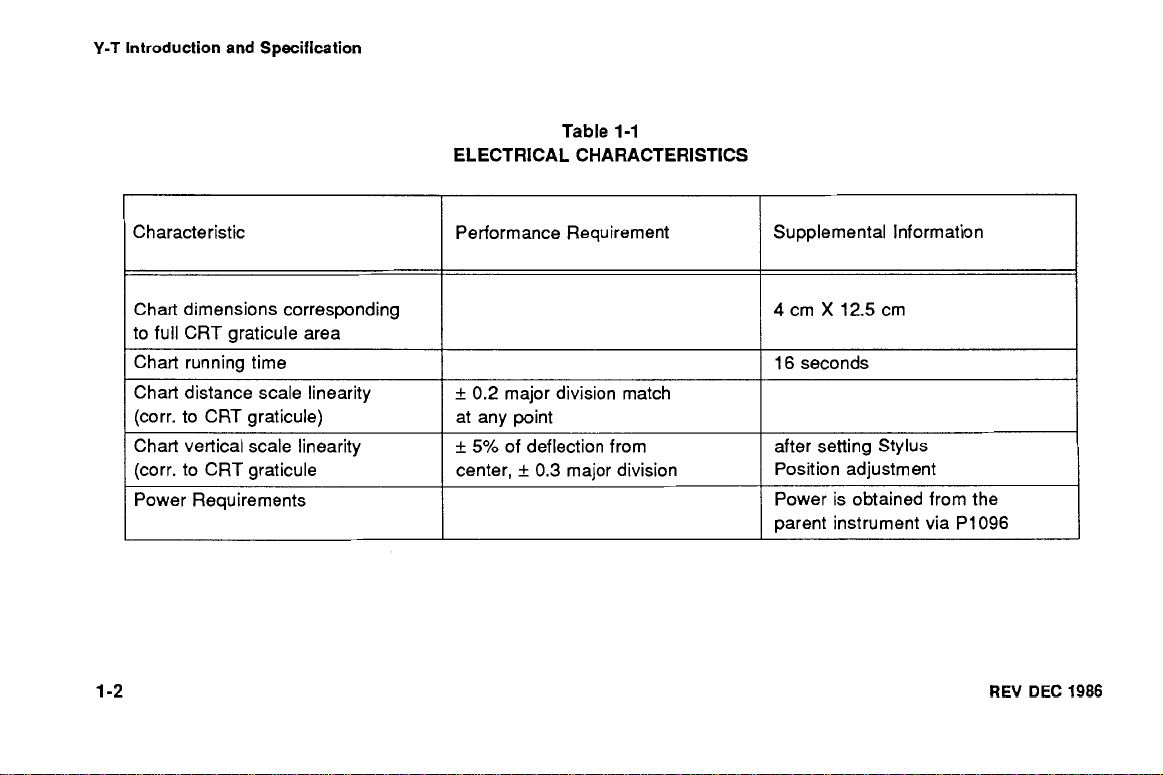

Table

1-1

ELECTRICAL CHARACTERISTICS

Characteristic Performance Requirement

Chart dimensions corresponding

to full CRT graticule area

Chart running time

Chart distance scale linearity

(corr. to CRT graticule)

Chart vertical scale linearity

(corr. to CRT graticule

Power Requirements

+

0.2 major division match

at any point

+

5%

of deflection from

+

0.3

center,

major division

Supplemental Information

16 seconds

after setting Stylus

Position adjustment

Power is obtained from the

parent instrument via P1096

REV

DEC

1986

Page 13

OPERATING INSTRUCTIONS

CAUTION

D

Turn the parent instrument's power switch

removing or installing the

Y-T

Chart Recorder.

Installation

The Tekronix Y-T Chart Recorder can be installed in the

instrument's plug-in module compartment. The LOCK

knob secures the chart recorder in the instrument.

Stylus Alignment

When the parent instrument's RECORD switch is

pressed, power is applied to the recorder stylus.

position of the stylus can then be aligned by adjusting

the STYLUS POSITION screw. Align the stylus to

correspond with the position of the CRT trace.

REV

DEC

1986

OFF

prior to

The

Chart Paper Alignment

To align the chart horizontally, pull the paper until a dark

line on the paper is aligned with the red reference line

visible through a sprocket hole.

Record

When the RECORD switch is pressed, then released, a

chart recording starts. The chart recording circuitry

automatically shuts off when the recording is completed.

Extra graph paper is run out to allow removal of the

recording. When removing the recording, tear paper

upward.

Page 14

Y-T

Operating Instructions

Evaluation

In evaluating a graph, the distance between two dark

horizontal lines corresponds to one vertical division of

the CRT display. The distance between two dark vertical

lines corresponds to one major horizontal division of the

CRT display.

Battery Operating Time

The chart recorder can make up to 20 graphs on a full

charge of the batteries; the instrument will still operate

for a minimum of 5 hours. After 20 graphs have been

made, the time that the instrument can be operated

without recharging the batteries will be reduced by

approximately three minutes per recording.

(1

500

Series)

Installing Chart Recorder Paper

Approximately 60 graphs can be made with one roll of

chart recorder paper for the 1500 TDR Series, or approx-

imately 120 for the OF

TDR

Series.

NOTE

Chart paper for the

is different. Check the Mechanical Parts List, Acces-

sories, section of this manual for the proper chart paper

part numbers.

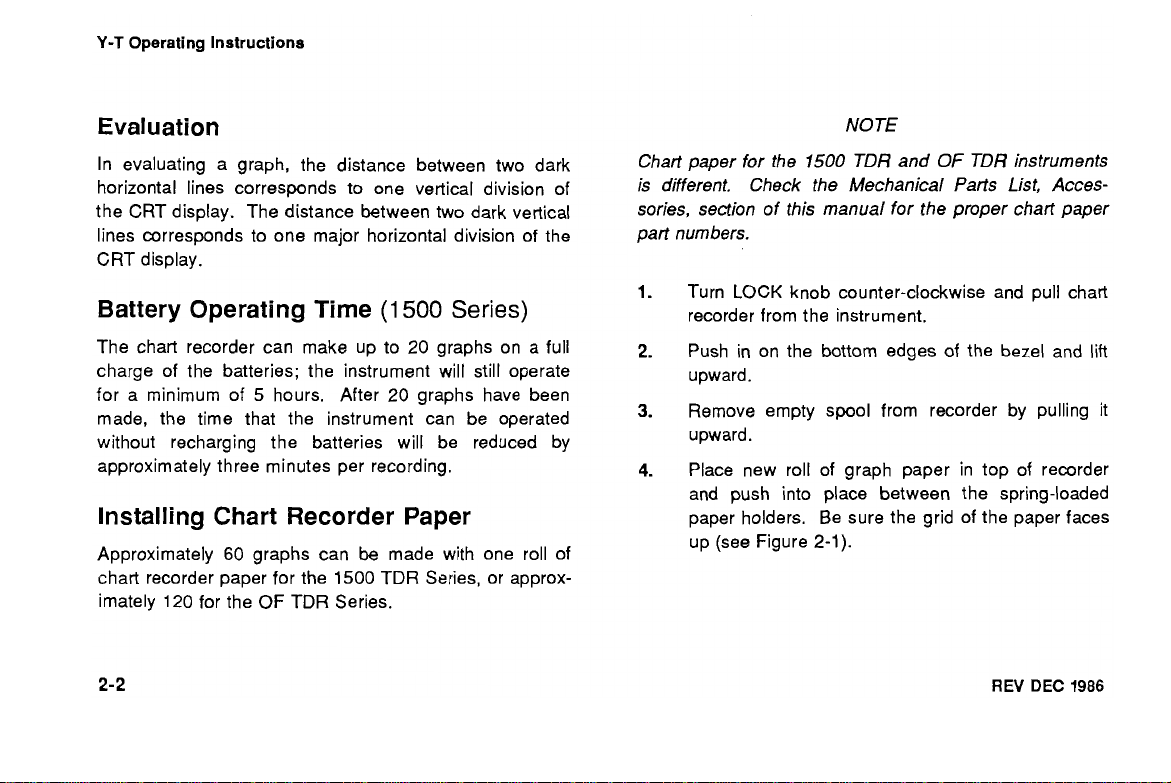

Turn LOCK knob counter-clockwise and pull chart

recorder from the instrument.

Push in on the bottom edges of the bezel and lift

upward.

Remove empty spool from recorder by pulling it

upward.

Place new roll of graph paper in top of recorder

and push into place between the spring-loaded

paper holders. Be sure the grid of the paper faces

up (see Figure

1500

2-1).

TDR

and

OF

TDR

REV

instruments

DEC

1986

Page 15

Fig.

2-1.

Y-T

Chart

-pp

Recorder.

Y-T

Operating Instructions

Pull the paper over the rollers and down the front

of the recorder. Lower the bezel until it latches

into place.

Align the graph paper so that one of the dark lines

on the paper is lined

up

with the red reference line

visible through a sprocket hole. This sets the

graph paper

so

that a recording will start at one of

the dark lines corresponding to the edge of the

CRT graticule.

Place the chart recorder back into the instrument,

then turn the

LOCK

knob clockwise to lock.

REV

DEC

1986

Page 16

This section describes the Chart Recorder circuitry using

the circuit diagrams at the back of this manual. The

Chart Recorder contains three basic circuits: the motor

voltage control, heater voltage regulator, and a pen drive

amplifier.

Motor-Voltage Control

When pin 4 of P1096 is switched to 0

Q1015 is turned on and acts as a switch, which applies

12 volts to the Motor Speed Control.

Motor current and torque load are sensed by R2026 and

U2035A, providing a signal to U20358, where it is com-

pared with

circuit U20356 and transistors Q1039 and Q1 024 form

voltage-controlled current source for the drive motor.

REV

DEC

a

reference voltage set by R1015. Integrated

1986

V,

transistor

Heater-Voltage Regulator

This circuit provides 3 A at 1.0 V to the stylus heating

a

element. The circuit is

Transistor Q2023 acts as a series switch that supplies

current to energy storage device L1029. Transistors

Q4021 and Q3023 form the sensing amplifier whose sig-

nal is amplified by Q3028, (23027, Q3026, and Q4027 in

order to switch Q2023. Diode CR2031 shunts the

current that flows through L1029 when Q2023 is turned

off. Resistor R4017 is used to set the output voltage at

1

V.

The 1 V switching supply is controlled by the stylus

heat control line (pin 12), which is grounded when stylus

heat is required.

a

series-switching regulator type.

Page 17

Y-T

Circuit Description

Pen-Drive Amplifier

The pen-drive amplifier consists of operational amplifier

U3034

Q4033.

adjustment,

chart paper. Gain of the amplifier is controlled by

R2033,

amplifier circuit provides amplification to either positive or

negative going inputs. The

-8

trolled by the chart recorder power switches in the parent

instrument.

Diodes

drive amplifier from high reverse voltages which may

occur on the

Thermistor

motor non-linearity.

and power amplifiers

STYLUS

POSITION, an external screwdriver

R2034,

is used to center the stylus on the

Q4030, (24032, Q3033,

an internal screwdriver adjustment. The power

+5

V

and

-5 V (+8

V

for

1500

Series) to the power amplifiers are con-

CR4030

and

5

5

RT1039

CR4031

V

(5

and

are used to protect the pen

8 V 1500

R1037

Series) power bus.

compensate for pen

V

and

and

Speed Sensing

A speed-sensing circuit consists of

tosensitive transistor

Q0182

is activated by the passing of each sprocket hole.

The on-off rate of

Q0182.

Q01 82

is an indication of the paper

motor speed. This activation rate is used to synchronize

the display sweep speed with the proper paper motor

speed.

DS0282,

and pho-

As the paper travels,

REV

DEC 1986

Page 18

CALIBRATION

for

1500

TDR

SERIES

Equipment Required for 1502

l.

50 R terminator (01 1-0123-00)

2.

Chart Recorder Extender (067-1 071 -00)

3.

3-inch screwdriver

Equipment Required for 1503

1.

Chart Recorder Extender (067-1 071 -00)

2.

3-inch screwdriver

REV

DEC

1986

1502 Control Settings:

rnp1DIV 200

FEETtD

DISTANCE DIAL 000

MULTIPLIER

DIELECTRICS All out

GAIN

CABLE

IV 20 (Metric

X

1

5

div. pulse

R

terminator

50

5)

Page 19

Y-T

Calibration

1503

Control Settings:

RET LOSS

OdB SET

DISTANCE DIAL

FEET/DIV

MULTIPLIER

DIELECTRICS

IMPULSE WIDTH

CABLE

Od

B

5

div. pulse

000

l0

(Metric

X1 0

All out

l

OOns

No termination

l)

Stylus Temperature and Gain Adjust-

ment

a.

Remove the chart recorder from the instrument.

b.

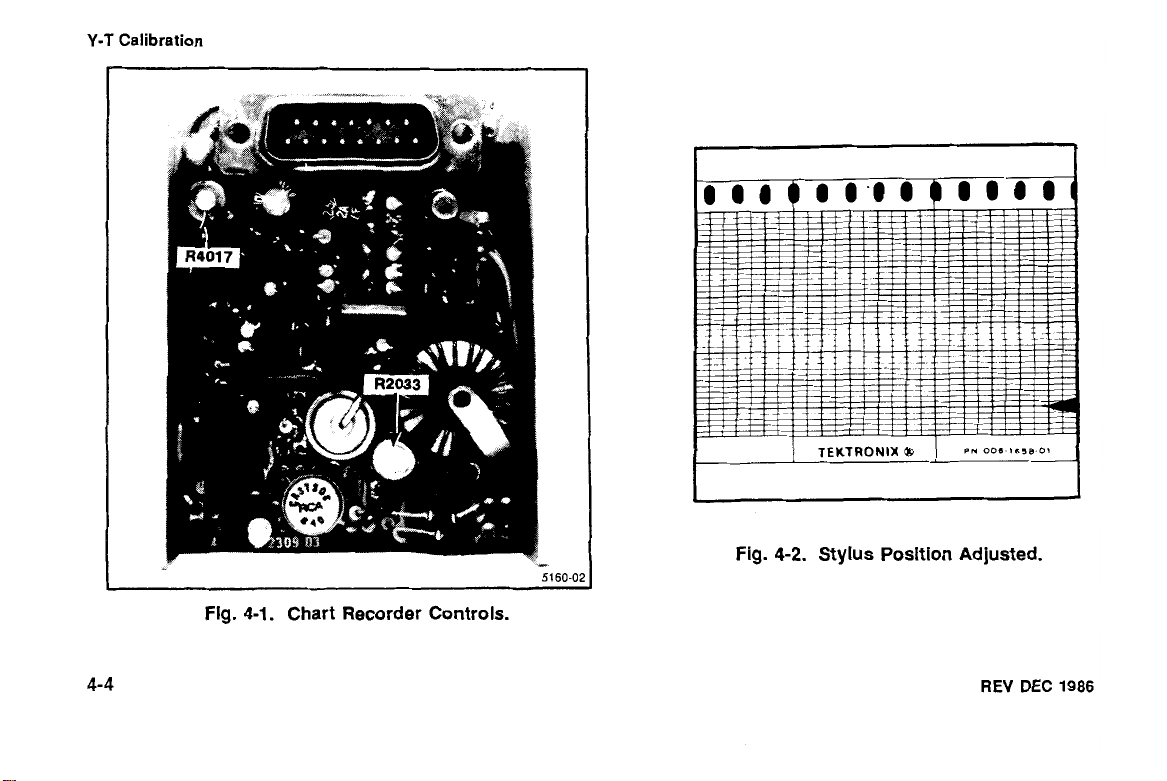

Adjust R4017 (STYLUS TEMP) clockwise to

increase the graph intensity or counterclockwise to

decrease the intensity. See Figures 4-1 or

location of chart recorder adjustments.

8-3

for

NOTE

Power consumption goes up as the stylus temperature

increases. Therefore, it is important to have the stylus

temperature as low as possible without sacrificing an

adequate remrding trace.

c.

Adjust R2033 (GAIN) clockwise to increase the

amplitude of the chart trace or counterclockwise to

decrease the amplitude of the trace.

After the chart recording has been made, pull the

d.

paper until a dark line is aligned with the red refer-

ence line seen through a sprocket hole.

Place the chart recorder back in the instrument.

e.

REV

JUN

1987

Page 20

Y-T

Calibration

Chart Recorder Checks

Using

ZERO

center the trace on the CRT. Baseline should be

one horizontal line from the bottom. The !eading

edge of the 1502 trace should be positioned on

the center graticule line. The leading edge of the

1503 trace should

from the lefi (arrow).

Adjust 1503 VAR for an

Adjust 0-dB SET (1502 GAIN) for a

pulse height.

Press RECORD switch momentarily (for stylus to

heat), then release.

Adjust STYLUS POSITION control so the baseline

position on the chart trace matches the CRT base-

line (see

REV

DEC

1986

REF and POSITION controls,

be

positioned one vertical line

8

division pulse width.

Fig.4-2).

5

division

e.

When the recording is complete, check that the

recording starts at the second division line from

the right. The amplitude of the pulse should match

that of the CRT (5 div.). If it does not, adjust the

chart recorder gain.

The position of the leading edge of the chart

recording should match the position

of

edge of the CRT pulse. (In the 1503, both the

leading and trailing edges should match.)

1

do not match within

minor division, re-check the

the horizontal timing as outlined in the parent

instrilment manual.

the leading

If

they

Page 21

Calibration

Y-T

-

l

Fig.

4-1. Chart Recorder Controls.

5160-C

Fig.

4-2.

Stylus Position Adjusted.

REV

DEC

1986

Page 22

Y-T

Calibration

I

REV

DEC

1986

Micro

Fig.

4-3.

MO

@

Chart Recorder Motors.

ESCAP

@

51

60-03

Fig.

4-4. Motor Speed Control.

Page 23

Y-T

Calibration

Motor Speed Adjustment

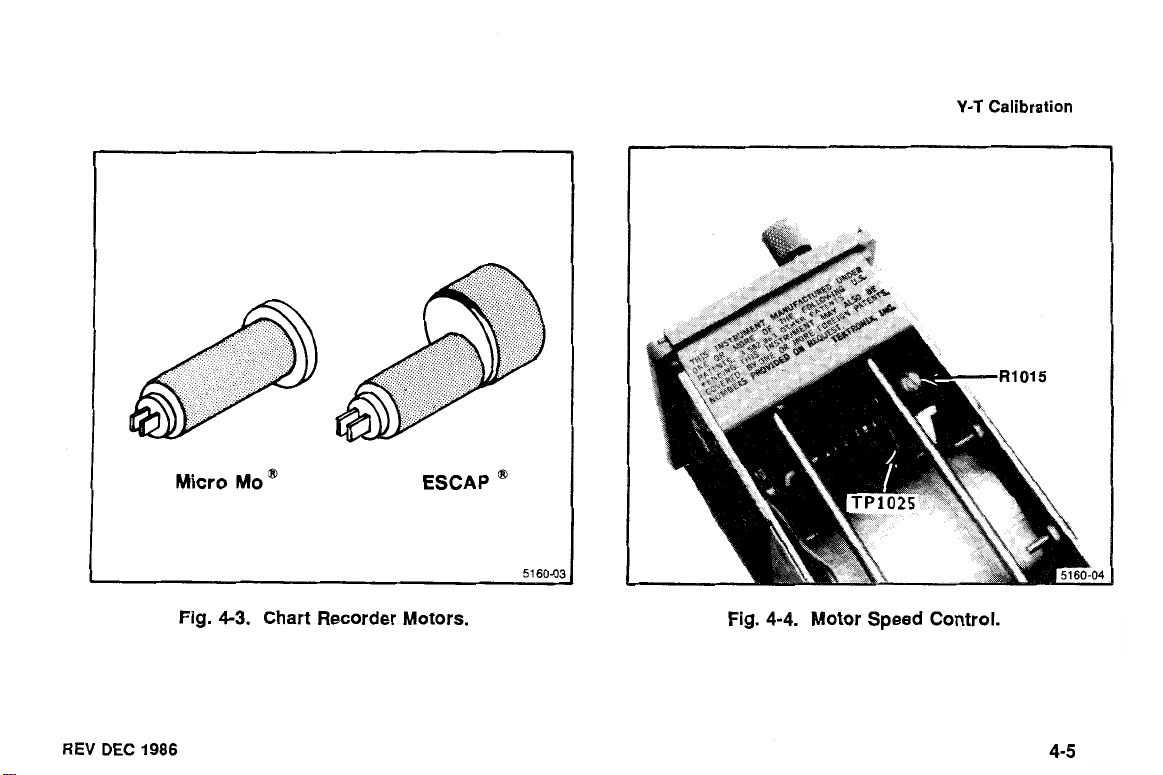

To make the motor speed adjustment determine

which motor has been used in your instrument

(see Figure

Attach a voltmeter probe to P1025 on the Motor

Speed Control board (see Figure 4-4).

With the Chart Recorder on the Chart Recorder

Extender (067-1 071-00) push the RECORD button

and, while the chart is running, adjust R1015 for

1.55

Remove the Chart Recorder Extender and replace

the Chart Recorder in the plug-in module compart-

ment.

4-3).

V

(MicroMo motor) or 1.79 V (ESCAP motor).

REV

DEC

1986

Page 24

Y-T

Calibration

ATION

Equipment Required

1.

OF TDR Series Service Kit (See parent manual)

2.

3-inch screwdriver

3.

Interlock Contact Ring (OF150/OF152)

(Some later instruments may not require this dev-

ice. See appropriate service manual.)

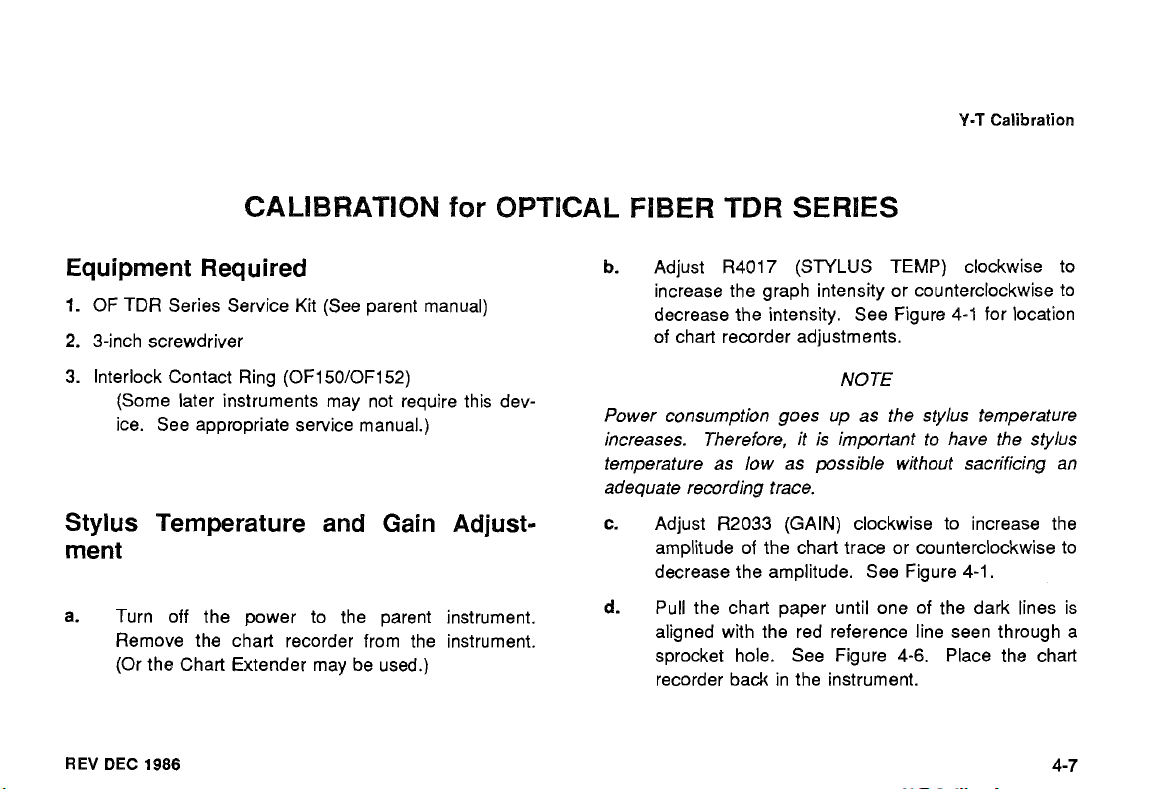

Stylus

merit

a.

REV

Temperature and

Turn off the power to the parent instrument.

Remove the chart recorder from the instrument.

(Or the Chart Extender may be used.)

DEC 1986

Gain

for

OPTl

Adjust-

ER

TDR

b.

Adjust ~4017 (STYLUS TEMP) clockwise to

increase the graph intensity or counterclockwise to

decrease the intensity. See Figure

of chart recorder adjustments.

Power consumption goes up as the stylus temperature

increases. Therefore, it is important to have the stylus

temperature as low as possible without sacrificing an

adequate recording trace.

c.

Adjust R2033 (GAIN) clockwise to increase the

amplitude of the chart trace or counterclockwise to

decrease the amplitude. See Figure

d.

Pull the chart paper until one of the dark lines is

aligned with the red reference line seen through

sprocket hole. See Figure

recorder

back

SE

NOTE

4-6.

in the instrument.

4-1

for location

4-1.

Place the chart

a

Page 25

Y-T

Calibration

Motor Speed Adjustment

To make the motor speed adjustment, determine

which motor has been used in your instrument

(see Figure 4-3).

Attach a voltmeter probe to P1025 on the Motor

Speed control board (see Figure 4-4).

With the chart recorder connected to the Chart

Recorder Extender, push the RECORD switch and

monitor the voltage. Adjust R1015 for 1.55

(Micromotor) or 1.79 V (ESCAP).

Remove the Chart Recorder Extender, and plug in

the Chart Recorder.

V

Chart Recorder Checks

a.

On the OF150 and OF152, install an Interlock

Contact Ring. (Not necessary on OF151, or later

models of the OF150 and OF152).

Put the instrument in the Calibration Aid Mode.

b.

Set the DISTIDIV on the OF151lOF152 to 10

C.

(OF150 to

d.

Use the POSITION control to set the straight

line on the CRT to the center graticule line.

Push and release the RECORD switch.

e.

While the chart is running, adjust the STYLUS

f.

POSITION on the chart recorder so the line being

drawn is on the center graticule line of the chart.

2).

The LCD readout should be 9.

REV DEC

1986

Page 26

Y-T

Calibration

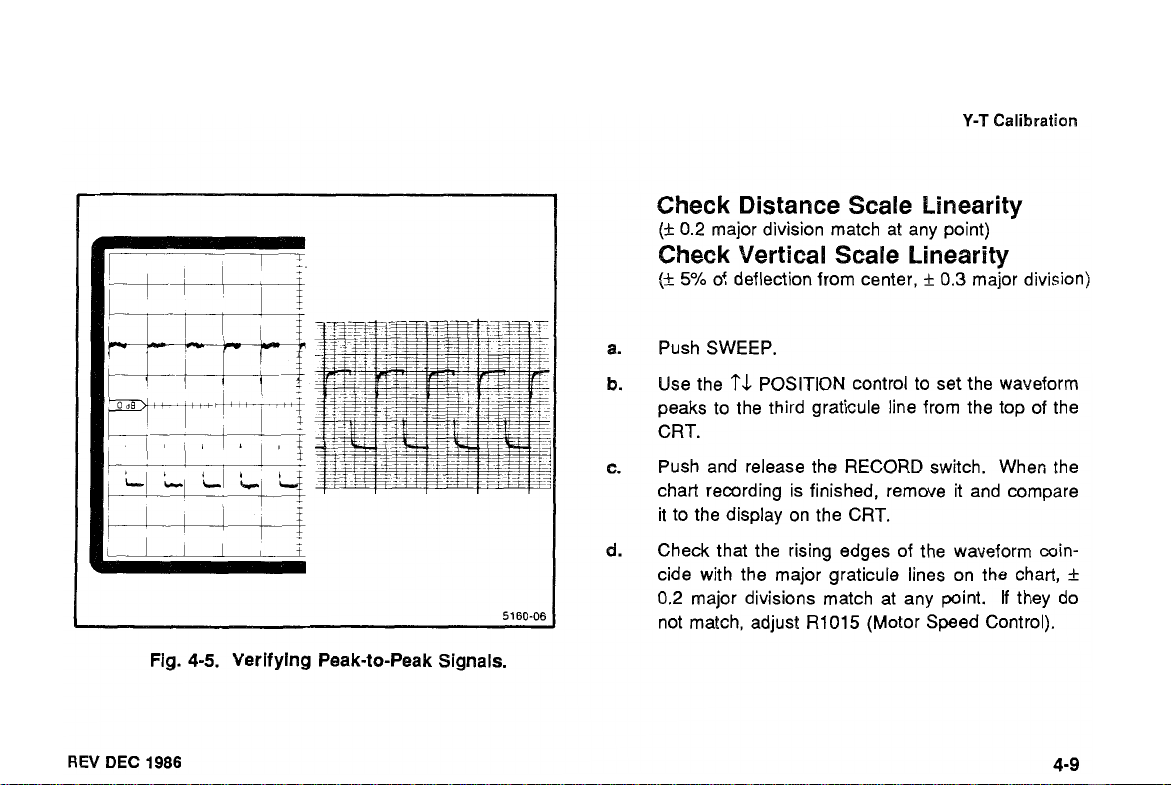

Check Distance Scale Linearity

(+

0.2

major division match at any point)

Check Vertical Scale Linearity

(+

5O/0

of deflection from center,

Push SWEEP.

+

0.3

major division)

1

REV

DEC

Fig.

1986

4-5.

Verifying

Peak-to-Peak

Signals.

5160-06

Use the

peaks to the third graticule line from the top of the

CRT.

Push and release the RECORD switch. Wher; the

chart recording is finished, remove it and compare

it to the display on the CRT.

Check that the rising edges of the waveform coin-

cide with the major graticule lines on the chart,

0.2

not match, adjust

'?L

POSITION control to set the waveform

major divisions match at any point.

R1015

(Motor Speed Control).

If

they do

+

Page 27

Y-T

Calibration

e.

Check that the peak-to-peak signal on the

display coincides with the major graticule lines on

the chart,

cule line,

they do not match, adjust R2033 (GAIN).

f.

Remove the Chart Recorder Extender, and plug in

the Chart Recorder.

i

5% of deflection from the center grati-

f

0.3 major division (see Figure 4-5).

CRT

If

I

Alignment indi

(red line)

Fig.

Major Graticule Line

4-6.

Aligning

Chart Paper.

REV DEC

1986

Page 28

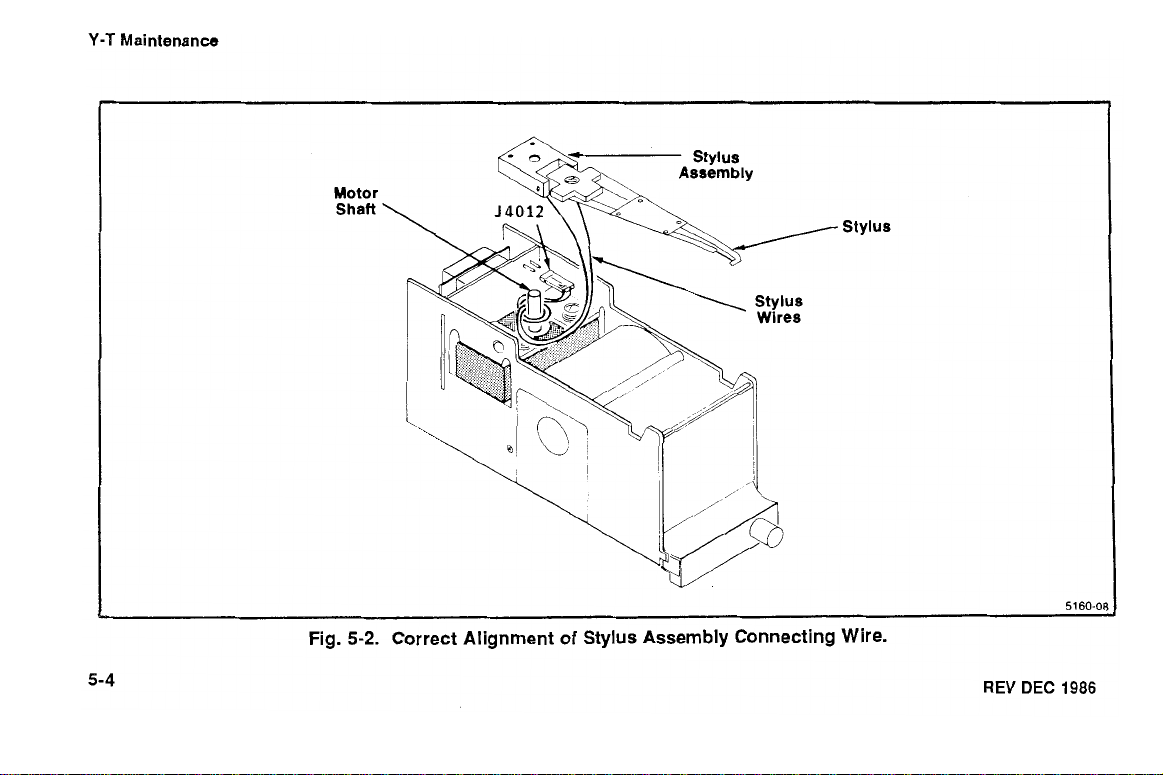

MAINTENANCE

Chart Recorder Repair

Except for the stylus and the rubber rollers, the chart

recorder is virtually maintenance free. Instructions for

replacing the stylus and the rubber rollers are given in

the following procedures. If replacement of other

mechanical parts should be necessary, refer to the

exploded views which are located in the mechanical

parts list section.

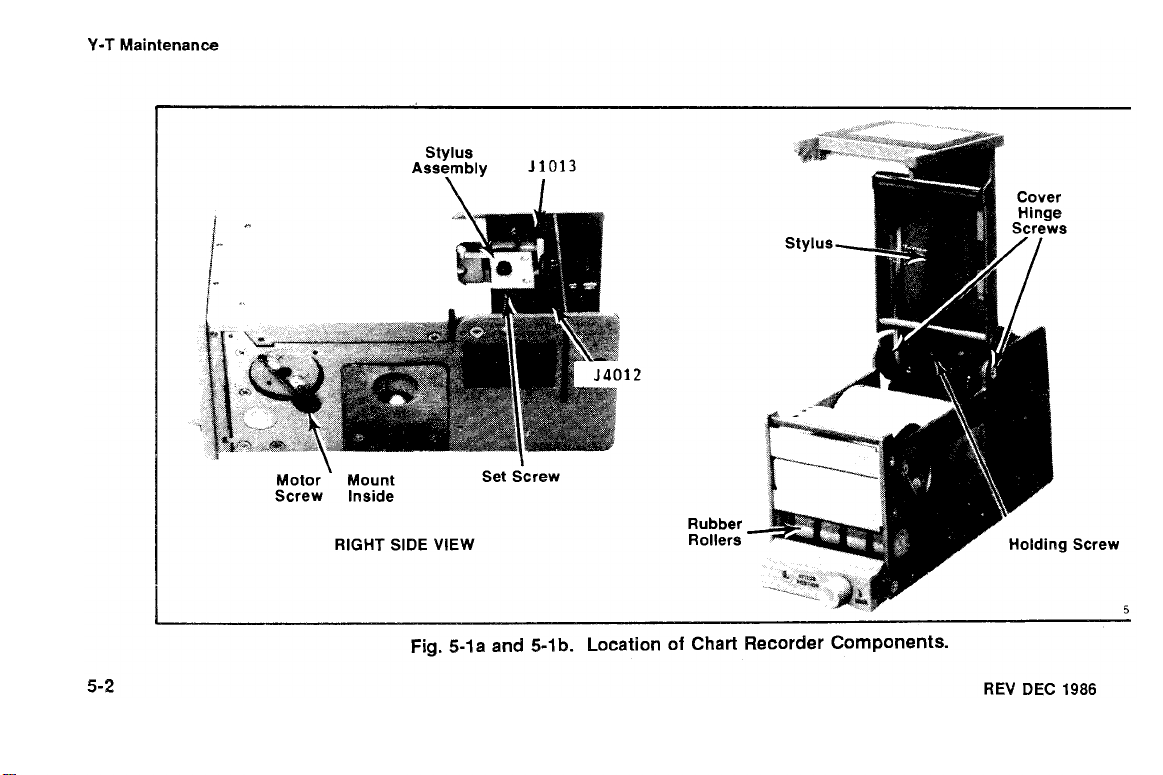

Changing the Stylus

1.

Disconnect P4012 from the circuit board (see Fig-

ure 5-1 a).

2.

Remove the two screws from the rear of the cover

and carefully remove the cover (see Figure 5-1

REV

DEC

1986

b).

Disconnect P1 01 3 from the circuit board.

3.

4.

Using a 0.05-inch allen wrench, loosen the set

screw and lift the assembly off the motor shaft.

Remove the holding screw from the stylus assem-

5.

bly.

6.

Separate the stylus and the holder.

Install a new stylus (Tek Part No. 11 9-0365-00).

7.

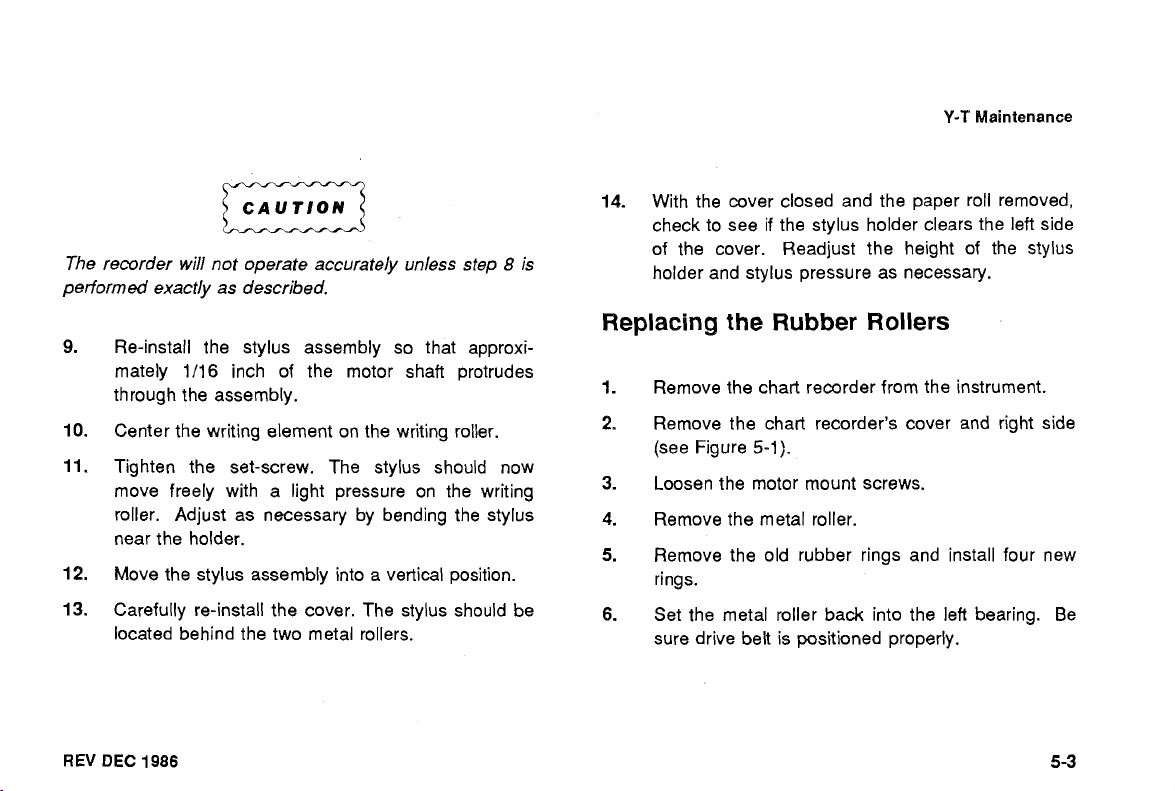

Loop the stylus wires around the motor shaft as

8.

shown in Figure 5-2. Connect P4012 and P1013.

Page 29

Y-T

Maintenance

Stylus

Assembly

\

Motor Mount Set screw

Screw Inside

RIGHT SIDE VIEW

J1013

Rubber

Rollers

Screw

5

Fig.

5-la and 5-1

b.

Location of

Chart

Recorder Components.

REV

DEC

1986

Page 30

CAUTION

m

The recorder

performed exactly as described.

will

not operate accurately unless step 8 is

Y-T

14.

With the cover closed and the paper roll removed,

check to see if the stylus holder clears the left side

of the cover. Readjust the height of the stylus

holder and stylus pressure as necessary.

Maintenance

Re-install the stylus assembly so that approxi-

mately

through the assembly.

Center the writing element on the writing roller.

Tighten the set-screw. The stylus should now

move freely with a light pressure on the writing

roller. Adjust as necessary by bending the stylus

near the holder.

Move the stylus assembly into a vertical position.

Carefully re-install the cover. The stylus should be

located behind the two metal rollers.

REV

DEC

1986

1/16

inch of the motor shaft protrudes

Replacing

1.

Remove the chart recorder from the instrument.

2.

Remove the chart recorder's cover and right side

(see Figure

3.

Loosen the motor mount screws.

4.

Remove the metal roller.

5.

Remove the old rubber rings and install four new

rings.

6.

Set the metal roller back into the left bearing. Be

sure drive belt is positioned properly.

the

Rubber Rollers

5-1

).

Page 31

Y-T

Maintenance

Motor

Shaft

Stylus

5160

(

5-4

Fig.

5-2.

Correct Alignment of Stylus Assembly Connecting Wire.

REV

DEC

1986

Page 32

7.

Replace the right side.

8.

Move the motor slightly to take up slack in the belt

and tighten the motor mount screws.

CAUTION

Do not overtighten the drive belt.

9.

Position the motor

clear of the paper roll and drive roller.

LC

network (circuit board

A2)

Y-T

Maintenance

Save and re-use the package in which your instrument

was shipped. If the original packaging is unfit for use, or

not available, repackage the instrument as follows:

Obtain a carton of corrugated cardboard having

1.

inside dimensions of no less than six inches more

than the instrument dimensions; this will allow for

cushioning. Refer to the following table for carton

test strength requirements.

SHIPPING CARTON TEST STRENGTH

Gross

Weight

(Ib)

I

Carton

Test Strength

(Ib)

I

REPACKING

If the Tektronix instrument is to be shipped to a Tektronix

Service Center for service or repair, attach a tag show-

ing: owner (with address) and the name of an individual

at your firm that can be contacted, complete instrument

serial number and description of the service required.

REV DEC

1986

FOR

SHIPMENT

2.

Surround the instrument with polyethylene sheet-

ing to protect the finish of the instrument.

Page 33

Y-T

Maintenance

Cushion the instrument on all sides by tightly pack-

3.

ing dunnage or urethane foam between carton and

instrument, allowing three inches on all sides.

4. Seal carton with shipping tape or industrial stapler.

REV

DEC

1986

Page 34

OPTIONS

No options are planned for the Tektronix

REV

DEC

9986

Y-T

Chart Recorder

at

this time.

Page 35

REPLACEABLE ELECTRICAL PARTS

PARTS ORDERING INFORMATION

Replacement parts are available from or through your

local Tektronix, Inc., Field Office or representative.

Changes to Tektronix instruments are sometimes made to

accomodate improved components as they become avail-

able and to provide the benefit of the latest circuit

improvements developed in our engineering department.

It is therefore important, when ordering parts, to include

the following information in your order: part number,

instrument type or number, serial number, and

modification number, if applicable.

If a part you have ordered has been replaced with

or improved part, your local Tektronix Field Office or

representative will contact you concerning any change in

REV

JUN

1987

a

new

part number.

Change information, if any, is incorporated on each

when the change occurs.

List

of

Assemblies

A

list of assemblies can

Replaceable Electrical Parts list. The assemblies are

listed in numerical order. When the complete component

number

bly in which the par! is located.

of

a part is known, this list will identify the assem-

be

found at the beginning of the

page

Page 36

Replaceable

Electrical

Parts

-

YT-

CHART RECORDER

Cross 1ndex:Mfr. Code Number

The Mfr. Code Number to Manufacturer index for the

Electrical Parts List is located immediately following this

introduction. The Cross Index provides codes, names,

and addresses of manufacturers of components listed in

the Replaceable Electrical Parts List.

to

Manufacturer

Abbreviations

Abbreviations conform to American National Standard

Y1

.l.

Component Number

(Column One of the Electrical

Parts List)

A numbering method has been used to identify assem-

blies, subassemblies, and parts. Examples of this

numbering method and typical expansions are illustrated

below.

Example a.

Component number

Assembly Circuit

number number

1234

Read: Resistor

Example

Read: Resistor

Only the circuit number will appear on the diagrams and

circuit board illustrations. Each diagram and circuit board

illustration is clearly marked with the assembly number.

Assembly numbers are also marked on the mechanical

b.

of assembly

Component number

Assembly Subassembly Circuit

number number number

1234

of subassy 2 of Assy

23

23

REV

JUN

1987

Page 37

Replaceable

Electrical

Parts

-

Yf-

CHART

RECORDER

exploded views located in the Replaceable Mechanical

Parts list. The component number is obtained by adding

the assembly number prefix to the circuit number.

The parts list is divided and arranged by assemblies in

numerical sequence (e.g., assembly

subassemblies and parts, precedes

subassemblies and parts).

Chassis-mounted parts have no assembly number prefix

and are listed at

Parts list.

Tektronix Part No.

This indicates the part number to

a

replacement part from Tektronix.

REV

JUN

1987

the

end

of

(Column Two)

the Replaceable Electrical

be

Al,

with its

A2,

with its

used when ordering

SerialIModel No.

Column three indicates the serial number of the first

instrument in which the part was used. Column four indi-

cates the serial number of the last instrument in which the

part was used. No entries indicates that the part is used

in all instruments.

Name

In the Replaceable Electrical Parts list, the Item

separated from the description by a colon

space limitations, the ltem Name may sometimes appear

incomplete. For further ltem Name identification, the

Federal Cataloging Handbook

possible.

and Description

(Columns Three and Four)

(Column Five)

(:).

Because of

H6-1

can be utilized where

Name

US.

is

Page 38

Replaceable Electrical Parts

Mfr.

Code (Column

This indicates the code number of the actual manufac-

turer of the part. (The Mfr. Code Cross Index begins on

the following page.)

Mfr.

Part

Number (Column Seven)

This column lists the manufacturer's part number.

Six)

-

YT-

CHART RECORDER

REV

JUN

1987

Page 39

M fr.

Code

Manufacturer

CROSS INDEX

Replaceable Electrical Parts

-

MFR. CODE NUMBER TO MANUFACTURER

Address

City,

-

State,

YT-

CHART RECORDER

Zip

REV

UNITED CHEMICON INC

NEC ELECTRON INC

MURATA ERIE NORTH AMERICAN INC

ALLEN-BRADEY COMPANY

TEXAS INSTRUMENTS, INC

RCA CORPORATION

GENERAL ELECTRIC COMPANY

AVX CERAMICS

MOTOROLA INC

UNION CARBIDE CORP

ITT SEMICONDUCTORS DIVISION

AMETEK INCIRODAN DIV

BOURNS INCtTRIMPOT PRODUCTS DIV.

PORTESCAP, US

SPRAGUE ELECTRIC CO.

LITELFUSE, INC.

TEKTRONIX. INC.

JUN 1987

1128

LEXINGTON AVE

252

HUMBOLDT COURT

1148

FRANKLIN RD SE

1201

2ND STREET SOUTH

13500

N CENTRAL EXPRESSWAY

ROUTE

202

W GENESEE ST

19th

AVE SOUTH P 0

E MCWWELL RD., P.O. BOX

5005

1

1901

MADISON AVE

2905

BLUE STAR ST.

1200

COLUMBIA AVE.

730

FIFTH AVENUE

87

MARSHALL ST.

800

E. NORTHWEST HWY

P.O. BOX

500

BOX

867

20923

ROCHESTER, NY

SUNNYVALE, CA

MARIElTA, GA

MILWAUKEE, WI

DALLAS, TX

SOMERVILLE, NY

AUBURN, NY

MYRTLE BEACH, SC

PHOENIX, AZ

CLEVELAND.

WEST PALM BEACH, FL

ANAHEIM, CA

RIVERSIDE, CA

NEW YORK, NY

NORTH ADAMS,

DES PLAINES. IL

BEAVERTON OR

30067

72265

13021

85036

OH

92806

92507

14606

94086

53204

08876

44101

10019

MA

60016

97077

29577

01247

Page 40

Replaceable

Electrical

Parts - YT- CHART RECORDER

A1 - CHART RECORDER

Ckt.No. Part No.

Eff.

Dscont Name & Description

CKT BOARD ASSY: CHART RECORDER

(

MFD BEFORE 5/24/87)

CKT BOARD ASSY:CHART RECORDER

(

MFD 5/24/87 - 6/1/87)

CKT BOARD ASSY:CHART RECORDER

(

MFD AFTER 6/1/87)

SEMICOND DVC:S1.35V,O.lA

SEMICOND DVC:S1,20V,5A

SEMICOND DVC:S1,30V,150rnA

SEMICOND DVC:S1,55V,200rnA

SEMICOND DVC:S1,55V,200rnA

Code Number

SRI 55E103MAA

SR215E104MAA

T3688686M006ASC8

SM25VB-470

T368A 105M050AZ

56XBB501AE

FUSE,CARTRIDGE:2A,125\1,5

SEC

REV

JUN

1987

Page 41

A1

-

CHART RECORDER

Ckt.No.

Part

No.

(cont)

Replaceable Electrical

Eff.

Dscont Name & Description Code Number

(SEE 1-62 RMPL)

(SEE 1-62 RMPL)

(SEE 1-62 RMPL)

(SEE 1-62 RMPL)

(SEE 1-62 RMPL)

(SEE 1-62 RMPL)

XSTR:SI,PNP 0471 3

(

MFD

BEFORE JUNE 1,1987)

XSTR:SI,PNP 0471 3

(

MFD

AFTER JUNE 1,1987)

XSTR:SI.PNP 01295

XSTR:SI,NPN 03508

XSTR:SI,PNP 03508

XSTR:SI,NPN 04713

Parts - YT- CHART RECORDER

REV

JUN

1987

Page 42

Replaceable Electrical Parts - YT- CHART RECORDER

A1 - CHART RECORDER

Ckt.No. Part No.

(cont)

Eff.

Dscont Name & Description

XSTR:SI,NPN

XSTR:SI,PNP

XSTR:SI,NPN,SEL FROM MJE521

Code Number

REV JUN

1987

Page 43

Replaceable Electrical Parts

-

YT-

CHART

RECORDER

REV

A1 - CHART RECORDER

Ckt.No.

JUN

1987

Part

No.

Eff.

(cont)

Dscont

Name

8

Description

Code

Number

CB6235

CB6235

CB1035

3329

P-L58-2a7

SPSN 0485503U

CB2435

Page 44

Replaceable Electrical Parts

A1

-

CHART RECORDER

Ckt.No.

Part

-

YT-

CHART RECORDER

(cont)

No.

Eff.

Dscont

Name & Description

Code Number

REV JUN

1987

Page 45

Replaceable Electrical

Parts

-

YT- CHART RECORDER

REV

A1 - CHART RECORDER

JUN

Ckt.No.

1987

Part

No.

(cont)

Eff.

Dscont

Name

&

Description

Code

Number

Page 46

Replaceable Electrical Parts - YT- CHART RECORDER

A2

-

MOTOR

Ckt.No. Part No.

SPEED

CONTROL

Eff.

Dscont Name 8 Description Code Number

CKT BD ASSY:MOTOR SPEED CONTROL

CAP.,FXD,CER DI:0.022p F,20%,50V

CAP.,FXD.CER DI:O.lp F,+80-20%,50V

SEMICOND DVC:FE,S1,25VslmA

(SEE 1-60 RMPL)

XSTR:SI,NPN

XSTR:SI,NPN

RES.,VAR,NONWW:2OK OHM,10%,0.5W

RES.,FXD,CMPSN:62K OHM,5%.0.125W

RES.,FXD,CMPSN:130K OHM,5%,0.125W

RES.,FXD,CMPSN:SlK OHM,5%,0.125W

RES.,FXD,CMPSN:100K OHM,5%,0.125W

RES.,FXD,CMPSN:6.2 OHM,5%,0.25W

REV

JUN

1987

Page 47

Replaceable Electrical Parts

-

YT-

CHART

RECORDER

REV JUN

A2 - MOTOR

Ckt.No.

1987

SPEED

Part

No.

CONTROL

Eff.

(cont)

Dscont Name & Description

(SEE

1-60

RMPL)

Code

Number

Page 48

Replaceable Electrical Parts - YT- CHART RECORDER

CHASSIS PARTS AND WlRE ASSEMBLIES

Ckt.No.

DS0282 150-1040-04 LED:RED,690nm,40mA MAX WILEADS & HLDR (1 50X) 80009 150-1040-01

Part

No.

Eff.

Dscont

Name & Description

-

CHASSIS MOUNTED PARTS

Code

Number

-

00182 151-0313-01 XSTR:NPN,SI FPT-106 W/HOLDER,WIRE

-

W1

001

WlRE ASSEMBLIES

198-2796-01 WIRE SET ELEC:670-1742-06 80009 198-2796-01

-

& CONN 80009 151 -031 3-01

REV

JUN

1987

Page 49

DIAGRAMS

AND

CIRCUIT

BOARD

ILLUSTRATIONS

Symbols

Graphic symbols and class designation letters are based

on ANSl Standard Y32.2-1975.

Logic symbology is based on ANSl Y32.12-1973 in terms

of positive logic. Logic symbols depict the logic function

performed and may differ from the manufacturer's data.

The overline on a signal name indicates that the signal

performs its intended function when it is in low state.

Abbreviations are based on ANSl Y1

Other ANSl standards that are used in the preparation of

diagrams by Tektronix, Inc. are:

Y14.15- 1966 Drafting Practices

Y14.2

-

REV

1973

DEC 1986

Line Conventions and Lettering

.l

-1

972.

-

Y10.5

1968 Letter Symbols for Quantities

Used in Electrical Science and

Electrical Engineering

American National Standards Institute

1430 Broadway

New York, New York 1001

8

Component Values

Electrical components shown on the diagrams are in the

following units unless noted otherwise:

Capacitors

Resistors

-

Values one or greater are in pico-

farads

(p

F).

Values less than one

are in microfarads

-

Ohms

(R

).

(p

F).

Page 50

Diagrams

Assembly Numbers

Each assembly in the instrument is assigned an assem-

bly number (e.g.,

on the circuit board outline on the diagram, in the title for

circuit board component location illustrations, and in the

lookup table for the schematic and corresponding com-

ponent locator illustration. The Replaceable Electrical

Parts list is arranged by assemblies in numerical

sequence. The components are listed alphabetically and

numerically by component number.

-

Y-T

Chart Recorder

--

The

information

below may appear in this manual

and

special symbols

and Grid Coordinates

A13).

The assembly number appears

--

The schematic diagram and circuit board component

A

location illustration have grids.

grid coordinates is provided for ease of locating the com-

ponent. Only the components illustrated on the facing

diagram are listed in the lookup table. When more than

one schematic diagram is used to illustrate circuitry on a

circuit board, the circuit board illustration may only

appear opposite the first diagram on which it is illus-

trated. The lookup table will list the diagram number of

other diagrams on which the circuitry of that circuit board

appears.

lookup table with the

REV

DEC

1986

Page 51

COMPONENT NUMBER EXAMPLE

REV

DEC

1986

-

t5Vi

ASSEMBLY CIRCUIT No

<h

FUNCTIONAL NAME

W0450A4

ERROR

AMPLIF'ER

C

,-P O("a

'h

'C')

FRONT PANEL

DENOTES A

PANEL CONTROL,

CONNECTOR, OR

INDICATOR

Page 52

PLUG

SPEED

STYLUS

t5V

IN

5ENS-

HEAT

-

-

(FROM

0

01

BE)

'Q

+5Y

-5V

GNO-

GND-

PAPER

)POOL

-

*+BY.

-8V

CHART-

FOR

1500

5ERIE5

--

CHART RECORDER

l

FROM

P1036-L

=

tozO

,CUbRT

PAPER

a

4

Page 53

Diagrams

-

Y-T

Chart

Recorder

REV

DEC

1986

ASSEMBLY

CIRCUIT SCHEM BOARD

NUMBER LOCATION LOCATION

C2034

84

c2

A1

CIRCUIT SCHEM BOARD

NUMBER LOCATION LOCATION

01

5 C1 A1

Q1

CIRCUIT SCHEM BOARD

NUMBER LOCATION LOCATIOI

R2034 D5 C2

Page 54

Diagrams

-

Y-T

Chart Recorder

5

J4037BACK

J4036 BACK

1

Fig.

8-1.

BACK.

Y-T

Chart Recorder Circuit Board.

5160-10

REV DEC

1986

Page 55

Diagrams

-

Y-T

Chart Recorder

REV

DEC

1986

CIRCUIT SCHEM BOARD

NUMBER

C201 9

C3026

CR2031 D1 C2

Q1 024 F1 B1

Q1039 F

R1015 El A1

LOCATION LOCATION

E2 A2

D1 B3

1

Fig.

B1

8-2.

ASSEMBLY

CIRCUIT SCHEM BOARD

NUMBER LOCATION

R201 4 E

R201 5

R201

6

R2024 El D2

R2025

R2026

R2029

R2035 E2 A3

A

B

A2

LOCATION

l

E

l

D1 A2

El B2

E2 B2

El B2

A2

A2

C

CIRCUIT SCHEM BOARD

NUMBER

R3015 E

R301 9

R3025 E2 B3

TPI 025 D2 B1

U2035A E2 C2

U20358 El C2

Motor Speed Control Circuit Board.

LOCATION LOCATION

l

E2 A3

A3

Page 56

Diagrams

-

Y-T

Chart

Recorder

IRCUIT BOARD

UMBER LOCATION

:IRCUlT BOARD

IUMBER LOCATDN

:IRCUIT BOARD

UMBER LCCATIOh

R2m5

R2m6

W017 83

W018 B3

R3018 B3

R3010 B3

R3021

R3022

R3023 82

R3024

R3025

R3026 B2

R3027 B2

R3028 83

R3030

R3031

R3034

R4017 A2

R4023 C3

R4025 B2

R4027 B2

R4033 C3

Fig.

82

D2

W

c3

W

C3

W

W

c3

8-3.

Modified Chart Recorder Board.

REV

JUN

1987

Page 57

EPLACEABLE

ME

PARTS ORDERING INFORMATION

Replacement parts are available from or through your

local Tektronix, Inc. Field Office or representative.

Changes to Tektronix instruments are sometimes made

to accomodate improved components as the become

available and to give you the benefit of the latest circuit

improvements developed in our engineering department.

It is, therefore, important, when ordering parts, to include

the following information in your order: Part number,

instrument type or number, serial number, and

modification number (if applicable).

REV

DEC

1986

ANlCAL

If

a part you have ordered has been replaced with a new

or improved part, your local Tektronix, Inc. Field Office

representative will contact you concerning any change in

part number.

Change information, if any, is incorporated on each

when the change occurs.

PAR

or

page

SPECIAL NOTES AND SYMBOLS

X000

OOX

Part first added at this serial number

Part removed after this serial number

Page 58

Replaceable Mechanical Parts

-

Y-T

Chart

Recorder

INDENTATION SYSTEM

This mechanical parts list is indented to indicate item

relationships. The following is an example of the inden-

tation system used in the description column:

&

Name

Assembly andlor Component

Attaching parts for this Assembly or Component

.

Detail Part of Assy or Component

.

Attaching parts for Detail Part

.

.

Parts of Detail Part

.

.

Attaching parts for Parts of Detail Part

Attaching Parts always appear in the same indentation

as the item it mounts, while the detail parts are indented

to the right. Indented items are part of, and included

Description

___*___

---*---

with, the next higher indentation. The separation

-

-

symbol indicates the end of attaching parts.

Attaching parts must be purchased separately,

unless otherwise specified.

-

- - * -

FIGURE AND INDEX NUMBERS

Items in this section are referenced by figure and index

numbers to the illustrations showing that part.

ITEM NAME

In this parts list, an ltem Name is separated from the

(:).

description by a colon

an ltem Name may sometimes appear as incomplete.

For further Item Name identification, the

Cataloging Handbook,

ble.

Because of space limitations,

U.S.

H6-1,

can be utilized where possi-

REV

Federal

DEC

1986

Page 59

If

ACTR

ADPTR

ALEN

AL

ASSEM

ASSY

ATTEN

AWG

BD

BRKT

BRS

BRZ

BSHG

CAB

CAP

CE R

CHAS

CKT

COMP

CONN

CVR

CPLG

CRT

DEG

DWR

INCH

NUMBER SIZE

ACNATOR

ADAPTER

ALGNMENT

ALUMINUM

ASSEMBLED

ASSEMBLY

ATTENUATOR

AMERICAN WlRE GUAGE

BOARD

BRACKET

BRASS

BRONZE

BUSHING

CABINET

CAPACITOR

CERAMIC

CHASSIS

CIRCUIT

COMPOSlTlON

CONNECTOR

COVER

COUPLING

CATHODE RAY TUBE

DEGREE

DRAWER

ELECTRN

ELEC

ELCTLT

ELEM

EPL

EQPT

EXT

FIL

FLEX

FLH

FLTR

FR

FSTNR

FT

FXD

GSKT

HDL

W

H

HEXHD

HEXSOC

HLCPS

HLEXT

HV

IC

ID

IDENT IDENTIFICATION

IMPLR IMPELLER

ELECTRON

ELECTRICAL

ELECTROLYTIC

ELEMENT

ELECTRICAL PARTS LIST

EQUIPMENT

EXTERNAL

FILLISTER HEAD

FLEXIBLE

FLAT HEAD

FILTER

or

FRAME

FASTENER

FOOT

FIXED

GASKET

HANDLE

HEXAGON

HEXAGONAL HEAD

HEXAGONAL SOCKET

HELICAL COMPRESSION

HELICAL EXTENSION

HIGH VOLTAGE

INTEGRATED CIRCUIT

INSIDE DIAMETER

FRONT

ABBREVIATIONS

IN INCH

INCAND

INSUL

INTL

LPHLDR

MCH

MECH

NIP

NONWW

ORD BY DESCR

OD

OVH

PHBRZ

PL

PLSTC

PN

PNH

PWR

RCPT

RE•˜

RGD

RLF

RTNR

SCH

SCOPE

SCR

SE

Replaceable Mechanical Parts - Y-T

SCT

INCANDESCENT

INSULATOR

INTERNAL

LAMP HOLDER

MACHINE

MECHANICAL

NIPPLE

NOT WlRE WOUND

ORDER BY DESCRIPTION

OUTSIDE DIAMETER

OVAL HEAD

PHOSPHOR BRONZE

or

PLATE

PLAIN

PLASTIC

PART NUMBER

PAN HEAD

POWER

RECEPTACLE

RESISTOR

RIGID

RELIEF

RETAINER

SOCKET HEAD

OSCILLOSCOPE

SCREW

SINGLE END

SEMICOND

SHLD

SHLDR

SKT

•˜L

SLVG

SPR

SQ

SST

STL

SW

T

TERM

THD

THK

TNSN

TPG

TRH

v

VA R

W1

WSHR

W

XFMR

XSTR

Chart

Recorder

SECTION

SEMICONDUCTOR

SHIELD

SHOULDERED

SOCKET

SLIDE

SLEEVING

SPRING

.SQUARE

STAINLESS STEEL

STEEL

SWITCH

TUBE

TERMINAL

THREAD

THICK

TENSION

TAPPING

TRUSS HEAD

VOLTAGE

VARIABLE

WITH

WASHER

WlRE WOUND

TRANSFORMER

TRANSISTOR

REV

DEC

1986

Page 60

Replaceable Mechanical Parts

-

Y-T

Chart Recorder

Mfr.

Code Manufacturer

NORTHWEST FASTENER SALES

LEWlS SCREW CO

PLASTOCK, INC.

AMP. INC.

MITE CORPORATION

FREEWAY CORPORATION

GRAPHIC CONTROLS CORP.

BERG ELECTRONICS. INC.

USM CORP., PARKER-KALON FASTENER DIV.

PORTESCAP

STANDARD PRESSED STEEL CO.

ALLEN MFG. CO.

ITT CANNON ELECTRIC

FISCHER SPECIAL MFG. CO.

HOLQKROME CO.

WALDES, KOHINOOR, INC.

WROUGHT WASHER MFG. CO.

TEKTRONIX, INC.

CROSS INDEX-MFR. CODE NUMBER

U

S

TO

MANUFACTURER

Address

7923 SW CIRRUS DRIVE

41 14 SOUTH PEORIA

380 CHESTNUT ST

P.0.BOX

446 BLAKE STREET

9301 ALLEN DRIVE

YOUK EXPRESSWAY

730 FIFTH AVENUE

BENSON EAST

P.O. DRAWER 570

666 E. DYER RD.

446 MORGAN STREET

31 BROOK ST. WEST

47-16 AUSTEL PLACE

2100 S.

P.O. BOX 500

3608

0

BAY ST.

City, State,

BEAVERTON, OR 97005

CHICAGO, IL 60609

NORWOOD,

HARRISBURG, PA 171

NEW HAVEN, CT 06515

CLEVELAND,

NEW CUMBERLAND, PA 17070

CAMPBELLSVILLE,

NEW YORK. NY 10019

JENKINTOWN, PA 19046

HARTFORD, CT 061 01

SANTA ANA, CA 92702

CINCINNATI, OH 45206

HARTFORD, CT 061 10

LONG ISLAND, NY 11 101

MILWAUKIE, WI 53207

BEAVERTON, OR 97077

Zip

NJ

OH

07648

44125

KY

05

42718

REV

DEC

1986

Page 61

Mfr.

Code

Manufacturer

Replaceable Mechanical Parts - Y-T

CROSS INDEX-MFR. CODE NUMBER TO MANUFACTURER

Address

City,

State,

Chart Recorder

Zip

REV DEC

83259 PARKER SEAL CO-OSSEAL, 10567 JEFFERSON BLVD

83309

83385 CENTRAL SCREW CO. 2530 CRESCENT DRIVE

86928 SEASTROM

95987 WECKESSER CO., INC.

ELECTRICAL SPECIALIN CO 21 3 E HARRIS AVE

MFG.

CO., INC. 701 SONORA AVENUE

4444

WEST IRVING PARK RD. CHICAGO, IL 60641

1986

CULVER CITY, CA 90231

SOUTH SAN FRANCISCO, CA 94080

BROADVIEW, IL 60153

GLENDALE, CA 91

201

Page 62

Replaceable Mechanical

Parts

-

Y-T

Chart Recorder

Fig.&

Index Tektronix SeriaVModel No.

No.

Part.No.

Eff.

Dscont.

Qty.

Name & Description

CHART RECORDER:OF15X ONLY

PLATE,BACKING:CHART PAPER

(ATTACHING PARTS)

SCREW,MACHINE:2-56 X ,250 FLH STL

---

---

BUSHING,SLEEVE:O.I31 ID X 0.125 L

.

KNOB:THUMBSCREW,CLEAR,O.I

. .

SETSCREW:4-40 X 0.125,STL,BLK,OXD

WASHER,FLAT:0.13 ID

FRAME SECTION,CABINET:LOWER FROM

(ATTACHING PARTS)

SCREW,TPG,TF:4-40 X 0.25 FLH STL

--F

---

RING,RETAINING:TYPE EXT.0.125 ID SFT

PIN,STR,THD:0.125 DIA X 6.417 L,AL

SHAFT,EXTENSION:0.125

CPLG,SHAFT,RGD:0.128 ID X 0.312 OD,AL

BEZEL ASSEMBLY:GENERAL PURPOSE

(ATTACHING PARTS)

NUT,SLEEVE:4-40 X 0.312,HEX,BRS

SCREW,MACHINE:4-40 X 0.25 FLH STL

X

0.375 OD.0.01 THK,NYLON

OD

X 4.44 L,AL

2 X 0.37

Mfr. Mfr.Part

Code Number

ORD BY DESCR

358-0378-00

366-0650-00

ORD BY DESCR

ORD BY DESCR

426-0852-01

ORD BY DESCR

220-0629-00

ORD BY DESCR

REV

JAN

1987

Page 63

Fig.&

Index Tektronix SerialIModel No.

Eff.

No. PartNo.

Dscont.

Qty.

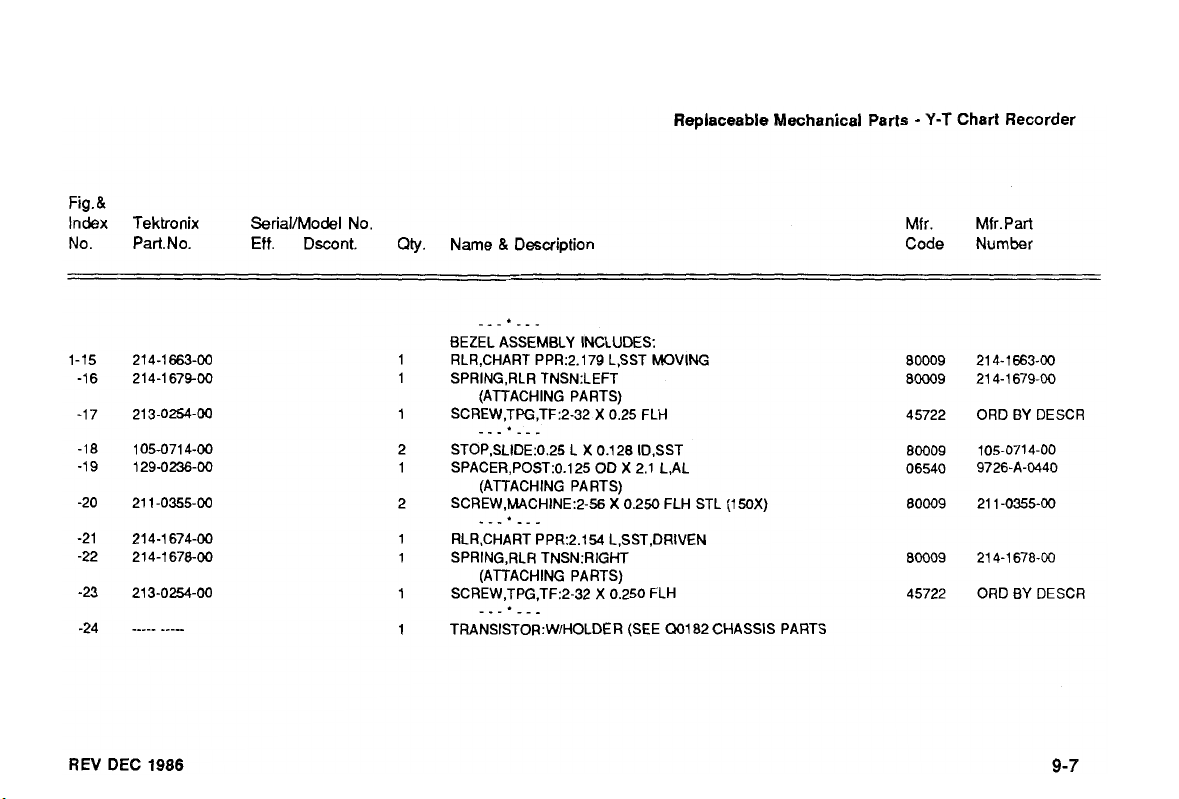

Name & Description

-_-*__-

BEZEL ASSEMBLY INCLUDES:

RLR,CHART PPR:2.179 L,SST MOVING

SPRING,RLR TNSN:LEFT

(ATTACHING PARTS)

SCREW,Tffi,TF:2-32

-__'___

STOP,SLIDE:O.25

SPACER,POST:O.I25 OD

(ATTACHING PARTS)

SCREW,MACHINE:2-56

--_*___

RLR,CHART PPR:2.154 L,SST,DRIVEN

SPRING,RLR TNSN:RIGHT

(ATTACHING PARTS)

SCREW,TPG,TF:2-32

---*___

TRANSIST0R:WlHOLDER (SEE

L

X

Replaceable Mechanical Parts

X

0.25 FLH

0.128 ID.SST

X

2.1 L,AL

X

0.250 FLH STL (150X)

X

0.250 FLH

Q01

82 CHASSIS PARTS

-

Y-T

Chart

Recorder

Mfr.

Mfr.Part

Code Number

BY

ORD

ORD BY DESCR

DESCR

REV

DEC

1986

Page 64

Replaceable Mechanical Parts

-

Y-T

Chart Recorder

Fig.&

Index Tektronix SeriallModel No.

No.

Part.No. Eff. Dscont.

Qty.

Name & Description

(ATTACHING PARTS)

SCREW,TPG,TF:2-32 X 0.250 FLH

___*___

HINGE HALF:STYLUS,MOVING UPPER

(ATTACHING PARTS)

NUT,PLAIN HEX:4-40 X 0.188,BRS CDPL

SCREW,MACHINE:4-40 X 0.250.PNH,STL CD PL

PIN.HINGE:0.75 L X 0.125 OD SST

___*___

HINGE HALF:SlYLUS,STATIONARY

(ATTACHING PARTS)

SCREW,MACHINE:4-40 X O.Z50,PNH,STL CD PL

___*___

HINGE HALF:STYLUS,MOVING LOWER

SPRING,PIN HINGE

STYLUS:CHT RCDR:W/W

(ATACHING PARTS)

SCR,ASSEM WSHR:6-32 X 0.438.DBL SEMS (OF15X)

TERMINAL LUG:0.146 ID

Mfr. Mfr.Part

Code Number

ORD BY DESCR

21 4-1 682-00

12161-50

ORD BY DESCR

21 4-1 749-00

21 4-1 681 -00

ORD BY DESCR

214-1682-01

21 4-1 680-00

11 9-0365-00

21 1-0602-00

5442-7

REV DEC

1986

Page 65

Fig.&

Index Tektronix SerialIModel No.

No.

Part.No.

Eff.

Dscont.

Qty.

Name & Description

Replaceable

Mechanical

Parts

Mfr.

Code

-

Y-T

Chart

Mfr.Part

Number

Recorder

REV

DEC

1986

SCRASSEM WSHR:6-32 X 0.312,DBL SEMS (150X)

___*___

STYLUS MOTOR WMIRES

(SEE B0295 CHASSIS PARTS)

HOLDER,PAPER:CHART ROLL

(AlTACHING PARTS)

SCREW,MACHINE:2-56 X 0.375 FLH

___*___

LED ASSY (SEE DS0282, CHASSIS PARTS)

(ATTACHING PARTS)

SCREW,TPG,TF:Z-32 X 0.25 FLH STL

CLAMP,LOOP:0.093 ID,NYLON

NUT,PLAIN HEX:2-56 X 0.188 BRS

WASHER,LOCK:SPLTT,O.02 THK,STL CD PL

WASHER,FLAT:0.093

-__*__-

FRONT SECTION,CHART:RIGHT

(ATTACHING PARTS)

SCREW,MACHINE:2-56 X 0.250 FLH STL

___*_._

BELT,POZ DRIVE:44 TOOTH,3.59 L X0.125 W

ID

CU BE

X 0.281 OD

ORD BY DESCR

352-0296-00

ORD BY DESCR

ORD BY DESCR

3132-2

12157-50

ORD BY DESCR

ORD BY DESCR

426-0838-01

BY

DESCR

ORD

44MX18-40DP

Page 66

Replaceable Mechanical Parts

-

Y-T

Chart Recorder

Fig.&

Index Tektronix SetiaVModel No.

No.

Part.No.

Eff.

Dscont

Qty.

Name & Desaiption

SPROCKET,WHEEL20 TOOTH.NYLON

BRACKET.CMPNT:MOTORAL

(ATTACHING PARTS)

SCRJCXZZM WSHR:4-40 X 0.312 DOUBLE SEMS

___*___

MOTOR.DC: (SEE -1, CHASSIS PARTS)

(ATTACHING PARTS)

SCREW,MACHINE:l-72

___.___

CKT BOARD ASSY:MOTOR SPEED

.TERMINAL.PIN:0.365 L X 0.025

(ATTACHING PARTS)

NUT,PLAIN HEX2-56

SCR,ASS€M WSHR2-56

_--*__.

CKT BOARD ASSYCHART RECORDER (SEE A1 REPL)

.TERMINAL.PIN:0.365 L X 0.025

.CONNECTOR,RCPT ELECEKT

.RES,VAR: (SEE A1

(ATTACHING PARTS)

NUT.PLAIN HEX:.25-32 X 0.312 BRS

X

0.1 25,FLH STL

X

0.188 BRS

X

0250 DOUBLE SEMS

R2034

REPL)

COHTROL

PH

BR2 GOLD

PH

BR2 GOLD

BD

MT.15 CONTACT

(SEE

A2

REPL)

Mfr.

Code

Mfr.Part

Number

ORD

BY

ORD

BY

12157-50

ORD

BY

REV

DEC

DESCR

DESCR

DESCR

1986

Page 67

Fig.

&

index Tektronix SerialIModel No.

Eff.

No. Part.No.

Dscont.

Qty.

Name & Description

Replaceable Mechanical Parts

Mfr. Mfr. Part

Code Number

-

Y-T

Chart Recorder

REV

DEC

1986

WASHER,FLAT:0.25 ID X 0.02 THK,STL

WASHER,FLAT:0.265 ID X 0.01 THK,TEFLON

___*_-_

CLAMP LOOP:0.3 DIA,PLASTIC

SOCKET,PIN TERM:U/W 0.019 DIA PINS

SPACER,POST:2.024 L,W12-56 THD EA END,AL

(ATTACHING PARTS)

SCREW,MACHINE:2-56 X 0.250

___.___

RLR,CHART PPR:0.250 DIA X 2.154 L

RLR,CHART PPR:0.125 DIA X 2.154 L

SPROCKET WHEEL:W/B?ISHING

RLR,CHART PPR:DRIVE CORE

PACKIFiG,PREFMD:0.549 ID

BUSHING,PLASTIC:0.730 DIA X 0.080 Wl.260 DIA

FRONT SECTION,CHART:LEFT

X

0.103 XSECT

ORD

BY

21 0-0992-00

343-0089-00

2-330808-7

ORD

21 4-1662-00

21 4-1 664-00

401 -0186.02

21 4-1 675-01

21 13En45D

426-0837-02

DESCR

129-0327-00

BY

DESCR

Page 68

Replaceable Mechanical

Parts

-

Y-T

Chart Recorder

REV DEC

1986

Page 69

Replaceable Mechanical Parts

-

Y-T

Chart Recorder

FIGURE

Y-T

CHART PAPER

9-2

9-1

3

Page 70

Replaceable

Mechanical Parts

Fig.&

Index Tektronix SeriaVModel No. Mfr. Mfr.Part

No. Part.No.

-

Y-T

Chart Recorder

Eff.

Dscont.

Qty.

Name & Description Code

Number

1 PAPER,RCDG,CHART:GRAY

(150X ONLY)

1 PAPE R,RCDG,CHART:GRAY 17405 ORD BY DESCR

(OF15X ONLY)

80009

006-1658-01

Page 71

ACCESSORIES

Standard Accessories

1 Instruction Manual (070-51 60-00)

1 Roll of Chart Paper (006-361 8-00)

(OF TDR Series only)

1

Roll

of

Chart Paper (006-1 658-01

(1 500 TDR Series only)

REV

DEC 1986

Optional Accessories

Chart Paper, 25-Roll Pack

(OF TDR Series only)

)

Chart Paper, 100-Roll Pack

(OF TDR Series only)

Chart Paper, 100-Roll Pack (006-1 658-02)

(1500 Series only)

(006-361 8-01)

(006-361 8-02)

Loading...

Loading...