Page 1

xx

WVR7200

Waveform Rasterizers

ZZZ

Installation and Safety

Instructions

*P071302400*

071-3024-00

Page 2

Page 3

xx

WVR7200

Waveform Rasterizers

ZZZ

Installation and Safety

Instructions

www.tektronix.com

071-3024-00

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifica tions and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. B o x 5 0 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worl dwid e, v isit www.tektronix.com to find contacts in your area.

Page 5

Table of Contents

Preface ............................................................................................................... 1

Documentation ................................................................................................. 1

General Safety Summary .......................................................................................... 2

Compliance Information........................................................................................... 4

EMC Compliance............................. ................................ ................................ . 4

Safety Compliance............................................................................................. 5

Environmental Considerations ........................................ ................................ ....... 6

Operating Requirements ........................................................................................... 7

Electrical Ratings .............................................................................................. 7

Environmental Ratings ........................................................................................ 8

Physical Specifications........................................................................................ 8

Rear-Panel Connectors............................................................................................. 9

Input and Output Connectors.... ................................ ................................ ............ 10

Basic Installation Procedure...................................... ................................ ................ 16

Before Installation ............................................................................................ 17

Installing in a Video System . ..... . ..... . ..... . .... . . .... . ..... . ..... . ..... . ..... . .... . ..... . ..... . ..... . ... . 19

Power-On and Power-Off Procedure ............................................................................ 22

ont-Panel Controls ............ ................................ .................................. ................ 23

Fr

はじめに.................................................................................................. 26

マニュアル ........................................................................................... 26

安全にご使用いただくために .......................................................................... 27

適合性に関する情報.................................................................................... 29

EMC 適合性......................................................................................... 29

安全性 ............................................................................................... 30

環境に関する考慮事項 ............................................................................ 31

動作の要件 .............................................................................................. 33

電気定格 ............................................................................................ 33

環境要件 ............................................................................................ 34

物理仕様 ............................................................................................ 34

リア・パネル・コネクタ.................................................................................... 35

入力/出力コネクタ ................................................................................ 36

基本的な設置手順 ...................................................................................... 43

設置の前に .......................................................................................... 44

ビデオ・システムへの設置.......................................................................... 46

電源投入、電源遮断の手順............................................................................ 48

フロント・パネル・コントロール .......................................................................... 49

前言 ...................................................................................................... 53

文档 .................................................................................................. 53

WVR7200 Installation and Safety Instructions i

Page 6

Table of Contents

常规安全概要 ........................................................................................... 54

符合性信息 .............................................................................................. 56

EMC 符合性 .......................................................................................... 56

安全符合性.......................................................................................... 57

环境注意事项....................................................................................... 58

操作要求................................................................................................. 59

电源额定值.......................................................................................... 59

环境额定值.......................................................................................... 60

物理技术规格....................................................................................... 60

后面板连接器 ........................................................................................... 61

输入和输出连接器 ................................................................................. 62

基本安装步骤 ........................................................................................... 68

安装之前 ............................................................................................ 69

在视频系统中安装 ................................................................................. 71

开机和关机步骤 ........................................................................................ 73

前面板控件 .............................................................................................. 74

ii WVR7200 Installation and Safety Instructions

Page 7

Preface

This document contains the following information:

Important safety precautions to avoid injury and prevent damage to this

product or any products connected to it

EMC (electromagnetic compliance), safety, and environmental standards

with which the instrument complies

Voltage, power, and environmental requirements to use the product

Installation procedure

Power-on and power-off procedure

Front-p

anel and rear-panel features

Documentation

The fol

product and shows where you can find it: in a printed manual, on the product

documentation CD-ROM, or on the Tektronix Web site at www.tektronix.com.

Table 1: Product documentation

Item Purpose Location

Installation and Safety Instructions

(this manual)

User Manual

Online Help

Specifications and Performance

Verification Technical R eference

WFM and WVR Series

Management Information

Database (MIB) Programmer

Manual

Service Manual Provides information about adjustments, repair, and

Provides safety and compliance information with

hardware installation instructions to present the

associated safety warnings. This manual is available

in English, Japanese, and Simplified Chinese.

Provides operation and application information.

In-depth instrument operation and UI help.

Specifications and procedures for checking instrument

performance.

SNMP command reference for remotely controlling the

instrument.

replaceable parts.

lowing table lists some of the documentation that is available for this

Printed manual and also

available in electronic format

at www.tektronix.com/manuals

Product Documentation

CD and available at

www.tektronix.com/manuals

On the instrument

Product Documentation

CD and available at

www.tektronix.com/manuals

Product Documentation

CD and available at

www.tektronix.com/manuals

Available at

www.tektronix.com/manuals

WVR7200 Installation and Safety Instructions 1

Page 8

General Safety Summary

General Safet

To Avoid Fire or Personal

Injury

ySummary

Review the fo

this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform ser vice procedures.

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avo id fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to a ny terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

llowing safety precautions to avoid injury and prevent damage to

Power Disconnect. The power cord disconnects the product from the power

source. Do not block the power cord; it must remain accessible to the user at

all times.

Do Not Operate Without Covers. Do not operate this product with covers or

panels removed.

Do Not Operate With Suspected Failures. If you suspect that there is damage to

this product, have it inspected by qualified service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when powe r is present.

Use Proper AC Adapter. Use only the AC adapter specified for this product.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual's installation instructions for

details on installing the product so it has proper ventilation.

2 WVR7200 Installation and Safety Instructions

Page 9

General Safety Summary

Terms in this Manual

Symbols and Terms on the

Product

These terms may

WAR NI NG . Warning s tatements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER in

the marking.

WARNING

read the marking.

CAUTIO

The following symbol(s) may appear on the product:

appear in this manual:

dicates an injury hazard immediately accessible as you read

indicates an injury hazard not immediately accessible as you

N indicates a hazard to property including the product.

WVR7200 Installation and Safety Instructions 3

Page 10

Compliance Information

Compliance In

EMC Compliance

EC Declaration of

Conformity – EMC

formation

This section

environmental standards with which the instrument complies.

Meets intent of Directive 2004/108/EC for Electromagnetic Compatibility.

Compliance was demonstrated to the following specifications as listed in the

Official Journal of the European Communities:

EN 55103:1996. Product family standard for audio, video, audio-visual and

entertainment lighting control apparatus for professional use.

Environment E2 – commercial and light industrial

Part 1 Emission

Part 2 Immunity

lists the EMC (electromagnetic compliance), safety, and

1,2

EN 55022:1987. Class B radiated and conducted emissions

EN 55103-1:1996 Annex A. Radiated magnetic field emissions

IEC 61000-4-2:2001. Electrostatic discharge immunity

IEC 61000-4-3:2006. RF electromagnetic field immunity

IEC 61000-4-4:2004. Electrical fast transient / burst immunity

IEC 61000-4-5:2005. Power line surge immunity

IEC 61000-4-6:2003. Conducted RF Immunity

IEC 61000-4-11:2004. Voltage dips and interruptions immunity

EN 55103-2:1996 Annex A Radiated magnetic field immunity

1

To ensure compliance with the EMC standards listed here, high-quality shielded interface cables should be used.

2

Inrush current: 8 A peak.

EN 61000-3-2:2006. AC power line harmonic emissions

EN 61000-3-3:1995. Voltage changes, fluctuations, and flicker

European Contact.

Tektronix UK, Ltd.

Western Peninsula

Western Road

Bracknell, RG12 1RF, United Kingdom

4 WVR7200 Installation and Safety Instructions

Page 11

Compliance Information

Australia / New Zealand

Declaration of

Conformity – EMC

Safety Compliance

EC Declaration o f

Conformity – Low Voltage

U.S. Natio nally Recognized

Testing Laboratory Listing

Canadian Certification

Complies with t

following standard, in accordance with ACMA:

EN 55022:1987

with EN 55103-1:1996.

Compliance was demonstrated to the following specification as listed in the

Official Journal of the European Communities:

Low Voltage Directive 2006/95/EC.

EN 61010-1: 2001. Safety requirements for electrical equipment for

measurement control and laboratory use.

UL 61010

equipment.

CAN/CSA-C22.2 No. 61010-1:2004. Safety requirements for electrical

equipm

he EMC provision of the Radiocommunications Act per the

. Radiated and conducted emissions, Class B, in accordance

-1:2004, 2

ent for measurement, control, and laboratory use. Part 1.

nd

Edition. Standard for electrical measuring and test

Additional Compliances

pment Type

Equi

Safety Class

Pollution Degree

cription

Des

IEC 61010-1: 2001. Safety requirements for electrical equipment for

measurement, control, and laboratory use.

Test and measuring equipment.

Class1–groundedproduct.

A measure of the contaminants that could occur in the environment around

within a product. Typically the internal environment inside a product is

and

considered to be the same as the external. Products should be used only in the

environment for which they are rated.

Pollution Degree 1. No pollution or only dry, nonconductive pollution occurs.

Products in this category are generally encapsulated, hermetically sealed, or

located in clean rooms.

Pollution Degree 2. Normally only dry, nonconductive pollution occurs.

Occasionally a temporary conductivity that is caused by condensation must

be expected. This location is a typical office/home environment. Temporary

condensation occurs only when the product is out of service.

WVR7200 Installation and Safety Instructions 5

Page 12

Compliance Information

Pollution Degree

Environme

Product End-of-Life

Pollution Degr

that becomes conductive due to condensation. These are sheltered locations

where neither temperature nor humidity is controlled. The area is protected

from direct sunshine, rain, or direct wind.

Pollution Degree 4. Pollution that generates persistent conductivity through

conductive dust, rain, o r snow. Typical outdoor locations.

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

ntal Considerations

This section provides information about the environmental impact of the product.

Observe the following guidelines when recycling an instrument or component:

Handling

Equipment Recycling.

Production of this equipment required the extraction and use of natural resources.

The equipment may contain substances that could be harmful to the environment

or human health if improperly handled at the product’s end of life. In order to avoid

release of such substances into the environment and to reduce the use of natural

rces, we encourage you to recycle this product in an appropriate system that

resou

will ensure that most of the materials are reused or recycled appropriately.

ee 3. Conductive pollution, or dry, nonconductive pollution

Restriction of Hazardous

Substances

This symbol indicates that this product complies with the applicable European

Union requirements according to Directives 2002/96/EC and 2006/66/EC

on waste electrical and electronic equipment (WEEE) and batteries. For

information about recycling options, c heck the Support/Service section of the

Tektronix Web site (www.tektronix.com).

Perchlorate Materials. This product contains one or more type CR lithium

batteries. According to the state of California, CR lithium batteries are

classified as perchlorate materials and require special handling. See

www.dtsc.ca.gov/hazardouswaste/perchlorate for additional information.

This product has been classified as Monitoring and Control equipment, and is

outside the scope of the 2002/95/EC RoHS Directive.

6 WVR7200 Installation and Safety Instructions

Page 13

Operating Requirements

Operating Req

Electrical Ratings

Power Requirements

uirements

This section

product safely and correctly. Refer to the complete product specifications for

additional information.

Power connector

The instrument has the following power requirements:

A single-phase power source with one current-carrying conductor at or near

earth-ground (the neutral conductor).

The power source frequency must be 50 or 60 Hz, and a operating voltage

range must be from 100 to 240 VAC, continuous.

provides the speci fi cations that you need to know to operate your

WAR NI NG . Toreduceriskoffire and shock, ensure the mains supply voltage

ations do not exceed 10% of the operating voltage range.

fluctu

Systems with both current-carrying conductors live with respect to ground

ch as phase-to-phase in multiphase systems) are not recommended as

(su

power sources.

NOTE. Only the line conductor is fused for over-current protection. The fuse is

internal and not user replaceable. Do not attempt to replace the fuse. If you

suspect the fuse has blown, return the unit to an authorized service center for

repair.

WVR7200 Installation and Safety Instructions 7

Page 14

Operating Requirements

Environmental Ratings

Table 2: Environmental performance

Category Standards or description

Temperature

Humidity

Altitude

Cooling The intake air vents in the front of the instrument must not be blocked and the rear exhaust

Operating 0 °C to +40 °C

Non Operating –40 °C to +75 °C

Operating 20% to 80% relative humidity (% RH) at up to +40 °C, non-condensing

Non Operating 5% to 90% RH (relative humidity) at up to +60 °C, non-condensing

Operating Up to 9,842 feet (3,000 meters)

Non Operating Up to 40,000 feet (12,192 meters)

quires at least 1 inch of clearance. No clearance is required above or below the

vents re

instrument.

Physic

al Specifications

Table 3: Physical characteristics

cteristic

Chara

Dimensions

Weight

Height

Width

Depth

Net

ipping

Sh

Cleaning

ard

Stand

nches (4.37 centimeters)

1.72 i

ches (48.26 centimeters)

19 in

25 inches (51.44 centimeters) (Not including cables)

20.

pounds (4.31 kilograms), maximum

9.5

pounds (8.62 kilograms), approximate

19

t required for the safe operation of the instrument. However, if you wish to

No

perform routine cleaning on the exterior of the instrument, refer to the user manual

on the Product Documentation CD that was shipped with your instrument.

8 WVR7200 Installation and Safety Instructions

Page 15

Rear-Panel Connectors

Rear-Panel Co

nnectors

The followin

rear-panel inputs are arranged in Slot 1 or Slot 2. Although these slots are not

labeled as such on the rear-panel, the center section corresponds to the Slot 1 Input

buttons on the front panel and usually contains the SDI or EYE inputs. The right

section of the rear panel corresponds to the Slot 2 Input buttons on the front panel,

and will contain the composite inputs, if present. (See Figure 4 on page 23.)

g figure shows the rear-panel with optional connectors. The

Figure 1: Rear-panel

WVR7200 Installation and Safety Instructions 9

Page 16

Rear-Panel Connectors

Input and Outp

Video Connectors

ut Connectors

SDI inputs are self-terminating inputs.

Inputs

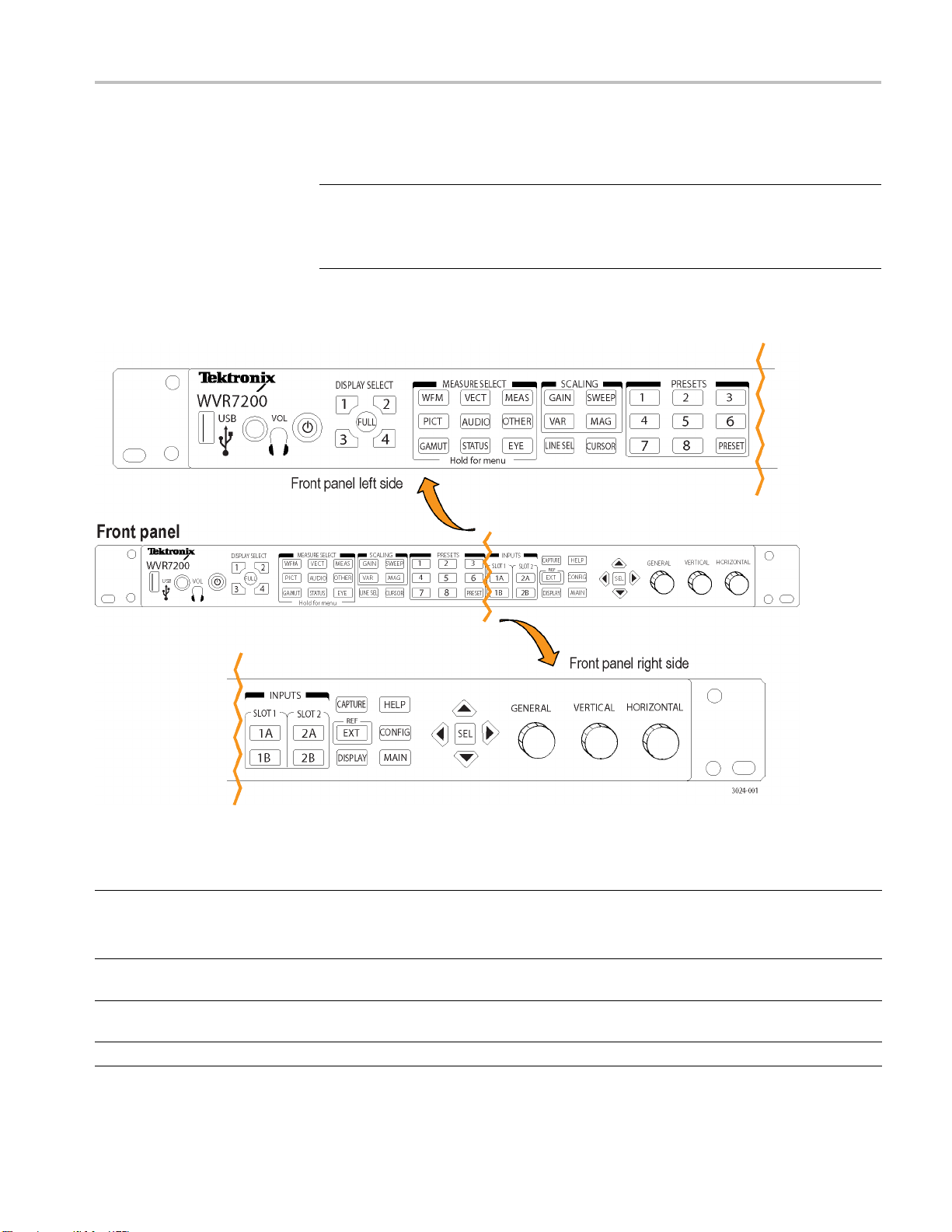

REF Loop. A synchronization input. The

input signa

composite video, or analog tri-level for HD.

Requires termination.

SDI A IN. Th

input.

SDI B IN. The digital B component serial digital

input.

SDI A OUT. Reclocked output of the SDI A input.

SDI B / CLK OUT. Reclocked output of the

SDI B inpu

instruments with Option PHY3.

Reference and Composite inputs are passive loop inputs.

NOTE. External termination for reference and composite inputs is required.

Connectors

l can be analog black burst, analog

e digital A component serial digital

Options PHY3

t. Also a recovered clock output for

10 WVR7200 Installation and Safety Instructions

Page 17

Rear-Panel Connectors

Inputs

CMPST A. The c omposite A analog input.

CMPST B. The c omposite B analog input.

SDI O UT. Can b

Loop Out, or Test Signal

1

Test Signal

e selected to output Pixmon,

1

.

is available for Option GEN only.

AES A/B Connectors

Inputs Connectors

These BNC connectors support AES audio

inputs.

Input A fo

Input A for AES channels 3 and 4

Input A for AES channels 5 and 6

Input A f

Default input B for AES channels 1 and 2

Default input B for AES channels 3 and 4

Default

Default input B for AES channels 7 and 8

1

r AES channels 1 and 2

Options AD and DPE

or AES channels 7 and 8

1

1

input B for AES channels 5 and 6

TheAESBconnectorscanbeconfigured to output embedded audio channels, decoded Dolby, or the AES A inputs.

1

1

Connectors

Analog

Input/Output

Connector

The Analog I/O connector is used to receive and send analog signals. The Analog

I/O connector is a 62-pin, D-subminiature connector. Pin assignments and pin

names are listed in the following figure and table.

ION. Use care when connecting the Analog Audio Output. Refer to the

CAUT

instrument specifications to ensure that the Audio Load and Output Power meet

specifications. Exceeding Analog Audio Output Power may result in damage

to the instrument.

Option AD Input./Output connector

WVR7200 Installation and Safety Instructions 11

Page 18

Rear-Panel Connectors

Pin Description

1 ANALOG_INPU

2 ANALOG_INPU

3 ANALOG_INP

4 ANALOG_IN

5 ANALOG_IN

6 ANALOG_I

7 ANALOG_

8 ANALOG_

9ANALOG

10 ANAL

11 ANAL

12 ANA

13 GND

14 AN

15 AN

16 A

17

18

1

2

21 ANALO G_OUTP UT_8_P Balanced differential analog audio output- Ch. 8, positive.

22 ANALOG_INPUT_A1_N Balanced differential analog audio input- Ch. 1, line A, negative.

23 ANALOG_INPUT_B1_N Balanced differential analog audio input- Ch. 1, line B, negative.

24 ANALOG_INPUT_A2_N Balanced differential analog audio input- Ch. 2, line A, negative.

25 ANALOG_INPUT_B2_N Balanced differential analog audio input- Ch. 2, line B, negative.

26 ANALOG_INPUT_A3_N Balanced differential analog audio input- Ch. 3, line A, negative.

27 ANALOG_INPUT_B3_N Balanced differential analog audio input- Ch. 3, line B, negative.

28 ANALOG_INPUT_A4_N Balanced differential analog audio input- Ch. 4, line A, negative.

29 ANALOG_INPUT_B4_N Balanced differential analog audio input- Ch. 4, line B, negative.

30 ANALOG_INPUT_A5_N Balanced differential analog audio input- Ch. 5, line A, negative.

31 ANALOG_INPUT_B5_N Balanced differential analog audio input- Ch. 5, line B, negative.

32 ANALOG_INPUT_A6_N Balanced differential analog audio input- Ch. 6, line A, negative.

33 ANALOG_INPUT_B6_N Balanced differential analog audio input- Ch. 6, line B, negative.

34 GND

35 ANALOG_OUTPUT_1_N Balanced differential analog audio output- Ch. 1, negative.

36 ANALOG_OUTPUT_2_N Balanced differential analog audio output- Ch. 2, negative.

37 ANALOG_OUTPUT_3_N Balanced differential analog audio output- Ch. 3, negative.

38 ANALOG_OUTPUT_4_N Balanced differential analog audio output- Ch. 4, negative.

OG_INPUT_B5_P

OG_INPUT_A6_P

LOG_INPUT_B6_P

ALOG_OUTPUT_1_P

ALOG_OUTPUT_2_P

NALOG_OUTPUT_3_P

ANALOG_OUTPUT_4_P

ANALOG_OUTPUT_5_P

9 ANALOG_OUTPUT_6_P

0 ANALOG_OUTPUT_7_P

T_A1_P

T_B1_P

UT_A2_P

PUT_B2_P

PUT_A3_P

NPUT_B3_P

INPUT_A4_P

INPUT_B4_P

_INPUT_A5_P

Balanced diff

Balanced diff

Balanced dif

Balanced di

Balanced di

Balanced d

Balanced

Balanced

Balance

Balanc

Balanc

Balan

nced differential analog audio output- Ch. 1, positive.

Bala

nced differential analog audio output- Ch. 2, positive.

Bala

anced differential analog audio output- Ch. 3, positive.

Bal

lanced differential analog audio output- Ch. 4, positive.

Ba

lanced differential analog audio output- Ch. 5, positive.

Ba

alanced differential analog audio output- Ch. 6, positive.

B

alanced differential analog audio output- Ch. 7, positive.

B

erential analog audio input- Ch. 1, line A, positive.

erential analog audio input- Ch. 1, line B, positive.

ferential analog audio input- Ch. 2, line A, positive.

fferential analog audio input- Ch. 2, line B, positive.

fferential analog audio input- Ch. 3, line A, positive.

ifferential analog audio input- Ch. 3, line B, positive.

differential analog audio i nput- Ch. 4, line A, positive.

differential analog audio i nput- Ch. 4, line B, positive.

d differential analog audio input- Ch. 5, line A, positive.

ed differential analog audio input- Ch. 5, line B, positive.

ed differential analog audio input- Ch. 6, line A, positive.

ced differential analog audio input- Ch. 6, line B, positive.

12 WVR7200 Installation and Safety Instructions

Page 19

Pin Description

39 ANALOG_OUT

40 ANALOG_OUT

41 ANALOG_OU

42 ANALOG_O

43– 62 No connection.

PUT_5_N

PUT_6_N

TPUT_7_N

UTPUT_8_N

Balanced diff

Balanced diff

Balanced dif

Balanced di

ferential analog audio output- Ch. 7, negative.

fferential analog audio output- Ch. 8, negative.

Rear-Panel Connectors

erential analog audio output- Ch. 5, negative.

erential analog audio output- Ch. 6, negative.

EXT DISPLAY Connector

Pin Assignment

PIX M ON Connector Pin

Assignment

This is the external display monitor output. The display resolution is 1024 x

768. The output supports DVI monitors directly and analog PC (RGB) monitors

with the use of a DVI-I to VGA adapter. The EXT DISPLAY connector is a

DVI-I connector with socket contacts.

EXT DISPLAY connector

This is the video picture output. The output is compatible with standard analog

PC monitors, either CRT or LCD-based. The PIX MON connector is a 15-pin

D-type connector with socket contacts.

PIX MON connector

Pin Pin name

1 Red Video

2

3 Blue Video

4 Not connected

5

6

7

8

9

10

11

12

13

Green Video

Ground

Red Ground

Green Ground

Blue Ground

Not Connected

Not Connected

Not Connected

Not Connected

Horizontal Sync

WVR7200 Installation and Safety Instructions 13

Page 20

Rear-Panel Connectors

REMOTE Connector Pin

Assignment

14

15

The REMOTE connector interface uses ground closures for remote control and

indicating to external equipment when alarms have occurred. The input of LTC is

Vertical Sync

Not Connected

through the REMOTE connector. The REMOTE connector is a 15-pin D-type

connector with socket contacts

NOTE. For m

ore information on Preset recall, refer to the Technical Reference

manual on the Product Documentation CD that was shipped with your instrument.

Remote c

Characteristic Pin out Preset functions

Connector Pin Assignments

1GND(In)

2 Reserved (I/O)

3 Reser

4 Reserved (In)

5 Reserved (In)

6GND(

7 Time Code Positive (LTC In)

8 Time Code Negative (LTC In)

9Gro

10 Preset 1 (In)

11 Preset 2 (In)

12 P

13 Preset 4 (In)

14 Preset 5 (In)

15 P

onnector preset functions.

ved (I/O)

In)

und Closure (Alarm Out)

reset 3 (In)

reset 6 (In)

Hex Binary

Pins 15,

14, 13,

12, 11,

10

F 11111

E XX1110 Preset 1

D XX1101 Preset 2

C

B XX1011 Preset 3

A XX1010

9 XX1001

8 XX1000 Preset 8

7

6X

5

4 XX0100 Preset 4

3 XX0011 Preset 3

2 XX0010 Preset 2

1 XX0001 Preset 1

0 XX0000 Unused

1

XX1100

XX0111 Preset 4 Preset 7

X0110

XX0101 Preset 5

Direct

mode

selection

none

Encoded

mode

selection

ion

No act

CMPST

TA

CMPS

SDI B

A

SDI

nnel B

Cha

annel A

Ch

reset 6

P

B

14 WVR7200 Installation and Safety Instructions

Page 21

Rear-Panel Connectors

Ethernet Connector

The instrument

connector is a standard RJ-45 connector.

Ethernet connector

provides a 10/100/1000 BaseT Ethernet interface. The Ethernet

WVR7200 Installation and Safety Instructions 15

Page 22

Basic Installation Procedure

Basic Installation Procedure

Your instrument is shipped in a fully enclosed metal chassis. You can operate the

instrument in the provided chassis or install the chassis in a standard, 19-inch

equipment ra

To install your instrument in a rack, follow the instructions that are included with

the optiona

cooling and clearance requirements. (See page 8, Environmental Ratings.)

CAUTION. Do not install this instrument in any cabinet; attempting to do so can

damage the instrument and the cabinet.

If you need to install your instrument in a custom application, such as a console,

be sure to provide adequate airflow and ensure that the intake air to the side vents

do not exceed 40 °C. Do not block or restrict the ventilating holes. Refer to the

Environmental Ratings section for cooling and clearance requirements. (See

page 8, E

ck.

l accessory kit. Also refer to the Environmental Ratings section for

nvironmental Ratings.)

When installing in a custom application, use the Rack Adapter clearances.

ON. To prevent risk of fire, adequate airflow must be maintained. Failure

CAUTI

to provide adequate airflow to the instrument could cause the instrument to

shut down. Inadequate airflow includes placing the instrument in any small,

enclosed room that lacks a ventilation system, such as a closet. If the airflow is

restricted or blocked and the instrument does not shut down, the instrument c ould

be permanently damaged and increases the risk of fire.

16 WVR7200 Installation and Safety Instructions

Page 23

Basic Installation Procedure

Before Instal

lation

Unpack the instrument and check that you have received all of the items listed

as standard accessorie s. You may want to save the shipping carton and packing

ncluding the anti-static bag) in case you need to ship the instrument.

Accessories

materials (i

The following table shows which items are shipped with your instrument

(Standard) and which items are available on the Tektronix Web site only

(Optional

). Check our Web site (www.tektronix.com) for the most current

information on accessories.

Accessory Standard Optional Tektronix part number

WVR7200 Waveform Rasterizers Installation and Safety Instructions

(English, Japanese, Simplified Chinese)

WVR7200 Waveform Rasterizers Product Documentation CD

This CD contains the following documents in PDF format. (All documents

are in English unless noted otherwise):

WVR7200 Waveform Rasterizers User Manual

WVR7200 Waveform Rasterizers Specifications and Performance

Verification Technical Reference

WFM and WVR Series Management Information Database (MIB)

Programmer Manual

WVR7200, WVR8200 and WVR8300 Waveform Rasterizers System

Integration Instructions

WVR7200 Waveform Rasterizers Release Notes

WVR7200 Waveform Rasterizers Declassification and Security Instructions

WVR7200 Waveform Rasterizers S ervice Manual

8RFP Option Remote Front Panel Instructions

WVR

Power Cord

071-3024-XX

063-4428-XX

077-0668-XX

077-0670-XX

071-0261-XX

077-0392-XX

077-0674-XX

077-0672-XX

077-0676-XX

071-2804-XX

Not applicable

NOTE. See the International Power Cords list that follows this table for

the type of power cord included with your instrument.

WVR7200 Installation and Safety Instructions 17

Page 24

Basic Installation Procedure

International

power cords. Your instrument was shipped with one of the following

power cord options. Power cords for use in North America are UL listed and CSA

certified. Cords for use in areas other than North America are approved by at least

one authority acceptable in the country to which the product is shipped.

Opt. A0 – North America power

Opt. A1 – Universal EUR power

Opt. A2 – Uni

ted Kingdom power

Opt. A3 – Australia power

Opt. A4 – 240 V, North America power

Opt. A5 – Switzerland power

Opt. A6 – Japan power

Opt. A10 – China power

1

9

Opt. A9

1

When ordering the A99 option, it is the responsibility of the end user to ensure that a certified power cord, for the

y or region it is installed, is used with this instrument.

countr

–NopowercordorACadapter

CAUTION. To reduce risk of fire and shock, use the certified power cord provided

with the product.

18 WVR7200 Installation and Safety Instructions

Page 25

Basic Installation Procedure

Installing in

For Monitori

Bit Stream of a Serial

ng the Video

a Video System

The instrument can operate almost anywhere in the distribution system. The

following diagrams for serial digital systems and for the analog composite inputs.

Route the incoming serial signal into one of the instrument SDI inputs.

Receiver

Figure

2: Options PHY3 and 3G

NOTE. See the Specifications and Performance Verification manual on the

Product Documentation CD for maximum-allowed cable lengths.

WVR7200 Installation and Safety Instructions 19

Page 26

Basic Installation Procedure

For Monitoring Composite

Signals

Figure 3: Option CPS

Connect your so

the rear-panel.

urces to the CMPST A or CMPST B loop-through inputs on

Line Termination

Your instrument uses passive loop-through, analog reference and composite video

inputs. Accordingly, the loop-through inputs must be terminated externally.

It is important that this external termination meets accuracy and return loss

requirements.

If the instrument is installed to monitor an operating link, the destination receiver

and the connecting cable serve as the termination. This monitoring connection

ks the performance of the entire path. The return loss of the instrument is

chec

sufficiently high that, in most cases, the destination receiver sets the system return

loss.

In cases where the instrument is placed at the end of a link, a BNC termination

must be installed on one side of the loop-through input. The termination must

be 75 Ω and DC coupled (good return loss extends to DC). An appropriate

termination is Tektronix part number 011-0102-00; this is a 75 Ω, End-of-Line

termination.

Return loss from composite signals must be >40 dB from DC to 6 MHz.

20 WVR7200 Installation and Safety Instructions

Page 27

Basic Installation Procedure

Compatibility of BNC

Center Pins

Most BNC connec

standard center pin. Some laboratory 75 Ω BNCconnectorsuseasmaller

diameter center pin. The BNC connectors on the instrument are designed to work

with the 50 Ω standard (large diameter) center pins.

NOTE. Do not use connectors or terminators with non-standard sized center pins.

Using pins that have a smaller diameter could cause intermittent connections.

tors for video equipment, whether 50 Ω or 75 Ω,usea50Ω

WVR7200 Installation and Safety Instructions 21

Page 28

Power-On and Power-Off Procedure

Power-On and P

AC Power Requirements

Power-On

ower-Off Procedure

This instrum

conductor at or near earth ground. The line conductor is fused for over-current

protection. A protective ground connection through the grounding conductor in

the power cord is essential for safe operation.

The instrument operates from an AC line frequency of 50 or 60 Hz, over the range

of 100-240 Volts, without the need for configuration, except the power cord.

(See page 18, International power cords.) The typical power draw is 140 Watts.

Refer to the WVR7200 Specifications and Performance Verification Technical

Reference on the Product Documentation CD for additional information on power

and envi

1. Connect the supplied power cord to the rear-panel power connector.

2. Press the power button on the instrument front-panel and the instrument will

turn on.

NOTE. The Standby button on the front-panel does not disconnect mains power.

Only t

ent operates from a single-phase power source with the neutral

ronmental requirements.

he power cord at the rear of the product can disconnect mains power.

Pow

er-Off

Ensure that the power cord is accessible when the product is operating.

1. Press the power button on the instrument front-panel to turn the instrument off.

2. To remove power completely, disconnect the power cord from the rear-panel

of the instrument.

22 WVR7200 Installation and Safety Instructions

Page 29

Front-Panel Controls

Front-Panel C

Layout and

Usage

ontrols

NOTE. Some of the controls that this section covers are option dependant. For a

list of the options that are installed on your instrument, press the CONFIG button.

In the con figuration menu, select the Utilities submenu. The View Instruments

Options entry lists the options installed on your instrument.

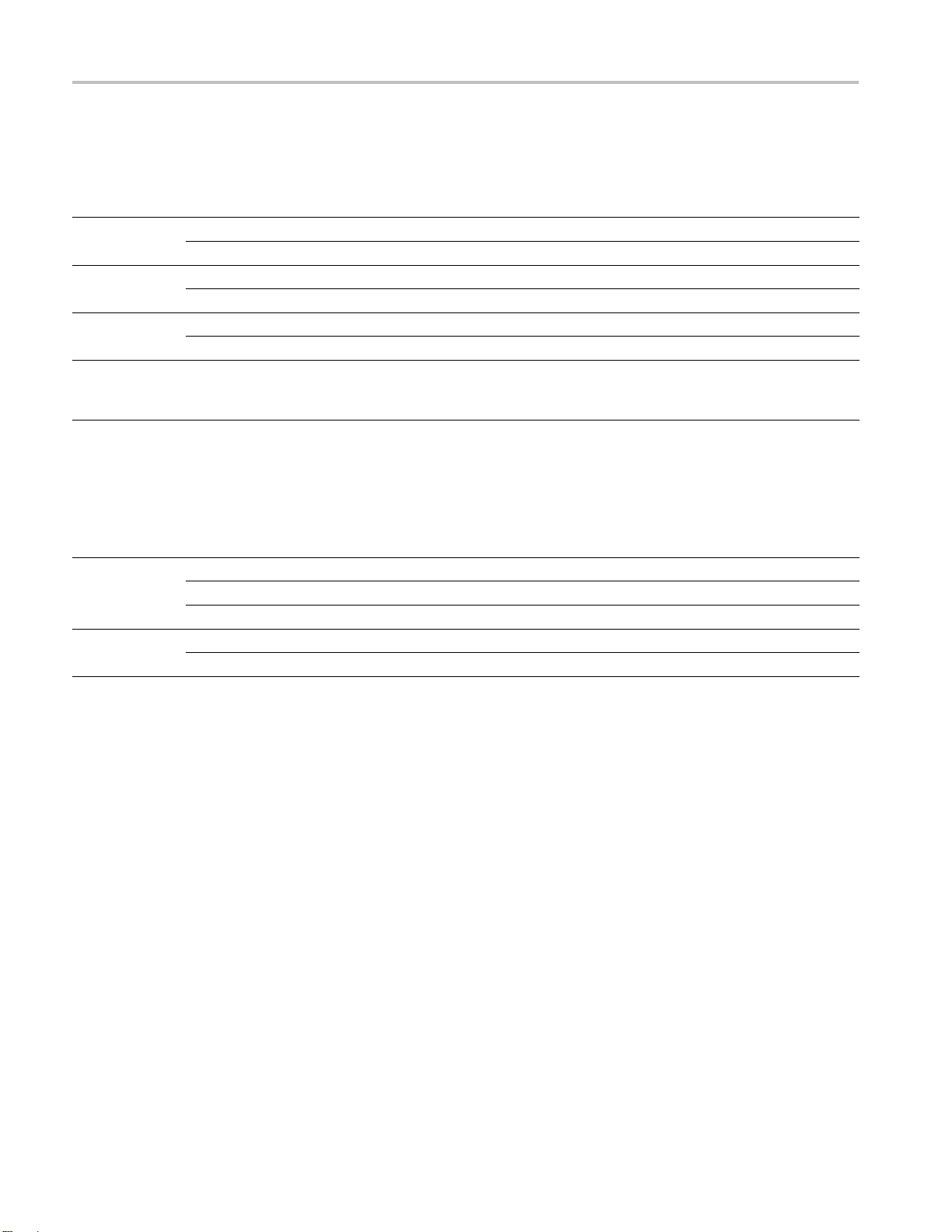

The front-panel elements shown below are described in the table that follows.

Figure 4: Front-panel

Control Element or Group Description

Power button

DISPLAY SELECT buttons Each numbered display select button corresponds to one of the four tiles of the display screen;

MEASURE SELECT buttons WFM, PICT, GAMUT, V ECT, A UDIO, STATUS, MEAS, OTHER, and EYE to select

WFM

WVR7200 Installation and Safety Instructions 23

Press to power on or off. The power button also indicates when the instrument is detecting a

ult (such as a fan failure) when it is red.

fa

NOTE. Red light shows briefly during start-up.

the FULL button toggles the display from full-screen view to four-tile view

measurements

Display of video waveform

Page 30

Front-Panel Controls

Control Element or Group Description

PICT Display of the picture generated by the video signal

GAMUT Display for checking the gamut of an SDI signal; select from one of three proprietary Tektronix

views

VECT Display of Vector or Lightning plots of color signals

AUDIO Optional display of level (meters), a phase (plot), and Surround Sound for monitoring audio

signals.

STATUS Various di

MEAS Access to

instruments with appropriate option(s) installed)

OTHER Display for checking the LTC amplitude and noise, and to verify LTC is locked to the video

EYE

SCALING buttons GAIN, VAR, LINE SEL, and MAG buttons to select scaling

GAIN To switch gain between 1x and a second gain setting for waveform displays. Press and hold to

VAR To adjust variable gain

SWEEP To select how waveform components are displayed and whether lines or fields are shown

MAG To select the magnification setting that you want

LINE SEL To toggle Line Select Mode on or off

CURSOR To measure waveforms with cursors

PRESETS To recall the factory preset, save a setup to a preset, recall an existing preset, and clone a

NPUTS buttons

I

CAPTURE

EXT

DISPLAY Access to waveform, graticule, and LCD backlight intensity. It also provides access to Infinite

HELP To display the online help

CONFIG Access to various configurable parameters, installed options, IP address, system upgrade,

MAIN

Up/Down/Left/Right Arrow keys

and SEL Button

General Knob

Vertical and Horizontal Knobs

Display for checking the transport layer of an SDI signal, including jitter (operation requires

Option PHY3)

acces

se

A, 1B, 2A, 2B, and EXT to select inputs. Slot 1 buttons, 1A and 1B, correspond to inputs

1

located in the center of the rear panel, such as the SDI or Eye inputs. Slot 2 buttons, 2A and

2B, correspond to inputs located in the right section of the rear panel, such as the composite

nputs.

i

To capture the display

To select the External Reference mode

Persistence mode.

and more

Access to SyncVu mode, SIM mode, and USB mount/unmount

To traverse between menu panes. Use SEL to set the selected parameter

To select or adjust a parameter and to navigate through a menu

Use to position waveforms when displayed in tiles or full screen. When the Audio tile is active,

use the Horizontal knob to adjust the headphone volume

splays to view signal status and information

Timing Measure, Data List, AV Delay, Bowtie, and ANC Data displays (available on

s menu for second setting.

tup between instruments

WAR NI NG . To prevent risk of hearing damage, always turn down the headphone audio level

before connecting a headphone into the headphone jack. Sound levels and impedance can

vary between headphones.

24 WVR7200 Installation and Safety Instructions

Page 31

Front-Panel Controls

Three Levels of Control

Scope of Controls

You control the

Frequently changed settings. The front-panel buttons control the most

commonly chan

tile. The knobs are used to adjust levels and make selections.

Tile-specific settings. Pop-up menus control parameters that are specificto

the tile in which they are displayed. The pop-up menus control less frequently

changed parameters such as the waveform display mode (for example,

changing t

pop-up menu, press and hold a front panel button for about one second. Most

buttons have a related pop-up menu.

Instrument-wide settings. The parameters in the Configuration menu are

instrument-wide settings. The configuration m enu controls settings that are

changed only occasionally, such as changing waveform color or setting the

network address.

Some controls are global and affect all tiles, while other controls only affect the

active tile. Generally speaking, if a control is configured by front-panel buttons or

by a pop-up menu, it is tile specific. (Exceptions are the Input buttons, and all

audio features, both of which are global.) If control is configuredbytheCONFIG

, selections are usually global.

menu

instrument on three levels:

ged parameters, such as which measurement appears in each

he waveform display mode from RGB to YPbPr). To display a

WVR7200 Installation and Safety Instructions 25

Page 32

はじめに

はじめに

このマニュアルでは次の項

目について説明します。

人体への損傷を避け、本製品や本製品に接続されている製品への損傷を

防止するための、安全

性に関する要注意事項

本製品が適合している EMC 基準、安全基準、および環境基準

本製品を使用するための電圧、電力、および環境要件

設置手順

電源投入、電源遮断の手順

フロント・パネルおよびリア・パネルの構成

マニュアル

本製品の関連マニュアルおよびそのメディアと参照先を、以下の表に示

します。マニュアルのメディアには、冊子、CD-ROM、Tektronix Web サイト

(www.tektronix.com)の 3 種類があります。

表4: 製品マニュアル

項目 内容 参照先

設置と安全性に関する手順書

(本マニ

ユーザ

オンライン・ヘルプ

仕様

ル・リファレンス

WVR & WFM シリーズ管理情

報

マー・マニュアル

サービス・マニュアル

ュアル)

・マニュアル

および性能検査のテクニカ

データベース(MIB)プログラ

安全性とコ

ウェアの設置手順および禁止事項(警告)につい

て説明します。英語版、日本語版、簡体字中国

語版の 3

操作方法および用途について説明します。 製品マニュアル CD。PDF 版は

操作方法とユーザ・インタフェースについて詳

細に説明します。

機器

説明します。

本機器をリモート制御するための SNMP コマン

ド・リファレンス

整、修理、部品交換について説明します。

調

ンプライアンスに関する情報、ハード

種類があります。

の仕様および性能チェック手順について

印刷マニュアル。PDF 版は

tektronix.com/manuals で

www.

入手できます。

.tektronix.com/manuals で

www

も入手できます。

機器上に表示

製品マニュアル CD。PDF 版は

www.tektronix.com/manuals で

手できます。

も入

製品マニュアル CD。PDF 版は

ww.tektronix.com/manuals で

w

も入手できます。

PDF 版 。

www.tektronix.com/manuals で

入手できます。

26 WVR7200 Installation and Safety Instructions

Page 33

安全にご使用いただくために

人体への損傷を避け、本製品や本製品に接続されている製品の破損を防止

するために、安全性に関する次の注意事項をよくお読みください。

安全のために、指示に従って本製品を使用してください。

資格のあるサービス担当者以外は、保守点検手順を実行しないでください。

安全にご使用いただくために

出火や人体への損傷を

避けるには

適切な電源コードを使用してください: 本製品用に指定され、使用される国で

認定された電源コードのみを使用してください。

本製品を接地してください: 本製品は、電源コードのグランド線を使用して接

地します。感電を避けるため、グランド線をアースに接続する必要があります。

本製品の入出力端子に接続する前に、本製品が正しく接地されていることを

確認してください。

すべての端子の定格に従ってください: 火災や感電の危険を避けるために、

本製品のすべての定格とマーキングに従ってください。本製品に電源を接続

する前に、定格の詳細について、製品マニュアルを参照してください。

共通端子を含むいかなる端子についても、その端子の定格の上限を超える電

位を加えないでください。

電源を切断してください: 電源コードの取り外しによって主電源が切り離され

ます。電源コードをさえぎらないでください。このコードは常にアクセス可能で

あることが必要です。

カバーを外した状態では使用しないでください: カバーやパネルを外した状

態で本製品を動作させないでください。

故障の疑いがあるときは使用しないでください: 本製品に故障の疑いがある

場合、資格を有するサー ビス担当者に検査を依頼してください。

回路の露出を避けてください: 電源がオンのときに、露出した接続部分やコン

ポーネントに触れないでください。

適切な AC アダプタを使用してください: 本製品専用の AC アダプタのみをご

使用ください。

湿気の多いところでは使用しないでください:

爆発しやすい環境では動作させないでください:

製品の表面を清潔で乾燥した状態に保ってください:

充分な換気を確保してください: ユーザ・マニュアルの設置手順を参照し、充

分な換気を確保してください。

WVR7200 Installation and Safety Instructions 27

Page 34

安全にご使用いただくために

本マニュアル内の用語

本製品に関する記号と用

語

このマニュアルでは次の用語

警告: 人体や生命に危害をおよぼすおそれのある状態や行為を示します。

注意: 本製品やその他の接続機器に損害を与えるおそれのある状態や行為

を示します。

本製品では、次の用語を使用します。

DANGER:ただちに人体や生命に危険をおよぼす可能性があることを示し

ます。

WARNING:人体や生命に危険をおよぼす可能性があることを示します。

CAUTION:本製品を含む周辺機器に損傷を与える可能性があることを示

します。

本製品では、次の記号を使用します。

を使用します。

28 WVR7200 Installation and Safety Instructions

Page 35

適合性に関する情報

適合性に関する情報

EMC 適合性

EC 適合宣言 - EMC

このセクションでは、本製

品が適合している EMC 基準、安全基準、および環

境基準について説明します。

指令 2004/108/EC 電磁環境両立性に適合します。『Official Journal of the

European Communities』に記載の以下の基準に準拠します。

EN 55103:1996: 業務用オーディオ、ビデオ、オーディオ・ビジュアル、および

娯楽照明制御機器

の製品群規格。

12

環境 E2 – 商業および軽工業用

第1部:エミッション

EN 55022:1987:クラス B 放射および伝導エミッション

EN 55103-1:1996 付属書類 A:磁場放射エミッション

第2部:イミュニティ

IEC 61

000-4-2:2001:静電気放電イミュニティ

IEC 61000-4-3:2006:RF 電磁界イミュニティ

IEC 61000-4-4:2004:電気的ファスト・トランジェント/バースト・イミュニ

ティ

IEC 61000-4-5:2005:電源サージ・イミュニティ

IEC 61000-4-6:2003:伝導 RF イミュニティ

IEC 61000-4-11:2004:電圧低下と遮断イミュニティ

EN 55103-2:1996 付属書類 A:磁場放射イミュニティ

1

に挙げた各種 EMC 規格に確実に準拠するには、高品質なシールドを持つインタフェー

ここ

ス・ケーブルが必要です。

2

電流:8 A ピーク

突入

EN 61000-3-2:2006: AC 電源ライン高調波エミッション

EN 61000-3-3:1995: 電圧の変化、変動、およびフリッカ

WVR7200 Installation and Safety Instructions 29

Page 36

適合性に関する情報

欧州域内連絡先:

Tektronix UK, Ltd.

Western Peninsula

Western Road

Bracknell, RG12 1RF, United Kingdom

オーストラリア/ニュー

ジーランド適合宣言 EMC

安全性

EC 適合宣言 - 低

令

米国の国家

関のリスト

カナダ認証

電圧指

認定試験機

ACMA に従い、次の規格に準拠することで Radiocommunications Act の EMC

条項に適合しています。

EN 55022:1987:クラス B、放射および伝導エミッション(EN 55103-1:1996

に準拠)

『Official Journal of the European Communities』に記載の以下の基準に準拠し

ます。

低電圧指令 2006/95/EC

EN 61010-1:2001:測定、制御および実験用途の電子装置に対する安全

基準。

UL 61010-1:2004 年第 2 版:電子計測機器および試験用機器の標準規格

CAN/CSA-C22.2 No.61010-1:2004:測定、制御、および実験用途の電子

装置に対する安全基準、第 1 部

その他の適合性

機器の種類

クラス

安全

30 WVR7200 Installation and Safety Instructions

IEC 61010-1:2001:測定、制御、および実験用途の電子装置に対する安

全基準

測定機器

クラス 1 - アース付き製品。

Page 37

適合性に関する情報

汚染度

汚染度

製品内部およびその周辺で発

製品の内部環境は外部環境と同じとみなされます。製品は、その製品に指定

されている環境でのみ使用してください。

汚染度 1:汚染なし、または乾燥した非導電性の汚染のみが発生します。

このカテゴリの製品は、通常、被包性、密封性のあるものか、クリーン・ルー

ムでの使用を想定したものです。

汚染度 2:通常、乾燥した非導電性の汚染のみが発生します。ただし、結

露によって一時的な導電性が発生することもまれにあります。これは、標準

的なオフィスや家庭内の環境に相当します。一時的な結露は製品非動作

時のみ発生します。

汚染度 3:伝導性のある汚染、または通常は乾燥して導電性を持たないが

結露時に導電性を帯びる汚染。これらは、温度、湿度のいずれも管理され

ていない屋内環境に相当します。日光や雨、風に対する直接の曝露から

は保護されている領域です。

汚染度 4:導電性のある塵、雨、または雪により持続的に導電性が生じて

いる汚染。これは一般的な屋外環境に相当します。

汚染度 2(IEC 61010-1 の定義による)。注:屋内使用のみについての評価で

す。

生する可能性がある汚染度の尺度です。通常、

環境に関する考慮事項

このセクションでは本製品が環境に及ぼす影響について説明します。

使用済み製品の処理方

法

機器またはコンポーネントをリサイクルする際には、次のガイドラインを順守し

てください。

機器のリサイクル:

本製品の製造には天然資源が使用されています。本製品には環境または人

体に有害となる可能性のある物質が含まれているため、製品を廃棄する際に

は適切に処理する必要があります。有害物質の放出を防ぎ、天然資源の使用

を減らすため、本製品の部材の再利用とリサイクルの徹底にご協力ください。

過塩素酸塩の取り扱い: 本製品には CR リチウム電池が搭載されて

います。CR リチウム電池はカリフォルニア州法により過塩素酸塩材と

して規定され、特別な取り扱いが求められています。詳細については、

www.dtsc.ca.gov/hazardouswaste/perchlorate を参照してください。

このマークは、本製品が WEEE(廃棄電気・電子機器)およびバッテ

リに関する指令 2002/96/EC および 2006/66/EC に基づき、EU の

諸要件に準拠していることを示しています。リサイクル方法について

は、Tektronix の Web サイト(www.tektronix.com)のサービス・セク

ションを参照してください。

WVR7200 Installation and Safety Instructions 31

Page 38

適合性に関する情報

有害物質に関する規制

この製品は Monitori

2002/95/EC RoHS Directive(電気・電子機器含有特定危険物質使用制限

指令)の適用範囲外です。

ng and Control(監視および制御)装置に分類され、

32 WVR7200 Installation and Safety Instructions

Page 39

動作の要件

電気定格

電源要件

動作の要件

このセクションでは、製品を安全かつ正しく使用するために把握しておくべき

仕様について説明します。詳細については、別途、製品の完全仕様をご覧く

ださい。

電源コネクタ

本製品の電源要件は次のとおりです。

アース近辺に 1 本の通電導体(中性線)を使用した単相電源。

電源の周波数は

Vです。

警告: 出火および感電のリスクを減らすため、主電源の電圧変動が動作電圧

レンジの 10% を超えていないことを確認してください。

2 本の通電導体が接地に対して通電状態のシステム(多相システムでの相

間など)は、電源として推奨されません。

注: ラ

蔵ヒューズはユーザによる交換を想定したものではありません。ヒューズの交換

はしないでください。ヒューズが飛んでいると思われる場合は、認定サービス・

センターに製品を返送して修理を受けてください。

イン側のみ、過電流保護のためにヒューズが付けられています。この内

50 Hz または 60 Hz、動作電圧の範囲は AC100 ~ 240

WVR7200 Installation and Safety Instructions 33

Page 40

動作の要件

環境要件

表 5: 環境性能

カテゴリ 規格または説明

温度

湿度

高度

冷却 機器前面の吸気孔がふさがれていないこと、および、背面の排気口周りに最低

動作時

非動作時

動作時

非動作時

動作時 9,842 フィート(3,000 m)以下

非動作時 40,000 フィート(12,192 m)以下

0 ℃ ~ +40 ℃

-40 ℃ ~ +75 ℃

結露しない状態、+40 ℃以下で 20% ~ 80% の相対湿度(% RH)

結露しない状態、+

2.54 cm(1 インチ)のスペースが確保されていること。機器の上部および下部の

スペースは不要

60 ℃以下で 5% ~ 90% の相対湿度(% RH)

。

物理仕様

表 6: 物理特性

特性 標準値

寸法

高さ 1.72 インチ(4.37 cm)

幅

奥行き

19 インチ(48.26 cm)

20.25 インチ(51.44 cm)(ケーブルを除く)

重量

清掃

本体

輸送

最大9.5ポンド(4.31kg)

約19ポンド(8.62kg)

本製品は特にクリーニングなどしなくても安全に操作できますが、定期的に本

の外部をクリーニングなさる場合は、付属のマニュアル CD に収録のマ

製品

ニュアルを参照してください。

34 WVR7200 Installation and Safety Instructions

Page 41

リア・パネル・コネクタ

以下の図に、オプションのコネクタを搭載したリア・パネルを示します。リア・パ

ネルの入力コネクタはスロット 1 およびスロット 2 に割り当てられています。リ

ア・パネルにはこれらの

せんが、フロント・パネルのスロット 1 入力ボタンに対応するリア・パネル中央

の領域には通常、SDI 入力または EYE 入力があります。フロント・パネルのス

ロット 2 入力ボタンに対応するリア・パネル右側の領域には、コンポジット入力

コネクタがあります(該当する場合)。 (35 ページの 図 5 参照)。

リア・パネル・コネクタ

スロットの位置がラベルで示されているわけではありま

図5: リア・パネル

WVR7200 Installation and Safety Instructions 35

Page 42

リア・パネル・コネクタ

入力/出力コネクタ

ビデオ・コネクタ

SDI 入力は自己ターミネーション入力です。

入力

REF LOOP: 同期入力。入力信号は、アナ

ログ・ブラック・バースト、アナログ・コンポ

ジット・ビデオ、または HD 用アナログ 3 値

が可能です。ターミネーションが必要です。

SDI A IN: デジタル A コンポーネント・シリ

アル・デジタル入力。

SDI B IN: デジタル B コンポーネント・シリ

アル・デジタル入力。

SDI A Out: SDI A 入力のリクロック出力。

SDI B/CLK Out: SDI B 入力のリクロック出

力。オプション PHY3 型使用時は、機器の

復元クロック信号も出力します。

コネクタ

オプション PHY3 型

リファレンス入力およびコンポジット入力は、パッシブ・ループ入力です。

注: リファレンス入力およびコンポジット入力は外部終端が必要です。

36 WVR7200 Installation and Safety Instructions

Page 43

リア・パネル・コネクタ

入力

CMPST A: コンポジッ

トAアナログ入力。

コネクタ

CMPST B: コンポジット B アナログ入力。

SDI Out: Pixm

Signal のいずれかの出力を選択できます

1

Test Signal

on、Loop Out、または Test

1

。

はオプション GEN 型使用時のみ、使用可能です。

AES A/B コネクタ

入力 コネクタ

これらの BNC コネクタは、AES オーディ

オ入力をサポート

AES チャンネル 1 および 2 の入力 A

AES チャンネル 3 および 4 の入力 A

AES チャンネル

AES チャンネル 7 および 8 の入力 A

AESチャンネル1および2のデフォルト

入力 B

1

AESチャンネル3および4のデフォルト

入力 B

1

AES チャンネ

入力 B

1

AESチャンネル7および8のデフォルト

入力 B

1

1

AES B コネクタは、エンベデッド・オーディオ・チャンネル、デコード済みドルビー、または AES A 入力を出力するように設定できます。

します。

5および6の入力A

ル5および6のデフォルト

オプション AD 型および DPE 型

アナログ入

出力コネクタ

アナログ I/O コネクタは、アナログ信号の送受信に使用します。アナログ I/O

コネクタは、62 ピンの D 型サブミニチュア・コネクタです。ピン配列およびピン

の名前は、

次の図および表のとおりです。

注意: アナログ・オーディオ出力の接続には注意が必要です。機器の仕様を

参照し、必ず仕様の範囲内の負荷と出力で使用してください。仕様の範囲を

超えたアナログ・オーディオ出力で使用すると、機器が損傷する可能性があり

ます。

WVR7200 Installation and Safety Instructions 37

Page 44

リア・パネル・コネクタ

オプション AD 型の入出力コネクタ

38 WVR7200 Installation and Safety Instructions

Page 45

ピン番号 説明

1ANALOG_INPU

2 ANALOG_INP

3ANALOG_INP

4 ANALOG_IN

5ANALOG_I

6 ANALOG_

7ANALOG_

8 ANALOG

9ANALO

10 ANAL

11 ANA

12 AN

13 GND

14 ANALOG_OUTPUT_1_P

15 ANALOG_OUTPUT_2_P

16 ANALOG_OUTPUT_3_P

17 ANALOG_OUTPUT_4_P

18 ANALOG_OUTPUT_5_P

19 ANALOG_OUTPUT_6_P

20 ANALOG_OUTPUT_7_P

21 ANALOG_OUTPUT_8_P

22 ANALOG_INPUT_A1_N

23 ANALOG_INPUT_B1_N

24 ANALOG_INPUT_A2_N

25 ANALOG_INPUT_B2_N

26 ANALOG_INPUT_A3_N

27 ANALOG_INPUT_B3_N

28 ANALOG_INPUT_A4_N

29 ANALOG_INPUT_B4_N

30 ANALOG_INPUT_A5_N

31 ANALOG_INPUT_B5_N

32 ANALOG_INPUT_A6_N

G_INPUT_A5_P

OG_INPUT_B5_P

LOG_INPUT_A6_P

ALOG_INPUT_B6_P

T_A1_P

UT_B1_P

UT_A2_P

PUT_B2_P

NPUT_A3_P

INPUT_B3_P

INPUT_A4_P

_INPUT_B4_P

平衡差動アナログ・オーディオ入力:チャンネル 1、ライン A、正相側

平衡差動アナログ・オーディオ入力:チャンネル 1、ライン B、正相側

平衡差動アナログ・オーディオ入力:チャンネル 2、ライン A、正相側

平衡差動アナログ・オーディオ入力:チャンネル 2、ライン B、正相側

平衡差動アナログ・オーディオ入力:チャンネル 3、ライン A、正相側

平衡差動アナログ・オーディオ入力:チャンネル 3、ライン B、正相側

平衡差動アナログ・オーディオ入力:チャンネル 4、ライン A、正相側

平衡差動アナログ・オーディオ入力:チャンネル 4、ライン B、正相側

平衡差動アナログ・オーディオ入力:チャンネル 5、ライン A、正相側

平衡差動アナログ・オーディオ入力:チャンネル 5、ライン B、正相側

平衡差動アナログ・オーディオ入力:チャンネル 6、ライン A、正相側

平衡差動アナログ・オーディオ入力:チャンネル 6、ライン B、正相側

平衡差動アナログ・オーディオ出力:チャンネル 1、正相側

平衡差動アナログ・オーディオ出力:チャンネル 2、正相側

平衡差動アナログ・オーディオ出力:チャンネル 3、正相側

平衡差動アナログ・オーディオ出力:チャンネル 4、正相側

平衡差動アナログ・オーディオ出力:チャンネル 5、正相側

平衡差動アナログ・オーディオ出力:チャンネル 6、正相側

平衡差動アナログ・オーディオ出力:チャンネル 7、正相側

平衡差動アナログ・オーディオ出力:チャンネル 8、正相側

平衡差動アナログ・オーディオ入力:チャンネル 1、ライン A、逆相側

平衡差動アナログ・オーディオ入力:チャンネル 1、ライン B、逆相側

平衡差動アナログ・オーディオ入力:チャンネル 2、ライン A、逆相側

平衡差動アナログ・オーディオ入力:チャンネル 2、ライン B、逆相側

平衡差動アナログ・オーディオ入力:チャンネル 3、ライン A、逆相側

平衡差動アナログ・オーディオ入力:チャンネル 3、ライン B、逆相側

平衡差動アナログ・オーディオ入力:チャンネル 4、ライン A、逆相側

平衡差動アナログ・オーディオ入力:チャンネル 4、ライン B、逆相側

平衡差動アナログ・オーディオ入力:チャンネル 5、ライン A、逆相側

平衡差動アナログ・オーディオ入力:チャンネル 5、ライン B、逆相側

平衡差動アナログ・オーディオ入力:チャンネル 6、ライン A、逆相側

リア・パネル・コネクタ

WVR7200 Installation and Safety Instructions 39

Page 46

リア・パネル・コネクタ

ピン番号 説明

33 ANALOG_INP

34 GND

35 ANALOG_OUTPUT_1_N

36 ANALOG_OUTPUT_2_N

37 ANALOG_OUTPUT_3_N

38 ANALOG_OUTPUT_4_N

39 ANALOG_OUTPUT_5_N

40 ANALOG_OUTPUT_6_N

41 ANALOG_OUTPUT_7_N

42 ANALOG_OUTPUT_8_N

43– 62

UT_B6_N

平衡差動アナログ・オーディオ入力:チャンネル 6、ライン B、逆相側

平衡差動アナログ・オーディオ出力:チャンネル 1、逆相側

平衡差動アナログ・オーディオ出力:チャンネル 2、逆相側

平衡差動アナログ・オーディオ出力:チャンネル 3、逆相側

平衡差動アナログ・オーディオ出力:チャンネル 4、逆相側

平衡差動アナログ・オーディオ出力:チャンネル 5、逆相側

平衡差動アナログ・オーディオ出力:チャンネル 6、逆相側

平衡差動アナログ・オーディオ出力:チャンネル 7、逆相側

平衡差動アナログ・オーディオ出力:チャンネル 8、逆相側

未接続

EXT DISPLAY コネクタの

ピン配列

PIX MON コネクタのピン

配列

これは、外部ディスプレイ・モニタ出力です。ディスプレイの解像度は 1024 x

768 です。DVI モニタは直接接続できますが、アナログ PC(RGB)モニタを接続

するには DVI-I/VGA アダプタが必要です。EXT DISPLAY コネクタは、ソケッ

ト接点付き DVI-I コネクタです。

EXT DISPLAY コネクタ

これは、映像出力です。この出力は CRT、LCD ベースの標準アナログ PC モ

ニタに対応しています。PIX MON コネクタは、ソケット接点付き 15 ピン D 型コ

ネクタです。

PIX MON コネクタ

ピン番号

1

2

3

4

ピンの名前

赤ビデオ信号

緑ビデオ信号

青ビデオ信号

未接続

40 WVR7200 Installation and Safety Instructions

Page 47

リア・パネル・コネクタ

REMOTE コネクタのピン

配列

5

6

7

8

9

10

11

12

13

14

15

グランド

赤グランド

緑グランド

青グランド

未接続

未接続

未接続

未接続

水平同期

垂直同期

未接続

REMOTE コネクタ・インタフェースは、リモート・コントロールにグランド・クロー

ジャを使用

し、アラームが発生すると外部機器に通知します。LTC の入力は、

REMOTE コネクタを通して行われます。REMOTE コネクタは、ソケット接点付

き 15 ピン D 型コネクタです。

注: プリセット呼び出し操作の詳細については、付属の製品マニュアル

CD-ROM に収録の『テクニカル・リファレンス』を参照してください。

WVR7200 Installation and Safety Instructions 41

Page 48

リア・パネル・コネクタ

REMOTE コネクタのプリ

特性 ピン出力 プリセット機能

コネクタ・ピン配列

1 GND(入力)

2 予約(入出力)

3 予約(入出力)

4 予約(入力)

5 予約(入力)

6 GND(入力)

7 タイム・コード正相(LTC 入力)

8タイム・コード逆

9グランド・クロージャ(アラーム

出力)

10 プリセット 1(

11 プリセット 2(入力)

12 プリセット 3(入力)

13 プリセット 4

14 プリセット 5(入力)

15 プリセット 6(入力)

相(LTC 入力)

入力)

(入力)

セット機能

16 進

F

E

D

CXX1100 SDIB

B

A

9XX1001

8XX1000

7

6XX0110

5

4XX0100

3XX0011

2XX0010

1XX000

0XX000

バイナリ・

ピン 15、

14、 13、

12、 11、

10

111111

XX1110

XX1101

XX1011

XX1010

XX0111

XX0101

ダイレクト・

モード選択

なし

プリセット 1

プリセット 2

プリセット 3

プリセット 4 プリセット 7

1

0

エンコードされ

たモード選択

動作しない

CMPST B

CMPST A

SDI A

チャンネル B

チャンネル A

プリセット 8

プリセット 6

プリセット 5

プリセット 4

プリセット 3

プリセット 2

プリセット 1

未定義

イーサネット・コネクタ

本製品は 10/100/1000 BaseT のイーサネット・インタフェースを装備していま

す。イーサネット・コネクタは、標準の RJ-45 コネクタです。

イーサネット・コネクタ

42 WVR7200 Installation and Safety Instructions

Page 49

基本的な設置手順

基本的な設置手順

本製品は金属製のシャーシ

シャーシのままでも使用できますが、標準の 19 インチ・ラックにマウントして使

用することもできます。

ラック・マウントの手順については、オプションのアクセサリ・キットに含まれてい

る指示書を参照してください。冷却と通気確保のための注意事項については、

「環境要件」のセクションを参照してください。 (34 ページ 「環境要件」 参照)。

注意: 本製品はキャビネット内では使用できません。キャビネット内で使用す

ると、本製品とキャビネットを損傷するおそれがあります。

コンソールへの埋め込みなど、独自の設置方法で本製品を使用する必要があ

る場合は、十分な通気を確保してください。また、側面の通気孔から取り込む

空気の温度が 40 ℃を超えないよう対処する必要があります。通気孔は絶対に

ふさがないでください。冷却と通気確保のための注意事項については、「環境

要件」のセクションを参照してください。 (34 ページ 「環境要件」 参照)。

独自の設置方法を採る場合、ラック・アダプタの空間要件を参考にしてくださ

い。

注意: 出

が不十分であると、本製品がシャットダウンすることもあります。クローゼットな

ど、換気設備の整っていない狭い密閉空間に本製品を設置した場合、十分な

通気を確保できません。通気が不十分または皆無の状態でありながらシャッ

ト・ダウンしない場合、本製品に回復不能な損傷が生じ、出火に至る危険性が

増大します。

火の危険性を回避するため、十分な通気を確保してください。通気

に組み込んだ状態で出荷されます。出荷時の

WVR7200 Installation and Safety Instructions 43

Page 50

基本的な設置手順

設置の前に

機器を開梱し、スタンダード・アクセサリとして記載されているすべての付属品

が含まれていることを確認してください。なお、機器の梱包に使用されていた

段ボールやパッキン(静

電気防止バッグなど)を捨てずに保管しておいてくだ

さい。将来、機器の移動が必要になったときに役に立ちます。

アクセサリ

以下の表に本製品のア

クセサリを示します。「スタンダード」列にマークのある

ものは本製品と同梱のアクセサリ、「オプショナル」列にマークのあるものは当

社 Web サイトでのみご購入いただけるアクセサリです。アクセサリの最新情報

については、当社 Web サイト(www.tektronix.com)を参照してください。

アクセサリ

WVR7200 型波形ラスタライザの設置および安全操作に関する指

示書(英語版、日本語版、簡体字中国語版)

WVR7200 型波形ラスタライザ製品ドキュメンテーション CD キット

この CD には、次のマニュアルが PDF 形式で収録されています

(言語が明記されていないマニュアルはすべて英語版です)。

WVR7200 型波形ラスタライザ・ユーザ・マニュアル

WVR7200 型波形ラスタライザの仕様および性能検査テクニ

カル・リファレンス

WVR & WFM シリーズ管理情報データベース(MIB)プロ

グラマー・マニュアル

WVR7200、WVR8200 型および WVR8300 型波形ラスタラ

イザのシステム統合指示書

WVR7200 型波形ラスタライザ・リリース・ノート

WVR7200 型波形ラスタライザの機密およびセキュリティに関する

指示書

WVR7200 型波形ラスタライザ・サービス・マニュアル

WVR8RFP 型オプションのリモート・フロント・パネルに関する指示書

スタンダードオプショ

ナル 当社部品番号

071-3024-XX

063-4428-XX

077-0668-XX

077-0670-XX

071-0261-XX

077-0392-XX

077-0674-XX

077-0672-XX

077-0676-XX

071-2804-XX

電源コード

なし

注: 同梱の電源コードの種類については、後出の「各国の電源

コード」のリストを参照してください。

44 WVR7200 Installation and Safety Instructions

Page 51

基本的な設置手順

各国の電源コード: 波形モニ

タには、次のいずれかの電源コード・オプション

が付属しています。北米用の電源コードは UL および CSA の認可を取得して

います。北米以外の地域用のコードは、当該国の機関(1 つ以上)により承認

されているものです。

Opt.A0:北米仕様電源

Opt.A1:ユニバーサル欧州仕様電源

Opt.A2:英国仕

様電源

Opt.A3:オーストラリア仕様電源

Opt.A4:北米仕様電源、240 V

Opt.A5:スイス仕様電源

Opt.A6:日本仕様電源

Opt.A10:中国仕様電源

1

9

Opt.A9

1

オプション A99 型をご注文の場合、本製品に使用する電源コードが国または地域の基準を満た

したものであ

:電源コードおよび AC アダプタなし

るかどうかは、お客様(エンド・ユーザ)の責任で確認していただくことになります。

注意: 出火または感電の危険性を減らすため、本製品には必ず基準に適合

した電源コードをご使用ください。

WVR7200 Installation and Safety Instructions 45

Page 52

基本的な設置手順

ビデオ・システムへの設置

この機器は、配信システムのほぼどの場所でも動作可能です。次の図は、シリ

アル・デジタル・システムの接続およびアナログ・コンポジット入力の接続を示

しています。

シリアル受信側のビデ

機器のいずれかの SDI 入力に入力シリアル信号を接続します。

オ・ビット・ストリームをモ

ニタする場合

図6: オプションPHY3型および3G型

注: 最大許容ケーブル長については、製品マニュアル CD に収録の『仕様お

よび性能検査』マニュアルを参照してください。

46 WVR7200 Installation and Safety Instructions

Page 53

基本的な設置手順

コンポジット信号のモニタ

図7: オプションCPS型

ライン・ターミネーション

リア・パネルのループ・スル

続します。

本製品では、パッシブ・ループスルーのアナログ・リファレンスおよびコンポジッ

ト・ビデオ入力を使用します。その入力に応じて、ループスルー入力を外部で

終端する必要があります。この外部ターミネーションは、確度要件とリターン・ロ

ス要件を満たす必要があります。

ー入力 CMPST A または CMPST B にソースを接

BNC センター・ピンの互

換性

この機器を動作リンクの監視のために設置する場合、接続先の受信部と接続

ケーブルはターミネーションとして機能します。この監視接続によって、パス全

体の性能がチェックされます。本製品のリターン・ロスは十分に高く、ほとんど

の場合、接続先の受信部によってシステムのリターン・ロスが決まります。

本製品をリンクの最後に配置する場合、ループスルー入力の片方に BNC ター

ミネーションを施す必要があります。ターミネーションは 75 Ω で、DC カップリ

ングされている必要があります(良好なリターン・ロスが DC に及びます)。適切

なターミネーションは 75 Ωライン終端(当社部品番号 011-0102-00)です。

コンポジット信号からのリターン・ロスは、DC ~ 6 MHz で > 40 dB です。

ほとんどのビデオ機器の BNC コネクタは、50 Ω または 75 Ω にかかわらず、

50 Ω の標準センター・ピンを使用します。一部の研究用の 75 Ω BNC コネク

タでは、小さい直径のセンター・ピンが使用されています。本製品の BNC コネ

クタは、50 Ω の標準(径が大きい方)センター・ピンで機能するように設計され

ています。

注: センター・ピンのサイズが標準外のコネクタやターミネータは使用しないで

ください。直径が小さいピンを使用すると、接続不良の原因になります。

WVR7200 Installation and Safety Instructions 47

Page 54

電源投入、電源遮断の手順

電源投入、電源遮断の手順

AC 電源要件

電源投入

本製品はアース近辺に中性

は、過電流保護のためにヒューズが付けられています。安全な操作のために

は、電源コード内の接地線を通じた保護用のグランド接続が不可欠です。

本波形モニタは、AC

であれば、電源コードを取り替えるだけで正常に動作します。(45 ページ 「各

国の電源コード」 参照)。一般的な消費電力は 140 W です。電源と環境要件

の詳細については、製品マニュアル CD の『WVR7200 型の仕様と性能検査テ

クニカルリファレンス』を参照してください。

1. 付属の電源コードをリア・パネルの電源コネクタに接続します。

2. フロント・パネルの電源ボタンを押して、電源を投入します。

注: フロント・パネルのスタンバイ・ボタンは、押しても主電源を切断できませ

ん。主電源を切断するには、リア・パネルの電源コードを抜く必要があります。

本製品操作時は、電源コードをアクセス可能な状態にしてください。

電源周波数 50 Hz または 60 Hz、100 ~ 240 V の範囲

線を使用した単相電源で動作します。ライン側に

電源の遮断

1. フロント・

2. 電源を完全に遮断するには、リア・パネルから電源コードを引き抜きます。

パネルの電源ボタンを押して、電源を遮断します。

48 WVR7200 Installation and Safety Instructions

Page 55

フロント・パネル・コントロール

注: このセクションに記載されているコントロールの一部は、オプションによって

異なります。本製品に搭載

ンを押します。設定メニューで、Utilities サブメニューを選択してください。View

Instruments Options に、本製品に搭載されているオプションが表示されます。

されているオプションを表示するには、CONFIG ボタ

フロント・パネル・コントロール

レイアウトと使用方法

次の図にフロント・

て説明します。

パネル要素を示し、それに続く表でそれらの各要素につい

図 8: フロント・パネル

コントロール要素またはグルー

プ説明

電源ボタン

DISPLAY SELECT ボタン Display Select ボタンの番号は、画面の 4 つのタイルに対応します。FULL ボタンを

WVR7200 Installation and Safety Instructions 49

電源を投入または遮断します。なお、ファンの故障などの障害が検出された場合、

電源ボタンは赤く点灯します。

注: 起動時に短時間だけ赤く点灯します。

押すと、全画面表示と 4 タイル表示を切り替えることができます。

Page 56

フロント・パネル・コントロール

コントロール要素またはグルー

プ説明

MEASURE SELEC

WFM

PICT

GAMUT

VECT

AUDIO

STATUS

MEAS

OTHER

EYE

NG ボタン

SCALI

GAIN

VAR

SWEEP

MAG

NE SEL

LI

CURSOR

PRESETS

T ボタン

WFM、PICT、GAM

タンで測定項目を選択します。

ビデオ波形を表示します。

ビデオ信号によって生成されるピクチャを表示します。

SDI 信 号のガマット

きます。

色信号のベクトルま

オーディオ信号を

ウンド・サウンドを表示します。

信号のステータス

タイミング測定

表示にアクセスします(該当するオプションが搭載されている場合)。

LTC の振幅とノイズをチェックする表示。LTC がビデオにロックされているかど

うかを確認できます。

ジッタなどの SDI 信号のトランスポート層をチェックするための表示。動作にはオプ

ション PHY3 型が必要です。

GAIN、

波形表示に使用するゲインを 1x とセカンド設定の間で切り替えます。セカンド設定

のメニューを表示するには、GAIN ボタンを長押しします。

可変ゲインを調節します。

波形成

拡大表示の倍率を選択します。

ライン・セレクト・モードのオンとオフを切り替えます。

カ

出

のプリセットを呼び出すこと、および機器間で設定を複製することが可能です。

VAR、LINE SEL、および MAG ボタンでスケールを選択します。

分の表示方法、ラインまたはフィールドを表示するかどうかを指定します。

ーソルを使用して波形を測定します。

荷時プリセットを呼び出すこと、現在の設定をプリセットとして保存すること、既存

UT、VECT、AUDIO、STATUS、MEAS、OTHER、および EYE ボ

をチェックする表示。当社独自の 3 つのビューから選択で

たはライトニングのプロットを表示します。

監視するレベル(メーター)およびフェーズ(プロット) およびサラ

および情報を表示します。

表示、データ・リスト表示、AV 遅延表示、ボータイ表示、ANC データ

INPUTS ボタン

CAPTURE

EXT

DISPLAY

HELP

1A、1B、2A、2B、および EXT で入力信号を選択します。スロット 1 のボタン 1A

および 1B は、リア・パネル中央の入力コネクタ(SDI または Eye など)に対応し

ます。 スロット 2 のボタン 2A および 2B は、リア・パネル右側の入力コネクタ

(コンポジット入力など)に対応します。

表示を取り込みます。

External Reference モー ドを選択します。

波形、目盛り。無限パーシスタンス・モードを選択することもできます。

オンライン・ヘルプを表示します。

50 WVR7200 Installation and Safety Instructions

Page 57

コントロール要素またはグルー

プ説明

CONFIG

各種設定パラメータ、搭載

レードなどにアクセスできます。

されているオプション、IP アドレス、システム・アップグ

フロント・パネル・コントロール

MAIN

上下左右の矢印キー、

SEL ボタン

汎用ノブ

垂直および水平ノブ

および

SyncVu モード、S

きます。

メニュー・ペインの移

タを設定します。

パラメータの選択または調節、およびメニュー項目の移動に使用します。

タイル表示または全画面表示で、波形の位置を指定するために使用します。オー

ディオ・タイルがア

IM モード、USB マウント/アンマウントの各機能にアクセスで

動に使用します。SEL ボタンを押して、選択したパラメー

クティブなときは、水平ノブでヘッドフォンの音量を調整できます。

警告: 聴覚障害の危険性を避けるため、ヘッドフォンは必ず音声レベルを下げた

状態でヘッドフォンジャックに接続してください。音声レベルとインピーダンスはヘッ

ドフォンによって

異なります。

WVR7200 Installation and Safety Instructions 51

Page 58

フロント・パネル・コントロール

3 レベルのコントロール

コントロールの範囲

本製品は、次の 3 つのレベル

頻繁に変更する設定:フロント・パネルの各種ボタンは、各タイルに表示

する測定内容など、頻繁に

はレベルの調整と選択に使用します。

タイル固有の設定:ポ

ラメータをコントロールします。ポップアップ・メニューは、波形の表示モー

ドなど、あまり頻繁に変更しないパラメータをコントロールします(波形表示

モードを RGB から YPbPr に変更するなど)。ポップアップ・メニューを表示

するには、フロント・パネルのボタンを約 1 秒押し続けます。ほとんどのボ

タンには、関連するポップアップ・メニューが割り当てられています。

機器全体の設定:Configuration メニューのパラメータは、機器全体の設定

です。Configuration メニューは、波形の色やネットワーク・アドレスの設定

など、変更頻度

コントロールには、機器全体およびすべてのタイルに影響するものと、アクティ

ブなタイルに

またはポップアップ・メニューで設定した制御内容は、アクティブなタイルにの

み適用されます(Input ボタンとすべてのオーディオ機能は例外で、これらは

全体に適用されます)。CONFIG メニューで設定した制御内容は、通常、機器

全体に適用されます。

の少ない設定をコントロールします。

のみ影響するものがあります。一般に、フロント・パネルのボタン

でコントロールできます。

変更するパラメータをコントロールします。ノブ

ップアップ・メニューは、表示されるタイルに固有のパ

52 WVR7200 Installation and Safety Instructions

Page 59

前言

文档

前言

本文档包含以下信息:

有关避免人身伤害,并防止损坏本产品或与本产品连接的任何产品的

安全性预防措施

仪器遵循的 EMC(电磁兼容性)、安全和环境标准

使用本产品的电压、功率和环境要求

安装步骤

开机和关机步骤

前面板和后面板功能

下表列出了为本产品提供的一些文档,并且显示了可从何处获取这些文

档: 以印刷手册形式提供,也可从产品文档 CD-ROM 或 Tektronix 网站

www.tektronix.com 上获取。

表 7: 产品文档

项目 用途 位置

安装和安全

用户手册 提供操作和应用信息。 可从产品文档 CD 中以及

在线帮助 详细的仪器操作和用户界面帮助。

技术规格和性能验证技术参考 技术规格和仪器性能检查步骤。 可从产品文档 CD 中以及

WFM 和 WVR 系列管理信息数

据库

修手册

维

性说明(本手册)

(MIB) 程序员手册

提供安全性

并以此介绍相关安全警告。 本手册提供英

文、日文和简体中文版本。

用于远程控制仪器的 SNMP 命令参考。 可从产品文档 CD 中以及

供有关调整、维修和可更换部件的信息。

提

和符合性信息以及硬件安装说明,

以印刷手册

www.tektronix.com/manuals

上获取该文档的电子版本

www.tektronix.com/manuals

上获取

可从仪器上访问

www.tektronix.com/manuals

取

上获

w.tektronix.com/manuals

ww

上获取

可从

ww.tektronix.com/manuals

w

上获取

形式提供,也可从

WVR7200 Installation and Safety Instructions 53

Page 60

常规安全概要

常规安全概要

详细阅读下列安全性预防措施,以避免人身伤害,并防止损坏本产品或与

本产品连接的任何产品。

为避免可能的危险,请务必按照规定使用本产品。

只有合格人员才能执行维修程序。

避免火灾或人身伤害

使用合适的电源线: 只

将产品接地: 本产品通过电源线的接地导线接地。 为避免电击,必须将

接地导线与大地相连。 在对本产品的输入端或输出端进行连接之前,请

务必将本产品正确接地。

遵循所有终端额

值和标记说明。 在连接产品之前,请先查看产品手册,了解额定值的详

细信息。

对任何终端(包括公共终端)施加的电压不要超过该终端的最大额定值。

断开电源: 电源线可以使产品断开电源。 不要阻挡电源线;用户必须能

随时触及电源线。

切勿开盖

有可疑故障时不要操作: 如果怀疑本产品已损坏,请让合格的维修人员进

行检查。

远离裸露电路: 电源接通后请勿接触外露的接头和元件。

使用合适的交流适配器: 只能使用为本产品指定的交流适配器。

操作: 外盖或面板打开时请勿操作本产品。

定值: 为避免火灾或电击危险,请遵循产品上所有的额定

使用本产品专用并经所在国家/地区认证的电源线。

请勿在潮湿环境下操作:

请勿在易燃易爆的气体中操作:

请保持产品表面清洁干燥:

保持适当的通风: 有关如何安装产品使其保持适当通风的详细信息,请参

阅手册中的安装说明。

54 WVR7200 Installation and Safety Instructions

Page 61

常规安全概要

本手册中的术语

产品上的符号和术语

本手册中可能使用以下术语:

警告: “警告”声明指出可能会造成人身伤害或危及生命安全的情况或

操作。

注意: “注意”声明指出可能对本产品或其他财产造成损坏的情况或操

作。

产品上可能出现以下术语:

DANGER(危险)表示您看到该标记时可直接导致人身伤害的危险。

WARNING(警告)表示您看到该标记时不会直接导致人身伤害的危险。

CAUTION(注意)表示可能会对本产品或其他财产带来的危险。

产品上可能出现

以下符号:

WVR7200 Installation and Safety Instructions 55

Page 62

符合性信息

符合性信息

EMC 符合性

此部分列出仪器遵循的 EMC(电磁兼容性)、安全和环境标准。

EC 一致性声明 - EMC

符合 Directive 2004/108/EC 有关电磁兼容性的要求。 已证明符合《欧

洲共同体公报》中所列的以下技术规格:

EN 55103:1

备的产品系列标准。

环境 E2 - 商业和

996: 专业用途的音频、视频、可视化音频和娱乐照明控制设

1,2

轻工业

第 1 部分 辐射

EN 55022:1987。 B 类放射和传导幅射

EN 55103-1:1996 附件 A。 放射性磁场的幅射

第 2 部分 抗干扰能力

IEC 61000-4-2:2001。 静电放电抗扰性

IEC 61

000-4-3:2006。 射频电磁场抗扰性

IEC 61000-4-4:2004。 电气快速瞬变/突发抗扰性

IEC 61000-4-5:2005。 电源线路浪涌抗扰性

IEC 61000-4-6:2003。 传导射频抗扰性

IEC 61000-4-11:2004。 电压骤降和中断抗扰性

EN 55103-2:1996 附件 A 放射性磁场的抗扰性

1

2

保符合上面列出的 EMC 标准,应使用高质量的屏蔽接口电缆。

为确

浪涌电流: 8 A 峰值。

EN 61000-3-2:2006: 交流电源线谐波辐射

EN 61000-3-3:1995: 电压变化、波动和闪变

欧洲联系方式:

Tektronix UK, Ltd.

Western Peninsula

Western Road

Bracknell, RG12 1RF, United Kingdom(英国)

56 WVR7200 Installation and Safety Instructions

Page 63

符合性信息

澳大利亚/新西兰符合性

声明 – EMC

安全符合性

EC 一致性声明 - 低电压

美国国家认可的测试实

验室列表

加拿大认证

其他符合性

根据 ACMA,符合 Radi

定的以下标准:

EN 55022:1987。 放射和传导辐射量,B 类,依照 EN 55103-1:1996。

经证明符合《欧洲共同体官方公报》中所列的以下技术规范:

低电压指令 2006/95/EC。

EN 61010-1: 2001。 测量、控制和实验室用电气设备的安全性要求。

UL 61010-1:2004,第 2 版。 电气测量和测试设备的标准。

CAN/CSA-C22.2 No. 61010-1:2004。 测量、控制和实验室用电气设

备的安全性要求。 第 1 部分。

IEC 61010-1: 2001。 测量、控制和实验室用电气设备的安全性要

求。

ocommunications Act(无线电通信法)有关 EMC 规

设备类型

安全级别

污染度说明

污染度

测试和测量设备。

1 级 - 接地产品。

对产品周围和产品内部环境中可能出现的污染的一种量度。 通常认为产

品的内部环境与外部环境相同。 产品只应该在其规定环境中使用。

污染度 1。 无污染或仅出现干燥、非传导性污染。 此类别的产品通

常进行了封装、密封或被置于干净的房间中。

污染度 2。 通常只发生干燥、非传导性污染。 偶尔会发生由凝结引

起的临时传导。 典型的办公室/家庭环境属于这种情况。 只有当产品

处于非使用状态时,才会发生临时凝结。

污染度 3。 传导性污染,或由于凝结会变成传导性污染的干燥、非传

导性污染。 此类场所为温度和湿度不受控制的建有遮盖设施的场所。

此类区域不受阳光、雨水或自然风的直接侵害。

污染度 4。 通过传导性的尘埃、雨水或雪而产生永久传导性的污染。

户外场所通常属于这种情况。

污染度 2(如 IEC 61010-1 中定义)。 注意: 仅适合在室内使用。

WVR7200 Installation and Safety Instructions 57

Page 64

符合性信息

环境注意事项

本部分提供有关产品对环境影响的信息。

产品报废处理

有害物质限制

回收仪器或元件时,请遵守下面的规程:

设备回收:

生产本设备需要提取和使用自然资源。 如果对本产品的报废处理不当,

则该设备中包含的某些物质可能会对环境或人体健康有害。 为避免将有

害物质释放到环境中

收本产品,以确保大部分材料可以得到恰当地重复使用或回收。

此符号表示该产品符合欧盟有关废旧电子和电气设备 (WEEE) 以及

电池的 2002/96/EC 和 2006/66/EC 号指令所规定的相关要求。 有

关回收方式的信息,请查看 Tektronix 网站 (www.tektronix.com)

上的 Support/Service(支持/服务)部分。

高氯酸盐材料: 此产品包含一个或多个 CR 型锂电池。 按照加州规

定,CR 锂电

www.dtsc.ca.gov/hazardouswaste/perchlorate。

根据其分类

Directive 规定的范畴。

池被归类为高氯酸盐材料,需要特殊处理。 详情参见

,本产品属于监视控制设备,不属于 2002/95/EC RoHS

,并减少对自然资源的使用,建议采用适当的方法回

58 WVR7200 Installation and Safety Instructions

Page 65

操作要求

操作要求

电源额定值

电源要求

本部分提供为安全正确地操

息,请参阅完整的产品技术规格。

电源连接器

仪器具有下列电源要求:

单相电源,其中有一根载流导线接地或近地(中性导线)。

电源频率必须为 50 或 60 Hz,工作电压范围必须为 100 到 240 VAC,

且为连续。

警告: 为减少起火和电击风险,请确保市电电源的电压波动不超过工作

电压范围的 10%。

作产品而需要了解的技术规格。 有关其他信

两条载流导线的接地均带电(例如多相位系统中的相间电压)的系统

不建议用作电源。

说明: 只有线路导线装有保险丝以提供过流保护。 保险丝为内置,不可

由用户

单元送回授权维修中心进行维修。

更换。 请勿尝试更换保险丝。 如果您怀疑保险丝熔断了,请将该

WVR7200 Installation and Safety Instructions 59

Page 66

操作要求

环境额定值

表 8: 环境性能

类别 标准或说明

温度

湿度

冷却 仪器前面板进气通风口不可堵住,后面的排气通风口至少需要 1 英寸空

工作状态

非工作状态

工作状态 在不高于 +40℃ 时,

非工作状态 在不高于 +60℃ 时,RH(相对湿度)为 5% 至 90%,无冷凝

工作状态 不高于 9,842 英尺(3,000 米)海拔高度

非工作状态 不高于 40,000

0℃ 至 +40℃

–40℃ 至 +75℃

英尺(12,192 米)

间。 仪器上方和下

相对湿度 (% RH) 为 20% 至 80%,无冷凝

方均不需要空间。

物理技术规格

表 9: 物理特性

特性 标准

尺寸

重量

高度

宽度

厚度 20.25 英寸(51.44 公分)(不包含电缆)

净重

1.72 英寸(4.37 公分)