Page 1

Service Manual

WVR500

Waveform/Vector Monitor

070-8897-01

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to performing service.

Page 2

Copyright T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of three (3) years from the date of shipment. If a product proves defective during this warranty period,

T ektronix, at its option, either will repair the defective product without charge for parts and labor, or will provide a

replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A P ARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Service Assurance

If you have not already purchased Service Assurance for this product, you may do so at any time during the product’s

warranty period. Service Assurance provides Repair Protection and Calibration Services to meet your needs.

Repair Protection extends priority repair services beyond the product’s warranty period; you may purchase up to three

years of Repair Protection.

Calibration Services provide annual calibration of your product, standards compliance and required audit documentation,

recall assurance, and reminder notification of scheduled calibration. Coverage begins upon registration; you may purchase

up to five years of Calibration Services.

Service Assurance Advantages

Priced well below the cost of a single repair or calibration

Avoid delays for service by eliminating the need for separate purchase authorizations from your company

Eliminates unexpected service expenses

For Information and Ordering

For more information or to order Service Assurance, contact your T ektronix representative and provide the information

below . Service Assurance may not be available in locations outside the United States of America.

Name VISA or Master Card number and expiration

Company date or purchase order number

Address Repair Protection (1,2, or 3 years)

City , State, Postal code Calibration Services (1,2,3,4, or 5 years)

Country Instrument model and serial number

Phone Instrument purchase date

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characteristics T ables 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Installation 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Instructions 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Controls 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Operating Modes 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On-Screen Readout 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Operation 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation

Theory of Operation 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Performance Verification 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Equipment List 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short-Form Performance Verification 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Long-Form Performance Verification 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedures

Adjustment Procedures 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Equipment List 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short-Form Adjustment Procedures 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Long-Form Adjustment Procedures 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WVR500 Waveform/Vector Monitor Service Manual

i

Page 6

Table of Contents

Maintenance

Options

Replaceable Parts

Maintenance 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Options 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging Instructions 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Replacement 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Procedures 6–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Equipment 6–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Flowchart 6–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord Options 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Parts 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

WVR500 Waveform/Vector Monitor Service Manual

Page 7

List of Figures

Table of Contents

Figure 2–1: The TVGF13 side-by-side rack adapter 2–2. . . . . . . . . . . . . .

Figure 2–2: The TVGF14 dual half-rack adapter 2–2. . . . . . . . . . . . . . . .

Figure 2–3: Operational jumper locations. 2–5. . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: WVR500 monitor rear panel 2–5. . . . . . . . . . . . . . . . . . . . . . .

Figure 2–5: WVR500 monitor front panel 2–8. . . . . . . . . . . . . . . . . . . . . .

Figure 2–6: On-screen readout display 2–12. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–7: Typical menu display 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–1: Front Panel board block diagram 3–1. . . . . . . . . . . . . . . . . . .

Figure 3–2: Partial Main board block diagram 3–2. . . . . . . . . . . . . . . . . .

Figure 3–3: Subcarrier generator block diagram 3–3. . . . . . . . . . . . . . . .

Figure 3–4: Vector demodulators block diagram 3–3. . . . . . . . . . . . . . . . .

Figure 3–5: Microprocessor circuitry block diagram 3–4. . . . . . . . . . . . .

Figure 3–6: Analog control ciruitry block diagram 3–5. . . . . . . . . . . . . . .

Figure 3–7: FPGA and RAMDAC circuitry block diagram 3–6. . . . . . . .

Figure 3–8: Rasterizer block diagram 3–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–9: Video out and power supply block diagram 3–8. . . . . . . . . . .

Figure 3–10: Serial Filter board block diagram 3–8. . . . . . . . . . . . . . . . . .

Figure 4–1: –3 dB marks on the vector graticule 4–16. . . . . . . . . . . . . . . . .

Figure 5–1: Location of the Calibration Enable jumper 5–4. . . . . . . . . . .

Figure 5–2: NTSC graticule showing the correct adjustment of

vector gain and symmetry 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–1: Removing the top cover 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–2: Removing the front-panel assembly 6–11. . . . . . . . . . . . . . . . .

Figure 6–3: Removing the Front Panel board 6–10. . . . . . . . . . . . . . . . . . .

Figure 6–4: Removing the power supply 6–10. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–5: Removing the Serial Filter board 6–12. . . . . . . . . . . . . . . . . . .

Figure 6–6: Removing the line filter 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–7: Main board BNC connectors 6–14. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–8: Removing the Main board 6–15. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–9: A2 and A3 circuit board test point locations 6–17. . . . . . . . . .

Figure 6–10: Troubleshooting flowchart 6–18. . . . . . . . . . . . . . . . . . . . . . . .

WVR500 Waveform/Vector Monitor Service Manual

iii

Page 8

Table of Contents

List of Tables

Figure 8–1: WVR 500 monitor exploded view 8–5. . . . . . . . . . . . . . . . . . .

Table 1–1: Vertical deflection system 1–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–2: DC restoration 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–3: Horizontal deflection system 1–5. . . . . . . . . . . . . . . . . . . . . . . .

Table 1–4: Synchronization 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–5: Vector mode 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–6: Power source 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–7: Physical characteristics 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–8: Environmental characteristics 1–8. . . . . . . . . . . . . . . . . . . . . .

Table 1–9: Certifications and compliances 1–9. . . . . . . . . . . . . . . . . . . . . .

Table 2–1: Operational jumper selections 2–4. . . . . . . . . . . . . . . . . . . . . .

Table 4–1: Verification required test equipment 4–1. . . . . . . . . . . . . . . . .

Table 4–2: Short-form performance verification 4–3. . . . . . . . . . . . . . . .

Table 5–1: Adjustment required test equipment 5–1. . . . . . . . . . . . . . . . .

Table 5–2: Short-form adjustment procedures 5–3. . . . . . . . . . . . . . . . . .

Table 5–3: Power supply test point voltages 5–5. . . . . . . . . . . . . . . . . . . .

Table 6–1: Required tools for module removal and replacement 6–7. . . .

Table 6–2: Required equipment for troubleshooting 6–17. . . . . . . . . . . . .

Table 8–1: Replaceable parts list column descriptions 8–2. . . . . . . . . . . .

iv

WVR500 Waveform/Vector Monitor Service Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

Injury Precautions

Use Proper Power Cord. To avoid fire hazard, use only the power cord specified

for this product.

Avoid Electric Overload. To avoid electric shock or fire hazard, do not apply a

voltage to a terminal that is outside the range specified for that terminal.

Avoid Overvoltage. To avoid electric shock or fire hazard, do not apply potential

to any terminal, including the common terminal, that varies from ground by

more than the maximum rating for that terminal.

Avoid Electric Shock. To avoid injury or loss of life, do not connect or disconnect

probes or test leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Do Not Operate Without Covers. To avoid electric shock or fire hazard, do not

operate this product with covers or panels removed.

Use Proper Fuse. To avoid fire hazard, use only the fuse type and rating specified

for this product.

Do Not Operate in Wet/Damp Conditions. To avoid electric shock, do not operate

this product in wet or damp conditions.

Do Not Operate in an Explosive Atmosphere. To avoid injury or fire hazard, do not

operate this product in an explosive atmosphere.

Symbols and Terms

WVR500 Waveform/Vector Monitor Service Manual

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

v

Page 10

General Safety Summary

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

Certifications and

Compliances

DANGER

High Voltage

Protective Ground

(Earth) T erminal

ATTENTION

Refer to Manual

Double

Insulated

Refer to the specifications section for a listing of certifications and compliances

that apply to this product.

vi

WVR500 Waveform/Vector Monitor Service Manual

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the main power by means

of the power cord or, if provided, the power switch.

Use Caution When Servicing the CRT. To avoid electric shock or injury, use

extreme caution when handling the CRT. Only qualified personnel familiar with

CRT servicing procedures and precautions should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

WVR500 Waveform/Vector Monitor Service Manual

vii

Page 12

Service Safety Summary

viii

WVR500 Waveform/Vector Monitor Service Manual

Page 13

Preface

This manual provides servicing information for the WVR500 monitor. Material

found in this volume is targeted at the service technician; detailed operating

information can be found in the WVR500 Waveform/Vector Monitor User

Manual.

Service Level Supported. This manual supports only Module Level (for module

exchange) servicing. Module Level servicing utilizes the block diagram and its

descriptions to isolate a problem to the circuits on a particular etched circuit

board.

Specific Content. Some of the information in this manual is shared with the user

manual; however, the depth of the material depends on the potential use. A quick

comparison will reveal that there are installation instructions in both manuals,

along with specifications, servicing, and operating instructions.

The operating instructions in the user manual are much more detailed than those

in the service manual. The need for a service technician is considerably less than

that of an end user. If the operating instructions in this manual are not complete

enough, please refer to the user manual for more detailed instructions.

The specifications contained in the Specifications section of this manual should

be used by the servicing technician. The specification tables contain step

numbers that cross reference to the Performance Verification section step

numbers to make it possible to document the test methods used to verify the

accuracy of the instrument.

Sections of this manual include the replaceable parts list, troubleshooting

procedures, and removal and replace procedures needed to isolate and replace

faulty modules. Replacement part ordering information can be found in the

Replaceable Parts section of this manual.

WVR500 Waveform/Vector Monitor Service Manual

ix

Page 14

Preface

Contacting Tektronix

Product

Support

Service

Support

For other

information

To write us Tektronix, Inc.

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Contact your local Tektronix distributor or sales office. Or visit

our web site for a listing of worldwide service locations.

http://www.tek.com

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

P.O. Box 1000

Wilsonville, OR 97070-1000

x

WVR500 Waveform/Vector Monitor Service Manual

Page 15

Specifications

Page 16

Page 17

Specifications

Product Description

This section contains a brief functional description of the WVR500 monitor,

followed by the characteristics tables.

The Tektronix WVR500 monitor is a rasterizing television waveform/vector

monitor which outputs a display signal to a remote monitor or video switcher.

It has dual standard (NTSC and PAL) capability with the functionality of a

waveform monitor, vectorscope, and picture monitor. The instrument is 8 1/2

inch wide by 1 1/2 inch high by 17 inches long, weighing 4 1/2 pounds, fitting

the standard half-rack applications. The instrument can be powered from AC

lines ranging from 90-250 V.

The WVR500 monitor uses a proprietary rasterizer which displays analog-like

waveforms and vectors on the remote monitor simultaneously with the appropriate measurement graticules. The rasterized waveform and vector displays can fill

the entire screen or be reduced to 1/4 sized windows overlaying the picture

monitor display. The picture monitor display cannot be resized.

Instrument operation is controlled by a microprocessor which polls the front-panel switches. The front-panel switches are the momentary touch type, several of

which have lighted functional indicators. Many of the monitoring functions are

selected through the on-screen menus, which are entered by pressing front-panel

buttons.

Displays can come from two channels of unterminated composite video input

loopthrough connectors on the rear panel. An external reference input allows for

the connection of an external sync signal. The rear-panel remote connector

allows for full instrument operation from a remote location.

The Waveform display mode provides three standard sweep rates: 1 Line

(5 ms/Div), 2 Line (10 ms/Div), and 2 Field. The line-rate sweeps can be

magnified X10 to additional sweep rates: 1 Line Mag (0.5 ms/Div), and 2 Line

Mag (1 ms/Div). The 2 Field sweep is magnified by approximately X20. Vertical

gain is either fixed at X1 or X5, or variable from 50% to 120% of the input

signal amplitude. The signal filter selections are Flat (no filter) and Luminance

(low pass filter), which can be displayed separately or in a parade display in the

2 Line and 2 Field sweeps. The Line Select mode allows specific lines to be

viewed. The Amplitude Alarm mode provides automatic video level monitoring

by highlighting the portion of the waveform exceeding the 100 IRE (1.0 V PAL)

graticule line.

WVR500 Waveform/Vector Monitor Service Manual

1–1

Page 18

Specifications

The Vectorscope display mode displays signals with the standard vectorscope

color bars amplitude and phase relationships. The vector display can also be used

to make differential gain and phase measurements. The +V display (PAL only)

overlays the –V axis on the +V axis to check the PAL system color encoders.

A full 360_ digital phase shifter, with 75% and 100% color bars settings, and

variable gain are provided.

The Picture Monitor display mode displays the video input signal as a picture.

The brightness, contrast, hue, and chroma of the display are set internally and are

not adjustable.

The Waveform-in-Picture display mode displays the Waveform Monitor and/or

the Vectorscope displays in 1/4-screen sized windows overlaying the Picture

Monitor display. The reduced displays can be made semi-transparent for full

viewing of the Picture display.

Options

Accessories

User Interface

Characteristics Tables

Refer to the Options section for a list of the available options for the WVR500

monitor.

Refer to the Replaceable Parts list for a list of the Standard and Optional

accessories.

Many of the instrument monitoring parameters are configured through the menu

system. The

menu access, while the numbered buttons are used to make selections from the

displayed menus. The large unlabeled center knob is called the General Purpose

(GP) Knob, and is assigned control of monitoring functions through the menu

system. Instructions on how to make menu selections begin on page 2–12.

The current setting of several of the front-panel controls are displayed in the

on-screen readout. A description of the on-screen readout begins on page 2–11.

The tables that follow specify instrument electrical characteristics, mechanical

characteristics, environmental characteristics, and certification. The tables are

logically grouped under specific functions, beginning with video input and

vertical channel specifications and ending with the instrument’s certifications.

MENU, PRESETS, DISPLAY, CONFIG, and CLEAR buttons control

1–2

Categories

Each table consists of a column that identifies the characteristics that are defined

by the entries in the description column. A single item in the category column

might have multiple description items, which could include performance

requirements, reference information, and performance verification step numbers.

WVR500 Waveform/Vector Monitor Service Manual

Page 19

Specifications

Descriptions

The second column of the two column format contains all of the descriptive

material about the listed characteristic. In addition, the performance verification

procedure step number, used to verify the characteristic, is also in this column.

Because this instrument is designed to operate on both PAL and NTSC standards, some of the tolerances are defined in millivolts and IRE units. In these

dual-value tolerances, the PAL values appear in parentheses.

Performance Requirements (Req). Items with this designation are critical to

instrument performance. In most cases they have a tolerance given and have a

performance verification step number accompanying them. However, there are a

few areas where instrument operation verifies that this performance requirement

is met.

Reference Information (RI). This is information about the operation of the

instrument that is important enough to place it with the performance requirements. In some cases there may be a tolerance listed, but these should be

considered as typical, not absolute.

Performance Verification Step. This item identifies the step number of the

Performance Verification procedure, located in Section 4, which tests the listed

requirement. Section 5 contains calibration information, if instrument readjustment becomes necessary.

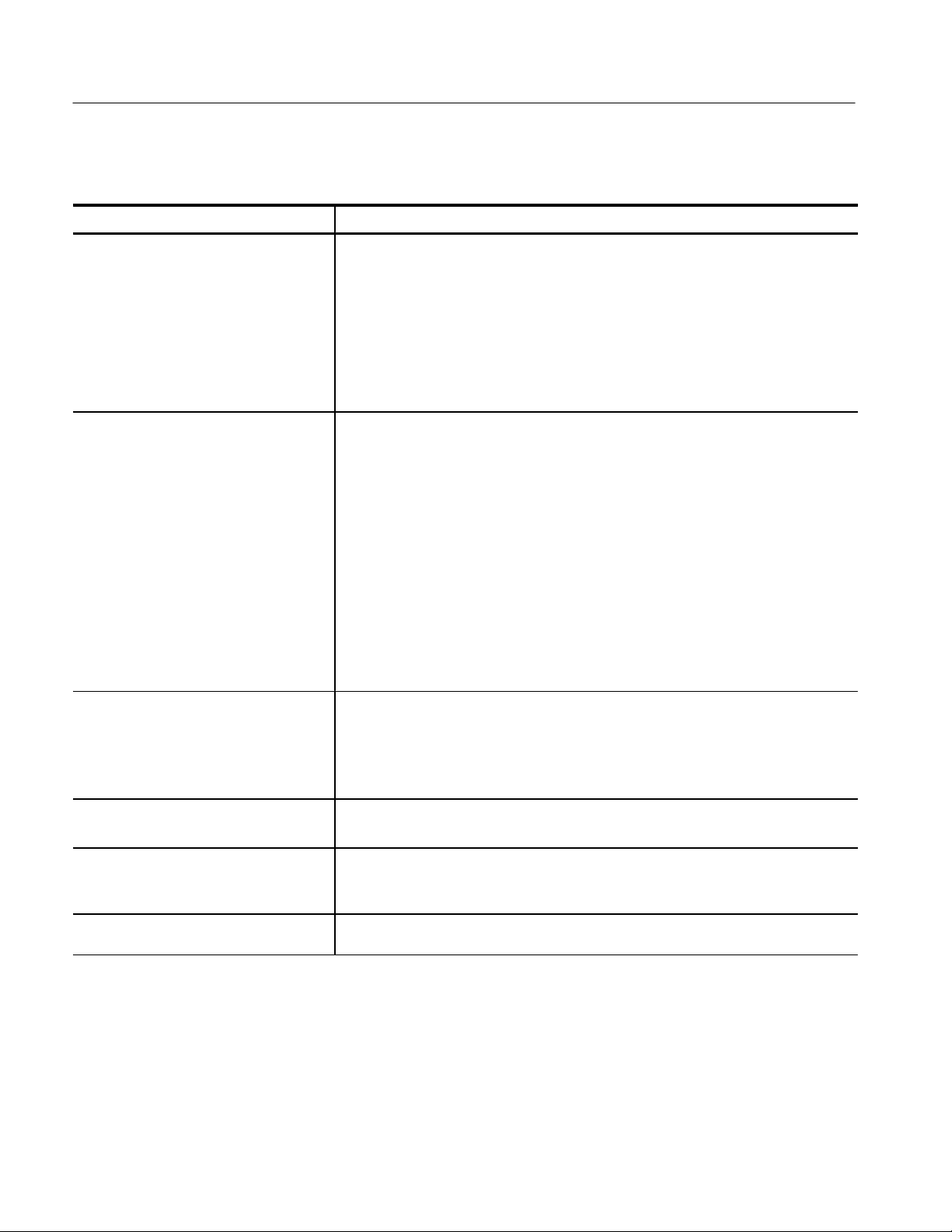

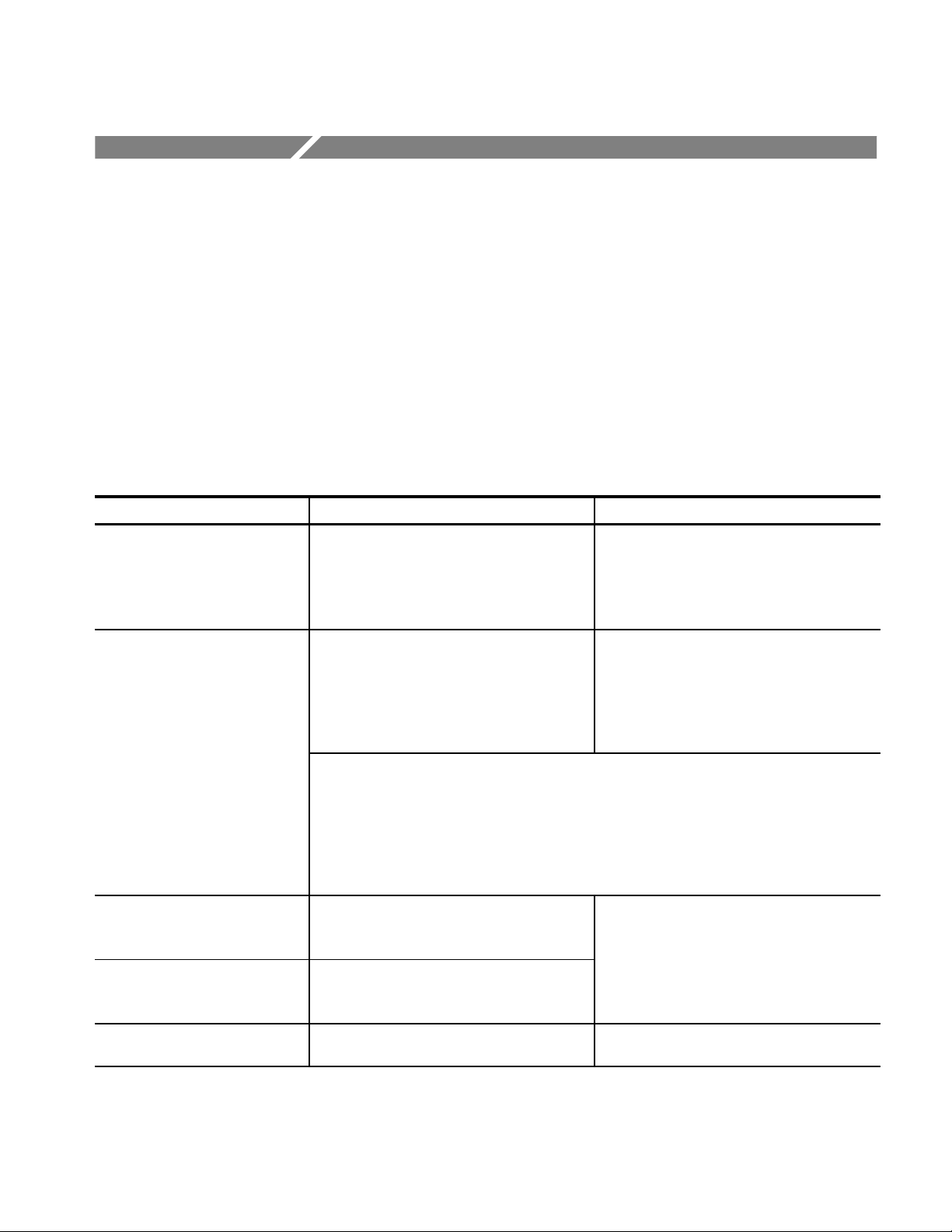

T able 1–1: Vertical deflection system

Category Description

Deflection Factor Req: 1 V Full Scale: 1 V input displayed within 1% of 140 IRE (1.0 V PAL).

RI: Flat filter selected.

Req: X5 Gain: Gain Accuracy ±5%.

RI: 1 V input signal.

Req: X5 Gain Registration: ≤1 major division of vertical shift from baseline between

unmagnified and magnified signal.

Req: Variable Gain Range: Input signals between 0.8 V and 2 V can be adjusted to

140 IRE (1.0 V PAL) display. 160 mV and 400 mV for X5 Gain.

Req: Position Range: 1 V signal can be positioned so that peak white and sync tip can

be placed at blanking level, with the DC Restorer Clamp on, regardless of gain

setting.

WVR500 Waveform/Vector Monitor Service Manual

1–3

Page 20

Specifications

T able 1–1: Vertical deflection system (cont.)

Category Description

Frequency Response Req: 1 V Full Scale: 50 kHz to 6 MHz within 2% of response at 50 kHz.

RI: Specifications apply for full screen height video input signal, with Variable

Gain off, and Flat filter selected.

Req: X5 Gain: 50 kHz to 6 MHz within 5% of response at 50 kHz.

RI: Flat filter selected.

Req: Luminance Filter: ≥30 dB attenuation at 4.00 MHz.

RI: Response at 15 kHz does not vary between Flat and Luminance filters by

more than 1%.

Transient Response RI: Specifications apply for full screen height video input signal, with Variable

Gain off, 1 V Full Scale or X5 Gain, using the 2T pulse and 2T bar.

Req: Pulse-to-Bar Ratio: X1: 0.99:1 to 1.01:1.

X5: 0.98:1 to 1.02:1.

Req: Field Rate Square Wave or V ertical Window Tilt: ≤1%.

Req: 25 s Bar Tilt: ≤1%.

Req: Overscan: ≤2% variation in baseline of 100 IRE (700 mV P AL) 12.5T (20T PAL)

modulated pulse as it is positioned over the middle 80% of the screen.

RI: Preshoot: ≤1%.

RI: Overshoot: X1: ≤2%.

X5: ≤4%.

RI: Ringing: X1: ≤2%.

X5: ≤4%.

Maximum Absolute Input Level Req: ±5 VDC + peak AC.

RI: Displays in excess of 200 IRE (1.428 V PAL) may cause frequency response

aberrations.

RI: Maximum Operating Input V oltage: Peak AC + DC should be within +8.0 V

and –5.6 V for proper operation.

DC Input Impedance Req: ≥15 k.

RI: Unterminated.

Return Loss (75 ) Req: ≥40 dB from 50 kHz to 6 MHz.

RI: CH-A and CH-B input channels, loopthrough terminated in 75 . Input in use

or not in use, instrument power on or off, all deflection factor settings.

Loopthrough Isolation RI: ≥70 dB of isolation between loopthroughs. Measured at FSC between CH-A,

CH-B, and EXT REF inputs.

1–4

WVR500 Waveform/Vector Monitor Service Manual

Page 21

Specifications

T able 1–1: Vertical deflection system (cont.)

Category Description

Crosstalk Between Channels RI: ≥70 dB of isolation between channels. Measured at FSC between CH-A,

CH-B, and EXT REF inputs.

Video Out RI: Differential Gain (50% APL): Within 1% with a 140 IRE (1.0 V PAL) unit

display .

RI: Differential Phase (50% APL): Within 1° with a 140 IRE (1.0 V PAL) unit

display.

Req: Return Loss (75 ): ≥30 dB from 50 kHz to 6 MHz.

RI: With the instrument turned on.

Req: Input to Video Out Gain Ratio: 1:1 ±5% @ 15 kHz.

RI: Picture display mode.

T able 1–2: DC restoration

Category Description

DC Restorer Clamp Time RI: Back Porch.

Frequency Response at 60 Hz (50 Hz PAL) Req: Attenuation of 60 Hz (50 Hz PAL) on Input signal:

Slow Mode – ≤20%.

Fast Mode – ≥90%.

Req: Blanking Level Shift with 10% to 90% APL Change: APL changes from 50% to

either 10% or 90% will cause blanking level shift of 1 IRE unit (7.14 mV PAL) or

less.

Req: Blanking Level Shift Due to Presence or Absence of Burst: 1 IRE unit (7.14 mV

PAL) or less shift from no color burst to presence of color burst.

T able 1–3: Horizontal deflection system

Category Description

Sweep Req: Sweep will occur in all Horizontal mode settings with or without synchronization.

2FLD Sweep Repetition Rate RI: Displays 2 full fields, including the field rate sync between them.

2FLD Sweep Magnification RI: Approximately X20.

1LINE Sweep Repetition Rate Req: Equal to the line-rate of applied video or external sync.

2LINE Sweep Repetition Rate Req: Equal to half the line-rate of applied video or external sync.

Sweep Length RI: 2LINE and 2FLD sweep length is nominally 12.5 divisions.

WVR500 Waveform/Vector Monitor Service Manual

1–5

Page 22

Specifications

T able 1–3: Horizontal deflection system (cont.)

Category Description

Timing Accuracy RI: All timing and linearity specifications exclude the first and last major divisions

of the unmagnified display.

Req: 10 ms/div. (2LINE): Within 2%.

Req: 5 ms/div. (1LINE): Within 2%.

Req: 1 ms/div. (2LINE + MAG): Within 2%.

Req: 0.5 ms/div . (1LINE + MAG): Within 3%.

Integral Linearity Req: Within 1%.

RI: Measured between the 10 ms and 110 ms points on the 10 ms/division sweep.

Sweep Magnifier Registration RI: Magnification occurs about the center of the screen.

Horizontal Position Req: Any portion of a synchronized video sweep can be positioned on screen in all

sweep modes.

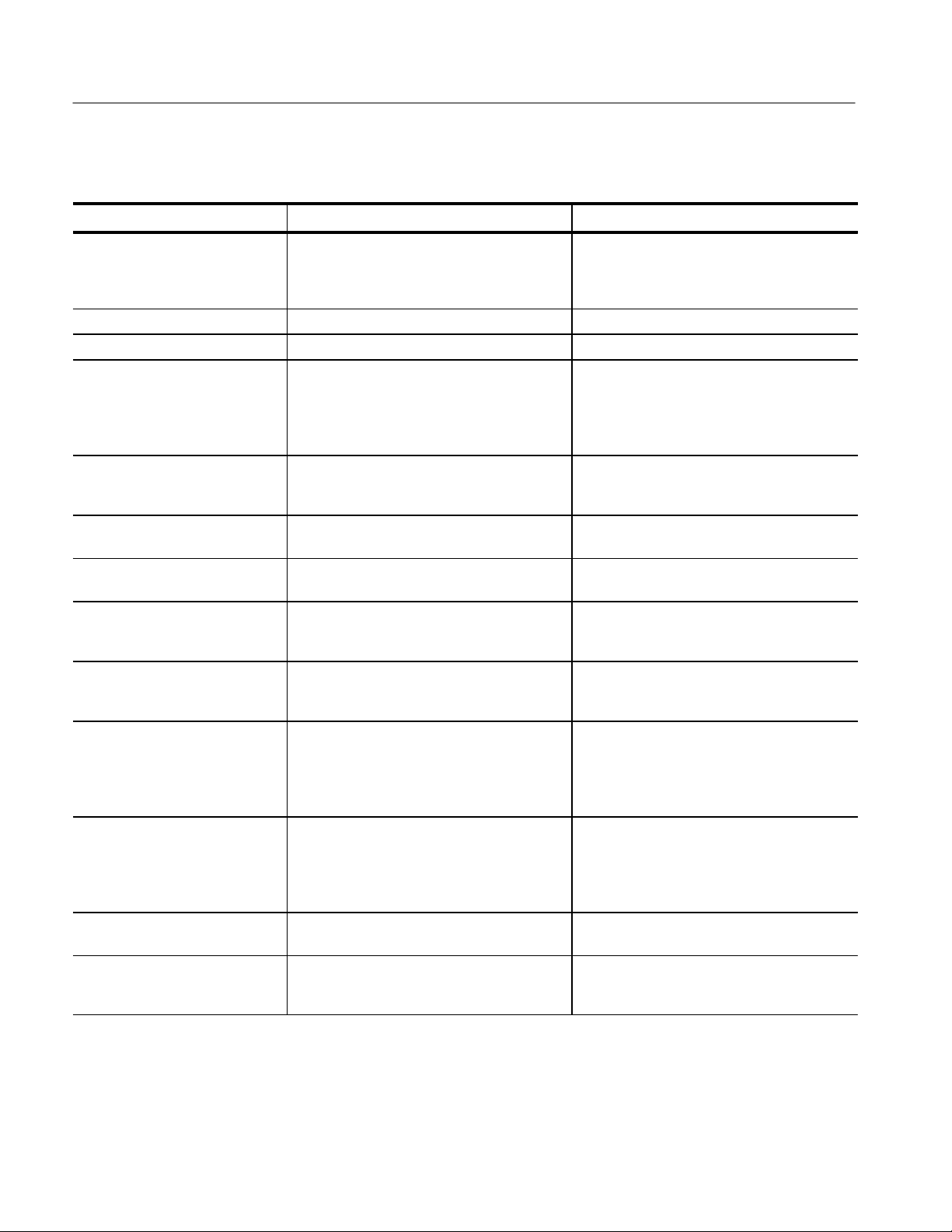

T able 1–4: Synchronization

Category

Input Requirements Req: Internal Reference, NTSC: Composite video or black burst with sync amplitudes

40 IRE ±6 dB.

Req: Internal Reference, P AL: Composite video or black burst with sync amplitudes

300 mV ±6 dB.

Req: External Reference: Sync amplitude between 143 mV and 4 V will synchronize

sweeps.

EXT REF Input Req: DC Input Impedance (Unterminated): ≥15 kW.

Req: Return Loss (75 W): ≥40 dB from 50 kHz to 6 MHz.

RI: Loopthrough terminated in 75 W, instrument power on or off.

RI: Absolute Maximum Input Voltage: ±12 VDC plus peak AC.

1–6

WVR500 Waveform/Vector Monitor Service Manual

Page 23

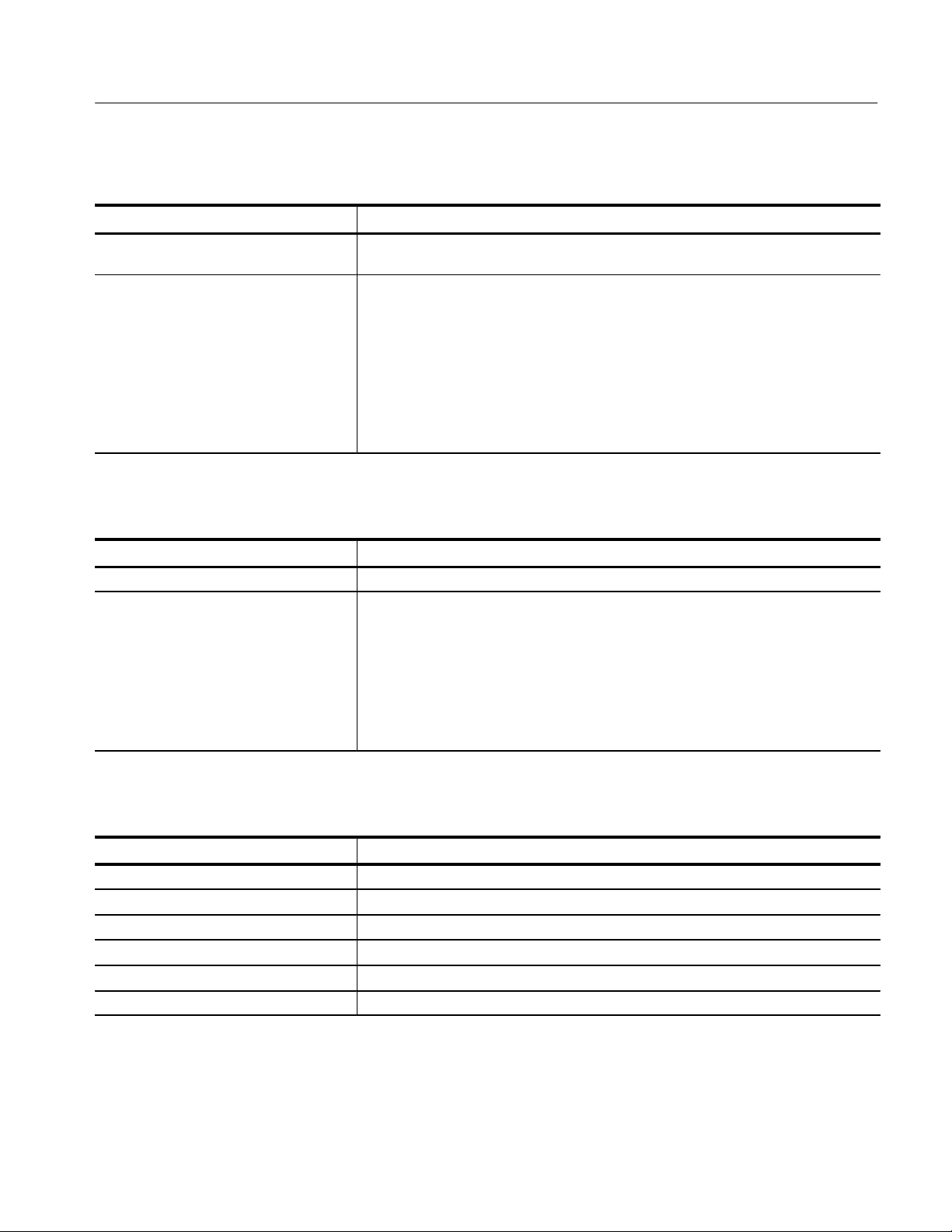

T able 1–5: Vector mode

Category Description

Chrominance Processing Req: Chrominance Bandwidth:

Upper –3 dB Point: F

Lower –3 dB Point: F

RI: Nominal Subcarrier Frequency (FSC)

NTSC: 3.579545 MHz.

PAL: 4.43361875 MHz.

RI: +V Mode (Applicable to PAL operation only): +V-type display as selected by

front-panel menu selection. When selected, V axis is inverted at a half

line-rate to produce a single vector display.

Display RI: Vector Phase Accuracy: ±1.25. Measured with color bar signal.

RI: Vector Gain Stability: Typically ±2.5%.

RI: Quadrature Phasing: Typically ±0.5.

Subcarrier Regenerator Req: Pull-In Range

NTSC: ±50 Hz of F

PAL: ±10 Hz of F

RI: Subcarrier Regenerator free runs in absence of appropriate signal. Reference

can be burst of either the displayed signal or the external reference signal.

RI: Pull-In Time: Within 1 second, with subcarrier frequency within 50 Hz (10 Hz

for PAL) of F

Req: Phase Shift with Subcarrier Frequency Change:

NTSC: ±2° from F

PAL: ±2° from F

Req: Phase Shift with Burst Amplitude Change: ±2_ from nominal burst amplitude to

±6 dB.

RI: Internal or External burst reference.

Req: Phase Shift with Input Channel Change: ±0.5_.

RI: With EXT REF selected.

Req: Phase Shift with Variable Gain Control: ±1_as gain is varied from +3 dB to –6 dB.

RI: Phase Control Range: 360_ continuous rotation.

Req: Burst Jitter: 0.5_ rms or less.

RI: With 140 IRE (1 V PAL) composite video input. Internal or external

referenced.

Display Characteristics RI: Differential Phase: ±1_.

RI: Differential Gain: ±1%.

RI: Measured with 140 IRE (1 V PAL) linearity signal (5-step, 10-step, or Ramp)

with 40 IRE (300 mV PAL) of subcarrier.

+500 kHz, ±100 kHz.

SC

–500 kHz, ±100 kHz.

SC

.

SC

.

SC

.

SC

to (FSC +50 Hz), or FSC to (FSC – 50 Hz).

SC

to (FSC +10 Hz), or FSC to (FSC – 10 Hz).

SC

Specifications

WVR500 Waveform/Vector Monitor Service Manual

1–7

Page 24

Specifications

T able 1–6: Power source

Category Description

Mains Voltage Range Req: 90–250 V.

Mains Frequency Range Req: 48 Hz to 66 Hz.

Power Consumption RI: 25 Watts maximum.

Power Fuse Rating Req: 250 V, 2 A, F-type.

T able 1–7: Physical characteristics

Category Description

Dimensions RI: Height: 1 3/4 inches (44.5 mm).

Width: 8 inches (203.2 mm).

Length: 18 1/2 inches (469.9 mm).

Weight RI: Approximately 4.0 lbs (approximately 1.8 kg).

T able 1–8: Environmental characteristics

Category Description

Temperature RI: Non-Operating: –55° C to +75° C.

Operating: 0° C to +50° C.

(IEC 1010-1 compliance to +40° C.)

Altitude RI: Non-Operating: To 50,000 feet.

Operating: To 15,000 feet.

(IEC 1010-1 compliance to 2000 meters.)

Equipment Type RI: Measurement (as defined in IEC 1010-1, Annex H).

Equipment Class RI: Class I (as defined in IEC 1010-1 Annex H).

Installation Category RI: Installation Category II (as defined in IEC 1010-1, Annex J). Note: Rated for

indoor use only.

Pollution Degree RI: Pollution Degree 2 (as defined in IEC 1010-1).

Vibration — Operating RI: 15 minutes each axis at 0.015 inch, frequency varied from 10–55–10 Hz in

1-minute cycles with instrument secured to vibration platform. 10 minutes

each axis at any resonant point or at 55 Hz if a resonant point is not found.

MIL-T-28800D, Paragraph 1.2.2, Class 3.

Shock — Non-Operating RI: 30 g, 1/2 sine, 11 ms duration, 3 shocks per surface (18 total).

Transportation RI: Qualified under NST A Test Procedure 1A, Category II (24 inch drop).

Humidity RI: Will operate at 95% relative humidity for up to five days.

1–8

WVR500 Waveform/Vector Monitor Service Manual

Page 25

Specifications

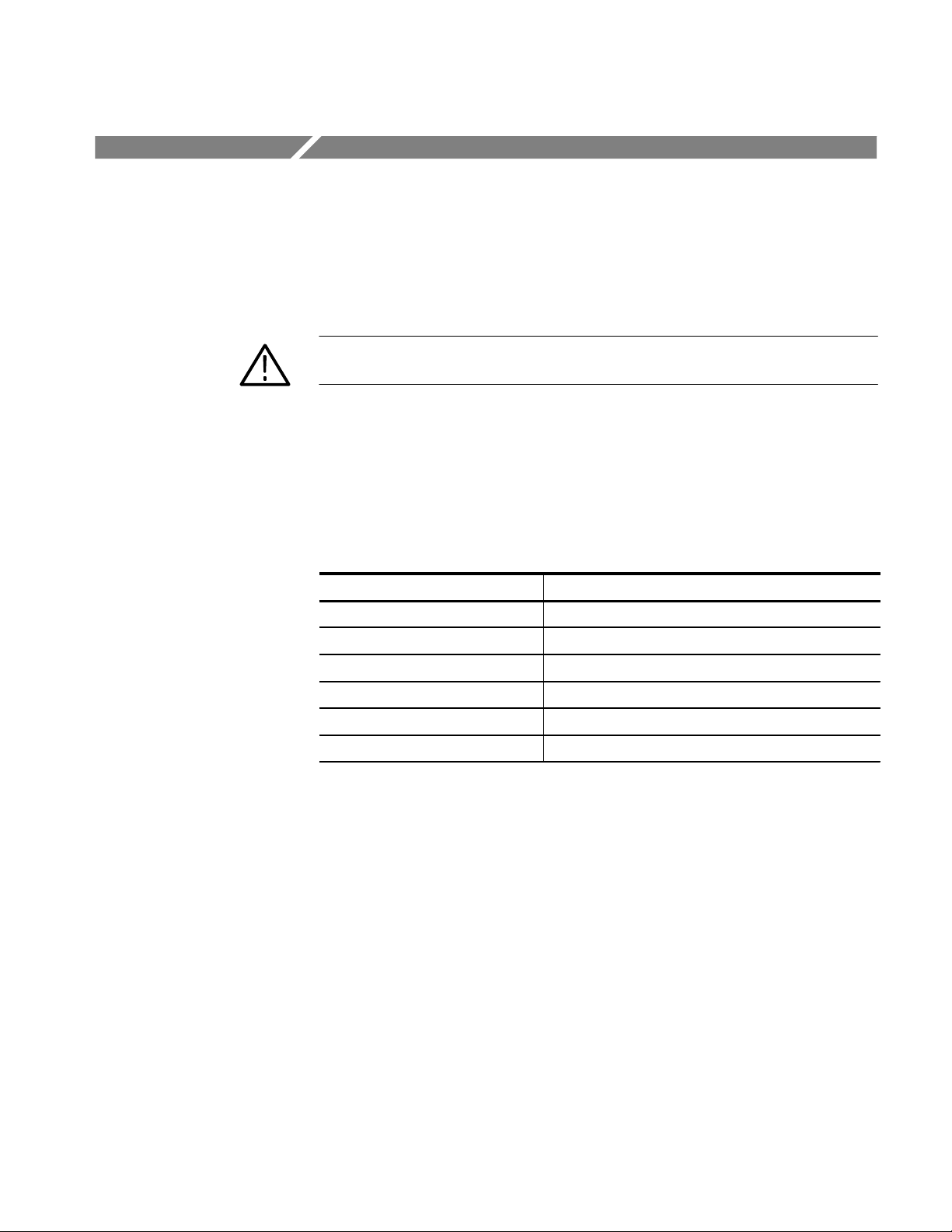

Table 1–9: Certifications and compliances

Category Description

EC Declaration of Conformity Compliance was demonstrated to the following specifications as listed in the Official

Journal of the European Communities:

EMC Directive 89/336/EEC:

EN 50081-1 (Emissions):

EN 55022 Class B Radiated and Conducted Emissions

EN 50082-1 (Immunity):

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast T ransient/Burst Immunity

Conditional Statements:

1. High quality shielded cables must be used to insure compliance to the

above listed standards.

Low Voltage Directive 73/23/EEC, Amended by 93/68/EEC:

EN 61010-1 Safety requirements for electrical equipment for measurement,

control, and laboratory use. Part 1: General Requirements.

Safety Standards

U.S. Nationally Recognized

Laboratory Listing

Canadian Certification CAN/CSA C22.2 No. 231 CSA Safety Requirements for Electrical and Electronic

European Union Compliance Low Voltage Directive 73/23/EEC, Amended by 93/68/EEC.

UL1244 Standard for Electrical and Electronic Measuring and Testing Equipment.

Measuring and Test Equipment.

EN61010-1 Safety Requirements for Electrical Equipment for Measurement, Control, and

Laboratory Use.

Additional Compliance IEC1010-1 Safety Requirements for Electrical for Measurement, Control, and

Laboratory Use.

Safety Certification Compliance

Temperature, operating +5 to +40_ C

Altitude (maximum operating) 2000 meters

Equipment Type T est and measuring

Safety Class Class I (as defined in IEC 1010–1, Annex H) – grounded product

Overvoltage Category Overvoltage Category II (as defined in IEC 1010–1, Annex J).

Pollution Degree Pollution Degree 2 (as defined in IEC 1010–1). Note: rated for indoor use only.

WVR500 Waveform/Vector Monitor Service Manual

1–9

Page 26

Specifications

1–10

WVR500 Waveform/Vector Monitor Service Manual

Page 27

Operating Information

Page 28

Page 29

Installation

Mechanical Installation

This section contains mechanical and electrical installation instructions, as well

as instrument operation instructions that relate to the service of the WVR500

monitor. The Operating Instructions section begins on page 2–7.

Before installing the WVR500 monitor, refer to the Environmental Characteristic

requirements, located in Table 1–8 of the Specifications section of this manual.

All qualification testing was performed with the factory shipped cabinet

installed. To guarantee compliance with specifications, only operate the

instrument in a cabinet or rackmount adapter.

Unpacking

Cabinet

Custom Installation

Rackmounting

Save the shipping carton and packing materials (including antistatic bag) in the

event it becomes necessary to ship the instrument to a Tektronix Service Center

for service or repair. Repackaging instructions are located in the Maintenance

section of this manual.

The WVR500 monitor is shipped installed in a cabinet. There are no optional

cabinets available.

For applications such as consoles, the instrument can be mounted with the front

molding flush or protruding from the console. In both cases, allow approximately three inches of rear clearance for BNC and power-cord connections. To mount

the instrument safely, attach it to a shelf strong enough to hold its weight.

The WVR500 monitor is a half-rack width and one rack unit high instrument. It

requires approximately three inches of rear clearance for power cord and cable

connections, and 20 inches in front of a rack for installation and removal of the

instrument.

Tektronix offers two optional rack adapters to rackmount the WVR500 monitor.

The rackmount adapters, TVGF13 and TVGF14, provide the proper electrical

environment, supply adequate shielding, minimize handling damage, and reduce

dust collection within the instrument. Contact your local Tektronix Field Office

or Service Center for ordering information.

WVR500 Waveform/Vector Monitor Service Manual

2–1

Page 30

Installation

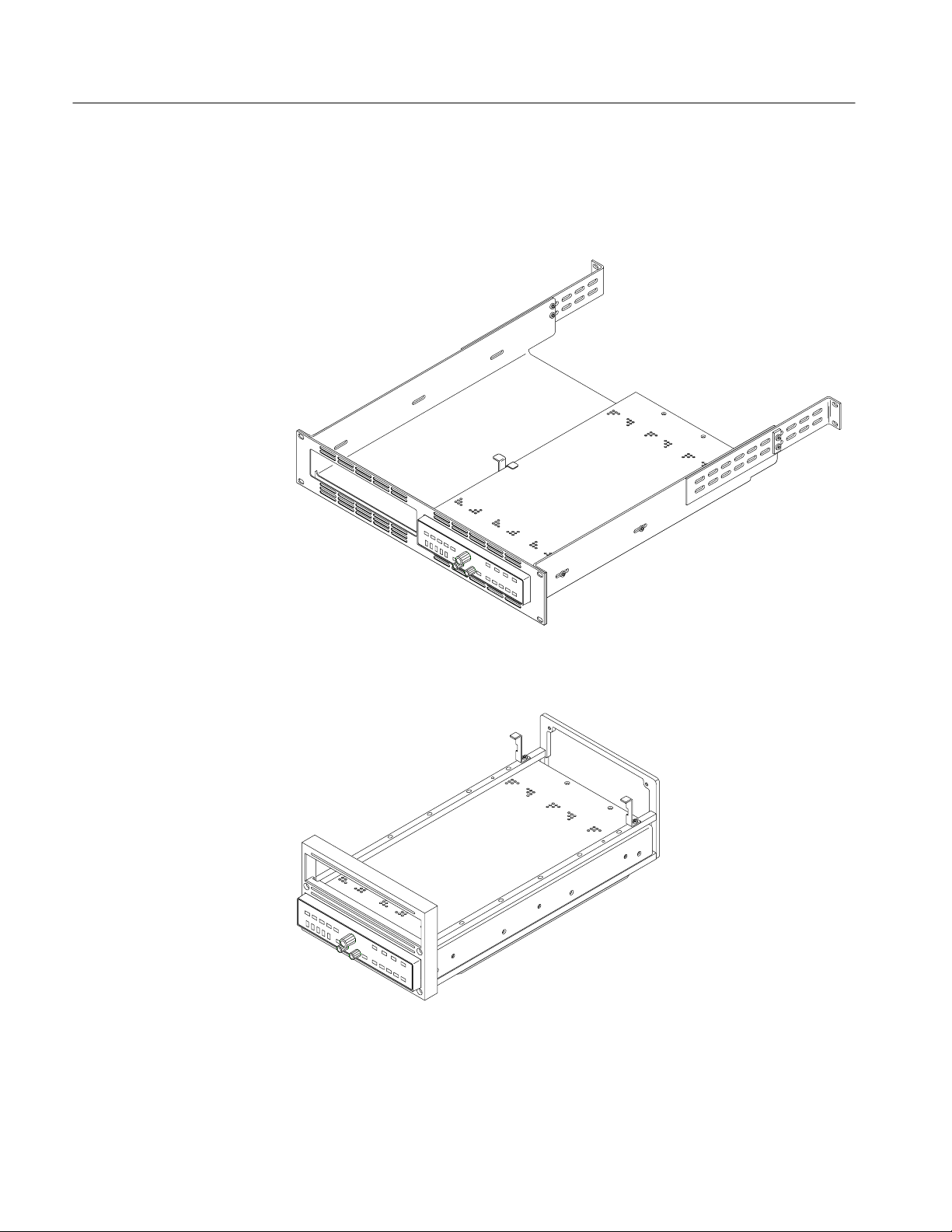

TVGF13. This rack adapter allows two Tektronix half-rack instruments to be

mounted side-by-side in a full rack application. The WVR500 monitor mounts in

either slot of the TVGF13 rack adapter. See Figure 2–1.

Figure 2–1: The TVGF13 side-by-side rack adapter

Figure 2–2: The TVGF14 dual half-rack adapter

2–2

WVR500 Waveform/Vector Monitor Service Manual

Page 31

Installation

TVGF14. This rack adapter mounts two Tektronix half-rack width and one rack

unit high instruments in a standard half-rack application. The WVR500 monitor

mounts in the lower slot of the TVGF14 rack adapter. See Figure 2–2.

Remote Monitor

Electrical Installation

Power Source

Mains Frequency and

Voltage Range

The WVR500 monitor does not have a built in display device, and is therefore

dependent on a remote monitor or video switcher to display its output. The

placement of the WVR500 monitor in a permanent location should take this

requirement into account.

The following electrical installation instructions provides information about the

power source, mains frequency and voltage range, power cord options, internal

operational jumpers, and rear-panel connectors.

The WVR500 monitor is designed to operate from a single-phase power source

having one of its current-carrying conductors at or near earth ground (the neutral

conductor). Only the line conductor is fused for over-current protection. Systems

that have both current-carrying conductors live with respect to ground (such as

phase-to-phase on multiphase systems) are not recommended as power sources.

A protective ground connection by way of the grounding conductor in the power

cord is essential for safe operation.

The WVR500 monitor operates at 50 and 60 Hz, over the range of 90–250 Volts,

without operator adjustment.

Power Switch

Fuse

WVR500 Waveform/Vector Monitor Service Manual

The WVR500 monitor does not have an external power switch. Power is

supplied and removed from the instrument by means of the power cord.

WARNING. When power is supplied, line voltage will be present in the instrument. Do not operate the WVR500 monitor without the cabinet installed or

serious injury could result.

The WVR500 monitor does not have an external power fuse. The fuse is located

internally on the Power Supply board. Refer all internal instrument servicing to a

qualified service person. The Maintenance section of this manual contains

instructions for replacing the power supply fuse on page 6–11.

2–3

Page 32

Installation

Power Cord

Operational Jumpers

Any of the power cord options listed in the Options section of this manual can be

ordered for the WVR500 monitor. If no power cord option is specified, instruments are shipped with a North American 125 V power cord.

Unless otherwise specified, power cords for use in North America are UL listed

and CSA certified. Power cords for use in areas other than North America are

approved by at least one test house acceptable in the country to which the

product is shipped.

There are only two operational modifications made to the WVR500 monitor

through internal jumper settings. Each input channel has a jumper for the

selection of AC or DC input coupling. In addition, there is a jumper that enables

the Calibration mode.

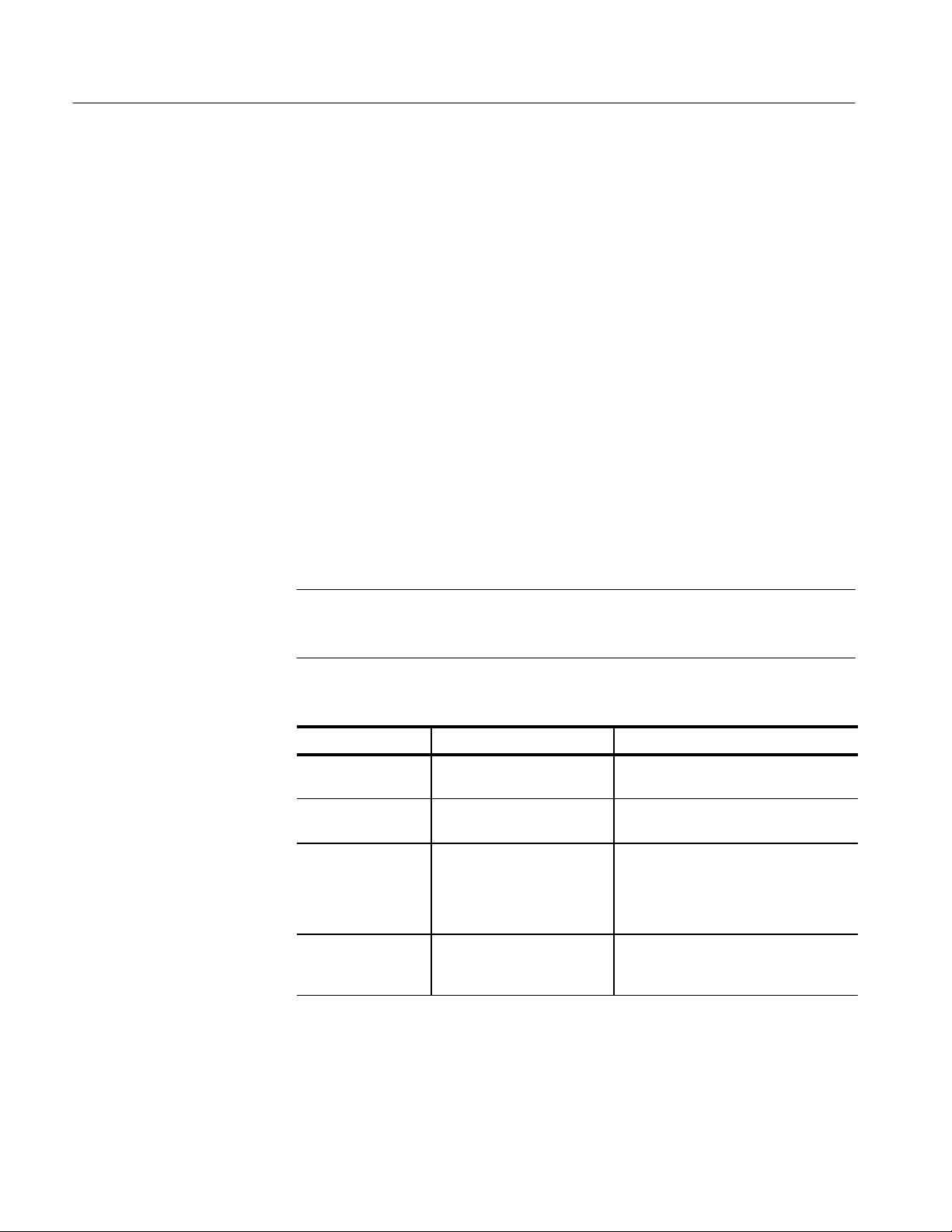

Table 2–1 lists the operational jumpers and their functions. Figure 2–3 shows the

location of the operational jumpers on the Main board.

The rest of the instrument configurations are changed through the on-screen

menus. Details of the menu operation are located in the Operating Instructions

section starting on page 2–12.

NOTE. There are jumpers in the WVR500 monitor that are for factory use only.

Leave the factory-use-only jumpers listed in Table 2–1 in their operating

positions.

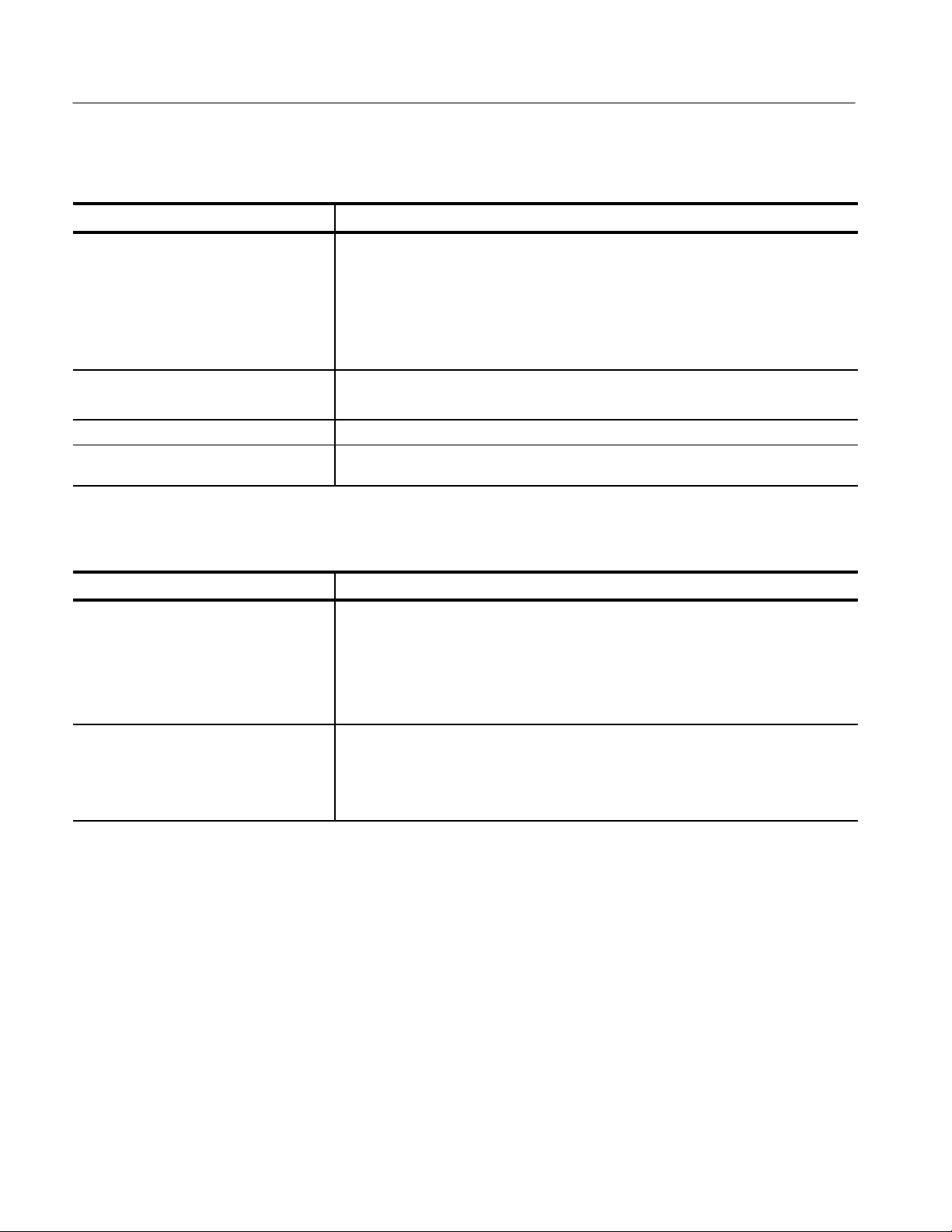

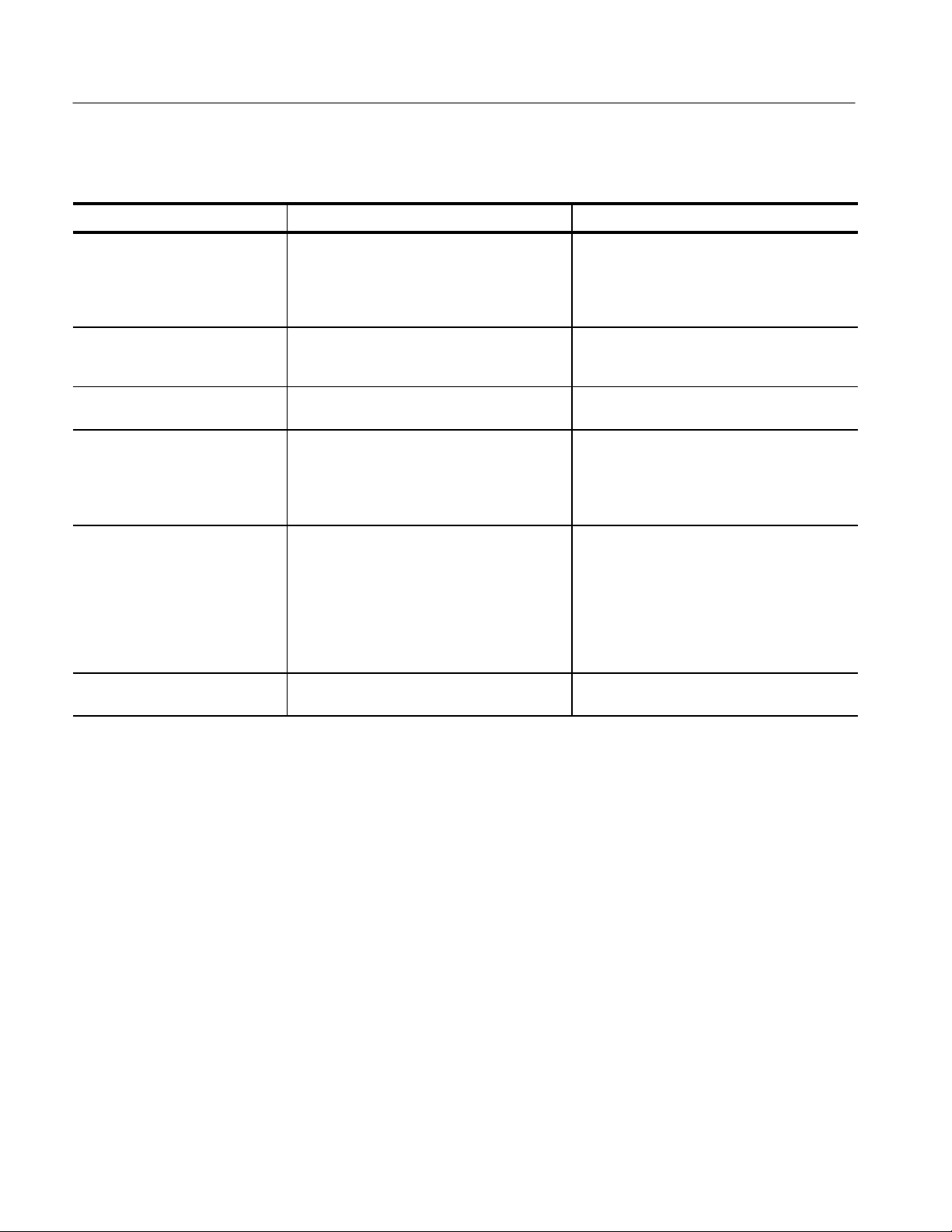

T able 2–1: Operational jumper selections

Jumper Number Name Function

A2J1 CHA Input Coupling 1-2 DC coupled

2-3 AC coupled (factory preset)

A2J2 CHB Input Coupling 1-2 DC coupled

2-3 AC coupled (factory preset)

A2J27 Calibration Mode Enable Calibration mode:

Jumper installed on both pins

Normal operation:

Jumper installed on one pin only

A2J17, A2J18,

A2J19, A2J20,

A2J100

Factory Use Only 1-2 Factory use only

2-3 Operating position

2–4

WVR500 Waveform/Vector Monitor Service Manual

Page 33

Installation

Rear Panel Connectors

J27

Calibration

mode enable

1

A2 Main board

Front of instrument

J2

CH B input

coupling

J1

CH A input

coupling

1

1

Figure 2–3: Operational jumper locations

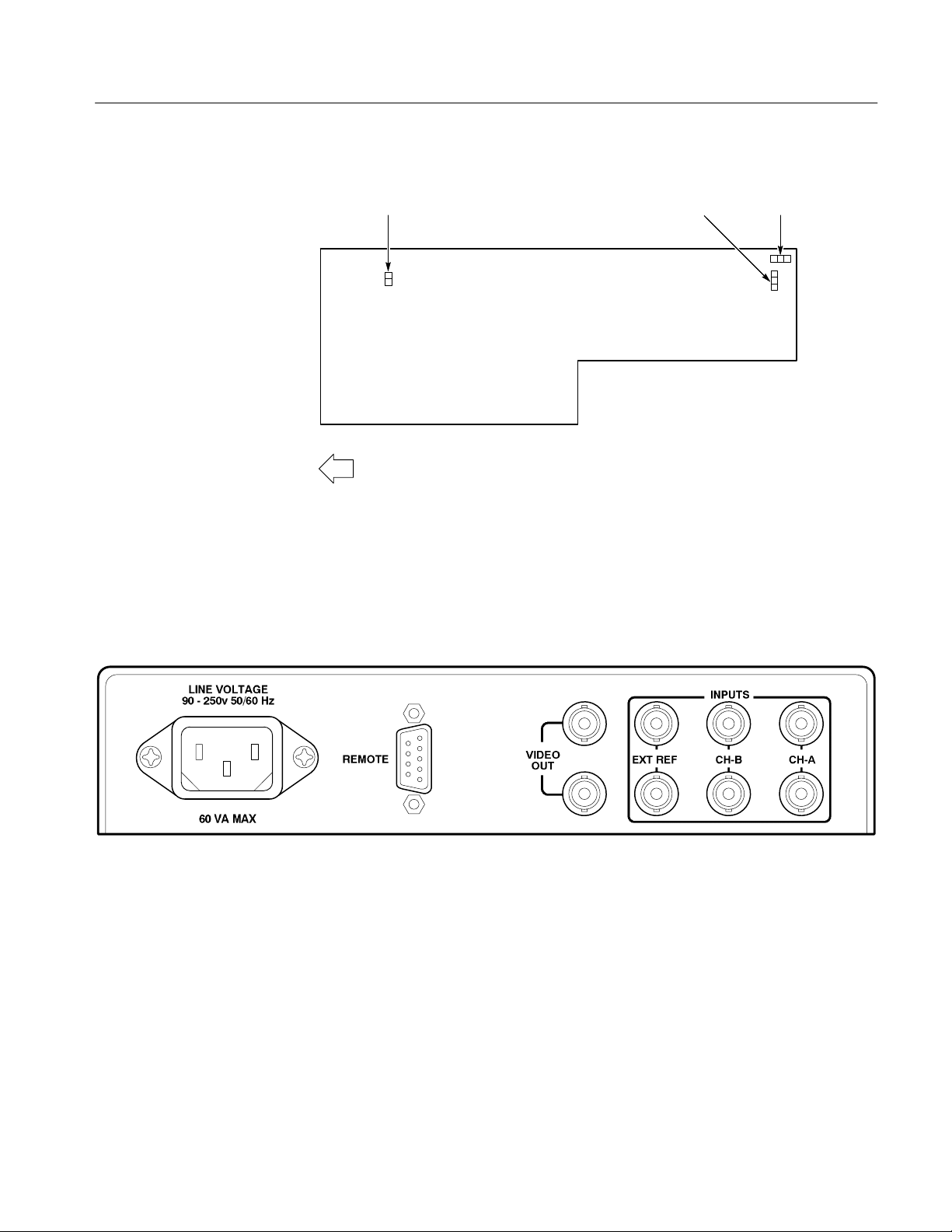

All of the WVR500 monitor external connectors are located on the instrument’s

rear panel. The rear panel is illustrated in Figure 2–4. General information about

the rear panel connectors is provided in the following paragraphs.

Figure 2–4: WVR500 monitor rear panel

Video Inputs. The two channels of video input use four 75 W compensated

loopthrough BNC connectors. These inputs are not internally terminated and

therefore require a 75 W external termination to provide accurate measurement

capabilities. The maximum operating input voltage for the video inputs is

±5 VDC plus peak AC.

WVR500 Waveform/Vector Monitor Service Manual

2–5

Page 34

Installation

External Reference. The external reference input uses two 75 W compensated

loopthrough BNC connectors. This input is not internally terminated and

therefore requires a 75 W external termination to provide accurate measurement

capabilities. The external reference input provides both external synchronizing

signals and external subcarrier input to the instrument. The input can be either a

black burst or composite-video signal.

Video Output. The two video output BNC connectors are a 75 W compensated

dual output of the video signal selected by the front-panel INPUT switch. These

outputs can be used to drive a picture monitor and/or a video switcher.

Remote. The RS232 remote connector is a 9-pin subminiature D-type with male

contacts that provides a serial interface for remote control. All front-panel

controls and menu settings can be set through this interface. Refer to the

WVR500 Waveform/Vector Monitor User Manual for detailed information about

the remote interface.

AC Power. The power connector is a standard AC plug receptacle for 120 or

240 VAC power mains. The plug is compatible with any of the power cord

options available with the WVR500 monitor. The monitor operates at 50 and

60 Hz, over the range of 90–250 Volts, without operator adjustment.

2–6

WVR500 Waveform/Vector Monitor Service Manual

Page 35

Operating Instructions

This section duplicates the operating information material contained in the

WVR500 Waveform/Vector Monitor User Manual. The basics of front-panel

operation and the menu system are presented here in a brief format for the

convenience of service personnel. Refer to the user manual when you need a

more complete explanation of instrument operation.

These operating instructions include the following descriptions:

Front-panel controls page 2–7

Special operating modes page 2–10

On-screen readout page 2–11

Menu operation page 2–12

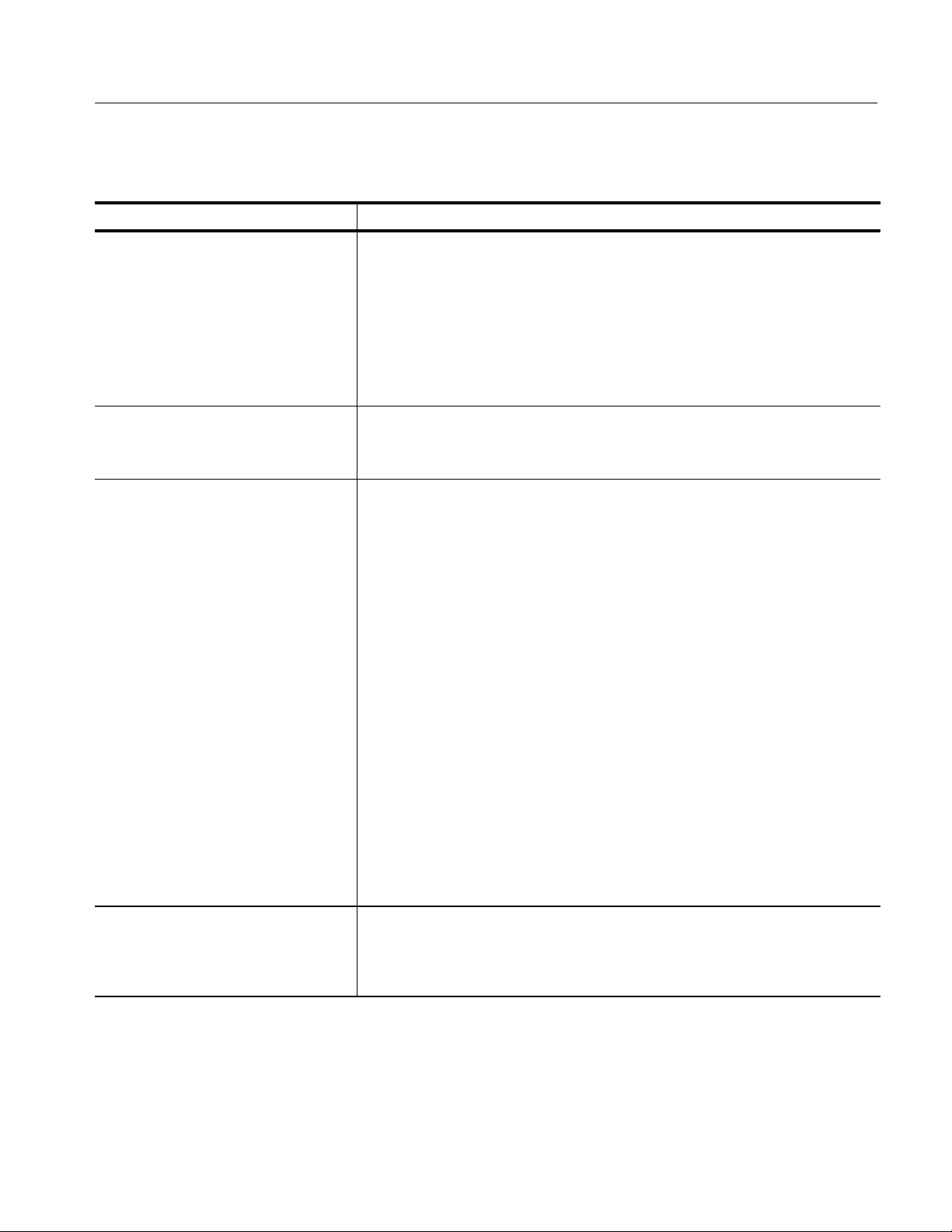

Front Panel Controls

The description of the front-panel controls begins with a generic overview of

control functionality. The overview is followed by description of each control

based on function. The WVR500 monitor front panel is shown in Figure 2–5; the

rear panel is shown in Figure 2–4 on page 2–5.

Overview

WVR500 Waveform/Vector Monitor Service Manual

The front-panel knobs are the continuous rotation type. The adjustment range

limit is reached when there are not any more visible display changes.

The large center knob has adjustment functions assigned to it through the menus.

This control is referred to as the General Purpose (GP) Knob.

The front-panel buttons are push and release toggle switches, with some of the

front-panel selections backlit to indicate the current setting.

The WVR500 monitor does not have an external power switch. The instrument

is turned on or off by plugging or unplugging the power cord from the power

source.

WARNING. If an appropriate power source is supplied to this instrument, line

voltage will be present in the instrument. Do not operate this instrument without

the cabinet installed or serious injury could result.

2–7

Page 36

Operating Instructions

Figure 2–5: WVR500 monitor front panel

Display Mode Selection

Input Channel Selection

Signal Reference

Selection

Press the WAVEFORM to provide a voltage vs. time display of the video signal.

Press the VECTOR button to present an XY plot of the demodulated chromi-

nance phase and amplitude portion of the video signal. The angle represents

chrominance phase, and the distance from the center represents chrominance

amplitude.

Press the PICTURE button to

Press the WV IN PIC (waveform in picture) button to

display the video signal as a picture.

display the waveform

monitor and/or vectorscope displays, reduced to 1/4-screen sized windows, over

the picture monitor display. The reduced displays can be made transparent to

view the entire picture display.

Press the INPUT button to toggle the

signals on the

CH A and CH B rear-panel connectors.

VIDEO OUT display signal between the

Only one input channel can be selected for display at a time. The currently

selected channel is shown by a lighted indicator.

Press the REF button to toggle the signal reference between

reference) and

EXT (external signal reference). The current signal reference is

INT (internal

shown by a lighted indicator. The instrument will operate from external reference

signals of either composite video or black burst.

Sweep Rate Selection

2–8

Sweep rate selection only applies to the Waveform display mode. The current

sweep rate is shown by a lighted indicator.

Press the SWEEP button to toggle the display through three sweep rates:

1LINE

(5 ms/Div.), 2LINE (10 ms/Div.), and 2FLD.

WVR500 Waveform/Vector Monitor Service Manual

Page 37

Operating Instructions

Press the MAG button to horizontally magnify the sweep to additional sweep

rates:

1LINE + MAG (0.5 ms/Div.), and 2LINE + MAG (1 ms/Div.). 2FLD + MAG

magnifies the sweep by approximately X20. An indicator lights when MAG is

selected.

Signal Gain

Signal Positioning

Filter Selection

The current sweep rate is displayed in the on-screen readout.

when

2FLD + MAG is selected.

X20 is displayed

Press the GAIN X5 button to vertically magnify the waveform monitor display

by X5. The vectorscope display is magnified by X5 in all directions. An

indicator lights when

GAIN X5 is selected.

Variable gain is activated through a menu selection in the Operating menu. The

waveform and vector display modes have separate variable gain adjustments.

VAR is displayed in the on-screen readout when variable gain is turned on.

Signal positioning

is controlled by the ↕ and ↔ knobs and applies to the

waveform monitor display only. In the vectorscope display, the signal is

auto-centered and the position is not adjustable.

Filter selections apply to the waveform display mode only. The current filter

selection is shown by a lighted indicator and the on-screen readout.

Press the FILTER button to toggle the waveform display through FLAT (no

filter),

both

parade, while

LUM (low-pass filtered for luminance display), and a parade display of

FLAT and LUM filters. 2LINE and 2FLD sweeps display the two filters in a

1LINE displays an overlay of the two filters.

Line Select Mode

Line Select mode allows the selection of a single line to display from lines

6 through 262 (3 through 312 PAL) of fields one and three, two and four, or all

fields of the input signal. The on-screen readout lists the currently selected line

and field numbers when the Line Select mode is turned on.

Press the LINE SEL button to toggle the Line Select mode on and off. An

indicator lights and any open menus are closed when the mode is turned on.

Line and field selections, as well as screen update speed, are made through the

waveform or vector display mode Operating menus after the Line Select mode

has been turned on. For basic information on the menu selections, see page 2–12.

Line Select mode is not displayed in

when Line Select is turned on, the sweep rate will automatically change to

1LINE. While Line Select is on, the SWEEP button will toggle between 1LINE

and 2LINE sweep rates only.

2LINE sweep, the line displayed on the left is the selected line.

In

WVR500 Waveform/Vector Monitor Service Manual

2FLD sweep. If 2FLD sweep is selected

2–9

Page 38

Operating Instructions

Menu Access

Instrument Reset

Menus are entered by pressing one of the following front-panel buttons:

PRESETS, DISPLAY, and CONFIG. Menus are exited by pressing the CLEAR

button, selecting a different menu, selecting another display mode, or by turning

on the Line Select mode.

The menu options displayed by each of the four menus, are dependant on the

current display mode. Several of the menus are multi-page, shown by the menu

selection option of

Extraordinary conditions may cause the WVR500 monitor front-panel controls to

become locked. To reset the instrument, unplug the power cord from the power

source and then plug it back in. If this reset does not unlock the controls, contact

your Tektronix field office for assistance.

Special Operating Modes

The Amplitude Alarm, Variable Gain, and Calibration operating modes are

entered through the menu system as described below.

Amplitude Alarm Mode

The Amplitude Alarm applies to the waveform monitor display only. When the

Amplitude Alarm has been turned on, any portion of the signal display exceeding the 100 IRE (1.0 V PAL) graticule line is highlighted. The Amplitude Alarm

is also visible in the waveform monitor portion of the Waveform-in-Picture

display mode. The Amplitude Alarm is turned on through the Waveform display

mode Operating menu. The characteristics of the highlighted portion of the

display, such as intensity and color, are set through the Display menu.

MENU,

MORE.

2–10

Variable Gain Mode

The Variable Gain mode is turned on through a menu selection in the Operating

menus of the waveform and vector display modes.

on-screen readout when variable gain is turned on.

Turning Variable Gain on in the waveform display mode does not turn it on in

the vector display mode. The two display modes have separate variable gain

adjustments and do not track with each other.

When Variable Gain is on, and the GP Knob has been assigned a different

control function, selecting variable gain from the menu will reassign the

GP Knob to variable gain control. A second press of the button will turn the

mode off.

The GP Knob is assigned to variable gain control, instead of the display mode

default, when entering the Waveform or Vector display modes if variable gain

was left on when that display mode was last exited.

WVR500 Waveform/Vector Monitor Service Manual

VAR is displayed in the

Page 39

Operating Instructions

Calibration Mode

On-Screen Readout

Readout Description

The Calibration mode is entered through a menu selection, which appears in the

Configure menu, after the movement of an internal jumper (A2J27).

The calibration adjustments are done entirely from the front panel. Detailed

information on the Calibration mode and instrument adjustments are located in

Adjustment Procedures on page 5–1.

The WVR500 monitor uses on-screen readouts to display the current front-panel

control settings when the Waveform or Vector display modes are selected. The

readout can be turned on or off through the Configure menu.

Figure 2–6 shows the locations of the readout messages.

1 The currently selected input channel; CH A or CH B.

2 The current monitoring standard; NTSC or PAL.

3 The current signal reference; Int (internal) or Ext (external).

4 The current filter selection. The readout is blank if Flat filter is selected. LP

(low pass) is displayed if Lum filter is selected. PAR (parade) is displayed if

both Flat and Lum filters are selected. The readout appears in this location in

Waveform display mode only. For the Vector display mode, this readout is in

location 7.

5 Displays the current state of variable gain. The readout is blank if variable

gain is off, and VAR is displayed when variable gain is turned on. The

readout appears in this location in the Waveform display mode only. For the

Vector display mode, this readout appears in location 7.

6 Displays the current function assigned to the GP Knob.

7 The filter selection and variable gain readout locations for the Vector display

mode only.

8 The message Missing Sync or Bad Sync is displayed when the signal

reference is lost. Missing Sync is displayed when there is no sync pulse

detected by the instrument. Bad Sync is displayed when a sync pulse is

detected but cannot be processed.

A Configuration menu selection turns the sync message on and off. The sync

message appears in different locations depending on the current display

mode. The sync message will not appear if the on-screen readout has been

turned off. In Picture display mode, the screen goes completely black if the

sync message or readout is turned off.

WVR500 Waveform/Vector Monitor Service Manual

2–11

Page 40

Operating Instructions

12345 6

7

8

CH A NTSC INT DV AR GAIN

100

PAR VAR

80

MISSING SYNC

60

40

20

0

–20

–40

LINE 16 ALL

PAR VAR

5US/D

TEK

910

Figure 2–6: On-screen readout display

9 Displays the currently selected line and field numbers when the Line Select

mode is turned on. The readout lists the selected line first, followed by the

field number. The Missing Sync or Bad Sync messages appear here in the

Waveform and Vector display modes when the signal reference is lost.

10 Displays the current sweep rate in the Waveform display mode only; 5US/D

for 1Line sweep, 10US/D for 2Line sweep, 0.5US/D for 1Line + Mag

sweep, 1US/D for 2Line + Mag sweep, and X20 for 2Field + Mag sweep.

No readout appears for 2Field sweep.

Menu Operation

Menu Control

2–12

The basics of operating the menu system is presented here in a brief format for

convenience. Refer to the WVR500 Waveform/Vector Monitor User Manual for a

complete explanation of instrument operation.

Menus are entered by pressing one of the following front-panel buttons:

PRESETS, DISPLAY, and CONFIG. Menus are exited by pressing the CLEAR

MENU,

button, selecting a different menu, selecting another display mode, or by turning

on the Line Select mode. The menu options displayed by each of the four menus,

are dependant on the current display mode. Several of the menus are multi-page,

shown by the menu selection option of

MORE.

Press the MENU button to display the Operating menu for the currently selected

display mode. Contents include variable gain and vector phase control, as well as

safe title and safe action windows.

WVR500 Waveform/Vector Monitor Service Manual

Page 41

Operating Instructions

Press the PRESETS button to display the Presets Recall/Store menu. This menu

allows you to save or recall up to four instrument front-panel and menu setups.

Press the DISPLAY button to enter the Display menu for the currently selected

display mode. Contents include signal and graticule intensity and color

adjustments. There are not any adjustments for focus or trace rotation, as they are

processed internally by the WVR500 monitor.

Press the CONFIG button to enter the Configure menu in the waveform and

vector display modes only. Several operating parameters, such as instrument

monitoring standard, DC restorer clamp speed, and graticule visibility are set in

this menu.

Press the CLEAR button once to clear the menu display, but leave the GP Knob

in control of any function assigned to it through the menus. Press the

CLEAR

button a second time to return the GP Knob to the default function of the current

display mode.

The GP KNOB is assigned control of various adjustments through the menus.

The current function assigned to the knob is displayed in the on-screen readout.

Making Menu Selections

The Numbered Buttons (1 through 5) are used to make menu selections while the

menus are displayed. Menu selections are made by pressing the numbered button

corresponding to the number appearing next to the desired menu selection.

Menu selections are made by pressing the Numbered Button corresponding to

the menu selection number. The highlight bar toggles through the menu

selections with each press of the Numbered Button. Selections can be made only

while the menu is displayed. Figure 2–7 shows a typical menu display.

When the WVR500 monitor is first powered up, the menus open to page one.

When a menu is reentered, it opens to the last menu page that was open.

Figure 2–7: Typical menu display

WVR500 Waveform/Vector Monitor Service Manual

2–13

Page 42

Operating Instructions

GP Knob Function Control

The center unlabeled knob is the General Purpose (GP) Knob. The variable

control knob is assigned various adjustment functions through the menus.

This adjustment knob is sensitive to quick turns. Adjustments should be made

with moderate knob-turning speed.

When a menu selection assigns control of a function to the GP Knob, a knob

icon appears in front of the function name in that menu. The current function of

the GP Knob is displayed next to a knob icon in the on-screen readout.

The GP Knob is assigned a default function entering a new display mode:

Waveform display mode assigns GP Knob control to signal intensity, or to

variable gain if the mode was left on when the display mode was last exited.

Vector display mode assigns GP Knob control to vector phase, or to variable

gain if the mode was left on when the display mode was last exited.

Picture display mode does not assign a function to the GP Knob.

Waveform-in-Picture display mode assigns GP Knob control to vector phase

when vector is one of the reduced displays. When waveform display only is

selected, the GP Knob is not assigned a function.

2–14

WVR500 Waveform/Vector Monitor Service Manual

Page 43

Theory of Operation

Page 44

Page 45

Theory of Operation

This section contains a block-level description of the WVR500 monitor circuitry.

This description is written at a level to facilitate troubleshooting to the replaceable module level.

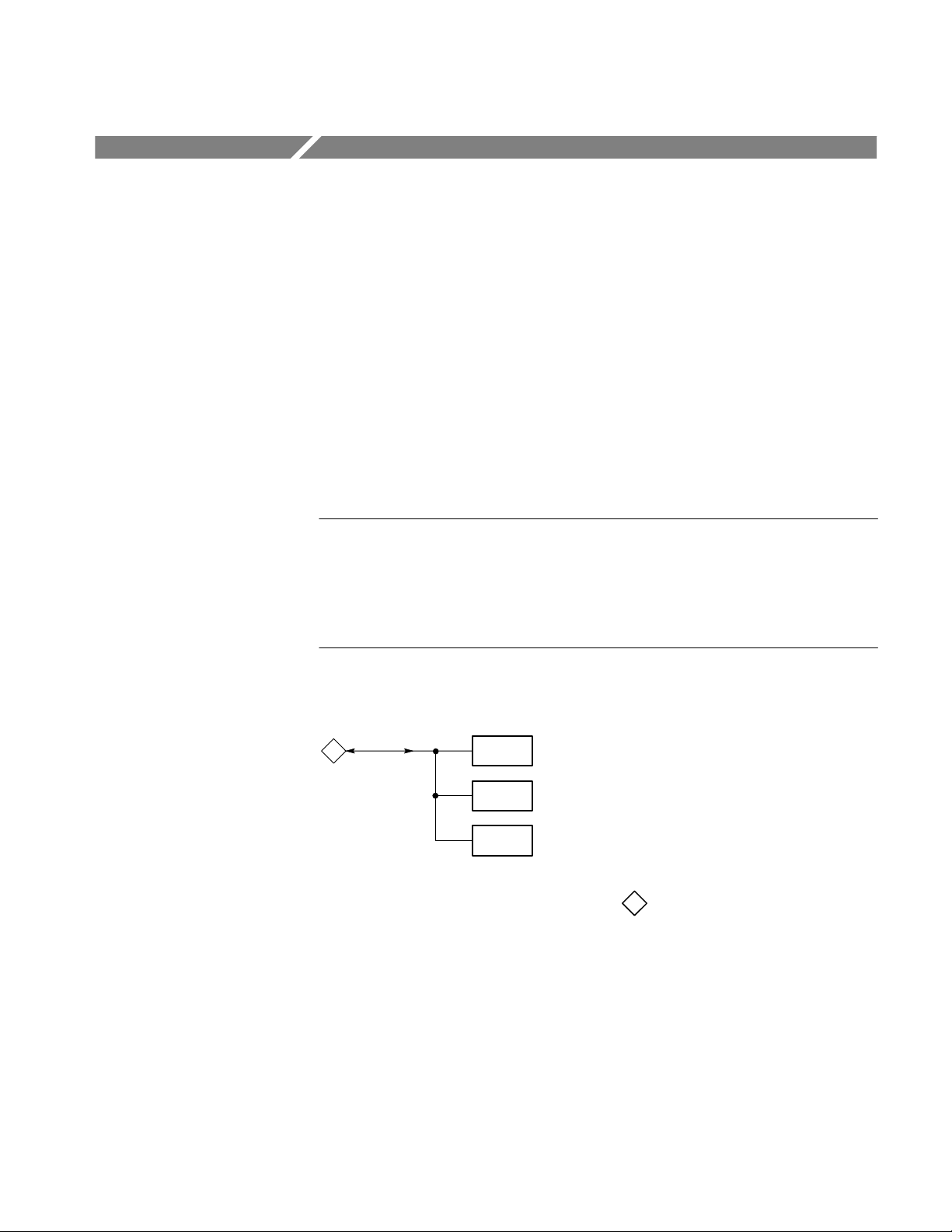

A1 Front Panel Board

A1U6 and A1U7 decode the button matrix so that the microprocessor can poll

front-panel activity using the serial interface (see Figure 3–1). A1U4 and A1U9

control the front-panel LED display. A1U8 provides A/D conversion of the

front-panel knobs. The front-panel settings for both gain and position provide

input to the vertical and horizontal amplifiers.

NOTE. The diamond numbers that appear in the figures are references to the

other block diagrams. The block diagram numbers appear at the end of the

figure caption. For example, in Figure 3–1, the diamond number 5 appears in

the block diagram. The circuitry that connects to the Front Panel board at the

point indicated by the diamond number 5 is shown in block diagram 5

(Figure 3–5 on page 3–4).

A2 Main Board

FRONT PANEL

SERIAL I/O

5

Figure 3–1: Front Panel board block diagram 1

The A2 Main Board in the WVR500 monitor provides most of the instrument’s

functionality. To simplify the description of the Main Board, its description is

broken down in major functional sections.

BUTTONS

LEDS

KNOBS

WVR500 Waveform/Vector Monitor Service Manual

3–1

Page 46

Theory of Operation

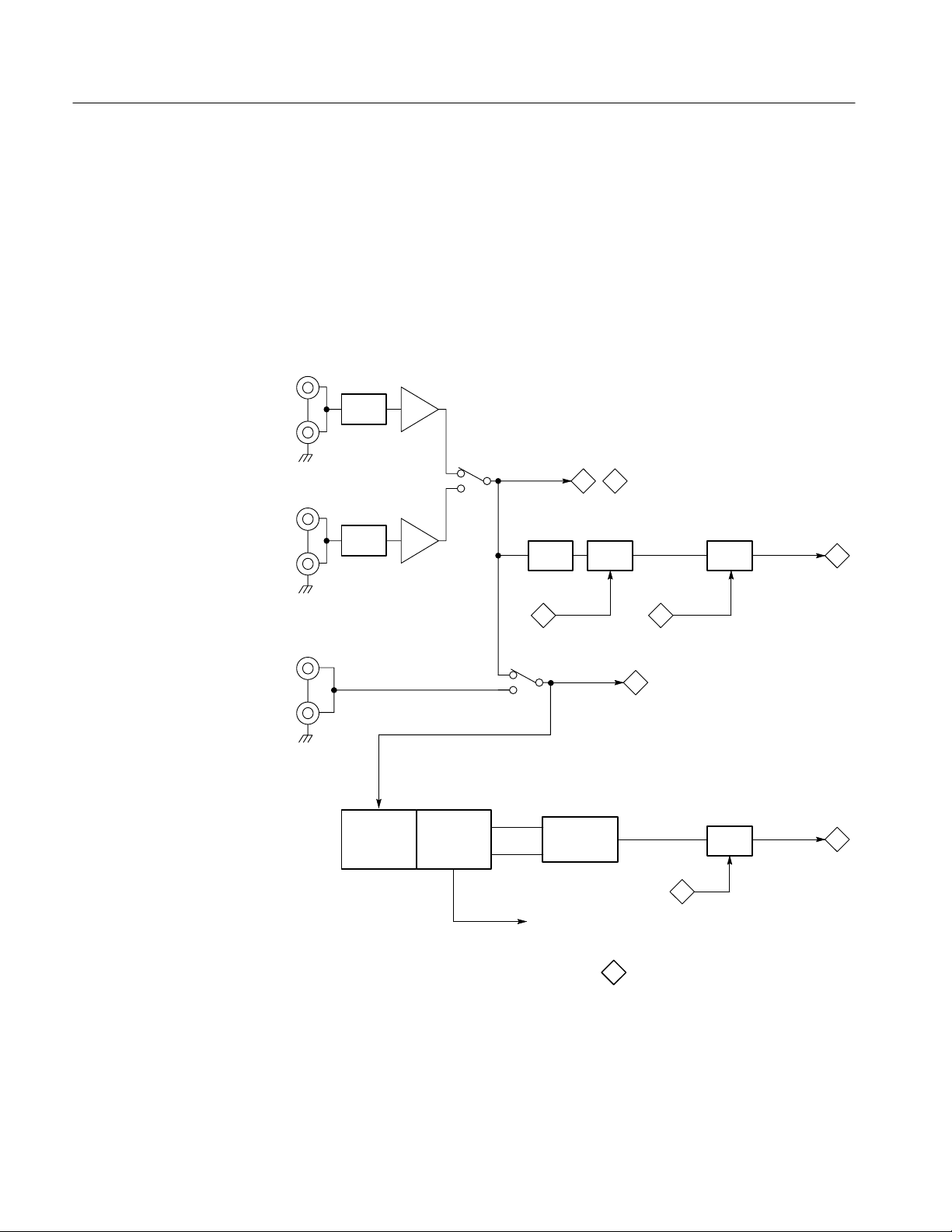

CH-A, CH-B, and

EXT REF

Entering in from the rear-panel connectors (see Figure 3–2), the CH-A and CH-B

input are AC or DC coupled, depending on the position of the jumper on A2J1.

A2U1 provides amplification buffering, with channel switching handled by

A2U117 and control signals from the microprocessor. For the EXT REF input,

A2Q9 provides the amplification buffering. A2U17 switches between internal

and external video reference using control signals from the microprocessor.

A2U18 buffers the reference signal and outputs the REF VID signal to the sync

separator and to the subcarrier sample circuitry.

CH-A

CPLG

CH-B

EXT

REF

INPUT

U117

CPLG

REFERENCE

SWITCH

INT

VIDEO

U17

4 9

CLAMP FILTER

FILTER

SELECT

3 4

REF

VIDEO

3

FILT

VIDEO VERT

GAIN

R–Y

VERT

OUT

8

3–2

SYNC

SEPARATOR

SWEEP

CONTROL/

VIDEO

REFERENCE

CONTROL

DISPLAY

SIGNALS

LTRIG

FTRIG

SWEEP

GENERATOR

Figure 3–2: Partial Main board block diagram 2

WVR500 Waveform/Vector Monitor Service Manual

SWEEP

SIG

4

B–Y

HORIZ

MAG

HORIZ

OUT

8

Page 47

Theory of Operation

Vector Demodulators

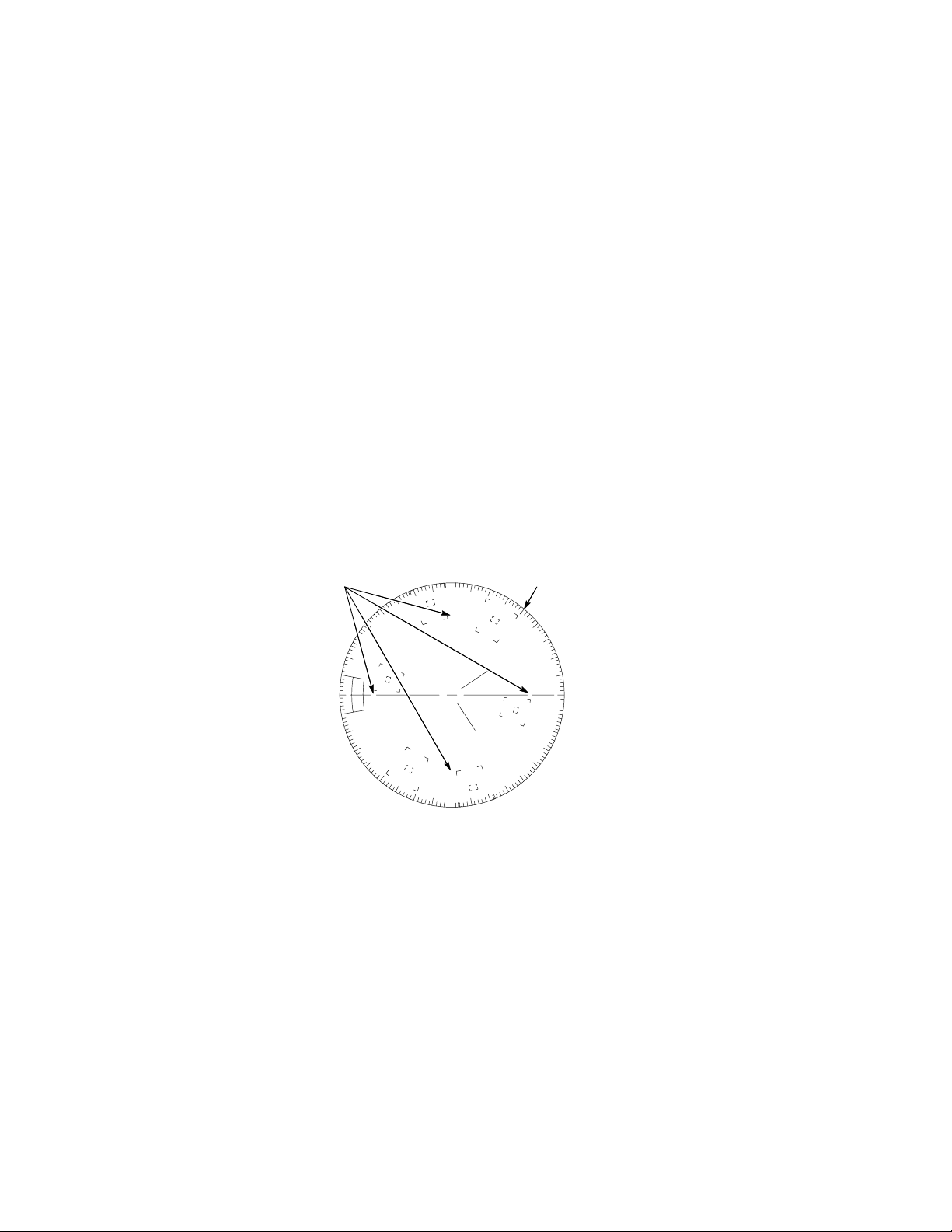

The subcarrier generator (see Figure 3–3) uses the NTSC and PAL selection

signals from the microprocessor to switch between the two oscillators, A2Y1 and

A2Y2. The subcarrier-sample circuitry uses video-control signals and commands

from the microprocessor and the REF VID signal to provide F_CNT reference

signal for the phase-lock loops. The sample circuit is made up by A2U36,

A2U32, A2U59A, A2U31, and the surrounding circuit. A2U34 generates the

ECL subcarrier signal as well as the quadrature signals for the vector demodulator. The video timing generator, A2U108, receives the ECL subcarrier and

generates the vertical and horizontal timing signals for the FPGA. The INT VID

signal is filtered, switched through A2U39A or B, and is passed through the gain

amplifier A2U45 (see Figure 3–4) before going to the vector demodulators.

ECL SUB

QUADRATURE SIGNALS

FILTER

SELECT

PAL

PLS

9

2

8

4

2

PAL

NTSC

REF VIDEO

SUBCARRIER

GENERATOR

SUBCARRIER

SAMPLE

Figure 3–3: Subcarrier generator block diagram 3

Vertical Signal Generation

The demodulators A2U41 and A2U42 use the quadrature signals and the video

signal to generate the R-Y and B-Y signals.

QUADRATURE SIGNALS

3 2

VECTOR

DEMODULATORS

2

INT VIDEO

X1/X5

GAIN

VECTORS

R–Y

B–Y

2

Figure 3–4: Vector demodulators block diagram 4

The clamp (see Figure 3–2) is activated through the front panel and is made up

primarily by A2U5 and A2U6. The clamped signal is then filtered by A2U7,

with filter switching handled by control signals to A2U3 parts A, B, and C. The

output signal, FILT VID, goes to the vertical amplifier, and the vertical amplifier

outputs either the FILT VID signal or the R-Y signal from the vectorscope

vertical demodulator.

WVR500 Waveform/Vector Monitor Service Manual

3–3

Page 48

Theory of Operation

Horizontal Signal

Generation

Microprocessor

A2U13 separates the sync from the REF VID signal (see Figure 3–2) and

generates two control signals used by the control and timing circuit. The sweep

control and timing components, along with the state machines in A2U21 and

A2U22, receive control signals from the sync separator and the microprocessor.

These signals are used to generate the display control signals and the timing

signals used by the rest of the instrument. The sweep generator is made up of

A2U20, A2Q7, and A2Q8. The sweep generator is controlled by either the line

or field trigger timing signals (LTRIG or FTRIG) coming from the state machine

A2U21. The horizontal amplifier outputs either the SWEEP SIG signal from the

sweep generator or the B-Y signal from the vectorscope horizontal demodulator.

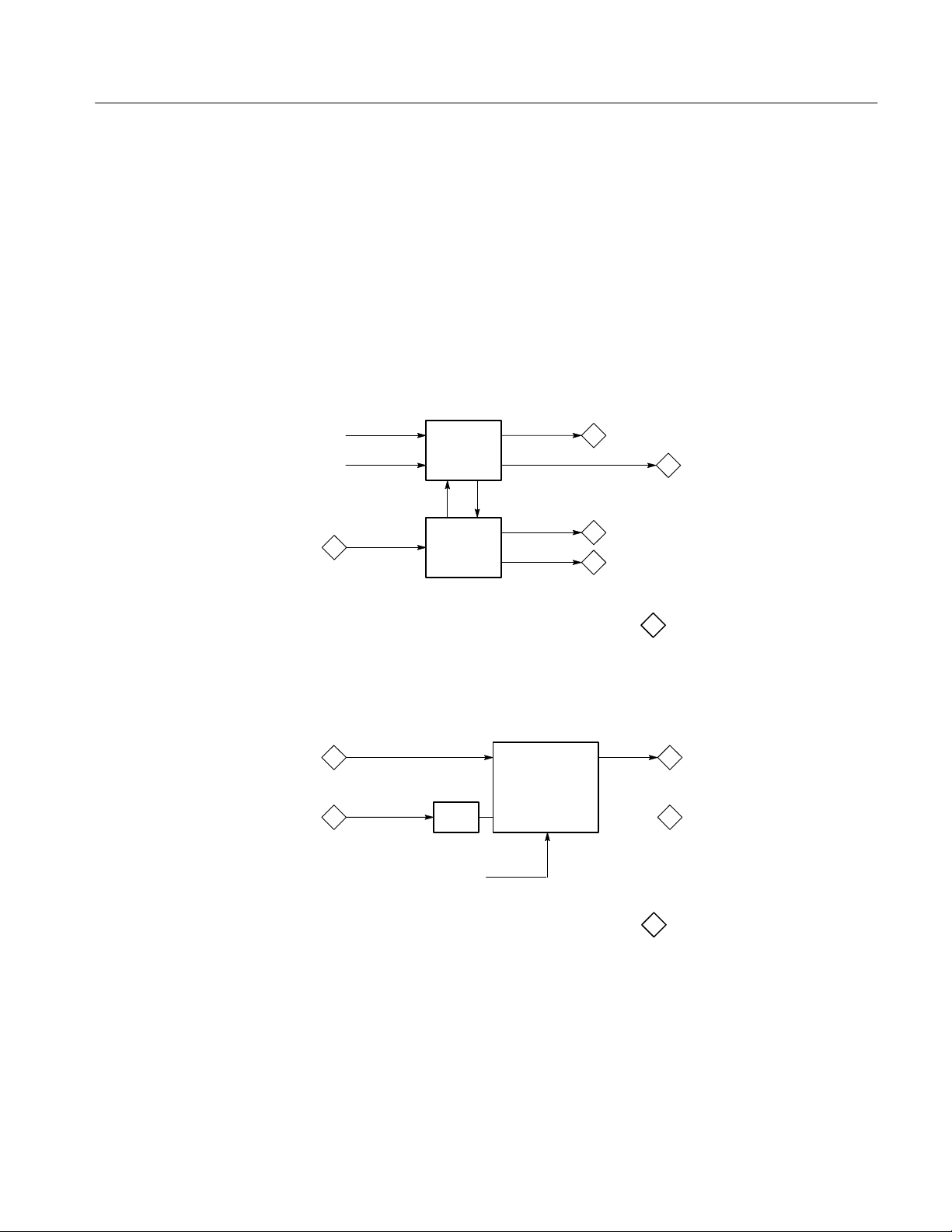

The microprocessor, A2U72 (see Figure 3–5), receives information from three

primary sources: (1) interrupt and timing signals from the video and display

circuitry, (2) the rear panel RS-232 port, and (3) the serial interface signals, SCK,

MISO, and MOSI, on the microprocessor. A2U82 buffers signals to and from the

microprocessor. A2U71 provides a reset to the microprocessor on instrument

power-up, or can provide a manual reset by shorting the pins on A2J8.

PERIPHERAL

CHIP SELECT

ADRS

DATA

PROC

INTFC

6

7

8

SERIAL I/O

1

RESET

w PROC

INTERRUPTS

RS-232

10

ADRS

DATA

DATA

ADRS

ADRS

ROM RAM

BUFFERS

CHIP

SELECTS

ADRS

DATA

DATA

ADRS

NVRAM

Figure 3–5: Microprocessor circuitry block diagram 5

The DAC (see Figure 3–6), A2U46, uses signals from the microprocessor to

generate analog control voltages for adjustable instrument functions. These

voltage signals are buffered by parts of A2U47, A2U48, A2U49, A2U50, and

A2U59. The serial latches, A2U51, A2U52, A2U53, and A2U54, receive serial

data and control signals from the microprocessor to output mode-enabling

analog-control logic to the rest of the instrument.

3–4

WVR500 Waveform/Vector Monitor Service Manual

Page 49

Theory of Operation

ANALOG

LOGIC

CONTROL

VOLTAGES

PROC

INTFC

5

PROC

INTFC

5

DAC

SERIAL

LATCHES

ANALOG

CONTROL

Figure 3–6: Analog control circuitry block diagram 6

The serial interface (see Figure 3–5) decodes peripheral-chip selection through

A2U70. The ROMs, A2U68 and A2U69, contain the instrument control

program. A2U79, A2U80, A2U81, and A2U84 serve as data and address buffers

for the control lines. A2U77 and A2U78 decode the chip selection information

using the address and data lines from the microprocessor. The buffered data and

address lines from the microprocessor go to the RAM, A2U66 and A2U67, and

the NVRAM. The NVRAM stores the instrument calibration constants and the

state of the instrument for use on instrument power-up. The microprocessor uses

the address and data lines to control the instrument, primarily through the FPGA,

RAM DAC, and the Rasterizer.

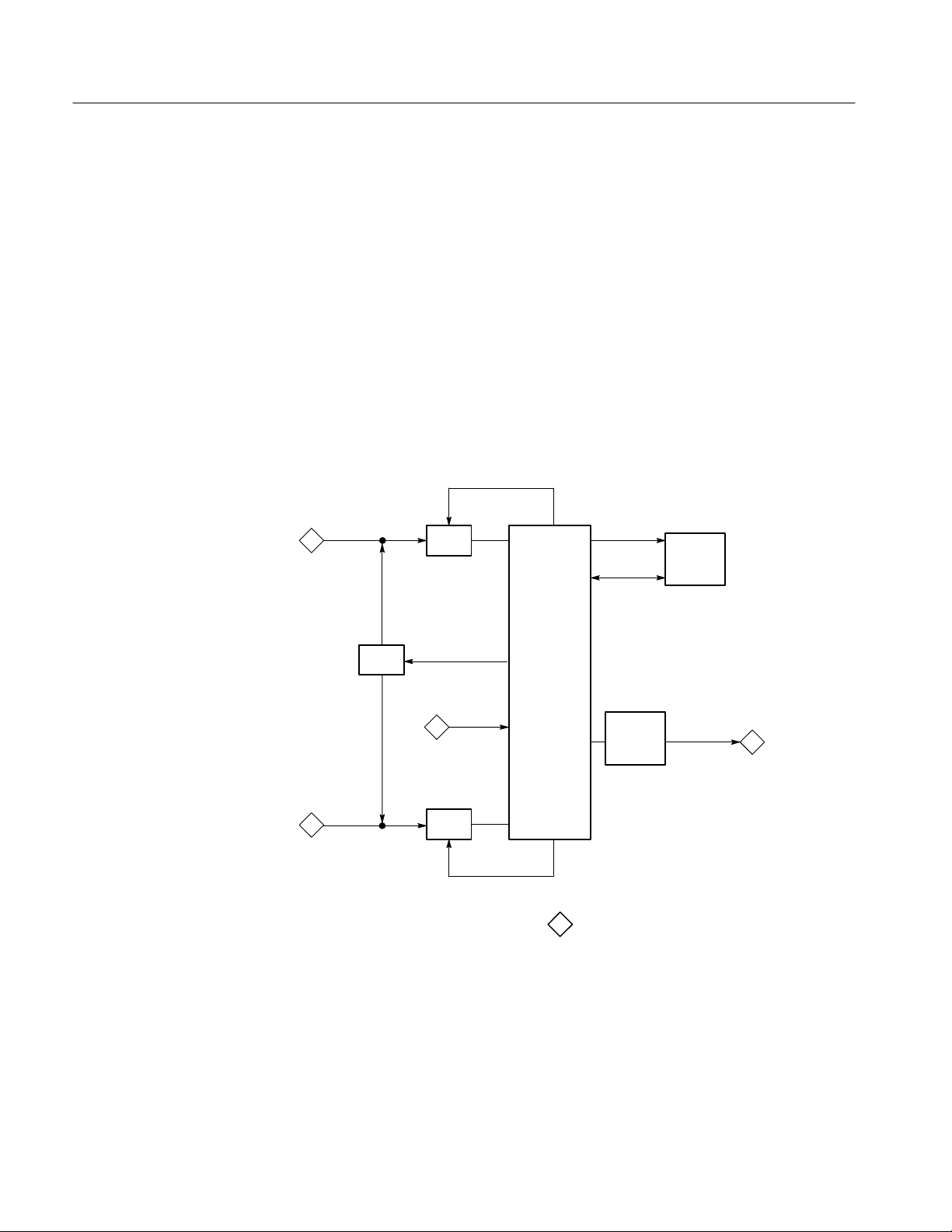

FPGA, RAM DAC, and

Rasterizer

The FPGA (see Figure 3–7), A2U86, provides control and timing signals to the

rest of the instrument. The FPGA looks at the video signal (WFM 0-7) coming

from line memory and makes decisions based on the input and the control codes

it receives from the rest of the system. The FPGA is configured using the serial

interface during initial instrument start-up. The FPGA sends control signals and

correct video timing to the RAM DAC. The RAM DAC uses the video and

control signals to generate RGB video signals to send to the encoder.

8

WFM (0-7)

5

PROC

INTFC

FPGA

& TIMING

SIGNALS

WFM (3-7)

WFM (0-2)

RAMDACCONTROL

R, G, B

9

Figure 3–7: FPGA and RAMDAC circuitry block diagram 7

WVR500 Waveform/Vector Monitor Service Manual

3–5

Page 50

Theory of Operation

The A/D converters (see Figure 3–8), A2U89 and A2U90, are controlled by the

rasterizer, with input from the dither generators, to sample the incoming video

signal. A2U94 and A2U97 generate controlled noise which improves the

appearance of the output signal. The rasterizer, A2U88, controls the sampling of

the vertical and horizontal signals coming through the A/D converters, and the

samples are buffered into display memory to be used in generating rasterized

output one line at a time.

The rasterizer provides an analog look to the display by using the variable

persistence algorithms stored in display memory, A2U95 and A2U96. They hold

the data used by the rasterizer to generate the line output and serve as data

storage while the rasterizer completes its algorithms. A2U92 is the line memory

controlled by the rasterizer to output the video signal (WFM 0-7) one line at a

time to the FPGA and the RAM DAC.

SAMPLE

VERT

OUT

2

DITHER

5

HORIZ

OUT

2

A/D

DITH (0-1)

PROC

INTFC

A/D

Y IN

RASTERIZER

X IN

SAMPLE

Figure 3–8: Rasterizer block diagram 8

ADRS

DATA

LINE

MEMORY

DISPLAY

MEMORY

WFM (0-7)

7

3–6

WVR500 Waveform/Vector Monitor Service Manual

Page 51

Theory of Operation

Video Out Generation

The encoder (see Figure 3–9), A2U111, uses the ECL subcarrier input from the

subcarrier generator to encode the rasterized RGB signals from the RAM DAC

and to provide an encoded NTSC or PAL signal to the output clamp. The clamp,

A2U112 and A2U113, forces the level of the encoded video signal to match that

of the INT VID signal. The mux, A2U109, switches rapidly between the internal

video and the encoded video. The video is buffered by A2U110 for output to the

rear-panel connectors.

INT VIDEO

2

7

ECL SUB

3

LINE