Page 1

Instruction Manual

TMS 871

1394 Bus Support Package

071-0637-00

There are no current European directives that

apply to this product. This product provides

cable and test lead connections to a test object of

electronic measuring and test equipment.

Warning

The servicing instructions are for use by

qualified personnel only. To avoid personal

injury, do not perform any servicing unless you

are qualified to do so. Refer to all safety

summaries prior to performing service.

Page 2

Copyright E T ektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

SOFTWARE WARRANTY

T ektronix warrants that the media on which this software product is furnished and the encoding of the programs on

the media will be free from defects in materials and workmanship for a period of three (3) years from the date of

shipment. If a medium or encoding proves defective during the warranty period, T ektronix will provide a

replacement in exchange for the defective medium. Except as to the media on which this software product is

furnished, this software product is provided “as is” without warranty of any kind, either express or implied.

T ektronix does not warrant that the functions contained in this software product will meet Customer’s

requirements or that the operation of the programs will be uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period. If T ektronix is unable to provide a replacement that is free from defects in materials and

workmanship within a reasonable time thereafter, Customer may terminate the license for this software product

and return this software product and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S PAYMENT IS

THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS

WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER

TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

HARDWARE WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If a product proves defective during this

warranty period, T ektronix, at its option, either will repair the defective product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by T ektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the T ektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than T ektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-T ektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 5

Table of Contents

Getting Started

Operating Basics

Preface ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Conventions ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Analyzer Documentation ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Support Description 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Analyzer Software Compatibility 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Accessories 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements and Restrictions 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to a System Under T est 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up the Support 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel Group Definitions 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquiring and Viewing Data 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquiring Data 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger Setups 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Clocking 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Options 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Data 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1394 Bus Packets 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

Probe Adapter Description 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Adapter Functions 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel Assignments 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Descriptions 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Verification

Functional Verification 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Adapter Circuit Description 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying Clock Activity Using an Oscilloscope 4–2. . . . . . . . . . . . . . . . . . . . . . . . .

Verifying Probe Adapter Functionality with the TLA System Activity Monitor 4–3

Troubleshooting 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Parts

Parts Ordering Information 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TMS 871 1394 Bus Support Package Instruction Manual

i

Page 6

Table of Contents

List of Figures

Figure 1–1: TMS 871 support package 1–1. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–2: Connecting the cables to the probe adapter 1–4. . . . . . . . . . .

Figure 1–3: Complete test setup 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: Trigger Setup Window 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: All Fields Display 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–3: Selected Fields Display 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: Truncated Data in a Selected Field 2–14. . . . . . . . . . . . . . . . . .

Figure 2–5: Packet Header Display 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–6: Packet Type Display 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–1: Dimensions of the probe adapter 3–3. . . . . . . . . . . . . . . . . . . .

Figure 4–1: SCLK/2 (system clock) signal test point 4–2. . . . . . . . . . . . . .

Figure 4–2: Activity pattern 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

TMS 871 1394 Bus Support Package Instruction Manual

Page 7

List of Tables

Table of Contents

Table 2–1: Displayed Channel Groups 2–1. . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–2: Error group symbol table definitions 2–2. . . . . . . . . . . . . . . .

Table 2–3: Event group symbol table definitions 2–3. . . . . . . . . . . . . . . .

Table 2–4: PCtrl group symbol table definitions 2–3. . . . . . . . . . . . . . . . .

Table 2–5: Speed group symbol table definitions 2–4. . . . . . . . . . . . . . . .

Table 2–6: Type group symbol table definitions 2–4. . . . . . . . . . . . . . . . .

Table 2–7: Last_Data group symbol table definitions 2–5. . . . . . . . . . . . .

Table 2–8: Tcode group symbol table definitions 2–5. . . . . . . . . . . . . . . .

Table 3–1: Electrical specifications 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–2: Environmental specifications* 3–3. . . . . . . . . . . . . . . . . . . . . .

Table 3–3: Certifications and compliances 3–3. . . . . . . . . . . . . . . . . . . . . .

Table 3–4: Channel group display order 3–4. . . . . . . . . . . . . . . . . . . . . . .

Table 3–5: Quad_Data group assignments 3–5. . . . . . . . . . . . . . . . . . . . . .

Table 3–6: Speed group assignments 3–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–7: Type group assignments 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–8: Event group assignments 3–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–9: Error group assignments 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–10: Count group assignments 3–7. . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–11: Last_Data group assignments 3–7. . . . . . . . . . . . . . . . . . . . . .

Table 3–12: Phy_Data group assignments 3–8. . . . . . . . . . . . . . . . . . . . . .

Table 3–13: Phy_Ctrl group assignments 3–8. . . . . . . . . . . . . . . . . . . . . . .

Table 3–14: Clock and qualifier channel assignments 3–8. . . . . . . . . . . .

Table 3–15: Signal descriptions 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–1: Equipment list 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TMS 871 1394 Bus Support Package Instruction Manual

iii

Page 8

Table of Contents

iv

TMS 871 1394 Bus Support Package Instruction Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Symbols and Terms

Connect and Disconnect Properly . Connect the probe output to the measurement

instrument before connecting the probe to the circuit under test. Disconnect the

probe input from the circuit under test before disconnecting the probe from the

measurement instrument.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and marking on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

TMS 871 1394 Bus Support Package Instruction Manual

v

Page 10

General Safety Summary

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

Protective Ground

(Earth) T erminal

CAUTION

Refer to Manual

Double

Insulated

vi

TMS 871 1394 Bus Support Package Instruction Manual

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the main power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

TMS 871 1394 Bus Support Package Instruction Manual

vii

Page 12

Service Safety Summary

viii

TMS 871 1394 Bus Support Package Instruction Manual

Page 13

Preface

This instruction manual contains specific information about the TMS 871 1394

Bus support package and is part of a set of information on how to operate this

product on compatible Tektronix logic analyzers.

If you are familiar with operating support packages on the logic analyzer for

which the TMS 871 1394 Bus support was purchased, you will probably only

need this instruction manual to set up and run the support.

If you are not familiar with operating support packages, you will need to

supplement this instruction manual with information on basic operations to set up

and run the support.

Each logic analyzer has basic information that describes how to perform tasks

common to support packages on that platform. This information can be in the

form of online help, an installation manual, or a user manual. For complete

information on packet types and field descriptions, refer to the IEEE 1394_1995

Standard and the IEEE 1394a supplement.

This manual provides detailed information on the following topics:

H Connecting the logic analyzer to the system under test

H Setting up the logic analyzer to acquire data from the system under test

H Acquiring and viewing data

H Using the probe adapter

Manual Conventions

This manual uses the following conventions:

H The term “system under test (SUT)” refers to the 1394 Bus system from

which data will be acquired.

H The term “logic analyzer” refers to the Tektronix logic analyzer for which

this product was purchased.

H The term “module” refers to the Tektronix logic analyzer module for which

this product was purchased.

Logic Analyzer Documentation

A description of other documentation available for each type of Tektronix logic

analyzer is located in the corresponding module user manual. The manual set

provides the information necessary to install, operate, maintain, and service the

logic analyzer and associated products.

TMS 871 1394 Bus Support Package Instruction Manual

ix

Page 14

Preface

Contacting Tektronix

Product

Support

Service

Support

For other

information

To write us

Website

For questions about using Tektronix measurement products, call

toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Tektronix offers extended warranty and calibration programs as

options on many products. Contact your local Tektronix

distributor or sales office.

For a listing of worldwide service centers, visit our web site.

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

Tektronix, Inc.

P.O. Box 1000

Wilsonville, OR 97070-1000

USA

Tektronix.com

x

TMS 871 1394 Bus Support Package Instruction Manual

Page 15

Getting Started

This chapter provides information on the following topics and tasks:

H A description of the TMS 871 1394 Bus support package

H Logic analyzer software compatibility

H Options and accessories

H Support restrictions

H How to connect to the system under test

Figure 1–1 shows components of the TMS 871 1394 Bus support package.

Figure 1–1: TMS 871 support package

TMS 871 1394 Bus Support Package Instruction Manual

1–1

Page 16

Getting Started

Support Description

The TMS 871 1394 Bus support package displays data from the IEEE 1394 High

Performance Serial Bus. The support runs on a compatible Tektronix logic

analyzer equipped with a 68-channel or wider module, and requires two P6434

probes.

A complete list of standard and optional accessories is provided at the end of the

parts list in the Replaceable Mechanical Parts chapter.

Logic Analyzer Software Compatibility

The TMS 871 application software requires Version 3.0 and higher of TLA 700

System software running on the logic analyzer, and Version 3.0 and higher of

TLA 700 LA module firmware on the modules you will be using.

Standard Accessories

Options

The probe adapter is shipped with the following standard accessories:

H TMS 871 Support SW Disk

H TMS 871 Support Instruction Manual

H 1394 cable

H 5V power supply

H North American power cord

The following options are available when ordering the TMS 871 Support:

H Option A1 Power Cord, Europe, 230 V

H Option A2 Power Cord, United Kingdom, 230 V

H Option A3 Power Cord, Australia, 230 V

H Option A5 Power Cord, Switzerland, 230 V

H Option 21 Add 2 P6434 Probes

1–2

TMS 871 1394 Bus Support Package Instruction Manual

Page 17

Requirements and Restrictions

You should review the general requirements and restrictions of 1394 Bus support

in the information on basic operations.

You should also review electrical, environmental, and mechanical specifications

in the Specifications chapter in this manual as they pertain to your system under

test, as well as the following descriptions of other support requirements and

restrictions.

Getting Started

System Clock Rate

Merged Module Pair

The TMS 871 support package can acquire data from the 1394 bus operating at

speeds of 100, 200, or 400 Mb/s.

If you have a pair of modules that are merged in the logic analyzer, you can

un-merge them (and use either one). If you want the modules to remain merged,

then the probe adapter must connect to the master module.

Connecting to a System Under Test

To connect the logic analyzer to the probe adapter, follow these steps:

CAUTION. Static discharge can damage the probe adapter, the probes, or the

module. To prevent static damage, handle all of these products only in a

static-free environment.

1. Plug the power supply into an appropriate power source.

2. Connect the DC plug to the probe adapter to provide power to the probe

adapter.

3. Connect the P6434 probes to the 1394 probe adapter. Align the probe tip with

the mating connector and gently connect as shown in Figure 1–2.

TMS 871 1394 Bus Support Package Instruction Manual

1–3

Page 18

Getting Started

Push down to latch after

probe is connected

Pin 1

Figure 1–2: Connecting the cables to the probe adapter

CAUTION. Incorrect handling of the P6434 probe while connecting it to the probe

adapter can result in damage to the probe or to the mating connector on the

probe adapter. To avoid damaging the probe and probe adapter, always position

the probe perpendicular to the mating connector and gently connect the probe.

4. Connect the module ends of the P6434 probes to the corresponding connec-

tors on the logic analyzer. The probe module ends are keyed.

NOTE. The right-side P6434 probe (as seen from the rear of the probe adapter)

connects to D1–D0 and C3–C2 connectors on the logic analyzer. This may not

match the color coding on a pre-labeled P6434 probe.

5. Connect the 1394 probe adapter to the 1394 system under test using the 6-pin

1394 cable supplied with the probe adapter, or any standard 6-pin 1394

cable. Use any of the three ports on the front of the probe adapter.

6. The complete test setup appears in Figure 1–3 on page 1–5.

1–4

TMS 871 1394 Bus Support Package Instruction Manual

Page 19

To Logic Analyzer

Getting Started

P6434 Probes (2)

To power

supply

TMS 871

To SUT

1394 Cable

Figure 1–3: Complete test setup

TMS 871 1394 Bus Support Package Instruction Manual

1–5

Page 20

Getting Started

1–6

TMS 871 1394 Bus Support Package Instruction Manual

Page 21

Setting Up the Support

This section describes how to set up the support and includes these topics:

H Channel group definitions

H Symbol table files

Remember that the information in this section is specific to the operations and

functions of the TMS 871 support package. Information on basic operations

describes general tasks and functions.

Before you acquire and display data, you need to load the support and specify

setups for clocking and triggering as described in the information on basic

operations. The support provides default values for each of these setups, but you

can change them as needed.

Channel Group Definitions

The software automatically defines channel groups for the support.

Channel Groups

The defined channel groups are Data, Speed, Type, Event, Error, Count,

Last_Data, Phy_Data, and Phy_Ctrl.

To see which signal is in which channel group, refer to the channel group

assignment tables beginning on page 2–2. Tables 2–2 through 2–6 show the

channel assignments for the setup.

T able 2–1: Displayed Channel Groups

Group name Display radix

Data HEX

Mnemonic NONE (disassembly text generated by support)

Speed SYM

Type SYM

Event SYM

Error SYM

Count DEC

Last_Data SYM

Phy_Data HEX

Phy_Ctrl SYM

1

1

1

1

1

1

Timestamp

1

These groups are acquired but not displayed in a default listing. They may be added

to the listing window by the user.

TMS 871 1394 Bus Support Package Instruction Manual

2–1

Page 22

Setting Up the Support

Symbols

The TMS 871 support supplies the following seven symbol table files:

H 1394_Error.tsf

H 1394_Event.tsf

H 1394_PCtrl.tsf

H 1394_Speed.tsf

H 1394_Type.tsf

H 1394_Last.tsf

H 1394_Tcode.tsf

Each file replaces specific channel group values with symbolic values when

Symbolic is the radix for the channel group.

Error Group

The symbol table file for the Error group is 1394_Error.

The error group represents hardware errors that can occur on the bus. The symbol

table shows the error code for the corresponding signal that was set. Multiple

errors are not covered by the table.

Table 2–2 shows the 1394_Error symbol table.

T able 2–2: Error group symbol table definitions

Error group value

Iso_Cycle_Lost

Cyc_Too_Long

State_Timeout

Quad_Align_Err

Symbol

-- 000000 No Error

ISO_LOST 100000 Isochronous cycle did not complete

ISO_LONG 010000 Isochronous cycle exceeds maximum time

TIMEOUT 001000 Phy stayed in one state too long

ALIGN_ERR 000100 Quad data not ending on quadlet boundary

ACK_ERR 000010 2nd nibble of ACK not logical inverse

SLFPKT_ERR 000001 2nd quadlet of self-ID pkt not logical inverse

Ack_Err

Self_Packet_Err

Description

2–2

TMS 871 1394 Bus Support Package Instruction Manual

Page 23

Setting Up the Support

Event Group

The symbol table file for the Event group is 1394_Event.

The event group collects the validation strobe that, with SysClk, determine the

packet is valid. The events are grouped for displaying added information in the

listing and for triggering use.

Table 2–3 shows the 1394_Event symbol table.

T able 2–3: Event group symbol table definitions

Event group value

Arb_Gap

Sub_Gap

Data_Rdy

Ack_Rcvd

Symbol

-- 000000 No event

ARB_GAP 100000 Arbitration gap detected

SUB_GAP 010000 Subaction gap detected

DA TA_RDY 001000 Quadlet data is valid

ACK_RCVD 000 100 Acknowledge data is valid

HW_ERROR 000010 Hardware error has occured

RESET XXXXX1 Bus reset detected

Reset

HW_Error

Description

PCtrl Group

The symbol table file for the PCtrl group is 1394_PCtrl.

The PCtrl group represents the PHY CTL signals as defined by 1394a. This

group is not normally displayed. The information is for those advanced users

who wish to look at the signals immediately available at the PHY-Link interface.

Table 2–4 shows the 1394_PCtrl symbol table.

T able 2–4: PCtrl group symbol table definitions

PCtrl group value

Symbol

IDLE 00 No activity

ST ATUS 10 PHY sending status info to link

RECEIVE 01 Packets being received

GRANT 00 PHY granting bus to link

Phy_Ctrl_0

Phy_Ctrl_1

Description

TMS 871 1394 Bus Support Package Instruction Manual

2–3

Page 24

Setting Up the Support

Speed Group

Type Group

The symbol table file for the Speed group is 1394_Speed.

The speed group indicates the bus speed as 100, 200, or 400 Mb/s.

Table 2–5 shows the 1394_Speed symbol table.

T able 2–5: Speed group symbol table definitions

Speed group value

Value

100 00 Speed is 100 Mb/s

200 10 Speed is 200 Mb/s

400 01 Speed is 400 Mb/s

– 11 Undefined

Speed_0

Speed_1

Description

The symbol table file for the Type group is 1394_Type.

The type group represents a collection of special packet identification signals.

Table 2–6 shows the 1394_Type symbol table.

T able 2–6: Type group symbol table definitions

Type group value

Bcast_Packet

Symbol

-- 000 Other packet type

BCAST 1XX Broadcast packet

SLFID X1X Self-Id packet

ISO XX1 Isochronous packet

Self_Id_Packet

Iso_Cyc

Description

2–4

TMS 871 1394 Bus Support Package Instruction Manual

Page 25

Setting Up the Support

Last_Data Group

Tcode Group

The symbol table file for the Last_Data group is 1394_Last.

The Last_Data symbols label the one bit (last data quadlet in a packet) as true or

false to clarify usage in Trigger Setups.

Table 2–7 shows the 1394_Last symbol table.

T able 2–7: Last_Data group symbol table definitions

Value

True 1

False 0

Last_Rx_Data

The symbol table file for the Tcode group is 1394_Tcode. It is used for trigger

setup to identify transaction codes in the Data group on the first quadlet of a

packet.

Table 2–8 shows the 1394_Tcode symbol table.

T able 2–8: Tcode group symbol table definitions

Tcode group value

Symbol

WR_REQ_QUAD XXXXXX0X Write Request for Data Quadlet

WR_REQ_BLK XXXXXX1X Write Request for Data Block

WR_RESP XXXXXX2X Write Response

RD_REQ_QUAD XXXXXX4X Read Request for Data Quadlet

RD_REQ_BLK XXXXXX5X Read Request for Data Block

RD_RESP_QUAD XXXXXX6X Read Request for Data Quadlet

RD_RESP_BLK XXXXXX7X Read Response for Data Block

CYC_ST AR T XXXXXX8X Cycle Start

LOCK_REQ XXXXXX9X Lock Request

ISOCH XXXXXXAX Isochronous or Streaming Data

LOCK_RESP XXXXXXBX Lock Response

Tcode

Description

Information on basic operations describes how to modify an existing symbol

table, create new symbol tables, and use symbolic values for triggering and

displaying other channel groups symbolically, such as the Address channel

group.

TMS 871 1394 Bus Support Package Instruction Manual

2–5

Page 26

Setting Up the Support

2–6

TMS 871 1394 Bus Support Package Instruction Manual

Page 27

Acquiring and Viewing Data

This section describes how to acquire data and view it in a listing window with

the following topics and tasks:

H Acquiring data

H Trigger setups

H Clocking options

H Display options

H Displaying data

Acquiring Data

Once you load the 1394 setup, you can specify the trigger, choose a clocking

mode, and acquire data.

If you have any problems acquiring data, refer to information on basic operations

in your online help.

Trigger Setups

The signals available on the 1394 bus allow for many triggering possibilities.

The .tla files include trigger setting examples, which will be similar to the

example shown in Figure 2–1 on page 2–8.

TMS 871 1394 Bus Support Package Instruction Manual

2–7

Page 28

Acquiring and Viewing Data

Figure 2–1: Trigger Setup Window

This trigger/capture state machine model can be used for a wide variety of

situations. In this example, the default is to store everything with the State 1

being used to identify certain packet types by a specific tcode bit pattern in the

first quadlet of the packet. The Last_Data group is TRUE only on the last quadlet

which allows State 2 to exclude (not store) the entire packet identified in State 1.

In this example, all Cycle Start packets are excluded from being stored and the

logic analyzer is triggered on an Isochronous packet.

Note that the custom clocking options also allow the user to not store long packet

data, gaps, and errors. As there is a limit to the number of clauses in a trigger

state (typically 4), the custom clocking option should be examined for more

complex triggering/storage situations.

Using the model shown in Figure 2–1, some variations useful to 1394 might be:

H Group Speed (symbolic). Can exclude packets labeled with a speed code. For

example, all 100Mb/s packets can be excluded. State 2 is not needed.

H Group Event (symbolic for event). Singles out specific types of qualifying

events. Overlaps custom clocking for gaps and errors. Useful for identifying

trigger point, such as triggering on a bus reset.

2–8

TMS 871 1394 Bus Support Package Instruction Manual

Page 29

Acquiring and Viewing Data

H Group Count>n. Can be used to store only the first n bytes of the packet.

State 2 is not needed. Note that this is covered for a value of 16 by a custom

clocking option.

H Type (symbolic for type). Allows broadcast, self-id packets, or iso packets to

be excluded. For more information, refer to Tables 3–7 and 3–13 on pages

3–6 and 3–8 for a description of the signals in this group. State 2 is not

needed.

H Group Count=1 and Group Data=(symbolic for tcode). Allows various

packet types to be excluded from storage. Used with State 2.

H Group Error=(symbolic for error). Singles out a specific type of error to not

store or to trigger on. State 2 is not needed.

H Group Count=n and Group Data=HEX. Generic way to specify a packet by

information known to be in a certain byte. For example, the destination

address which is the first 16 bytes of the first quadlet for several different

packet types. Used with State 2 to exclude capture from the identified

quadlet through the end of the packet.

Custom Clocking

Clocking Mode

The TMS 871 will add the selection 1394 to the Load Support Package dialog

box, under the File pulldown menu. Once the 1394 support has been loaded, the

Custom clocking mode selection in the logic analyzer Setup menu is also

enabled. Custom will be the default selection whenever the 1394 support has

been loaded.

When Custom is selected, the TMS 871 support will modify the Custom

Clocking Options menu to display three options:

H Clocking Mode

H Quadlet Capture

H Packet Truncation

The selections for these three options are defined below.

The Clocking Mode option allows the user to select either Normal or Raw Phy

modes of clocking. Normal mode is used for disassembly and for all groups

except Phy_Data and Phy_Ctrl. In Normal mode, different clock options are

available.

Raw Phy mode clocks at twice the rate of Normal mode (the Phy-Link SCLK

signal rate) and is used for acquiring the low-level Phy_Ctrl and Phy_Data group

signals only. Because of the different clocking, other group values may or may

TMS 871 1394 Bus Support Package Instruction Manual

2–9

Page 30

Acquiring and Viewing Data

not be valid when acquired. Raw Phy mode is not useful for disassembly. When

this mode is selected, the settings of the other two clocking options have no

effect.

Quadlet Capture

Packet Truncation

There are four quadlet capture selections possible, listed below. These only take

effect when the Clocking Mode is set to Normal. The All Valid selection is the

default.

H All Valid. The all valid selection qualifies quadlets for acquisition by looking

for a Data_Rdy, Arb_Gap, Sub_Gap, Ack_Rcvd, HW_Error, or Reset signal

in the Event group (see Table 3–8 on page 3–6). This selection captures all

the valid quadlets which include gaps, acks, and errors.

H All Valid, no gaps. Same as All Valid except Arb_Gap and Sub_Gap events

are not captured.

H All Valid, no errors. Same as All Valid except errors (HW_errors) are not

captured.

H All Valid, no gaps or errors. Same as All Valid except no gaps or errors are

captured.

There are two selections possible here: None and After 16 quadlets. None is the

default. These only take effect when the Clocking Mode is set to Normal.

H None. There is no attempt to truncate packets.

H After 16 quadlets. Only quadlets up to and including the 16th quadlet in each

packet will be captured in this mode.

Display Options

2–10

The TMS 871 disassembles the fields of the packets specified in 1394-1995 and

1394a standards. The TMS 871 displays various levels of packet detail as

selected by choosing one of five disassembly modes as described in Displaying

Data on page 2–11.

TMS 871 1394 Bus Support Package Instruction Manual

Page 31

Displaying Data

Acquiring and Viewing Data

There are six formats to display 1394 bus cycles:

H Waveform (Timing)

H Listing (State):

H All Fields

H Selected Fields

H Truncated Data

H Packet Header

H Packet Type

All Listing modes are available through the Disassembly Properties menu of the

Listing display.

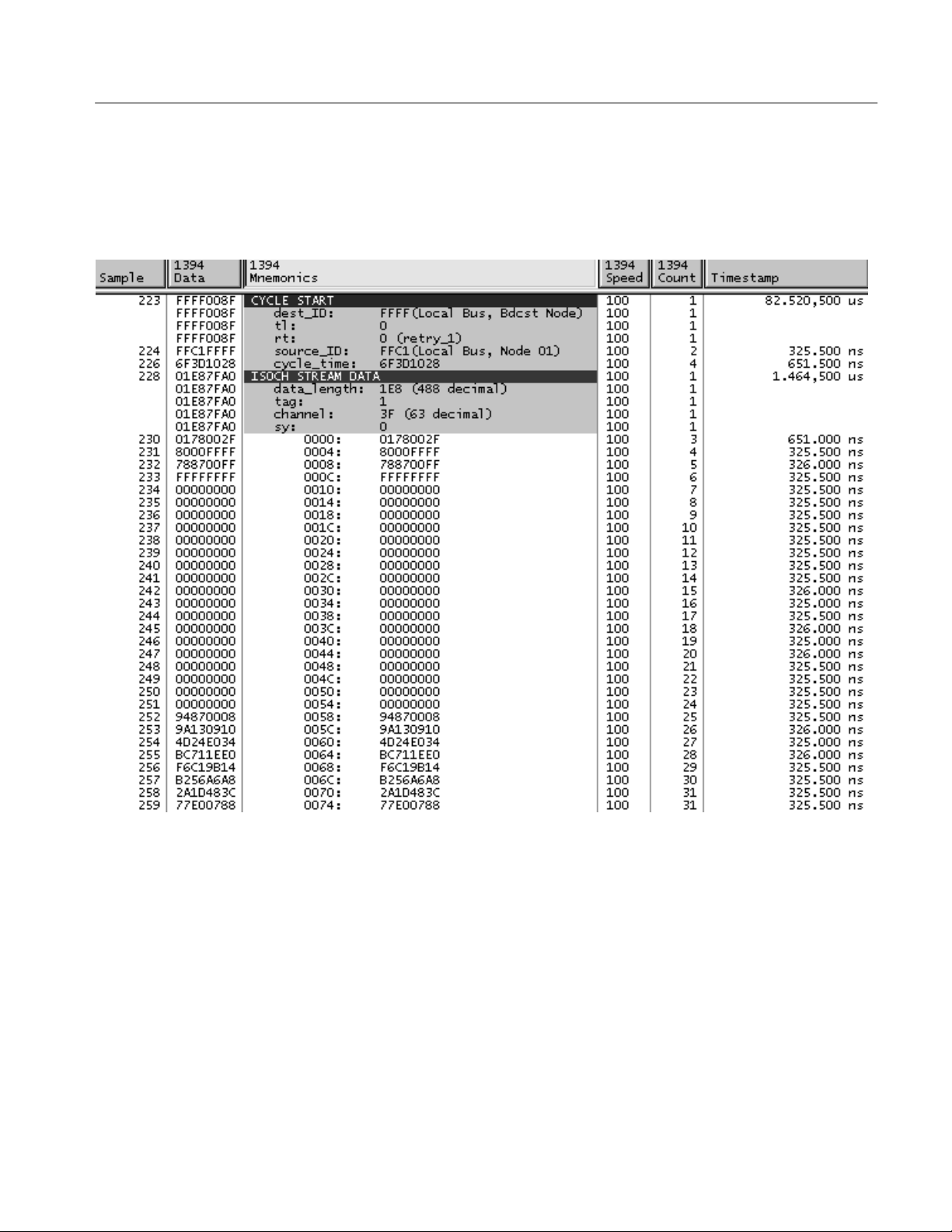

All Fields

All captured data (packet data, packet header, gaps, errors, and ack data) will be

displayed in this mode. Refer to Figure 2–2 on page 2–12.

All numeric values in the 1394 Mnemonics column are in hexadecimal, unless

otherwise specified.

TMS 871 1394 Bus Support Package Instruction Manual

2–11

Page 32

Acquiring and Viewing Data

Figure 2–2: All Fields Display

2–12

TMS 871 1394 Bus Support Package Instruction Manual

Page 33

Acquiring and Viewing Data

Selected Fields

In this mode, only the most significant packet header data fields will be displayed

and/or disassembled, along with all data. Gaps will not be displayed, nor will

header or data CRC’s. Ack data and errors will be displayed. Refer to Figure 2–3.

Figure 2–3: Selected Fields Display

TMS 871 1394 Bus Support Package Instruction Manual

2–13

Page 34

Acquiring and Viewing Data

Truncated Data

This mode displays selected fields, but only the first 16 data quadlets of any data

field. Refer to Figure 2–4.

Figure 2–4: Truncated Data in a Selected Field

2–14

TMS 871 1394 Bus Support Package Instruction Manual

Page 35

Acquiring and Viewing Data

Packet Header

This mode displays the selected header fields, without data quadlets. Refer to

Figure 2–5.

Figure 2–5: Packet Header Display

TMS 871 1394 Bus Support Package Instruction Manual

2–15

Page 36

Acquiring and Viewing Data

Packet Type

Figure 2–6: Packet Type Display

1394 Bus Packets

This mode displays errors and Ack data, but only one line for each packet (packet

type) is displayed . Refer to Figure 2–6.

Refer to the IEEE 1394_1995 Standard and the IEEE 1394a supplement for

complete information on packet types and field descriptions.

2–16

TMS 871 1394 Bus Support Package Instruction Manual

Page 37

Specifications

This chapter contains the following information:

H Probe adapter description

H Specification tables

H Channel assignment tables

H Signal descriptions

Probe Adapter Description

The probe adapter consists of an enclosed unit with three 6-pin connectors for

1394 Bus connections, and two 34-pin connectors for the LA interconnect (via

P6434 probes). Power is provided by an external power supply that plugs into the

back of the probe adapter. Signals from the 1394 Bus cable flow into the probe

adapter and through the P6434 probes to the logic analyzer.

All probe adapter circuitry is powered from an external power supply which must

supply 5-15 volts DC, at 350 milliamps maximum. The adapter has an internal

fuse and circuitry which protects against damage from reversed-polarity power

supply connections.

The probe adapter contains 3-port, 1394a-compliant PHY circuitry. The probe

adapter, following 1394 protocols, causes a bus reset when connected, when it

arbitrates for a node on the bus. Once connected, the probe adapter does not

generate any traffic from the Link layer, and does not expect any traffic to be

addressed to it.

After connecting, the probe adapter monitors all PHY-link data and conditions

the data with an on-board FPGA to generate signals for acquisition and triggering

by the logic analyzer.

The signals presented by the probe adapter to the logic analyzer are TTL level

with a clocking speed of 50 MHz or less. The probe adapter does not cause

excessive loading on critical signals.

TMS 871 1394 Bus Support Package Instruction Manual

3–1

Page 38

Specifications

Probe Adapter Functions

The probe adapter captures the following types of bus packets and events.

H Asynch Quadlet

H Isoch Quadlet

H Self ID Quadlet

H Phy Config Quadlet

H Ack Byte

H Arb Gap

H Sub-Action Gap

H Bus Reset

The following Hardware Errors are detected:

Specifications

H Isochronous cycle lost

H Isochronous cycle too long

H State timeout

H Quadlet alignment error

H Acknowledge packet error

H Self ID packet error

These specifications are for a probe adapter connected between a compatible

Tektronix logic analyzer and a 1394-1995 or 1394a-compliant device. The

system must be connected in a legal 1394 topology and running at S100, S200, or

S400 speeds. Table 3–1 shows the electrical requirements of the probe adapter in

order for the support to acquire correct data.

T able 3–1: Electrical specifications

Characteristics Requirements

Probe Adapter DC power requirements

5 V Vcc Voltage 4.75–5.25 VDC

5 V Vcc Current I max (calculated) 350 mA

3–2

TMS 871 1394 Bus Support Package Instruction Manual

Page 39

Specifications

Table 3–2 shows the environmental specifications.

T able 3–2: Environmental specifications*

Characteristic Description

Temperature

Maximum operating +50° C (+122° F)

Minimum operating 10° C (+50° F)

Non-operating –50° C to +75° C (–67° to +167° F)

* Designed to meet Tektronix standard 062-2847-00 class 5.

Table 3–3 shows the compliances that apply to the probe adapter.

T able 3–3: Certifications and compliances

EMC Compliance Meets the intent of Directive 89/336/EEC for Electromagnetic

Compatibility when it is used with the product(s) stated in the

specifications table. Refer to the EMC specification published for the

stated products. May not meet the intent of the directive if used with

other products.

FCC Compliance Emissions comply with FCC Code of Federal Regulations 47, Part 15,

Subpart B, Class A Limits.

Figure 3–1 shows the dimensions of the probe adapter.

34.29 mm

1.35 in

156.21 mm

99.98 mm

3.70 in

6.15 in

Figure 3–1: Dimensions of the probe adapter

TMS 871 1394 Bus Support Package Instruction Manual

3–3

Page 40

Specifications

Channel Assignments

Channel assignments shown in Table 3–5 through Table 3–14 use the following

conventions:

H All signals are required by the support unless indicated otherwise.

H Channels are shown starting with the most significant bit (MSB) descending

to the least significant bit (LSB). Note that 1394 convention labels the most

significant bit as zero.

H Section:channel refers to the module channel number.

The group assignment tables indicate whether the signal is required for custom

clocking and/or the disassembly. Required signals must be connected to properly

strobe and login bus data into acquisition memory, and to disassemble the

acquired bus data.

Channel groups will be displayed in the order shown in Table 3–4.

T able 3–4: Channel group display order

Group name Display radix

Data HEX

Mnemonic None (disassembly text generated by support package

software)

Speed SYM

Type SYM (default not displayed)

Event SYM (default not displayed)

Error SYM (default not displayed)

Count DEC

Last_Data SYM (default not displayed)

Phy_Data HEX (default not displayed)

Phy_Ctrl SYM (default not displayed)

Timestamp

3–4

TMS 871 1394 Bus Support Package Instruction Manual

Page 41

Specifications

Table 3–5 shows the probe section and channel assignments for the Quad group

and the signal to which each channel connects. By default, this channel group is

displayed in hexadecimal.

T able 3–5: Quad_Data group assignments

Required for clocking

Bit order Section:channel Signal name

31 A3:7 Data_0 Disassembly

30 A3:6 Data_1 Disassembly

29 A3:5 Data_2 Disassembly

28 A3:4 Data_3 Disassembly

27 A3:3 Data_4 Disassembly

26 A3:2 Data_5 Disassembly

25 A3:1 Data_6 Disassembly

24 A3:0 Data_7 Disassembly

23 A2:7 Data_8 Disassembly

22 A2:6 Data_9 Disassembly

21 A2:5 Data_10 Disassembly

20 A2:4 Data_11 Disassembly

19 A2:3 Data_12 Disassembly

18 A2:2 Data_13 Disassembly

17 A2:1 Data_14 Disassembly

16 A2:0 Data_15 Disassembly

15 A1:7 Data_16 Disassembly

14 A1:6 Data_17 Disassembly

13 A1:5 Data_18 Disassembly

12 A1:4 Data_19 Disassembly

11 A1:3 Data_20 Disassembly

10 A1:2 Data_21 Disassembly

9 A1:1 Data_22 Disassembly

8 A1:0 Data_23 Disassembly

7 A0:7 Data_24 Disassembly

6 A0:6 Data_25 Disassembly

5 A0:5 Data_26 Disassembly

4 A0:4 Data_27 Disassembly

3 A0:3 Data_28 Disassembly

2 A0:2 Data_29 Disassembly

1 A0:1 Data_30 Disassembly

0 A0:0 Data_31 Disassembly

or disassembly

TMS 871 1394 Bus Support Package Instruction Manual

3–5

Page 42

Specifications

Table 3–6 shows the Speed group assignments. The default radix of the Speed

group is SYMBOLIC. The symbol table filename is 1394_Speed.

T able 3–6: Speed group assignments

Required for clocking

Section:channel Signal name

C3:1 Speed_0 No

C3:0 Speed_1 No

or disassembly

Table 3–7 shows the Type group assignments. The default radix of the Type

group is SYMBOLIC. The symbol table filename is 1394_Type.

T able 3–7: Type group assignments

Required for clocking

Section:channel Signal name

C2:7 Bcast_Packet No

C2:6 Self-Id_Packet No

C2:5 Iso_Cyc No

or disassembly

Table 3–8 lists the Event group assignments. The default radix of the event group

is SYMBOLIC. The symbol table filename is 1394_Event.

T able 3–8: Event group assignments

Required for clocking

Section:channel Signal name

C2:3 Arb_Gap Both

C2:2 Sub_Gap Both

C2:1 Data_Rdy Both

C2:0 ACK_Rcvd Both

CLK:1 HW_Error Both

CLK:3 Reset Both

or disassembly

3–6

TMS 871 1394 Bus Support Package Instruction Manual

Page 43

Specifications

Table 3–9 lists the Error group assignments. The default radix of the Error group

is SYMBOLIC. The symbol table filename is 1394_Error.

T able 3–9: Error group assignments

Required for clocking

Section:channel Signal name

C3:7 Iso_Cycle_Lost No

C3:6 Cyc_Too_Long No

C3:5 State_Timeout No

C3:4 Quad_Align_Err No

C3:3 Ack_Err No

C3:2 Self_Packet_Err No

or disassembly

Table 3–10 shows the Count group assignments. The default radix of the Count

group is DECIMAL.

T able 3–10: Count group assignments

Required for clocking

Section:channel Signal name

CLK:2 Count_0 Disassembly

D1:3 Count_1 Disassembly

D1:2 Count_2 Disassembly

D1:1 Count_3 Disassembly

D1:0 Count_4 Disassembly

or disassembly

Table 3–11 shows the Last_Data group assignments. The default radix of the

Last_Data group is SYMBOLIC. The symbol table filename is 1394_Last.

T able 3–11: Last_Data group assignments

Required for clocking

Section:channel Signal name

D1:5 Last_Rx_Data No

or disassembly

TMS 871 1394 Bus Support Package Instruction Manual

3–7

Page 44

Specifications

Table 3–12 shows the Phy_Data group assignments. The default radix of the

Phy_Data group is HEX.

T able 3–12: Phy_Data group assignments

Required for clocking

Section:channel Signal name

D0:7 Phy_Data_0 No

D0:6 Phy_Data_1 No

D0:5 Phy_Data_2 No

D0:4 Phy_Data_3 No

D0:3 Phy_Data_4 No

D0:2 Phy_Data_5 No

D0:1 Phy_Data_6 No

D0:0 Phy_Data_7 No

or disassembly

Table 3–13 shows the Phy_Ctrl group assignments. The default radix of the

Phy_Ctrl group is SYMBOLIC. The symbol table filename is 1394_PCtrl.

T able 3–13: Phy_Ctrl group assignments

Required for clocking

Section:channel Signal name

D1:7 Phy_Ctrl_0 No

D1:6 Phy_Ctrl_1 No

or disassembly

Table 3–14 lists the Clock and Qualifier channel assignments that are used as

clocks and/or qualifiers to the Clocking State Machine.

T able 3–14: Clock and qualifier channel assignments

Section:channel Signal name

CLK:0 Sys Clk

CLK:1 HW_Error

CLK:2 Count_0

CLK:3 Reset

C2:0 Ack_Rcvd

C2:1 Data_Rdy

C2:2 Sub_Gap

C2:3 Arb_Gap

3–8

TMS 871 1394 Bus Support Package Instruction Manual

Page 45

Signal Descriptions

Specifications

This section includes a table that lists all of the signals generated by the probe

adapter with a short description of each. See Table 3–15.

T able 3–15: Signal descriptions

Signal name Description

SysClk Master clock at half the rate of the PHY_Link SCLK signal.

Arb_Gap Indicates an arbitration gap has been detected on the 1394 bus.

Sub_Gap Indicates a subaction gap has been detected on the 1394 bus.

Data_Rdy Indicates the data quadlet on the data lines has changed and is valid. This

signal is also used to strobe the data quadlet and most control signals into

the logic analyzer.

Ack_Rcvd Indicates an acknowledge packet is being transsmitted on the bus and is

present on the 8 least significant bits of quadlet data (Data[24:31]).

Count[0:4] These bits indicate the count of the current quadlet being transmitted during

the packet. Legal values for the count bits are from 1 through 30, inclusive. A

count value of 31 is used to indicate a quadlet count value greater than 30.

Speed[0:1] These bits indicate the speed of the data being transmitted. See Table 2–5.

Bcast_Packet This signal is asserted during all broadcast packets. A broadcast packet is

detected when the destination ID of a packet is 3FF:3F (the 16 bit destination

ID is all ones). This signal will remain asserted during the entire packet

transfer, including the arbitration and subaction gap periods. This signal will

be deasserted only upon the detection of a packet whose destination ID is not

3FF:3F.

Iso_Cyc This signal will be asserted upon detection of a cycle start packet and will

remain asserted during the entire isochronous data transfer cycle.

Self_Id_Packet Indicates the current quadlet is part of a self-ID packet.

Data[0:31] Data from the 1394 bus are presented on these data lines in quadlet format.

Acknowledge packets are also presented on the 8 least significant bits of the

data lines.

Phy_Ctrl[0:1] The CTL signals from the PHY-Link interface used for low level acquisitions.

Phy_Data[0:7] The data signals from the PHY-Link interface used for low level acquisitions.

Last_Rx_Data Indicates the current quadlet is the final quadlet of the packet.

Reset Indicates that a bus reset state has been detected on the 1394 bus.

HW_Error Indicates that a hardware error has occurred. This signal is strobed when any

of the six specific hardware errors occurs (described below), and is used as

the hardware error strobe signal.

Iso_Cycle_Lost This error signal is asserted with HW_Error when an isochronous cycle did

not complete.

Iso_Cycle_Too_Long This error signal is asserted with HW_Error when an isochronous cycle

exceeded the maximum time.

TMS 871 1394 Bus Support Package Instruction Manual

3–9

Page 46

Specifications

T able 3–15: Signal descriptions (cont.)

Signal name Description

State_Timeout This error signal is asserted with HW_Error when the PHY stayed in a

particular state too long. This is usually caused by a loop in the cable

topology.

Quad_Align_Err This error signal is asserted with HW_Error when the quadlet data did not

end on a quadlet boundary.

Ack_Err This error signal is asserted with HW_Error when the second nibble of an ack

packet is not the logical inverse of the first nibble packet.

Self_Packet_Err This error signal is asserted with HW_Error when the second quadlet of a

self-ID packet is not the logical inverse of the first quadlet of the self-ID

packet.

3–10

TMS 871 1394 Bus Support Package Instruction Manual

Page 47

WARNING

The following servicing instructions are for use only by qualified personnel. To

avoid injury, do not perform any servicing other than that stated in the operating

instructions unless you are qualified to do so. Refer to all Safety Summaries

before performing any service.

Page 48

Page 49

Functional Verification

This chapter contains the following topics:

H Verifying Probe Adapter Clock Activity-verifies internal probe adapter

circuitry

H Verifying Probe Adapter Functionality with a TLA System-verifies internal

probe adapter circuitry and P6434 interface to the logic analyzer

H Troubleshooting

Probe Adapter Circuit Description

The probe adapter contains a three-port, 1394a-compatible, commercial PHY

chip to connect to the 1394 bus system under test and to monitor bus traffic. An

on-board FPGA conditions the PHY-Link signals for acquisition and display by

the logic analyzer. The probe adapter uses an external power supply to furnish

the 5 volts necessary to power the circuitry. An internal, resettable thermal fuse is

used for circuit protection. You can monitor the system clock signal (PHY-Link

SCLK/2) to verify the circuitry is active when the probe adapter is on.

Equipment Required

Table 4–1 lists the equipment you will need to verify circuit operation. You can

use an oscilloscope to check the system clock presence, or view the signal

activity if a logic analyzer is available.

T able 4–1: Equipment list

Item description Recommended example

Screwdriver Phillips #2

DMM TX1, TX3

Oscilloscope (25 MHz minimum, TTL level) TDS210

Logic Analyzer (optional) TLA 700 with 68-channel module

Two Logic Analyzer Probes (optional) P6434

TMS 871 1394 Bus Support Package Instruction Manual

4–1

Page 50

Functional Verification

Verifying Clock Activity Using an Oscilloscope

For verifying the probe adapter functionality, there is a diagnostic test point

connected to the SysClk signal which may be used with an oscilloscope to

determine basic operation of the PHY and link chips.

Use the following procedure to verify clock activity in the probe adapter:

1. Plug in the power supply and connect the power jack to the circuit board.

2. Verify the green LED on the front of the probe adapter is lit. If it is not lit,

either power is not being supplied correctly to the probe adapter or the probe

adapter is defective. See Troubleshooting on page 4–4.

3. To access the interal test point, remove the two philips screws accessible

from the bottom of the probe adapter case.

4. Remove the top half of the probe adapter case, exposing the top of the circuit

board.

5. Connect an oscilloscope probe to the SCLK/2 test point. See Figure 4–1.

4–2

SCLK/2

SCLK/2 test point

Figure 4–1: SCLK/2 (system clock) signal test point

6. Verify that a TTL-level square wave signal at about 25 MHz is present.

Absence of this signal indicates the circuit is not operating correctly. See

Troubleshooting on page 4–4.

Note that SCLK/2 is the system clock, and it must be active for the custom

clocking feature to acquire any data at all.

TMS 871 1394 Bus Support Package Instruction Manual

Page 51

Functional Verification

Verifying Probe Adapter Functionality with the TLA System Activity Monitor

If you have a logic analyzer, module, and probes are available, use the following

procedure to verify the probe adapter functionality:

1. Plug in the power supply and connect the power jack to the probe adapter.

2. Verify the green LED on the front of the probe adapter is lit. If it is not lit,

either power is not being supplied correctly to the probe adapter or the probe

adapter is defective. See Troubleshooting on page 4–4.

3. Power on the system and load the 1394 support from the logic analyzer

application. The probe adapter should not be connected to a 1394 bus system

for this test.

4. Connect the logic analyzer module to the 1394 probe adapter with two P6434

probes. Note that one P6434 connects to A3–A2 and A1–A0 and the other

P6434 connector connects to C3–C2 and D1–D0 as indicated on the probe

adapter rear panel.

5. Using the supplied 1394 cable, connect any two of the three 1394 ports

together to form a 1394 bus loop.

6. Wait for 1 or 2 seconds and then disconnect the cable from both ports.

7. View the activity window in the setup window of the TLA 700 application.

Look for an activity pattern as shown in Figure 4–2. Deviations from this pattern

indicate the probe adapter circuitry is not operating correctly or there may be a

problem with the logic analyzer probe hookup. Note that CK0 is the system clock

and must be active for the support’s custom clocking to acquire any data at all.

Figure 4–2: Activity pattern

TMS 871 1394 Bus Support Package Instruction Manual

4–3

Page 52

Functional Verification

Troubleshooting

If the probe adapter does not appear to function, and the cable and probe

connections appear good, you may have a power supply problem. Perform the

following steps to verify the power supply is working:

1. Disconnect the power supply from the back of the probe adapter.

2. Check the output with a DMM-it should measure 5 volts.

If the power supply does not measure 5 volts, replace it and verify the probe

adapter functions correctly.

If the power supply is not the problem, the fuse inside the probe adapter might be

tripped. Do the following steps to reset the fuse:

1. Disconnect the power to the probe adapter.

2. Wait 3 or 4 seconds.

3. Reconnect the power to the probe adapter.

4. If the green LED is lit, retest the probe adapter, using either the Oscilloscope

or the Activity Monitor checks. If the probe adapter still does not work, the

probe adapter unit might be defective. Contact your local Tektronix service

center.

5. If the green LED is not lit, and the power supply is not the problem, the

probe adapter unit might be defective. Contact your local Tektronix service

center.

If the square-wave signal is absent when performing the oscilloscope check, the

probe adapter unit might be defective. Contact your local Tektronix service

center.

If the Activity Monitor check fails, the probe adapter unit might be defective.

Contact your local Tektronix service center.

4–4

TMS 871 1394 Bus Support Package Instruction Manual

Page 53

Replaceable Parts

This chapter contains a list of the replaceable components for the TMS 871 1394

Bus support.

Parts Ordering Information

Replacement parts are available through your local Tektronix field office or

representative.

Changes to Tektronix products are sometimes made to accommodate improved

components as they become available and to give you the benefit of the latest

improvements. Therefore, when ordering parts, it is important to include the

following information in your order:

H Part number

H Instrument type or model number

H Instrument serial number

H Instrument modification number, if applicable

If you order a part that has been replaced with a different or improved part, your

local Tektronix field office or representative will contact you concerning any

change in part number.

Change information, if any, is located at the rear of this manual.

Using the Replaceable Parts List

The tabular information in the Replaceable Parts List is arranged for quick

retrieval. Understanding the structure and features of the list will help you find

all of the information you need for ordering replacement parts. The following

table describes the content of each column in the parts list.

TMS 871 1394 Bus Support Package Instruction Manual

5–1

Page 54

Replaceable Parts

Parts list column descriptions

Column Column name Description

1 Figure & index number Items in this section are referenced by figure and index numbers to the exploded view illustrations

that follow.

2 Tektronix part number Use this part number when ordering replacement parts from Tektronix.

3 and 4 Serial number Column three indicates the serial number at which the part was first effective. Column four

indicates the serial number at which the part was discontinued. No entries indicates the part is

good for all serial numbers.

5 Qty This indicates the quantity of parts used.

6 Name & description An item name is separated from the description by a colon (:). Because of space limitations, an

item name may sometimes appear as incomplete. Use the U.S. Federal Catalog handbook H6-1

for further item name identification.

7 Mfr. code This indicates the code of the actual manufacturer of the part.

8 Mfr. part number This indicates the actual manufacturer’s or vendor’s part number.

Abbreviations

Chassis Parts

Mfr. Code to Manufacturer

Cross Index

Abbreviations conform to American National Standard ANSI Y1.1-1972.

Chassis-mounted parts and cable assemblies are located at the end of the

Replaceable Parts List.

The table titled Manufacturers Cross Index shows codes, names, and addresses of

manufacturers or vendors of components listed in the parts list.

5–2

TMS 871 1394 Bus Support Package Instruction Manual

Page 55

Replaceable Parts

Manufacturers cross index

Mfr.

code

80009 TEKTRONIX INC 14150 SW KARL BRAUN DR

14310 AULT INC 7105 NORTHLAND TERRACE MINNEAPOLIS, MN 55428–1534

22526 FCI/BERG ELECTRONICS INC 825 OLD TRAIL ROAD ETTERS, PA 17319–9769

S3109 FELLER U.S. CORPORATION 72 VERONICA AVE

TK1373 PATELEC–CEM 10156 TORINO

TK2541 AMERICOR ELECTRONICS LTD UNIT–H

TK2548 XEROX CORPORATION 14181 SW MILLIKAN WA Y BEAVERT ON, OR 97005

TK6318 DATA TRANSIT 612 MINDY WA Y SAN JOSE, CA 95123

Manufacturer Address City , state, zip code

PO BOX 500

UNIT #5

VAICENTALLO

62/456

2682 W COYLE AVE

BEAVERT ON, OR 97077-0001

SOMERSET, NJ 08873

ITALY,

ELK GROVE VILLAGE, IL 60007

Replaceable parts list

Fig. &

index

number

5–1 119-6253-00 1 ADAPTER,PROBE:1394 ASSEMBL Y,TMS871 OPT 01 TK6318 119-6253-00

–2 119-5061-01 1 POWER SUPPL Y:25W,5V 5A,CONCENTRIC 2MM,90-265V,

–3 161-0104-00 1 CA ASSY,PWR:3,18 AWG,98 L,250V/10AMP,RT ANG,IEC320,

–4 012–1567–00 1 CA ASSY:IEEE 1394, 48 L,STANDARD FIREWIRE CABLE 22526 84865–122D

5–2–1 P6434 2 P6434 MASS TERMINATION PROBE, OPT 21

Tektronix part

number

071-0637-00 1 MANUAL,TECH:INSTRUCTION,TMS871 TK2548 071-0637-00

161-0104-06 1 CA ASSY,PWR:3,1.0MM SQ,250V/10A,2.5 METER,RTANG,

161-0104-07 1 CA ASSY,PWR:3,1.0MM SQ,240V/10A,2.5 METER,RTANG,

161-0104-05 1 CA ASSY,PWR:3,1.0MM SQ,250V/10A,2.5 METER,RTANG,

161-0167-00 1 CA ASSY,PWR:3,0.75MM SQ,250V/10A,2.5 METER,RTANG,

* Check the P6434 manual for detailed replaceable part information.

Serial no.

effective

Serial no.

discont’d

Qty Name & description

STANDARD ACCESSORIES

47-63 HZ IEC,15X8.6X5 CM, UL,CSA, TUV,IEC,SELF

RCPT X STR,NEMA 15-5P,W/CORD GRIP

OPTIONS AND OPTIONAL ACCESSORIES

IEC320,RCPT,EUROPEAN,SAFETY CONTROLLED, OPT A1

IEC320,RCPT X 13A,UNITED KINGDOM,SAFETY CONTROLLED, OPT A2

IEC320,RCPT,AUSTRALIA,SAFETY CONTROLLED, OPT A3

IEC320,RCPT,SWISS,NO CORD GRIP,SAFETY CONTROLLED,

OPT A5

Mfr.

code

14310 SW108KA0002F01

S3109 ORDER BY

Mfr. part number

DESCRIPTION

* 80009 ORDER BY

DESCRIPTION

TK1373 ORDER BY

TK2541 ORDER BY

TK1373 161-0104-05

S3109 ORDER BY

DESCRIPTION

DESCRIPTION

DESCRIPTION

TMS 871 1394 Bus Support Package Instruction Manual

5–3

Page 56

Replaceable Parts

1

2

3

4

Figure 5–1: TMS 871 replaceable parts

1

Figure 5–2: TMS 871 options/optional accessories

5–4

TMS 871 1394 Bus Support Package Instruction Manual

Loading...

Loading...