Page 1

Instruction Manual

TMS808

AGP4X Bus State Support

071-0560-03

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(i i) of the

Rights in Technical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software -- Restricted Rights clause at FAR 52.227-19, as applicable.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered tradem arks of Tektronix, Inc.

Page 3

SOFTWARE WARRANTY

Tektronix warrants that the media on which thi s software product is furnished and the encoding of the programs on

the media will be free from defects in materi als and workmanship for a period of three (3) months from the date of

shipment. If a medium or encoding proves defective during the warranty period, Tektronix will provide a

replacement in exchange for the defective medium. Except as to the media on which this software product is

furnished, this software product is provided “as is” without warranty of any kind, either express or implied.

Tektronix does not warrant that the functions contained in this software product will meet Customer’s

requirements or that the operation of the programs will be uninte rrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period. If Tektronix is unable to provide a replacement that is free from defects in materials and

workmanship within a reasonable time thereafter, Customer may terminate the license for this software product

and return this software product and any associated materials for credit or refund.

THIS W ARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER W ARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S PAYMENT IS

THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS

WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER

TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

HARDWARE WARRANTY

Tektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If a product proves defective during this

warranty period, Tektronix, at its option, either will repair the defective product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair da mage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modific ation or integration increases the time

or difficulty of servicing the product.

THIS W ARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER W ARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 5

Table of Contents

Getting Started

General Safety Summary v...................................

Service Safety Summary vii....................................

Preface ix...................................................

Manual Conventions ix..............................................

Logic Analyzer Documentation ix.....................................

Contacting Tektronix x..............................................

Probe Adapter Description 1--1.........................................

Support Package Description 1--1.......................................

Logic Analyzer Software Compatibility 1--2...............................

Logic Analyzer Configuration 1--2......................................

Requirements and Restrictions 1--3......................................

Connecting the Logic Analyzer to a System Under Test 1--4..................

Channel Assignments 1--9.............................................

Channel Charts 1--21..................................................

Standard Accessories 1--28.............................................

Options 1--28........................................................

Troubleshooting Guide 1--28............................................

Operating Basics

Specifications

Diagrams

Replaceable Parts List

Index

Setting Up the Support 2--1.....................................

Channel Group Definitions 2--1.........................................

Symbols 2--1.......................................................

HowDataisAcquired 2--6.............................................

Custom Clocking 2--6.............................................

Clocking Options 2--6.............................................

Setup/Hold Adjustment Procedure 2--7...............................

Signals Not On the Probe Adapter 2--11................................

Extra Channels 2--11...............................................

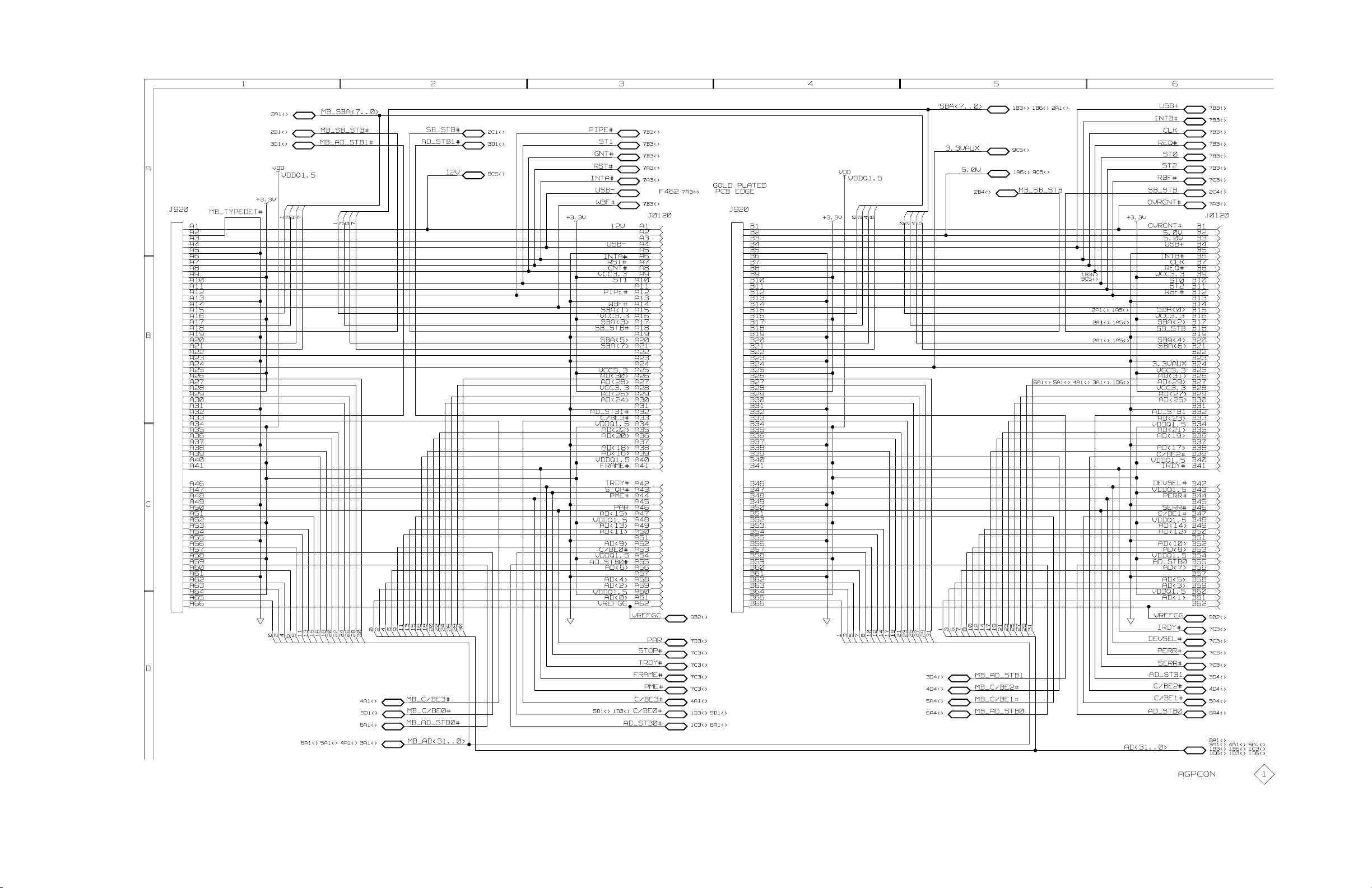

Circuit Description 3--1...............................................

Specifications 3--4..................................................

Loading and Equivalent Circuits 3--6.....................................

Symbols 4--1.......................................................

Component Values 4--1...............................................

Graphic Items and Special Symbols Used in This Manual 4--1.................

Component Locator Diagrams 4--1......................................

TMS808 AGP4X Bus State Support

i

Page 6

Table of Contents

List of Figures

Figure 1--1: Connecting the probe adapter boards together 1--5.......

Figure 1--2: Connecting the graphics card to the probe adapter 1--6...

Figure 1--3: Connecting the probe adapter and graphics card

to the system 1--7...........................................

Figure 1--4: Connecting the probes to the probe adapter 1--8.........

Figure 1--5: Selecting the data transfer rate 1--9....................

Figure 2--1: Examples of sufficient setup/hold times 2--9.............

Figure 2--2: Setup:AGP4X window 2--9...........................

Figure 2--3: Custom option window 2--10...........................

Figure 2--4: Setup/hold time violation examples 2--10.................

Figure 3--1: Block diagram for AD bus 3--2........................

Figure 3--2: Block diagram for the SBA bus 3--3....................

Figure 3--3: Qualifier generation 3--4.............................

Figure 3--4: Equivalent circuit loads for the probe adapter 3--7.......

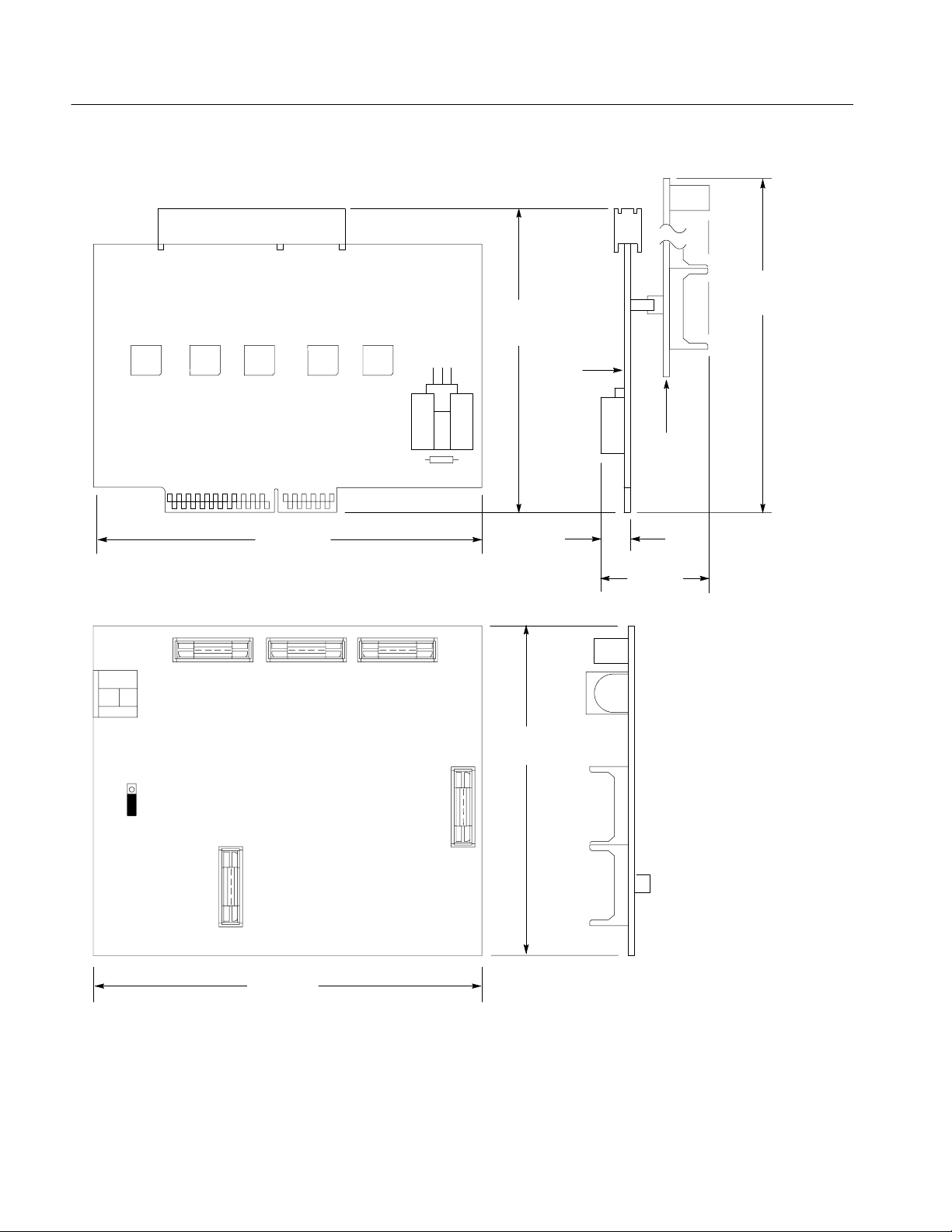

Figure 3--5: Probe adapter dimensions 3--8........................

Figure 5--1: AGP4X probe adapter exploded view 5--4...............

ii

TMS808 AGP4X Bus State Support

Page 7

List of Tables

Table of Contents

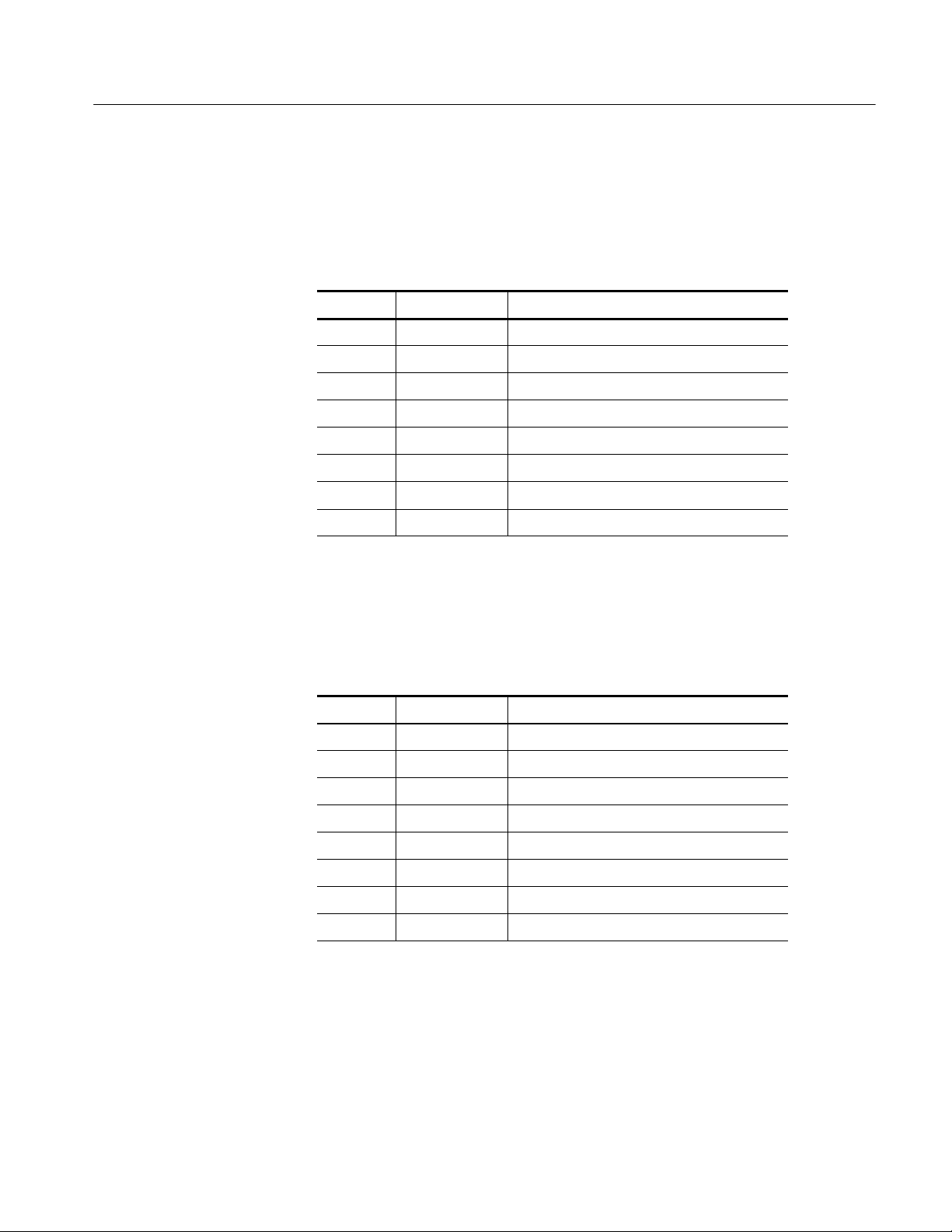

Table 1--1: AD[31:0] group assignments 1--10.......................

Table 1--2: AGP_Data_Hi channel group assignments 1--11...........

Table 1--3: AGP_Data_Lo channel group assignments 1--12...........

Table 1--4: BE_Hi channel group assignments 1--13..................

Table 1--5: BE_Lo channel group assignments 1--13.................

Table 1--6: Command channel group assignments 1--13..............

Table 1--7: Status group assignments 1--14.........................

Table 1--8: SBA[7:0] group assignments 1--14.......................

Table 1--9: SBA_Hi channel group assignments 1--15................

Table 1--10: SBA_Lo channel group assignments 1--15...............

Table 1--11: Control channel group assignments 1--16................

Table 1--12: Misc channel group assignments 1--16..................

Table 1--13: D_AD_Strobe channel group assignments 1--17..........

Table 1--14: D_SB_Strobe channel group assignments 1--17...........

Table 1--15: Clock and qualifier channel assignments 1--17...........

Table 1--16: Channel groups required for clocking 1--18..............

Table 1--17: Channel groups not required for clocking 1--20...........

Table 1--18: Signals on the probe adapter that are not acquired 1--21...

Table 1--19: Clock channels 1--21.................................

Table 1--20: Qual channels 1--21.................................

Table 1--21: 32 Channel Address_Lo section on the lower module 1--22.

Table 1--22: 32 Channel Address_Hi Section on the Lower Module 1--23

Table 1--23: 32 Channel Data_Hi section on the higher module 1--24...

Table 1--24: 32 Channel Data_Lo section on the lower module 1--25....

Table 1--25: 32 Channel Control section (sorted by channel number)

on the lower module 1--26...................................

Table 1--26: 32 Channel Control Section (sorted by login group) on the lower

module 1--27...............................................

Table 2--1: Command group symbol table definitions 2--1............

Table 2--2: Status group symbol table definitions 2--3...............

Table 2--3: Control group symbol table definitions 2--4..............

Table 2--4: SBA_Hi Command group symbol table definitions 2--5....

Table 3--1: Electrical specifications 3--4...........................

Table 3--2: Environmental specifications1 3--5.....................

Table 3--3: Lossy delay line values 3--6............................

TMS808 AGP4X Bus State Support

iii

Page 8

Table of Contents

iv

TMS808 AGP4X Bus State Support

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is indirectly grounded through the grounding

conductor of the mainframe power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground. Before making connections to the

input or output terminals of the product, ensure that the product is properly

grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and marking on the product. Consult the product manual for further ratings

information before making connections to the product.

Connect the ground lead of the probe to earth ground only.

Use Proper AC Adapter. Use only the AC adapter specified for this product.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

TMS808 AGP4X Bus State Support

v

Page 10

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) Terminal

CAUTION

Refer to Manual

Double

Insulated

vi

TMS808 AGP4X Bus State Support

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

TMS808 AGP4X Bus State Support

vii

Page 12

Service Safety Summary

viii

TMS808 AGP4X Bus State Support

Page 13

Preface

This instruction manual contains specific information about the

TMS 808 AGP4X bus support package and is part of a set of information on how

to operate this product on compatible Tektronix logic analyzers.

If you are familiar with operating bus support packages on the logic analyzer for

which the TMS 808 AGP4X support was purchased, you will probably only

need this instruction manual to set up and run the support package.

If you are not familiar with operating bus support packages, you will need to

supplement this instruction manual with information on basic operations to set

up and run the support package.

Information on basic operations of bus support packages is included with each

product. Each logic analyzer includes basic information that describes how to

perform tasks common to support packages on that platform. This information

can be in the form of online help, an installation manual, or a user manual.

This manual provides detailed information on the following topics:

H Connecting the logic analyzer to the system under test

H Setting up the logic analyzer to acquire data from the system under test

H Acquiring and viewing data

Manual Conventions

This manual uses the following conventions:

H The phrase “information on basic operations” refers to the logic analyzer

online help, an installation manual, or a user manual covering the basic

operations of bus support.

H The term “logic analyzer” refers to the Tektronix logic analyzer for which

this product was purchased.

Logic Analyzer Documentation

A description of other documentation available for each type of Tektronix logic

analyzer is located in the user manual of the corresponding module. The manual

set provides the information necessary to install, operate, maintain, and service

the logic analyzer and its associated products.

TMS808 AGP4X Bus State Support

ix

Page 14

Preface

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, pl ease leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

x

TMS808 AGP4X Bus State Support

Page 15

Getting Started

Page 16

Page 17

Getting Started

This chapter contains information on the TMS 808 AGP4X bus support and

information on connecting your logic analyzer to your system under test.

Probe Adapter Description

The probe adapter is nonintrusive hardware that allows the logic analyzer to

acquire data from a bus in its own operating environment with little effect, if any,

on the target system. Information on basic operations in your online help contains

a figure showing the logic analyzer connected to a typical probe adapter. Refer to

that figure while reading the following description.

The probe adapter consists of an extender board and an interface board. The

extender board includes a straddle-mount AGP4X connector that accepts the

original AGP4X card. The extender board has signal conditioning circuitry on it

which extracts proper digital signals from the composite wave on the

transmission lines. The extender board also includes a 114-pin Mictor connector

that transfers the conditioned signals to the interface board. For more detailed

information on the probe adapter refer to the Circuit description on page 3--1.

The interface board contains digital logic which processes the AGP signals for

the logic analyzer to acquire. Mictor connectors on the interface board accept

P6434 probes from the logic analyzer.

The probe adapter accommodates the AGP4X bus and is powered with an

external supply.

Support Package Description

The TMS 808 bus support package acquires and displays data from systems

based on the Intel AGP4X bus.

To use this support efficiently, refer to information on basic operations, in your

online help, and the following documents:

H Accelerated Graphics Port Interface Specification, Intel, Version 2.0, 1998

The AGP interface specification uses the 66 MHz PCI (PCI Local Bus Specification) as an operational baseline and provides four significant performance

extensions or enhancements to the PCI specification which are intended to

optimize the AGP for high performance 3D graphics applications. These AGP

extensions are not described in, or required by, the PCI Local Bus Specification.

TMS808 AGP4X Bus State Support

1--1

Page 18

Getting Started

These extensions are:

H Deeply pipelined memory read and write operations, fully hiding memory

access latency.

H Demultiplexing of address and data on the bus, allowing almost 100% bus

efficiency.

H New AC timing in the 3.3 V electrical specification that provides for one,

two, or four data transfers per 66 MHz clock cycle, allowing for real data

throughput in excess of 500 MB/s.

H A new low voltage electrical specification that allows four data transfers per

66--MHz clock cycle, providing real data throughput of up to 1 GB/s.

These enhancements are realized through the use of sideband signals. The PCI

specification has not been modified in any way, and the AGP interface specification has specifically avoided the use of any of the reserved fields, encodings,

pins, and so on, in the PCI specification. The intent is to utilize the PCI design

base while providing a range of graphics-oriented performance enhancements

with varying complexity/performance tradeoffs available to the component

provider.

AGP neither replaces nor diminishes the necessity of PCI in the system. This

high speed port (AGP) is physically, logically, and electrically independent of the

PCI bus. It is an additional connection point in the system. It is intended for the

exclusive use of visual display devices; all other I/O devices will remain on the

PCI bus. The add-in slot defined for AGP uses a new connector body (for

electrical signaling reasons) which is not compatible with the PCI connector; PCI

and AGP boards are not mechanically interchangeable.

Logic Analyzer Software Compatibility

The label on the TMS 808 support floppy disk states which version of logic

analyzer software the support is compatible with.

Logic Analyzer Configuration

For use with a TLA 700 Series, the TMS 808 support requires a minimum of two

102-channel modules that are merged. Modules must be 200 MHz minimum.

Merged modules must be of the same memory depth. If not, the shallower

module will determine the depth of the merged module pair. The modules must

be merged before microprocessor support is loaded. The TLA 700 does not retain

micro support when a merged configuration is unmerged.

1--2

TMS808 AGP4X Bus State Support

Page 19

Requirements and Restrictions

Review the electrical specifications in the Specifications chapter in this manual

as they pertain to your system under test, as well as the following descriptions of

other AGP4X support requirements and restrictions.

The AGP4X support does not have the ability to connect transferred data and the

requests that generated them.

Hardware Reset. If a hardware reset occurs in your AGP4X system during an

acquisition, the application may acquire an invalid sample.

System Clock Rate. The AGP4X support can acquire data from the bus operating

atspeedsofupto66MHz.

Nonintrusive Acquisition. The AGP4X microprocessor support will not intercept,

modify, or present signals back to the system under test, with the exception noted

under Use of TYPEDET#.

Getting Started

1.5V Operation Only. The AGP4X support can be used with only AGP4X and

AGP2X 1.5 V systems. The AGP2X support will not work with 3.3 V systems.

The AGP4X support will not work with 1X AGP systems. Contact Tektronix for

1X and 2X 3.3V support.

Data Transfer Rate. The AGP4X support will not work with 1X AGP systems.

Contact Tektronix for 1X and 2X, 3.3V support.

Use of TYPEDET#. The TYPEDET# signal is connected to ground on the

motherboard and is unconnected on the AGP4X connector. This will force the

motherboard logic to use 1.5 V signaling.

AGP Modes not Verified. PIPE# mode and AGP fast writes are not tested, so

Tektronix cannot guarantee functionality.

State Mode Display. The state mode waveform display must not be used to

observe signals that have a repetition rate greater than the sampling frequency.

For example, the AD[31:0], Strobes, SBA[7:0], and BE signals will yield

incorrect values in the State mode waveform window. This is because the

sampling rate is 133 MHz, where as these signals; AD[31:0], Strobes, SBA[7:0],

and BE, can change at a rate of 266 MHz and may not show a steady state.

TMS808 AGP4X Bus State Support

1--3

Page 20

Getting Started

MagniVu. Timing signals displayed in groups AD[31:0] and SBA[7:0] should not

be used for accurate timing measurements.

Threshold. The AGP4X support hardware uses GND-based threshold for

detecting the levels, rather than using Vrefgc or Vrefcg. So a change in interface

voltage levels may appear as changes in timings.

Connecting the Logic Analyzer to a System Under Test

To connect the probes to AGP4X signals in the system under test, follow these

steps:

1. Power off your system under test. It is not necessary to power off the logic

analyzer.

CAUTION. Static discharge can damage the bus, the probes, and the logic

analyzer module. To prevent static damage, handle these components only in a

static-free environment.

Always wear a grounding wrist strap, heel strap, or similar device while

handling the bus.

2. To discharge your stored static electricity, touch the ground connector located

on the back of the logic analyzer.

3. Place the system under test on a horizontal, static-free surface.

4. Plug the probe interface board into the graphics card extender as shown in

Figure 1--1 on page 1--5.

5. Secure the two boards together with the hardware provided.

1--4

TMS808 AGP4X Bus State Support

Page 21

Spacers (4)

Getting Started

Screws (8)

Probe interface board

Graphics card extender

Figure 1--1: Connecting the probe adapter boards together

TMS808 AGP4X Bus State Support

1--5

Page 22

Getting Started

6. Plug the graphics card into the probe adapter. The video out silk-screen

symbol on the probe interface board should point to the same side as the

XGA video connector on the graphics card, as shown in Figure 1--2.

CAUTION. To prevent damaging the graphics card, probe adapter, or system

under test when power is applied, be sure to connect the AGP graphics card to

the probe adapter properly .

NOTE. The TMS 808 product only supports 1.5V graphics cards.

XGA video connector (typical)

Both facing

same side

Graphics card

Probe interface board

Graphics card extender

1--6

Figure 1--2: Connecting the graphics card to the probe adapter

TMS808 AGP4X Bus State Support

Page 23

Getting Started

NOTE. The graphics card must be plugged into the probe adapter for proper

operation.

7. Plug the probe adapter into the system under test as shown in Figure 1--3.

CAUTION. To prevent damaging the graphics card, probe adapter, or system

under test when power is applied, be sure to connect the probe adapter to the

system under test properly .

XGA video connector (typical)

Graphics card

Power supply

connector

Probe interface board

Pin 1

Graphics card extender

Index key

(not present

on all system

boards)

System

under test

Figure 1--3: Connecting the probe adapter and graphics card to the system

TMS808 AGP4X Bus State Support

1--7

Page 24

Getting Started

8. Connect the power supply to J0290 on the probe adapter. See Figure 1--4.

Plug the power supply into the appropriate AC power source.

9. Use the P6434 probes to connect to the Mictor connectors on the probe

interface board. See Figure 1--4. These are connected to the signal pins as

shown in Table 1--1 through Table 1--12.

10. Connect the module ends of the P6434 probes to the corresponding connectors (match label colors) on the logic analyzer. The probe module ends are

keyed.

11. Apply forced air cooling across the probe adapter and AGP graphics card

consistent with the recommendations of the manufacturer.

Graphics card

To power supply

Probe interface board

Graphics card extender

System

under test

Figure 1--4: Connecting the probes to the probe adapter

P6434 probes (5)

1--8

TMS808 AGP4X Bus State Support

Page 25

Getting Started

12. The data transfer rate (2X or 4X) must be selected using J0590 on the probe

interface board. See Figure 1--5 for jumper location and settings.

2X

J0590

J0590

4X

Figure 1--5: Selecting the data transfer rate

Channel Assignments

Channel assignments listed in Table 1--1 through Table 1--12 use the following

conventions:

H All signals are required by the support unless indicated otherwise.

H Channels are listed starting with the most significant bit (MSB), descending

to the least significant bit (LSB).

H A pound sign (#) following a signal name indicates an active low signal.

H Channel group assignments are for all modules unless otherwise noted.

H The module in the higher-numbered slot is referred to as the HI module and

the module in the lower-numbered slot is referred to as the LO module.

The TLA 704 logic analyzer has the lower-numbered slots on the top and the

TLA 711 logic analyzer has the lower-numbered slots on the left.

TMS808 AGP4X Bus State Support

1--9

Page 26

Getting Started

Table 1--1 lists the probe section and channel assignments for the AD[31:0] group

and the bus signal for each channel connect. By default, this channel group is

displayed in hexadecimal.

Table 1--1: AD[31:0] group assignments

Bit order Section:channel AGP4X signal name

31 Lo_A3:7 AD31

30 Lo_A3:6 AD30

29 Lo_A3:5 AD29

28 Lo_A3:4 AD28

27 Lo_A3:3 AD27

26 Lo_A3:2 AD26

25 Lo_A3:1 AD25

24 Lo_A3:0 AD24

23 Lo_A2:7 AD23

22 Lo_A2:6 AD22

21 Lo_A2:5 AD21

20 Lo_A2:4 AD20

19 Lo_A2:3 AD19

18 Lo_A2:2 AD18

17 Lo_A2:1 AD17

16 Lo_A2:0 AD16

15 Lo_A1:7 AD15

14 Lo_A1:6 AD14

13 Lo_A1:5 AD13

12 Lo_A1:4 AD12

11 Lo_A1:3 AD11

10 Lo_A1:2 AD10

9 Lo_A1:1 AD9

8 Lo_A1:0 AD8

7 Lo_A0:7 AD7

6 Lo_A0:6 AD6

5 Lo_A0:5 AD5

4 Lo_A0:4 AD4

3 Lo_A0:3 AD3

2 Lo_A0:2 AD2

1 Lo_A0:1 AD1

0 Lo_A0:0 AD0

1--10

TMS808 AGP4X Bus State Support

Page 27

Getting Started

Table 1--2 lists the probe section and channel assignments for the AGP_Data_Hi

group and the bus signal for each channel connect. By default, this channel group

is displayed in hexadecimal.

Table 1--2: AGP_Data_Hi channel group assignments

Bit order Section:channel AGP4X signal name

31 Hi_D3:7 D_D63

30 Hi_D3:6 D_D62

29 Hi_D3:5 D_D61

28 Hi_D3:4 D_D60

27 Hi_D3:3 D_D59

26 Hi_D3:2 D_D58

25 Hi_D3:1 D_D57

24 Hi_D3:0 D_D56

23 Hi_D2:7 D_D55

22 Hi_D2:6 D_D54

21 Hi_D2:5 D_D53

20 Hi_D2:4 D_D52

19 Hi_D2:3 D_D51

18 Hi_D2:2 D_D50

17 Hi_D2:1 D_D49

16 Hi_D2:0 D_D48

15 Hi_D1:7 D_D47

14 Hi_D1:6 D_D46

13 Hi_D1:5 D_D45

12 Hi_D1:4 D_D44

11 Hi_D1:3 D_D43

10 Hi_D1:2 D_D42

9 Hi_D1:1 D_D41

8 Hi_D1:0 D_D40

7 Hi_D0:7 D_D39

6 Hi_D0:6 D_D38

5 Hi_D0:5 D_D37

4 Hi_D0:4 D_D36

3 Hi_D0:3 D_D35

2 Hi_D0:2 D_D34

1 Hi_D0:1 D_D33

0 Hi_D0:0 D_D32

TMS808 AGP4X Bus State Support

1--11

Page 28

Getting Started

Table 1--3 lists the probe section and channel assignments for the AGP_Data_Lo

group and the bus signal for each channel connect. By default, this channel group

is displayed in hexadecimal.

Table 1--3: AGP_Data_Lo channel group assignments

Bit order Section:channel AGP4X signal name

31 Lo_D3:7 D_D31

30 Lo_D3:6 D_D30

29 Lo_D3:5 D_D29

28 Lo_D3:4 D_D28

27 Lo_D3:3 D_D27

26 Lo_D3:2 D_D26

25 Lo_D3:1 D_D25

24 Lo_D3:0 D_D24

23 Lo_D2:7 D_D23

22 Lo_D2:6 D_D22

21 Lo_D2:5 D_D21

20 Lo_D2:4 D_D20

19 Lo_D2:3 D_D19

18 Lo_D2:2 D_D18

17 Lo_D2:1 D_D17

16 Lo_D2:0 D_D16

15 Lo_D1:7 D_D15

14 Lo_D1:6 D_D14

13 Lo_D1:5 D_D13

12 Lo_D1:4 D_D12

11 Lo_D1:3 D_D11

10 Lo_D1:2 D_D10

9 Lo_D1:1 D_D9

8 Lo_D1:0 D_D8

7 Lo_D0:7 D_D7

6 Lo_D0:6 D_D6

5 Lo_D0:5 D_D5

4 Lo_D0:4 D_D4

3 Lo_D0:3 D_D3

2 Lo_D0:2 D_D2

1 Lo_D0:1 D_D1

0 Lo_D0:0 D_D0

1--12

TMS808 AGP4X Bus State Support

Page 29

Getting Started

Table 1--4 lists the probe section and channel assignments for the BE_Hi group

and the bus signal for each channel connect. By default, this channel group is

displayed as binary.

Table 1--4: BE_Hi channel group assignments

Bit order Section:channel AGP4X signal name

3 Lo_C0:7 D_BE7

2 Lo_C0:6 D_BE6

1 Lo_C0:5 D_BE5

0 Lo_C0:4 D_BE4

Table 1--5 lists the probe section and channel assignments for the BE_Lo group

and the bus signal for each channel connect. By default, this channel group is

displayed as binary.

Table 1--5: BE_Lo channel group assignments

Bit order Section:channel AGP4X signal name

3 Lo_C0:3 D_BE3

2 Lo_C0:2 D_BE2

1 Lo_C0:1 D_BE1

0 Lo_C0:0 D_BE0

Table 1--6 lists the probe section and channel assignments for the Command

group and the bus signal for each channel connect. The symbol table file name is

AGP4X_Command. By default, this channel group is displayed as symbols.

Table 1--6: Command channel group assignments

Bit order Section:channel AGP4X signal name

6 Lo_C1:7 IRDY#

5 Lo_C2:3 FRAME#

4 CLK:0 PIPE#

3 Lo_C1:5 C/BE3#

2 Lo_C1:4 C/BE2#

1 Lo_C1:3 C/BE1#

0 Lo_C1:2 C/BE0#

TMS808 AGP4X Bus State Support

1--13

Page 30

Getting Started

Table 1--7 lists the probe section and channel assignments for the Status group

and the bus signal for each channel connect. The symbol table file name is

AGP4X_Status. By default, this channel group is displayed as symbols.

Table 1--7: Status group assignments

Bit order Section:channel AGP4X signal name

3 Lo_C2:1 GNT#

2 Hi_A0:2 ST2

1 Hi_A0:1 ST1

0 Hi_A0:0 ST0

Table 1--8 lists the probe section and channel assignments for the SBA[7:0] group

and the bus signal for each channel connect. By default, this channel group is

displayed as hexadecimal.

Table 1--8: SBA[7:0] group assignments

Bit order Section:channel AGP4X signal name

7 Lo_C3:7 SBA7

6 Lo_C3:6 SBA6

5 Lo_C3:5 SBA5

4 Lo_C3:4 SBA4

3 Lo_C3:3 SBA3

2 Lo_C3:2 SBA2

1 Lo_C3:1 SBA1

0 Lo_C3:0 SBA0

1--14

TMS808 AGP4X Bus State Support

Page 31

Getting Started

Table 1--9 lists the probe section and channel assignments for the SBA_Hi group

and the bus signal for each channel connect. By default, this channel group is

displayed as hexadecimal.

Table 1--9: SBA_Hi channel group assignments

Bit order Section:channel AGP4X signal name

7 Hi_A3:7 D_SBA15

6 Hi_A3:6 D_SBA14

5 Hi_A3:5 D_SBA13

4 Hi_A3:4 D_SBA12

3 Hi_A3:3 D_SBA11

2 Hi_A3:2 D_SBA10

1 Hi_A3:1 D_SBA9

0 Hi_A3:0 D_SBA8

Table 1--10 lists the probe section and channel assignments for the SBA_Lo

group and the bus signal for each channel connect. By default, this channel group

is displayed as hexadecimal.

Table 1--10: SBA_Lo channel group assignments

Bit order Section:channel AGP4X signal name

7 Hi_A2:7 D_SBA7

6 Hi_A2:6 D_SBA6

5 Hi_A2:5 D_SBA5

4 Hi_A2:4 D_SBA4

3 Hi_A2:3 D_SBA3

2 Hi_A2:2 D_SBA2

1 Hi_A2:1 D_SBA1

0 Hi_A2:0 D_SBA0

TMS808 AGP4X Bus State Support

1--15

Page 32

Getting Started

Table 1--11 lists the probe section and channel assignments of the Control group

and the bus signal for each channel connect. The symbol table file name is

AGP4X_Control. By default, this channel group is displayed as symbols.

Table 1--11: Control channel group assignments

Bit order Section:channel AGP4X signal name

13 CLK:1 RST#

12 Hi_A0:5 PME#

11 Hi_A0:3 RBF#

10 Hi_A1:3 SERR#

9 Hi_A1:7 PERR#

8 Hi_A1:6 PAR

7 Hi_A1:5 REQ#

6 Lo_C2:1 GNT#

5 CLK:0 PIPE#

4 Lo_C2:3 FRAME#

3 Lo_C1:7 IRDY#

2 Lo_C1:6 TRDY#

1 Hi_A1:4 DEVSEL#

0 Lo_C2:0 STOP#

Table 1--12 lists the probe section and channel assignments for the Misc group

and the bus signal for each channel connect. By default, this channel group is

displayed as hexadecimal.

Table 1--12: Misc channel group assignments

Bit order Section:channel AGP4X signal name

10 Lo_C2:7 AD_STB0

9 Lo_C2:6 AD_STB0#

8 Lo_C2:5 AD_STB1

7 Lo_C2:4 AD_STB1#

6 Lo_C1:1 SB_STB

5 Lo_C1:0 SB_STB#

4 Hi_A1:2 OVRCNT#

3 Hi_A0:4 WBF#

2 Hi_A0:7 INTA#

1 Hi_A0:6 INTB#

0 CLK:3 CLK

1--16

TMS808 AGP4X Bus State Support

Page 33

Getting Started

Table 1--13 lists the probe section and channel assignments for the D_AD_Strobe

group and the bus signal for each channel connect. The default radix of this

channel group is binary.

Table 1--13: D_AD_Strobe channel group assignments

Bit order Section:channel AGP4X signal name

1 Lo_C2:2 D_AD_STB

1

The prefix D_ indicates that the signal is derived on the probe adapter.

1

Table 1--14 lists the probe section and channel assignments for the D_SB_Strobe

group and the bus signal for each channel connect. The default radix of this

channel group is binary.

Table 1--14: D_SB_Strobe channel group assignments

Bit order Section:channel AGP4X signal name

1 Qual:0 D_SB_STB

1

The prefix D_ indicates that the signal is derived on the probe adapter.

1

Table 1--15 lists the probe section and channel assignments for the clock probes

(not part of any group) and the AGP4X signal to which each channel connects.

Table 1--15: Clock and qualifier channel assignments

LA section and probe AGP4X signal name

CLK:0 PIPE#

CLK:1 RST#

CLK:2 D_PCI_STATUS#

CLK:3 CLK

Lo_C2:0 STOP#

Lo_C2:1 GNT#

Lo_C2:2 D_AD_STB

Lo_C2:3 FRAME#

QUAL:0 D_SB_STB

QUAL:1 NC

TMS808 AGP4X Bus State Support

1--17

Page 34

Getting Started

Table 1--16 lists the AGP4X bus signals required by the Clocking State Machine (CSM) to properly strobe and log in the bus bus cycles into acquisition

memory. Signals required for any probe adapter circuitry, if that circuitry is

required for custom acquisition, must also be included.

Table 1--16: Channel groups required for clocking

TLA 700 channel AGP4X signal name

Lo_A3:7--0 AD[31:0]

Lo_A2:7--0 (AD[31:0] Group)

Lo_A1:7--0

Lo_A0:7--0

Hi_D3:7--0 D_D[63:32]

Hi_D2:7--0 (AGP_Data_Hi Group)

Hi_D1:7--0

Hi_D0:7--0

Lo_D3:7--0 D_D[31:0]

Lo_D2:7--0 (AGP_Data_Lo Group)

Lo_D1:7--0

Lo_D0:7--0

Lo_C0:7--4 D_BE[7--4]

(BE_Hi Group)

Lo_C0:3--0 D_BE[3--0]

(BE_Lo Group)

Lo_C1:7 IRDY#

Lo_C2:3 FRAME#

CLK:1 RST#

Lo_C1:5 C/BE3#

Lo_C1:4 C/BE2#

Lo_C1:3 C/BE1#

Lo_C1:2 C/BE0#

(Command Group)

Lo_C2:1 GNT#

1--18

Hi_A0:2--0 ST[2--0]

(Status Group)

Hi_A3:7--0 D_SBA[15--8]

(SBA_Hi Group)

TMS808 AGP4X Bus State Support

Page 35

Table 1--16: Channel groups required for clocking (Cont.)

TLA 700 channel AGP4X signal name

Hi_A2:7--0 D_SBA[7--0]

(SBA_Lo Group)

QUAL:0 D_SB_STB

Hi_A0:5 PME#

Hi_A0:3 RBF#

Hi_A1:3 SERR#

Hi_A1:7 PERR#

Hi_A1:6 PAR

Hi_A1:5 REQ#

Lo_C2:1 GNT#

CLK:1 RST#

Lo_C2:3 FRAME#

Getting Started

Lo_C1:7 IRDY#

Lo_C1:6 TRDY#

Hi_A1:4 DEVSEL#

Lo_C2:0 STOP#

(Control Group)

CLK:0 PIPE#

CLK:1 RST#

CLK:2 D_PCI_STATUS#

CLK:3 CLK

(Clock and Qualifiers)

Lo_C2:0 STOP#

Lo_C2:1 GNT#

Lo_C2:2 D_AD_STB

Lo_C2:3 FRAME#

(Qualifiers)

TMS808 AGP4X Bus State Support

1--19

Page 36

Getting Started

Table 1--17 lists channel groups not required for clocking by the AGP4X support.

Table 1--17: Channel groups not required for clocking

TLA 700 channel AGP4X signal name

Hi_A1:2 OVRCNT#

Hi_A0:7 INTA#

Hi_A0:6 INTB#

Hi_A0:4 WBF#

Lo_C2:7 AD_STB0

Lo_C2:6 AD_STB0#

Lo_C2:5 AD_STB1

Lo_C2:4 AD_STB1#

Lo_C1:1 SB_STB

Lo_C1:0 SB_STB#

Lo_C3:7-0 SBA[7-0]

Acquisition Setup. The AGP4X support will affect the logic analyzer setup menus

and submenus by modifying existing fields and adding micro-specific fields.

The AGP4X support will add the selections AGP4X and AGP2X to the Load

Support Package dialog box, located under the File pulldown menu. Once the

AGP4X support has been loaded, the Custom clocking mode selection in the

module Setup menu is also enabled.

1--20

TMS808 AGP4X Bus State Support

Page 37

Getting Started

Table 1--18 lists the signals that are available on test pads on the probe adapter,

but not connected to the Mictor connectors.

Table 1--18: Signals on the probe adapter that are not acquired

AGP4X pin number AGP4X signal name

B4 USB+

A4 USB--

A66 Vrefgc

B66 Vrefcg

A34 Vddq1.5

A28 Vcc3.3

B24 3.3Vaux

B2 5.0V

A1 12.0V

Channel Charts

Tables 1--19 through 1--26 identify the signal names assigned to the acquisition

channel numbers on the logic analyzer.

Table 1--19: Clock channels

CLK or

TLA clock channel

CLK:3 CLK Both CLK

CLK:2 QUAL D_PCI_STATUS#

CLK:1 QUAL RST#

CLK:0 QUAL PIPE#

Qual

Active

CLK edge

AGP4X signal name

Table 1--20: Qual channels

TLA Qual channel AGP4X signal name

QUAL:1 NC

QUAL:0 D_SB_STB

TMS808 AGP4X Bus State Support

1--21

Page 38

Getting Started

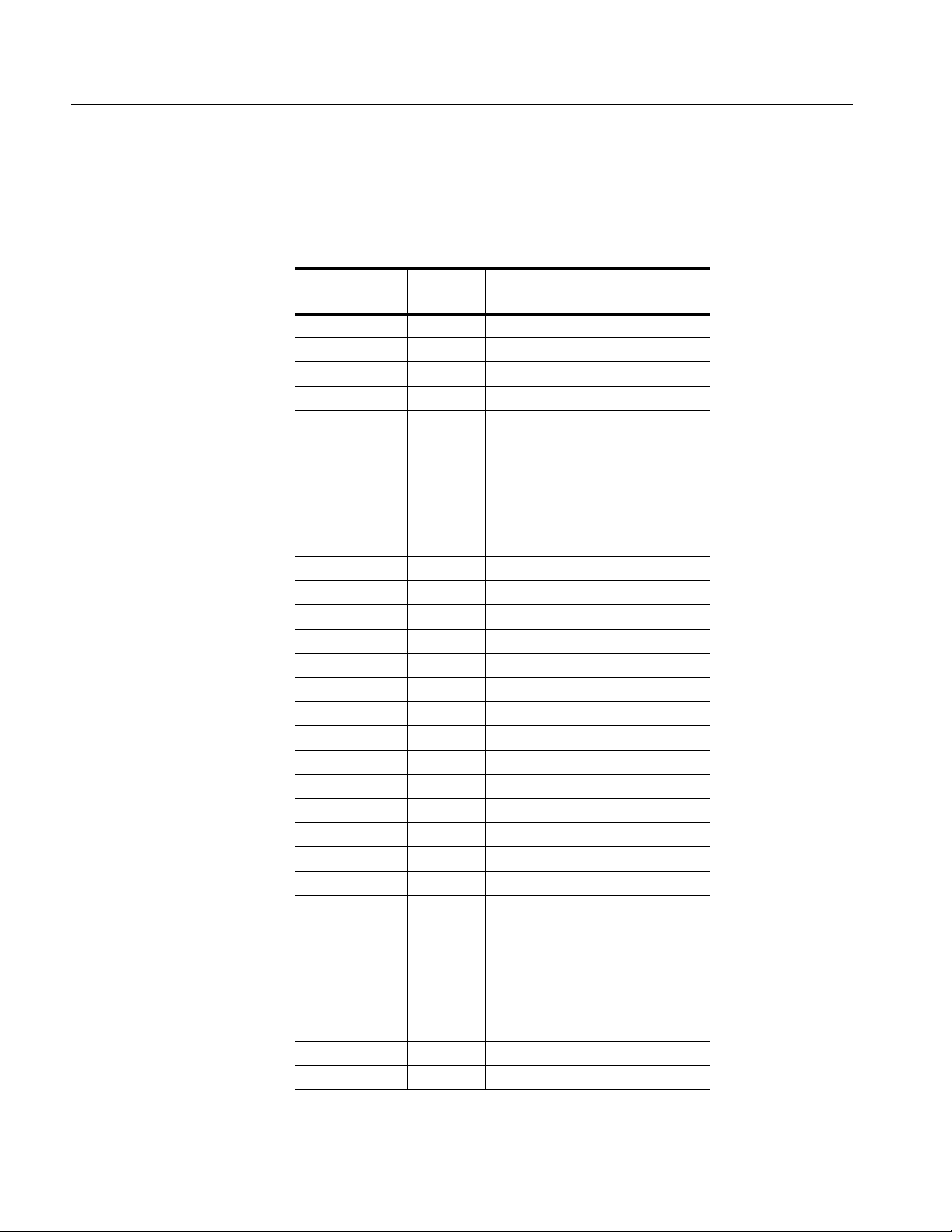

Table 1--21: 32 Channel Address_Lo section on the lower

module

TLA acquisition

channel

Lo_A3:7 LOGA7 AD31

Lo_A3:6 LOGA7 AD30

Lo_A3:5 LOGA7 AD29

Lo_A3:4 LOGA7 AD28

Lo_A3:3 LOGA6 AD27

Lo_A3:2 LOGA6 AD26

Lo_A3:1 LOGA6 AD25

Lo_A3:0 LOGA6 AD24

Lo_A2:7 LOGA5 AD23

Lo_A2:6 LOGA5 AD22

Lo_A2:5 LOGA5 AD21

Lo_A2:4 LOGA5 AD20

Lo_A2:3 LOGA4 AD19

Lo_A2:2 LOGA4 AD18

Lo_A2:1 LOGA4 AD17

Lo_A2:0 LOGA4 AD16

Lo_A1:7 LOGA3 AD15

Lo_A1:6 LOGA3 AD14

Lo_A1:5 LOGA3 AD13

Lo_A1:4 LOGA3 AD12

Lo_A1:3 LOGA2 AD11

Lo_A1:2 LOGA2 AD10

Lo_A1:1 LOGA2 AD9

Lo_A1:0 LOGA2 AD8

Lo_A0:7 LOGA1 AD7

Lo_A0:6 LOGA1 AD6

Lo_A0:5 LOGA1 AD5

Lo_A0:4 LOGA1 AD4

Lo_A0:3 LOGA0 AD3

Lo_A0:2 LOGA0 AD2

Lo_A0:1 LOGA0 AD1

Lo_A0:0 LOGA0 AD0

Login

group

AGP4X signal name

1--22

TMS808 AGP4X Bus State Support

Page 39

Table 1--22: 32 Channel Address_Hi Section on the lower

module

Getting Started

TLA acquisition

channel

Hi_A3:7 LOGA7 D_SBA15

Hi_A3:6 LOGA7 D_SBA14

Hi_A3:5 LOGA7 D_SBA13

Hi_A3:4 LOGA7 D_SBA12

Hi_A3:3 LOGA6 D_SBA11

Hi_A3:2 LOGA6 D_SBA10

Hi_A3:1 LOGA6 D_SBA9

Hi_A3:0 LOGA6 D_SBA8

Hi_A2:7 LOGA5 D_SBA7

Hi_A2:6 LOGA5 D_SBA6

Hi_A2:5 LOGA5 D_SBA5

Hi_A2:4 LOGA5 D_SBA4

Hi_A2:3 LOGA4 D_SBA3

Hi_A2:2 LOGA4 D_SBA2

Hi_A2:1 LOGA4 D_SBA1

Hi_A2:0 LOGA4 D_SBA0

Hi_A1:7 LOGA3 PERR#

Hi_A1:6 LOGA3 PAR

Hi_A1:5 LOGA3 REQ#

Hi_A1:4 LOGA3 DEVSEL#

Hi_A1:3 LOGA2 SERR#

Hi_A1:2 LOGA2 OVRCNT#

Hi_A1:1 LOGA2 NC

Hi_A1:0 LOGA2 NC

Hi_A0:7 LOGA1 INTA#

Hi_A0:6 LOGA1 INTB#

Hi_A0:5 LOGA1 PME#

Hi_A0:4 LOGA1 WBF#

Hi_A0:3 LOGA0 RBF#

Hi_A0:2 LOGA0 ST2

Hi_A0:1 LOGA0 ST1

Hi_A0:0 LOGA0 ST0

Login

group

AGP4X signal name

TMS808 AGP4X Bus State Support

1--23

Page 40

Getting Started

Table 1--23: 32 Channel Data_Hi section on the higher

module

TLA acquisition

channel

Hi_D3:7 LOGD7 D_D63

Hi_D3:6 LOGD7 D_D62

Hi_D3:5 LOGD7 D_D61

Hi_D3:4 LOGD7 D_D60

Hi_D3:3 LOGD6 D_D59

Hi_D3:2 LOGD6 D_D58

Hi_D3:1 LOGD6 D_D57

Hi_D3:0 LOGD6 D_D56

Hi_D2:7 LOGD5 D_D55

Hi_D2:6 LOGD5 D_D54

Hi_D2:5 LOGD5 D_D53

Hi_D2:4 LOGD5 D_D52

Hi_D2:3 LOGD4 D_D51

Hi_D2:2 LOGD4 D_D50

Hi_D2:1 LOGD4 D_D49

Hi_D2:0 LOGD4 D_D48

Hi_D1:7 LOGD3 D_D47

Hi_D1:6 LOGD3 D_D46

Hi_D1:5 LOGD3 D_D45

Hi_D1:4 LOGD3 D_D44

Hi_D1:3 LOGD2 D_D43

Hi_D1:2 LOGD2 D_D42

Hi_D1:1 LOGD2 D_D41

Hi_D1:0 LOGD2 D_D40

Hi_D0:7 LOGD1 D_D39

Hi_D0:6 LOGD1 D_D38

Hi_D0:5 LOGD1 D_D37

Hi_D0:4 LOGD1 D_D36

Hi_D0:3 LOGD0 D_D35

Hi_D0:2 LOGD0 D_D34

Hi_D0:1 LOGD0 D_D33

Hi_D0:0 LOGD0 D_D32

Login

group

AGP4X signal name

1--24

TMS808 AGP4X Bus State Support

Page 41

Table 1--24: 32 Channel Data_Lo section on the lower

module

Getting Started

TLA acquisition

channel

Lo_D3:7 LOGD7 D_D31

Lo_D3:6 LOGD7 D_D30

Lo_D3:5 LOGD7 D_D29

Lo_D3:4 LOGD7 D_D28

Lo_D3:3 LOGD6 D_D27

Lo_D3:2 LOGD6 D_D26

Lo_D3:1 LOGD6 D_D25

Lo_D3:0 LOGD6 D_D24

Lo_D2:7 LOGD5 D_D23

Lo_D2:6 LOGD5 D_D22

Lo_D2:5 LOGD5 D_D21

Lo_D2:4 LOGD5 D_D20

Lo_D2:3 LOGD4 D_D19

Lo_D2:2 LOGD4 D_D18

Lo_D2:1 LOGD4 D_D17

Lo_D2:0 LOGD4 D_D16

Lo_D1:7 LOGD3 D_D15

Lo_D1:6 LOGD3 D_D14

Lo_D1:5 LOGD3 D_D13

Lo_D1:4 LOGD3 D_D12

Lo_D1:3 LOGD2 D_D11

Lo_D1:2 LOGD2 D_D10

Lo_D1:1 LOGD2 D_D9

Lo_D1:0 LOGD2 D_D8

Lo_D0:7 LOGD1 D_D7

Lo_D0:6 LOGD1 D_D6

Lo_D0:5 LOGD1 D_D5

Lo_D0:4 LOGD1 D_D4

Lo_D0:3 LOGD0 D_D3

Lo_D0:2 LOGD0 D_D2

Lo_D0:1 LOGD0 D_D1

Lo_D0:0 LOGD0 D_D0

Login

group

AGP4X signal name

TMS808 AGP4X Bus State Support

1--25

Page 42

Getting Started

Table 1--25: 32 Channel Control section (sorted by channel

number) on the lower module

TLA acquisition

channel

Lo_C3:7 LOGC7 SBA7

Lo_C3:6 LOGC6 SBA6

Lo_C3:5 LOGC5 SBA5

Lo_C3:4 LOGC4 SBA4

Lo_C3:3 LOGC7 SBA3

Lo_C3:2 LOGC6 SBA2

Lo_C3:1 LOGC5 SBA1

Lo_C3:0 LOGC4 SBA0

Lo_C2:7 LOGC7 AD_STB0

Lo_C2:6 LOGC6 AD_STB0#

Lo_C2:5 LOGC5 AD_STB1

Lo_C2:4 LOGC4 AD_STB1#

Lo_C2:3%

Lo_C2:2%* LOGC6 D_AD_STB

Lo_C2:1%* LOGC5 GNT#

Lo_C2:0%

Lo_C1:7 LOGC3 IRDY#

Lo_C1:6 LOGC2 TRDY#

Lo_C1:5 LOGC1 C/BE3#

Lo_C1:4 LOGC0 C/BE2#

Lo_C1:3 LOGC3 C/BE1#

Lo_C1:2 LOGC2 C/BE0#

Lo_C1:1 LOGC1 SB_STB

Lo_C1:0 LOGC0 SB_STB#

Lo_C0:7 LOGC3 D_BE7

Lo_C0:6 LOGC2 D_BE6

Lo_C0:5 LOGC1 D_BE5

Lo_C0:4 LOGC0 D_BE4

Lo_C0:3 LOGC3 D_BE3

Lo_C0:2 LOGC2 D_BE2

Lo_C0:1 LOGC1 D_BE1

Lo_C0:0 LOGC0 D_BE0

* Indicates the channel is a qualifier

*

*

Login

group

LOGC7 FRAME#

LOGC4 STOP#

AGP4X signal name

1--26

TMS808 AGP4X Bus State Support

Page 43

Table 1--26: 32 Channel Control Section (sorted by login

group) on the lower module

Getting Started

TLA acquisition

channel

Lo_C3:7 LOGC7 SBA7

Lo_C3:3 LOGC7 SBA3

Lo_C2:7 LOGC7 AD_STB0

Lo_C2:3* LOGC7 FRAME#

Lo_C3:6 LOGC6 SBA6

Lo_C3:2 LOGC6 SBA2

Lo_C2:6 LOGC6 AD_STB0#

Lo_C2:2* LOGC6 D_AD_STB

Lo_C3:5 LOGC5 SBA5

Lo_C3:1 LOGC5 SBA1

Lo_C2:5 LOGC5 AD_STB1

Lo_C2:1* LOGC5 GNT#

Lo_C3:4 LOGC4 SBA4

Lo_C3:0 LOGC4 SBA0

Lo_C2:4 LOGC4 AD_STB1#

Lo_C2:0* LOGC4 STOP#

Lo_C1:7 LOGC3 IRDY#

Lo_C1:3 LOGC3 C/BE1#

Lo_C0:7 LOGC3 D_BE7

Lo_C0:3 LOGC3 D_BE3

Lo_C1:6 LOGC2 TRDY#

Lo_C1:2 LOGC2 C/BE0#

Lo_C0:6 LOGC2 D_BE6

Lo_C0:2 LOGC2 D_BE2

Lo_C1:5 LOGC1 C/BE3#

Lo_C1:1 LOGC1 SB_STB

Lo_C0:5 LOGC1 D_BE5

Lo_C0:1 LOGC1 D_BE1

Lo_C1:4 LOGC0 C/BE2#

Lo_C1:0 LOGC0 SB_STB#

Lo_C0:4 LOGC0 D_BE4

Lo_C0:0 LOGC0 D_BE0

* Indicates the channel is a qualifier

Login

group

AGP4X signal name

TMS808 AGP4X Bus State Support

1--27

Page 44

Getting Started

Standard Accessories

Options

The TMS 808 Support is shipped with the following standard accessories:

H TMS 808 Support SW Disk

H TMS 808 Support Instruction Manual

H TLA 700 Series Micro Installation Sheet

The following options are available when ordering the TMS 808 Support:

H Option 11--Add Probe Adapter

H Option 21--Add P6434 Mass-Termination Probes (5)

H Option A1 Power Cord

Troubleshooting Guide

H Option A2 Power Cord

H Option A3 Power Cord

H Option A5 Power Cord

H Option A99 Delete Power Cord

This Troubleshooting Guide is provided to ensure that the probe adapter is

functioning correctly. It is recommended that you read the following bullets.

CAUTION. Ensure that the probe adapter is properly plugged in the correct

orientation. Please note that it is possible to insert the probe adapter in a

universal socket in an incorrect orientation, which may damage the probe

adapter and the system under test (see Figure 1--2 on page 1--6). The label

‘video out’ on the probe adapter indicates the direction in which a normal

display adapter would have its video out connector.

H Make sure that power is reaching the probe adapter. To verify this, look at the

green LED near the heat sink on the extender board of the probe adapter. It

will be on; if it is not, it may indicate that the power adapter is not properly

plugged in or powered on. If the LED is still not on, the probe adapter may

have a problem that needs servicing.

1--28

TMS808 AGP4X Bus State Support

Page 45

Getting Started

H Make sure that all the Mictor connectors are plugged in correctly. The

activity window (select the Show Activity button on the Setup panel) may be

used to verify this. Run a test program on the system under test and verify

that the signals are showing activity (toggling) as expected.

H The Show Activity window can also be used to detect which mode of AGP

the system is running. When a program that uses AGP transfers is being run

on the system under test, the following can be observed:

H AD_STB0 (C2:7) toggles in the case of any AGP activity

H SB_STB (C1:1) toggles if the system uses side band for address queuing

H The complementary strobes AD_STB0# (C2:6) and SB_STB# (C1:0)

toggle when the transfer rate is 4X (but not in 2X).

H Please note when using an AGP 2X system that you must change the jumper

(J0590) on the adapter board (see Figure 1--5 on page 1--9 for J0590

location) and load the separate support package named AGP 2X. Also, the

TMS 808 supports only 1.5V signaling.

H While triggering on data being transferred by AGP protocol, avoid triggering

on AD bus signals. Since AD bus signals change faster than the custom

sampling rate, there are chances of false triggering. Instead use

AGP_Data_Hi or AGP_Data_Lo groups. Normally, the first and third data in

a cycle appear on the Data_hi group.

H Signals that change state faster than the custom sampling rate when observed

in the state waveform window, may appear as incorrect representations.

These include the AD bus, SBA bus and the strobes.

TMS808 AGP4X Bus State Support

1--29

Page 46

Getting Started

1--30

TMS808 AGP4X Bus State Support

Page 47

Operating Basics

Page 48

Page 49

Setting Up the Support

This section provides information on how to set up the support. The information

covers the following topics:

H Symbol table files

H Clocking options

The information in this section is specific to the operations and functions of the

TMS 808 AGP4X support on any Tektronix logic analyzer for which it can be

purchased.

Before you acquire and display disassemble data, you need to load the support

and specify the setups for clocking and triggering as described in the information

on basic operations. The support provides default values for each of these setups,

but you can change them as needed.

Channel Group Definitions

The software automatically defines channel groups for the support. The channel

groups for the AGP4X support are AD[31:0], AGP_Data_Hi, AGP_Data_Lo,

BE_Hi, BE_Lo, Command, Status, SBA_Hi, SBA_Lo, Control, Misc,

D_AD_Strobe and D_SB_Strobe. If you want to know which signal is in which

group, refer to the channel assignment tables beginning on page 1--10.

Symbols

The TMS 808 support supplies four symbol table files. Each file replaces specific

channel group values with symbolic values when Symbolic is the radix for the

channel group.

Table 2--1 shows the name, bit pattern, and meaning for the symbols in the file

AGP4X_Command, the Command channel group symbol table.

Table 2--1: Command group symbol table definitions

Command group value

IRDY# C/BE2#

Symbol

- X11 XXXX

Bus_Fault X00 XXXX

FRAME# C/BE1#

PIPE# C/BE0#

TMS808 AGP4X Bus State Support

C/BE3#

Meaning

Not an AGP or PCI command

Bus Fault

2--1

Page 50

Setting Up the Support

Table 2--1: Command group symbol table definitions (cont.)

Command group value

IRDY# C/BE2#

Symbol Meaning

FRAME# C/BE1#

PIPE# C/BE0#

AGP_Rd_LP X10 0000

AGP_Rd_HP X10 0001

AGP_Wr_LP X10 0100

AGP_Wr_HP X10 0101

AGP_Lg_Rd_LP X10 1000

AGP_Lg_Rd_HP X10 1001

AGP_Flush X10 1010

AGP_Fence X10 1100

AGP_Ext_Addr X10 1101

AGP_Lg_Rd X10 100X

AGP_Rd X10 000X

AGP_Wr X10 010X

AGP_Cmd X10 XXXX

PCI_Int_Ack 101 0000

PCI_Special 101 0001

PCI_I/O_Rd 101 0010

PCI_I/O_Wr 101 0011

PCI_Mem_Rd 101 0110

PCI_Mem_Wr 101 0111

PCI_Config_Rd 101 1010

PCI_Config_Wr 101 1011

PCI_Mem_Rd_Mul 101 1100

PCI_Ext_Addr 101 1101

PCI_Mem_Rd_Line 101 1110

PCI_Mem_Rd_Inv 101 1111

C/BE3#

AGP Low Priority Read

AGP High Priority Read

AGP Low Priority Write

AGP High Priority Write

AGP Low Priority Long Read

AGP High Priority Long Read

AGP Flush command

AGP Fence command

AGP Extended Address command

AGP Long Read

AGP Read

AGP Write

Any AGP command

PCI Interrupt Acknowledge

PCI Special command

PCI Input/Output Read

PCI Input/Output Write

PCI Memory Read

PCI Memory Write

PCI Configuration Read

PCI Configuration Write

PCI Memory Read Multiple

PCI Extended Address

PCI Memory Read Line

PCI Memory Write and Invalidate

2--2

TMS808 AGP4X Bus State Support

Page 51

Table 2--1: Command group symbol table definitions (cont.)

Command group value

IRDY# C/BE2#

Symbol Meaning

FRAME# C/BE1#

PIPE# C/BE0#

PCI_I/O_R/W 101 001X

PCI_Mem_R/W 101 011X

PCI_Config_R/W 101 101X

PCI_Cmd 101 XXXX

~ 001 XXXX

C/BE3#

PCI Input/Output Read/Write

PCI Memory Read/Write

PCI Configuration Read/Write

Any PCI command

PCI data (not the last data)

Table 2--2 shows the name, bit pattern, and meaning for the symbols in the file

AGP4X_Status, the Status channel group symbol table.

Table 2--2: Status group symbol table definitions

Setting Up the Support

Status group value

ST2

Symbol

GNT# ST0

ST1

- 1XXX

Grant 0111

Rd_LP 0000

Rd_HP 0001

Wr_LP 0010

Wr_HP 0011

Rd 000X

Wr 001X

Rd/Wr 00XX

LP 00X0

HP 00X1

Meaning

Grant not asserted

Transaction Request

Low Priority Read

High Priority Read

Low Priority Write

High Priority Write

Any Read

Any Write

Any Read or Write

Any Low Priority

Any High Priority

TMS808 AGP4X Bus State Support

2--3

Page 52

Setting Up the Support

Table 2--3 shows the name, bit pattern, and meaning for the symbols in the file

AGP4X_Control, the Control channel group symbol table.

Table 2--3: Control group symbol table definitions

Control group value

RBF# REQ# IRDY#

Symbol

RST# PERR# PIPE# DEVSEL#

PME# PAR FRAME# STOP#

Reset 0X XXXX XXXX XXXX

Sys_Err 1X X0XX XXXX XXXX

Par_Err 1X XX0X XXXX XXXX

AGP_Addr 1X XXXX XX01 111X

PCI_Addr 1X XXXX XX10 111X

PCI_Data 1X XXXX XX1X 0001

PCI_Abort 1X XXXX XX1X 0X10

PCI_Discon 1X XXXX XX1X 0X00

IRDY_TRDY 1X XXXX XXXX 00XX

IRDY 1X XXXX XXXX 0XXX

TRDY 1X XXXX XXXX X0XX

Rd_Buf_Fl 1X 0XXX XXXX XXXX

Grant 1X XXXX X0XX XXXX

Request 1X XXXX 0XXX XXXX

Stop 1X XXXX XXXX XXX0

Dev_Sel 1X XXXX XXXX XX0X

Pwr_Mgmt_En 10 XXXX XXXX XXXX

Pipe 1X XXXX XX01 XXXX

Frame 1X XXXX XX10 XXXX

- 11 111X 1111 1111

SERR# GNT# TRDY#

Meaning

Reset

System Error

Parity Error

AGP Address

PCI Address

PCI Data

PCI Target Abort

PCI Target Disconnect

IRDY/TRDY asserted

IRDY asserted

TRDY asserted

Read Buffer Full

Grant asserted

Request asserted

Stop asserted

Device Select asserted

Power Management Enable

PIPE asserted

Frame asserted

Bus inactive

2--4

TMS808 AGP4X Bus State Support

Page 53

Table 2--4 shows the name, bit pattern, and meaning for the symbols in the file

AGP4X_SBA_Cmd, the SBA_Hi Command channel group symbol table.

Table 2--4: SBA_Hi Command group symbol table definitions

SBA_Hi Command group value

D_SBA15 D_SBA11

D_SBA14 D_SBA10

Symbol

SYNC

NOP

Type_4

Type_3

Invalid

Rd_LP

Rd_HP

Reserved

Reserved

Wr_LP

Wr_HP

Reserved

Reserved

L_Rd_LP

L_Rd_HP

Flush

Reserved

Fence

DAC

Reserved

Reserved

Invalid

Type_1

Reserved

D_SBA13 D_SBA9

D_SBA12 D_SBA8

1111 1110

1111 1111

1110 XXXX

1100 XXXX

1101 XXXX

1000 000X

1000 010X

1000 100X

1000 110X

1001 000X

1001 010X

1001 100X

1001 110X

1010 000X

1010 010X

1010 100X

1010 110X

1011 000X

1011 010X

1011 100X

1011 110X

10XX XX1X

0XXX XXXX

1111 0XXX

Setting Up the Support

Meaning

Synchronization cycle

NOP

Extended address

Upper address

Invalid

Read, low priority

Read, high priority

Reserved command

Reserved command

Write, low priority

Write, high priority

Reserved command

Reserved command

Long read, low priority

Long read, high priority

Flush command

Reserved command

Fence command

Dual address cycle

Reserved command

Reserved command

Invalid

Lower address

Reserved command

TMS808 AGP4X Bus State Support

2--5

Page 54

Setting Up the Support

How Data is Acquired

This part of the chapter explains how the module acquires AGP4X signals using

the TMS 808 software and probe adapter. This part also provides additional

information on bus signals accessible on or not accessible on the probe adapter,

and on extra probe channels available for you to use for additional connections, if

any.

Custom Clocking

Clocking Options

A special clocking program is loaded to the module every time you load the

AGP4X or AGP2X support. This special clocking is called Custom.

With Custom clocking, the module logs in signals from multiple groups of

channels at different times as they become valid on the AGP4X bus. The module

then sends all the logged-in signals to the trigger machine and to the memory of

the module for storage.

Although all cycle types are acquired, there are too many to illustrate in this

manual. Refer to the AGP4X Interface Specifications for descriptions of the other

cycle types.

There are two field settings in the clocking options for the AGP4X and AGP2X:

Address Enqueuing and Acquisition Edge. The first field is called Address

Enqueuing, and its selections are as follows:

H On AD Bus Only

H On SBA Bus Only Default

The selection On AD Bus Only is used to indicate the enqueuing of the addresses

using the PIPE# signal. The addresses are now available on the AD[31..0] bus in

this mode. The On AD Bus Only is used whenever the AGP master (AGP4X

connector) uses the AD bus in a multiplexed manner for transferring and data

information.

2--6

The selection On SBA Bus Only is used to indicate the enqueuing of the

addresses using the Side Band strobe signals. The addresses are now available on

the SBA[7..0] bus in this mode. The On SBA Bus Only selection is used

whenever the AGP master (AGP4X connector) has implemented side band

signals and uses them to enqueue requests. The On SBA Bus Only selection is

potentially the higher performance method; therefore, its defined as the default.

The second field is called Acquisition Edge, and its selections are as follows:

H Active Cycles Only Default

H Rising Only

H Falling Only

TMS808 AGP4X Bus State Support

Page 55

Setting Up the Support

H Rising & Falling

The selection Active Cycles Only clocks in only those cycles which have valid

data on the AD[31..0], SBA[7..0], C/BE[3-0]#, and the ST[2..0] buses. The

Active Cycles Only selection is used to acquire data. In this mode the AGP4X

support will correctly identify valid cycles and display them. Active Cycles Only

is defined as the default.

The selection Rising Only CLK Edge clocks in all the channels on the rising

edge of the AGP CLK signal. The Rising Only selection will not acquire AGP

cycles correctly, but can acquire PCI type cycles, even if qualifying signals are

not present.

The following selections Falling Only and Rising & Falling are used only if data

capture at the particular edge of AGP clock is important, even if the qualifying

signals are not present.

The selection Falling Only CLK Edge clocks in all the channels on the falling

edge of the AGP CLK signal.

Setup/Hold Adjustment

Procedure

The selection Rising & Falling CLK Edge clocks in all the channels on both the

rising and falling edges of the AGP CLK signal.

The purpose of this Setup/Hold adjustment procedure is to determine if the

Setup/Hold values need to be adjusted to remove timing violations, so that the

state data will be accurately displayed on the logic analyzer. The minimum

Setup/Hold requirement for logic analyzer using merged modules is 2.5 ns/0 ns

typical (3.5 ns/0 ns worst case).

The AGP4X support uses CLK edges to log in both the CLK synchronous and

source synchronous signals. The source synchronous signals can be shifted in

time with respect to the CLK according to the AGP specifications. Therefore, the

D_AD_STB or the D_SB_STB may not be stable within the Setup/Hold time

period required by the logic analyzer with respect to the rising or falling AGP

CLK edge. This may cause a Setup/Hold violation in the logic analyzer.

The signal D_AD_STB is a derived signal which is used to do the Setup/Hold

adjustment of the D_AD_Strobe, AGP_Data_Hi, AGP_Data_Lo, BE_Hi and

BE_Lo groups. The D_AD_STB signal is in the D_AD_Strobe group.

Similarly, the signal D_SB_STB is a derived signal which is used to do the

Setup/Hold adjustment of the D_SB_Strobe, SBA_Hi and SBA_Lo groups. The

D_SB_STB signal is in the D_SB_Strobe group.

Follow all steps, review the case studies and Figures 2--1 through 2--4 to

determine if the Setup/Hold adjustments are required. You may also want to

review the previous Setup/Hold statements.

1. Check that your graphics card is programmed for 4X mode.

TMS808 AGP4X Bus State Support

2--7

Page 56

Setting Up the Support

2. Start a looping graphics program.

3. Load the AGP4X software from the disk to the logic analyzer.

4. To load the AGP4X support package from the logic analyzer System

window, select the File menu > Load Support Package.

5. From the Load Support Package window, select AGP4X, select load, and

then select Yes.

Setup MagniVu. Follow these steps to set up a MagniVu window:

1. From the logic analyzer System window, select the Window menu > New

Data Window.

2. From the New Data Window, select Waveform, select Next, select AGP4X

MagniVu, and then select Next.

3. Select finish. The New Data Window disappears and a waveform window is

displayed.

Set Up the Trigger. Follow these steps to set up the Trigger to capture the

D_AD_STB signal:

1. Select the System window, and then select Trig.

2. From the Trigger: AGP4X window, select If and fill in the four displayed

fields with the following information.

First field Channel

Second field AD_STB_0

Third field =

Fourth field Low

3. Select OK.

4. Select the Waveform window, and then select Run. Wait for the TLA to

capture and display the D_AD_STB waveform.

2--8

TMS808 AGP4X Bus State Support

Page 57

Setting Up the Support

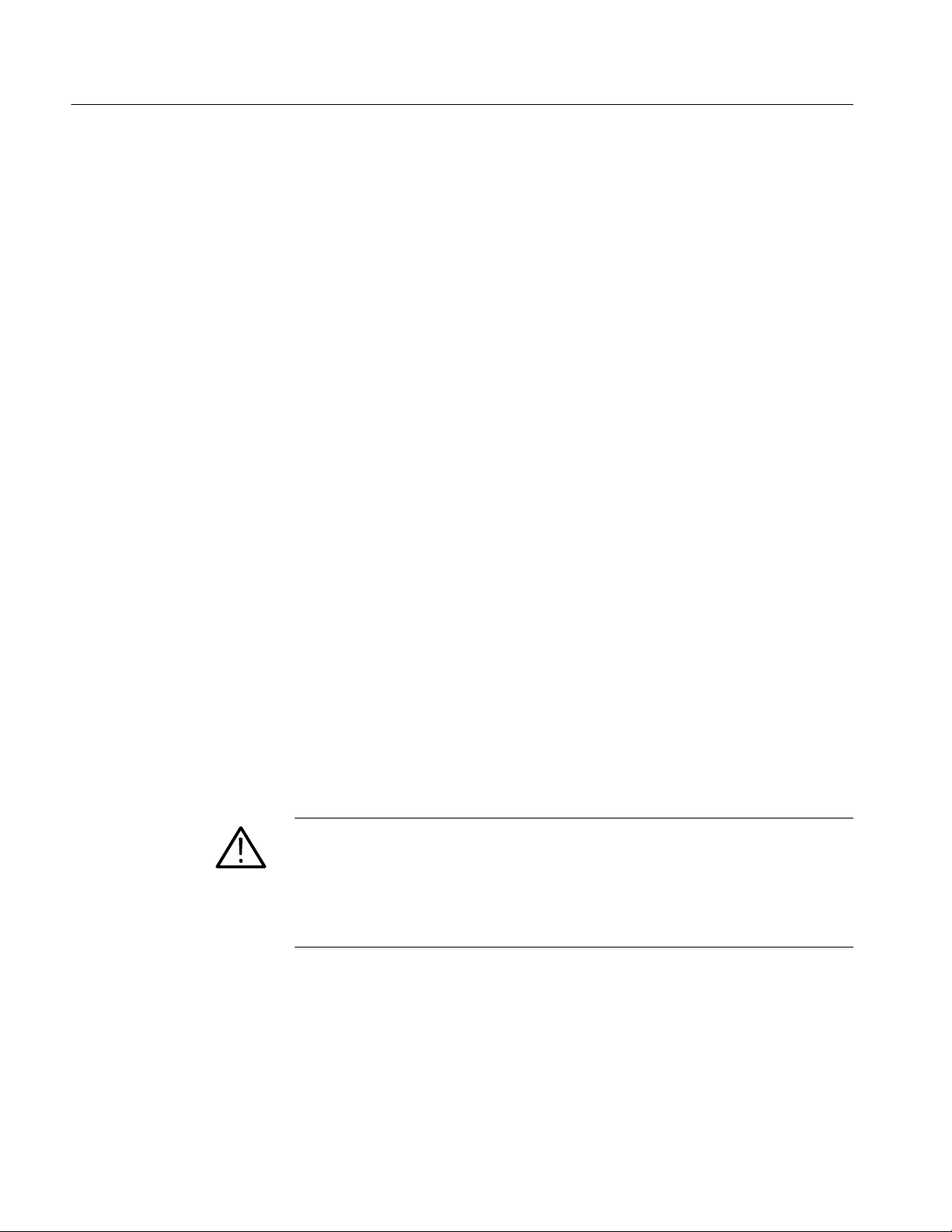

Consider the following case:

In Figure 2--1, the D_AD_STB signal has sufficient Setup/Hold time with respect

to the CLK edge. In this case, no adjustment is required.

2.5 ns

CLK

D_AD_STB

Signal change occurs greater than 2.5 ns

before a rising or falling CLK edge

2.5 ns

Figure 2--1: Examples of sufficient setup/hold times

Consider the next case:

In Figure 2--4, the D_AD_STB signal is changing within 2.5 ns of the CLK edge.

You will need to modify the default Setup/Hold values by following these steps:

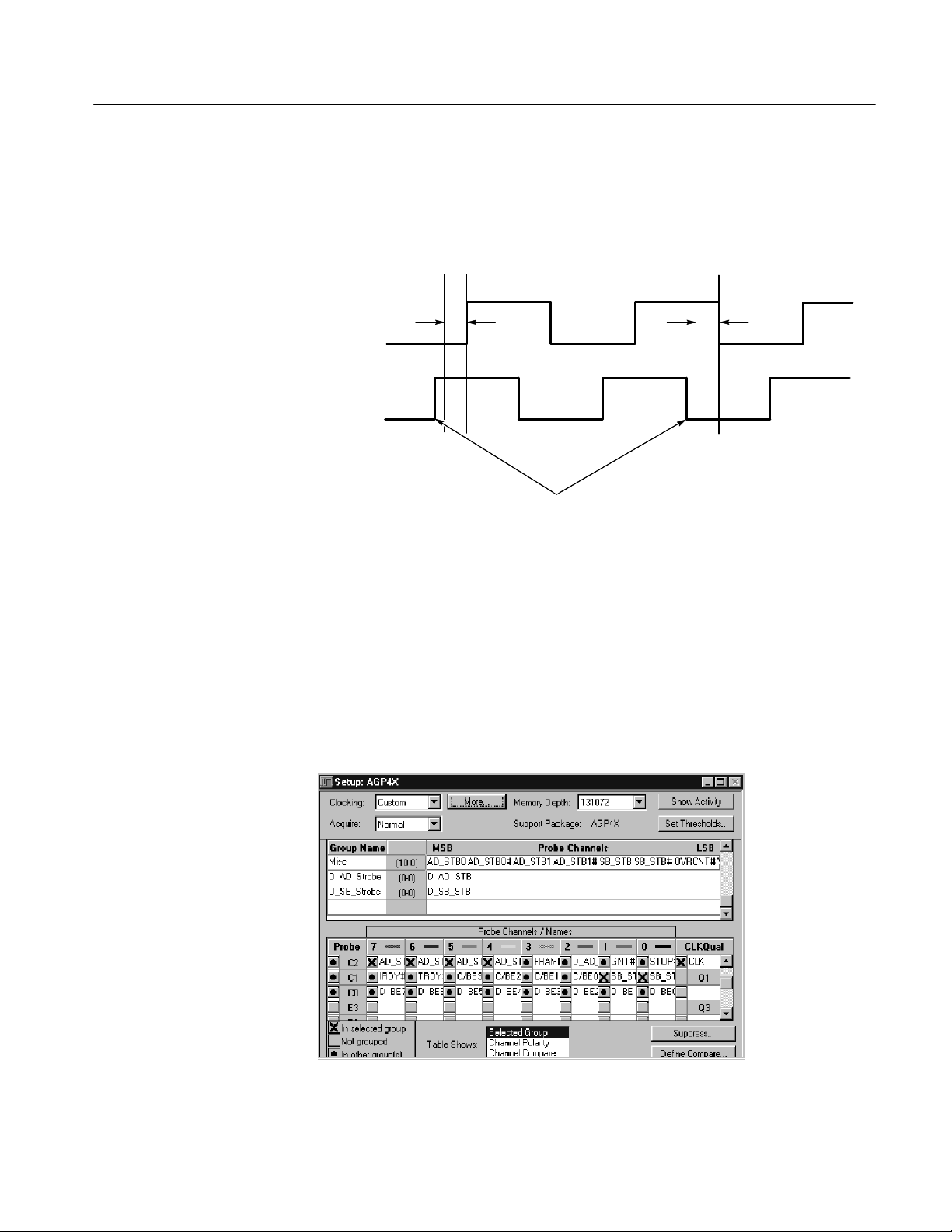

1. In the System window, click Setup. In the Setup:AGP4X window, click More

(see Figure 2--2).

Figure 2--2: Setup:AGP4X window

TMS808 AGP4X Bus State Support

2--9

Page 58

Setting Up the Support

2. In the Custom Options window, under the Setup/Hold Window, scroll down

and click on the Support Package Default heading for D_AD_Strobe.

3. Select --500 ps/2.5 ns. Click OK (see Figure 2--3).

Figure 2--3: Custom option window

In this case, the Setup/Hold value is --0.5 ns Setup/2.5ns Hold. Each case may

require different values. Be sure to select Setup/Hold values that are not violated

by D_AD_STB.

2.5 ns

CLK

D_AD_STB

2.5 ns

Signal change occurs within

2.5 ns of rising CLK edge

Signal change occurs within

2.5 ns of falling CLK edge

Figure 2--4: Setup/hold time violation examples

Once the Setup/Hold values for the D_AD_STB signal (that is, the

D_AD_Strobe group) are determined, the same values must be entered in the

AGP_Data_Hi, AGP_Data_Lo, BE_Hi and BE_Lo groups.

2--10

TMS808 AGP4X Bus State Support

Page 59

Setting Up the Support

NOTE. Since the AD_STB timings with respect to CLK can be different for READs

and WRITEs, the Setup/Hold time should satisfy the condition in both cases so

that data can be accurately logged for AGP READs and AGP WRITEs.

Similarly, the Setup/Hold values for the D_SB_STB signal (that is, D_SB_Strobe

group) are determined and the same values are to be entered in the SBA_Hi and

SBA_Lo groups.

Signals Not On the Probe

Adapter

Extra Channels

The TMS 808 probe adapter provides access for all of the AGP4X signals.

The following channels on the logic analyzer are left free for you to connect to

other signals of interest:

H Hi_E3:7-0 (for 136 channel module only)

H Hi_E2:7-0 (for 136 channel module only)

H Hi_E1:7-0 (for 136 channel module only)

H Hi_E0:7-0 (for 136 channel module only)

H Hi_C3:7-0

H Hi_C1:7-0

H Hi_C0:7-0

H Hi_A1:1-0

TMS808 AGP4X Bus State Support

2--11

Page 60

Setting Up the Support

2--12

TMS808 AGP4X Bus State Support

Page 61

Specifications

Page 62

Page 63

Specifications

Circuit Description

This chapter contains information regarding the specifications of the support.

AGP4X support uses two distinctive types of transactions on the same physical

bus, depending on which of the signals the transaction is synchronized to. The

first set is synchronized to the 66 MHz AGP clock, and the second set is

synchronized to the strobe signals. The timing relationship of the Strobe signals

to the Clock is described in detail in the Accelerated Graphics Port Interface

Specification, Intel, Version 2.0, 1998.

The AGP bus is a point to point bus and its behavior with an added third load is

not specifified. If a third load (like the probe adapter) is added, it is the responsibility of the user to ensure that the system meets the AGP Interface specifications. The loading information and equivalent circuits for the probe adapter is

provided on page 3--6. The critical timing constraints are mainly in the form of

skew budget, which are separately allocated for the motherboard and the AGP4X

connector.

The interface point between the motherboard and the AGP4X connector comes

on the transmission line of the signals. So when probing the signals at the

connector, you will encounter a composite signal made of the ongoing transmission and the reflection from the receiving end, as the AGP bus is source

terminated. As the signaling period reduces and approaches the transit time over

the bus length, it becomes very difficult to extract valid data from the composite

waveform. In the case of TMS 808 support, circuitry on the extender board

performs the task of extracting digital signals from the composite wave present

on the bus.

Once the digital signals are extracted, the transactions need to be captured by the

Logic Analyzer. The two issues involved are a high data rate (266 MHz), that is

more than the logic analyzer module can handle and two types of synchronization, as mentioned previously.

The first issue, high data rate, is handled by demultiplexing the data, reducing the

rate to 133 MHz. At this rate, the logic analyzer is able to directly acquire the

data presented. The respective Strobe signals are used to latch data in latches, and

both edges of the AGP clock are used to log these latched outputs.

The second issue, two types of synchronization, are shown in the block diagram

of the logic circuit, which implements demultiplexing the data (see Figure 3--1).

TMS808 AGP4X Bus State Support

3--1

Page 64

Specifications

AD [31--0]

AD_STB0

RST~

AD_STB0#

AD [31--0]

Figure 3--1: Block diagram for AD bus

The first data value on the 32-bit bus is latched into latch D1 by the falling edge

of AD_STB0. In fact, the lower significant 16 bits uses AD_STB0 and the upper

significant 16 bits uses AD_STB1, but for simplicity, the block diagram shows

only a single 32 bit latch. The falling edge of the complementary strobe

AD_STB0# latches the second data in D2, at the same time moving the data at

the output of D1 into another latch D3. This is done to avoid the D1 data being

overwritten by the next edge of the AD_STB0. More than three strobe edges

cannot be accommodated in one half cycle of AGP clock, so the TLA always

gets a chance to acquire the data before it gets overwritten. When lower speed

(1X, PCI for example) cycles are being run, TLA picks up the AD bus information directly from the bus rather than from the latched output. On the user

interface, the latched AD bus data appears as AGP_Data_Hi and AGP_Data_Lo.

D1

D2

CLK

CLK

MR

MR

Q1

Q2

D3

CLK

32 bits

MR

Q3

32 bits32 bits

To TL A

64 bits

3--2

The same principle is applied on the side band signals, using another set of

latches (see Figure 3--2).

TMS808 AGP4X Bus State Support

Page 65

Specifications

SBA [7--0]

SB_STB

RST~

SB_STB#

SBA [7--0]

Figure 3--2: Block diagram for the SBA bus

The 32-bit AD bus splits into a 64-bit bus at the logic analyzer input, and the

8-bit SBA bus splits into 16 bits. After this, latched data is valid up to 7.5 ns, in

most cases it will provide the necessary setup time for the logic analyzer, even if

the AGP clock is used for logging in data. In rare instances, the clock-edge-tostrobe timing may have a setup/hold violation in the logic analyzer. In this case,

the adjustable Setup/Hold values of the logic analyzer can be used to make

accurate data acquisitions.

D1 Q1

CLK

D2

CLK

MR

Q2

MR

D3 Q3

CLK

MR

8 bits

8 bits8 bits

To TL A

16 bits

For the logic analyzer to detect the availability of fresh data, a qualifier is

required that can be reliably acquired at the same acquisition speed. Since no

signal from the AGP bus can be used for this purpose, two signals are derived

from the strobe. A single-toggle flip-flop is used to generate the common

qualifier D_AD_STB. Data is always logged in as 64 bits into the logic analyzer.

Only when the second set of data arrives on the falling edge of the AD_STB0#,

is the data logged in as 64 bits. Also, the support makes use of the fact that there

are always 4 falling edges occurring in the AGP4x; irrespective, of whether the

data is valid or not. Similarly another qualifier is derived for the SBA signals (see

Figure 3--3).

TMS808 AGP4X Bus State Support

3--3

Page 66

Specifications

TQ

AD_ STB0#

MR

RST~

D_AD_STB

Figure 3--3: Qualifier generation

The AGP 2X support included with this package operates in a similar manner.

The only difference is that the derived qualifiers get replaced by the corresponding strobe signals themselves.

The support masters all signals in all three cases; when an AGP transfer is on the