Page 1

Instruction Manual

TMS711

320C6211/C6711 Microprocessor Support

071-0877-00

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © T ektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

SOFTWARE WARRANTY

T ektronix warrants that the media on which this software product is furnished and the encoding of the programs on

the media will be free from defects in materials and workmanship for a period of three (3) months from the date of

shipment. If a medium or encoding proves defective during the warranty period, T ektronix will provide a

replacement in exchange for the defective medium. Except as to the media on which this software product is

furnished, this software product is provided “as is” without warranty of any kind, either express or implied.

T ektronix does not warrant that the functions contained in this software product will meet Customer’s

requirements or that the operation of the programs will be uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period. If T ektronix is unable to provide a replacement that is free from defects in materials and

workmanship within a reasonable time thereafter, Customer may terminate the license for this software product

and return this software product and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S PAYMENT IS

THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS

WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER

TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Table of Contents

Getting Started

Operating Basics

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Conventions ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Support Package Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Analyzer Software Compatibility 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Analyzer Configuration 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements and Restrictions 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functionality Not Supported 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features not T ested 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Miscellaneous 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Logic Analyzer to a System Under T est 1–5. . . . . . . . . . . . . . . . . . .

Setting Up the Support 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Support Software 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel Group Definitions 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Support Package Setups 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clocking 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquiring and Viewing Disassembled Data 2–13. . . . . . . . . . . . . . . . . . . . .

Acquiring Data 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Disassembled Data 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Display Format 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Display Format 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Display Format 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Flow Display Format 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subroutine Display Format 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing How Data is Displayed 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Display Selections 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Micro Specific Fields 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Marking Cycles 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing an Example of Disassembled Data 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

Replaceable Parts

Index

TMS711 320C6211/C6711 Microprocessor Support

i

Page 6

Table of Contents

List of Figures

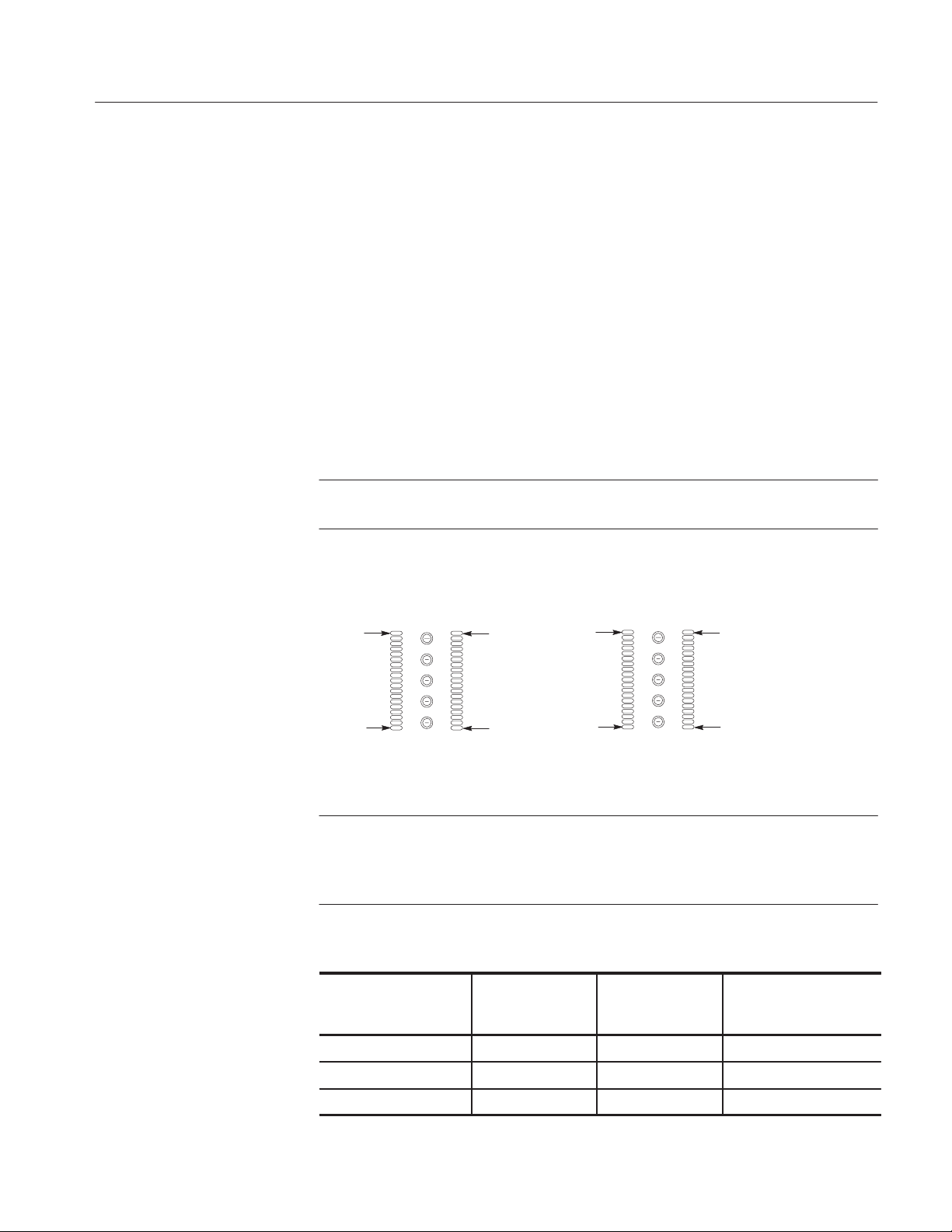

Figure 2–1: Bus timing for the SBSRAM Read cycle with a burst of four

data transitions 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: SDSRAM Write cycles with a burst of four data

transitions 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–3: Bus timing for the ASYNC read cycle 2–7. . . . . . . . . . . . . . .

Figure 2–4: Bus timing for the ASYNC write cycle 2–8. . . . . . . . . . . . . . .

Figure 2–5: Bus timing for the SDRAM fetch cycle with

CAS latency of 3 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–6: SDRAM Write cycle with default of four data transitions 2–11

Figure 2–7: Hardware display format 2–15. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–8: 2–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–1: Pin assignments for a Mictor connector

(component side) 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

TMS711 320C6211/C6711 Microprocessor Support

Page 7

List of Tables

Table of Contents

Table 2–1: Signal acquisition in SBSRAM Read cycle 2–4. . . . . . . . . . . .

Table 2–2: Signal acquisition in SBSRAM Write cycle 2–6. . . . . . . . . . .

Table 2–3: Signal acquisition in ASYNC Write cycle 2–8. . . . . . . . . . . . .

Table 2–4: Signal acquisition in ASYNC Write cycle 2–9. . . . . . . . . . . . .

Table 2–5: Signal acquisition in SDRAM fetch cycle with

CAS latency of 3 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–6: Signal acquisiton in SDRAM write cycle with

CAS latency of 3 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–7: Description of special characters in the display 2–13. . . . . . . .

Table 2–8: Cycle type definitions 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–9: C6211/C6711 Compatible SDRAM Memory

Configuration 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–1: C6211 Electrical specifications 3–1. . . . . . . . . . . . . . . . . . . . .

Table 3–2: C6711 Electrical Specifications 3–2. . . . . . . . . . . . . . . . . . . . .

Table 5–1: Control symbol table definitions 5–1. . . . . . . . . . . . . . . . . . . .

Table 5–2: Address channel group assignments 5–3. . . . . . . . . . . . . . . . .

Table 5–3: Data channel group assignments 5–3. . . . . . . . . . . . . . . . . . . .

Table 5–4: Control channel group assignments 5–5. . . . . . . . . . . . . . . . . .

Table 5–5: Async channel group assignments 5–5. . . . . . . . . . . . . . . . . . .

Table 5–6: CEnable channel group assignments 5–5. . . . . . . . . . . . . . . . .

Table 5–7: BEnable channel group assignments 5–5. . . . . . . . . . . . . . . . .

Table 5–8: Misc channel group assignments 5–6. . . . . . . . . . . . . . . . . . . .

Table 5–9: Clock and Qualifier channel assignments 5–6. . . . . . . . . . . . .

Table 5–10: CPU to Mictor connections for Mictor A pins 5–7. . . . . . . .

Table 5–11: CPU to Mictor connections for Mictor D pins 5–9. . . . . . . .

Table 5–12: CPU to Mictor connections for Mictor C pins 5–10. . . . . . . .

Table 5–13: CPU to Mictor connections for CEnable 5–10. . . . . . . . . . . . .

Table 5–14: CPU to Mictor connections for BEnable 5–10. . . . . . . . . . . . .

Table 5–15: CPU to Mictor connections for Misc 5–11. . . . . . . . . . . . . . . .

Table 5–16: CPU to Mictor connections for clock and qualifiers 5–11. . .

TMS711 320C6211/C6711 Microprocessor Support

iii

Page 8

Table of Contents

iv

TMS711 320C6211/C6711 Microprocessor Support

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

To Avoid Fire or Personal Injury

Connect and Disconnect Properly . Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is indirectly grounded through the grounding

conductor of the mainframe power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground. Before making connections to the

input or output terminals of the product, ensure that the product is properly

grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and marking on the product. Consult the product manual for further ratings

information before making connections to the product.

The common terminal is at ground potential. Do not connect the common

terminal to elevated voltages.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

TMS711 320C6211/C6711 Microprocessor Support

v

Page 10

General Safety Summary

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) T erminal

CAUTION

Refer to Manual

Double

Insulated

vi

TMS711 320C6211/C6711 Microprocessor Support

Page 11

Preface

Manual Conventions

This instruction manual contains specific information about the TMS711

320C6211/C6711 microprocessor support package and is part of a set of

information on how to operate this product on compatible Tektronix logic

analyzers.

If you are familiar with operating microprocessor support packages on the logic

analyzer for which the TMS711 320C6211/C6711 support was purchased, you

will only need this instruction manual to set up and run the support.

If you are not familiar with operating microprocessor support packages, you will

need to supplement this instruction manual with information on basic operations

to set up and run the support. See Manual Conventions below for more information.

This manual uses the following conventions:

H The term “disassembler” refers to the software that disassembles bus cycles

into instruction mnemonics and cycle types.

H The phrase “information on basic operations” refers to online help, an

installation manual, or a user manual covering the basic operations of

microprocessor support.

TMS711 320C6211/C6711 Microprocessor Support

vii

Page 12

Preface

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

1-503-627-2400

6:00 a.m. – 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

viii

TMS711 320C6211/C6711 Microprocessor Support

Page 13

Getting Started

Page 14

Page 15

Getting Started

This chapter contains information on the TMS711 320C6211/C6711 microprocessor support package, and information on connecting your logic analyzer to

your system under test.

Support Package Description

The TMS711 320C6211/C6711microprocessor support package displays

disassembled data from systems based on the Texas Instruments C6211/C6711

microprocessor.

To use this support efficiently, you need to have the items listed in the information on basic operations and the following documents:

H TMS320C6000 CPU and Instruction Set Reference Guide, Literature

Number: SPRU189D, March 1999.

H TMS320C6000 Peripheral Reference Guide, Literature Number: SPRU190C,

April 1999.

H TMS320C6000 EMIF to External SDRAM/SGRAM Interface, Literature

Number: SPRA433A, June 1999.

H TMS320C6000 EMIF to External SBSRAM Interface, Literature Number:

SPRA533A, April 1999.

H TMS320C6000 Digital Signal Processor Data Sheet, Literature Number:

SPRS073, March 1999.

H TMS320C6000 EMIF to External Asynchronous SRAM Interface, Literature

Number: SPRA542, April 1999.

Information on basic operations also contains a general description of support.

Logic Analyzer Software Compatibility

The floppy disk label on the microprocessor support states which version of logic

analyzer software this support is compatible with.

TMS711 320C6211/C6711 Microprocessor Support

1–1

Page 16

Getting Started

Logic Analyzer Configuration

The TMS711 320C6211/C6711support requires a minimum of one 102-channel

module.

NOTE. It is recommended that a logic analyzer acquisition module with a

maximum bus speed of 100 MHz be required when ECLKOUT = 100 MHz

(maximum). For ECLKOUT above 100 MHz (maximum), a logic analyzer

acquisition module with a maximum bus speed of 200 MHz is required.

Requirements and Restrictions

You should review the general requirements and restrictions of microprocessor

support packages in the information on basic operations as they pertain to your

system under test.

System Clock Rate

NonIntrusive Acquisition

Disabling the Instruction

Cache

L2 Cache

You should also review electrical, environmental, and mechanical specifications

in Specifications on page 3–1 as they pertain to your system under test, as well as

the following descriptions of other C6211/C6711 support requirements and

restrictions.

The operating speeds that the C6211/C6711

C6211/C6711 microprocessor are listed on Table 3–1. These specification were

valid at the time this manual was printed. Please contact your Tektronix Sales

Representative for current information on the fastest devices supported.

Acquiring microprocessor bus cycles will be non intrusive to the system under

test. That is, the C6211/C6711 support will not intercept, modify, or present

signals back to the system under test.

To display disassembled acquired data, you must disable the internal instruction

cache. Disabling the cache makes all instruction prefetches visible on the bus

they then can be acquired and displayed disassembled.

Do not configure L2 cache as cache; or external memory bus cycle acquisitions

will not occur with L2 cache.

support can acquire data from the

1–2

Write Cycle

SBSRAM Write Cycle and SDRAM Write Cycle have the same control values,

so they are represented by a single name. For example SDWRITE/SBSWRITE

for a given sequence in the control column, but the corresponding mnemonic

TMS711 320C6211/C6711 Microprocessor Support

Page 17

Getting Started

column will have clear cut labels, for example ( SDRAM WRITE CYCLE ) and

( SBSRAM WRITE CYCLE ).

Read Cycle

Opcode Fetch/Data Read.

Symbol 11111[bin]

Conditional Branches

SBSRAM Read Cycle and SDRAM Read Cycle have same control values, so

they are represented by a single name. For example SDREAD/SBSREAD for a

given sequence in the control column, but the corresponding mnemonic column

will have clear cut labels, for example ( SDRAM READ CYCLE ) and

( SBSRAM READ CYCLE ).

The C6211/C6711 support does not provide a signal to distinguish between Data

Read and Opcode Fetch. The TMS711 320C6211/C6711 support makes a

reasonable estimate at looking at the address values of a few sequences around

the current sequence or by looking at the processor signal. Yet, in some instances

you may need to use the Mark Opcode function.

The Control symbol table does not have a symbol for 11111[bin], since it can

mean SDRAM Read, Write, or Fetch.

Flushes cannot be shown for conditional branches (where Condition is True)

when the branch instruction is in the first fetch packet, and the target address is in

third and fourth fetch packet from the fetch packet which has Branch instructions

(in either forward or reverse branches).

Alternate Fetch Packet

Branch Instructions

Memory Types

SBSRAM 4

Memory-Space Signals

If a conditional branch instruction is in the fetch packet, and the target address is

in the alternate fetch packet (from the fetch packet which has the branch

instruction; for example 1 to 3 , 2 to 4, or 3 to 5) we do not show flushes, since

fetch packets appear in sequence.

For branch instructions (both conditional and unconditional): B.S2 IRP, B.S2

NRP and B.S2 src2reg, we do not show whether a branch was taken or not in the

listing window of our disassembly. Since we cannot get the contents of the

registers IRP, NRP, Bxx that have the target address.

The C6211/C6711

memory types: SDRAM, SBSRAM, and ASYNC, at a time.

SBSRAM 4 word burst Read and write cycles are supported. But SBSRAM 6

word burst Read and write cycles not supported due to timing considerations.

All Memory space signals CE[3–0]~ must be connected to the logic analyzer.

support disassembles the execution from any one of the

TMS711 320C6211/C6711 Microprocessor Support

1–3

Page 18

Getting Started

External Memory

In the C6211

programs only at addresses in multiples of 0x20; for example, 80000000,

80000020,80000040. Hence, the user input fields for entering the start address of

the Interrupt-Service-Fetch packets must be appropriate.

Functionality Not Supported

Microprocessor

Alternate Bus master

The signals: HPI, MCBSP 0 & 1, and JTAG are not acquired. If you want to view

these signals, you need to find an alternate way to probe them.

Alternative bus master transactions are acquired by the C6211/C6711 support and

are not disassembled.

Features not Tested

The C6211/C6711 support has been tested for C6711 floating point instructions

by editing the refmem. The C6211/C6711 support is not evaluated by acquiring

cycles from a dedicated C6711 evaluation board.

external memory you can download the C6211/C6711 support

Miscellaneous

The C6211/C6711 support disassembles SDRAM, SBSRAM and ASYNC

memory cycles. The C6211/C6711 support is not tested for SBSRAM and

ASYNC cycles. This C6211/C6711 support has been tested only with 32bit

SDRAM cycles.

The C6211/C6711 support has not been tested for Interrupts.

The C6211/C6711 support has not been tested for Big Endian mode.

The Address shown for the SDRAM ACTV cycle is the row address for the

corresponding user input for the SDRAM Address Configuration.

1–4

TMS711 320C6211/C6711 Microprocessor Support

Page 19

Connecting the Logic Analyzer to a System Under Test

You can use channel probes, clock probes, and leadsets with a commercial test

clip (or adapter) to make connections between the logic analyzer and your system

under test.

To connect the probes to C6211/C6711 signals in the system under test using a

test clip, follow these steps:

1. Turn off power to your system under test. It is not necessary to turn off

power to the logic analyzer.

CAUTION. Static discharge can damage the microprocessor, the probes, and the

logic analyzer module. To prevent static damage, handle these components only

in a static-free environment.

Always wear a grounding wrist strap, heel strap, or similar device while

handling the microprocessor.

Getting Started

2. To discharge your stored static electricity, touch the ground connector located

on the back of the logic analyzer. If you are using a test clip, touch any of the

ground pins on the clip to discharge stored static electricity from the test clip.

CAUTION. Failure to place the system under test on a horizontal surface before

connecting the test clip can permanently damage the pins on the microprocessor.

3. Place the system under test on a horizontal static-free surface.

4. Use Tables 5–2 through 5–16 beginning on page 5–3 to connect the channel

probes to C6211/C6711 signal pins on the test clip or in the system under

test.

Use leadsets to connect at least one ground lead from each channel probe and

the ground lead from each clock probe to ground pins on your test clip.

TMS711 320C6211/C6711 Microprocessor Support

1–5

Page 20

Getting Started

1–6

TMS711 320C6211/C6711 Microprocessor Support

Page 21

Operating Basics

Page 22

Page 23

Setting Up the Support

The information in this section is specific to the operations and functions of the

TMS711 320C6211/C6711 microprocessor support on any Tektronix logic

analyzer for which it can be purchased.

Before you acquire and display disassembled data, you need to load the support

and specify setups for clocking and triggering as described in the information on

basic operations. The microprocessor support provides default values for each of

these setups as well as user-definable settings.

Installing the Support Software

NOTE. Before you install any software, it is recommended you verify that the

microprocessor support software is compatible with the logic analyzer software.

To install the TMS711 320C6211/C6711 software on your Tektronix logic

analyzer, follow these steps:

1. Insert the floppy disk in the disk drive.

2. Click the Windows Start button, point to Settings, and click Control Panel.

3. In the Control Panel window, double-click Add/Remove Programs.

4. Follow the instructions on the screen for installing the software from the

To remove or uninstall software, follow the above instructions and select

Uninstall. You must close all windows before you uninstall any software.

Channel Group Definitions

The software automatically defines channel groups for the support. The channel

groups for the TMS711 320C6211/C6711 support are Address, Data, Control,

Async, CEnable, BEnable, and Misc. The channel groups tables begin on page

5–1.

floppy disk.

TMS711 320C6211/C6711 Microprocessor Support

2–1

Page 24

Setting Up the Support

Support Package Setups

The TMS711 320C6211/C6711 software installs C6211 support package setup

file.

Clocking

C6211 Setup

Options

This setup provides disassembly support. All signals are not inverted and

displayed as they appear electrically on the front side bus.

Disassembly channel groups:

Address Data Async CEnable

BEnable Misc

The TMS711 320C6211/C6711support offers a microprocessor-specific clocking

mode for the C6211/C6711 microprocessor. This clocking mode is the default

selection whenever you load the TMS711 320C6211/C6711 support.

Disassembly will not be correct with the Internal or External clocking modes.

Information on basic operations describes in more detail how to use these clock

selections for general purpose analysis.

H Internal clocking is used for timing and is based on the clock generated by a

Tektronix logic analyzer. You can configure the clock rate from 50 ms down

to 4 ns resolution.

H External clocking is used when you configure the clocking of data based on

logical combinations of clocks and qualifiers.

2–2

TMS711 320C6211/C6711 Microprocessor Support

Page 25

Setting Up the Support

Custom Clocking

When Custom is selected, the Custom Clocking Options menu will have the

subtitle C6211

will also be displayed.

The TMS711 320C6211/C6711support has three clock state machines (CSM).

There is one select field with the label Memory Type: that field will contain the

following selections: ASYNC, SBSRAM, and SDRAM.

Memory operation type:

ASYNC Selects CSM for ASYNC (default)

SBSRAM Selects CSM for SBSRAM

SDRAM Selects CSM for SDRAM

CAS Latency . Choose this field for only SDRAM Clocking state machine. There

are two options:

Two Choose for CAS latency two

Three Choose for CAS latency three

Setup and Hold Time. The user can change the Setup and Hold time window of all

the signal groups. The default Setup time is 2.5 ns and the Hold time is 0 ns. The

user defined Setup and Hold will have precedence over any default Setup and

Hold time.

Microprocessor Clocking Support added, and the clocking options

NOTE. The signals present in the Async group are also present in the Control

group. The Setup and Hold values entered for the first one of those groups are

used for all instances of that channel in the other groups.

TMS711 320C6211/C6711 Microprocessor Support

2–3

Page 26

Setting Up the Support

Á

Á

Á

Á

Á

Á

Á

Á

БББББ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

БББББ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

БББББ

Á

Á

Á

Á

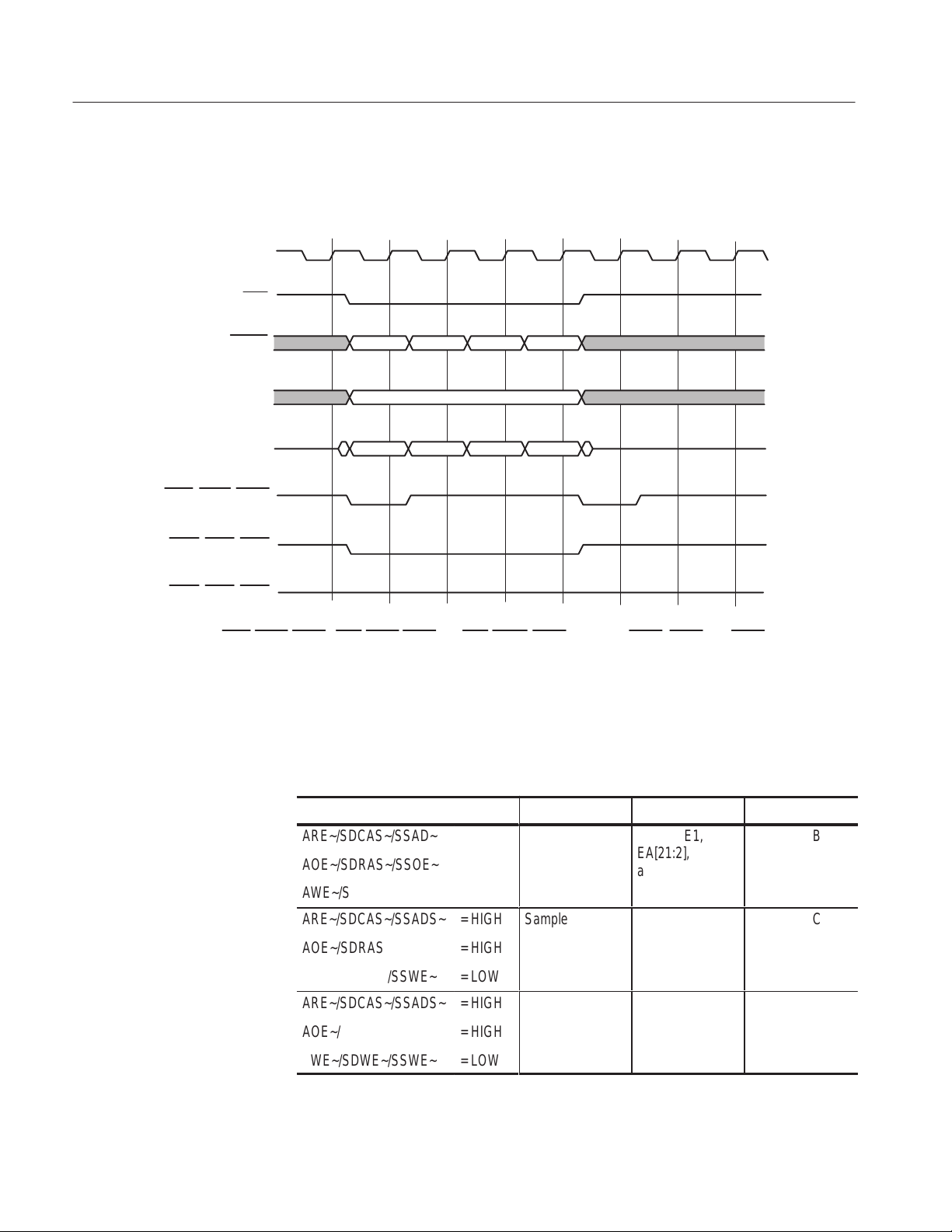

ECLKOUT

Figures 2–1 through 2–6 illustrate the bus timing for the SBSRAM, ASYNC, and

SDRAM memory operations. The Custom Clock is the rising edge of the

ECLKOUT.

CEx

BE(3:0)

EA(21:2)

ED(31:0)

BE1

BE2

BE3 BE4

EA

Q1 Q2 Q3 Q4

ARE/SDCAS/SSADS*

AOE/SDRAS/SSOE

*

AWE/SDWE/SSWE*

ABCDEFGH

Note: *ARE/SDCAS/SSADS, AOE/SDRAS/SSOE and AWE/SDWE/SSWE operate as SSADS, SSOE and SSWE,

respectively, during SBSRAM accesses.

Figure 2–1: Bus timing for the SBSRAM Read cycle with a burst of four data

transitions

2–4

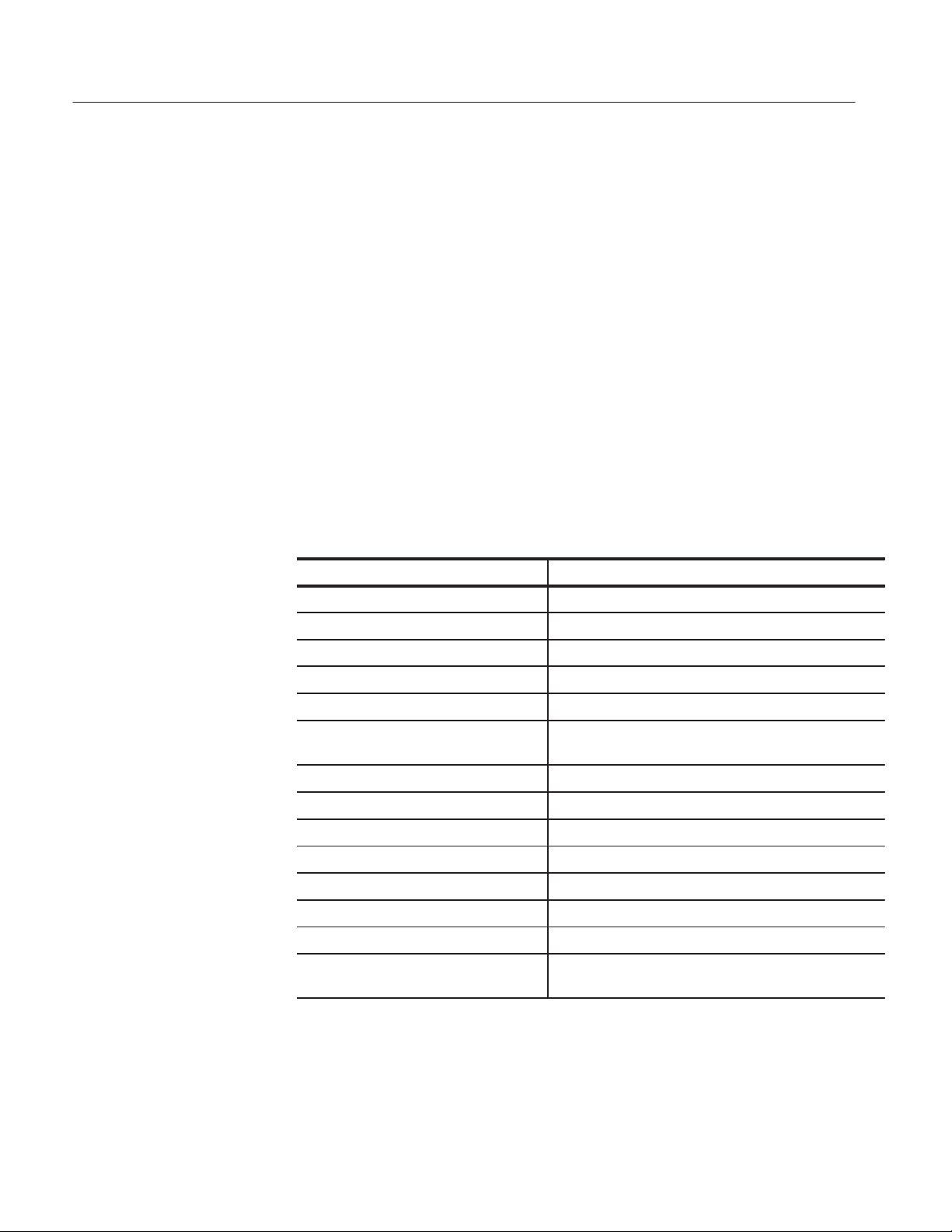

T able 2–1: Signal acquisition in SBSRAM Read cycle

Qualifiers Operation Signals Custom Clock

ARE~/SDCAS~/SSADS~

БББББ

AOE~/SDRAS~/SSOE~

БББББ

AWE~/SDWE~/SSWE~

ARE~/SDCAS~/SSADS~

БББББ

AOE~/SDRAS~/SSOE~

БББББ

AWE~/SDWE~/SSWE~

БББББ

ARE~/SDCAS~/SSADS~

БББББ

AOE~/SDRAS~/SSOE~

БББББ

AWE~/SDWE~/SSWE~

= LOW

ÁÁ

= HIGH

ÁÁ

= HIGH

= HIGH

ÁÁ

= LOW

ÁÁ

= HIGH

ÁÁ

= HIGH

ÁÁ

= LOW

ÁÁ

= HIGH

Sample and

Master

ÁÁÁÁ

ÁÁÁÁ

Sample and

ÁÁÁÁ

Master

ÁÁÁÁ

ÁÁÁÁ

Sample and

Master

ÁÁÁÁ

ÁÁÁÁ

CEx~, BE1,

EA[21:2]

ÁÁÁÁ

ÁÁÁÁ

BE2

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

BE3, Q1

ÁÁÁÁ

ÁÁÁÁ

At position B

ÁÁÁ

ÁÁÁ

At position C

ÁÁÁ

ÁÁÁ

ÁÁÁ

At position D

ÁÁÁ

ÁÁÁ

TMS711 320C6211/C6711 Microprocessor Support

Page 27

T able 2–1: Signal acquisition in SBSRAM Read cycle (Cont.)

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Qualifiers Custom ClockSignalsOperation

ARE~/SDCAS~/SSADS~

БББББ

AOE~/SDRAS~/SSOE~

БББББ

AWE~/SDWE~/SSWE~

БББББ

ARE~/SDCAS~/SSADS~

БББББ

AOE~/SDRAS~/SSOE~

БББББ

AWE~/SDWE~/SSWE~

ARE~/SDCAS~/SSADS~

БББББ

AOE~/SDRAS~/SSOE~

БББББ

AWE~/SDWE~/SSWE~

БББББ

= HIGH

ÁÁ

= LOW

ÁÁ

= HIGH

ÁÁ

= HIGH

ÁÁ

= LOW

ÁÁ

= HIGH

= LOW

ÁÁ

= LOW

ÁÁ

= HIGH

ÁÁ

Sample and

ÁÁÁÁ

Master

ÁÁÁÁ

ÁÁÁÁ

Sample and

Master

ÁÁÁÁ

ÁÁÁÁ

Sample and

ÁÁÁÁ

Master

ÁÁÁÁ

ÁÁÁÁ

BE4, Q2

ÁÁÁ

ÁÁÁ

ÁÁÁ

Q3

ÁÁÁ

ÁÁÁ

Q4

ÁÁÁ

ÁÁÁ

ÁÁÁ

Setting Up the Support

At position E

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

At position F

ÁÁÁÁ

ÁÁÁÁ

At position G

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

TMS711 320C6211/C6711 Microprocessor Support

2–5

Page 28

Setting Up the Support

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ECLKOUT

Figure 2–2 shows the bus timing for the SBSRAM Write cycle with a burst of 4

data transitions.

CEx

BE(3:0)

EA(21:2)

ED(31:0)

BE1

Q1 Q2 Q3 Q4

BE2 BE3 BE4

EA

ARE/SDCAS/SSADS*

AOE/SDRAS/SSOE

*

AWE/SDWE/SSWE*

ABCDEFGH

Note: *ARE/SDCAS/SSADS, AOE/SDRAS/SSOE and AWE/SDWE/SSWE operate as SSADS, SSOE and SSWE,

respectively, during SBSRAM accesses.

Figure 2–2: SDSRAM Write cycles with a burst of four data transitions

T able 2–2: Signal acquisition in SBSRAM Write cycle

2–6

Qualifiers Operation Signals Custom Clock

ARE~/SDCAS~/SSAD~

ББББББ

AOE~/SDRAS~/SSOE~

ББББББ

AWE~/SDWE~/SSWE~

ББББББ

ARE~/SDCAS~/SSADS~

AOE~/SDRAS~/SSOE~

ББББББ

ББББББ

AWE~/SDWE~/SSWE~

ARE~/SDCAS~/SSADS~

ББББББ

AOE~/SDRAS~/SSOE~

ББББББ

AWE~/SDWE~/SSWE~

ББББББ

= LOW

Á

= HIGH

Á

= LOW

Á

= HIGH

= HIGH

Á

Á

= LOW

= HIGH

Á

= HIGH

Á

= LOW

Á

Sample and

Master

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

Sample and

Master

ÁÁÁÁ

ÁÁÁÁ

Sample and

Master

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

CEx~, BE1,

EA[21:2],

ÁÁÁÁ

and Q1

ÁÁÁÁ

ÁÁÁÁ

BE2, Q2

ÁÁÁÁ

ÁÁÁÁ

BE3, Q3

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

At position B

ÁÁÁ

ÁÁÁ

ÁÁÁ

At position C

ÁÁÁ

ÁÁÁ

At position D

ÁÁÁ

ÁÁÁ

ÁÁÁ

TMS711 320C6211/C6711 Microprocessor Support

Page 29

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ECLKOUT

Setting Up the Support

T able 2–2: Signal acquisition in SBSRAM Write cycle (Cont.)

Qualifiers Custom ClockSignalsOperation

ARE~/SDCAS~/SSADS~

БББББ

AOE~/SDRAS~/SSOE~

БББББ

AWE~/SDWE~/SSWE~

БББББ

ARE~/SDCAS~/SSADS~

БББББ

AOE~/SDRAS~/SSOE~

БББББ

AWE~/SDWE~/SSWE~

= HIGH

ÁÁ

= HIGH

ÁÁ

= LOW

ÁÁ

= LOW

ÁÁ

= HIGH

ÁÁ

= HIGH

Sample and

ÁÁÁÁ

Master

ÁÁÁÁ

ÁÁÁÁ

Come out of the

loop

ÁÁÁÁ

ÁÁÁÁ

BE4, Q4

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

–––

ÁÁÁÁ

ÁÁÁÁ

At position E

ÁÁÁ

ÁÁÁ

ÁÁÁ

At position F

ÁÁÁ

ÁÁÁ

Figure 2–3 shows the bus timing for the ASYNC Read cycle memory operations.

Setup = 2 Strobe = 4 Not ready = 3 Hold = 1

CEx

BE(3:0)

EA(21:2)

ED(31:0)

AOE/SDRAS/SSOE

ARE/SDCAS/SSADS*

AWE/SDWE/SSWE*

*

ABCDEFGH

Note: *ARE

/SDCAS/SSADS, AOE/SDRAS/SSOE and AWE/SDWE/SSWE operate as ARE, AOE and AWE, during

ASYNC accesses. Data group is delated by 1 Clock.

Figure 2–3: Bus timing for the ASYNC read cycle

BE

Address

Read data

TMS711 320C6211/C6711 Microprocessor Support

2–7

Page 30

Setting Up the Support

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

T able 2–3: Signal acquisition in ASYNC Write cycle

Qualifiers Operation Signals Custom Clock

AOE~/SDRAS~/SSOE~

ББББББ

ARE~/SDCAS~/SSADS~

ББББББ

AWE~/SDWE~/SSWE~

ББББББ

AOE~/SDRAS~/SSOE~

ББББББ

ARE~/SDCAS~/SSADS~

ББББББ

AWE~/SDWE~/SSWE~

= LOW

Á

= LOW

Á

= HIGH

Á

= LOW

Á

= HIGH

Á

= HIGH

Sample

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

Master

ÁÁÁÁ

ÁÁÁÁ

CEx~, BE,

ÁÁÁÁ

Address, and

Data

ÁÁÁÁ

ÁÁÁÁ

The signals

sampled at

ÁÁÁÁ

position G

ÁÁÁÁ

At positions

ÁÁÁ

A to G

ÁÁÁ

ÁÁÁ

At position H

ÁÁÁ

ÁÁÁ

Figure 2–4 shows the bus timing for the ASYNC Write cycle memory opera-

tions.

Setup = 2 Strobe = 4 Not ready = 3 Hold = 1

ECLKOUT

CEx

BE(3:0)

EA(21:2)

ED(31:0)

ARE/SDRAS/SSOE*

AOE/SDCAS/SSADS

AWE/SDWE/SSWE*

BE

Address

Address

*

ABCDEFGH

Note: *ARE/SDCAS/SSADS, AOE/SDRAS/SSOE and AWE/SDWE/SSWE operate as ARE, AOE and AWE, during

ASYNC accesses.

Figure 2–4: Bus timing for the ASYNC write cycle

2–8

TMS711 320C6211/C6711 Microprocessor Support

Page 31

Setting Up the Support

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

T able 2–4: Signal acquisition in ASYNC Write cycle

Qualifiers Operation Signals Custom Clock

AOE~/SDRAS~/SSOE~

БББББ

ARE~/SDCAS~/SSADS~

БББББ

AWE~/SDWE~/SSWE~

БББББ

AOE~/SDRAS~/SSOE~

БББББ

ARE~/SDCAS~/SSADS~

БББББ

AWE~/SDWE~/SSWE~

= HIGH

ÁÁ

= HIGH

ÁÁ

= LOW

ÁÁ

= HIGH

ÁÁ

= HIGH

ÁÁ

= HIGH

Sample

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

Master

ÁÁÁÁ

ÁÁÁÁ

CEx~, BE,

ÁÁÁÁ

Address, and

Data

ÁÁÁÁ

ÁÁÁÁ

The signals

sampled at posi-

ÁÁÁÁ

tion G

ÁÁÁÁ

At positions A to

ÁÁÁ

G

ÁÁÁ

ÁÁÁ

At position H

ÁÁÁ

ÁÁÁ

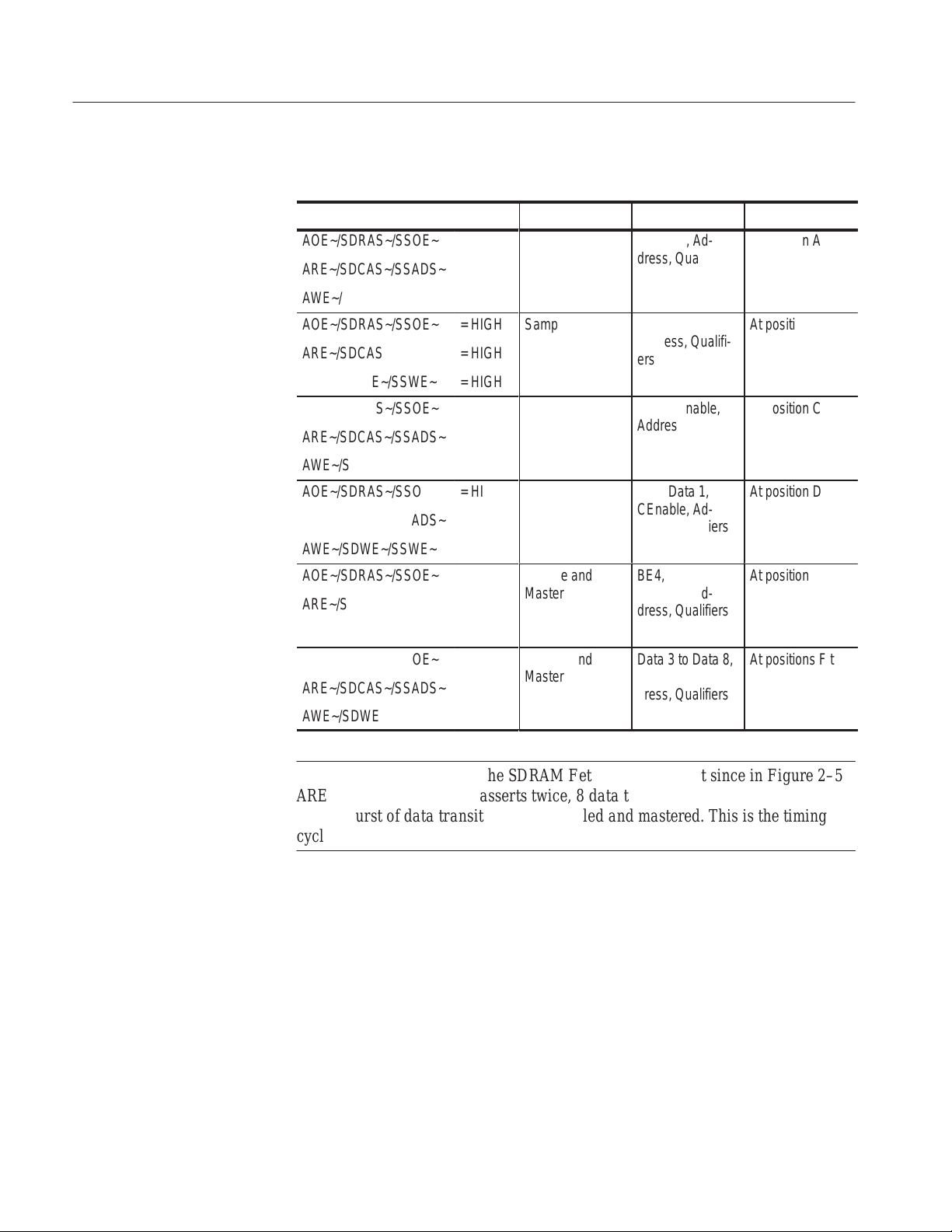

Figure 2–5 shows a SDRAM Fetch cycle with CAS latency = 3.

Note: *ARE/SDCAS/SSADS, AOE/SDRAS/SSOE and AWE/SDWE/SSWE operate as SDCAS SDRAS and

SDWE

Figure 2–5: Bus timing for the SDRAM fetch cycle with CAS latency of 3

TMS711 320C6211/C6711 Microprocessor Support

, during SDRAM accesses.

2–9

Page 32

Setting Up the Support

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

T able 2–5: Signal acquisition in SDRAM fetch cycle with CAS latency of 3

Qualifiers Operation Signals Custom Clock

AOE~/SDRAS~/SSOE~

ББББББ

ARE~/SDCAS~/SSADS~

ББББББ

AWE~/SDWE~/SSWE~

ББББББ

AOE~/SDRAS~/SSOE~

ББББББ

ARE~/SDCAS~/SSADS~

ББББББ

AWE~/SDWE~/SSWE~

AOE~/SDRAS~/SSOE~

ББББББ

ARE~/SDCAS~/SSADS~

ББББББ

AWE~/SDWE~/SSWE~

ББББББ

AOE~/SDRAS~/SSOE~

ББББББ

ARE~/SDCAS~/SSADS~

ББББББ

AWE~/SDWE~/SSWE~

AOE~/SDRAS~/SSOE~

ББББББ

ARE~/SDCAS~/SSADS~

ББББББ

AWE~/SDWE~/SSWE~

ББББББ

AOE~/SDRAS~/SSOE~

ББББББ

ARE~/SDCAS~/SSADS~

ББББББ

AWE~/SDWE~/SSWE~

= HIGH

Á

= LOW

Á

= HIGH

Á

= HIGH

Á

= HIGH

Á

= HIGH

= HIGH

Á

= HIGH

Á

= HIGH

Á

= HIGH

Á

= LOW

Á

= HIGH

= HIGH

Á

= HIGH

Á

= HIGH

Á

= HIGH

Á

= HIGH

Á

= HIGH

Sample and

ÁÁÁÁ

Master

ÁÁÁÁ

ÁÁÁÁ

Sample and

Master

ÁÁÁÁ

ÁÁÁÁ

Sample and

ÁÁÁÁ

Master

ÁÁÁÁ

ÁÁÁÁ

Sample and

Master

ÁÁÁÁ

ÁÁÁÁ

Sample and

ÁÁÁÁ

Master

ÁÁÁÁ

ÁÁÁÁ

Sample and

Master

ÁÁÁÁ

ÁÁÁÁ

CEnable, Ad-

ÁÁÁÁ

dress, Qualifiers

ÁÁÁÁ

ÁÁÁÁ

BE1, CEnable,

Address, Qualifi-

ÁÁÁÁ

ers

ÁÁÁÁ

BE2, CEnable,

ÁÁÁÁ

Address, Qualifiers

ÁÁÁÁ

ÁÁÁÁ

BE3, Data 1,

CEnable, Ad-

ÁÁÁÁ

dress, Qualifiers

ÁÁÁÁ

BE4, Data 2,

ÁÁÁÁ

CEnable, Address, Qualifiers

ÁÁÁÁ

ÁÁÁÁ

Data 3 to Data 8,

CEnable, Ad-

ÁÁÁÁ

dress, Qualifiers

ÁÁÁÁ

At position A

ÁÁÁ

ÁÁÁ

ÁÁÁ

At position B

ÁÁÁ

ÁÁÁ

At position C

ÁÁÁ

ÁÁÁ

ÁÁÁ

At position D

ÁÁÁ

ÁÁÁ

At position E

ÁÁÁ

ÁÁÁ

ÁÁÁ

At positions F to

next 5 following

ÁÁÁ

clocks

ÁÁÁ

2–10

NOTE. The default burst in the SDRAM Fetch cycle is 4, but since in Figure 2–5

ARE~/SDCASE~/SSADS~ asserts twice, 8 data transitions appear in the bursts.

So this burst of data transitions was sampled and mastered. This is the timing

cycle behavior usually seen on the logic analyzer.

TMS711 320C6211/C6711 Microprocessor Support

Page 33

Setting Up the Support

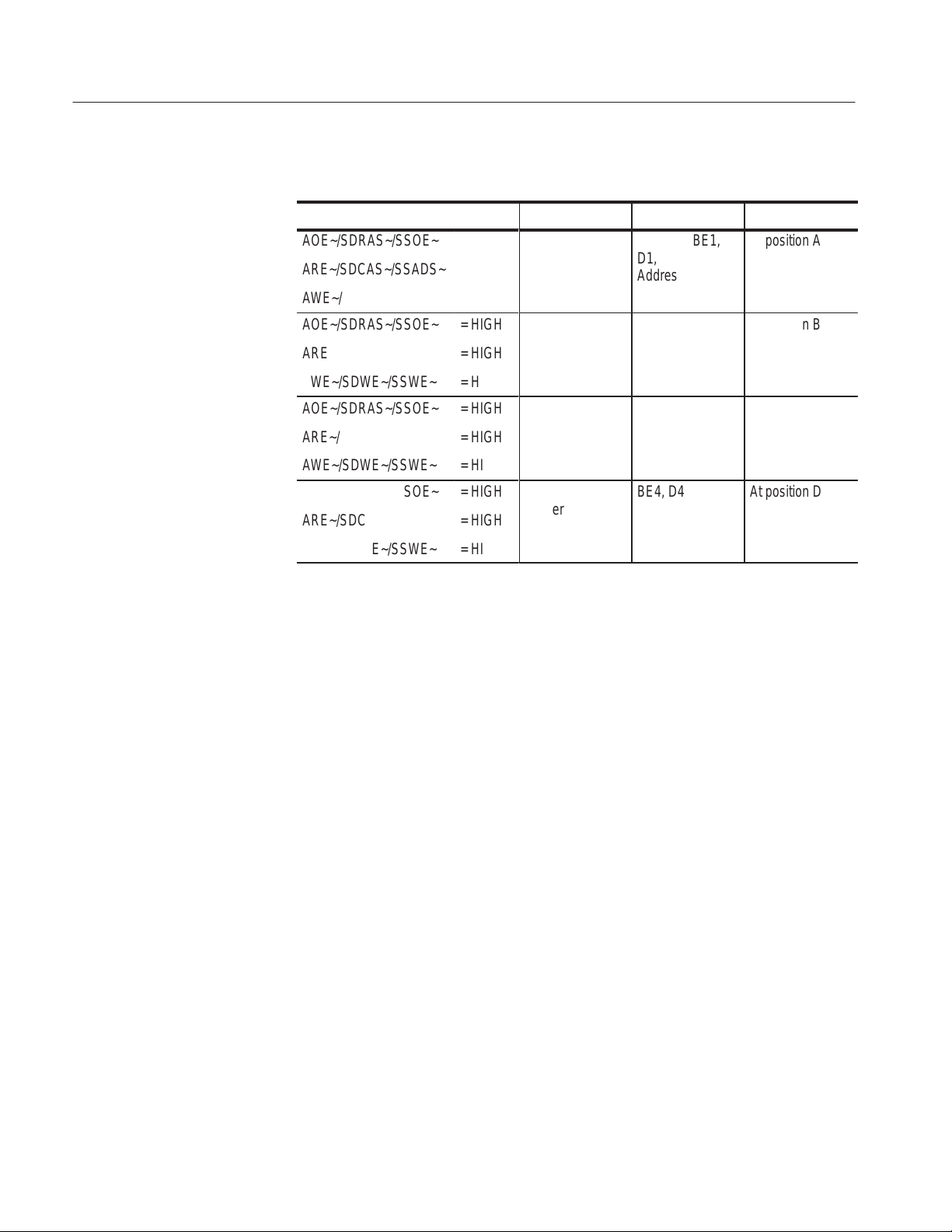

Figure 2–6 shows a SDRAM Write cycle with a default of four data transitions.

Write

ECLKOUT

CEx

BE(3:0)

EA(21:13)

EA(11:2)

EA12

ED(31:0)

AOE/SDRAS/SSOE

ARE/SDCAS/SSADS*

AWE/SDWE/SSWE*

BE1 BE2

Bank

Column

D1

*

ABCD

D2

BE3 BE4

D3 D4

Figure 2–6: SDRAM Write cycle with default of four data transitions

TMS711 320C6211/C6711 Microprocessor Support

2–11

Page 34

Setting Up the Support

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

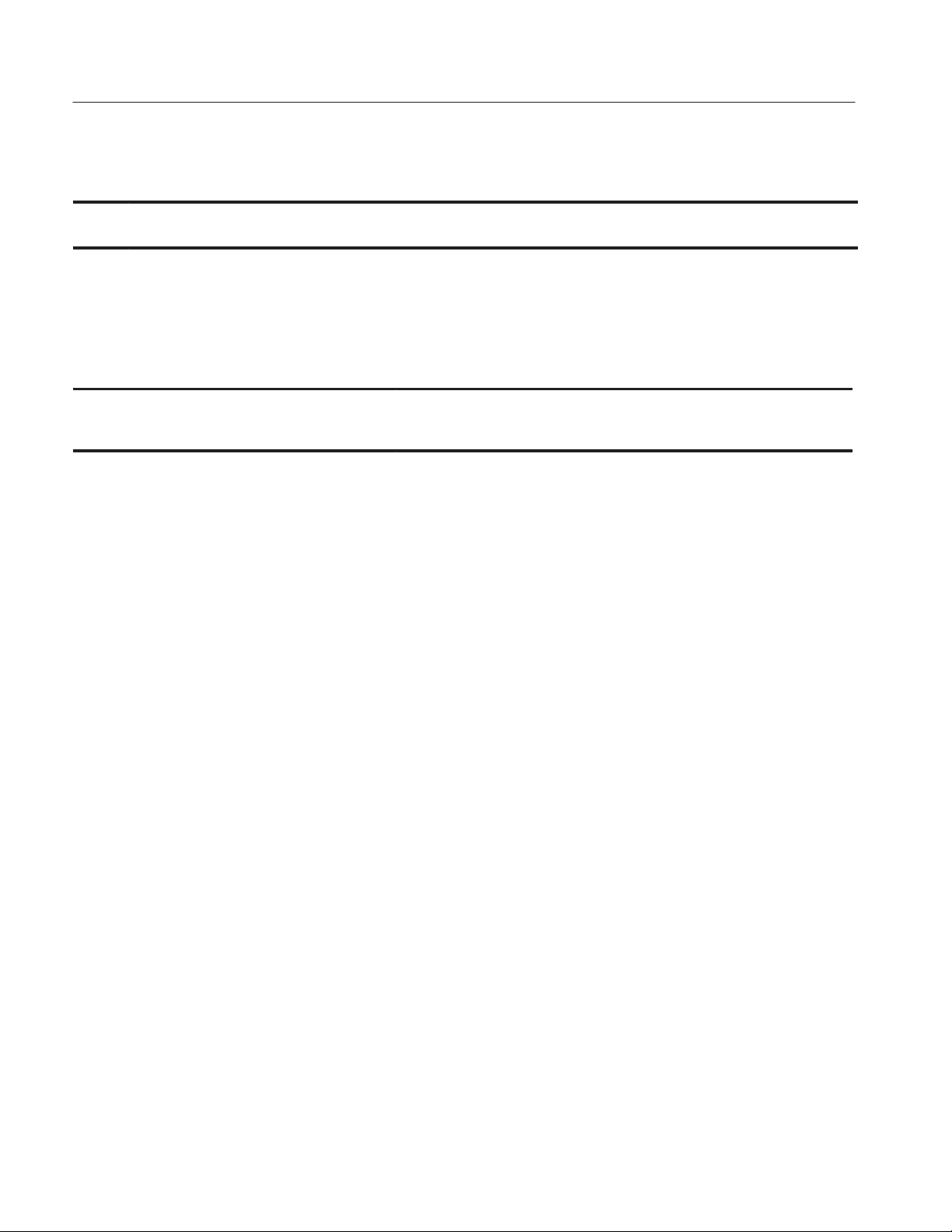

T able 2–6: Signal acquisiton in SDRAM write cycle with CAS latency of 3

Qualifiers Operation Signals Custom Clock

AOE~/SDRAS~/SSOE~

ББББББ

ARE~/SDCAS~/SSADS~

ББББББ

AWE~/SDWE~/SSWE~

ББББББ

AOE~/SDRAS~/SSOE~

ББББББ

ARE~/SDCAS~/SSADS~

ББББББ

AWE~/SDWE~/SSWE~

AOE~/SDRAS~/SSOE~

ББББББ

ARE~/SDCAS~/SSADS~

ББББББ

AWE~/SDWE~/SSWE~

ББББББ

AOE~/SDRAS~/SSOE~

ББББББ

ARE~/SDCAS~/SSADS~

ББББББ

AWE~/SDWE~/SSWE~

= HIGH

Á

= LOW

Á

= LOW

Á

= HIGH

Á

= HIGH

Á

= HIGH

= HIGH

Á

= HIGH

Á

= HIGH

Á

= HIGH

Á

= HIGH

Á

= HIGH

Sample and

ÁÁÁÁ

Master

ÁÁÁÁ

ÁÁÁÁ

Sample and

Master

ÁÁÁÁ

ÁÁÁÁ

Sample and

ÁÁÁÁ

Master

ÁÁÁÁ

ÁÁÁÁ

Sample and

Master

ÁÁÁÁ

ÁÁÁÁ

CEnable, BE1,

ÁÁÁÁ

D1,

Address,Qualifi-

ÁÁÁÁ

ers

ÁÁÁÁ

BE2, D2

ÁÁÁÁ

ÁÁÁÁ

BE3, D3

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

BE4, D4

ÁÁÁÁ

ÁÁÁÁ

At position A

ÁÁÁ

ÁÁÁ

ÁÁÁ

At position B

ÁÁÁ

ÁÁÁ

At position C

ÁÁÁ

ÁÁÁ

ÁÁÁ

At position D

ÁÁÁ

ÁÁÁ

2–12

TMS711 320C6211/C6711 Microprocessor Support

Page 35

Acquiring and Viewing Disassembled Data

Acquiring Data

Once you load the C6211/C6711 support, choose a clocking mode, and specify

the trigger, you are ready to acquire and disassemble data.

If you have any problems acquiring data, refer to information on basic operations

in your online help or Appendix A: Error Messages and Disassembly Problems in

the basic operations user manual.

Viewing Disassembled Data

You can view disassembled data in six display formats: Timing, State, Hardware,

Software, Control Flow, and Subroutine. The information on basic operations

describes how to select the disassembly display formats.

NOTE. Selections in the Disassembly property page (the Disassembly Format

Definition overlay) must be set correctly for your acquired data to be disassembled correctly. Refer to Changing How Data is Displayed on page 2–16.

The default display format displays the Address, Data, and Control channel

group values for each sample of acquired data.

If a channel group is not visible, you must use the Disassembly property page to

make the group visible.

The disassembler displays special characters and strings in the instruction

mnemonics to indicate significant events. Table 2–7 lists these special characters

and strings and gives a definition of what they represent.

T able 2–7: Description of special characters in the display

Character or string displayed Definition

>> The instruction was manually marked.

t

Indicates the number shown is in decimal, such as #12t

TMS711 320C6211/C6711 Microprocessor Support

2–13

Page 36

Acquiring and Viewing Disassembled Data

Timing Display Format

Hardware Display Format

The timing-waveform display format file is provided for the TLA 700 Series

support. The timing-waveform display format file will set up and display the

following waveforms:

Address (busform)

Data (busform)

ASYNC (busform)

Control (busform)

CEnable (busform)

BEnable (busform)

ECLKOUT (busform)

In Hardware display format, the disassembler displays certain cycle type labels in

parentheses. Table 2–8 lists cycle type labels and gives a definition of the cycle

they represent. Reads to interrupt and exception vectors will be labeled with the

vector name.

T able 2–8: Cycle type definitions

Cycle Type

( RESET CYCLE )

( ALTERNATE BUS MASTER CYCLE )

Definition

Indicates system RESET

Indicates HOLD cycle

( SDRAM DEAC/DCAB CYCLE )

( SDRAM ACTV CYCLE )

( FLUSH )

( EXTENSION )

( ASYNC READ CYCLE) Indicates ASYNC memory READ cycle

( SBSRAM READ CYCLE) Indicates SBSRAM READ cycle

( SDRAM READ CYCLE) Indicates SDRAM READ cycle

( SBSRAM WRITE CYCLE) Indicates SBSRAM WRITE cycle

( ASYNC WRITE CYCLE) Indicates ASYNC WRITE cycle

( SDRAM WRITE CYCLE) Indicates SDRAM WRITE cycle

( SBSRAM MRS CYCLE )

( UNKNOWN CYCLE )

Indicates SDRAM DEAC or DCAB cycle

Indicates SDRAM ACTV cycle

Indicates a cycle was fetched but not executed

Indicates an extension to the preceding instruction

opcode

Indicates SDRAM MRS cycle

Indicates a combination of control bits are unexpected or

unrecognized

The external address bus has 19 lines EA21:EA2 lines for EMIF (External

Memory Interface). However, the address internal to the processor are 32 bits.

This 32 bit address is calculated based on Byte Enables, Chip Enables (Memory

Space Enables) and user inputs. The Data bus has 32 lines ED31:ED0

2–14

TMS711 320C6211/C6711 Microprocessor Support

Page 37

Acquiring and Viewing Disassembled Data

Figure 2–7 shows an example of a Hardware display.

Software Display Format

Control Flow Display

Format

Subroutine Display

Format

Figure 2–7: Hardware display format

The Software display format displays only the first fetch of executed instructions.

Flushed cycles and extensions are not shown, even though they are part of the

executed instruction. Read extensions will be used to disassemble the instruction,

but they will not be displayed as a separate cycle in the Software display format.

Data reads and writes are not displayed.

The Control Flow display format displays only the first fetch of instructions that

cause a branch in the addressing and special cycles to change the flow of control.

Instructions that generate a change in the flow of control in the C6211/C6711

microprocessor are as follows:

B IRP B disp B NRP B reg

The Subroutine display format displays only the first fetch of subroutine call and

return instructions. It will display conditional subroutine calls if they are

considered to be taken.

Instructions that generate a subroutine call or a return in the C6211/C6711

microprocessor are as follows:

B IRP B NRP

TMS711 320C6211/C6711 Microprocessor Support

2–15

Page 38

Acquiring and Viewing Disassembled Data

Changing How Data is Displayed

There are common fields and features that allow you to further modify displayed

data to suit your needs. You can make common and optional display selections in

the Disassembly property page (the Disassembly Format Definition overlay).

Optional Display

Selections

Micro Specific Fields

You can make optional selections for acquired disassembled data. In addition to

the common selections (described in the information on basic operations), you

can change the displayed data in the following ways:

Show: Hardware (default)

Software

Control Flow

Subroutine

Highlight: Software (default)

Control Flow

Subroutine

None

Disasm Across Gaps: Yes (default)

No

Endian Mode. This field allows the user to indicate a C6211 processor configuration for viewing data from memory. The following selections will be available in

the following order.

Little Endian (default)

Big Endian

2–16

The C6211

memory CE0,CE1,CE2,CE3 where user can read and write. The C6211/C6711

support can have three types of memories, ASYNC, SDRAM, SBSRAM. Any of

these memory types can be allotted to any of the Memory spaces. So the

following user inputs are required to know which memory is allotted to which

memory spaces.

CE0 Space control. The user needs to enter the C6211 CE0 Space control

Register’s value. This field gives the memory type and the buswidth of that

particular memory.

FFFFFF30 (default)

Processor has a single Memory Map. This memory map has four

TMS711 320C6211/C6711 Microprocessor Support

Page 39

Acquiring and Viewing Disassembled Data

CE1 space control. The user needs to enter the C6211 CE1 Space control

Register’s value. This field gives the memory type and the buswidth of that

particular memory.

FFFFFF23 (default)

CE2 space control. The user needs to enter the C6211 CE2 Space control

Register’s value. This field gives the memory type and the buswidth of that

particular memory.

FFFFFF23 (default)

CE3 Space control. The user needs to enter the C6211 CE3 Space control

Register’s value. This field gives the memory type and the buswidth of that

particular memory.

FFFFFF23 (default)

SDRAM Control Register. The user needs to enter the C6211 SDRAM Control

register value. This gives the Row and Column address pins which are required

for address calculation.

06117000 (default)

SDRAM Read Latency . The user needs to enter the CAS latency of SDRAM Read

cycle.

Three (default)

CE0 ST ART ADDR. The user needs to enter the Start address of the CE0 address

space for the board.

80000000 (default)

CE1 ST ART ADDR. The user needs to enter the Start address of the CE1 address

space for the board.

90000000 (default)

CE2 ST ART ADDR. The user needs to enter the Start address of the CE2 address

space for the board.

A0000000 (default)

TMS711 320C6211/C6711 Microprocessor Support

2–17

Page 40

Acquiring and Viewing Disassembled Data

CE3 ST ART ADDR. The user needs to enter the Start address of the CE3 address

space for the board.

B0000000 (default)

SDRAM ADDR Configuration Field. The following Table 2–9 lists the common

configuration of SDRAM that are fully supported by

column SDRAM Address configuration lists numbers 1 through 11. The user must

choose one of these numbers for the appropriate SDRAM Memory configuration

on their board. The default value in in the SDRAM ADDR configuration field is

1. For the TI C6211

DSK kit, the C6211/C6711 support uses 0x3 in the SDRAM

ADDR Configuration Field.

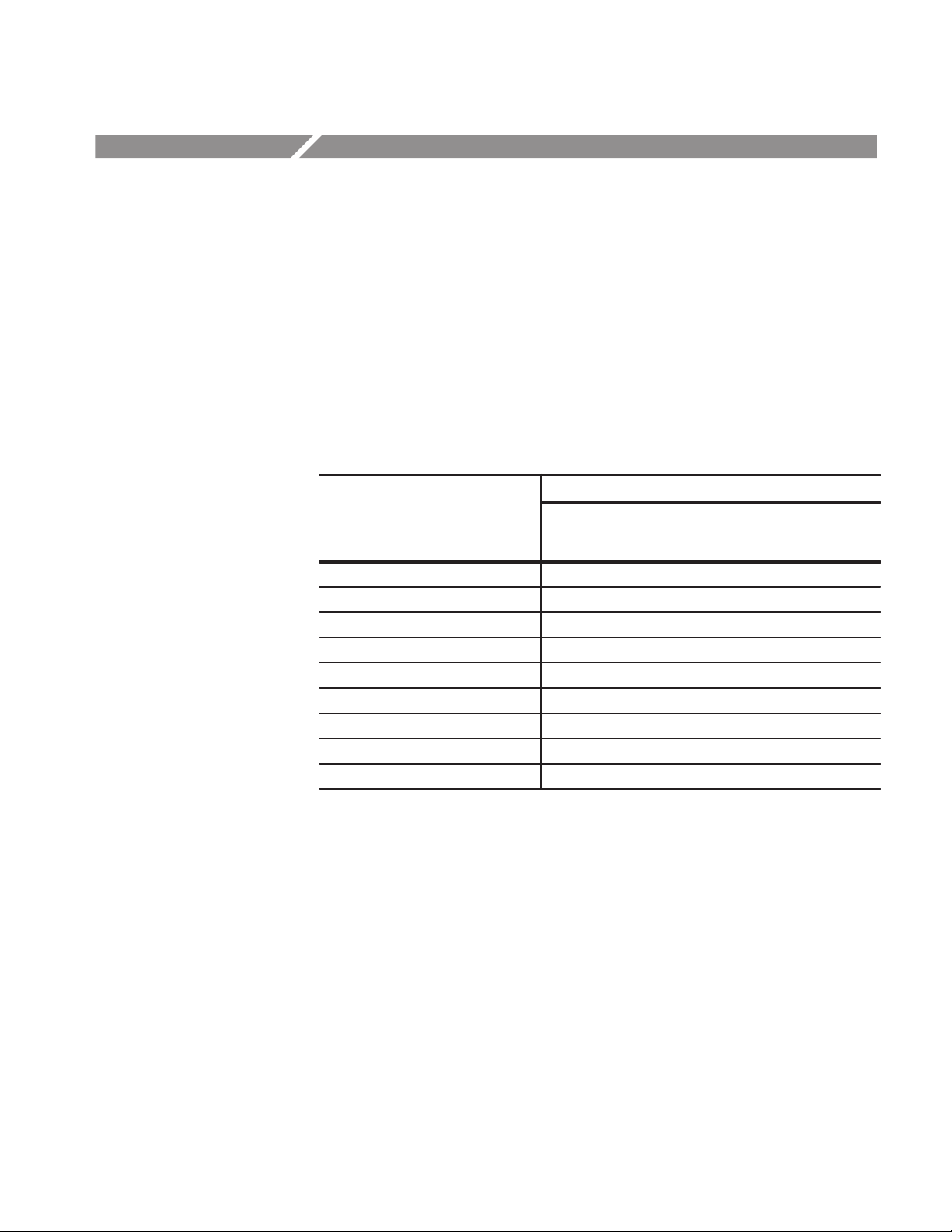

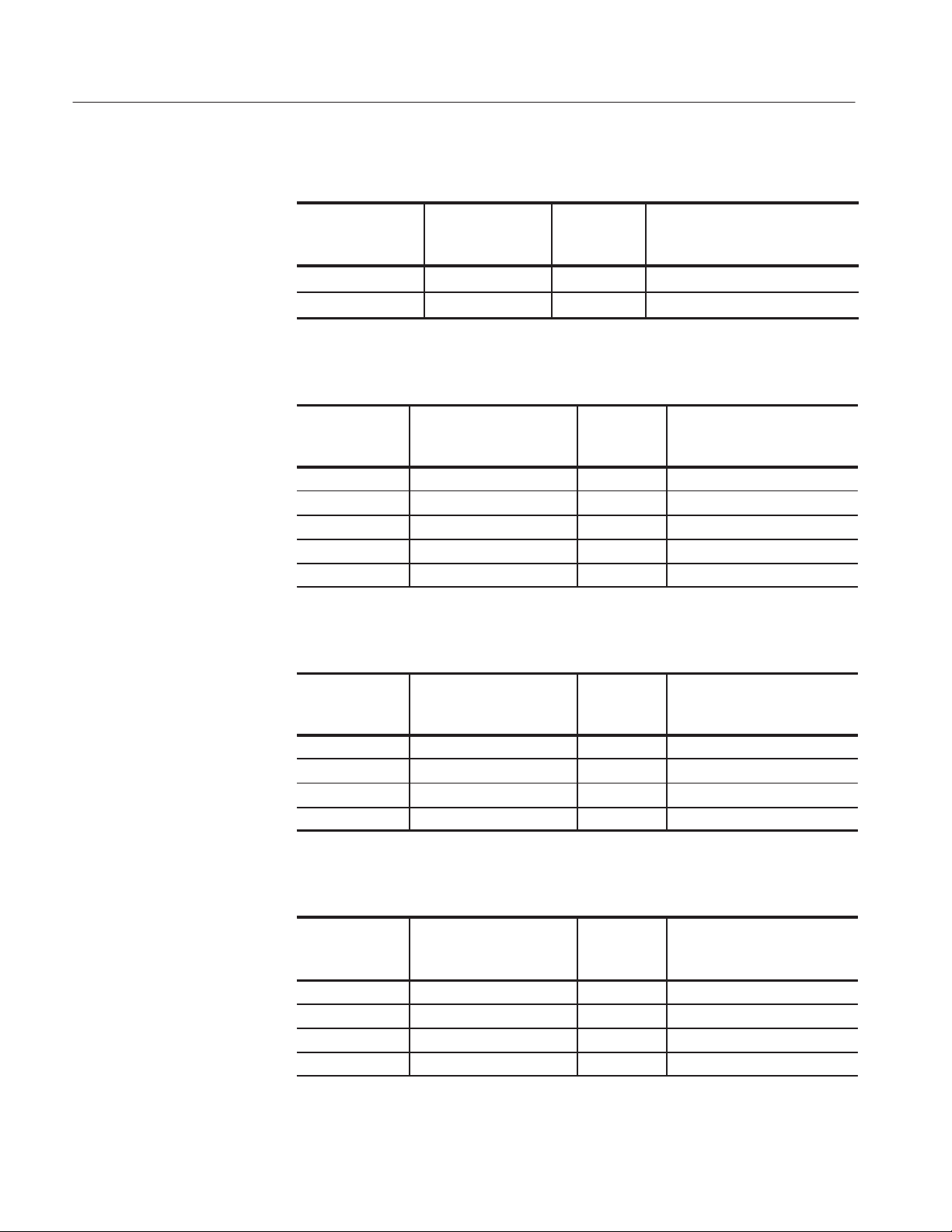

T able 2–9: C6211/C6711 Compatible SDRAM Memory Configuration

C6211/C6711 EMIF. The

SDRAM

size

16

Mbit

64

Mbit

128

Mbit

256

Mbit

AddressMax

Devices/

Banks Width Depth

2 x4 2M 8 16M SDRAM

2

2 x16 512K 2 4M SDRAM

4 x4 4M 8 64M SDRAM

4

4

4 x32 512K 1 8M SDRAM

4 x8 4M 4 64M SDRAM

4 x16 2M 2 32M SDRAM

4 x8 8M 4 128M SDRAM

4 x16 4M 2 64M SDRAM

x8 1M 4 8M SDRAM

x8 2M 4 32M SDRAM

x16 1M 2 16M SDRAM

CE

able

space

(MBytes)

EMIF

EMIF

EMIF

EMIF

EMIF

EMIF

EMIF

EMIF

EMIF

EMIF

EMIF

Column

Address

A9 – A0

EA11 – EA2

A8 – A0

EA10 – EA2

A7 – A0

EA9 – EA2

A9 – A0

EA11 – EA2

A8– A0

EA10 – EA2

A7 – A0

EA9 – EA2

A7 – A0

EA9 – EA2

A9 – A0

EA11 – EA2

A8 – A0

EA10 – EA2

A9 – A0

EA11 – EA2

A8– A0

EA10 – EA2

Row

Address

A10 – A0

EA12 – EA2

A10 – A0

EA12 – EA2

A10 – A0

EA12 – EA2

A11 – A0

EA13 – EA2

A11 – A0

EA13 – EA2

A11 – A0

EA13 – EA2

A10 – A0

EA12 – EA2

A11 – A0

EA13 – EA2

A11– A0

EA13 – EA2

A12 – A0

EA14 – EA2

A12– A0

EA14 – EA2

Bank

Select

A11

EA13

A11

EA13

A11

EA13

A13–A12

EA15–EA14

A13–A12

EA15–EA14

A13–A12

EA15–EA14

A12–A11

EA14–EA13

A13–A12

EA15–EA14

A13–A12

EA15–EA14

A14–A13

EA16–EA15

A14–A13

EA16–EA15

Prechange

A10

EA12

A10

EA12

A10

EA12

A10

EA12

A10

EA12

A10

EA12

A10

EA12

A10

EA12

A10

EA12

A10

EA12

A10

EA12

SDRAM

Address

configuration

1

2

3

4

5

6

7

8

9

10

11

2–18

TMS711 320C6211/C6711 Microprocessor Support

Page 41

Acquiring and Viewing Disassembled Data

The following user input fields for the C6211/C6711 support has a 256 word size

Interrupt Service Table (IST). The IST is a table of fetch packets that contain

code for servicing each of the Interrupts. The IST contains 16 fetch packets. Each

Interrupt Service Routine is 32 bytes. The RESET has the Highest priority, NMI

the second highest, and the lowest priority Interrupts are INT4 to INT15. The

reset fetch packet must be located at address 0, but the rest of the interrupts, NMI

and INT4–INT15, can be relocated anywhere within the IST (256 word

boundary). Also, this IST can be relocated to any address location.

NOTE. Since there are no Interrupt acknowledge signals and signals which tell

which interrupt is being serviced, the user must enter the start address where the

Service-Routine-Fetch packets are located.

NMI_FP_ADDR. The user needs to enter the 32 bit physical address; for example,

Start Address, of the NonMaskable Interrupt-Service-Routine Fetch Packet in the

Interrupt Service Table.

00000020 (default)

INT4_FP_ADDR. The user needs to enter the 32 bit physical address; for example,

Start Address, of the external interrupt EXT_INT4 Service-Routine-Fetch Packet

in the Interrupt Service Table.

00000080 (default)

INT5_FP_ADDR. The user needs to enter the 32 bit physical address; for example,

Start Address, of the external interrupt EXT_INT5 Service-Routine-Fetch Packet

in the Interrupt Service Table.

000000A0 (default)

INT6_FP_ADDR. The user needs to enter the 32 bit physical address; for example,

Start Address, of the external interrupt EXT_INT6 Service-Routine-Fetch Packet

in the Interrupt Service Table.

000000C0 (default)

INT7_FP_ADDR. The user needs to enter the 32 bit physical address; for example,

Start Address, of the external interrupt EXT_INT7 Service-Routine-Fetch Packet

in the Interrupt Service Table.

000000E0 (default)

TMS711 320C6211/C6711 Microprocessor Support

2–19

Page 42

Acquiring and Viewing Disassembled Data

INT8_FP_ADDR. The user needs to enter the 32 bit physical address; for example,

Start Address, of the external interrupt EXT_INT8 Service-Routine-Fetch Packet

in the Interrupt Service Table.

00000100 (default)

INT9_FP_ADDR. The user needs to enter the 32 bit physical address; for example,

Start Address, of the external interrupt EXT_INT9 Service-Routine-Fetch Packet

in the Interrupt Service Table.

00000120 (default)

INT10_FP_ADDR. The user needs to enter the 32 bit physical address; for

example, Start Address, of the external interrupt EXT_INT10 Service-RoutineFetch Packet in the Interrupt Service Table.

00000140 (default)

INT11_FP_ADDR. The user needs to enter the 32 bit physical address; for example,

Start Address of the external interrupt EXT_INT11 Service-Routine-Fetch Packet

in the Interrupt Service Table.

00000160 (default)

INT12_FP_ADDR. The user needs to enter the 32 bit physical address; for

example, Start Address of the external interrupt EXT_INT12 Service-RoutineFetch Packet in the Interrupt Service Table.

00000180 (default)

INT13_FP_ADDR. The user needs to enter the 32 bit physical address; for

example, Start Address of the external interrupt EXT_INT13 Service-RoutineFetch Packet in the Interrupt Service Table.

000001A0 (default)

INT14_FP_ADDR. The user needs to enter the 32 bit physical address; for

example, Start Address of the external interrupt EXT_INT14 Service-RoutineFetch Packet in the Interrupt Service Table.

2–20

000001C0 (default)

TMS711 320C6211/C6711 Microprocessor Support

Page 43

Acquiring and Viewing Disassembled Data

INT15_FP_ADDR. The user needs to enter the 32 bit physical address; for

example, Start Address of the external interrupt EXT_INT15 Service-RoutineFetch Packet in the Interrupt Service Table.

000001E0 (default)

Marking Cycles

TMS711 320C6211/C6711support allows marks to be placed by using the

The

Mark Opcode button. The Mark Opcode will always be available. If the sample

being marked is not an Address cycle or Data cycle of the potential bus master,

the Mark Opcode selections will be replaced by a note indicating that “An

Opcode Mark cannot be placed at the selected data sample.”

When a cycle is marked, this character >> is displayed immediately to the left of

the Mnemonics column. Cycles can be unmarked by using the Undo Mark

selection, which will remove this character >>. If more than one set of sequences

are marked, then the user can undo the marks by using the “Remove all Marks”

option.

The following cycle marks will be available:

H Reads can be marked as Opcode, Fetch, or Flash

H Fetch can be marked as Read or Flush

H Flush can be marked as Fetch or Opcode

Viewing an Example of Disassembled Data

A demonstration system file (or demonstration reference memory) is provided so

you can see an example of how your C6211/C6711 microprocessor bus cycles

and instruction mnemonics look when they are disassembled. Viewing the system

file is not a requirement for preparing the module for use and you can view it

without connecting the logic analyzer to your system under test.

TMS711 320C6211/C6711 Microprocessor Support

2–21

Page 44

Acquiring and Viewing Disassembled Data

2–22

TMS711 320C6211/C6711 Microprocessor Support

Page 45

Specifications

Page 46

Page 47

Specifications

Specification Tables

This chapter contains information regarding the specifications of the TMS711

320C6211/C6711

microprocessor support.

Tables 3–1 and 3–2 list the electrical requirements the system under test must

produce for the TMS711 320C6211/C6711 support to acquire correct data.

T able 3–1: C6211 Electrical specifications

Characteristics Requirements

System under test clock rate

Maximum specified clock rate:

ASYNC memory

SBSRAM memory

SDRAM memory

Tested clock rate

Minimum setup time required † 2.5 ns

Minimum hold time required † 0 ns

* Please contact your Tektronix Sales Representative for current information on the

tested clock rate.

† Logic analyzer setup times are estimated for all signals for the supported memory

cycles. However , you can change both the setup and hold times.

*

100 MHz

100 MHz

100 MHz

100 MHz

TMS711 320C6211/C6711 Microprocessor Support

3–1

Page 48

Specifications

T able 3–2: C6711 Electrical Specifications

Characteristics Requirements

Sytem under test clock rate

Maximum specified clock rate:

ASYNC memory

SBSRAM memory

SDRAM memory

Tested clock rate

Minimum setup time required 2.5 ns

Minimum hold time required 0 ns

* Please contact your Tektronix Sales Representative for current information on the

tested clock rate.

† Logic analyzer setup times are estimated for all signals for the supported memory

cycles. However , you can change both the setup and hold times.

*

100 MHz

100 MHz

100 MHz

–––

3–2

TMS711 320C6211/C6711 Microprocessor Support

Page 49

Replaceable Parts

Page 50

Page 51

Replaceable Parts

This section contains a list of the replaceable parts for the TMS711

320C6211/C6711 C6211/C6711 microprocessor support product.

Parts Ordering Information

Replacement parts are available through your local Tektronix field office or

representative.

Changes to Tektronix products are sometimes made to accommodate improved

components as they become available and to give you the benefit of the latest

improvements. Therefore, when ordering parts, it is important to include the

following information in your order.

H Part number

H Instrument type or model number

H Instrument serial number

H Instrument modification number, if applicable

Abbreviations

Mfr. Code to Manufacturer

Cross Index

If you order a part that has been replaced with a different or improved part, your

local Tektronix field office or representative will contact you concerning any

change in part number.

Abbreviations conform to American National Standard ANSI Y1.1–1972.

The table titled Manufacturers Cross Index shows codes, names, and addresses

of manufacturers or vendors of components listed in the parts list.

TMS711 320C6211/C6711 Microprocessor Support

4–1

Page 52

Replaceable Parts

Manufacturers cross index

Mfr.

code

TK2548 XEROX CORPORATION 14181 SW MILLIKAN WA Y BEAVERT ON, OR 97005

Manufacturer Address City, state, zip code

Replaceable parts list

Fig. &

index

number

Tektronix

part number

071–0877–00 1 MANUAL, TECH: INSTRUCTIONS, C62XX, TMS711 TK2548 071–0877–00

Serial no.

effective

Serial no.

discont’d

Qty Name & description Mfr. code Mfr. part number

STANDARD ACCESSORIES

4–2

TMS711 320C6211/C6711 Microprocessor Support

Page 53

Reference

Page 54

Page 55

Reference: Channel Groups

This section lists the Symbol table and the Channel group tables for disassembly

and timing.

Symbol Table

Table 5–1 lists the name, bit pattern, and meaning for the symbols in the file

C6211_Ctrl, the Control channel group symbol table.

T able 5–1: Control symbol table definitions

Symbol

RESET 0XXXX

HOLD_ACK 10XXX

SDREAD/SBREAD 1 1 1 0 1

ASREAD 11001

SDWRITE/SBWRTIE 11100

ASWRITE 11110

SDRAM_ACTV 11011

SDRAM_DCAB/DEAC 11010

SDRAM_MRS 11000

Control group value

HOLDA~

AOE~/SDRAS~/SSOE~

RESET AWE~/SDWE~/SSWE~

ARE~/SDCAS~/SSADS~

TMS711 320C6211/C6711 Microprocessor Support

5–1

Page 56

Reference:Channel Groups

Channel Assignments

Channel assignments listed in Tables 5–2 through 5–4 use the following

conventions:

H All signals are required by the support unless indicated otherwise.

H Channels are listed starting with the most significant bit (MSB), descending

to the least significant bit (LSB).

H Channel group assignments are for all modules unless otherwise noted.

H An Tilde symbol (~) following a signal name indicates an active low signal.

H An equals symbol (=) following a signal name indicates that it is double

probed.

H The module in the lower-numbered slot is referred to as the HI module and

the module in the lower-numbered slot is referred to as the LO module.

The portable logic analyzer has the lower numbered slots on the top and the

benchtop logic analyzer has the lower numbered slots on the left.

The channel assignment groups will be displayed in the following order:

Group name Display radix

Address Hexadecimal

Data Hexadecimal

Mnemonic None

Control Symbolic

Async Off

CEnable Off

BEnable Off

Misc Off

5–2

TMS711 320C6211/C6711 Microprocessor Support

Page 57

Reference:Channel Groups

Table 5–2 lists the probe section and channel assignments for the Address group

and the microprocessor signal to which each channel connects. By default the

Address channel group assignments are displayed in hexadecimal.

T able 5–2: Address channel group assignments

Bit order Section:channel C6211/C6711 signal name

31 A3:7 NC

21 A2:5 NC

20 A2:4 NC

19 A2:3 EA21

18 A2:2 EA20

17 A2:1 EA19

16 A2:0 EA18

15 A1:7 EA17

14 A1:6 EA16

13 A1:5 EA15

12 A1:4 EA14

11 A1:3 EA13

10 A1:2 EA12

9 A1:1 EA11

8 A1:0 EA10

7 A0:7 EA9

6 A0:6 EA8

5 A0:5 EA7

4 A0:4 EA6

3 A0:3 EA5

2 A0:2 EA4

1 A0:1 EA3

0 A0:0 EA2

Table 5–3 lists the probe section and channel assignments for the Data group and

the microprocessor signal to which each channel connects. By default the Data

channel group assignments are displayed in hexadecimal.

T able 5–3: Data channel group assignments

Bit order Section:channel C6211/C6711 signal name

31 D3:7 ED31

30 D3:6 ED30

TMS711 320C6211/C6711 Microprocessor Support

5–3

Page 58

Reference:Channel Groups

T able 5–3: Data channel group assignments (cont.)

Bit order C6211/C6711 signal nameSection:channel

29 D3:5 ED29

28 D3:4 ED28

27 D3:3 ED27

26 D3:2 ED26

25 D3:1 ED25

24 D3:0 ED24

23 D2:7 ED23

22 D2:6 ED22

21 D2:5 ED21

20 D2:4 ED20

19 D2:3 ED19

18 D2:2 ED18

17 D2:1 ED17

16 D2:0 ED16

15 D1:7 ED15

14 D1:6 ED14

13 D1:5 ED13

12 D1:4 ED12

11 D1:3 ED11

10 D1:2 ED10

9 D1:1 ED9

8 D1:0 ED8

7 D0:7 ED7

6 D0:6 ED6

5 D0:5 ED5

4 D0:4 ED4

3 D0:3 ED3

2 D0:2 ED2

1 D0:1 ED1

0 D0:0 ED0

5–4

TMS711 320C6211/C6711 Microprocessor Support

Page 59

Reference:Channel Groups

Table 5–4 lists the probe section and channel assignments for the Control group

and the microprocessor signal to which each channel connects. The default radix

of the Control group is SYMBOLIC on the logic analyzer. The symbol table file

name is C6211_Ctrl on the logic analyzer.

T able 5–4: Control channel group assignments

Bit order Section:channel C6211/C6711 signal name

4 C2:1 AOE~/SDRAS~/SSOE~

3 C2:0 AWE~/SDWE~/SSWE~

2 C2:2 ARE~/SDCAS~/SSADS~

1 C3:5 HOLDA~

0 C3:6 RESET~

By default Table 5–5 Async channel group assignments are not displayed.

T able 5–5: Async channel group assignments

Bit order Section:channel C6211/C6711 signal name

2 C2:1 AWE~/SDWE~/SSWE~

1 C2:0 ARE~/SDCAS~/SSADS~

0 C2:2 AOE~/SDRAS~/SSOE~

By default Table 5–6 CEnable channel group assignments are not displayed.

T able 5–6: CEnable channel group assignments

Bit order Section:channel C6211/C6711 signal name

3 C1:3 CE3~

2 C1:2 CE2~

1 C1:1 CE1~

0 C1:0 CE0~

By default Table 5–7 BEnable channel group assignments are not displayed.

T able 5–7: BEnable channel group assignments

Bit order Section:channel C6211/C6711 signal name

3 C1:7 BE3~

2 C1:6 BE2~

TMS711 320C6211/C6711 Microprocessor Support

5–5

Page 60

Reference:Channel Groups

T able 5–7: BEnable channel group assignments (cont.)

Bit order C6211/C6711 signal nameSection:channel

1 C1:5 BE1~

0 C1:4 BE0~

By default Table 5–8 Misc channel group assignments are not displayed.

T able 5–8: Misc channel group assignments

Bit order Section:channel C6211/C6711 signal name

0 Clock:3 ECLKOUT

Table 5–9 lists the probe section and clock and qualifier channel assignments.

The clock probes are not part of any group.

T able 5–9: Clock and Qualifier channel assignments

Section:channel C6211/C6711 signal name

CLK:3 ECLKOUT

C2:0 ARE~/SDCAS~/SSADS~

C2:1 AWE~/SDWE~/SSWE~

C2:2 AOE~/SDRAS~/SSOE~

Acquisition Setup. The TMS711 320C6211/C6711support affects the logic

analyzer setup menus (and submenus) by modifying existing fields and adding

micro-specific fields.

The TMS711 320C6211/C6711 support adds the selection C6211 to the Load

Support Package dialog box, under the File pulldown menu. Once the C6211

support has been loaded, the Custom clocking mode selection in the module

Setup menu is also enabled.

5–6

TMS711 320C6211/C6711 Microprocessor Support

Page 61

CPU To Mictor Connections

To probe the microprocessor you will need to make connections between the

CPU and the Mictor pins of the P6434 Mass Termination Probe. Refer to the

P6434 Mass Termination Probe manual, Tektronix part number 070-9793-xx, for

more information on mechanical specifications. Tables 5–10 through 5–16 list

the CPU pin to Mictor pin connections.

Tektronix uses a counterclockwise pin assignment. Pin-1 is located at the top

left, and pin-2 is located directly below it. Pin-20 is located on the bottom right,

and pin-21 is located directly above it.

AMP uses an odd side-even side pin assignment. Pin-1 is located at the top left,

and pin-3 is located directly below it. Pin-2 is located on the top right, and pin-4

is located directly below it (see Figure 5–1).

NOTE. When designing Mictor connectors into your system under test, always

follow the Tektronix pin assignment.

Reference:Channel Groups

Tektronix Pinout AMP Pinout

Pin 1

Pin 19

Pin 38

Pin 20

Pin 1

Pin 37

Pin 2

Pin 38

Figure 5–1: Pin assignments for a Mictor connector (component side)

NOTE. To protect the CPU and the inputs of the module, it is recommended that a

180 W resistor is connected in series between each ball pad of the CPU and each

pin of the Mictor connector. The resistor must be within 1/2 inch of the ball pad

of the CPU.

T able 5–10: CPU to Mictor connections for Mictor A pins

AMP

Logic analyzer

channel

A0:0 EA2 A38 A20

C6211/C6711

signal name

Mictor A

pin number

Tektronix

Mictor A

pin number

A0:1 EA3 A36 A21

A0:2 EA4 A34 A22

TMS711 320C6211/C6711 Microprocessor Support

5–7

Page 62

Reference:Channel Groups

T able 5–10: CPU to Mictor connections for Mictor A pins (cont.)

AMP

Logic analyzer

channel

A0:3 EA5 A32 A23

A0:4 EA6 A30 A24

A0:5 EA7 A28 A25

A0:6 EA8 A26 A26

A0:7 EA9 A24 A27

A1:0 EA10 A22 A28

A1:1 EA11 A20 A29

A1:2 EA12 A18 A30

A1:3 EA13 A16 A31

A1:4 EA14 A14 A32

A1:5 EA15 A12 A33

A1:6 EA16 A10 A34

A1:7 EA17 A8 A35

A2:0 EA18 A37 A19

A2:1 EA19 A35 A18

C6211/C6711

signal name

Mictor A

pin number

Tektronix

Mictor A

pin number

A2:2 EA20 A33 A17

A2:3 EA21 A31 A16

A2:4 NC A29 A15

A2:5 NC A27 A14

A2:6 NC A25 A13

A2:7 NC A23 A12

A3:0 NC A21 A11

A3:1 NC A19 A10

A3:2 NC A17 A9

A3:3 NC A15 A8

A3:4 NC A13 A7

A3:5 NC A11 A6

A3:6 NC A9 A5

A3:7 NC A7 A4

5–8

TMS711 320C6211/C6711 Microprocessor Support

Page 63

T able 5–11: CPU to Mictor connections for Mictor D pins

Reference:Channel Groups

AMP

C6211/C6711

LA channel

D0:0 ED0 D38 D20

D0:1 ED1 D36 D21

D0:2 ED2 D34 D22

D0:3 ED3 D32 D23

D0:4 ED4 D30 D24

D0:5 ED5 D28 D25

D0:6 ED6 D26 D26

D0:7 ED7 D24 D27

D1:0 ED8 D22 D28

D1:1 ED9 D20 D29

D1:2 ED10 D18 D30

D1:3 ED11 D16 D31

D1:4 ED12 D14 D32

D1:5 ED13 D12 D33

D1:6 ED14 D10 D34

signal name

Mictor D

pin number

Tektronix

Mictor D

pin number

D1:7 ED15 D8 D35

D2:0 ED16 D37 D19

D2:1 ED17 D35 D18

D2:2 ED18 D33 D17

D2:3 ED19 D31 D16

D2:4 ED20 D29 D15

D2:5 ED21 D27 D14

D2:6 ED22 D25 D13

D2:7 ED23 D23 D12

D3:0 ED24 D21 D11

D3:1 ED25 D19 D10

D3:2 ED26 D17 D9

D3:3 ED27 D15 D8

D3:4 ED28 D13 D7

D3:5 ED29 D11 D6

TMS711 320C6211/C6711 Microprocessor Support

5–9

Page 64

Reference:Channel Groups

T able 5–11: CPU to Mictor connections for Mictor D pins (cont.)

AMP

C6211/C6711

LA channel

D3:6 ED30 D9 D5

D3:7 ED31 D7 D4

signal name

Mictor D

pin number

Tektronix

Mictor D

pin number

T able 5–12: CPU to Mictor connections for Mictor C pins

AMP

C6211/C6711

LA channel