Page 1

Instruction Manual

TMS 231

MC3X0 Microprocessor Support

071-0891-00

www.tektronix.com

Page 2

Copyright © T ektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

SOFTWARE WARRANTY

T ektronix warrants that the media on which this software product is furnished and the encoding of the programs on

the media will be free from defects in materials and workmanship for a period of three (3) months from the date of

shipment. If a medium or encoding proves defective during the warranty period, T ektronix will provide a

replacement in exchange for the defective medium. Except as to the media on which this software product is

furnished, this software product is provided “as is” without warranty of any kind, either express or implied.

T ektronix does not warrant that the functions contained in this software product will meet Customer’s

requirements or that the operation of the programs will be uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period. If T ektronix is unable to provide a replacement that is free from defects in materials and

workmanship within a reasonable time thereafter, Customer may terminate the license for this software product

and return this software product and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S PAYMENT IS

THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS

WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER

TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Table of Contents

Getting Started

Operating Basics

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Conventions vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix viii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Support Package Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Analyzer Software Compatibility 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Analyzer Configuration 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements and Restrictions 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limitation of the Support 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functionality Not T ested 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Logic Analyzer to a System Under T est 1–2. . . . . . . . . . . . . . . . . . .

Setting Up the Support 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Support Software 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel Group Definitions 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Support Package Setups 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clocking 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Clocking 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquiring and Viewing Disassembled Data 2–9. . . . . . . . . . . . . . . . . . . . .

Acquiring Data 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Disassembled Data 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Display Format 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Display Format 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Display Format 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Flow Display Format 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subroutine Display Format 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing How Data is Displayed 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Display Selections 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Micro-Specific Fields 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Marking Cycles 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing an Example of Disassembled Data 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

Specification T ables 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Parts

Parts Ordering Information 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TMS231 MC3X0 Microprocessor Support

i

Page 5

Table of Contents

Reference

Index

Symbol Table 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel Assignments 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPU To Mictor Connections 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

TMS231 MC3X0 Microprocessor Support

Page 6

List of Figures

Table of Contents

Figure 2–1: MC3X0 _RIM sample point and master sample point 2–3. .

Figure 2–2: MC3X0 _EIM sample point and master sample point 2–5. .

Figure 2–3: MC3X0 _CORE(MLB) sample point and master

sample point 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: Hardware display format 2–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–1: Pin assignments for a Mictor connector

(component side) 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TMS231 MC3X0 Microprocessor Support

iii

Page 7

Table of Contents

List of Tables

Table 2–1: Description of special characters in the display 2–9. . . . . . . .

Table 2–2: Cycle type labels and definitions 2–10. . . . . . . . . . . . . . . . . . . .

Table 2–3: Interrupt and exception labels 2–15. . . . . . . . . . . . . . . . . . . . . .

Table 3–1: Electrical specifications 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–1: MC3X0 _Ctrl group symbol table definitions 5–1. . . . . . . . . .

Table 5–2: Address channel group assignments 5–3. . . . . . . . . . . . . . . . .

Table 5–3: Data channel group assignments 5–4. . . . . . . . . . . . . . . . . . . .

Table 5–4: Proc_Mode channel group assignments 5–5. . . . . . . . . . . . . .

Table 5–5: Control channel group assignments 5–5. . . . . . . . . . . . . . . . . .

Table 5–6: Chip_Select channel group assignments 5–6. . . . . . . . . . . . . .

Table 5–7: Interrupt channel group assignments 5–6. . . . . . . . . . . . . . . .

Table 5–8: Misc channel group assignments 5–6. . . . . . . . . . . . . . . . . . . .

Table 5–9: Clock and Qualifier channel assignments 5–7. . . . . . . . . . . . .

Table 5–10: Signals required for clocking and disassembly 5–8. . . . . . . .

Table 5–11: Signals not required for clocking and disassembly 5–9. . . . .

Table 5–12: CPU to Mictor connections for clock and qualifiers 5–11. . .

Table 5–13: CPU to Mictor connections for Mictor A pins 5–11. . . . . . . .

Table 5–14: CPU to Mictor connections for Mictor D pins 5–12. . . . . . . .

Table 5–15: CPU to Mictor connections for Mictor C pins 5–13. . . . . . . .

iv

TMS231 MC3X0 Microprocessor Support

Page 8

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

TMS231 MC3X0 Microprocessor Support

v

Page 9

General Safety Summary

vi

TMS231 MC3X0 Microprocessor Support

Page 10

Preface

Manual Conventions

This instruction manual contains specific information about the TMS231 MC3X0

microprocessor support package and is part of a set of information on how to

operate this product on compatible Tektronix logic analyzers.

If you are familiar with operating microprocessor support packages on the logic

analyzer for which the TMS231 MC3X0 support was purchased, you will only

need this instruction manual to set up and run the support.

If you are not familiar with operating microprocessor support packages, you will

need to supplement this instruction manual with information on basic operations

to set up and run the support. See Manual Conventions below for more information.

This manual uses the following conventions:

H The term “disassembler” refers to the software that disassembles bus cycles

into instruction mnemonics and cycle types.

H The phrase “information on basic operations” refers to your online help or a

user manual covering the basic operations of microprocessor support.

TMS231 MC3X0 Microprocessor Support

vii

Page 11

Preface

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

1-503-627-2400

6:00 a.m. – 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

viii

TMS231 MC3X0 Microprocessor Support

Page 12

Getting Started

Page 13

Getting Started

This section contains information on the TMS231 MC3X0 microprocessor

support package and on connecting your logic analyzer to your system under test.

Support Package Description

The TMS231 MC3X0 microprocessor support package displays disassembled

data from systems based on the MCORE MC3X0 microprocessor.

To use this support efficiently, you need to have the items listed in the information on basic operations and M3X0 User Manual, M340 Specification v1.1,

11/20/98.

Information on basic operations also contains a general description of support.

Logic Analyzer Software Compatibility

The floppy disk label on the microprocessor support states which version of logic

analyzer software this support is compatible with.

Logic Analyzer Configuration

The TMS231 MC3X0 support requires a minimum of one 102-channel module.

Requirements and Restrictions

You should review the general requirements and restrictions of microprocessor

support packages as they pertain to your system under test.

You should also review electrical specifications in Specifications on page 3–1 as

they pertain to your system under test, as well as the following descriptions of

other MC3X0 support requirements and restrictions.

System Clock Rate

The operating speeds that the MC3X0

microprocessor are listed on Table 3–1. These specifications were valid at the

time this manual was printed. Please contact your Tektronix Sales Representative

for current information on the fastest devices supported.

support can acquire data from the MC3X0

TMS231 MC3X0 Microprocessor Support

1–1

Page 14

Getting Started

NonIntrusive Acquisition

Disabling the Instruction

Cache

Acquiring microprocessor bus cycles is nonintrusive to the system under test.

That is, the MC3X0 support does not intercept, modify, or present signals back to

the system under test.

To display disassembled acquired data, you must disable the internal instruction

cache. Disabling the cache makes all instruction prefetches visible on the bus so

they can be acquired and displayed disassembled.

Limitation of the Support

8 Bit Mode

Multiple Instructions

In 8 bit mode if the Data comes in higher than 3 bytes D[31:24], D[23:16] and

D[15:8] it is not supported.

If multiple Branch instructions and MultiRead/Write instructions are entering the

fetch queue then the TMS231 MC3X0 support may not disassemble correctly. In

these cases the Mark Opcode Option can be used for correct disassembly.

Functionality Not Tested

H RIM mode

H 16 bit Upper and Lower modes

H 8 bit mode

Since the modes for RIM, 16 bit Upper and Lower, and 8 bit are not tested, even

though they are supported, the disassembly may be incorrect.

Connecting the Logic Analyzer to a System Under Test

You can use channel probes, clock probes, and leadsets with a commercial test

clip (or adapter) to make connections between the logic analyzer and your system

under test.

1–2

TMS231 MC3X0 Microprocessor Support

Page 15

Getting Started

To connect the probes to MC3X0 signals in the system under test using a test

clip, follow these steps:

1. Power off your system under test. It is not necessary to power off the logic

analyzer.

CAUTION. To prevent static damage, handle the microprocessor, the probes, and

the logic analyzer module components only in a static-free environment. Static

discharge can damage these components.

Always wear a grounding wrist strap, heel strap, or similar device while

handling the microprocessor.

2. To discharge your stored static electricity, touch the ground connector located

on the back of the logic analyzer. If you are using a test clip, touch any of the

ground pins on the clip to discharge stored static electricity from the test clip.

CAUTION. To prevent damage to the pins on the microprocessor, place the system

under test on a horizontal surface before connecting the test clip.

3. Place the system under test on a horizontal static-free surface.

4. Use Tables 5–2 through 5–12 beginning on page 5–3 to connect the channel

probes to MC3X0 signal pins on the test clip or in the system under test.

Use leadsets to connect at least one ground lead from each channel probe and

the ground lead from each clock probe to ground pins on your test clip.

TMS231 MC3X0 Microprocessor Support

1–3

Page 16

Getting Started

1–4

TMS231 MC3X0 Microprocessor Support

Page 17

Operating Basics

Page 18

Setting Up the Support

The information in this section is specific to the operations and functions of the

TMS231 MC3X0 microprocessor support on any Tektronix logic analyzer for

which it can be purchased.

Before you acquire and display disassembled data, you need to load the support

and specify setups for clocking and triggering as described in the information on

basic operations in your logic analyzer online help. The microprocessor support

provides default values for each of these setups as well as user-definable settings.

Installing the Support Software

NOTE. Before you install any software, it is recommended that you verify that the

microprocessor support software is compatible with the logic analyzer software.

To install the TMS231 MC3X0 software on your Tektronix logic analyzer, follow

these steps:

1. Insert the floppy disk in the disk drive.

2. Click the Windows Start button, point to Settings, and click Control Panel.

3. In the Control Panel window, double-click Add/Remove Programs.

4. Follow the instructions on the screen for installing the software from the

To remove or uninstall software, close all windows, and then follow the above

instructions and select Uninstall.

Channel Group Definitions

The software automatically defines channel groups for the support. The channel

groups for the TMS231 MC3X0 support are Address, Data, Control, Chip Select,

Proc_Mode, Interrupt, and Misc. The channel group tables begin on page 5–1.

floppy disk.

TMS231 MC3X0 Microprocessor Support

2–1

Page 19

Setting Up the Support

Support Package Setups

The TMS231 MC3X0 software installs MC3X0 support package setup file.

Clocking

MC3X0 Setup

Options

This setup provides disassembly support. Signals are displayed as they appear

electrically on the front side bus.

The TMS231 MC3X0 support offers a microprocessor-specific clocking mode

for the MC3X0 microprocessor. This clocking mode is the default selection

whenever you load the TMS231 MC3X0 support.

Disassembly is not correct when using the Internal or External clocking modes.

Information on basic operations in your online help describes in more detail how

to use these clock selections for general purpose analysis.

H Internal clocking is used for timing and is based on the clock generated by a

Tektronix logic analyzer. You can configure the clock rate from 50 ms down

to 4 ns resolution.

H External clocking is used when you configure the clocking of data based on

logical combinations of clocks and qualifiers.

Custom Clocking

When Custom is selected, the Custom Clocking Options menu has the subtitle

MC3X0

also displayed.

The TMS231 MC3X0 support has three clocking options.

H MC3X0

H MC3X0

H MC3X0 _CORE(MLB)

Microprocessor Clocking Support added, and the clocking options are

_RIM

_EIM

2–2

TMS231 MC3X0 Microprocessor Support

Page 20

Setting Up the Support

MC3X0 _RIM

After loading the MC3X0

support and choosing one of the previous clocking

options, the following disassembly support selections are available. These

Disassembly support selections are defined based on the actual control signals

available to the system under test

.

Disassembly support selections:

H Use Control Signals Default (most accurate disassembly)

H Clock Edge With R/W~

H Clock Edge Without R/W~

Use Control Signals (Default). The Use Control Signals selection acquires signals

(RST~, OE~, TA~ and SHS~) with the greatest amount of accuracy. Signals are

sampled at every clock edge when the control signals are active. The master

strobe occurs when the clock signal line changes from low to high. Figure 2–1

shows the sample point and master sample point for acquiring the signals.

CLKOUT

ADDRESS

EB [3:0]~

RST~

SHS~

TA~

OE~

DATA (Read)

DATA (Write)

Sample Point

for EB

Sample Point for

Address, Data, Control

and

Master Point

Figure 2–1: MC3X0 _RIM sample point and master sample point

TMS231 MC3X0 Microprocessor Support

2–3

Page 21

Setting Up the Support

Clock Edge With R/W~. The Clock Edge With R/W~ is best used when you want

to distinguish a read cycle from a write cycle, even though extra data is saved

that may cause errors in the disassembly. With this selection, signals are acquired

at every clock cycle without any qualifier. On every falling edge Byte Enable

signals are sampled and on every rising edge Address, Control, and Data signals

are sampled and saved.

Clock Edge Without R/W~. The Clock Edge Without R/W~ is best used when you

have not aquired control signals for acquisition.

Signals are acquired at every clock cycle without any qualifier. On every falling

edge Byte Enable signals are sampled and on every rising edge Address, Control

and Data signals are sampled and saved. This selection does not distinguish a

read cycle from a write cycle so extra data is saved that may cause errors in the

disassembly.

2–4

TMS231 MC3X0 Microprocessor Support

Page 22

Setting Up the Support

MC3X0 _EIM

Use Control Signals (Default). The Use Control Signals selection acquires signals

with the greatest amount of accuracy. Signals are sampled at every rising clock

edge when the control signals (RST~, OE~ and R/W~) are active. The master

strobe occurs when the clock signal line changes from low to high. Figure 2–2

shows the sample point and master sample point for acquiring the signals.

CLKOUT

ADDRESS

EB [3:0]~

RST~

R/W~ (Read)

R/W~ (Write)

OE~

DATA (Read)

DATA (Write)

Sample Point

for EB

Sample Point for

Address, Data, Control

and

Master Point

Figure 2–2: MC3X0 _EIM sample point and master sample point

Clock Edge With R/W~. The Clock Edge With R/W~ is best used when you want

to distinguish a read cycle from a write cycle; unfortunately, this selection saves

extra data causing errors in the disassembly. With this selection, signals are

acquired at every clock cycle without any qualifier. On every falling edge Byte

Enable signals are sampled and on every rising edge Address, Control, and Data

signals are sampled and saved.

TMS231 MC3X0 Microprocessor Support

2–5

Page 23

Setting Up the Support

Clock Edge Without R/W~. The Clock Edge Without R/W~ is best used when you

have not acquired control signals for acquisition.

Signals are acquired at every clock cycle without any qualifier. On every falling

edge Byte Enable signals are sampled and on every rising edge the Address,

Control and Data signals are sampled and saved. This selection does not

distinguish a read cycle from a write cycle, extra data is saved that may cause

errors in the disassembly.

MC3X0_CORE(MLB)

Use Control Signals (Default). The Use Control Signals selection acquires signals

with the greatest amount of accuracy. Signals are sampled at every rising clock

edge when the control signals (RST~, TREQ~ and TA~) are active. The master

strobe occurs when the clock signal line changes from low to high. Figure 2–3

shows the sample point and master sample point for acquiring the signals.

CLKOUT

ADDRESS

EB [3:0]~

RST~

TREQ~

TA~

DATA (Read)

2–6

DATA (Write)

Sample Point for

Address and

Control

Sample Point for

Data and Master Point

Figure 2–3: MC3X0 _CORE(MLB) sample point and master sample point

Clock Edge With R/W~. The Clock Edge With R/W~selection is best used when

you want to distinguish a read cycle from a write cycle; unfortunately, this

selection saves extra data causing errors in the disassembly. With this selection,

signals are acquired at every clock cycle without any qualifier. On every falling

edge, Address and Control signals are sampled and on every rising edge Data

signals are sampled and saved.

TMS231 MC3X0 Microprocessor Support

Page 24

Setting Up the Support

Clock Edge Without R/W~. The Clock Edge Without R/W~ is best used when you

have not acquired control signals for acquisition.

Signals are acquired at every clock cycle without any qualifier. On every falling

edge Address and Control signals are sampled and on every rising edge Data

signals are sampled and saved. This selection does not distinguish a read cycle

from a write cycle, so extra data is saved that may cause errors in the disassembly.

Setup and Hold Time. You can change the Setup and Hold time window of all the

signal groups. The default Setup time is 2.5 ns and the Hold time is 0 ns. The

Setup and Hold that you defined has precedence over any default Setup and Hold

time.

TMS231 MC3X0 Microprocessor Support

2–7

Page 25

Setting Up the Support

2–8

TMS231 MC3X0 Microprocessor Support

Page 26

Acquiring and Viewing Disassembled Data

Acquiring Data

Once you load the TMS231 MC3X0 support, choose a clocking mode, and specify

the trigger, you are ready to acquire and disassemble data.

If you have any problems acquiring data, refer to information on basic operations

in your logic analyzer online help or Appendix A: Error Messages and

Disassembly Problems in your logic analyzer user manual.

Viewing Disassembled Data

You can view disassembled data in six display formats: Timing, State, Hardware,

Software, Control Flow, and Subroutine. The information on basic operations

describes how to select the disassembly display formats.

NOTE. Selections in the Disassembly property page (the Disassembly Format

Definition overlay) must be set correctly for your acquired data to be disassembled correctly. Refer to Changing How Data is Displayed on page 2–12.

The default display format displays the Address, Data, Control, Proc_Mode,

ChipSelect, and Interrupt channel group values for each sample of acquired data

along with Sample, Mnemonic, and Timestamp.

Any channel group or display column can be made visible by selecting the Add

column option in the Disassembly property page.

The disassembler displays special characters and strings in the instruction

mnemonics to indicate significant events. Table 2–1 lists these special characters

and strings and gives a definition of what they represent.

T able 2–1: Description of special characters in the display

Character or string displayed Definition

#

> Indicates that there is sufficient room on the screen to show

>> On the TLA 700 Indicates that the instruction was manually marked as a

Indicates an immediate value.

all available data.

program fetch.

TMS231 MC3X0 Microprocessor Support

2–9

Page 27

Acquiring and Viewing Disassembled Data

T able 2–1: Description of special characters in the display (cont.)

Character or string displayed Definition

t

Indicates the number shown is in decimal, such as #12t.

Timing Display Format

Hardware Display Format

****

Indicates that there is insufficient data available for complete

disassembly of the instruction; the number of asterisks

indicates the width of the data that is unavailable. Each two

asterisks represent one byte.

The Timing-Waveform display format file is provided for the TLA 700 Series

support. The timing-waveform display format file sets up and displays the

following waveforms:

CLKOUT

Address (busform)

Data (busform)

RST~

R/W~

OE~

EB~[0:3]

CS~[1:4]

In Hardware display format, the disassembler displays certain cycle type labels in

parentheses. Table 2–2 lists cycle type labels and gives a definition of the cycle

they represent. Reads to interrupt and exception vectors are labeled with the

vector name.

2–10

T able 2–2: Cycle type labels and definitions

Cycle Type

( RESET )

( DATA RETRIEVAL ERROR ) Indicates invalid DATA READ cycle

( READ ) Indicates DATE READ cycle

( WRITE ) Indicates DATE WRITE cycle

( EXTENSION)

( FLUSH )

( READ or WRITE )

( UNKNOWN )

Definition

Indicates system RESET

Indicates an extension to a preceding instruction opcode

Indicates a cycle was fetched but not executed

Indicates a noninstruction sequence when R/W~ is not

used

Indicates a combination of control bits are unexpected or

unrecognized

TMS231 MC3X0 Microprocessor Support

Page 28

Acquiring and Viewing Disassembled Data

Figure 2–4 shows an example of a Hardware display.

Software Display Format

Control Flow Display

Format

Figure 2–4: Hardware display format

The Software display format displays only the first fetch of executed instructions.

Flushed cycles and extensions are not shown, even though they are part of the

executed instruction. Read extensions are used to disassemble the instruction, but

they are not displayed as a separate cycle in the Software display format. Data

reads and writes are not displayed.

The Control Flow display format displays only the first fetch of instructions that

cause a branch in the addressing and special cycles to change the flow of control.

Instructions that generate a change in the flow of control in the MC3X0

microprocessor are as follows:

BF Branch on condition false

BR Branch

BT Branch on condition true

JMP Jump

JMPI Jump indirect

TMS231 MC3X0 Microprocessor Support

2–11

Page 29

Acquiring and Viewing Disassembled Data

Subroutine Display

Format

The Subroutine display format displays only the first fetch of subroutine call or

return instructions. It can display conditional subroutine calls if they are

considered to be taken.

Instructions that generate a subroutine call or a return in the MC3X0 microprocessor are as follows:

BSR Branch on subroutine

JSR Jump to subroutine

JMP Jump

JSRI Jump to subroutine indirect

RTE Return from exception

RFI Return from interrupt

BKPT Break Point

TRAP Trap

Changing How Data is Displayed

Common fields and features allow you to further modify displayed data to suit

your needs. You can make common and optional display selections in the

Disassembly property page (the Disassembly Format Definition overlay).

Optional Display

Selections

You can make optional selections for acquired disassembled data. In addition to

the common selections (described in the information on basic operations), you

can change the displayed data in the following ways:

Show: Hardware (default)

Software

Control Flow

Subroutine

Highlight: Software (default)

Control Flow

Subroutine

None

Disasm Across Gaps: No (default)

Yes

2–12

TMS231 MC3X0 Microprocessor Support

Page 30

Acquiring and Viewing Disassembled Data

Micro-Specific Fields

Endian Mode. Indicate the MC3X0 processor configuration for viewing data from

memory in the following order:

Little Endian (default)

Big Endian

Interface. Select the interface type:

RIM (default)

EIM

CORE(MLB)

Data Port Width. Indicate the data port width:

32-bit port (default)

16-bit port (D15:D0)

16-bit port (D31:D16)

8-bit port (D7:D0)

R/W~ Signal. Indicate whether the R/W~ signal is available:

Available (default)

Not Available

CS Mode. Indicate whether the Chip select CS[0:5] signals are available in the

system:

CS Available (default)

Not Available

Vector Base Register. Enter the base address of the Interrupt Vector table:

0x00000000 (default)

RIM CS1 Base Address. Enter the base address for the Chip select (CS1) for RIM

Interface:

0x00000000 (default)

RIM CS2 Base Address. Enter the base address for the Chip select (CS1) for RIM

Interface:

0x00000000 (default)

TMS231 MC3X0 Microprocessor Support

2–13

Page 31

Acquiring and Viewing Disassembled Data

БББББББББББББББББББББ

БББББББББББББББББББББ

БББББББББББББББББББББ

Á

БББББББББББББББББББББ

Á

БББББББББББББББББББББ

БББББББББББББББББББББ

БББББББББББББББББББББ

БББББББББББББББББББББ

БББББББББББББББББББББ

RIM CS3 Base Address. Enter the base address for the Chip select (CS1) for RIM

Interface:

0x00000000 (default)

RIM CS4 Base Address. Enter the base address for the Chip select (CS1) for RIM

Interface:

0x00000000 (default)

Marking Cycles

TMS231 MC3X0 support allows marks on potential instruction fetch cycles

The

(which includes read extensions and flush cycles.) Cycle marks are not available

if the cursor is placed on other cycle marks. To place a cycle mark use the Mark

Opcode button. The Mark Opcode button functions when disassembly is

available.

If the cycle being marked, is not a potential instruction fetch cycle (which

includes read extensions and flush cycles), the Mark Opcode selections are

replaced by a note indicating that “An Opcode Mark cannot be placed at the

selected data sample.”

When a cycle is marked, this character, >>, is displayed immediately to the left

of the Mnemonics column. Cycles can be unmarked by using the Undo Mark

selection, which removes this character, >>. If more than one set of sequences are

marked, then the you can undo the marks using the Remove all Marks option.

The following cycle marks are available for instruction fetch cycles in the 8 bit

Data Port:

Opcode

Extension

Flush

Read

ÁÁÁÁ

Write

Undo Mark

Marks the cycle as an instruction opcode

Marks the cycle as an extension to an instruction opcode

Marks the cycle as a flushed cycle

Marks the cycle as a read cycle (if the R/W~ signal is not available)

ББББББББББББББББББББ

Marks the cycle as a write cycle (if the R/W~ signal is not available)

Removes all marks from the current sample

The following cycle marks are available for instruction fetch cycles in the 16 bit

Data Port:

Opcode

Read

Write

Marks the cycle as an instruction opcode

Marks the cycle as a read cycle (if the R/W~ signal is not available)

Marks the cycle as a write cycle (if the R/W~ signal is not available)

2–14

TMS231 MC3X0 Microprocessor Support

Page 32

Acquiring and Viewing Disassembled Data

Á

Á

Displaying Exception

Labels

Flush

Undo Mark

Marks the cycle as a flushed cycle

Removes all marks from the current sample

The following cycle marks are available for instruction fetch cycles in the 32 bit

Data Port:

Opcode_Opcode

Opcode_Flush

Flush_Opcode

Extension

Flush

Read

ÁÁÁÁ

Write

Undo Mark

Marks the cycle as an instruction opcode and opcode

Marks the cycle as an instruction opcode and flush

Marks the cycle as a flush and instruction opcode

Marks the cycle as an extension to an instruction opcode

Marks the cycle as a flushed cycle

Marks the cycle as a read cycle (if the R/W~ signal is not available)

ББББББББББББББББББББ

Marks the cycle as a write cycle (if the R/W~ signal is not available)

Removes all marks from the current sample

The disassembler can display TMS231 MC3X0 exception labels. The exception

table must reside in external memory for interrupt and exception cycles to be

visible to the disassembler.

You can enter the table prefix in the Exception Prefix field. The Exception Prefix

field provides the disassembler with the offset address; enter a three-digit

hexadecimal value corresponding to the prefix of the exception table.

These fields are located in the Disassembly property page (Dissembled Format

Definition overlay).

Table 2–3 lists the

TMS231 MC3X0 interrupt and exception labels.

T able 2–3: Interrupt and exception labels

Vector

Number

0 0x000 (RESET)

1 0x004 (MISALIGNED ACCESS)

2 0x008 (ACCESS ERROR)

3 0x00C (DIVIDE BY ZERO)

4 0x010 (ILLEGAL INSTRUCTION)

5 0x014 (PRIVILEGE VIOLATION)

6 0x018 (TRACE EXCEPTION)

7 0x01C (BREAKPOINT EXCEPTION)

Offset Displayed interrupt or exception name

TMS231 MC3X0 Microprocessor Support

2–15

Page 33

Acquiring and Viewing Disassembled Data

T able 2–3: Interrupt and exception labels (Cont.)

Vector

Number

8 0x020 (UNRECOVERABLE ERROR)

9 0x024 (Idly4 ERROR)

10 0x028 (INT AUTOVECTOR)

11 0x02C (FINT AUTOVECTOR)

12 0x030 (RESERVED (HAI))

13 0x034 (RESERVED (FP))

14 0x038 (TLB INST MISS EXCEPTION)

15 0x03C (TLB DATA MISS EXCEPTION)

16 to190x040 to

0x04C

20 to300x050 to

0x078

31 0x07C (SYSTEM DESCRIPTOR POINTER)

32 to

127

0x080 to

0x1FC

Displayed interrupt or exception nameOffset

(TRAP #0 TO 3 INSTRUCTION VECTOR)

(RESERVED)

(RESERVED)

Viewing an Example of Disassembled Data

A demonstration system file (or demonstration reference memory) is provided on

your MC3X0 software support disk so you can see an example of how your

MC3X0 microprocessor bus cycles and instruction mnemonics look when they

are disassembled. Viewing the system file is not a requirement for preparing the

module for use. You can view the system file without connecting the logic

analyzer to your system under test.

2–16

TMS231 MC3X0 Microprocessor Support

Page 34

Specifications

Page 35

Specifications

Specification Tables

This section contains information regarding the specifications of the

TMS231 MC3X0

Tables 3–1 list the electrical requirements that the system under test must

produce for the TMS231 MC3X0 support to acquire correct data.

T able 3–1: Electrical specifications

Characteristics Requirements

System under test clock rate

Maximum specified clock rate: 100 MHz

Tested clock rate

Minimum setup time required 2.5 ns

Minimum hold time required 0 ns

* Please contact your Tektronix Sales Representative for current information on the

tested clock rate.

microprocessor support.

*

100 MHz

TMS231 MC3X0 Microprocessor Support

3–1

Page 36

Specifications

3–2

TMS231 MC3X0 Microprocessor Support

Page 37

Replaceable Parts

Page 38

Replaceable Parts

This section contains a list of the replaceable components for the

TMS231 MC3X0 hardware support product.

Parts Ordering Information

Replacement parts are available through your local Tektronix field office or

representative.

Changes to Tektronix products are sometimes made to accommodate improved

components as they become available and to give you the benefit of the latest

improvements. Therefore, when ordering parts, it is important to include the

following information in your order:

H Part number

H Instrument type or model number

H Instrument serial number

H Instrument modification number, if applicable

If you order a part that has been replaced with a different or improved part, your

local Tektronix field office or representative will contact you concerning any

change in part number.

Change information, if any, is located at the rear of this manual.

Using the Replaceable Parts List

The tabular information in the Replaceable Parts List is arranged for quick

retrieval. Understanding the structure and features of the list will help you find

all of the information you need for ordering replacement parts. The following

table describes the content of each column in the parts list.

TMS231 MC3X0 Microprocessor Support

4–1

Page 39

Replaceable Parts

Parts list column descriptions

Column Column name Description

1 Figure & index number Items in this section are referenced by figure and index numbers to the exploded view

illustrations that follow.

2 Tektronix part number Use this part number when ordering replacement parts from Tektronix.

3 and 4 Serial number Column three indicates the serial number at which the part was first effective. Column four

indicates the serial number at which the part was discontinued. No entries indicates the part is

good for all serial numbers.

5 Qty This indicates the quantity of parts used.

6 Name & description An item name is separated from the description by a colon (:). Because of space limitations, an

item name may sometimes appear as incomplete. Use the U.S. Federal Catalog handbook

H6-1 for further item name identification.

7 Mfr. code This indicates the code of the actual manufacturer of the part.

8 Mfr. part number This indicates the actual manufacturer’s or vendor’s part number.

Abbreviations

Chassis Parts

Mfr. Code to Manufacturer

Cross Index

Abbreviations conform to American National Standard ANSI Y1.1–1972.

Chassis-mounted parts and cable assemblies are located at the end of the

Replaceable Electrical Parts List.

The table titled Manufacturers Cross Index shows codes, names, and addresses

of manufacturers or vendors of components listed in the parts list.

4–2

TMS231 MC3X0 Microprocessor Support

Page 40

Manufacturers cross index

Mfr.

code

TK2548 XEROX CORPORATION 14181 SW MILLIKAN WA Y BEAVERT ON, OR 97005

Manufacturer Address City, state, zip code

Replaceable parts list

Fig. &

index

number

Tektronix

part number

071-0891-00

Serial no.

effective

Serial no.

discont’d

Qty Name & description Mfr. code Mfr. part number

STANDARD ACCESSORIES

1 MANUAL, TECH: INSTRUCTIONS, MC3X0, TMS231 TK2548

Replaceable Parts

071-0891-00

TMS231 MC3X0 Microprocessor Support

4–3

Page 41

Replaceable Parts

4–4

TMS231 MC3X0 Microprocessor Support

Page 42

Reference

Page 43

Reference: Tables

This section lists the Symbol table and the Channel group tables for disassembly

and timing.

Symbol Table

Table 5–1 lists the name, bit pattern, and meaning for the symbols in the file

MC3X0_Ctrl, the Control channel group symbol table.

T able 5–1: MC3X0 _Ctrl group symbol table definitions

Control group value

R/W~ EB3~

Symbol

RESET 0 X X X XX XXXX RESET

DATA_RETR_ERR 1 0 X X XX XXXX Data Retrieval Error

WRITE 1 1 0 X XX XXXX Data Write

READ 1 1 1 X XX XXXX Data Read

UNKNOWN X X X X XX XXXX Unknown

RST~ TSIZ0 EB1~

TEA~ OE~ EB0~

TSIZ1 EB2~

Meaning

TMS231 MC3X0 Microprocessor Support

5–1

Page 44

Reference:Tables

Channel Assignments

Channel assignments listed in Tables 5–2 through 5–8 use the following

conventions:

H All signals are required by the support unless indicated otherwise.

H Channels are listed starting with the most significant bit (MSB), descending

to the least significant bit (LSB).

H Channel group assignments are for all modules unless otherwise noted.

H A tilde symbol (~) following a signal name indicates an active low signal.

H An equals symbol (=) following a signal name indicates that it is double

probed.

H The module in the lower-numbered slot is referred to as the HI module and

the module in the lower-numbered slot is referred to as the LO module.

The portable logic analyzer has the lower-numbered slots on the top, and the

benchtop logic analyzer has the lower-numbered slots on the left.

The channel assignment groups are displayed in the following order:

Group name Display radix

Address Hexadecimal

Data Hexadecimal

Mnemonic None

Control Symbolic

Chip_select BIN

Proc_Mode BIN

Interrupt BIN

Misc Off

5–2

TMS231 MC3X0 Microprocessor Support

Page 45

Reference:Tables

Table 5–2 lists the probe section and channel assignments for the Address group

and the microprocessor signal to which each channel connects. By default the

Address channel group assignments are displayed in hexadecimal.

T able 5–2: Address channel group assignments

Bit order Section:channel MC3X0 signal name

31 A3:7 A31

30 A3:6 A30

29 A3:5 A29

28 A3:4 A28

27 A3:3 A27

26 A3:2 A26

25 A3:1 A25

24 A3:0 A24

23 A2:7 A23

22 A2:6 A22

21 A2:5 A21

20 A2:4 A20

19 A2:3 A19

18 A2:2 A18

17 A2:1 A17

16 A2:0 A16

15 A1:7 A15

14 A1:6 A14

13 A1:5 A13

12 A1:4 A12

11 A1:3 A11

10 A1:2 A10

9 A1:1 A9

8 A1:0 A8

7 A0:7 A7

6 A0:6 A6

5 A0:5 A5

4 A0:4 A4

3 A0:3 A3

2 A0:2 A2

1 A0:1 A1

0 A0:0 A0

TMS231 MC3X0 Microprocessor Support

5–3

Page 46

Reference:Tables

Table 5–3 lists the probe section and channel assignments for the Data group and

the microprocessor signal to which each channel connects. By default the Data

channel group assignments are displayed in hexadecimal.

T able 5–3: Data channel group assignments

Bit order Section:channel MC3X0 signal name

31 D3:7 D31

30 D3:6 D30

29 D3:5 D29

28 D3:4 D28

27 D3:3 D27

26 D3:2 D26

25 D3:1 D25

24 D3:0 D24

23 D2:7 D23

22 D2:6 D22

21 D2:5 D21

20 D2:4 D20

19 D2:3 D19

18 D2:2 D18

17 D2:1 D17

16 D2:0 D16

15 D1:7 D15

14 D1:6 D14

13 D1:5 D13

12 D1:4 D12

11 D1:3 D11

10 D1:2 D10

9 D1:1 D9

8 D1:0 D8

7 D0:7 D7

6 D0:6 D6

5 D0:5 D5

4 D0:4 D4

3 D0:3 D3

2 D0:2 D2

1 D0:1 D1

0 D0:0 D0

5–4

TMS231 MC3X0 Microprocessor Support

Page 47

Reference:Tables

Table 5–4 lists the probe section and channel assignments for the Proc_Mode

group and the microprocessor signal to which each channel connects. The default

radix of the Proc_Mode group is Binary on the logic analyzer.

T able 5 –4: Proc_Mode channel group assignments

Bit order Section:channel MC3X0 signal name

10 C2:7 PSTAT3

9 C2:6 PSTAT2

8 C2:5 PSTAT1

7 C2:4 PSTAT0

6 C3:6 TC2

5 C3:5 TC1

4 C3:4 TC0

3 C1:7 SEQ~

2 C1:2 BIGEND~

1 C1:0 IFETCH

0 C1:6 BURST~\BAA~

Table 5–5 lists the probe section and channel assignments for the Control group

and the microprocessor signal to which each channel connects. The default radix

of the Control group is Symbolic on the logic analyzer. The symbol table file

name is MC3X0_Ctrl.

T able 5–5: Control channel group assignments

Bit order Section:channel MC3X0 signal name

9 C2:3 RST~

8 C3:7 TEA~

7 C2:2 R/W~

6 C3:3 TSIZ1

5 C3:2 TSIZ0

4 C2:1 OE~*

3 C0:7 EB3~*

2 C0:6 EB2~*

1 C0:5 EB1~*

0 C0:4 EB0~*

* Indicates the signal is supported by RIM and EIM interface

TMS231 MC3X0 Microprocessor Support

5–5

Page 48

Reference:Tables

By default, Chip_Select channel group assignments in Table 5–6 are shown

displayed as binary.

T able 5–6: Chip_Select channel group assignments

Bit order Section:channel MC3X0 signal name

5 C1:5 CS5~

4 C1:4 CS4~*

3 C0:3 CS3~*

2 C0:2 CS2~*

1 C0:1 CS1~*

0 C0:0 CS0~

* Indicates the signal is supported by RIM and EIM interface

[

Indicates the signal is supported by EIM interface

[

[

By default, Interrupt channel group assignments in Table 5–7 are displayed as

binary.

T able 5–7: Interrupt channel group assignments

Bit order Section:channel MC3X0 signal name

1 C3:1 FINT~

0 C3:0 INT~

By default, Misc channel group assignments listed in Table 5–8 are not

displayed.

T able 5–8: Misc channel group assignments

Bit order Section:channel MC3X0 signal name

5 Clock:3 TREQ~

4 C2:0 TBUSY~

3 C1:3 ABORT~

2 Clock:2 SHS~

5–6

1 Clock:1 TA~

0 C1:1 RSTOUT~

TMS231 MC3X0 Microprocessor Support

Page 49

Reference:Tables

Table 5–9 lists the probe section and clock and qualifier channel assignments.

The clock probes are not part of any group.

T able 5–9: Clock and Qualifier channel assignments

MC3X0 signal

Section:channel

CLK:0 CLKOUT –

CLK:1 TA~ –

CLK:2 SHS~ –

CLK:3 TREQ~ –

C2:0 TBUSY~ –

C2:1 OE~ –

C2:2 R/W~ –

C2:3 RST~ –

QUAL:0 Not used 102 & 136 channel

QUAL:1 Not used 102 & 136 channel

QUAL:2 Not used 136 channel only

QUAL:3 Not used 136 channel only

name

Comments

Acquisition Setup. The TMS231 MC3X0 support affects the logic analyzer setup

menus (and submenus) by modifying existing fields and adding micro-specific

fields.

The TMS231 MC3X0 support adds the selection MC3X0 to the Load Support

Package dialog box, under the File pulldown menu. After the MC3X0 support is

loaded, the Custom clocking mode selection in the module Setup menu is

enabled.

TMS231 MC3X0 Microprocessor Support

5–7

Page 50

Reference:Tables

Table 5–10 lists the signals required for Clock and Disassembly.

T able 5–10: Signals required for clocking and disassembly

Section:channel MC3X0 signal name

A31–A24 A3

A23–A16 A2

A15–A8 A1

A7–A0 A0

D31–D24 D3

D23–D16 D2

D15–D8 D1

D7–D0 D0

CLKOUT Clock:0

TA~ Clock:1

SHS~ Clock:2

TREQ~ Clock:3

CS5~ C1:5

CS4~ C1:4

CS3~ C0:3

CS2~ C0:2

CS1~ C0:1

CS0~ C0:0

RST~ C2:3

TEA~ C3:7

R/W~ C2:2

TSIZ1 C3:3

TSIZ0 C3:2

OE~ C2:1

EB3~ C0:7

EB2~ C0:6

EB1~ C0:5

5–8

EB0~ C0:4

PSTAT3 C2:7

PSTAT2 C2:6

PSTAT1 C2:5

TMS231 MC3X0 Microprocessor Support

Page 51

T able 5–10: Signals required for clocking and disassembly (cont.)

Section:channel MC3X0 signal name

PSTAT0 C2:4

TC2 C3:6

TC1 C3:5

TC0 C3:4

SEQ~ C1:7

BIGEND~ C1:2

IFETCH C1:0

BURST~\BAA~ C1:6

FINT~ C3:1

INT~ C3:0

Reference:Tables

Table 5–11 lists the signals not required for Clock and Disassembly.

T able 5–11: Signals not required for clocking and

disassembly

Section:channel MC3X0 signal name

TBUSY~ C2:0

ABORT~ C1:3

RSTOUT~ C1:1

TMS231 MC3X0 Microprocessor Support

5–9

Page 52

Reference:Tables

CPU To Mictor Connections

To probe the microprocessor you need to make connections between the CPU

and the Mictor pins of the P6434 Mass Termination Probe. Refer to the P6434

Mass Termination Probe manual, Tektronix part number 070-9793-xx, for more

information on mechanical specifications. Tables 5–12 through 5–14 list the

CPU pin to Mictor pin connections.

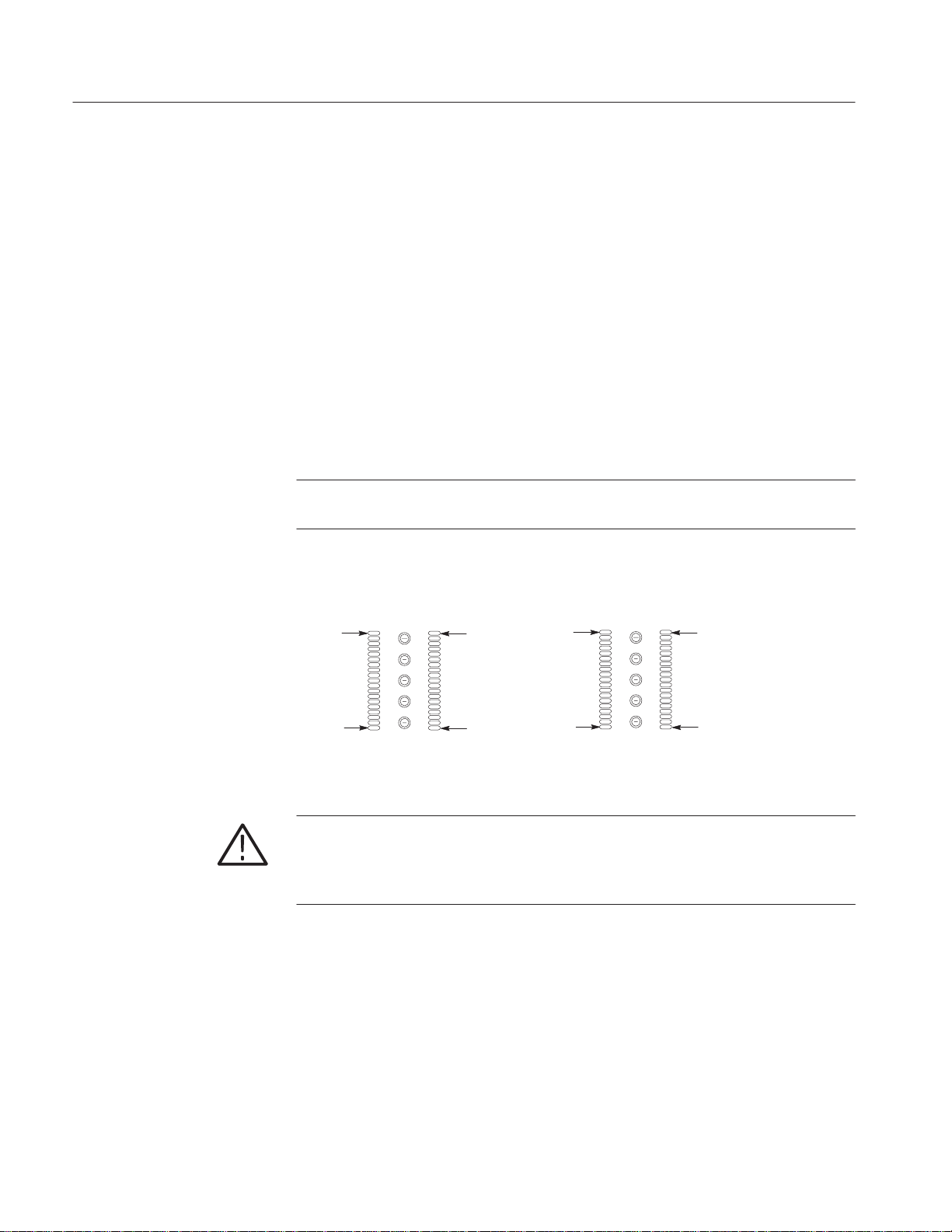

Tektronix uses a counterclockwise pin assignment. Pin 1 is located at the top left,

and pin 2 is located directly below it. Pin 20 is located on the bottom right, and

pin 21 is located directly above it.

AMP uses an odd side-even side pin assignment. Pin 1 is located at the top left,

and pin 3 is located directly below it. Pin 2 is located on the top right, and pin 4

is located directly below it (see Figure 5–1).

NOTE. When designing Mictor connectors into your system under test, always

follow the Tektronix pin assignment.

Tektronix Pinout AMP Pinout

Pin 1

Pin 19

Pin 38

Pin 20

Pin 1

Pin 37

Pin 2

Pin 38

Figure 5–1: Pin assignments for a Mictor connector (component side)

CAUTION. To protect the CPU and the inputs of the module, it is recommended

that a 180 W resistor be connected in series between each ball pad of the CPU

and each pin of the Mictor connector. The resistor must be within 1/2 inch of the

ball pad of the CPU.

5–10

TMS231 MC3X0 Microprocessor Support

Page 53

T able 5–12: CPU to Mictor connections for clock and qualifiers

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Reference:Tables

Tektronix

LA channel

Clock:3

Clock:2 QUAL

Clock:1 QUAL

Clock:0 CLK

QUAL:3

QUAL:2

QUAL:1

БББББ

QUAL:0

MC3X0

signal name

TREQ~

SHS~

TA~

CLKOUT

––

––

––

ÁÁÁÁ

––

БББББ

C

mictor

pin number

C3

D36

A36

A3

––

––

––

––

T able 5–13: CPU to Mictor connections for Mictor A pins

Tektronix

Logic analyzer

channel

A0:0

MC3X0

signal name

A0

mictor A

pin number

A20

AMP

mictor C

pin number

C5

D6

A6

A5

––

––

––

БББББ

––

AMP

mictor A

pin number

A38

A0:1

A0:2

A0:3

A0:4

БББББ

A0:5

A0:6

A0:7

A1:0

A1:1

A1:2

A1:3

БББББ

A1:4

A1:5

A1:6

A1:7

A2:0

A1

A2

A3

A4

ÁÁÁÁ

A5

A6

A7

A8

A9

A10

A11

ÁÁÁÁ

A12

A13

A14

A15

A16

A21

A22

A23

A24

БББББ

A25

A26

A27

A28

A29

A30

A31

БББББ

A32

A33

A34

A35

A19

A36

A34

A32

A30

БББББ

A28

A26

A24

A22

A20

A18

A16

БББББ

A14

A12

A10

A8

A37

TMS231 MC3X0 Microprocessor Support

5–11

Page 54

Reference:Tables

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

Á

Á

ББББББ

Á

Á

Á

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

Á

Á

ББББББ

Á

Á

Á

ББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

Á

Á

Á

БББББББББ

Á

Á

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

T able 5–13: CPU to Mictor connections for Mictor A pins (cont.)

Logic analyzer

channel

A2:1

A2:2

A2:3

A2:4

A2:5

A2:6

A2:7

БББББ

A3:0

A3:1

A3:2

A3:3

A3:4

A3:5

A3:6

БББББ

A3:7

MC3X0

signal name

A17

A18

A19

A20

A21

A22

A23

БББББ

A24

A25

A26

A27

A28

A29

A30

БББББ

A31

Tektronix

mictor A

pin number

A18

A17

A16

A15

A14

A13

A12

ÁÁÁÁ

A11

A10

A9

A8

A7

A6

A5

ÁÁÁÁ

A4

AMP

mictor A

pin number

A35

A33

A31

A29

A27

A25

A23

БББББ

A21

A19

A17

A15

A13

A11

A9

БББББ

A7

5–12

T able 5–14: CPU to Mictor connections for Mictor D pins

LA channel

D0:0

D0:1

D0:2

D0:3

D0:4

ÁÁÁÁ

D0:5

D0:6

D0:7

D1:0

D1:1

MC3X0

signal name

D0

D1

D2

D3

D4

БББББ

D5

D6

D7

D8

D9

Tektronix

mictor D

pin number

D20

D21

D22

D23

D24

ÁÁÁ

D25

D26

D27

D28

D29

AMP

mictor D

pin number

D38

D36

D34

D32

D30

D28

D26

D24

D22

D20

TMS231 MC3X0 Microprocessor Support

БББББББ

Page 55

T able 5–14: CPU to Mictor connections for Mictor D pins (cont.)

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

Á

Á

ÁÁÁÁ

Á

Á

Á

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

Á

Á

ÁÁÁÁ

Á

Á

Á

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

Á

Á

ÁÁÁÁ

Á

Á

Á

ÁÁÁÁ

Reference:Tables

LA channel

D1:2

D1:3

D1:4

D1:5

D1:6

D1:7

D2:0

ÁÁÁÁ

D2:1

D2:2

D2:3

D2:4

D2:5

D2:6

D2:7

ÁÁÁÁ

D3:0

MC3X0

signal name

D10

D11

D12

D13

D14

D15

D16

БББББ

D17

D18

D19

D20

D21

D22

D23

БББББ

D24

Tektronix

mictor D

pin number

D30

D31

D32

D33

D34

D35

D19

ÁÁ

D18

D17

D16

D15

D14

D13

D12

ÁÁ

D11

AMP

mictor D

pin number

D18

D16

D14

D12

D10

D8

D37

ББББББББ

D35

D33

D31

D29

D27

D25

D23

ББББББББ

D21

D3:1

D3:2

D3:3

D3:4

D3:5

D3:6

ÁÁÁÁ

D3:7

D25

D26

D27

D28

D29

D30

БББББ

D31

D10

D9

D8

D7

D6

D5

ÁÁ

D4

D19

D17

D15

D13

D11

D9

ББББББББ

D7

T able 5–15: CPU to Mictor connections for Mictor C pins

Tektronix

LA channel

C3:7

C3:6

C3:5

MC3X0

signal name

TEA~

TC2

TC1

mictor C

pin number

C4

C5

C6

AMP

mictor C

pin number

C7

C9

C11

TMS231 MC3X0 Microprocessor Support

5–13

Page 56

Reference:Tables

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

T able 5–15: CPU to Mictor connections for Mictor C pins (cont.)

LA channel

C3:4

C3:3

C3:2

C3:1

C3:0

C2:7

C2:6

ÁÁÁÁ

C2:5

C2:4

C2:3 (Qual)

C2:2 (Qual)

C2:1 (Qual)

C2:0 (Qual)

C1:7

ÁÁÁÁ

C1:6

MC3X0

signal name

TC0

TSIZ1

TSIZ0

FINT~

INT~

PSTAT3

PSTAT2

ББББББ

PSTAT1

PSTAT0

RST~

R/W~

OE~

TBUSY~

SEQ~

ББББББ

BURST~\BAA~

Tektronix

mictor C

pin number

C7

C8

C9

C10

C11

C12

C13

ÁÁ

C14

C15

C16

C17

C18

C19

C35

ÁÁ

C34

AMP

mictor C

pin number

C13

C15

C17

C19

C21

C23

C25

БББББББ

C27

C29

C31

C33

C35

C37

C8

БББББББ

C10

C1:5

C1:4

C1:3

C1:2

C1:1

C1:0

ÁÁÁÁ

C0:7

C0:6

C0:5

C0:4

C0:3

C0:2

C0:1

ÁÁÁÁ

C0:0

CS5~

CS4~

ABORT~

BIGEND~

RSTOUT~

IFETCH

ББББББ

EB3~

EB2~

EB1~

EB0~

CS3~

CS2~

CS1~

ББББББ

CS0~

C33

C32

C31

C30

C29

C28

ÁÁ

C27

C26

C25

C24

C23

C22

C21

ÁÁ

C20

C12

C14

C16

C18

C20

C22

БББББББ

C24

C26

C28

C30

C32

C34

C36

БББББББ

C38

5–14

TMS231 MC3X0 Microprocessor Support

Page 57

Index

Page 58

Index

A

About this manual set, vii

Acquiring data, 2–9

Address, T ektronix, viii

Address group, channel assignments, 5–3

Application, logic analyzer configuration, 1–1

B

Bus cycles, displayed cycle types, 2–10

C

Channel assignments

address group, 5–3

Chip_Select, 5–6

clocks and qualifiers, 5–7

Control, 5–5

data group, 5–4

Interrupt, 5–6

Misc group, 5–6

Proc_Mode, 5–5

Channel groups, 2–1

visibility , 2–9

Chip_Select, channel assignments, 5–6

Clock channel assignments, 5–7

Clock rate, 1–1

SUT, 3–1

Clocking, custom, 2–2

Clocking Options

external clocking, 2–2

internal clocking, 2–2

Connections

CPU to Mictor, 5–10

no probe adapter, 1–2

Contacting T ektronix, viii

Control, channel assignments, 5–5

Control flow display format, 2–11

Control group, symbol table, 5–1

CPU to Mictor connections, 5–10

CS mode, 2–13

Custom clocking, 2–2

Cycle types, 2–10

D

Data

acquiring, 2–9

disassembly formats

control Flow, 2-11

hardware, 2-10

software, 2-11

subroutine, 2-12

timingĆDisplay, 2-10

Data display , changing, 2–12

Data group, channel assignments, 5–4

Data Port Width, 2–13

Definitions

disassembler, vii

information on basic operations, vii

Demonstration file, 2–16

Disassembled data

cycle type definitions, 2–10

viewing, 2–9

viewing an example, 2–16

Disassembler

definition, vii

logic analyzer configuration, 1–1

setup, 2–1

Disassembly format definition overlay, 2–12

Disassembly property page, 2–12

Display formats

control Flow, 2–11

hardware, 2–10

software, 2–11

special characters, 2–9

subroutine, 2–12

timing-Display, 2–10

E

Electrical specifications, 3–1

clock rate, 3–1

Endian mode, 2–13

H

Hardware display format, 2–10

cycle type definitions, 2–10

Hold time, minimum, 3–1

TMS231 MC3X0 Microprocessor Support

Index–1

Page 59

Index

I

Installing support software, 2–1

Interface, 2–13

Interrupt, channel assignments, 5–6

L

Logic analyzer

configuration for disassembler, 1–1

configuration for the application, 1–1

software compatibility, 1–1

M

Manual

conventions, vii

how to use the set, vii

Mark Cycle function, 2–14

Mark Opcode function, 2–14

Marking cycles, definition of, 2–14

Micro Specific Fields

CS mode, 2–13

Data Port Width, 2–13

endian mode, 2–13

interface, 2–13

R/W~ signal, 2–13

RIM CS base addresses, 2–13

vector base register, 2–13

Mictor to CPU connections, 5–10

Misc group, channel assignments, 5–6

without a probe adapter, 1–2

RIM CS Base Addresses, 2–13

S

Service support, contact information, viii

Set up time, minimum, 3–1

Setups

disassembler, 2–1

support, 2–1

Signals not required for Clocking and Disassembly, 5–9

Signals required for Clocking and Disassembly, 5–8

Software display format, 2–11

Special characters displayed, 2–9

Specifications, 3–1

electrical, 3–1

Subroutine display format, 2–12

Support, setup, 2–1

Support package setups

disassembly, 2–2

timing, 2–2

Support setup, 2–1

Symbol table, control channel group, 5–1

System file, demonstration, 2–16

T

T echnical support, contact information, viii

T ektronix, contacting, viii

T erminology, vii

Timing-display format, 2–10

P

Phone number, Tektronix, viii

Probe adapter, not using one, 1–2

Proc_Mode, channel assignments, 5–5

Product support, contact information, viii

R

R/W~Signal, 2–13

Reference, channel assignments, 5–2

Reference memory, 2–16

Restrictions, 1–1

Index–2

U

URL, T ektronix, viii

V

Vector base register, 2–13

Viewing disassembled data, 2–9

W

Web site address, T ektronix, viii

TMS231 MC3X0 Microprocessor Support

Loading...

Loading...