Page 1

Instruction Manual

TMS 109

P54 & P55 Microprocessor Support

070-9811-00

There are no current European directives that

apply to this product. This product provides

cable and test lead connections to a test object of

electronic measuring and test equipment.

Warning

The servicing instructions are for use by

qualified personnel only. To avoid personal

injury, do not perform any servicing unless you

are qualified to do so. Refer to all safety

summaries prior to performing service.

Page 2

Copyright T ektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and are

protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

SOFTWARE WARRANTY

T ektronix warrants that the media on which this software product is furnished and the encoding of the programs on

the media will be free from defects in materials and workmanship for a period of three (3) months from the date of

shipment. If a medium or encoding proves defective during the warranty period, T ektronix will provide a

replacement in exchange for the defective medium. Except as to the media on which this software product is

furnished, this software product is provided “as is” without warranty of any kind, either express or implied.

T ektronix does not warrant that the functions contained in this software product will meet Customer’s

requirements or that the operation of the programs will be uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period. If T ektronix is unable to provide a replacement that is free from defects in materials and

workmanship within a reasonable time thereafter, Customer may terminate the license for this software product

and return this software product and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S PAYMENT IS

THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS

WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER

TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

HARDWARE WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If a product proves defective during this

warranty period, T ektronix, at its option, either will repair the defective product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by T ektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the T ektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than T ektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-T ektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 5

Table of Contents

Getting Started

General Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface: Microprocessor Support Documentation xi. . . . . . . . . . . . . . . .

Manual Conventions xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Analyzer Documentation xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Support Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Analyzer Software Compatibility 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Analyzer Configuration 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements and Restrictions 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Probe Adapter 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLK Jumper 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly/Timing Jumper 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tracking Jumper 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Address Synthesis Jumper 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D/P# Signal Jumper 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to a System Under T est 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventional Probe Adapter 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low-Profile Probe Adapter with a High-Density Probe 1–10. . . . . . . . . . . . . . . .

Applying and Removing Power 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Basics

Setting Up the Support 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel Group Definitions 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clocking Options 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquiring and Viewing Disassembled Data 2–5. . . . . . . . . . . . . . . . . . . . .

Acquiring Data 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Disassembled Data 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Display Format 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Display Format 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Flow Display Format 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subroutine Display Format 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing How Data is Displayed 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Display Selections 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dual Microprocessors Execution Tracing 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Branch Trace Messages 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Out-Of-Order Fetches 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speculative Prefetch Cycles 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cache Invalidation Cycles 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Burst Cycles 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Management Mode (SMM) 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MMX Instruction Set 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

i

Page 6

Table of Contents

Specifications

Maintenance

Marking Cycles 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Exception Vectors 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing an Example of Disassembled Data 2–20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Adapter Description 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Differences 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Mode 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chip Set Mode 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How Data is Acquired 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Clocking 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clocking Options 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alternate Microprocessor Connections 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signals Not On the Probe Adapter 3–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Extra Channels 3–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signals on the High-Density Probe 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Adapter Circuit Description 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Signal Leads 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Protective Sockets 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Fuse 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Electrical Parts

Parts Ordering Information 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Electrical Parts List 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Mechanical Parts

Parts Ordering Information 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Mechanical Parts List 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Index

ii

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 7

List of Figures

Table of Contents

Figure 1–1: Jumper locations on the conventional probe adapter 1–5. . .

Figure 1–2: Jumper locations on the low-profile probe adapter 1–5. . . .

Figure 1–3: Placing a microprocessor into the conventional probe

adapter 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–4: Connecting probes to the conventional probe

adapter 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–5: Placing the conventional probe adapter onto the

SUT 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–6: Placing a microprocessor into the low-profile probe

adapter 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–7: Placing the low-profile probe adapter onto the SUT 1–12. . . .

Figure 1–8: Connecting clock and channel probes to a high-density

probe 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–9: Connecting LO and HI cables to a high-density

probe 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–10: Power jack location on the conventional probe

adapter 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–11: Power jack location on the low-profile probe

adapter 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: Hardware display format 2–8. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: Data displayed from the Primary and Dual

microprocessors 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–3: Disassembled data displayed from the Primary

microprocessor only 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: Disassembled data displayed from the Dual

microprocessor only 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–5: Display of target and source Branch Trace

Messages 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–6: Speculative Prefetch cycles 2–16. . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–1: Dimensions of the low-profile probe adapter 3–5. . . . . . . . . .

Figure 3–2: Dimensions of the conventional probe adapter 3–6. . . . . . . .

Figure 3–3: Nonpipelined single and Burst Transfer cycles 3–18. . . . . . . .

Figure 3–4: Pipelined cycles 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–5: Location of J1140 and J1150 on the conventional

probe adapter 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–6: Location of J1700 and J1701 on the low-profile

probe adapter 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

iii

Page 8

Table of Contents

List of Tables

Figure 4–1: Location of the fuse on the conventional probe

adapter 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–2: Location of the fuse on the low-profile probe

adapter 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–1: Jumper positions and function 1–3. . . . . . . . . . . . . . . . . . . . . .

Table 1–2: Disassembly/Timing jumper information 1–4. . . . . . . . . . . . .

Table 1–3: Probe adapter exceptions for the 136-channel

module 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–4: High-density probe exceptions for the 136-channel

module 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–1: Control group symbol table definitions 2–2. . . . . . . . . . . . . . .

Table 2–2: Meaning of special characters in the display 2–6. . . . . . . . . .

Table 2–3: Cycle type definitions 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–4: Trace Processor and Other Processor field selections 2–12. . .

Table 2–5: Exception vectors for Real Addressing mode 2–18. . . . . . . . . .

Table 2–6: Exception vectors for Protected Addressing mode 2–19. . . . . .

Table 3–1: Jumper positions and function 3–2. . . . . . . . . . . . . . . . . . . . . .

Table 3–2: Electrical specifications 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–3: Environmental specifications 3–4. . . . . . . . . . . . . . . . . . . . . . .

Table 3–4: Certifications and compliances 3–4. . . . . . . . . . . . . . . . . . . . . .

Table 3–5: Address group channel assignments 3–8. . . . . . . . . . . . . . . . . .

Table 3–6: Data group channel assignments 3–9. . . . . . . . . . . . . . . . . . . . .

Table 3–7: Data_Lo group channel assignments 3–10. . . . . . . . . . . . . . . . .

Table 3–8: Control group channel assignments 3–11. . . . . . . . . . . . . . . . . .

Table 3–9: DataSize group channel assignments 3–12. . . . . . . . . . . . . . . . .

Table 3–10: 136-channel module: Cache group channel

assignment 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–11: 136-channel module: Misc group channel

assignments 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–12: 192-channel module: Cache group channel

assignments 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–13: 192-channel module: Debug group channel

assignments 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–14: 192-channel module: APIC group channel

assignments 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 9

Table of Contents

Table 3–15: 192-channel module: Priv_Bus group channel

assignments 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–16: 192-channel module: Parity group channel

assignments 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–17: 192-channel module: Misc group channel

assignments 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–18: Clock channel assignments 3–16. . . . . . . . . . . . . . . . . . . . . . . .

Table 3–19: P54/P55 signals on J1140/J1700 3–21. . . . . . . . . . . . . . . . . . . .

Table 3–20: J1150/J1701 jumper pin assignments 3–23. . . . . . . . . . . . . . .

Table 3–21: Extra channels 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–22: 136-channel module: Signals on the high-density

probe 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–1: Microprocessor signal delays when using the probe

adapter 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

v

Page 10

Table of Contents

vi

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly . Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and marking on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Use Proper AC Adapter. Use only the AC adapter specified for this product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

vii

Page 12

General Safety Summary

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) T erminal

CAUTION

Refer to Manual

Double

Insulated

viii

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 13

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the main power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

ix

Page 14

Service Safety Summary

x

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 15

Preface: Microprocessor Support Documentation

This instruction manual contains specific information about the TMS 109

P54/P55 microprocessor support and is part of a set of information on how to

operate this product on compatible Tektronix logic analyzers.

If you are familiar with operating microprocessor supports on the logic analyzer

for which the TMS 109 P54/P55 support was purchased, you will probably only

need this instruction manual to set up and run the support.

If you are not familiar with operating microprocessor supports, you will need to

supplement this instruction manual with information on basic operations to set up

and run the support.

Information on basic operations of microprocessor supports is included with each

product. Each logic analyzer has basic information that describes how to perform

tasks common to supports on that platform. This information can be in the form

of online help, an installation manual, or a user manual.

This manual provides detailed information on the following topics:

H Connecting the logic analyzer to the system under test

Manual Conventions

H Setting up the logic analyzer to acquire data from the system under test

H Acquiring and viewing disassembled data

H Using the probe adapter

This manual uses the following conventions:

H The term disassembler refers to the software that disassembles bus cycles

into instruction mnemonics and cycle types.

H The phrase “information on basic operations” refers to online help, an

installation manual, or a basic operations of microprocessor supports user

manual.

H In the information on basic operations, the term XXX used in field selections

and file names must be replaced with P54C. This is the name of the

microprocessor in field selections and file names you must use to operate the

P54/P55 support.

H The term system under test (SUT) refers to the microprocessor-based system

from which data will be acquired.

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

xi

Page 16

Preface: Microprocessor Support Documentation

H The term logic analyzer refers to the Tektronix logic analyzer for which this

product was purchased.

H The term module refers to a 136-channel or a 192-channel module.

H P54/P55 refers to all supported variations of the P54 and P55 micropro-

cessors unless otherwise noted.

H A pound sign (#) following a signal name indicates an active low signal.

Logic Analyzer Documentation

A description of other documentation available for each type of Tektronix logic

analyzer is located in the corresponding module user manual. The manual set

provides the information necessary to install, operate, maintain, and service the

logic analyzer and associated products.

Contacting Tektronix

Product

Support

Service

Support

For other

information

To write us Tektronix, Inc.

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or, contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Contact your local Tektronix distributor or sales office. Or, visit

our web site for a listing of worldwide service locations.

http://www.tek.com

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

P.O. Box 1000

Wilsonville, OR 97070-1000

xii

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 17

Getting Started

Page 18

Page 19

Getting Started

Support Description

This chapter provides information on the following topics and tasks:

H A description of the TMS 109 microprocessor support package

H Logic analyzer software compatibility

H Your system under test requirements

H Support restrictions

H How to configure the probe adapter

H How to connect to the system under test (SUT)

H How to apply power to and remove power from the probe adapter

The TMS 109 microprocessor support package disassembles data from systems

that are based on the Intel P54C, P54CM, P55C, and P55CM microprocessors.

The support runs on a compatible Tektronix logic analyzer equipped with a

136-channel module or a 192-channel module.

Refer to information on basic operations to determine how many modules and

probes your logic analyzer needs to meet the minimum channel requirements for

the TMS 109 microprocessor support.

The TMS 109 supports the P54C, P54CM, P55C, and P55CM microprocessors in

a 296-pin PGA package.

The low-profile probe adapter requires a 192-Channel High-Density Probe to

make connections from the logic analyzer to your SUT.

A complete list of standard and optional accessories is provided at the end of the

parts list in the Replaceable Mechanical Parts chapter.

To use this support efficiently, you need to have the items listed in the information on basic operations as well as the P54/P55 Microprocessor User’s Manual,

Intel, 1997.

Information on basic operations also contains a general description of supports.

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

1–1

Page 20

Getting Started

Logic Analyzer Software Compatibility

The label on the microprocessor support floppy disk states which version of logic

analyzer software the support is compatible with.

Logic Analyzer Configuration

To use the TMS 109 support, the Tektronix logic analyzer must be equipped with

either a 136-channel module or a 192-channel module at a minimum. The

module must be equipped with enough probes to acquire clock and channel data

from signals in your P54/P55-based system.

Refer to information on basic operations to determine how many modules and

probes the logic analyzer needs to meet the channel requirements.

Requirements and Restrictions

You should review the general requirements and restrictions of microprocessor

supports in the information on basic operations as they pertain to your SUT.

You should also review electrical, environmental, and mechanical specifications

in the Specifications chapter in this manual as they pertain to your system under

test, as well as the following descriptions of other P54/P55 support requirements

and restrictions.

System Clock Rate. The TMS 109 support can acquire data from the P54/P55

microprocessor at speeds of up to 66.66 MHz

SUT Power. Whenever the SUT is powered off, be sure to remove power from

the probe adapter. Refer to Applying and Removing Power at the end of this

chapter for information on how to remove power from the probe adapter.

Disabling the Instruction Cache. To disassemble acquired data, you must disable

the internal instruction cache. Disabling the cache makes all instruction

prefetches visible on the bus so they can be acquired and disassembled.

Cache Invalidation Cycles. Cache Invalidation addresses are not acquired.

1

.

1–2

Bus Hold Cycles. Bus Hold cycles are not acquired while the RESET signal is

active.

1

Specification at time of printing. Contact your Tektronix sales representative for

current information on the fastest devices supported.

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 21

Getting Started

AHOLD Signal. If the AHOLD signal is active (high) during a Writeback cycle (a

four cycle Burst Write), the acquired address is undefined.

Burst Cycles. The P54/P55 microprocessor expects the memory system to

increment addresses during a Burst cycle. When viewing disassembled data, the

disassembler synthesizes the addresses. When viewing state data, the addresses

appear to be identical.

Probe Mode Cycles. Probe Mode cycles are not identified.

Directory T able and Descriptor Table Reads and Writes. These reads and writes are

not disassembled.

Bus Anomalies. Some combinations of instructions and operating modes of the

microprocessor can cause additional cycles to be fetched. This behavior is

unpredicatable, not documented, and can cause the disassembler to misinterpret if

fetched cycles were or were not executed. This is most likely to occur during

Floating Point operations.

Configuring the Probe Adapter

There are five jumpers on each probe adapter. Table 1–1 lists the jumper

positions and functions.

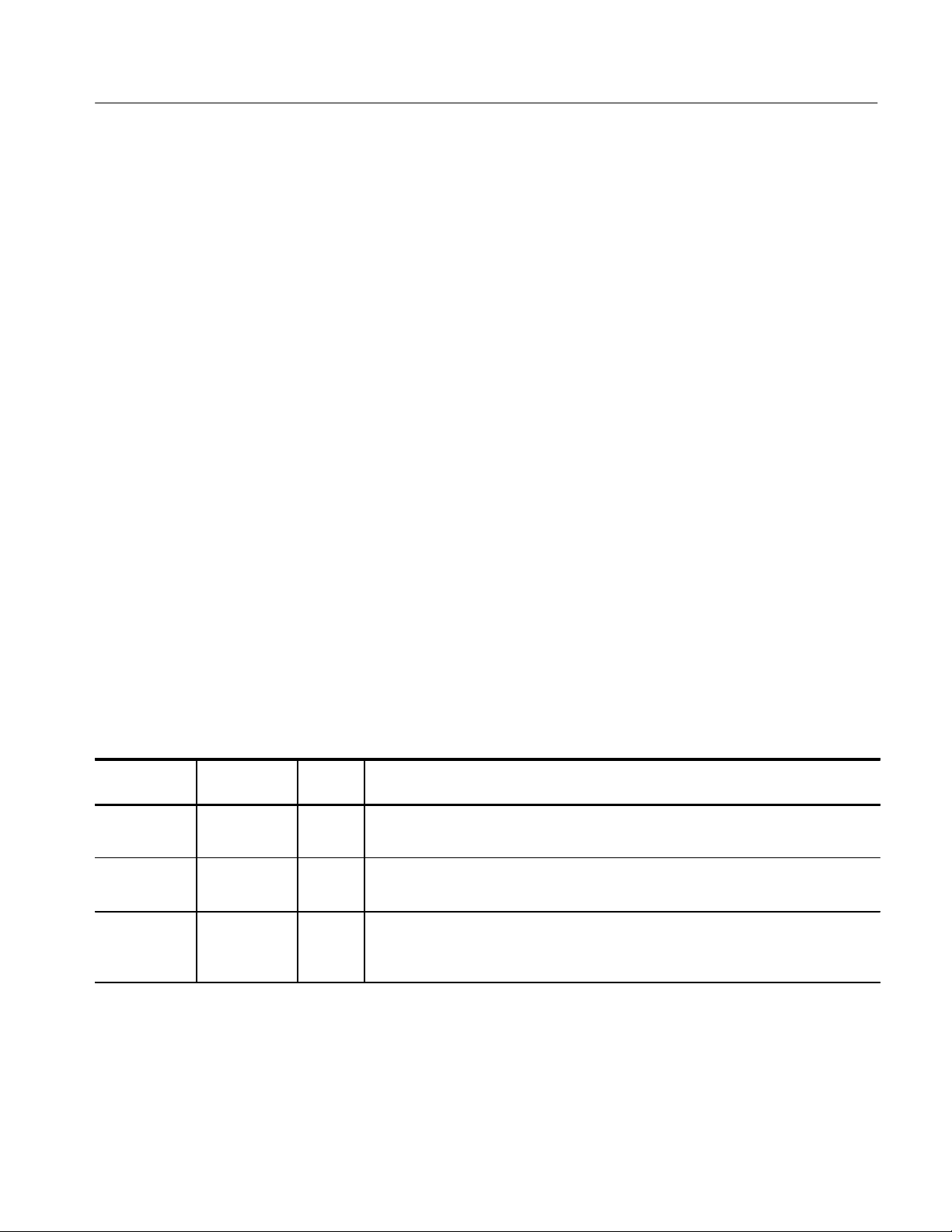

T able 1–1: Jumper positions and function

Conventional

probe adapter

J1 155 J1501 1–2

J1 160 J1500 1–2

J1 165 J1401 1–2

Low-profile

probe adapter

Position Function

Match the P54/P55 microprocessor system speed at 40–80 MHz

2–3

2–3

2–3

Match the P54/P55 microprocessor system speed at 25–50 MHz

Configure probe adapter for Custom clocking (disassembly)

Configure probe adapter for timing analysis

Enable tracking of burst and pipelined cycles while BOFF# and HLDA are asserted

Disable tracking of burst and pipelined cycles while BOFF# and HLDA are asserted. This

setting can be used if an external master’s signal timing is different from that of the P54C.

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

1–3

Page 22

Getting Started

T able 1–1: Jumper positions and function (cont.)

Conventional

probe adapter

J1 170 J1400 1–2

J1340 J1404 1–2

Low-profile

probe adapter

2–3

OPEN

CLK Jumper

Disassembly/Timing

Jumper

FunctionPosition

Enable Address Synthesis (A(2:0) are derived from BE(7:0)#)

Disable Address Synthesis (A(2:0)=0)

Acquire the D/P# signal from pin AE35 of the socket being probed

Acquire the D/P# signal from an external source. If this jumper is left open, you must

route the D/P# signal to pin 1 of this jumper from an external source. This allows you to

probe your system from the Dual socket as long as the D/P# signal is accessible on the

system board.

The CLK jumper (J1155 on the conventional probe adapter or J1501 on the

low-profile probe adapter) should be placed in the ≥45 position to acquire data

from a system running at or faster than 45 MHz. The jumper should be placed in

the <45 position to acquire data from a system running slower than 45 MHz.

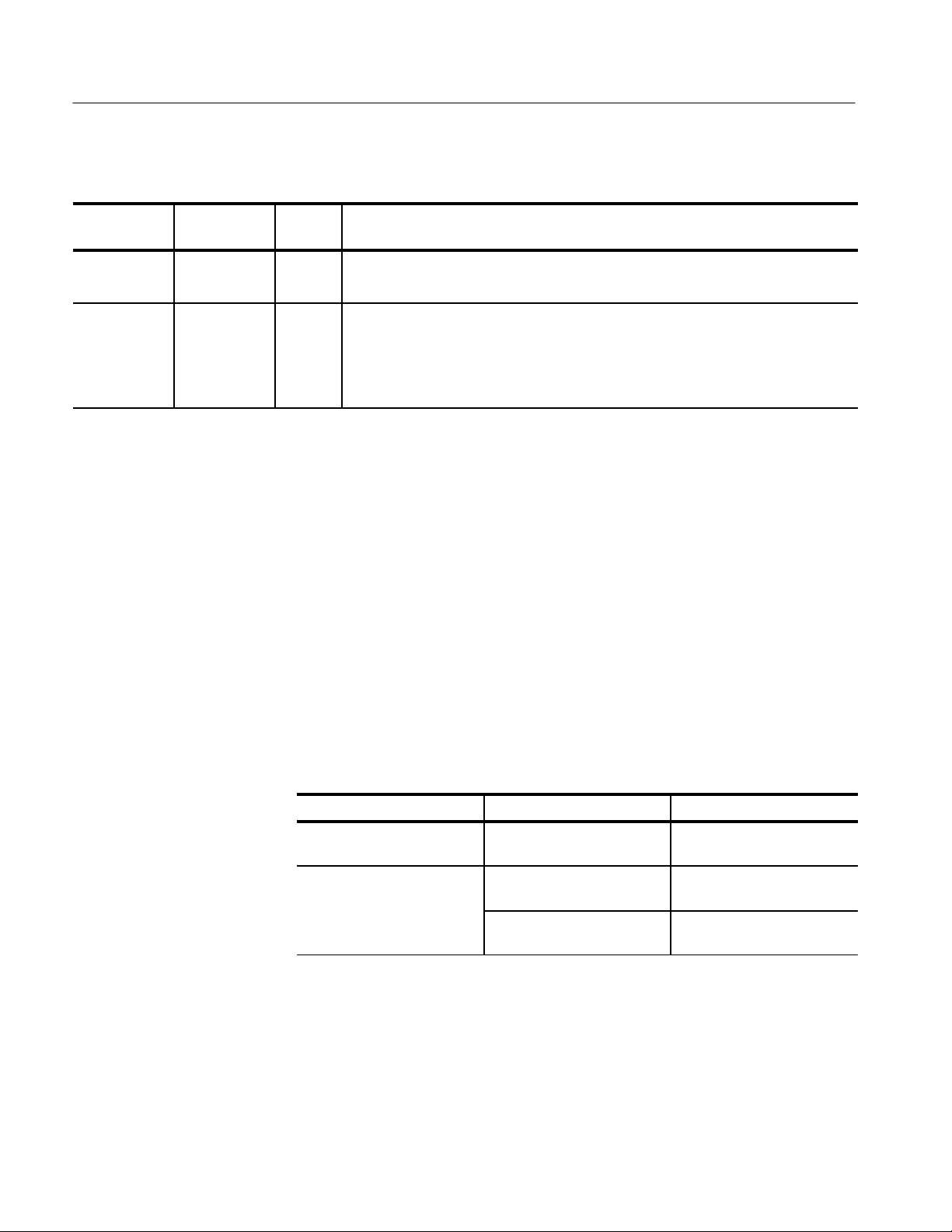

Figure 1–1 shows the location of J1155 on the conventional probe adapter;

Figure 1–2 shows the location of J1501 on the low-profile probe adapter.

The Disassembly/Timing jumper (J1160 on the conventional probe adapter or

J1500 on the low-profile probe adapter) should be placed in the D position to

acquire disassembled data and in the T position to acquire timing data.

Table 1–2 shows how to position this jumper depending on the type of clocking

you are using and the type of display you want to view.

T able 1–2: Disassembly/T iming jumper information

J1160/J1500 position Clocking Data window

D (Disassembly)

T (Timing) Internal Waveform window, or Timing

Custom Listing window, Disassembly,

State, or Graph displays

display

External Waveform window , Listing

window, or Timing display

Figure 1–1 shows the location of J1160 on the conventional probe adapter;

Figure 1–2 shows the location of J1500 on the low-profile probe adapter.

1–4

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 23

J1170

Getting Started

J1340

J1155

J1160

J1165

Figure 1–1: Jumper locations on the conventional probe adapter

J1401

J1400

J1404

J1501

J1500

Figure 1–2: Jumper locations on the low-profile probe adapter

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

1–5

Page 24

Getting Started

Tracking Jumper

Address Synthesis

Jumper

The Tracking jumper (J1165 on the conventional probe adapter or J1401 on the

low-profile probe adapter) should not need to be moved from the default position

(pins 1 and 2 connected).

The only time this jumper should be moved is when the tracking circuitry

malfunctions. An indication of such a malfunction is when you see activity on

the bus during a BOFF or HLDA cycle that is uncharacteristic of the P54/P55

microprocessor. When the jumper is in the 2, 3 position, the circuitry on the

probe adapter does not track BOFF and HLDA cycles. A data sample will show

that such a cycle occurred but it will not contain meaningful information.

This jumper only affects the probe adapter when the Disassembly/Timing jumper

(J1160 on the conventional probe adapter or J1500 on the low-profile probe

adapter) is in the D position.

Figure 1–1 shows the location of J1165 on the conventional probe adapter;

Figure 1–2 shows the location of J1401 on the low-profile probe adapter.

When the Address Synthesis jumper (J1170 on the conventional probe adapter or

J1400 on the low-profile probe adapter) is in position 1, 2, A(2:0) are derived

from the BE(7:0)# signals and stored in the acquisition memory with the rest of

the address.

D/P# Signal Jumper

When the jumper is in position 2, 3, it disables address synthesis, A(2:0)=0.

Figure 1–1 shows the location of J1170 on the conventional probe adapter;

Figure 1–2 shows the location of J1400 on the low-profile probe adapter.

When the D/P# signal jumper (J1340 on the conventional probe adapter or J1404

on the low-profile probe adapter) is in the 1, 2 position, the D/P# signal is

acquired from pin AE35 of the socket being probed.

When the jumper is open (not connected), it acquires the D/P# signal from an

external source, and you will have to route the D/P# signal to pin 1 of this jumper

externally. This allows you to probe your system from the dual socket as long as

the D/P# signal is accessible on the SUT.

Figure 1–1 shows the location of J1340 on the conventional probe adapter;

Figure 1–2 shows the location of J1404 on the low-profile probe adapter.

1–6

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 25

Connecting to a System Under Test

Before you connect to the SUT, you must connect the probes to the module.

Your SUT must also have a minimum amount of clear space surrounding the

microprocessor to accommodate the probe adapter. Refer to the Specifications

chapter in this manual for the required clearances.

The channel and clock probes shown in this chapter are for a 136-channel

module. The probes will look different if you are using a 192-channel module.

The general requirements and restrictions of microprocessor supports in the

information on basic operations shows the vertical dimensions of a channel or

clock probe connected to square pins on a circuit board.

Getting Started

Conventional Probe

Adapter

To connect the logic analyzer to a SUT using a conventional PGA probe adapter,

follow these steps:

1. Turn off power to your SUT. It is not necessary to turn off power to the logic

analyzer.

CAUTION. Static discharge can damage the microprocessor, the probe adapter,

the probes, or the module. To prevent static damage, handle all of the above only

in a static-free environment.

Always wear a grounding wrist strap or similar device while handling the

microprocessor and probe adapter.

2. To discharge your stored static electricity, touch the ground connector located

on the back of the logic analyzer. Then, touch any of the ground pins of the

probe adapter to discharge stored static electricity from the probe adapter.

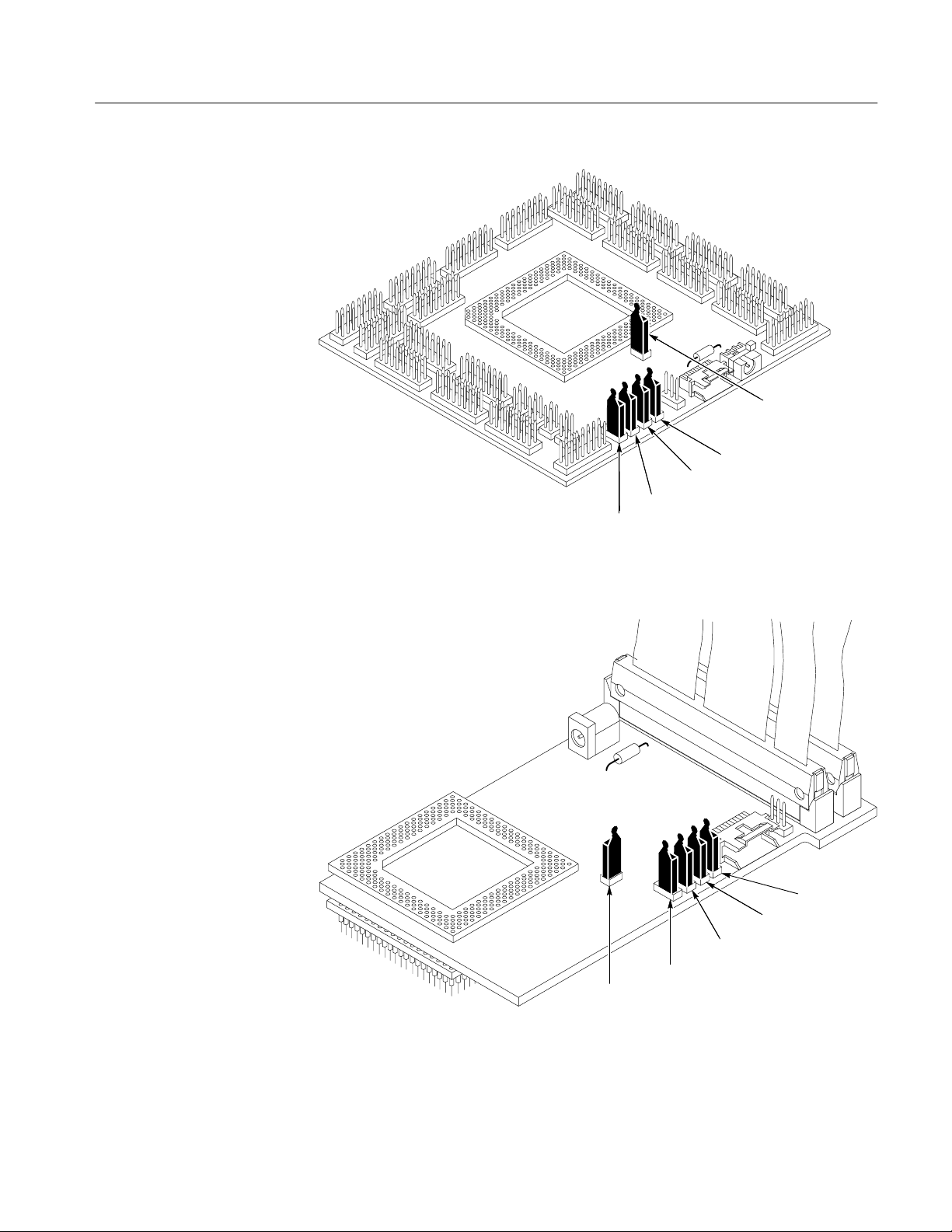

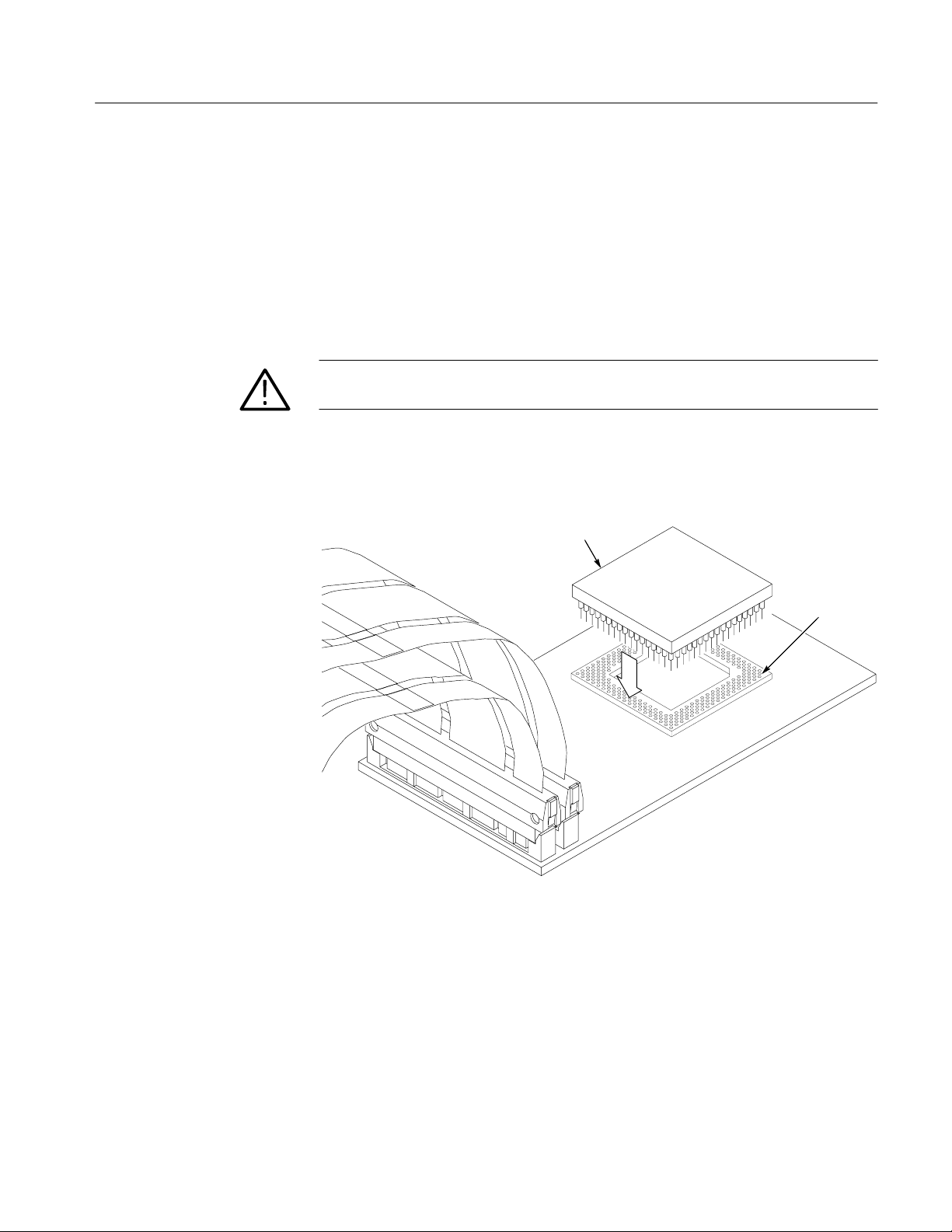

3. Place the probe adapter onto the antistatic shipping foam to support the probe

as shown in Figure 1–3. This prevents the circuit board from flexing and the

socket pins from bending.

4. Remove the microprocessor from your SUT.

5. Line up the pin 2B indicator on the probe adapter board with the pin 2B

indicator on the microprocessor.

CAUTION. Failure to correctly place the microprocessor into the probe adapter

might permanently damage the microprocessor once power is applied.

6. Place the microprocessor into the probe adapter as shown in Figure 1–3.

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

1–7

Page 26

Getting Started

Microprocessor

Probe adapter

Foam

Figure 1–3: Placing a microprocessor into the conventional probe adapter

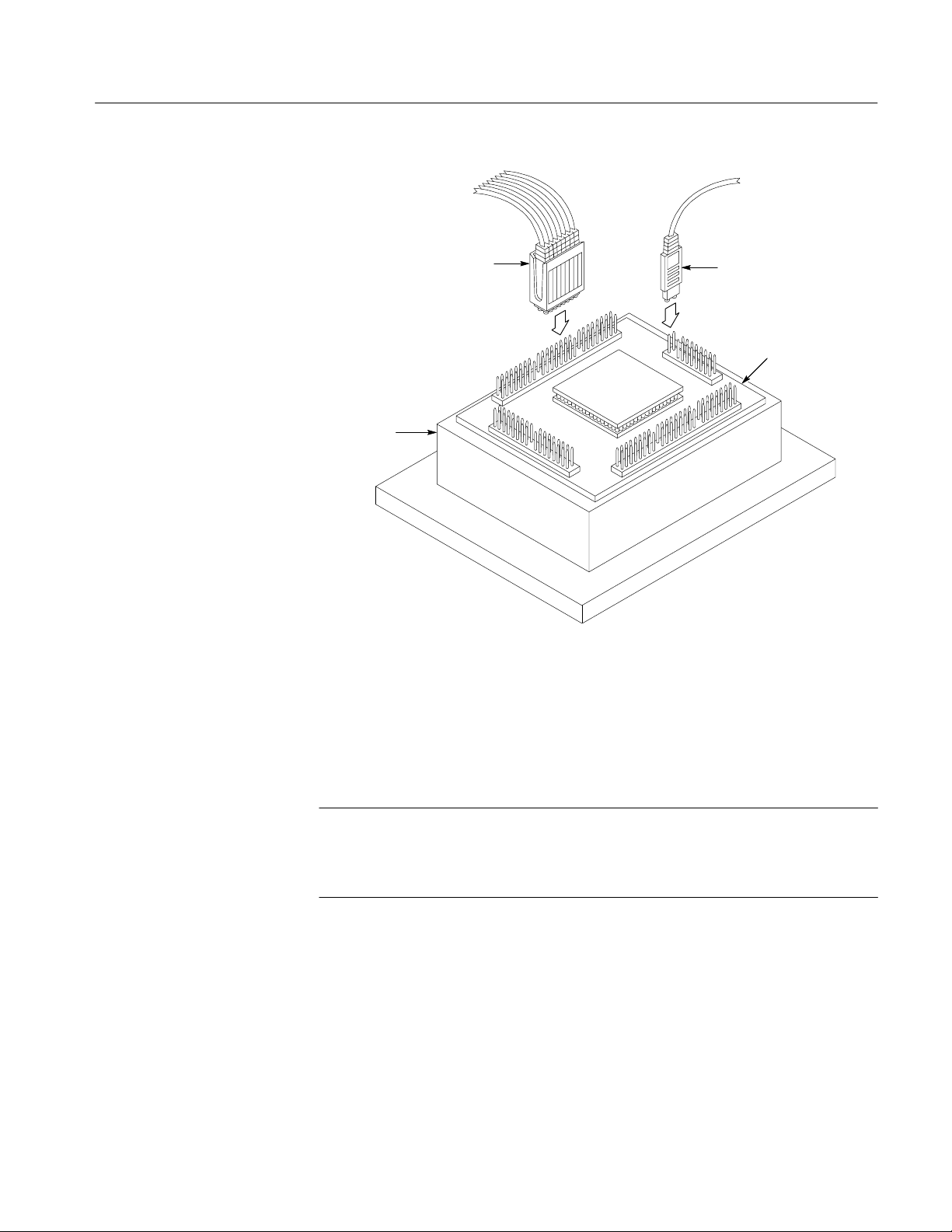

7. Connect the channel and clock probes to the probe adapter as shown in

Figure 1–4. For the 192-channel module, match the channel groups and

numbers on the probe labels to the corresponding HI_ and LO_pins on the

probe adapter. Match the ground pins on the probes to the corresponding pins

on the probe adapter.

For the 136-channel module, match the channel groups and numbers on the

probe labels to the corresponding LO_ pins on the probe apapter. There are

some exceptions; they are shown in Table 1–3.

T able 1–3: Probe adapter exceptions for the 136-channel module

Section Connect to probe adapter pins

E3, E2, E1, E0 HI_A3, HI_A2, HI_A1, HI_A0

C1, C0 HI_C3, HI_C2

1–8

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 27

Getting Started

8-channel probe

and podlet holder

Hold the channel probes by the podlet

holder when connecting them to the

probe adapter. Do not hold them by

the cables or necks of the podlets.

Foam

Clock probe

Figure 1–4: Connecting probes to the conventional probe adapter

Probe adapter

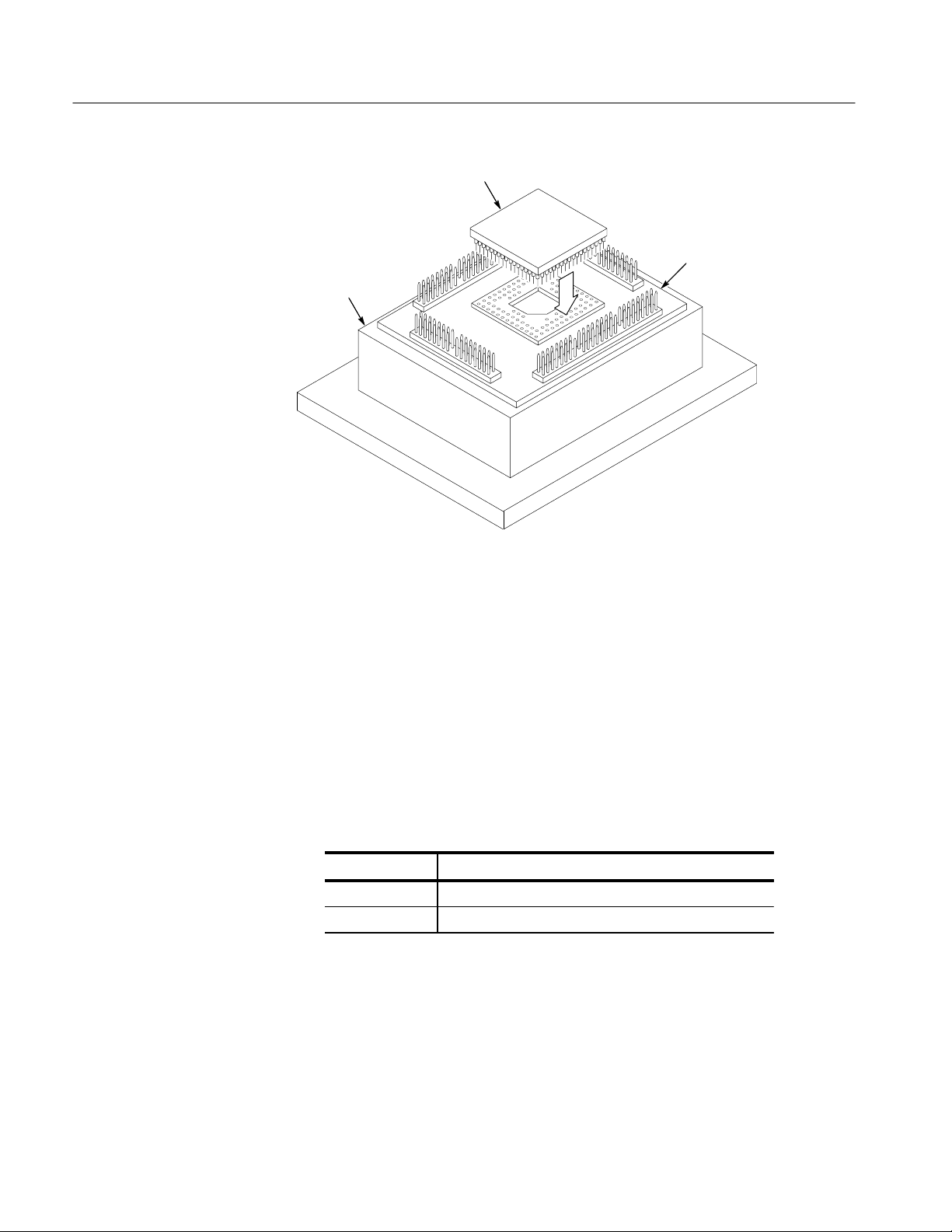

8. Line up the pin 2B indicator on the probe adapter board with the pin 2B

indicator on your SUT.

9. Place the probe adapter onto the SUT as shown in Figure 1–5.

NOTE. You might need to stack one or more replacement sockets between the SUT

and the probe adapter to provide sufficient vertical clearance from adjacent

components. However, keep in mind that this might increase loading, which can

reduce the electrical performance of your probe adapter.

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

1–9

Page 28

Getting Started

SUT socket

Low-Profile Probe Adapter

with a High-Density Probe

Figure 1–5: Placing the conventional probe adapter onto the SUT

If a probe adapter has one or two high-density cables (probe adapter does not

have pins to which the channel and clock probes connect), the probe adapter

requires a high-density probe to make connections between the logic analyzer

and a SUT.

To connect the logic analyzer to a SUT using the low-profile PGA probe adapter

and a high-density probe, follow these steps:

1. Turn off power to your SUT. It is not necessary to turn off power to the logic

analyzer.

CAUTION. Static discharge can damage the microprocessor, the low-profile probe

adapter, the probes, or the module. To prevent static damage, handle all of the

above only in a static-free environment.

Always wear a grounding wrist strap or similar device while handling the

microprocessor and low-profile probe adapter.

1–10

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 29

Getting Started

2. To discharge your stored static electricity, touch the ground connector located

on the back of the logic analyzer. Then, touch the black foam on the

underside of the probe adapter to discharge stored static electricity from the

probe adapter.

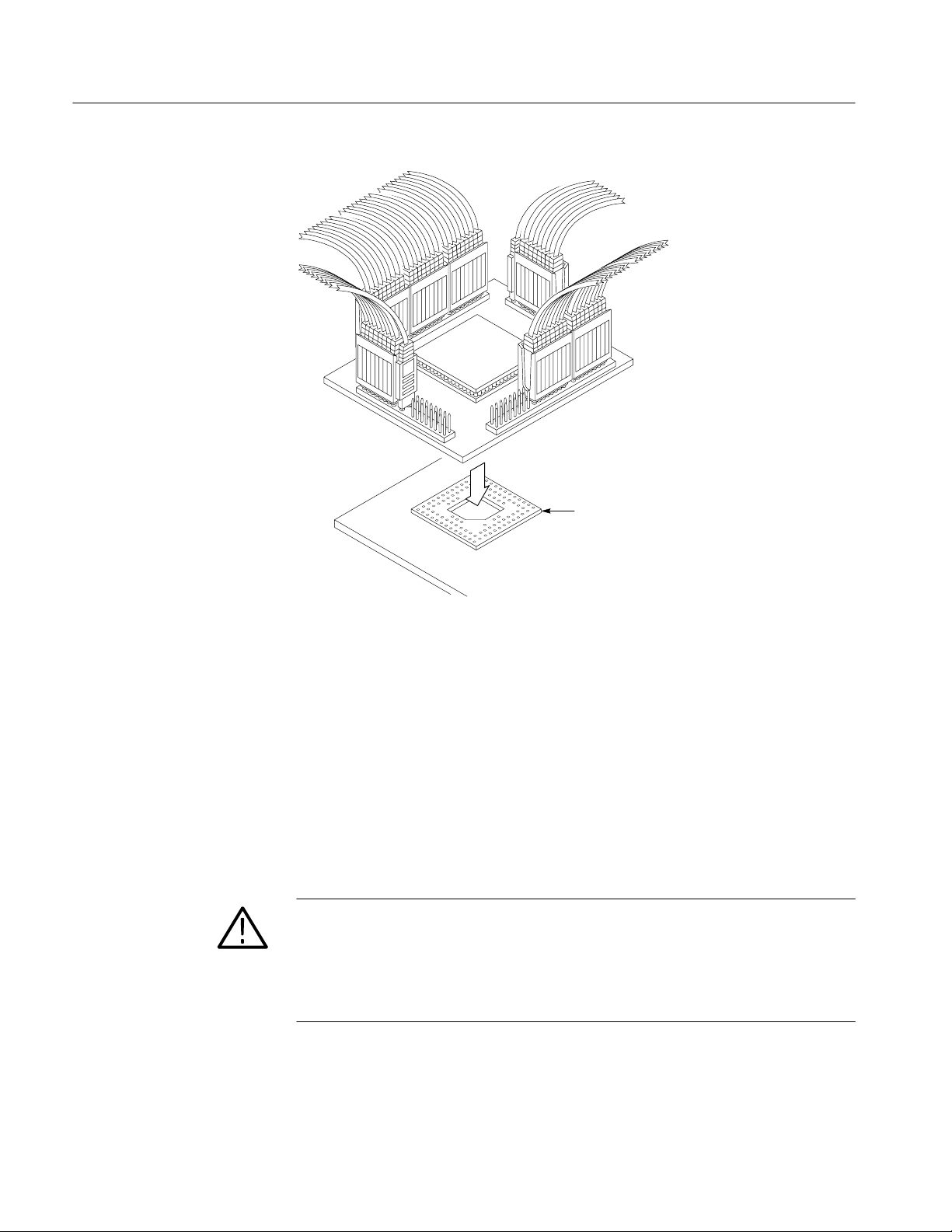

3. Remove the microprocessor from the SUT.

4. Line up the pin 2B indicator on the probe adapter board with the pin 2B

indicator on the microprocessor.

CAUTION. Failure to correctly place the microprocessor into the probe adapter

might permanently damage the microprocessor once power is applied.

5. Place the microprocessor into the probe adapter as shown in Figure 1–6.

Microprocessor

Pin 2B

Figure 1–6: Placing a microprocessor into the low-profile probe adapter

6. Remove the black foam from the underside of the probe adapter.

7. Line up the pin 2B indicator on the probe adapter board with the pin 2B

indicator on the SUT.

8. Place the probe adapter onto the SUT as shown in Figure 1–7.

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

1–11

Page 30

Getting Started

NOTE. You might need to stack one or more replacement sockets between the SUT

and the probe adapter to provide sufficient vertical clearance from adjacent

components. However, keep in mind this might increase loading, which can

reduce the electrical performance of the probe adapter.

SUT socket

Pin 2B

Figure 1–7: Placing the low-profile probe adapter onto the SUT

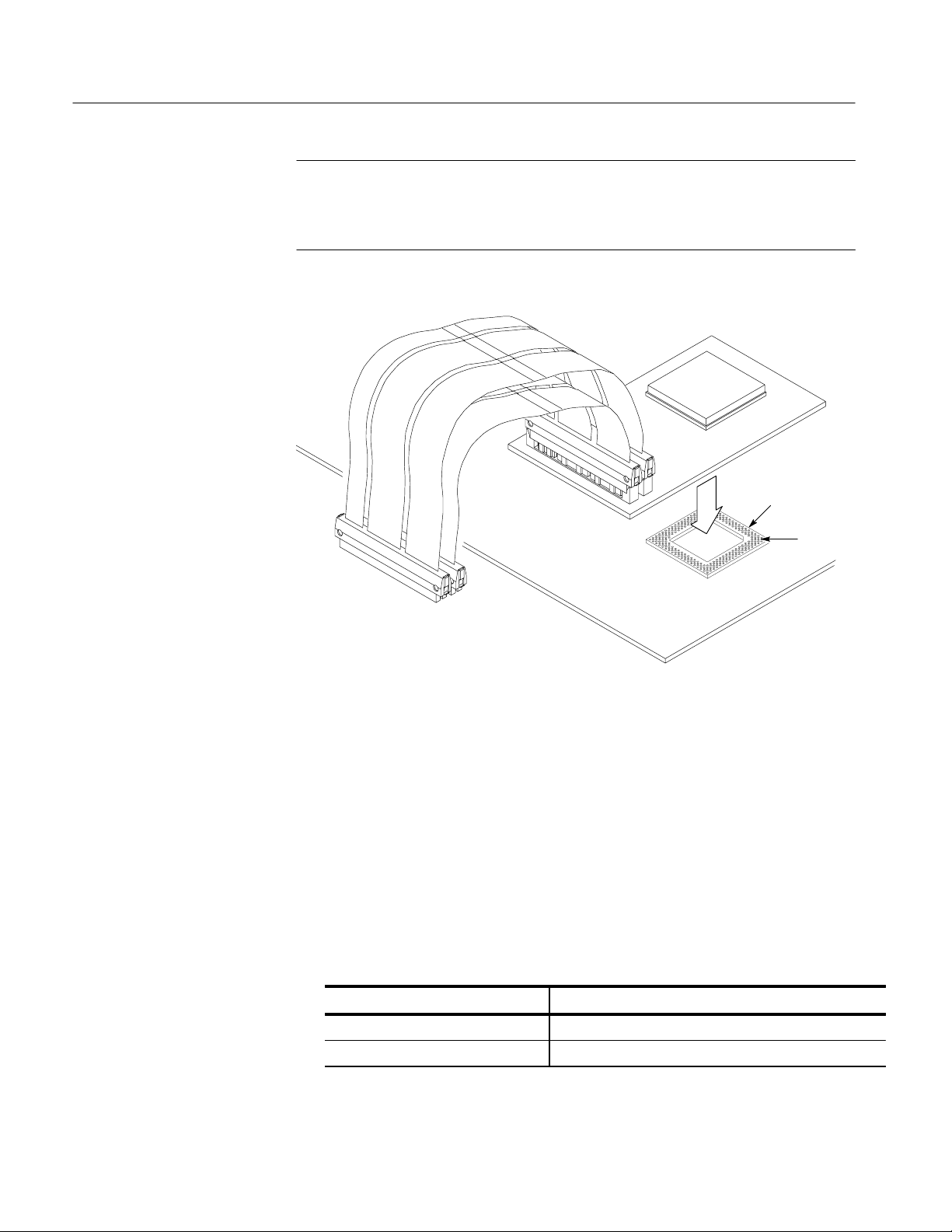

9. Connect the clock and channel probes to the high-density probe as shown in

Figure 1–8. For the 192-channel module, match the channel groups and

numbers on the probe labels to the corresponding HI_ and LO_pins on the

high-density probe. Match the ground pins on the probes to the corresponding pins on the probe adapter.

For the 136-channel module, match the channel groups and numbers on the

probe labels to the corresponding LO_ pins on the high-density probe. There

are some exceptions; they are shown in Table 1–4.

T able 1–4: High-density probe exceptions for the 136-channel module

Section Connect to high-density probe pins

E3, E2, E1, E0 HI_A3, HI_A2, HI_A1, HI_A0

C1, C0 HI_C3, HI_C2

1–12

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 31

Getting Started

Match the ground pins on the probes to the corresponding pins on the probe

adapter.

Clock probe

Hold the 8-channel probes by the

podlet holder when connecting them to

the high-density probe. Do not hold

them by the cables or necks of the

podlets.

8-channel probe

and podlet holder

Channels connect to

the logic analyzer

High-density probe

Figure 1–8: Connecting clock and channel probes to a high-density probe

10. Align pin 1 on the LO cable connector, the end on the narrowest cable strip

of the cable, with pin 1 on the LO connector on the high-density probe.

Connect the cable to the connector as shown in Figure 1–9.

NOTE. The LO cable is 12 inches long; the HI cable is 13 inches long.

11. Align pin 1 on the HI cable connector, the end on the narrowest cable strip of

the cable, with pin 1 on the HI connector on the high-density probe. Connect

the cable to the connector as shown in Figure 1–9.

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

1–13

Page 32

Getting Started

HI cable

Pin 1 end

LO cable

High-density probe

Figure 1–9: Connecting LO and HI cables to a high-density probe

Applying and Removing Power

A power supply for the P54/P55 probe adapter is included with the support. The

power supply provides +5 volts power to the probe adapter. The center connector

of the power jack connects to Vcc.

NOTE. Whenever the SUT is powered off, be sure to remove power from the probe

adapter.

1–14

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 33

Getting Started

To apply power to the P54/P55 probe adapter and SUT, follow these steps:

CAUTION. Failure to use the +5 V power supply provided by Tektronix might

permanently damage the probe adapter and P54/P55 microprocessor. Do not

mistake another power supply that looks similar for the +5 V power supply.

1. Connect the +5 V power supply to the jack on the probe adapter. Figure 1–10

shows the location of the jack on the conventional probe adapter. Figure 1–11

shows the location of the jack on the low-profile probe adapter.

CAUTION. Failure to apply power to the probe adapter before applying power to

your SUT might permanently damage the P54/P55 microprocessor and SUT.

2. Plug the power supply for the probe adapter into an electrical outlet.

3. Power on the SUT.

Figure 1–10: Power jack location on the conventional probe adapter

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Power jack

1–15

Page 34

Getting Started

Power jack

Figure 1–11: Power jack location on the low-profile probe adapter

To remove power from the SUT and P54/P55 probe adapter, follow these steps:

CAUTION. Failure to power down your SUT before removing the power from the

probe adapter might permanently damage the P54/P55 microprocessor and SUT.

1. Power off the SUT.

2. Unplug the power supply for the probe adapter from the electrical outlet.

1–16

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 35

Operating Basics

Page 36

Page 37

Setting Up the Support

This section provides information on how to set up the support. Information

covers the following topics:

H Channel group definitions

H Clocking options

H Symbol table files

Remember that the information in this section is specific to the operations and

functions of the TMS 109 P54/P55 support on any Tektronix logic analyzer for

which it can be purchased. Information on basic operations describes general

tasks and functions.

Before you acquire and disassemble data, you need to load the support and

specify setups for clocking and triggering as described in the information on

basic operations. The support provides default values for each of these setups,

but you can change them as needed.

Channel Group Definitions

Clocking Options

The software automatically defines channel groups for the support. For the

136-channel module, the channel groups for the P54/P55 support are Address,

Data, Data_Lo, Control, DataSize, Cache, and Misc. For the 192-channel

module, the channel groups for the P54/P55 support are Address, Data, Data_Lo,

Control, DataSize, Cache, Debug, APIC, Priv_Bus, Parity, and Misc. If you want

to know which signal is in which group, refer to the channel assignment tables

beginning on page 3–7.

The TMS 109 support offers a microprocessor-specific clocking mode for the

P54/P55 microprocessors. This clocking mode is the default selection whenever

you load the P54C support.

A description of how cycles are sampled by the module using the TMS 109

support and probe adapter is found in the Specifications chapter.

Disassembly will not be correct with the Internal or External clocking modes.

Information on basic operations describes how to use these clock selections for

general purpose analysis.

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

2–1

Page 38

Setting Up the Support

Symbols

The clocking option for the TMS 109 support is Alternate Bus Master Cycles.

An alternate bus master cycle is defined as the cycle in which the P54/P55

microprocessor gives up the bus to an alternate device (a DMA device or another

microprocessor). These types of cycles are acquired when you select Included.

Backoff cycles will always be acquired regardless of the Alternate Bus Master

Cycles selection.

The TMS 109 support supplies one symbol table file. The P54C_Ctrl file

replaces specific Control channel group values with symbolic values when

Symbolic is the radix for the channel group.

Table 2–1 shows the name, bit pattern, and meaning for the symbols in the file

P54C_Ctrl, the Control channel group symbol table.

T able 2–1: Control group symbol table definitions

Control group value

D/P# BUSCHK# LAST_D M/IO#

Symbol

INIT SMIACT# AHOLD D/C#

IRESET_L LOCK# HLDA W/R#

PRDY SCYC BOFF#

Meaning

Reset

Primary processor opcode read

Dual processor opcode read

Opcode read

Primary processor locked read cycle

Dual processor locked read cycle

Locked read cycle

Primary processor locked write cycle

Dual processor locked write cycle

Locked write cycle

Primary processor nonopcode read

Dual processor nonopcode read

Read from memory, nonopcode

Primary processor write to memory

Dual processor write to memory

Write to memory

2–2

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 39

T able 2–1: Control group symbol table definitions (cont.)

Control group value

D/P# BUSCHK# LAST_D M/IO#

Symbol Meaning

INIT SMIACT# AHOLD D/C#

IRESET_L LOCK# HLDA W/R#

P_I/O_RD 0X0 XXXX XXX0 1010

D_I/O_RD 1X0 XXXX XXX0 1010

I/O_RD* XX0 XXXX XXX0 1010

P_I/O_WR 0X0 XXXX XXX0 1011

D_I/O_WR 1X0 XXXX XXX0 1011

I/O_WR* XX0 XXXX XXX0 1011

P_MEM_R/W* 0X0 XXXX XXX0 111X

D_MEM_R/W* 1X0 XXXX XXX0 111X

MEM_R/W* XX0 XXXX XXX0 111X

P_I/O_R/W* 0X0 XXXX XXX0 101X

D_I/O_R/W* 1X0 XXXX XXX0 101X

I/O_R/W* XX0 XXXX XXX0 101X

P_READ* 0X0 XXXX XXX0 1X10

D_READ* 1X0 XXXX XXX0 1X10

READ* XX0 XXXX XXX0 1X10

P_WRITE* 0X0 XXXX XXX0 1X11

D_WRITE* 1X0 XXXX XXX0 1X11

WRITE* XX0 XXXX XXX0 1X11

P_INT_ACK 0X0 XXXX XXX0 1000

D_INT_ACK 1X0 XXXX XXX0 1000

INT_ACK* XX0 XXXX XXX0 1000

P_SPECIAL 0X0 XXXX XXX0 1001

D_SPECIAL 1X0 XXXX XXX0 1001

SPECIAL* XX0 XXXX XXX0 1001

P_RESERVE 0X0 XXXX XXX0 1101

D_RESERVE 1X0 XXXX XXX0 1101

RESERVE* XX0 XXXX XXX0 1101

ALT_B_MTR XX0 XXXX XXX1 XXXX

BOFF XX0 XXXX XXXX 0XXX

PRDY SCYC BOFF#

Primary processor I/O read cycle

Dual processor I/O read cycle

I/O read cycle

Primary processor I/O write cycle

Dual processor I/O write cycle

I/O write cycle

Any primary processor read or write

Any dual processor read or write

Any memory read or write cycle

Any primary processor I/O cycle

Any dual processor I/O cycle

Any I/O read or write cycle

Any primary processor read cycle

Any dual processor read cycle

Any read cycle

Any primary processor write cycle

Any dual processor write cycle

Any write cycle

Primary processor int. acknowledge

Dual processor int. acknowledge

Interrupt acknowledge cycle

Primary processor special cycle

Dual processor special cycle

Special cycle

Primary processor reserved

Dual processor reserved

Reserved

Alternate bus master cycle

Backoff cycle

Setting Up the Support

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

2–3

Page 40

Setting Up the Support

T able 2–1: Control group symbol table definitions (cont.)

Control group value

D/P# BUSCHK# LAST_D M/IO#

Symbol Meaning

INIT SMIACT# AHOLD D/C#

IRESET_L LOCK# HLDA W/R#

P_BUSCHCK 0X0 X0XX XXX0 1XXX

D_BUSCHCK 1X0 X0XX XXX0 1XXX

BUSCHCK* XX0 X0XX XXX0 1XXX

P_LOCKED 0X0 X1X0 XXXX XXXX

D_LOCKED 1X0 X1X0 XXXX XXXX

LOCKED* XX0 X1X0 XXXX XXXX

P_SPLTCYC* 0X0 X1X0 1XXX XXXX

D_SPLTCYC* 1X0 X1X0 1XXX XXXX

SPLTCYC* XX0 X1X0 1XXX XXXX

P_SMM* 0X0 XX0X XXXX XXXX

D_SMM* 1X0 XX0X XXXX XXXX

SMM* XX0 XX0X XXXX XXXX

PRIMARY* 0XX XXXX XXXX XXXX

DUAL* 1XX XXXX XXXX XXXX

*

Symbols used only for triggering; they are not displayed.

PRDY SCYC BOFF#

Primary processor buscheck

Dual processor buscheck

Buscheck

Any primary processor locked cycle

Any dual processor locked cycle

Any locked cycle

Primary processor split cycle

Dual processor split cycle

Split cycle

The primary processor is in smm

The dual processor is in smm

Either processor is in smm

Any primary processor cycle

Any dual processor cycle

Information on basic operations describes how to use symbolic values for

triggering and for displaying other channel groups symbolically, such as the

Address channel group.

2–4

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 41

Acquiring and Viewing Disassembled Data

This section describes how to acquire data and view it disassembled. Information

covers the following topics and tasks:

H Acquiring data

H Viewing disassembled data in various display formats

H Cycle type labels

H Changing the way data is displayed

H Changing disassembled cycles with the mark cycles function

Acquiring Data

Once you load the P54C support, choose a clocking mode, and specify the

trigger, you are ready to acquire and disassemble

If you have any problems acquiring data, refer to information on basic operations

in your online help or Appendix A: Error Messages and Disassembly Problems in

the basic operations user manual.

data.

Viewing Disassembled Data

You can view disassembled data in four display formats: Hardware, Software,

Control Flow, and Subroutine. The information on basic operations describes

how to select the disassembly display formats.

NOTE. Selections in the Disassembly property page (the Disassembly Format

Definition overlay) must be set correctly for your acquired data to be disassembled correctly. Refer to Changing How Data is Displayed on page 2–10.

The default display format shows the Address, Data, Data_Lo, and Control

channel groups for each sample of acquired data. The Data and Data_Lo groups

are shown in one column.

The disassembler displays special characters and strings in the instruction

mnemonics to indicate significant events. Table 2–2 shows these special

characters and strings, and gives a definition of what they represent.

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

2–5

Page 42

Acquiring and Viewing Disassembled Data

T able 2–2: Meaning of special characters in the display

Character or string displayed Meaning

or m

The instruction was manually marked as a program fetch

****

#

(16) or (32)

SMM

(MMX)

-ā-ā

-

* ILLEGAL INSTRUCTION *

Indicates there is insufficient data available for complete

disassembly of the instruction; the number of asterisks

indicates the width of the data that is unavailable. Each two

asterisks represent one byte.

Indicates an immediate value

Indicates that the fetch is from a 16- or 32-bit code segment

size and disassembled accordingly. If the mnemonic fills the

entire column width, the (16) or (32) will not be displayed.

Indicates a System management mode cycle.

Indicates an MMX instruction; appears at the end of the

mnemonic

Hyphens (–) in the Data column indicate invalid bytes as

determined by the BE7#-BE0# signals. When one of the two

data groups does not contain valid bytes for a nonfetch

cycle, the line for the group with the invalid bytes is not

displayed. When neither data group contains valid bytes,

both lines are displayed; this is an unexpected condition.

A hyphen in front of a cycle type label indicates a bus cycle

from the microprocessor not being traced.

Decoded as an illegal instruction

2–6

Logic analyzer software does not allow more than 32 channels in each channel

group. Therefore, two channel groups are used to acquire 64-bit wide P54/P55

microprocessor data: Data (D63-D32) and Data_Lo (D31-D0).

To handle the display of disassembled data from both data groups, the

disassembler may display more than one line for each data sample. For samples

with two display lines, data displayed under the Data column of the first line is

from the Data_Lo group (D31-0); data displayed under the Data column of the

second line is from the Data group (D63-32). Figure 2–1 on page 2–8 shows

examples of multiple display lines used to display Data_Lo and Data group

information.

The disassembler synthesizes the A2-A0 signals.

Aborting Lengthy Disassembly . When acquiring data from two microprocessors,

the disassembler might take a long time to display disassembled data. This could

be caused by the combination of selections in the Trace Processor and Other

Processor fields in the Disassembly property page (Disassembly Format

Definition overlay).

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 43

Acquiring and Viewing Disassembled Data

An example where this might occur is when the Trace Processor field is set to

DUAL, and the Other Processor field is set to Suppress. If the acquisition data

only contains data from the Primary microprocessor, then the disassembler might

take a long time to display disassembled cycle types or instruction mnemonics.

You can interrupt the disassembler by hitting the Break Key. If the disassembler

does not find any displayable data, it will revert back to the Hardware display

format with default settings.

Hardware Display Format

In Hardware display format, the disassembler displays certain cycle type labels in

parentheses. Table 2–3 shows these cycle type labels and gives a definition of the

cycle they represent. Reads to interrupt and exception vectors will be labeled

with the vector name.

The disassembler always displays at least one line of information. Because

fetches should have valid data for the Data and Data_Lo groups, most fetches

should use at least two display lines. For example, a fetch cycle can show both an

instruction, and a READ EXTENSION or FLUSH (or both).

T able 2–3: Cycle type definitions

Label Description

( RESET )

( MEM READ )

( LOCKED MEM READ )

( MEM WRITE )

( LOCKED MEM WRITE )

( IO READ )

( IO WRITE )

A reset cycle

A nonlocked memory read cycle that is not an opcode fetch

A locked memory read cycle that is not an opcode fetch

Any nonlocked memory write

Any locked memory write

Read from an I/O port

Write to an I/O port

( INT ACK )

( SHUTDOWN )

( CACHE FLUSH )

( HALT )

( WRITE-BACK )

( FLUSH ACK )

( BRANCH TRACE: TARGET )

( BRANCH TRACE: SOURCE )

( STOP GRANT ACK )

( RESERVED )

( ALTERNATE BUS MASTER )

Interrupt acknowledge cycle

Shutdown/special bus cycle; BE7:BE0 = 11111110

Cache flush/special bus cycle; BE7:BE0 = 1 1111101

Halt/special bus cycle; BE7:BE0 = 11111011

Write back/special bus cycle; BE7:BE0 = 1 111011 1

Flush Ack/special bus cycle; BE7:BE0 = 1 1101111

Branch Trace Message/special bus cycle; BE7:BE0 = 1101 1111

Branch Trace Message/special bus cycle; BE7:BE0 = 1101 1111

Stop Grant cycle; cycle type is HAL T/SPECIAL;

BE7:BE0 = 1111101 1

Reserved

Bus is released to an Alternate Bus Master

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

2–7

Page 44

Acquiring and Viewing Disassembled Data

T able 2–3: Cycle type definitions (Cont.)

Label Description

( BACK OFF )

Back Off bus cycle

( UNKNOWN )

( BURST LINE FILL )*

An invalid/unknown bus cycle

Fetch cycle computed to be a burst fill. The data is fetched but

will not be executed, it is part of a 32 byte fetch. It will possibly

be stored in cache.

( BACKOFF/BURST FLUSH )*

( EXTENSION )*

( FLUSH )*

( DUAL FETCH )

( PRIMARY FETCH )

Burst/Fetch cycle computed to be flushed due to a back off

Fetch cycle computed to be an opcode extension

Fetch cycle computed to be flushed

Nondisassembled fetch cycle from the Dual processor

Nondisassembled fetch cycle from the Primary processor

* Computed cycle types. * Computed cycle types.

Figure 2–1 shows an example of the Hardware display.

1 2 3

Sample Address Data Mnemonic Timestamp

-------------------------------------------------------------------------------000388AE FF33F633 XOR EDI,EDI (32)

15 000408A0 C033CB00 - ( DUAL FETCH ) 100 ns

000408A4 C933DB33 - ( DUAL FETCH )

4

5

16 000388B0 ABFFE1C3 RETS (32) 100 ns

000388B4 B6EFFFEF ( FLUSH )

17 000408A8 ED33D233 - ( DUAL FETCH ) 100 ns

000408AC FF33F633 - ( DUAL FETCH )

18 000388B8 FFB7D7FA ( FLUSH ) 100 ns

000388BC FFFFFDFF ( FLUSH )

19 000408B0 BDDF26C3 - ( DUAL FETCH ) 100 ns

000408B4 FF27FFBF - ( DUAL FETCH )

20 000207F4 00000005 ( MEM READ ) 100 ns

21 000408B8 5DBE5FED - ( DUAL FETCH ) 100 ns

000408BC 7FFEFBFB - ( DUAL FETCH )

22 000388C0 44875050 ( FLUSH ) 100 ns

000388C4 04870824 ( FLUSH )

23 000307F4 00000005 - ( MEM READ ) 100 ns

24 00038800 00009DE8 ( FLUSH ) 100 ns

00038805 000EBE00 MOV ESI,#0000000E (32)

25 000408C0 44875050 - ( DUAL FETCH ) 100 ns

000408C4 04870824 - ( DUAL FETCH )

6 7

2–8

Figure 2–1: Hardware display format

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 45

Acquiring and Viewing Disassembled Data

1

Sample Column. Lists the memory locations for the acquired data.

2

Address Group. Lists data from channels connected to the P54/P55 address

bus.

3

Data Column. Lists data from channels connected to D63-D32 and/or

D31-D0 of the P54/P55 microprocessor data bus. Refer to the general

description of viewing disassembled data for information on how the

disassembler determines when to display information for the Data group.

4

This part of the sample is displaying data from channels connected to

D31-D0 of the P54/P55 microprocessor data bus.

5

This part of the sample is displaying data from channels connected to

D63-D32 of the P54/P55 microprocessor data bus.

6

Mnemonic Column. Lists the disassembled instructions and cycle types.

7

Timestamp. Lists the timestamp values when a timestamp selection is made.

Information on basic operations describes how you can select a timestamp.

Software Display Format

Control Flow Display

Format

The Software display format shows only the first fetch of executed instructions.

Flushed cycles and extensions are not shown, even though they are part of the

executed instruction. Read extensions will be used to disassemble the instruction,

but will not be displayed as a separate cycle in the Software display format. Data

reads and writes are not displayed.

Out-of-order fetches are shown in the order the fetches are executed. An asterisk

indicates an out-of-order fetch. The sample number of the out-of-order fetch will

not be displayed if the previous executed instruction has a higher sample number.

The sample number of the out-of-order fetch will be displayed if the previous

executed instruction has a smaller sample number.

Since you cannot place the cursor on an instruction without a sample number,

you will not be able to scroll to some out-of-order fetch instructions. To scroll to

these instructions, you will have to switch to the Hardware display format.

The Control Flow display format shows only the first fetch of instructions that

change the flow of control.

Instructions that generate a change in the flow of control in the P54/P55

microprocessor are as follows:

CALL IRET RET

INT JMP RSM

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

2–9

Page 46

Acquiring and Viewing Disassembled Data

Instructions that might generate a change in the flow of control in the P54/P55

microprocessor are as follows:

BOUND JL/JNGE JNP/JPO

DIV JLE/JNG JNS

IDIV JNB/JAE/JNC JO

INTO JNBE/JA JP/JPE

JB/JNAE/JC JNE/JNZ JS

JBE/JNA JNL/JGE LOOP

JCXZ/JECXZ JNLE/JG LOOPNZ/LOOPNE

JE/JZ JNO LOOPZ/LOOPE

If a conditional jump branches to an address that is reached sequentially (no

address break in the fetch sample), the disassembler cannot determine if the

branch was taken. If there are two conditional jump instructions close together

that branch to the same fetch line, then the disassembler may not be able to

determine which conditional jump was actually taken. You can use the mark

cycle function to correct the disassembly. Refer to Marking Cycles later in this

section.

Subroutine Display

Format

The Subroutine display format shows only the first fetch of subroutine call and

return instructions. It will display conditional subroutine calls if they are

considered to be taken.

Instructions that generate a subroutine call or a return in the P54/P55 microprocessor are as follows:

CALL INT IRET RET RSM

Instructions that might generate a subroutine call or a return in the P54/P55

microprocessor are as follows:

BOUND DIV IDIV INTO

Changing How Data is Displayed

There are common fields and features that allow you to further modify displayed

data to suit your needs. You can make common and optional display selections in

the Disassembly property page (the Disassembly Format Definition overlay).

You can make selections unique to the P54/P55 support to do the following tasks:

H Change how data is displayed across all display formats

2–10

H Change the interpretation of disassembled cycles

H Display exception vectors

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 47

Acquiring and Viewing Disassembled Data

NOTE. All information defined in these fields pertain to the microprocessor that is

being traced.

Optional Display

Selections

You can make optional selections for disassembled

common selections (described in the information on basic operations), you can

change the displayed data in the following ways:

H Specify the code segment size

H Choose an interrupt table

H Specify the starting address of the interrupt table

H Specify the size of the interrupt table

H Select to trace the Primary or Dual microprocessor

H Choose whether to display or suppress the hardware cycles from the

microprocessor not being traced

The P54/P55 support has six additional fields: Code Segment Size, Interrupt

Table, Interrupt Table Address, Interrupt Table Size, Trace Processor, and Other

Processor. These fields appear in the area indicated in the information on basic

operations.

Code Segment Size. You can select the default code size: 32-bit or 16-bit. The

default code size is 16 bit.

data. In addition to the

Interrupt Table. You can specify if the interrupt table is Real, Virtual, or Protected.

(Selecting Virtual is equivalent to selecting Protected.) The default is Real.

Interrupt Table Address. You can specify the starting address of the interrupt table

in hexadecimal. The default starting address is 0x00000000.

Interrupt Table Size. You can specify the size of the interrupt table in hexadecimal.

The default size is 0x400.

Trace Processor. You can select to disassemble data from the Primary or Dual

microprocessor.

Other Processor. The “other” microprocessor is the one not being traced (not

selected in the Trace Processor field). You can select to display or to suppress its

bus cycles.

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

2–11

Page 48

Acquiring and Viewing Disassembled Data

Dual Microprocessors

Execution Tracing

When acquiring data from a SUT with two microprocessors, the disassembler

can trace the execution flow of one microprocessor and display the hardware

cycle types of the microprocessor not being traced. This means that the software

disassembles only the instructions executed from the microprocessor being

traced.

You can trace instructions from either the Primary microprocessor or the Dual

microprocessor. You can also choose to display or not display (suppress) data

from the microprocessor not selected in the Trace Processor field of the

Disassembly property page (Disassembly Format Definition overlay).

To set up the mode of tracing, you need to set the Trace Processor and Other

Processor fields in the Disassembly property page. Table 2–4 shows the

combinations of Trace Processor and Other Processor field selections and their

effects.

T able 2–4: Trace Processor and Other Processor field selections

Trace Processor Other Processor Effect

Primary Suppress Disassemble the Primary microprocessor only

Primary Display Cycles Disassemble the Primary microprocessor and

display the hardware cycles of the Dual

microprocessor

Dual Suppress Disassemble the Dual microprocessor only

Dual Display Cycles Disassemble the Dual microprocessor and

display the hardware cycles of the Primary

microprocessor

Figure 2–2 shows disassembled data from the Primary microprocessor and

hardware cycles from the other microprocessor. A hyphen to the left of the

mnemonic indicates data from the other microprocessor.

2–12

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

Page 49

Acquiring and Viewing Disassembled Data

Sample Address Data Mnemonic Control

-------------------------------------------------------------------------------16 000388B0 ABFFE1C3 RETS (32) P_FETCH

000388B4 B6EFFFEF ( FLUSH ) P_FETCH

17 000408A8 ED33D233 - ( DUAL FETCH ) D_FETCH

000408AC FF33F633 - ( DUAL FETCH ) D_FETCH

18 000388B8 FFB7D7FA ( FLUSH ) P_FETCH

000388BC FFFFFDFF ( FLUSH ) P_FETCH

19 000408B0 BDDF26C3 - ( DUAL FETCH ) D_FETCH

000408B4 FF27FFBF - ( DUAL FETCH ) D_FETCH

20 000207F4 00000005 ( MEM READ ) P_MEM_RD

21 000408B8 5DBE5FED - ( DUAL FETCH ) D_FETCH

000408BC 7FFEFBFB - ( DUAL FETCH ) D_FETCH

22 000388C0 44875050 ( FLUSH ) P_FETCH

000388C4 04870824 ( FLUSH ) P_FETCH

23 000307F4 00000005 - ( MEM READ ) D_MEM_RD

24 00038800 00009DE8 ( FLUSH ) P_FETCH

00038805 000EBE00 MOV ESI,#0000000E (32) P_FETCH

25 000408C0 44875050 - ( DUAL FETCH ) D_FETCH

000408C4 04870824 - ( DUAL FETCH ) D_FETCH

26 0003880A 0AB90000 MOV ECX,#0000000A (32) P_FETCH

0003880F F3000000 REPZ (32) P_FETCH

Figure 2–2: Data displayed from the Primary and Dual microprocessors

Figure 2–3 shows disassembled data from the Primary microprocessor only. Data

from the Dual microprocessor is suppressed and not displayed.

Sample Address Data Mnemonic Control

-------------------------------------------------------------------------------16 000388B0 ABFFE1C3 RETS (32) P_FETCH

000388B4 B6EFFFEF ( FLUSH ) P_FETCH

18 000388B8 FFB7D7FA ( FLUSH ) P_FETCH

000388BC FFFFFDFF ( FLUSH ) P_FETCH

20 000207F4 00000005 ( MEM READ ) P_MEM_RD

22 000388C0 44875050 ( FLUSH ) P_FETCH

000388C4 04870824 ( FLUSH ) P_FETCH

24 00038800 00009DE8 ( FLUSH ) P_FETCH

00038805 000EBE00 MOV ESI,#0000000E (32) P_FETCH

26 0003880A 0AB90000 MOV ECX,#0000000A (32) P_FETCH

0003880F F3000000 REPZ (32) P_FETCH

28 00038810 003668AD LODSD (32) P_FETCH

00038811 003668AD PUSH #00000036 (32) P_FETCH

00038816 026A0000 PUSH #02 (32) P_FETCH

30 00038818 4668026A PUSH #02 (32) P_FETCH

0003881A 4668026A PUSH #00000046 (32) P_FETCH

0003881F 6A000000 PUSH #02 (32) P_FETCH

Figure 2–3: Disassembled data displayed from the Primary microprocessor only

TMS 109 P54 & P55 Microprocessor Support Instruction Manual

2–13