Page 1

Instruction Manual

TMS 105

386SX Microprocessor Support

070-9808-00

There are no current European directives that

apply to this product. This product provides

cable and test lead connections to a test object of

electronic measuring and test equipment.

Warning

The servicing instructions are for use by

qualified personnel only. To avoid personal

injury, do not perform any servicing unless you

are qualified to do so. Refer to all safety

summaries prior to performing service.

Page 2

Copyright T ektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and are

protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

SOFTWARE WARRANTY

T ektronix warrants that the media on which this software product is furnished and the encoding of the programs on

the media will be free from defects in materials and workmanship for a period of three (3) months from the date of

shipment. If a medium or encoding proves defective during the warranty period, T ektronix will provide a

replacement in exchange for the defective medium. Except as to the media on which this software product is

furnished, this software product is provided “as is” without warranty of any kind, either express or implied.

T ektronix does not warrant that the functions contained in this software product will meet Customer’s

requirements or that the operation of the programs will be uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period. If T ektronix is unable to provide a replacement that is free from defects in materials and

workmanship within a reasonable time thereafter, Customer may terminate the license for this software product

and return this software product and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S PAYMENT IS

THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS

WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER

TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

HARDWARE WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If a product proves defective during this

warranty period, T ektronix, at its option, either will repair the defective product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by T ektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the T ektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than T ektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-T ektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 5

Table of Contents

Getting Started

Operating Basics

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface: Microprocessor Support Documentation ix. . . . . . . . . . . . . . . .

Manual Conventions ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Analyzer Documentation x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Support Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Analyzer Software Compatibility 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Analyzer Configuration 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements and Restrictions 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Probe Adapter 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to a System Under T est 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PQFP Probe Adapter 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Without a Probe Adapter 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up the Support 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel Group Definitions 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clocking Options 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquiring and Viewing Disassembled Data 2–5. . . . . . . . . . . . . . . . . . . . .

Acquiring Data 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Disassembled Data 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Display Format 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Display Format 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Flow Display Format 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subroutine Display Format 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing How Data is Displayed 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Display Selections 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Marking Cycles 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Exception Vectors 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing an Example of Disassembled Data 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

Probe Adapter Description 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel Assignments 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How Data is Acquired 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Clocking 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clocking Options 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alternate Microprocessor Connections 3–1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signals On the Probe Adapter 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TMS 105 386SX Microprocessor Support Instruction Manual

i

Page 6

Table of Contents

Extra Channels 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Maintenance 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Adapter Circuit Description 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Signal Leads 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Protective Sockets 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Electrical Parts

Replaceable Electrical Parts 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Electrical Parts List 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Mechanical Parts

Replaceable Mechanical Parts 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Mechanical Parts List 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Index

ii

TMS 105 386SX Microprocessor Support Instruction Manual

Page 7

List of Figures

Table of Contents

Figure 1–1: Connecting probes to a PQFP probe adapter 1–4. . . . . . . . .

Figure 1–2: Placing a PQFP probe adapter onto the SUT 1–5. . . . . . . . .

Figure 2–1: Hardware display format 2–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–1: Dimensions of the probe adapter 3–4. . . . . . . . . . . . . . . . . . . .

Figure 3–2: 386SX bus timing (pipelined and nonpipelined) 3–10. . . . . . .

TMS 105 386SX Microprocessor Support Instruction Manual

iii

Page 8

Table of Contents

List of Tables

Table 1–1: Supported microprocessors 1–1. . . . . . . . . . . . . . . . . . . . . . . .

Table 1–2: 386SX signal connections for channel probes 1–6. . . . . . . . . .

Table 1–3: 386SX signal connections for clock probes 1–8. . . . . . . . . . . . .

Table 2–1: Control group symbol table definitions 2–2. . . . . . . . . . . . . . .

Table 2–2: Meaning of special characters in the display 2–6. . . . . . . . . .

Table 2–3: Cycle type definitions 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–4: Exception vectors for Real Addressing mode 2–10. . . . . . . . . .

Table 2–5: Exception vectors for Protected Addressing mode 2–11. . . . . .

Table 3–1: Electrical specifications 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–2: Environmental specifications* 3–3. . . . . . . . . . . . . . . . . . . . . .

Table 3–3: Certifications and compliances 3–3. . . . . . . . . . . . . . . . . . . . . .

Table 3–4: Address group channel assignments 3–5. . . . . . . . . . . . . . . . . .

Table 3–5: Data group channel assignments 3–6. . . . . . . . . . . . . . . . . . . . .

Table 3–6: Control group channel assignments 3–6. . . . . . . . . . . . . . . . . .

Table 3–7: Intr group channel assignments 3–7. . . . . . . . . . . . . . . . . . . . .

Table 3–8: Copr group channel assignments 3–7. . . . . . . . . . . . . . . . . . . .

Table 3–9: Misc group channel assignments 3–8. . . . . . . . . . . . . . . . . . . .

Table 3–10: Clock channel assignments 3–8. . . . . . . . . . . . . . . . . . . . . . . .

Table 3–11: Extra module sections and channels 3–12. . . . . . . . . . . . . . . .

iv

TMS 105 386SX Microprocessor Support Instruction Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

To Avoid Fire or

Personal Injury

Connect and Disconnect Properly . Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and marking on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

TMS 105 386SX Microprocessor Support Instruction Manual

v

Page 10

General Safety Summary

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) T erminal

CAUTION

Refer to Manual

Double

Insulated

vi

TMS 105 386SX Microprocessor Support Instruction Manual

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the main power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

TMS 105 386SX Microprocessor Support Instruction Manual

vii

Page 12

Service Safety Summary

viii

TMS 105 386SX Microprocessor Support Instruction Manual

Page 13

Preface: Microprocessor Support Documentation

This instruction manual contains specific information about the TMS 105 386SX

microprocessor support package and is part of a set of information on how to

operate this product on compatible Tektronix logic analyzers.

If you are familiar with operating microprocessor support packages on the logic

analyzer for which the TMS 105 386SX support was purchased, you will

probably only need this instruction manual to set up and run the support.

If you are not familiar with operating microprocessor support packages, you will

need to supplement this instruction manual with information on basic operations

to set up and run the support.

Information on basic operations of microprocessor support packages is included

with each product. Each logic analyzer has basic information that describes how

to perform tasks common to support packages on that platform. This information

can be in the form of online help, an installation manual, or a user manual.

This manual provides detailed information on the following topics:

H Connecting the logic analyzer to the system under test

Manual Conventions

H Setting up the logic analyzer to acquire data from the system under test

H Acquiring and viewing disassembled data

H Using the probe adapter

This manual uses the following conventions:

H The term disassembler refers to the software that disassembles bus cycles

into instruction mnemonics and cycle types.

H The phrase “information on basic operations” refers to online help, an

installation manual, or a basic operations of microprocessor supports user

manual.

H In the information on basic operations, the term XXX or P54C used in field

selections and file names must be replaced with 386SXA. This is the name of

the microprocessor in field selections and file names you must use to operate

the 386SX support.

H The term system under test (SUT) refers to the microprocessor-based system

from which data will be acquired.

TMS 105 386SX Microprocessor Support Instruction Manual

ix

Page 14

Preface: Microprocessor Support Documentation

H The term logic analyzer refers to the Tektronix logic analyzer for which this

product was purchased.

H The term module refers to a 102/136-channel or a 96-channel module.

H 386SXA refers to all supported variations of the 386SX and 80387 micropro-

cessors unless otherwise noted.

H A tilde (~) a signal name indicates an active low signal.

Logic Analyzer Documentation

A description of other documentation available for each type of Tektronix logic

analyzer is located in the corresponding module user manual. The manual set

provides the information necessary to install, operate, maintain, and service the

logic analyzer and associated products.

Contacting Tektronix

Product

Support

Service

Support

For other

information

To write us Tektronix, Inc.

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or, contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Contact your local Tektronix distributor or sales office. Or, visit

our web site for a listing of worldwide service locations.

http://www.tek.com

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

P.O. Box 1000

Wilsonville, OR 97070-1000

x

TMS 105 386SX Microprocessor Support Instruction Manual

Page 15

Getting Started

Page 16

Page 17

Getting Started

Support Description

This chapter provides information on the following topics and tasks:

H A description of the TMS 105 microprocessor support package

H Logic analyzer software compatibility

H Your system under test requirements

H Support restrictions

H How to configure the probe adapter

H How to connect to the system under test (SUT)

The TMS 105 microprocessor support package disassembles data from systems

that are based on the Intel or AMD 386SX microprocessor. The support runs on

a compatible Tektronix logic analyzer equipped with a 102/136-channel module

or a 96-channel module.

Refer to information on basic operations to determine how many modules and

probes your logic analyzer needs to meet the minimum channel requirements for

the TMS 105 microprocessor support.

Table 1–1 shows the microprocessors and packages from which the TMS 105

support can acquire and disassemble data.

T able 1–1: Supported microprocessors

Name Package

Intel/Amd 386SX PQFP

Amd A386SXL PQFP

Intel 80387 PQFP

A complete list of standard and optional accessories is provided at the end of the

parts list in the Replaceable Mechanical Parts chapter.

TMS 105 386SX Microprocessor Support Instruction Manual

1–1

Page 18

Getting Started

To use this support efficiently, you need to have the items listed in the information on basic operations as well as the following manuals:

H The 386SX Microprocessor User’s Manual, Intel, 1994

H The 386SX Programmer’s Reference Manual, Intel, 1994

H The 16/32-Bit Embedded Processors Manual, Intel, Inc.

H The 387SX Hardware Reference Manual, Intel, Inc.

H The A386SX Microprocessor User’s Manual, AMD, Corp.

Information on basic operations also contains a general description of supports.

Logic Analyzer Software Compatibility

The label on the microprocessor support floppy disk states which version of logic

analyzer software the support is compatible with.

Logic Analyzer Configuration

To use the 386SXA support, the Tektronix logic analyzer must be equipped with

either a 102/136-channel module, or a 96-channel module at a minimum. The

module must be equipped with enough probes to acquire channel and clock data

from signals in your 386SX-based system.

Refer to information on basic operations to determine how many modules and

probes the logic analyzer needs to meet the channel requirements.

Requirements and Restrictions

You should review the general requirements and restrictions of microprocessor

supports in the information on basic operations as they pertain to your SUT.

You should also review electrical, environmental, and mechanical specifications

in the Specifications chapter in this manual as they pertain to your system under

test, as well as the following descriptions of other 386SX support requirements

and restrictions.

System Clock Rate. The TMS 105 support can acquire data from the 386SX

microprocessor at speeds of up to 25 MHz

1

.

1–2

1

Specification at time of printing. Contact your Tektronix sales representative for

current information on the fastest devices supported.

TMS 105 386SX Microprocessor Support Instruction Manual

Page 19

Configuring the Probe Adapter

The probe adapter does not require any configuration.

Connecting to a System Under Test

Before you connect to the SUT, you must connect the probes to the module.

Your SUT must also have a minimum amount of clear space surrounding the

microprocessor to accommodate the probe adapter. Refer to the Specifications

chapter in this manual for the required clearances.

The channel and clock probes shown in this chapter are for a 102/136-channel

module. The probes will look different if you are using a 96-channel module.

The general requirements and restrictions of microprocessor supports in the

information on basic operations shows the vertical dimensions of a channel or

clock probe connected to square pins on a circuit board.

Getting Started

PQFP Probe Adapter

To connect the logic analyzer to a SUT using a PQFP probe adapter, follow these

steps:

1. Turn off power to your SUT. It is not necessary to turn off the logic analyzer.

CAUTION. Static discharge can damage the microprocessor, the probe adapter,

the probes, or the module. To prevent static damage, handle all the above only in

a static-free environment.

Always wear a grounding wrist strap or similar device while handling the

microprocessor and probe adapter.

2. To discharge your stored static electricity, touch the ground connector located

on the back of the logic analyzer. Then, touch any of the ground pins of the

probe adapter to discharge stored static electricity from the probe adapter.

3. Place the probe adapter onto the antistatic shipping foam to support the probe

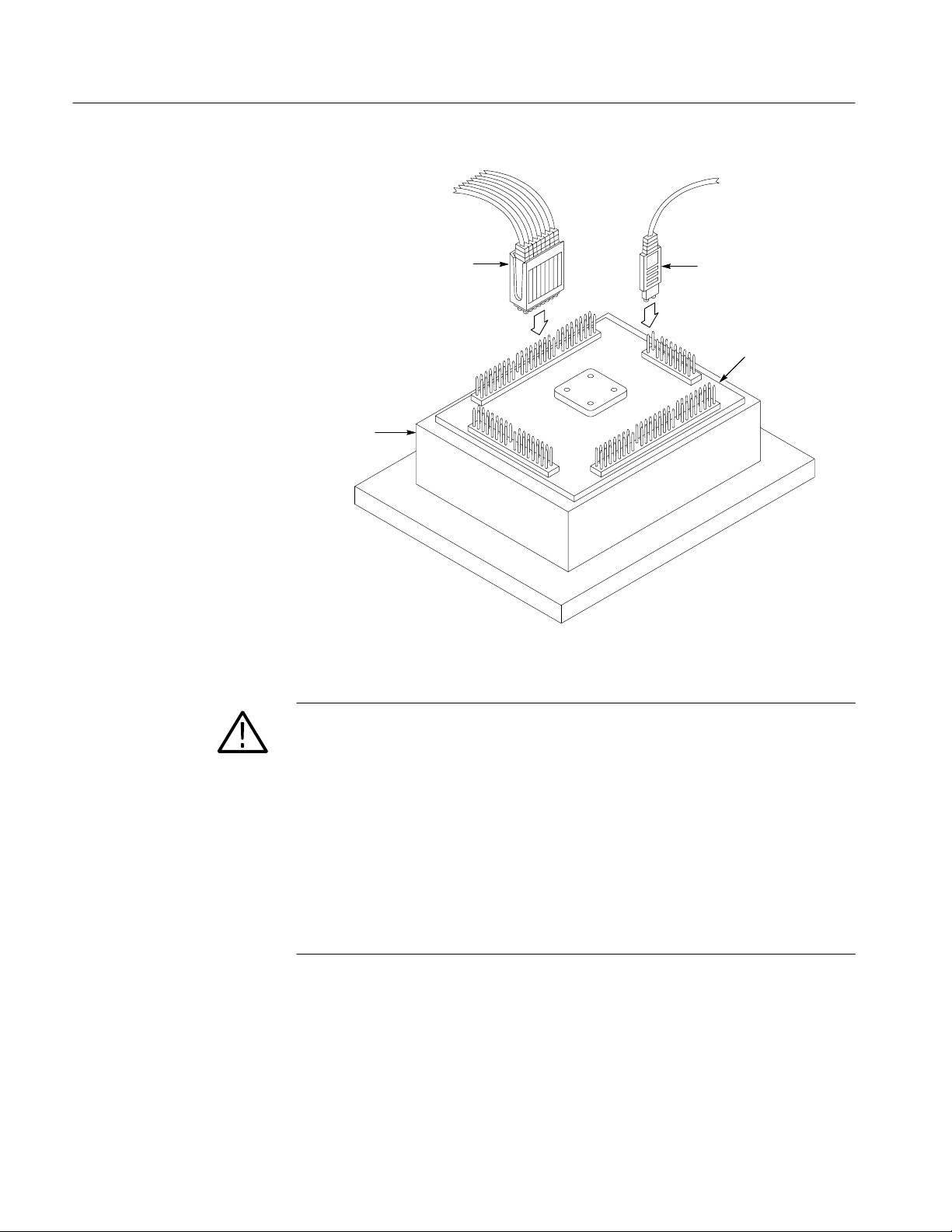

as shown Figure 1–1. This prevents the circuit board from flexing.

4. Connect the channel and clock probes to the probe adapter as shown in

Figure 1–1. Match the channel groups and numbers on the probe labels to the

corresponding pins on the probe adapter. Match the ground pins on the

probes to the corresponding pins on the probe adapter.

TMS 105 386SX Microprocessor Support Instruction Manual

1–3

Page 20

Getting Started

Channel probe

and podlet holder

Hold the channel probes by the podlet

holder when connecting them to the

probe adapter. Do not hold them by

the cables or necks of the podlets.

Foam

Figure 1–1: Connecting probes to a PQFP probe adapter

Clock probe

Probe adapter

CAUTION. This JEDEC

PQFP (Plastic Quad Flat Pack) probe adapter has been

equipped with a clip that has been designed for tight tolerances.

The clip supports only Plastic Quad Flat Pack devices that conform to the

JEDEC M0-069 October 1990 specification. Attaching the clip to a device that

does not conform to this JEDEC standard can easily damage the clip’s connection pins and/or the microprocessor, causing the probe adapter to malfunction.

Please contact your IC manufacturer to verify that the microprocessor you are

targeting conforms to the JEDEC specification.

For best performance and long probe life, exercise extreme care when connecting

the probe to the microprocessor.

5. Line up the pin 1 indicator on the microprocessor with the pin 1 indicator on

the target head of the circuit board.

1–4

TMS 105 386SX Microprocessor Support Instruction Manual

Page 21

Getting Started

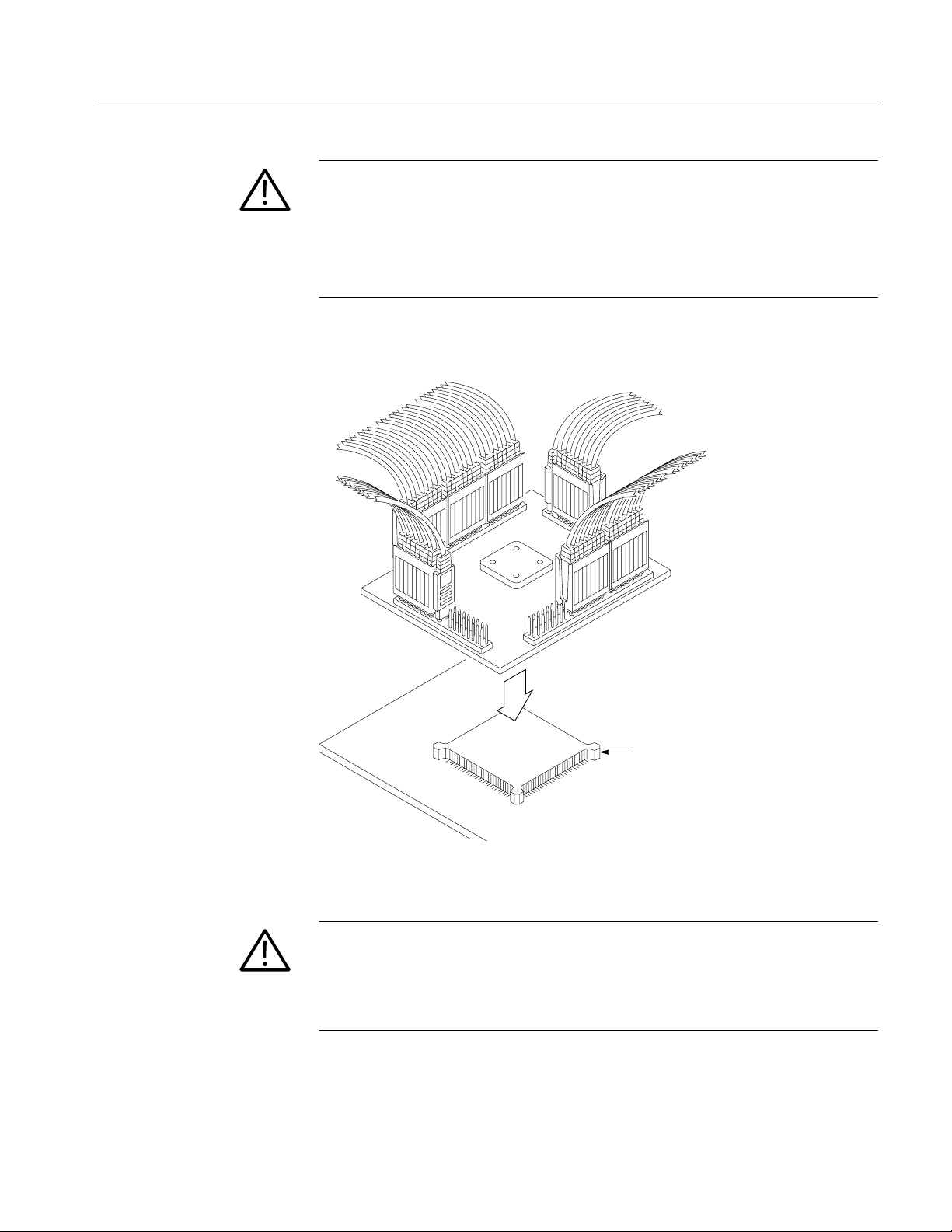

CAUTION. Failure to correctly place the probe adapter onto the microprocessor

might permanently damage all electrical components when power is applied.

Center the clip on the microprocessor and apply an equal downward force on all

four sides of the clip, slightly rocking the probe adapter in a clockwise circle.

Do not apply leverage to the probe adapter when installing or removing it.

6. Place the probe adapter onto the SUT as shown in Figure 1–2.

Figure 1–2: Placing a PQFP probe adapter onto the SUT

CAUTION. The probe adapter board might slip off or slip to one side of the

microprocessor because of the extra weight of the probes. This can damage the

microprocessor

and the SUT. To prevent this from occurring, stabilize the probe

adapter by placing a non-conductive object (such as foam) between the probe

adapter and the SUT.

TMS 105 386SX Microprocessor Support Instruction Manual

Microprocessor

1–5

Page 22

Getting Started

Without a Probe Adapter

You can use channel probes, clock probes, and leadsets with a commercial test

clip (or adapter) to make connections between the logic analyzer and your SUT.

To connect the probes to 386SX signals in the SUT using a test clip, follow these

steps:

1. Turn off power to your SUT. It is not necessary to turn off power to the logic

analyzer.

CAUTION. Static discharge can damage the microprocessor, the probes, or the

module. To prevent static damage, handle all of the above only in a static-free

environment.

Always wear a grounding wrist strap or similar device while handling the

microprocessor.

2. To discharge your stored static electricity, touch the ground connector located

on the back of the logic analyzer. If you are using a test clip, touch any of the

ground pins on the clip to discharge stored static electricity from it.

3. Use Table 1–2 to connect the channel probes to 386SX signal pins on the test

clip or in the SUT.

Use leadsets to connect at least one ground lead from each channel probe and

the ground lead from each clock probe to ground pins on your test clip.

T able 1–2: 386SX signal connections for channel probes

Section:channel 386SX signal Section:channel 386SX signal

A2:7 A23 A3:7 PEREQ*

A2:6 A22 A3:6 ERROR~*

A2:5 A21 A3:5 BUSY~*

A2:4 A20 A3:4 Not connected

A2:3 A19 A3:3 LOCK~*

A2:2 A18 A3:2 W/R~*

A2:1 A17 A3:1 D/C~*

A2:0 A16 A3:0 M/IO~*

A1:7 A15 D1:7 D15

A1:6 A14 D1:6 D14

A1:5 A13 D1:5 D13

A1:4 A12 D1:4 D12

A1:3 A11 D1:3 D11

A1:2 A10 D1:2 D10

1–6

TMS 105 386SX Microprocessor Support Instruction Manual

Page 23

T able 1–2: 386SX signal connections for channel probes (cont.)

Section:channel 386SX signalSection:channel386SX signal

A1:1 A9 D1:1 D9

A1:0 A8 D1:0 D8

A0:7 A7 D0:7 D7

A0:6 A6 D0:6 D6

A0:5 A5 D0:5 D5

A0:4 A4 D0:4 D4

A0:3 A3 D0:3 D3

A0:2 A2 D0:2 D2

A0:1 A1 D0:1 D1

A0:0 A0 D0:0 D0

C3:7

C3:6 Not connected C2:6 BHE~*

C3:5 Not connected C2:5 CLK*§

C3:4

C3:3

C3:2

C3:1

C3:0 HOLD* C2:0

* Signal not required for disassembly.

INTR_L*[

NA_L~*[

NMI_L*[

NA~*[

PIPE_D*}

C2:7

C2:4 RESET_L*

C2:3

C2:2 ADS~

C2:1

INTR[

NMI[

READY~[

HLDA*[

Getting Started

[ Signal not required for disassembly.

]

Denotes signal derived on the probe adapter.

w

CLK2 divided by two.

TMS 105 386SX Microprocessor Support Instruction Manual

1–7

Page 24

Getting Started

Table 1–3 shows the clock probes and the 386SX signal to which they must

connect for disassembly to be correct.

T able 1–3: 386SX signal connections for clock probes

Section:channel 386SX signal

CK:3 PIPE_D

CK:2 CLK

CK:1 NA_L~

CK:0 RESET_L

* Denotes signals latched on the probe adapter.

[ Signal not required for disassembly.

4. Align pin 1 or A1 of your test clip with the corresponding pin 1 or A1 of the

386SX microprocessor in your SUT and attach the clip.

1–8

TMS 105 386SX Microprocessor Support Instruction Manual

Page 25

Operating Basics

Page 26

Page 27

Setting Up the Support

This section provides information on how to set up the support. Information

covers the following topics:

H Channel group definitions

H Clocking options

H Symbol table files

Remember that the information in this section is specific to the operations and

functions of the TMS 105 386SX support on any Tektronix logic analyzer for

which it can be purchased. Information on basic operations describes general

tasks and functions.

Before you acquire and disassemble data, you need to load the support and

specify setups for clocking and triggering as described in the information on

basic operations. The support provides default values for each of these setups,

but you can change them as needed.

Channel Group Definitions

Clocking Options

The software automatically defines channel groups for the support. The channel

groups for the 386SX support are Address, Data, Control, Intr (Interrupt), Copr

(Coprocessor), and Misc (Miscellaneous). If you want to know which signal is in

which group, refer to the channel assignment tables beginning on page 3–4.

The TMS 105 support offers a microprocessor-specific clocking mode for the

386SX microprocessor. This clocking mode is the default selection whenever you

load the 386SXA support.

A description of how cycles are sampled by the module using the support and

probe adapter is found in the Specifications chapter.

TMS 105 386SX Microprocessor Support Instruction Manual

2–1

Page 28

Setting Up the Support

Symbols

Disassembly will not be correct with the Internal or External clocking modes.

Information on basic operations describes how to use these clock selections for

general purpose analysis.

The clocking option for the TMS 105 support is DMA Cycles. A DMA cycle is

defined as the cycle in which the 386SX microprocessor gives up the bus to an

alternate device (a DMA device or another microprocessor). These types of

cycles are acquired when you select Included.

The TMS 105 support supplies one symbol table file. The 386SXA_Ctrl file

replaces specific Control channel group values with symbolic values when

Symbolic is the radix for the channel group.

Table 2–1 shows the name, bit pattern, and meaning for the symbols in the file

386SXA_Ctrl, the Control channel group symbol table.

T able 2–1: Control group symbol table definitions

Control group value

RESET_L LOCK~

BHE~ M/IO~

Symbol

MEM_READ

MEM_WRITE

I/O_READ

I/O_WRITE

MEM_RD/WR

I/O_RD/WR

READ

WRITE

INT ACK

HLDA D/C~

READY~ W/R~

Meaning

Non-opcode fetch locked memory read

Any locked memory write

Memory code read (Opcode Fetch)

Non-opcode fetch memory read cycle

Any memory write

Read from an I/O port

Write to an I/O port

Non-opcode fetch memory read or write

Read from or write to an I/O port

Any memory or I/O read cycle, except

Opcode Fetch or Interrupt Acknowledge

Any memory or I/O write cycle

Responding to Interrupt

2–2

TMS 105 386SX Microprocessor Support Instruction Manual

Page 29

Setting Up the Support

T able 2–1: Control group symbol table definitions (cont.)

Control group value

RESET_L LOCK~

BHE~ M/IO~

Symbol Meaning

HAL T/SHUT

LOCKED

RESERVED*

DMA

HIGH_XFER

RESET

HLDA D/C~

READY~ W/R~

HAL T: Address=2; SHUTDOWN: Address=0

Inseparable back–to–back cycles

Reserved

Bus released to an Alternate Bus Master

Transfer on D15–D8

Latched RESET signal asserted

* Symbols used only for triggering; they are not displayed.

Information on basic operations describes how to use symbolic values for

triggering and for displaying other channel groups symbolically, such as the

Address channel group.

TMS 105 386SX Microprocessor Support Instruction Manual

2–3

Page 30

Setting Up the Support

2–4

TMS 105 386SX Microprocessor Support Instruction Manual

Page 31

Acquiring and Viewing Disassembled Data

This section describes how to acquire data and view it disassembled. Information

covers the following topics and tasks:

H Acquiring data

H Viewing disassembled data in various display formats

H Cycle type labels

H Changing the way data is displayed

H Changing disassembled cycles with the mark cycles function

Acquiring Data

Once you load the 386SXA support, choose a clocking mode, and specify the

trigger, you are ready to acquire and disassemble

If you have any problems acquiring data, refer to information on basic operations

in your online help or Appendix A: Error Messages and Disassembly Problems in

the basic operations user manual.

data.

Viewing Disassembled Data

You can view disassembled data in four display formats: Hardware, Software,

Control Flow, and Subroutine. The information on basic operations describes

how to select the disassembly display formats.

NOTE. Selections in the Disassembly property page (the Disassembly Format

Definition overlay) must be set correctly for your acquired data to be disassembled correctly. Refer to Changing How Data is Displayed on page 2–8.

The default display format shows the Address, Data, and Control channel group

values for each sample of acquired data.

The disassembler displays special characters and strings in the instruction

mnemonics to indicate significant events. Table 2–2 shows these special

characters and strings, and gives a definition of what they represent.

TMS 105 386SX Microprocessor Support Instruction Manual

2–5

Page 32

Acquiring and Viewing Disassembled Data

T able 2–2: Meaning of special characters in the display

Character or string displayed Meaning

**** Indicates there is insufficient data available for complete

# Indicates an immediate value

t Indicates the number shown is in decimal, such as #12t

(16) or (32) Indicates that the fetch is from a 16- or 32-bit code segment

* ILLEGAL INSTRUCTION * Decoded as an illegal instruction

The instruction was manually marked as a program fetch

disassembly of the instruction; the number of asterisks

indicates the width of the data that is unavailable. Each two

asterisks represent one byte.

size and disassembled accordingly

Hardware Display Format

In Hardware display format, the disassembler displays certain cycle type labels in

parentheses. Table 2–3 shows these cycle type labels and gives a definition of the

cycle they represent. Reads to interrupt and exception vectors will be labeled

with the vector name.

T able 2–3: Cycle type definitions

Cycle type Definition

( CO I/O RD ) A cycle reading data from an I/O port in the coprocessor

( CO I/O WR ) A cycle writing data to an I/O port in the coprocessor

( DMA CYCLE ) A direct memory access cycle

( EXTENSION ) A read cycle of either an extension long word or a word of an

instruction

( FLUSH ) Instruction flushed from the pipeline

( HALT ) Address = 2 ( Address bit 1 = 1)

( INT ACK ) An interrupt acknowledge cycle

( INVALID CYCLE ) An illegal cycle; an unrecognized combination of control group

values

( I/O READ ) A cycle reading data from an I/O port

2–6

( I/O WRITE ) A cycle writing data to an I/O port

( LOCKED MEM READ ) Any locked cycle during which data is read from memory except:

opcode fetch, extension, or interrupt acknowledge

( LOCKED MEM WRITE ) Any locked cycle during which data is written to memory

( MEM READ ) Any cycle during which data is read from memory except: opcode

fetch, extension, or interrupt acknowledge

TMS 105 386SX Microprocessor Support Instruction Manual

Page 33

Acquiring and Viewing Disassembled Data

T able 2–3: Cycle type definitions (cont.)

Cycle type Definition

( MEM WRITE ) Any cycle during which data is written to memory

( RESERVED ) Any cycle during which the control group bit pattern indicates

reserved

( RESET ) Latched reset signal asserted

( SHUTDOWN ) Shutdown Cycle; Address = 0

* Computed cycle types.

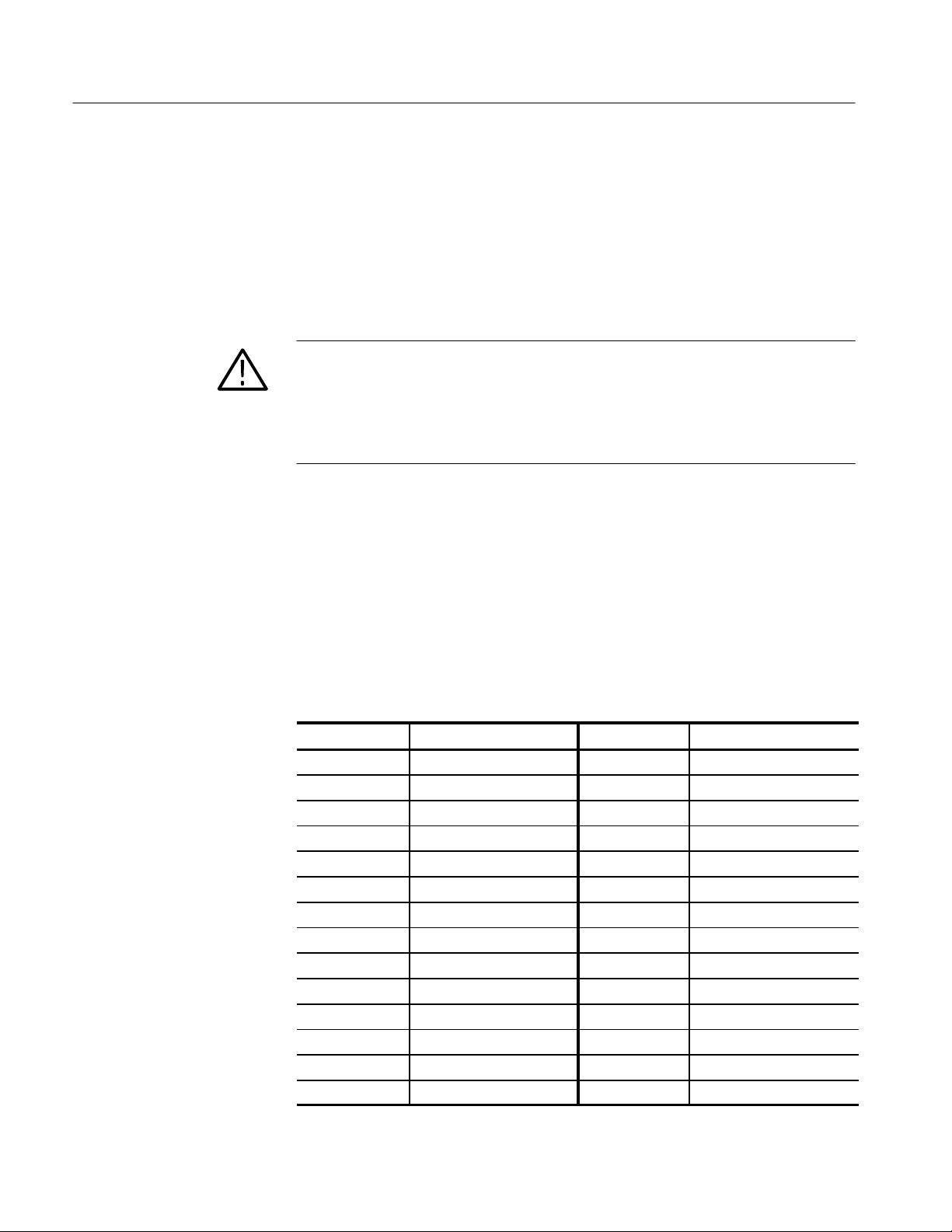

Figure 2–1 shows an example of the Hardware display.

1 2 3 4 5

Sample Address Data Mnemonic Timestamp

-------------------------------------------------------------------------------T 0 033510---061E--PUSH-DS--------------------------(32)------------------

033511 061E PUSH ES (32)

1 033512 A00F PUSH FS (32) 320 ns

2 033514 A80F PUSH GS (32) 300 ns

3 033500 0014 ( MEM WRITE ) 130 ns

4 0334FC 0014 ( MEM WRITE ) 310 ns

5 0334F8 0014 ( MEM WRITE ) 320 ns

6 033516 9AE8 CALLS 0335B5 (32) 500 ns

7 033518 0000 ( EXTENSION ) 310 ns

8 0334F4 0014 ( MEM WRITE ) 190 ns

9 03351A BE00 ( EXTENSION ) 500 ns

10 03351C 0000 ( FLUSH ) 310 ns

11 0334F0 051B ( MEM WRITE ) 120 ns

12 0334F2 0000 ( MEM WRITE ) 310 ns

13 0335B5 3321 XOR EAX,EAX (32) 510 ns

14 0335B7 33C0 XOR EBX,EBX (32) 310 ns

15 0335B9 33DB XOR ECX,ECX (32) 310 ns

16 0335BB 33C9 XOR EDX,EDX (32) 310 ns

17 0335BD 33D2 XOR EBP,EBP (32) 320 ns

18 0335BF 33ED XOR ESI,ESI (32) 310 ns

19 0335C1 33F6 XOR EDI,EDI (32) 310 ns

20 0335C3 C3FF RETS (32) 310 ns

Figure 2–1: Hardware display format

1

Sample Column. Lists the memory locations for the acquired data.

2

Address Group. Lists data from channels connected to the 386SX Address

bus.

3

Data Group. Lists data from channels connected to the 386SX Data bus.

TMS 105 386SX Microprocessor Support Instruction Manual

2–7

Page 34

Acquiring and Viewing Disassembled Data

4

Mnemonic Column. Lists the disassembled instructions and cycle types.

5

Timestamp. Lists the timestamp values when a timestamp selection is made.

Information on basic operations describes how you can select a timestamp.

Software Display Format

Control Flow Display

Format

Subroutine Display

Format

The Software display format shows only the first fetch of executed instructions.

Flushed cycles and extensions are not shown, even though they are part of the

executed instruction. Read extensions will be used to disassemble the instruction,

but will not be displayed as a separate cycle in the Software display format. Data

reads and writes are not displayed.

The Control Flow display format shows only the first fetch of instructions that

change the flow of control.

Instructions that generate a change in the flow of control in the 386SX

microprocessor are as follows:

BOUND JB/JNAE/JC JNB/JAE/JNC JNS

CALL JBE/JNA JNBE/JA JO

DIV JCXZ/JECXZ JNE/JNZ JP/JPE

IDIV JE/JZ JNL/JGE JS

INT JL/JNGE JNLE/JG LOOP

INTO JLE/JNG JNP/JPO LOOPNZ/LOOPNE

IRET JMP JNO LOOPZ/LOOPE

RET

The Subroutine display format shows only the first fetch of subroutine call and

return instructions. It will display conditional subroutine calls if they are

considered to be taken.

Instructions that generate a subroutine call or a return in the 386SX microprocessor are as follows:

BOUND DIV INT IRET

CALL IDIV INTO RET

Changing How Data is Displayed

There are common fields and features that allow you to further modify displayed

data to suit your needs. You can make common and optional display selections in

the Disassembly property page (the Disassembly Format Definition overlay).

You can make selections unique to the 386SX support to do the following tasks:

H Change how data is displayed across all display formats

2–8

TMS 105 386SX Microprocessor Support Instruction Manual

Page 35

Acquiring and Viewing Disassembled Data

H Change the interpretation of disassembled cycles

H Display exception vectors

There are no optional fields for this support package. Refer to the information on

basic operations for descriptions of common fields.

Optional Display

Selections

You can make optional selections for disassembled

common selections (described in the information on basic operations), you can

change the displayed data in the following ways:

H Specify the default code segment size.

H Choose an interrupt table.

H Specify the size of the interrupt table.

H Specify the starting address of the interrupt table.

The 386SX support has four additional fields: Code Segment Size, Interrupt

Table, Interrupt Table Address, and Interrupt Table Size. These fields appear in

the area indicated in the information on basic operations.

Code Segment Size. You can select the default code size: 32-bit or 16-bit. The

default code size is 16 bit.

Interrupt Table. You can specify if the interrupt table is Real, Virtual, or Protected.

(Selecting Virtual is equivalent to selecting Protected.) The default is Real.

Interrupt Table Address. You can specify the starting address of the interrupt table

in hexadecimal. The default starting address is 0x00000000.

data. In addition to the

Interrupt Table Size. You can specify the size of the interrupt table in hexadecimal.

The default size is 0x400.

Marking Cycles

TMS 105 386SX Microprocessor Support Instruction Manual

The disassembler has a Mark Opcode function that allows you to change the

interpretation of a cycle type. Using this function, you can select a cycle and

change it to one of the following cycle types:

H Opcode (the first word of an instruction)

H Extension (a subsequent word of an instruction)

H Flush (an opcode or extension that is fetched but not executed)

H Anything (any valid opcode, extension or flush)

2–9

Page 36

Acquiring and Viewing Disassembled Data

Mark selections are as follows:

Any OPCODE

OPCODE Any

Ext Ext

Flush Flush

16Ćbit Default Segment Size

32Ćbit Default Segment Size

Undo marks on this cycle

You can also use the Mark Opcode function to specify the default segment size

mode (16-bit or 32-bit) for the cycle. The segment size selection changes the

cycle the cursor is on and the remaining cycles to the end of memory or to the

next mark.

Information on basic operations contains more details on marking cycles.

Displaying Exception

Vectors

The disassembler can display exception vectors. You can select to display the

interrupt vectors for Real, Virtual, or Protected modes in the Interrupt Table field.

(Selecting Virtual is equivalent to selecting Protected.)

You can relocate the table by entering the starting address in the Interrupt Table

Address field. The Interrupt Table Address field provides the disassembler with

the offset address; enter an eight-digit hexadecimal value corresponding to the

offset of the base address of the exception table. The Interrupt Table Size field

lets you specify a three-digit hexadecimal size for the table.

You can make these selections in the Disassembly property page (the Disassembly Format Definition overlay).

Table 2–4 lists the 386SX exception vectors for the Real Addressing mode.

T able 2–4: Exception vectors for Real Addressing mode

Exception

number

0 0000

1 0004

2 0008

3 000C

4 0010

5 0014

6 0018

7 001C

Location in IV* table

(in hexadecimal)

Displayed exception name

DIVIDE ERROR

DEBUG EXCEPTIONS

NMI INTERRUPT

BREAKPOINT INTERRUPT

INTO DETECTED OVERFLOW

BOUND RANGE EXCEEDED

INVALID OPCODE

COPROCESSOR NOT AVAILABLE

2–10

TMS 105 386SX Microprocessor Support Instruction Manual

Page 37

Acquiring and Viewing Disassembled Data

T able 2–4: Exception vectors for Real Addressing mode (cont.)

Exception

number

8 0020

9-1 1 0024-002C

12 0030

13 0034

14-15 0038-003C

16 0040

17-31 0044-007C

32-255 0080-03FC

* IV means interrupt vector.

Location in IV* table

(in hexadecimal)

Displayed exception name

DOUBLE FAULT

RESERVED

STACK EXCEPTION

SEGMENT OVERRUN

RESERVED

COPROCESSOR ERROR

RESERVED

USER DEFINED

Table 2–5 lists the exception vectors for the Protected Addressing mode.

T able 2–5: Exception vectors for Protected Addressing mode

Exception

number

0 0000

1 0008

2 0010

3 0018

4 0020

5 0028

6 0030

7 0038

8 0040

9 0048

10 0050

11 0058

12 0060

13 0068

14 0070

15 0078

16 0080

17-31 0090-00F8

32-255 0100-07F8

* IDT means interrupt descriptor table.

Location in IDT*

(in hexadecimal)

Displayed exception name

DIVIDE ERROR

DEBUG EXCEPTIONS

NMI INTERRUPT

BREAKPOINT INTERRUPT

INTO DETECTED OVERFLOW

BOUND RANGE EXCEEDED

INVALID OPCODE

DEVICE NOT AVAILABLE

DOUBLE FAULT

RESERVED

INVALID TSS

SEGMENT NOT PRESENT

STACK EXCEPTION

GENERAL PROTECTION

PAGE FAULT

RESERVED

COPROCESSOR MODE

RESERVED

USER DEFINED

TMS 105 386SX Microprocessor Support Instruction Manual

2–11

Page 38

Acquiring and Viewing Disassembled Data

Viewing an Example of Disassembled Data

A demonstration system file (or demonstration reference memory) is provided so

you can see an example of how your 386SX microprocessor bus cycles and

instruction mnemonics look when they are disassembled. Viewing the system file

is not a requirement for preparing the module for use and you can view it without

connecting the logic analyzer to your SUT.

Information on basic operations describes how to view the file.

2–12

TMS 105 386SX Microprocessor Support Instruction Manual

Page 39

Specifications

Page 40

Page 41

Specifications

This chapter contains the following information:

H Probe adapter description

H Specification tables

H Dimensions of the probe adapter

H Channel assignment tables

H Description of how the module acquires 386SX signals

H List of other accessible microprocessor signals and extra probe channels

Probe Adapter Description

The probe adapter is nonintrusive hardware that allows the logic analyzer to

acquire data from a microprocessor in its own operating environment with little

effect, if any, on that system. Information on basic operations contains a figure

showing the logic analyzer connected to a typical probe adapter. Refer to that

figure while reading the following description.

Configuration

The probe adapter consists of a circuit board and a socket for a 386SX

microprocessor. The probe adapter connects to the microprocessor in the SUT.

Signals from the microprocessor-based system flow from the probe adapter to the

channel groups and through the probe signal leads to the module.

All circuitry on the probe adapter is powered from the SUT.

The probe adapter accommodates the Intel 386SX microprocessor in a 100-pin

PQFP package.

The probe adapter does not require any configuration.

TMS 105 386SX Microprocessor Support Instruction Manual

3–1

Page 42

Specifications

Specifications

These specifications are for a probe adapter connected between a compatible

Tektronix logic analyzer and a SUT. Table 3–1 shows the electrical requirements

the SUT must produce for the support to acquire correct data.

In Table 3–1, for the 102/136-channel module, one podlet load is 20 k in

parallel with 2 pF. For the 96-channel module, one podlet load is 100 k in

parallel with 10 pF.

T able 3–1: Electrical specifications

Characteristics Requirements

SUT DC power requirements

Voltage 4.75-5.25 VDC

Current I max (calculated) 590 mA

I typ (measured) 395 mA

SUT clock rate Max. 25 MHz

Minimum setup time required

All signals 4 ns

Minimum hold time required

NA~ 5.5 ns

All other signals 4 ns

Specification

Measured typical SUT signal loading AC load DC load

Address, Data, BLE~ 5 pF + 1 podlet 1 podlet

NMI, INTR, NA~ 14 pF + 1 podlet 16R8–5 in parallel with 1 podlet

3–2

CLK2 10 pF 16R8–5 clock

HLDA, ADS~, READY~ 9 pF + 1 podlet 1 podlet in parallel with 22V10–10

RESET 18 pF 16R8–5 + 22V10–10

All other signals 5 pF + 1 podlet 1 podlet

TMS 105 386SX Microprocessor Support Instruction Manual

Page 43

Table 3–2 shows the environmental specifications.

T able 3–2: Environmental specifications*

Characteristic Description

Temperature

Specifications

Maximum operating

Minimum operating 0° C (+32° F)

Non-operating –55° C to +75° C (–67° to +167° F)

Humidity 10 to 95% relative humidity

Altitude

Operating 4.5 km (15,000 ft) maximum

Non-operating 15 km (50,000 ft) maximum

Electrostatic immunity The probe adapter is static sensitive

* Designed to meet Tektronix standard 062-2847-00 class 5.

[

Not to exceed 386SX microprocessor thermal considerations. Forced air cooling

might be required across the CPU.

+50° C (+122° F)[

Table 3–3 shows the certifications and compliances that apply to the probe

adapter.

T able 3–3: Certifications and compliances

EC Compliance There are no current European Directives that apply to this product.

TMS 105 386SX Microprocessor Support Instruction Manual

3–3

Page 44

Specifications

Figure 3–1 shows the dimensions of the probe adapter. Information on basic

operations shows the vertical clearance of the channel and clock probes when

connected to a probe adapter.

70 mm

(2.75 in)

35 mm

(1.38 in)

Pin A1

55 mm

(2.15 in)

27 mm

(1.07 in)

Channel Assignments

12 mm (.46 in)

Figure 3–1: Dimensions of the probe adapter

Channel assignments shown in Table 3–4 through Table 3–10 use the following

conventions:

H All signals are required by the support unless indicated otherwise.

H Channels are shown starting with the most significant bit (MSB) descending

to the least significant bit (LSB).

H Channel group assignments are for all modules unless otherwise noted.

H A tilde (~) following a signal name indicates an active low signal.

3–4

TMS 105 386SX Microprocessor Support Instruction Manual

Page 45

Specifications

Table 3–4 shows the probe section and channel assignments for the Address

group and the microprocessor signal to which each channel connects. By default,

this channel group is displayed in hexadecimal.

T able 3–4: Address group channel assignments

Bit

order

23 A2:7 A23

22 A2:6 A22

21 A2:5 A21

20 A2:4 A20

19 A2:3 A19

18 A2:2 A18

17 A2:1 A17

16 A2:0 A16

15 A1:7 A15

14 A1:6 A14

13 A1:5 A13

12 A1:4 A12

11 A1:3 A1 1

10 A1:2 A10

9 A1:1 A9

8 A1:0 A8

7 A0:7 A7

6 A0:6 A6

5 A0:5 A5

4 A0:4 A4

3 A0:3 A3

2 A0:2 A2

1 A0:1 A1

0 A0:0 A0

Section:channel 386SX signal name

TMS 105 386SX Microprocessor Support Instruction Manual

3–5

Page 46

Specifications

Á

Á

Á

Table 3–5 shows the probe section and channel assignments for the Data group

and the microprocessor signal to which each channel connects. By default, this

channel group is displayed in hexadecimal.

T able 3–5: Data group channel assignments

Bit

order

15 D1:7 D15

14 D1:6 D14

13 D1:5 D13

12 D1:4 D12

11 D1:3 D11

10 D1:2 D10

9 D1:1 D9

8 D1:0 D8

7 D0:7 D7

6 D0:6 D6

5 D0:5 D5

4 D0:4 D4

3 D0:3 D3

2 D0:2 D2

1 D0:1 D1

0 D0:0 D0

Section:channel 386SX signal name

3–6

Table 3–6 shows the probe section and channel assignments for the Control

group and the microprocessor signal to which each channel connects. By default,

this channel group is displayed symbolically.

T able 3–6: Control group channel assignments

Bit

order

7

6

5

4

Á

Section:channel 386SX signal name

C2:4

C2:6

C2:0

C2:1

ÁÁÁÁ

RESET_L*

BHE~*

HLDA* [

READY~[

БББББББББББ

TMS 105 386SX Microprocessor Support Instruction Manual

Page 47

T able 3–6: Control group channel assignments (cont.)

Á

Á

Á

Á

Á

Á

Bit

order

3

A3:3

386SX signal nameSection:channel

LOCK~*

Specifications

2

1

0

Á

A3:0

A3:1

A3:2

ÁÁÁÁ

M/IO~*

D/C~*

W/R~*

БББББББББББ

* Denotes signals used for disassembly.

[ Denotes signals used for micro clocking.

Table 3–7 shows the probe section and channel assignments for the Intr group

and the microprocessor signal to which each channel connects. By default, this

channel group is not visible.

T able 3–7: Intr group channel assignments

Bit

order

3

2

1

0

Section:channel 386SX signal name

Á

C3:3

ÁÁÁÁ

C3:7

C2:3

C2:7

NMI_L* [

БББББББББББ

INTR_L* [

NMI[

INTR[

* Denotes signals latched on the probe adapter.

[ Signal not required for disassembly.

Table 3–7 shows the probe section and channel assignments for the Copr group

and the microprocessor signal to which each channel connects. By default, this

channel group is displayed not visible.

T able 3–8: Copr group channel assignments

Bit

order

2

1

0

Section:channel 386SX signal name

A3:5

A3:6

A3:7

BUSY~*

ERROR~*

PEREQ*

* Signal not required for disassembly.

TMS 105 386SX Microprocessor Support Instruction Manual

3–7

Page 48

Specifications

Á

Á

Á

Table 3–9 shows the probe section and channel assignments for the Misc group

and the microprocessor signal to which each channel connects. By default, this

channel group is not visible.

T able 3–9: Misc group channel assignments

Bit

order

5

Á

4

Section:channel 386SX signal name

C3:0

ÁÁÁÁ

C3:4

HOLD*

БББББББББББ

NA_L~* [

3

2

1

0

C3:2

C2:2

C3:1

C2:5

NA~* [

ADS~

PIPE_D* }

CLK* §

* Signal not required for disassembly.

[ Denotes signal latched on the probe adapter.

]

Denotes signal derived on the probe adapter.

w

CLK2 divided by two.

Table 3–10 shows the probe section and channel assignments for the clock probes

(not part of any group) and the 386SX signal to which each channel connects.

T able 3–10: Clock channel assignments

Section:channel 386SX signal name

CK:3 PIPE_D

CK:2 CLK

CK:1 NA_L~

CK:0 RESET_L

3–8

TMS 105 386SX Microprocessor Support Instruction Manual

Page 49

How Data is Acquired

Specifications

This part of this chapter explains how the module acquires 386SX signals using

the TMS 105 software and probe adapter. This part also provides additional

information on microprocessor signals accessible on or not accessible on the

probe adapter, and on extra probe channels available for you to use for additional

connections.

Custom Clocking

A special clocking program is loaded to the module every time you load the

386SXA support. This special clocking is called Custom.

With Custom clocking, the module logs in signals from multiple groups of

channels at different times as they become valid on the 386SX bus. The module

then sends all the logged-in signals to the trigger machine and to the memory of

the module for storage.

In Custom clocking, the module clocking state machine (CSM) generates one

master sample for each microprocessor bus cycle, no matter how many clock

cycles are contained in the bus cycle.

TMS 105 386SX Microprocessor Support Instruction Manual

3–9

Page 50

Specifications

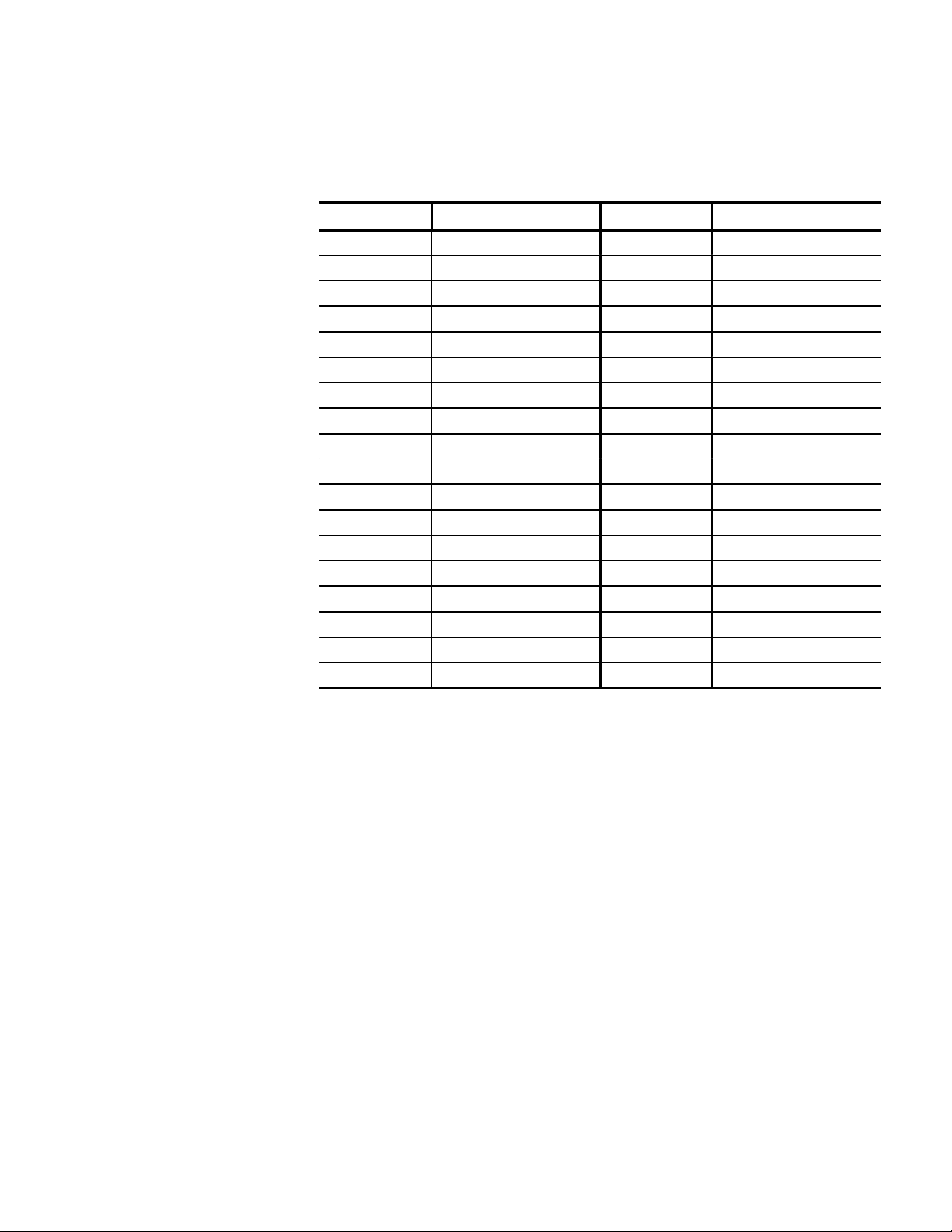

Figure 3–2 shows the sample points and the master sample point.

CLK

A23–A1

ADS~

NAL~

PIPE*PIPE*

Ready~

D15-D0

idle

Sample

Points

DC

Master

Sample

Point

idle

[

Nonpipelined

T1 T2 T1 T2 T2P T1P T2P T1P T2I Ti

A1 A2 A3 A4

A1 A2 A3 A4

D1 D2 D3 D4

(Write

D1)

Sample

Points

Master

Sample

AC*

DC

Point

[

(Read D2) (Read D3) (Read D4)

Sample

Points

AC*

Sample

Points

DC

Master

Sample

Point

Sample

Points

[

AC*

Pipelined

Sample

Points

[

DC

Master

Sample

Point

Sample

Points

AC*

* Signals sampled where AC appears are NAL~, NA~, BHE~, RESET_L, ADS~, HLDA, A23–A1,

A0/BLE~, PEREQ, ERROR~, BUSY~, and FLT~.

[ Signals sampled where DC appears are INTR_L, NMI_L, PIPE_D, INTR, CLK, NMI, READY~,

LOCK~, W/R~, D/C~, M /IO~, and D15–D0.

Figure 3–2: 386SX bus timing (pipelined and nonpipelined)

3–10

TMS 105 386SX Microprocessor Support Instruction Manual

Page 51

Specifications

Clocking Options

The clocking algorithm for the 386SX support has two variations: DMA Cycles

Excluded and DMA Cycles Included.

A DMA cycle is defined as any bus cycle initiated under the control of an

alternate bus master. It does not need to be a DMA controller, such as an 82380.

It can be another microprocessor; it need only follow the basic bus protocol of

the 386SX, requiring only the CLK, NA~, ADS~, READY~, and HLDA signals.

It may support bus pipelining. DMA cycles are identified by the assertion of the

HLDA.

To display DMA cycles, they must appear at the 386SX socket where they can be

coupled to the probe adapter. To ensure they do so, you must enable and set

system buffering to route the address, data, and control bus signals to the 386SX.

This buffering configuration may require modification of the system under test.

The DMA Cycles field has two options:

H Excluded

Whenever HLDA is high, DMA cycles do not log or store data. Normal

logging and storage resumes when HLDA returns low. Bus cycles driven by

the 386SX microprocessor will be logged in.

H Included

When HLDA is low, all bus cycles are logged in, including DMA cycles,

provided system under test follows the 386SX bus transfer protocol and that

its SUT bus buffer is configured (as described above) to provide DMA cycles

at the 386SX socket.

Alternate Microprocessor Connections

You can connect to microprocessor signals that are not required by the support so

that you can do more advanced timing analysis. These signals might or might not

be accessible on the probe adapter board. The following paragraphs and tables

list signals that are or are not accessible on the probe adapter board.

For a list of signals required or not required for disassembly, refer to the channel

assignment tables beginning on page 3–4. Remember that these channels are

already included in a channel group. If you do connect these channels to other

signals, you should set up another channel group for them.

Signals On the Probe

Adapter

All 386SX microprocessor signals are accessible on the probe adapter.

TMS 105 386SX Microprocessor Support Instruction Manual

3–11

Page 52

Specifications

Extra Channels

Table 3–11 lists extra sections and channels that are left after you have connected

all the probes used by the support. You can use these extra channels to make

alternate SUT connections.

T able 3–11: Extra module sections and channels

Module Section: channels

102-channels C3:6, C3:5, C1:7-0, C0:7-0, D3:7-0, D2:7-0, Qual:1, Qual:0

136-channels C3:6, C3:5, C1:7-0, C0:7-0, D3:7-0, D2:7-0, E3:7-0, E2:7-0, E1:7-0, E0:7-0,

Qual:3-0

96-channels C3:6, C3:5, C1:7-0, C0:7-0, D3:7-0, D2:7-0

These channels are not defined in any channel group and data acquired from

them is not displayed. To display data, you will need to define a channel group.

3–12

TMS 105 386SX Microprocessor Support Instruction Manual

Page 53

WARNING

The following servicing instructions are for use only by qualified personnel. To

avoid injury, do not perform any servicing other than that stated in the operating

instructions unless you are qualified to do so. Refer to all Safety Summaries

before performing any service.

Page 54

Page 55

Maintenance

Page 56

Page 57

Maintenance

This section contains a circuit description of the probe adapter.

Probe Adapter Circuit Description

The TMS 105 probe adapter accommodates the 386SX microprocessor in a

100-pin PQFP package.

The probe adapter board consists of three PALs. The first PAL, a 16R8–5, is used

to divide the clock signal in half and synchronize the output with RESET. When

RESET is active the output is held high.

The second PAL, another 16R8–5, is programmed to behave as a D flip-flop. It is

used to latch the NMI, INTR, and NA~ signals.

The third PAL, a 22V10–10 is used to determine if the SUT is in pipelined mode.

This PAL generates a PIPE_D output which remains high during a pipelined bus

transaction. Since the user may press the Start key in the middle of a pipelined

bus transaction, and the module has no history of what happened before the start

key was pressed, this PAL allows the module to determine when to start logging

signals.

The 22V10–10 also latches the RESET signal when it is active, and it remains

latched until the first clock after the RESET goes inactive.

Replacing Signal Leads

Information on basic operations describes how to replace signal leads (individual

channel and clock probes).

Replacing Protective Sockets

Information on basic operations describes how to replace protective sockets.

TMS 105 386SX Microprocessor Support Instruction Manual

4–1

Page 58

Maintenance

4–2

TMS 105 386SX Microprocessor Support Instruction Manual

Page 59

Replaceable Electrical Parts

Page 60

Page 61

Replaceable Electrical Parts

This chapter contains a list of the replaceable electrical components for the

TMS 105 386SX microprocessor support. Use this list to identify and

order replacement parts.

Parts Ordering Information

Replacement parts are available through your local Tektronix field office or

representative.

Changes to Tektronix products are sometimes made to accommodate improved

components as they become available and to give you the benefit of the latest

improvements. Therefore, when ordering parts, it is important to include the

following information in your order:

H Part number

H Instrument type or model number

H Instrument serial number

H Instrument modification number, if applicable

If you order a part that has been replaced with a different or improved part, your

local Tektronix field office or representative will contact you concerning any

change in part number.

Change information, if any, is located at the rear of this manual.

Using the Replaceable Electrical Parts List

The tabular information in the Replaceable Electrical Parts List is arranged for

quick retrieval. Understanding the structure and features of the list will help you

find all of the information you need for ordering replacement parts. The

following table describes each column of the electrical parts list.

TMS 105 386SX Microprocessor Support Instruction Manual

5–1

Page 62

Replaceable Electrical Parts

Parts list column descriptions

Column Column name Description

1 Component number The component number appears on diagrams and circuit board illustrations, located in the diagrams

section. Assembly numbers are clearly marked on each diagram and circuit board illustration in the

Diagrams section, and on the mechanical exploded views in the Replaceable Mechanical Parts list

section. The component number is obtained by adding the assembly number prefix to the circuit

number (see Component Number illustration following this table).

The electrical parts list is arranged by assemblies in numerical sequence (A1, with its subassemblies

and parts, precedes A2, with its subassemblies and parts).

Chassis-mounted parts have no assembly number prefix, and they are located at the end of the

electrical parts list.

2 Tektronix part number Use this part number when ordering replacement parts from Tektronix.

3 and 4 Serial number Column three indicates the serial number at which the part was first effective. Column four indicates

the serial number at which the part was discontinued. No entry indicates the part is good for all serial

numbers.

5 Name & description An item name is separated from the description by a colon (:). Because of space limitations, an item

name may sometimes appear as incomplete. Use the U.S. Federal Catalog handbook H6-1 for

further item name identification.

6 Mfr. code This indicates the code number of the actual manufacturer of the part.

7 Mfr. part number This indicates the actual manufacturer’s or vendor’s part number.

Abbreviations

Component Number

List of Assemblies

Chassis Parts

Mfr. Code to Manufacturer

Cross Index

Abbreviations conform to American National Standard ANSI Y1.1–1972.

Component number

A23A2R1234 A23 R1234

Assembly number Circuit number

Read: Resistor 1234 (of Subassembly 2) of Assembly 23

A2

Subassembly number

(optional)

A list of assemblies is located at the beginning of the electrical parts list. The

assemblies are listed in numerical order. When a part’s complete component

number is known, this list will identify the assembly in which the part is located.

Chassis-mounted parts and cable assemblies are located at the end of the

Replaceable Electrical Parts List.

The table titled Manufacturers Cross Index shows codes, names, and addresses of

manufacturers or vendors of components listed in the parts list.

5–2

TMS 105 386SX Microprocessor Support Instruction Manual

Page 63

Replaceable Electrical Parts

Manufacturers cross index

Mfr.

code

TK0875 MATSUO ELECTRONICS INC 831 S DOUBLAS ST EL SEGUNDO CA 92641

TK2058 TDK CORPORATION OF AMERICA 1600 FEEHANVILLE DRIVE MOUNT PROSPECT, IL 60056

53387 3M COMPANY ELECTRONIC PRODUCTS DIV 3M AUSTIN CENTER AUSTIN TX 78769–2963

80009 TEKTRONIX INC 14150 SW KARL BRAUN DR

Manufacturer Address City, state, zip code

PO BOX 500

BEAVERT ON OR 97077–0001

Replaceable electrical parts list

Component

number

A1 671–2441–00 CIRCUIT BD ASSY:386SX,PQFP100 SOLDERED,PROBE

A1C100 283–5003–00 CAP,FXD,CERAMIC:MLC;0.01UF,10%,50V,X7R,1206 TK2058 C3216X7R1H103K–

A1C110 283–5004–00 CAP,FXD,CERAMIC:MLC;0.1UF,10%,25V,X7R,1206 TK2058 C3216X7R1E104K–

A1C120 283–5004–00 CAP,FXD,CERAMIC:MLC;0.1UF,10%,25V,X7R,1206 TK2058 C3216X7R1E104K–

A1C122 283–5004–00 CAP,FXD,CERAMIC:MLC;0.1UF,10%,25V,X7R,1206 TK2058 C3216X7R1E104K–

A1C145 283–5003–00 CAP,FXD,CERAMIC:MLC;0.01UF,10%,50V,X7R,1206 TK2058 C3216X7R1H103K–

A1C215 283–5004–00 CAP,FXD,CERAMIC:MLC;0.1UF,10%,25V,X7R,1206 TK2058 C3216X7R1E104K–

A1C230 283–5004–00 CAP,FXD,CERAMIC:MLC;0.1UF,10%,25V,X7R,1206 TK2058 C3216X7R1E104K–

A1C320 283–5004–00 CAP,FXD,CERAMIC:MLC;0.1UF,10%,25V,X7R,1206 TK2058 C3216X7R1E104K–

A1C325 283–5003–00 CAP,FXD,CERAMIC:MLC;0.01UF,10%,50V,X7R,1206 TK2058 C3216X7R1H103K–

A1C330 283–5004–00 CAP,FXD,CERAMIC:MLC;0.1UF,10%,25V,X7R,1206 TK2058 C3216X7R1E104K–

A1C340 290–5005–00 CAP ,FXD,TANT:;47UF,10%,10V,5.8MM X 4.6MM TK0875 267M–1002–476–K

A1C350 283–5003–00 CAP,FXD,CERAMIC:MLC;0.01UF,10%,50V,X7R,1206 TK2058 C3216X7R1H103K–

A1J100 ––––––––––– CONN,HDR:PCB,;MALE,STR,2 X 40,0.1 CTR,0.235

A1J120 ––––––––––– CONN,HDR:PCB,;MALE,STR,2 X 40,0.1 CTR,0.235

A1J240 ––––––––––– CONN,HDR:PCB,;MALE,STR,2 X 40,0.1 CTR,0.235

A1J250 ––––––––––– CONN,HDR:PCB,;MALE,STR,2 X 40,0.1 CTR,0.235

A1J330 ––––––––––– CONN,HDR:PCB,;MALE,STR,2 X 40,0.1 CTR,0.235

A1J345 ––––––––––– CONN,HDR:PCB,;MALE,STR,2 X 40,0.1 CTR,0.235

Tektronix

part number

Serial no.

effective

Serial no.

discont’d

Name & description

ADAPTER;

(SEE RMPL)

(SEE RMPL)

(SEE RMPL)

(SEE RMPL)

(SEE RMPL)

(SEE RMPL)

Mfr.

code

80009 6712441XX

Mfr. part number

A1P230 ––––––––––– CLIP,ELEC:ASSEMBLY,PQFP10

A1U100 160–8837–00 IC,DIGITAL:STTL,PLD;PAL,16R8,5NS,210MA,CLOCK–DIV 80009 160–8837–00

A1U200 160–8855–00 IC,DIGITAL:STTL,PLD;PAL,16R8,5NS,210MA,LATCH 80009 160–8855–00

A1U300 160–8838–01 IC,DIGITAL:PLD;OTP,22V10,10NS,71MHZ,180MA 80009 160–8838–00

(SEE RMPL)

TMS 105 386SX Microprocessor Support Instruction Manual

5–3

Page 64

Replaceable Electrical Parts

5–4

TMS 105 386SX Microprocessor Support Instruction Manual

Page 65

Replaceable Mechanical Parts

Page 66

Page 67

Replaceable Mechanical Parts

This chapter contains a list of the replaceable mechanical components for the

TMS 105 386SX microprocessor support. Use this list to identify and order

replacement parts.

Parts Ordering Information

Replacement parts are available through your local Tektronix field office or

representative.

Changes to Tektronix products are sometimes made to accommodate improved

components as they become available and to give you the benefit of the latest

improvements. Therefore, when ordering parts, it is important to include the

following information in your order:

H Part number

H Instrument type or model number

H Instrument serial number

H Instrument modification number, if applicable

If you order a part that has been replaced with a different or improved part, your

local Tektronix field office or representative will contact you concerning any

change in part number.

Change information, if any, is located at the rear of this manual.

Using the Replaceable Mechanical Parts List

The tabular information in the Replaceable Mechanical Parts List is arranged for

quick retrieval. Understanding the structure and features of the list will help you

find all of the information you need for ordering replacement parts. The

following table describes the content of each column in the parts list.

TMS 105 386SX Microprocessor Support Instruction Manual

6–1

Page 68

Replaceable Mechanical Parts

Parts list column descriptions

Column Column name Description

1 Figure & index number Items in this section are referenced by figure and index numbers to the exploded view illustrations

that follow.

2 Tektronix part number Use this part number when ordering replacement parts from Tektronix.