Page 1

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Instruction Manual

Tektronix

/

TM502A

Power Module

070-6502-01

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to the Safety Summary prior to

performing service.

Please check for change information at the rear

of this manual .

First Printing: January I 993

Revised Printing: December 1993

•

Page 2

•

•

•

Instrument Serial Numbers

Each instrument manufactured by Tektronix has a serial number on a panel insert or tag, or stamped on the

chassis. The first letter in the serial number designates the country of manufacture. The last five digits of the

serial number are assigned sequentially and are unique to each instrument. Those manufactured in the

United States have six unique digits. The country of manufacture is identified as follows:

B010000

E200000

J300000

H700000

Instruments manufactured for Tektronix by external vendors outside the United States are assigned a two digit

alpha code to identify the country of manufacture (e.g., JP for Japan, HK for Hong Kong, IL for Israel, etc.).

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

Printed in U.S.A.

Copyright

patents, issued and pending. The following are registered trademarks: TEKTRONIX, TEK, TEKPROBE, and

SCOPE-MOBILE.

© Tektronix, Inc., 1993. All rights reserved. Tektronix products are covered by U.S. and foreign

Tektronix, Inc., Beaverton, Oregon, USA

Tektronix United Kingdom, Ltd., London

Sony/Tektronix, Japan

Tektronix Holland, NV, Heerenveen, The Netherlands

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Page 3

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

WARRANTY

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year from the

date of shipment. If any such product proves defective during this warranty period, Tektronix, at its option, either will repair the

defective product without charge for parts and labor, or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty

period and make suitable arrangements for the performance of service. Customer shall be responsible for packaging and

shipping the defective product to the service center designated by Tektronix, with shipping charges prepaid. Tektronix shall

pay for the return of the product to Customer if the shipment is to a location within the country in which the Tektronix service

center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any other charges for

products returned to any other locations .

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate maintenance

and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting from attempts by

personnel other than Tektronix representatives to install, repair or service the product; b) to repair damage resulting from

improper use or connection to incompatible equipment; or c) to service a product that has been modified or integrated with

other products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF ANY OTHER

WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX' RESPONSIBILITY TO REPAIR OR

REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR

BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES .

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Page 4

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Page 5

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Specification

Operating Instructions

Contents

Operators Safety Summary .................................. .

Service Safety Summary .................................... .

Specification ............................................... .

Instrument Description .................................. .

Performance Conditions ................................. .

Operating Instructions ...................................... .

Power Source .......•...................................

Power Usage/ Loading Considerations ................... .

Line Voltage Selection/Fuse Replacement ................ .

Handleffilt Stand Installation ............................ .

Operating Temperature .................................. .

Power Modules .......•..................................

Family Compatibility .••..................................

Module Installation ....•..................................

Plug-in Retainer Clip Information ....................... .

Power-on Procedure .................................. .

iii

V

1-1

1-1

1-1

2-1

2-1

2-1

2-1

2-3

2-4

2-4

2-4

2-4

2-5

2-5

•

•

•

•

•

•

•

•

•

•

•

•

Maintenance

TM 502A Instruction Manual

Maintenance ..........•.....................................

Static Sensitive Components ............................ .

Cleaning ............................................... .

Obtaining Replacement Parts ............................ .

Preventive Maintenance and Calibration .................. .

Soldering Techniques ................................... .

Removing the Cabinet ................................... .

Removing the Circuit Board ............................. .

Removing the Voltage Selector/Fuse Holder Assembly .... .

Replacing the Series Pass Transistor ..................... .

Packaging information .................................. .

3-1

3-1

3-2

3-3

3-3

3-4

3-4

3-4

3-5

3-5

3-6

i

Page 6

•

•

Options

Replaceable Electrical Parts

Diagrams and Circuit Board Illustrations

Symbols ...••...........................................

Component Values ...................................... .

Graphic Items and Special Symbols Used in This Manual .. .

Component Locator Diagrams ........................... .

Replaceable Mechanical Parts

Index

6-1

6-1

6-2

6-2

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

ii

Contents

•

•

•

•

•

Page 7

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

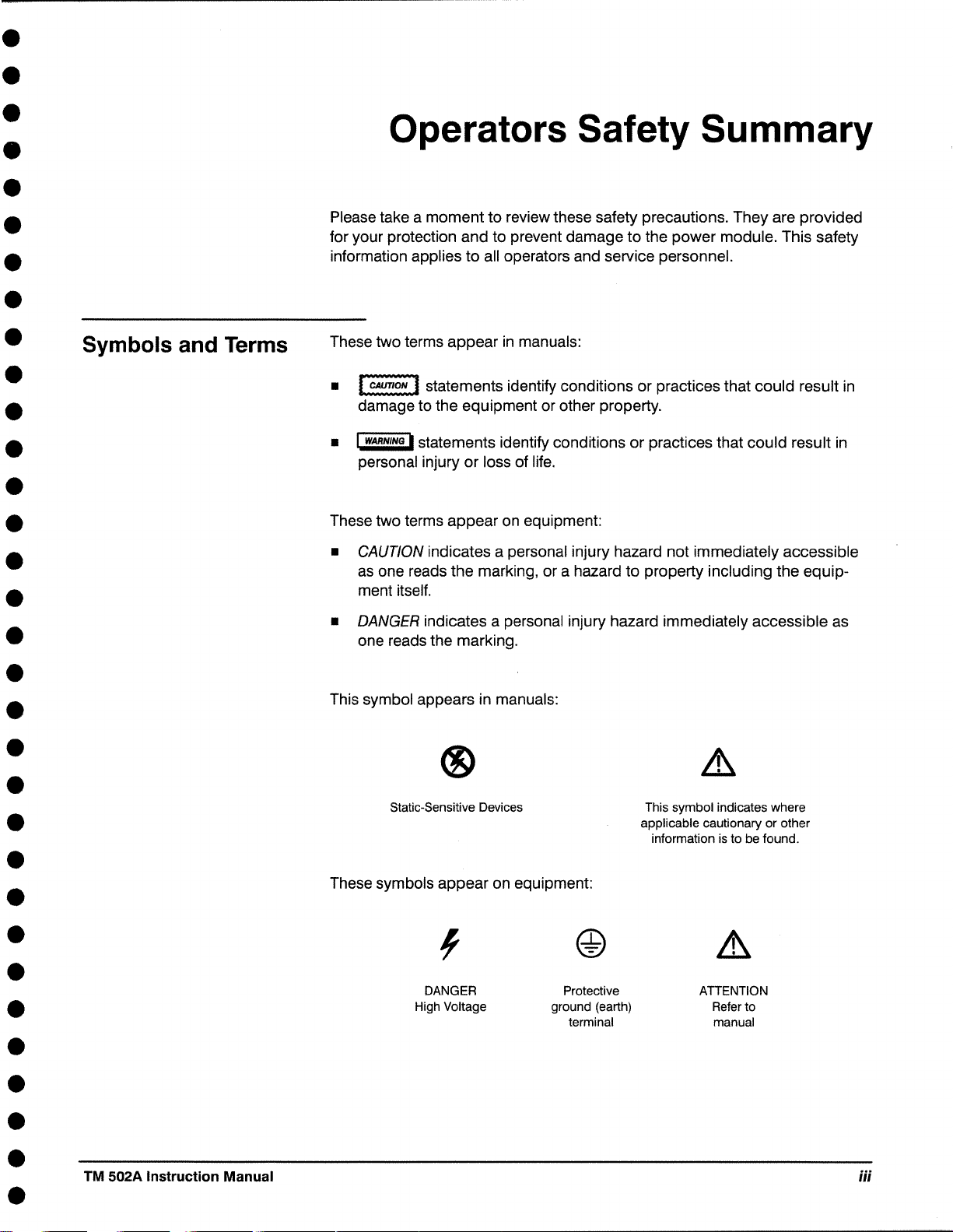

Symbols and Terms

Operators Safety Summary

Please take a moment to review these safety precautions. They are provided

for your protection and to prevent damage to the power module. This safety

information applies to all operators and service personnel.

These two terms appear in manuals:

•

~

damage to the equipment or other property .

• I wARNtNG I statements identify conditions or practices that could result in

personal injury or loss of life .

These two terms appear on equipment:

• CAUTION indicates a personal injury hazard not immediately accessible

as one reads the marking, or a hazard to property including the equipment itself .

statements identify conditions or practices that could result in

•

•

•

•

•

•

•

•

•

•

•

•

•

• DANGER indicates a personal injury hazard immediately accessible as

one reads the marking .

This symbol appears in manuals:

®

Static-Sensitive Devices

These symbols appear on equipment:

DANGER

High Voltage

Protective

ground (earth)

terminal

This symbol indicates where

applicable cautionary or other

information is to be found .

ATTENTION

Refer to

manual

•

•

•

•

TM 502A Instruction Manual

iii

Page 8

•

•

Specific Precautions

Observe all of these precautions to ensure your personal safety and to

prevent damage to either the power module or equipment connected to it.

Power Source

The power module is intended to operate from a power source that will not

apply more than 250

supply conductor and ground. A protective ground connection, through the

grounding conductor in the power cord, is essential for safe system operation.

Grounding the Power Module

The power module is grounded through the power cord. To avoid electric

shock, plug the power cord into a properly wired receptacle where earth

ground has been verified by a qualified service person. Do this before making connections to the input or output terminals of the power module.

Without the protective ground connection, all parts of the power module are

potential shock hazards. This includes knobs and controls that may appear

to be insulators.

Use the Proper Power Cord

Vrms between the supply conductors or between either

•

•

•

•

•

•

•

•

•

•

•

•

•

Use only the power cord and connector specified for your product. Use only

a power cord that is in good condition.

Use the Proper Fuse

To avoid fire hazard, use only the fuse specified in the parts list for your

product, matched by type, voltage rating, and current rating.

Do Not Remove Covers or Panels

To avoid personal injury, do not operate the power module without the

panels or covers.

Take Antistatic Precautions

Wear an antistatic grounding wrist strap when working with the input connectors on the power module.

Do Not Operate in Explosive Atmospheres

The power module provides no explosion protection from static discharges

or arcing components. Do not operate the power module in an atmosphere

of explosive gases.

•

•

•

•

•

•

•

•

•

•

•

•

•

iv

Safety

•

•

•

•

Page 9

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Service Safety Summary

For Qualified Service Personnel Only

Refer also to the preceding Operators Safety Summary

Do Not Service Alone

Do not perform internal service or adjustment of this product unless another

person capable of rendering first aid and resuscitation is present.

Use Care When Servicing With Power On

Dangerous voltages may exist at several points in this product. To avoid

personal injury, do not touch exposed connections and components while

power is on .

Disconnect power before removing protective panels, soldering, or replacing

components .

Power Source

The power module is intended to operate from a power source that will not

apply more than 250

supply conductor and ground. A protective ground connection, through the

grounding conductor in the power cord, is essential for safe system operation .

Vrms between the supply conductors or between either

•

•

•

•

•

•

•

•

•

•

•

•

•

TM 502A Instruction Manual

V

Page 10

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

vi

Safety

•

•

•

•

•

•

Page 11

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Instrument

Description

Performance

Conditions

Specification

The TM 502A is a two compartment-wide power module for the

TM 500-series of modular instrumentation. The power module accepts up to

two independently functional plug-in modules to form a compact, versatile,

and low-cost instrumentation system. The TM 502A is a basic power source

for plug-in modules of the TM 500 series family. It provides unregulated de

and ac supplies and nondedicated power transistors for plug-in usage .

The values listed in this section are valid only when the instrument is

operated at an ambient temperature between

0°c and +so0c.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

TM 502A Instruction Manual

1-1

Page 12

•

•

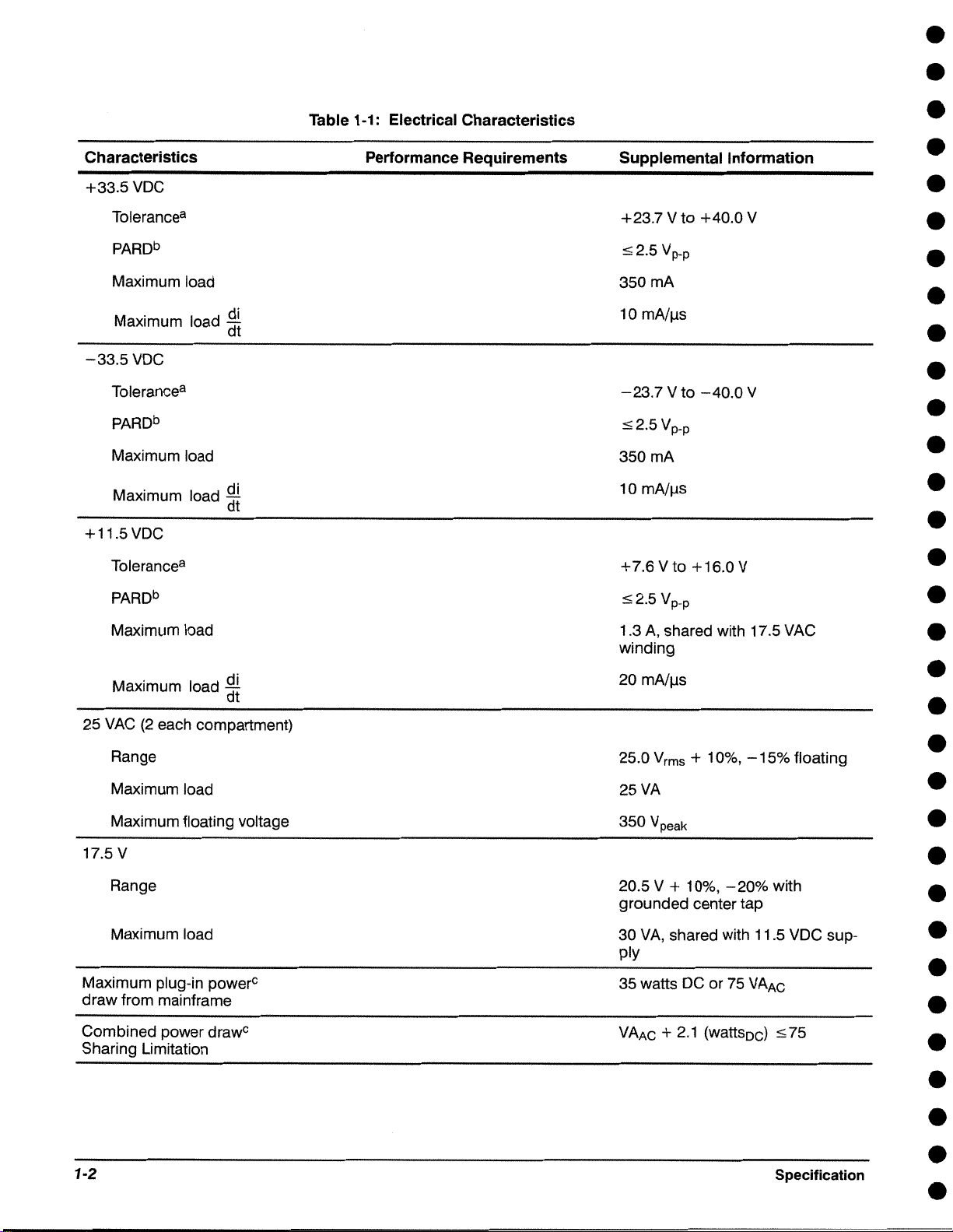

Characteristics

+33.5 VDC

Tolerance

PARDb

Maximum load

Maximum load

-33.5 VDC

Tolerance

PARDb

Maximum load

Maximum load

+11.5 VDC

Tolerance

Maximum load

8

8

8

~i

~i

Table 1-1 : Electrical Characteristics

Performance Requirements

Supplemental Information

+23.7 V to +40.0 V

::52.5 Vp-p

350mA

10 mA/µs

-23.7 V to -40.0 V

::52.5 Vp-p

350mA

10 mA/µs

+7.6 V to +16.0 V

::52.5 Vp-p

1 .3 A, shared with 17 .5 VAC

winding

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Maximum load

25 VAC (2 each compartment)

Range

Maximum load

Maximum floating voltage

17.5 V

Range

Maximum load

Maximum plug-in power

draw from mainframe

Combined power drawc

Sharing Limitation

~!

0

20 mA/µs

25.0 Vrms + 10%, -15% floating

25VA

350 Vpeak

20.5 V + 10%, -20% with

grounded center tap

30 VA, shared with 11.5 VDC supply

35 watts DC or 75 VAAc

VAAc + 2.1 (wattsoc)

:s; 75

•

•

•

•

•

•

•

•

•

•

•

•

1-2

Specification

•

•

•

Page 13

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Table 1-1: Electrical Characteristics (Cont.)

Characteristics

Total Power from Mainframe

Total power drawc

(all compartments combined)

Series Pass Transistors

Type

Maximum dissipation

Source Power Requirements

Voltage Ranges

Line Frequency

Maximum Power Consumption

Fuse Data

Performance Requirements

Supplemental Information

VAAc + 2.1 (watts

One NPN and PNP per compart-

ment

7.5 W each, 15 W total

Selectable:

100 V, 120 V, 220 V, and 240 V

nominal line

50/60 Hz

Approximately 120 W

0

± 10%

c) :s; 75

•

•

•

•

•

•

•

•

•

•

•

•

•

100 V, 120 V ranges

220 V, 240 V ranges

Miscellaneous

Maximum recommended plug-in

power dissipation

One-wide

Two-wide

Recommended adjustment interval

8

Worst case: Low line with full load and high line with no load. These limits Include PARO .

hPeriodic and Random Deviation. See National Electrical Manufacturers Association (NEMA) Standards Publication No. PY1-1972.

CAt nominal line voltage .

1.0 A, 3 AG, slow blow, 250 V

0.5 A, 3 AG, slow blow, 250 V

10 to15 W

25to 35 W

1000 hours or 6 months

•

•

•

•

•

TM 502A Instruction Manual

REV DEC 1993

1-3

Page 14

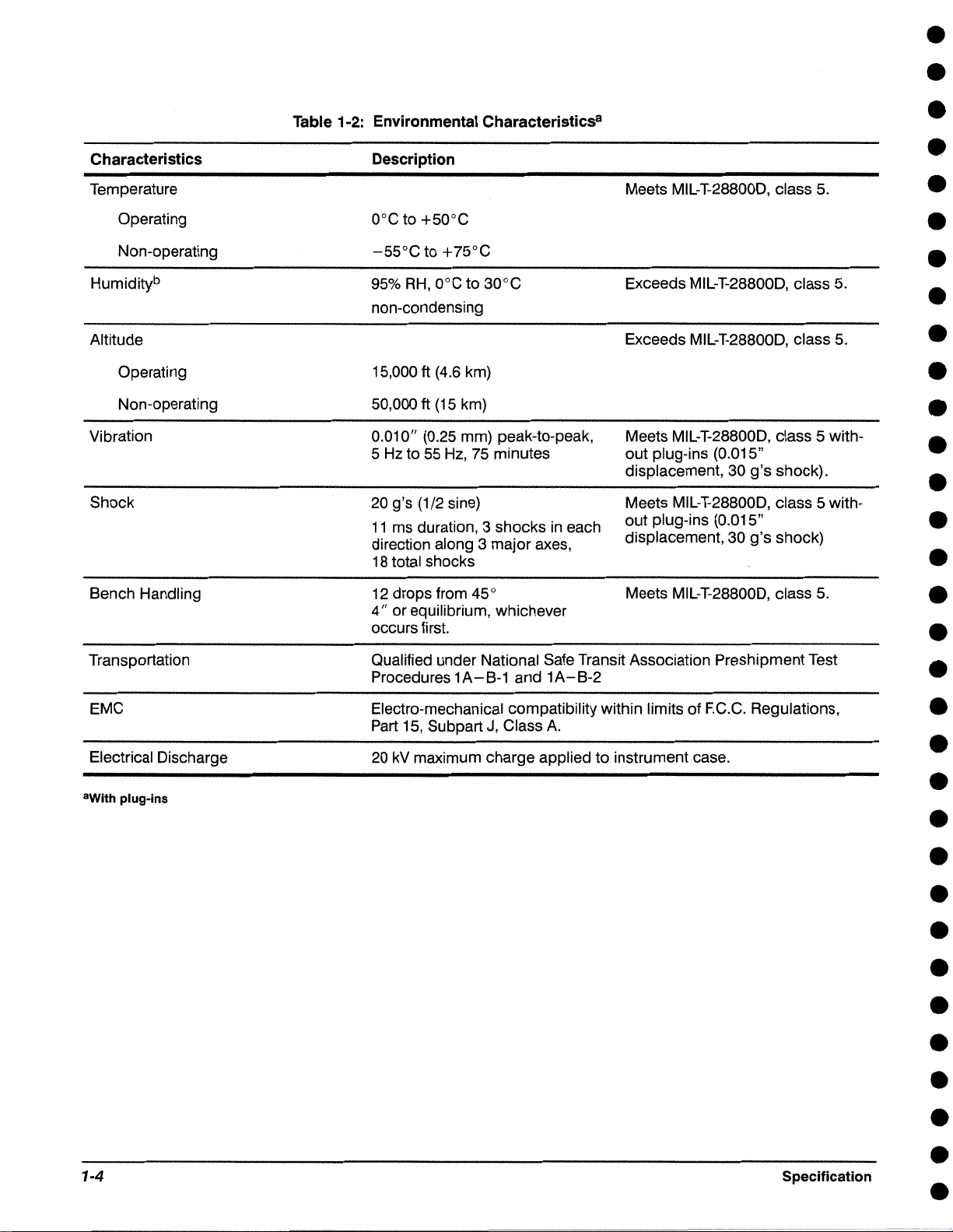

Table 1-2: Environmental Characteristics

•

•

8

•

Characteristics

Temperature

Operating

Non-operating

Humidityb

Altitude

Operating

Non-operating

Vibration

Shock

Bench Handling

Transportation

EMC

Description

Meets MIL-T-28800D, class 5.

0°c to +50°C

-55°C to + 75°C

95% RH, 0°C to 30°C

non-condensing

15,000 ft (4.6 km)

50,000 ft (15 km)

O" (0.25 mm) peak-to-peak,

0.01

5 Hz to 55 Hz, 75 minutes

20 g's (1/2 sine)

11 ms duration, 3 shocks in each

direction along 3 major axes,

18 total shocks

12 drops from 45°

4" or equilibrium, whichever

occurs first.

Qualified under National Safe Transit Association Preshipment Test

Procedures 1A-B-1 and 1A-B-2

Electro-mechanical compatibility within limits of F.C.C. Regulations,

Part 15, Subpart J, Class

A.

Exceeds MIL-T-28800D, class 5.

Exceeds MIL-T-28800D, class 5.

Meets MIL-T-28800D, class 5 without plug-ins (0.015"

displacement, 30 g's shock).

Meets MIL-T-28800D, class 5 with-

out plug-ins (0.015"

displacement, 30 g's shock)

Meets MIL-T-28800D, class 5.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Electrical Discharge

awith plug-ins

1-4

20 kV maximum charge applied to instrument case.

Specification

•

•

•

•

•

•

•

•

•

•

•

•

•

Page 15

•

•

•

•

•

•

•

•

•

•

•

•

•

•

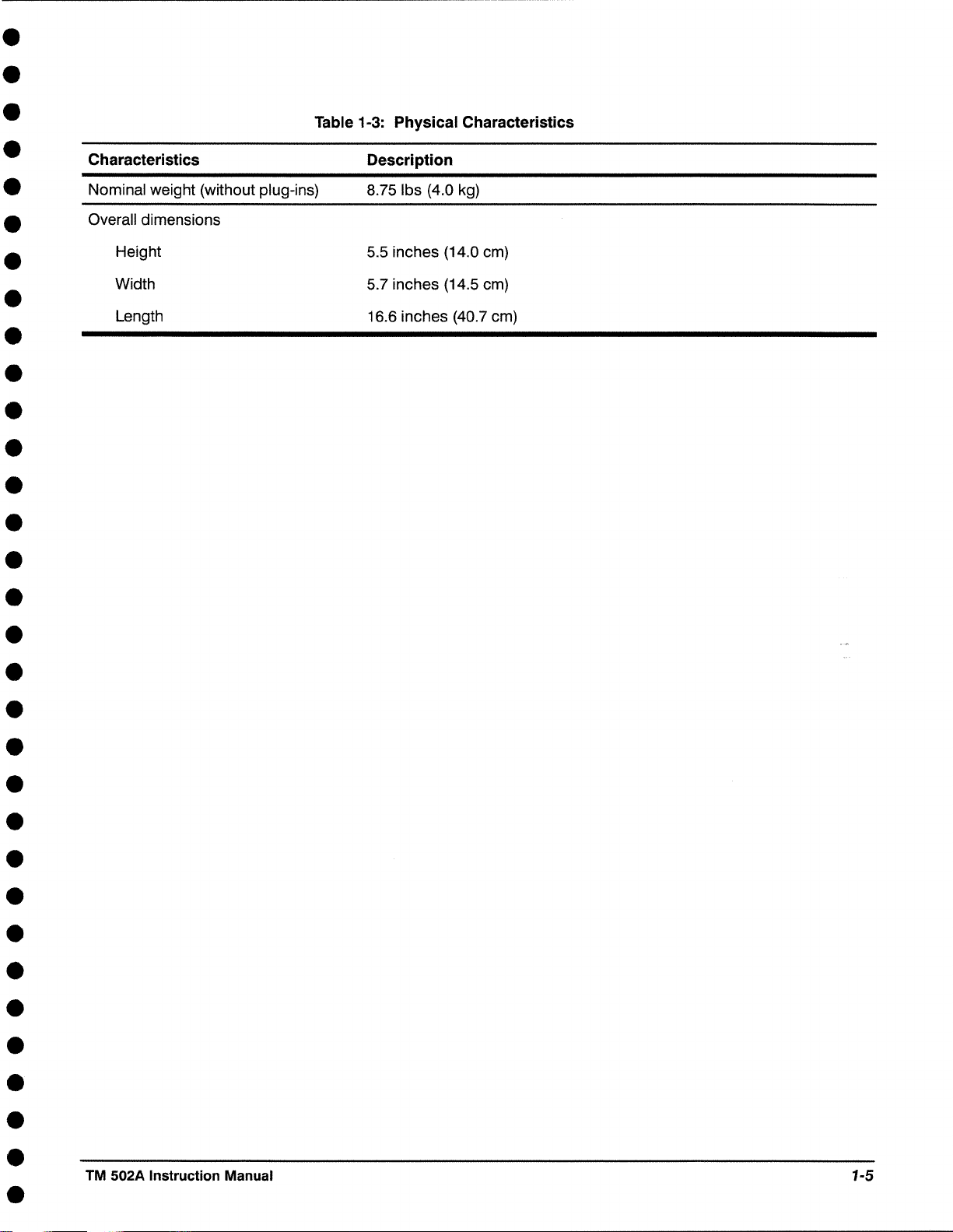

Characteristics

Nominal weight (without plug-ins)

Overall dimensions

Height

Width

Length

Table 1-3: Physical Characteristics

Description

8.75 lbs (4.0 kg)

5.5 inches (14.0 cm)

5.7 inches (14.5 cm)

16.6 inches (40.7 cm)

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

TM 502A Instruction Manual

1-5

Page 16

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

1-6

Specification

•

•

•

•

•

•

Page 17

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

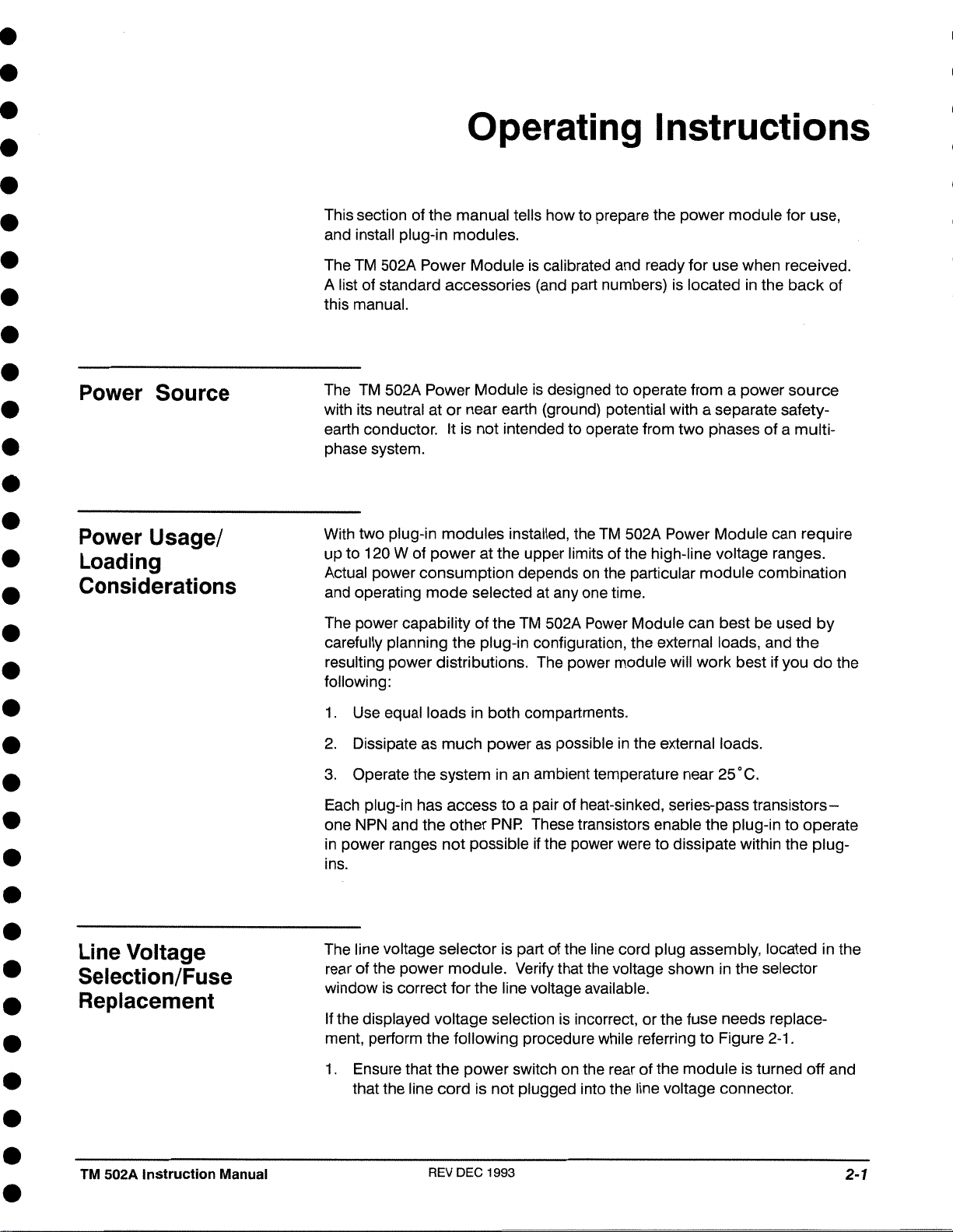

Power Source

Power Usage/

Loading

Considerations

Operating Instructions

This section of the manual tells how to prepare the power module for use,

and install plug-in modules .

The TM 502A Power Module is calibrated and ready for use when received.

A list of standard accessories (and part numbers) is located in the back of

this manual.

The TM 502A Power Module is designed to operate from a power source

with its neutral at or near earth (ground) potential with a separate safetyearth conductor. It is not intended to operate from two phases of a multi-

phase system .

With two plug-in modules installed, the TM 502A Power Module can require

up to 120 W of power at the upper limits of the high-line voltage ranges .

Actual power consumption depends on the particular module combination

and operating mode selected at any one time .

The power capability of the TM 502A Power Module can best be used by

carefully planning the plug-in configuration, the external loads, and the

resulting power distributions. The power module will work best if you do the

following:

1. Use equal loads in both compartments .

2. Dissipate as much power as possible in the external loads.

3. Operate the system in an ambient temperature near 25°C .

•

•

•

•

•

•

•

•

•

•

•

•

Line Voltage

Selection/Fuse

Replacement

TM 502A Instruction Manual

Each plug-in has access to a pair of heat-sinked, series-pass transistors-

one NPN and the other PNP. These transistors enable the plug-in to operate

in power ranges not possible if the power were to dissipate within the plugins .

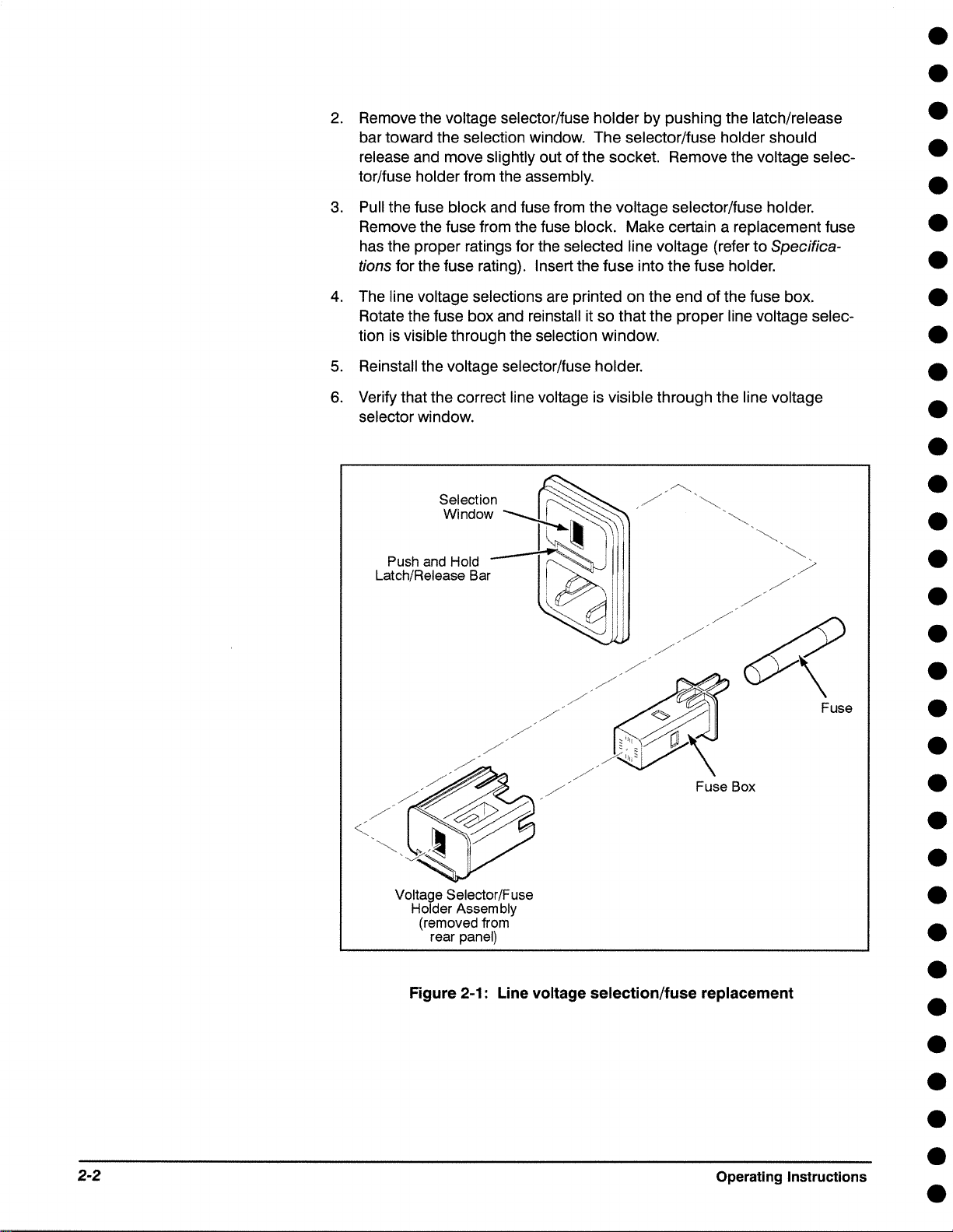

The line voltage selector is part of the line cord plug assembly, located in the

rear of the power module. Verify that the voltage shown in the selector

window is correct for the line voltage available.

If the displayed voltage selection is incorrect, or the fuse needs replacement, perform the following procedure while referring to Figure 2-1 .

1. Ensure that the power switch on the rear of the module is turned off and

that the line cord is not plugged into the line voltage connector .

REV DEC 1993

2-1

Page 18

•

•

2. Remove the voltage selector/fuse holder by pushing the latch/release

bar toward the selection window. The selector/fuse holder should

release and move slightly out of the socket. Remove the voltage selec-

tor/fuse holder from the assembly.

3. Pull the fuse block and fuse from the voltage selector/fuse holder.

Remove the fuse from the fuse block. Make certain a replacement fuse

has the proper ratings for the selected line voltage (refer to Specifica-

tions for the fuse rating). Insert the fuse into the fuse holder.

4. The line voltage selections are printed on the end of the fuse box.

Rotate the fuse box and reinstall it so that the proper line voltage selec-

tion is visible through the selection window.

5. Reinstall the voltage selector/fuse holder.

6. Verify that the correct line voltage is visible through the line voltage

selector window.

Push and Hold

Latch/Release Bar

•

•

•

•

•

•

•

•

•

•

•

•

•

/

/

/

/

/

/

Fuse Box

Voltage Selector/Fuse

Holder Assembly

(removed from

rear panel)

Figure 2-1: Line voltage selection/fuse replacement

•

•

•

Fuse

•

•

•

•

•

•

•

•

•

•

2-2

Operating Instructions

•

•

•

•

Page 19

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Handle/Tilt Stand

Installation

Before you install the handle, check the handle kit contents against the

following list:

Phillips screws

2

metal washers

2

lock washers

2

plastic locking buttons

2

1 metal handle

A Phillips screwdriver is the only tool required.

Perform the following steps to install the handle/tilt stand .

1. Turn off the power switch and disconnect the line cord .

•

•

•

•

•

•

•

•

•

•

•

•

•

•

/

Figure 2-2: Handle installation

2. Remove any plug-in modules .

3. On each side of the power module (approximately 2 inches (5 cm) from

the front edge) is a black plug. Remove each plug by pushing it out

from the inside of the power module.

4. From outside of the power module, place the plastic locking button in

the handle slot and into the square hole in the side panel, as shown in

Figure 2-2. Note that the rounded edges of the button must face the top

and bottom panels of the power module as shown in the illustration .

•

•

•

TM 502A Instruction Manual

2-3

Page 20

Operating

Temperature

5. Place the metal washer inside the side panel over the hole in the button.

6. Install and tighten the Phillips screw.

Repeat the procedure for the other end of the handle.

The TM 502A Power Module can operate in an ambient air temperature

range of o·c to +so·c (32°F to +122°F). Since the TM 502A Power

Module can be stored in temperatures between -ss·c and +75°C (-67°F

+ 167°F), allow the instrument chassis to return to within the temperature

to

operating limits before applying power.

•

•

•

•

•

•

•

•

•

•

Power Modules

Family Compatibility

It is not necessary to use both plug-in compartments to operate the power

module.

Turn the power module off before inserting or removing the plug-in;

otherwise, damage can occur to the plug-in circuitry.

Mechanically, the TM 500-series plug-in modules are very similar to other

Tektronix product families. However, they are not

Therefore, the TM 502A interface has barriers on the mating connectors

between pins 6 and 7 to ensure that incompatible plug-ins cannot be in-

serted. (Pin 1 is on the connector end near the bottom side of the power

module.) A compatible module will have a matching slot between pins 6

and 7 of its main circuit board edge connector. This slot and barrier com-

bination is the primary keying assignment.

electrically compatible.

•

•

•

•

•

•

•

•

•

•

•

•

•

Module Installation

2-4

The modularity of this instrumentation system provides for a host of functions to be performed by the plug-in modules. Specific functions are

grouped into families of classes, of which there may be several plug-in

module members. For example, some classes are power supplies, signal

sources, measurement, and so forth. Each modular member of a functional

family will have a second slot peculiar to its family assignment located in its

edge connector. The TM 502A can "program" one or both compartments to

accept only members of that family by installing a second barrier in the

interface connector to match the module's slot location. Contact the nearest

Tektronix field office to order additional barriers.

Operating Instructions

•

•

•

•

•

•

•

•

•

Page 21

•

•

•

Perform the following steps to install a module in the TM 502A Power

Module .

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

1 . Check the location of the plastic barriers on the TM 502A interconnect-

ing jack to ensure that their locations match the slots in the edge of the

plug-in module's main circuit board. If they do not match, refer the

qualified service personnel to the Maintenance section of this manual for

more information .

2. Align the plug-in module chassis with the upper and lower guides of the

selected compartment. Push the module in and press firmly to seat the

circuit board in the interconnecting jack. (Remove the plug-in module

by pulling on the release latch in the lower left corner of the plug-in

module.)

Plug-in Retainer Clip Information

The retainer clip is used to ensure that an installed plug-in module can not

come out of the power module while it is moved or transported. Note that

plug-in modules cannot be removed or inserted with the retainer clip

installed .

1. Perform the following steps to install the retainer clip:

2. Stand the power module on end.

3. Remove the round-head Phillips screw located on the bottom side of the

TM 502A Power Module just behind the front casting .

4. Align the hole in the retainer clip with the following: the chassis hole, the

clip extending forward and into the module opening, and the bottom

edge of the plug-in module(s) .

5. Reinstall the screw .

•

•

•

•

•

•

•

•

•

•

•

•

TM 502A Instruction Manual

Power-on Procedure

After completing the power module preparation and plug-in module installation instructions, install the power cord and connect the power cord to the

proper power outlet. Turn on the power switch on the rear of the power

module. Some plug-ins have independent power switches, usually labeled

"OUTPUT," that control power from the mainframe power to the plug-in .

2-5

•

Page 22

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

2-6

Operating Instructions

•

•

•

•

•

•

Page 23

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

WARNING I

The following servicing instructions are for use only by qualified

personnel.

other than that contained in the operating instructions unless you

are qualified to do so. Refer to the Operator's Safety Summary and

the Service Safety Summary prior

To avoid personal injury, do not perform any servicing

to performing any service .

•

•

•

•

•

•

•

•

•

Page 24

Page 25

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Static Sensitive

Components

Maintenance

This section provides maintenance and service information for the TM 502A

power module .

Static discharge can damage any semiconductor component in this

instrument .

This instrument contains electrical components that are susceptible to

damage from static discharge. See Table

various classes of semiconductors. Static voltages of

common in unprotected environments .

Table 3-1 : Relative Susceptibility to Static Discharge Damage

3-1 for relative susceptibility of

1 kV to 30 kV are

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Semiconductor Classes

MOS or CMOS microcircuits, or discrete or linear

microcircuits with MOS inputs (Most Sensitive)

ECL

Schottky signal diodes

Schottky TTL

High-frequency bipolar transistors

JFETs

Linear microcircuits

Low-power Schottky TTL

TTL (Least Sensitive)

8

Voltage equivalent for levels:

1 = 100 to 500 V

2

= 200to500V

3

= 250V

(Voltage discharged from a 100 pF capacitor through a resistance of 100

4=500V

5

= 400to600V

6

= 600to800V

7

= 400 to 1000 V (est.)

8

= 900V

9

= 1200V

Relative

Susceptibility

Levelsa

1

2

3

4

5

6

7

8

9

Q) •

•

•

•

TM 502A Instruction Manual

3-1

Page 26

•

•

Observe the following precautions to avoid damage:

1. Minimize handling of static-sensitive components.

2. Transport and store static-sensitive components or assemblies in their

original containers, on a metal rail, or on conductive foam. Label any

package that contains static-sensitive assemblies or components.

3. Discharge the static voltage from your body by wearing a wrist strap

while handling these components. Servicing static-sensitive assemblies

or components should be performed only at a static-free work station by

qualified service personnel.

4. Nothing capable of generating or holding a static charge should be

allowed on the work station surface.

5. Keep the component leads shorted together whenever possible.

6. Pick up components by the body, never by the leads.

7. Do not slide the components over any surface.

8. Avoid handling components in areas that have a floor or work surface

covering capable of generating a static charge.

9. Use a soldering iron that is connected to earth ground.

10. Use only special antistatic suction type or wick type desoldering tools.

•

•

•

•

•

•

•

•

•

•

•

•

•

Cleaning

This instrument should be cleaned as often as operating conditions require.

Loose dust accumulated on the outside of the instrument can be removed

with a soft cloth or small brush. Remove dirt that remains with a soft cloth

dampened in a mild detergent and water solution. Do not use abrasive

cleaners.

The best way to clean the interior is to blow off the accumulated dust with

dry, low-velocity air (approximately 5 lb/in

dampened with a mild detergent and water solution.

Circuit boards and components must be dry before applying power.

Avoid using chemical cleaning agents which can damage plastic

parts. Avoid chemicals containing benzene, toluene, zylene, acetone, or similar solvents.

2

)

or use a soft brush or cloth

•

•

•

•

•

•

•

•

•

•

•

•

•

3-2

Maintenance

•

•

•

•

Page 27

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Obtaining

Replacement Parts

Electrical and mechanical parts can be obtained through your local Tektronix

field office or representative. However, it may be possible to obtain many of

the standard electronic components from a local commercial source. Before

purchasing or ordering a part from a source other than Tektronix, Inc., check

the Replaceable Electrical Parts List for the proper value, rating, tolerance,

and description .

NOTE

When selecting replacement parts, remember that the physical size

and shape of

ment.

Some parts are manufactured or selected by Tektronix, Inc., to satisfy particular requirements or are manufactured for Tektronix, Inc., to our specifica-

tions. Most of the mechanical parts used in this instrument have been

manufactured by Tektronix. To determine the manufacturer, refer to the

Replaceable Parts List and the Cross Reference index, Mfr. Code Number to

Manufacturer .

When ordering replacement parts from Tektronix, include the following

information:

1. Instrument type and option number.

2. Instrument serial number .

a component may affect its performance in the instru-

•

•

•

•

•

•

•

•

•

•

•

•

•

Preventive

Maintenance and

Calibration

3. A description of the part (if electrical, include complete circuit number) .

4. Tektronix part number .

The TM 502A power module does not require preventive maintenance or

calibration.

WARNING I

Dangerous voltages exist at several points throughout the power

module.

removed, do not touch exposed connections or components.

Some transistors have voltages present on their cases. Disconnect

power before removing the cabinet and cleaning or replacing parts .

If you must operate the power module with the covers

•

•

•

TM 502A Instruction Manual

3-3

Page 28

•

•

Soldering Techniques

WARNING I

To avoid electric-shock hazard, disconnect the instrument from the

power source before soldering.

The reliability and accuracy of this instrument can be maintained only if

proper soldering techniques are used when repairing or replacing parts.

General soldering techniques which apply to maintenance of any precision

electronic equipment should be used when working on this instrument. Use

only 60/40 rosin-core, electronic grade solder. The choice of soldering iron is

determined by the repair to be made.

When soldering on circuit boards or small wiring, use only a 15 watt, pencil

type soldering iron. A higher wattage soldering iron can cause the etched

circuit wiring to separate from the board base material and melt the insulation from small wiring. Always keep the soldering iron tip properly tinned to

ensure the best heat transfer to the solder joint. Apply only enough heat to

remove the component or to make a good solder joint. To protect heat

sensitive components, hold the component lead with a pair of long-nose

pliers between the component body and the solder joint. Use a solder

removing wick to remove excess solder from connections or to clean circuit

board pads.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Removing the

Cabinet

Removing the

Circuit Board

•

Before removing the cabinet, turn the power switch off and disconnect the

power cord. Remove any plug-in modules and the handle assembly.

Use the following steps to remove the cabinet:

1 . Remove the two screws on the side and one screw on the bottom

holding the cabinet to the TM 502A front casting.

2. Remove the four screws on the bottom and one screw on the back

holding the power supply to the cabinet.

3. Slide the power supply assembly out through the front of the cabinet.

•

•

•

•

•

•

4. Reinstall the cabinet to remove any shock hazards and to protect the

interior from dust.

•

•

Use the following procedure to remove the circuit board from the TM 502A

power module.

1. Remove the power supply assembly from the power module. Refer to e

Removing the Cabinet earlier in this section for instructions on removing

the cabinet. •

•

•

3-4

Maintenance

•

•

•

Page 29

•

•

•

2. On the power supply assembly, remove the screws on each side that

secure the series-pass transistor clamp; remove the clamp .

•

•

•

•

•

•

•

•

•

•

•

•

•

Removing the Voltage

Selector/Fuse Holder

Assembly

3. Remove the four screws on the interface connector side of the power

supply assembly that secure the circuit board to the chassis.

4. Disconnect the two connectors going to the transformer from the circuit

board .

5. Slide the circuit board out of the power supply assembly .

Use the following procedure to remove the voltage selector/fuse holder

assembly.

1. Remove the cabinet and the circuit board. Refer to

and Removing the Circuit Board earlier in this section .

net

2. Disconnect the connectors from the terminals on the back of the voltage

selector/fuse holder assembly and label each wire .

Do not apply excessive force to the locking tabs. Excessive pressure will break or reduce the strength of the plastic .

Removing the Cabi-

•

•

•

•

•

•

•

•

•

•

•

•

•

Replacing the Series

Pass Transistor

3. The assembly has a locking tab on two sides that secure it in the chas-

sis hole. Push one tab in carefully, pulling gently on the assembly from

the outside, until the side releases.

4. Repeat the previous step to release the other side .

5. Pull the assembly through the chassis hole to the outside while taking

care not to damage the capacitors .

Use the following procedure to replace the series pass transistor.

NOTE

You must apply a new adhesive insulator plate to the transistor

before installing it. Do not use the insulating plate from the old

transistor to maintain the proper insulating characteristics .

1 . If you have not already done so, remove the cabinet and the circuit

board as described earlier in this section.

2. Unsolder and remove the transistor from the circuit board .

•

•

•

TM 502A Instruction Manual

3-5

Page 30

•

•

3. Carefully bend the new transistor leads according to the dimensions in

Figure 3-1. The illustration shows the actual size of the leads so that you

can physically compare the lead angles.

r

0.370"1

'( I

I

i,(0.318~:

Correct transistor lead angles.

Figure 3-1: Series pass transistor replacement (actual size)

4. Apply the new adhesive insulator plate to the transistor side with the

exposed metal.

Correct relationship to circuit board.

•

•

•

•

•

•

•

•

•

•

•

•

Packaging

information

5. Reinstall the circuit board into the power supply assembly.

6. Insert the leads of the replacement transistor into the circuit board holes

with the insulating plate facing the metal chassis.

7. Reinstall the transistor clamp.

8. Solder the transistor onto the board while applying minimum heat with

the soldering iron.

9. Reinstall the assembly into the power module cabinet.

10. Reinstall the power module handle assembly.

A list of standard accessories and part numbers is located at the end of the

Replaceable Mechanical Parts list.

If the TM 502A power module is to be shipped to a Tektronix service center

for service or repair, attach a tag showing the name and address of the

owner and the name of an individual at your firm that can be contacted.

Include the complete instrument serial number and a description of the

required service.

Save and use the packaging in which your instrument was originally •

shipped. If the original packaging is unfit for use or is not available, repack- •

age the instrument using the following steps:

•

•

•

•

•

•

•

•

•

•

•

•

3-6

1. Surround the instrument with polyethylene sheeting to protect the finish

of the instrument.

Maintenance

e

•

•

•

Page 31

•

•

•

•

•

•

•

•

•

•

•

•

•

•

2. Obtain a carton of corrugated cardboard of the correct carton strength

(275 pounds per square inch) with the inside dimensions of no less than

six inches more than the instrument dimensions .

3. Cushion the instrument by tightly packing three inches of dunnage or

urethrane foam between the carton and the instrument on all sides .

4. Seal the carton with shipping tape or an industrial stapler .

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

TM 502A Instruction Manual

3-7

Page 32

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

3-8

Maintenance

•

•

•

•

•

•

Page 33

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Options

The following options are available for the TM 502A Power Module .

Option 11-deletes handle/tilt stand

Option 13-adds storage plug-in

Option A 1 -changes the power to Universal European (230 V, 10 A, 50 Hz)

Option A2-changes the power to United Kingdom (230 V, 10 A, 50 Hz)

Option A3-changes the power to Austrialian (230 V, 10 A, 50 Hz)

Option A4-changes the power to North American (230 V, 1

Option AS-changes the power to Switzerland (230 V, 1

O A, 60 Hz)

O A, 50 Hz)

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

TM 502A Instruction Manual

4-1

Page 34

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

4-2

Options

•

•

•

•

•

•

Page 35

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Parts Ordering

Information

List of Assemblies

Replaceable Electrical Parts

Replacement parts are available from or through your local Tektronix, Inc.

field office or representative .

When ordering parts, include the following information in your order: part

number, instrument type or number, serial number, and modification number

if applicable .

If a part you have ordered has been replaced with a new or improved part,

your local Tektronix, Inc. field office or representative will contact you concerning any change in part number .

Change information, if any, is located at the rear of this manual.

A list of assemblies can be found at the beginning of the electrical parts list.

The assemblies are listed in numerical order. When the complete compo-

nent number of a part is known, this list will identify the assembly in which

the part is located .

•

•

•

•

•

•

•

•

•

•

•

•

•

Cross Index-Mfr .

Code Number to

Manufacturer

Abbreviations

Component Number

(column 1 of the parts list)

The Mfg. Code Number to Manufacturer Cross Index for the electrical parts

list is located immediately after this page. The cross index provides codes,

names, and addresses of manufacturers of components listed in the electri-

cal parts list.

Abbreviations conform to American National Standard Y1 .1.

Example a. component number

A23R1234 A23 R1234

Assembly number///

Read: Resistor 1234 of Assembly 23

Example b.

A23A2R1234 A23 A2 R1234 Circuit

Assembly numbe~ / Subassembly number ~-number

Read: Resistor 1234 of Subassembly 2 of Assembly 23

~

-~~

Circuit number

component number

/ / ,_

--------

•

•

•

TM 502A Instruction Manual

5-1

Page 36

The circuit component's number appears on the diagrams and circuit board

illustrations. Each diagram and circuit board illustration is clearly marked

with the assembly number. Assembly numbers are also marked on the

mechanical exploded views located in the mechanical parts list. The component number is obtained by adding the assembly number prefix to the circuit

number.

The electrical parts list is divided and arranged by assemblies in numerical

sequence (e.g., assembly A1 with its subassemblies and parts, precedes

assembly A2 with its subassemblies and parts).

•

•

•

•

•

•

•

Tektronix Part No.

(column 2 of the parts list)

Serial No.

(columns 3 & 4 of the parts list)

Name & Description

(column five of the parts list)

Chassis-mounted parts have no assembly number prefix and are located at

the end of the electrical parts list.

Indicates part number to be used when ordering replacement part from

Tektronix.

Column three (3) indicates the serial number at which the part was first

used. Column four (4) indicates the serial number at which the part was

removed. No serial number entered indicates part is good for all serial

numbers.

In the parts list, an item name is separated from the description by a

colon(:). Because of space limitations, an item name may sometimes appear as incomplete. For further item name identification, the U.S. Federal

Catalog handbook H6-1 can be utilized where possible.

•

•

•

•

•

•

•

•

•

•

•

•

•

Mfr. Code

(column 6 of the parts list)

Mfr. Part No.

(column 7 of the parts list)

5-2

Indicates the code number of the actual manufacturer of the part. (Code to

name and address cross reference can be found immediately after this

page.)

Indicates actual manufacturer's part number.

Replaceable Electrical Parts

•

•

•

•

•

•

•

•

•

•

•

•

Page 37

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

CROSS INDEX - MFR. CODE NUMBER TO MANUFACTURER

Mfr .

Code

S3629 SCHURTER AG H 2015 SECOND STREET

TK1727 PHILIPS NEDERLAND BV POSTBUS 90050

TK1997 COLUMBIA GORGE CENTER 2940 THOMPSEN RD

0J7N9 MCXINC 30608 SAN ANTONIO ST

03508

04222

04713

14936

18796 MURATA ERIE NORTH AMERICAN INC 1900 W COLLEGE AVE

24165 SPRAGUE ELECTRIC CO 267 LOWELL ROAD

26742

61935 SCHURTER INC

7W718

71400 BUSSMANN 114OLD STATE RD ST LOUIS MO 63178

75498

80009 TEKTRONIX INC

91637

95238 CONTINENTAL CONNECTOR CORP 34-63 56TH ST

Manufacturer

C/O PANEL COMPONENTS CORP

AFDELONCO

GENERAL ELECTRIC CO WGENESEEST AUBURN NY 13021

SEMI-CONDUCTOR PRODUCTS DEPT

AVX CERAMICS 19TH AVE SOUTH

DIV OF AVX CORP PO BOX867

MOTOROLA INC 5005 E MCDOWELL RD

SEMICONDUCTOR PRODUCTS SECTOR

GENERAL INSTRUMENT CORP

DISCRETE SEMI CONDUCTOR DIV

STATE COLLEGE OPERATIONS

METHODE ELECTRONICS INC 7447 W WILSON AVE

MARQUARDT SWITCHES INC

DIV OF COOPER INDUSTRIES INC PO BOX 14460

MULTICOMP INC

DALE ELECTRONICS INC 2064 12TH AVE

Address

600WJOHN ST HICKSVILLE NY 11802

1016 CLEGG COURT

2711 ROUTH 20 EAST

3005 SW 154TH TERRACE #3 BEAVERTON OR 97006

14150 SW KARL BRAUN DR

PO BOX500

PO BOX609

PO BOX879

City, State, Zip Code

BERKELEY CA 94170

5600 PB EINDHOVEN THE

NETHERLANDS

HOOD RIVER OR 97031

HAYWARD CA 94544

MYRTLE BEACH SC 29577

PHOENIX AZ 85008-4229

STATE COLLEGE PA 16801-2723

HUDSON NH 03051

CHICAGO IL 60656-4548

PETALUMA CA 94952-1152

CAZENOVIA NY 13035-1219

BEAVERTON OR 97077-0001

COLUMBUS NE 68601-3632

WOODSIDE NY 11377-2121

•

•

•

•

•

•

•

•

•

•

•

TM 502A Instruction Manual

5-3

Page 38

•

•

Component Tektronix Serial No.

Number Part No. Effective Dscont Name & Description

A1 671 -0211 -00 B010100 B013420

A1 671 -0211 -01

A1C2010 281-0774-00 CAP,FXD,CER Dl:0.022MFD,20%, 1 00V

A1C2020 281-0774-00

A1C2025 281-0774-00

A1C2030 290-1186-00

A1C2040 281-0774-00

A1C4010 290-1187-00

A1C4040 290-1186-00

A1C5010 281-0774-00 CAP,FXD,CER Dl:0.022MFD,20%, 1 00V

A1C5050 281-0774-00 CAP,FXD,CER Dl:0.022MFD,20%, 1 00V

A1CR3010

A1CR3015

A1CR3020

A1CR3030

A1CR4030

A1CR4040 152-0198-00

A1J1010

A1J1040 131-2484-00

152-0198-00

152-0198-00

152-0198-00

152-0666-00

152-0198-00

131-2527-00

B013421

CIRCUIT BD ASSY:POWER SUPPLY 80009 671021100

CIRCUIT BD ASSY:POWER SUPPLY

CAP,FXD,CER Dl:0.022MFD,20%, 1 00V

CAP,FXD,CER Dl:0.022MFD,20%, 1 00V 04222 SA101E223MAA

CAP,FXD,ELCTLT:4700UF,20%,50WVDC 24165 81 D472M050KD5

CAP,FXD,CER Dl:0.022MFD,20%, 1 00V 04222 SA 101 E223MAA

CAP,FXD,ELCTLT: 18000UF,20%, 16WVDCSNAP MT 24165 81D183M016KD5

CAP,FXD,ELCTLT:4700UF,20%,50WVDC 24165 81 D472M050KD5

SEMICOND DVC,Dl:RECT,Sl,200V,3A,A2491 N4721 03508

SEMICOND DVC,Dl:RECT,Sl,200V,3A,A2491 N4721 03508

SEMICOND DVC,Dl:RECT,Sl,200V,3A,A2491 N4721 03508 1N5624

DIODE,RECT:BRIDGE,800V,IF=.75A@ 85 DEG C 14936 W08G-1

SEMICOND DVC,Dl:RECT,Sl,200V,3A,A2491 N4721 03508

SEMICOND DVC,Dl:RECT,Sl,200V,3A,A2491 N4721 03508 1N5624

CONN,HDR PWR:PCB,;MALE,STR,1 X 7,0.156 CTR

CONN,HDR PWR:PCB,;MALE,STR,1 X 8,0.156 CTR

Mfr.

Code Mfr. Part No.

80009 671021101

04222 SA 101 E223MAA

04222

04222 SA 101 E223MAA

04222 SA 101 E223MAA

26742 3107-11-207-01

26742 3109-11-208-01

SA 101 E223MAA

1N5624

1N5624

1N5624

•

•

•

•

•

•

•

•

•

•

•

•

•

A1J3020 131-1078-00

A1J3050 131-1078-00

315-0102-00

A1R3030 303-0202-00

A1R3035 303-0202-00

A1R5030 303-0511 -00

C100

C200

F100

F100

P100 119-2679-00 8010100 B010807

P100 119-2679-01 8010808 8011482

P100 119-3357-01 B011483

02010

02010

02050

283-0959-00

283-0959-00 CAP,FXD,CER Dl:0.01 UF,20%,250VAC

159-0019-00

159-0032-00

119-3358-00

151 -0373-00 8010100 8013420

151-0938-00 8013421

151-0373-00

8010100 8013420

CONN,EDGECARD:PCB,;STR,2 X 28,0.156 CTR 95238

CONN,EDGECARD:PCB,;STR,2 X 28,0.156 CTR 95238

RES,FXD,FILM:1 K OHM,5%,0.25W

RES,FXD,CMPSN:2K OHM,5%,1W 91637 CMF65-42 2 KOH

RES,FXD,CMPSN:2K OHM,5%, 1 W

RES,FXD,CMPSN:510 OHM,5%,1W 91637 CMF65-42 510 OH

CHASSIS PARTS

CAP,FXD,CER Dl:0.01 UF,20%,250VAC

(PART OF P100)

(PART OF P100)

FUSE,CARTRIDGE:3AG, 1 A,250V,SLOW BLOW

(STANDARD ONLY)

FUSE,CARTRIDGE:3AG,0.5A,250V,SLOW BLOW

(OPTION A 1,A2,A3,A4,A5 ONLY)

PWR,ENTRY MDL::PNL,SNAP-IN;MALE,IEC,15 AM S3629 KEC4303.0093 AN

PWR,ENTRY MDL::PNL,SNAP-IN;MALE,IEC, 15 AMP TK1997 119-2679-01

PWR,ENTRY MDL::PNL,SNAP-IN;MALE,IEC, 15 AMP TK1997 119-3357-01

DRAWER,FUSE:FUSE DRAWER AND VOLTAGE 61935 4303.2814.01

(PART OF P100)

TRANSISTOR:PNP,Sl,TO-127

TRANSISTOR,PWR:BIPOLAR,PNP;90V, 1 0A,2.5 MHZ 04713 MJF2955

TRANSISTOR:PNP,Sl,TO-127

TK1727 SFR25 2322-181

91637

18796 DE7150F103MVA 1

18796 DE7150F103MVA 1 -

71400 MDL1

71400

04713

04713

X600-11-56Y25GD

X600-11 - 56Y25GD

CMF65-42 2 KOH

MDL 1/2

SJE925

SJE925

•

• A1R3020

•

•

•

•

•

•

•

•

•

•

•

•

•

5.4

Replaceable Electrical Parts

•

•

Page 39

•

•

•

•

•

Component Tektronix Serial No.

Number

02050 151-0938-00 B013421

03010 151-0436-00 B010100 B013420

03010 151-0937-00 B013421

Part No. Effective Dscont

& Description Code

Name

TRANSISTOR,PWR:BIPOLAR,PNP;90V, 1 0A,2.5 MHZ 04713 MJF2955

TRANSISTOR:NPN,Sl,SEL,TO-127 04713 SJE966

TRANSISTOR,PWR:BIPOLAR,NPN;90V, 1 0A,2.5 MHZ 04713 MJF3055

Mfr.

Mfr. Part No.

•

•

•

•

•

•

•

•

•

•

•

•

03050 151-0436-00 B010100 B013420

03050

S100

T100 120-1759-00 B010100 B016000

T100 120-1759-01

T100 120-1759-02

W100 196-3176-00

W100 196-3176-01

W100 196-3176-02

W200 196-3175-00

W300 196-3175-01

W400 196-3175-01

151-0937-00

260-1961-00

B013421

B016001 B023538

B023539

B010100 B012966

B012967 B023538

B023539

TRANSISTOR:NPN,Sl,SEL,TO-127 04713 SJE966

TRANSISTOR,PWR:BIPOLAR,NPN;90V, 1 0A,2.5 MHZ 04713 MJF3055

SWITCH,ROCKER:DPST,6(4)A,250V

TRANSFORMER,PWR:PRIM TAPPED

TRANSFORMER,PWR:PRIM TAPPED,48-440HZ 75498

TRANSFORMER,PWR:PRIM TAPPED,48-440HZ 75498 128-7003-02

LEAD,ELECTRICAL:18 AWG,5.0 L,5-4 0J7N9

LEAD,ELECTRICAL:18 AWG,5.25 L,5-4 0J7N9

LEAD,ELECTRICAL:18 AWG,5.25 L,5-4 0J7N9

LEAD,ELECTRICAL:18 AWG,5.0 L,9-N 80009

(PART OF P100)

LEAD,ELECTRICAL:18 AWG,5.0 L,0-N TK1997

(PART OF P100)

LEAD,ELECTRICAL:18 AWG,5.0 L,0-N

(PART OF P100)

7W718 1802.1121

75498 128-7003-00

128-7003-01

ORDER BY DESC

ORDER BY DESC

ORDER BY DESC

196317500

ORDER BY DESC

TK1997 ORDER BY DESC

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

TM 502A Instruction Manual

REV DEC 1993

5-5

Page 40

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

5-6

Replaceable Electrical Parts

•

•

•

•

•

•

Page 41

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Diagrams and Circuit Board Illustrations

Symbols

This section contains the, block diagrams, circuit board illustrations, compo-

nent locator tables, and schematic diagrams for the TM502A .

Graphic symbols and class designation letters are based on ANSI Standard

Y32.2-1975. Abbreviations are based on ANSI Y1 .1-1972 .

Logic symbology is based on ANSI/IEEE Standard 91-1984 in terms of

positive logic. Logic symbols depict the logic function performed and can

differ from the manufacturer's data.

The tilde ( ~) preceding a signal name indicates that the signal performs its

intended function when in the low state .

Other standards used in the preparation of diagrams by Tektronix, Inc.,

include the following:

• Tektronix Standard 062-2476 Symbols and Practices for Schematic

Drafting

• ANSI Y14.159-1971 Interconnection Diagrams

• ANSI Y32.16-1975 Reference Designations for Electronic Equipment

•

•

•

•

•

•

•

•

•

•

•

•

•

Component Values

• MIL-HDBK-63038-1A Military Standard Technical Manual Writing Hand-

book

Electrical components shown on the diagrams are in the following units

unless noted otherwise:

Capacitors:

Resistors:

Values one or greater are in picofarads (pF). Values less

than one are in microfarads (µF) .

Values are in Ohms (Q).

•

•

•

TM 502A Instruction Manual

6-1

Page 42

•

•

Graphic Items and

Special Symbols

Used in This Manual

Locator Grld----------- ...

Functlon Block---------

Board Outline----- .. ,

Internal

Refer to Waveform

Assembly Number

Digital Ground -t-+-----:==:+:::::::---'

Refer to Assembly

& Diagram Number

Another Diagram,

Same Board , """

Assembly Number---------- . Diagram

& Board Name

Tltle

Screw------------

Ad/ustment

Offboard

Connector

Active Low---i.---

Signal From ___ _, / Voltage

-t-+----+----

---i.---

Signal .__ ____

Figure 6-1: Graphic Items and Special Symbols Used in This Manual

Each assembly in the instrument is assigned an assembly identifier (for

example, MAIN or A3). The assembly identifier appears on the circuit board

outline on the diagram (see Figure 6-1), in the title for the circuit board

component location illustration, and in the lookup table for the schematic

diagram and corresponding component locator illustration. The Replaceable

Electrical Parts list is arranged by assembly in numerical sequence; the

components are listed by component number.

--- Power Termination

Component on

back of board

Strap

w,

Jes I eea Jae

63

-+5V ~~'-.,./,

,____....__7!::><J~~!:r::-:::-i""i

..,__••-"T ... lA_L_A_5_Tl-MI-NG_a_o._Ro_._ ___ -... -_ -_ -_ -_ -_ -...::----- Decoupled

SYN GENERATOR As(y, Diagram Number

a1s• "

20

"

'----+---- Heat Sink

" ,.._ ___ Assembly Number

~

Male Coaxial

Connector

Female Coaxial

Connector

Name

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Component Locator

Diagrams

6-2

The schematic diagram and circuit board component location illustrations

have grids marked on them. The component lookup tables refer to these

grids to help you locate a component. The circuit board illustration appears

only once; its lookup table lists the diagram number of all diagrams on

which the circuitry appears.

Diagrams and Circuit Board Illustrations

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Page 43

•

•

•

The following table describes the power module interface pin assignements

as viewed from the front panel.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

A Side B Side

Pin Description

No permanent 1/0 assignments. Refer

to plug-in module manuals for specific

assignments. assignments.

25

Vac winding 13 13 25 Vac winding

+35.5 V filter 12 12 +35.5 V filter

Base lead of PNP Series-Pass.

Emitter lead of PNP Series-Pass

±33.5 V common return

-35.5 V filtered de

Emmitter lead of NPN Series-Pass

Base lead of NPN Series-Pass

17.5 Vac winding

+ 11.5 V common return 4

+ 11.5 V common return 3 3 + 11.5 V common return

+ 11.5 V filtered de 2

25 Vac winding 1

Pin#

28 28

27

26

25 25

24 24

23

22

21

20

19 19

18 18

17

16 16

15

14 14

11

10 10 ±33.5 V common return

9

8 8

7

6

5

Pin#

27

26

23

22

21

20

17

15

11

9 ±33.5 V common return

7

6

5

4

2

1

Pin Description

No permanent 1/0 assignments. Refer

to plug-in module manuals for specific

Collector lead of PNP Series-Pass

-35.5

V filtered de

Collector lead of NPN Series-Pass

No connection

17.5

Vac winding

+ 11.5 V common return

+ 11.5 V filtered de

25 Vac winding

•

•

•

•

•

•

•

•

TM 502A Instruction Manual 6-3

Page 44

•

•

•

0

5

C\I

0

0

5

T""

-,

-,

0

3

T""

~

0

It)

0

C\I

0

•

•

•

•

•

0

It)

0

5

(')

0::

()

0

5

(')

0

C\I

0

g

(')

0:: 0::

() ()

J3020

~1!1~18

'

®

C4040

C2030

J3050

0

It)

0

(')

0

()

~

00

•

•

•

•

•

•

•

•

Figure 6-2: A 1-Power Supply circuit board assembly

•

•

•

•

•

•

•

•

•

•

•

•

•

6-4

Diagrams and Circuit Board Illustrations

•

•

•

Page 45

••••••••••••••••••••••••••••••••

-I

i:

(11

~

:I

i

g,

o·

:I

i:

ID

:I

C

!!.

~~

F100

W400

Cl>

U1

EJ

~

-1----------

S100 X X W200

/f'- /f'-

W300

'\1-' P700 '\I-'

~

~

~

~

1

P

15-1 240VAC j

P116-1 220VAC :

P117-1 120VAC j

P118-1 100VAC j

P119-1

I A1 POWER SUPPLY BOARD I

T100

I

I

roo-,; ) ""'~ y I ,j'

I

I

I

('°'-' ; > ""~ l I ' :j: • "

I

I

I

I

P104-1

I

P106-1

I

I

I

I

I

P104-1 ) J1040-6

I

P111 1 ) J1010-4

~

(113-1 ; ) J1040-4 f

) J1010-1 25 VAC

) J1040-1 25 VAC

C2030

J_ +

~

R3035

T l'2K

CR4030

CR4040

J_ + l R3030

T ~2K

J1040-7

4700µF

C4040

4700µF

~~g2~

1 I V 13

1

Q2010

+33.5V I J2, J2, I I .12, .12

~

~~'/I V

! I fL f / +33.5V COMMON ! I _,9/

<}

-33.5V I ,8, ,8, I 1 ,8, ,8

a~)

CR3010

J1010-I

)5

) l 822µF ,1/

f ..1.. C4010 I

I 822µF * I

C4010

18000µF

J1010-3 25 VAC l C5010 I

I I

, J1040-3 25 VAC 1 C5050

C2010

.822µF

CR3015

17.5 VAC

+11.5VCOMMON

+11.5V

y bJ

A J3020 B

~

~

~

~

~

~

~

~

~

~

~

~

~

~

C

C

~

~

~

g

~

~

g

~

~

~

14

~

I I 1 C2040

11

I

l}

T .822µF I r~

I 11

~

" -~ "

Q~

~~

I 5 I I 5

I ,2, ,2, I +11.5V

:£

\5/

4, I V

3,

,1/

~

I +11.5V COMMON

T .822µF

1,1,,

J3050

A B

~

~

~

~

~ ~

~ ~

~ ~

~ ~

~

~

C C

~ ~

~

~

~ ~

~ ~

~ ~

~

~

~

~

:B-

l}

~

7

y

6

V

Page 46

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

6-6

Diagrams and Circuit Board Illustrations

•

•

•

•

•

•

Page 47

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Parts Ordering

Information

Replaceable Mechanical Parts

This section contains a list of the mechanical components that are replace-

able for the TM502A. As described below, use this list to identify and order

replacement parts .

Replacement parts are available from or through your local Tektronix, Inc.,

service center or representative.

Changes to Tektronix instruments are sometimes made to accommodate

improved components as they become available and to give you the benefit

of the latest circuit improvements. Therefore, when ordering parts, it is

important to include the following information in your order:

• Part number

• Instrument type or model number

• Instrument serial number

• Instrument modification number, if applicable

•

•

•

•

•

•

•

•

•

•

•

•

•

Using the

Replaceable Parts

List

If a part you order has been replaced with a different or improved part, your

local Tektronix service center or representative will contact you concerning

any change in the part number .

The tabular information in the Replaceable Parts List is arranged for quick

retrieval. Understanding the structure and features of the list will help you

find the all the information you need for ordering replacement parts.

Item Names

In the Replaceable Parts List, an Item Name is separated from the description by a colon(:). Because of space limitations, an Item Name may sometimes appear as incomplete. For further Item Name identification, U.S.

Federal Cataloging Handbook H6-1 can be used where possible .

•

•

•

•

TM 502A Instruction Manual

7-1

Page 48

•

•

Indentation System

This parts list is indented to show the relationship between items. The

following example is of the indentation system used in the Description

column:

1 2 3 4 5

Assembly and/or Component

Attaching parts for Assembly and/or Component

Detail Part of Assembly and/or Component

Attaching parts for Detail Part

Parts of Detail Part

Attaching parts for Parts of Detail Part

Attaching parts always appear at the same indentation as the item it

mounts, while the detail parts are indented to the right. Indented items are

part of, and included with, the next higher indentation. Attaching parts must

be purchased separately, unless otherwise specified.

Abbreviations

Abbreviations conform to American National Standards Institute (ANSI)

standard Y1 .1

Name & Description

(END ATTACHING PARTS)

(END ATTACHING PARTS)

(END ATTACHING PARTS)

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

7-2

Replaceable Mechanical Parts

•

•

•

Page 49

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

CROSS INDEX - MFR. CODE NUMBER TO MANUFACTURER

Mfr .

Code Manufacturer

S3109 FELLER 72 VERONICA AVE SUMMERSET NJ 08873

S3629 SCHURTER AG H 2015 SECOND STREET BERKELEY CA 94170

TK0435

TK0977 ELECTRICAL INSULATION SUPPLIERS, INC 3549 NWYEON PORTLAND OR 97210

TK1569 GERHART STAMPING INC 1116 W ISABEL ST BURBANK CA 91506

TK1943

TK1997

08445

0JR05 TRIQUEST CORP

0J7N9 MCXINC

0KBZ5

0KB01 STAUFFER SUPPLY 810 SE SHERMAN PORTLAND OR 97214

04713

07416 NELSON NAME PLATE CO

12327 FREEWAY CORP

18796 MURATA ERIE NORTH AMERICAN INC

2K262 BOYD CORP 6136 NE 87th AVE PORTLAND OR 97220

26742

29870 VICTOR CORP

55285 BERGQUIST CO INC THE 5300 EDINA INDUSTRIAL BLVD MINNEAPOLIS MN 55435-3707

61935 SCHURTER INC 1016 CLEGG COURT PETALUMA CA 94952-1152

7W718

72228

75498 MULTICOMP INC 3005 SW 154TH TERRACE #3 BEAVERTON OR 97006

80009 TEKTRONIX INC 14150 SW KARL BRAUN DR BEAVERTON OR 97077-0001

86928 SEASTROM MFG CO INC 701 SONORA AVE GLENDALE CA 91201-2431

95238 CONTINENTAL CONNECTOR CORP 34-63 56TH ST WOODSIDE NY 11377-2121

C/O PANEL COMPONENTS CORP

LEWIS SCREW CO 4300 S RACINE AVE CHICAGO IL 60609-3320

-(DIST)

NEILSEN MANUFACTURING INC 3501 PORTLAND ROAD NE SALEM OR 97303

COLUMBIA GORGE CENTER 2940 THOMPSEN RD

ELECTRI-CORD MFG CO INC 312 EAST MAIN ST WESTFIELD PA 16950

MORELLIS Q

MOTOROLA INC 5005 E MCDOWELL RD

SEMICONDUCTOR PRODUCTS SECTOR

STATE COLLEGE OPERATIONS

METHODE ELECTRONICS INC 7447 W WILSON AVE CHICAGO IL 60656-4548

MARQUARDT SWITCHES INC 2711 ROUTH 20 EAST CAZENOVIA NY 13035-1219

AMCA INTERNATIONAL CORP 459 MT PLEASANT

CONTINENTAL SCREW CO DIV

& D PLASTICS 181216TH AVE FOREST GROVE OR 97116

Address

UNIT4

3000 LEWIS AND CLARK HWY

30608 SAN ANTONIO ST

3191 CASITAS

9301 ALLEN DR

1900 W COLLEGE AVE

PO BOX20038

618 MAIN STREET WEST WARWICK RI 02893

PO BOX500

PO BOX879

City, State, Zip Code

HOOD RIVER OR 97031

VANCOUVER WA 98661 -2999

HAYWARD CA 94544

PHOENIX AZ 85008-4229

LOS ANGELES CA 90039-2410

CLEVELAND OH 44125-4632

STATE COLLEGE PA 16801-2723

NEW BEDFORD MA 02742

•

•

•

•

•

•

•

TM 502A Instruction Manual

7-3

Page 50

•

•

Fig. &

Index Tektronix

No. Part No. Effective Dscont Qty 12345 Name & Description

1-1

-2

-3

-4

-5

-6

-7

-7.1

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-22.1

426-2214-01

211-0503-00

351-0286-08

213-0813-00

367-0381-00

367-0381-01

367-0381-02

134-0196-01

211-0008-00

210-1307-00

210-0993-00

441-1813-00

441-1813-01

212-0023-00

211-0504-00

348-0640-00

214-3026-00

348-0430-00

407-3641-00

407-3641 -01

214-4289-01

211 -0102-00

--- ----

----

-

-

211 -0008-00

214-1593-02

--- -- - .CONN,HDR PWR:PCB,;MALE,STR,1 X 7,0.156

-- ----

175-4306-00 B013421

Serial No.

FRAME,PNL,CAB.:FINISHED

ATTACHING PARTS

SCREW,MACHINE:6-32 X 0.188,PNH,STL TK0435 ORDER BY DESC

3

2

2

B010100

B010465 B022458 HANDLE,BOW:0.125 X 0.75,ALUMINUM

B022459 HANDLE,BOW:0.125 X 0.75,ALUMINUM

B010100 B010464

B010465

B010100

B023539 CHAS,PWR SUPPLY:ALUMINUM

B010100

B012111

B013421

B010100 B013420 CIRCUIT BD ASSY:POWER SUPPLY

B013421 CIRCUIT BD ASSY:POWER SUPPLY

B010464

2

2

2

2

2 WASHER,FLAT:0.143ID X 0.75 OD X 0.051,BRS

B023538

4

4

4

5

B012110 2

B013420 2

2

4

4

2

2

4

END ATTACHING PARTS

GUIDE.PL-IN UNl:LOWER,NYLON

ATTACHING PARTS

SCREW,TPG,TF:4-20,0.312L,PLASTITE,FLH,STL

END ATTACHING PARTS

HANDLE,BOW:0.125 X 0.75,ALUMINUM

(REMOVE FOR OPTION 11)

ATTACHING PARTS

KNOB ASSEMBLY:REPLACEMENT

KNOB ASSEMBLY:TM502A

SCREW,MACHINE:4-40 X 0.25,PNH,STL

WASHER,LOCK:0.115 ID,SPLIT,0.025 THK,SI BRZ

END ATTACHING PARTS

CHAS,PWR SUPPLY:ALUMINUM

ATTACHING PARTS

SCREW,MACHINE:8-32 X 0.375,PNH,STL

SCREW,MACHINE:6-32 X 0.250,PNH,STL

END ATTACHING PARTS

GROMMET,PLASTIC:BLACK,ROUND,0.188 ID

SPRING,GROUND:CU BE

BUMPER,PLASTIC:BLACK POLYURETHANE

BRKT,CLAMP:ALUMINUM

BRACKET,CLAMP:TM502A(rM503A

HEAT SINK,XSTR:ALUMINUM TK1943 ORDER BY DESC

ATTACHING PARTS