Page 1

070-2088-02

Tektronix, Inc.

P.O.Box 500 Beaverton, Oregon 97077 Phone 644-0767

First

Printing NOV

1975

Page 2

Page 3

SECTION 1

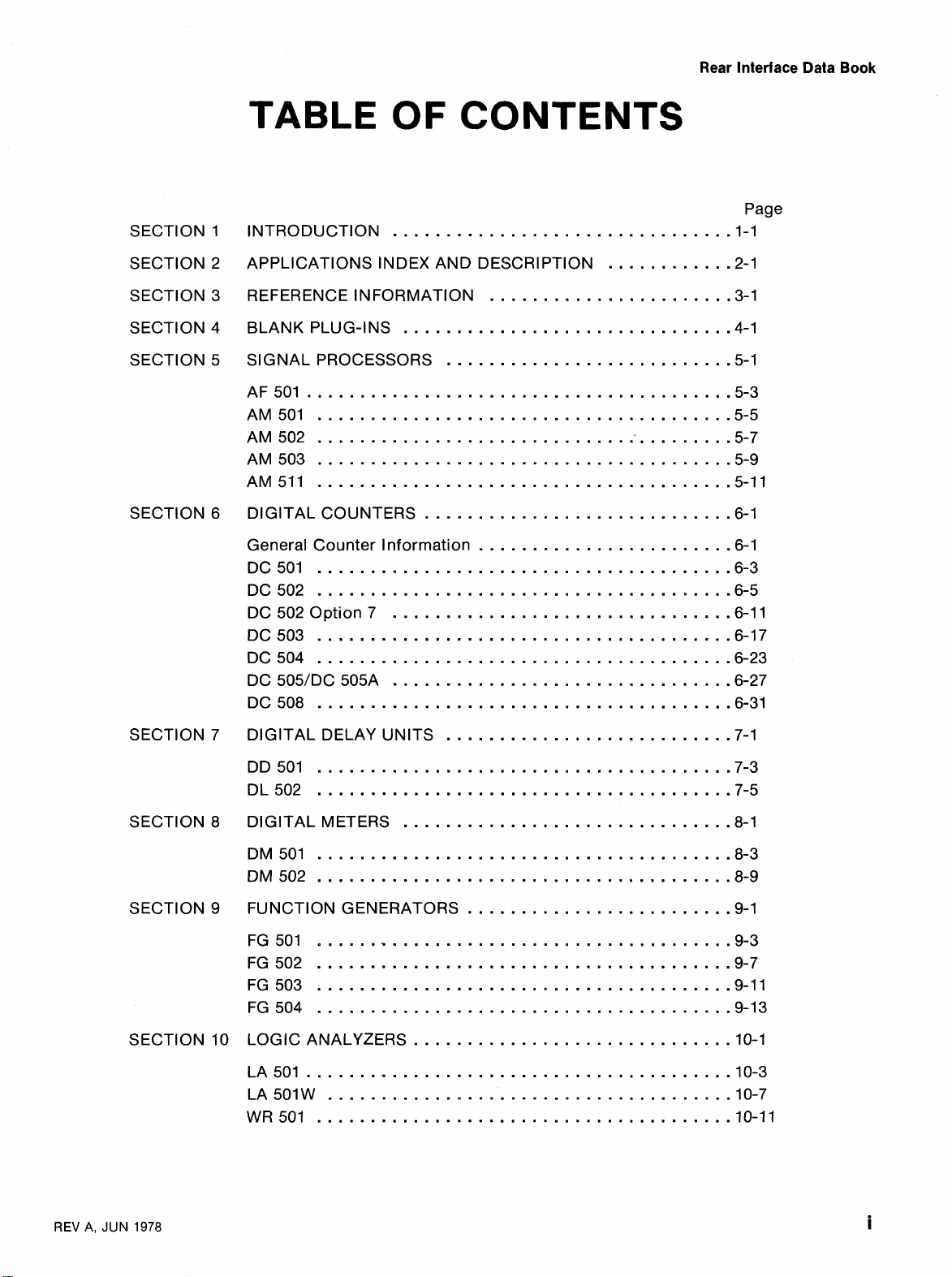

TABLE OF CONTENTS

INTRODUCTION

................................

Rear Interface Data

Page

1.1

Book

SECTION 2

SECTION 3

SECTION 4

SECTION 5

SECTION 6

APPLICATIONS INDEX AND DESCRIPTION

REFERENCE INFORMATION

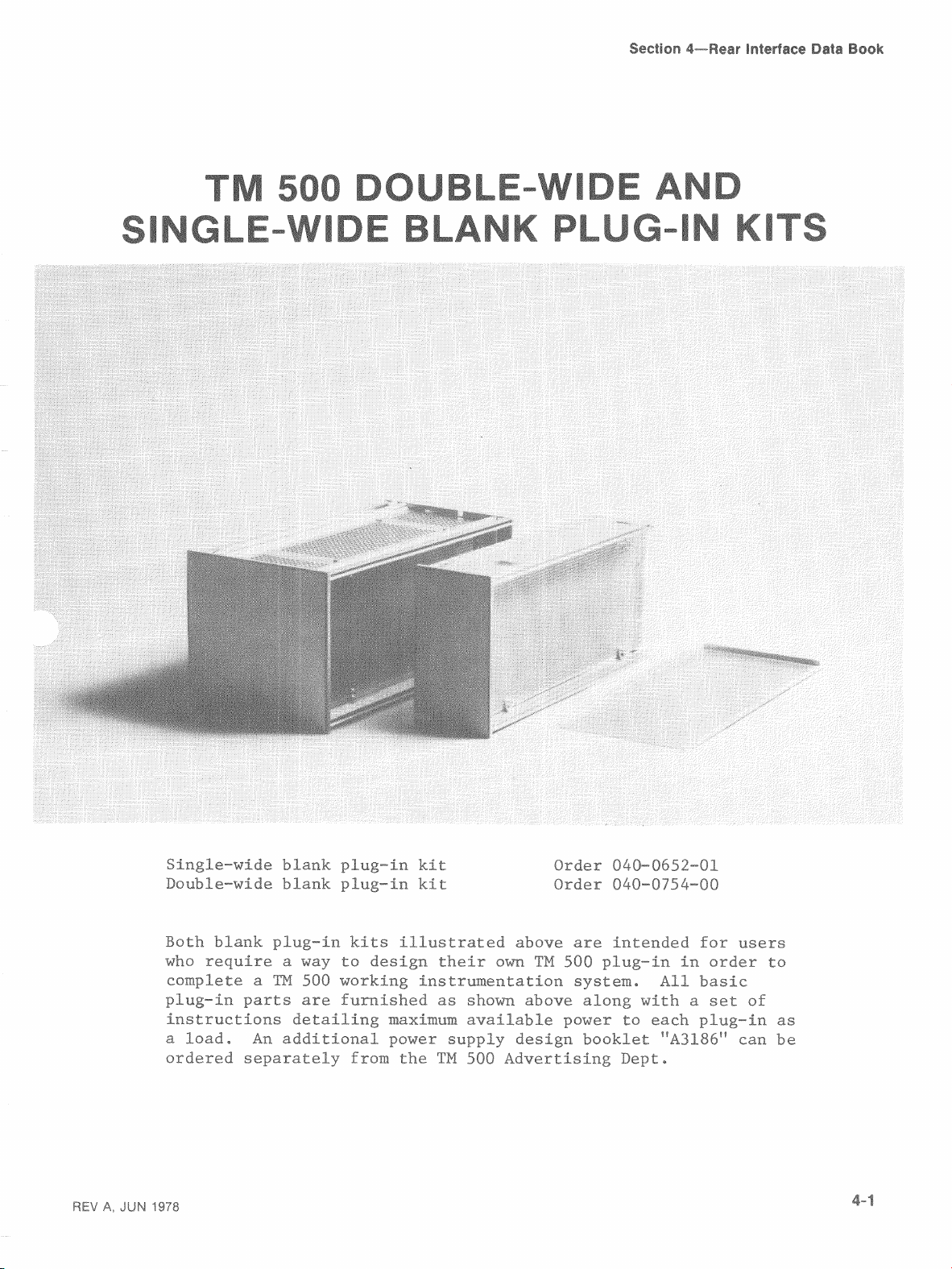

BLANK PLUG-INS

SIGNAL PROCESSORS

DIGITAL COUNTERS

General Counter l nformation

DC501

DC502

DC 502 Option

DC503

DC504

DC 505/DC 505A

DC508

.......................................

.......................................

.......................................

.......................................

.......................................

...............................

.............................

7

................................

................................

.......................

...........................

........................

............

2.1

3.1

4.1

5.1

6.1

6.1

6-3

6-5

6.11

6-17

6-23

6.27

6-31

SECTION 7

SECTION 8

SECTION 9

SECTION 10

DIGITAL DELAY UNITS

DIGITAL METERS

FUNCTION GENERATORS 9.1

LOGIC ANALYZERS

...........................

...............................

.........................

.............................

-10-1

7.1

8.1

REV

A.

JUN

1978

Page 4

Rear Interface Data

Book

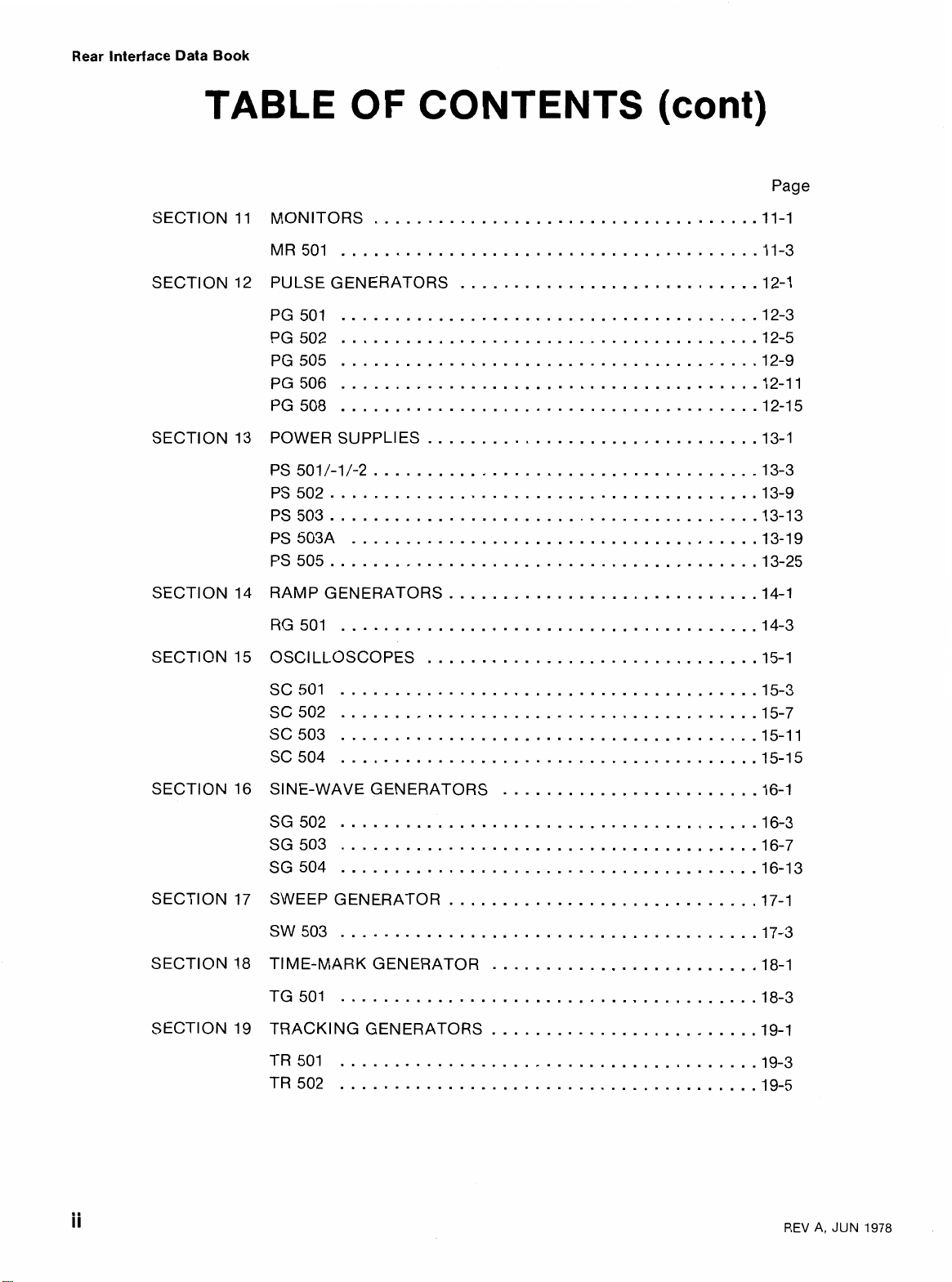

TABLE

SECTION

SECTION

SECTION

OF CONTENTS

MONITORS

11

PULSE GENERATORS

12

POWER SUPPLIES

13

(cont)

...................................

...........................

..............................

Page

.I 1.1

.I 2.1

.I 3.1

SECTION

SECTION

SECTION

SECTION

SECTION

SECTION

RAMP GENERATORS

14

15

OSCl LLOSCOPES

16

SINE-WAVE GENERATORS

17

SWEEP GENERATOR

TIME-MARK GENERATOR

18

19

TRACKING GENERATORS

............................

..............................

.......................

............................

........................

........................

-14-1

.I 5.1

-16-1

.I

7.1

.I 8.1

.I 9.1

REV

A.

JUN

1978

Page 5

Section 1-Rear Interface Data Book

INTRODUCTION

The TEKTRONIX TM 500 line of modular instrumentation offers a

new approach to electronic tests and measurements. In the past,

monolithic signal sources such as function generators, sine-wave

oscillators, pulse generators, ramp generators, and dc power

supplies were often interconnected to

oscilloscopes for accurate electrical set-ups or measurements of

frequency, period, pulse width, rise and fall times, ac-dc currents,

and voltages. The front panel interconnections between these

monolithic instruments can often become a

and cables

that obscures one's view of displays and interferes with

convenient operation of front panel controls.

The promise of a better way is here today in the rear interconnecting

interface system of

TM

500 modular instrumentation. No one except

TEKTRONIX offers such an easy-to-interconnect-and-use system.

DMMs, digital counters, and

confusing

maze

of wires

In almost

all TM 500 plug-in instruments, a duplication of front panel

input and output connections appears on the plug-ins' rear edge

circuit board connector. Since each plug-in connector is located

inside the power mainframe on a common rear interface circuit board,

plug-ins can be interfaced to

connecting wires and cables easily installed by the user.

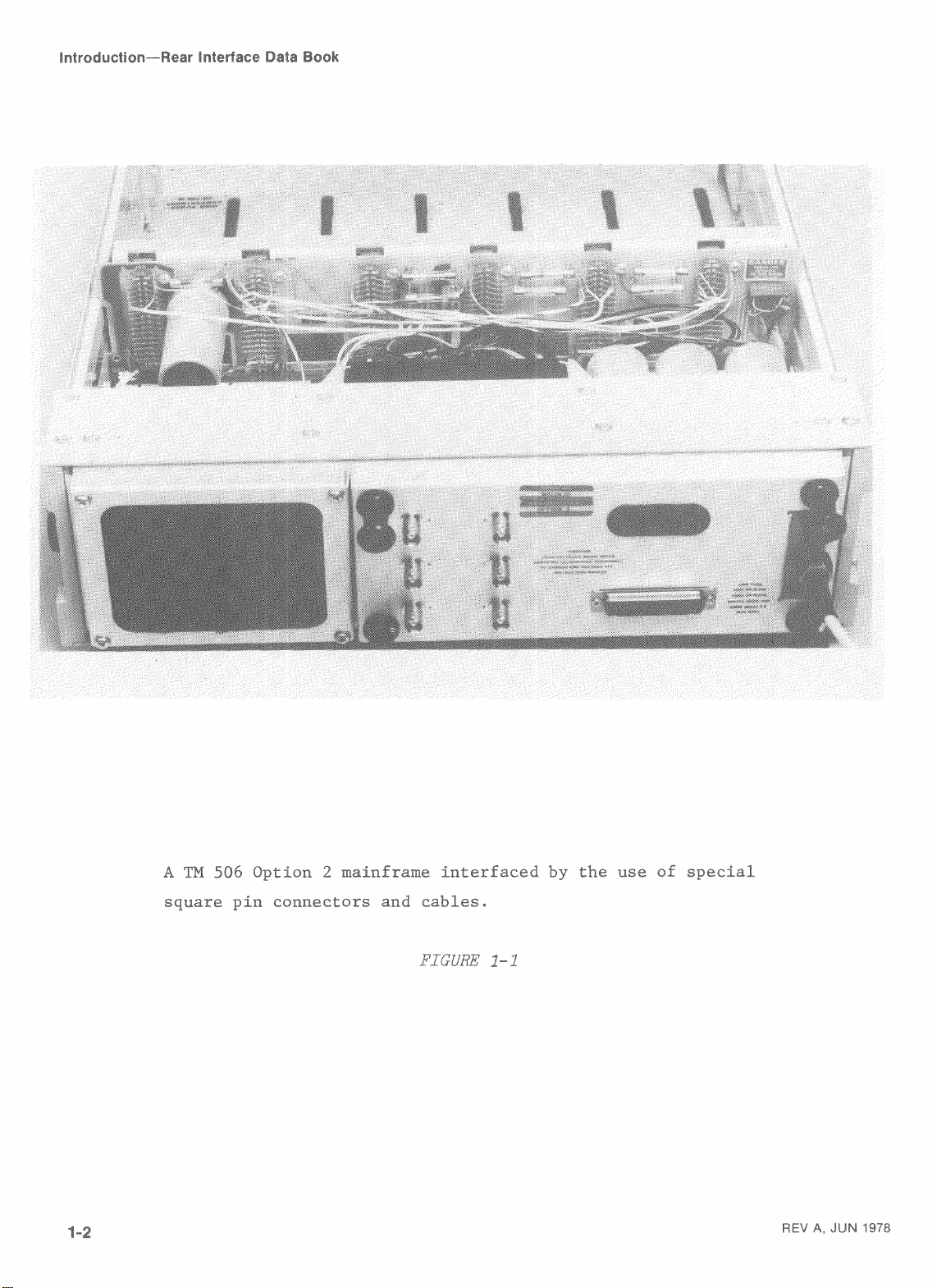

FIGURE

1-1. The number of possible interfacing schemes is only

limited by the imagination. For example, the DM 502

"talk to" one another by way of inter-

SEE

DMM

rear input

terminals can be interconnected to an alongside PS 503A power

supply for accurately setting power supply voltages.

permanently connected to the power

supply because a special

The DMM is not

INT-EXT front panel switch can be pressed; thereby returning the

DMM to external full function capability. The operation of external

circuits under test can now be measured by the use of standard probes

or external wire connections. Another similar example could include

interfacing the DC 505A universal counter-timer's dc trigger level

output to the

DMM

for setting up the counter's channel A and B LEVEL

controls. Accurate time measurements can now be made by setting the

LEVEL control to DMM-displayed dc voltages representing 10 to 90%

amplitude points

for rise times and 50% amplitude points for pulse

widths. The list can go on and on. However, sooner or later one

"HOW

gets around to asking the question,

ments together to form my own viable instrument package?"

do I connect these instru-

This rear

interface manual will suggest some ideas on interconnected systems

and provide readily-accessible reference data so that you can easily

design your own special purpose test set.

REV

A,

The APPLICATIONS INDEX describes some of the already-in-use interconnect

application ideas. The section on BACKGROUND INFORMATION presents ways

to obtain the most useful interface scheme. The MODULE DATA section

provides signal input and output pin numbers for all

JUN

1978

TM

500 plug-ins.

Page 6

Page 7

Introduction-Rear Interface Data Book

By the way,

presently illustrated, just drop us a pencil sketch and a

sentence describing your unique idea.

addressed as follows:

if you have a new way to interconnect

Information should be

TEKTRONIX

TM

500

P.O. Box 500

Beaverton,

,

INC

M/S

94-396

Oregon 97077

.

TM

500

not

REV

A,

JUN

1978

Page 8

Page 9

Section 2-Rear Interface Data Book

APPLICATIONS INDEX

AND

DESCRIPTION OF THE APPLICATIONS INDEX

The following APPLICATIONS INDEX was intended to be used as a

quick reference guide to a more complete description of

applications. These applications fall into two generalized categories, consisting of

multi-instrument applications. In the first case, most users are

aware of generalized instrument applications. As a result, only the

unusual single instrument applications are mentioned in the

index. Single instrument applications requiring lengthy descriptions are located under the specific instrument MODULE DATA section.

In the second case, multi-instrument applications may be either

located in the MODULE DATA section under the primary important

instrument or as an application note made available from the

TEKTRONIX TM 500 Advertising Dept. See address below.*

DESCRIPTION

(1)

single instrument applications, and

APPLICATIONS INDEX

TM

500

(2)

NOTE:

*

See fo

DC 505A Trigger Level Output

Network Attenuation or Gain Measurement

PS 503A Voltage Regulation via Remote Sensing

PS 503A Output Voltage Controlled by External Resistance

Programming

PS 503A Output Voltage Controlled by External Voltage

Programming

Waveform Generation System

Integration through V to

Function Generator Swept Frequency Applications

Power Supplies Driven by Signal Sources

AC Microvoltmeter

TEKTRONIX,

P.

0. Box 500

l

lowing pages for app Zication descriptions.

INC.

Advertising Dept., M/S

Beaverton, Oregon 9 70

76-260

7

7

F

Conversion

REV

A.

JUN

1978

Page 10

Applications Index and Description-Rear Interface Data Book

1.

DC 505A TRIGGER LEVEL OUTPUT CONNECTION

TO AN ALONGSIDE DMM

Any

TM

500

DMM

can be used to read out the A and B trigger "level

DC

outff of the

facing feature

A

interval

-+

505A

is

B

measurements.

universal counter. The benefit of this inter-

improved accuracy in making width B and time

These features are acquired by using a

the

DC

505A

gate lamp,

to measure the

DMM,

+E

in conjunction with

peak and the

-E

peak levels

of the pulse train to be counted. The peak-to-peak measurement

then used to determine the correct setting of the level controls

for the measurement of interest.

The actual connections between the

DMM

and

DC

505A

are made as

illustrated below:

DMM

28B

28A

2.

NETWORK ATTENUATION OR GAIN MEASUREMENT

+

+

signal

ground

The dBm or dBV measurement capability of the

DC

505A

-+

22A

-+

17A

'

DM

502

can be used

to measure the attenuation or gain of a network under test when

driven by an SG

502

audio generator. Audio network analysis can be

performed on networks such as filters and amplifiers.

is

Upon completion of interface connections (see below), operation

consists of pressing

Press back to

loss in dB

EXT

is

obtained by subtracting the input and output levels.

DM

502

INT

button to read network input level.

for network output level. The network gain or

The actual connections between instruments to be interfaced follow:

3.

The

plus or minus

502

SG

28A

(SIG OUT)

27A

(SIG GND)

FRONT PANEL

BNC

OUT

-

-

PS

503A VOLTAGE REGULATION VIA REMOTE SENSING

20

V

NETWORK

-

-

INPUT (SIG)

INPUT

OUTPUT

OUTPUT

(GND)

(SIG)

(GND)

DM

502

28B (HI)

28A

(LO)

-

-

FRONT PANEL

FRONT PANEL (LO)

(HI)

power supply regulation can be improved by

REV

A,

JUN

1978

Page 11

Applications Index and Description-Rear Interface Data

Book

remote sensing

DATA section.

4.

at

the load. For more details see PS 503A MODULE

PS 503A OUTPUT VOLTAGE CONTROLLED

BY

EXTERNAL

RESISTANCE PROGRAMMING

The plus or minus 20 V power supply can be controlled via resistance

programming through the

program resistance values and interconnections may be found in the

PS 503A MODULE DATA section.

5. PS 503A OUTPUT VOLTAGE CONTROLLED

rear

interface. Specific details on

BY

EXTERNAL

VOLTAGE PROGRAMMING

The plus or minus 20 V power supplies can be controlled via an

external voltage source through the rear interface.

supplies can now be independently swept from

slew

interconnection and external voltage control information may be

found in the PS 503A MODULE DATA section.

rate depends on the load and the output voltage d~/dt. Specific

6.

GENERATING COMPLEX WAVEFORMS WITH TM 500 INSTRUMENTS

0 to 20 volts. The

One or both

The generation of a variety of differently-shaped signals can be

produced by an RG 501 Ramp Generator, two PG 505 Pulse Generators,

and an

such

provide a means of determing signal periods, durations,

fall

For complete details on this Waveform Generation System, write the

TM 500 Advertising Dept. for application note #75M 1.0.

Measurement transducers are often used to produce a voltage that

is

liquid, or electrical energy. But, frequently

to know the total number of units that have been measured by the

transducer during some

it

particular TM 500 instruments can be configured together to provide

this voltage to frequency conversion. The transducer output

first processed by a signal conditioning

Amplifier. The resulting output

frequency conversion in a function generator such as an FG 501 or

FG 502. The output frequency

counter. For more complete information on this application, write

the TM 500 Advertising Dept. for application note #75M 2.0.

AM

501 Operational Amplifier.

as

the SC 501 or SC 502 can be used along with this system to

times,

proportional to the

is

to know the

delay

7.

times

INTEGRATION THROUGH V TO F CONVERSION

rate

as

well as peak-to-peak signal amplitudes.

rate

time

at any particular point in

of flow of something like a gas, a

interval like a second or a day, than

is

An alongside TM 500 oscilloscope

rise

and

it

is

more important

time.

AM

501 or

is

applied to produce an analog to

displayed on an alongside digital

AM

Three

is

502 Operational

REV

A,

JUN

1978

Page 12

Applications Index and Description-Rear Interface Data Book

8.

FUNCTION GENERATOR SWEPT FREQUENCY

AND TWO-TONE APPLICATIONS

Although this application was written specifically for the FG 501,

the underlying principles apply equally

function generators such as the FG 502 and FG 503.

generator can be made to change

by the instantaneous applied voltage appearing at the VCF input

connector. For example, a voltage ramp applied to the VCF input

will

be used for FSK applications where the FG 501 dial setting

mark frequency and the positive amplitude

For more complete information on this application, write the TM 500

Advertising Dept. for the application note entitled "FG 501 Swept

Frequency

provide a linear change in output frequency.

tage will provide two output tones, the output frequency of which

determined by the specific levels of the top and bottom portions of

the square wave. For example, the two-tone output capability could

application^.^'

its

well

output frequency as determined

to the more recent

A

function

A

square-wave vol-

is

the space frequency.

is

BNC

the

is

9.

POWER SUPPLIES DRIVEN

Any of the analog programmable power supplies such as PS 501,

PS 503, or PS 503A plug-ins can be driven by an adjacent signal

or function generator to provide a low source impedance suitable

for delivering higher currents into

load examples would include drive relays, lamps, small motors,

loudspeakers,

output frequency and

Specific information on voltage driving power supply sense inputs

can be found in the MODULE DATA section under Power Supply

Notes.

The

AM

502 and

When the

interface SIGNAL

to the

DM

the

display on the 2-volt ranges. This measurement application can be

used in setting up low audio signal output levels from an adjacent

audio signal source such as the SG 502.

AM

DM

501

etc.

DM

501

501's rear

will

The power supply

risetime

10.

501 can provide ac and dc microvolt measurements.

is

set

for a gain of 1000 (dc-coupled) and

OUT

(28A) and SIGNAL OUT GROUND (27A) are connected

HI

INPUT (28B) and LO INPUT (28A), respectively,

provide a 2 millivolt dc or ac full scale digital

up to

MICROVOLTMETER

BY

SIGNAL SOURCES

a

low impedance load. Some

will

its

follow the signal sources

slew rate limitations.

Interface

its

rear

REV

A,

JUN

1978

Page 13

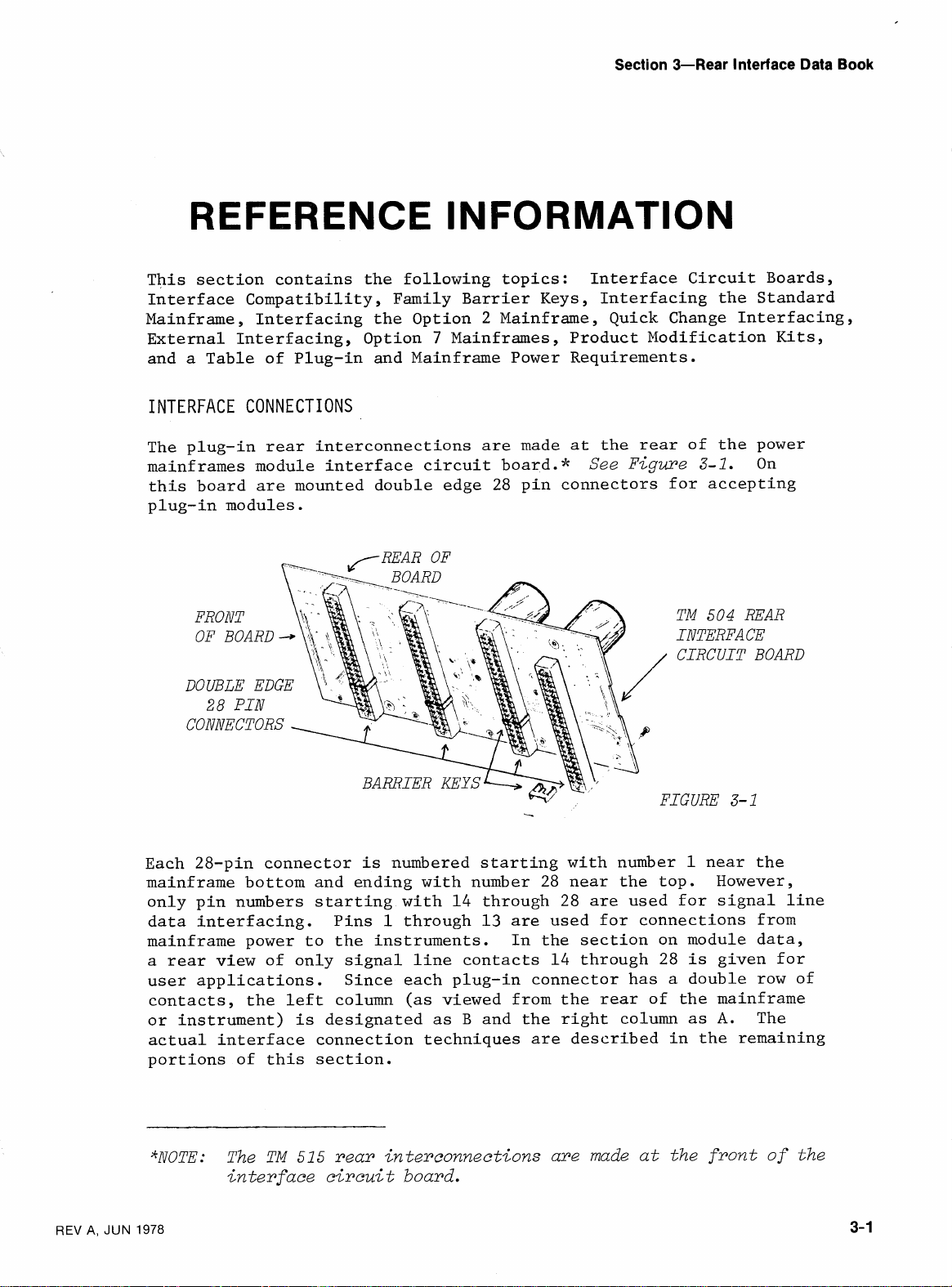

Section 3-Rear Interface Data Book

REFERENCE INFORMATION

This section contains the following topics: Interface Circuit Boards,

Interface Compatibility, Family Barrier Keys, Interfacing the Standard

Mainframe, Interfacing the Option 2 Mainframe, Quick Change Interfacing,

7

External Interfacing, Option

and a Table of Plug-in and Mainframe Power Requirements.

Mainframes, Product Modification

INTERFACE CONNECTIONS

Kits,

The plug-in rear interconnections are made

mainframes module interface circuit board.*

this board are mounted double edge

plug-in modules.

--

OF BOARD

COPJNECTORS

Each 28-pin connector

mainframe bottom and ending with number 28 near the top. However,

only pin numbers starting with 14 through 28 are used for signal line

data interfacing.

mainframe power to the instruments. In the section on module data,

a rear view of only signal line contacts

user applications. Since each plug-in connector has a double row of

contacts, the left column (as viewed from the rear of the mainframe

or instrument)

actual interface connection techniques are described in the remaining

portions of this section.

-.

is

/REAR

is

Pins

designated as B and the right column as

1

OF

numbered starting with number

through 13 are used for connections from

28 pin connectors for accepting

at

the rear of the power

See Figwe

14 through 28

3-1. On

TM

504

REAR

INTERFACE

CIRCUIT BOARD

1

near the

is

given for

A.

The

REV

A,

JUN

*NOTE:

1978

The

TM

525

rear interconnections are made at the front of the

interface circuit board.

Page 14

Reference Information-Rear Interface' Data Book

INTERFACE COMPATIBILITY

An

important feature of the

instruments in a mainframe to each other, or to external equipment, via

the "rear interface". Physically, the rear interface consists of

upper 30 edge-card connections at each plug-in compartment, (2) optional

connectors on the mainframe rear panel, and

to make connections from plug-in to plug-in, or from plug-in to rear connector, and hence to external equipment.

TM

500-Series

is

the ability to interconnect

(3)

any wiring or cabling used

(1)

the

The wiring or cabling portion of most

tomer installed.

A

large number of unique interconnections are possible.

Because of the variety of instruments

TM

500 interconnect systems

comprising the

TM

500 family,

is

cus-

it

was

decided to make the interface a custom system with no factory installed bus

lines or truly "standard" pin assignments. However, instruments are grouped

I/O

into families with similar

which permits physical lockout of plug-ins from other families.

characteristics and an optional keying system

Use of the

optional keying system (with barrier keys) minimizes the possibility of introducing the wrong plug-in into a mainframe compartment when the mainframe

has been wired for specialized rear interface connections. However, the

assignment of family keys

not intended to make sure that a system

will

be

is

fully functional when plug-ins are installed, only that nothing destructive

of hardware (internal or external)

will

stalled. In other words, the main compatibility rules

occur if the wrong plug-in

are:

is

in-

Instruments having dissimilar input/output characteristics are grouped

into different families.

system,

it

is

possible that installing a plug-in of the wrong family

may be destructive of hardware.

If the rear interface

Install family barrier keys in the

is

wired to configure a

mainframe to avoid possible damage to equipment.

Although family members have similar input/output characteristics,

their basic functions may differ drastically.

Only a keying system

with a unique key or combination for every individual instrument type

would assure system operation.

Therefore,

it

is

only required that

family members are neither conducive nor susceptible to hardware failure (destructive)

if plugged into a compartment wired for a different

member of the same family.

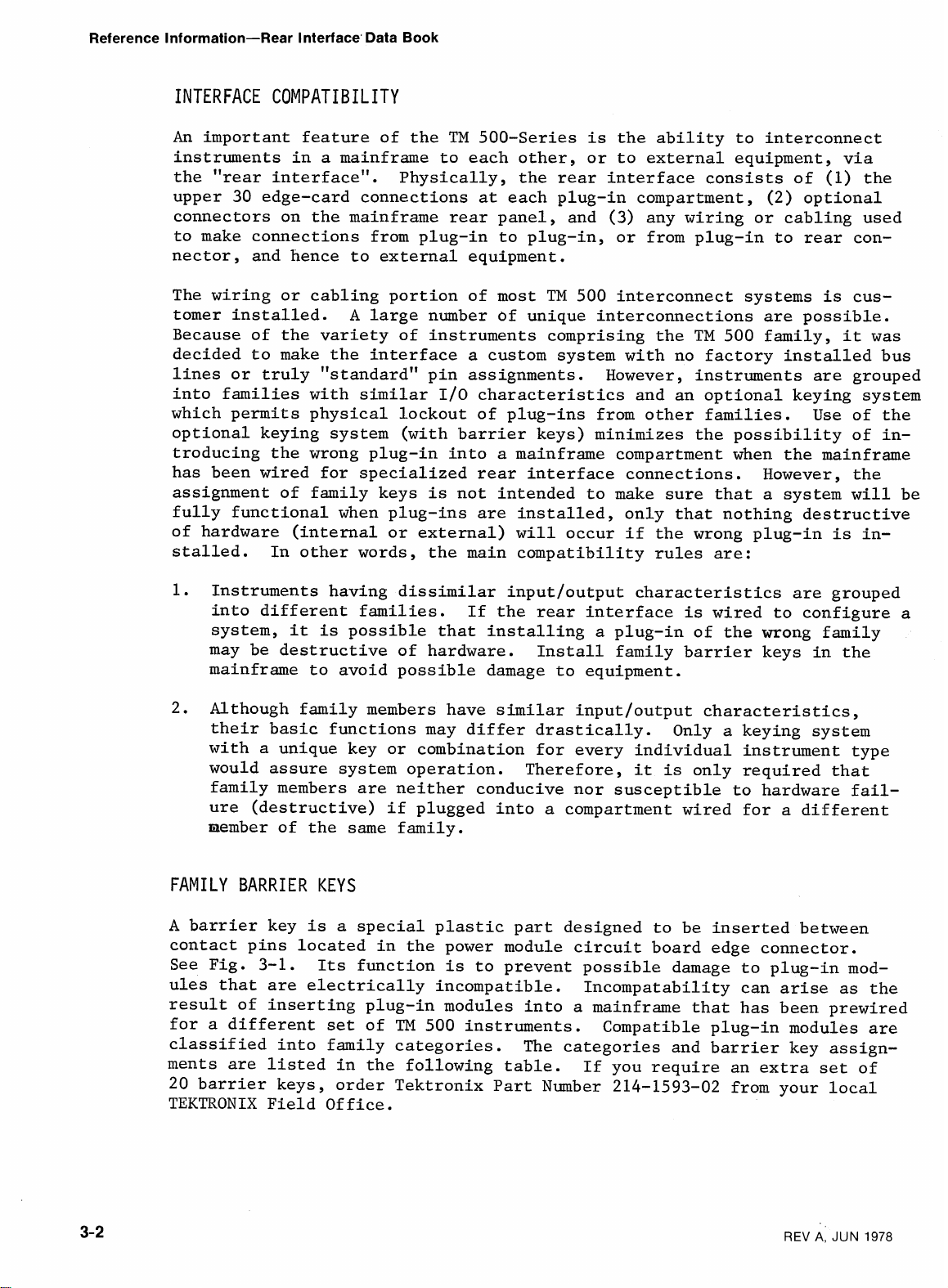

FAMILY BARRIER KEYS

A

barrier key

contact pins located in the power module circuit board edge connector.

See Fig.

ules that are electrically incompatible.

result of inserting plug-in modules into a mainframe that has been prewired

for a different

classified into family categories.

ments are listed in the following table.

20 barrier keys, order Tektronix Part Number 214-1593-02 from your local

TEKTRONIX

is

a special plastic part designed to be inserted between

3-1.

Its

function

set

Field Office.

of

is

to prevent possible damage to plug-in mod-

TM

500 instruments.

Incompatability can arise as the

Compatible plug-in modules are

The categories and barrier key assign-

If you require an extra set of

REV

A,

JUN

1978

Page 15

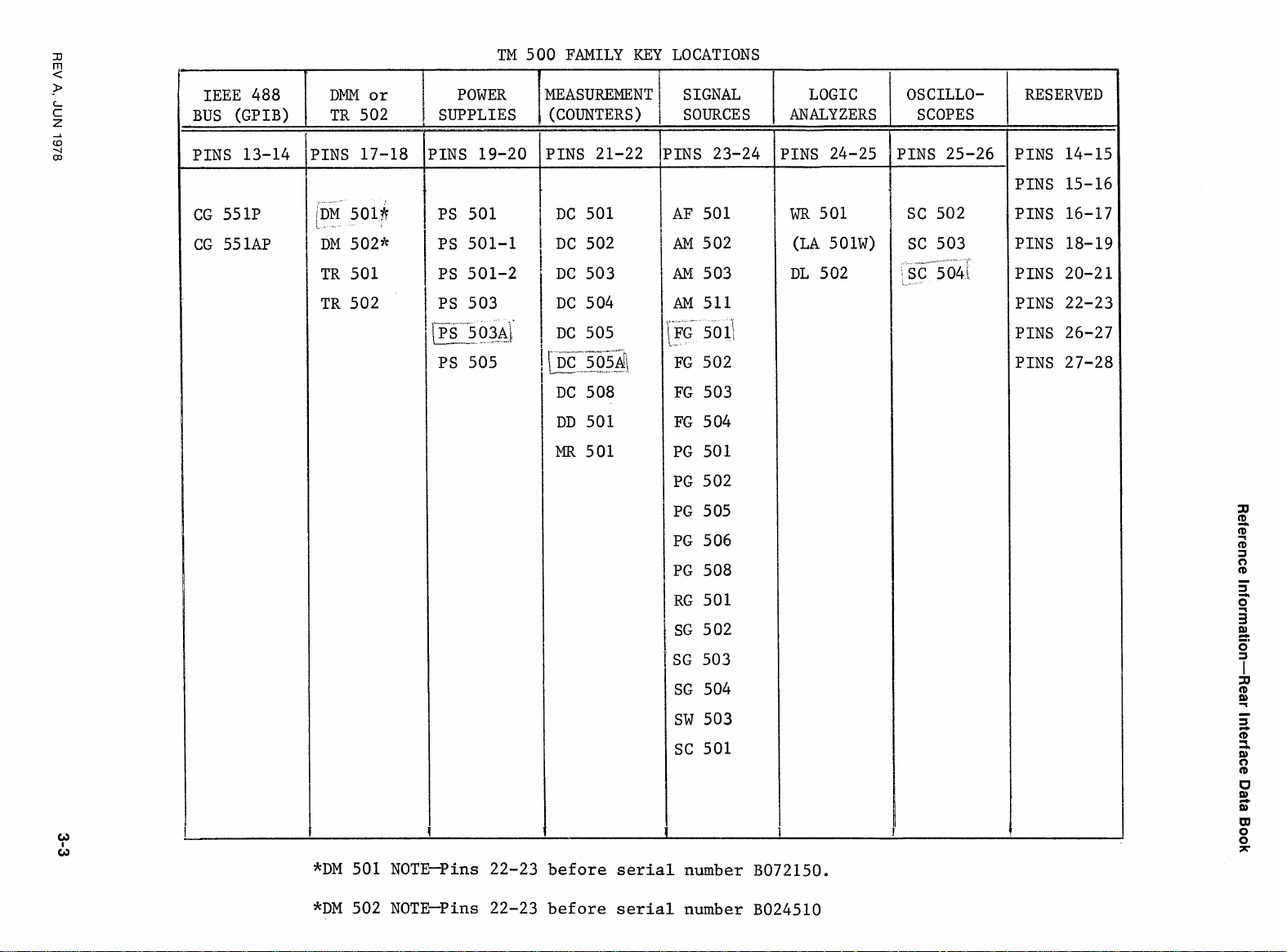

TM 500 FAMILY KEY LOCATIONS

IEEE

BUS

PINS 13-14

488

(GPIB)

DMM

or

TR 502

'INS 17-18

POWER

SUPPLIES

INS 19-20 IPINS 21-22

MEASUREMENT

(COUNTERS

)

INS 23-24

SIGNAL

SOURCES

LOGIC

ANALYZERS

WR

501

(LA 501W)

OSCILLO-

SCOPES

RESERVED

PINS 14-15

PINS 15-16

PINS 16-17

PINS 18-19

PINS 20-21

PINS 22-23

PINS 26-27

PINS 27-28

*DM 501 NOTE-Pins 22-23 before

*DM 502 NOTE-Pins 22-23 before

serial

serial

number B072150.

number B024510

Page 16

Reference Information-Rear Interface Data Book

With a barrier in place in the mainframe connector,

instruments belonging to one of the above-listed families cannot

be inserted into the mainframe wired for a different plug-in

is

family. The key to this lockout feature

of the barrier key into the double edge 28-pin connector.

plug-ins belonging to a specific family can be inserted into the

module compartment containing the desired family key because of

a corresponding slot cut into the mating plug-in circuit board

at the family key location.

INTERFACING TM 500

the actual placement

plug-in

All

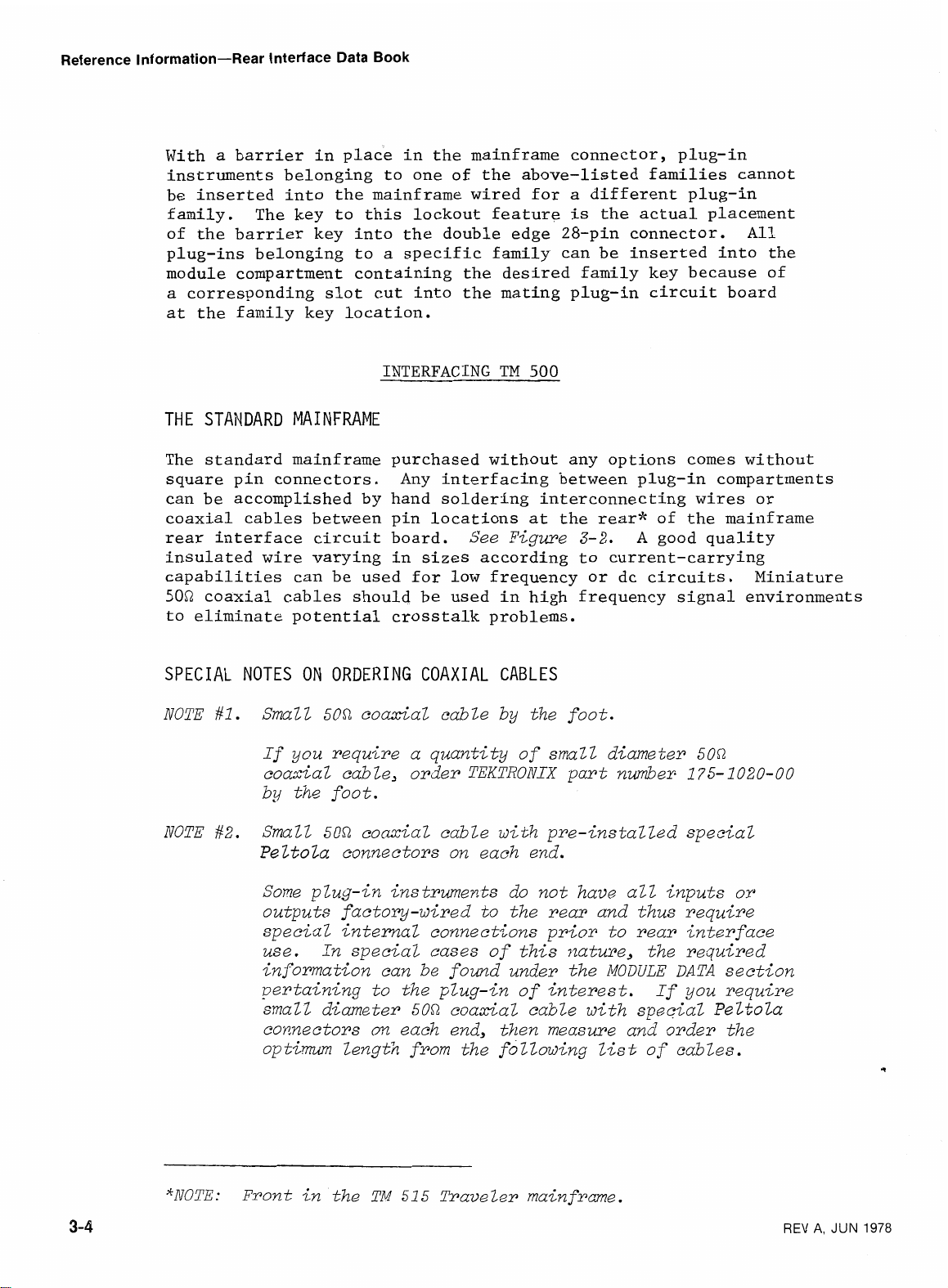

THE STANDARD MAINFRAME

The standard mainframe purchased without any options comes without

square pin connectors.

can be accomplished by hand soldering interconnecting wires or

coaxial cables between pin locations at the rear* of the mainframe

rear interface circuit board.

insulated wire varying in sizes according to current-carrying

capabilities can be used for low frequency or dc circuits. Miniature

50Q coaxial cables should be used in high frequency signal environments

to eliminate potential crosstalk problems.

Any interfacing between plug-in compartments

See Figure

3-2.

A

good quality

SPECIAL NOTES ON ORDERING COAXIAL CABLES

NOTE #l.

NOTE #2.

Small 50R coaxial cable by the foot.

If

you require a quantity of small diameter 50R

coaxial cab le, order TEKTRONIX part nwnber 1 75- 1020-00

by the foot.

Small 50R coaxial cable with pre-installed special

PeZtoZa connectors on each end.

Some plug-in

instruments do not have all inputs or

outputs factory-wired to the rear and thus require

special internal connections prior to rear interface

use. In special cases of this nature, the required

information can be fomd under the MODULE DATA section

pertaining to the plug-in of interest.

small diameter 50R coakal cable with special PeZtoZa

connectors on each end, then measure and order the

optimwn length from the following list

If you require

of

cables.

*NOTE:

Front

in

the

TM

-

-

515

T~aveler mainfmme.

REV

A,

JUN

1978

Page 17

Page 18

Reference Information-Rear Interface Data Book

IWORTANT NOTE:

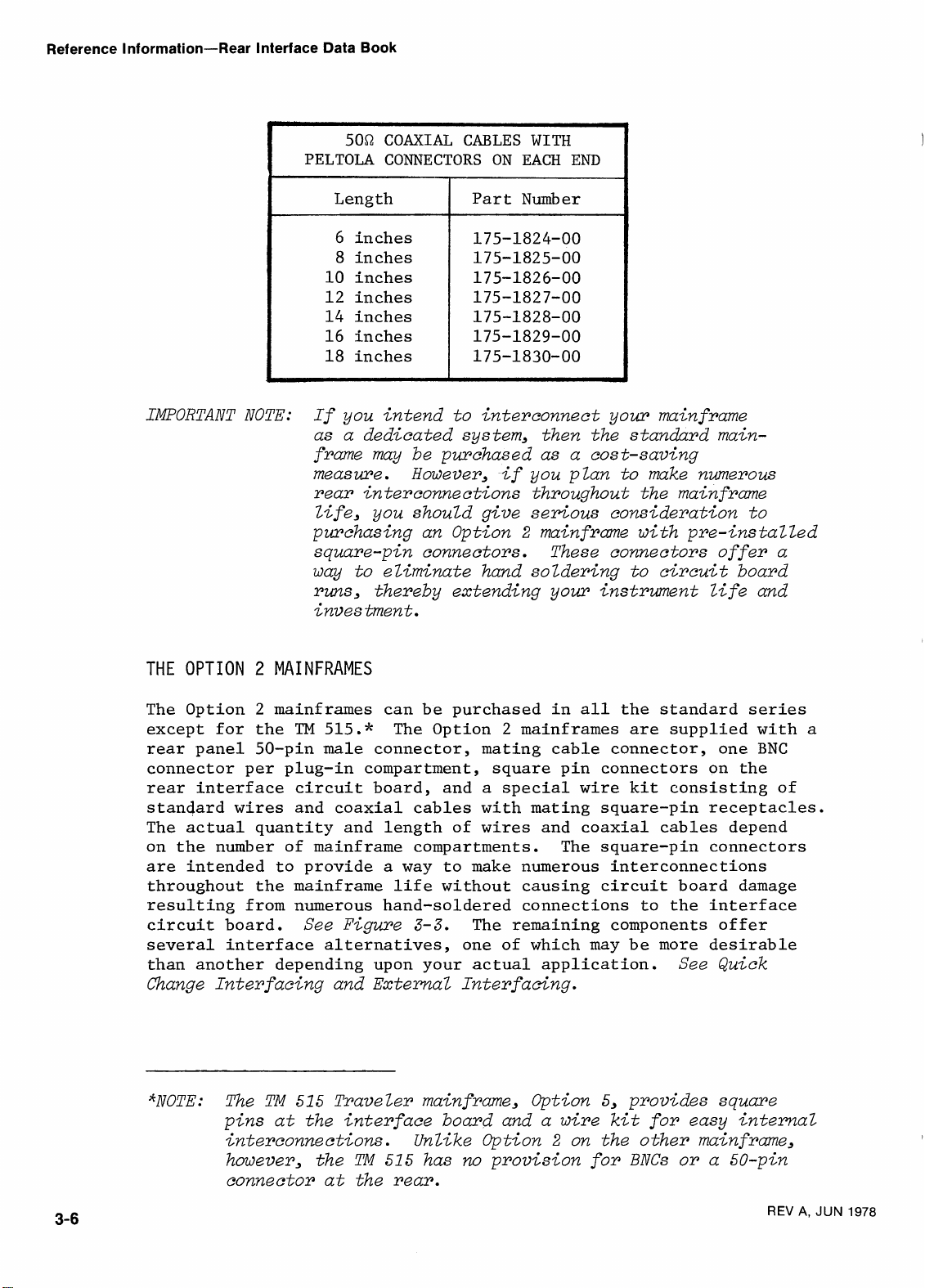

50f2 COAXIAL CABLES

PELTOLA CONNECTORS

Length

6

inches

8 inches

10 inches

12 inches

14

inches

16 inches

18 inches

Part Number

ON

WITH

EACH

END

If you intend to interconnect your mainframe

as a dedicated system, then the standard mainframe may be purchased as a cost-saving

measme. However, if you plan to make numerous

rear interconnections throughout the mainframe

life, you should give serious consideration to

2

purchasing an Option

mainframe with pre-installed

square-pin connectors. These connectors offer a

way to eliminate hand soldering to circuit board

runs, thereby extending your instrument life and

investment.

THE OPTION 2 MAINFRAMES

The Option 2 mainframes can be purchased in all the standard series

except for the

rear panel 50-pin male connector, mating cable connector, one

connector per plug-in compartment, square pin connectors on the

rear interface circuit board, and a special wire kit consisting of

standard wires and coaxial cables with mating square-pin receptacles.

The actual quantity and length of wires and coaxial cables depend

on the number of mainframe compartments. The square-pin connectors

are intended to provide a way to make numerous interconnections

throughout the mainframe life without causing circuit board damage

resulting from numerous hand-soldered connections to the interface

circuit board.

several interface alternatives, one of which may be more desirable

than another depending upon your actual application.

Change Interfacing and External

"NOTE: The

pins at the interface board and a wire kit for easy internal

interconnections.

however, the

connector at the rear.

TM

515.h The Option 2 mainframes are supplied with a

See Figure

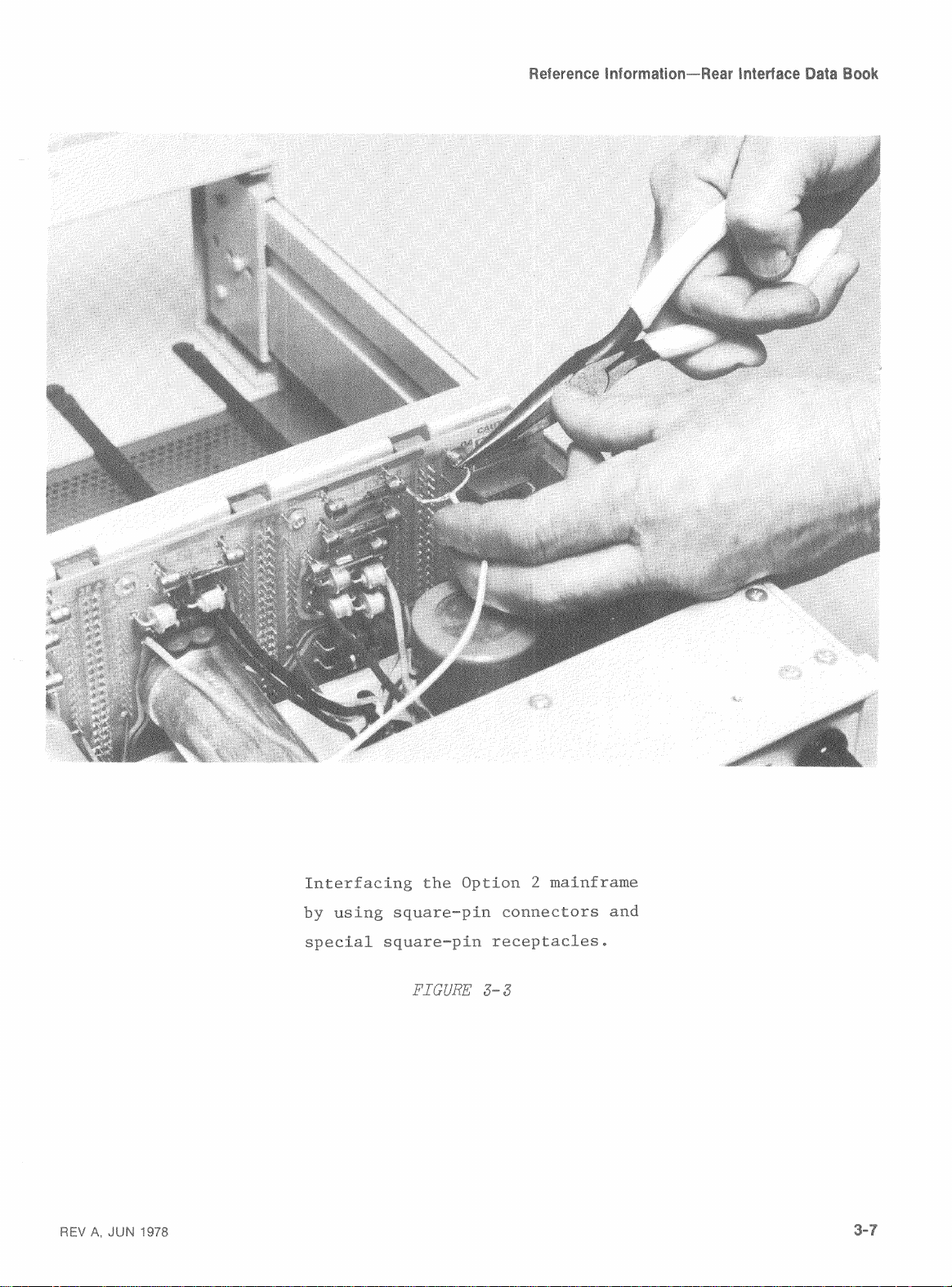

3-3.

The remaining components offer

Interfacing.

TM

515 Traveler mainframe, Option

Unlike Option

TM

515

has

no

provision for BNCs or a 50-pin

See Quick

5,

provides square

2

on the other mainframe,

BNC

REV

A,

JUN

1978

Page 19

Page 20

Reference Information-Rear Interface Data Book

QUICK CHANGE INTERFACING

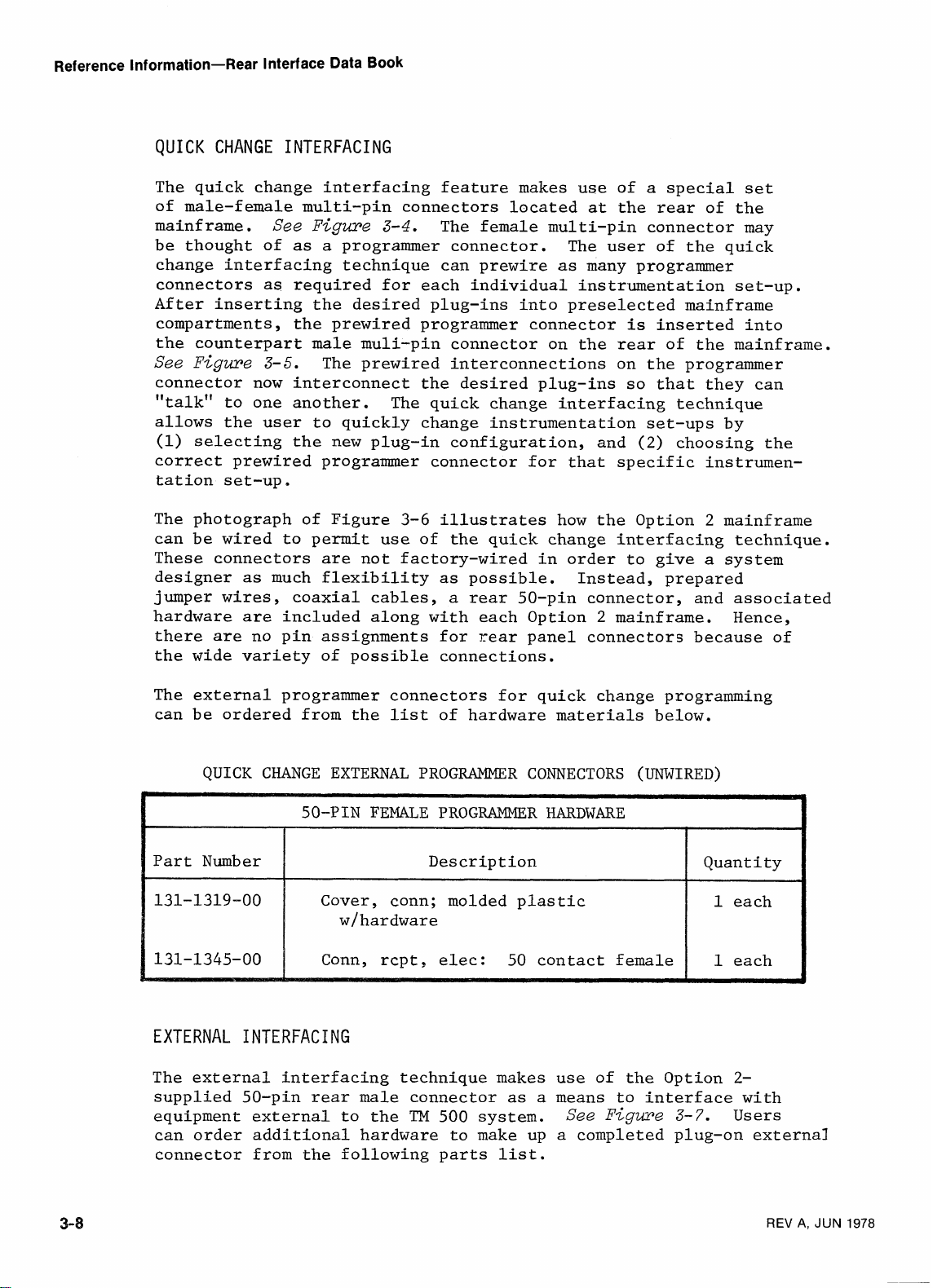

The quick change interfacing feature makes use of a special set

of male-female multi-pin connectors located at the rear of the

mainframe.

See Figure

3-4. The female multi-pin connector may

be thought of as a programmer connector.

change interfacing technique can prewire as many programmer

connectors as required for each individual instrumentation set-up.

After inserting the desired plug-ins into preselected mainframe

compartments, the prewired programmer connector is inserted into

the counterpart male muli-pin connector on the rear of the mainframe.

See Figure

3-5. The prewired interconnections on the programmer

connector now interconnect the desired plug-ins so that they can

"talk" to one another.

The quick change interfacing technique

allows the user to quickly change instrumentation set-ups by

(1)

selecting the new plug-in configuration, and (2) choosing the

correct prewired programmer connector for that specific instrumentation set-up

.

The user of the quick

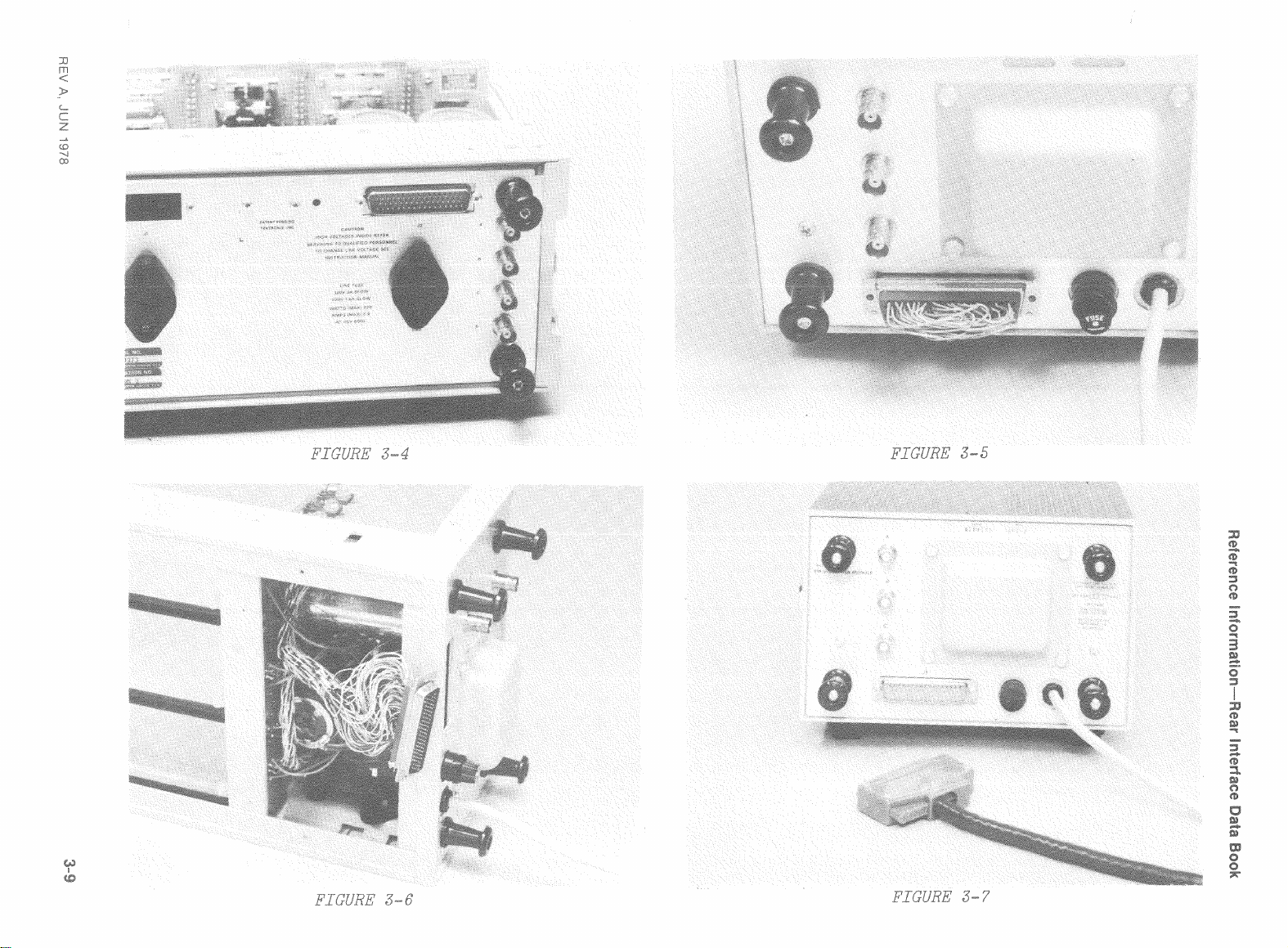

The photograph of Figure

3-6

illustrates how the Option 2 mainframe

can be wired to permit use of the quick change interfacing technique.

These connectors are not factory-wired in order to give a system

designer as much flexibility as possible. Instead, prepared

jumper wires, coaxial cables, a rear 50-pin connector, and associated

hardware are included along with each Option 2 mainframe.

Hence,

there are no pin assignments for rear panel connectors because of

the wide variety of possible connections.

The external programmer connectors for quick change programming

can be ordered from the list of hardware materials below.

--

50-PIN

FEMALE

PROGRAMMER

HARDWARE

Part Number Description Quantity

1

131-1319-00 Cover, conn; molded plastic

each

wlhardware

131-1345-00 Conn, rcpt, elec: 50 contact female

1

each

EXTERNAL INTERFACING

The external interfacing technique makes use of the Option

2-

supplied 50-pin rear male connector as a means to interface with

equipment external to the

TM

500 system.

See Figure

3-7.

Users

can order additional hardware to make up a completed plug-on external

connector from the Following parts list.

REV

A,

JUN

1978

Page 21

Page 22

Reference Information-Rear Interface Data Book

Part Number

131-1319-00

131-1345-00

WTE:

The number of wires contained within the external connector

cable depends upon the specific user's requirements.

EXTERNAL

Cover, conn; molded plastic wlhardware

Conn, rcpt, elec: 50 contact female

CABLE CONNECTOR

50-PIN FEMALE

Description

HARDWARE

CONNECTOR

Quantity

1

each

1

each

The

external multi-conductor cable should be obtained from a

ZocaZ multi-conductor cab Ze supplier or vendor.

CAUTION:

Center for service, please notify the service center that the mainframe has been 'interfaced.

return of your instrument.

module and plug-in(s) to the service center.

In the event your mainframe

This

It

will

is

advisable to return both power

is

sent to a TEKTRONIX Service

save money and expedite the

THE OPTION 7 MAINFRAMES

The following described bus wires and barrier keys are added to the

'EM

rear interface connector boards in the following

modules in order to provide rear interface connections between the

DC

508 Option 7 Counter (or other Option 7 counters), TR 502 Tracking

Generator, and SW 503 Sweep Generator.

Bus Wires. Six-conductor ribbon cable (Tektronix Part Number

00)

TM

is

used to make bus runs between the

503,

TM

504,

TM

506, TM 515

following points.

B14 on J10, 520, and 530

B15 on J10, 520, and 530 J10, 520, and 530

B16 on J10, 520, and 530 are plug-in connectors.

B17 on

J10, 520, and 530 See Power Module instruction

I318 on J10, 520, and 530 Manual.

A18 on J10, 520, and 530

Plastic barrier keys (Tektronix Part Number 214-1593-02) are inserted

between pins 21 and 22 on J10 (Counter slot), between pins 23 and 24

on 520 (Sweep Generator slot), and pins 17 and 18 on 530 (Tracking Generator slot).

500-series power

175-0829-

Once the above bus connections are made and barrier keys inserted, the

three connectors so changed are system dedicated and the three slots

should be used only for system-dedicated

plug-En modules.

REV

A,

JUN

1978

Page 23

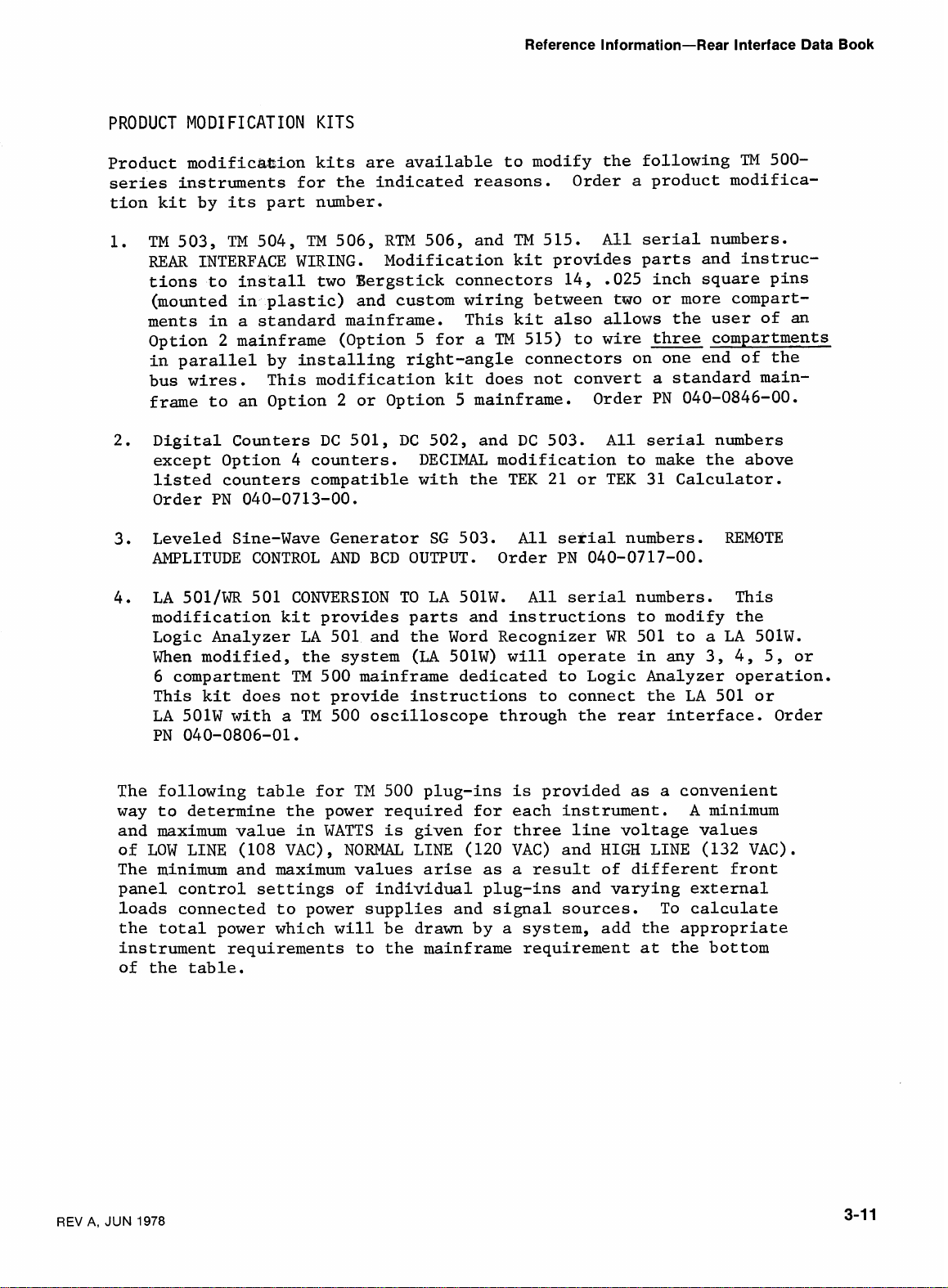

PRODUCT MOD1 FICATION KITS

Reference Information-Rear Interface Data Book

Product rnodificta.&ion kits are available to modify the following

series

tion kit by

instruments for the indicated reasons. Order a product modifica-

its

part number.

All

TM

503,

REAR

TM

504, TM 506,

INTERFACE

WIRING.

RTM

506, and

TM

Modification kit provides parts and instruc-

tions to install two Bergstick connectors

(mounted in plastic)

and custom wiring between two or more compart-

515.

14, -025 inch square pins

serial numbers.

ments in a standard mainframe. This kit also allows the user of an

TM

Option 2 mainframe (Option 5 for a

515) to wire three compartments

in parallel by installing right-angle connectors on one end of the

bus

wires.

frame to an Option

Digital Counters

except Option 4 counters.

This modification kit does not convert a standard main-

2

or Option 5 mainframe. Order PN 040-0846-00.

DC

501,

DC

502, and

DC

503.

All

serial numbers

DECIMAT., modification to make the above

listed counters compatible with the TEK 21 or TEK 31 Calculator.

Order PN 040-0713-00.

All

Leveled Sine-Wave Generator SG 503.

AND

BCD

AMPLITUDE CONTROL

OUTPUT. Order PN 040-0717-00.

LA 5011~~ 501 CONVERSION TO LA 501W.

serial numbers. REMOTE

All

serial numbers. This

modification kit provides parts and instructions to modify the

Logic Analyzer LA 501 and the Word Recognizer

When modified, the system

6 compartment

TM

500 mainframe dedicated to Logic Analyzer operation.

This kit does not provide instructions

TM

LA 501W with a

500 oscilloscope through the rear interface. Order

(LA

501~)

will

to connect the LA 501 or

WR

501 to a LA 501W.

operate in any 3, 4, 5, or

PN 040-0806-01.

TM

500-

REV

The

following table for

way to determine the power required for each instrument.

and maximum value in WATTS

of LOW LINE (108 VAC), NORMAL LINE (120 VAC) and

TM

500 plug-ins

is

given for three line voltage values

is

provided as a convenient

A

HIGH

LINE (132 VAC).

The minimum and maximum values arise as a result of different front

panel control settings of individual plug-ins and varying external

loads connected to power supplies and signal sources. To calculate

the

total power which

will

be drawn by a system, add the appropriate

instrument requirements to the mainframe requirement at the bottom

of the table.

A,

JUN

1978

minimum

Page 24

Reference Information-Rear Interface Data Book

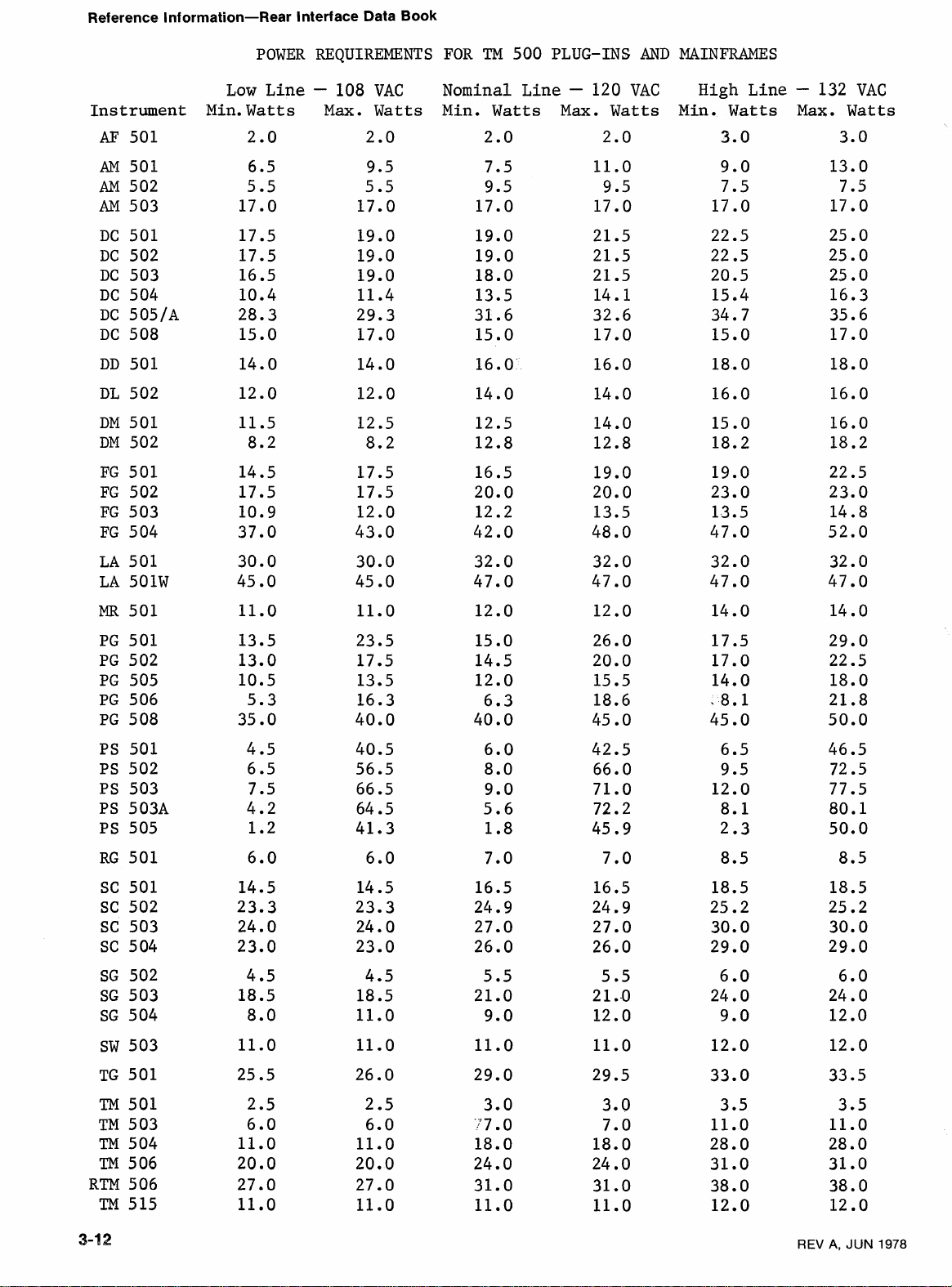

POWER REQUIREMENTS FOR

Low Line - 108

VAC

Instrument Min.Watts Max. Watts

'I'M

500

PLUG-INS

Nominal Line - 120

Min.

Watts Max. Watts Min. Watts Max. Watts

AND

MAINFRAMES

VAC

High Line

-

132

VAC

TM

TM

TM

TM

RTM

TM

501

503

504

506

506

515

REV A,

JUN

1978

Page 25

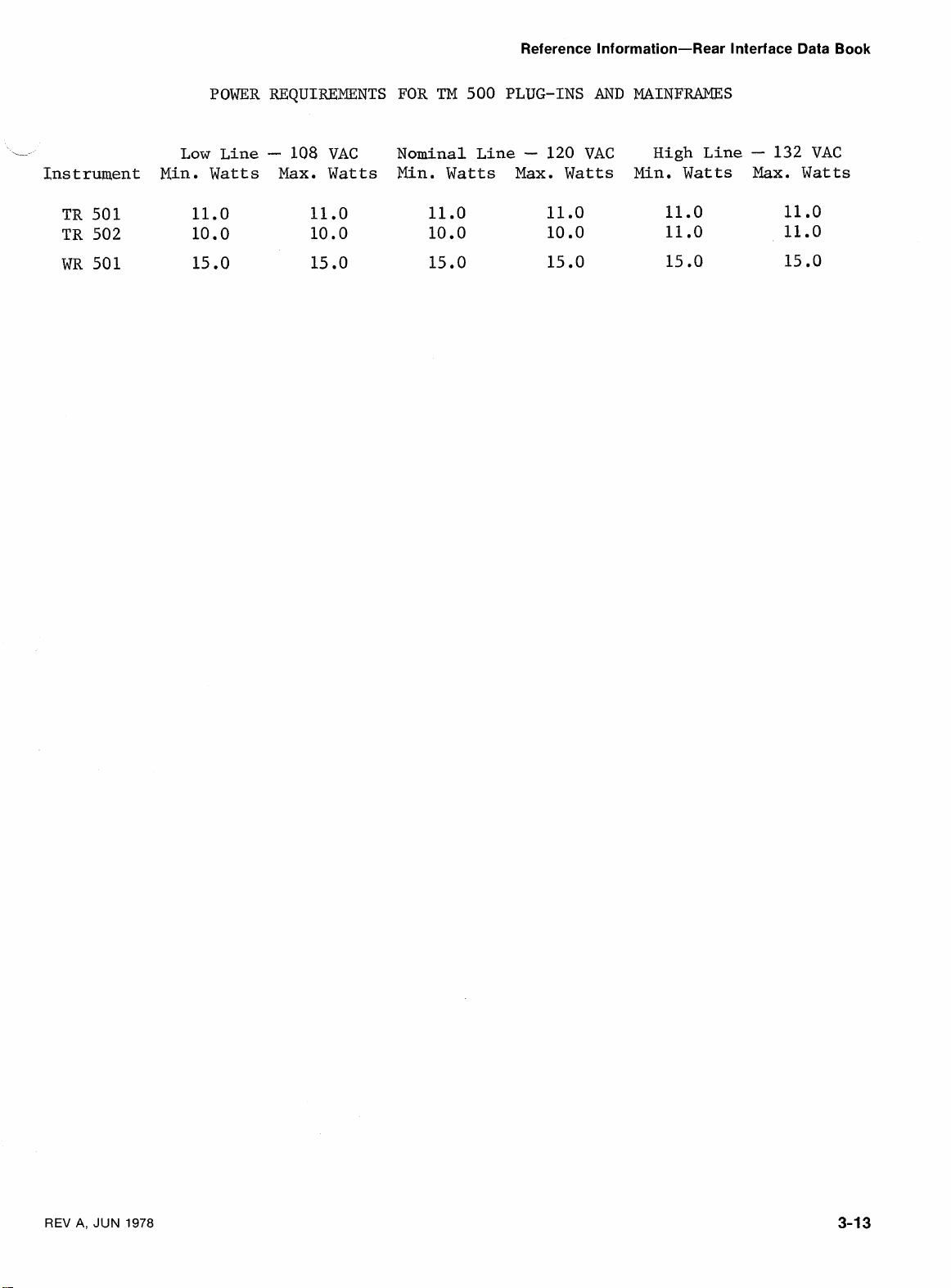

Reference Information-Rear Interface Data Book

POWER WQUIIXEXENTS

L-

Low Line - 108

VAC

FOR

TM

500 PLUG-INS

Nominal Line - 120

AND

VAC

MAINFRAJ!ES

High Line - 132

Instrument Min. Watts Max. Watts Min. Watts Max. Watts Min. Watts Max. Watts

VAC

REV

A,

JUN

1978

Page 26

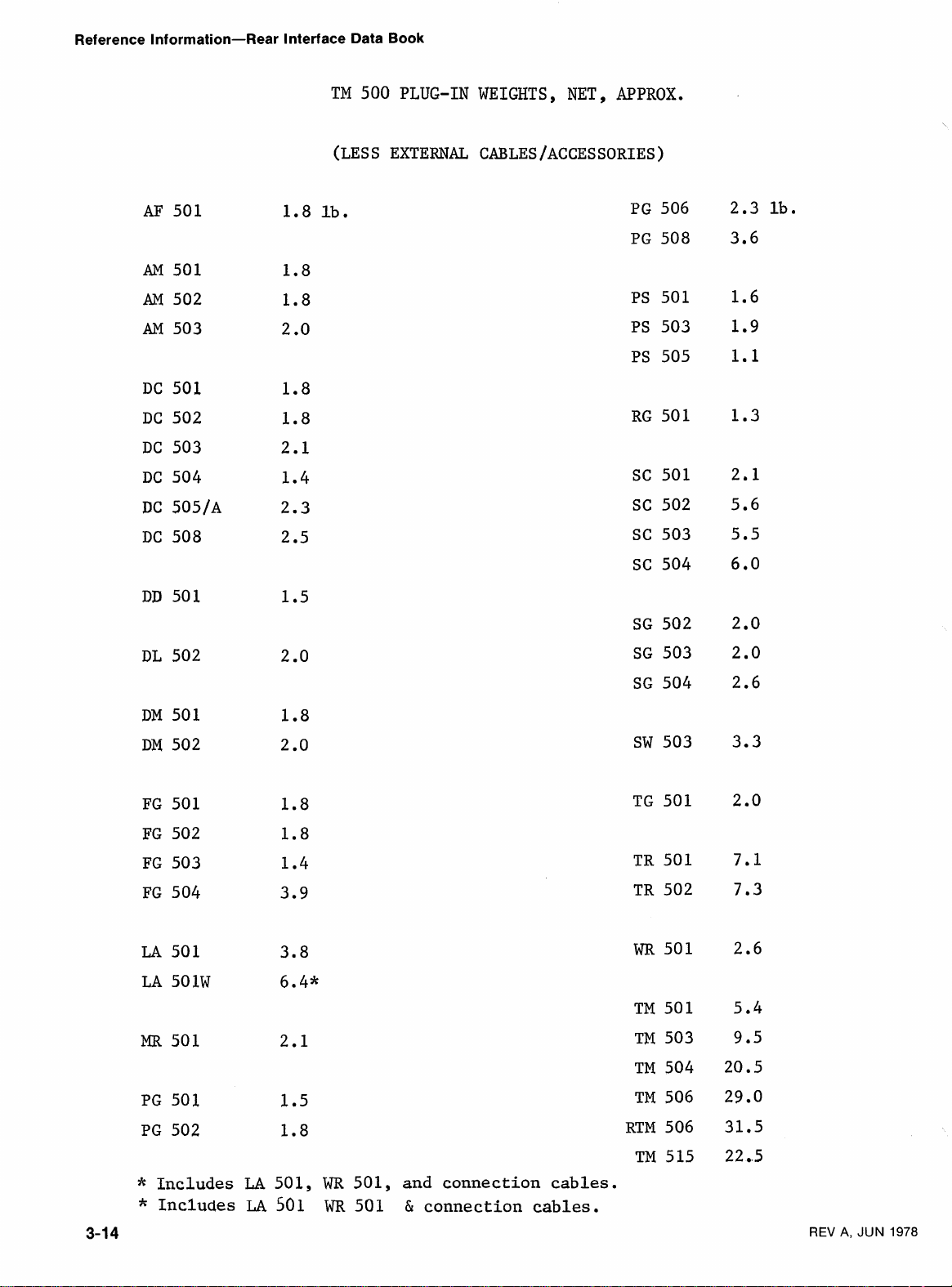

Reference Information-Rear Interface Data Book

TM

500

PLUG-IN WEIGHTS, NET, APPROX.

(LESS EXTERNAL CABLES/ACCESSORIES)

1.8 lb.

1.8

1.8

.o

2

1.8

1.8

2.1

la4

2.3

2.5

1.5

2 a0

2.3 lb.

3.6

1.6

1.9

1.1

1.3

2.1

5.6

5.5

6.0

2.0

2.0

2.6

3-1

*

*

4

Includes

Inclucies

LA

LA

1.8

2.0

501,

501

WR

501, and connection cables.

WR

501

&

connection

cables.

WR

501

TM 501

TM 503

TM 504

TM 506

RTM 506

TM 515

3.3

2.0

7.1

7.3

2.6

5.4

9.5

20.5

29.0

31.5

22,5

REV

A,

JUN

1978

Page 27

Page 28

Page 29

Section

5-Rear

SIGNAL PROCESSORS

Interface Data Book

REV

A,

JUN

1978

Page 30

Signal Processors-Rear Interface Data Book

REV

A,

JUN

1978

Page 31

Signal Processors-Rear Interface Data Book

AF

501

Plug-In or Power Module

ASSIGNMENTS

FUNCTION

Ground (Amplifier Output)

Tri gger Output

I

1

28B

cONTAcTs

-,

l

1

-

-

25B 25A

Rear

ASSIGNMENTS

CONTACTS FUNCTION

28A

Amplifier Output

27A

Ground (Trigger Output)

26A

View

REV

A,

JUN

1978

CAUTION

When a Power Module compartment has been selected for the

AF

502

and wired for a speciaZized interface system, a

pZas

kit

barrier (Tektronix Part Number

be insta2Zed in a key slot between contacts

the Power Module.

Do not insert any

ModuZe and do not use excessive force when inserting the

plug-in.

TM

500

Series phg-in in a live Power

224-

2593-02) should

23

and

24

on.

Page 32

Signal Processors-Rear Interface Data Book

AF

501

INTERFACE

Amplifier

Contact

when switch S210 (internal Output)

specifications for contact

front-panel connector.

Tri gger

Contact 27B

connector when switch S310 (internal Trig out)

The specifications

the front-panel connector.

Ground

Contacts

is

switched to ground at the same time the

to the rear interface by S310, while contact

at the same time

by

S210.

Output

28A

is

Output

is

(Tri gger

27A

and

placed in parallel with the front-panel OUTPUT connector

28A

placed in parallel with the front-panel

for contact 27B are the same as those stated for

Output

28B

the

and

Amp1

are both switched to chassis ground.

Amplifier Output

IIOTES

is

set to Int position.

are the same as those stated for the

i fier

Output)

Trigger Output

is

switched to the rear interface

is

28B

The

TRIG

set to Int position.

is

switched to ground

OUT

Contact

is

switched

27A

REV

A,

JUN

1978

Page 33

Signal Processors-Rear Interface Data Book

AM

501

Plug-In

ASSIGNMENTS

FUNCTION CONTACTS

(+)

signal in

-

Signal In

or Power

Ground

Ground

28~

25~

24B

221321s

-!

Module

CONTACTS

14-

28~

-

27~

+-

26A

25~

21A

-

20A

Rear

ASSIGNMENTS

Signal

View

FUNCTION

Out

Ground

19A

-

18A

17A

16A

15E

14B

CAUTION

When a Power Module compartment has been selected

AM

for the

face system, a plastic barrier (Tektronix Part

Nwnber 224-2593-021

slot between contacts

502 and wired for a specialiaed inter-

should be installed in a key

23

5A

14~

and 24 on the Power Module.

None of these assignments are

factory wired. See INTERFACE

NOTES for wiring instructions.

NOTE

REV

A,

JUN

Do not insert any TM 500 Series plug-in in a live

Power Module and do not use excessive force when

inserting the plug-in.

1978

Page 34

Signal Processors-Rear interface Data Book

AM

501

Introducti on

None of the rear pin connectors (except power supply connections)

are factory wired.

28B

have their own solder pads

wire his own input and output connections to the rear interface. The

pin assignments

compatibility with other TM

Instead, pins 21A through

listed on page

I

NTERIACE

500

NOTES

(holes)

1

are suggested in order to ensure

Series instruments.

28A

and

21B

through

to allow the user to hard

Signal

Pin

for signals obtained from a specific point in a simple or complex

operational amplifier feedback circuit.

not always the same point that

output connectors.

solder

pin

point may be located on the circuit board or at one of the front panel

output connectors, depending on your circuit requirements.

you can disconnect an undesirable front panel output connection.

Using

pin

Circuit Board.

not be desirable to connect pin

27A

connected to the rear interface must take this

Out

(contact

28A

at the rear connector should be thought of as an output terminal

#22

or

#26

28A

to the desired point in the operational amplifier circuit.

#22

or

#26

27A

to the large foil area marked

would be a "floating" connection and the design of external circuitry

28A)

To connect pin

wire (of the proper length) from the solder pad for

wire, solder the proper length from the solder pad for

In some types of operational amplifier circuitry,

and Ground (Contact

A

specific output terminal

is

connected to one of the front panel

28A

to the specific output terminal,

GND

on the

27A

to

GND

(chassis); in those cases pin

27A)

If

necessary,

"A"

side of the Main

fact under consideration.

is

This

it

Making Signal Input and Ground Connections

Use

$22

or

#26

wire to hard wire the - Signal In (inverting input) from

the solder pad (hole) for

pin

22B

to the large foil area labeled

Circuit Board.

inverting input)

GND

the

22B.

cable instead of standard gauge wire.

connections for pin

High frequency signals may require the use of miniature coaxial

Perform the same operations for the

from pin 24B to the input of your circuit and hard wire

21B

to the input of your circuit.

GND

on the

25B

in the same manner as stated for pin

"A"

side of the Main

+

Signal In (non-

Hard wire

may

NOTE

If

more than a foot or two of coaxial cable is connected

to the rear interface output contact (pin

28AI,

an

isolation resistor equal in value to the coaxial cable

impedance should be inserted in series with the center

conductor of cable.

is to reduce ringing effects due to

The purpose of the series resistor

loading factors.

REV

A,

JUN

1978

Page 35

Plug-in or Power Module Rear View

ASSIGNMENTS

FUNCTION CONTACTS

278

26B

+

Signal In Ground

+

Signal In

-

Signal In Ground

258

248-

23B

22~

4

--'

-.

--,

-

Signal

Processors-Rear Interface Data Book

--

-

ASSIGNMENTS

CONTACTS FUNCTION

1-

27A

Signal

Out

Ground

AM

502

-

Signal In

When a Power Module compartment has been selected

for the

system, a plastic barrier (Tektronix Part Nwnber

224-1593-02) should be installed in a key slot

between contacts

AM

218,

7A

-

16~

15E

CAUTION

502

wired for a specialized interface

23

and 24 on the Power Module.

1

5A

Signal Out and aZZ grounds

are factory wired. See the

INTERFACE NOTES for Signal

In wiring instructions.

NOTE

REV

A,

JUN

1978

Do not insert any TM

Power Module and do not use excessive force when

inserting the plug-in.

500

Series plug-in in a live

Page 36

Signal Processors-Rear Interface Data Book

AM

502

INTERFACE

Signal

Pins

27A

Out from the front panel bnc connector to use the output signal on

pin

Signal

These input connections must be user wired. Use the center conductor

of a miniature

(solder) the

from the associated solder pads at the rear connector pins to the

appropriate

coaxial cable shields

chassis ground connections (pin

-

Signal In).

Out

(Contact

28A

and

27A

is

chassis ground.

28A.

28A)

and Signal

are factory wired to rear interface contacts. Pin

It

is

Input Connections (contacts

50

S2

coaxial cable (about

+

Signal In (pin

+

and - front panel bnc connectors. Solder the associated

(braids) to the associated solder pads for the

NOTES

Out

Ground (Contact

not necessary to disconnect the Signal

24B,

21B,

24B)

and the - Signal In (pin

25B

for + Signal In and pin

25B,

and

11

inches long) to hard wire

27A)

22B)

21B)

22B

for

NOTE

The addition of coaxiai! cable connections

to the front pane2 bnc connector increases

the input

capaci tance

.

REV

A,

JUN

1978

Page 37

Signal Processors-Rear Interface Data Book

AM

503

Plug-In

ASSIGNMENT$

FUNCTION

or

Power

CONTACTS

Module

1

ASSIGNMENTS

CONTACTS

-

28~

Signal Output

Rear

FUNCTI

View

ON

-

19A

Signal Out and Ground are factory wired.

17A

nal input assignments.

-

16A

Each Rear Interface Connection shown has its

nection pad. See Interface Notes.

CAUTION

When a Power Module compartment has been selected for

the

AM

503

and

wired for a specialized interface sys-

a

tem,

should be installed in a key slot between contacts

and

Do not insert any

Module and do not use excessive force when inserting the

plug-in.

plastic barrier (Tektronix Part Nwnber 224-1593-02)

24

on the Power Module.

TM

500 Series plug-in in a live Power

NOTE

There are no sig-

own

through-hole-plated con-

23

REV

A,

JUN

1978

Page 38

Signal Processors-Rear Interface Data Book

AM

503

I

NTERFACE

NOTES

Signal

Pins

rear interface. To provide the output signal on

necessary to disconnect the coaxial lead from the rear of the

front panel bnc connector

the coaxial connector,

interface pin

located for the

Output (contact

28A

and

27A

are the only pins that are factory wired to the

28A.

AM

28A)

5480. 5480

No other input/output assignments are al-

503 at this time.

and Ground (contact

(OUTPUT INTO

50

R) and insert it into

is located close to rear

27A)

28A,

it is

Impedance Matching

The output from the

provides this load at the rear interface when the signal output

from

600

disconnect

manual)

28A

is connected to a device with an input resistance of

R, or greater.

R480. R480

.

AM

503 requires a 50 R load.

If

the device has an input impedance of

is located next to

5480

R480 (49.9

(see instruction

R)

50

R,

REV

A,

JUN

1978

Page 39

Signal Processors-Rear Interface

Data

AM

Book

511

Plug-In

ASSIGNMENTS

FUNCTION

or

Power

CON

rACTS

Module

ASSIGNMENTS

CONTACTS

Rear View

FUNCTION

REV

Each Rear Interface Connection shown has its own through-hole-plated

connection pad.

CA

UTION

When a Power Module compartment has been selected for the

AM

512 and

wired for a specialized interface system, a plastic barrier (TekCronix

Part Number 214-2593-02) should be installed in a key slot between

23

and

24

contacts

Do not insert any

on the Power Module.

TM

500 Series plug-in in a live Power Module and do

not we excessive force when inserting the plug-in.

A,

JUN

1978

Page 40

Page 41

Section 6-Rear Interface Data Book

DIGITAL COUNTERS

REV

A,

JUN

1978

Page 42

Digital Counters-Rear Interface Data Book

NOTES

REV

A,

JUN

1978

Page 43

Digital Counters-Rear Interface Data Book

General Counter Information

GENERAL

TTL

Voltage

The words

rear contacts under specific conditions. TTL specifications are as

follows:

exists from

LO

voltages between

+2.0

maximum value.

V

and

Time-Ladder

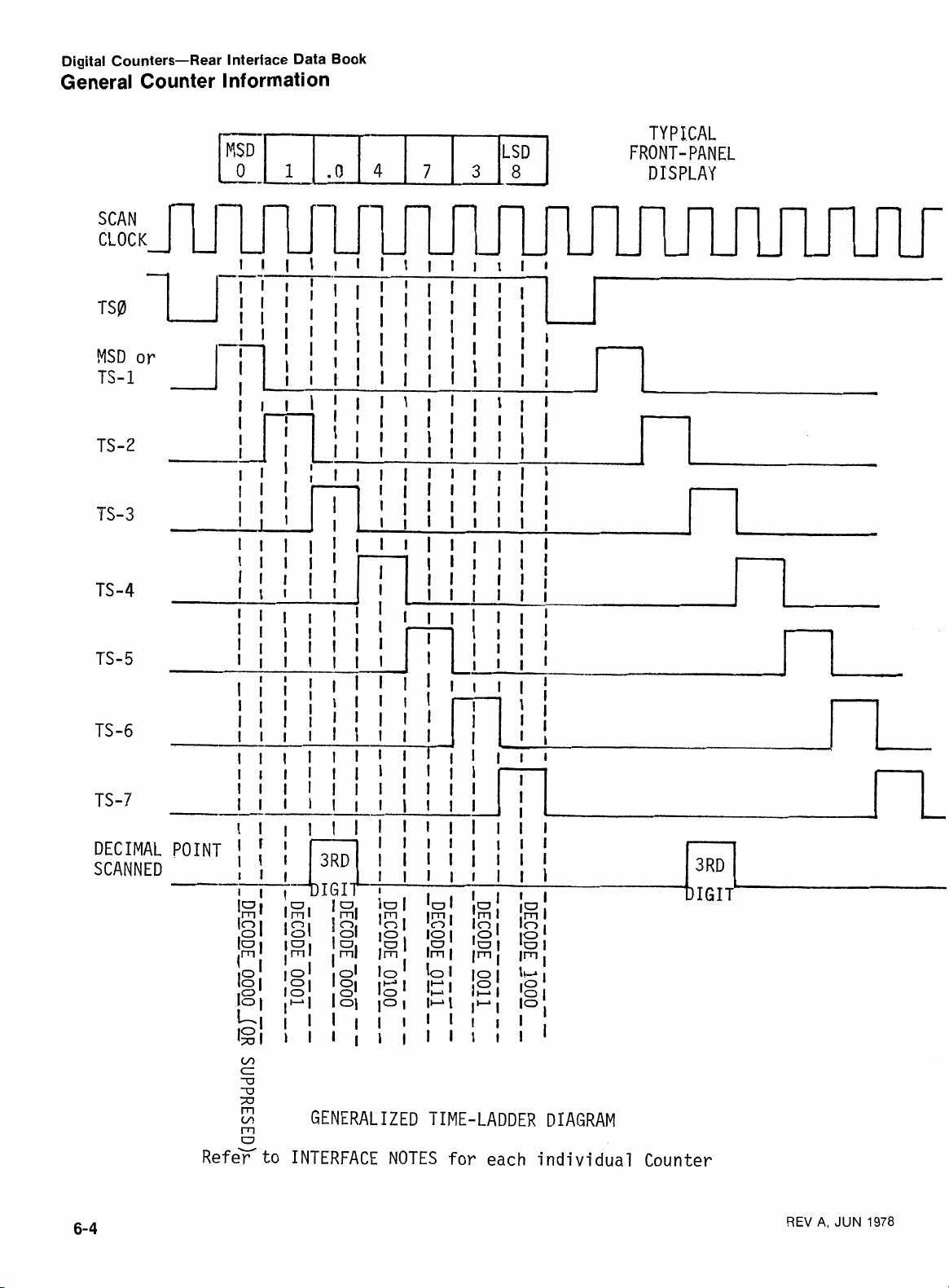

All of the counters use time-slot pulses derived from a Scan Clock

signal to select a particular decimal digit

front-panel LED display.

the basic time relationships between waveforms discussed under the

INTERFACE

forms available at the rear interface. The waveforms are to be used

only as a guide when interpreting the individual data discussed for

each Counter.

Levels

"HI"

and

A

TTL

+2.4

+.

5.0

Di

agram

NOTES

"LO"

LO

output exists from

V to

0.0

V.

Where

for each Counter. No one Counter has all of the wave-

COUKIER

refer to TTL voltage levels present on the

+5.0

V.

V

and

TTL

The following

INFORMATION

0.0

V

to

0.4

V.

A TTL

Rear interface inputs will accept TTL

+0.8

V.

TTL

HI

inputs must be between

currents are given, the quantity is a

that is displayed on a

time-ladder diagram illustrates

HI

-

output

NOTE

fiorough understanding

Q

f

the schematic diagrams

and the exact internaZ connections for input/output

lines to the rear contacts

TM

will

500

interface system.

instruction manuaZsl

your speciaZized

ffound

be an aid in designing

in individual

REV

A.

JUN

1978

Page 44

Digital Counters-Rear Interface Data Book

General Counter Information

TYPICAL

FRONT- PANEL

DISPLAY

DECIMAL POINT

SCANNED

----

I

111

Ill

~efe7 to

m

V,

m

0

j

GENERALIZED TIME-LADDER DIAGRAM

INTERFACE

NOTES

for

each

individual Counter

REV

A,

JUN

1978

Page 45

Digital Counters-Rear Interface Data Book

Plug-In or Power Module Rear View

DC

501

Decimal Point

MHz

light or

(Dl)

Output

External

Internal

Output

Scan

MSD

ASSIGNMENTS

FUNCTION CONTACTS

(D2)

Decimal

Scan

Clock

Qverf

(TS-1)

BCD

BCD

Data

Output

Point

Clock

low Output

Good Output

(2)

(8)

Input

(2

kHz)

Output

Output

Output

288

26B

27B

23B

'"

228-1 p2zA

21~4 k21A

20B- 20A

18B 18A

178

CONTACTS

-1

1-

,

3

-+

"1

-4

1

,

1-

ASSIGNMENTS

28~

27~

26~

25~

19A

17A

Internal Scan Clock Disable Input

Reset

TS@

BCD

BCD

Signal Input Ground

FUNCTION

Input/Output

(Time Slot Zero) Output

(4)

Output

(1)

Output

Decimal

(Optional

When a Power Module cornpartmerat has been selected for the

wired for a specialized interface system,

Part Nder 214-2593-08).skould

contacts

Do not insert any

do not use excessive force when inserting

REV

A,

JUN

Point

29

1978

(03)

Output

-

See

Notes)

and 22 on the Power ModuZe.

TM

550

15~4

Series plug-in in a live Power Module

)C15A

4

Avk

CAUTION

ba

installed in a key slot between

14A

a

the

Clock-In/Clack-out

(Optional

plastic barrier (Te'ektronix

plug-in.

-

DC

See Notes)

502

and

and

Page 46

Digital Counters-Rear Interface Data Book

DC

501

I

FS[ERlACE

BCD

Outputs

Contacts 20B,

interface. The count (front-panel display)

digit method, with the decimal digit sequence being from left to right (MSD

to

LSD

as observed on the front-panel display). The binary levels for each

decimal digit use positive-true logic

is

capable of driving

(8,

4,

2,

1

Code)

20A, 21B and 19A provide

6

TTL

loads (10

NOTES

BCD

data directly to the Power Module

is

(HI

=

1,

mA).

transmitted in a serial-by-decimal

LO

=

0).

Each output data line

Decimal

TTL

on contacts

switch and front-panel decimal point location.

from left to right on the front-panel display,

levels are caused by a switch contact closure to chassis ground, except for

an Option

be above chassis ground by about

Poi nt/Front-Panel Status

logic levels are transmitted directly to contacts 27B and 28B.

27B

and

28B

is

related to the position of the MEASUREMENT

2

instrument where

CONTACT DISPLAY

LIGHT

MHz

MHz

kHz

kHz

GATE

Outputs

AUTO

0.4

ON

Decimal points are numbered

(See Table below.)

gate operation can cause the

volt.

MEASUREMENT

I

DECIMAL POINT

.oooo

.ooooo

.OOO

.oooo

000

(D2)

(Dl

)

(D3)

(~2)

(None)

INTERVAL

MANUAL (Start

LO

The data

INTERVAL

All

LO

levels to

Sec

Sec

Sec

Sec

NOTE

If a direct active-Zow level output is desired for

(.ODD),

03

stranded wire be connected from the switch end of

R284

with your externaz equipment.

to an unassigned rear contact that is compatible

suggested.

it

is suggested that a

#22

or

#26

AE

Rear contact Z5B is

REV

A,

JUN

1978

Page 47

Digital Counters-Rear Interface Data Book

DC

501

Data

A

at each updating of the

MHz clock,

MHz

1.2 microseconds. The Data Good output (19B) goes

internal gate

AUTO gate selection period (option 2). The storage register

HI

This contact

be used as either a Reset Input or Reset Output function. Contact 26A

normally at a

positions of the MEASUREMENT INTERVAL switch),

other count.

Good

positive-true Data Good pulse

clock (option 1) produces a pulse duration that varies between 0.2 and

the positive-going edge of the Data Good pulse. Rear contact 19B also goes

and remains

(totalize) position.

Reset

tions (when changing the MEASUREMENT INTERVAL switch positions). Rear contact

26A does not go

Output

the pulse duration varies between 0.5 and 1.5 microseconds; a

Input/Output

(Contact

time

selected by the MEASUREMENT INTERVAL switch position or

HI

as long as the MEASUREMENT INTERVAL switch

(contact

is

directly wired to the front panel RESET pushbutton and can

HI

level and goes LO when the RESET button

LO

when the

19B)

transmitted directly

is

DC

501 storage register.

This output

will

26A)

DC

501 clears

to

rear

For an instrument with a

HI

immediately after the

is

is

drive at least 6 TTL loads.

is

pushed

or between switch detent posi-

its

own internal circuitry for an-

contact 19B

1

5

updated on

in the MANUAL

is

(for any

it

To use 26A as a counter Reset Input function,

external switch contact closure to ground or driven LO by an open-collector

9

logic gate capable of sinking

Scan

These three functions

wave) Internal Scan Clock signal

a

nal Scan Clock Disable)

to LSD, with the rising edge of each Scan Clock period selecting the decimal

digit to be displayed.

BCD

Internal Scan Clock).

Scan Clock period. Using the Internal Scan Clock signal

millis&conds for a complete display scanning cycle.

This requires that an external

the Scan Clock signal.

Setting rear contact 27A to a TTL low disables the Internal Scan Clock and

allows the application of an External Scan Clock signal to rear contact

The External Scan Clock should be a TTL signal, with a maximum frequency of

1

Clock

continuous output to the rear interface as long as rear contact 27A (Inter-

output lines for one complete Scan Clock period (500 microseconds for

Output,

Input,

and

are

all wired directly to rear contacts.

is

held

The binary levels

All

the

BCD

data

is

(decode)

MHz

and a fall

2

kHz, if desired). Consequently, the time of a complete display scan and

time-slot pulse duration will change accordingly.

time

during the negative half of

of less than 100 nanoseconds (frequency may be less than

TTL current loads

Disable

HI.

of the time-slot pulses have a duration equal to a

BCD

(Contacts

(TTL)

is

applied to rear contact 24B, providing

The decimal digits are scanned from MSD

for a selected digit remain on the

decoder be driven by the falling edges of

can be

(15

24B,

set

to a LO by an

mA).

25B, and 27A)

A

2 kJ3z (square

it

takes about

The ideal

the Scan Clock period.

time

4

to read

25B.

REV

A,

JUN

1978

6-7

Page 48

Digital Counters-Rear Interface Data Book

DC

501

One advantage of the External Scan Clock and Internal Scan Clock Disable inputs

is

to allow the user to design a

data at a faster or slower rate than

frequency External Scan Clock be applied continuously to rear contact 25B,

although

BCD

the time-ladder diagram for an example of using the External Scan Clock and

Internal Scan Clock disable pulse.

it

could be done.

data capture, but could also cause false front;panel displays.

BCD

A

continuous

data capture system that extracts

It

is

2

kHz.

1

MHz

not intended that a high-

External Scan Clock would allow

Refer to

the

Time-Slot

TS@

on rear contact 25A

to a Scan Clock period and occurs

is

a pulse that predicts

and 19A

a

synchronizing pulse for external equipment, used as a latch pulse, or to

clear/reset external digital circuitry.

The MSD (TS-1)

also has a duration equal to a Scan Clock period and occurs once per complete

display scanning cycle. Some users may prefer to use the MSD

pulse for synchronizing external equipment, rather than using the TS@ pulse.

TS@

and TS-1 are the only time-slot pulses directly wired to rear contact.

Overflow Indication (Contact

Rear contact

conditions;

the storage register

the next input count;

by increasing the

overflowing the display).

OVERFLOW light

Zero

will

be

23B

(1) when the

(TSP) and MSD

equivalent to the MSD during TS-1,

output on rear contact 22B

(TS-1).

is

a TTL negative-going pulse that has a duration equal

that the next BCP output data on contact 20B, 20A, 21B

(contacts

once per complete display scanning cycle.

is

a

238)

is

normally at a LO level.

DC

is

full of nines

(2)

MEASUREMENT

is

on.

501

is

operated in the

(9999999

when making high-resolution frequency measurements

INTERVAL

Contact

by a factor of 10 or greater

23B

is

This contact goes

HI

and time that the front-panel

25A

and

22~)

This pulse may be used as

TTL

positive-going pulse that

(left-side digit)

HI

under two

MANUAL

display), contact 23B goes

(Totalize) mode and

(deliberately

HI

It

on

Signal Input (contact

Rear contact 16A

signals to be counted or measured are applied to contact

switch must be in the INT position.

load (~101) and miniature

to this contact on the Option 2 Power Module interface. Connect the coaxialcable shield to rear contact

cations apply when signals are applied to contact 16A.

end of

RlOl

converts the input resistance to

is

16A

and

17A)

directly wired to the front-panel

1

is

MQ.

50

Contact 16A

ohm

RF

cable should be used to connect signals

17A

for a Signal Input Ground. Input specifi-

EXT

-

INT switch.

16A,

terminated into a

Lifting the ground

the

front-panel

REV

50

A,

When

ohm

JUN

1978

Page 49

Page 50

NOTES

REV

A,

JUN

1978

Page 51

Digital Counters-Rear Interface Data Book

Plug-In or Power Module Rear View

DC

502

ASSIGNMENTS

FUNCTION CONTACTS

Decimal Point

MHz

light

(Dl)

Output

External Scan Clock Input

Internal Scan Clock (2

Output

or

Data Good Output

(D2)

Output

Dechal Point

Overflow Output

BCD

(2)

Output

BCD

(8)

Butput

kHz)

288

-,

I

26B

25B

4

238-

24B

I

21

4

208

+

9B-

ASSIGNMENTS

CONTACTS FUNCTION

-

27~

,

26A

+

25A

-

17A

-

16A

Internal Scan Clock Disable Input

Reset Input/Output

TSQ (~irne Slot Zero) Output

Signal Input Ground

Signal Input See Notes

Decimal Point (~3) Output

(Optional

When a Pomr ModuZs compartment has been seZected for the

wired for a spscialized interface system, a pZastio barrier (Tektronix

Part Number

contacts

Do

not

do not use sxcessive force when inserting the plug-in.

-

214-2593-02)

22

and

insert

See Notes)

22

on

any

TM

550

the

,

5B

,

14B

CAUTION

should

Powsr

Series plug-in in a live Power Module

be

instaZZed in a key slot between

ModuZe,

-

14A

Clock-In/Clock-out

(Optional

-

See Notes)

DC

502

and

md

REV

A,

JUN

1978

Page 52

Digital Counters-Rear Interface Data Book

DC

502

INTERFACE

BCD

Outputs

Contacts

Module interface. The count (front-panel display)

serial-by-decimal digit method, with the decimal digit sequence being

from left to right

The binary levels for each decimal digit

(HI

=

1,

(10

mA).

Decimal

TTL logic levels are transmitted directly to rear contacts

data

INTERVAL switch and front-panel decimal point location,

Decimal points are numbered from left to right in the display.

tables are applicable to standard

LO

on

levels are caused

(8,

4,

2,

1

Code)

20B,

LO

Poi

these contacts

20A, 21B and 19A provide

(MSD to LSD as observed on the front-panel display).

=

0).

Each output data line

nt/Front-Panel Status Outputs

is

related to the position of the

by

a switch-contact closure to chassis ground.

NOTES

DC

502

BCD

data directly to the Power

is

transmitted in a

are

expressed in positive logic

is

capable of driving 6 TTL loads

27B

and

MEASUREMENT

(See Table below.)

or an Option 1 instrument.

28B.

The following

The

All

DIRECT INPUT

I

CONTACT

I

PRESCALE INPUT

DISP

LIGHT ON

MHz

MHz

kHz

kHz

Gate

MHz

MHz

MHz

kHz

Gate

AY

DECIMAL POINT

.OOOO (D2)

.OOOOO (Dl)

.OOO (D3)

.OOOO

000

.OOO (03)

.OOOO (DZ)

,

.OOOOO (Dl)

i

I

.OOO

i

000

(D2)

(None) MAN (Start)

(D3)

(None)

I

1

1

I

!

MEASUREMENT

INTERVAL

.O1 Sec

Sec

.I

1

Sec

10

Sec

.O1 Sec

.I

Sec

1

Sec

10

Sec

MAN (Start)

REV

A,

JUN

1978

Page 53

Digital Counters-Rear Interface Data Book

NOTE

If

a direct active-low level output is desired

03

(.

for

0001,

wire from the switch end of

connect

a

#22

or

R248

#26

AWG

stranded

to an unassigned rear contact that is compatibZe with your

external equipment.

Rear contact

15B

is suggested.

DC

502

Data

A

at each updating of the

1

5

1.2 microseconds. The Data Good output goes

gate time selected by the MEASUREMENT INTERVAL switch position.

register

Rear contact 19B also goes

INTERVAL switch

will

Reset

This contact

be used as either a counter Reset Input or Rest Output function.

26A

detent positions.

circuitry for another count.

To

by

collector logic gate capable of sinking

Good

Output

positive-true Data Good pulse

MHz

clock,

MHz

clock (Option 1) produces a pulse duration that varies between 0.2 and

is

updated on the positive-going edge of the Data eood pulse.

drive at least 6 TTL loads.

Input/Output

is

normally at a HI

(for any position of the MEASUREMENT

use 26A as a counter Reset Input function,

an external switch contact closure to ground or driven LO

(contact

the pulse duration varies between 0.5 and 1.5 microseconds;

is

in either of the

(Contact

is

directly wired to the front-panel RESET pushbutton and can

26A does not go LO when the

198)

is

transmitted directly to rear contact

DC

502 storage register.

HI

immediately after the internal

HI

and remains

MAN

HI

as long as the MEASUREMENT

(~otalize) positions.

%A),

level and goes LO when the

INTERVAL

9

switch),

DC

it

TTL current loads (15

For an instrument with a

RESET

502

can be set to a

button

or between switch

clears

its

by

19B

The storage

This output

Contact

is

pushed

own internal

LO

level

an open-

mA).

a

Scan

These thsree functions are all wired directly to rear contacts.

wave) Internal Scan Clock signal (TTL)

a continuous output to the rear interface as long as rear contact 27A

MSD to LSD,

decimal digit to be displayed.

remain on the

microseconds for Internal Scan Clock).

a duration equal to a Scan Clock period.

signal,

The ideal time to read

a Scan Clock period. This requires that an external

by the falling edge of the Scan Clock signal.

REV

A,

Clock

(~nternal Scan Clock Disable)

JUN

1978

Output,

with the rising edge of each Scan Clock period selecting the

BCD

it

takes about 4 milliseconds for a complete display scanning cycle.

Input,

output lines for one complete Scan Clock period (500

and

(decode) the

Disable

is

held

The binary levels for a selected digit

(Contacts

is

applied to rear contact 24B, providing

HI.

BCD

The decimal digits are scanned from

All

Using the Internal Scan Clock

data

24B,

of the time-slot pulses have

is

during the negative half of

258,

and

BCD

decoder be gated

27A)

A

2

kHz

(square

6-1

3

Page 54

Digital Counters-Rear Interface Data Book

DC

502

Setting rear contact

allows the application of an External Scan Clock signal to rear contact 25B.

The External Scan Clock should be a TTL signal with a maximum frequency of

MHz

and a fall

2

Hz,

time-slot pulse duration will change accordingly.

One advantage of the External Scan Clock and Internal Scan Clock Disable inputs

is

at a faster or slower rate than

External Scan Clock signal be applied continuously to rear contact 25B,

it

capture, but can also cause false front-panel displays,

Time

Time Slot Zero

has a duration equal to a Scan Clock period and occurs once per complete display cycle.

contacts 20B, 20A, 21B, and 19A will be equivalent to the most: significant

digit during TS-1. This pulse can be used as a synchronizing pulse for external

equipment,

digital circuitry.

if

to allow the user to design a

can be done.

Slot

time

desired).

Zero

and

(TsQ) on rear contact 25A

TS@

used

27A

to a

of

less

Consequently, the

A

continuous

MSD

(Contacts

is a pulse that predicts that the next

as a larch

TK

LO

disables the Internal Scan Clock and

than 100 nanoseconds (frequency may be less than

2

1

MHz

pulse,

time

BCD

data capture system that extracts the data

kHz.

External Scan Clock signal allows

25A

and

or

a

a

of a complete display scan and

It

is

not intended that a high-frequency

22B)

is

a TTL negative-going pulse that

clearlreset pulse for external

BCD

data

BCD

to

appear on

1

although

data

The

MSD

(TS-1) output on rear contact 22B

has

also

display scanning cycle.

digit) pulse for synchronizing external equipment, rather than using the TSO)

pulse.

rear contacts.

Overflow

Rear contact 23B

conditions:

storage registers

on the next input count;

by

increasing

23B

Signal

a duration equal to a Scan Clock period and occurs once per complete

Some users

Ts~ and MSD (TS-1) are the only time-slot pulses directly wired to the

Indication (Contact

is

HI

Input

(1)

the

any

time

(Contacts

It

problems

attention

continuities along a high- frequency signal path.

is

normally

when the

are

full of nines

MEASWME,NT

that the front-panel

16A

is

important to consider

238)

at

DC

502

(2)

when making high-resolution frequency measurements

INTERVAL

and

at

high

$0

lead dress,

may

a LO level.

is

operated in a

(9999999

17A)

NOTE

frequencies.

is

a TTL positive-going pulse that

prefer to use the

This contact goes

MAN

display), contact

by

a

factor of 10 or greater.

OVERFLOW

VSWR

terminations,

light

and cross-talk

Pay particuZar

MSD

(left-side

HI

under two

(Totalize) mode and the

23B

goes

HI

Contact

is

on

and

dis-

Rear

contacts

16A

and

17A

are

not

directly

wired

to

the input and ground

REV

A,

JUN

1978

Page 55

Page 56

Digital Counters-Rear Interface Data

Book

NOTES

REV

A,

JUN

1978

Page 57

Digital Counters-Rear Interface Data Book

DC

502

Option

7

Plug-In

ASSIGNMENTS

FUNCTION

Decimal Point (~2) Output

MHz light or Decimal Point

(Dl) Output

External Scan Clock Input

Internal Scan Clock (2 kHz)

Output

Overflow Output

(TS-1) Output

MSD

BCD

(2) Output

BCD

(8)

Output

or

Power

CONTACTS

Module

ASSIGNMENTS

CONTACTS

Internal Scan Clock Disable Input

Reset lnput/Output

TS@

BCD

Rear

(Time Slot Zero) Output

(4)

View

FUNCTION

Output

Opt

BCD

Data Good Output

7

Opt

Opt

7

7

Track. Gen. Identify

Start Count

Counter Identify

Opt

7

Phase Lock

7

Opt

Non-Sweep

CAUTION

When a Power Module compartment has been selected for the

(1) Output

Opt

7

GATE

Signal Input Ground

Signal Input

clock-In/Clock-Out

-

(Optional

See Notes)

DC

1

502 and