Page 1

TLA7S08 & TLA7S16

Serial Analyzer Modules

Technical Reference

This document applies to TLA System Software Version 5.1

or higher

Warning

These servicing instructions are for use by qualified personnel

only. To avoid personal injury, do not perform any servicing

unless you are qualified to do so. Refer to all safety summaries

prior to performing service.

www.tektronix.com

071-2188-00

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

PCI Express is a registered trademark of PCI-SIG®.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O . B o x 5 00

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

World wi de, vis i t www.tektronix.com to find contacts in your area.

Page 3

Warranty 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be ne

the property of Tektronix.

w or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulti

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTR

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ng from attempts by personnel other than Tektronix representatives to install, repair or service the product;

ONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

Page 4

Page 5

Table of Contents

General Safety Summary ......................................................................................... iv

Service Safety Summary........................................ ................................ .................. vi

Preface ............................................................................................................. vii

Manual Conven

Related Documentation ..................................................................................... vii

Introduction ........................................................................................................ ix

Service Strategy..................................... .................................. ........................ ix

Service Offerings ............................................................................................. ix

Maintenance......................................................................................................... 1

Preventing E

Inspection and Cleaning.......................... ................................ ............................. 1

Removal and Installation ................... ................................ .................................. ..... 5

Tools Required ................................................................................................. 5

Torque Requirements.......................................................................................... 5

Covers.............. .................................. ................................ ........................... 6

Local Proces

Acquisition Board ... ... . ... . ... .... ... . ... . ... ... . ... . ... .... ... . ... . ... ... . ... . ... .... ... . ... . ... ... . ... . ... . 9

EMI Gaskets................................................................................................... 10

Troubleshooting.................................................................................................... 13

Check for Common Problems ........................... ................................ .................... 14

Eliminate Other Problem Sources........................................................................... 15

Troublesho

Updating the Module Firmware..... ................................ ................................ ........ 20

Repackaging Instructions ......................................................................................... 21

Parts List............................................................................................................ 22

Parts Ordering Information .................................................................................. 22

Using the Replaceable Parts List............................................................................ 23

tions............................................ ................................ ............. vii

SD ................................................................................................ 1

sor Unit (LPU) Board .......................................................................... 8

ot the Module .................................................................................... 15

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual i

Page 6

Table of Contents

List of Figure

Figure 1: Installing the cover onto the chassis .. . ... ... . ... .... ... . ... ... . ... . ... .... ... . ... ... . ... . ... .... ... . . 6

Figure 2: Sea

Figure 3: Rear EMI gasket removal ............................................................................. 10

Figure 4: Side EMI gasket installation.......................................................................... 11

Figure 5: TLA7S08 &TLA7S16 chassis and cover ........... ................................ ................ 24

Figure 6: TLA7S08 &TLA7S16 circuit board assemblies.................................................... 26

Figure 7: TLA7S08 &TLA7S16 internal cables and connectors......................................... .... 28

ting the cover on the chassis...... ................................ ................................ . 7

s

ii TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 7

List of Tables

Table i: Related Documentation ............. ................................ ................................ ... viii

Table 1: Exte

Table 2: Internal inspection check list..... ................................ .................................. ..... 3

Table 3: Tools required for circuit board replacement.......................................................... 5

Table 4: Failure symptoms and possible causes.................................... ............................ 14

Table 5: Diagnostic tests.......................................................................................... 19

Table 6: Parts list column descriptions.......................................... ................................ 23

rnal inspection check list........................................................................... 2

Table of Contents

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual iii

Page 8

General Safety Summary

General Safet

To Avoid Fire or Personal

Injury

ySummary

Review the fol

this product or any products connected to it.

To avoid pote

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions re

Ground the Product. This product is indirectly grounded through the grounding

conductor of the mainframe power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground. Before making connections to

the input or output terminals of the product, ensure that the product is properly

grounde

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and mark

information before making connections to the product.

The inp

uts are not rated for connection to mains or Category II, III, or IV circuits.

lowing safety precautions to avoid injury and prevent damage to

ntial hazards, use this product only as specified.

lated to operating the system.

d.

ings on the product. Consult the product manual for further ratings

TermsinthisManual

Do not apply a potential to any terminal, including the common terminal, that

exceed

Power Disconnect. The power cord disconnects the product from the power source.

Do not

Do Not Operate Without Covers. Do not operate this product with covers or panels

remov

Do Not Operate With Suspected Failures. If you suspect that there is damage to this

prod

Avoid Exposed Circuitry. Do not touch exposed connections and components

when

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

det

These terms may appear in this manual:

s the maximum rating of that terminal.

block the power cord; it must remain accessible to the user at all times.

ed.

uct, have it inspected by qualified service personnel.

power is present.

ails on installing the product so it has proper ventilation.

iv TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 9

General Safety Summary

WAR N ING. Warning statements identify conditions or practices that could result

in injury or lo

CAUTION. Caution statements identify conditions or practices that could result in

damage to th

ss of life.

is product or other property.

Symbols and Terms on the

Product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the marking.

WARNING indicates an injury hazard not immediately accessible as you

read the marking.

CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual v

Page 10

Service Safety Summary

Service Safet

y Summary

Only qualified

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in t

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

his product. Disconnect power, remove battery (if applicable), and

personnel should perform service procedures. Read this Service

vi TLA7S08 & T LA7S16 Serial Analyzer Technical Reference Manual

Page 11

Preface

Manual Conventions

Preface

This manual uses certain conventions that you should be familiar with before

attempting service.

Acquisition Board

LPU Board

Maintenance Procedures

Modules

Replaceable Parts

The acquisition board is one of the circuit boards inside the instrument module.

The circuit board receives and stores acquisition data from the probes and works

with the Local Processor Unit (LPU) board to provide information to the operator

of the instrument.

The Local Processor Unit (

instrumentmodule that provides the main communications interface with the

acquisition board and the mainframe.

Maintenance procedures are used for fault isolation and repair to the circuit board

level or to the replaceable part level.

Throughout this manual, the terms “module” or “instrument module” refers to

a logic analyzer, serial analyzer, or pattern generator unit that mounts inside a

mainframe. A module is composed of circuit boards, interconnecting cables, and

a user-accessible front panel.

This manual refers to any field-re

specifically by its name or generically as a repla ceable part. In general, a

replaceable part is any circuit board or assembly that is listed in the replaceable

parts list near the end of this manual.

LPU) board is one of the circuit boards inside the

placeable assembly or mechanical part

Safety

Symbols and terms related to safety appear in the S afety Summary found at the

beginning of this manual.

Related Documentation

The following table lists related documentation available for your instrument. The

documentation is available on the TLA Documentation CD, included with your

instrument, and on the Tektronix Web si

To obtain documentation not specified in the table, contact your local Tektronix

representative.

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual vii

te (www.Tektronix.com).

Page 12

Preface

Table i: Relate

Item Purpose Location

TLA Quick Star

Online Help

Installation

Installation Manuals

XYZs of Logic Analyzers

TLA Product Specifications Complete list of TLA product

TPI.NET Documentation

Field upgrade kits

d Documentation

t User Manual

Quick Reference Cards

Basic operational overview

In depth operation and UI help

Basic install

Detailed first-time installation information

Introductio

specifications

Detailed inf

logic analyzer using .NET

Upgrade information for your logic

analyzer product

ation information

n to logic analyzer basics

ormation for controlling the

Optional Service Manuals Self-service documentation for modules

and mainframes

TLA Application Software Release Notes Software description, compatibility,

impact of changes, contact information,

installation, upgrade, and operational

notes, and known issues.

Go to Start→All Programs→Tektronix

logic Analyzer→TLA Release Notes

viii TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 13

Introduction

Service Strategy

This manual contains information needed to service the TLA7S08 and

TLA7S16 serial analyzer modules.

To prevent personal injury or damage to the instrument, consider the following

requirements before attempting service:

Read the General Safety Summary and Service Safety Summary found at

the beginning of this manual.

The procedures in this m anual should only be performed by a qualified service

person.

Be sure to follow all warnings, cautions and notes.

This manual supports and contains information needed for periodic maintenance

of the instrument. It supports and contains

corrective maintenance:

Supports removal and replacement of boards or assemblies.

the following information for

Service Offerings

Warranty Repair Service

Calibration and Repair

Service

Supports removal and replacement of the mechanical parts listed in the parts

lists.

This manual does not support component-level fault isolation and replacement.

Tektronix provides service to cover repair under warranty as well as other services

that are designed to meet your specific service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians are equipped to service the instrument.

Services are provided at Tektronix Services Centers and on-site at your facility,

depending on your location.

Tektronix warrants this product for one year from date of purchase. The warranty

is located behind the title page in this manual. Tektronix technicians provide

warranty service at most Tektronix service locations worldwide. The Tektronix

product catalog lists all service locations worldwide.

In addition to warranty repair, Tektronix Service offers calibration and other

services which provide solutions to your service needs and quality standards

compliance requirements.

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual ix

Page 14

Introduction

The following s

and/or repair of your portable mainframe.

Service Options. Tektronix Service Options can be selected at the time you

purchase your instrument. You select these options to provide the services that

best meet your service needs.

Service Agreement. If ser vice options are not added to the instrument purchase,

then service agreements are available on an annual basis to provide calibration

services or post-warranty repair coverage. Service agreements may be customized

to meet special turn-around time and/or on-site requirements.

Service on

“per-incident” basis that is available with standard prices.

Self Service. Tektronix supports repair to the replaceable-part level by providing

for circuit board exchange.

Use this service to reduce down-time for repair by exchanging circuit boards for

remanufactured ones. Tektronix ships updated and tested exchange boards. Each

board comes with a 90-day service warranty.

For More Information. Contact your local Tektronix service center or sales

engineer for more information on any of the Calibration and Repair Services

just described.

ervices can be tailored to fit your requirements for calibration

Demand. Tektronix offers calibration and repair services on a

x TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 15

Maintenance

Preventing ESD

WAR N ING. To avoid electric shock, always power off the instrument and

disconnect the power cord before cleaning or servicing the instrument.

When perform

adhere to the following precautions to avoid damaging internal circuit boards and

their components due to electrostatic discharge (ESD).

CAUTION. Many components within the instrument are susceptible to static

discharge damage.

Service the instrument only in a static-free environment. Observe standard

handling p

Minimize handling of static-sensitive circuit boards.

Transport and store static-sensitive circuit boards in their static protected

containers or on a metal rail. Label any package that contains static-sensitive

boards.

Discharge the static voltage from your body by wearing a grounded antistatic

wrist st

Nothing capable of generating or holding a static charge should be allowed

on the w

Handle circuit boards by the edges when possible.

ing any service which requires internal access to the instrument,

recautions for static-sensitive devices.

rap while handling these circuit boards.

ork station surface.

Do not slide the circuit boards over any surface.

Avoid handling circuit boards in areas that have a floororwork-surface

covering capable of generating a static charge.

Inspe

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual 1

ction and Cleaning

The instrument is inspected mechanically and electrically before shipment. It

should be free of marks or scratches and should meet or e xceed all electrical

spec

transit. Retain the packaging in case shipment for repair is necessary. If there

is damage or deficiency, contact your local Tektronix representative. Cleaning

procedures consist of exterior and interior cleaning. Periodic cleaning reduces

instrument breakdown and increases reliability. Clean the instrument as needed,

based on your operating environment.

ifications. To confirm this, inspect for physical damage incurred during

Page 16

Maintenance

Exterior Inspection

Modules that ap

pear to have been dropped or otherwise abused should be checked

thoroughly to verify correct operation and performance. Immediately repair

defects that could cause personal injury or lead to further damage to the benchtop

controller, expansion module, or the mainframes that the module plug into.

Table 1: External inspection check list

Item Inspect for Repair actio

Front panel

Front and rear connectors Broken shells, cracked

Accessories

Cracks, scr

deformations, missing or

damaged retainer screws,

or ejector h

insulation

contacts

Dirt in connectors

Missing items or parts of

items, ben

frayed cables, and damaged

connectors

atches,

andles

, and deformed

t pins, broken or

Replace def

missing parts.

Replace de

Clear dirt out of connectors.

Replace damaged or

missing parts, frayed

cables.

n

ective or

fective parts.

CAUTION. To prevent damage to electrical components from moisture during

external cleaning, use only enough liquid to dampen the cloth or applicator.

Exterior Cleaning

Procedure

Interior Inspection

Clean the exterior surfaces with a soft dry lint-free cloth, or a soft-bristle brush.

If any dirt remains, use a soft cloth or swab dipped in a 75% isopropyl alcohol

solution. Use a swab to clean narrow spaces around controls and connectors. Do

not use abrasive cleaning compounds.

CAUTION. Avoid g etting moisture inside the instrument during exterior cleaning;

ust enough moisture to dampen the cloth or swab.

use j

Use only deionized water when cleaning. Use a 75% isopropyl alcohol solution

as a cleanser and rinse with deionized or distilled water.

Do not use chemical cleaning agents; they may damage the chassis. Avoid

chemicals that contain benzene, toluene, xylene, acetone, or similar solvents.

Remove the module covers to access the inside of the instrument for inspection

and cleaning. (See page 6, Covers.) Inspect the internal portions of the modules

and the mainframes for damage and wear. Defects found should be repaired

immediately.

2 TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 17

Maintenance

Interior

Cleaning

Procedure

Table 2: I ntern

Item Inspect for Repair action

Circuit boards

Solder connections Cold so lder or rosin joints

Wiring and ca

Chassis Dents, deformations, and

al inspection check list

Loose, broken

solder connections.

Burned circuit boards.

Burned, brok

circuit-run plating

bles

Loose plugs o

Burned, broken, or frayed

wiring

damaged har

, or corroded

en, or cracked

r connectors.

dware

Return to a Tek

Service Center.

Return to a Te

Service Center.

Firmly seat c

Repair or replace parts with

defective wires or cables.

Straighten, repair, or replace

defective h

tronix

ktronix

onnectors.

ardware.

CAUTION. To prevent damage from electrical arcing, ensure that circuit boards

and components are dry before applying power.

Use a dry, low-velocity stream of air to clean the interior of the modules and the

mainframes. Use a soft-bristle brush for cleaning around components. If you must

use a liquid for minor interior cleaning, use a 75% isopropyl alcohol solution and

rinse w

ith deionized or distilled water.

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual 3

Page 18

Maintenance

4 TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 19

Removal and Installation

This section provides detailed instructions for removing or installing parts of the

module. The procedures in this sectio n assume that you already have removed

the module from the mainframe. Removal and installation instructions are not

provided for all replaceable parts. (See page 22, Parts List.)

Tools Required

WAR N ING. Be

Summary and Service Safety Summary found at the beginning of this manual.

When performing any service which requires internal access to the instrument,

avoid damaging internal circuit boards and their components by electrostatic

discharge (ESD). (See page 1, Preventing ESD.)

The follow

of the instrument.

Table 3: Tools required for circuit board replacement

Description Example

Screwdriver with a T-9 and a T-10 Torx tip Standard tool

1/4-inch nut driver Standard tool

9/16-inch nut driver Standard tool

Needle-n

fore doing any procedures in this manual, read the General Safety

ing table lists the tools needed to replace the internal components

ose pliers

Standard tool

Torque

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual 5

Requirements

Tighten all T-9 and T-10 screws to 4 in-lbs. Tighten standoff posts to 8 in-lbs.

Page 20

Removal and Installation

Covers

Removal

Installation

Refer to the exploded view of the module to remove the covers. (See Figure 6.)

Use the following procedure to install the covers:

NOTE. Install the cover tightly against the chassis. This will ensure that the

module fits into adjacent slots in the mainframe.

1. Place the module on its right side.

CAUTION. To prevent damage to the module during the installation process,

reinstall the cover exactly as described in steps 2 through 9.

If the cov

it in a mainframe.

2. Insert t

er is not properly seated, the module can be damaged when you install

he cover at an angle such that the front edge of the cover engages

with the EMI gaskets on the back of the front panel. Then push the rear of

the cover in place.

Figure 1: Installing the cover onto the chassis

3. Make sure that the cover is fully seated (no gaps) against the front and rear

ssis flanges.

cha

6 TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 21

Removal and Installation

Figure 2: Seating the cover on the chassis

4. While holding the cover in place, install the four T-10 Torx-drive screws

nearest the front of the module (two on each side of the cover), to secure the

cover t

5. Slide the rear panel on the chassis and install the two rear panel T-10

Torx-d

6. Gently squeeze the chassis flange and rear pan els flange together while

tight

rotate, otherwise the module may not seat properly when installed in the

mainframe.

7. Install the two remaining T-10 Torx-drive screws nearest the rear of the

module (one on each side of the cover).

8. Place the cover onto the chassis.

9. Chec

o the chassis.

rive screws.

ening the screws on the sides. This ensures that the rear panel does not

k and tighten all screws.

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual 7

Page 22

Removal and Installation

Local Process

Installation

or Unit (LPU) Board

NOTE. When placing an order for a replacement LPU board or an LPU exchange

board from the Tektronix Exchange Center, you must supply the model number,

serial number, and firmware level.

Removal

Refer to the exploded view of the module to remove the LPU board. (See

Figure 6.)

CAUTION. Handle the LPU board gently to avoid breaking the front panel LED

extension.

Use the following procedure to install the LPU board:

1. Place the LPU board (component side down) over the chassis and insert the

tabs on the LPU board into the front subpanel.

2. Line up the pins on the 160-pin connector from the LPU board to the

acquisition board and gently press the LPU board in place.

3. Install the five T-10 Torx screws to secure the LPU board to the chassis.

4. Install the co

ver. (See page 6, Covers.)

8 TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 23

Acquisition Board

Removal and Installation

Removal

Installation

Use the following procedure to remove the acquisition board:

1. Remove the cover. (See page 6, Covers.)

2. Remove the Lo

(LPU) Board.)

3. Turn the chas

from the acquisition board.

4. Remove the t

5. Carefully separate the probe interface board from the acquisition board by

gently pul

6. Slide the probe interface board away from the front panel and out of the

chassis.

7. Disconnect the four coaxial cables on the acquisition board.

8. Remove the three T-10 screws located near the front of the acquisition board.

9. Carefully slide the acquisition board away from the front panel until the probe

connectors clear the front panel. Then lift the circuit board out of the chassis.

Use the following procedure to install the acquisition board:

cal Processor Unit Board. (See page 8, Local Processor Unit

sis over and use a 1/4 nut driver to remove the five spacer posts

wo screws securing the probe interface board.

ling up on the mating connector.

1. Place the acquisition board into the chassis.

2. Careful

fit snuggly into the front panel slots.

3. Instal

4. Slide the probe interface board into the front panel and out of the chassis.

5. Carefully join the probe interface board to the acquisition board by gently

pressing down on the mating connector.

6. Install the two screws securing the probe interface board.

7. Install the five spacer posts that secure the acquisition board to the chassis.

8. Connect the four analog output cables from the front panel to the acquisition

board.

9. Install the LPU board. (See page 8, Local Processor Unit (LPU) Board.)

10. Install the cover. (See page 6, Covers.)

ly slide the acquisition board into the chassis until the probe connectors

l the three T-10 screws located near the front of the acquisition board.

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual 9

Page 24

Removal and Installation

EMI Gaskets

Removal

Use the following procedure to remove the EMI gaskets:

For the two rear gaskets on the cover:

1. Remove the cover.

2. Lift the gasket fingers and rotate the gasket off.

For the two re

1. Remove the LPU board and the acquisition board.

2. Lift the gasket fingers and rotate the gasket off.

ar gaskets on the chassis:

Figure 3: Rear EMI gasket removal

10 TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 25

Removal and Installation

Installation

Use the followi

1. Position each gasket so the gasket fingers face the outside of the module.

CAUTION. To a v

2. Pick up each gasket at the end where the gasket finger is formed up. Then

rotate the gasket on. As you do this, lift up any fingers that bind to the chassis

or cover.

3. Slide each gasket gently from side to side to ensure that the gasket snaps

in place.

ng pro cedure to install the EMI gaskets:

oidbreakingthegasketfingers, do not lift the fingers too high.

Figure 4: Side EMI gasket installation

4. Reinstall the acquisition board and the LPU board if you removed them to

install the rear EMI gaskets.

5. Install the cover. (See page 6, Covers.)

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual 11

Page 26

Removal and Installation

12 TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 27

Troubleshooting

This section provides troubleshooting information at the circuit board level. There

are no parts on the circuit boards (other th an the ones listed in the parts list) that

are replaceable.

In most cases, faults are isolated to circuit boards or assemblies, but not to

individual components on those boards. (See page ix, Service Strategy.) Fault

isolation i s to the following circuit boards and replaceable parts:

LPU board

Acquisition board

WAR N ING. Before performing any procedures in this manual, read the General

Safety Summary and Service Safety Summary found at the beginning of this

manual.

When performing any service which requires internal access to the instrument,

avoid dam

discharge (ESD). (See page 1, Preventing ESD.)

aging internal circuit boards and their components by electrostatic

This sec

within the module. The processisasfollows:

1. Check fo

2. Eliminate the mainframe, probes, and other modules as the source of the

3. Identify the failed replaceable part within the module. (See page 15,

tion contains information and procedures designed to h elp isolate faults to

r common problems. (See page 14, Check for Common Problems.).

s). (Seepage15,Eliminate Other Problem Sources.)

fault(

eshoot the Module.)

Troubl

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual 13

Page 28

Troubleshooting

Check for Comm

on Problems

The following table lists common prob lems related to the instrument module

and possible causes. The list is not exhaustive, but it may help you eliminate

aproblemtha

CAUTION. To avoid damaging the instrument module or the mainframe, be sure to

power down the mainframe before removing or reinstalling any modules.

Table 4: Failure symptoms and possible causes

Symptom Possible cause(s)

Modules not recognized

Module does not pass the normal power on

diagnostics (READY indicator not green)

Module loses settings when power is turned

off

Module w ill not acquire data or the acquired

data is incorrect

tiseasytofix.

Modules not fully inserted; make sure front

of module is flush with front panel

Mainframe power supply failure; contact

local Tektronix service center

Corrupted module firmware; reinstall

firmware. (See page 20, Updating the

Module Firmware.)

Module logical address switches set to 00.

Reset the switches to FF.

Module not fully inserted; make sure front of

module is flush with front panel

Module failure. (See page 15, Troubleshoot

the Module.) If necessary, contact local

Tektronix service center

Module failure. (See page 15, Troubleshoot

the Module.) If necessary, contact local

Tektronix service center

NV RAM failure. Replace the LPU board.

(See page 8, Local Processor Unit (LPU)

Board.)

Module failure. (See page 15, Troubleshoot

the Module.) If necessary, contact local

Tektronix service center

Faulty probe, leadset, or probe adaptor

14 TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 29

Troubleshooting

Eliminate Oth

er Problem Sources

Substitute Good Module

The module is part of the Tektronix Logic Analyzer Family, which consists

of one or more instrument modules installed in either a benchtop or portable

mainframe. T

other modules as possible sources of failures.

If you have available a known-good module, perform the following procedure:

1. Remove the suspect module from the mainframe.

2. Install a known-good module in the same slot as the suspected module (verify

that address s witches on the rear of the module are set to same address as

the module that you are replacing).

3. Power-on the instrument and check for normal operation.

4. If the failure symptoms are still present with the known-good module

installed, the problem most likely is in the mainframe or in the attached

probes, not in the module.

5. To eliminate the probes, use known-good probes and verify that the probes

are properly c onnected to the SUT.

he following procedures will help you eliminate the mainframe and

NOTE. Vi

isolate failures to individual modules or to the mainframe.

6. If the i

Troubleshoot the Module

Follow the procedure in this section to identify the failed part within the

module. This procedure requires that the module is installed in a fully functional

mainframe. If you have not determined that the mainframe is functional, or if

you suspect the problem might be in a probe or in another module, you need to

eli

Equipment Required

The basic troubleshooting procedures require minimal test equipment. There are

no accessible test points to measure voltages.

ewing the diagnostic window from the TLA application may help you

nstrument operates normally with the known-good module and

with known-good probes, the suspect module needs to be repaired. (See

Troubleshoot the Module.)

minate those possibilities. (See page 15, Eliminate Other Problem Sources.)

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual 15

Page 30

Troubleshooting

Preparation

Diagnostic Procedures

The fault isola

Recognize codes flashed by the front-panel LEDs during power up

Are familiar with the power-on diagnostics

To fill these requirements, read the following topics before performing the Fault

Isolation Procedure. (See page 17, Fault Isolation Procedure.)

The following diagnostic procedures will help you diagnose problems.

Power-On Diagnostics. Power-on diagnostics check basic functionality of the

instrument at every power on. If any failures occur at power on, the screen

displays t

If there are no diagnostic failures when you power on the instrument, you

can displa

Calibration and Diagnostics from the System menu.

Extended Diagnostics. The extended diagnostics execute more thorough tests

than the power-on diagnostics. Using the extended diagnostics, you can do the

following tasks:

Run tests individually or as a group

tion procedure requires that you:

he calibration and diagnostics property sheet.

y and run the calibration and diagnostics property sheet by selecting

Run tests once or continuously

Run tests until failures occur

Certain diagnostic tests will fail if probes are attached. For best results, run the

diagnostics with probes disconnected from the module.

To run the extended diagnostics, do the following steps:

1. Discon

2. Start the TLA application if it is not already running.

3. From the System menu, select Calibration and Diagnostics.

4. Select the Extended Diagnostics property page.

5. Select the individual tests, group of tests, or all tests.

6. Click the Run button.

While

When the tests are complete, either a Pass or Fail indication displays adjacent

to each test.

nect the probes from the instrument.

the tests are executing, the word Running displays adjacent to the tests.

16 TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 31

Troubleshooting

Fault Isolation Procedure

The Primary Tro

module. Use the following procedure with the tree: To determine if module is

recognized, perform the following steps:

1. Install the module into a k nown-good mainframe.

2. Before you po

ARM’D, and TRIG’D front panel indicators.

3. Power on the m

a. Verify that the green READY indicator turns on while the d iagnostics

are being ch

module is not being recognized which indicates possible problems on

the LPU board.

b. Verify that after a few seconds the ACCESSED indicator turns on. The

indicator stays on while the module is accessed by the controller. After

the TLA application starts, the indicator blinks anytime the controller

accesses the module.

4. If the previous s teps are not verified, the module is not recognized. Proceed

as the troubleshooting tree instructs.

5. If diagnostic failures occur, replace the circuit board indicated by the

troubleshooting tree or see the diagnostics table. (See page 19, Diagnostics

Tabl e .)

ubleshooting Tree provides troubleshooting steps that test the

wer on the mainframe, look at the READY, ACCESSED

ainframe and note how the front panel indicators respond.

ecked. If the green READY indicator does not turn on, the

If any of the Kernel test groups fail (ROM check, LPU RAM, LPU Address

decode, etc.) replace the LPU board.

If the kernel group passes, but there are other failures, replace the acquisition

board. Also, ensure that the probes are disconnected from the module before

ng the diagnostics.

runni

If multiple tests fail, the problem could be power-supply related problems

mainframe. If replacing the acquisition board does not remedy the

or the

failures, try replacing the LPU board.

NOTE. Due to the module design, there are no accessible test points on the module

to connect external test equipment to isolate faults to an individual circuit board.

6. Replace the faulty circuit board. (See page 5, Removal and Installation.)

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual 17

Page 32

Troubleshooting

Primary Troubl

eshooting

Chart

18 TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 33

Troubleshooting

Diagnostics Table

The following t

able will help you isolate a problem to one of the circuit boards in

the module.

Table 5: Diagnostic tests

Circuit Board Group & test Power-on Extended

LPU board

Acquisition

board

Kernel Tests

ROM Check

LPU RAM

LPU Address Decode

NVRAM Check

Interface Tes

FPGA Addressi

Trigger

Acquisition RA

Acquisition RAM 1

Acquisition RAM 2

SERDES 0

SERDES 1

Acquisition RAM Tests

Acquisition RAM 0

Acquisition RAM 1

Acquisition RAM 2

Miscellaneous Te

At-Speed Acquir

ts

ng

M0

sts

e

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual 19

Page 34

Troubleshooting

Updating the Module Firmware

After you install the PCI Express Support software and restart the instrument, a

message may appear on the screen indicating that your current module firmware is

unsupported by the currently installed software. A new version of the firmware

must be installed on the instrument so that it will work with the latest PCI Express

Support soft

1. If you haven’t already done so, exit the TLA application.

2. Click Start → All Programs → Tektronix Logic Analyzer → TLA Firmware

Loader.

3. Select your mainframe instrument from the TLA Connection dialog box.

You are given a choice to load Mainframe or Instrument Module Firmware.

Click the Load button in the Instrument Module Firmware section (bottom

part of the dialog box).

4. You may be prompted about cycling the power on the mainframe after

completing the upgrade operation. Click Yes to continue.

ware.

The instrument will scan the mainframe to detect all installed modules, and to

determine which modules have firmware that needs to be upgraded.

5. Select your module(s) from the list displayed in the Supported list box near

the top of the window. If you are updating the firmware for more than one

module,

from the list.

6. Select

7. Navigate to C:\Program Files\TLA 700\Firmware and select the file

TLA7Sx

NOTE. Be sure to correctly associate your module with this file. Note the slot

number in the title bar so that you select the correct module.

8. Click OK. You will be prompted to confirm your action; click Yes.

The pr

minutes.

9. When

Exit the firmware loader program and power down the instrument. You

must power down the instrument to allow the software application to start

up properly.

note the locations of the modules in the mainframe and select them

Load Firmware from the Execute menu.

x.lod.

ogram will begin to load the firmware. The process may take several

the process is complete, the firmware has been loaded for the module.

20 TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 35

Repackaging Instructions

If at all possible, use the original packaging to ship or store the instrument. If the

original packaging is not available, use a corrugated cardboard shipping carton

having a test

at least six inches (15.25 cm) greater than the instrument dimensions. Add

cushioning material to prevent the instrument from moving around in the shipping

container. Seal the shipping carton with an industrial stapler or strapping tape.

strength of at least 275 pounds (125 kg) and with an inside dimension

Repackaging Instructions

Shipping the Instrument to

the Service Center

Storage

Contact the Service Center to get an RMA (return material authorization) number,

and any return or shipping information you may need.

If the instrument is being shipped to a Tektronix Service Center, enclose the

following information:

The RMA number

The owner

Name and phone number of a contact person

Type of instrument and serial n umber

Reason for returning

A complete description of the service required

Mark the address of the Tektronix Service Center and the return address on the

shipping carton in two prominent locations.

When no

environment. The following environmental characteristics apply for both shipping

and storage:

Temperature range: -40 °F to +160 °F (-40 °C to +71 °C)

’s address

t used in a mainframe, store the serial analyzer module in a clean, dry

ude: To 9843 feet (3000 meters)

Altit

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual 21

Page 36

Parts List

Parts List

This chapter contains a list of the replaceable parts for the TLA7S08 & TLA7S16

Serial Analyzer Modules. Use this chapter to order replacement parts for your

instrument.

for those product modules.

Parts Ordering Information

Replacement parts are available through your local Tektronix field office

or representative. Changes to Tektronix products are sometimes made to

accommodate improved components as they become available and to give you the

benefit of the latest improvements. Therefore, when ordering parts, it is important

to include the following information in your order.

Refer to the individual module service manuals for replaceable parts

Part number (see Part Number Revision Level below)

Instrument type or model number

Part Number Revision

Level

Instrument serial number

Instrument modification number, if applicable

If you ord

local Tektronix field office or representative will contact you concerning any

change in part number.

Tektro

part. For most parts in this manual, you will find the letters XX in place of the

revision level number.

When you order parts, Tektronix will provide you with the most current part for

your product type, serial number, and modification (if applicable). At the time of

your

your product, based on the information you provide.

er a part that has been replaced with a different or improved part, your

nix part numbers contain two digits representing the revision level of the

order, Tektronix will determine the part number revision level needed for

22 TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 37

Using the Replaceable Parts List

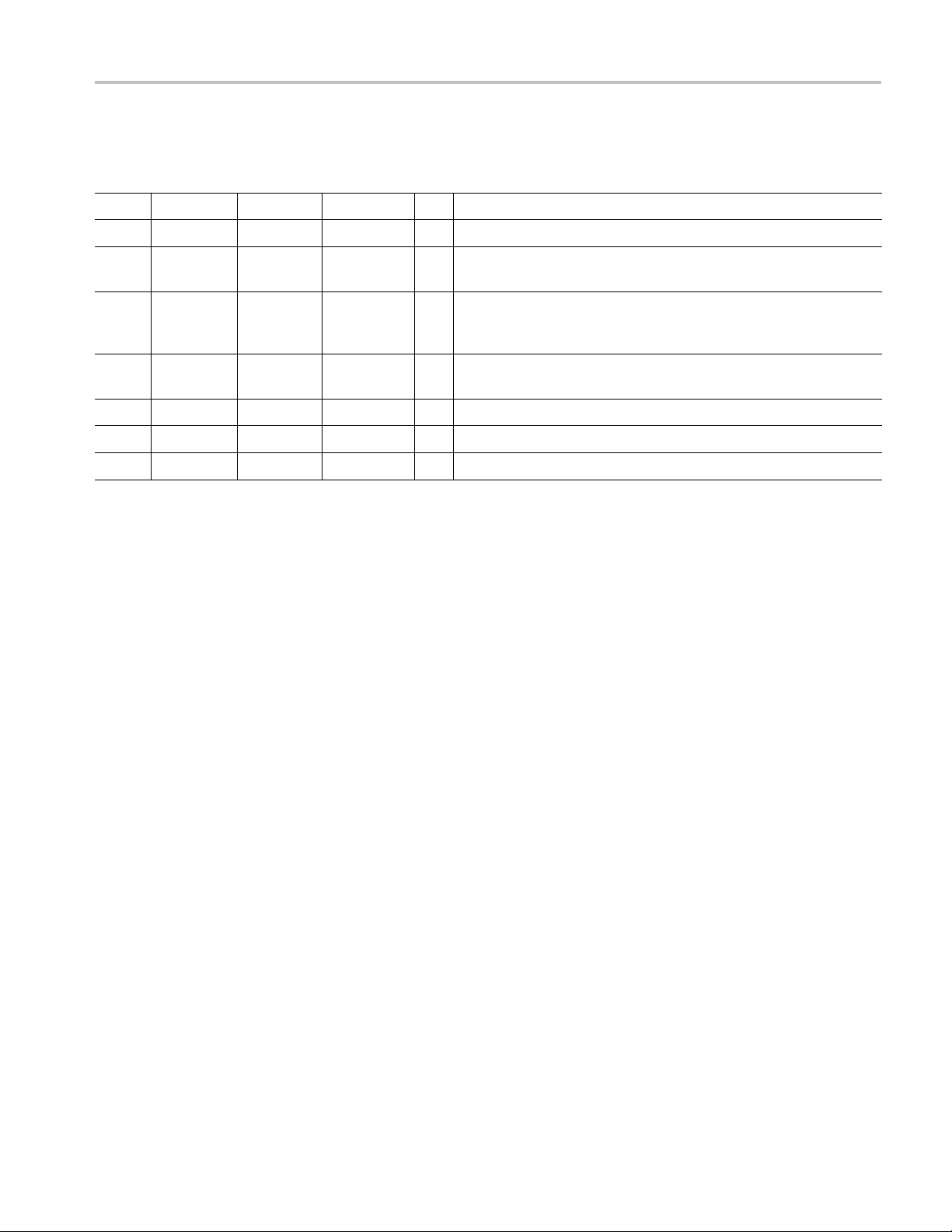

Thefollowingtabledescribeseachcolumn in the replaceable parts lists.

Table 6: Parts list column descriptions

Column number Column name Description

1

2 Tektronix part number Use this part number when

3 and 4

5

6

Figure & index number

Serial number Column 3 indicates the

Qty Quantity of parts used.

Name & description

Figure and index numbers

intheexplodedview

illustrations.

ordering replacement parts

from Tektronix.

serial number at which

the part was fi rst effective.

Column 4 indicates the

serial number at which the

part was discontinued. No

entries in either column

indicates the part is good for

all serial numbers.

An item name is separated

from the description by a

colon ( :). Because of space

limitations, an item name

may sometimes appear

incomplete. Use the U. S.

Federal Catalog Handbook

H6-1 for further item name

identification.

Parts List

Abbrev

iations

Abbreviations conform to American National Standard ANSI Y1.1-1972.

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual 23

Page 38

Parts List

Fig. &

index

number

Tektronix

part number

Serial no.

effective

Serial no.

discont’d Qty Name & description

5-1 348-1365-XX 2

5-2 200-5013-XX 1

5-3 211-0409-XX 8

5-4 348-1537-XX 6

5-5

5-5

5-6 386-7490-XX 1

441-2488-XX 1

441-2490-XX 1

SHLD GSKT, ELE

7.5 L , RIVIT MTG, SNAP-IN , RIVIT SPACING 1.5 INCH, BECU

COVER

SCR, ASSEM WSHR; 4-40 X 0.312, PNH, 410 SS PASSIVATED, T-10

TORX DR

GASKET, EMI; CLIP-ON, 1.98 L, BE CU, TIN PLATED, W/T LANCES

CHASSIS, ASSEMBLY, X16, MAIN, TLA7S16

CHASSIS, AS

BRACKET, END (TWO WIDE)

C; SYMETRICAL SLOTTED FINGER, 0.350 W X

SEMBLY; X8, MAIN, TLA7S08

Figure 5: TLA7S08 &TLA7S16 chassis and cover

24 TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 39

Fig. &

index

number

Tektronix

part number

Serial no.

effective

Parts List

Serial no.

discont’d Qty Name & description

6-1 664-6142-XX 1

6-2 211-0409-X X 10

6-3 679-6219-XX 1

6-4 348-1866-XX 4

6-5 220-0272-XX 4

6-6 664-6181-XX 1

6-6 664-6336-X

6-7 129-1478-XX

X

CIRCUIT BD ASS

SCR, ASSEM WSHR; 4-40 X 0.312, PNH, 410 SS PASSIVATED, T-10

TORX DR

CIRCUIT BOARD ASSY; PROBE INTERFACE BD

GASKET, SHIELD

JACK, NUT, 4-

CIRCUIT BO ARD ASSEMBLY; TLA7S16 MODULE ACQUISITION

1

CIRCUIT BO ARD ASSEMBLY; TLA7S08 MO DULE; ACQ UISITION

5

SPACER, POS

4-40 INT THD X 6-32 EXTERNAL THD, NICKEL

Y; LPU BOARD, TESTED

40

T; 1.738 L, 1.113 SPACING, W/ 0.35 L, 0.25 HEX, W/

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual 25

Page 40

Parts List

Figure 6: TLA7S08 &TLA7S16 circuit board assemblies

26 TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Page 41

Parts List

Fig. &

index

number

7-1 174-5366-X X 2

7-2 437-0520-X X 1

7-3 367-0483-X X 1

7-4 367-0484-X X 1

7-5

7-6 672-6285-X X 1

7-7

7-8 211-0372-XX 2

Tektronix

part

number

211-0409-XX 4

174-5392-X

Serial n o.

effective

X

Serial no.

discont’d Qty Name & description

CABLE ASSEMBL

FAN ASSY

HANDLE; INJECTOR/EJECTOR ASSEMBLY, TWO WIDE, W/KEYING,

SPRING LOADED, PLASTIC, 20% GLASS-FILLED SILVER GRAY

HANDLE; INJECTOR/EJECTOR ASSEMBLY, TWO WIDE, W/OUT

KEYING, SPRING LOADED, PLASTIC, 20% GLASS-FILLE D SILVER

GRAY

SCR, ASSEM WSHR; 4-40 X 0.312, PNH, 410 SS PASSIVATED, T-10

TORX DR

CIRCUIT BD ASSY; REFERENCE CLOCK FILTER BD W/CABLES

2

CABLE ASSEMBLY (REFERENCE CLOCK JUMPER)

SCREW, 4-4

Y, COAXIAL 50 OHM, MCX TO SMA

0, T-10 TORX DR

TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual 27

Page 42

Parts List

Figure 7: TLA7S08 &TLA7S16 internal cables and connectors

28 TLA7S08 & TLA7S16 Serial Analyzer Technical Reference Manual

Loading...

Loading...